Cigarette packet or cigarette carton tear tape structure and transparent tear tape pasting device

A sticking device and transparent packaging technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of difficult removal, inconvenient disassembly, and difficulty in tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

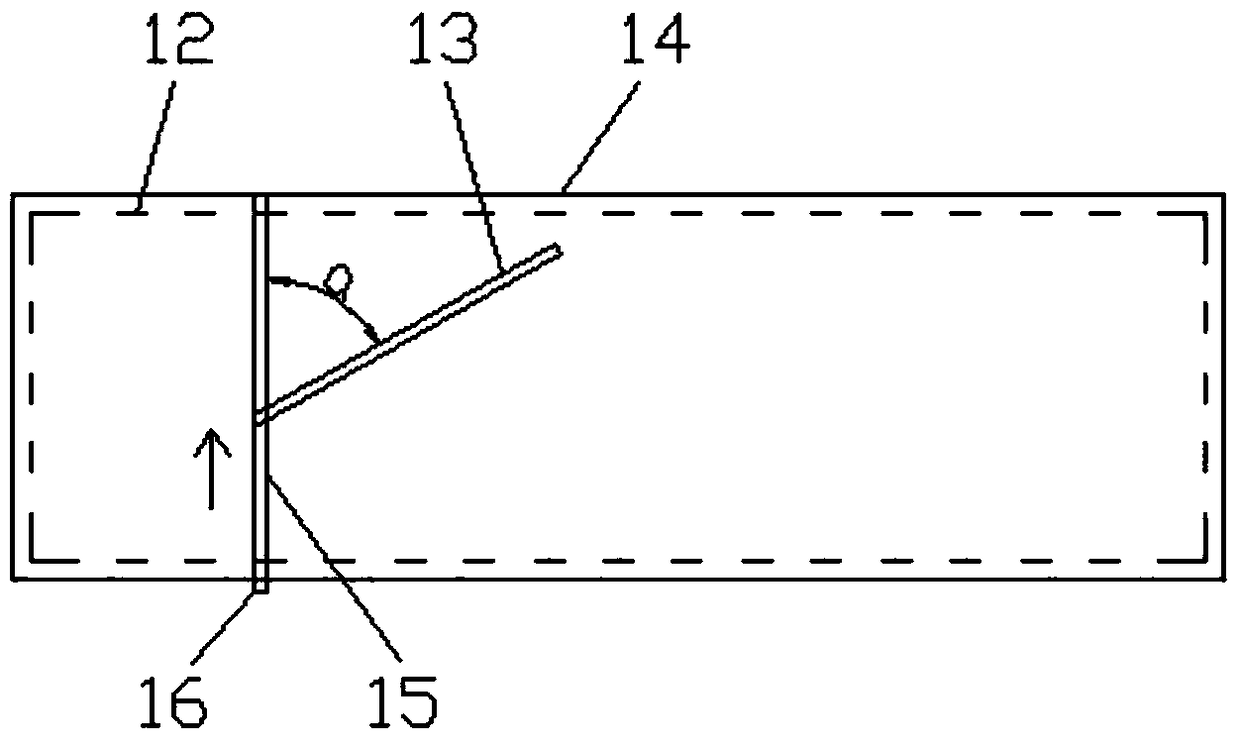

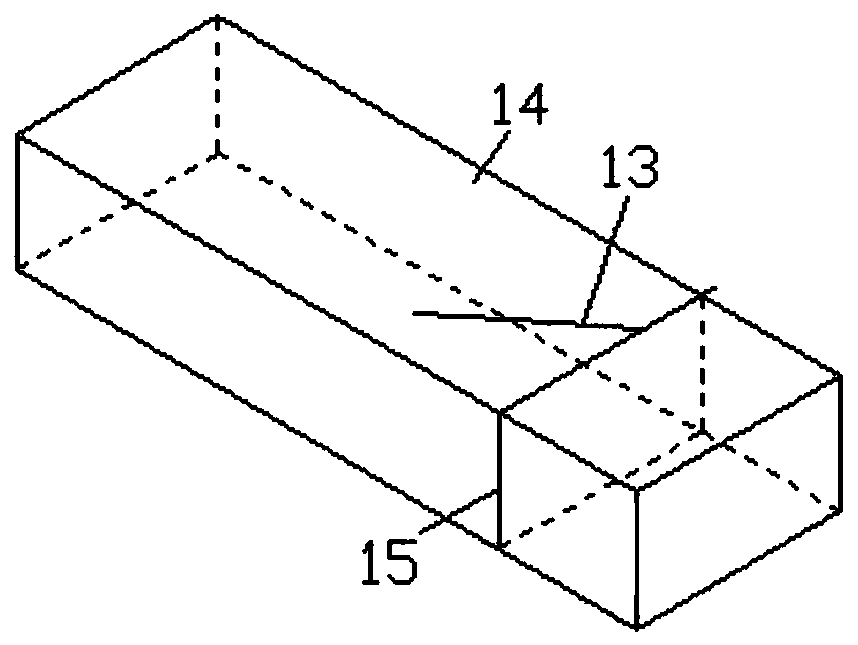

[0024] Depend on figure 1 and figure 2 The shown cigarette package or rod cigarette pull wire structure includes a packaging box 12 and a transparent wrapping paper 14 wrapped outside the packaging box 12. The packaging box 12 is a cigarette package packaging box or a cigarette packaging box. In this embodiment, the packaging box 12 is a cigarette packing box, and the packing box 12 is a rectangular box extending longitudinally from left to right, and the transparent wrapping paper 14 wrapped outside the packing box 12 is also in a rectangular shape, and the transparent wrapping paper 14 includes a front end, a rear end, a left end, and a right end Face, upper end face and lower end face;

[0025] The transparent wrapping paper 14 is provided with a main pull wire 15, the main pull wire 15 wraps around the transparent wrapping paper 14 along a rectangle, the main pull wire 15 wraps around the transparent wrapping paper 14 or a certain cross-section of the cigarette, and the ...

Embodiment 2

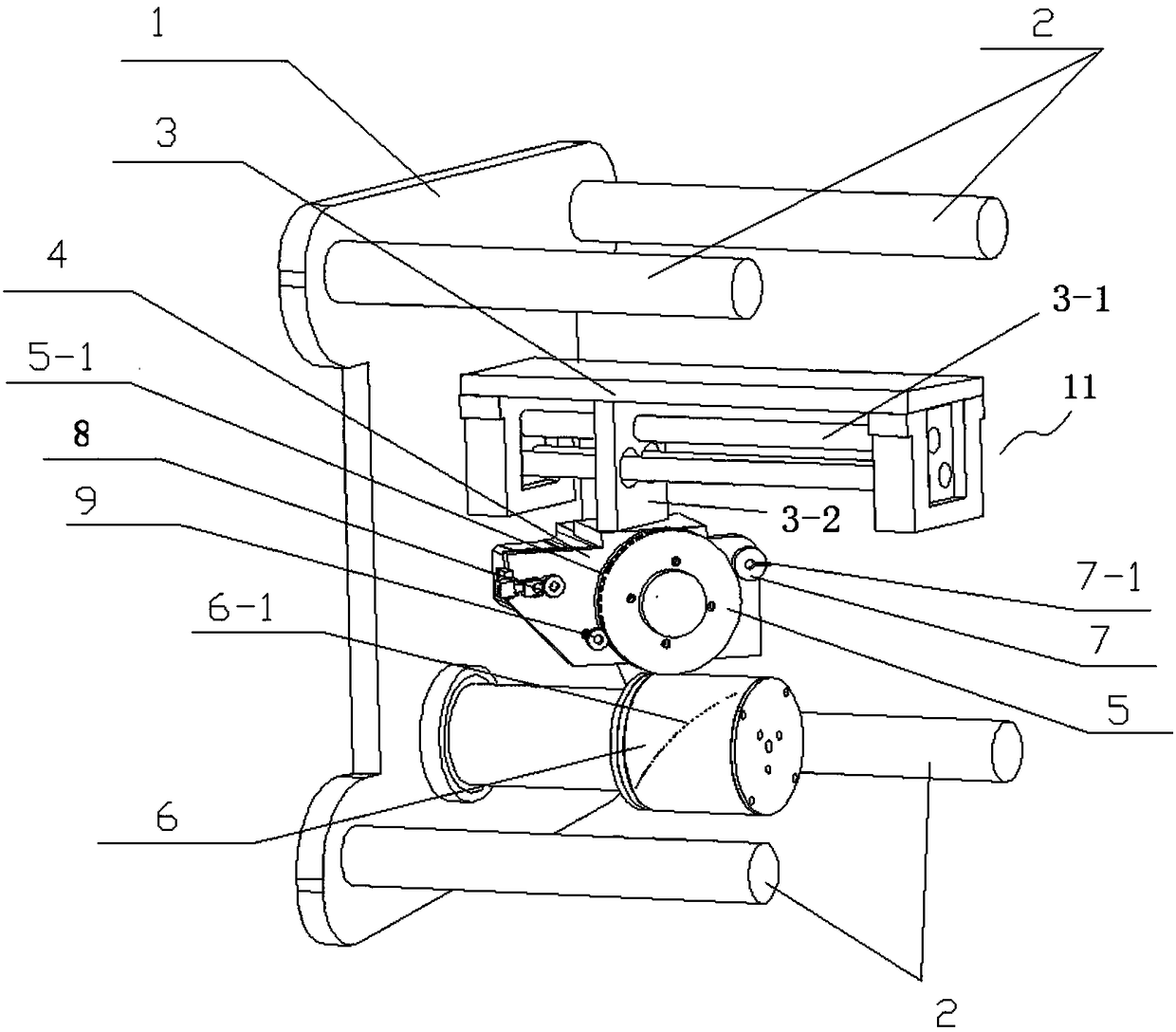

[0030] Depend on image 3 and Figure 4 The shown transparent backguy pasting device is matched with Embodiment 1, and the transparent backguy pasting device is used for pasting the oblique backguy in Embodiment 1 for the transparent paper, which includes a bracket, and the bracket is a guide bracket 1, and the guide bracket 1 There are at least two guide rollers 2, preferably, four rotatable guide rollers 2 are distributed along a rectangle on the guide bracket 1, the guide rollers 2 are arranged horizontally front and back, and the four guide rollers 2 are respectively located at the four corners of the rectangle.

[0031] The guide bracket 1 is provided with a pull wire mechanism and a rolling pasting drum 6 . The bracing mechanism and the rolling and pasting drum 6 are all located in the area surrounded by four guide rollers 2, and the guide rollers 2 are parallel to the axial direction of the rolling and pasting drum 6.

[0032]The central axis of the rolling paste drum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com