Repairing tape for photovoltaic module backboard, and bonding process and application thereof

A photovoltaic module and repair tape technology, applied in photovoltaic power generation, adhesives, electrical components, etc., can solve problems such as easy generation of air bubbles, impact on insulation and water resistance, and further improvement in bonding efficiency, so as to avoid cracking and repair quality Controllable, labor- and transportation-cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

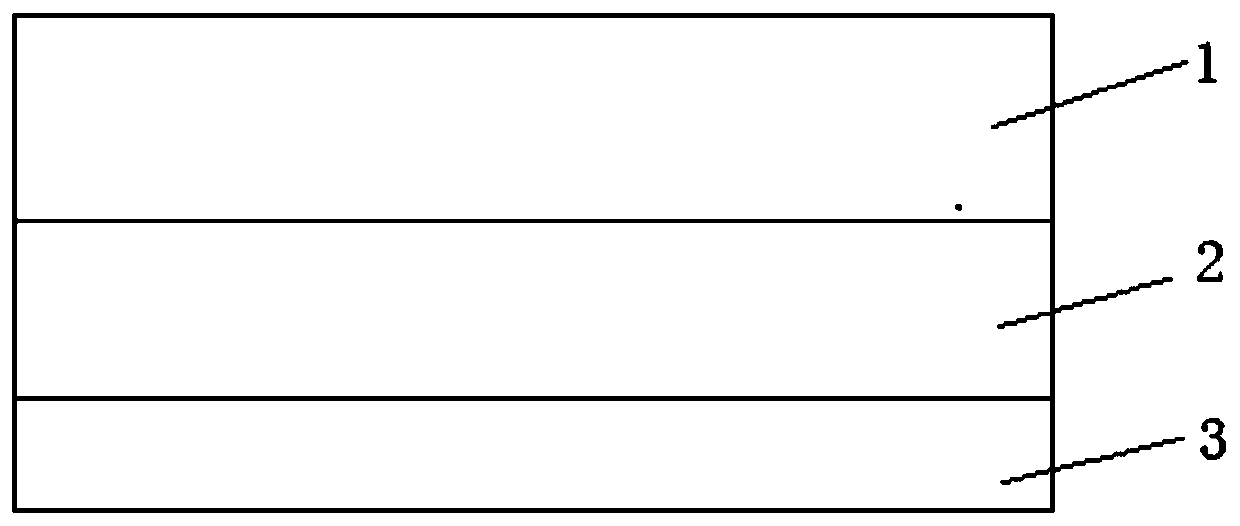

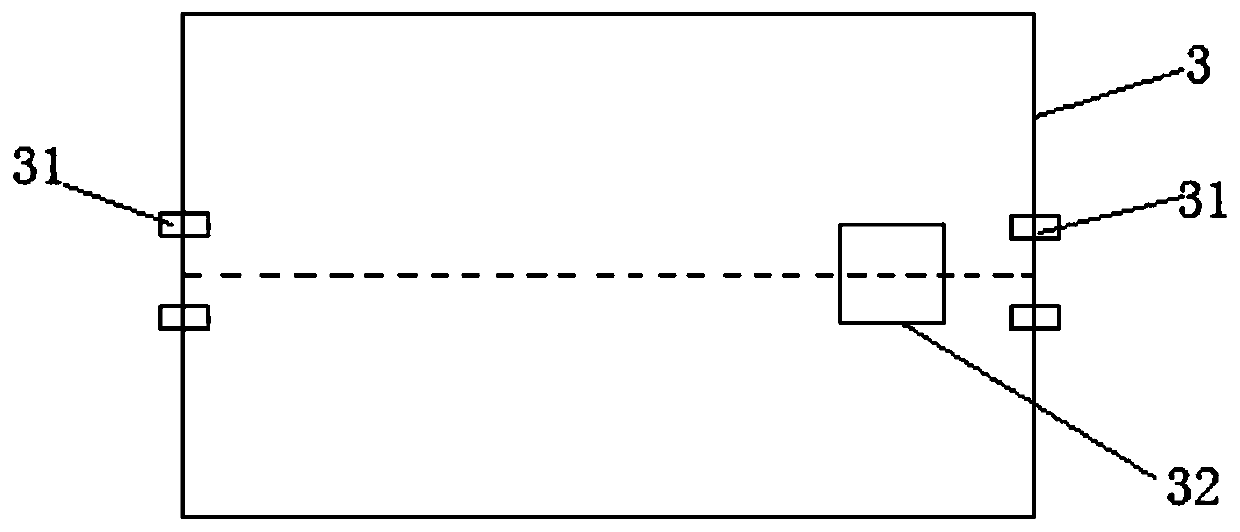

[0047] Such as figure 1 As shown, a repair adhesive tape for a photovoltaic module backplane includes a base material layer 1, a functional adhesive layer 2, and a release material layer 3 arranged sequentially from top to bottom, and the base material layer 1 and the functional adhesive layer 2 are integrated Surface structure, the release material layer 3 is a two-stage release material layer, each section of the two-stage release material layer is provided with a hand tearing tape 31, and one side of the repair tape for the photovoltaic module backplane is provided with a The notch 32 of the box, the two-stage structure is divided into two parts along the center line of the notch. As a preferred solution, each section of the two-stage release material layer is provided with two opposite tearing tapes 31 along the centerline direction of the gap 32, so that each section of the release material layer is torn apart, such as figure 2 shown. Wherein, as a preferred solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com