Patents

Literature

109results about How to "Structural rules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bracket material for bone tissue engineer and preparation method thereof

InactiveCN101417145AImprove mechanical propertiesGood biocompatibilityProsthesisDrug biological activityProtein C

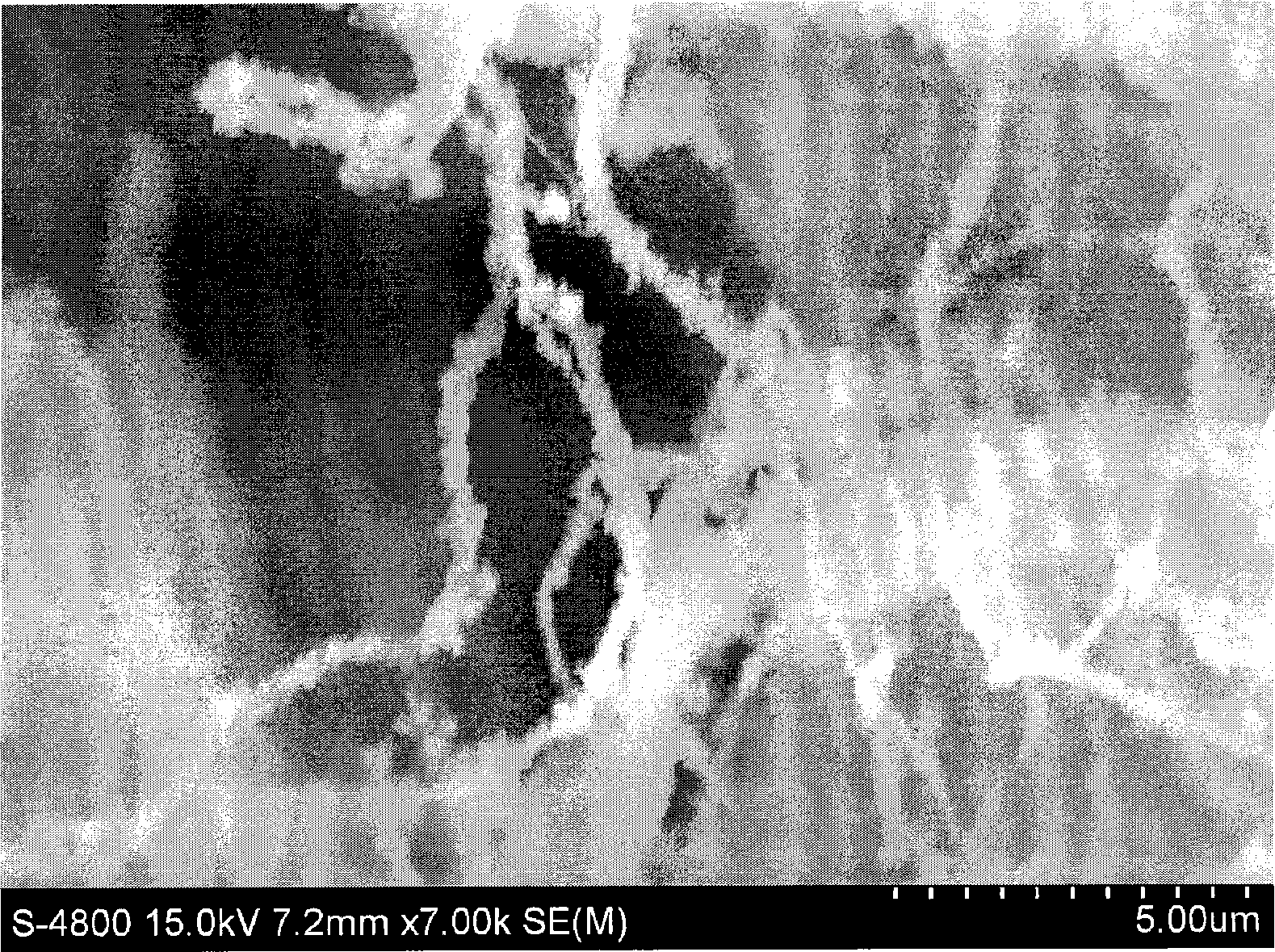

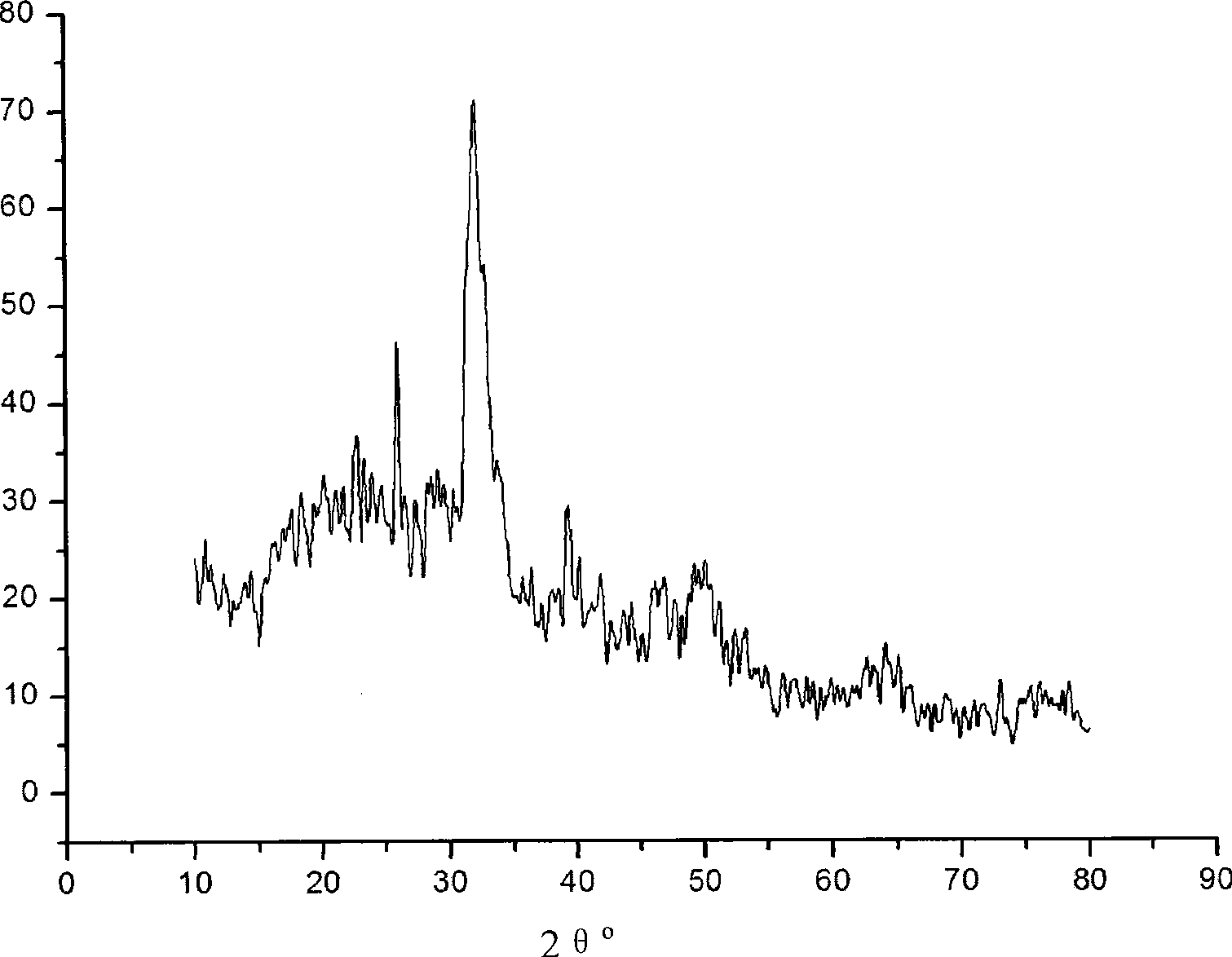

The invention relates to a bracket material used for an osseous tissue project, and a preparation method thereof. Firstly, the bracket of a type I collagen is extracted from a small fresh pigskin by a mature extracting technique. Then, the bracket is further expanded in a Tris cushion liquid, the pH of which is equal to 8.8 to obtain a natural porous collagen bracket by the treatments of freezing and drying. The bracket is respectively and repeatedly mineralized in a CaCl2 liquid and in (NH4)2HPO4 liquid or mineralized in simulated body fluid for a long period to lead the weakly crystallized HA to be uniformly settled into the collagen bracket; and then a pigskin collagen-hydroxyapatite ossein is obtained by the treatments of freezing and drying to replace the natural bracket material. The invention not only maintains the natural bracket structure of the collagen in an organism, but also has the advantages of low material cost, simple devices, short period and easy operation. The obtained compound bracket material used for the pigskin collagen-hydroxyapatite osseous tissue project has the characteristics of high intensity, large toughness, non-antigenicity, higher biological activity as well as degradation and releasing control.

Owner:SHANDONG UNIV

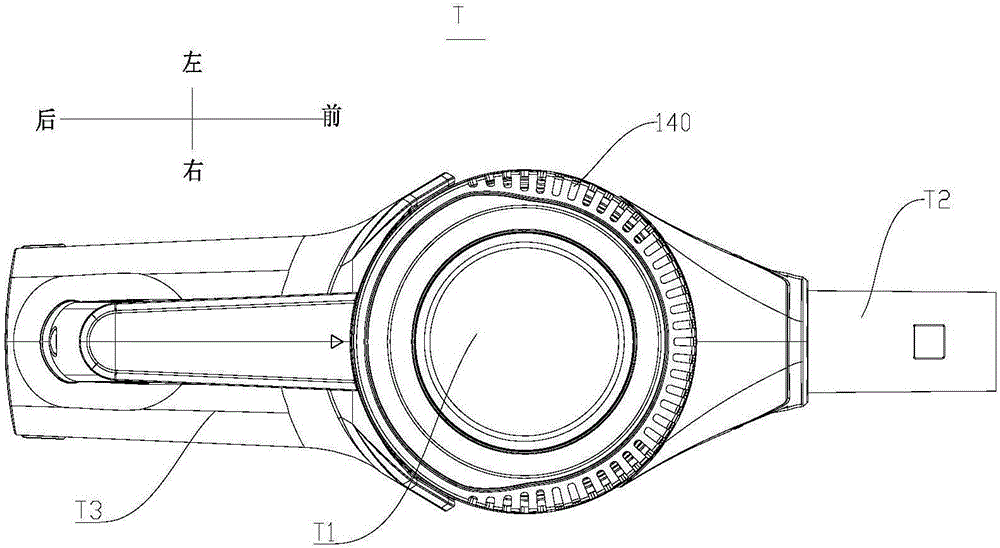

Handheld vacuum cleaner

ActiveCN106618375AAdapt to the development requirements of miniaturizationCompact structureSuction filtersSuction nozzlesMiniaturizationEngineering

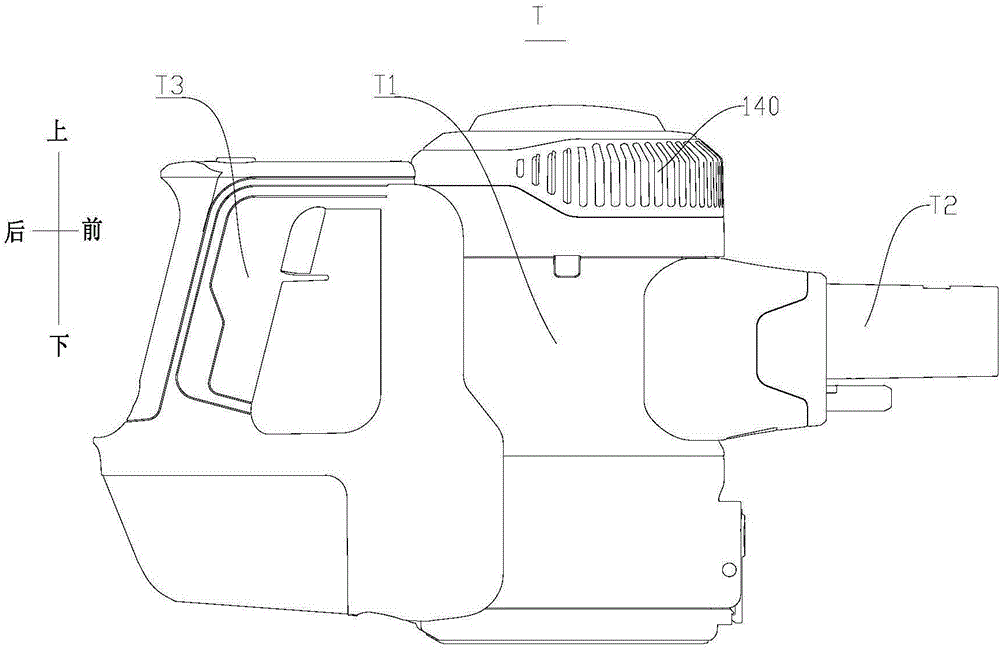

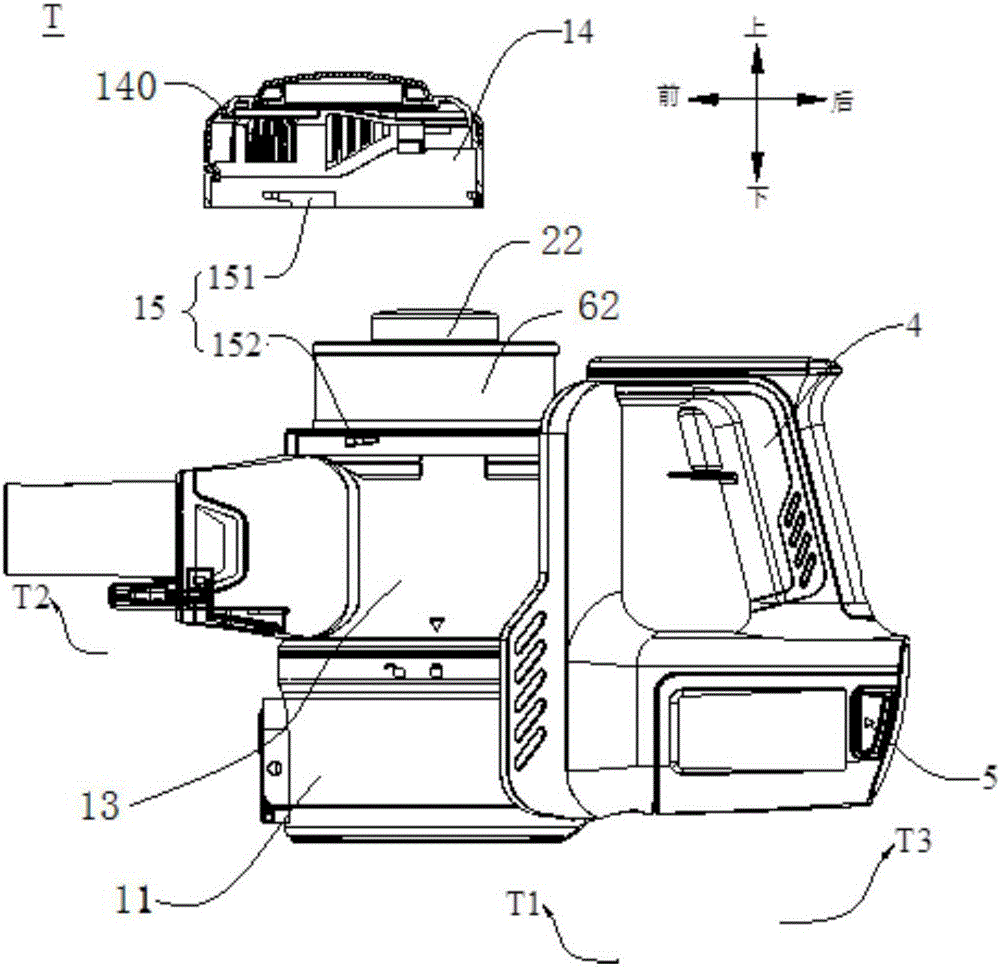

The invention discloses a handheld vacuum cleaner which comprises a dust cup assembly, a suction nozzle assembly and a handle assembly. The dust cup assembly comprises a cup shell and an airflow generation device and a cyclone separation device which are arranged in the cup shell, the airflow generation device is arranged above the cyclone separation device and located at the downstream side of the cyclone separation device, and an exhaust outlet is formed in the top of the cup shell; the suction nozzle assembly is transversely installed on the cup shell, and a suction channel is defined out; the handle assembly is installed on the cup shell and used for achieving holding. According to the handheld vacuum cleaner, the airflow channel in the cup shell is effectively shortened, the flowing direction of airflow in the cup shell basically does not change, the vacuum degree loss is reduced, and energy consumption is reduced; accordingly, the structure of the dust cup assembly is more compact, smaller, more exquisite and more regular, the miniaturization development requirement of the handheld vacuum cleaner is met, and carrying of a user is convenient.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

Polyurethane hard-foam composition and polyurethane hard-foam plastic prepared from same

The invention discloses a polyurethane hard-foam composition and a polyurethane hard-foam plastic prepared from the same. The polyurethane hard-foam composition comprises polyisocyanate, polyether glycol, polyester polyol I, additive flame retardant and foaming agent, wherein the polyester polyol I is flame-retardant polyester polyol. The flame-retardant polyester polyol is added in the polyurethane hard-foam composition, so that the consumption of the additive flame retardant can be reduced; and the plastification action of the additive flame retardant on the polyurethane hard-foam plastic can be reduced, the Van der Waals force among macromolecular chains of polyurethane can be increased, and the relative slippage among the macromolecular chains can be reduced, thereby reducing the sizes of foaming pores formed by the composition. Meanwhile, the Van der Waals force among the macromolecular chains is increased, so that the rigidity of the pore walls of the foaming pores in the polyurethane hard-foam plastic can be increased, thereby ensuring that the foaming pores are more regular in structure and the deformation degree of the foaming pores is weakened. The foaming pores are small in size and stable in structure, and can enhance the compression strength and creep property of the polyurethane hard-foam plastic.

Owner:北京碧海云智新材料技术有限公司

Non-cadmium lead stibium slab lattice alloy for traction type accumulator

InactiveCN101295789ASolve the problem of thermal crackingSmall and uniform crystal grainsElectrode carriers/collectorsRare-earth elementAlloy

The invention discloses a cadmium free lead-antimony grid alloy for traction batteries. The lead-antimony alloy contains antimony, mischmetal and lead and the weight percentage of the antimony in the lead-antimony alloy is 0.5 to 4.5 percent, that of the mischmetal is 0.05 to 2 percent and the rest is the lead. The grid alloy adds rare earth elements into the lead-antimony alloy and causes the grains of the alloy to become small and even, thereby solving the problem of the hot cracking of the lead-antimony alloy and obviously improving and increasing the toughness, aging strength and corrosion resistance of the alloy. Meanwhile, the adding of the rare earth obviously inhibits the growth of the Pb(II) oxide film and reduces the impedance thereof, thus improving the charging and discharging performance and the deep circulation of the battery. Batteries for electric vehicles combined by lead-acid battery grids produced by the alloy have the advantages of corrosion resistance, deep circulation, high-current discharge and long service life.

Owner:上海飞轮有色冶炼厂

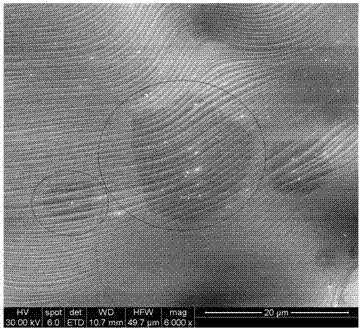

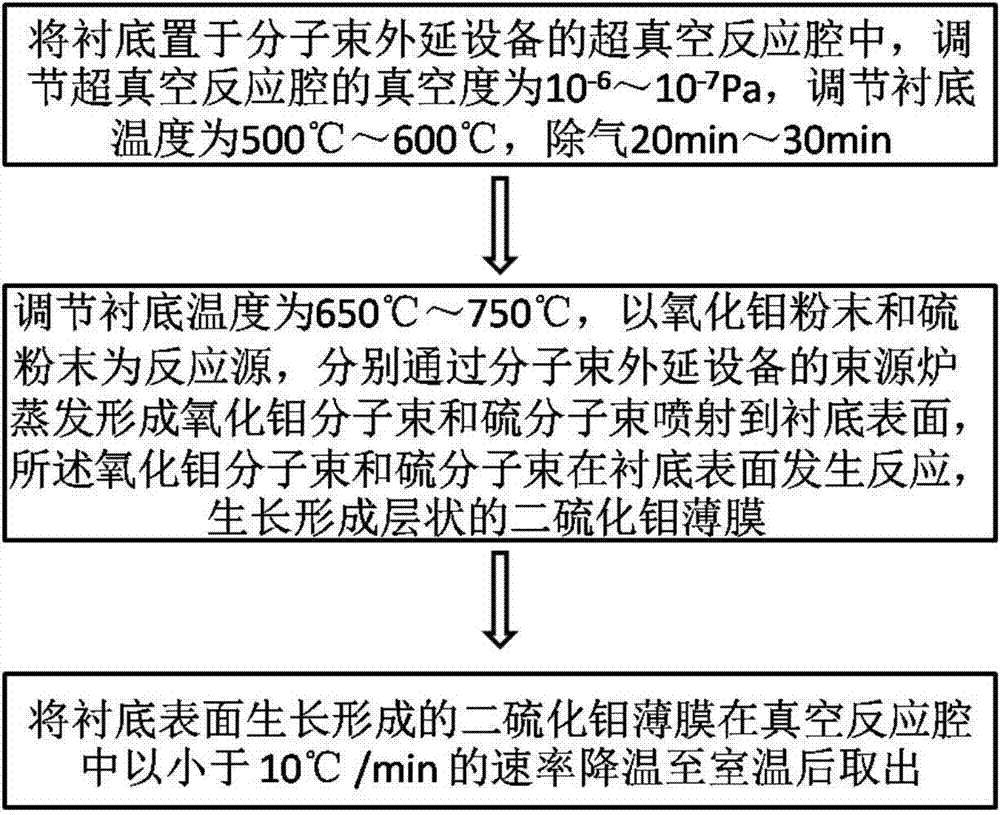

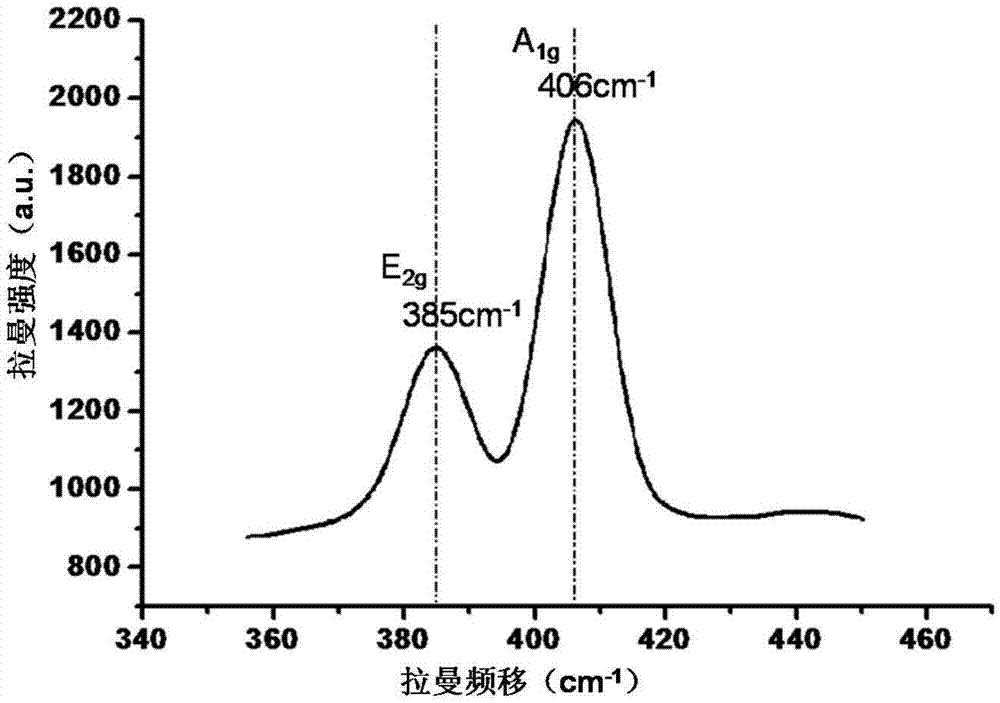

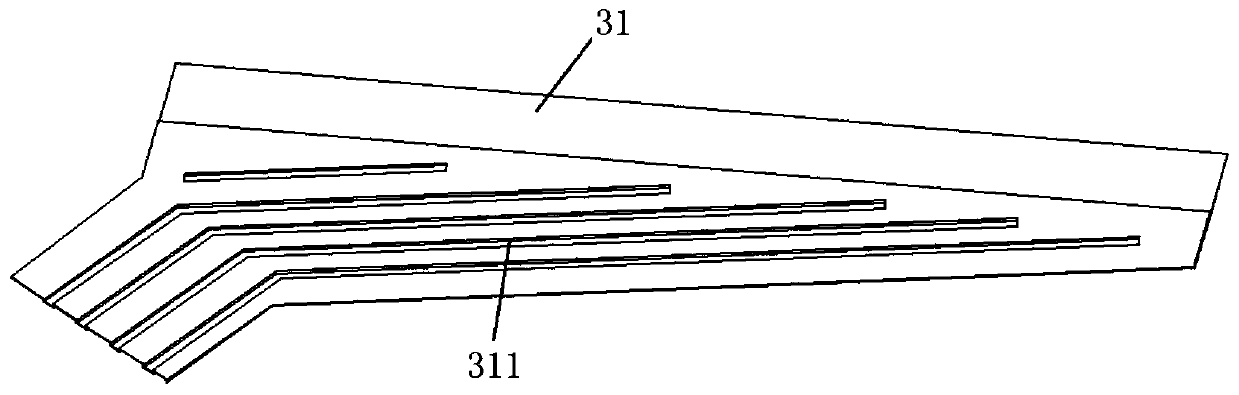

Preparation method for laminated molybdenum disulfide film

ActiveCN104746137AFlat surfaceStructural rulesPolycrystalline material growthFrom chemically reactive gasesSulfurBeam source

The invention discloses a preparation method for a laminated molybdenum disulfide film. An MBE (Molecular Beam Epitaxy) method is adopted. The preparation method comprises the following steps of 1) placing a substrate in an ultra-vacuum reaction cavity of an MBE instrument, adjusting the vacuum degree of the ultra-vacuum cavity to be (10<-6>)-(10<-7>)Pa, adjusting the temperature of the substrate to be 500-600 DEG C, and degassing for 20-30 minutes; 2) adjusting the temperature of the substrate to be 650-750 DEG C, taking molybdenum oxide powder and sulphur powder as reaction sources, evaporating the molybdenum oxide powder and sulphur powder respectively through a beam source furnace of the MBE instrument to form a molybdenum oxide molecular beam and a sulphur molecular beam, spraying the molybdenum oxide molecular beam and the sulphur molecular beam on the surface of the substrate, and reacting the molybdenum oxide molecular beam and the sulphur molecular beam on the surface of the substrate to form the laminated molybdenum disulfide film through growing. According to the preparation method, the laminated molybdenum disulfide film with controllable repetitive layers, regular growing structure and smooth surface is prepared through the MBE technology.

Owner:厦门烯成石墨烯科技有限公司

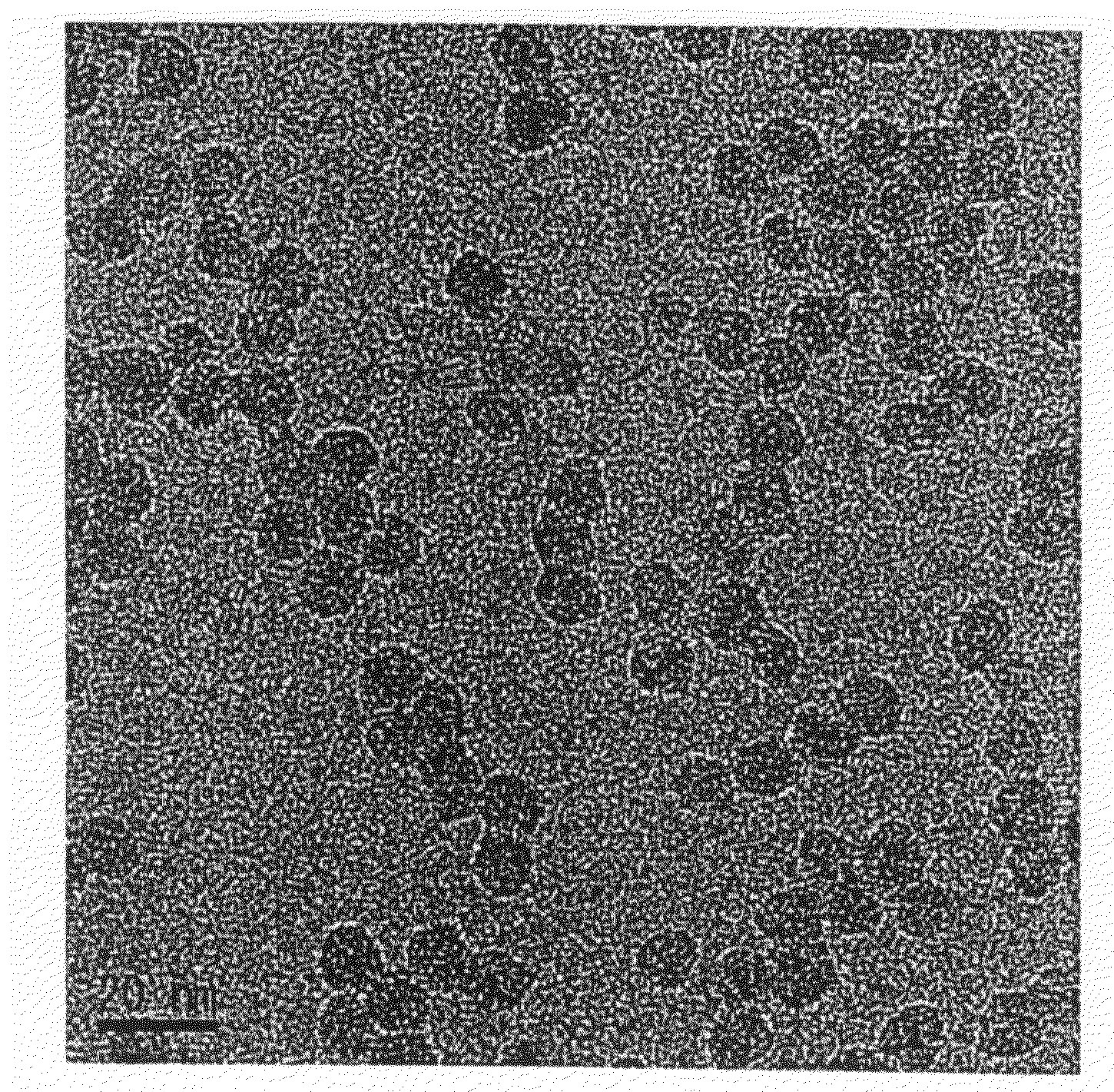

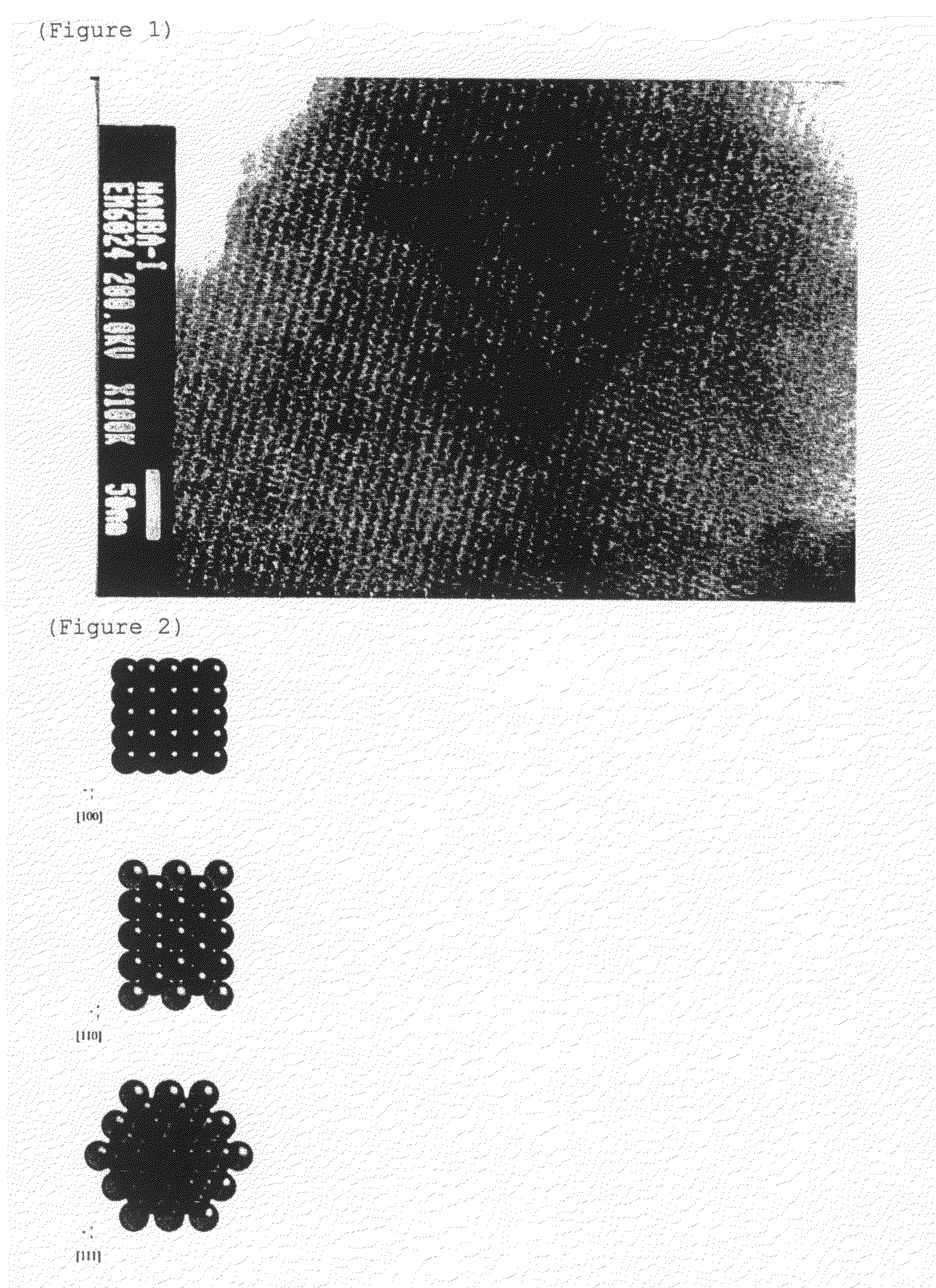

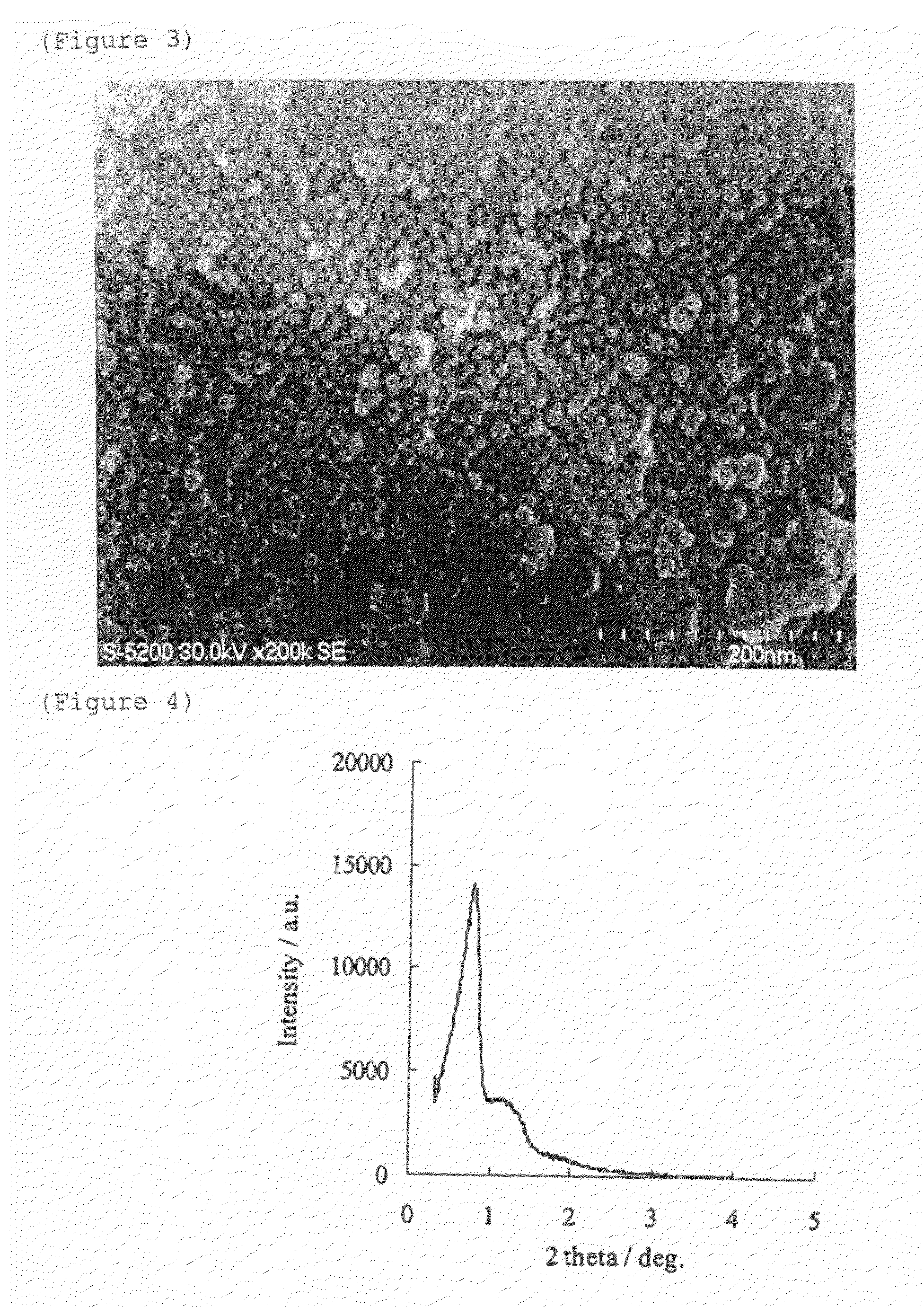

Regularly Arranged Nanoparticulate Silica and Process for Producing the Same

A novel silica which is in the form of ultrafine particles having mesopores and has a regular structure; and a process for producing the silica. The silica is a self-organized nanoparticulate silica characterized in that the average particle diameter is 4 to 30 nm, preferably 6 to 20 nm, and these particles are regularly arranged so as to form a primitive cubic lattice. The self-organized nanoparticulate silica is produced by mixing an alkoxysilane with an aqueous solution of a basic amino acid, reacting the mixture at 40 to 100° C., and subjecting the reaction mixture to drying and preferably to subsequent burning. Also provided is a process for producing fine silica particles having a particle diameter of 4 to 30 nm, which comprises mixing a solution of an alkoxysilane compound having 1 to 4 alkoxy groups with a solution of a basic amino acid and reacting the mixture at 20 to 100° C. to cause hydrolysis and condensation polymerization.

Owner:JAPAN SCI & TECH CORP

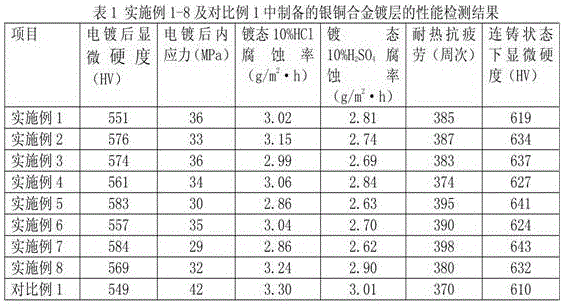

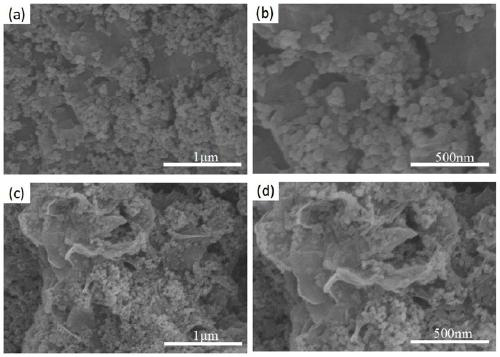

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

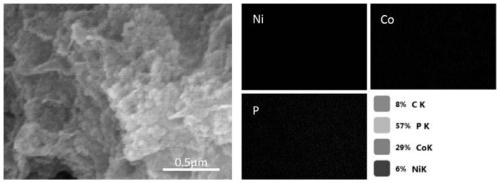

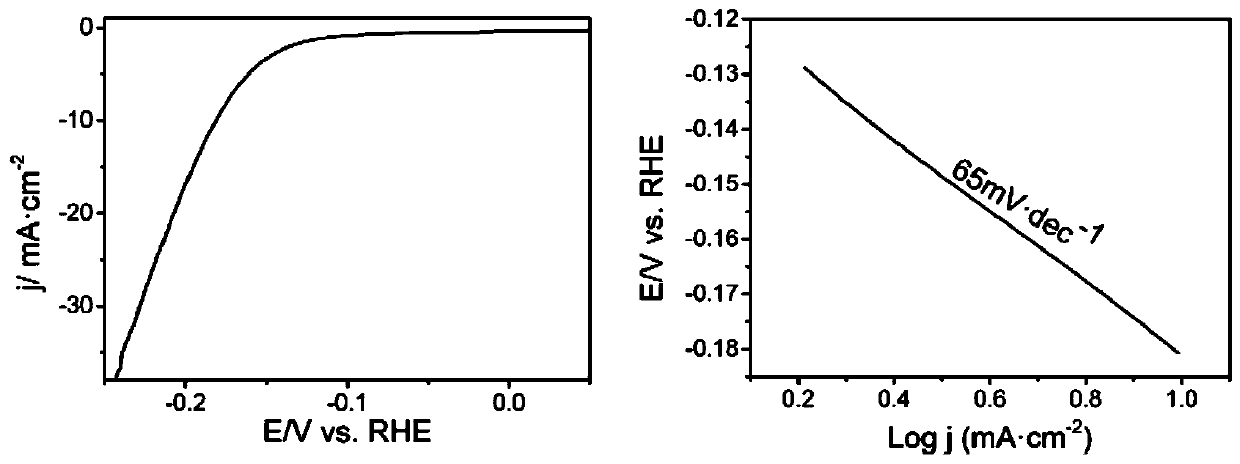

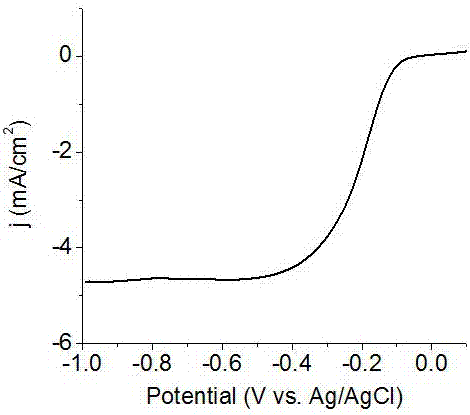

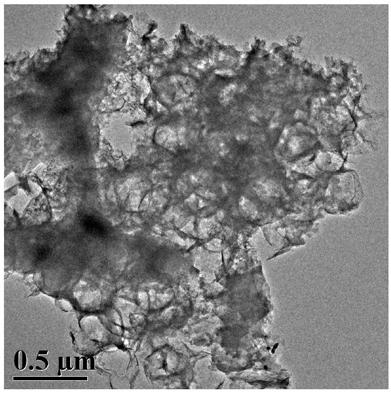

Preparation method of bimetallic phosphide composite reduction graphene nano electrocatalytic material

InactiveCN110124702ALow costSimple methodCatalyst activation/preparationElectrodesFreeze-dryingNickel acetate tetrahydrate

The invention discloses a preparation method of a bimetallic phosphide composite reduction graphene nano electro-catalytic material, which comprises the following steps of: 1) dissolving graphene oxide in water, and ultrasonically homogenizing; 2) respectively adding nickel acetate tetrahydrate and cobalt acetate tetrahydrate into graphene oxide solution, and uniformly stirring to obtain solutionA; 3) dissolving 2,5-dihydroxyterephthalic acid and sodium hydroxide in deionized water, and uniformly stirring to obtain solution B; (4) uniformly mix and reacting solution A and solution B, centrifugally collect to obtain precipitate, washing that precipitate, and freeze drying to obtain bimetallic MOF composite graphene oxide nano material containing Ni and Co; 5) respectively placing the material obtained in the step 4) and sodium hypophosphite in a tube furnace, raising the temperature under inert atmosphere and keeping the temperature for a period of time, and cooling to room temperatureto obtain Ni and Co-containing bimetallic phosphide composite reduction graphene nano electrocatalytic material NiCO / P-rGO. The method has simple operation and low cost, and the obtained material hasbetter electrocatalytic performance.

Owner:ZHEJIANG UNIV

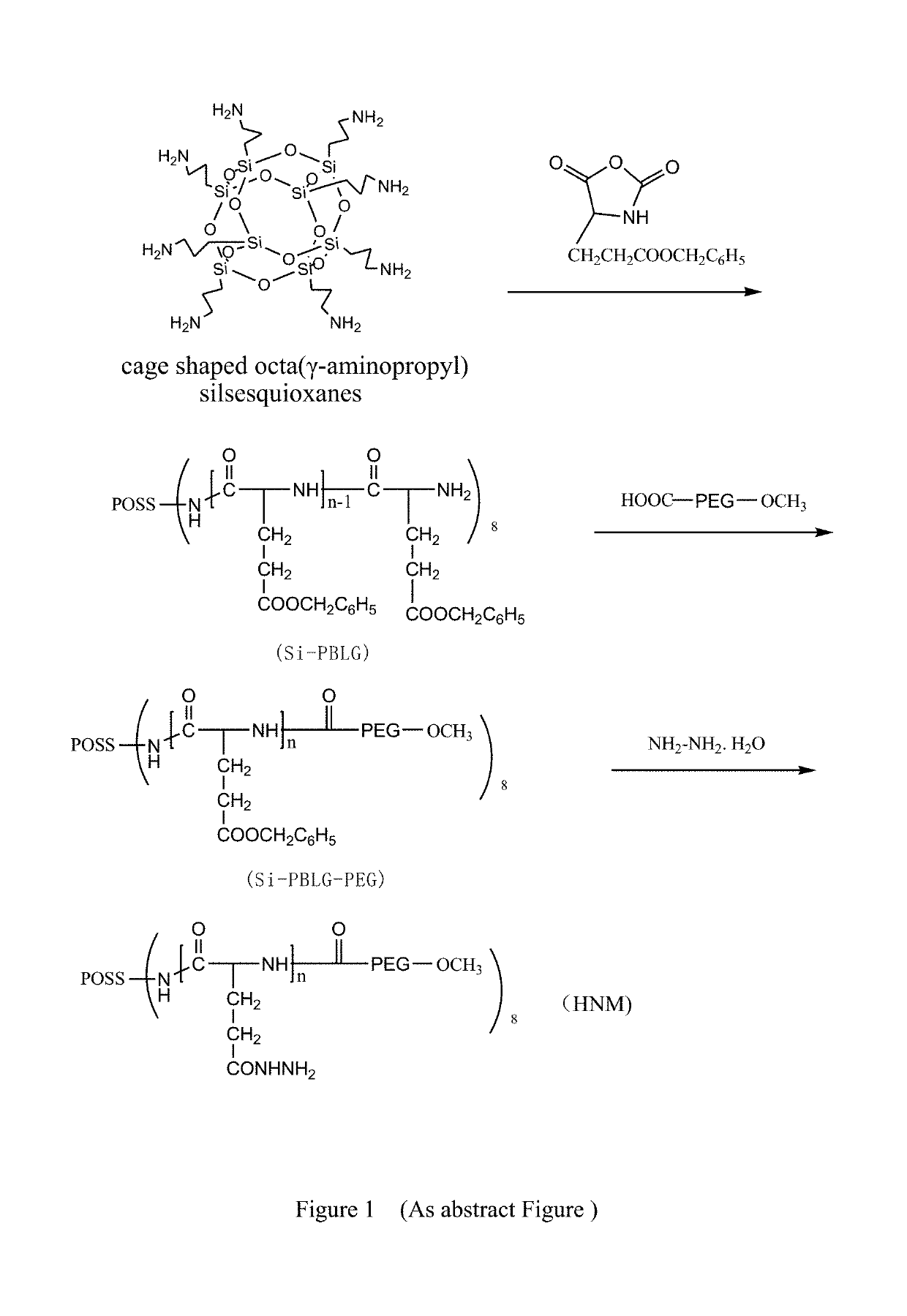

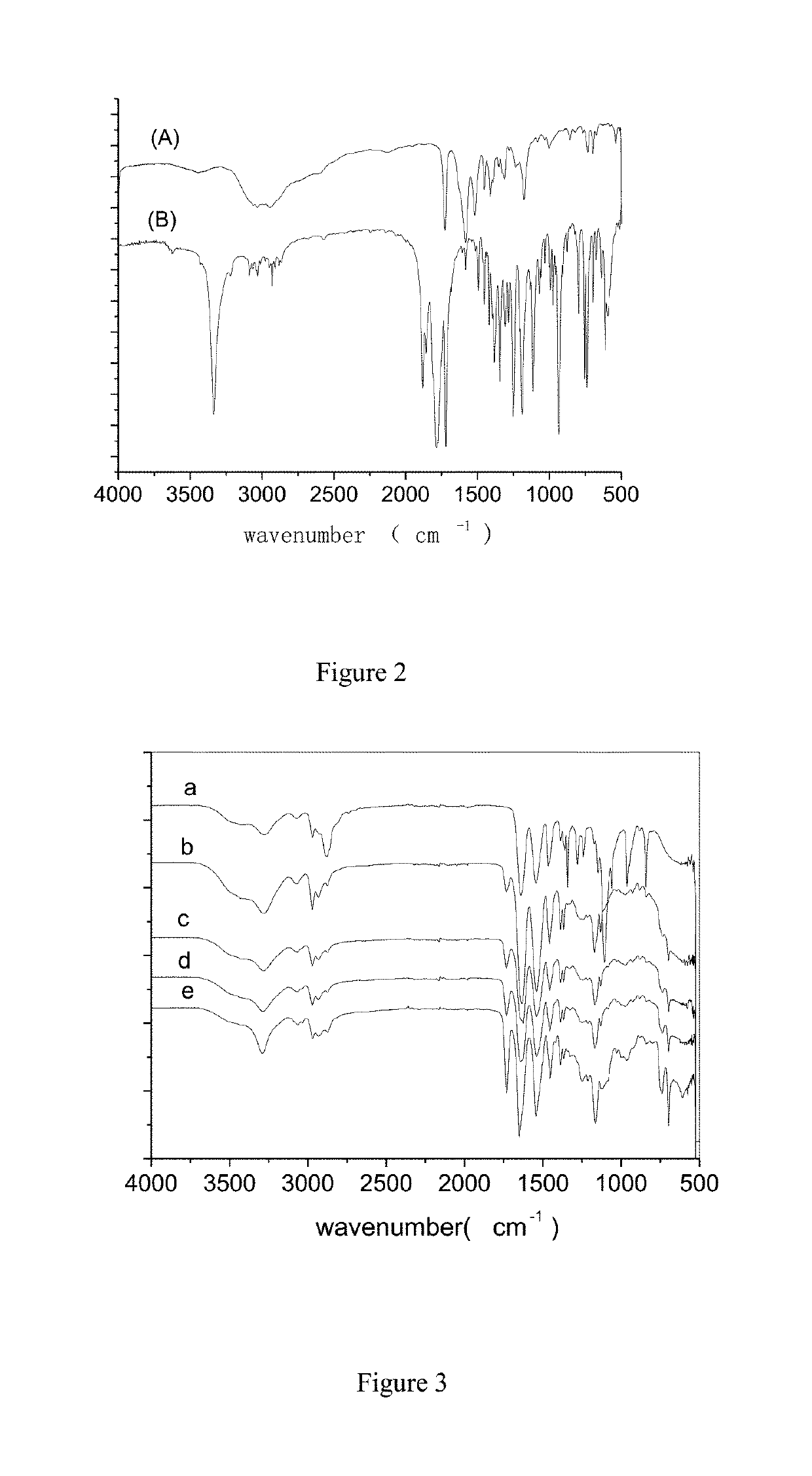

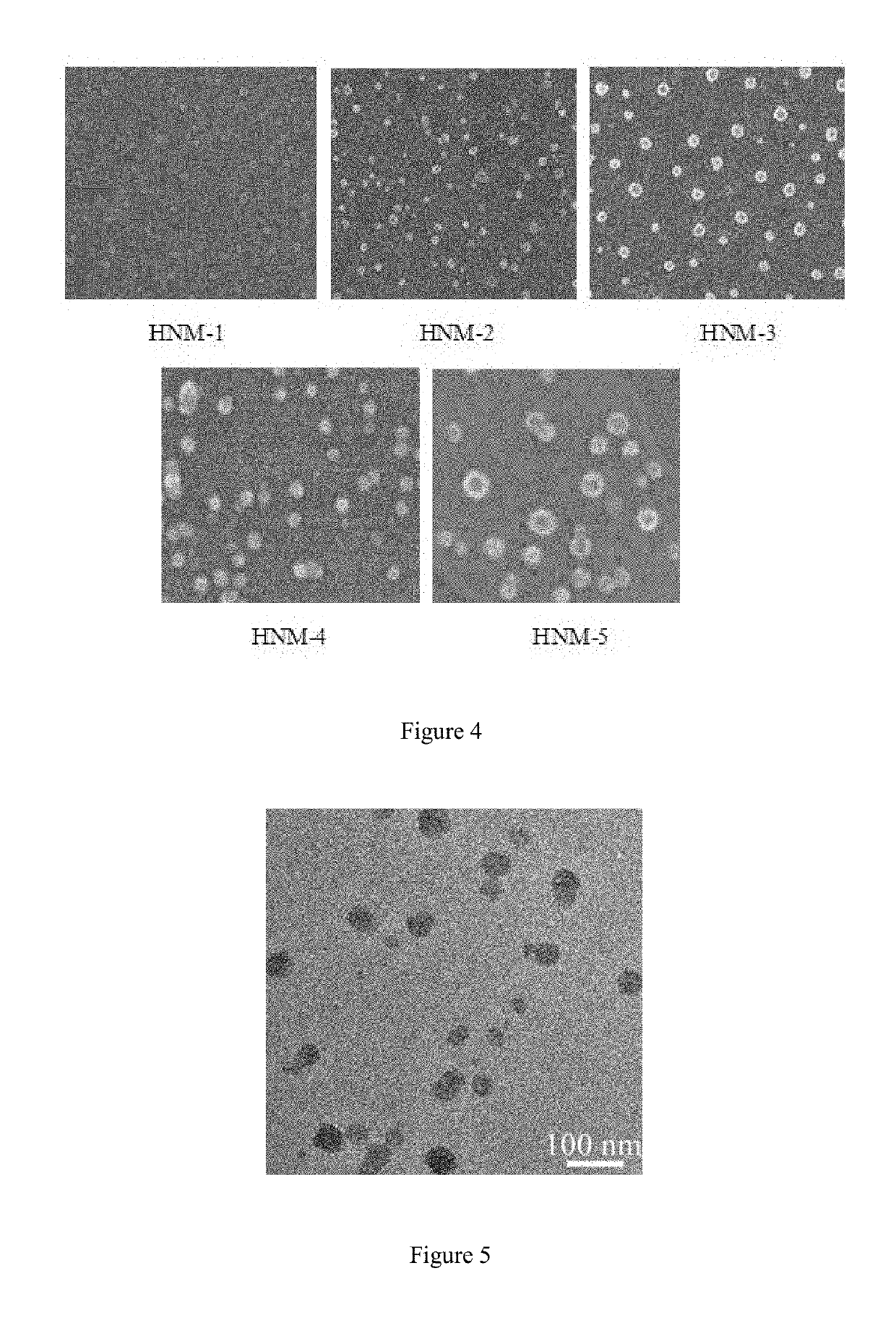

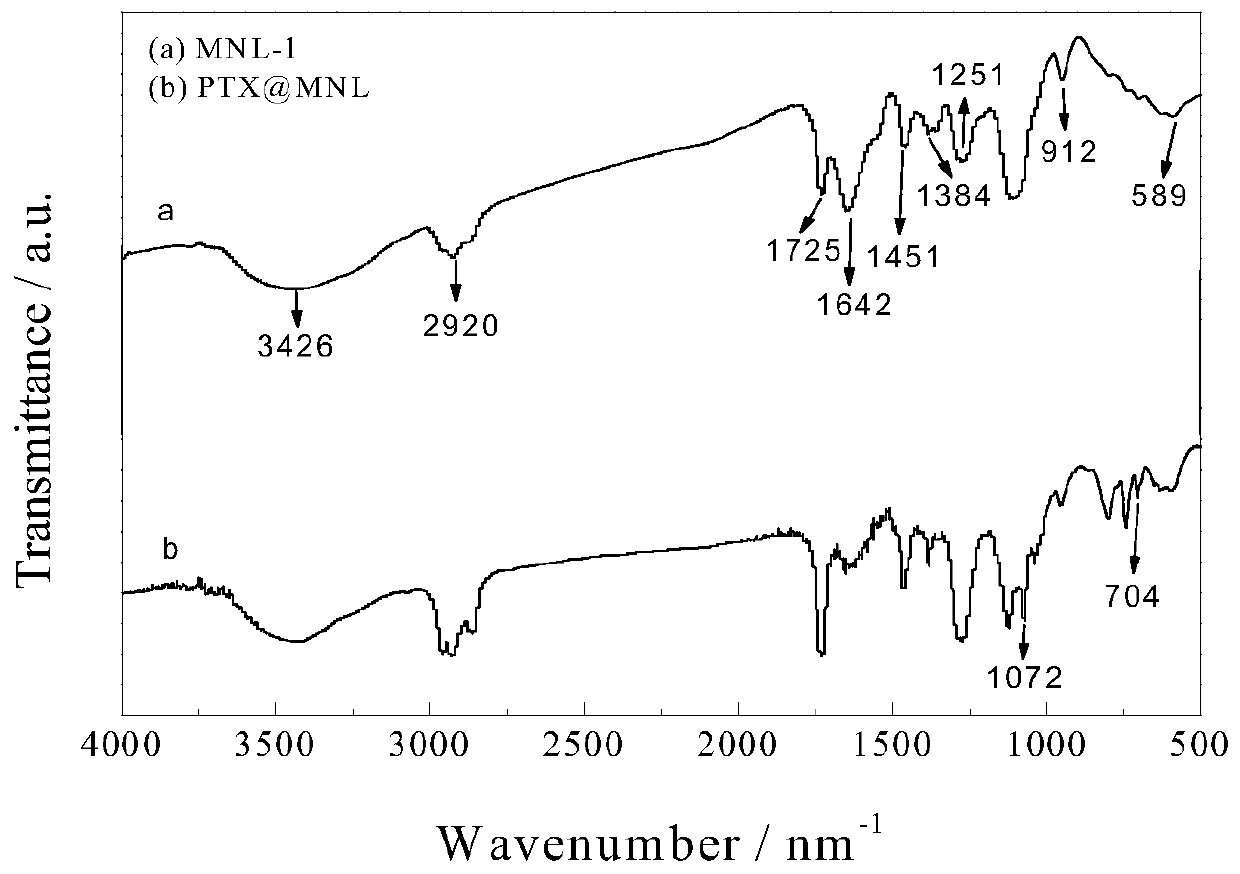

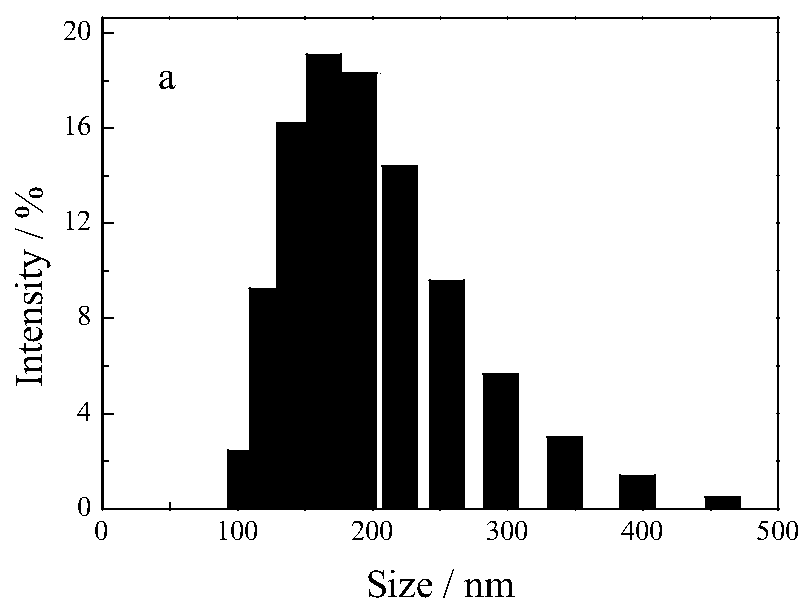

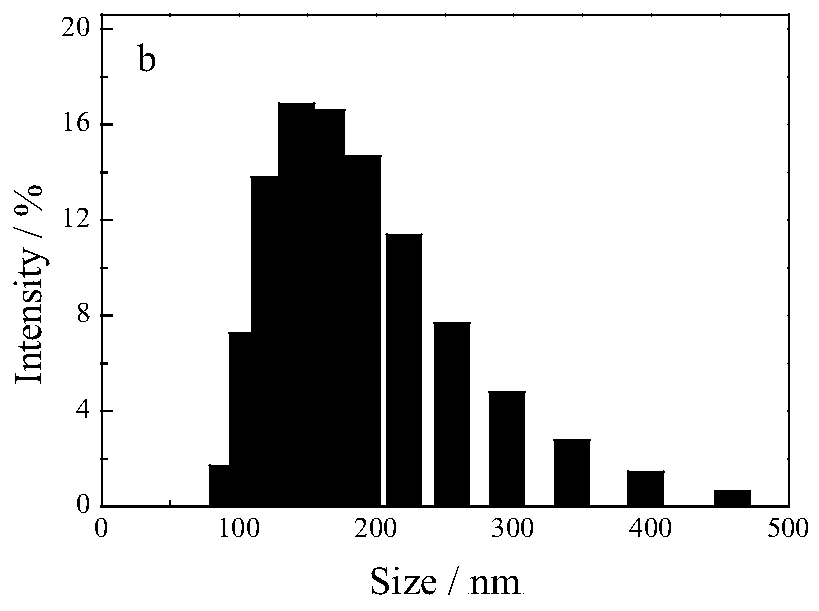

A method for preparation of hybrid amphiphilic star copolymer nano micelles

ActiveUS20190110987A1Structural rulesControllable sizeOrganic active ingredientsEmulsion deliveryHydrazine compoundSide chain

Hybrid amphiphilic star copolymer nano micelles are prepared in the invention. Cage shaped octa(γ-aminopropyl) silsesquioxanes is selected as the inorganic part, and L-glutamic benzyl ester-five membered ring anhydride is ring-opening polymerized by the initiation of amino groups on the surface of cage shaped octa(γ-aminopropyl) silsesquioxanes, producing copolymers with cage shaped octa(γ-aminopropyl) silsesquioxanes as nucleus and poly (L-glutamic-benzyl ester) as arms. The copolymers reacts with monomethoxy poly (ethylene glycol) carboxylic acid by condensation. Finally, the benzyl groups in the side chains of poly (L-glutamic acid-benzyl ester) are converted into hydrazine groups by acylhydrazination to obtain hybrid amphiphilic star copolymer nano micelles. The micelles can load doxorubicin, they are safe to human body and have good application prospects.

Owner:JIANGNAN UNIV

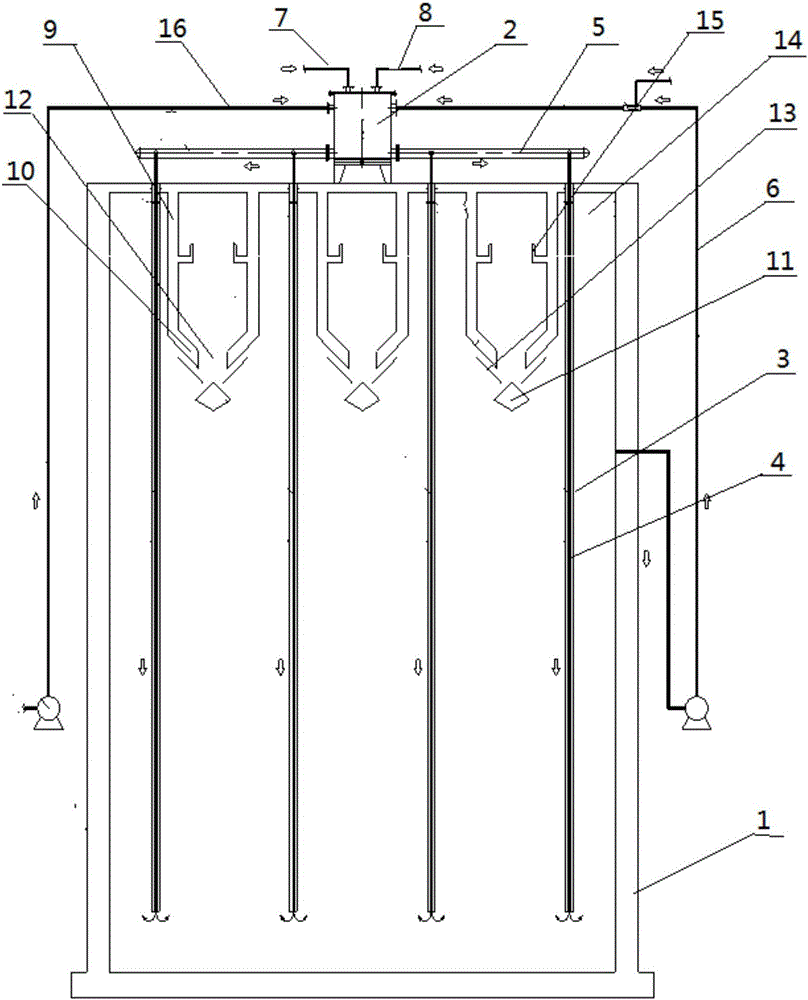

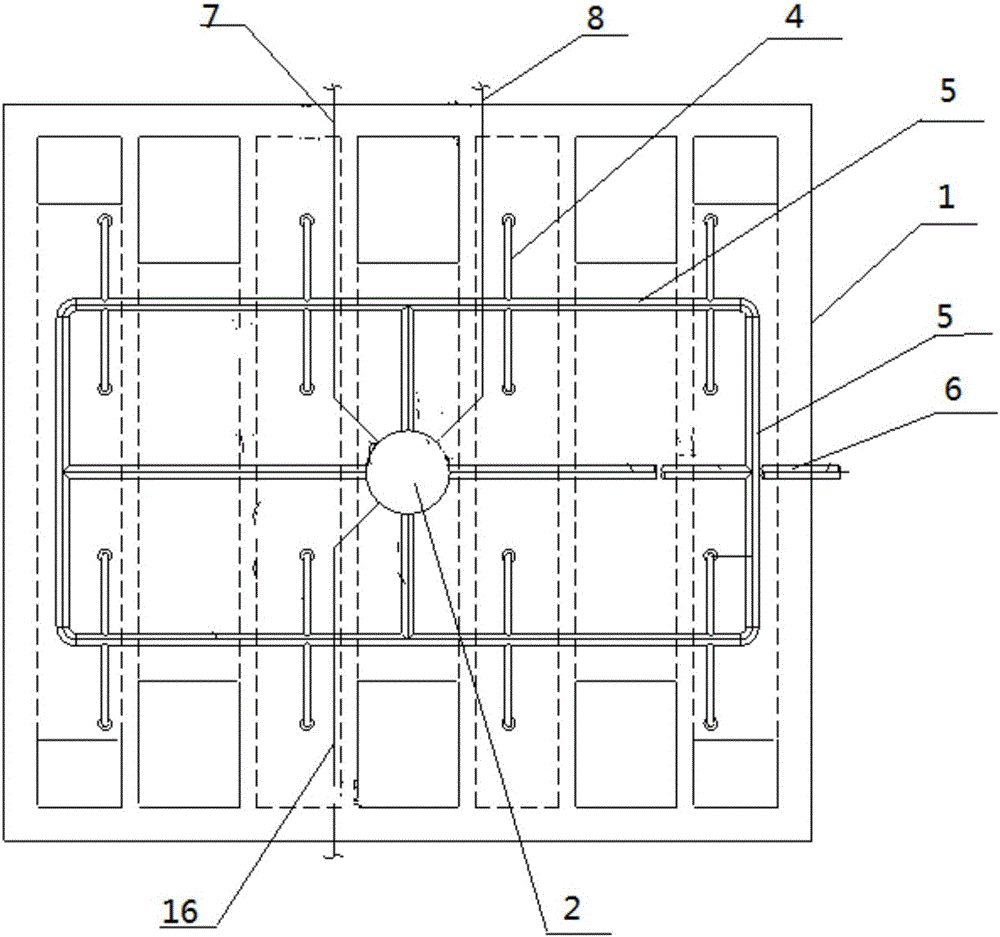

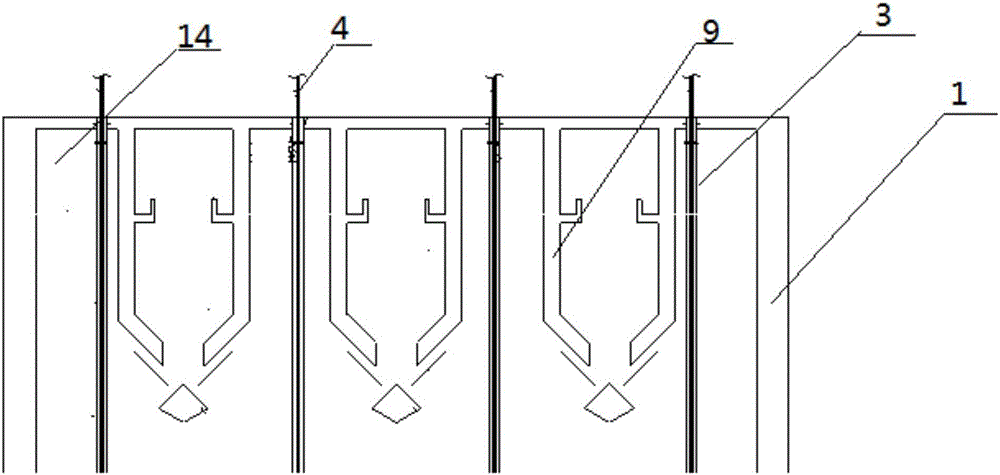

Online-maintenance up-flow anaerobic reactor

ActiveCN105776536AAvoid maintenance difficultiesImprove installation accuracyTreatment with anaerobic digestion processesWater qualityEngineering

The invention discloses an online-maintenance up-flow anaerobic reactor which comprises a reactor body, wherein a three-phase separation unit and a water distribution unit are arranged in the reactor body; the water distribution unit comprises a pressure water distributor and multiple water distribution pipelines extending to the lower part of the reactor body; the water distribution pipeline comprises a sleeve and a detachable water distribution branch pipe arranged in the sleeve; and the water distribution branch pipe is communicated with the pressure water distributor. The aims at providing the online-maintenance up-flow anaerobic reactor which can conveniently and quickly respond to the situation of scale blockage of pipeline, realizes uniform water distribution and low mounting difficulty and improves the effluent quality.

Owner:GUANGZHOU SINOVAST ENERGY ENVIRONMENT GRP

Magnetism/temperature/pH tri-responsive nanogel and preparation method thereof

InactiveCN109745285AEasy to operateMild experimental conditionsOrganic active ingredientsAerosol deliveryCross-linkRelease time

The invention discloses a magnetism / temperature / pH tri-responsive nanogel medicine carrying system capable of carrying combined chemotherapy drug of the breast cancer, namely paclitaxel, and disclosesa preparation method of magnetic nanogel. The preparation method comprises the steps that Fe3O4 nano particles are prepared by adopting a chemically modified coprecipitation method, polyacrylic acid(PAA) and N-isopropylacrylamide (NIPAM) are taken as monomers, divinylbenzene (DVB) is taken as a cross-linking agent, Fe3O4 is taken as a nuclear body material, and the magnetic nanogel is prepared by adopting a miniemulsion co-polymerization method. The preparation method of the magnetic nanogel has the advantages that the magnetic nanogel loaded with the paclitaxel is synthesized through the miniemulsion polymerization method, the operation is simple, the experiment conditions are mild, and the synthesized nanogel is regular in appearance and uniform in dispersion, and has good temperaturesensibility and pH-sensitivity. Test results show that drug encapsulation efficiency is high, and the slow-release time is as long as 14 days.

Owner:JINLING INST OF TECH

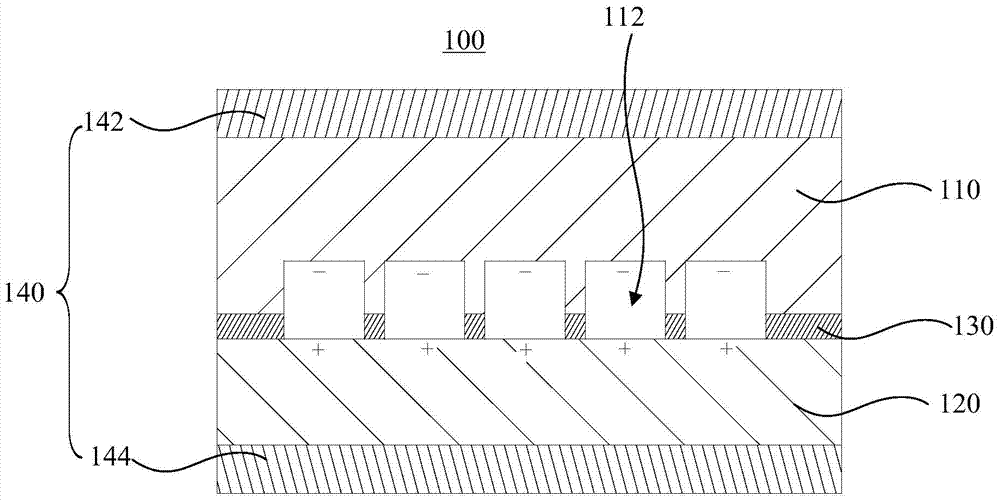

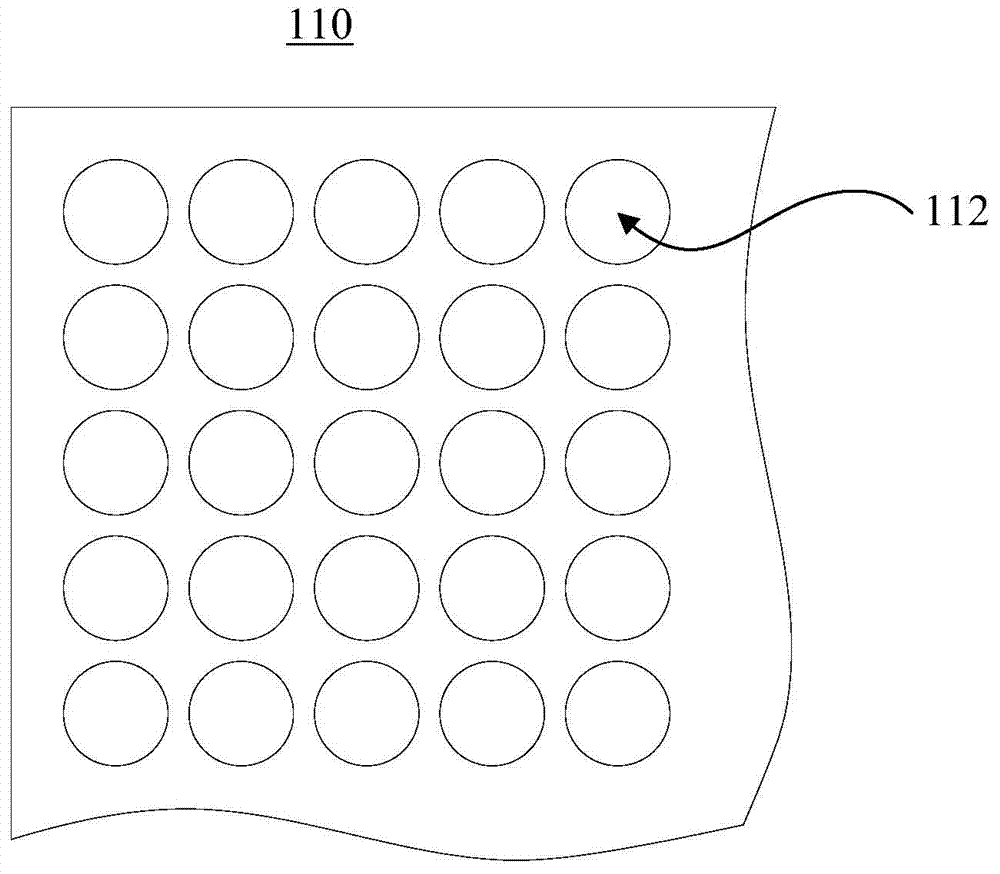

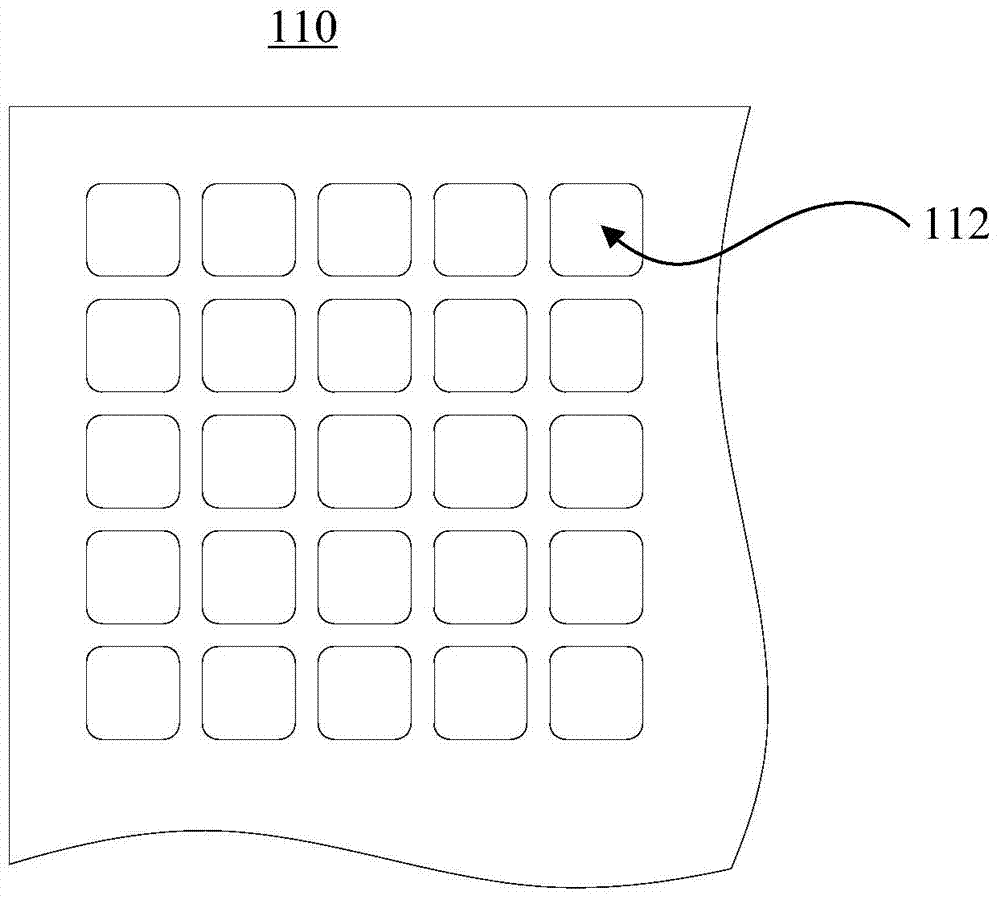

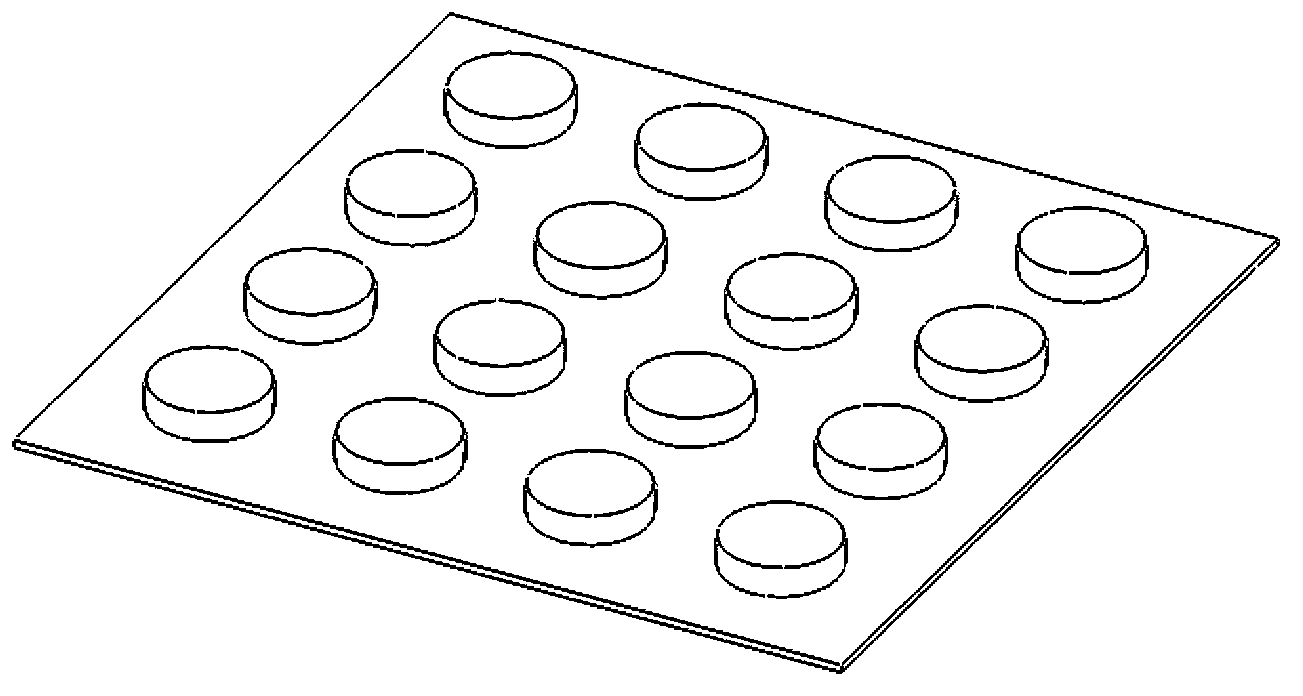

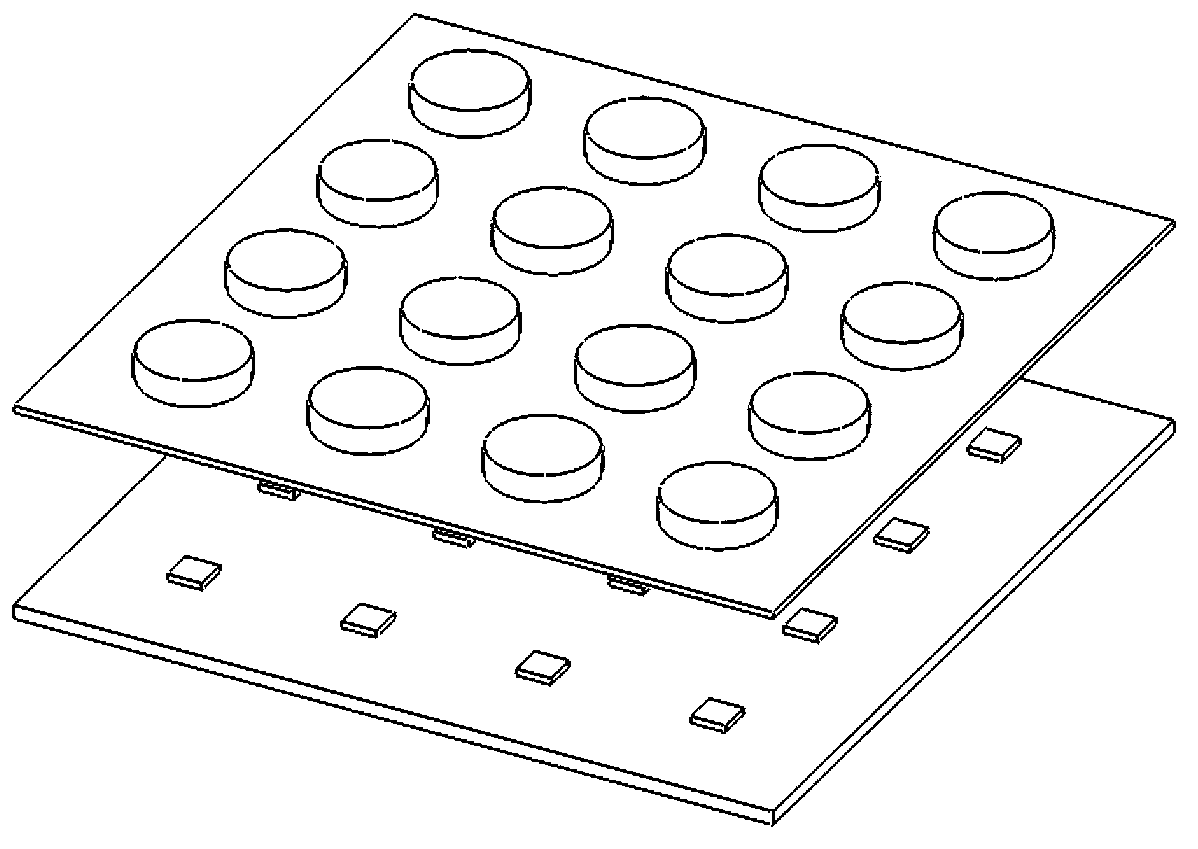

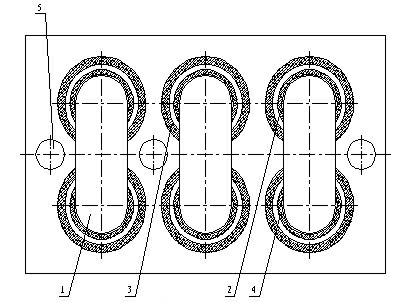

Piezoelectret structure and preparation method thereof

ActiveCN103700761AAvoid it happening againAvoid churnPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionElectricitySurface layer

The invention discloses a piezoelectret structure, which comprises a first electret film, a second electret film, a first adhesive layer and an electrode, wherein a plurality of first grooves distributed in arrays are formed in the surface of the first electret film; electric charges with opposite polarities are stored in the first and second electret films after the first and second electret films are polarized respectively; the surface, adjacent to groove openings of the first grooves, of the first electret film is coated with the first adhesive layer which is used for combining the first and second electret films; the first grooves form regular and ordered hole structures after the first and second electret films are combined. The piezoelectret structure is formed sequentially by polarization and combination, so that bulk charges of which the polarity is opposite to that of the electric charges on the surface close to the hole structures can be prevented from being generated on a surface layer of the piezoelectret structure; in addition, the first and second electret films of the piezoelectret structure are combined in an adhesion way, so that inner electric charge loss caused by the high temperature of heat fusion is avoided. In addition, the invention provides a method for preparing the piezoelectret structure.

Owner:SHENZHEN HORN AUDIO

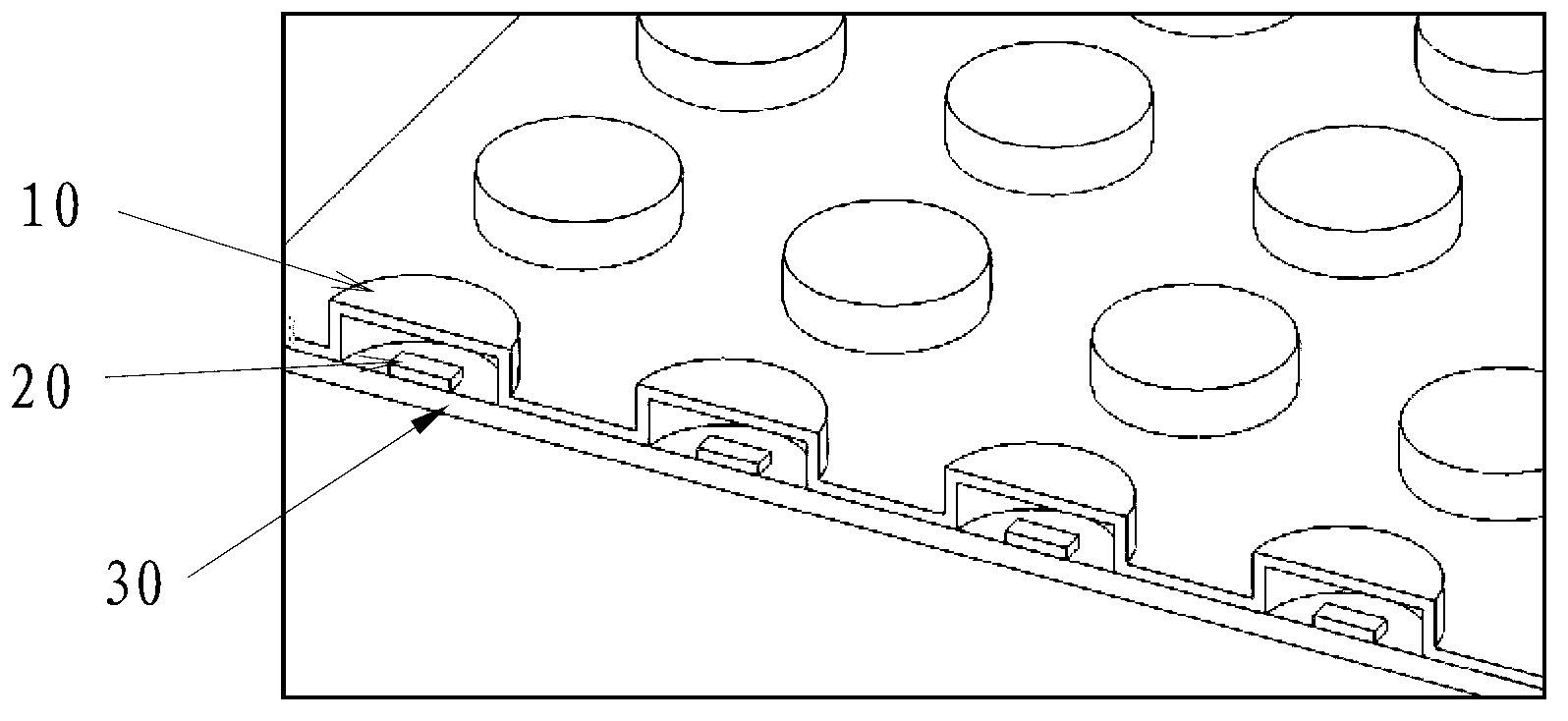

LED packaging structure utilizing distant fluorescent powder layer and manufacturing method of LED packaging structure

ActiveCN103022325AAddress reliabilityOvercoming Bad Motivation ProblemsPlanar light sourcesSolid-state devicesNanotechnologyBatch manufacturing

Owner:HKUST LED FPD TECH R&D CENT AT FOSHAN

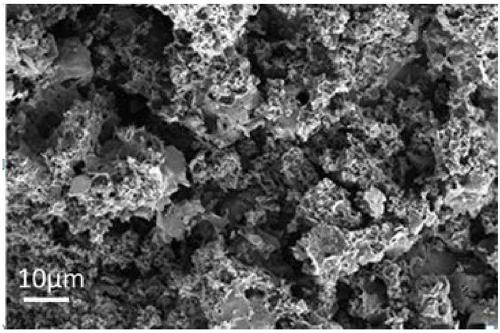

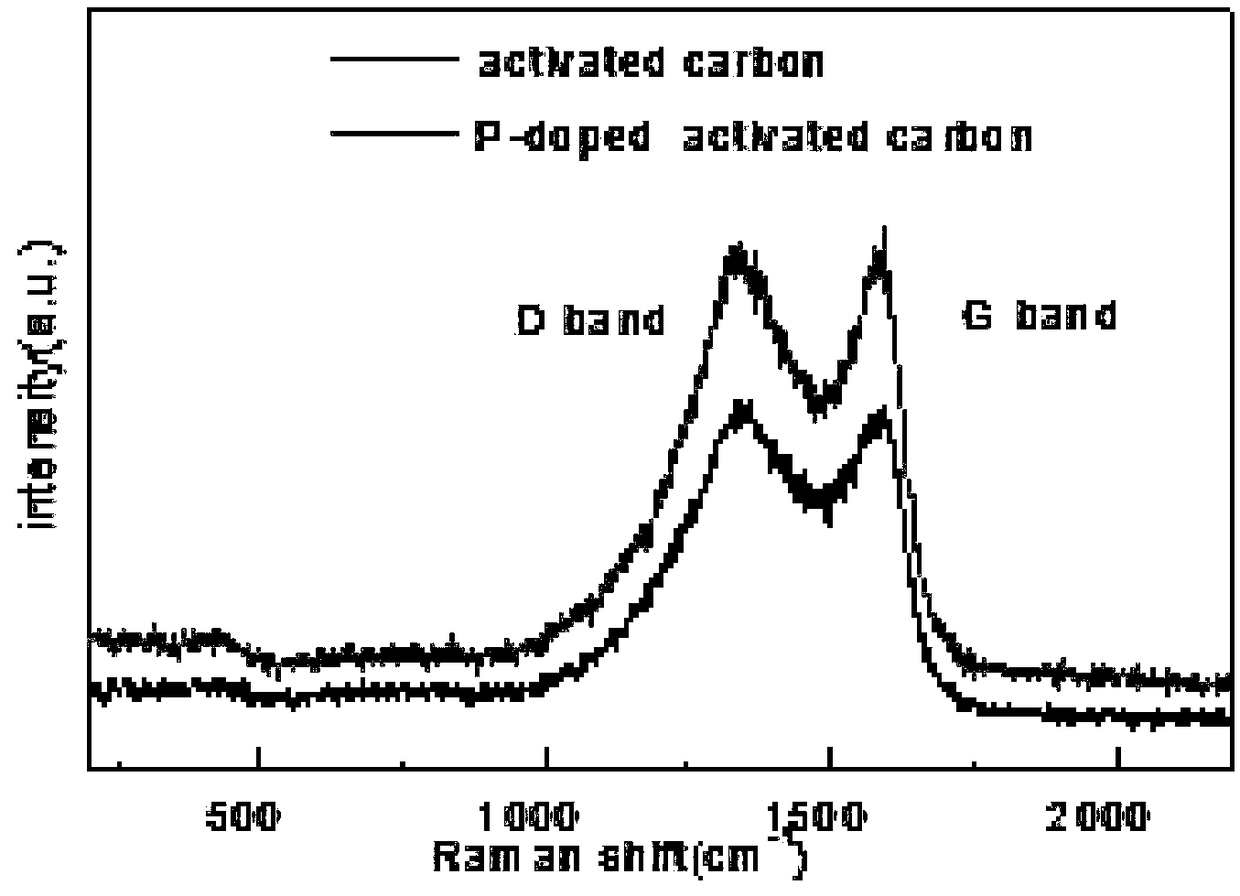

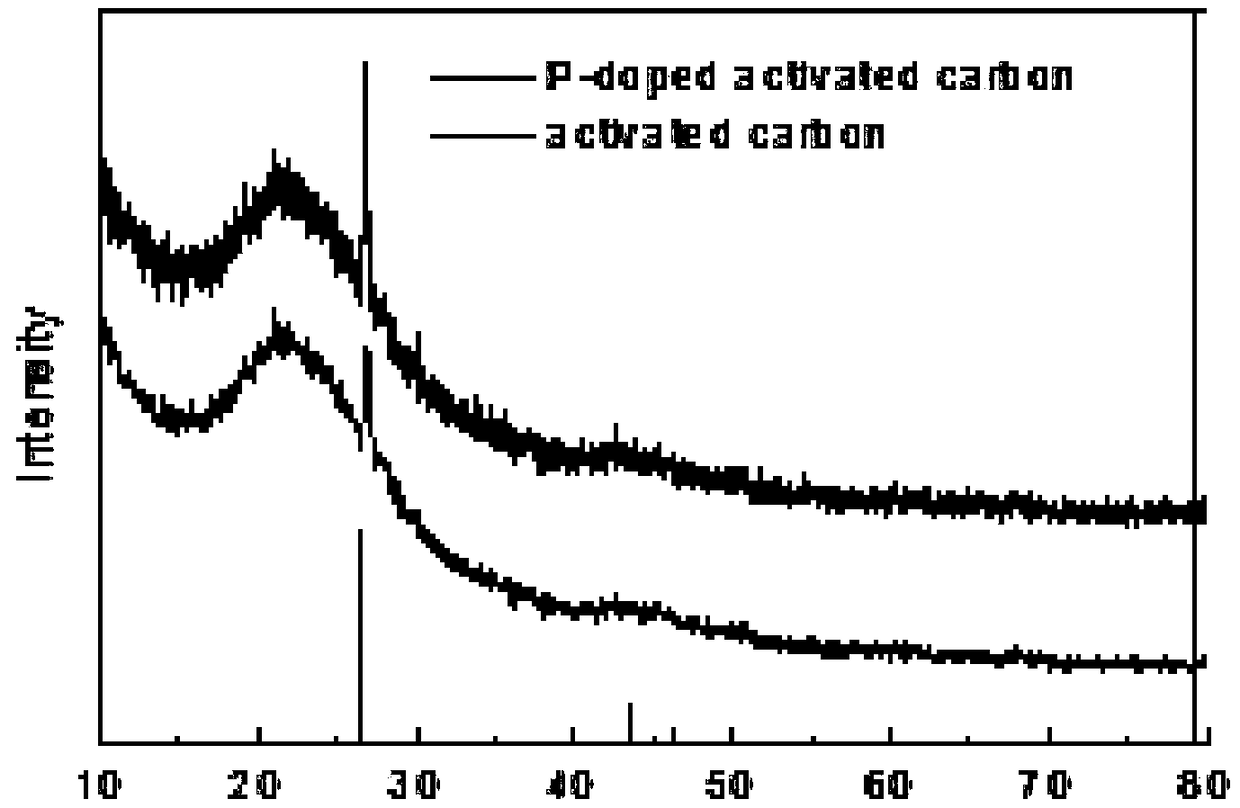

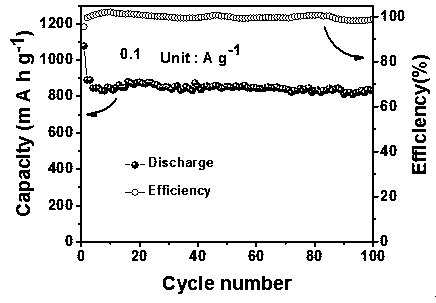

Method for manufacturing lithium ion negative electrode activated carbon from sunflower discs, electrode and testing method

InactiveCN109354015AHigh phosphorus contentImprove performanceCarbon compoundsCell electrodesBiomassActivated carbon

The invention discloses a method for manufacturing lithium ion negative electrode activated carbon from sunflower discs. The method comprises drying and cracking raw materials, performing simple waterheating and sintering, acid-pickling, washing and drying obtained products to obtain phosphorous-doped biomass activated carbon serving as a lithium ion negative electrode material. The prepared phosphorous-doped biomass activated carbon is high in specific capacity and coulombic efficiency and good in circulating stability and is an excellent lithium ion battery negative electrode material.

Owner:HEFEI UNIV OF TECH

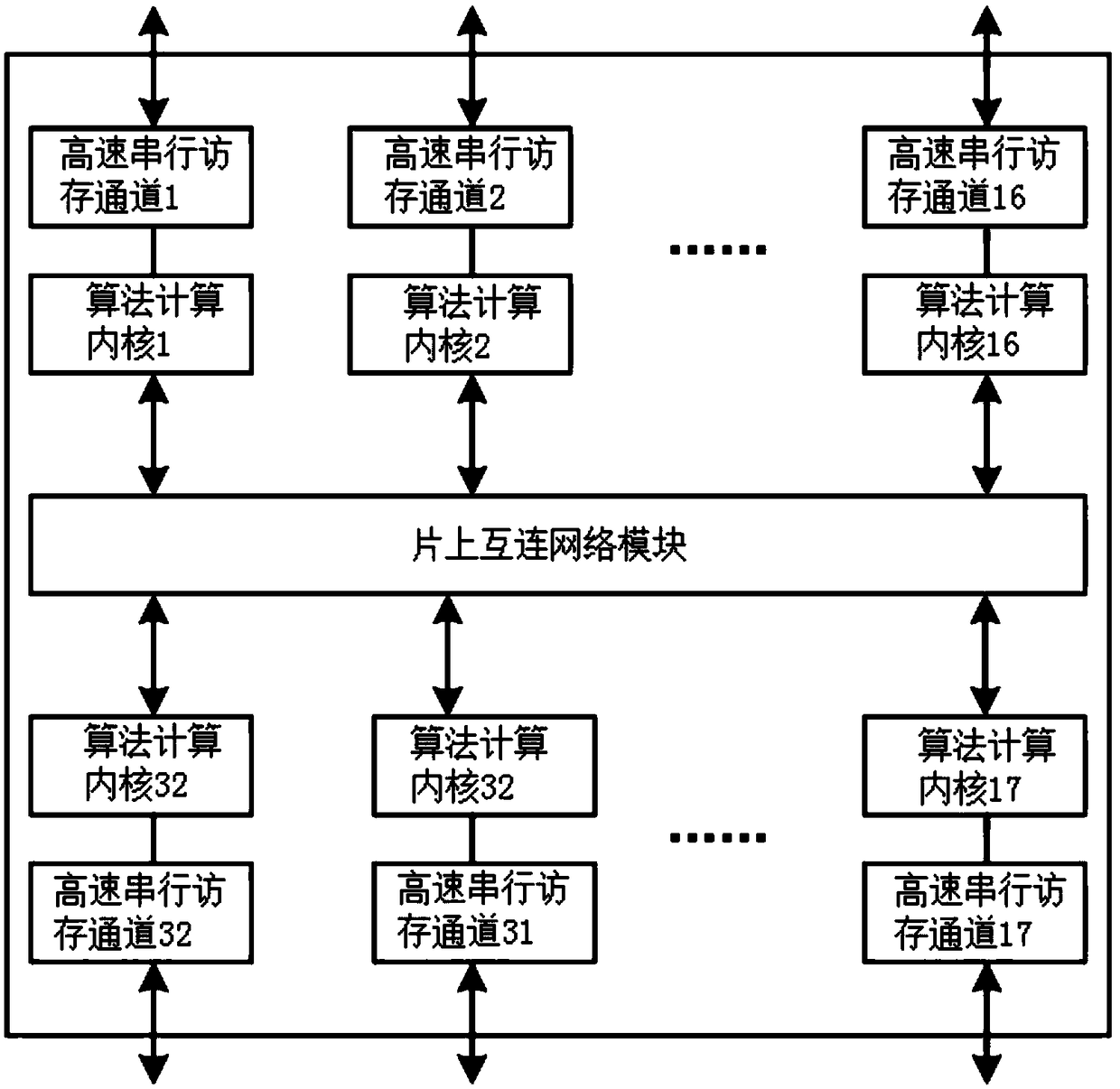

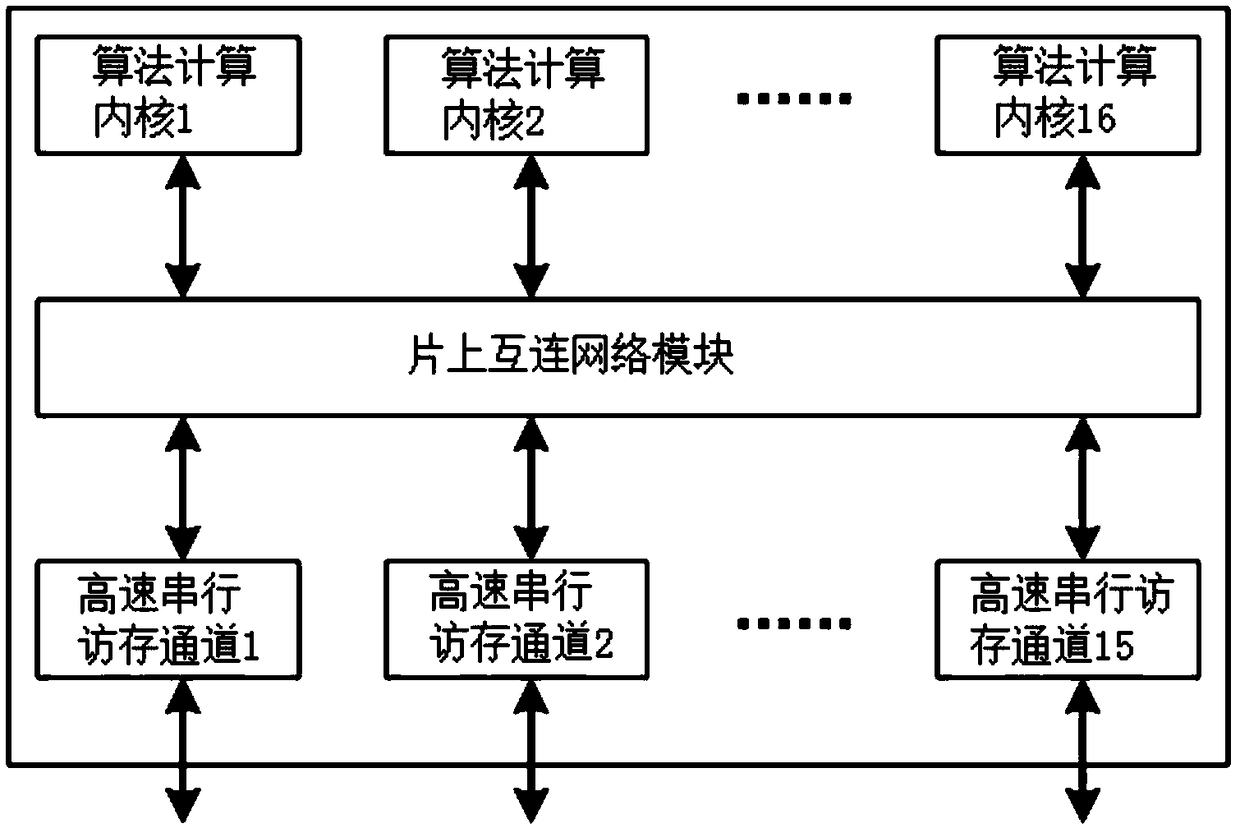

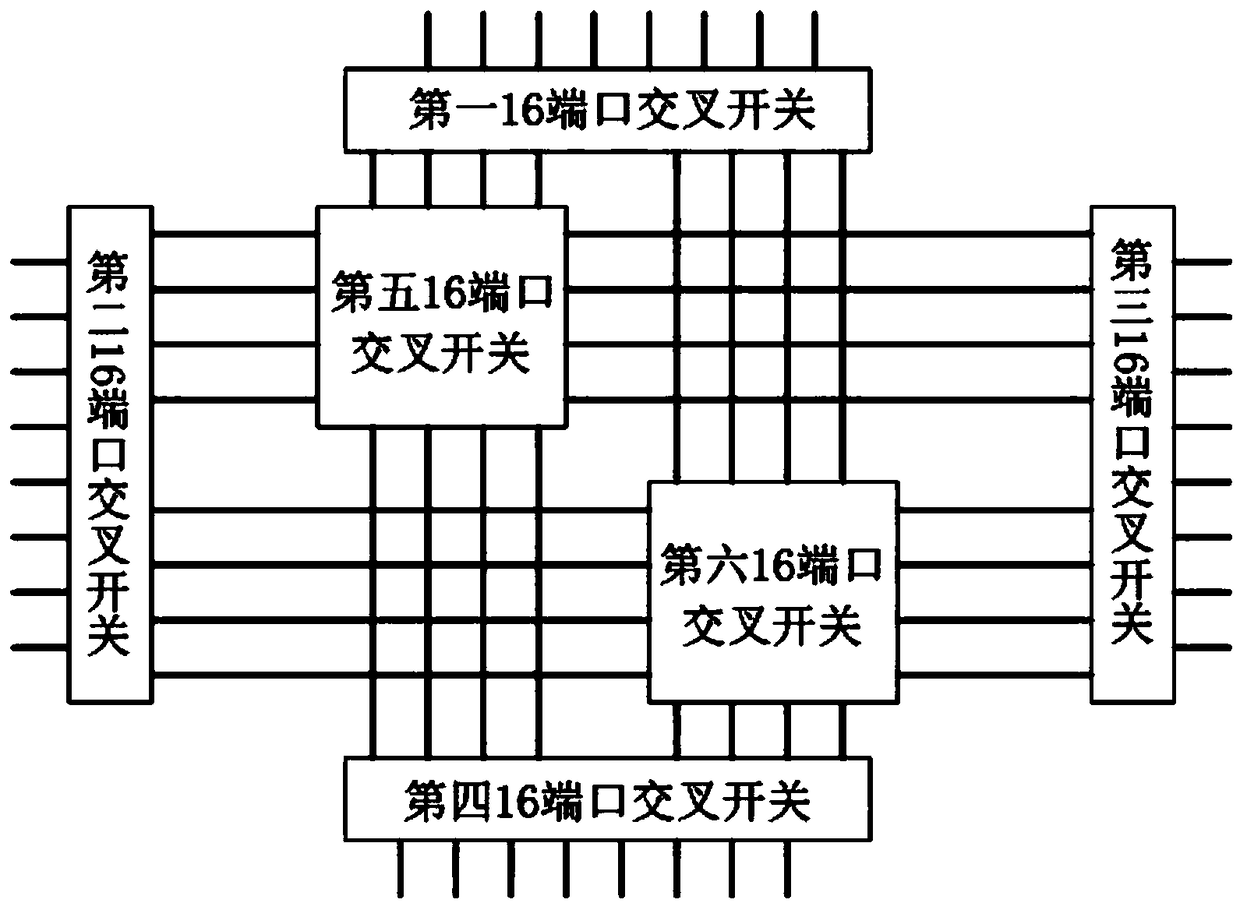

A memory access intensive algorithm acceleration chip with multiple high speed serial memory access channels

InactiveCN109240980AIncrease the number ofStructural rulesArchitecture with single central processing unitElectric digital data processingComputer architectureSystem architecture design

The invention relates to the field of computer system structure and integrated circuit design, an access-intensive algorithm acceleration chip having a plurality of high-speed serial access channels is disclosed, includes a plurality of algorithm computation cores for performing data processing operations in the algorithm and a plurality of high speed serial access memory channels, the high speedserial access channel is connected with the off-chip memory chip. The implementation mode of the on-chip interconnection network module includes single bus, multi-bus, ring network, two-dimensional mesh or crossover switch. A memory access intensive algorithm acceleration chip with a plurality of high-speed serial memory access channel, the invention can flexibly expand the number of high-speed serial memory access channels according to the algorithm processing requirements so as to expand the memory access bandwidth, support various address mapping modes, and support the algorithm to accelerate the direct data transmission between chips, thus providing better flexibility for the whole machine system architecture design.

Owner:深圳市安信智控科技有限公司

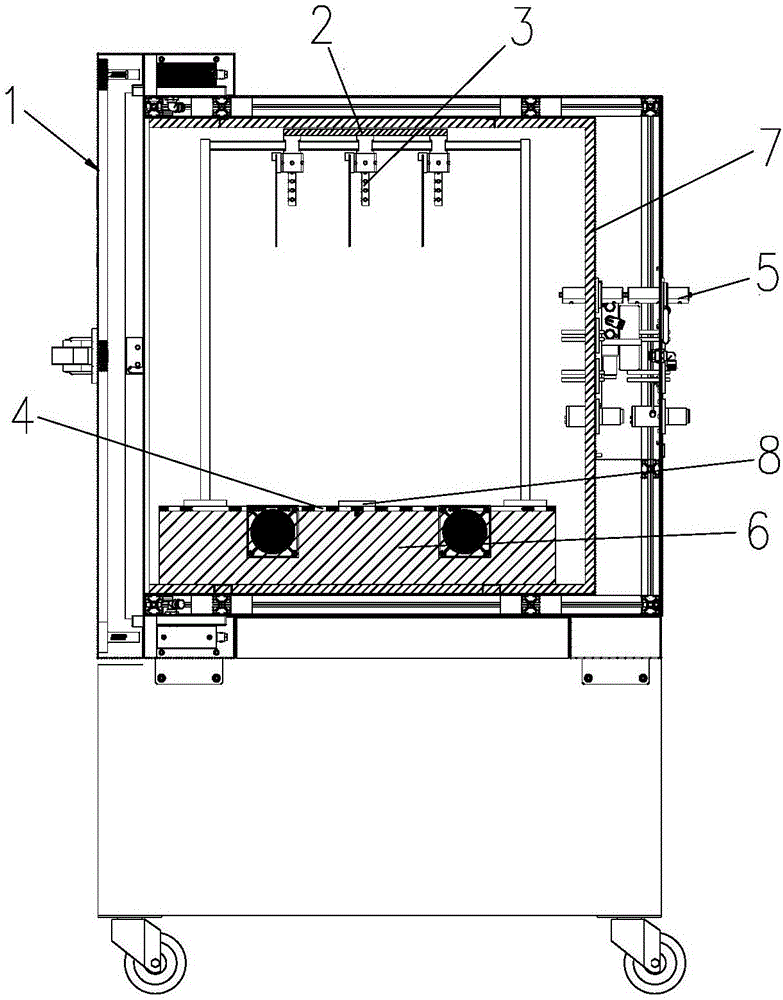

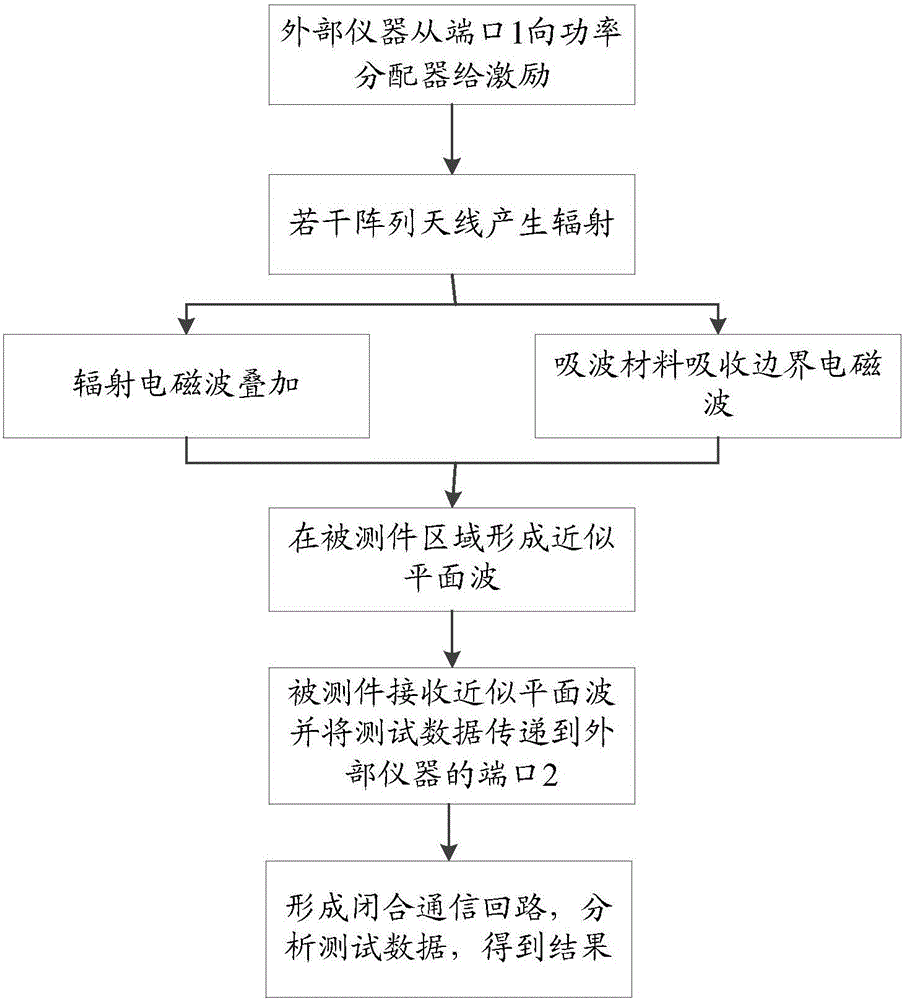

Electromagnetic wave cell based on array antennas

ActiveCN106850086AImprove test accuracyStructural rulesRadio transmissionTransmission monitoringPhysicsRadio frequency

The invention is applicable to the technical field of detection of wireless communication terminals and provides an electromagnetic wave cell based on array antennas. The electromagnetic wave cell comprises a power distributor, a plurality of array antennas, a testing platform and a high-speed data filtering interface, wherein the power distributor is located on a side wall in the electromagnetic wave cell; the plurality of array antennas are arrayed at equal interval and are connected with the power distributor; signal radiation directions of the plurality of array antennas are vertical to the upper surface of the testing platform; the power distributor is used for providing equal-amplitude and cophase excitation for the plurality of array antennas at the same time; the plurality of array antennas are used for generating radiation signals for a space respectively according to excitation, and the radiation signals are overlapped to form quasi-plane waves, so that a static region is formed on a surface of the testing platform for storing a detected part; the high-speed data filtering interface is located on the side wall of the electromagnetic wave cell and is used for transmitting a signal with a radio frequency performance of the detected part. The electromagnetic wave cell provided by the invention can be used for carrying out an accurate radio frequency performance test on a wireless communication terminal product.

Owner:SHENZHEN TOJOIN COMM TECH

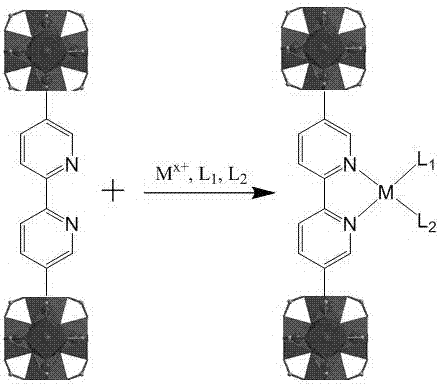

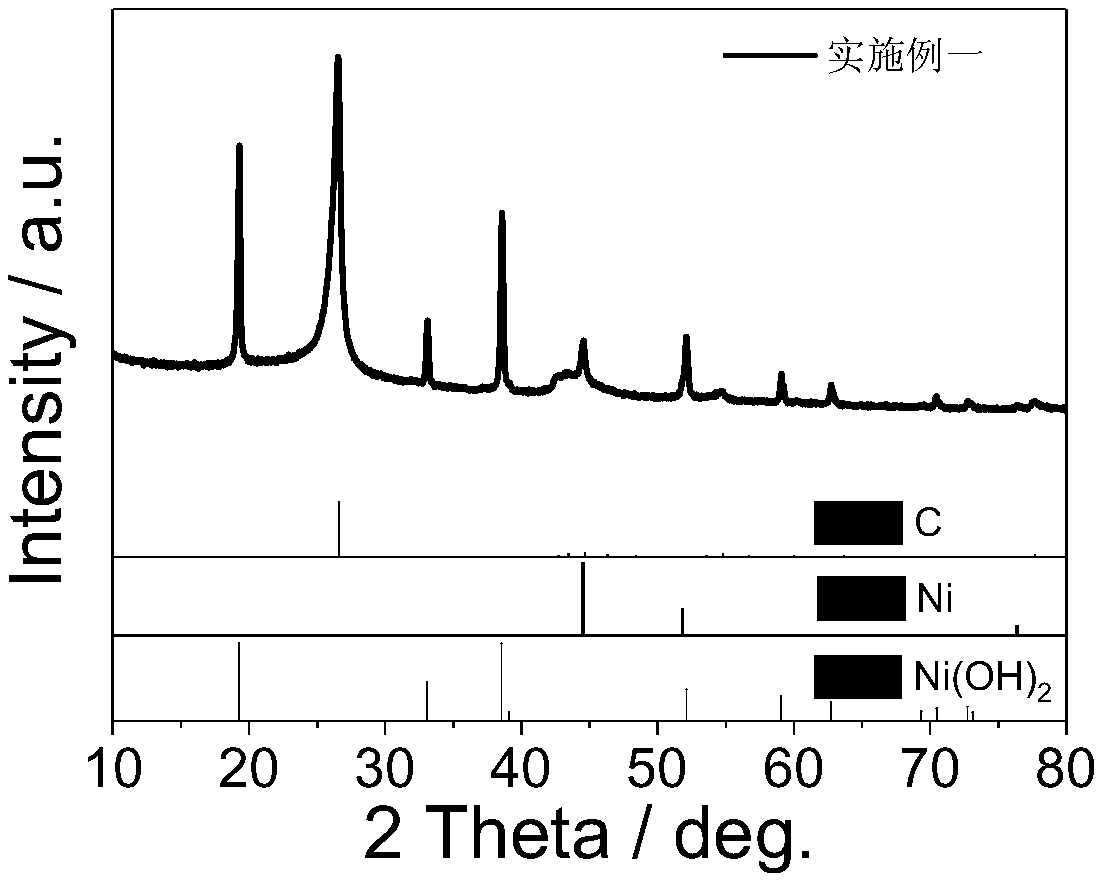

Novel transition metal-modified redox catalyst and preparation method thereof

ActiveCN107887616AStructural rulesActive ingredient adjustableCell electrodesChemical technologyCarbonization

The invention relates to the field of chemical technologies of carbon materials, and in particular relates to a novel transition metal-modified redox catalyst and a preparation method thereof. A metal-organic frame compound acquired by modification of monatomic transition metal after coordination is used as a precursor, and the novel transition metal-modified redox catalyst is acquired by carbonization and subsequent acid treatment methods. The method provided by the invention is different from the transition metal modification method by using a traditional impregnation method and a physical hybrid method, and has the characteristics that the transition metal active sites with high dispersity can be acquired, enhancement on catalytic activity of the catalyst in an oxygen reduction reactionis facilitated, and the novel transition metal-modified redox catalyst can be used as a substitute catalyst of a traditional platinum catalyst.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

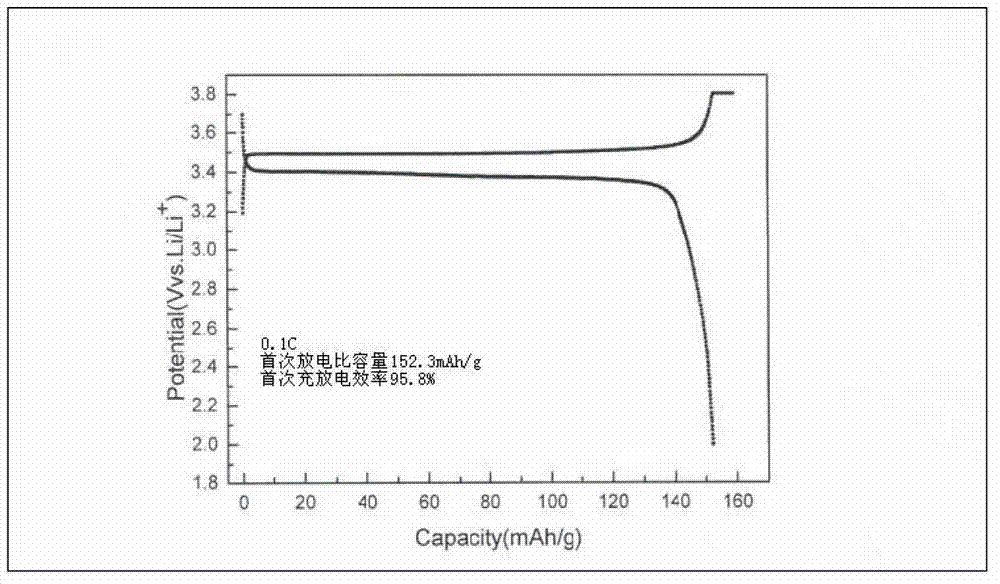

Method for preparing lithium iron phosphate material by raw material solid phase dry grinding

InactiveCN102856546AUniform particle sizeEasy to mixCell electrodesPhosphorus compoundsSolventSolid phases

The invention relates to a raw material solid phase dry grinding technology, in particular to a method for preparing a lithium iron phosphate material by raw material solid phase dry grinding, and belongs to the field of preparation of a lithium battery material. According to the method, a novel high temperature solid phase dry closed-loop grinding system combining an ultrafine grinding technology with an air classification technology is adopted; raw materials of a lithium iron phosphate cathode material are subjected to nano-scale grinding and mixingl and the raw materials are sintered to obtain the nano-scale lithium iron phosphate cathode material. The invention aims to solve the problems of irregular morphology of a precursor, wide particle size distribution and nonuniform physical and chemical composition of a product, which are caused by large particle size, wide distribution and nonuniform mixing of the raw materials. The invention overcomes the defects of pollution of ammonia and an organic solvent to the environment and energy consumption, which is caused by the wet grinding material drying, in the conventional high temperature solid phase production. Moreover, in the production process, only harmless gases such as CO2, water and the like are discharged; and a lithium iron phosphate green environmental-friendly production process is really implemented.

Owner:JIANGSU FREY NEW ENERGY

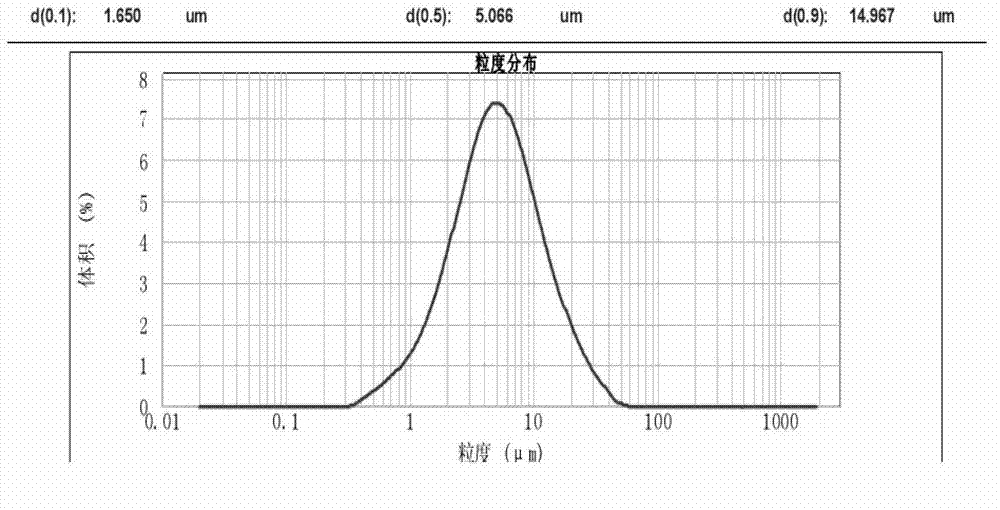

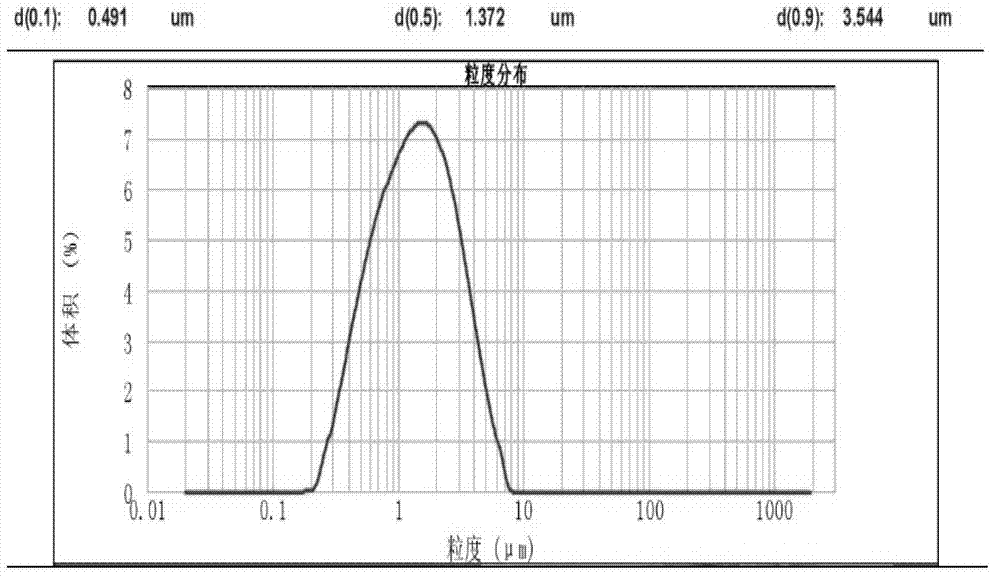

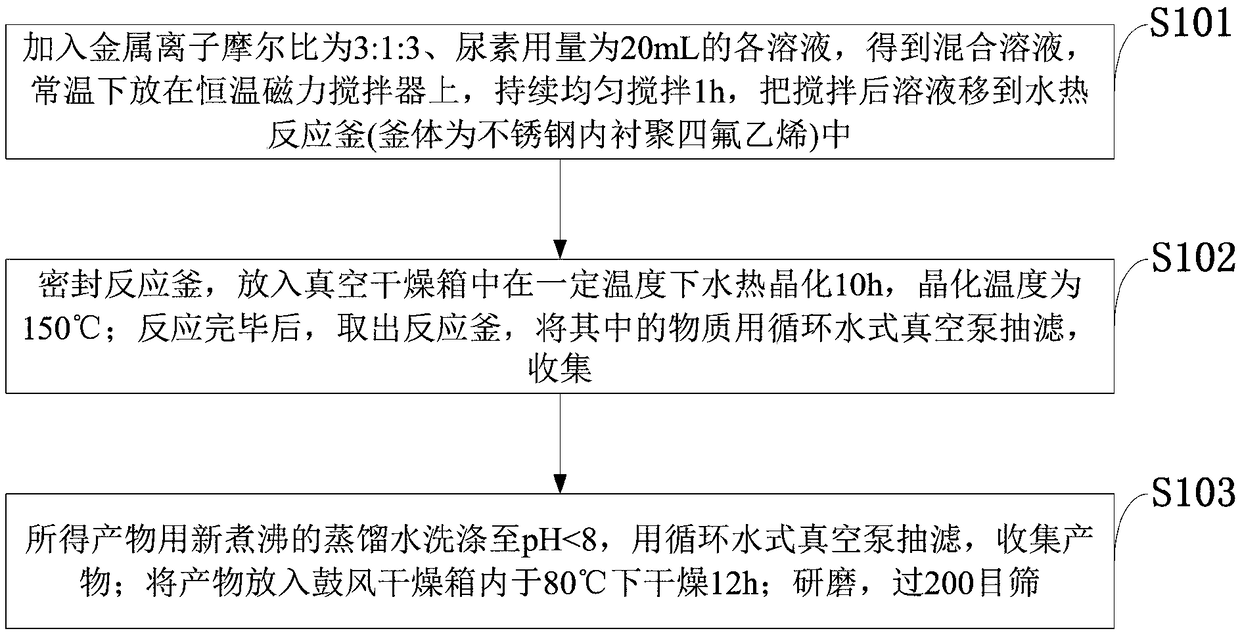

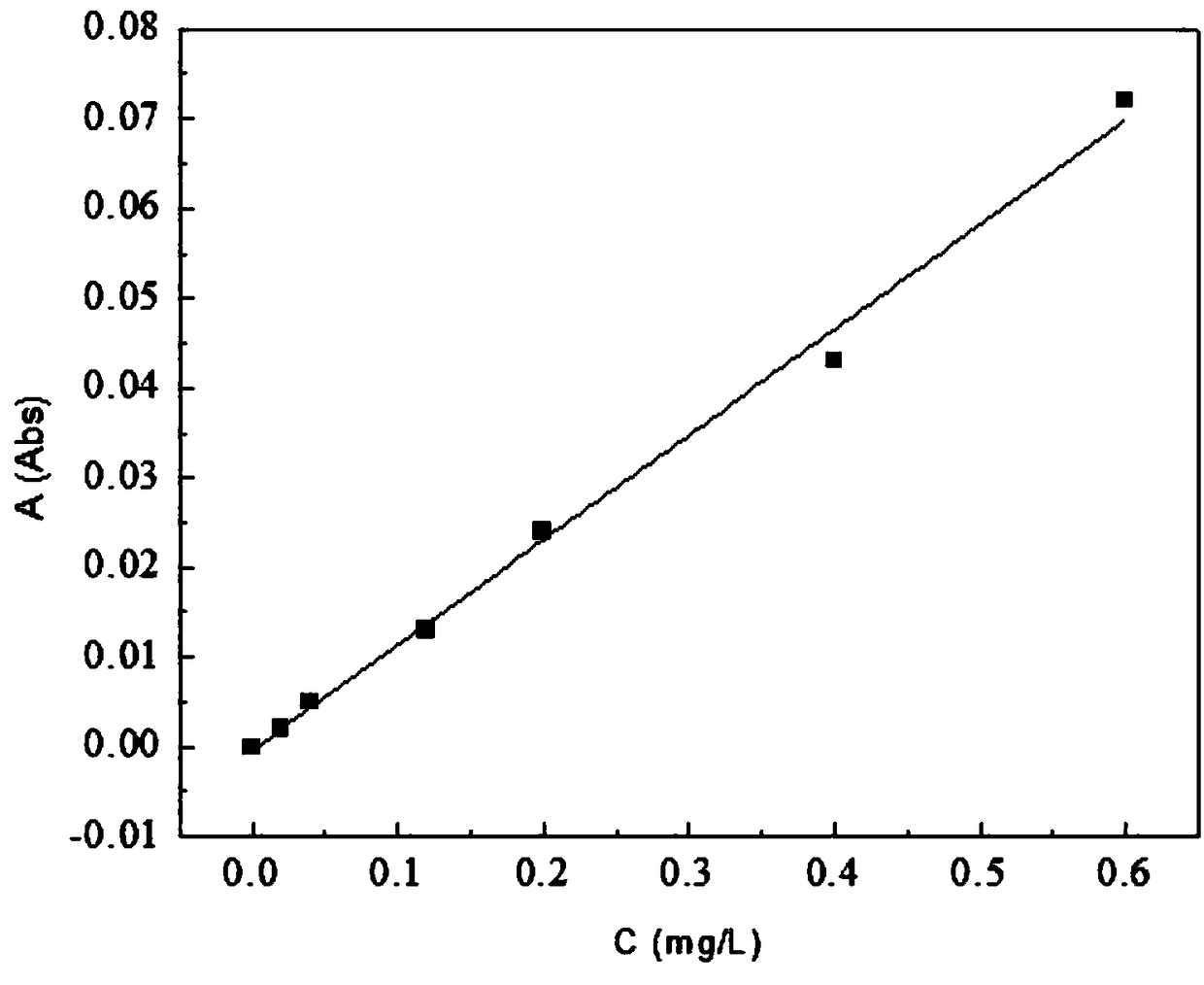

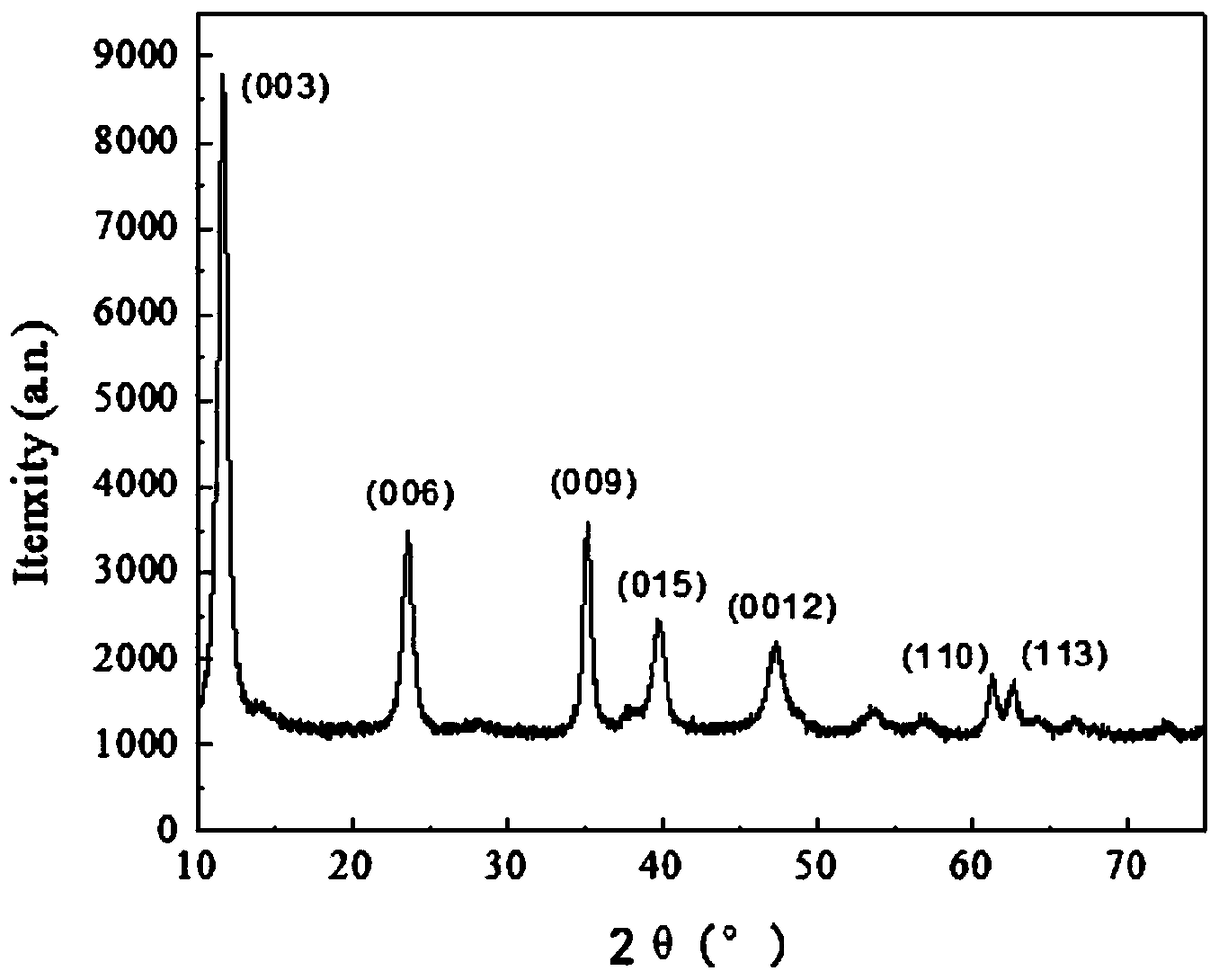

Ni-Mg-Al type hydrotalcite and preparation method and application thereof

InactiveCN109331772ADiffraction peaks are sharpHigh crystallinityOther chemical processesWater contaminantsVacuum pumpAir blast

The invention belongs to the technical field of aluminum compounds, and discloses Ni-Mg-Al type hydrotalcite and a preparation method and application thereof. The preparation method comprises the following steps: adding various solutions having a urea use amount of 20 mL in a metal ion mole ratio of 3:1:3 to obtain a mixed solution, putting the mixed solution on a constant-temperature magnetic stirrer at normal temperature, continuously and uniformly stirring for 1 h, and transferring the stirred solution into a hydrothermal reaction kettle; sealing the reaction kettle, putting the reaction kettle into a vacuum drying box for hydrothermal crystallization at certain temperature for 10 h, wherein the crystallization temperature is 150 DEG C; at the end of the reaction, taking out the reaction kettle, sucking and filtering a substance therein with a circulating water type vacuum pump, and collecting the substance; washing the obtained product with new boiled distilled water till the pH isless than 8, sucking and filtering with the circulating water type vacuum pump, and collecting a product; putting the product into an air blasting drying box for drying at 80 DEG C for 12 h; grindingthe product, and sieving the product with a sieve of 200 meshes. The phosphorus removal rate for simulated phosphorus-containing wastewater reaches 95.21 percent.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

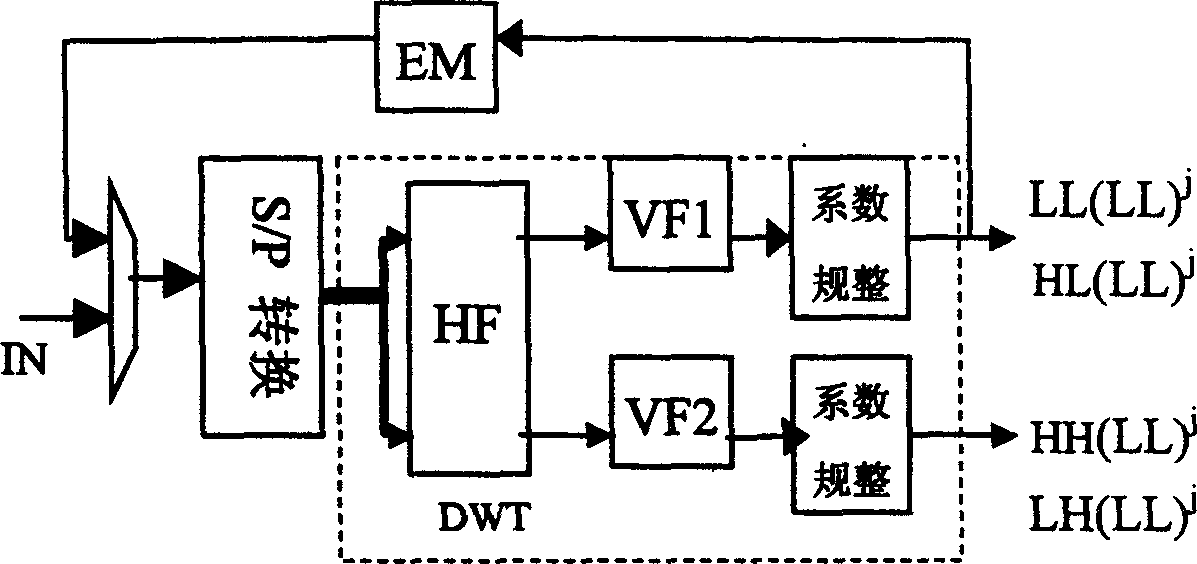

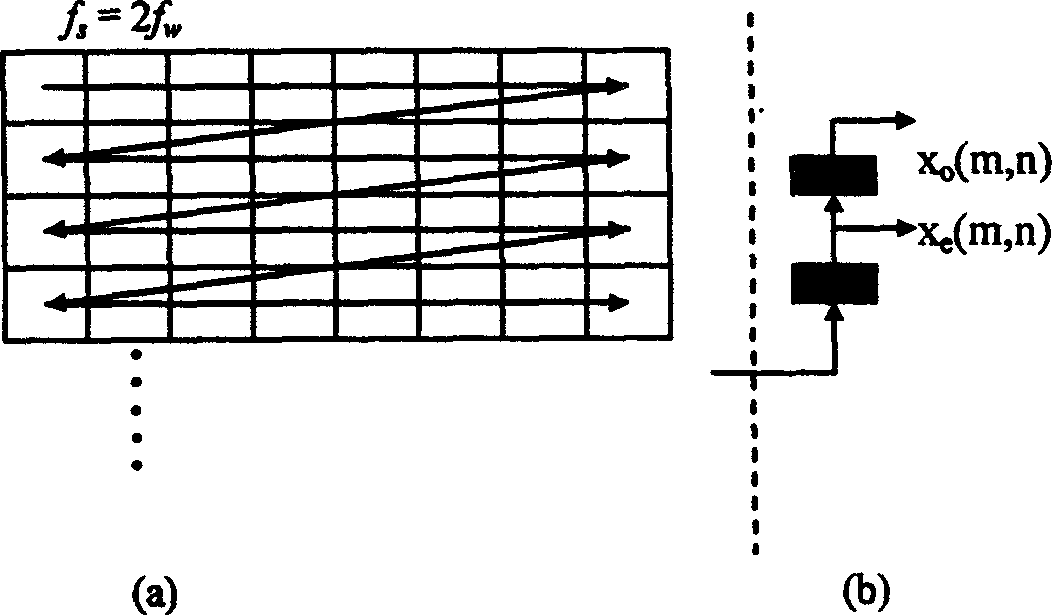

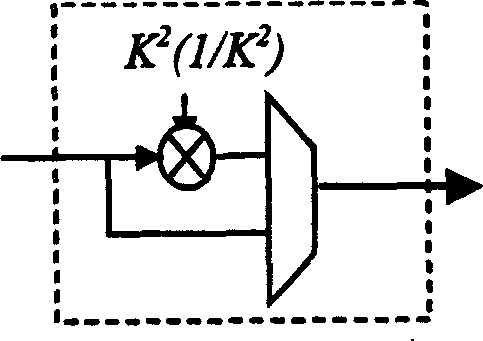

Parallel two-dimension discrete small wave transform circuit

InactiveCN1589021AReduce system areaSmall system footprintTelevision systemsDigital video signal modificationVertical filterInterface circuits

A parallel two-dimentional scattered small wave transformation circuit aims at reducing hardware cost and system time delay and realizing parallel quick direct two-dimentional scattered small wave transformation including a selector connected with signals a data serial / parallel conversion interface circuit, a master transform circuit in 2 out-2 in structure containing a horizontal filter, a first and a second vertical parallel filters connected with it, output of then is connected with an output coefficient flywheel unit, the horizontal filter is a 2 out-2 in structure each vertical filter is a single in and out structure an output signal of the output system flywheel unit is connected to the external memory output to an input end of the selector.

Owner:HUAZHONG UNIV OF SCI & TECH

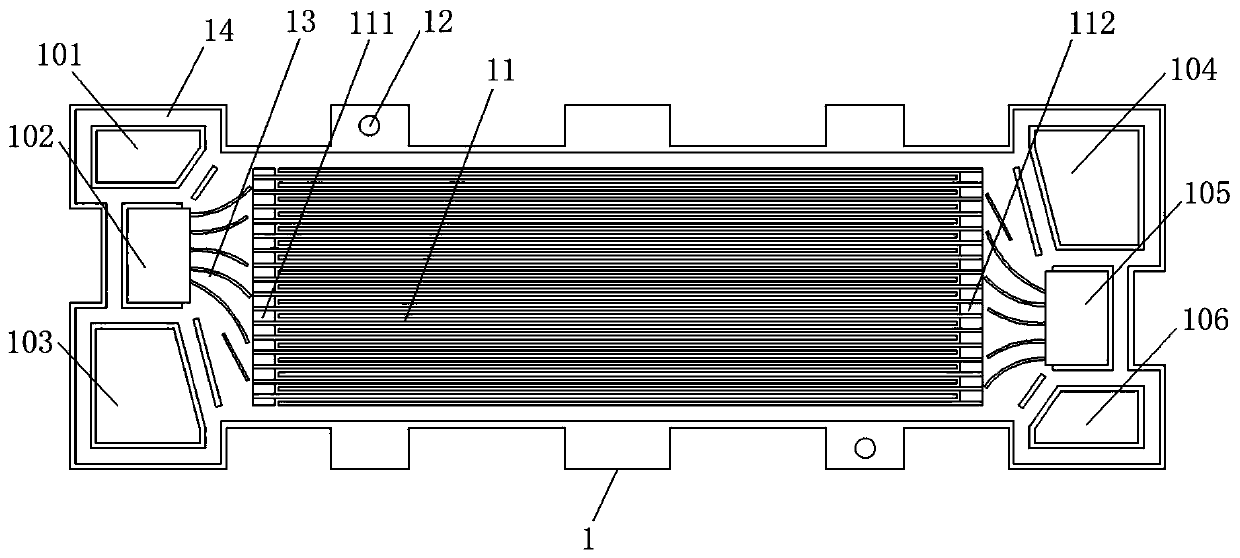

Bipolar plate, fuel cell unit, fuel cell and manufacturing method thereof

ActiveCN111554950AImprove diffusion abilityImprove power generation performanceFinal product manufactureSealing/support meansFuel cellsEngineering

The invention relates to a bipolar plate, a fuel cell unit, a fuel cell and a manufacturing method thereof, and relates to the technical field of fuel cells. According to the main technical scheme, the bipolar plate comprises an anode plate and a cathode plate, wherein a flow channel at a power generation area of the anode plate is set as an interdigital flow channel; and the flow channels in thepower generation area of the cathode plate are set to be parallel flow channels. The anode plate comprises an anode plate body and a fuel distribution cover plate, and the cathode plate comprises a cathode plate body and an oxidant distribution cover plate. The fuel cell unit comprises a membrane electrode and the bipolar plate. The fuel cell comprises a plurality of the fuel cell units. The method is mainly used for improving the diffusion capacity of the fuel in the fuel cell to the catalyst layer, avoiding the flooding phenomenon of the cathode of the fuel cell, and realizing the uniform circulation of the fluid on the cooling liquid side and the gas side while enhancing the mass transfer.

Owner:浙江锋源氢能科技有限公司 +1

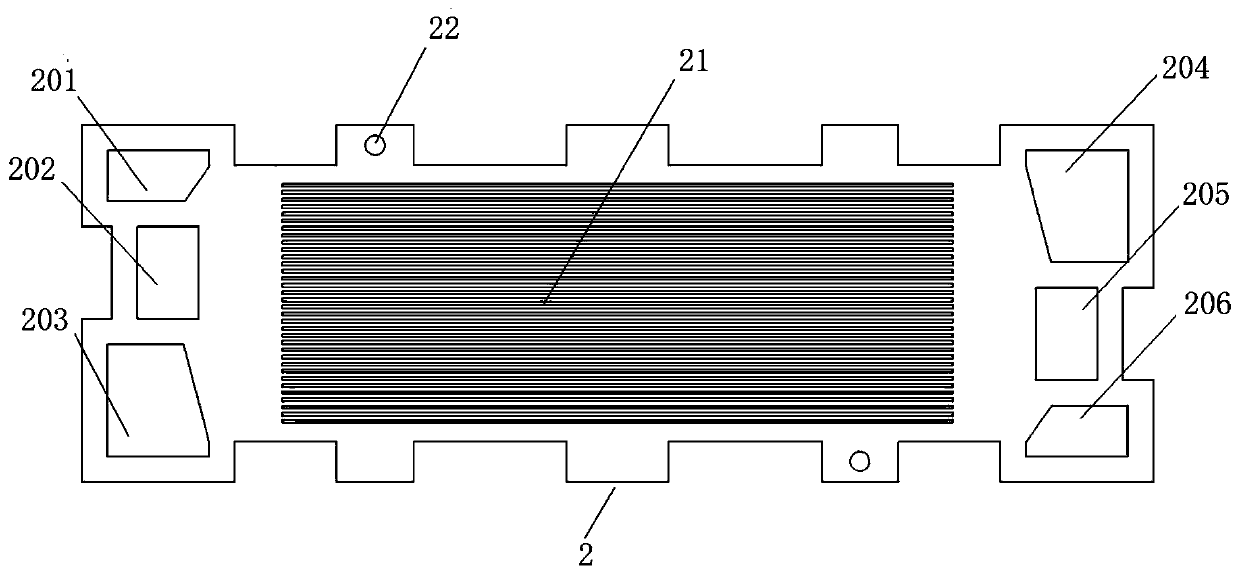

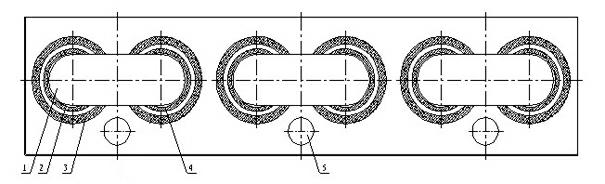

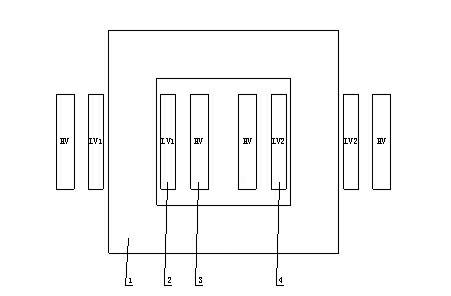

High-capacity three-body split winding type transformer

InactiveCN102436920AReduce footprintReduce in quantityTransformers/inductances coils/windings/connectionsFixed transformersLow voltageFuel tank

The invention relates to a high-capacity three-body split winding type transformer and belongs to the technical field of transformers. The technical scheme is that: three transformer bodies are arranged in a transformer oil tank, and each body is a phase; each body is provided with a square iron core (1), and each square iron core is provided with two iron core columns; each iron core column is provided with a low-voltage winding and a high-voltage winding from the inner side to the outer outside; the high voltage end of the transformer is used for no-load voltage regulation, and the low voltage end is split into two windings; the low-voltage windings of the two iron core columns on each body are led out respectively, and the two three-phase low-voltage windings (2, 4) form two angular connections; and the high-voltage windings (3) of the two iron core columns on each body are led out in parallel, and the three-phase high-voltage windings form a star-shaped connection. The high-capacity three-body split winding type transformer is a three-phase transformer of which the high voltage end is used for the no-load voltage regulation, and the low voltage end is in a double-splitting structure, the occupied area of the transformer is reduced, the mechanical force of the high-capacity split winding type transformer is effectively reduced during sudden short circuit, and the safety and reliability of the operation of products are improved.

Owner:BAODING TIANWEI GRP CO LTD

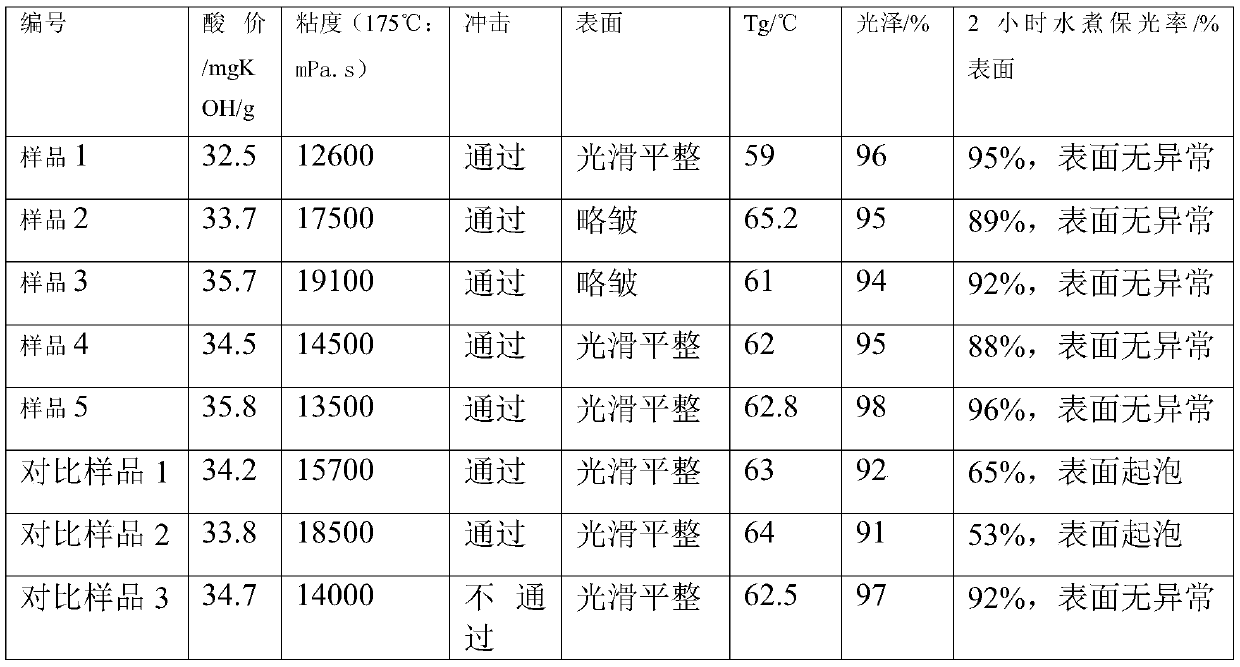

Polyester resin for TGIC cured high-gloss powder coating and preparation method of polyester resin

ActiveCN110028880AImprove hydrolysis resistanceHigh glossPowdery paintsPolyester coatingsPolyester resinAccelerant

The invention discloses polyester resin for a TGIC cured high-gloss powder coating and a preparation method of the polyester resin. The formula of the polyester resin comprises the following components in percentage by mass: 25-33% of neopentyl glycol, 0.5-1.5% of neopentyl glycol mono(hydroxypivalate), 3-7% of ethylene glycol, 1-3% of 2-butyl-2-ethyl-1,3-propylene glycol, 48-61% of terephthalic acid and 4.1-11.4% of an end-capping agent. The polyester resin prepared according to the formula and the preparation method disclosed by the invention is cured with TGIC, and a coating film with the gloss of 97% or above, bright surface and excellent boiling resistance can be prepared without adding an additional wetting accelerant.

Owner:新中法高分子材料股份有限公司

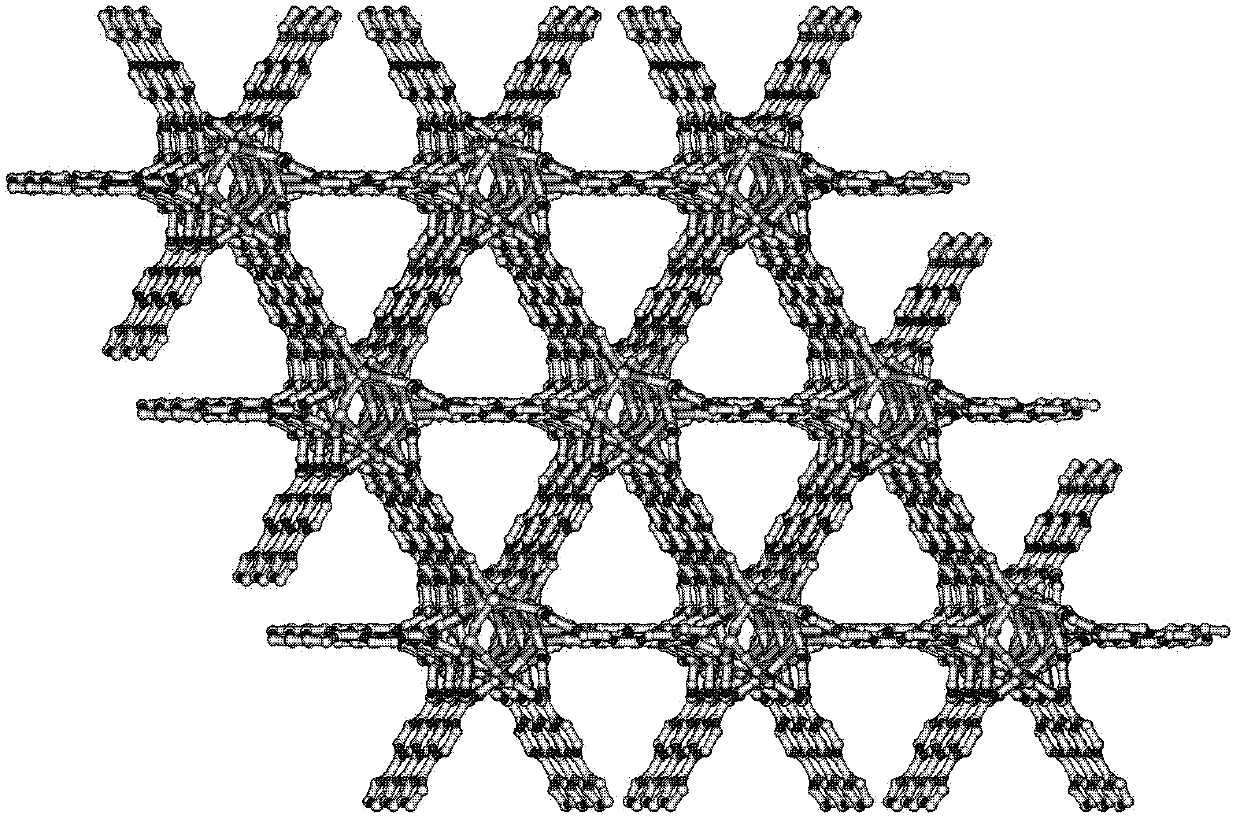

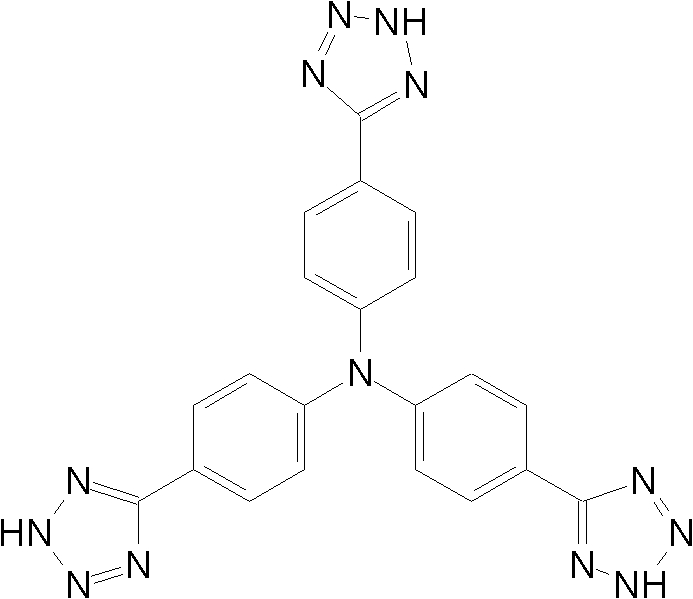

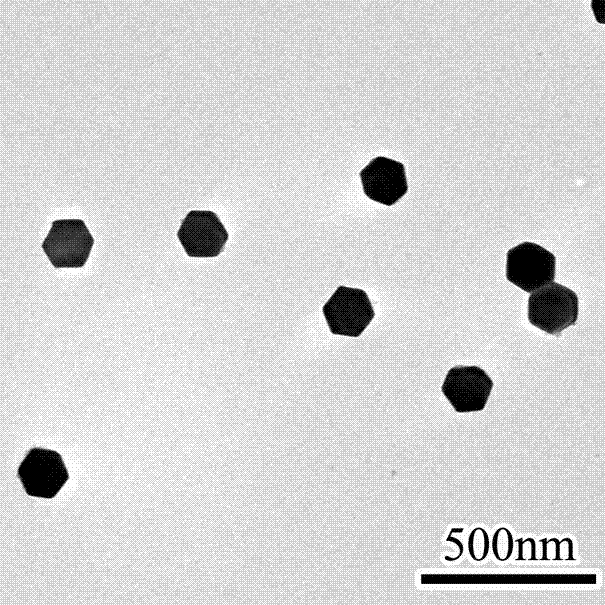

Copper-azole microporous crystalline material and preparation method thereof

InactiveCN102532169AMaterial Structure RulesUniform channel sizeCopper organic compoundsCopper chlorideCrystalline materials

The invention discloses a nano porous crystalline material {[Cu (HTCPZ) 0.5]} infinity and a preparation method thereof. The preparation method of the nano porous crystalline material is characterized in that: 3-(4-tetrazole-phenyl) amine and copper chloride are subjected to solvothermal synthesis according to a molar ratio of 1:(3-15) at a temperature of 80-180 DEG C; the molecular formula of the obtained Cu-based microporous crystalline material is {[Cu (HTCPZ) 0.5]} infinity, wherein HTCPZ is 3-(4-tetrazole-phenyl) amine which is a tridentate ligand having the following molecular structure shown in the accompany drawing; and the porous crystalline material is a hexagonal system crystalline material, the space group is P6122, the size range of a pore canal is 1-1.2nm, and the inner surface of the pore canal contains a coordinatively unsaturated surface of metal Cu. The preparation method provided by the invention has the advantages of simpleness, mild reaction conditions, high yield and high purity of products. The porous crystalline material prepared by the invention has the advantages of uniform pore canal, nanopore size, and metal center immobilizing.

Owner:UNIV OF SCI & TECH OF CHINA

Sodium yttrium tetrafluoride/ ferroferric oxide/carbon multifunctional nano material and preparation method thereof

InactiveCN103694989ARealize the packageStructural rulesMaterial nanotechnologyInorganic material magnetismCarbon layerSolvothermal reaction

The invention relates to preparation of an inorganic nano material and discloses a sodium yttrium tetrafluoride / ferroferric oxide / carbon multifunctional nano material and a preparation method thereof. A chemical expression of the nano material is as follows: NaYF4:Yb, Er / Tm@Fe3O4@C. The preparation method of the sodium yttrium tetrafluoride / ferroferric oxide / carbon multifunctional nano material comprises the following steps: A, uniformly dispersing up-conversion fluorescent nanoparticles into cyclohexane; B, mixing dispersion liquid with acetone; C, adding dicyclopentadienyl iron into mixed liquid, and sufficiently stirring; D, carrying out ultrasonic action onto the mixed liquid after the dicyclopentadienyl iron is dissolved; E, slowly adding hydrogen peroxide into the mixed liquid, and stirring uniformly; F, transferring the mixed liquid into a high-pressure reaction kettle which takes tetrafluoroethylene as a substrate, and carrying out solvothermal reaction; and G, after the solvothermal reaction is ended, naturally cooling, centrifuging and cleaning. According to the preparation method disclosed by the invention, package of Fe3O4 on the surface of an up-conversion material is realized by one step, and a carbon layer is formed on the surface of the up-conversion material, so that the material has hydrophilicity and high biocompatibility.

Owner:ZHEJIANG NORMAL UNIVERSITY

Preparation method of Fe7S8@C nanorod materials applied to high performance lithium ion batteries

ActiveCN109449407AUnique structureUniform shapeCell electrodesSecondary cellsButton batteryOrganic matter

The invention relates to the technical field of preparation of nano negative electrode materials, in particular to a preparation method of Fe7S8@C nanorod materials applied to high performance lithiumion batteries. The method comprises the following steps: 1) preparing a Fe7S8 precursor by hydrothermal method; 2) obtaining a high-purity Fe7S8 nanorod by heat treatment; 3) performing organic layercoating on the prepared Fe7S8 by a solution method to prepare a Fe7S8@PDA nanorod; and 4) performing heat treatment on the prepared Fe7S8@PDA nanorod to carbonize the organic matter to obtain a Fe7S8@C nanorod, finally fabricating the obtained Fe7S8@C nanorod into a button cell, and performing electrochemical test. The invention has the advantages of simple formula, simple operation, good repeatability, high purity of the product, rich raw materials, environment-friendly type, regular material structure and good stability, and has high capacity and good rate performance as the negative electrode material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

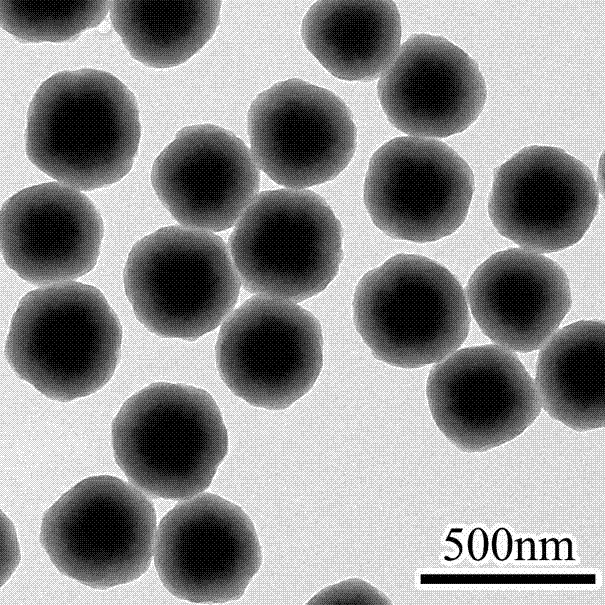

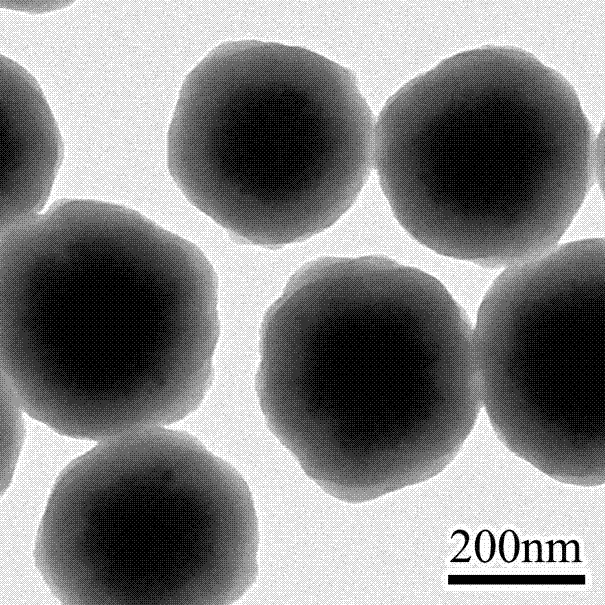

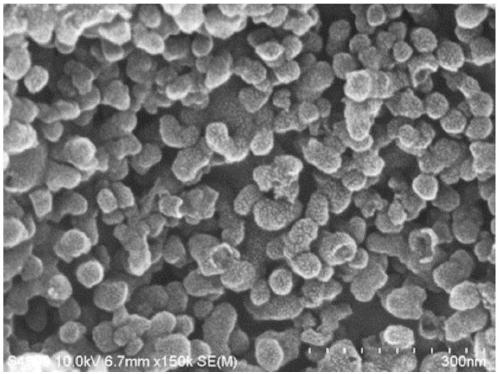

Preparation method of hollow carbon nanosphere

ActiveCN109678137AWide variety of sourcesLow costMaterial nanotechnologyOther chemical processesCarbon nanosphereNickel acetate

The invention provides a preparation method of a hollow carbon nanosphere. The hollow carbon nanosphere is prepared from acorn kernel powder serving as a carbon source and nickel acetate serving as anickel source with a calcined carbon method. The method is simple, the process is easy to control, the acorn kernel powder is wide in source and low in cost, and the prepared hollow carbon nanosphereis regular in structure, uniform in particle size which is 30 to 50 nm, high in absorbility and large in specific surface area. The method is suitable for preparing the hollow carbon nanosphere.

Owner:INNER MONGOLIA MEDICAL UNIV

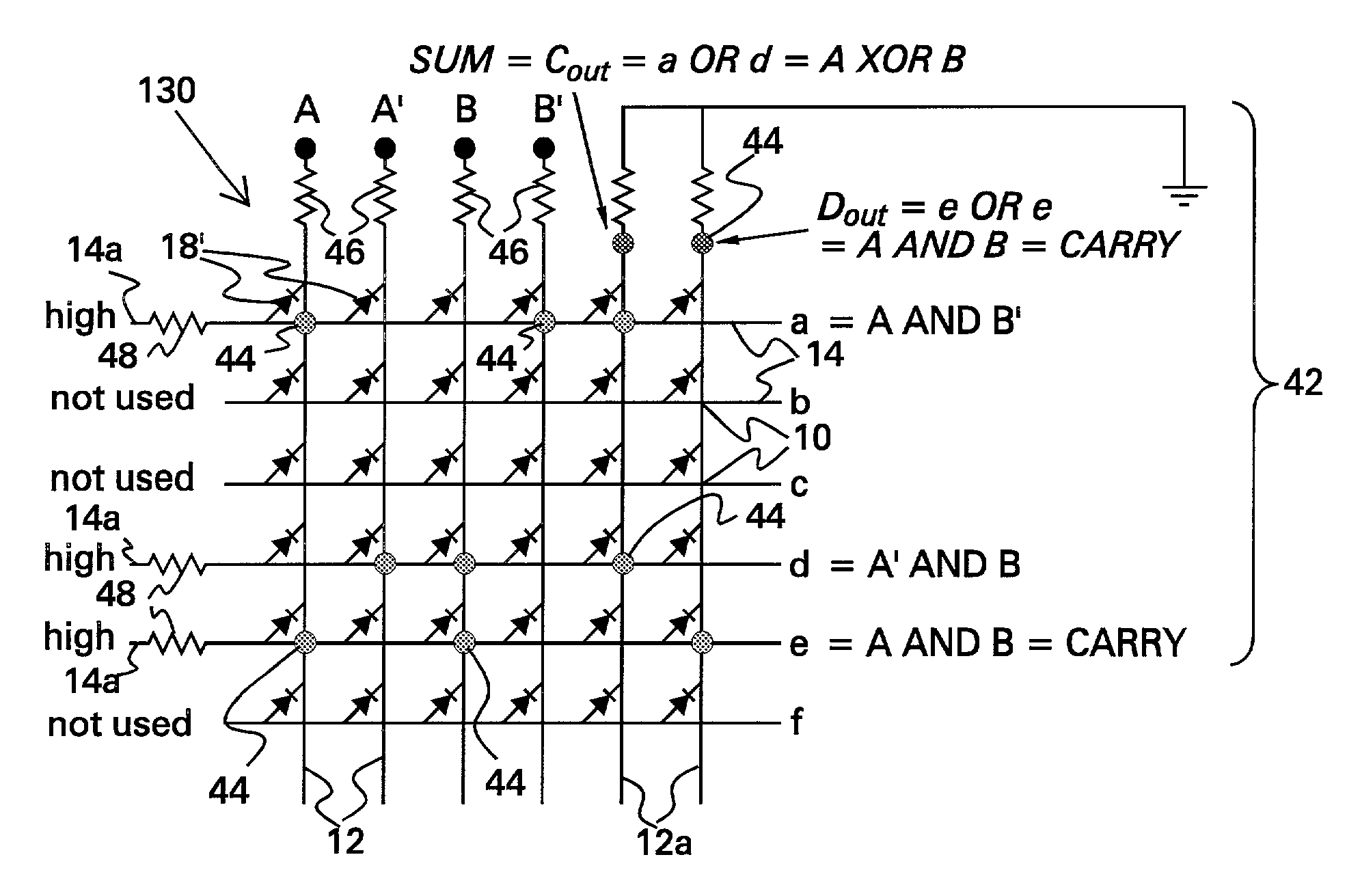

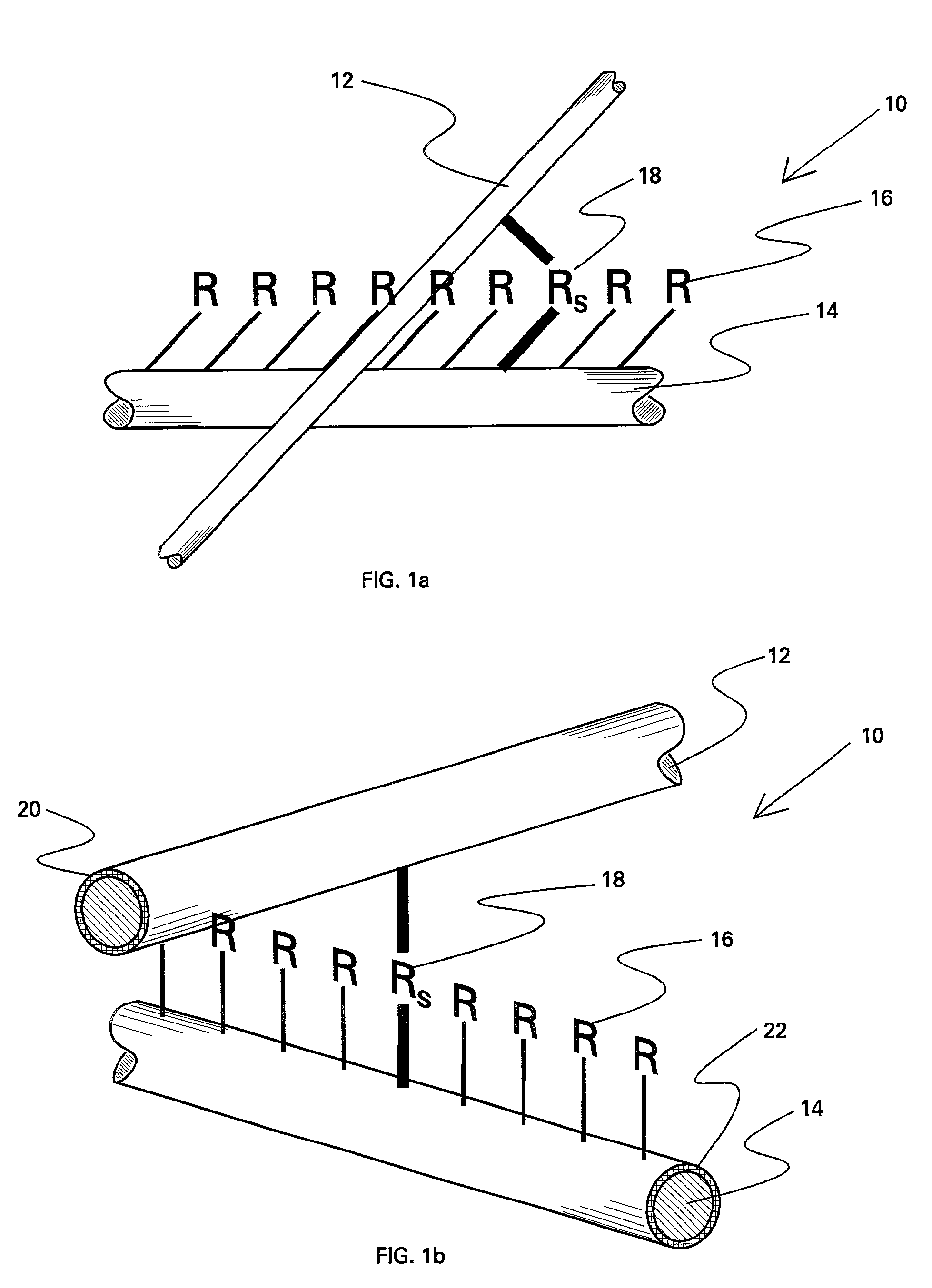

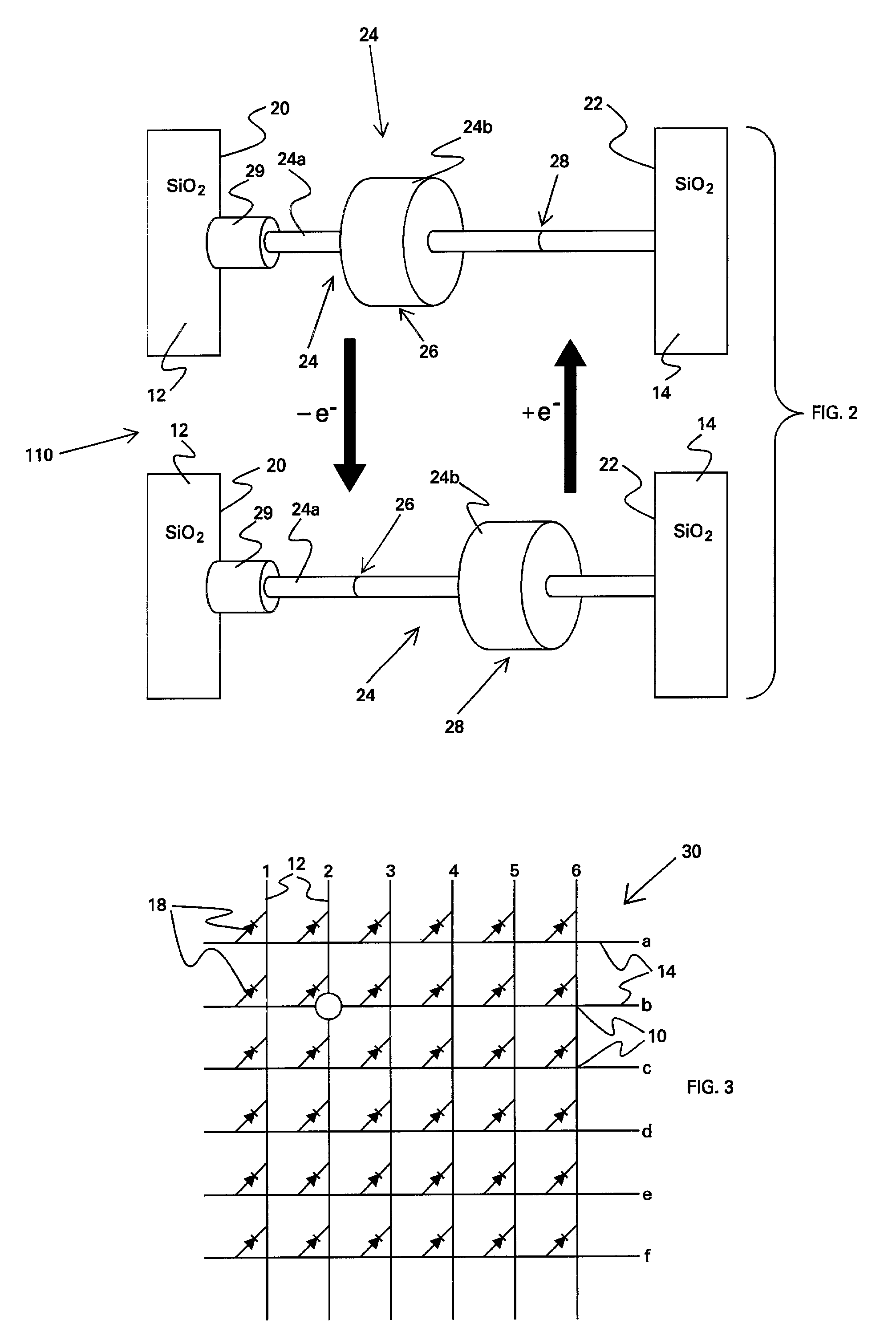

Molecular wire crossbar logic (MWCL)

InactiveUS7948271B1Structural rulesLogic circuits characterised by logic functionNanoinformaticsSoftware engineeringMolecular wire

A programmable logic array (PLA) comprising a two-dimensional array of a plurality of nanometer-scale switches is provided. Each switch comprises a pair of crossed wires which form a junction where one wire crosses another and at least one connector species connecting the pair of crossed wires in the junction. The connector species comprises a bi-stable molecule. A plurality of switches is configurable as an AND gate and a plurality of switches is configurable as an OR gate.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +2

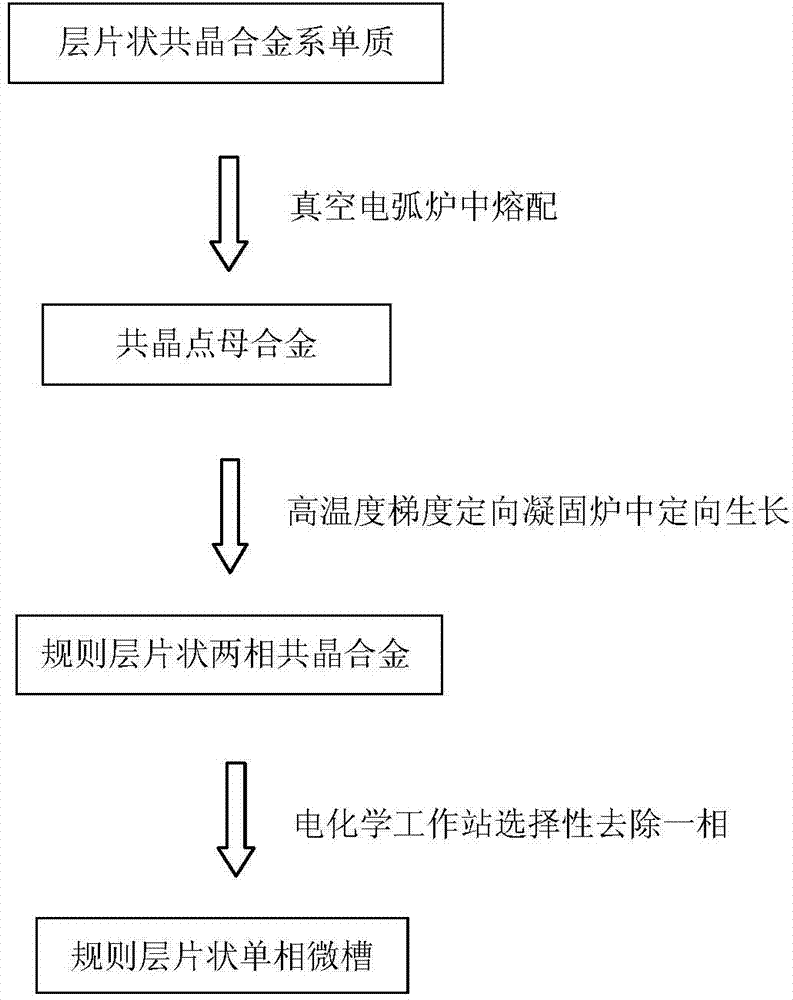

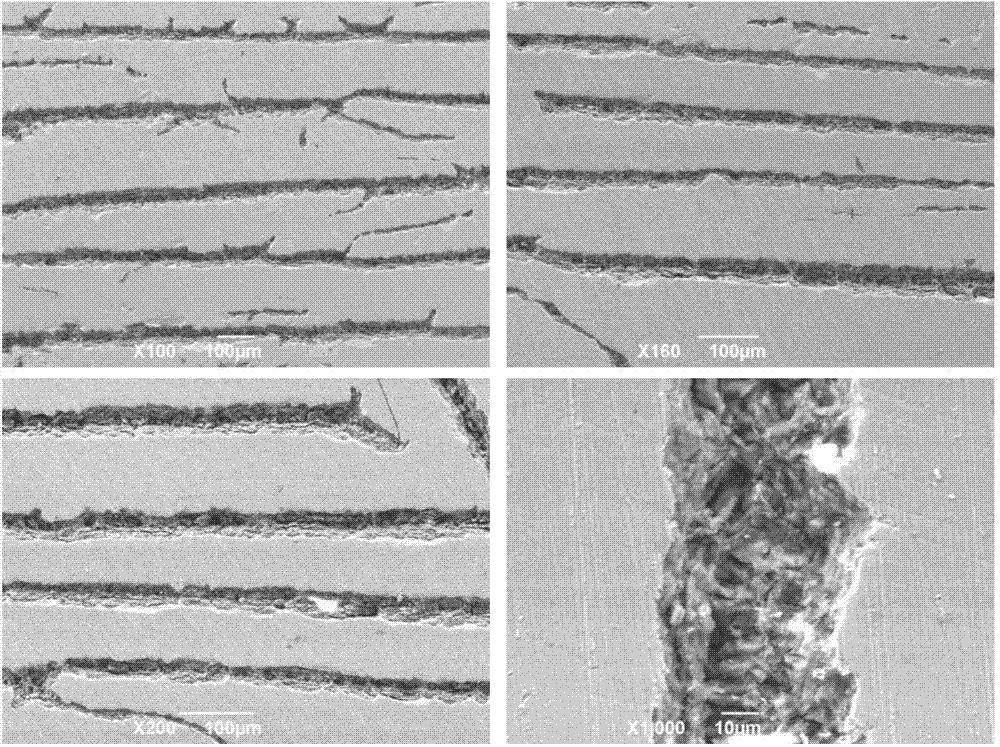

Method for preparing continuous regular lamellar microgroove based on lamellar eutectic alloy system

ActiveCN104846430AHigh dimensional control accuracyEasy to makePolycrystalline material growthFrom frozen solutionsElectrode potentialSelective leaching

Owner:深圳市脑潜能实业发展有限公司

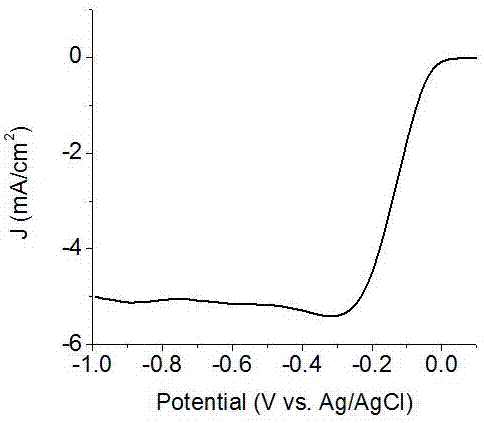

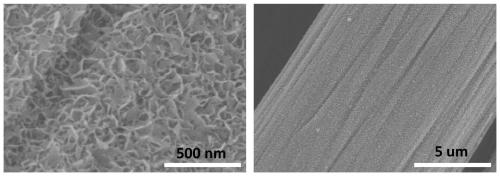

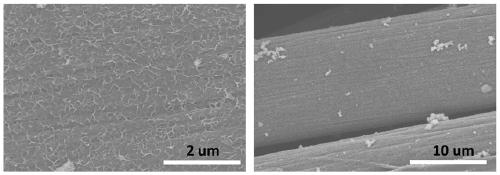

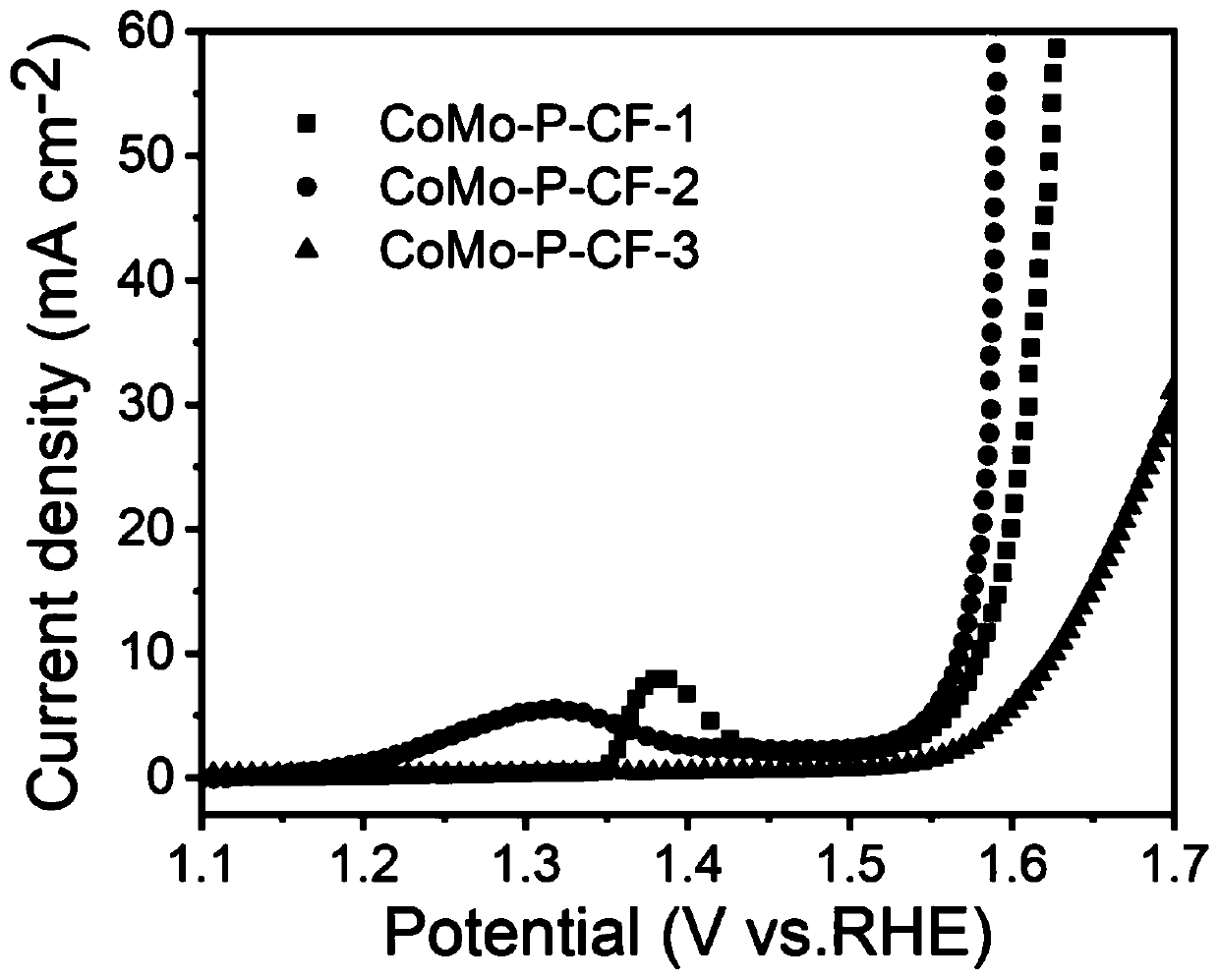

Preparation method of multi-element metal phosphorus-doped electrocatalyst based on binary LDH derivation

InactiveCN111111718APrecisely controllable compositionImprove conductivityPhysical/chemical process catalystsTube furnaceCobalt salt

The invention discloses a multi-element metal phosphorus-doped electrocatalyst based on binary LDH derivation. A preparation method for the multi-element metal phosphorus-doped electrocatalyst comprises the following steps: 1) mixing ethylene glycol and deionized water to obtain a mixed solvent; 2) dissolving a cobalt salt, a molybdenum salt and urea in the mixed solvent, and carrying out uniformstirring to obtain a solution A; 3) adding hydrophilic carbon cloth into the solution A, and carrying out a reaction to obtain CoMo-LDH-CF; and 4) placing the CoMo-LDH-CF material in a tubular furnace, placing a magnetic boat filled with sodium hydrogen hypophosphite at the upper stream of the tubular furnace, raising a temperature in an inert atmosphere, keeping the temperature, and carrying outcooling to room temperature to obtain the binary LDH-derived metal phosphorus-doped electrocatalyst CoMo-P-CF containing double metals, i.e., Co and Mo. After the cobalt-molybdenum bimetallic LDH material growing on the carbon cloth is synthesized by a hydrothermal method, the cobalt-molybdenum bimetallic LDH material is subjected to high-temperature heat treatment and reacts with sodium hydrogenhypophosphite to obtain a Co-and-Mo-containing bimetallic binary phosphorus-doped electrocatalytic material with a large specific surface area and a regular structure, and the material has the advantages of accurate and controllable composition and favorable conductivity.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com