Membrane module of filter

A membrane module and mechanical technology, applied in the field of membrane separation, can solve the problems of easy clogging and pollution, difficult cleaning and regeneration, complex manufacturing process, etc., and achieve the effect of reducing cleaning difficulty, simple and practical treatment process, and improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

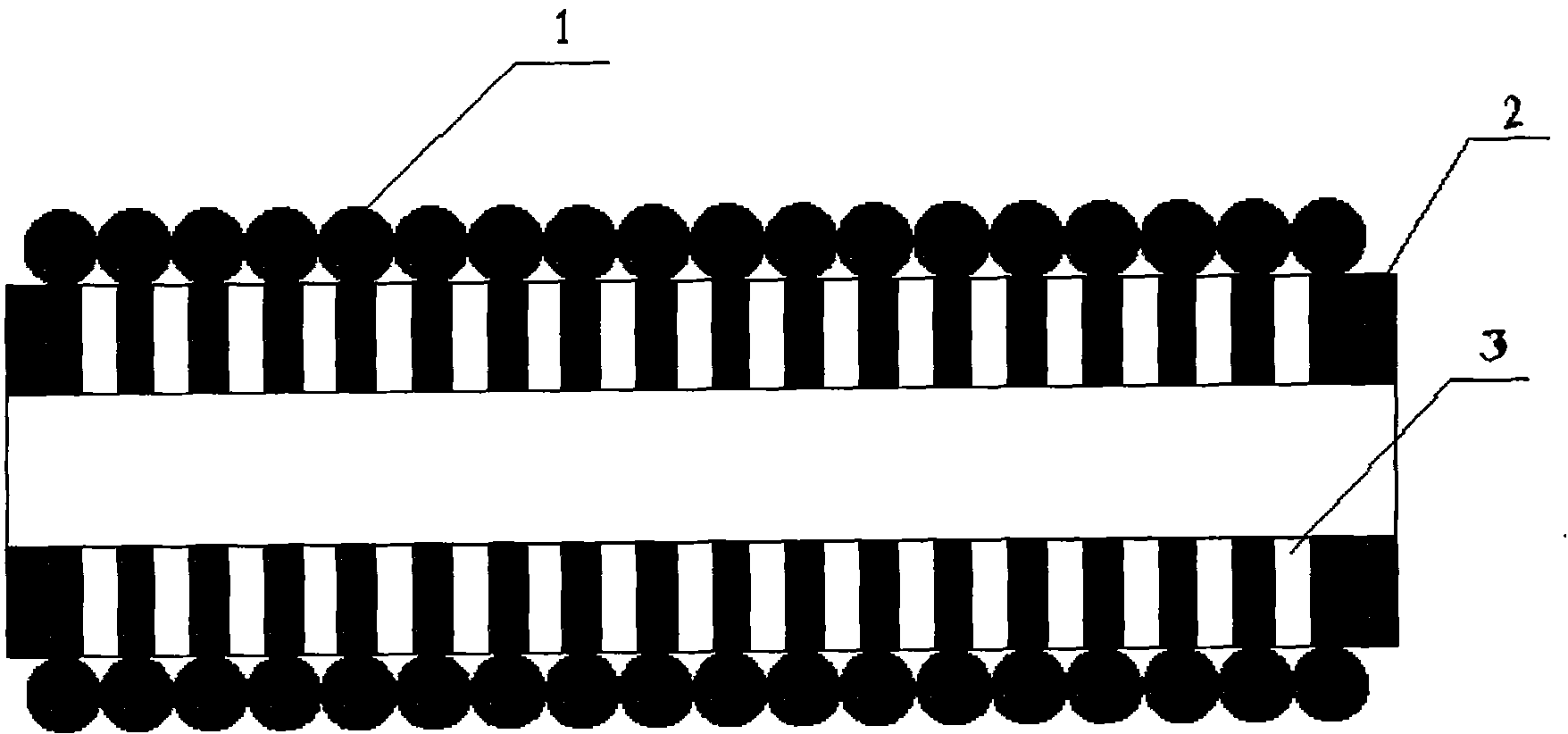

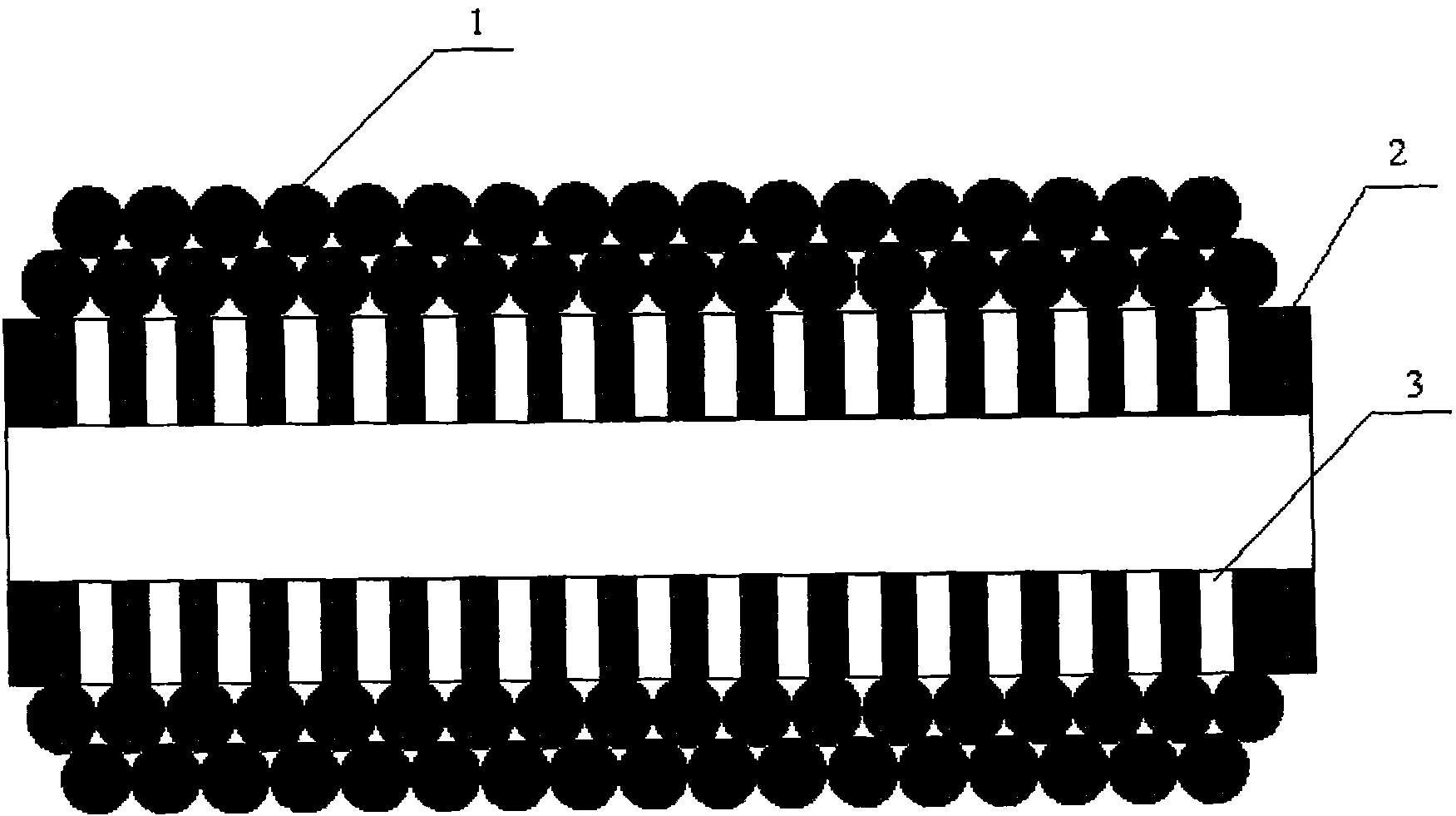

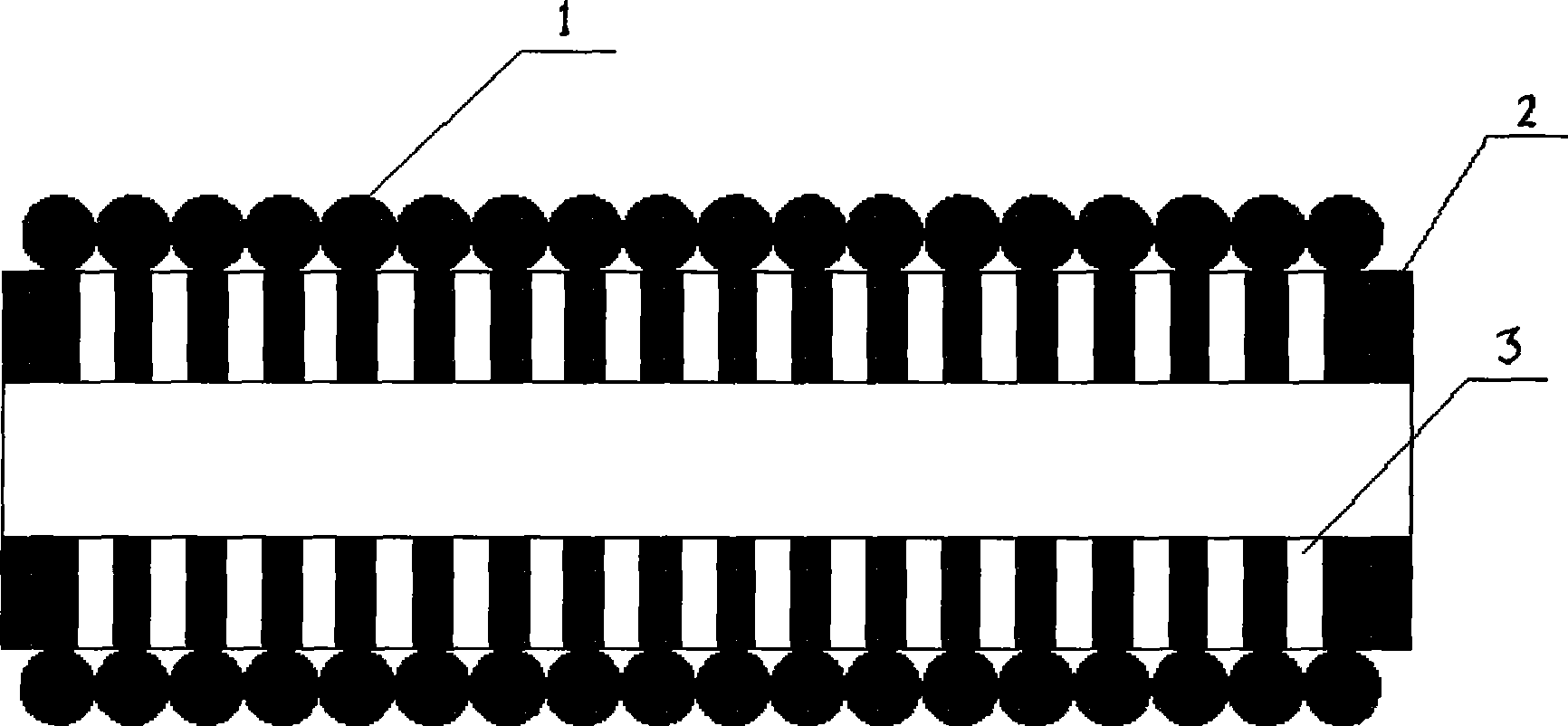

[0024] A filter mechanical membrane module, such as 1 or figure 2 Shown, the present invention is achieved through the following technical solutions:

[0025] 1) Use a computerized automatic winding machine to tightly wind the filaments in turn and fix them on a support with holes or grooves to form a filter mechanical membrane;

[0026] 2) Assemble the filter mechanical membranes of different specifications from large to small according to the filament gap to form a sandwich structure, and use end plates and sealing rings to form different chambers to make a multi-stage membrane module.

[0027] The filament described in step 1) is nylon filament with smooth surface, firmness, good toughness and corrosion resistance, and the wire diameter is 0.05mm.

[0028] The support body described in step 1) is a solid, corrosion-resistant, and high-temperature-resistant tubular structure material.

[0029] Step 1) The aperture on the support body is 0.03mm, and the distribution densit...

Embodiment 2

[0033] A filter mechanical membrane module, the structure is the same as that of Example 1, the difference is that the filament described in step 1) is a copper wire with smooth surface, firmness, good toughness and corrosion resistance, and the wire diameter is 0.1mm. The support body described in step 1) is a solid, corrosion-resistant, and high-temperature-resistant material with a flat plate structure. Step 1) The aperture on the support body is 0.05mm, and the distribution density is 1×10 7 ~1×10 9 piece / m 2 .

Embodiment 3

[0035] A filter mechanical membrane module, the structure is the same as that of Example 1, the difference is that the filament described in step 1) is a synthetic wire with a smooth surface, firmness, good toughness, and corrosion resistance, and the wire diameter is 0.3mm. The support body described in step 1) is a material of firm, corrosion-resistant, and high-temperature-resistant tubular structure. The upper aperture of the support body described in step 1) is 0.3mm, and the distribution density is 1×10 6 ~1×10 8 piece / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com