Laser dynamic anti-counterfeiting tear tape for cigarette and production technology thereof

A technology of anti-counterfeit pull wire and production process, which is applied in the fields of application, tobacco, and packaged cigarettes, etc. It can solve the problems of low imitation threshold and changing attractiveness of cigarette pull wire promotions, etc. It achieves high number of wires, fine structure, increased visual effects and The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

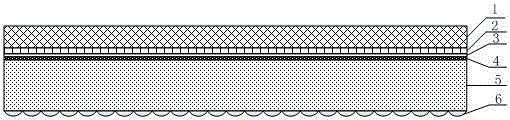

[0026] Such as figure 1 As shown, a laser dynamic anti-counterfeiting pull wire for cigarettes includes a base film layer 1, and a coating layer 2 sequentially arranged on the base film layer 1, an information layer 3, a glue layer 4, a thickening medium layer 5 and a grating layer 6 , wherein the base film layer 1 is a PET film with a thickness of 15um, the thickened dielectric layer 5 is a PET film with a thickness of 35um, and the grating layer 6 is UV glue with a thickness of 10um.

[0027] Taking the text "Jinghua Technology" as a specific example of the information layer, the production process of the laser dynamic anti-counterfeiting pull wire for cigarettes includes the following steps:

[0028] 1) Holographic plate making: According to the number of lines of the anti-counterfeit pull grating grating layer, the total thickness of the anti-counterfeit pull wire and the observation distance, different pixels of the pattern and / or text information are shifted to the left ...

Embodiment 2

[0036]A laser dynamic anti-counterfeiting pull wire for cigarettes, comprising a base film layer 1, and a coating layer 2 sequentially arranged on the base film layer 1, an information layer 3, a glue layer 4, a thickening medium layer 5 and a grating layer 6, wherein, The base film layer 1 is a PET film with a thickness of 12um, the thickened dielectric layer 5 is a PET film with a thickness of 30um, and the grating layer 6 is UV glue with a thickness of 15um.

Embodiment 3

[0038] A laser dynamic anti-counterfeiting pull wire for cigarettes, comprising a base film layer 1, and a coating layer 2 sequentially arranged on the base film layer 1, an information layer 3, a glue layer 4, a thickening medium layer 5 and a grating layer 6, wherein, The base film layer 1 is a PET film with a thickness of 18um, the thickened dielectric layer 5 is a PET film with a thickness of 40um, and the grating layer 6 is UV glue with a thickness of 8um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com