Rod type core bar bending restrain steel support

A technology of buckling restraint and steel support, which is applied in the direction of building components, earthquake resistance, etc., can solve the problems of large difference in stiffness and stability, complex constrained structure structure, and difficult support construction and installation. The effect of simple force and structure, and simplified construction, installation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

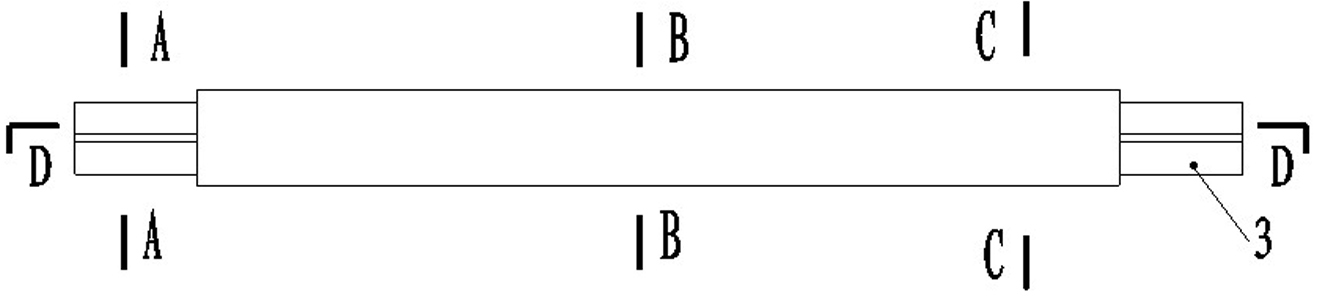

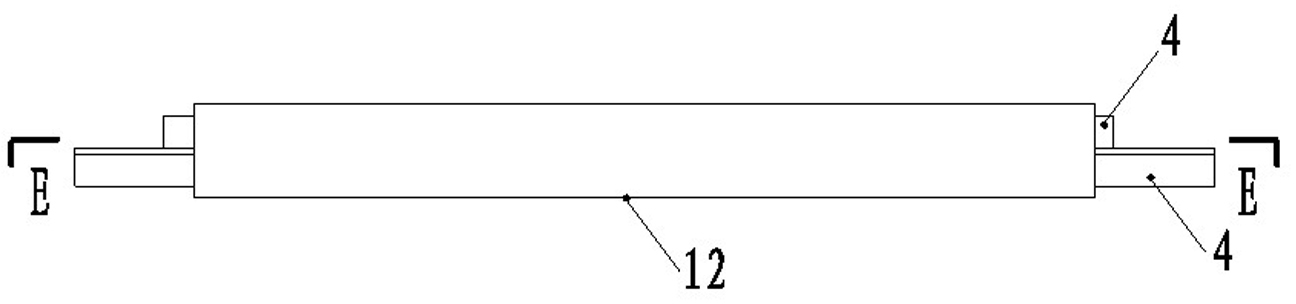

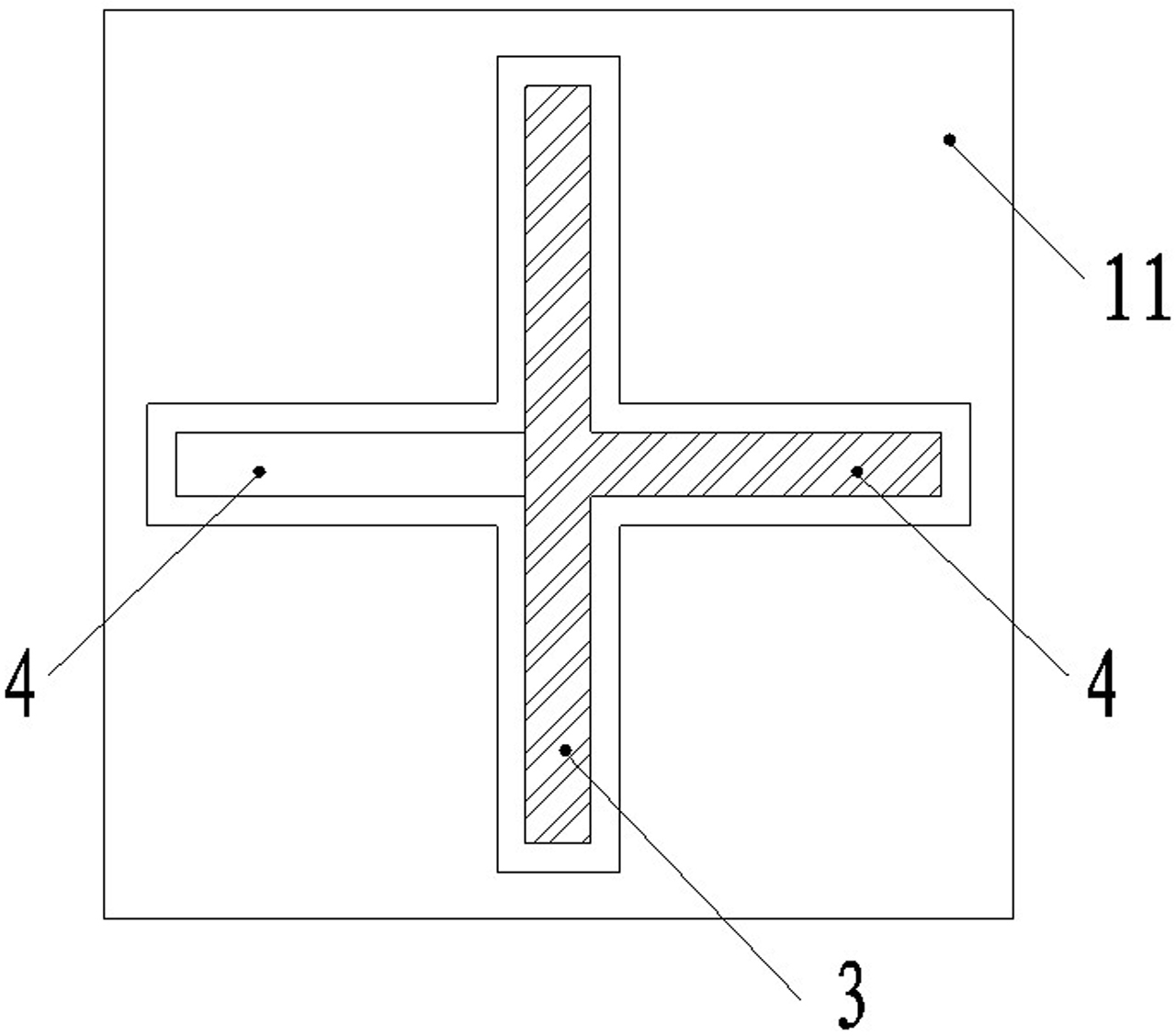

[0039] The bar-type core rod buckling restraint steel support includes the core main stress steel part and the external constraint steel part. The core main stress steel part includes the energy dissipation section 1 in the middle and the conversion sections fixed at the axial ends of the energy dissipation section 1. 2 and the installation section 5 fixed on the outside of the two conversion sections 2, the energy dissipation section 1 is a solid steel rod or a hollow steel pipe, and the installation section 5 includes a joint steel plate 3 and a stiffening steel plate 4 fixed orthogonally along its axial direction; external restraint steel The components include local restraint steel pieces and overall restraint steel pieces. The local restraint steel pieces include a core rod steel sleeve 6 that is sleeved around the energy dissipation section 1 and has an air gap between it and the energy dissipation section 1. The overall restraint steel piece includes a The extension stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com