Basement floor slab construction method based on stand column assembly type fixing

A construction method and basement floor technology, which can be used in infrastructure engineering, excavation, artificial islands, etc., can solve the problems of increased vertical calculation length, loss of restraint of columns, and weakened column bearing capacity, so as to achieve material selection and upgrade Stability and bearing capacity, the effect of improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

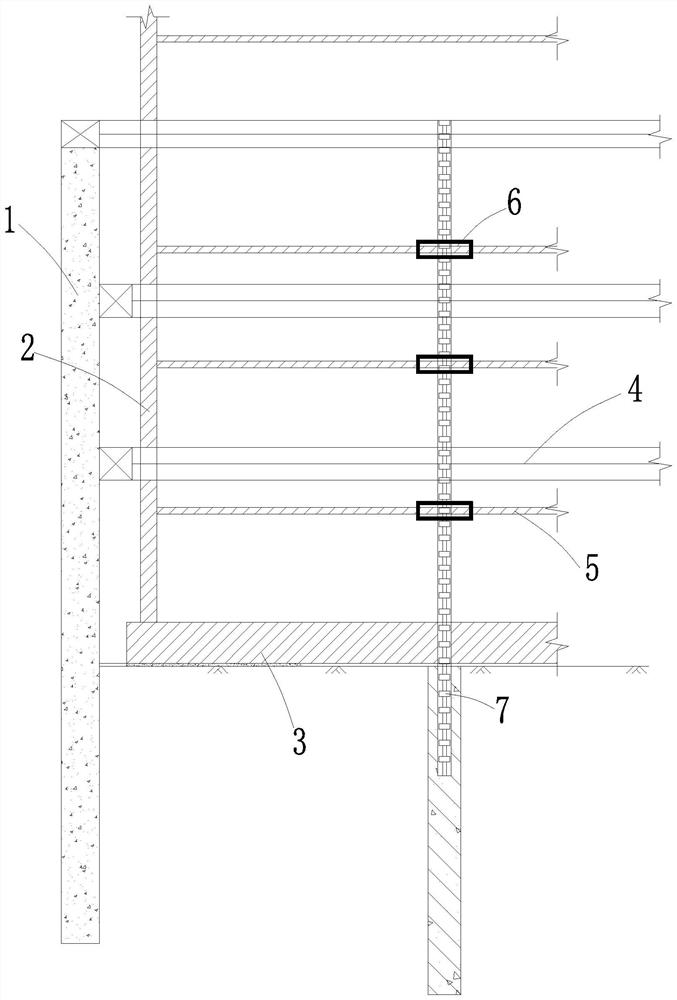

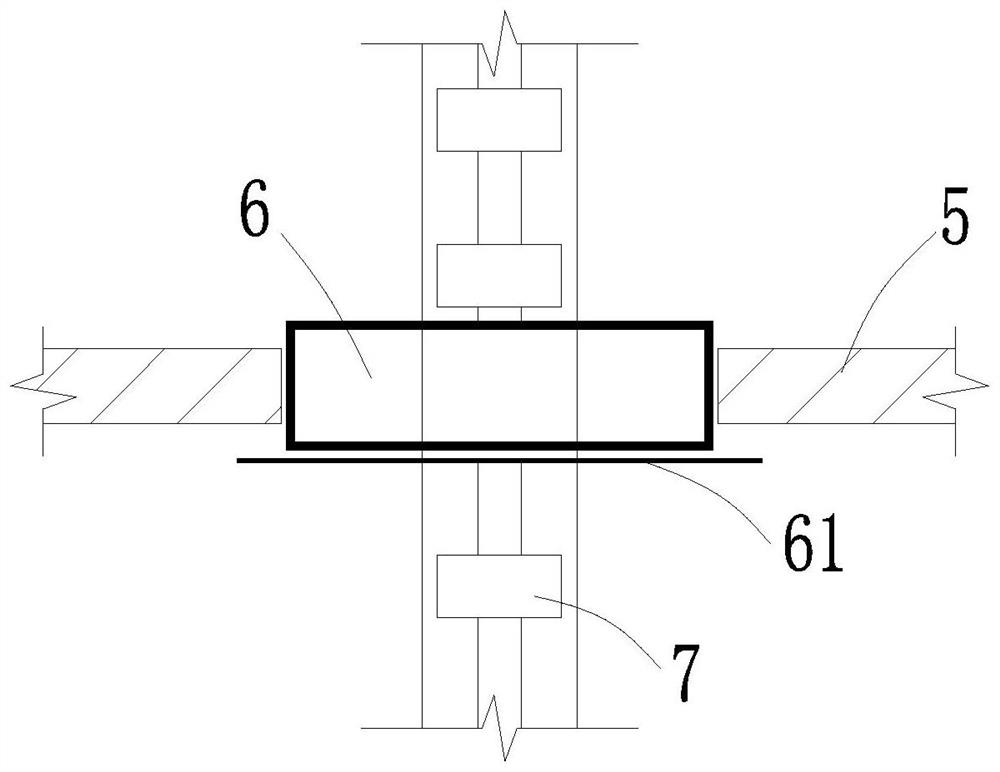

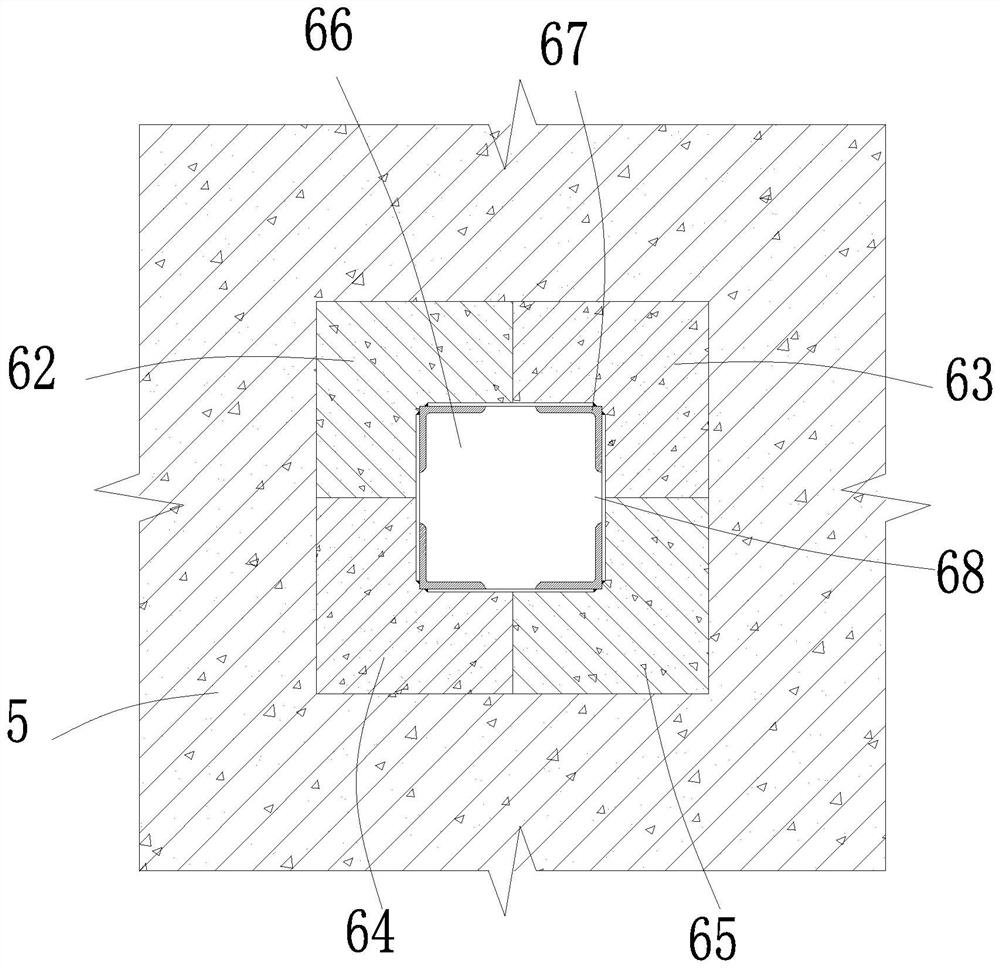

[0034] refer to Figure 1-4 As shown in the figure, the basement floor construction method based on the prefabricated and fixed column includes the following steps:

[0035] S1: Construct supporting pile 1, column 7, supporting beam 4 according to the requirements of the design drawings, and excavate the foundation pit to the bottom of the pit;

[0036] S2: Construct the basement floor 3, the basement exterior wall 2, and the bottom floor 5 in sequence. The bottom floor 5 reserves the hole space for the prefabricated fixture, and the floor 5 other than the reserved hole is poured with concrete, and the prefabricated fixture is installed in the reserved hole range. 6 and then remove the support beam 4 on the bottom floor;

[0037] S3: Continue the construction of the basement exterior wall 2, the sub-upper floor slab 5, reserve the hole space for the prefabricated fixing device for the sub-upper floor slab 5, and pour concrete for the floor slab 5 other than the reserved hole,...

Embodiment 2

[0047] refer to Figure 1-2 , 5-6, the basement floor construction method based on the prefabricated and fixed column, specifically includes the following steps:

[0048] S1: Construct supporting pile 1, column 7, supporting beam 4 according to the requirements of the design drawings, and excavate the foundation pit to the bottom of the pit;

[0049] S2: Construct the basement floor 3, the basement exterior wall 2, and the bottom floor 5 in sequence. The bottom floor 5 reserves the hole space for the prefabricated fixture, and the floor 5 other than the reserved hole is poured with concrete, and the prefabricated fixture is installed in the reserved hole range. 6 and then remove the support beam 4 on the bottom floor;

[0050] S3: Continue the construction of the basement exterior wall 2, the sub-upper floor slab 5, reserve the hole space for the prefabricated fixing device for the sub-upper floor slab 5, and pour concrete for the floor slab 5 other than the reserved hole, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com