Patents

Literature

112results about How to "Improve local stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

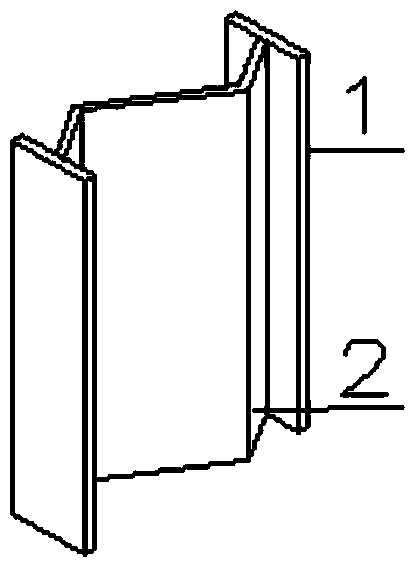

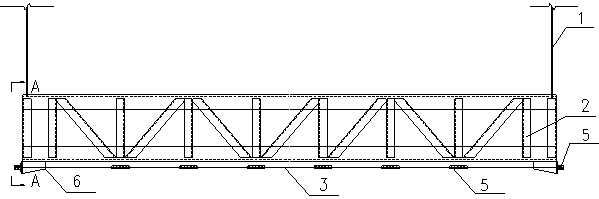

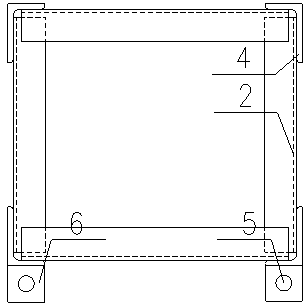

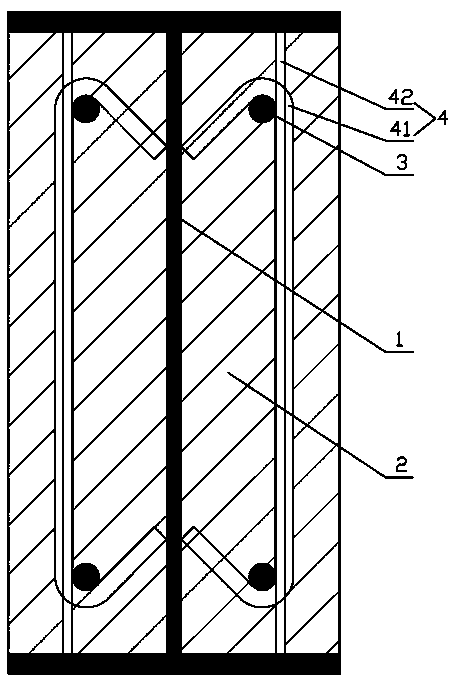

Steel box girder matched with cellular steel web plate

InactiveCN103132649AImprove the bending capacityIncreased bending stiffnessGirdersJoistsMetallurgyBox girder

The invention discloses a steel box girder matched with a cellular steel web plate. The steel box girder comprises two H-shaped steel or I-shaped steel used as web plate components of the steel box girder, further comprises a steel top plate, a steel bottom plate, a clapboard and a reinforcing rib and is characterized in that a plurality of through holes of the same shapes and intervals are formed in two web plates; the steel top plate and the steel bottom plate of the steel box girder are fixedly connected with upper flanges or lower flanges of the web plate components respectively; and a certain number of transverse clapboards and the reinforcing rib are configured. Compared with a solid web steel box girder, the cellular steel box girder disclosed by the invention has the advantages that the resistance capacity and bending resistance rigidity can be increased by about 30% under the condition of same steel use amount; the torsional rigidity of the cellular steel box girder is also greatly increased; simultaneously, the overall stability of the web plate cellular component and the local stability of an overhung flange of the box girder are improved; the use amount of steels is reduced, so that the cost is reduced; and furthermore, the steel box girder disclosed by the invention is attractive in appearance and convenient to maintain.

Owner:GUANGXI UNIV +1

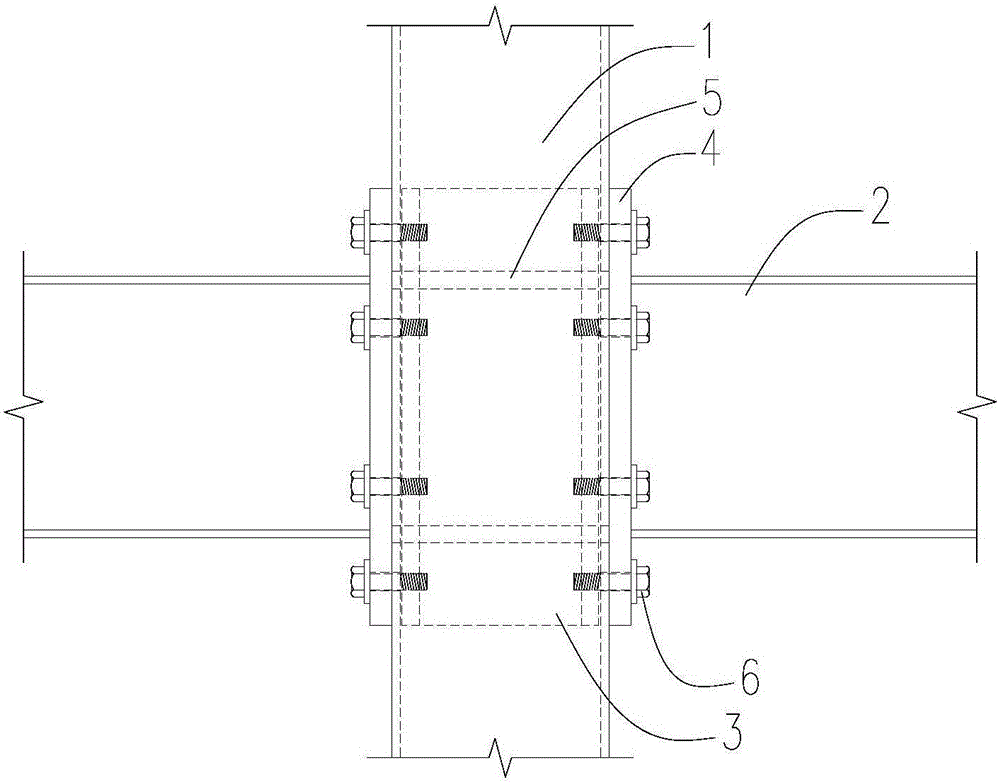

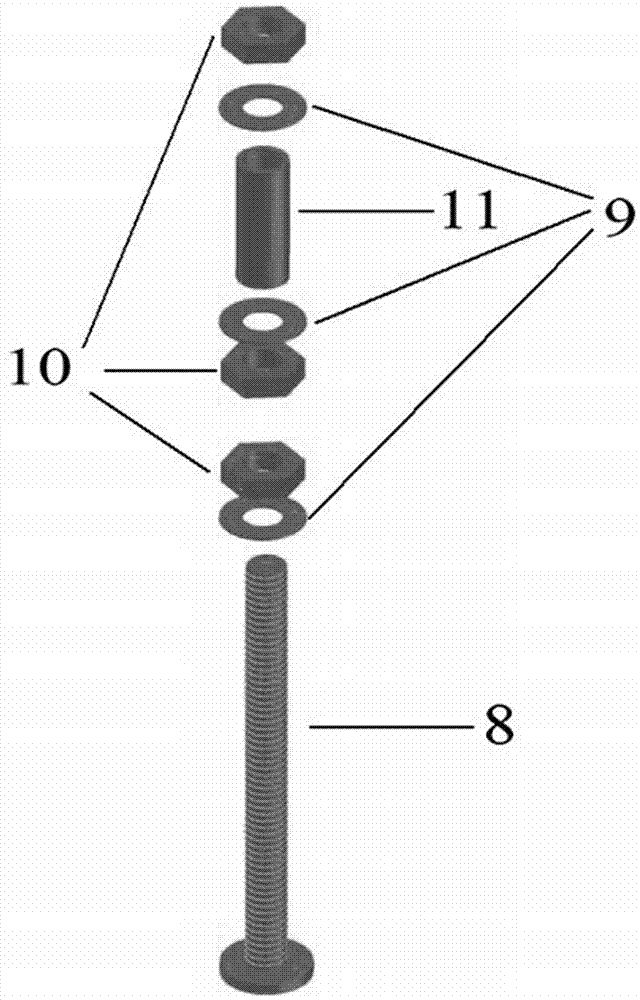

Rectangular steel pipe column and H-shaped steel beam inner sleeve type unilateral bolt connection node

ActiveCN105971118AEasy to fixIncreased shear capacityBuilding constructionsMaterials scienceBolt connection

The invention relates to a rectangular steel pipe column and H-shaped steel beam inner sleeve type unilateral bolt connection node. The structure is simple, the performance is good, the defect that a unilateral bolt is prone to be pulled out is overcome, and the assemblage degree is high. The node comprises a rectangular steel pipe column, H-shaped steel beams, a through pull rod and high-strength bolts; a steel sleeve is coaxially arranged in the rectangular steel pipe column, and extended end-plates are welded to the ends of the H-shaped steel beams; the steel sleeve is provided with positioning circular holes and tapping bolt holes; the extended end-plates and the rectangular steel pipe column are provided with multiple bolt holes in a paired mode in the axial direction of the rectangular steel pipe column, and a connecting wall panel and an opposite wall panel of the rectangular steel pipe column are each provided at least two positioning circular holes in the axial direction of the rectangular steel pipe column; the bolt holes are formed corresponding to the tapping bolt holes and the positioning circular holes on the same side, and the through pull rod penetrates through the positioning circular holes and is used for positioning the steel sleeve and the rectangular steel pipe column; the high-strength bolts sequentially penetrate through the bolts holes in the extended end-plates and the bolt holes in the rectangular steel pipe column to be fixedly connected with the corresponding tapping bolt holes in the steel sleeve.

Owner:CHANGAN UNIV

Square steel pipe fabricated column-prefabricated superposed beam integrally-fabricated frame and construction method

InactiveCN104499568ALabor savingImprove product qualityClimate change adaptationBuilding material handlingSteel tubeHigh performance concrete

The invention discloses a square steel pipe fabricated column-prefabricated superposed beam integrally-fabricated frame and a construction method. The frame comprises a square steel pipe with inner and outer ribs, a square steel pipe casing with connecting wing plates and a prefabricated superposed beam. The square steel pipe is formed by rolling once, a thin centrifugally-produced concrete protective wall is arranged inside the square steel pipe, and high-performance concrete wraps the square steel pipe, so that a square steel pipe fabricated column is formed. The square steel pipe casing with the connecting wing plates is used for vertical connection between one upper square steel pipe fabricated column and one lower square steel pipe fabricated column as well as connection between the prefabricated superposed beam and the square steel pipe fabricated column. Short I-beams are arranged at the ends of the prefabricated superposed beam, and the prefabricated superposed beam is connected with the connecting wing plates on the square steel pipe casing through high-strength bolts. An engineered cementitious composite or fiber reinforced cement composite is poured in beam-column joint connection areas. The concrete fabricated superposed beam is connected with prefabricated floor slabs as well as the prefabricated floor slabs are connected both through fiber reinforced composite plastic boards. A prefabricated house has the advantages of reasonable stress, convenience in construction, high joint ductility, good endurance and anti-seismic performance and the like.

Owner:SOUTHEAST UNIV

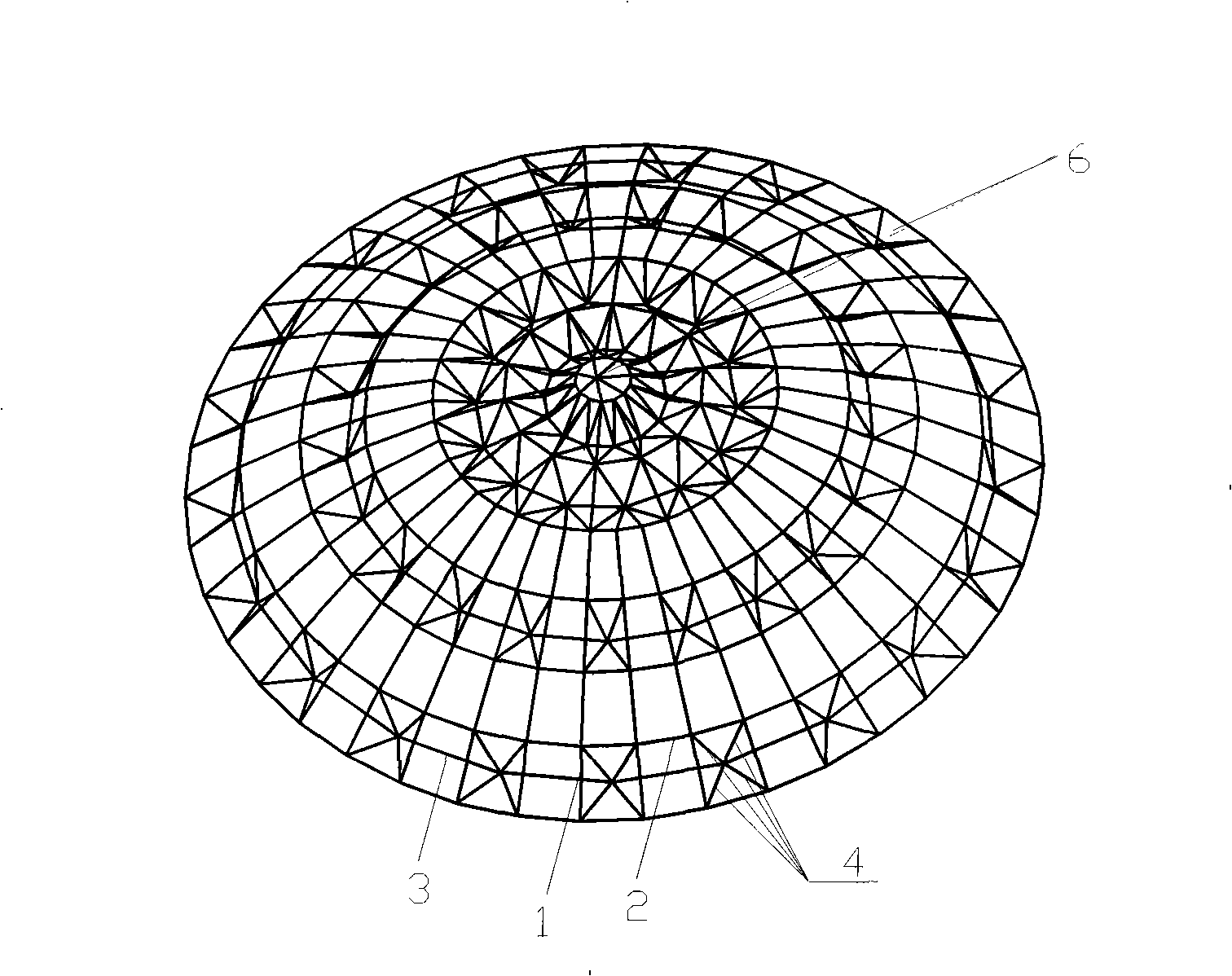

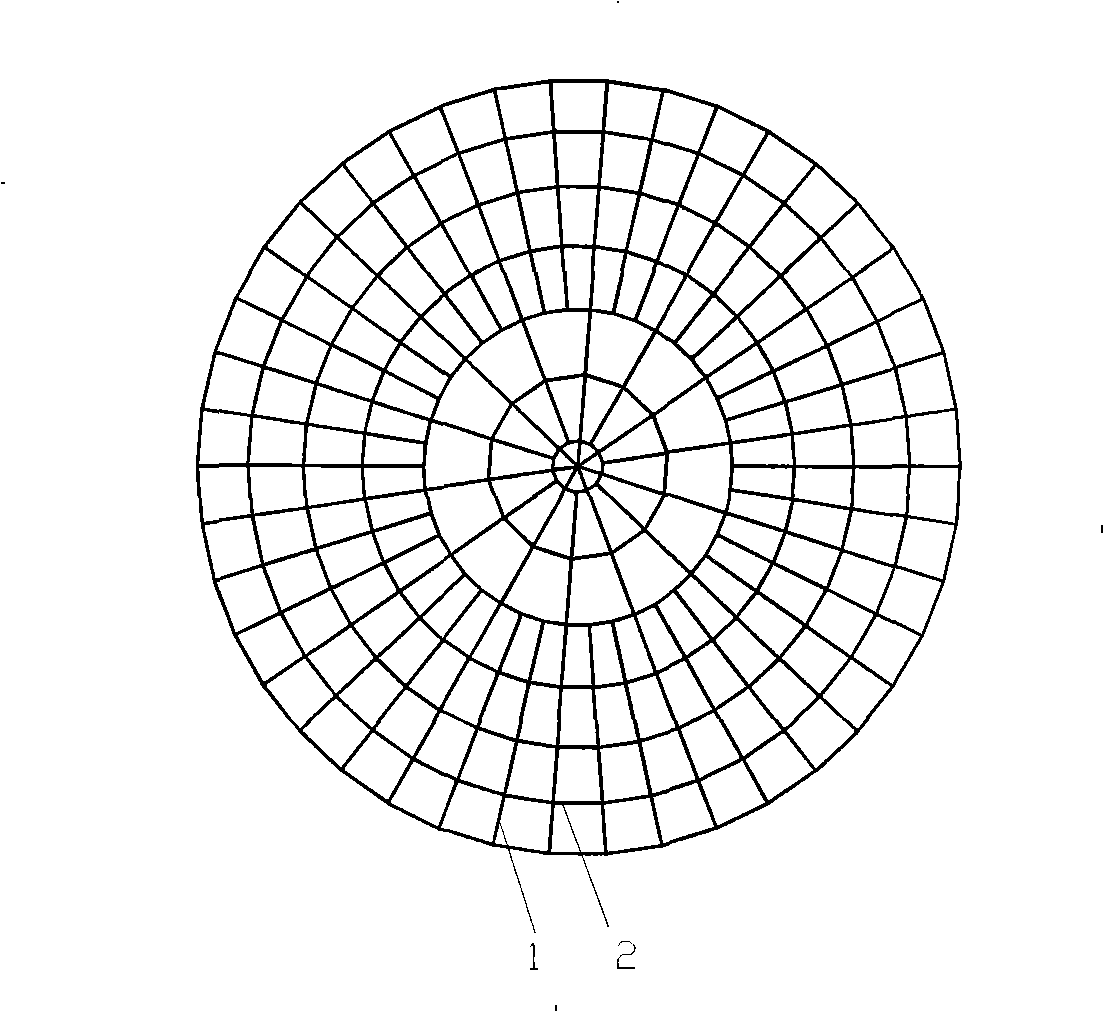

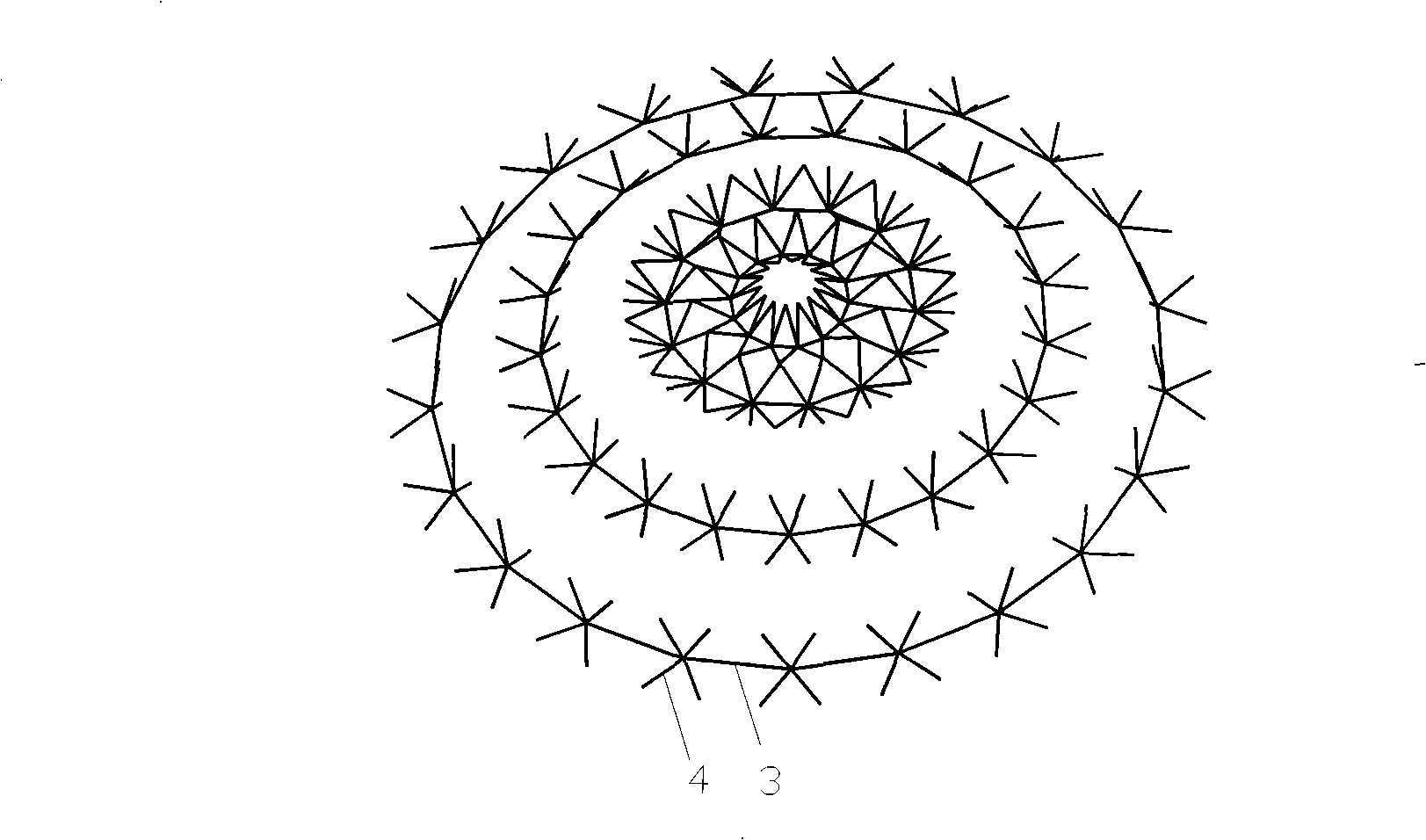

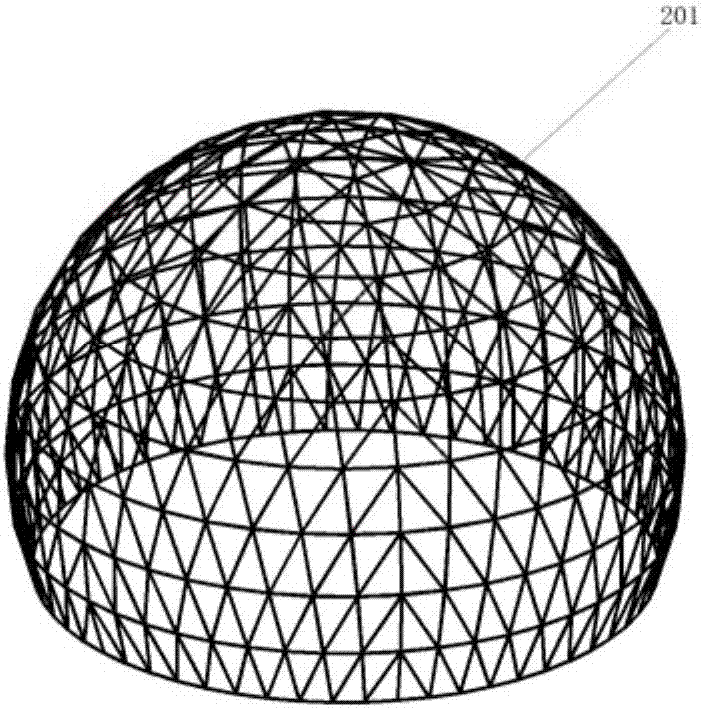

Local double layer open chord spherical reticulated shell

ActiveCN101260704AReduce steel consumptionSparsely arrangedBuilding roofsArched structuresPre stressEngineering

The invention discloses a local double-layer string reticulated spherical shell, comprising an upper layer, a middle layer and a lower layer, wherein, the upper layer is a spherical surface which consists of radial bars and circumferential bars and is arranged in a heel ring grid shape, a plurality of circumferential bars are connected to form the woof of the spherical surface, radial bars are connected between connections of the radial bars of two adjacent woofs to form the warp of the spherical surface, the connections of the circumferential bars are connected with one ends of the radial bars, while the other ends of the radial bars are hinged with the top point in the center of the spherical shell; the middle layer comprises a plurality of unit pyramids which are uniformly and alternately arranged on the heel ring grid of the upper layer along the warp direction and the woof direction and have cone tops connected with circumferential ropes of the lower layer; and the circumferential ropes are in closed arrangement along the circumferential direction, and inherent stress is exerted through tensioning the circumferential ropes in the structure. The local double-layer string reticulated spherical shell has the advantages of clear structure stress, concise and permeable construction effect, is a self equilibrating system under the deadweight effect without horizontal thrust, and has each upper chord joint provided with a web member so as to improve the stability of the structure.

Owner:SHENGYUAN GROUP +1

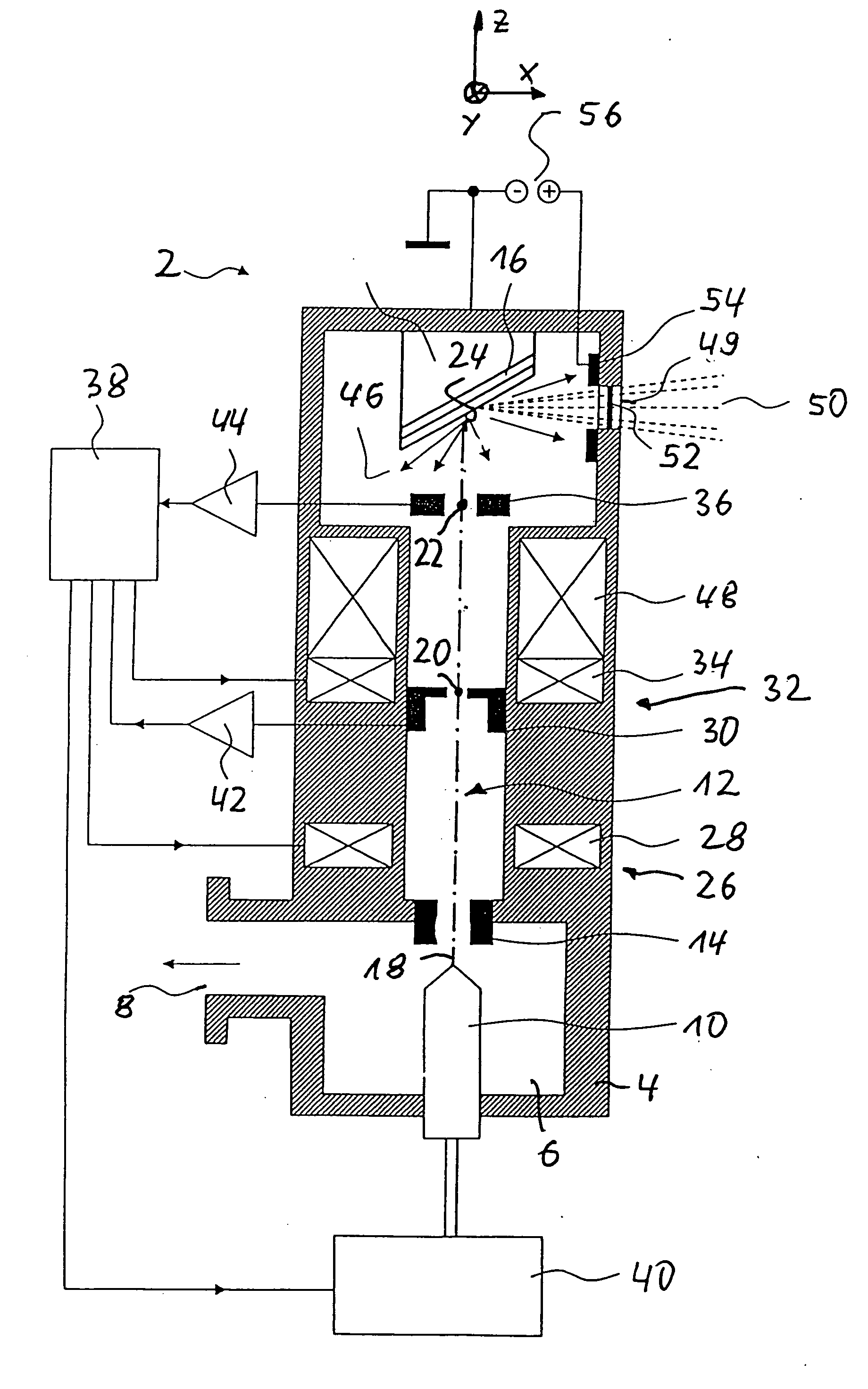

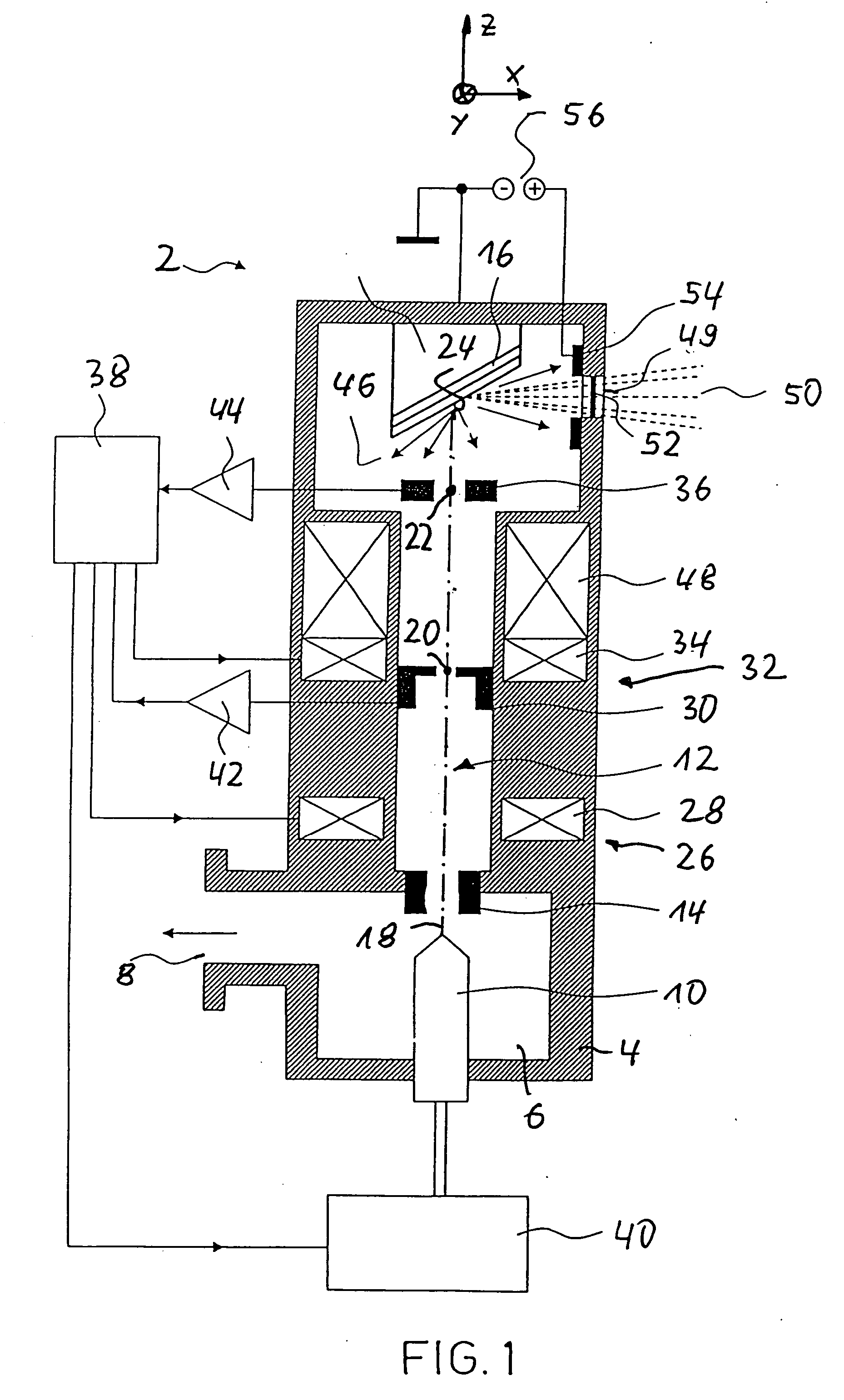

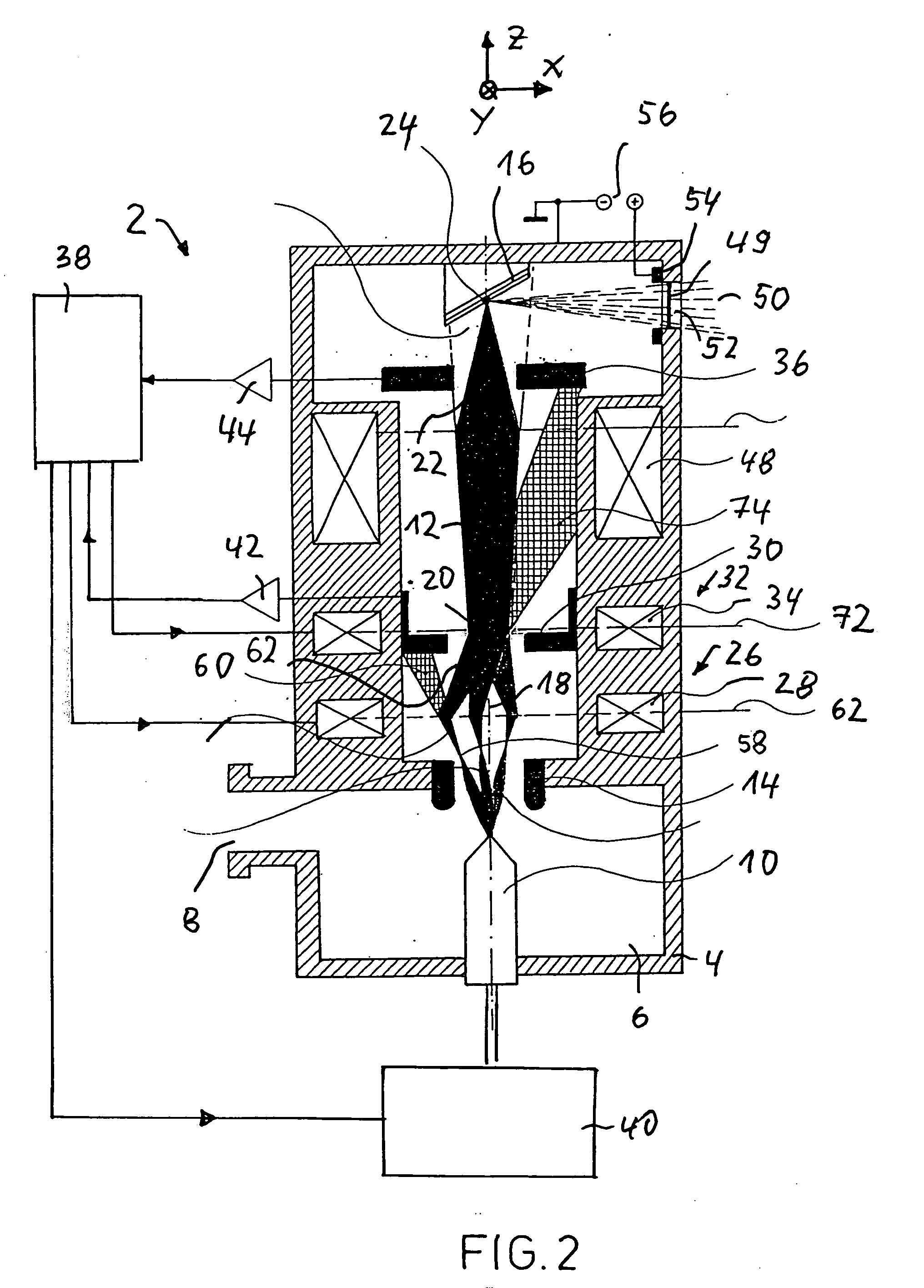

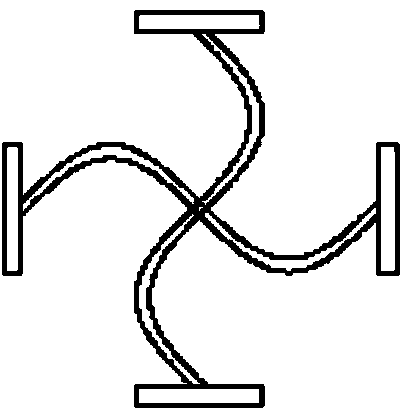

Device for generating X-ray or XUV radiation

InactiveUS20070051907A1Reduce pointsImprove stabilityRadiation pyrometryCathode ray concentrating/focusing/directingParticle beamRadiation

Device for generating X-ray or XUV radiation includes a device for directing a particle beam of electrically charged particles towards a target. A deflection device for deflecting the particle beam is such that the central axis of the particle beam passes through a first point of deflection and a second point of deflection located at a distance from the first point of deflection in the direction of propagation of the beam. The first and second points of deflection lie on an axis in line with a determined or determinable point of impact of the particle beam with the target. The particle beam can be deflected by the deflection device in the direction of propagation of the beam in the region of one point of deflection independently from of a deflection of the particle beam in the region of the other point of deflection.

Owner:COMET

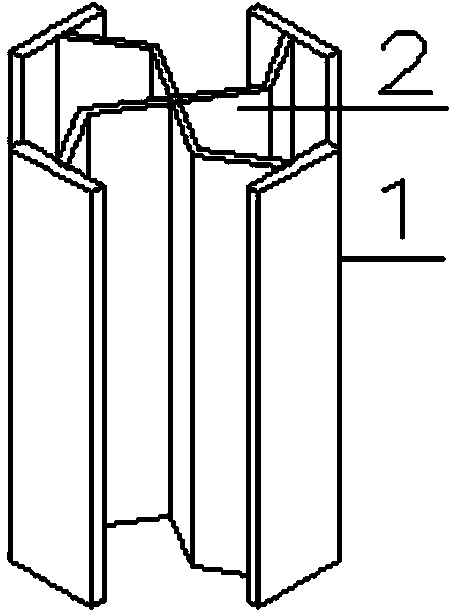

Inner sleeve type unilateral bolt connecting joint of steel tube column and H-shaped steel girder

The invention relates to an inner sleeve type unilateral bolt connecting joint of a steel tube column and an H-shaped steel girder which is simple in structure, good in performance and reliable in joint quality. The inner sleeve type unilateral bolt connecting joint comprises the steel tube column, the H-shaped steel girder, a steel sleeve, a transverse partition plate, externally-extended end plates and high-strength bolts, wherein the steel sleeve is arranged coaxially in the steel tube column; the transverse partition plate is fixed to a flange of the H-shaped steel girder in the steel sleeve in a coplanar mode; the externally-extended end plates are welded at the ends of the H-shaped steel girder; and the high-strength bolts penetrate through the externally-extended end plates. Tapping bolt holes are formed in the steel sleeve and matched with the high-strength bolts. A plurality of bolt holes are formed in a pair mode in the externally-extended end plates and the steel tube column in the axial direction of the steel tube column. At least two positioning circular holes are formed in a connecting wall plate and an opposite wall plate correspondingly by the steel tube column in the axial direction of the steel tube column. The bolt holes and the tapping bolt holes on the same side are formed oppositely. The positioning circular holes on the same side are formed oppositely. The high-strength bolts sequentially penetrate through the bolt holes in the externally-extended end plates and the bolt holes in the steel tube column and are connected with the tapping bolt holes corresponding to the steel sleeve, and are tightened and fixed according to the designed pretension force of the high-strength bolts.

Owner:CHANGAN UNIV

Anti-slide pile on slope

This is an anti-slide pile, its section form is as V word, its angle between two surface 10-150 deg. When the soil body has partly deformed, the soil of slide layer would move along the two outside faces of the V form pile its density become more and more, and move forward the space between two form piles, in the slope body may partly form arching, then the part's stable be strengthened, and whole the slope body are more stable, then the moisture content in the slide layer may be removed out between the space quickly, in the same time, the V-form surface may resolve the pressure of the slide pile: effetely.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

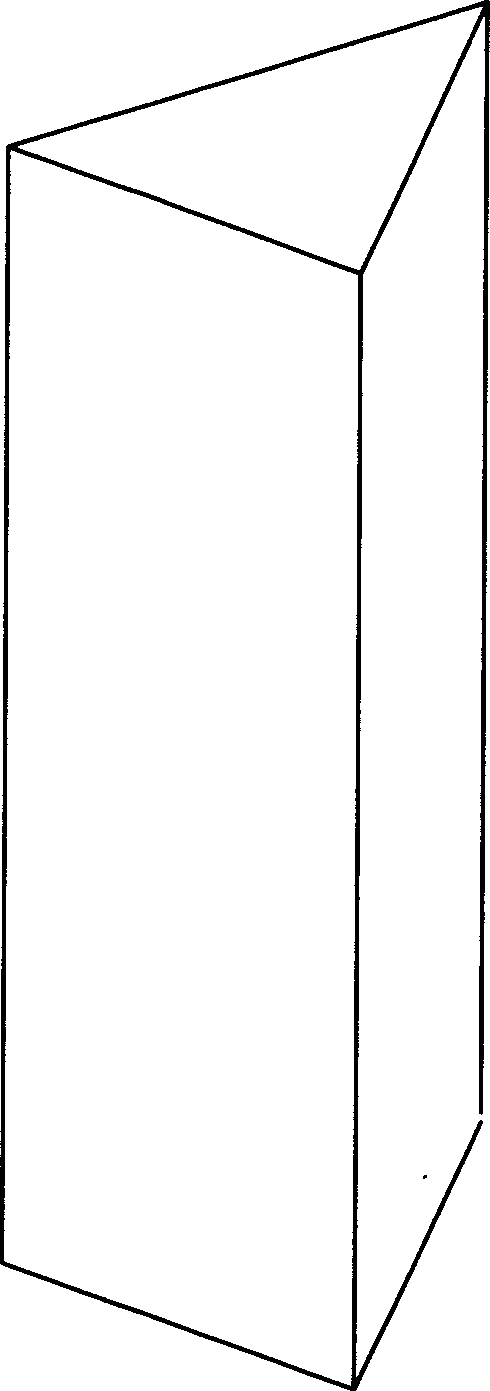

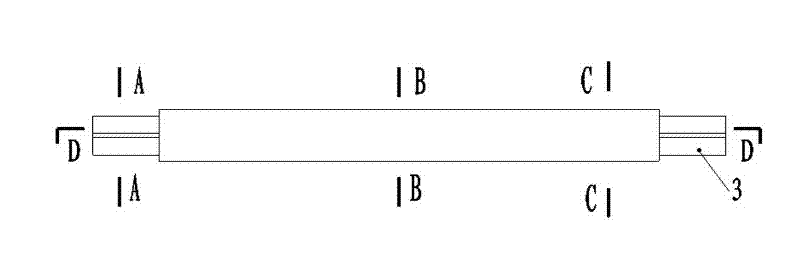

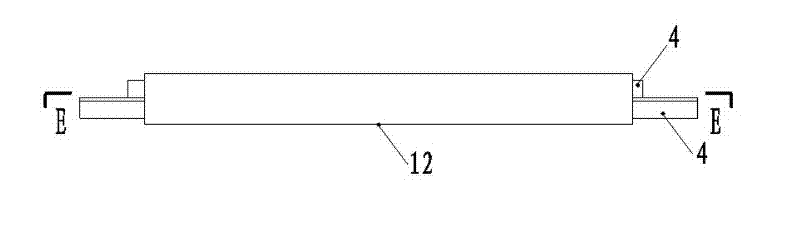

Rod type core bar bending restrain steel support

InactiveCN101974950AReliable constraintsLateral restraint is effectiveShock proofingBuckling-restrained braceSteel frame

The invention relates to a rod type core bar bending restrain steel support which solves the problems of large difference of rigidity and stability of all directions of an energy dissipation section of the traditional bending restrain support, difficult support installation and complex restrain construction. A core main stress part comprises an energy dissipation section, conversion sections and an installation section, wherein the energy dissipation section is a solid steel bar or hollow steel pipe; an outer restrain steel part comprises a local restrain steel member and an integral restrain steel member, the local restrain steel member comprises a core bar steel sleeve, the integral restrain steel member comprises a delay steel frame fixed outside the core bar steel sleeve and an auxiliary steel cylinder; one section of the two conversion section is in friction contact with the steel cylinder of the conversion section and a gap is remained between the core bar steel sleeve and the delay steel frame. The section of the energy dissipation section of the support has uniform size in all directions, which eliminates the difference of the rigidity and the stability of different directions, thus the local stable bearing capacity and the integral bending-preventing capacity are high, and the working reliability under large axial direction strain and strong shock is high; and the rod type core bar bending restrain steel support is convenient for installation, and is suitable for engineering earthquake fortification and reinforcement.

Owner:山西恒晋减震科技股份有限公司

Design method of reinfored rift pile for securing slope

The invention discloses a new design method for slope fixing piles. The method uses soil doming theory, the slide resisting piles are arranged with V type, the aperture direction of the V type faces to the slope. The slide resisting force can be upgraded about 20% in the invention, compared with current pile with the same projection area. Many local arc are formed in the slope, though the soil has local deformation, it will be compacted tighter and tighter, thus the local stability if enhanced, and the whole slope is more stable because of the slide resisting piles.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

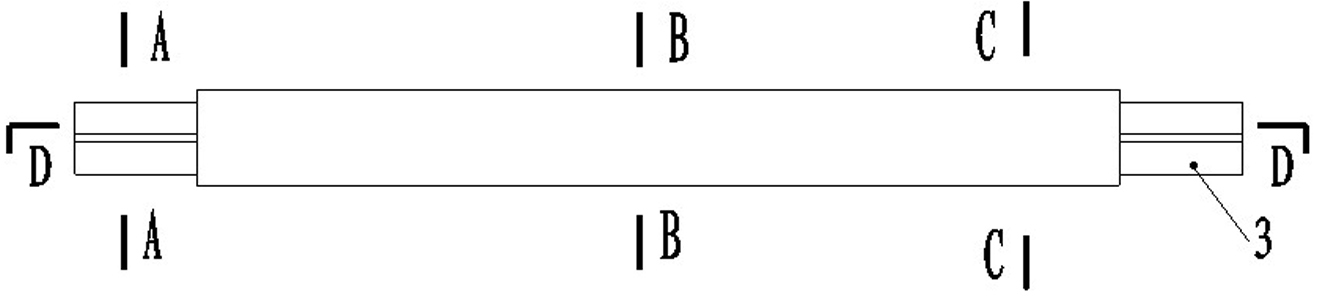

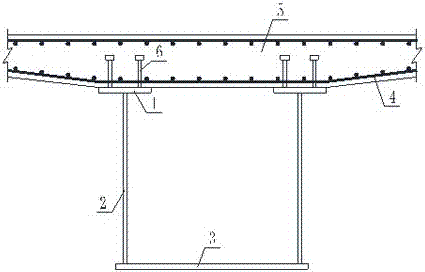

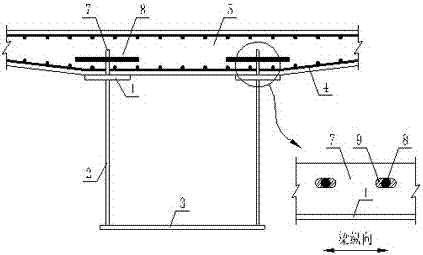

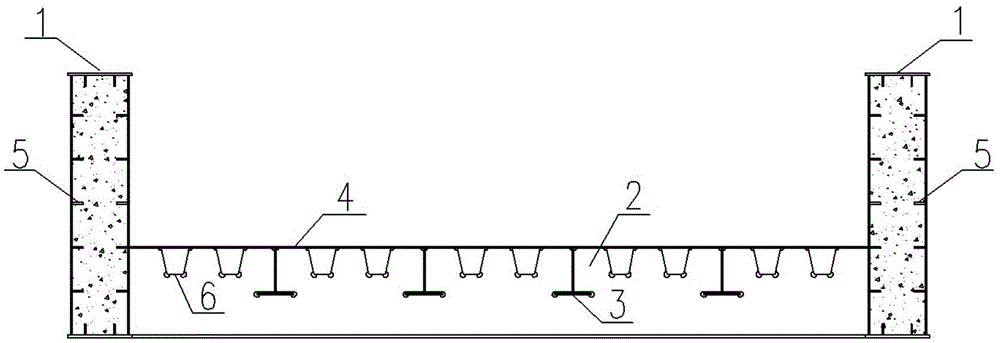

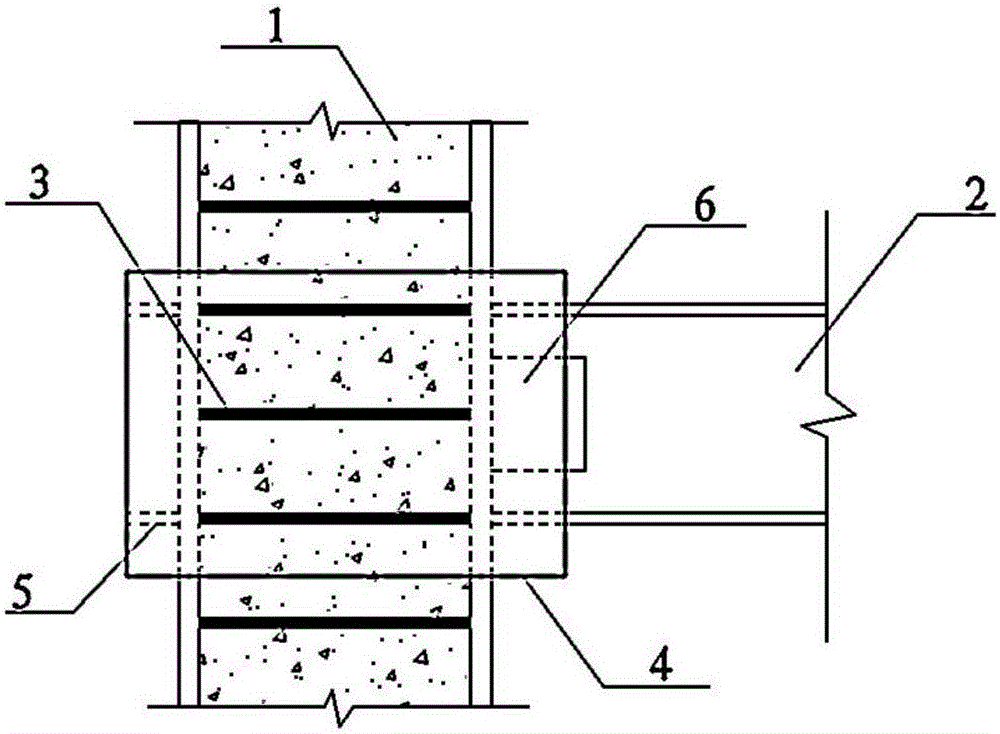

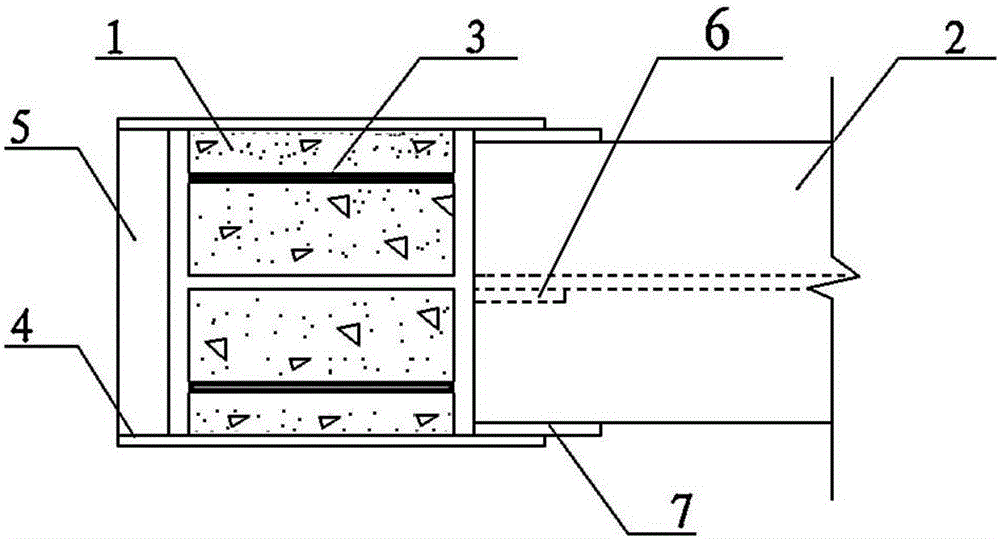

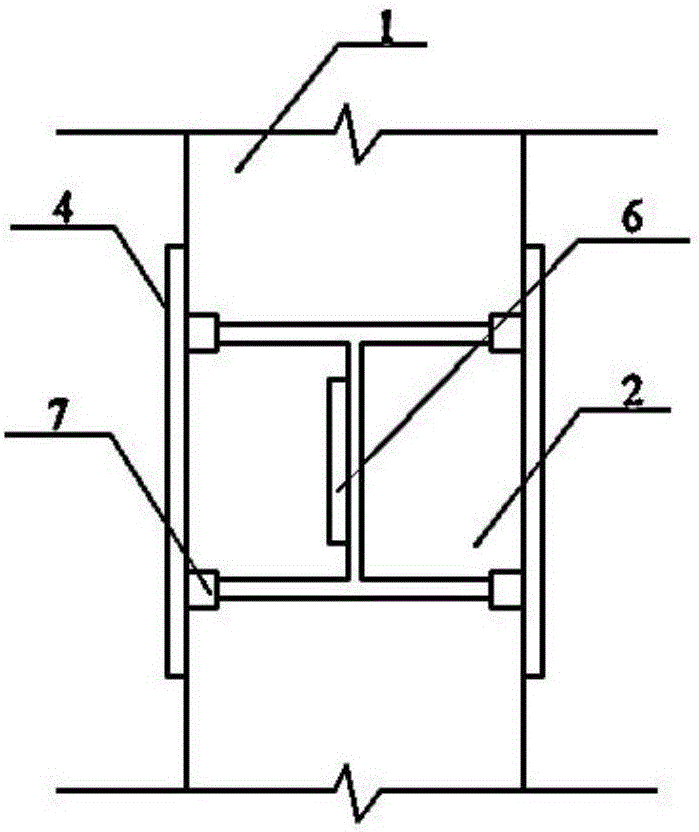

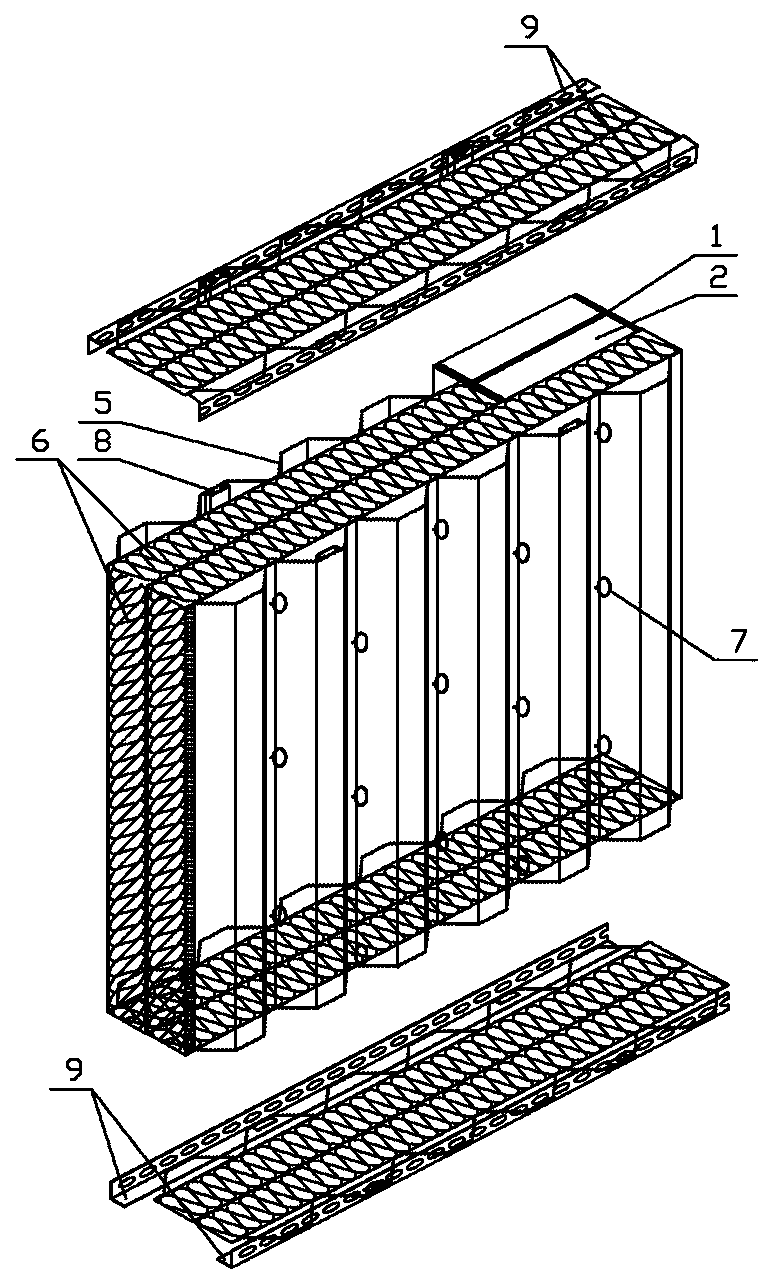

Fireproof and buckling-restrained fabricated composite beam and construction method

ActiveCN107313540AImprove local stabilityImprove bearing capacityFloorsFire proofingRebarTreatment costs

The invention discloses a fireproof and buckling-restrained fabricated composite beam, and belongs to the field of house construction. The fireproof and buckling-restrained fabricated composite beam mainly comprises a prefabricated reinforced concrete slab, a wrapped concrete steel beam, a friction-type high-strength bolt connect set and a rubber sleeve; the prefabricated reinforced concrete slab and the wrapped concrete steel beam are connected into a whole through the friction-type high-strength bolt connect set and the rubber sleeve. According to the fireproof and buckling-restrained fabricated composite beam, through combination of the design philosophy of a recoverable structure, the prefabricated reinforced concrete slab, the wrapped concrete steel beam, the friction-type high-strength bolt connect set and the rubber sleeve are combined mutually, the bearing capacity of steel components is improved, the anti-corrosion and fireproof treatment cost of the steel components is saved, the suitable range of the composite beam is enlarged, fabricated construction of the composite beam is achieved, the time spent on in-situ reinforced assembling, concrete pouring and concrete maintenance is saved, the construction period is shortened to a large extent, the construction efficiency is improved, and the fireproof and buckling-restrained fabricated composite beam has wide application prospects in building structures with steel structures.

Owner:TAIYUAN UNIV OF TECH

Rod type core bar bending restrain steel support

InactiveCN101974950BImprove local stabilityImprove buckling resistanceShock proofingBuckling-restrained braceSteel frame

The invention relates to a rod type core bar bending restrain steel support which solves the problems of large difference of rigidity and stability of all directions of an energy dissipation section of the traditional bending restrain support, difficult support installation and complex restrain construction. A core main stress part comprises an energy dissipation section, conversion sections and an installation section, wherein the energy dissipation section is a solid steel bar or hollow steel pipe; an outer restrain steel part comprises a local restrain steel member and an integral restrainsteel member, the local restrain steel member comprises a core bar steel sleeve, the integral restrain steel member comprises a delay steel frame fixed outside the core bar steel sleeve and an auxiliary steel cylinder; one section of the two conversion section is in friction contact with the steel cylinder of the conversion section and a gap is remained between the core bar steel sleeve and the delay steel frame. The section of the energy dissipation section of the support has uniform size in all directions, which eliminates the difference of the rigidity and the stability of different directions, thus the local stable bearing capacity and the integral bending-preventing capacity are high, and the working reliability under large axial direction strain and strong shock is high; and the rodtype core bar bending restrain steel support is convenient for installation, and is suitable for engineering earthquake fortification and reinforcement.

Owner:山西恒晋减震科技股份有限公司

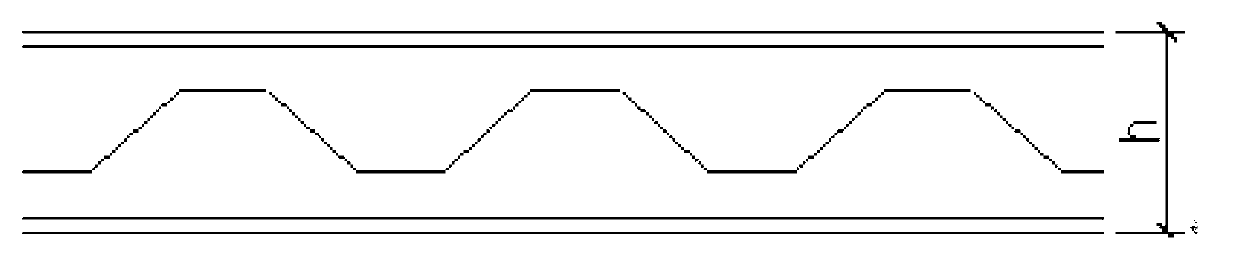

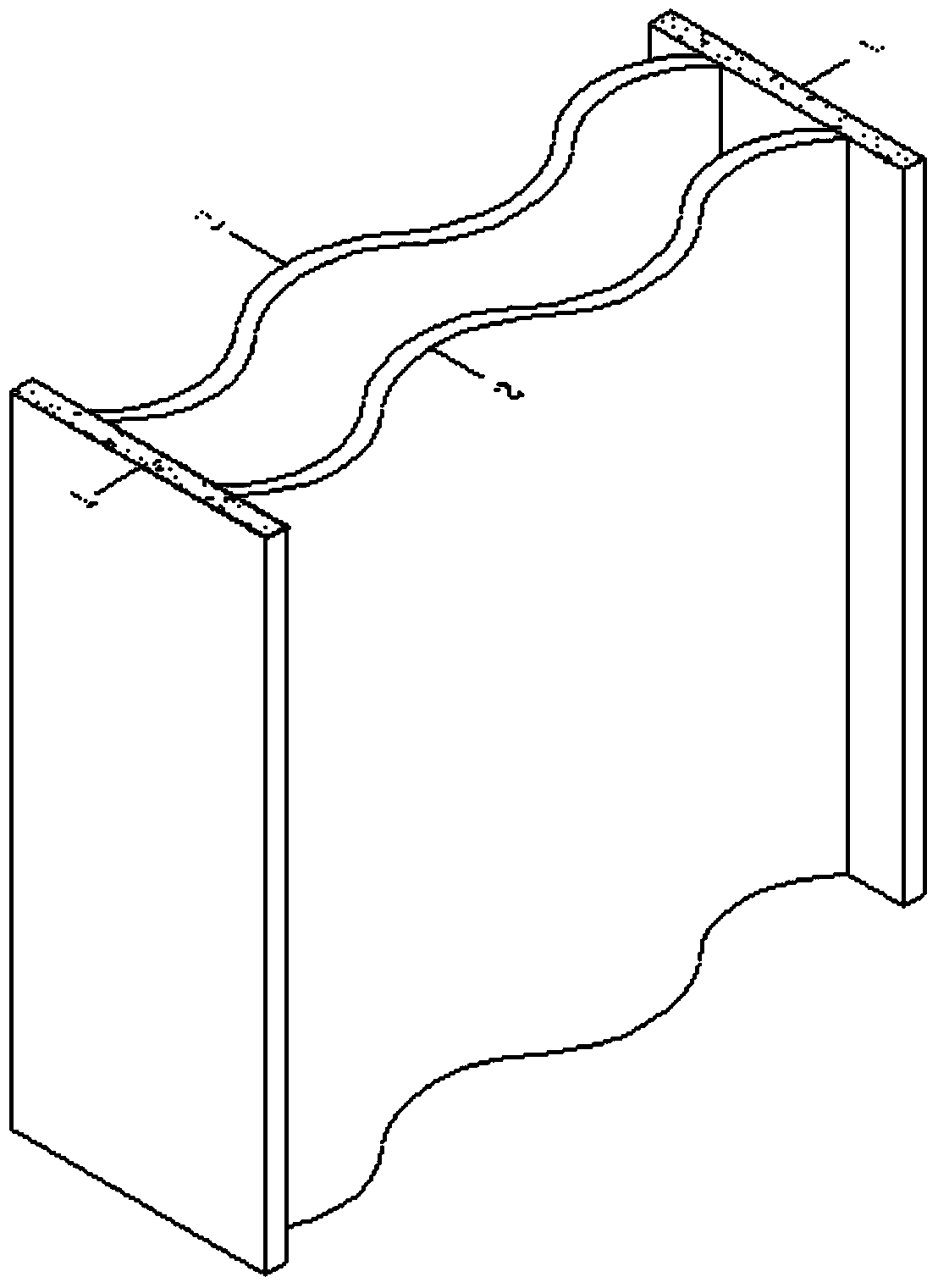

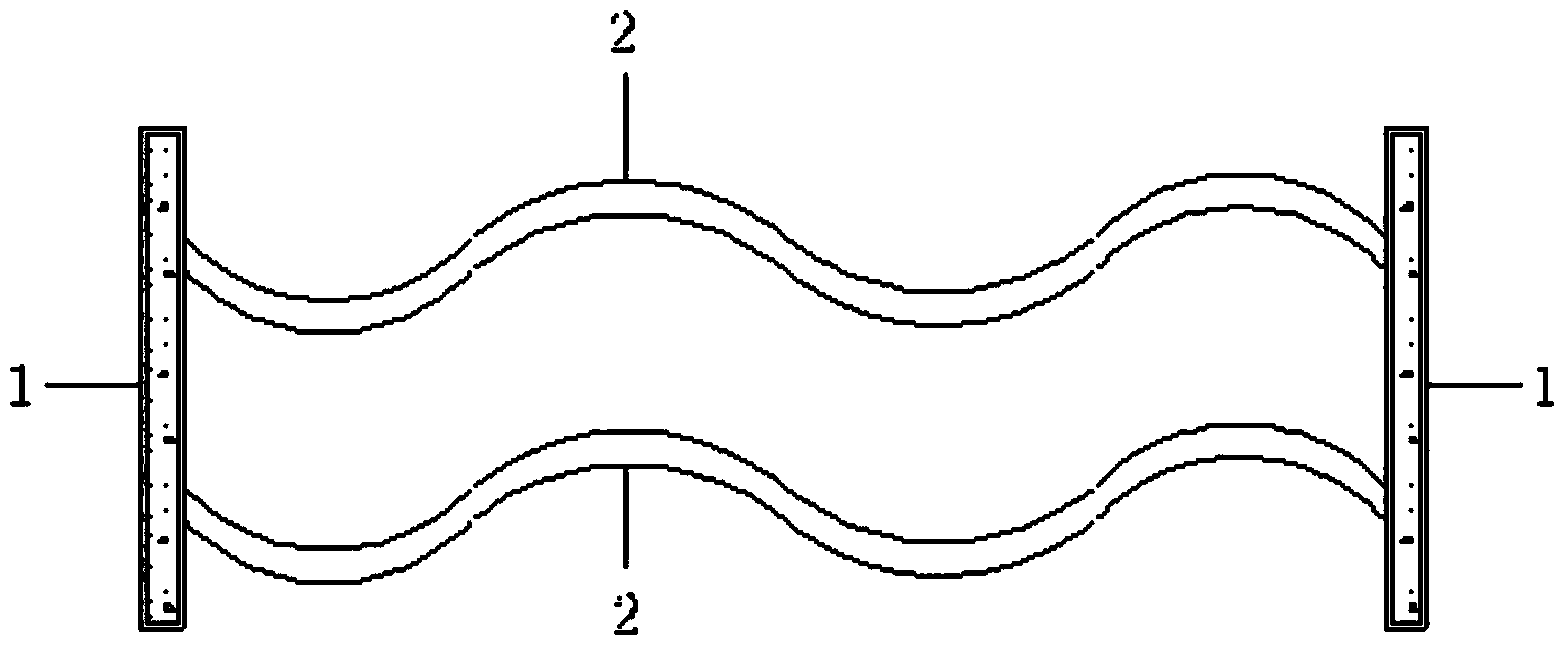

Corrugated web steel column with cross-shaped section

InactiveCN103835437AReduce usageSection composition is reasonableStrutsPillarsEngineeringSteel columns

The invention discloses a corrugated web steel column with a cross-shaped section. The corrugated web steel column comprises corrugated steel webs and plain plate flanges and is formed by welding an H-shaped corrugated web steel and two T-shaped corrugated web steel or welding four T-shaped corrugated web steel or welding three corrugated steel webs and four plain plate flanges, wherein the connection points of the corrugated steel webs and the plain plate flanges are in the middle of the width of the plain plate flanges, and the corrugated steel webs are curved, folded or trapezoidal. The steel column is reasonable in section composition, has good mechanical properties, high bearing capacity, good ductility, excellent anti-seismic property and simple structure, is convenient and fast to produce and process, saves steel and is low in cost.

Owner:NANJING UNIV OF TECH

H-shaped corrugated web steel column

InactiveCN103835438AReduce usageSection composition is reasonableStrutsPillarsEngineeringSteel columns

The invention discloses an H-shaped corrugated web steel column. The H-shaped corrugated web steel column comprises a corrugated steel web and two plain plate flanges, wherein the corrugated steel web is arranged between the two plain plate flanges; the connection points of the corrugated steel web and the plain plate flanges are in the middle of the width of the plain plate flanges; the corrugated steel web is curved, folded or trapezoidal. The steel column is reasonable in section composition, has good mechanical properties, high bearing capacity, good ductility, excellent anti-seismic property and simple structure, is convenient and fast to produce and process, saves steel and is low in cost.

Owner:NANJING TECH UNIV

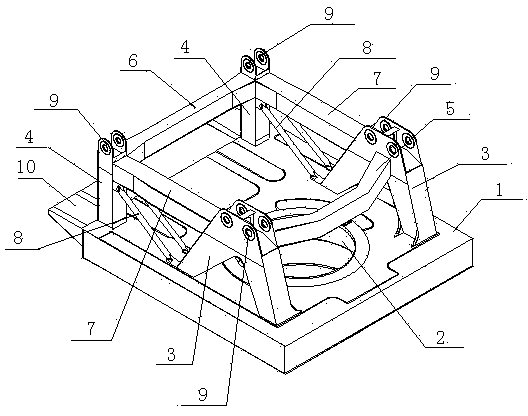

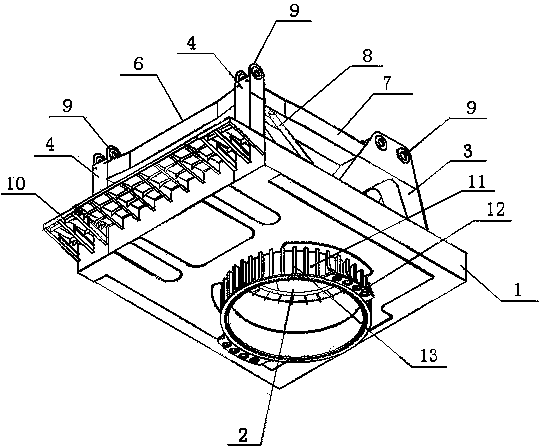

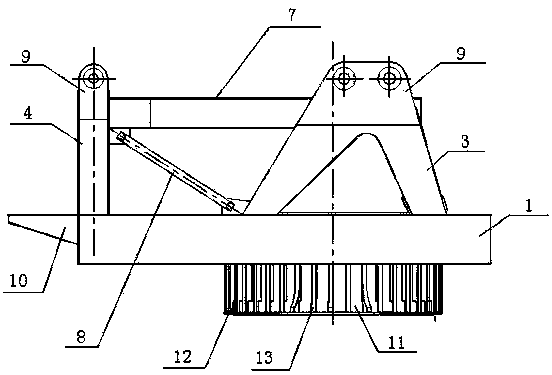

Large-scale pile winding type offshore platform crane revolving platform

The invention relates to a large-scale pile winding type offshore platform crane revolving platform which comprises a body. A pile passing hole is formed in the center of the body, front supports are welded on the upper surfaces of the two corners of the front portion of the body respectively, rear supports are welded on the upper surfaces of the two corners of the rear portion of the body respectively, the two front supports are connected through a front cross beam, the two rear supports are connected through a rear cross beam, the front supports and the rear supports are connected through side cross beams, inclined supporting rods are arranged on the lower portions of the side cross beams respectively, and shaft seats used for allowing crane jibs and propeller struts to be arranged are arranged on the two front supports and the two rear supports respectively. A luffing winch mounting platform is welded on the rear portion of the body, a cylinder is welded on the lower portion of the body, a swing mechanism mounting flange is welded on the lower portion of the cylinder, the cylinder corresponds to the pile passing hole, and multiple T-shaped longitudinal reinforcing ribs are evenly distributed on the outer circumferential face of the cylinder. The large-scale pile winding type offshore platform crane revolving platform has the advantages of being compact in structure, low in self-weight and reasonable in stress, and enabling mechanical components to be arranged conveniently.

Owner:NANTONG RAINBOW HEAVY MACHINERIES

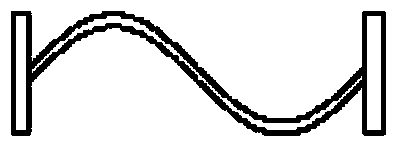

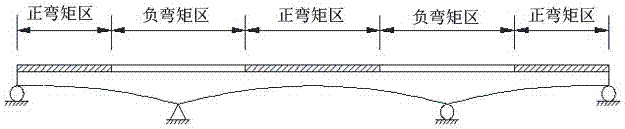

Longitudinal shear nonresistant perforated steel plate anti-pulling connecting piece and construction method thereof

ActiveCN106988200AEffectively release tensile stressIncreased efficiency of longitudinal prestressingBridge structural detailsBridge materialsPre stressEconomic benefits

The invention provides a longitudinal shear nonresistant perforated steel plate anti-pulling connecting piece and a construction method thereof, relates to a connecting piece applied to a bridge structure and belongs to the technical field of bridge structures. The connecting piece is used for connecting a steel beam and a concrete plate and comprises a steel plate provided with long circular holes and penetrating steel bars. The portions, on the two sides of the penetrating steel bars, of the long circular holes are filled with elastic materials. The connecting piece steel plate is welded to an upper flange plate of the steel beam. The connecting piece is adopted in a hogging moment area of a steel-concrete continuous composite beam bridge, tensible stress of the concrete plate in the hogging moment area can be effectively decreased, the longitudinal prestress leading-in degree of the concrete plate is improved, long-term performance and durability of the concrete plate are improved, and meanwhile, the connecting piece has a reliable anti-pulling capability and can resist the lifting effect of the concrete plate relative to the steel beam. According to the connecting piece, materials are convenient to take, and the connecting piece is simple in structure, rapid in construction and rational in stress and has good technical and economic benefits.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Concrete slant component upper supporting system and construction method for same

InactiveCN106917508AImprove stabilityEliminate destructionForms/shuttering/falseworksShoresSupporting systemSurface layer

The invention discloses a concrete slant component upper supporting system and a construction method for the same. The concrete slant component upper supporting system is built on a completed reinforced concrete slant component and comprises a plurality of concrete steps arranged on a slope of the reinforced concrete slant component; the slope of the reinforced concrete slant component is provided with anti-shearing slots and vertical insertion ribs cast with the concrete steps; each concrete step is provided with elongated I-shaped steel; a supporting rack is built over the I-shaped steel; and supporting stand columns of the supporting rack are supported on the I-shaped steel. With arrangements of the concrete steps and the increase of the I-shaped steel, concentrated force of the supporting rack can be converted into uniform-distribution force, so damage to a top plate surface layer can be eliminated; and a cross section of each stand column is evenly stressed, so perpendicularity can be guaranteed and local stability of the column member can be enhanced.

Owner:ZHONGTIAN CONSTR GROUP

Steel box concrete slot type girder bridge

The invention discloses a steel box concrete combination slot type girder bridge. The steel box concrete combination slot type girder bridge comprises at least two steel box concrete structure main girders, wherein a steel bridge deck structure is fixedly connected between the two adjacent steel box concrete main girders; the steel box concrete structure main girders comprise steel box structure main girders, wherein concrete structures integrally formed with the steel box structure main girders are fully casted in the steel box structure main girders; the steel bridge deck structure is arranged at the lower parts of the steel box concrete structure main girders; the steel bridge deck structure and the two steel box concrete structure main girders respectively positioned on two sides of the steel bridge deck structure form a slot type structure. The steel box concrete slot type girder bridge disclosed by the invention not only has the advantages of a conventional steel slot type girder bridge, but also fully exerts respective characteristics of steel and concrete materials, and has the characteristics of reasonable forced system high bearing capacity, large rigidity, good anti fatigue property and the like; at the stages of construction and use, the safety, the reliability, the durability and the risk resistance of the conventional structure are improved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

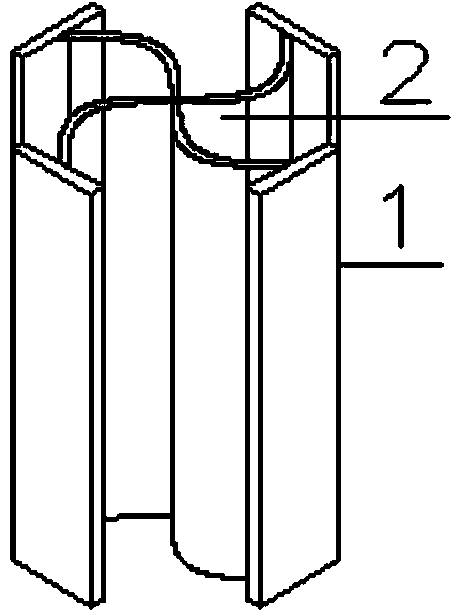

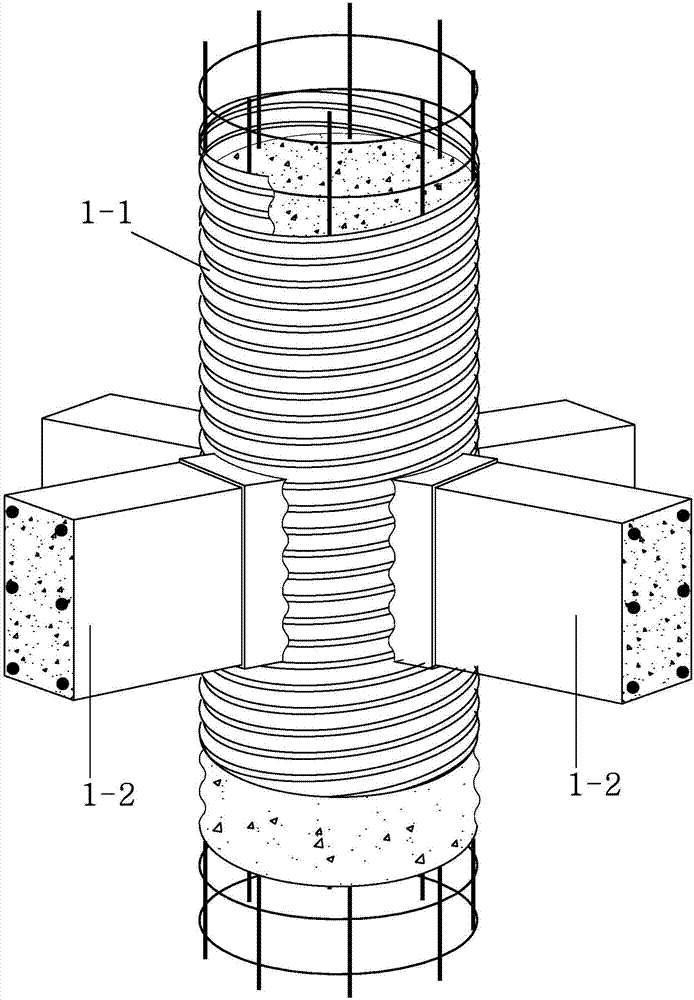

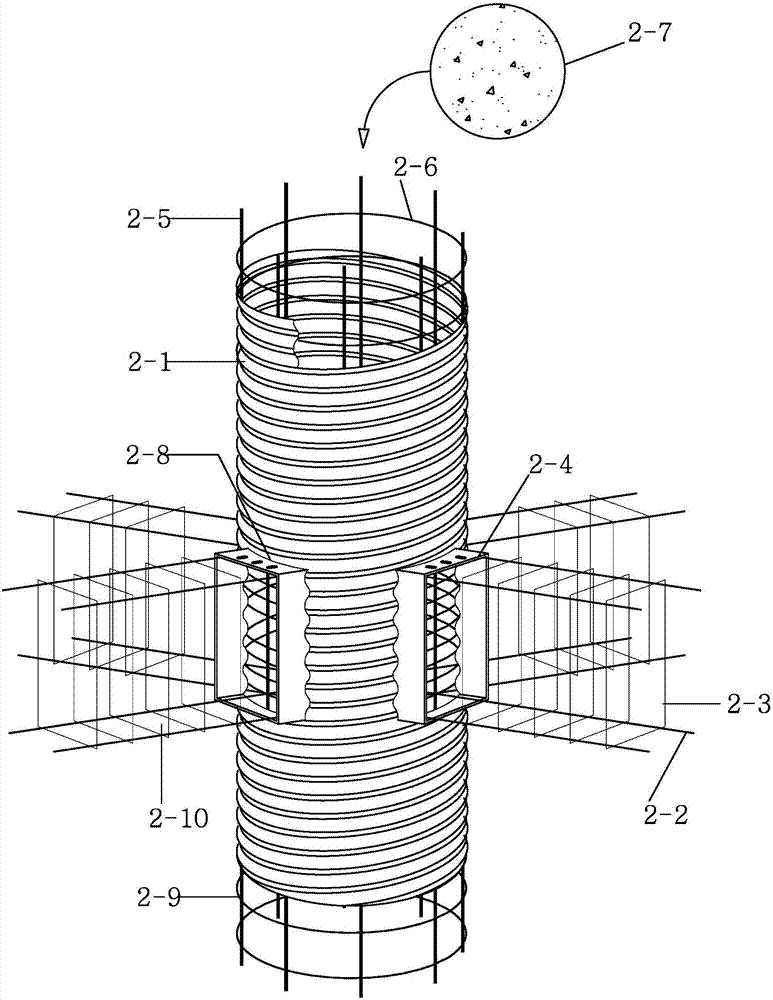

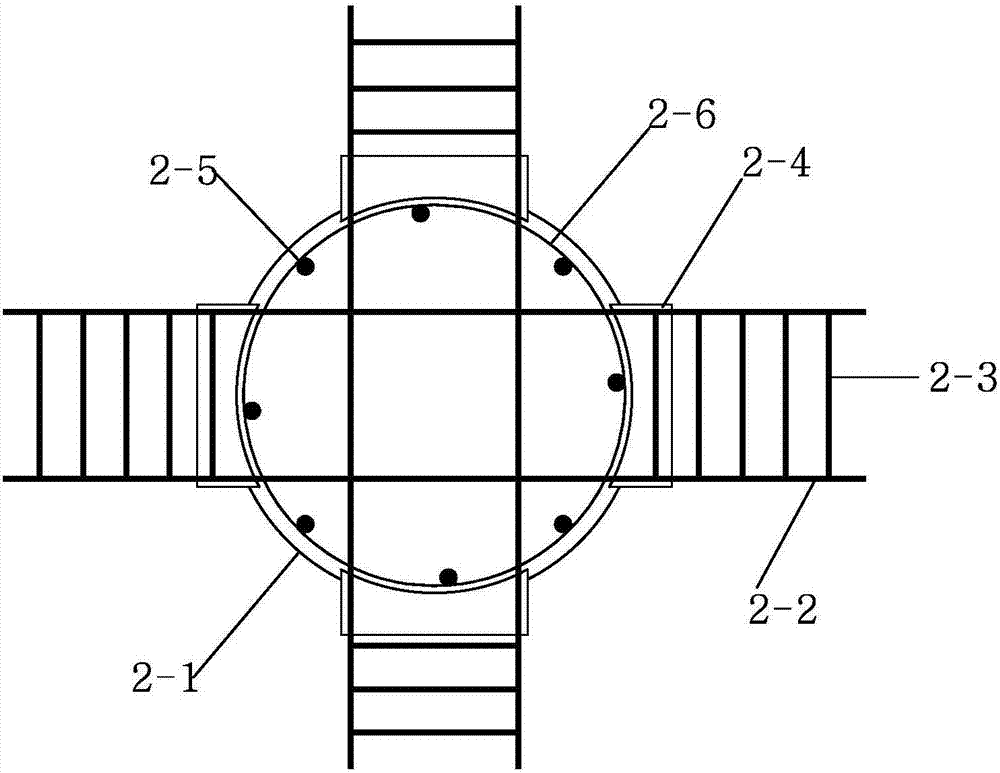

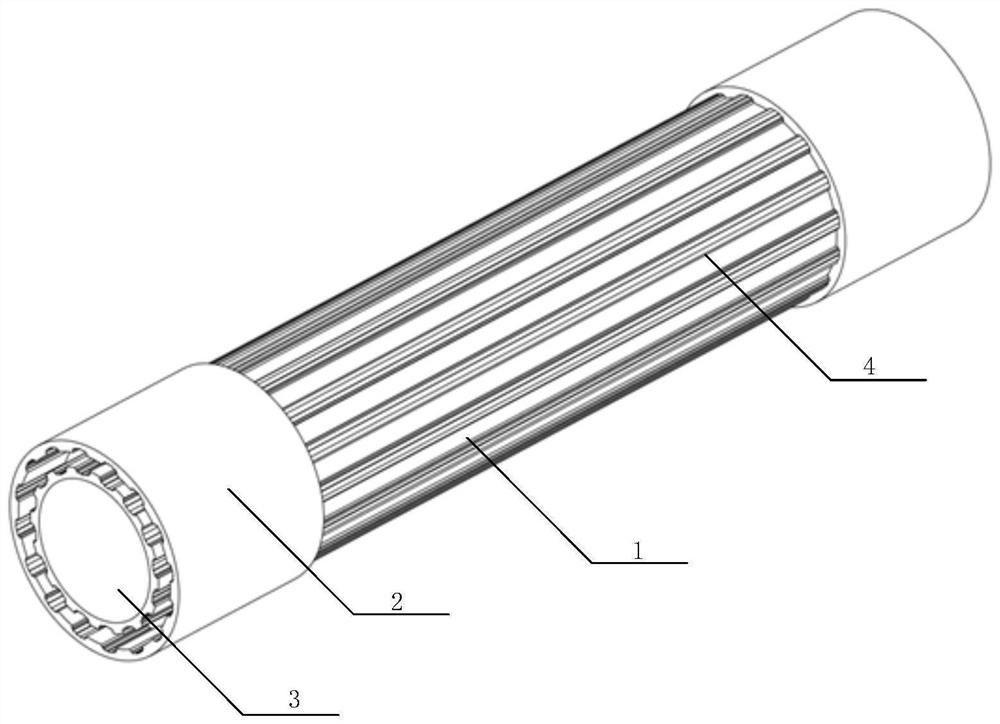

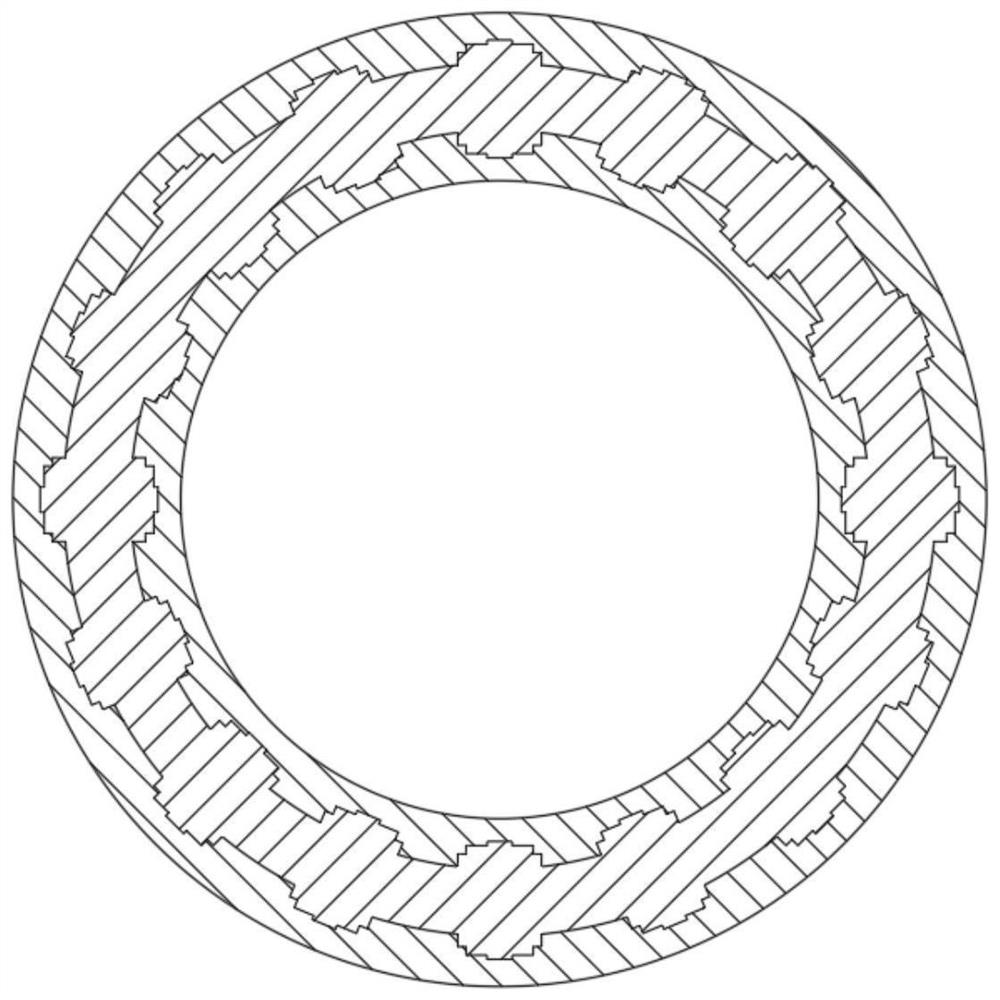

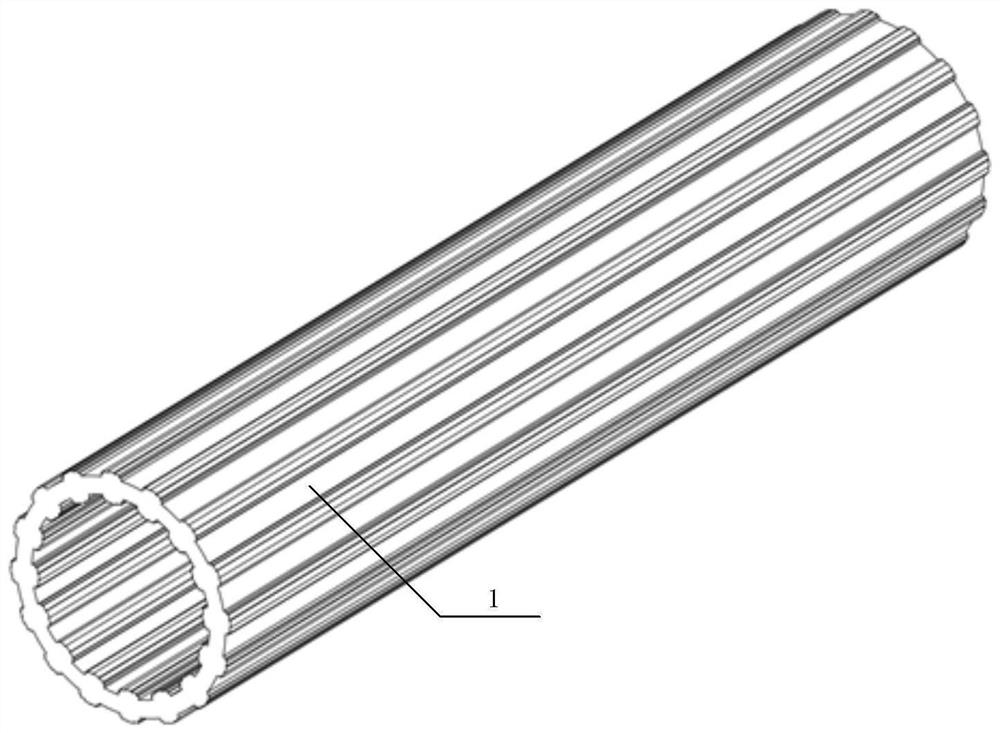

Corrugated steel pipe reinforced concrete column

InactiveCN107012988ASimple structureFast constructionStrutsPillarsReinforced concrete columnSteel bar

The invention discloses a corrugated steel pipe reinforced concrete column, relates to a reinforced concrete column, and aims to solve a problem that beam-column connection nodes in a frame structure composed of existing steel pipe reinforced concrete columns and reinforced concrete beams are complex in stress, difficult in construction and unable to ensure performance under stress, and problems that a node core region in the frame structure composed of steel pipe restrained reinforced concrete columns and the reinforced concrete beams is not easy to realize a design principle of 'strong column, weak beam and stronger node', steel pipes are easy to bend, and columns are complex in construction. The corrugated steel pipe reinforced concrete column comprises a column body (1-1) and two reinforced concrete beams (1-2); the two reinforced concrete beams (1-2) are perpendicular to each other to form a plane; the plane horizontally penetrates the vertically arranged column (1-1). The corrugated steel pipe reinforced concrete column provided by the invention is used in the construction industry.

Owner:HARBIN INST OF TECH

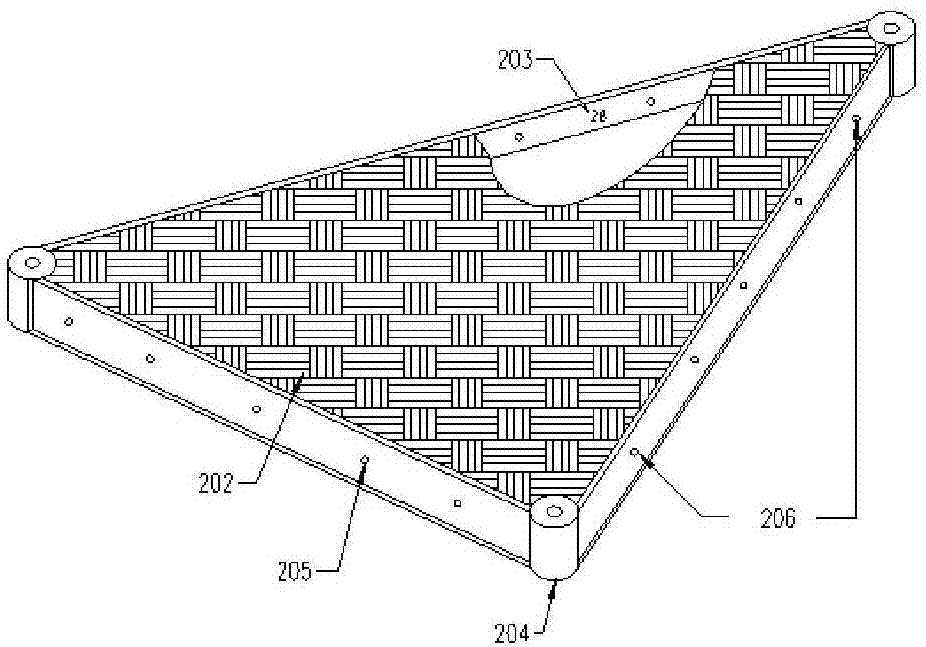

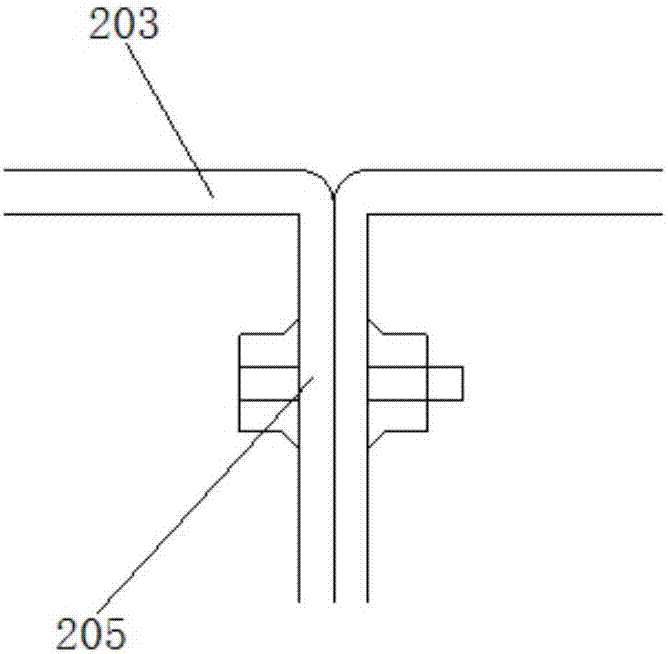

Truss type radome

InactiveCN107275778AEasy to disassembleAvoid interferenceRadiating element housingsRadarMetallic materials

The invention discloses a truss type radome which adopts a hollow truncated spherical skeleton. A plurality of triangular rib units are arranged on the skeleton to be spliced into the truss type radome, and each of the triangular rib units comprises three ribs and a radome skin which is arranged on the surface of the triangular rib unit. The triangular rib unit and the radome skin are made of basalt fiber. The truss type radome adopts the hollow truncated spherical skeleton and splices the plurality of triangular rib units on the skeleton to form the radome. Each of the triangular rib units comprises the three ribs and the radome skin which is arranged on the surface of the triangular rib unit. In order to facilitate the factory production and installation, the triangular units are used to easily remove the radome, so that transport, use and maintenance are convenient. The top of each fiber rib has a certain flange facilitating assembly and bonding later. The triangular rib units and the radome skins are made of the basalt fiber material, which can effectively avoid the interference of metal materials on a radar antenna.

Owner:XI AN JIAOTONG UNIV

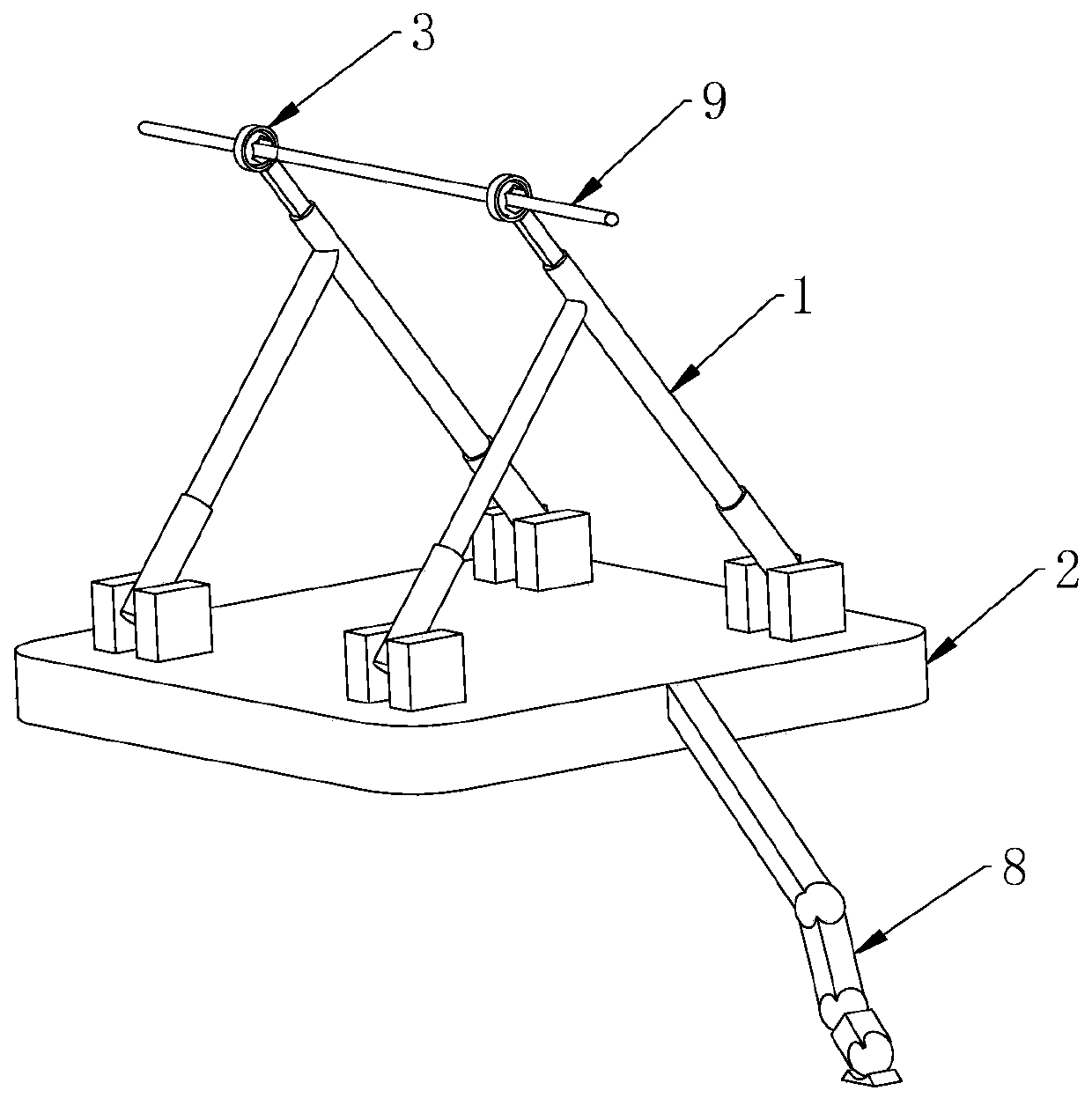

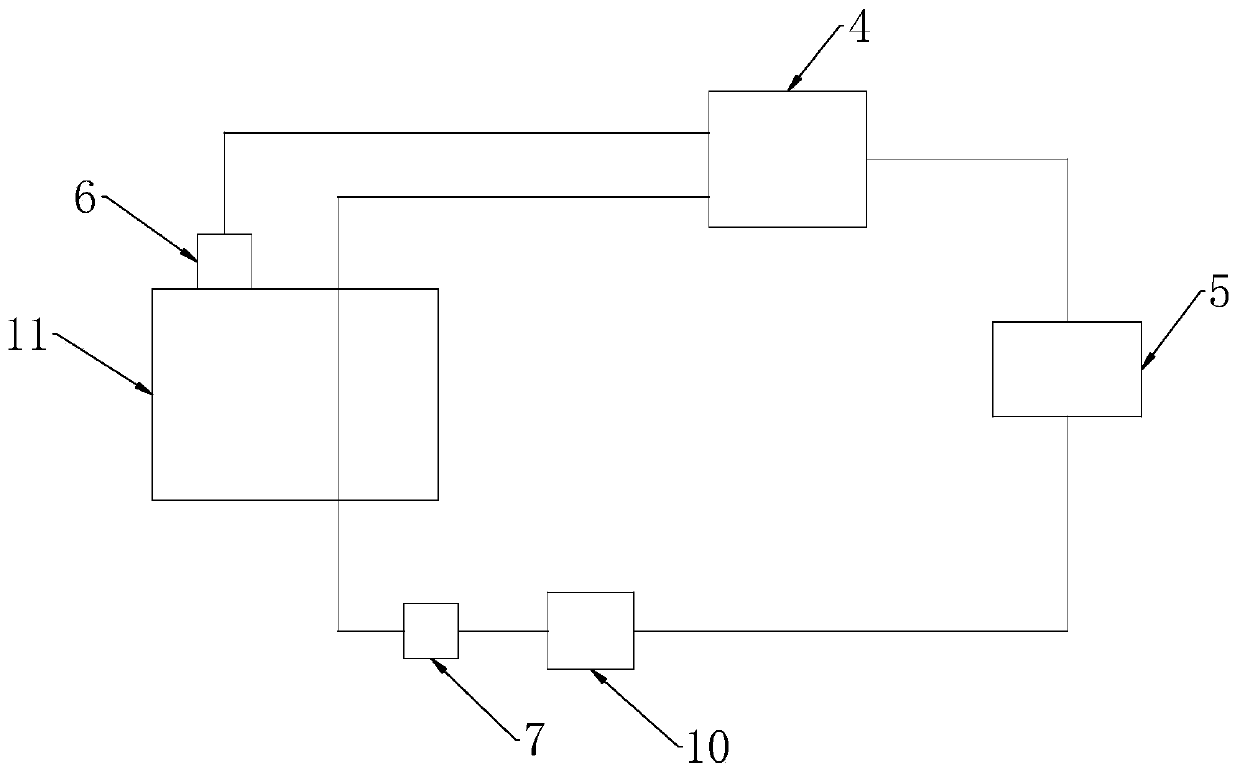

Dynamic adjusting device, dynamic adjusting system and using method of system

PendingCN110279470ASmall sizeSave spaceSurgical navigation systemsSurgical manipulatorsEngineeringMechanical engineering

The invention provides a dynamic adjusting device, a dynamic adjusting system and a using method of the system. The dynamic adjusting device comprises at least two adjusting assemblies located in different planes; each adjusting assembly comprises at least two telescopic parts, one end of each telescopic part is hinged to a connecting platform, the other ends of the at least two telescopic parts are hinged with each other, the other end of at least one telescopic part in each adjusting assembly is further connected with a spherical hinge structural part, and one end of each of the at least two telescopic parts in the other adjusting assembly is hinged to the connecting platform. According to the dynamic adjusting device, the adjusting assemblies are arranged in different planes respectively, the telescopic parts are hinged to the connecting platform, the spherical hinge structural parts are connected to one ends of the telescopic parts, one unique straight line can be determined through the hinge point of the two spherical hinge structural parts, and actuating elements can act along the straight line. Besides, the dynamic adjusting device further has the advantages of simple structure and small size.

Owner:BEIJING ROSSUM ROBOT TECH CO LTD

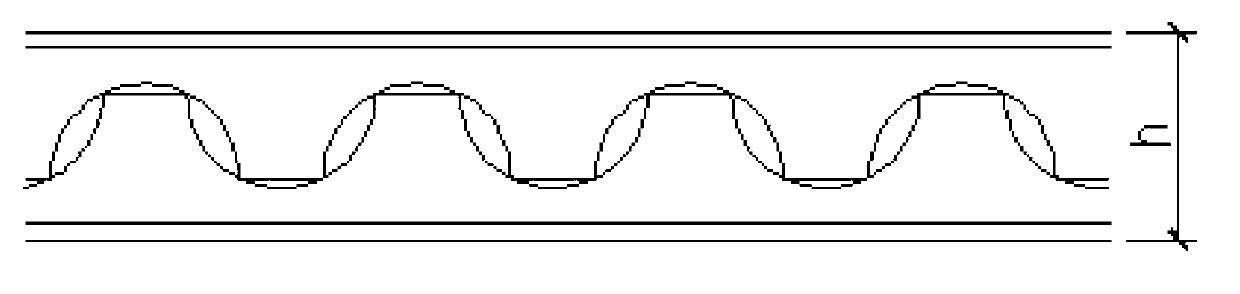

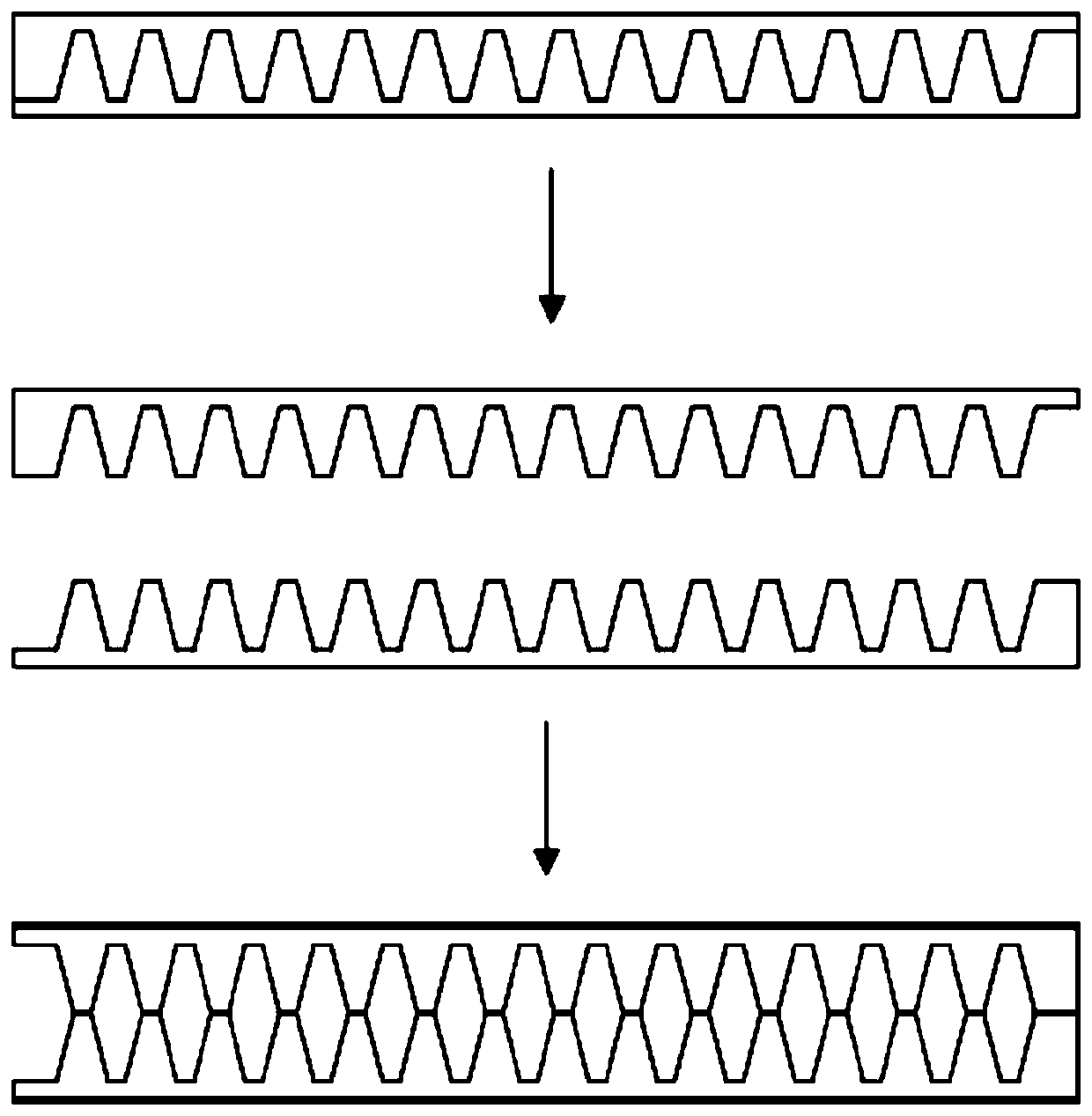

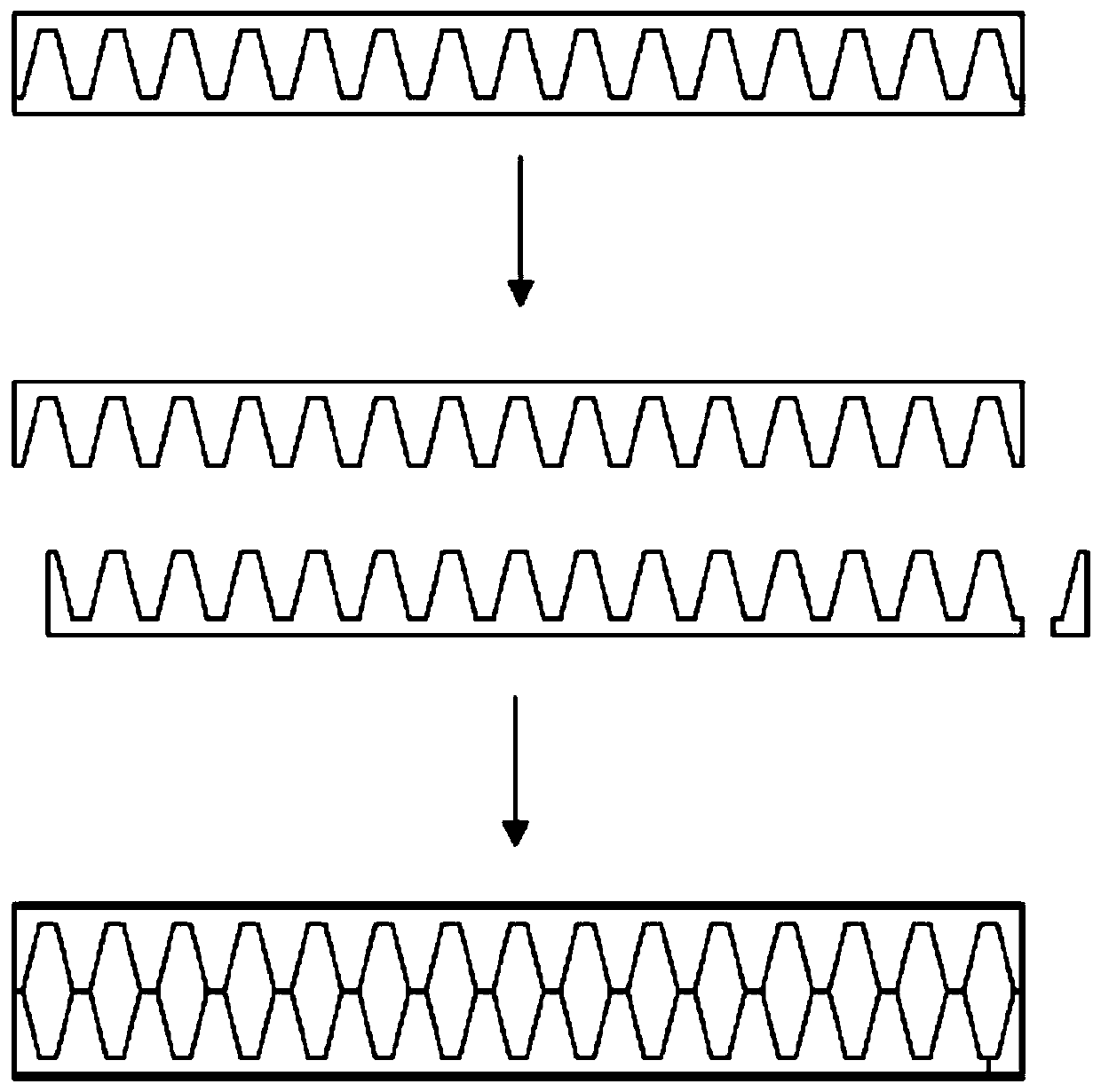

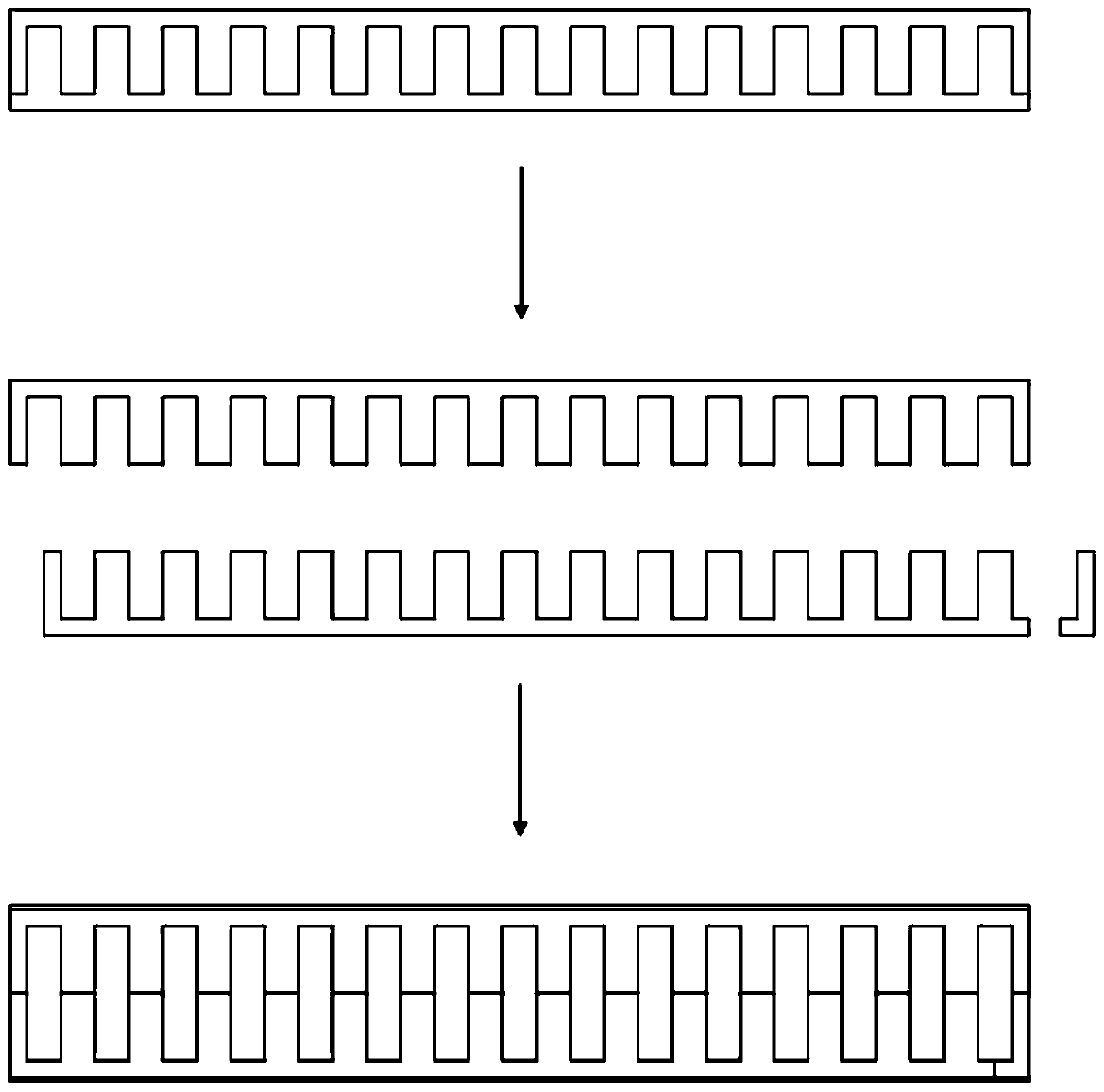

Staggered-welding type cast-in-place wrapped castellated beam with web openings

InactiveCN109930747ATake advantage ofIncreased beam heightLoad-supporting elementsPolygonal lineReinforced concrete

The invention discloses a staggered-welding type cast-in-place wrapped castellated beam with web openings. The castellated beam comprises a steel skeleton consisting of main beams and a secondary beam, wherein the main beams and the secondary beam are all produced by I-shaped beams, and the I-shaped beams comprises webs and top flanges and bottom flanges respectively arranged on the upper and lower sides of the webs; each I-shaped beam is cut along a preset fold line on the web of the I-shaped beam into two steel beams with a toothed side edge, and the toothed side edges of the two steel beamsare welded in a staggered way to form the main beam or the secondary beam with the web openings; after the steel skeleton is prefabricated, longitudinal reinforcements and pipelines are arranged on the steel skeleton, wherein lower longitudinal reinforcements and pipelines all penetrate the openings on the webs, upper longitudinal reinforcements pass through the upper parts of the top flanges, concrete is poured after the longitudinal reinforcements and the pipelines are arranged, the steel skeleton is wrapped by the concrete, so that a whole module is formed by the steel skeleton and a reinforced concrete floor. The castellated beam disclosed by the invention has large second moment of area and flexural capacity, and good energy-dissipating capacity under an earthquake load effect.

Owner:BEIJING UNIV OF TECH

Component and joint integrated composite material pre-tightening force longitudinal fractal tooth connecting device

PendingCN114458934AAvoid secondary processingReduce the difficulty of assemblyElongated constructional elementsComposite materialMaterials science

Owner:NANJING UNIV OF TECH

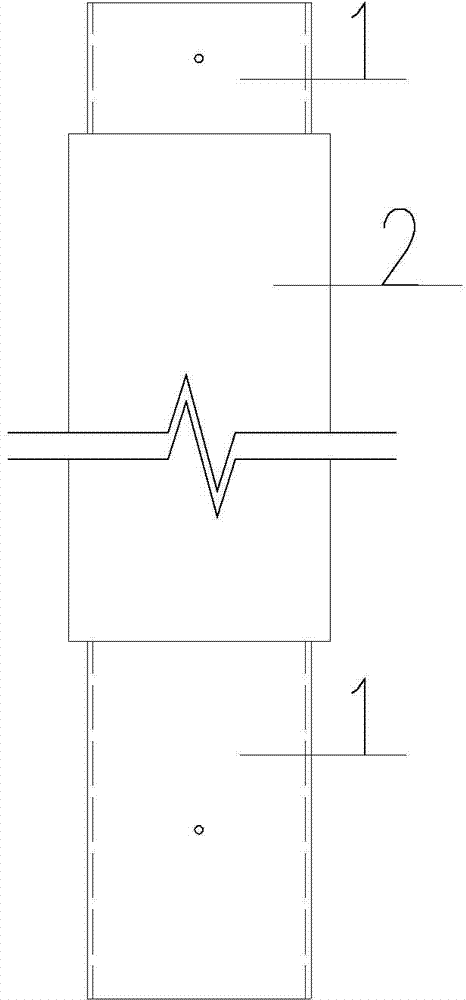

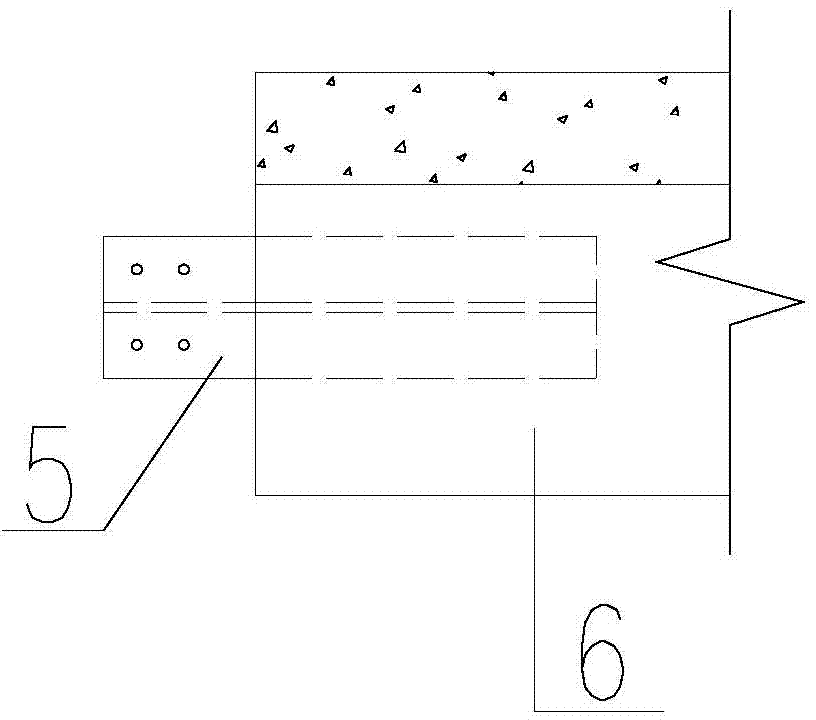

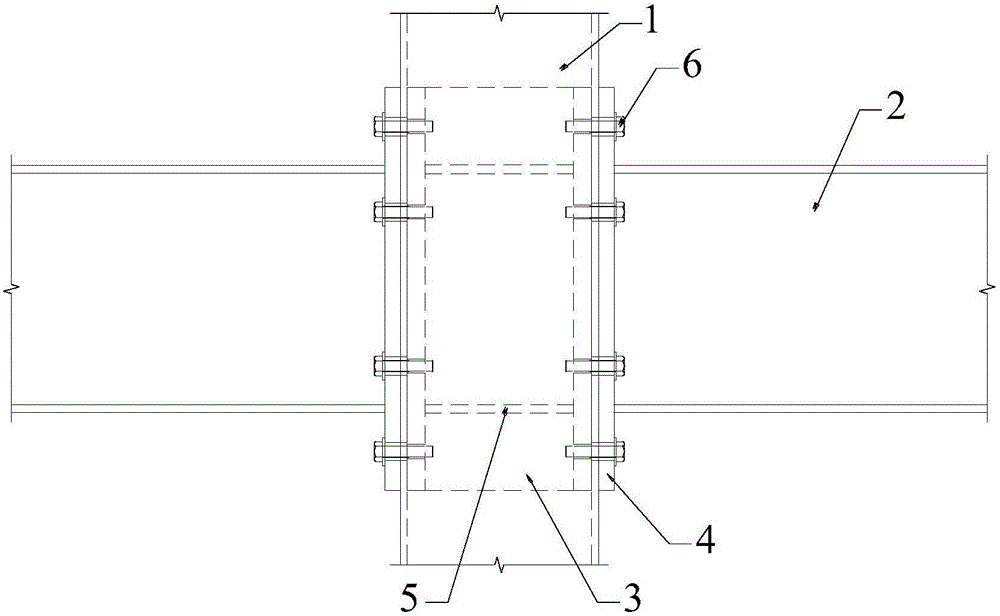

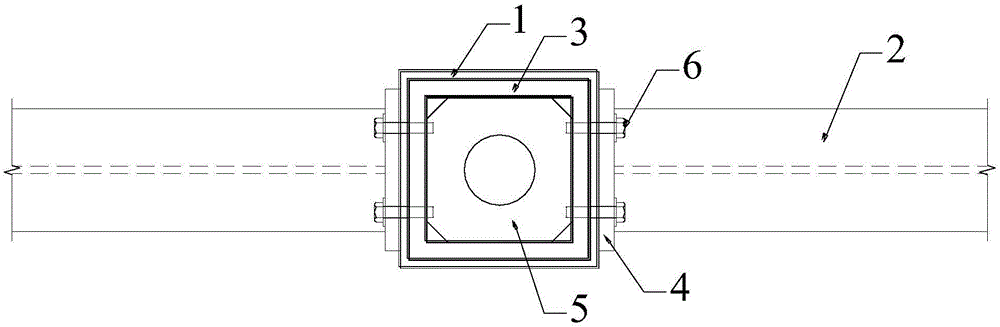

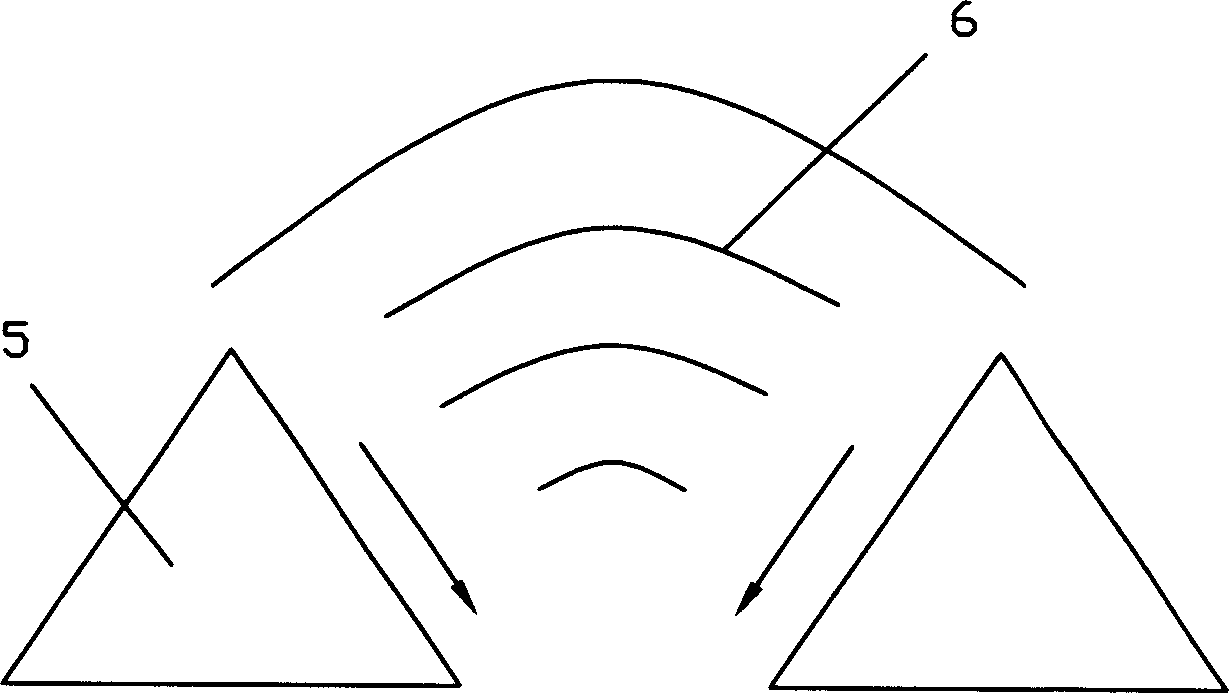

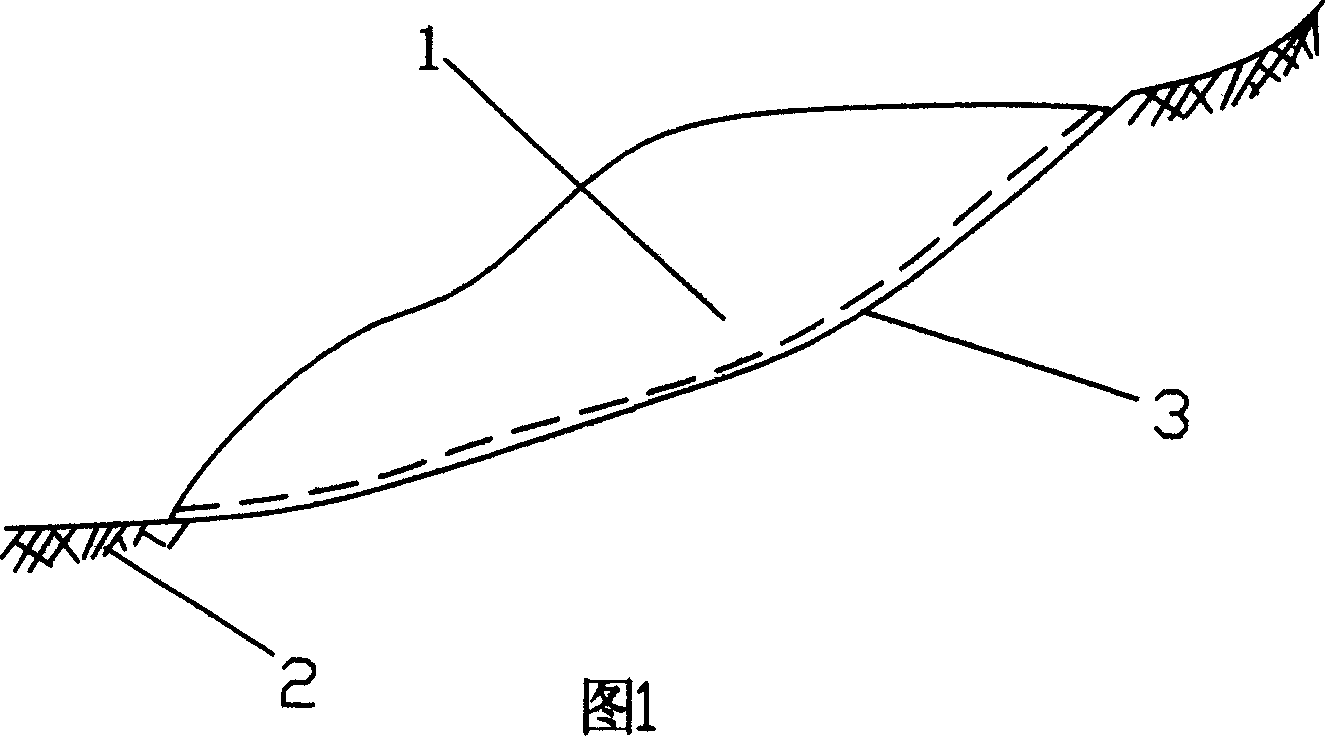

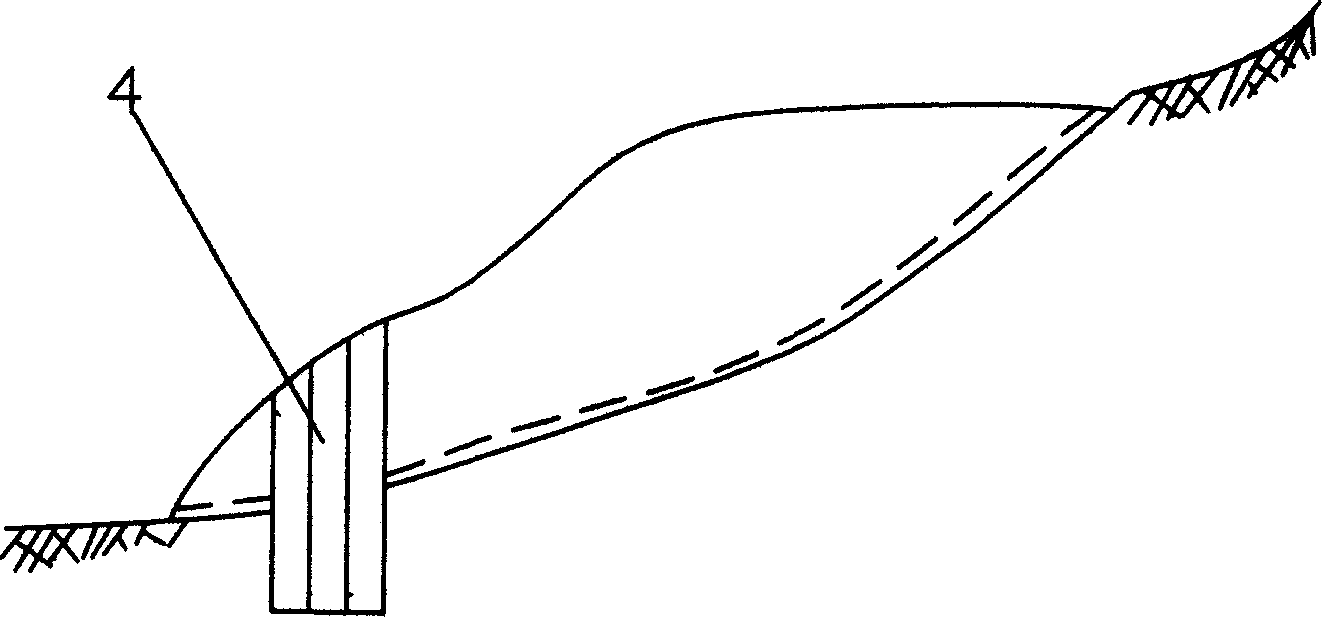

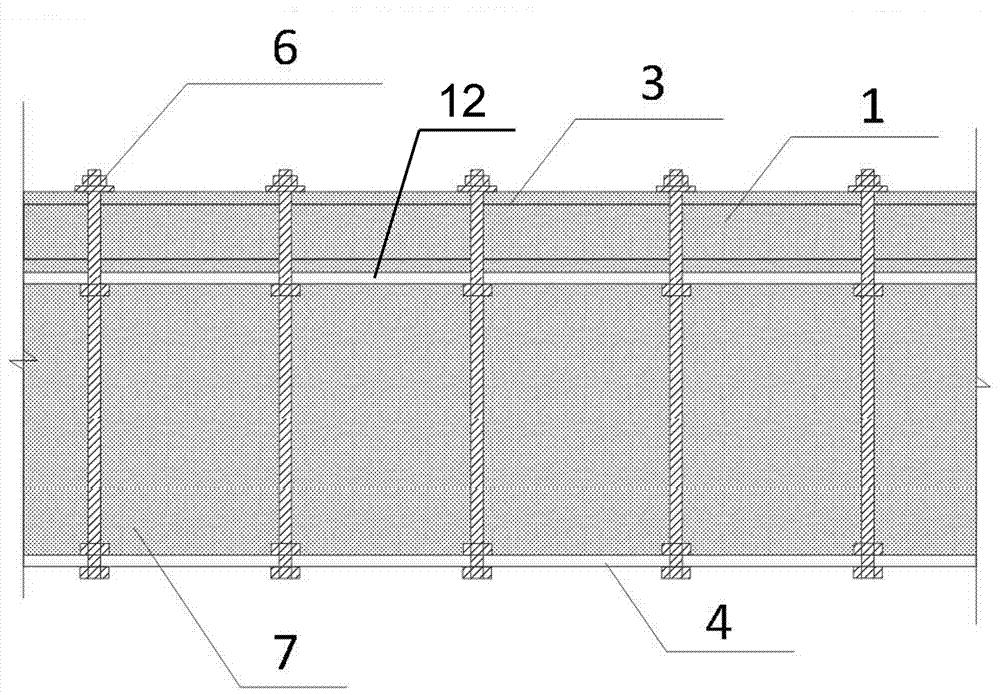

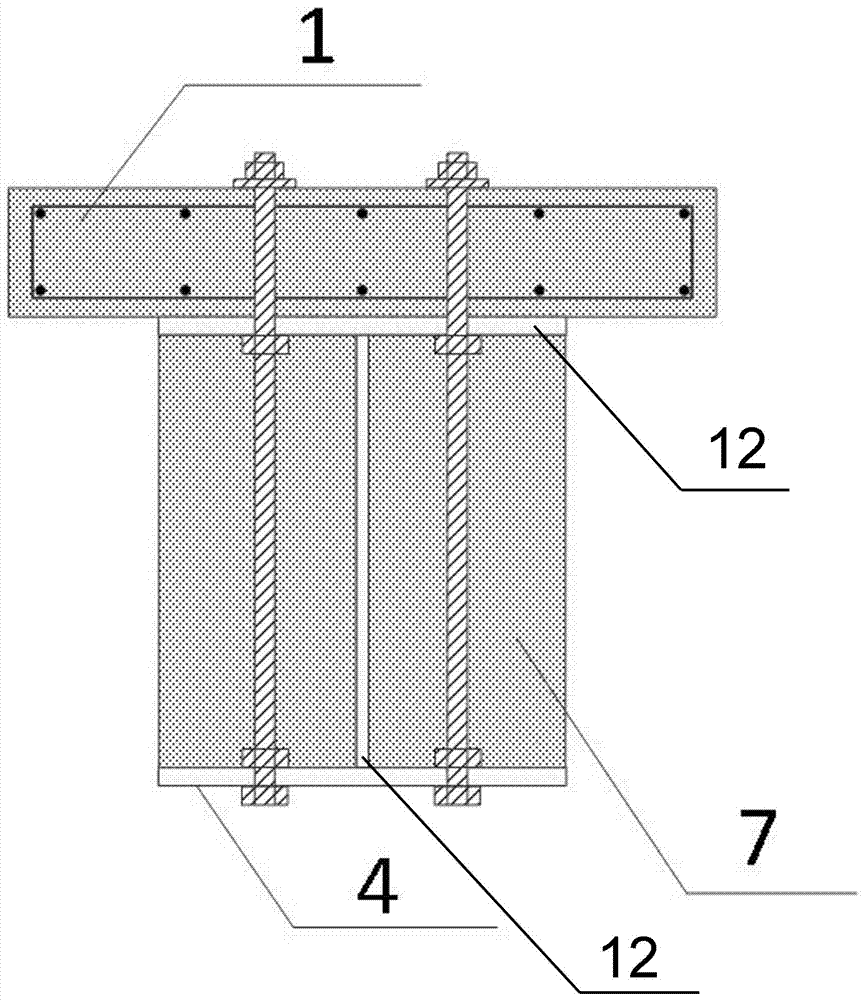

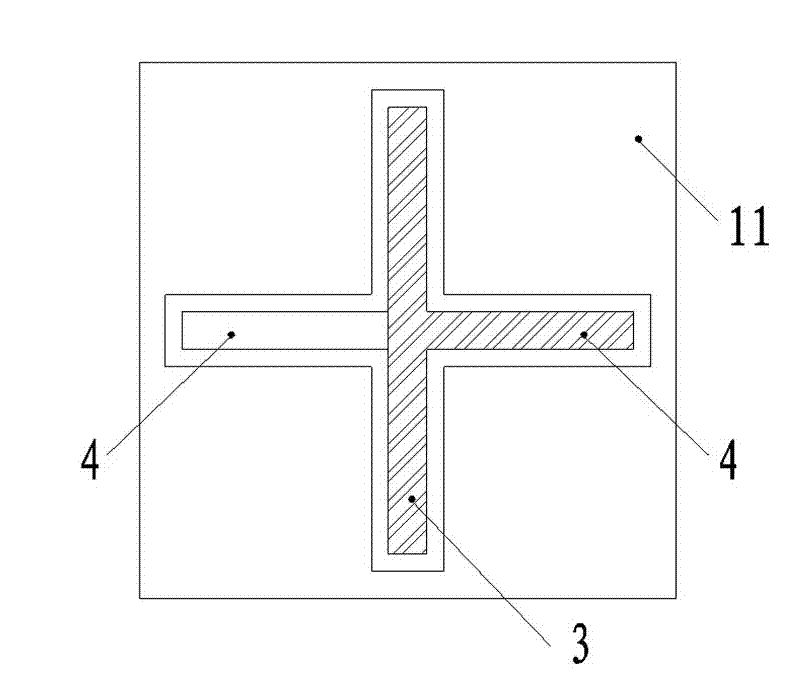

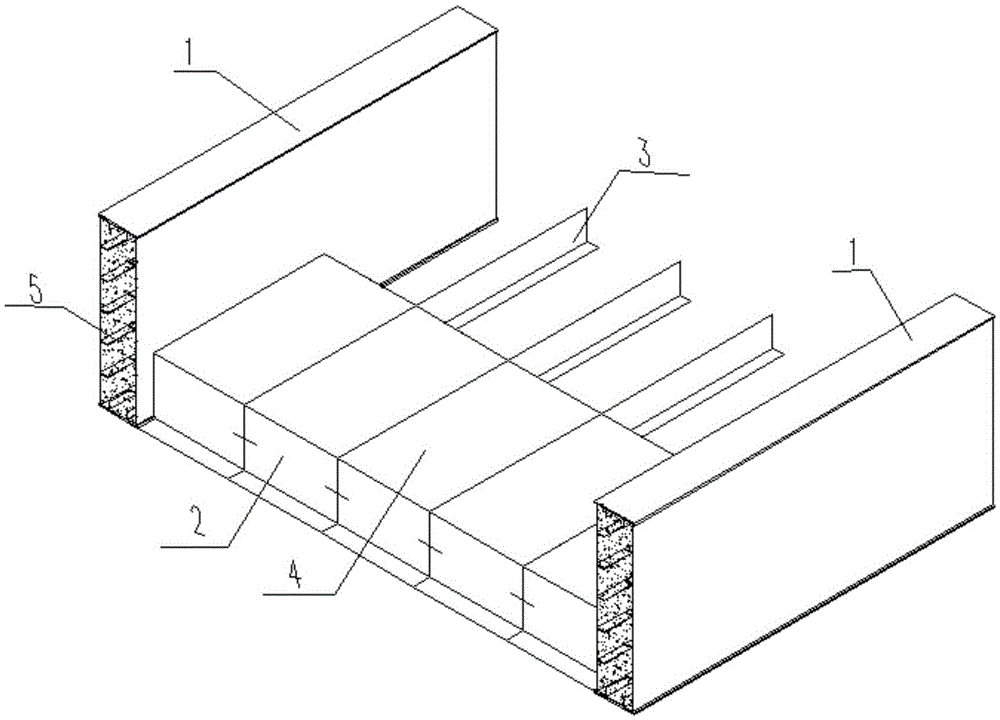

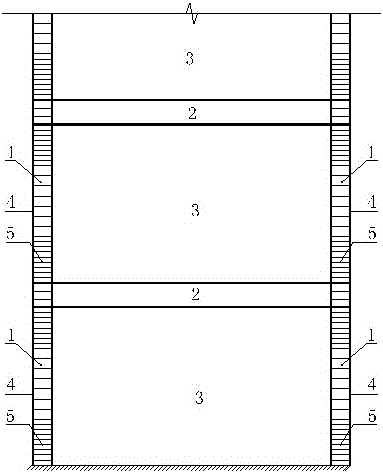

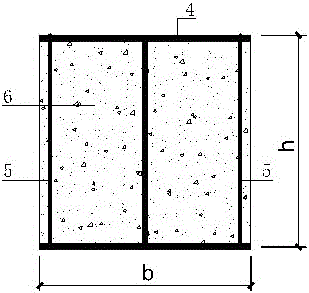

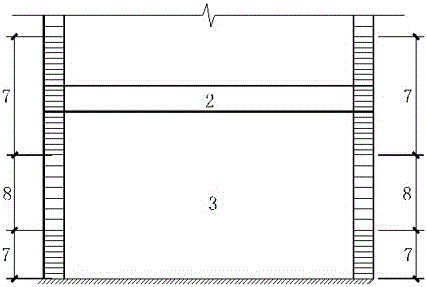

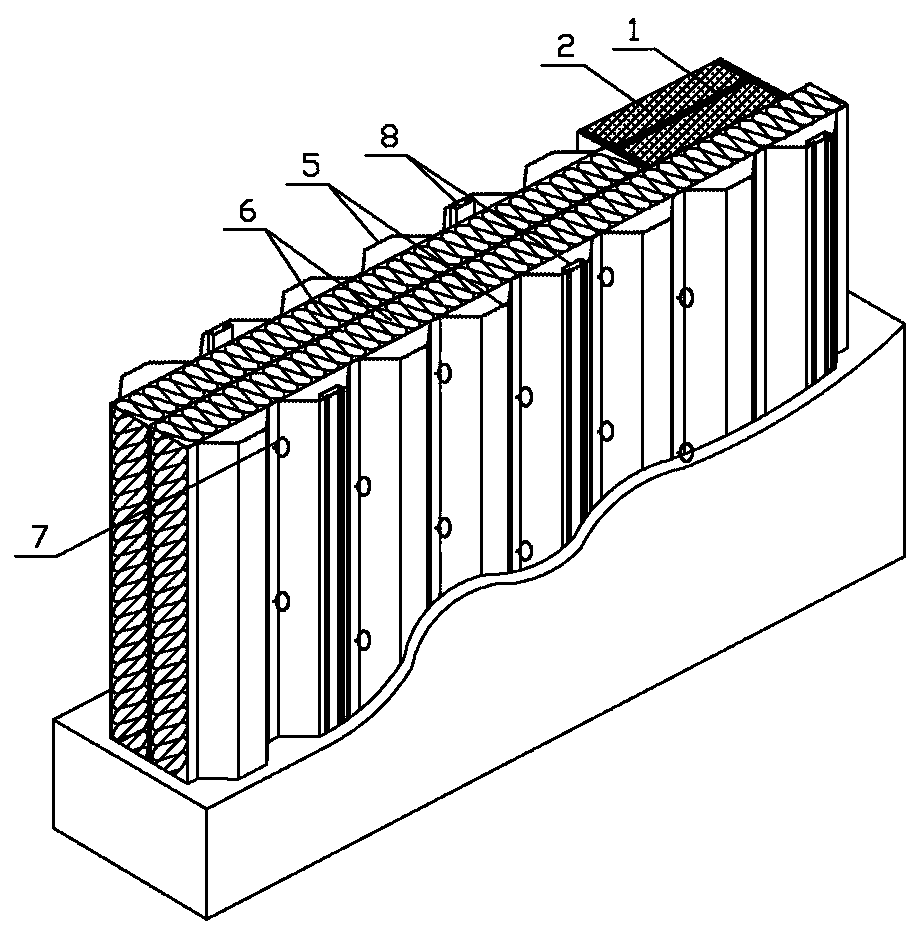

Steel plate shear wall structure suitable for high-rise/super high-rise buildings in high-seismic-intensity regions

Provided is a steel plate shear wall structure suitable for high-rise / super high-rise buildings in high-seismic-intensity regions. A profile steel PEC pillar is used for replacing a common steel framework pillar, and is composed of an H-shaped PEC pillar body (1), a framework beam (2) and a built-in steel plate (3). The H-shaped PEC pillar body is a combined pillar with high strength and rigidity, and a part of the combined pillar is wrapped with concrete. The H-shaped PEC pillar body is composed of profile steel (4), tie bars (5) and the concrete (6). The tie bars (5) are welded to the portion between an upper flange and a lower flange of the H-shaped steel (4). The pillar top and the pillar bottom are subjected to the densification treatment, so that the pillar top and the pillar bottom are each divided into a densified area (7) and a non-densified area (8).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

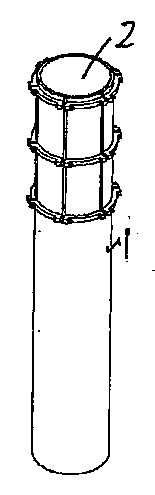

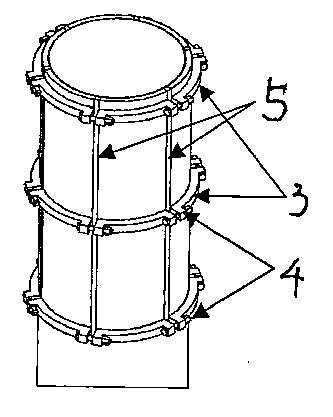

Self-stress adjustable concrete filled steel tubular column

InactiveCN103866906ASimple structureEasy to manufactureStrutsBridge structural detailsMaterials sciencePolymer

The invention discloses a self-stress adjustable concrete filled steel tubular column. The self-stress adjustable concrete filled steel tubular column comprises a steel tube, wherein the upper part of the steel tube is provided with symmetric longitudinal groove seams, a core concrete column is arranged in the steel tube, a plurality of transverse strengthening ribs which tightly hold the steel tube are arranged on the outer surface of the steel tube, two adjacent ribs are connected by virtue of a bolt and a nut, each longitudinal groove seam of the steel tube is sealed by virtue of a filling strip made of a high-elasticity polymer, and cylindrical surfaces, divided by the groove seams, of the upper part of the steel tube shrink inwards when two adjacent ribs are screwed by the bolts so as to eliminate a pumping area. Due to the adoption of the self-stress adjustable concrete filled steel tubular column, with the arrangement of an adjustable self-stress steel barrel, the structure is simple, the manufacturing is convenient, and the cost is low; by virtue of the tightening of the adjacent ribs on the steel barrel, the symmetric cylindrical surfaces of the steel barrel can be incurved and deform, so that the pumping area can be completely eliminated, and the core concrete is compressed to form the self stress.

Owner:NANTONG UNIVERSITY

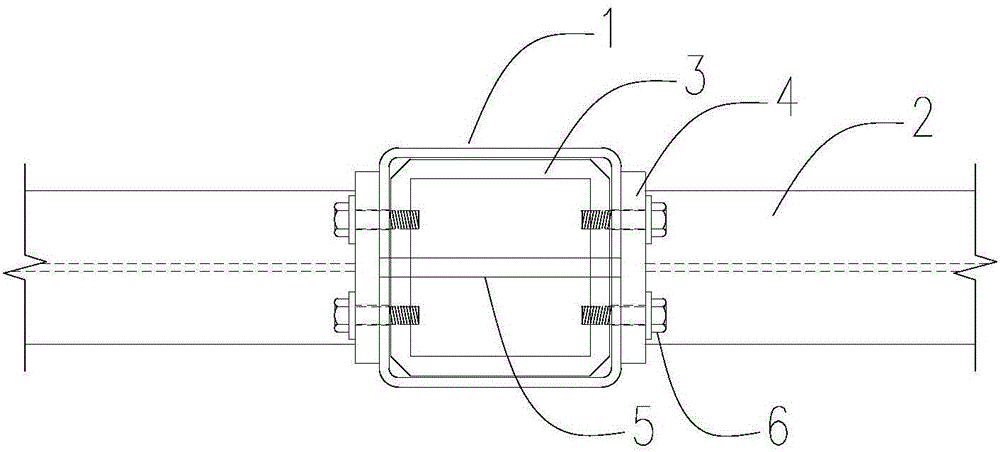

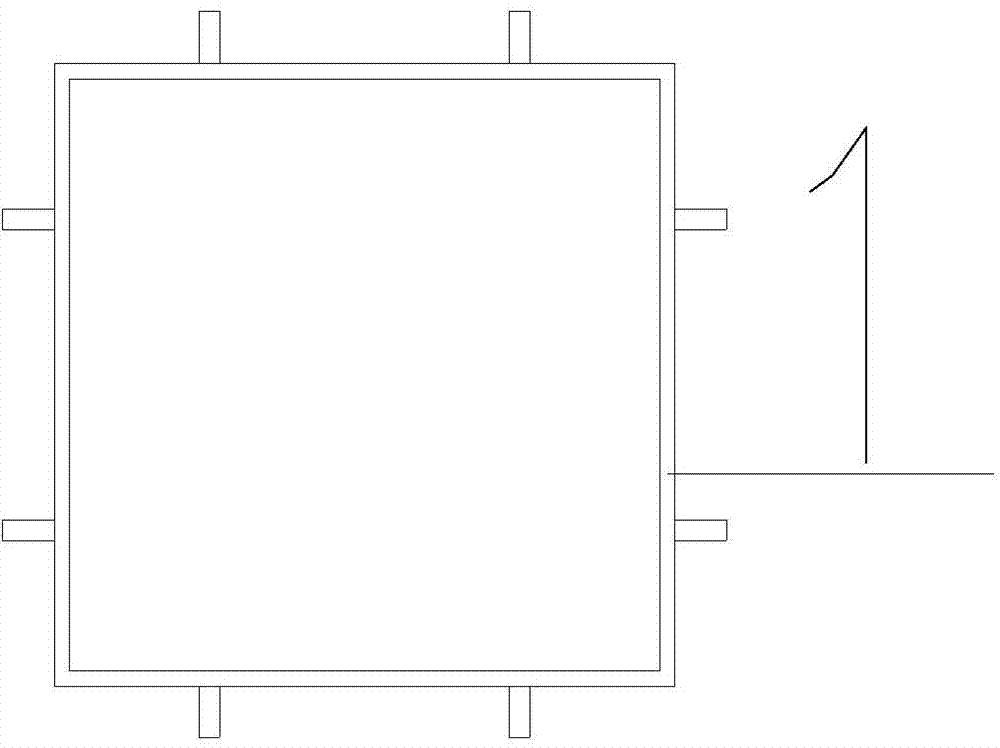

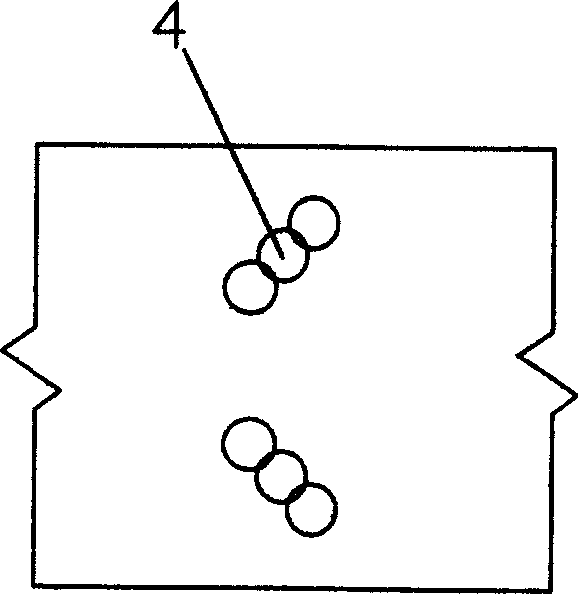

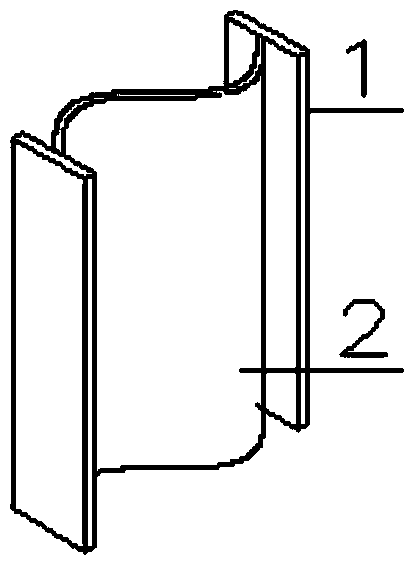

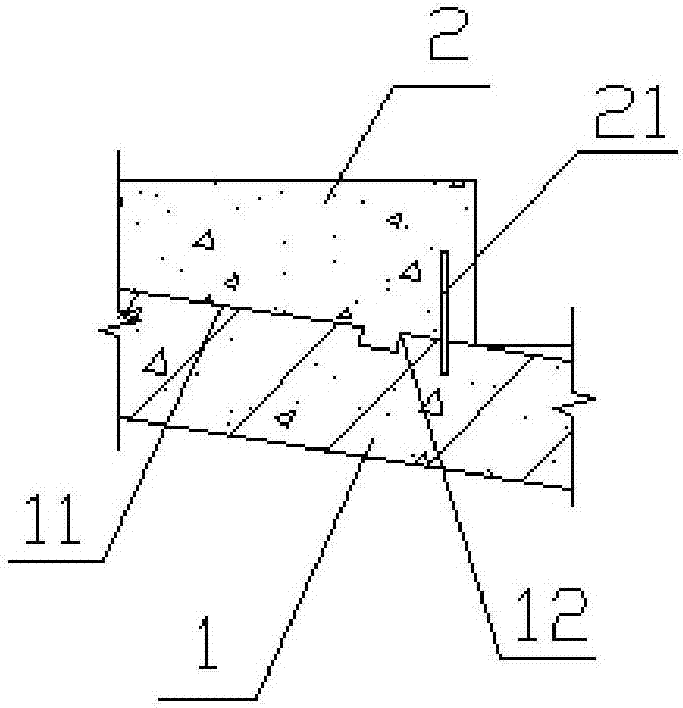

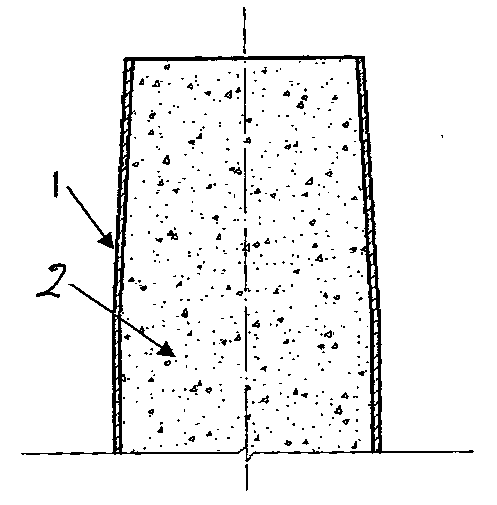

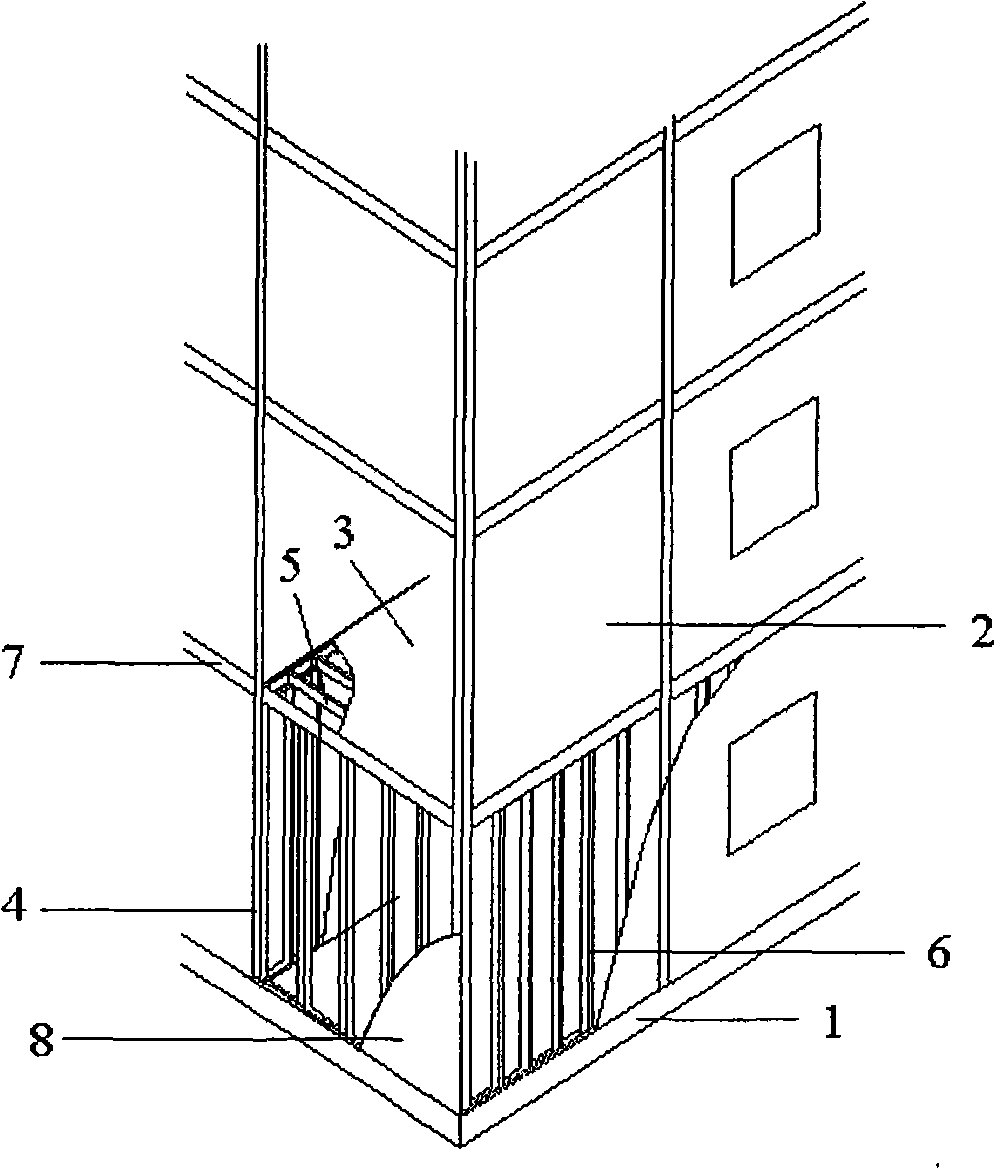

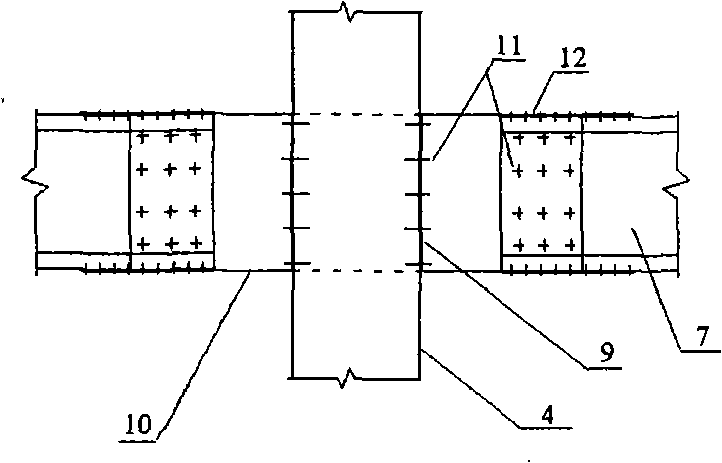

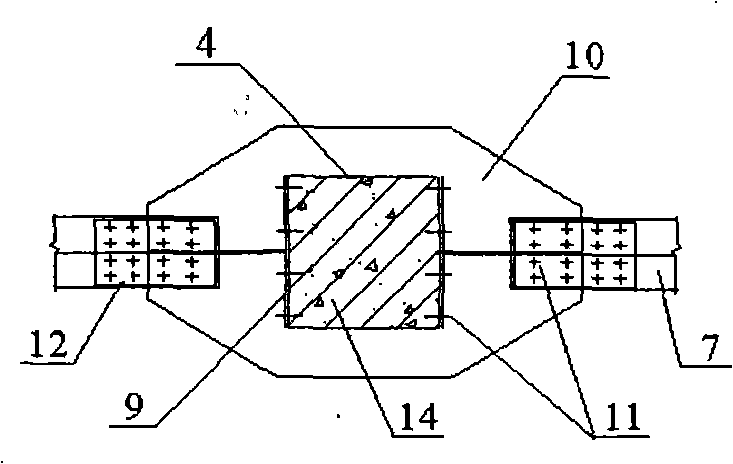

Connecting joint for H-section steel partially encased recycled concrete composite column and H-section steel girder

InactiveCN105952003AAvoid destructionImprove local stabilityBuilding constructionsMaterials scienceSteel box girder

The invention discloses a connecting joint for an H-section steel partially encased recycled concrete composite column and an H-section steel girder. The connecting joint comprises the composite column and the H-section steel girder. The composite column comprises H-section steel, a plurality of transverse pull rods welded to flange plates on the two sides of the H-shaped steel in the length direction of the H-section steel, recycled concrete, side plates, a reinforcing plate and an additional plate. A containing cavity formed by an H-section steel web plate and the flange plates is filled with the recycled concrete, and the side plates, the reinforcing plate and the additional plate are welded to the joint of the grinder and the column. The side plates are parallel to the H-section steel web plate. The reinforcing plate is located at one side of the composite column, and the two ends of the reinforcing plate are welded to the side plates respectively. The additional plate is vertically welded to the flange plates of the H-section steel. A web plate of the H-section steel girder and the additional plate are welded, and flange plates of the H-section steel girder and the flange plates of the H-section steel are welded and fixed. According to the connecting joint, the side plates, the additional plate and the connecting plate are additionally welded to the joint of the girder and the column, so that the connecting joint has good ductility, the natural period of vibration of the structure is prolonged, the amplitude is reduced, and earthquake damage is reduced.

Owner:HOHAI UNIV

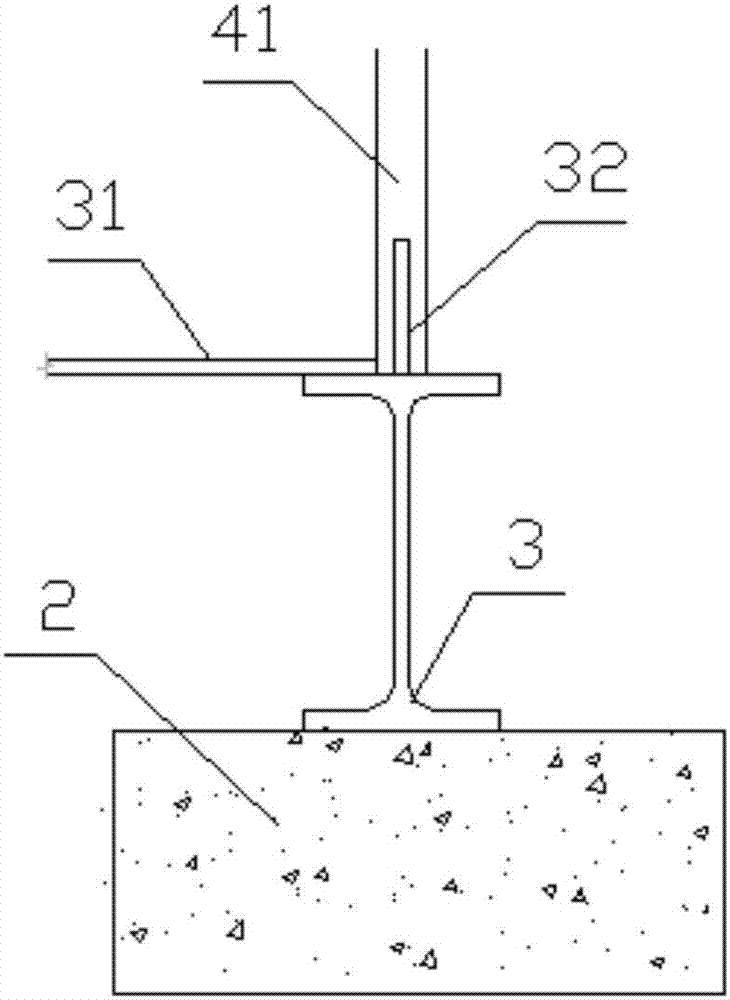

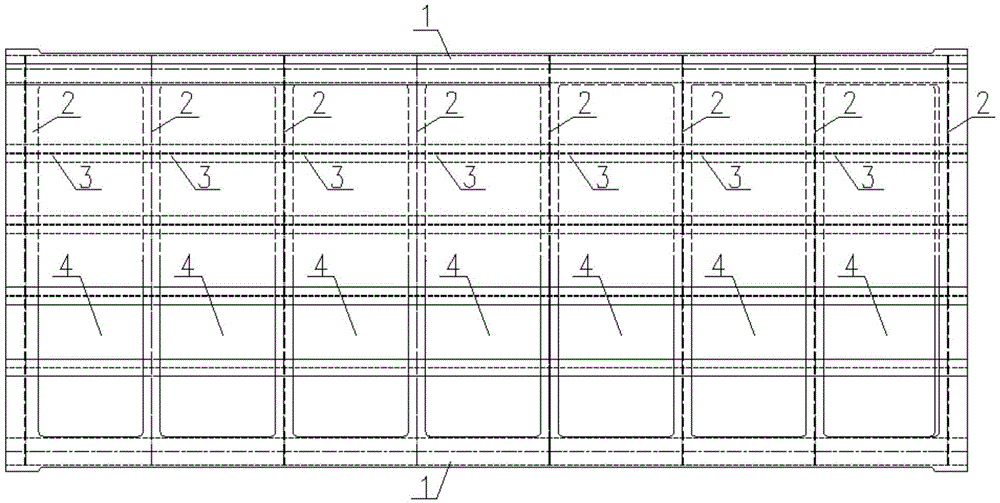

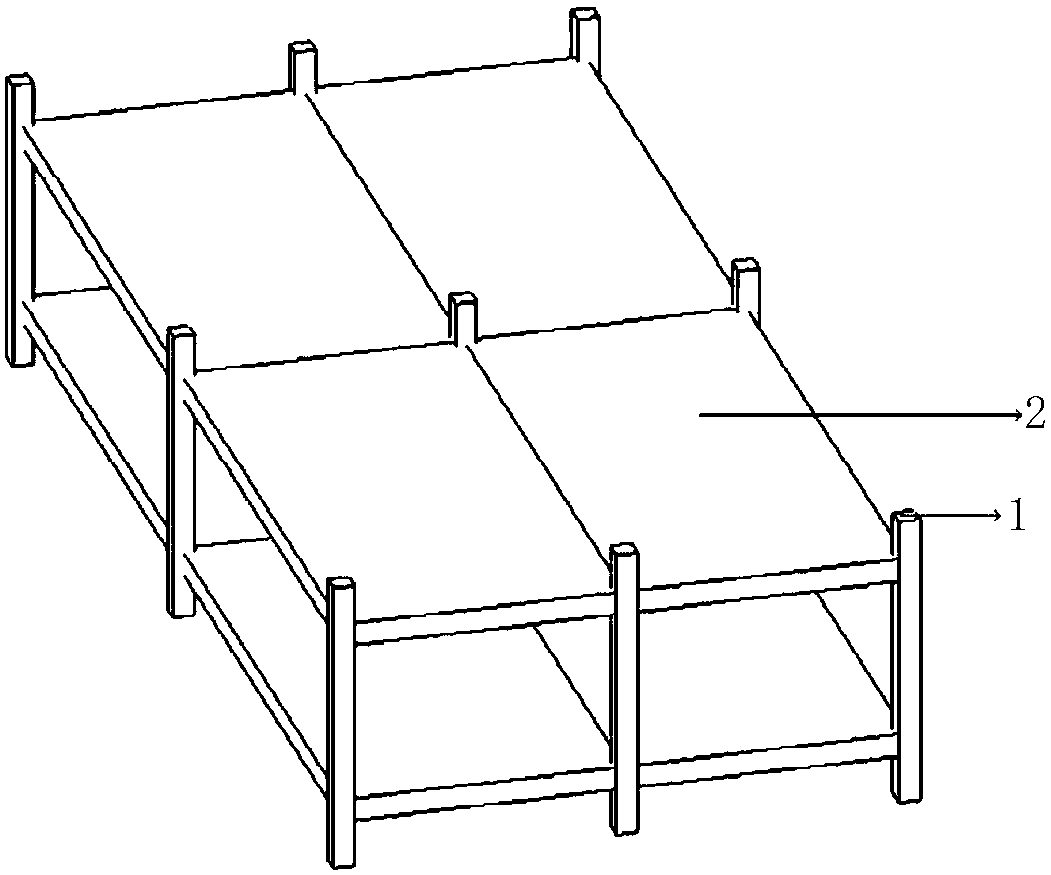

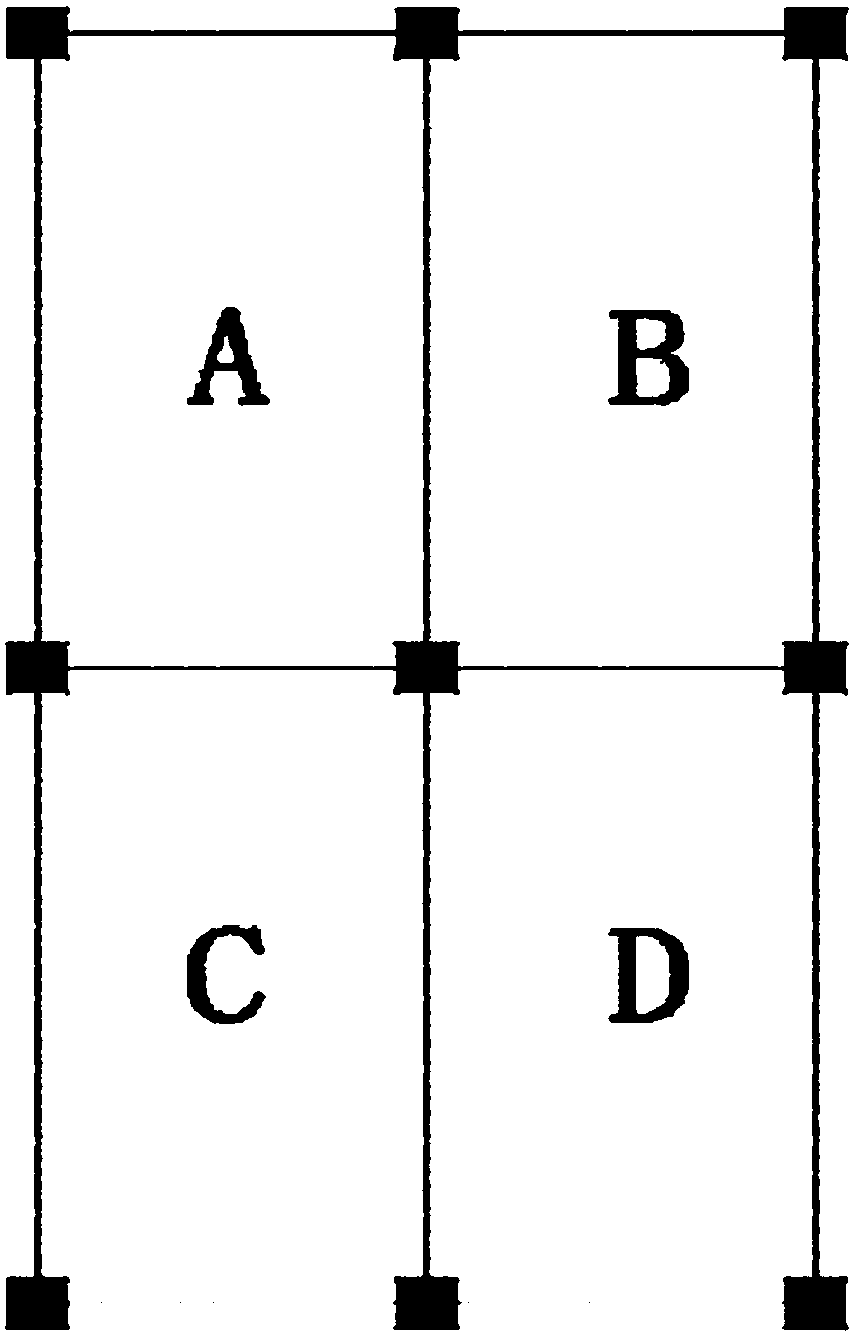

Square steel pipe column-concealed beam floor slab fabricated system adopting Z-shaped connecting

The invention provides a square steel pipe column-concealed beam floor slab fabricated system adopting Z-shaped connecting, and belongs to the technical field of structural engineering. The square steel pipe column-concealed beam floor slab fabricated system adopting Z-shaped connecting comprises square steel pipe columns, concealed beam floor slab modules and Z-shaped joints. Beams prefabricatedin a factory serve as frames of beam-slab overall modules, and prefabricated concrete is poured at the bottoms of the beams; in the construction site, the concealed beam floor slab modules and the square steel pipe columns are connected through the Z-shaped joints; then pipelines can be freely laid on prefabricated concrete layers, the pipelines between the different slabs penetrate through holesin beam webs, and after laying is completed, lightweight concrete is poured; and through beam-slab integration of the concealed beam floor slabs, upper flanges and lower flanges of the beams are pre-embedded in the concrete of the floor slabs, thus the local stability of components is improved, and the problems of fire protection and corrosion prevention of the steel structural beams are solved. Through the modes that the holes are formed in the webs and the floor slabs are poured in a layered mode, individualized arrangement of the pipelines is facilitated, and later maintenance and transformation are convenient; and factory and fabricated modes are combined, the construction speed is increased, and the square steel pipe column-concealed beam floor slab fabricated system adopting Z-shapedconnecting adapt to development of a fabricated steel structure.

Owner:BEIJING UNIV OF TECH

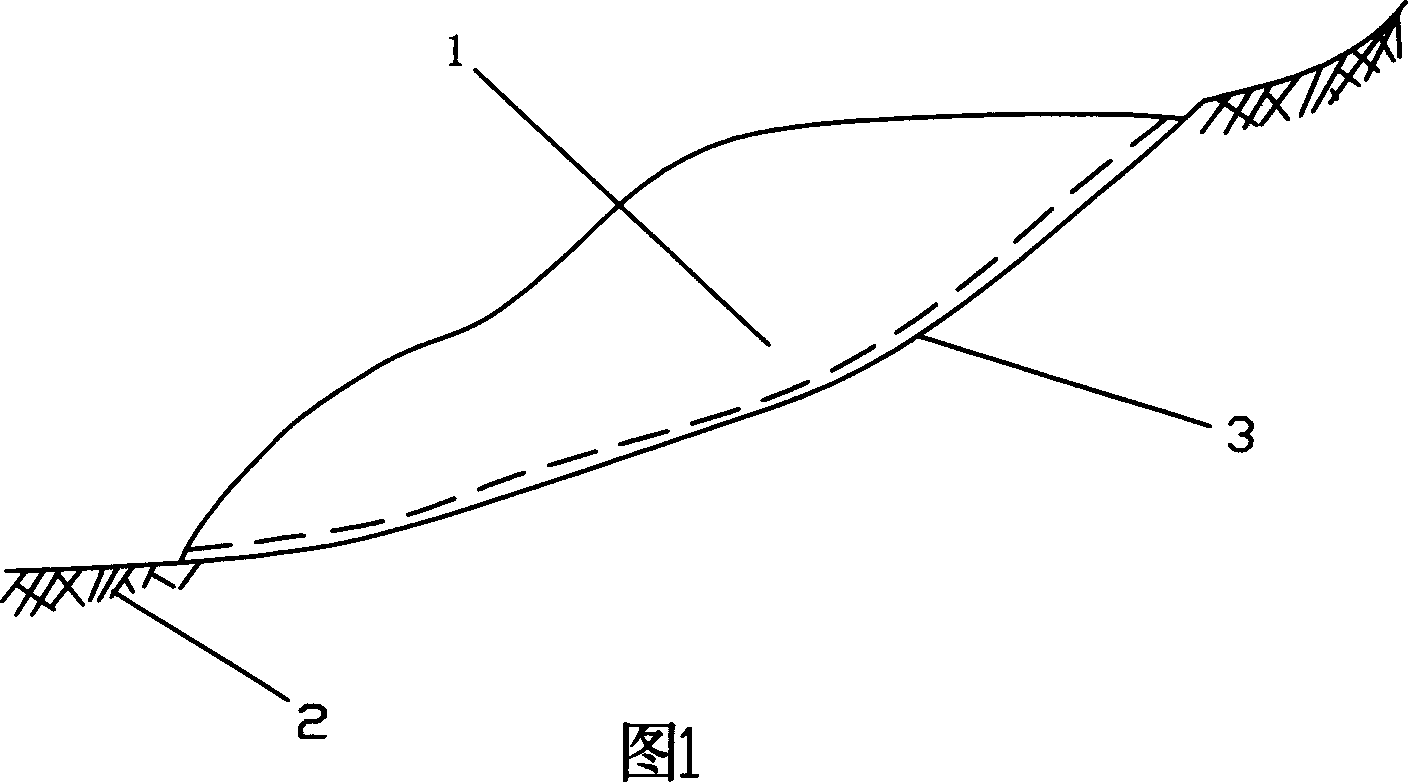

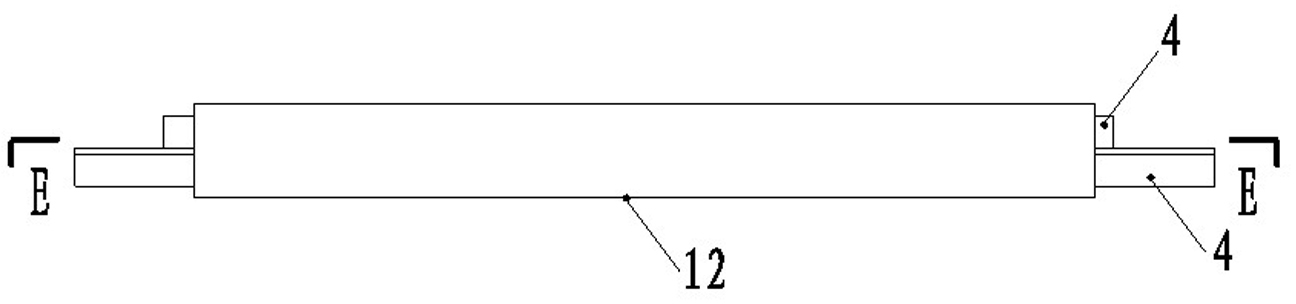

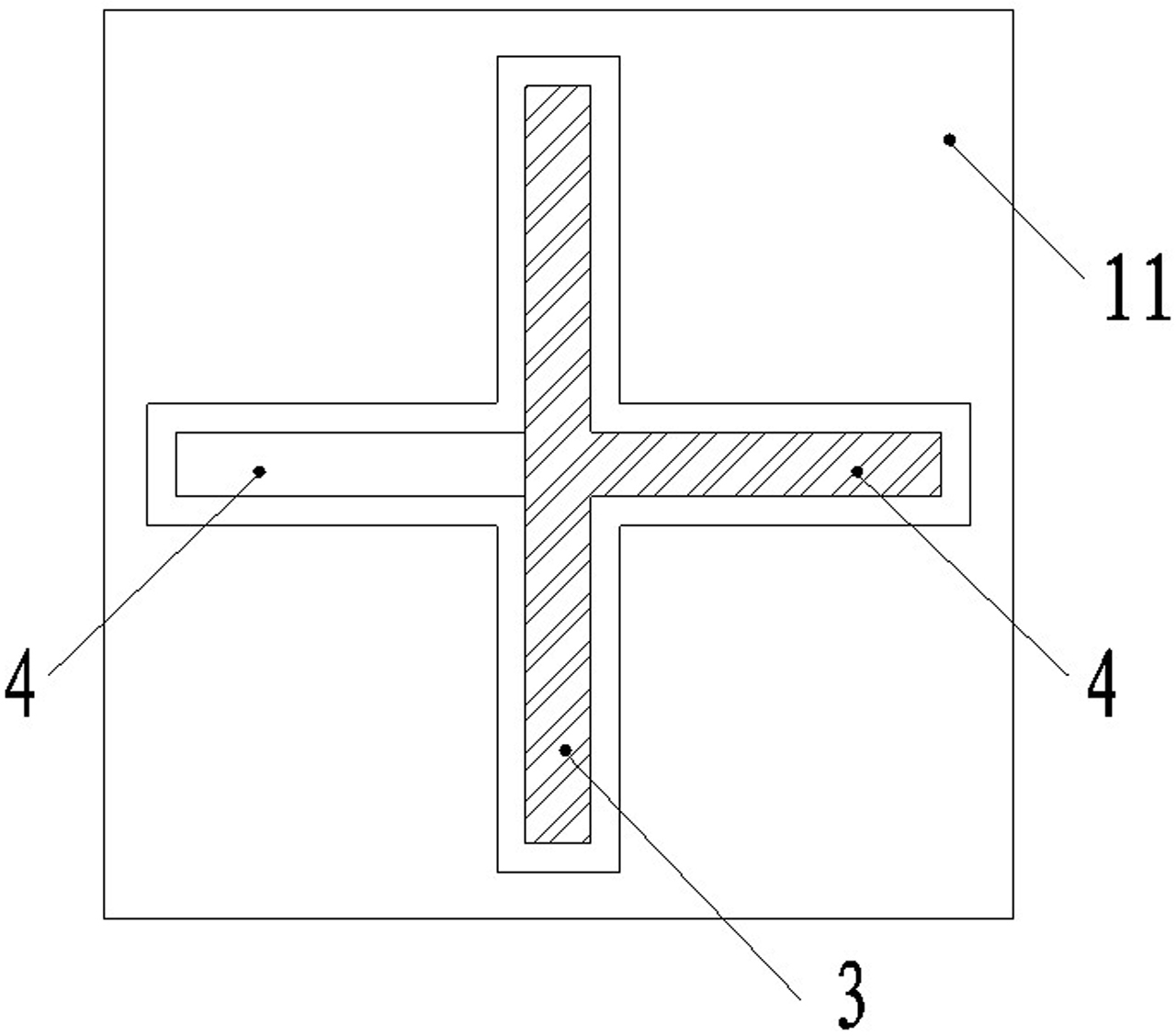

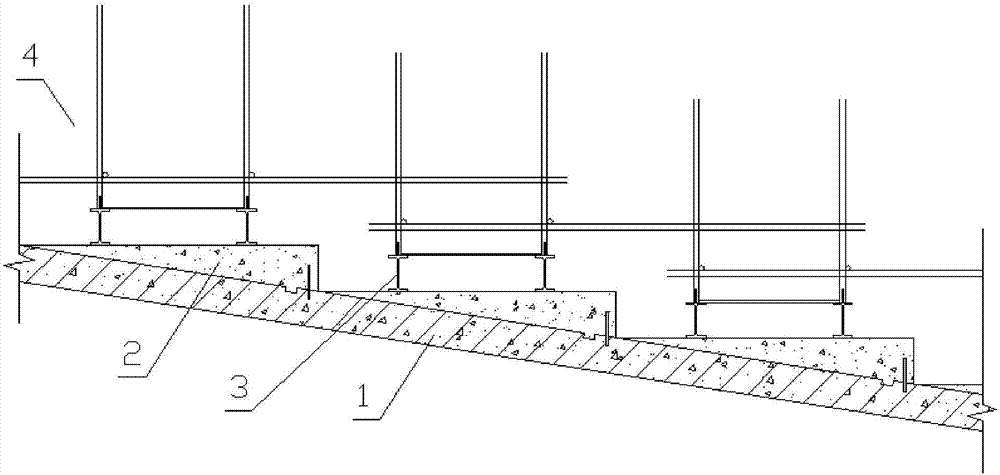

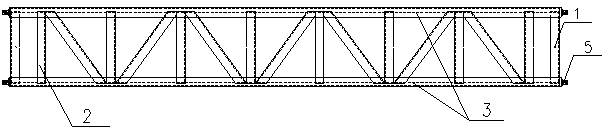

Method for designing prestress adjustable support for detecting and strengthening

InactiveCN103938555AImprove local stabilityReduce material consumptionBridge erection/assemblyBridge strengtheningStructural deformationPre stress

The invention relates to a method for designing a prestress adjustable support for detecting and strengthening, and belongs to the field of detecting and strengthening of bridges and tunnels in civil engineering. According to the method for designing the prestress adjustable support for the detecting and the strengthening, steel wire ropes, light high-strength alloy materials I, adjustable prestressed steel, light high-strength alloy materials II, anchorage devices and anchoring steel plates are included. Through the application of prestress, the material consumption of the lower edge of the support can be reduced so as to achieve the purpose of lowering the self weight; due to the adjustability of the tensile force of prestressed steel bars, a working platform of the support can be economically and widely applied to bridge detecting, strengthening and maintaining tasks with various bearing requirements, the structural deformation is reduced, and the problems of the bearing capability and the safe using of the bridge detecting support are solved fundamentally. The self weight of the working platform of the support is lowered, meanwhile, the self rigidity and the spanning capability of the structure can be improved, the application range of the bridge detecting support can be expanded through the adjustability of the tensile force of the prestressed steel bars, and thus the working platform of the bridge detecting support can be repeatedly used.

Owner:KUNMING UNIV OF SCI & TECH

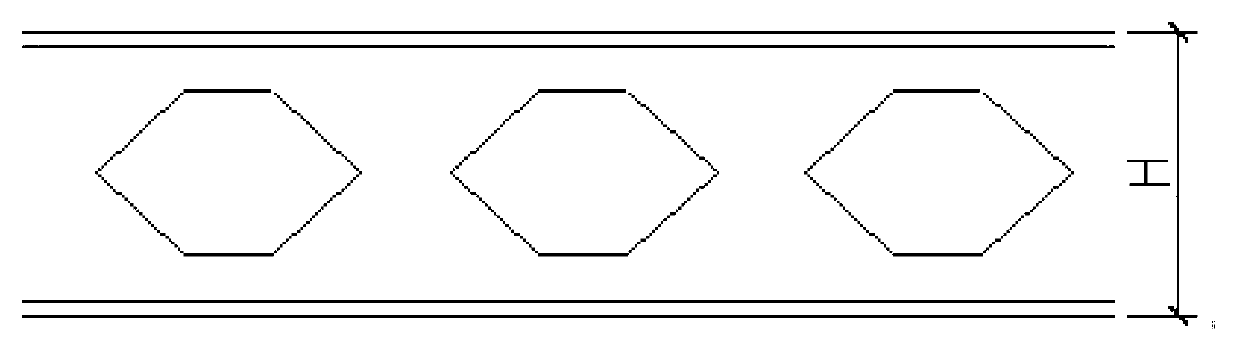

Box-section column of corrugated steel web-concrete filled steel tube flange combination

InactiveCN104328867AImprove mechanical performanceImprove the stable bearing capacityStrutsPillarsSteel columnsSteel tube

The invention discloses a box-section column of a corrugated steel web-concrete filled steel tube flange combination. Two webs and two flanges are connected to form a box-shaped structure, wherein the webs are corrugated steel webs; the periodically repeated corrugated edges of the corrugated steel webs are perpendicular to the length direction of a component; the non-corrugated edges of the corrugated steel webs are welded to the two width ends of the flanges; the flanges are concrete filled steel tube flanges including steel tubes and concrete in the steel tubes; the concrete is self-compacting concrete. According to the box-section column of corrugated steel web-concrete filled steel tube flange combination disclosed by the invention, the structural behavior of the box-section column of existing flat webs is improved and the comprehensive cost of the project is not increased significantly, so that the box-section column of corrugated steel web-concrete filled steel tube flange combination can be applied widely in projects.

Owner:NANJING UNIV OF TECH

Steel-concrete frame structure, wall body structure and passive house

The invention belongs to the building field, and particularly relates to a steel-concrete frame structure, a wall body structure and a passive house. The steel-concrete frame structure comprises an H-shaped steel, construction steel bars are arranged between an upper flange and a lower flange of the H-shaped steel, the position between the upper flange and the lower flange of the H-shaped steel isfilled with concrete, and the H-shaped steel, the construction steel bars and the concrete are connected into a whole. Compared with the prior art, the steel-concrete frame structure, the wall body structure and the passive house have the following technical effects that prefabrication performance and assembling performance are achieved, respective structure advantages of structural steel and concrete are combined, the structure integral stability is good, and the advantages of fire prevention, corrosion prevention, economy, lightweight and high applicability are achieved.

Owner:程丹松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com