Sodium yttrium tetrafluoride/ ferroferric oxide/carbon multifunctional nano material and preparation method thereof

A technology of triiron tetroxide and sodium tetrafluoroyttrium, which is applied in chemical instruments and methods, nanotechnology, luminescent materials, etc., can solve the problems of inability to achieve uniform packaging, low chemical stability, and low composition of functional materials. Achieve the effects of regular structure, fluorescent properties, strong magnetism and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

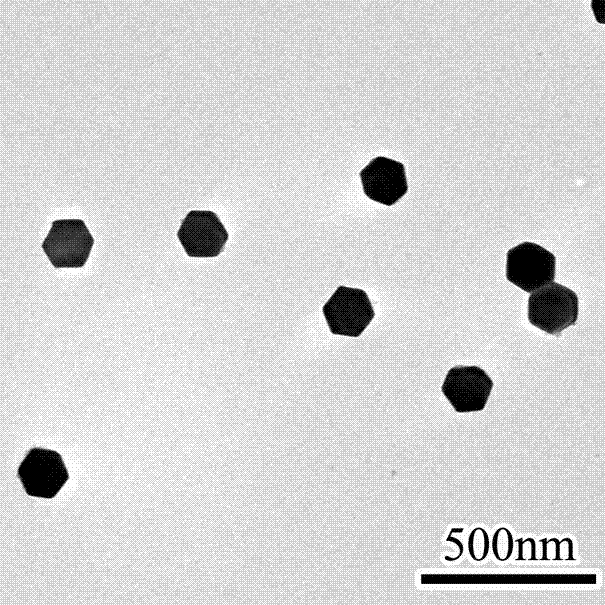

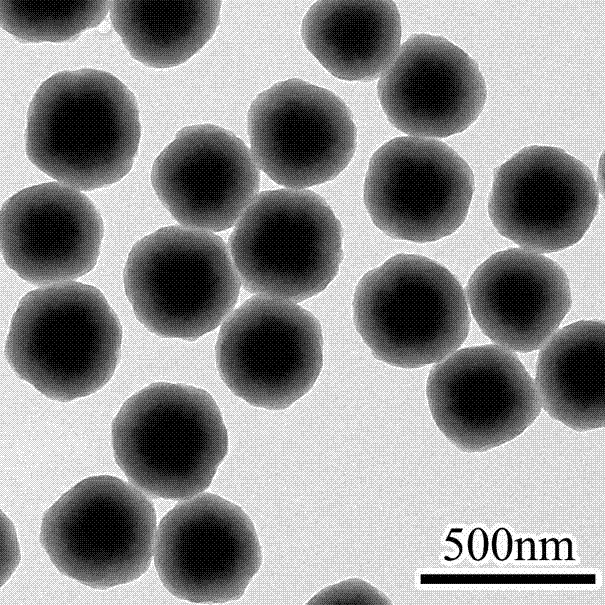

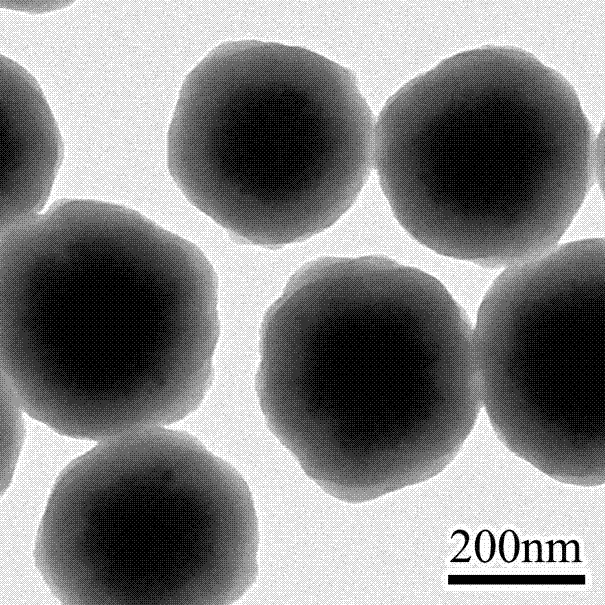

[0037] Sodium tetrafluoroyttrium / ferric oxide / carbon multifunctional nanomaterial, its chemical expression is: NaYF 4 :Yb,Er / Tm Fe 3 o 4 C; where, "" means wrapping.

[0038]The preparation method of the above sodium tetrafluoroyttrium / triiron tetroxide / carbon multifunctional nanomaterial comprises the following steps in turn:

[0039] A. NaYF prepared by high temperature oil phase synthesis 4 Up-conversion fluorescent nanoparticles, uniformly dispersed in cyclohexane;

[0040] B. mixing the dispersion of upconversion fluorescent nanoparticles with acetone;

[0041] C. Add ferrocene to the mixture and stir thoroughly;

[0042] D. After the ferrocene is dissolved, the mixed solution is subjected to ultrasonication;

[0043] E. Slowly add hydrogen peroxide into the mixture and stir evenly;

[0044] F. Transfer the mixed solution to a high-pressure reactor with tetrafluoroethylene as the substrate, and carry out solvothermal reaction;

[0045] G. After the solvothermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com