Patents

Literature

344results about How to "High emission intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphor and manufacturing method of the same, and light emitting device using the phosphor

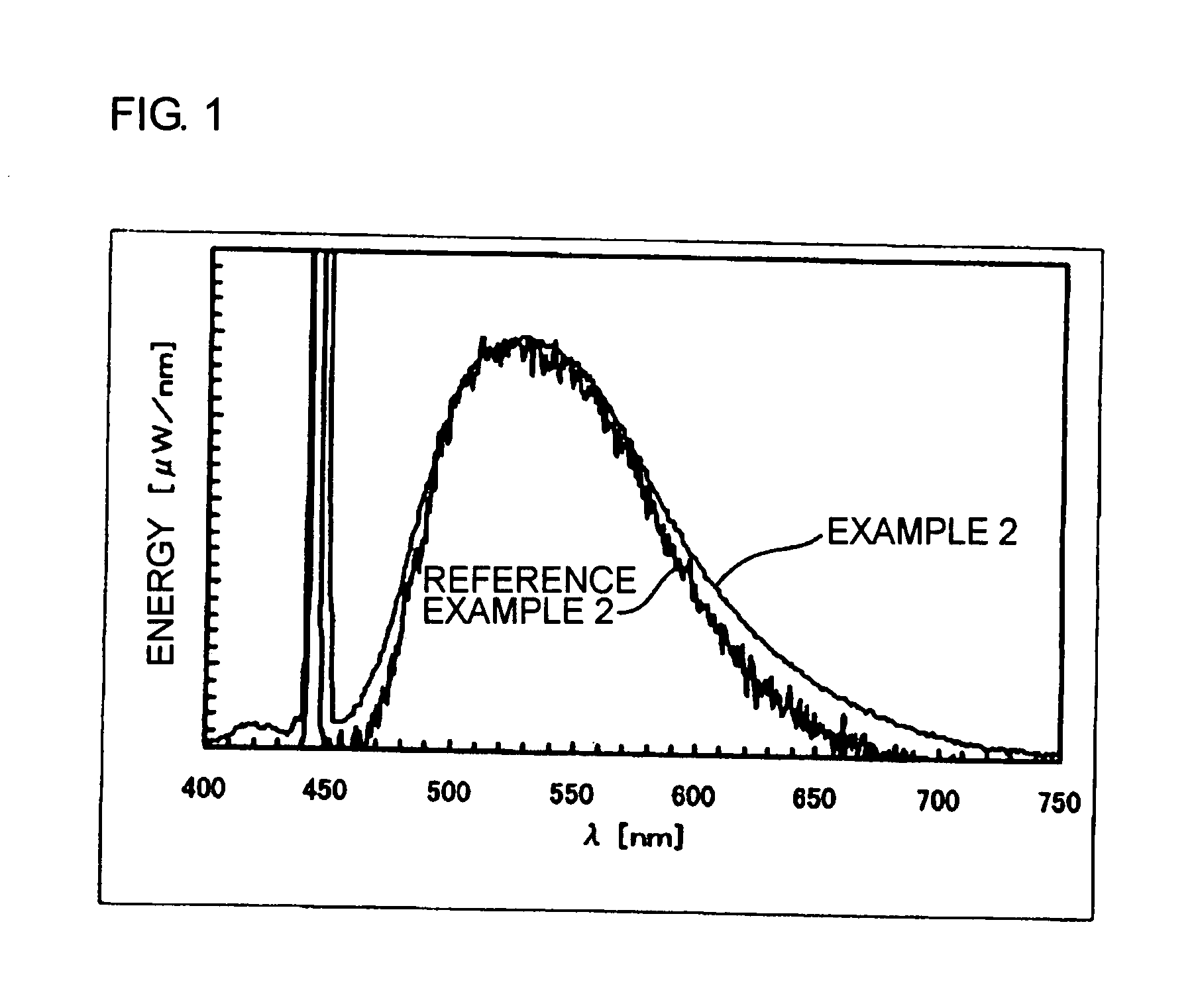

InactiveUS20060197439A1High emission intensityImprove luminanceDischarge tube luminescnet screensElectroluminescent light sourcesEmission efficiencyUltraviolet

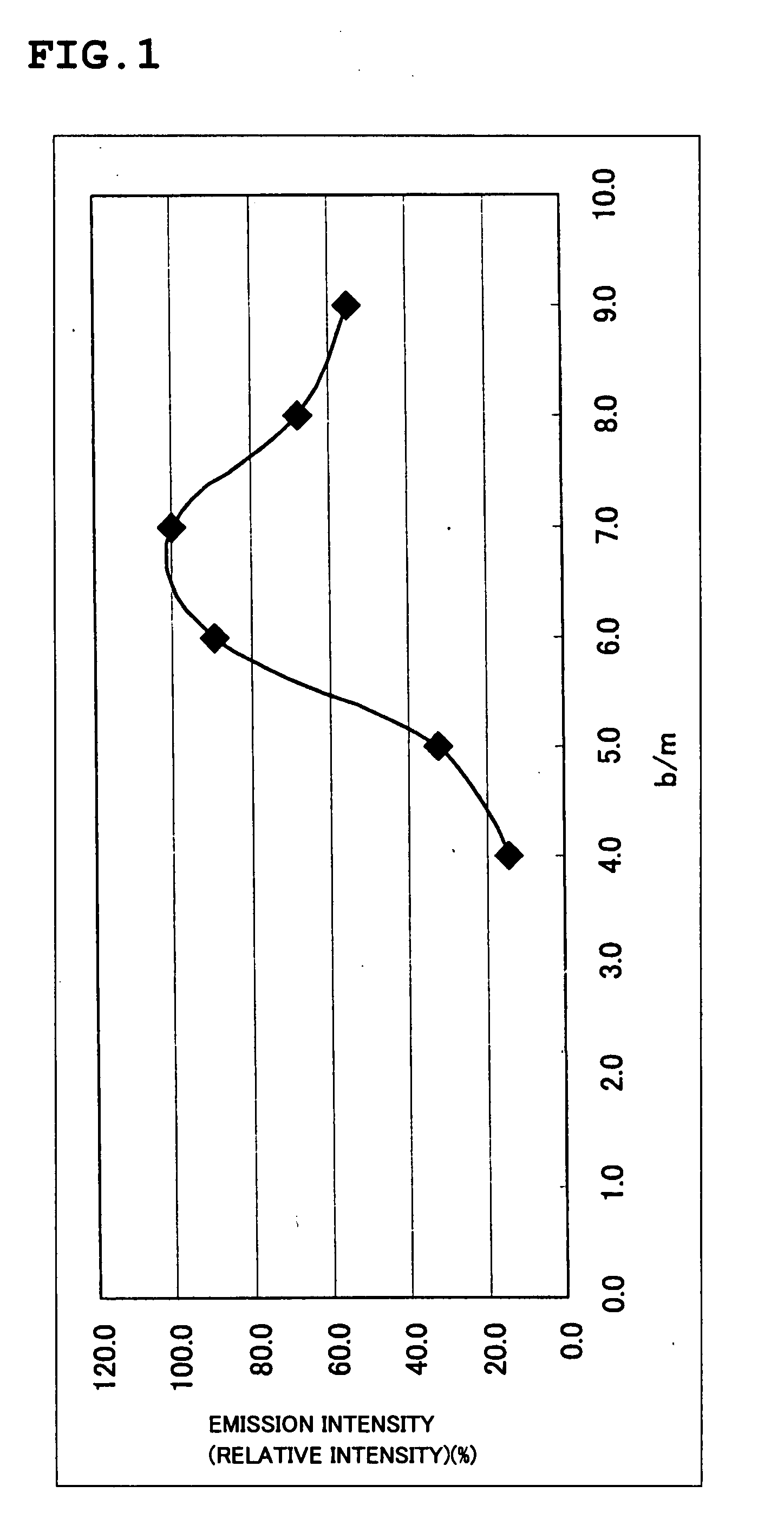

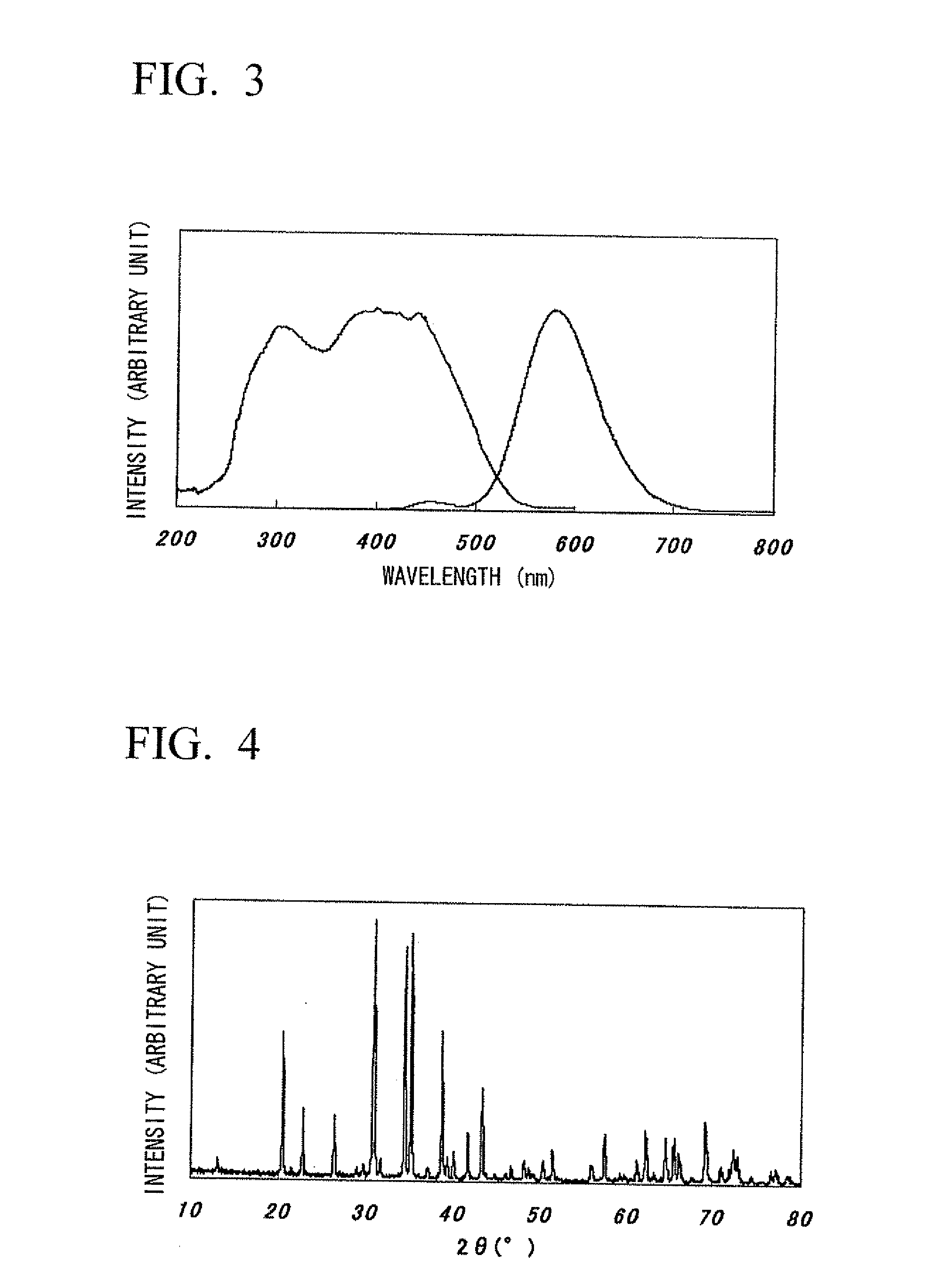

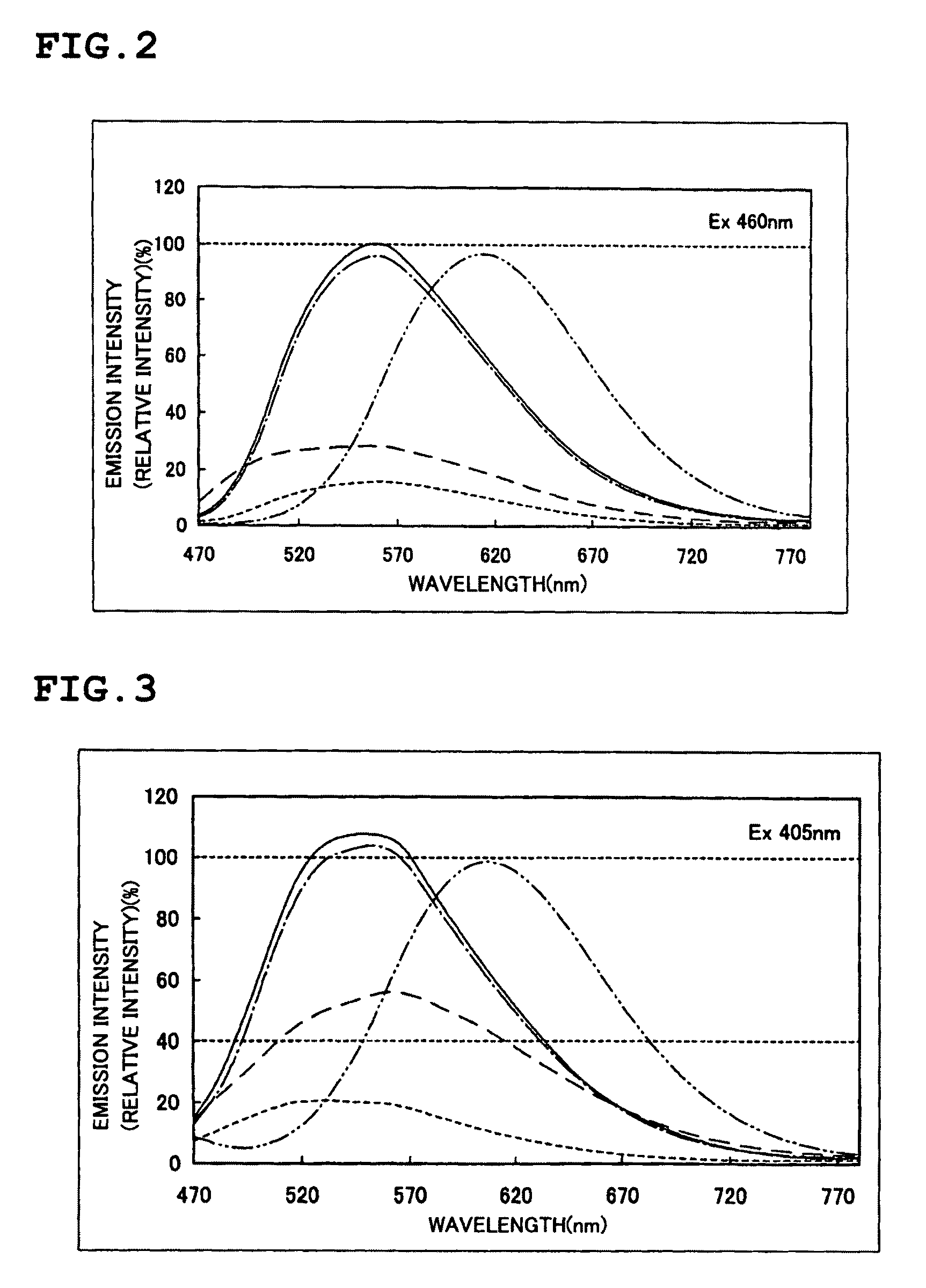

To provide a phosphor having an emission spectrum with a broad peak in a range from green color to yellow color, having a broad and flat excitation band capable of using lights of broad range from near ultraviolet / ultraviolet to blue lights as excitation lights, and having excellent emission efficiency and luminance. The problem is solved by providing the phosphor expressed by a general composition formula MmAaBbOoNn:Z (where element M is one or more kinds of elements having bivalent valency, element A is one or more kinds of elements having tervalent valency, element B is one or more kinds of elements having tetravalent valency, O is oxygen, N is nitrogen, and element Z is one or more kinds of elements acting as the activator.), satisfying 4.0<(a+b) / m<7.0, a / m≧0.5, b / a>2.5, n>o, n=2 / 3 m+a+4 / 3 b−2 / 3 o.

Owner:MITSUBISHI CHEM CORP

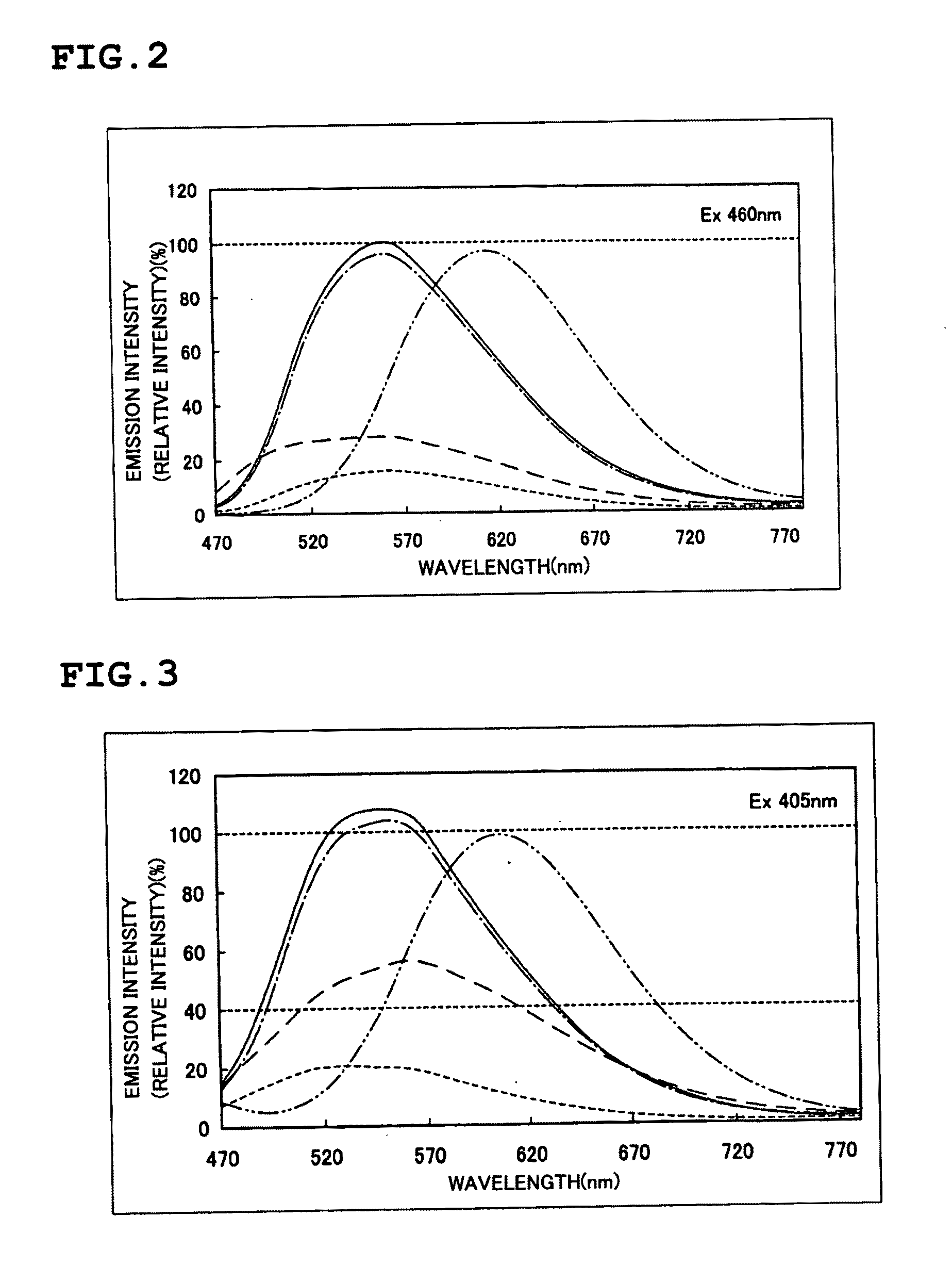

Phosphor and manufacturing method therefore, and light source using the phosphor

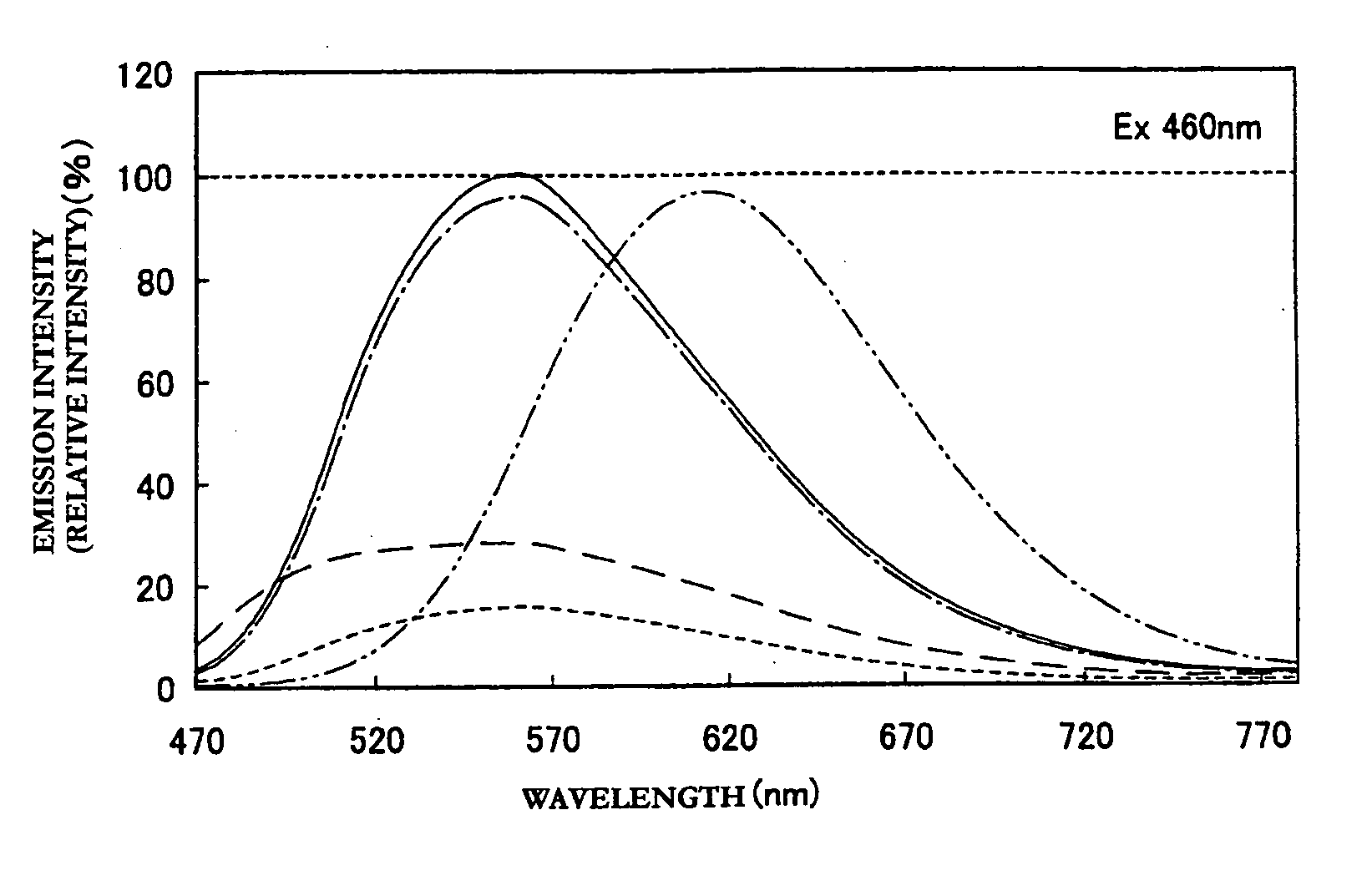

ActiveUS20060043337A1Increase intensityHigh luminanceDischarge tube luminescnet screensLamp detailsLuminous intensityUltraviolet

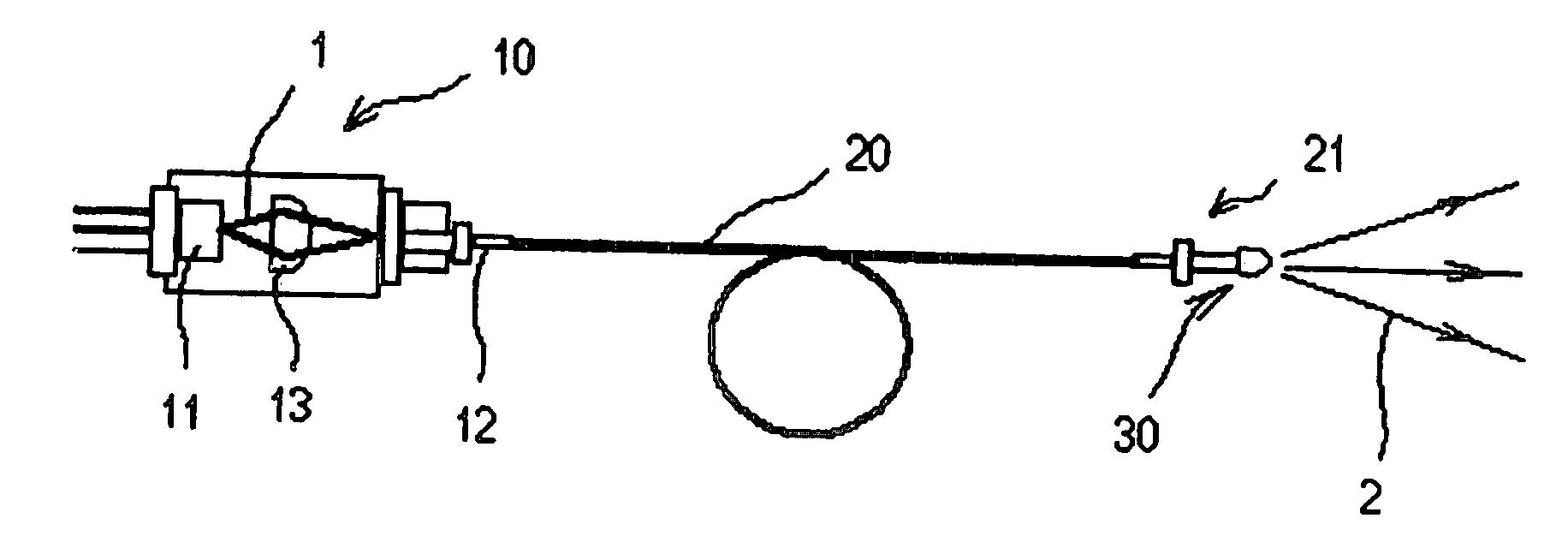

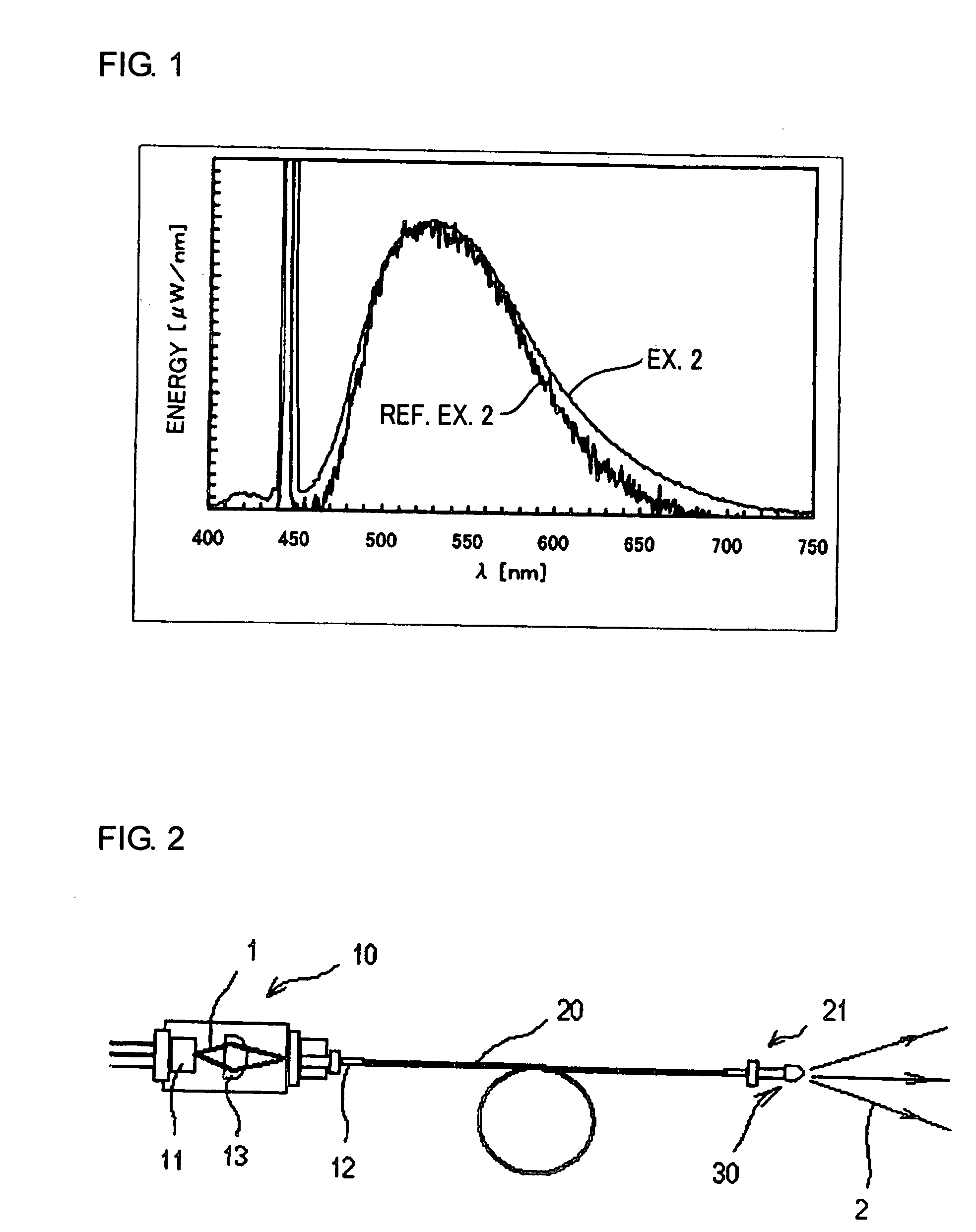

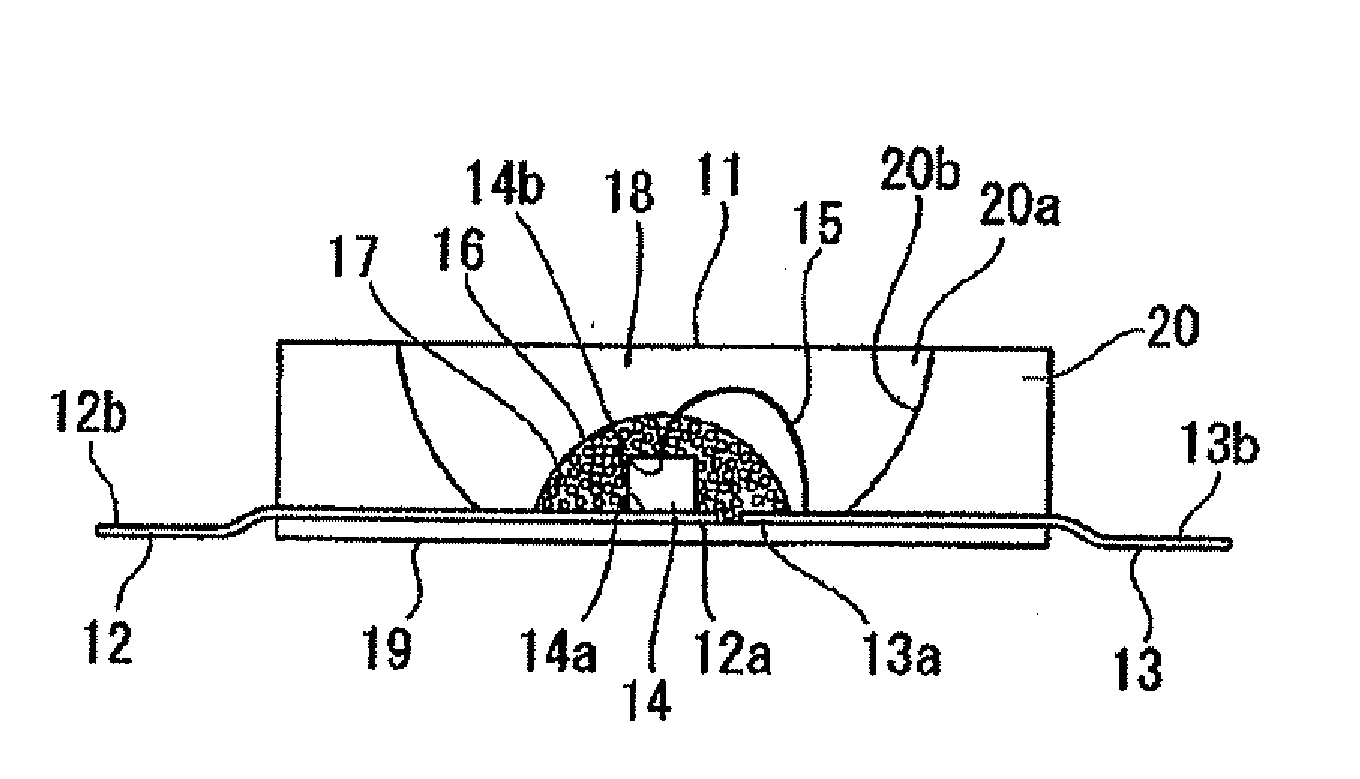

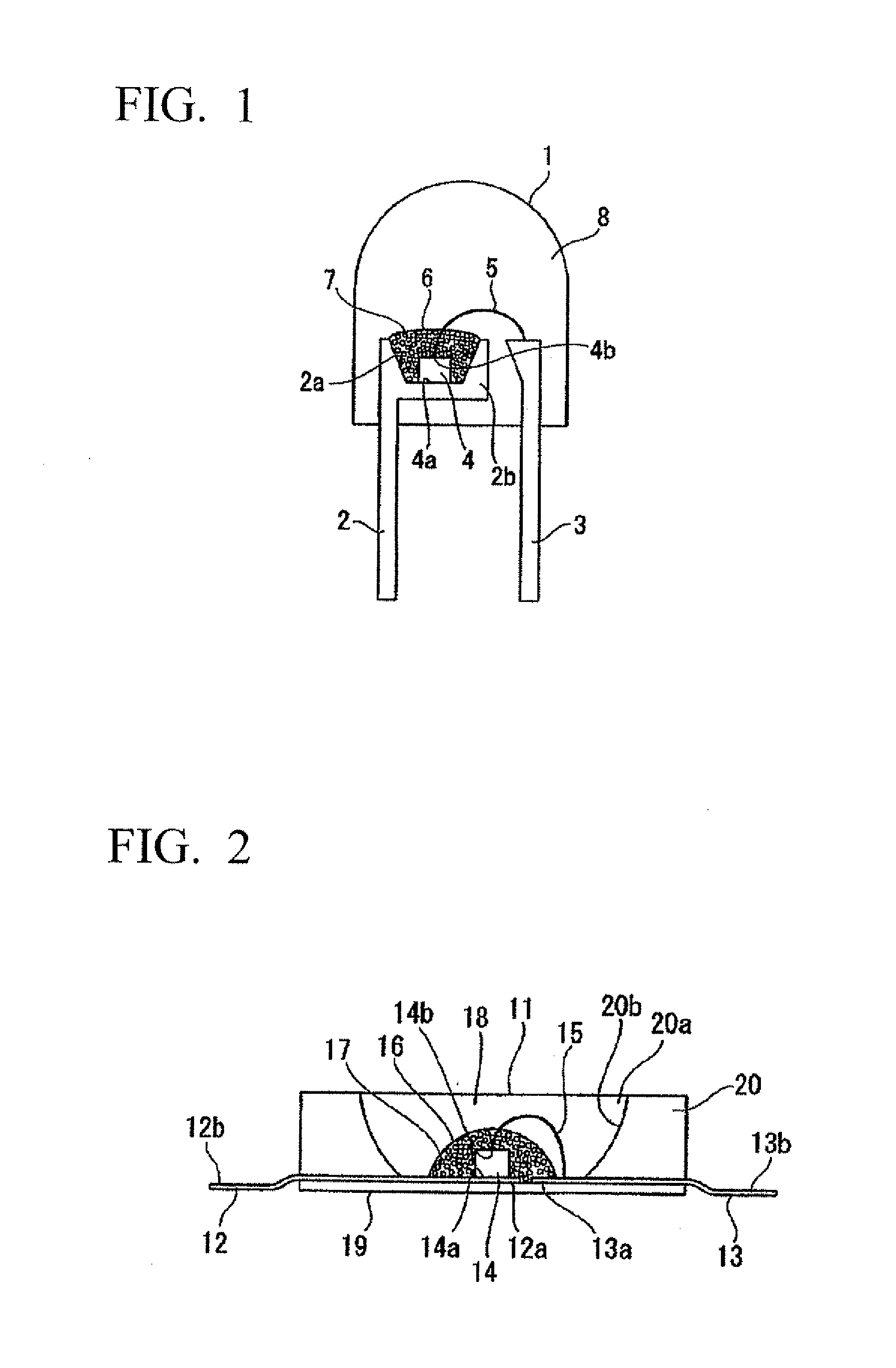

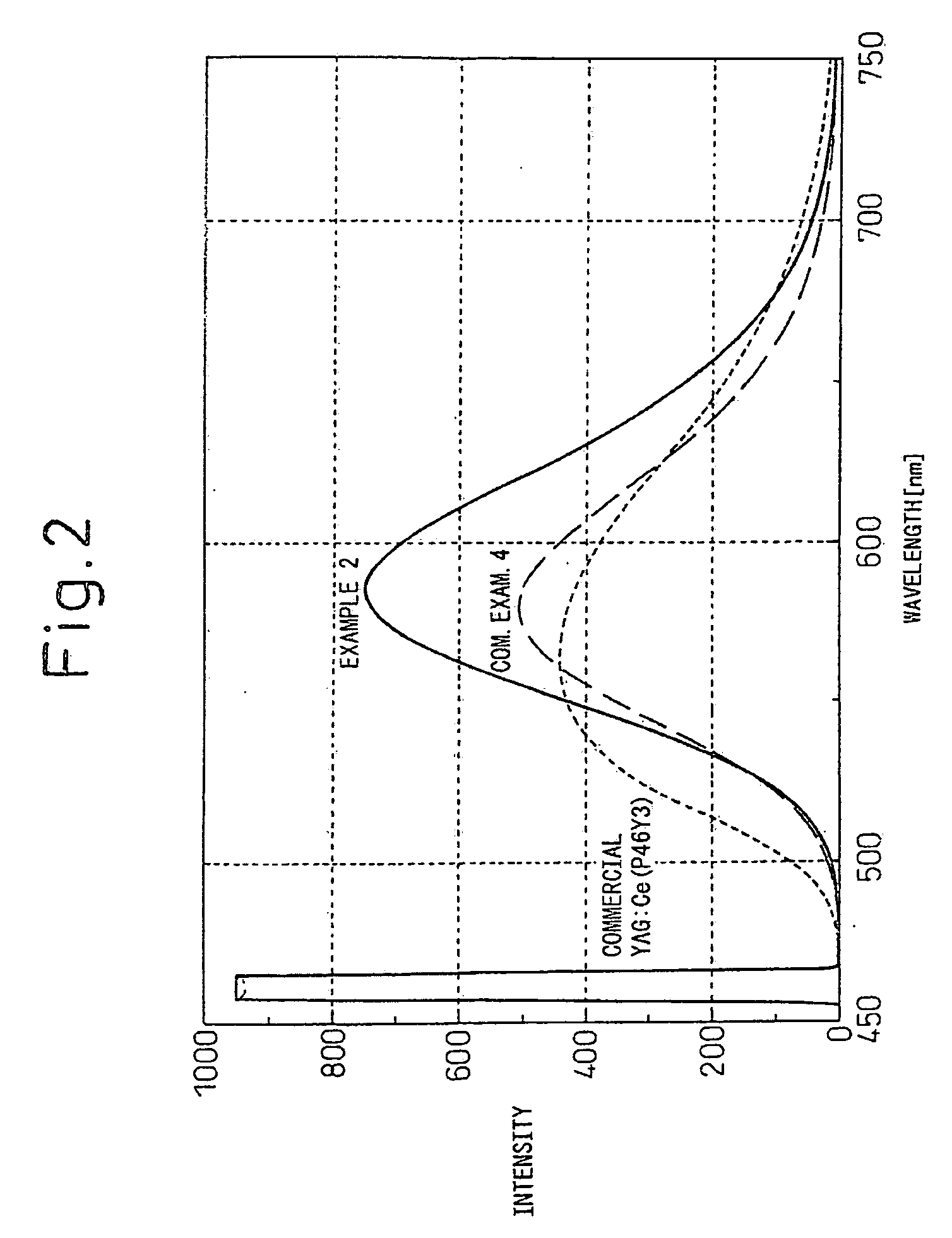

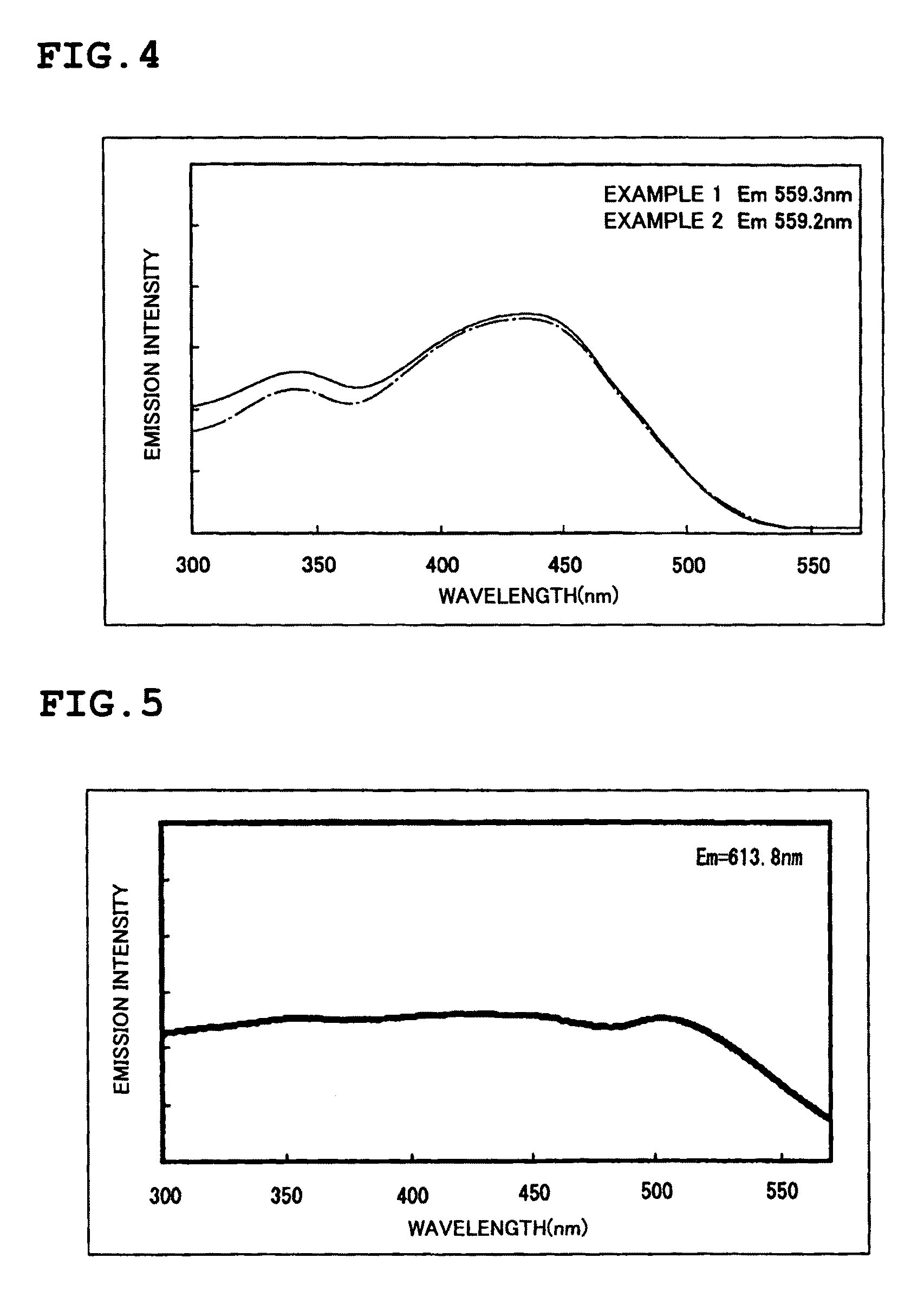

To provide a phosphor having a broad emission spectrum with a peak in the range from yellow color to red color (wavelength from 570 nm to 620 nm), having a flat excitation band with large area on the long wavelength side from near ultraviolet / ultraviolet to green color (wavelength from 250 nm to 550 nm), and excellent in emission intensity and luminance, and a method of manufacturing the same, and also a light source such as white LED using the phosphor. As raw materials, Ca3N2(2N), AlN(3N), Si3N4(3N), and Eu2O3(3N) are prepared, and out of each raw material, 0.950 / 3 mol of Ca3N2. 2 mol of AlN, 4 / 3 mol of Si3N4, and 0.050 / 2 mol of Eu2O3 are weighed, and the raw materials thus weighed are mixed by using a mortar. The raw materials thus mixed are put in a BN crucible, and retained / fired for 3 hours at 1700° C. in a nitrogen atmosphere, and thereafter cooled from 1700° C. to 200° C., to thereby obtain the phosphor expressed by a composition formula Ca0.950Al2Si4O0.075N7.917:Eu0.050.

Owner:NICHIA CORP +1

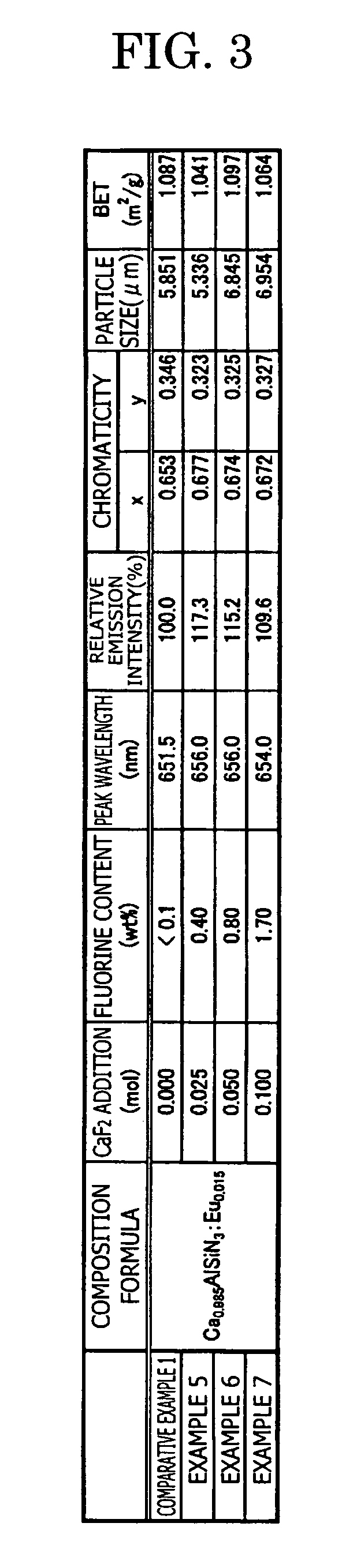

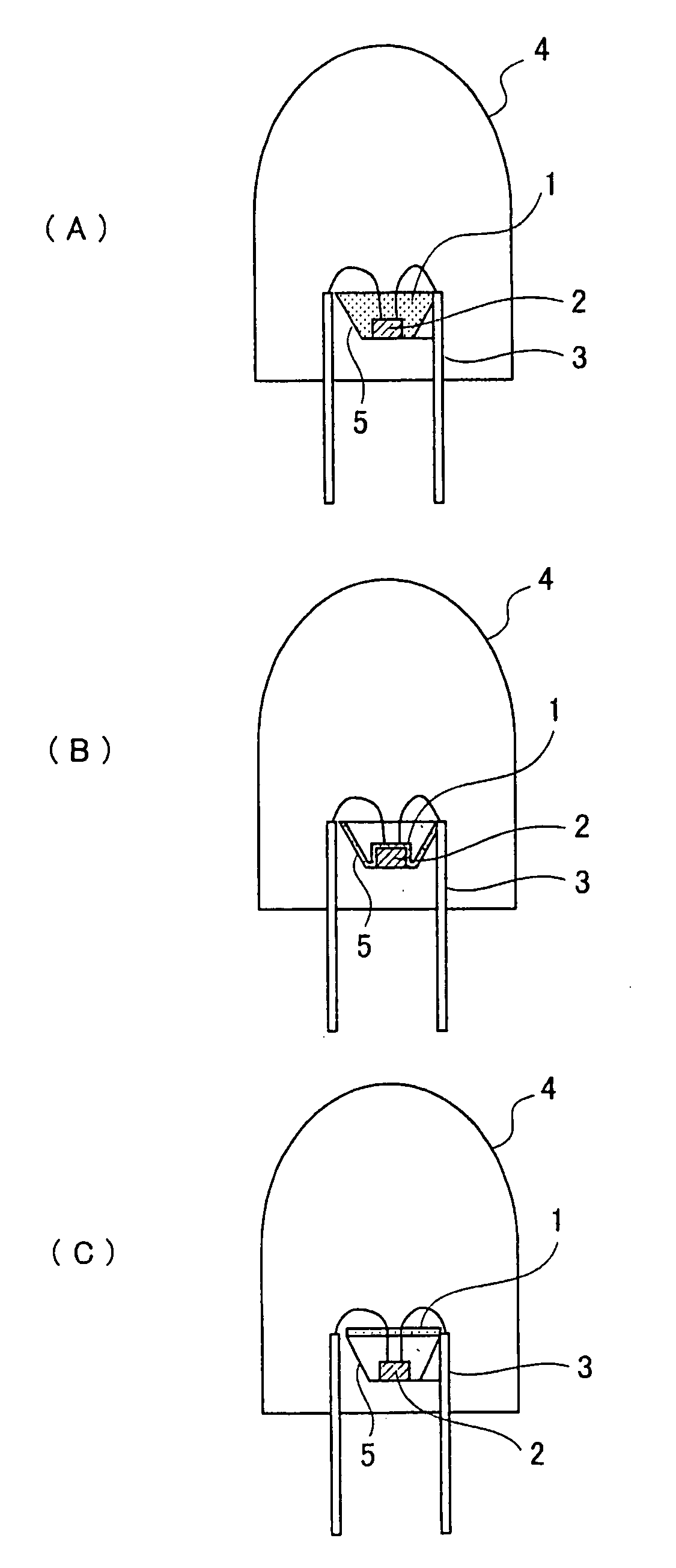

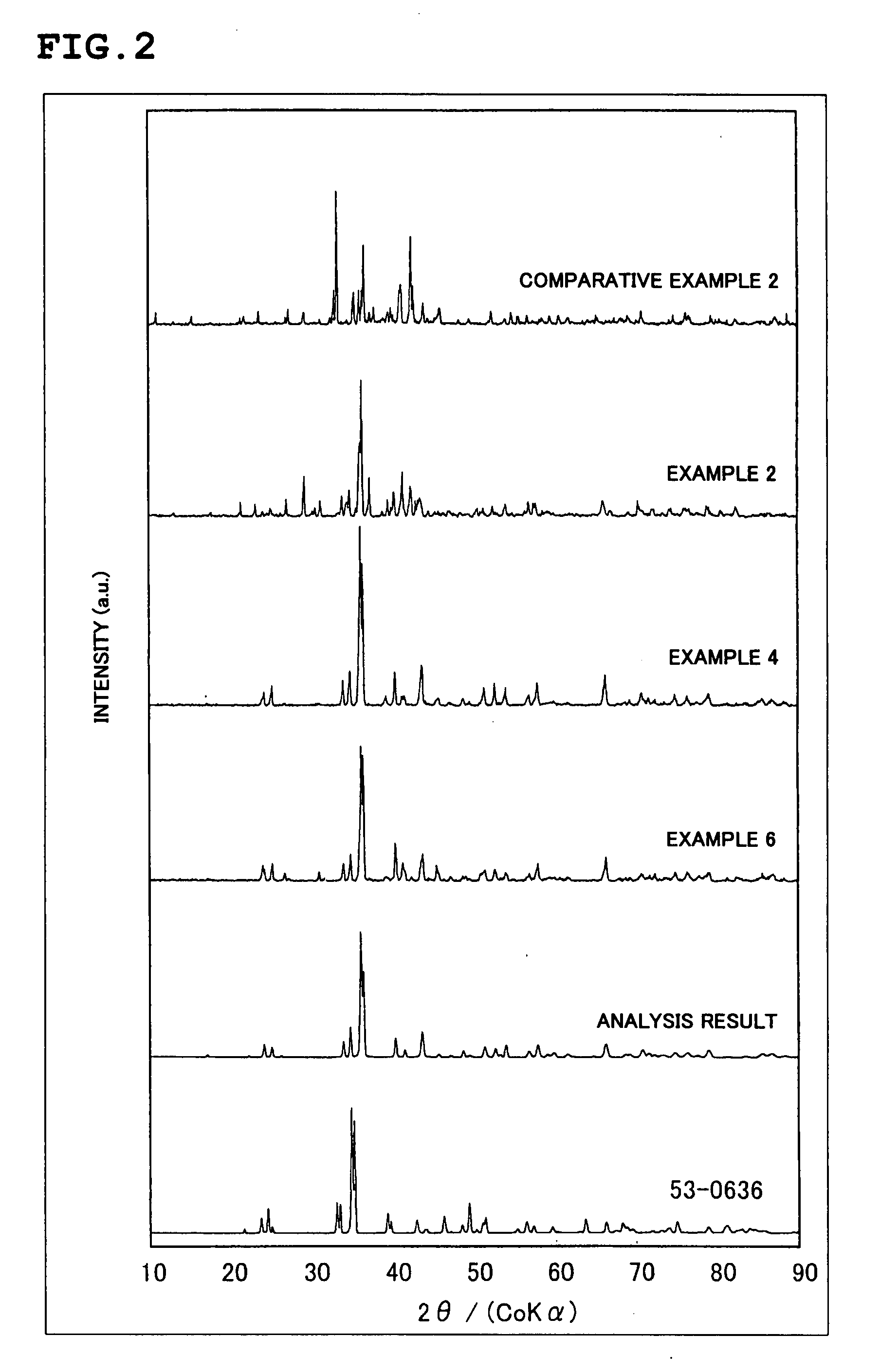

Phosphor and manufacturing method for the same, and light source

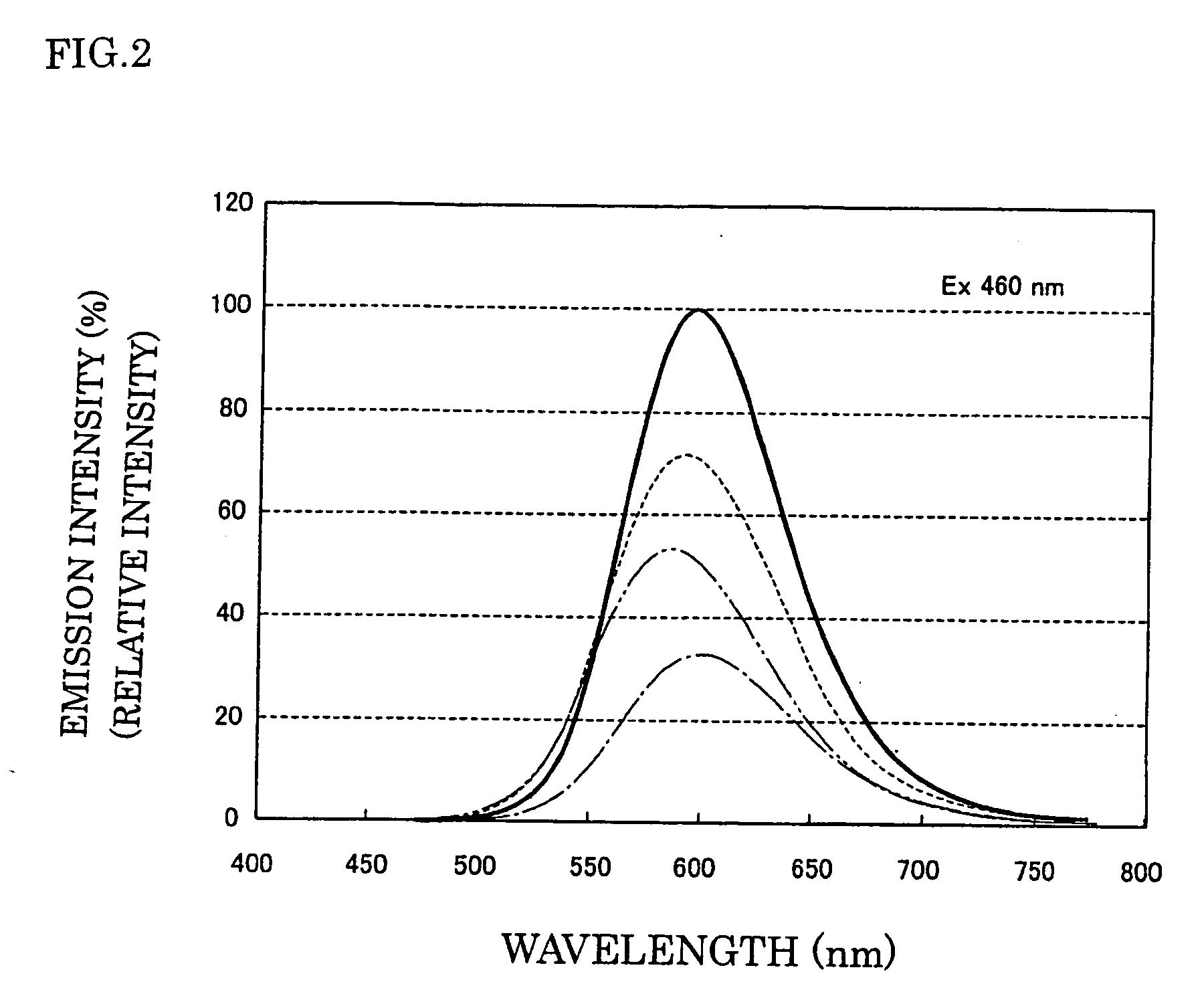

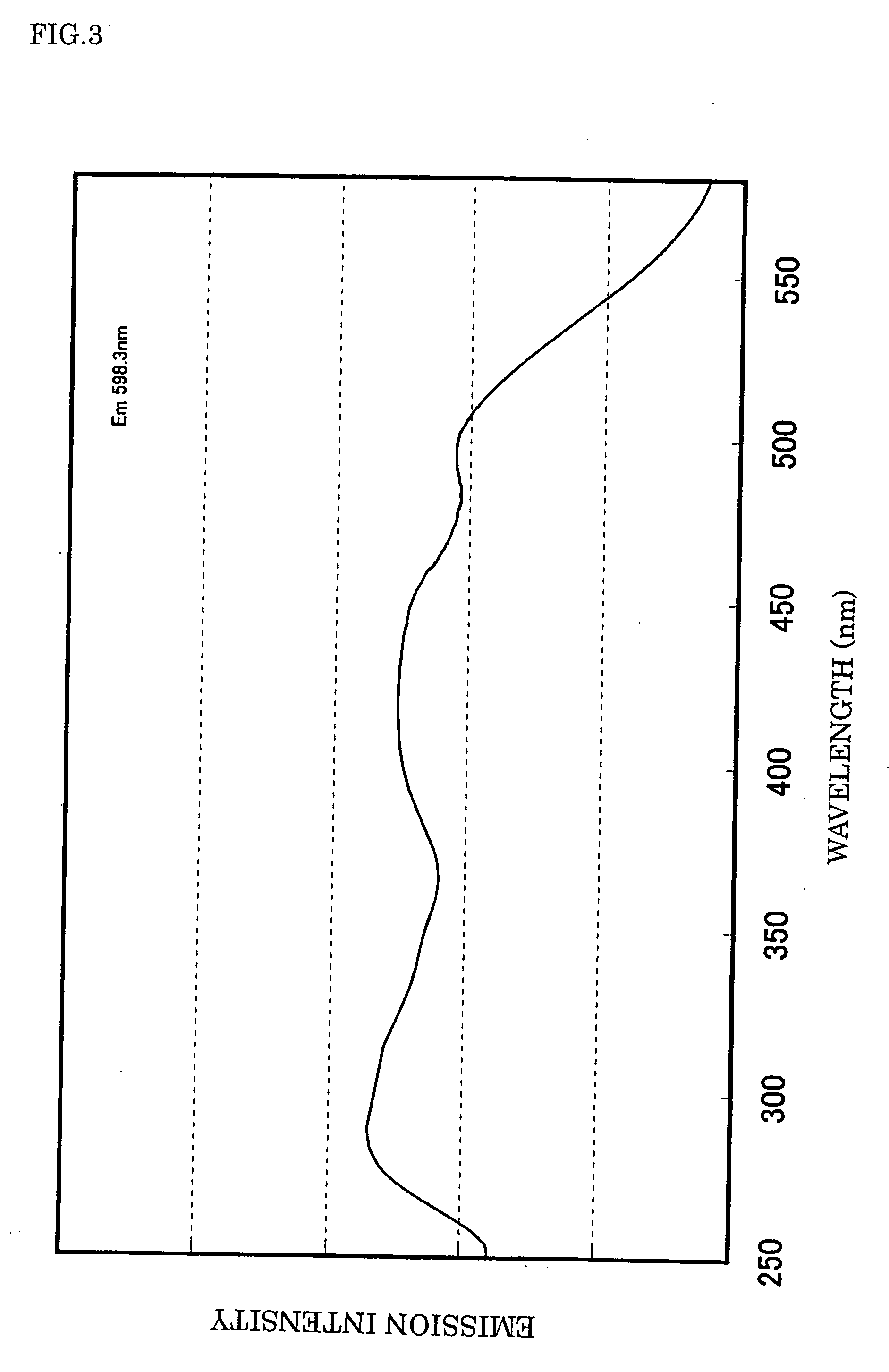

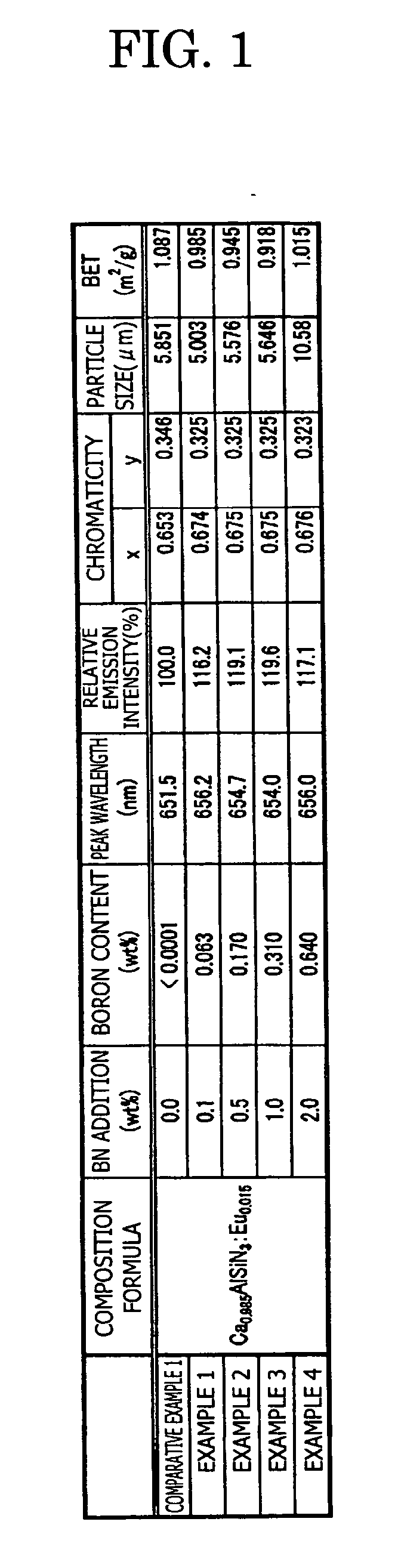

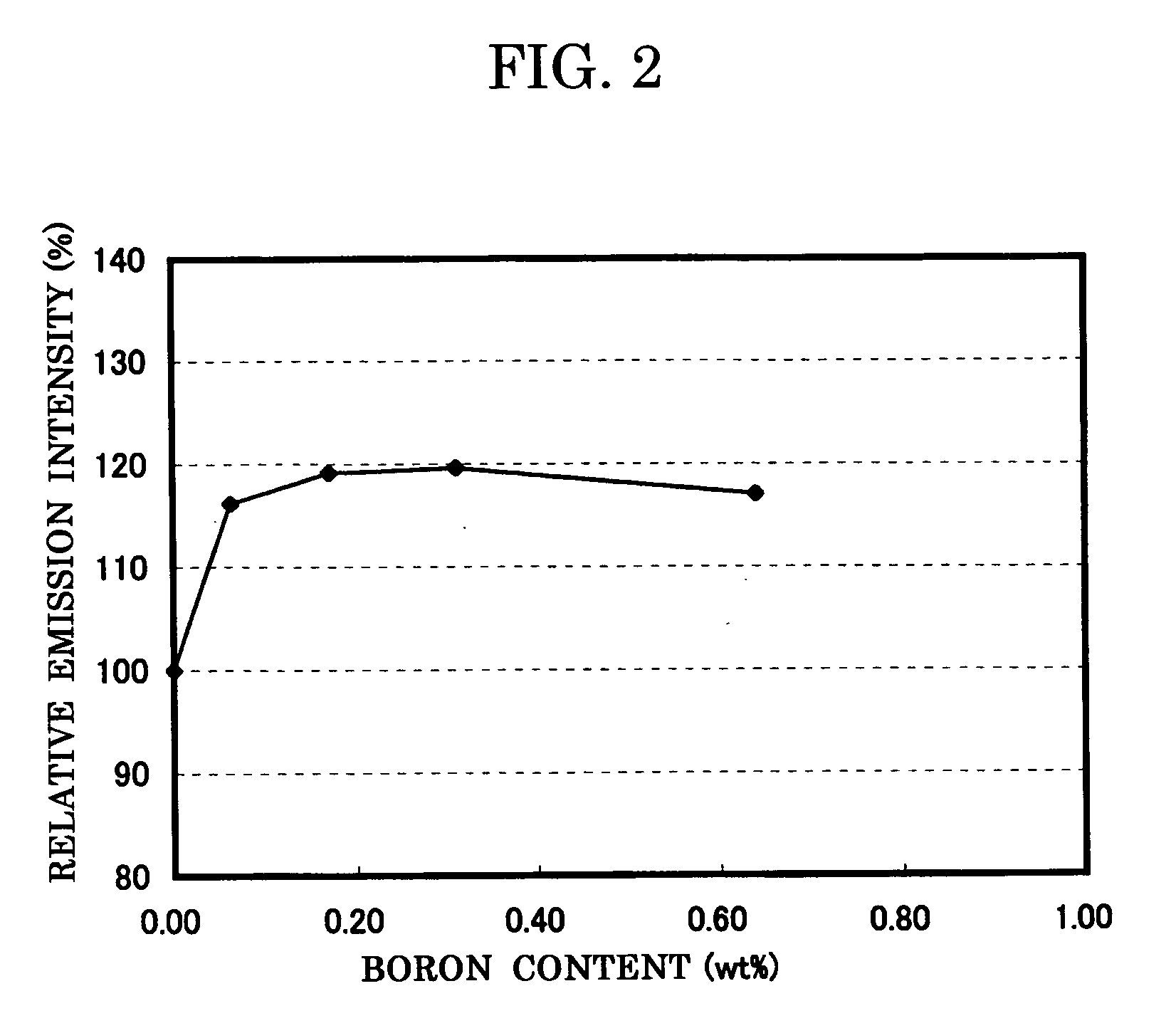

ActiveUS20060065878A1Improve emission efficiencyImprove efficiencySynthetic resin layered productsCellulosic plastic layered productsRare-earth elementUltraviolet

To provide a phosphor having an emission spectrum with a broad peak in a range from yellow color to red color (580 nm to 680 nm) and an excellent excitation band on the longer wavelength side from near ultraviolet / ultraviolet of excitation light to visible light (250 nm to 550 nm), and having an improved emission intensity. The phosphor is provided, which is given by a general composition formula expressed by MmAaBbOoNn:Z, (wherein element M is more than one kind of element having bivalent valency, element A is more than one kind of element having tervalent valency selected from the group consisting of Al, Ga, In, Tl, Y, Sc, P, As, Sb, and Bi, element B is more than one kind of element having tetravalent valency, O is oxygen, N is nitrogen, and element Z is more than one kind of element selected from rare earth elements or transitional metal elements, satisfying m>0, a>0, b>0 o≧0, and n=2 / 3m+a+4 / 3b−2 / 3o), and further containing boron and / or fluorine.

Owner:CITIZEN ELECTRONICS CO LTD +1

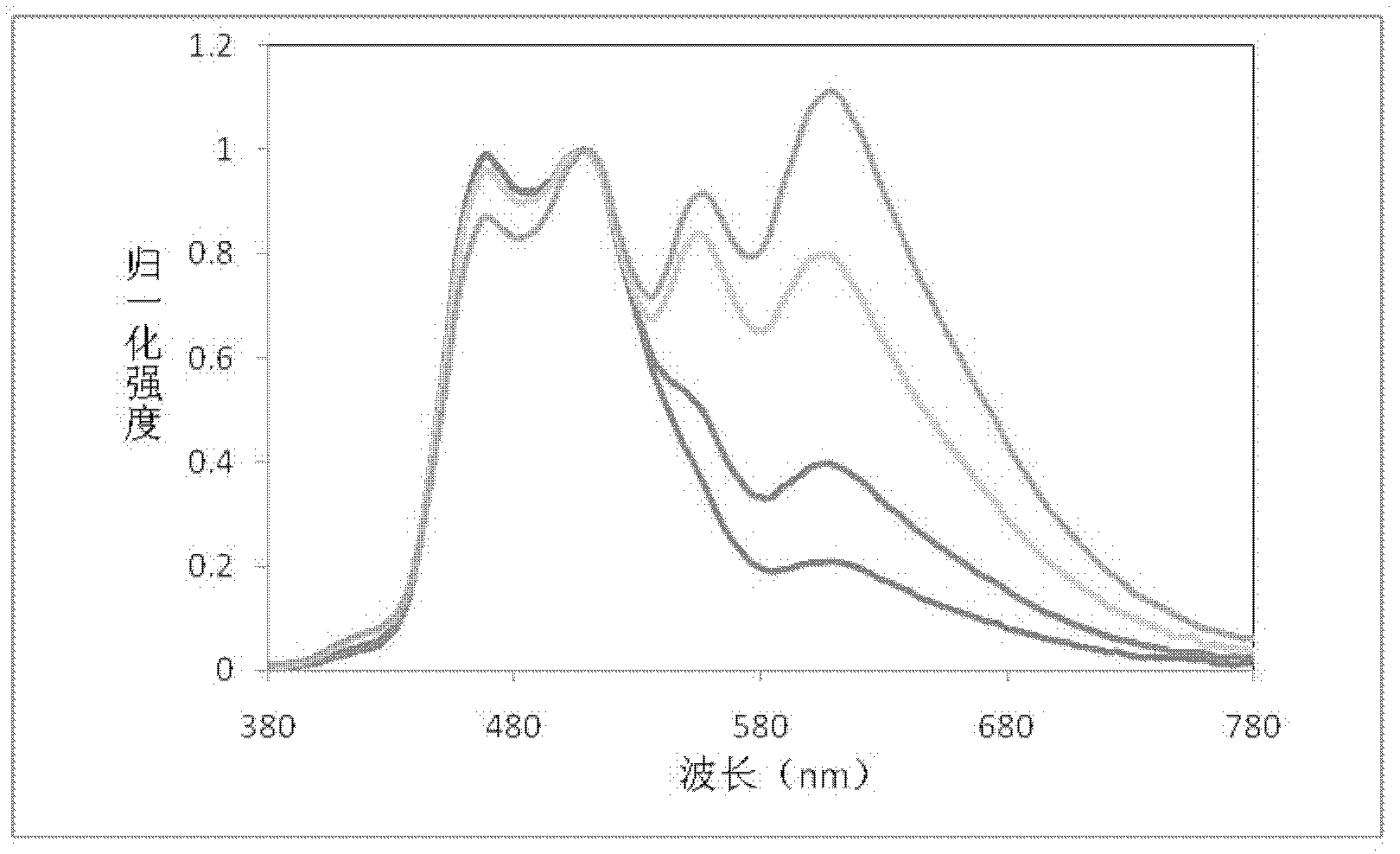

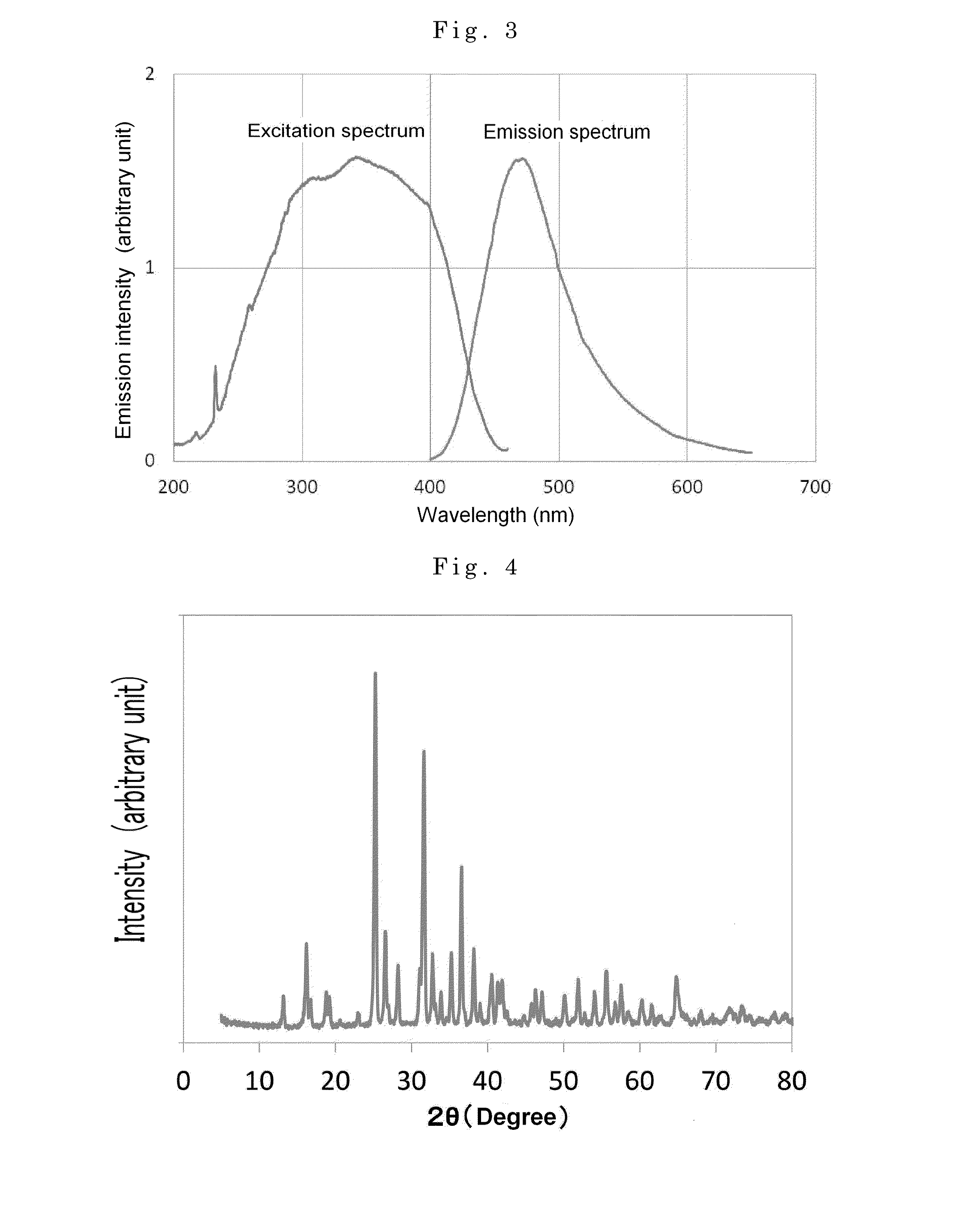

Phosphor, Phosphor Sheet, and Manufacturing Method Therefore, and Light Emission Device Using the Phosphor

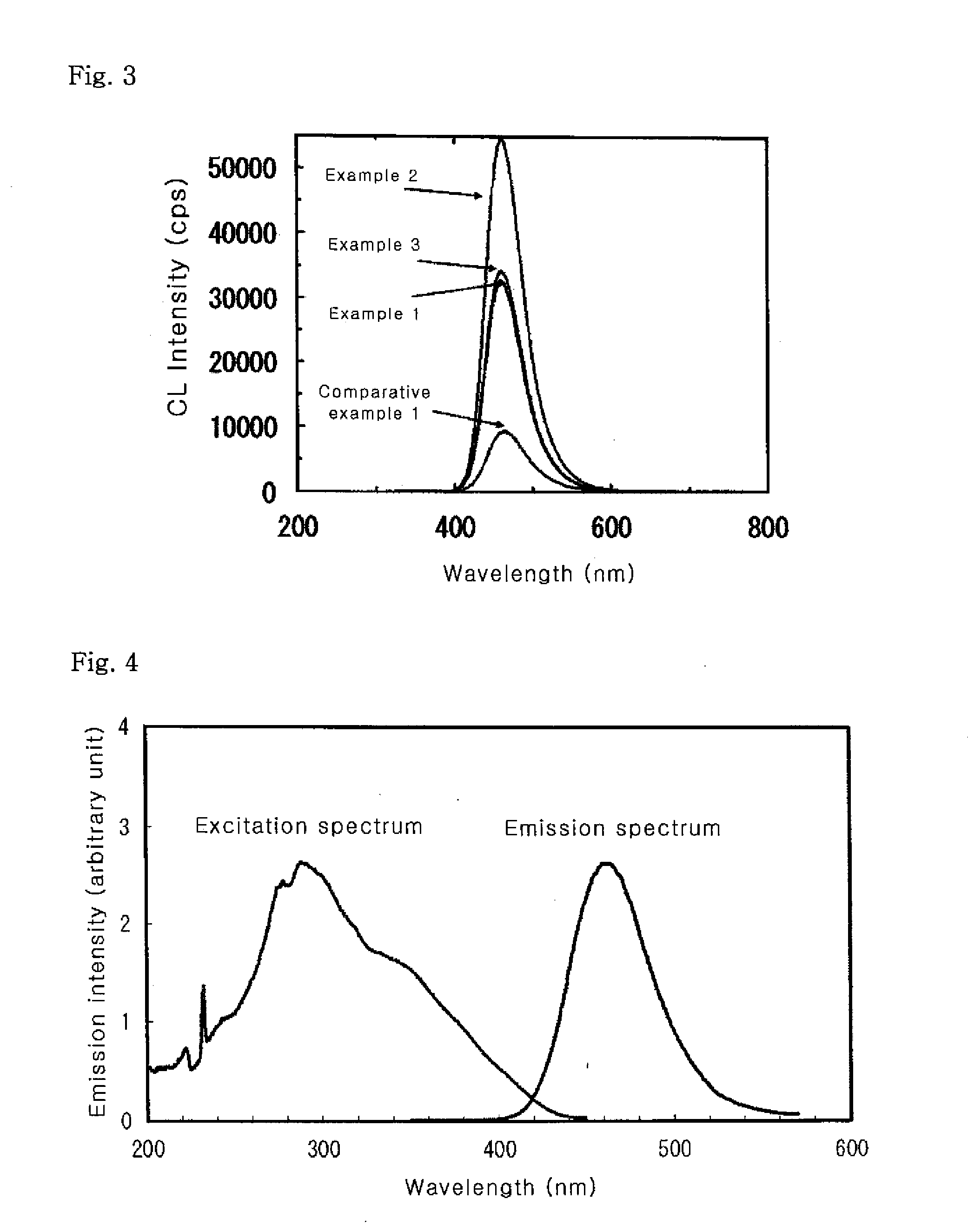

InactiveUS20090026915A1High efficient excitation bandImprove emission efficiencyDischarge tube luminescnet screensLamp detailsUltravioletEmission efficiency

To provide a phosphor having a broad emission spectrum in a range of blue color (in a peak wavelength range from 400 nm to 500 nm), having a broad flat excitation band in a near ultraviolet / ultraviolet range, and having excellent emission efficiency and emission intensity / luminance. The phosphor is given as a general composition formula expressed by MmAaBbOoNn:Z, (where element M is the element having bivalent valency, element A is the element having tervalent valency, element B is the element having tetravalent valency, O is oxygen, N is nitrogen, and element Z is more than one kind of element acting as an activator), satisfying 5.0<(a+b) / m<9.0, 0≦a / m≦2.0, 0≦o≦n, n=2 / 3m+a+4 / 3b−2 / 3o, and has an emission spectrum with a maximum peak in the wavelength range from 400 nm to 500 nm under an excitation of the light in a wavelength range from 250 nm to 430 nm.

Owner:MITSUBISHI CHEM CORP

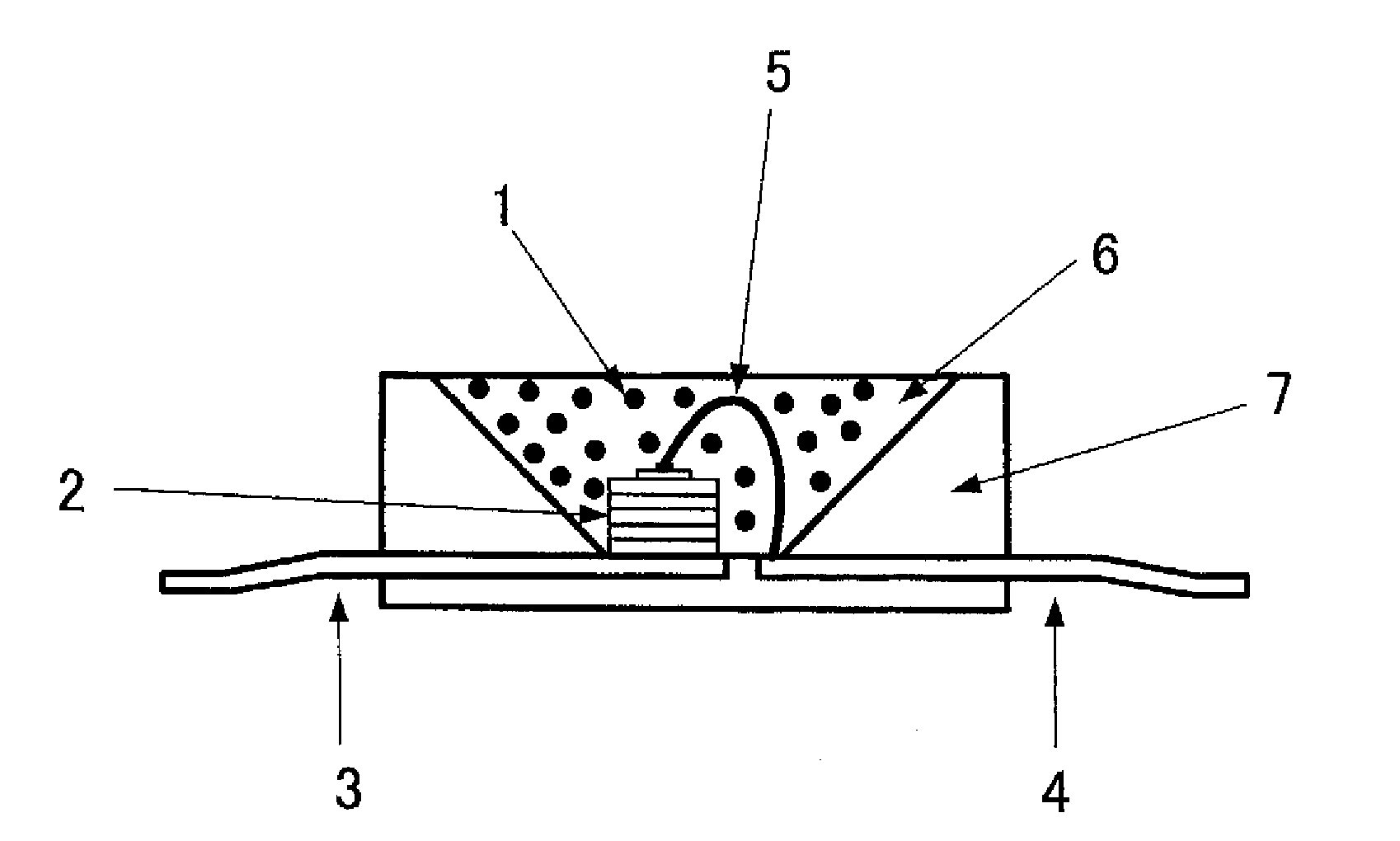

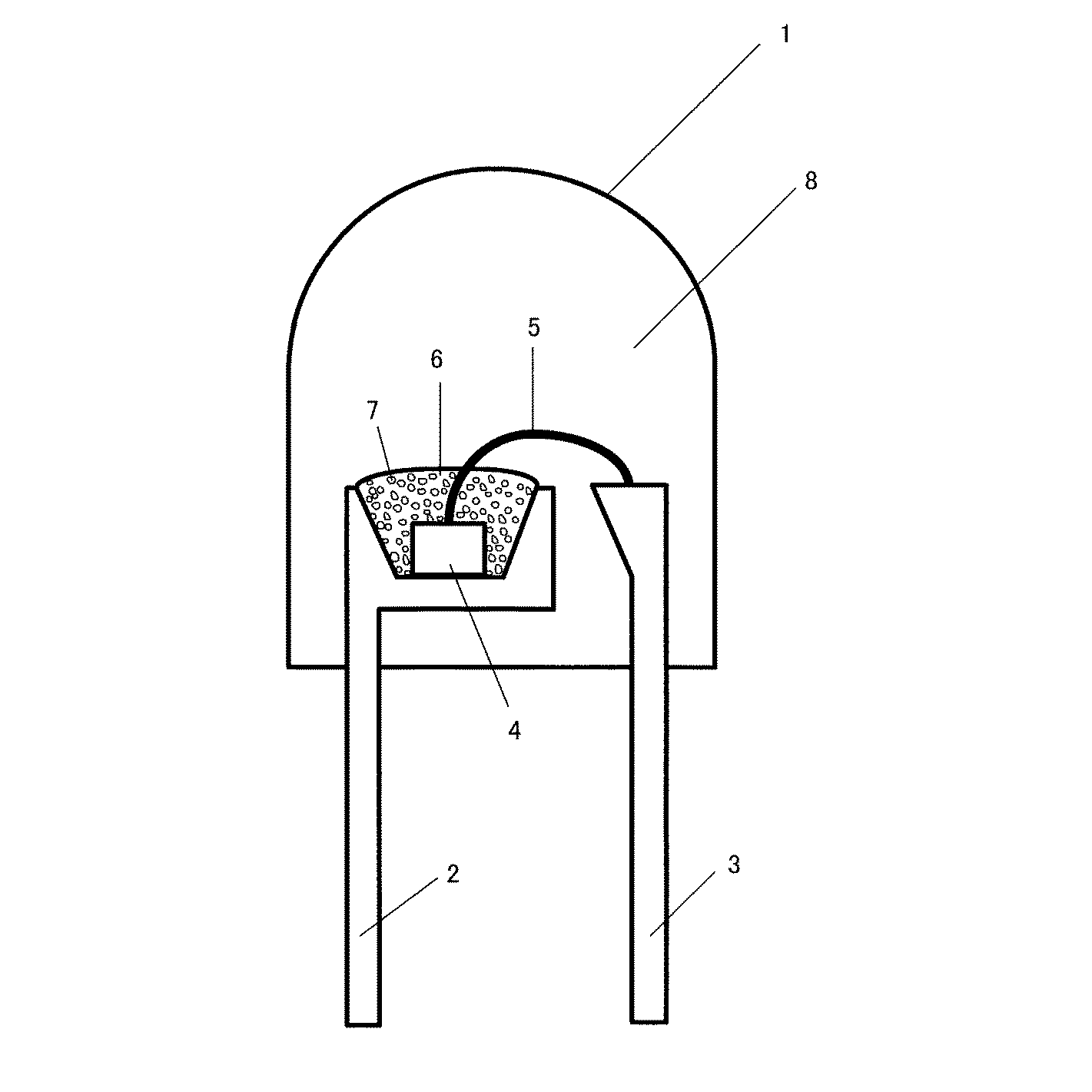

Light emitting apparatus

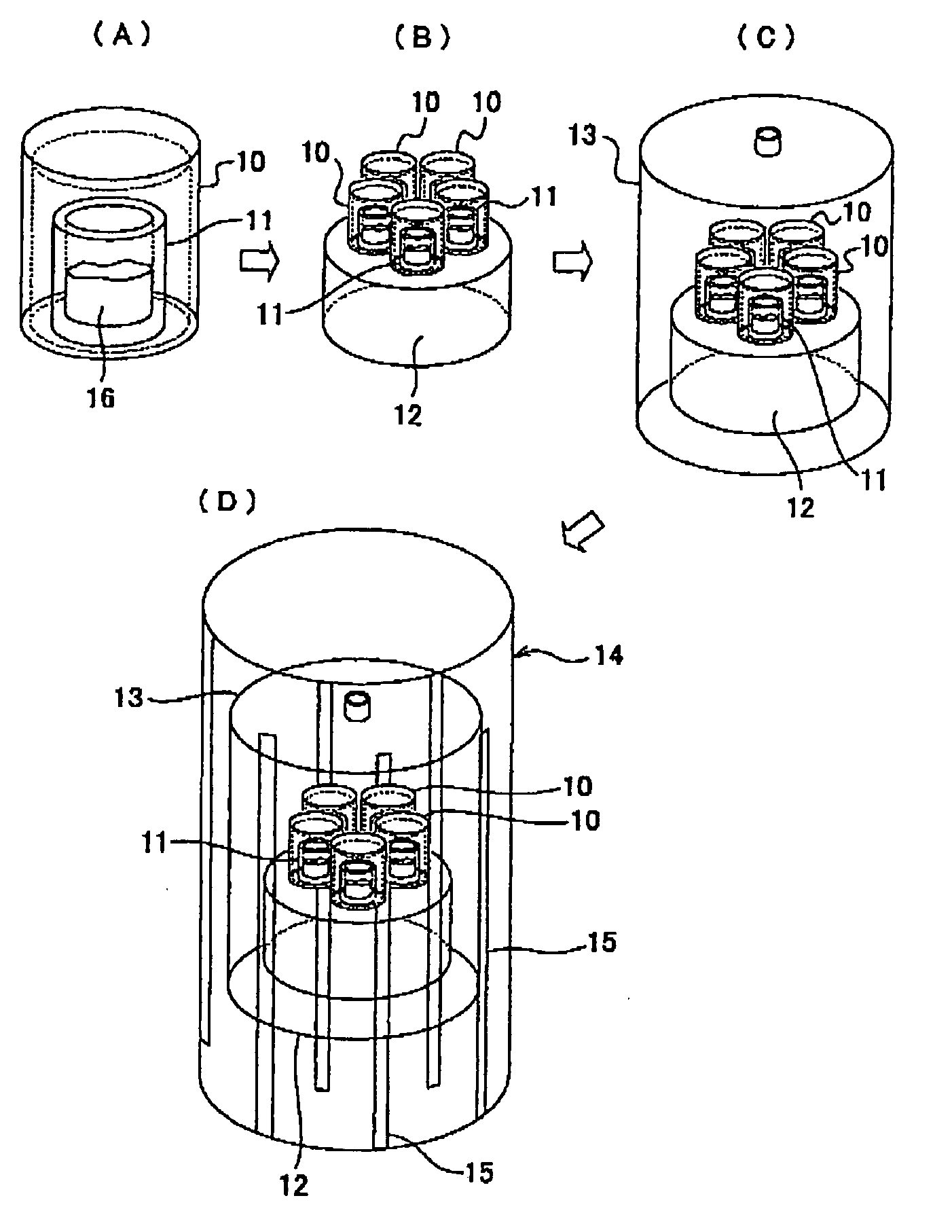

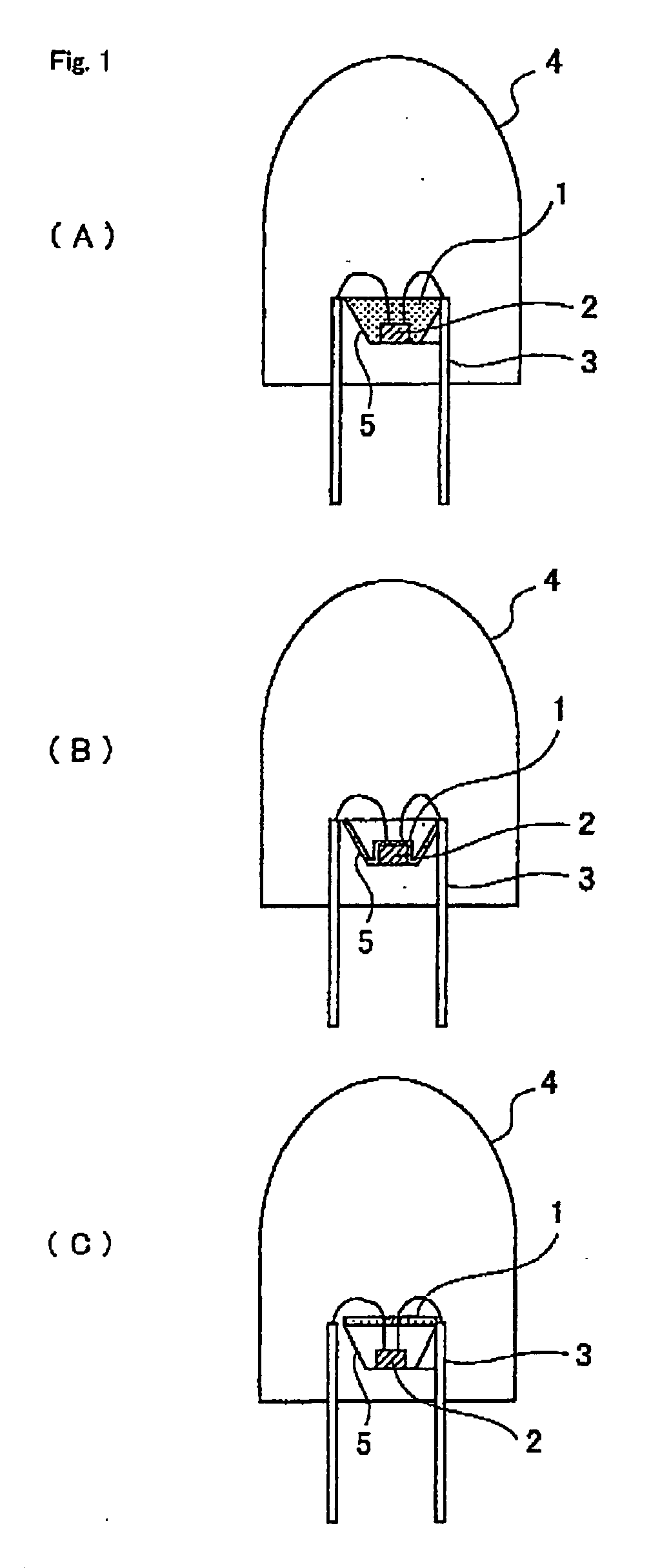

ActiveUS20080030976A1High emission intensityImprove reliabilityDischarge tube luminescnet screensLamp detailsWeather resistancePhosphor

A light emitting apparatus with high emission intensity and that is superior in weather resistance and reliability is obtained. The light emitting apparatus includes a light source and a wavelength-converting member for converting the wavelength of light emitted from the light source, wherein the wavelength-converting member contains a phosphor subjected to a cleaning treatment and / or a coating treatment, in a glass material having a composition of SiO2: 30 to 50%, Li2O: 0 to 15%, Na2O: 0 to 10%, K2O: 0 to 10%, Li2O+Na2O+K2O: 20 to 30%, B2O3: 5 to 15%, MgO: 0 to 10%, BaO: 0 to 10%, CaO: 0 to 10%, SrO: 0 to 10%, Al2O3: 0 to 10%, ZnO: 0 to 15%, TiO2: 10 to 20%, Nb2O5: 1 to 5%, La2O3: 0 to 5%, and TiO2+Nb2O5+La2O3: 11 to 20% by mole percentage.

Owner:NICHIA CORP

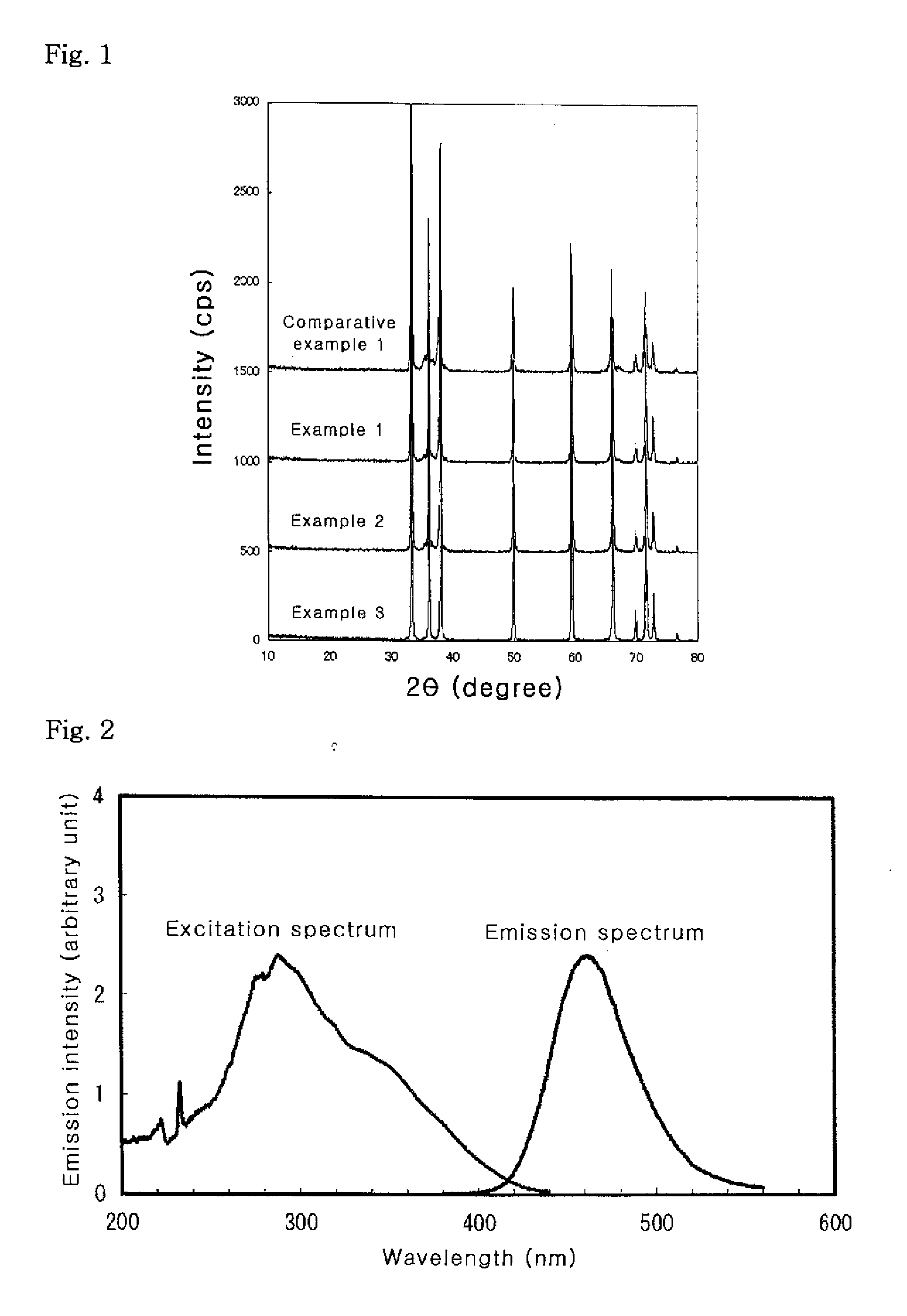

Fluorescent substance, method for producing the same, and light-emitting device using the same

ActiveUS20100164367A1High emission intensityGood dispersionLayered productsSolid-state devicesFluorescenceCrystal structure

The present invention provides a fluorescent substance exhibiting higher brightness as compared to conventional fluorescent substances, a method for producing the same, and a light-emitting device using such a fluorescent substance. Specifically, the fluorescent substance comprises an α-sialon crystal structure having the same crystal structure with an α-type silicon nitride crystal, which includes at least an M(0) element (where M(0) represents one or two elements selected from Sr and La), an M(1) element (where M(1) represents one or more elements selected from Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm and Yb), Si, Al, and nitrogen.

Owner:NAT INST FOR MATERIALS SCI

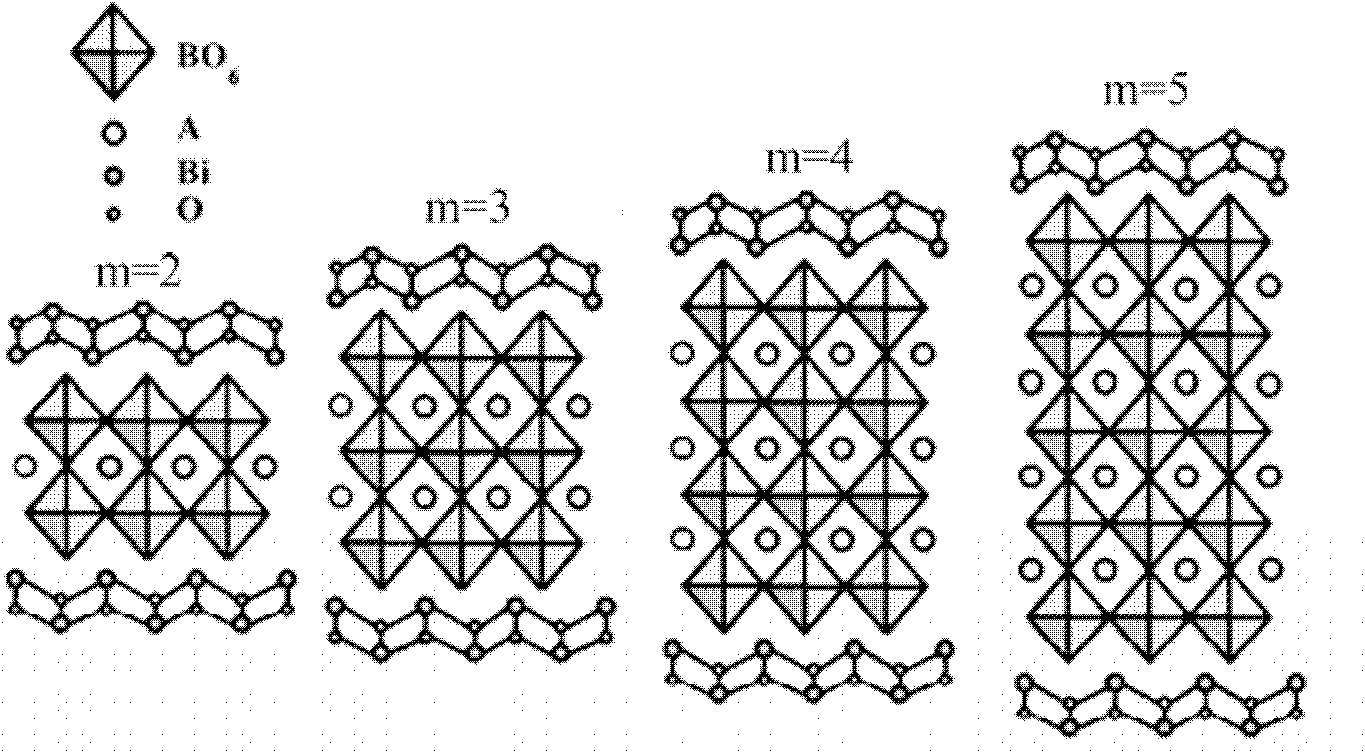

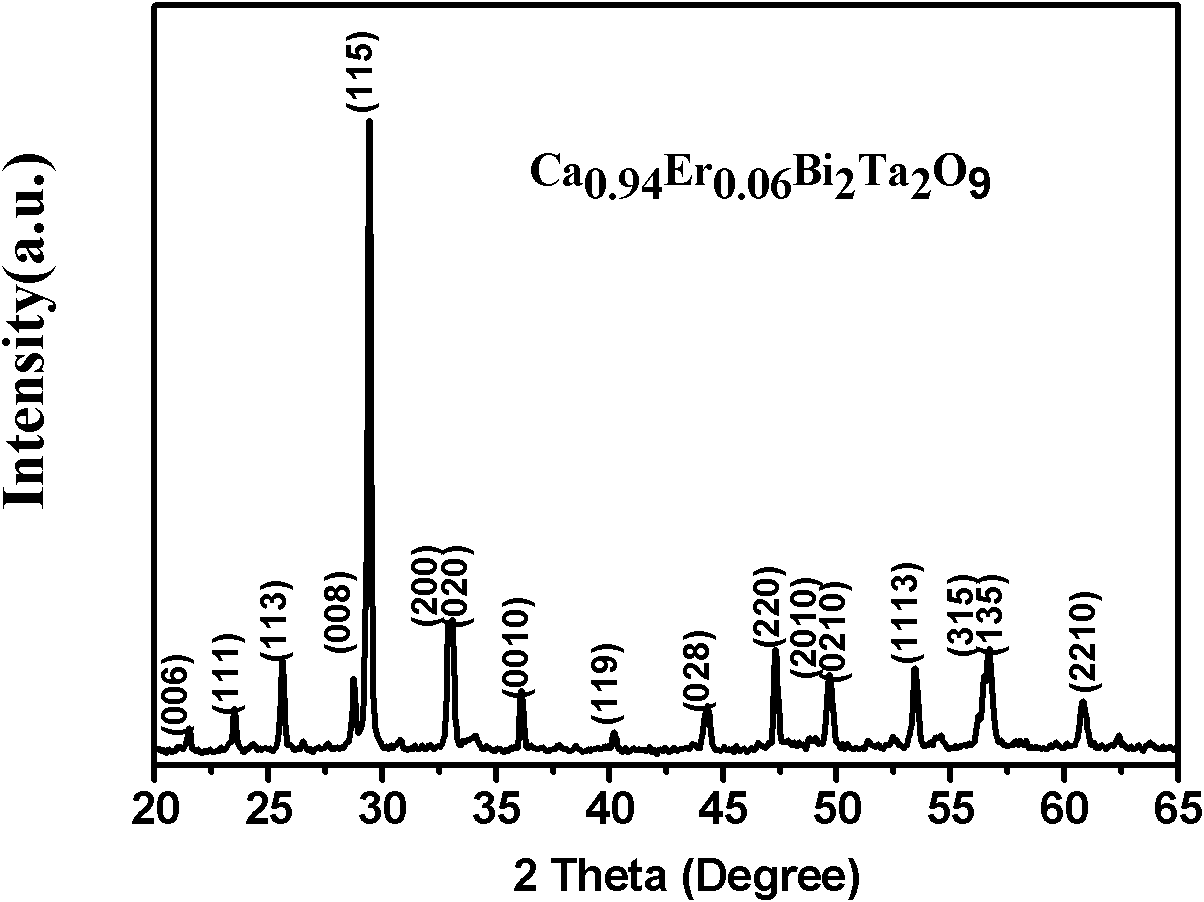

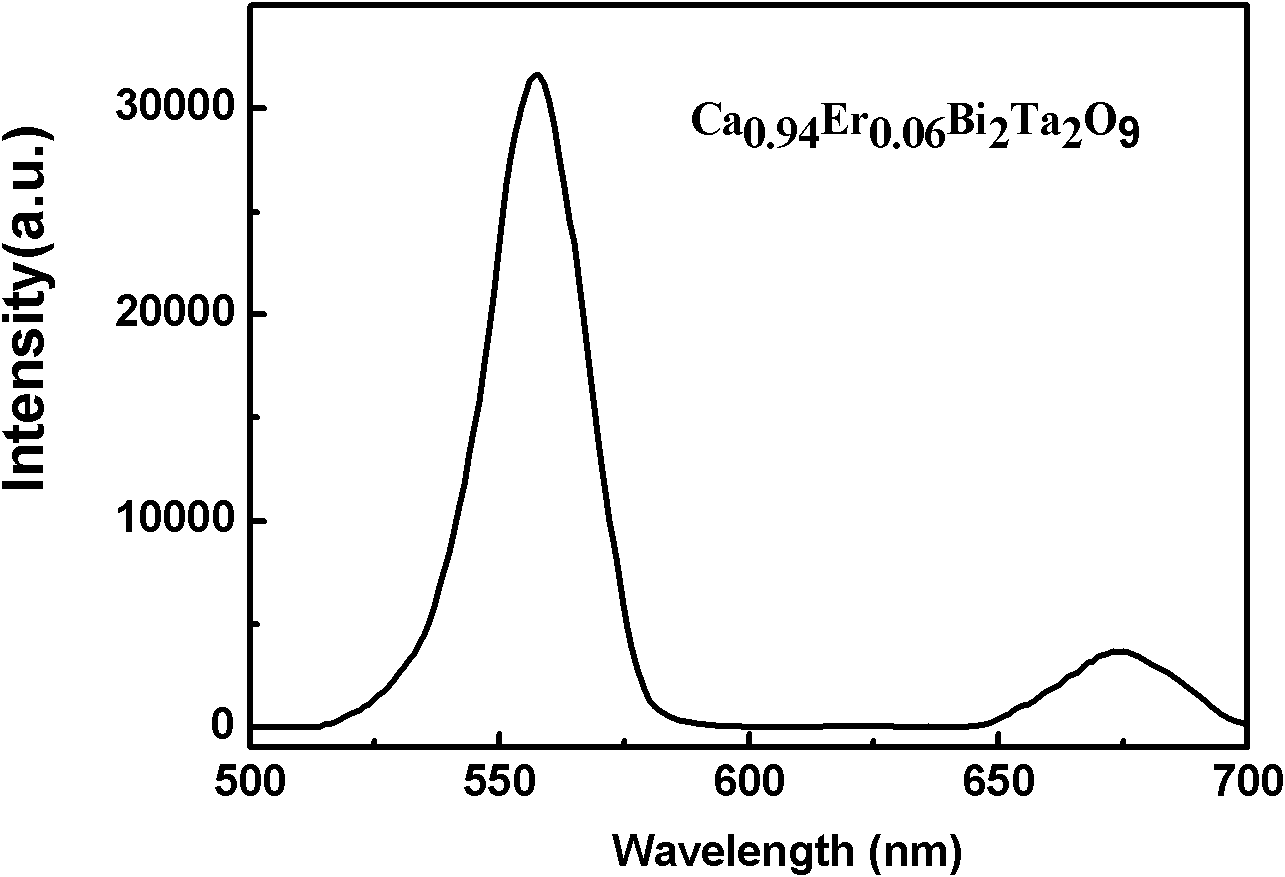

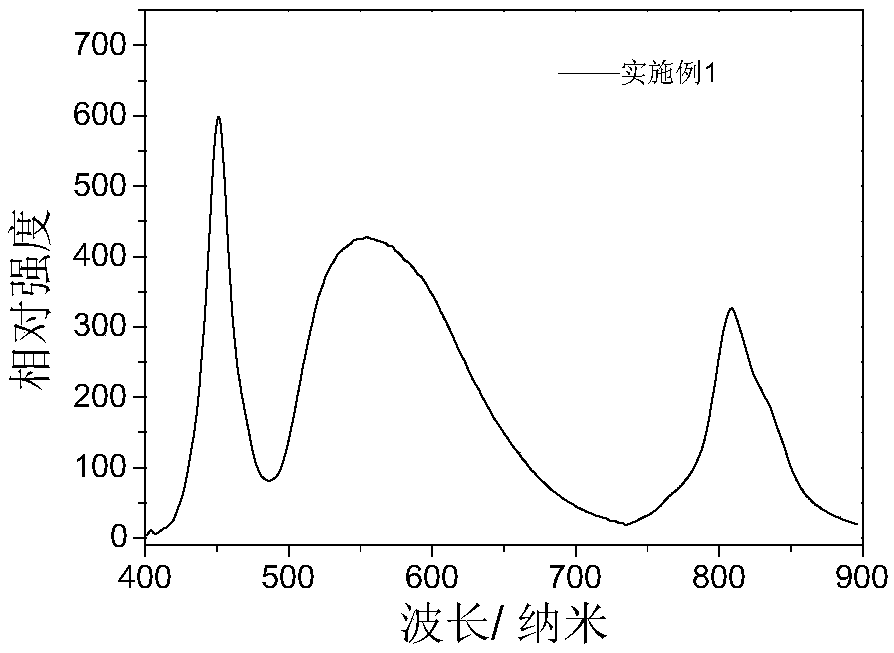

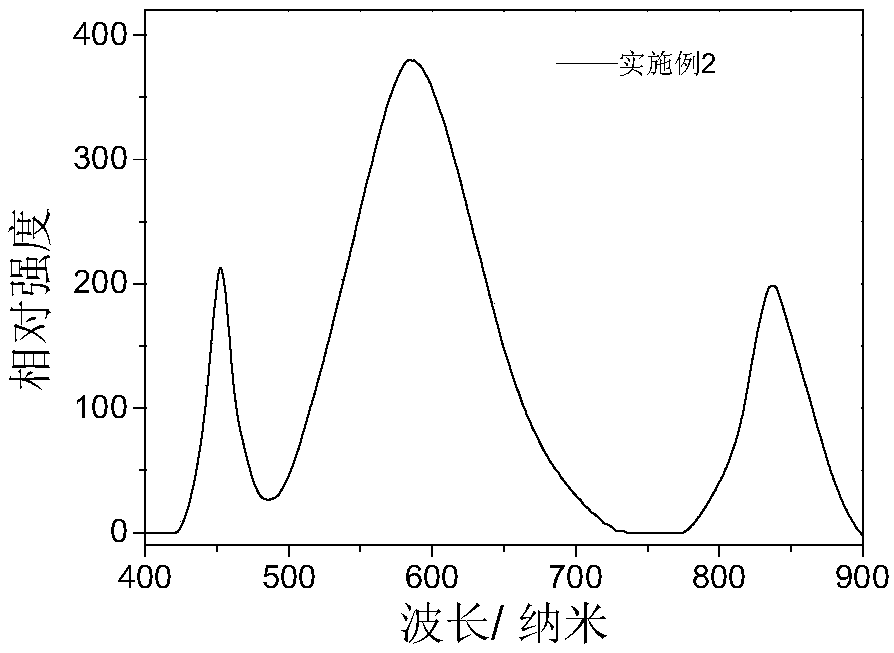

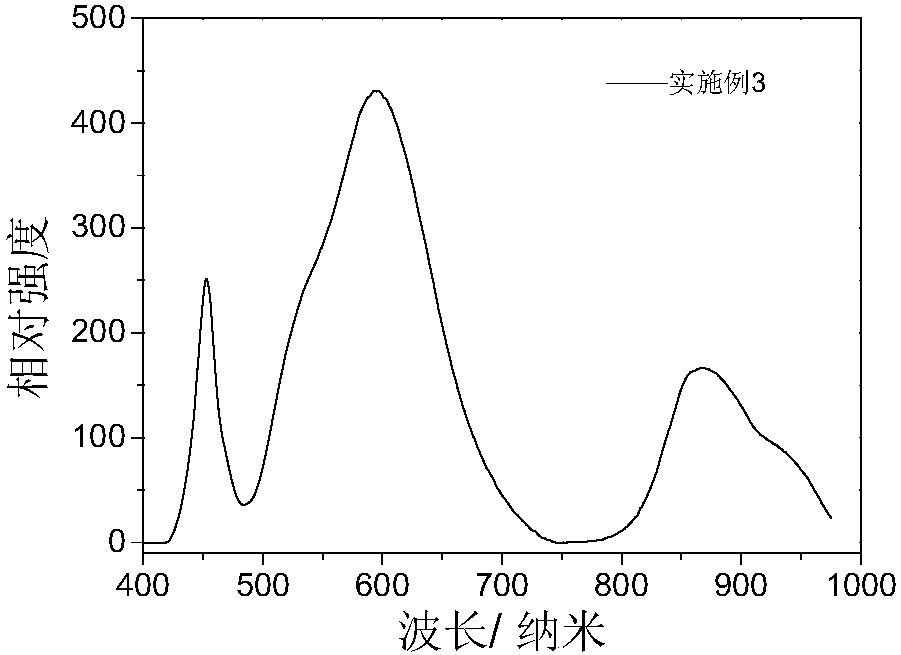

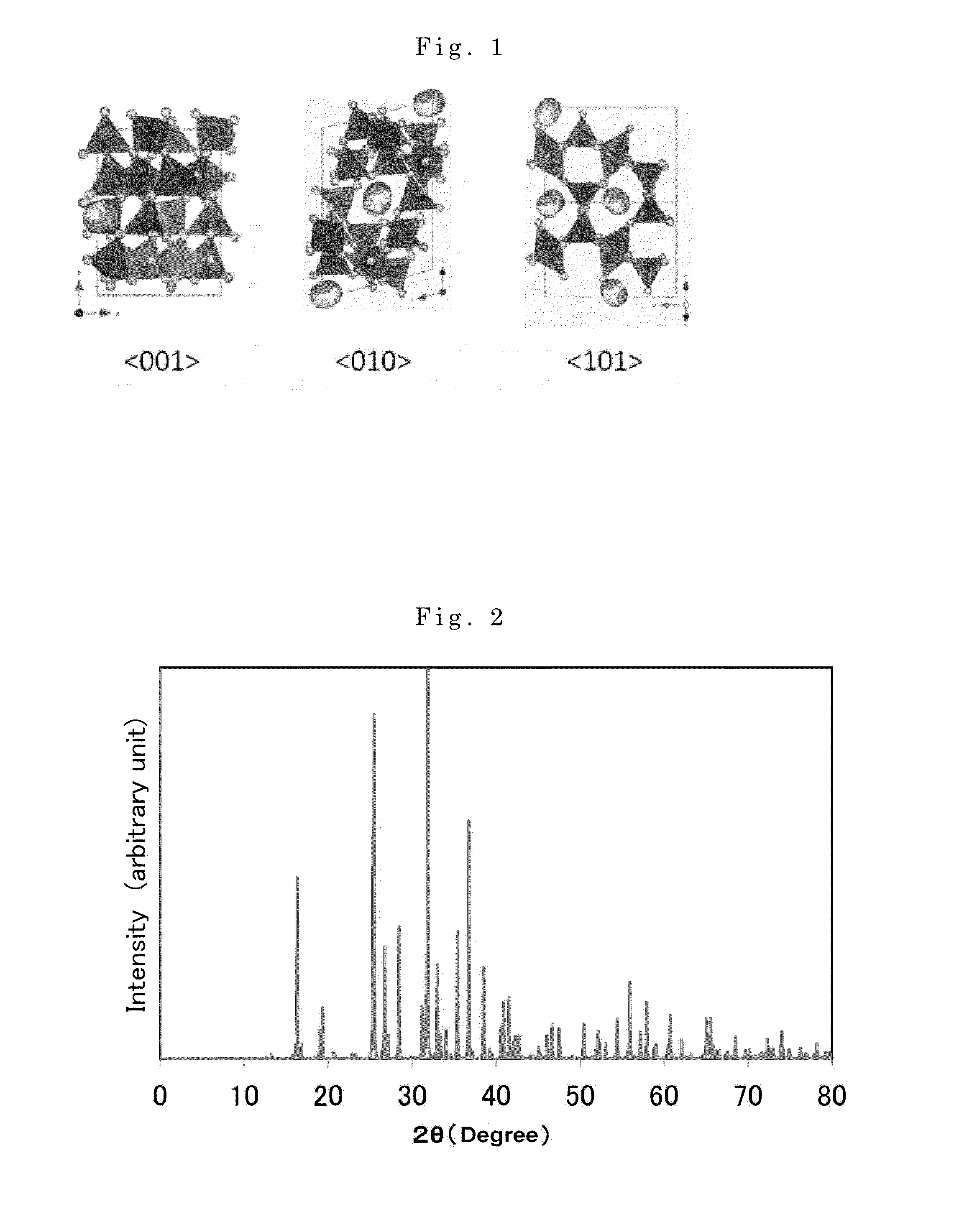

Bismuth layered perovskite-like structure oxide up-conversion luminescent piezoelectric material and preparation method thereof

InactiveCN102276248AHigh emission intensityThe synthesis process is simpleChemistryThree dimensional display

The invention relates to an infrared-excited oxide up-conversion luminescence piezoelectric material of a bismuth lamellar perovskite-like structure and a preparation method thereof. The up-conversion luminescence piezoelectric material has a chemical general formula of Am-1-x-RxYbyBi2BmO3M<+3>, wherein R is selected from Er<3+>, Ho<3+> and Tm<3+>, A is selected from Bi<3>, Ca<2+>, Sr<2+>, Ba<2+>, Pb<2+>, Na<+>, K<+>, La<3+> and Y<3+>, B is selected from Ti<4+>, Zr<4+>, Nb<5+>, Ta<5+>, W<6+> and Mo<6+>, m is a positive integer not smaller than 2 and not more than 8, x is not smaller than 0.000001 and not more than 0.3, and y is not smaller than 3.0 and not more than 0.6. The up-conversion luminescence piezoelectric material is prepared by adopting a solid-phase reaction method, has the characteristics of good thermal stability, good chemical stability, easiness for synthesis, high luminous intensity and adjustable color, and can be widely applied to various aspects such as three-dimensional display, infrared detection, counterfeiting prevention, solar cells and photoelectric integration, micro-electro-mechanical systems, photoelectric sensing and the like.

Owner:TONGJI UNIV

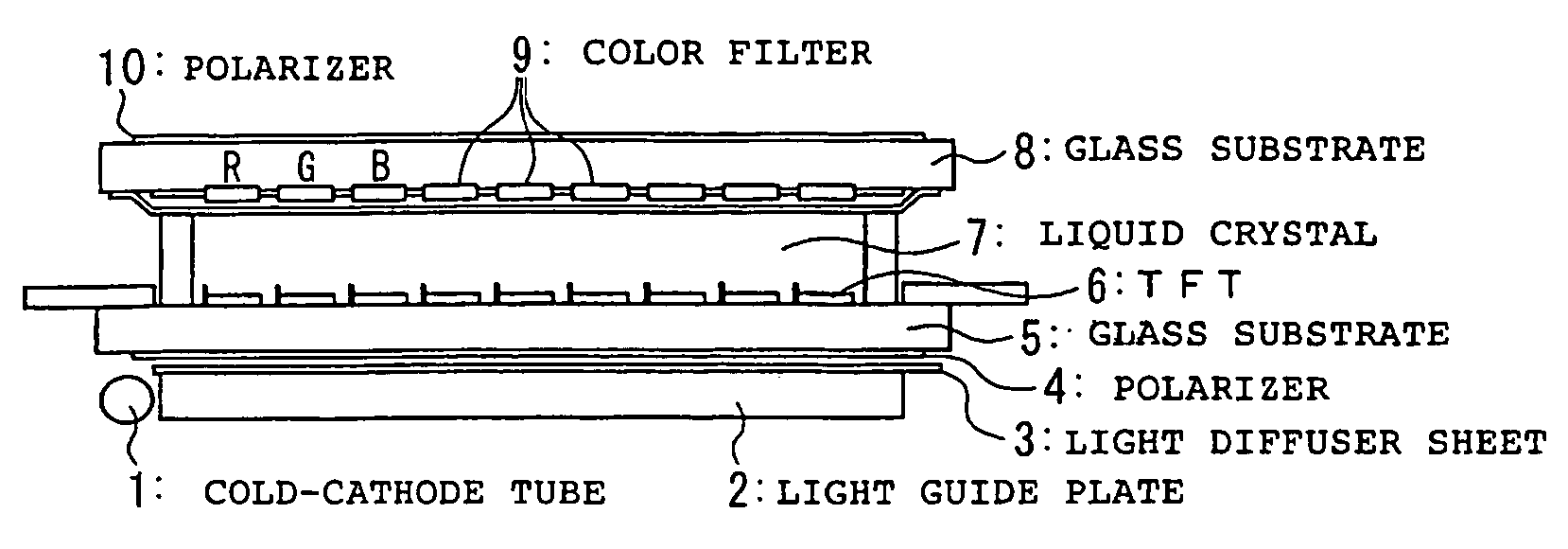

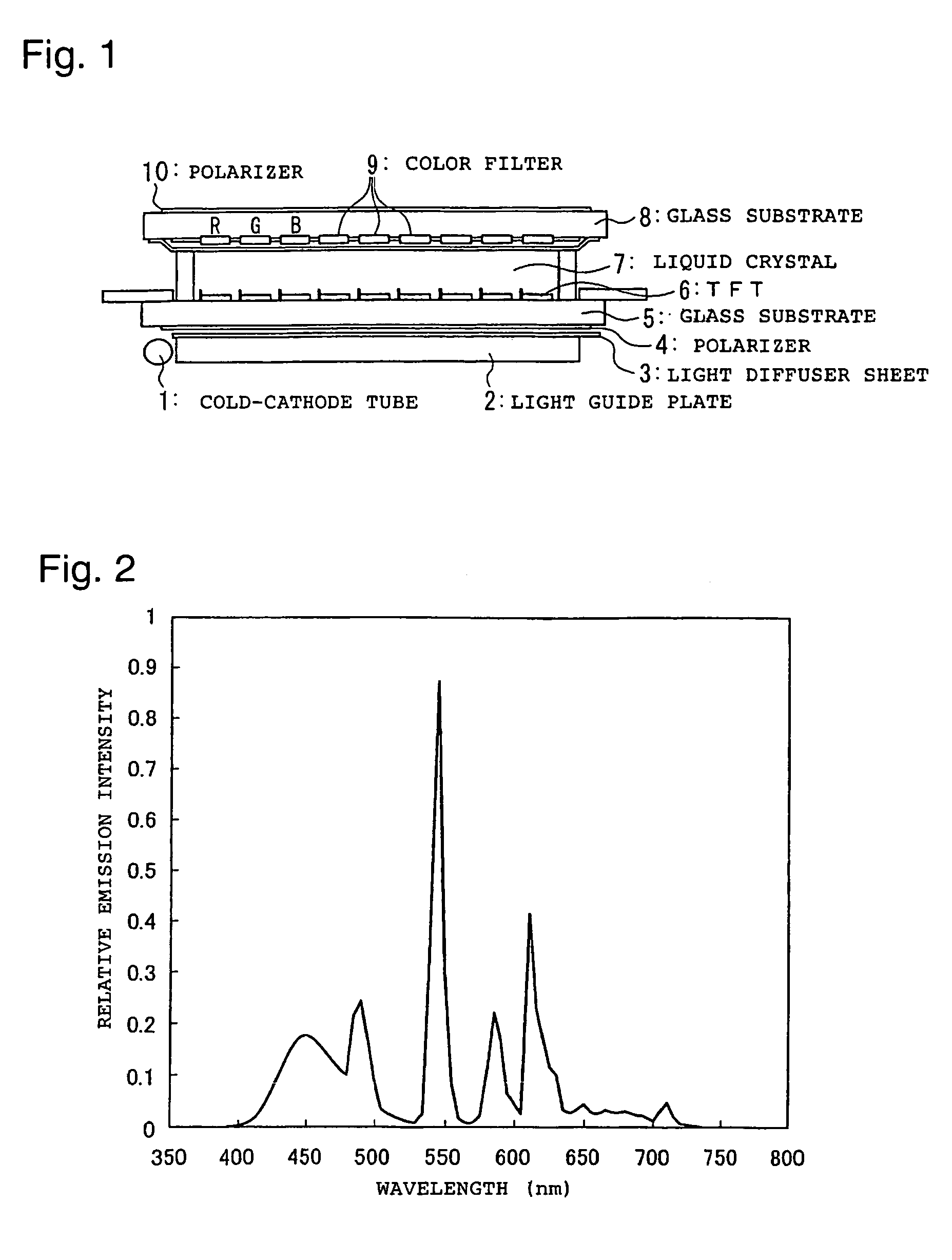

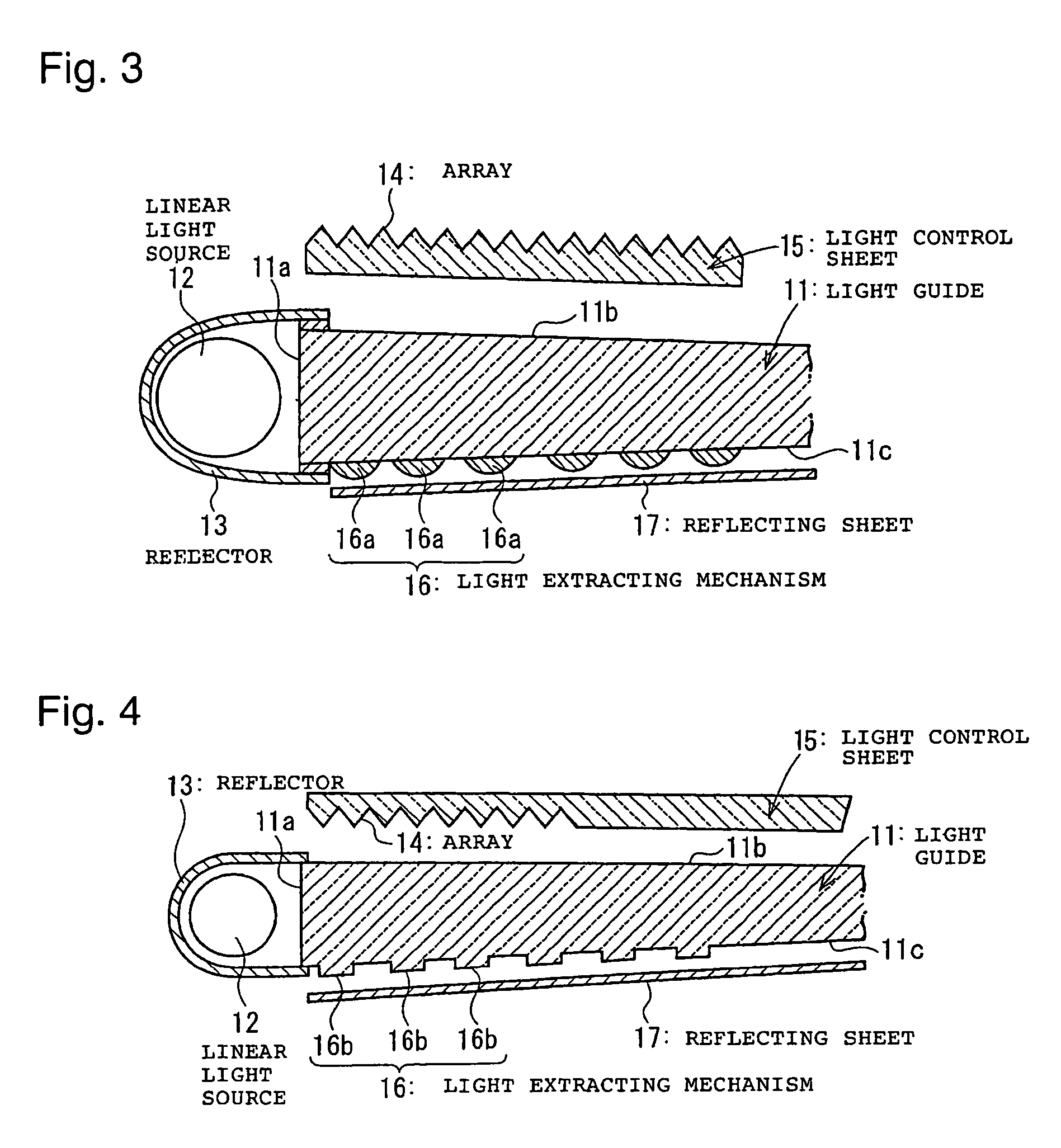

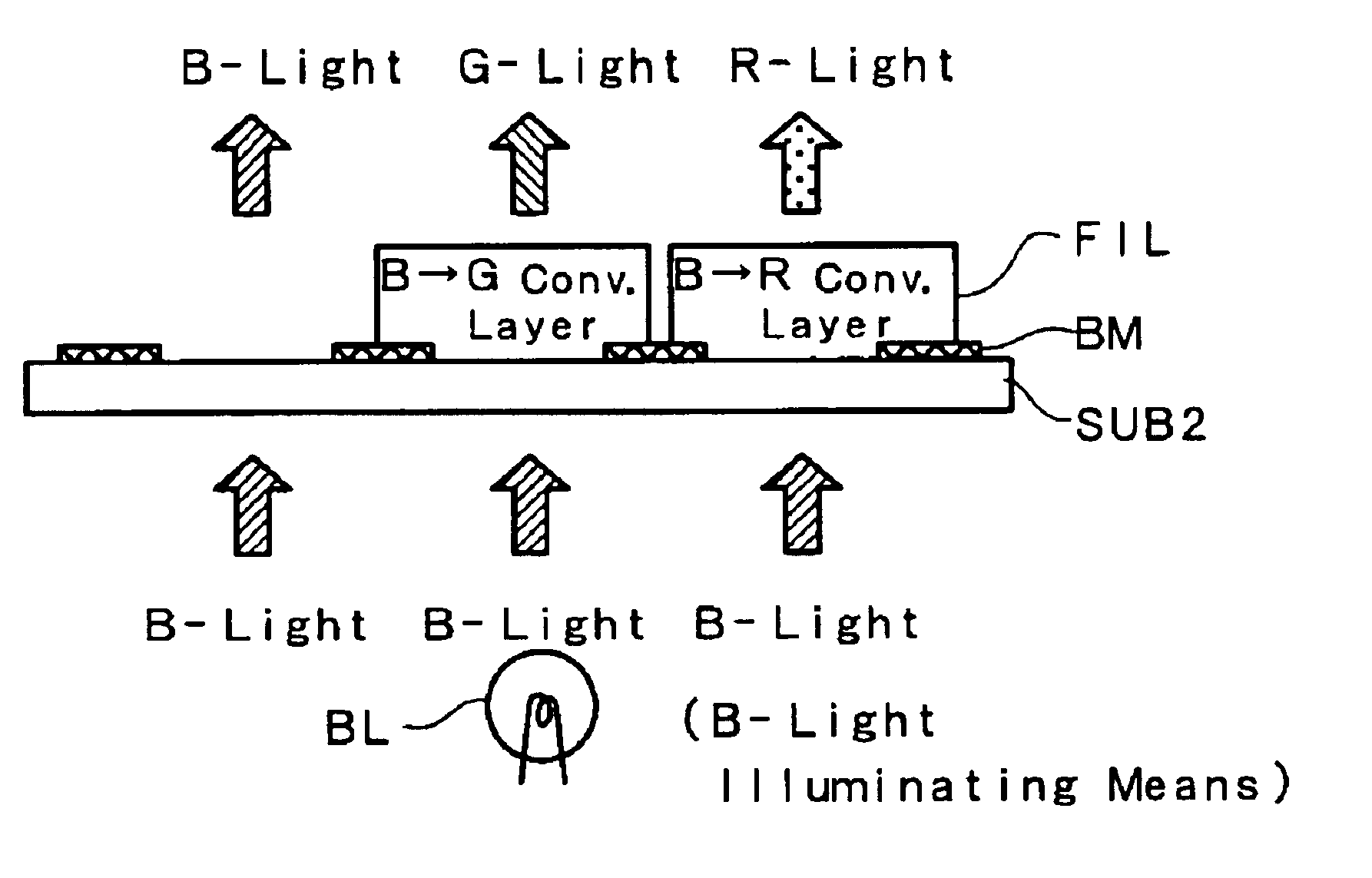

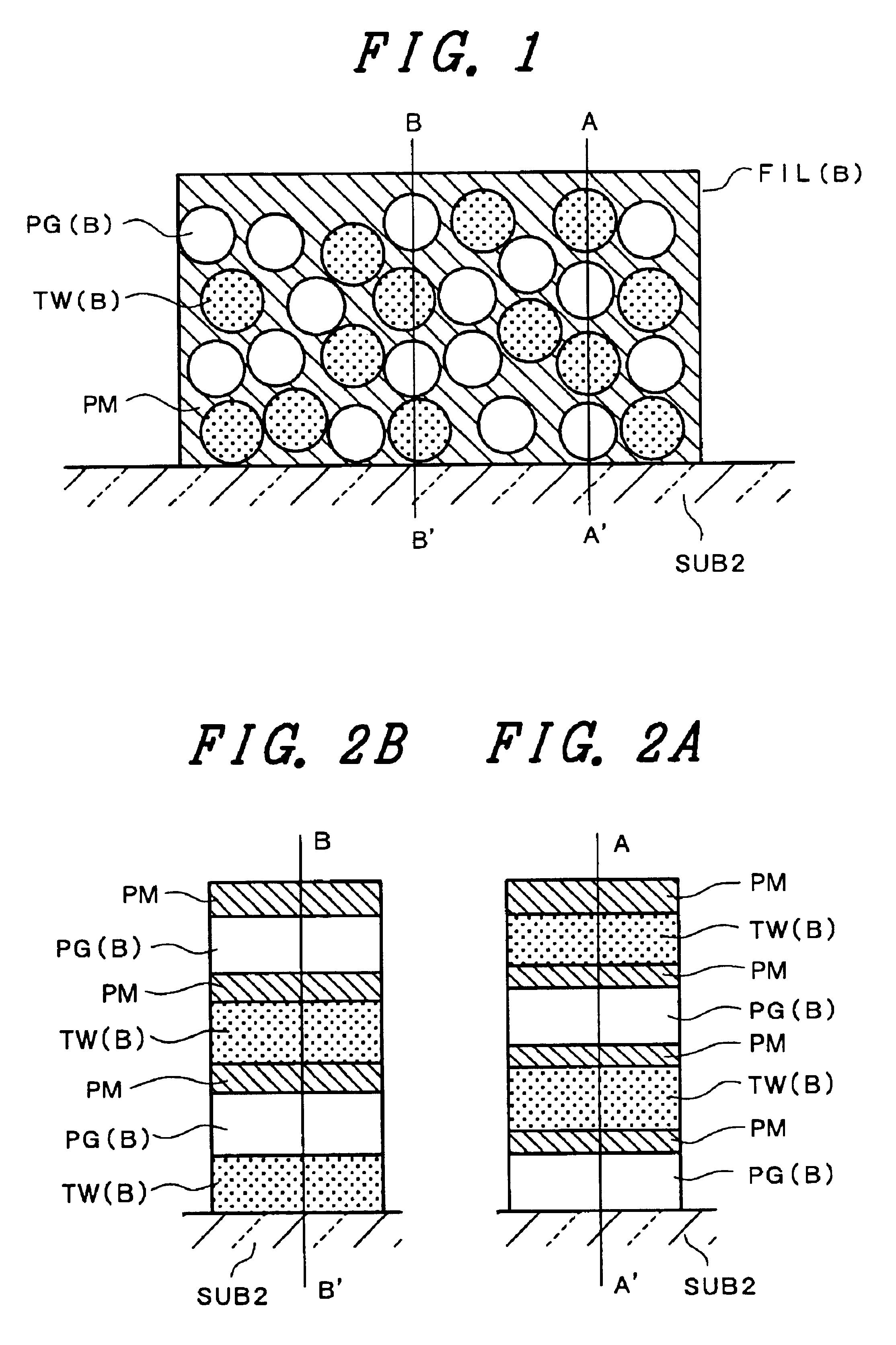

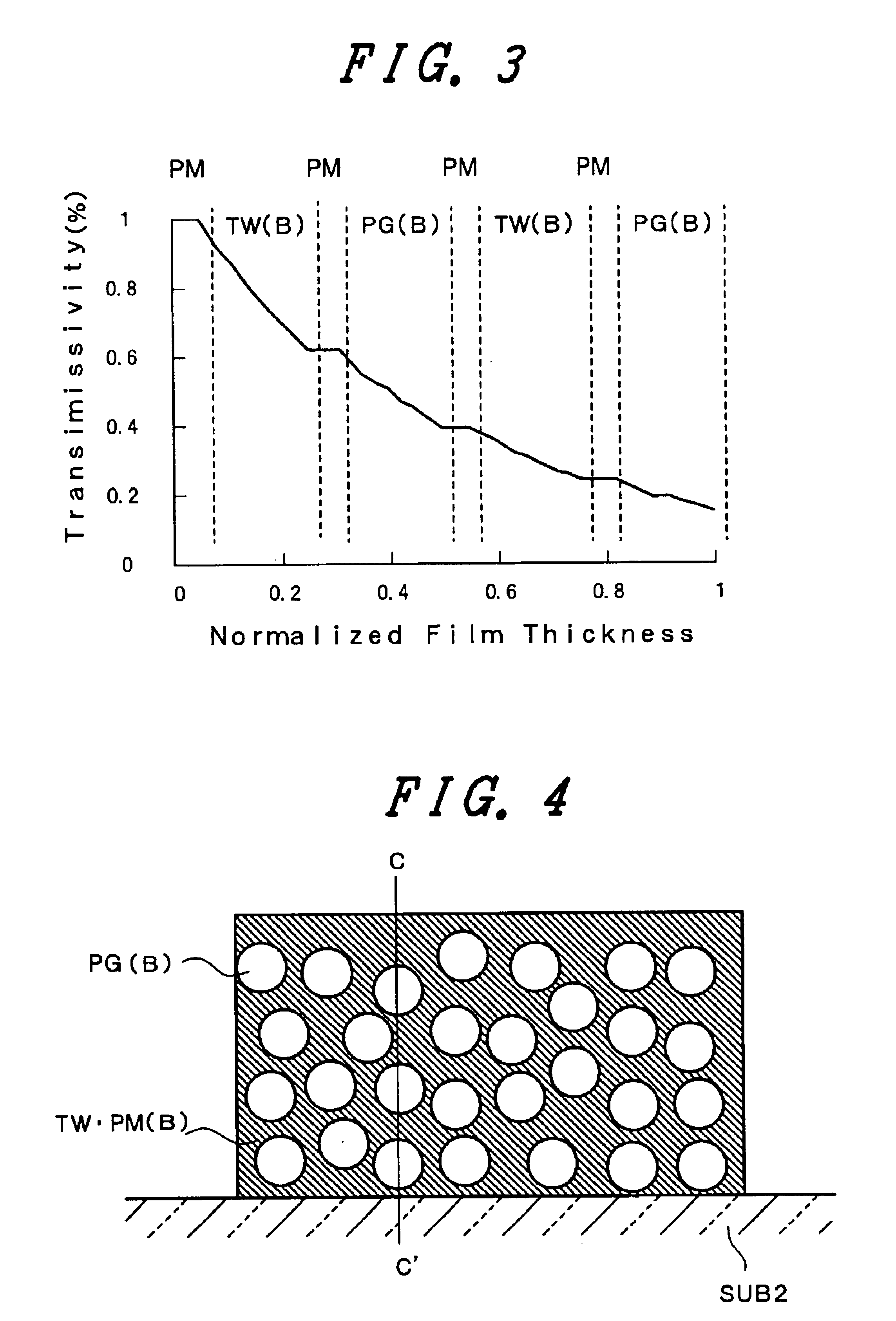

Color liquid crystal display devices

InactiveUS7006172B2High emission intensityIncrease brightnessOptical filtersPlanar/plate-like light guidesLiquid-crystal displayTransmission illumination

The invention relates to a color liquid crystal display device with a combination of light shutters that utilize a liquid crystal, a color filter having color elements of at least three colors of red, green and blue corresponding to the light shutters, and a backlight for transmission illumination.

Owner:MITSUBISHI CHEM CORP

Sialon-based oxynitride phosphor and production method thereof

InactiveUS20090284948A1Prevent excessive aggregationLess fusionDischarge tube luminescnet screensElectric discharge tubesLanthanideElectron

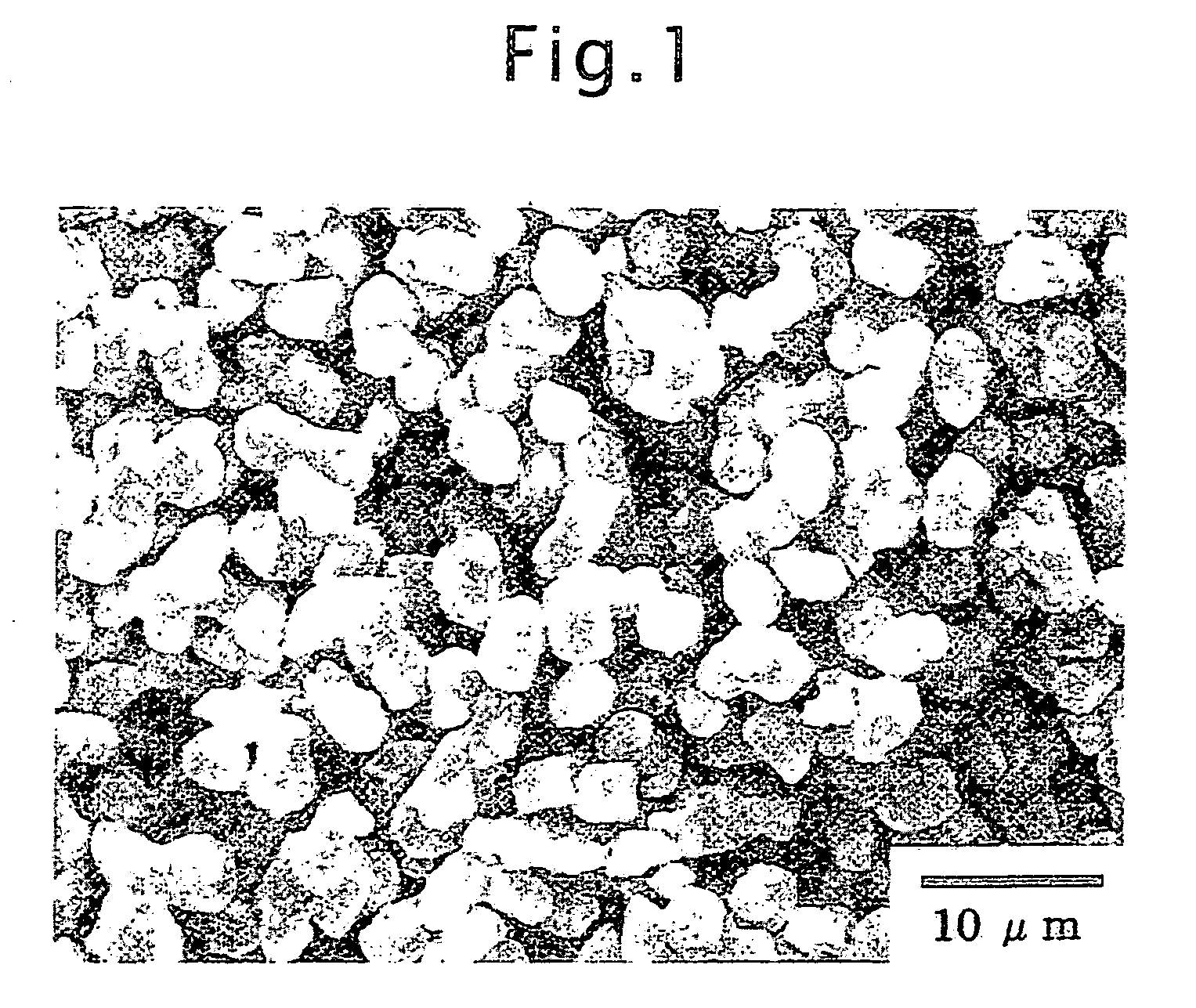

The present invention relates to an oxynitride phosphor comprising an α-sialon as the main component, which is represented by the general formula: MxSi12−(m+n)Al(m+n)OnN16−n:Lny (wherein 0.3≦x+y<1.5, 0<y<0.7, 0.3≦m<4.5, 0<n<2.25, and assuming that the atomic valence of the metal M is a and the atomic valence of the lanthanide metal Ln is b, m=ax+by) and in which the aggregation index, A1=D50 / DBET≦3.0 or the aggregation index A2=D50 / Dparticle≦3.0; and a production method and usage of the phosphor.The phosphor of the present invention has less aggregation and a narrow particle size distribution, and therefore is easy to uniformly mix with a resin or the like, and a high-brightness white LED can be easily obtained.D50 [μm]: The median diameter in the grain size distribution curve.DBET [μm]: The equivalent-sphere diameter calculated on the basis of a BET specific surface area.Dparticle [μm]: The primary particle diameter measured by the image analysis of a scanning electron micrograph.

Owner:UBE IND LTD

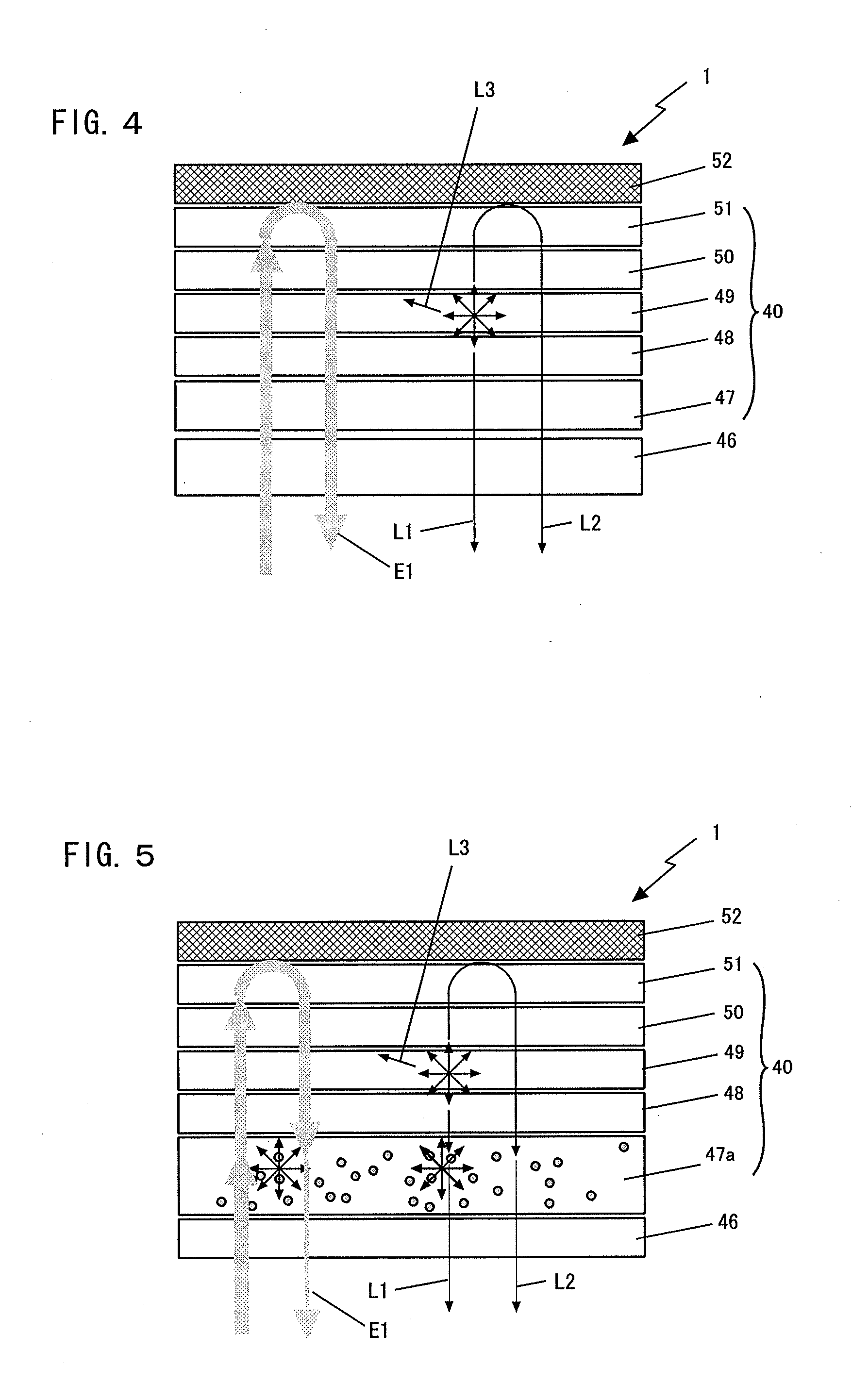

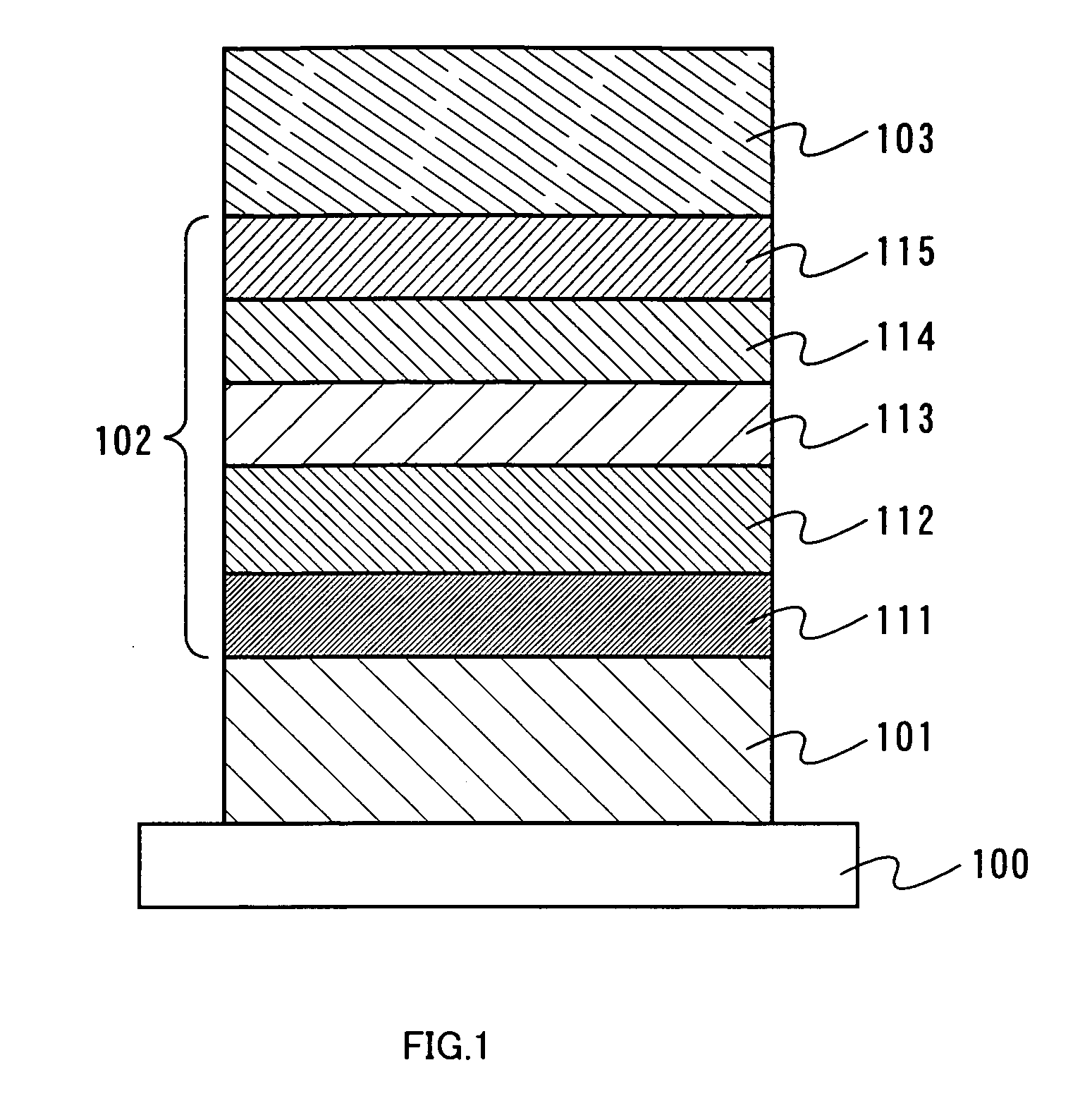

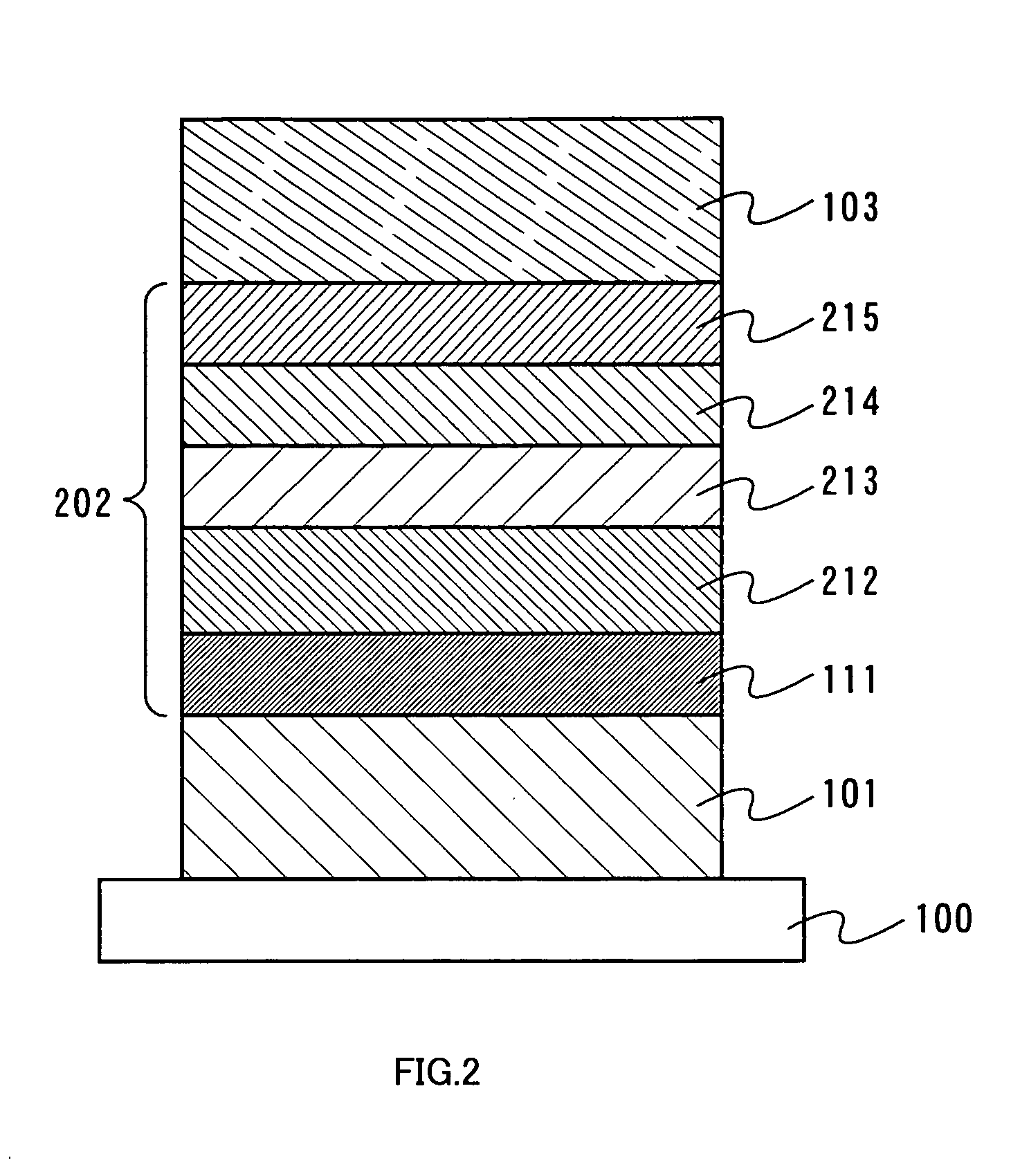

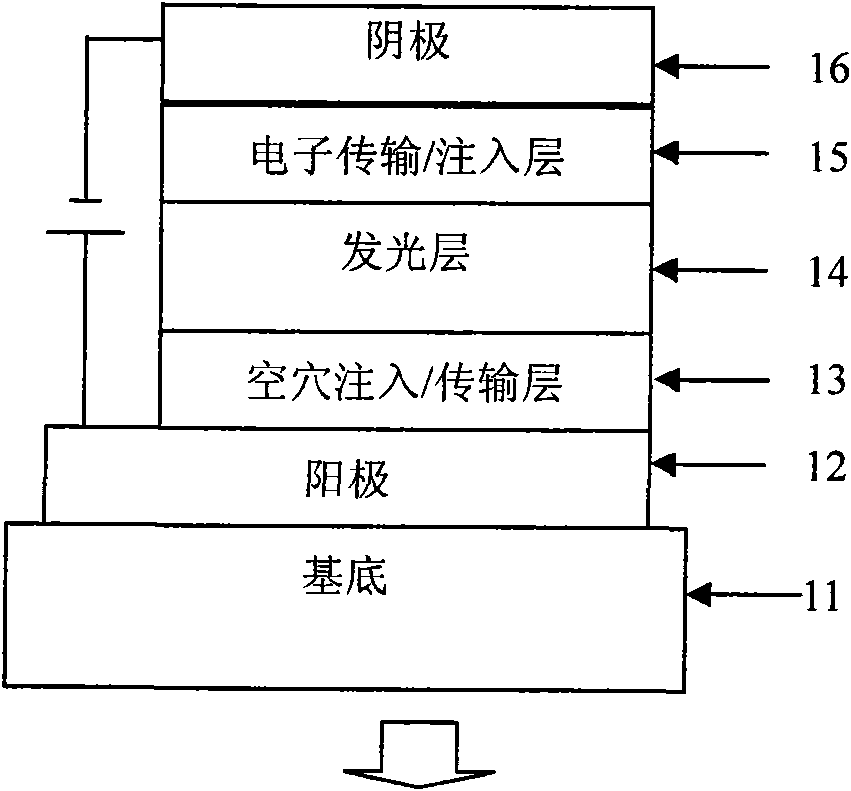

Organic light-emitting device

InactiveUS20110062481A1Reduce the impact of interferenceHigh yieldMaterial nanotechnologyElectroluminescent light sourcesLuminous intensityOrganic light emitting device

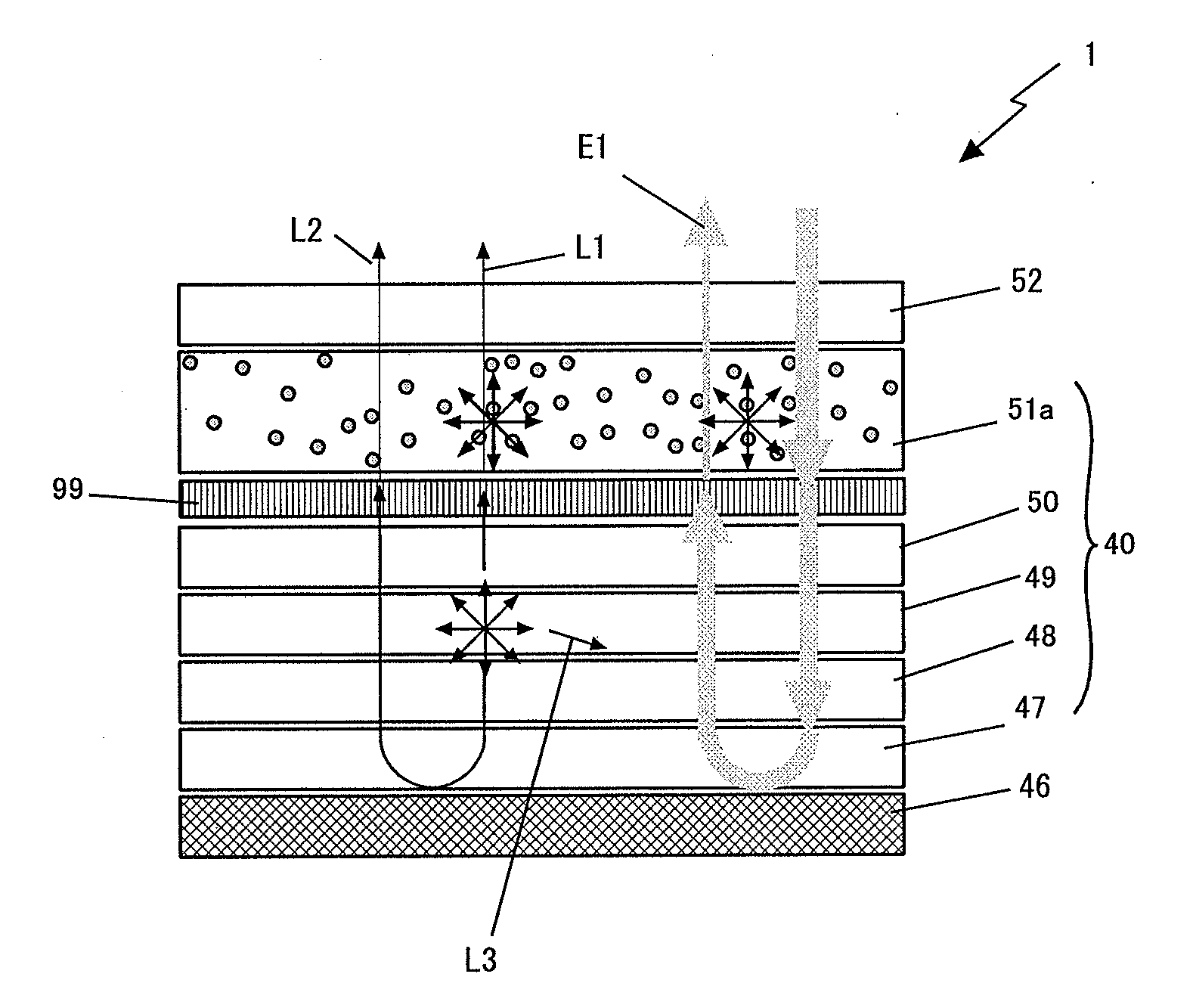

An organic light-emitting device cutting off ambient light while keeping emission intensity includes a pair of first and second electrodes opposed to each other; and a plurality of organic semiconductor layers layered and disposed between the first and second electrodes, wherein the organic semiconductor layers include an organic light-emitting layer, the organic semiconductor device further comprising a light-scattering layer layered and disposed between the organic light-emitting layer and at least one of the first and second electrodes. The light-scattering layer includes: organic materials having carrier injection and transport characteristics of transporting electrons and / or holes; and plural particles dispersed among the organic materials so that light emitted from the organic light-emitting layer is passed therethrough.

Owner:PIONEER CORP

Phosphor and Manufacturing Method Therefore, and Light Emission Device Using the Phosphor

InactiveUS20090236963A1High emission intensityImprove luminanceDischarge tube luminescnet screensLamp detailsUltravioletOxygen

To provide a phosphor having an emission spectrum with a broad peak in a range from green color to yellow color, having a broad and flat excitation band capable of using lights of broad range from near ultraviolet / ultraviolet to blue lights as excitation lights, and having excellent emission efficiency and luminance. The problem is solved by providing the phosphor expressed by a general composition formula MmAaBbOoNn:Z (where element M is one or more kinds of elements having bivalent valency, element A is one or more kinds of elements having tervalent valency, element B is one or more kinds of elements having tetravalent valency, O is oxygen, N is nitrogen, and element Z is one or more kinds of elements acting as the activator.), satisfying 4.0<(a+b) / m<7.0, a / m=0.5, b / a>2.5, n>o, n=2 / 3m+a+4 / 3b−2 / 3o, and having an emission spectrum with a peak wavelength of 500 nm to 650 nm when excited by light in a wavelength range from 300 nm to 500 nm.

Owner:MITSUBISHI CHEM CORP

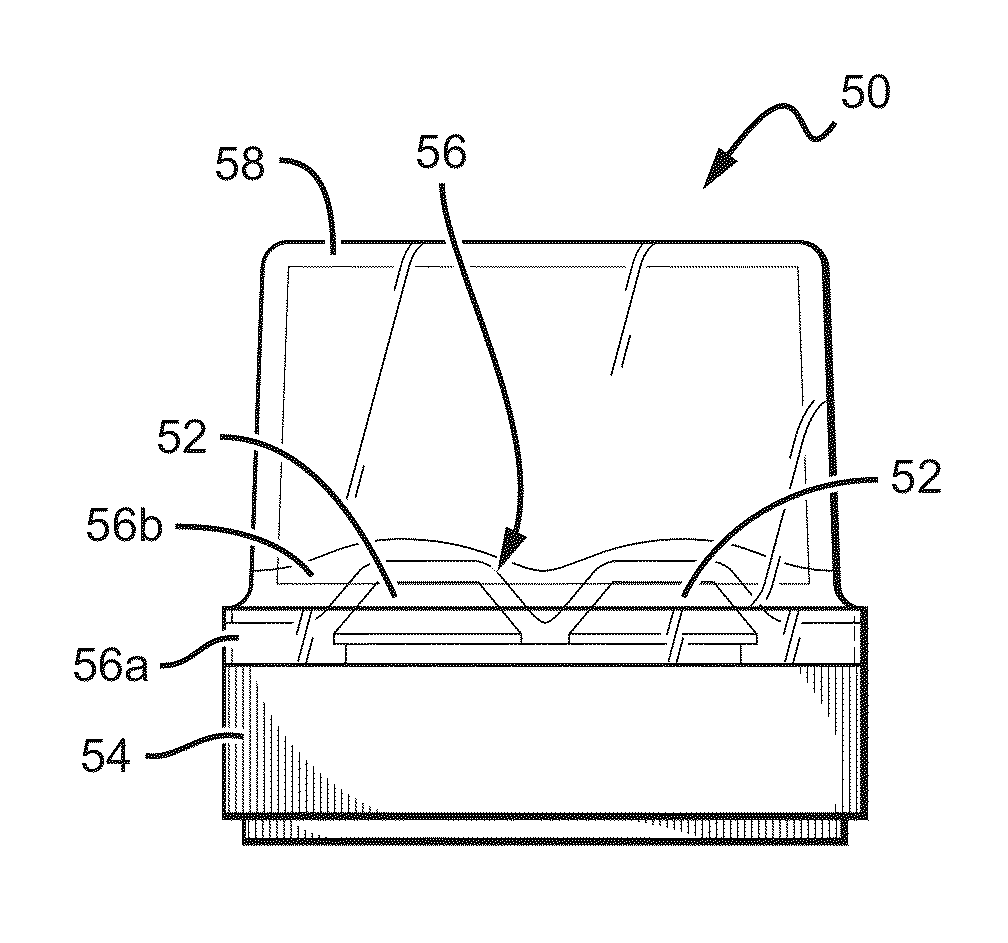

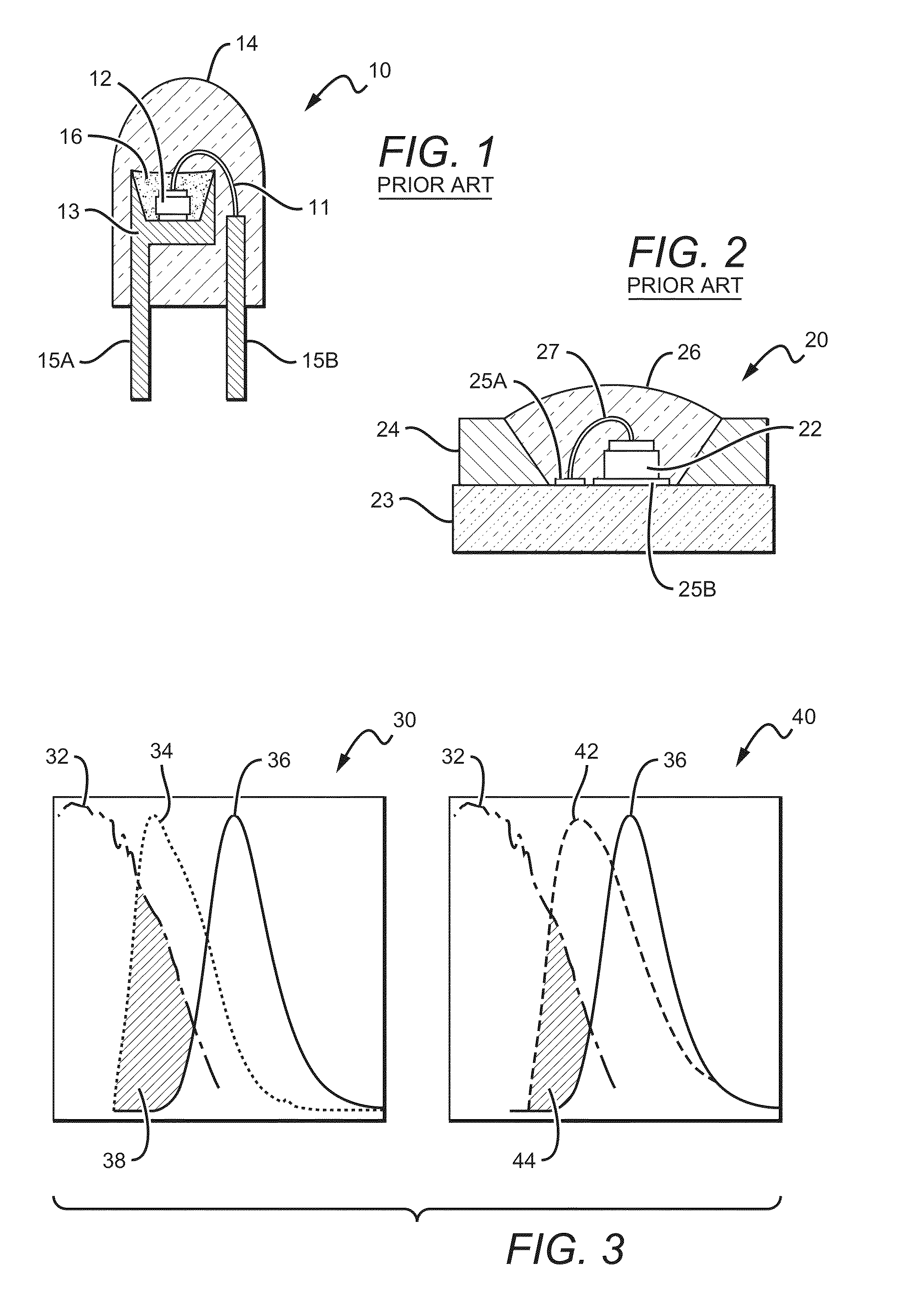

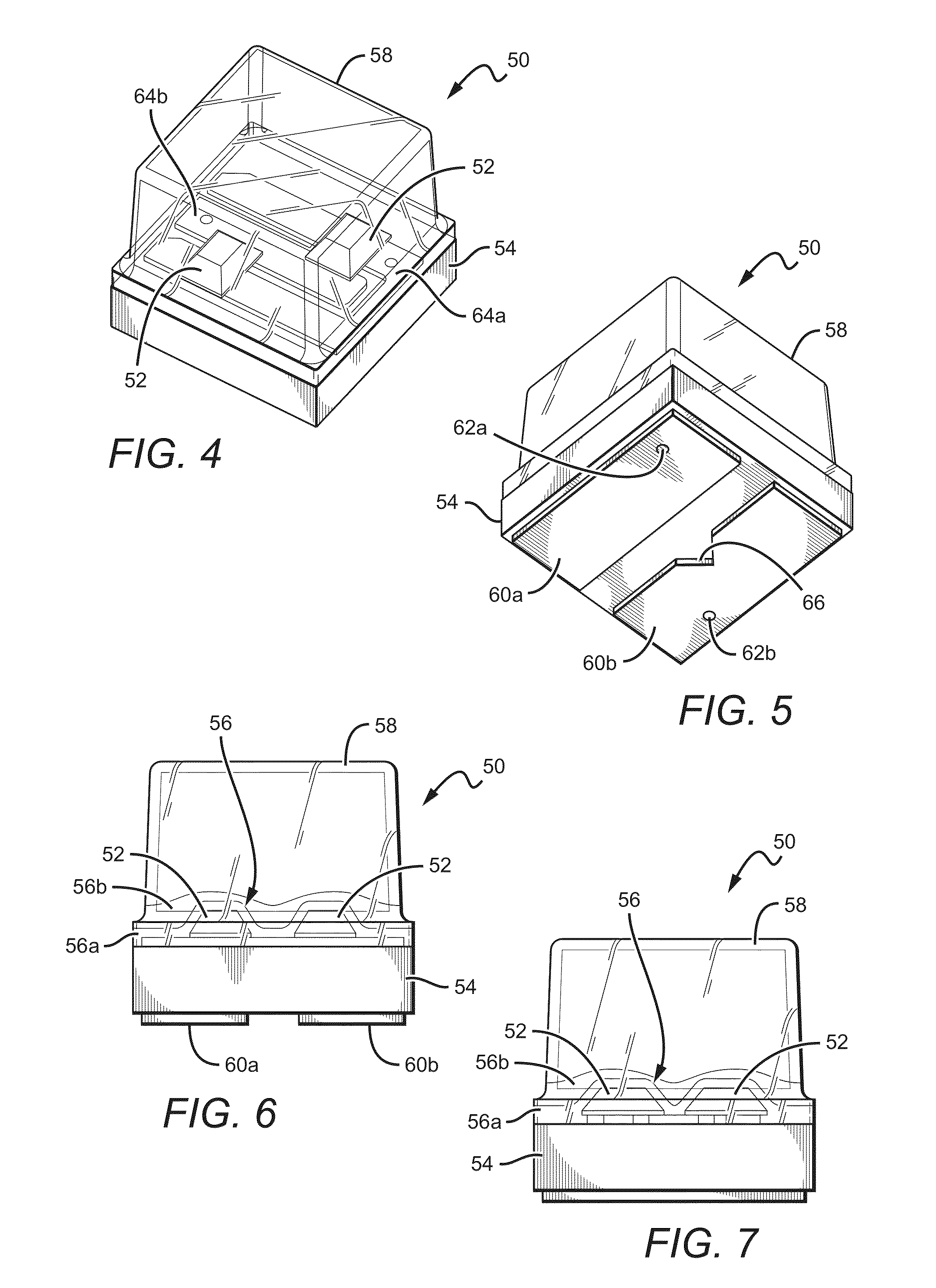

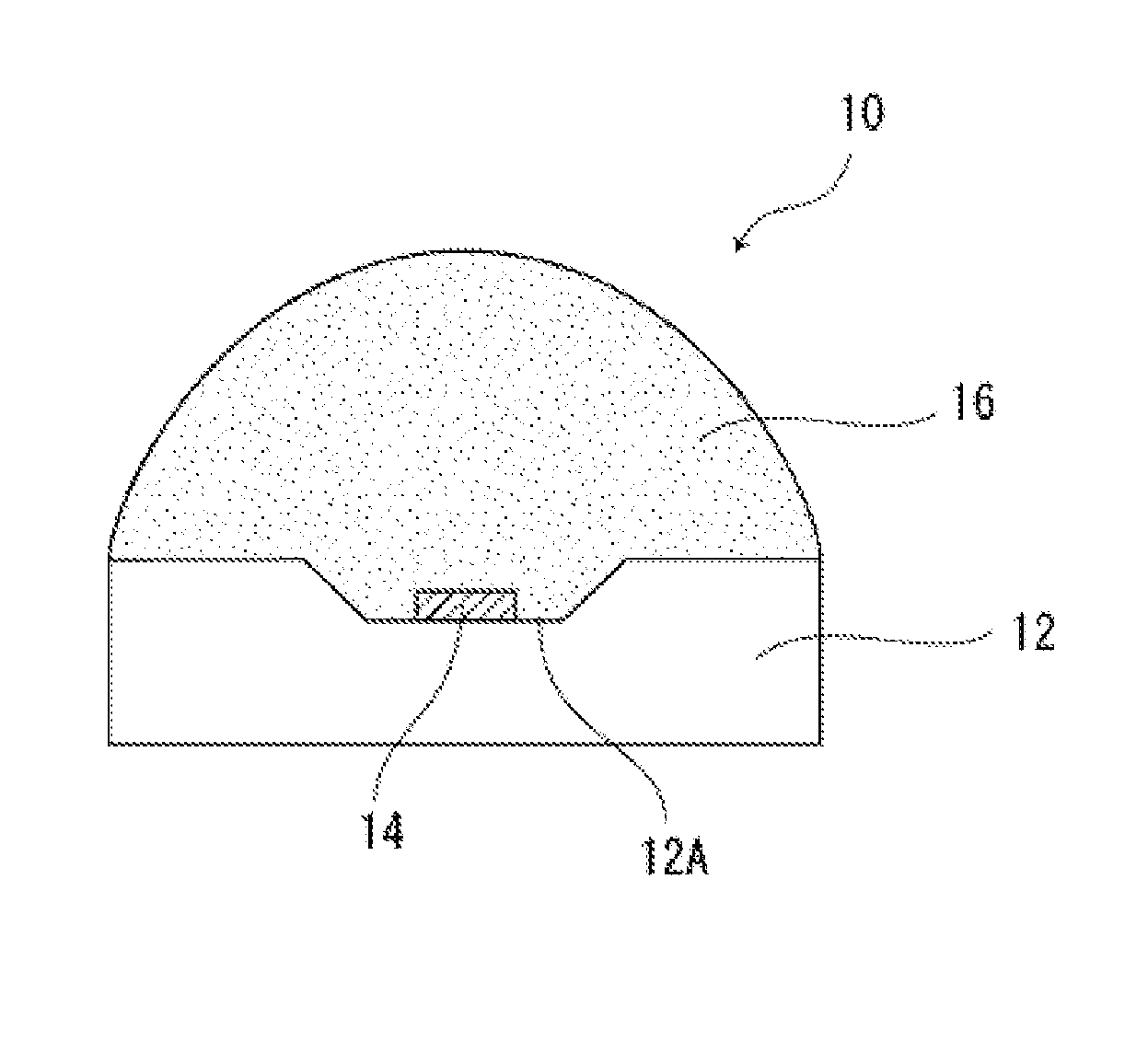

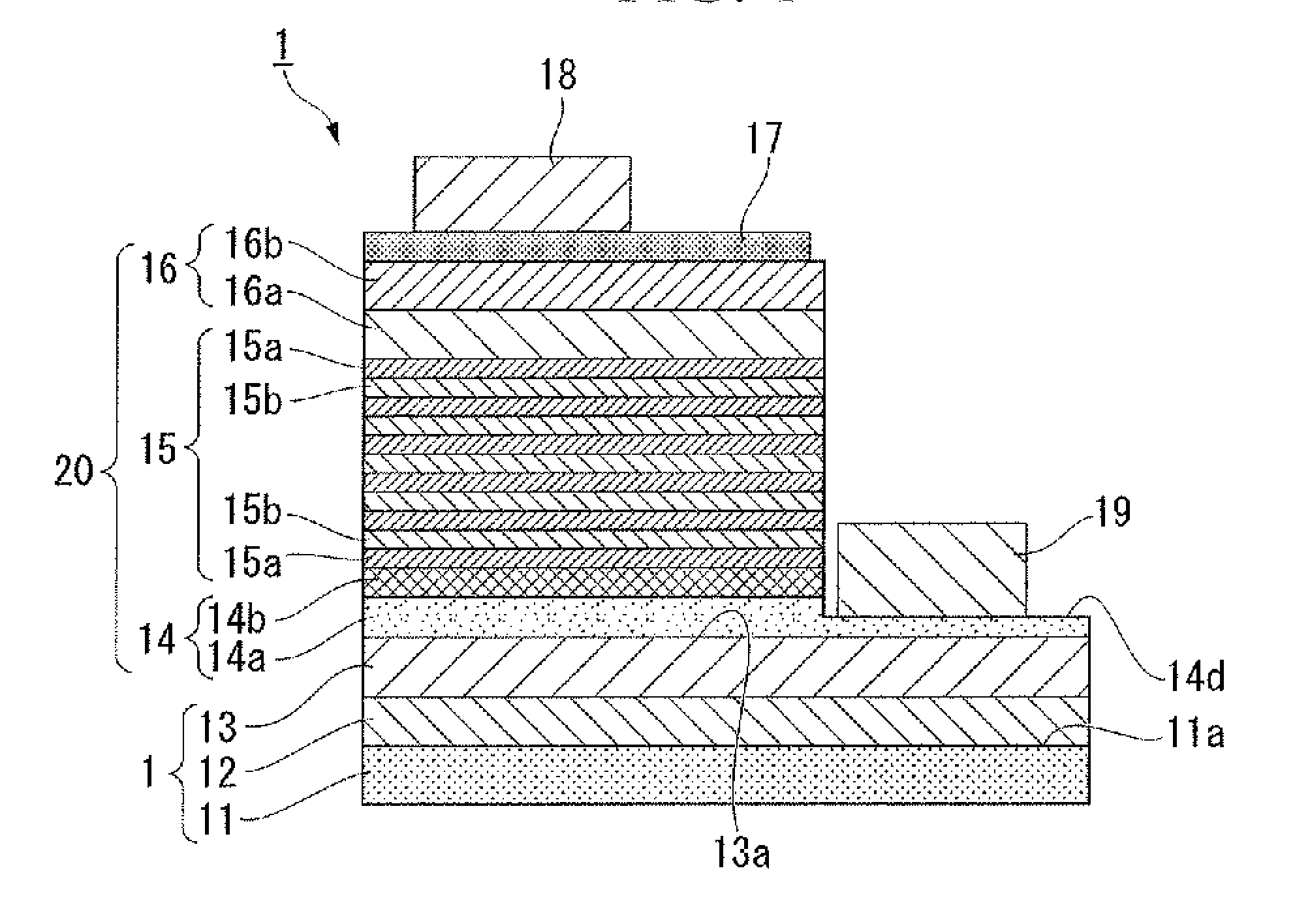

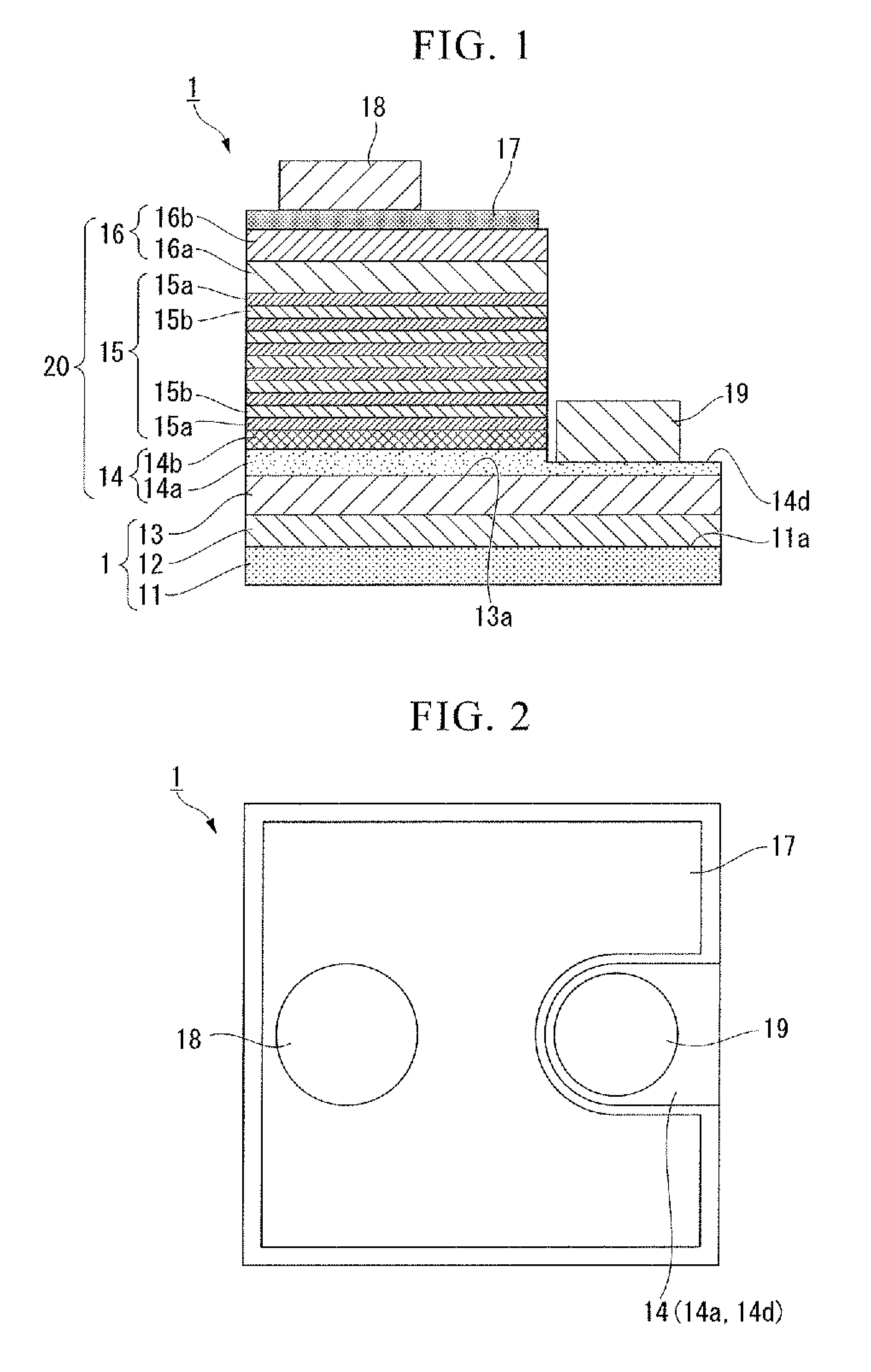

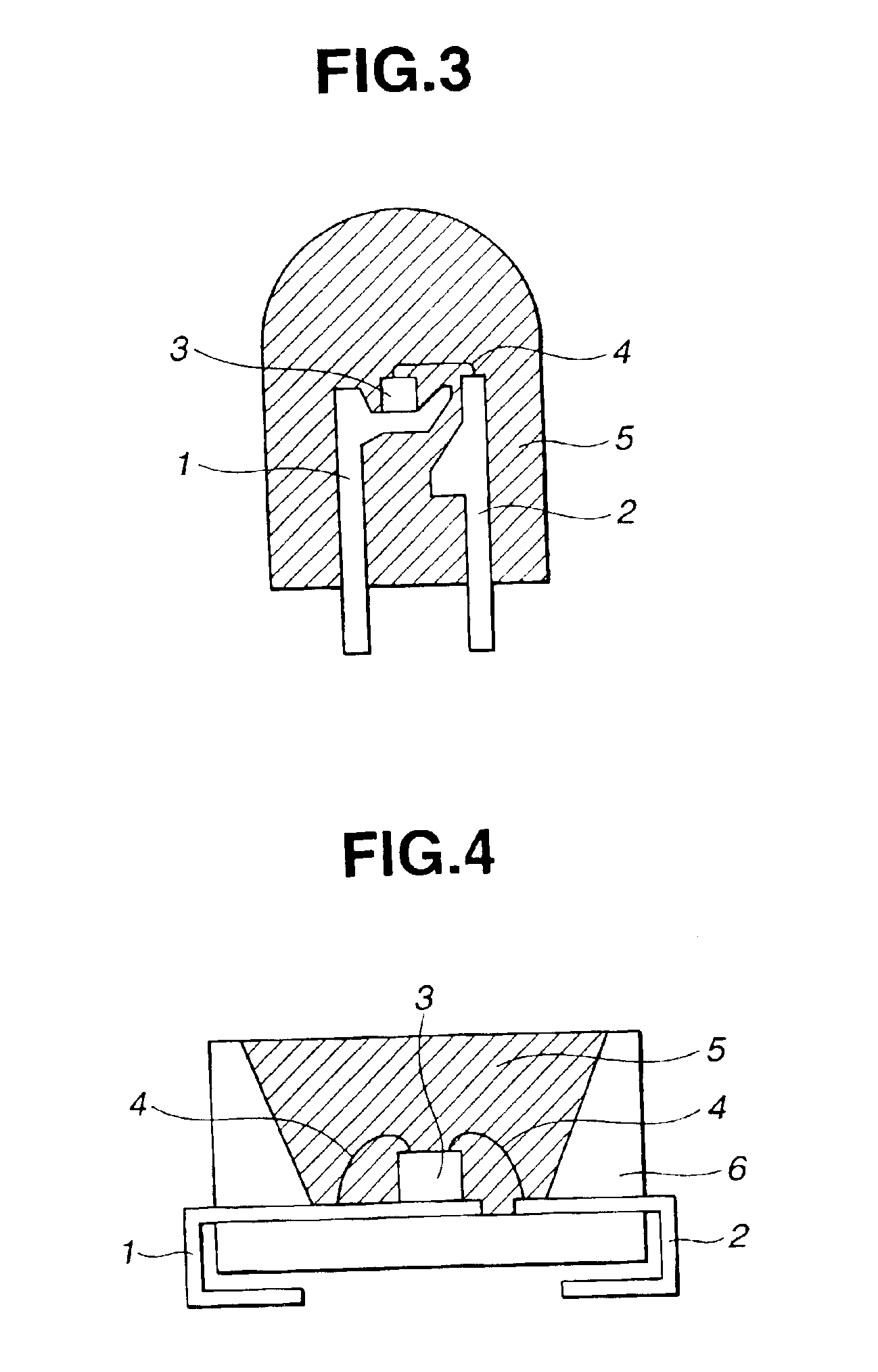

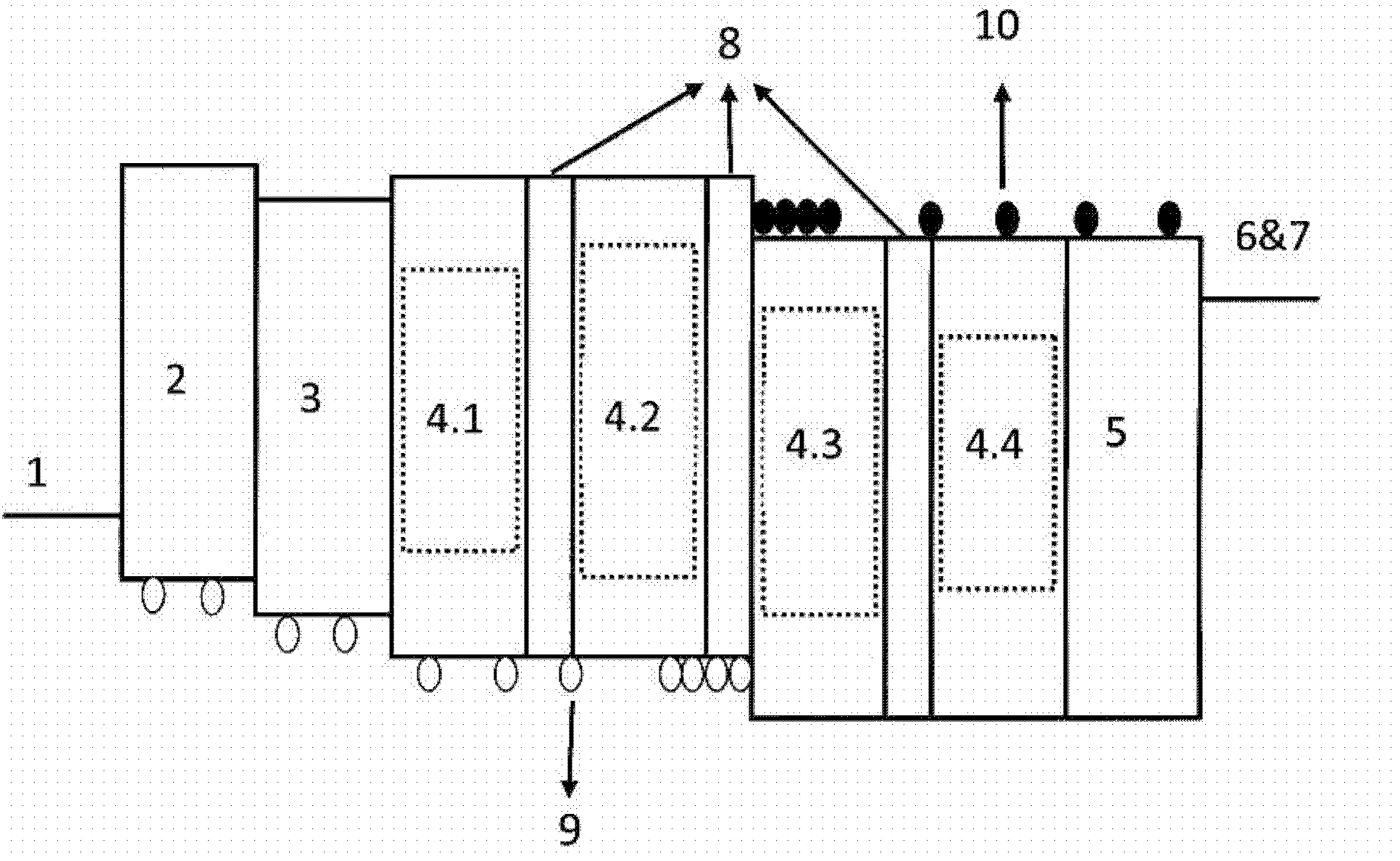

Multi-layer conversion material for down conversion in solid state lighting

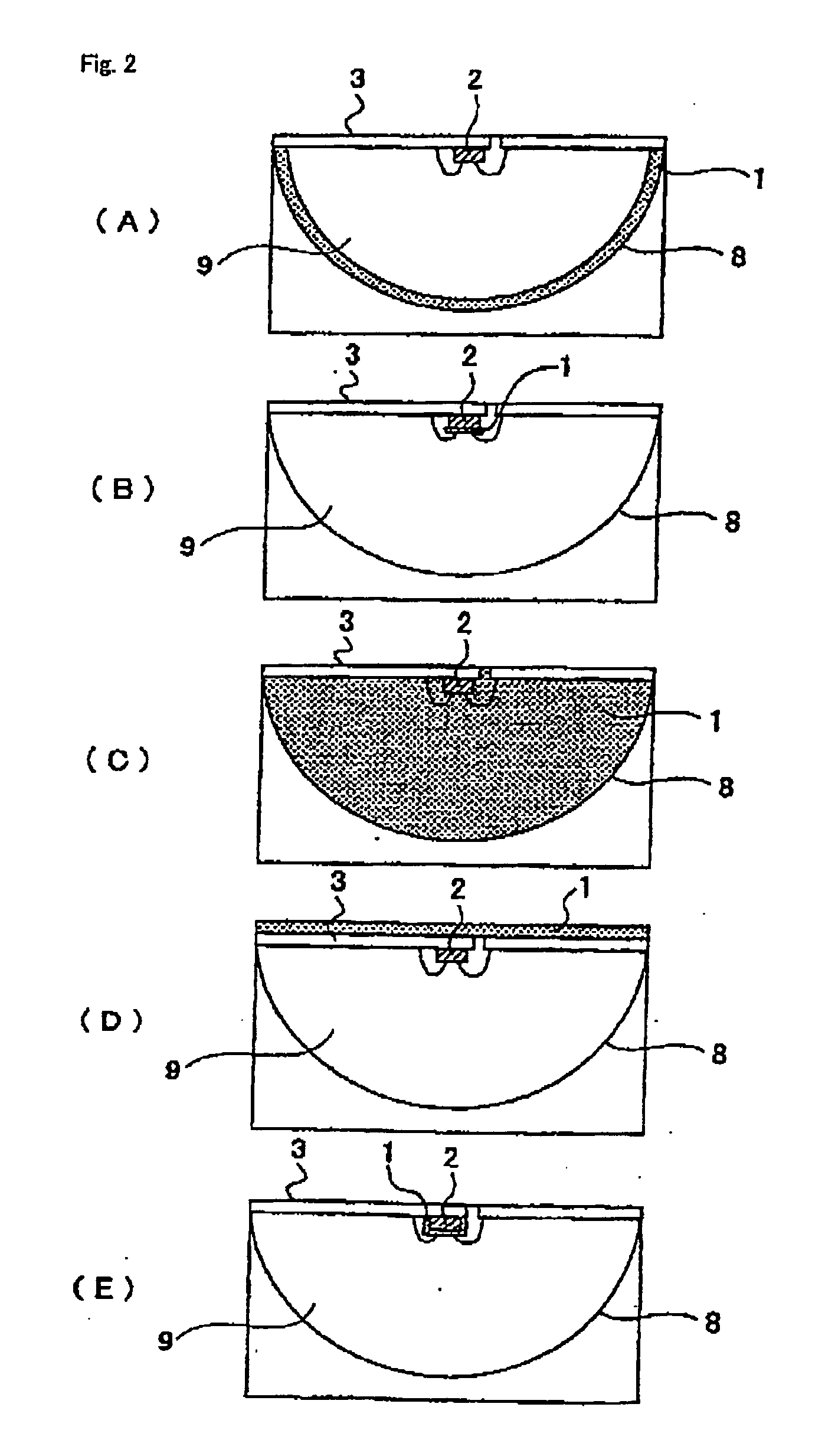

ActiveUS20140367713A1Improve featuresHigh emission intensityLight source combinationsSolid-state devicesPhosphorEngineering

Light emitting diodes are disclosed that utilize multiple conversion materials in the conversion process in order to achieve the desired emission color point. Different embodiments of the present invention can comprise different phosphor types in separate layers on, above or around one or a plurality of LED chips to achieve the desired light conversion. The LEDs can then emit a desired combination of light from the LED chips and conversion material. In some embodiments, conversion materials can be applied as layers of different phosphor types in order of longest emission wavelength phosphor first, followed by shorter emission phosphors in sequence as opposed to applying in a homogeneously mixed phosphor converter. The conversion material layers can be applied as a blanket over the LED chips and the area surrounding the chip, such as the surface of a submount holding the LED chips.

Owner:CREELED INC

Phosphor and manufacturing method therefore, and light emission device using the phosphor

InactiveUS7887718B2Emission intensity and luminance is not loweredExcellent durability against heat and waterDischarge tube luminescnet screensLamp detailsUltravioletPeak value

To provide a phosphor having an emission spectrum with a broad peak in a range from green color to yellow color, having a broad and flat excitation band capable of using lights of broad range from near ultraviolet / ultraviolet to blue lights as excitation lights, and having excellent emission efficiency and luminance. The problem is solved by providing the phosphor expressed by a general composition formula MmAaBbOoNn:Z (where element M is one or more kinds of elements having bivalent valency, element A is one or more kinds of elements having tervalent valency, element B is one or more kinds of elements having tetravalent valency, O is oxygen, N is nitrogen, and element Z is one or more kinds of elements acting as the activator), satisfying 4.0<(a+b) / m<7.0, a / m=0.5, b / a>2.5, n>o, n=2 / 3m+a+4 / 3b−2 / 3o, and having an emission spectrum with a peak wavelength of 500 nm to 650 nm when excited by light in a wavelength range from 300 nm to 500 nm.

Owner:MITSUBISHI CHEM CORP

Phosphor, manufacturing method of phosphor sheet and phosphor, and light emitting device using the phosphor

ActiveUS20100001631A1Less shiftingImprove emission efficiencyDischarge tube luminescnet screensCathode ray tubes/electron beam tubesUltravioletOxygen

To provide a phosphor given by a general composition formula expressed by MmAaBbOoNn:Z, (wherein element M is one or more kinds of elements having bivalent valency, element A is one or more kinds of elements having tervalent valency, element B is one or more kinds of elements having tetravalent valency, O is oxygen, N is nitrogen, and element Z is one or more kind of activating agent, satisfying m>0, a>0, b>0, o≧0, and n>0), with a change rate of a ratio of element B atoms to the total numbers of atoms being smaller by 10% or the change rate of oxygen atoms to the total numbers of atoms being smaller by 40% in a range from a particle surface up to depth 2000 nm, having a broad emission spectrum in a range of blue color, having a broad flat excitation band in a range of near ultraviolet / ultraviolet, and having excellent emission efficiency, emission intensity, and luminance.

Owner:NICHIA CORP +1

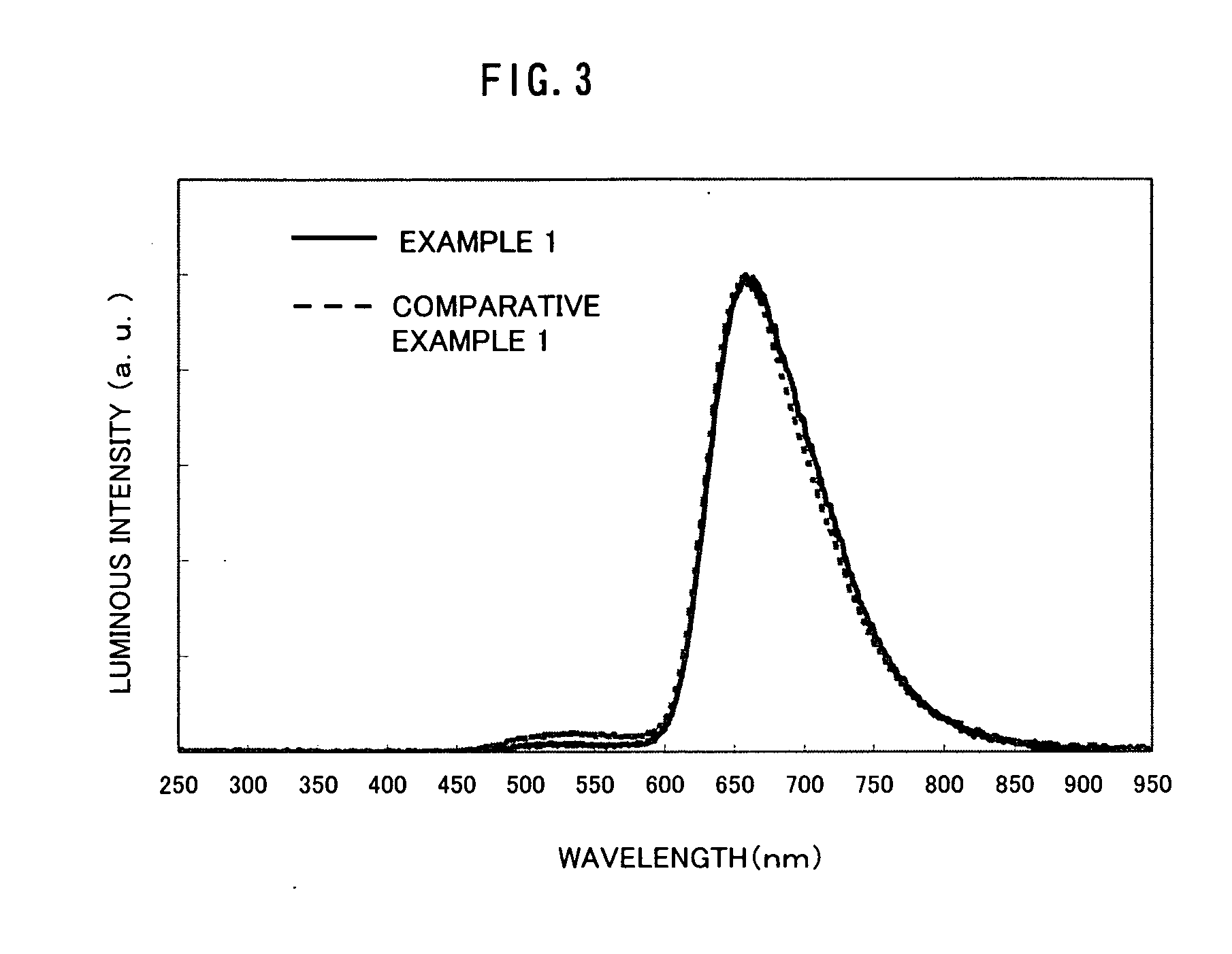

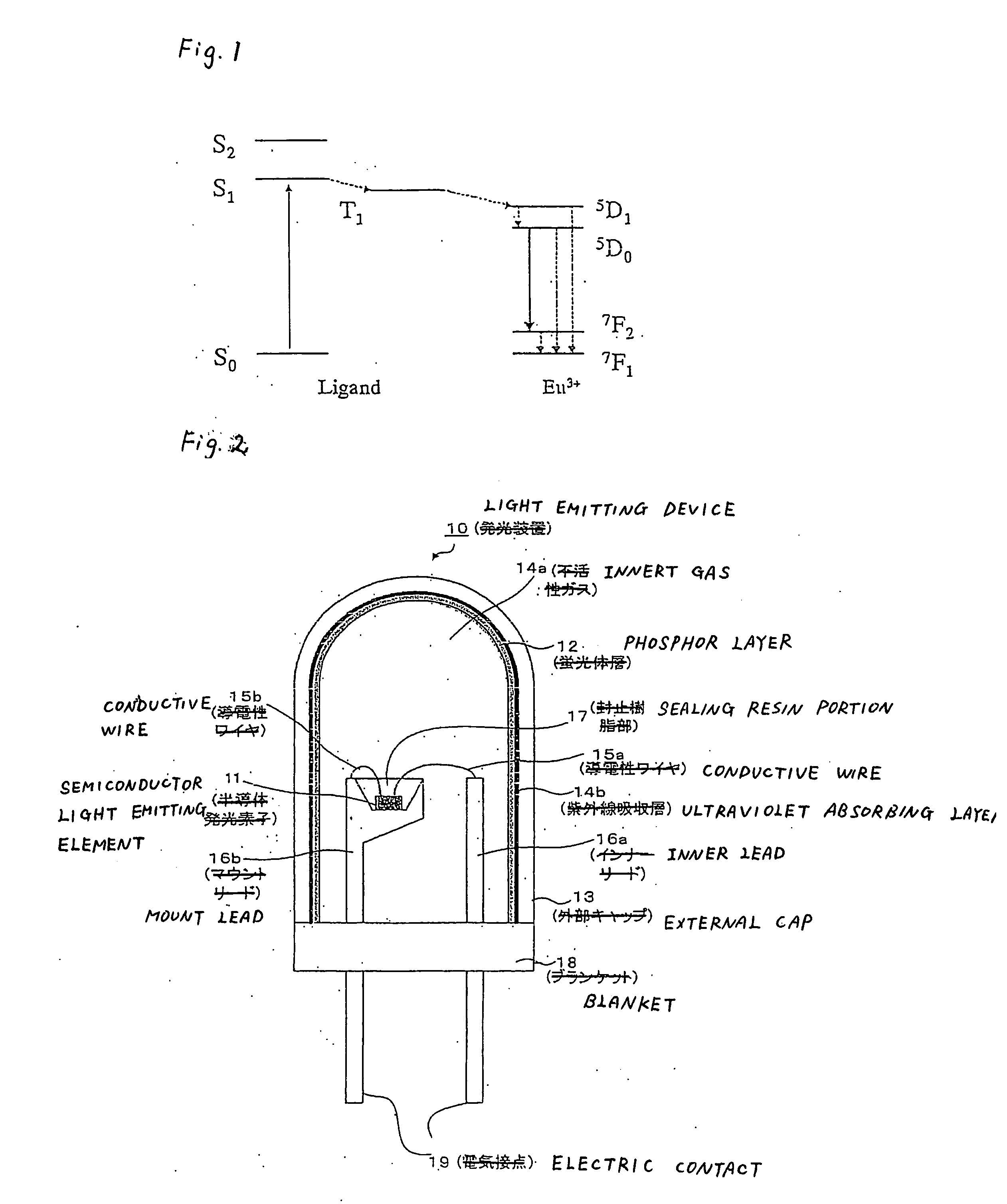

Light-emitting element and light-emitting device

InactiveUS20060263637A1High emission intensityDischarge tube luminescnet screensElectroluminescent light sourcesChemistryVisibility

The present invention provides a substance that is capable of emitting red phosphorescence which is closer to a chromaticity coordinate for red of NTSC standard. The present invention provides an organometallic complex represented by a general formula (1). In the formula (1), R1 to R3 are individually either hydrogen, a halogen element, an acyl group, an alkyl group, an alkoxyl group, an aryl group, a cyano group, or a heterocyclic group. At least of R1 to R3 represents an electron withdrawing group. M is one of an element of Group 9 and an element of Group 10, and n=2 when the M is an element of Group 9 while n=1 when the M is an element of Group 10. In such an organometallic complex, red phosphorescence with higher visibility which is closer to a chromaticity coordinate for red of NTSC standard can be emitted.

Owner:SEMICON ENERGY LAB CO LTD

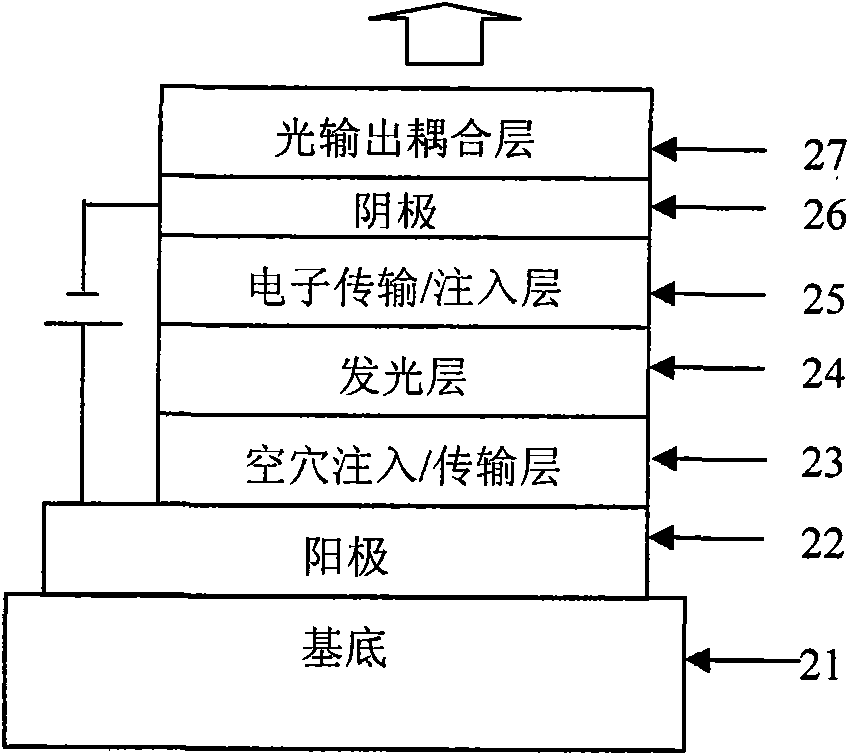

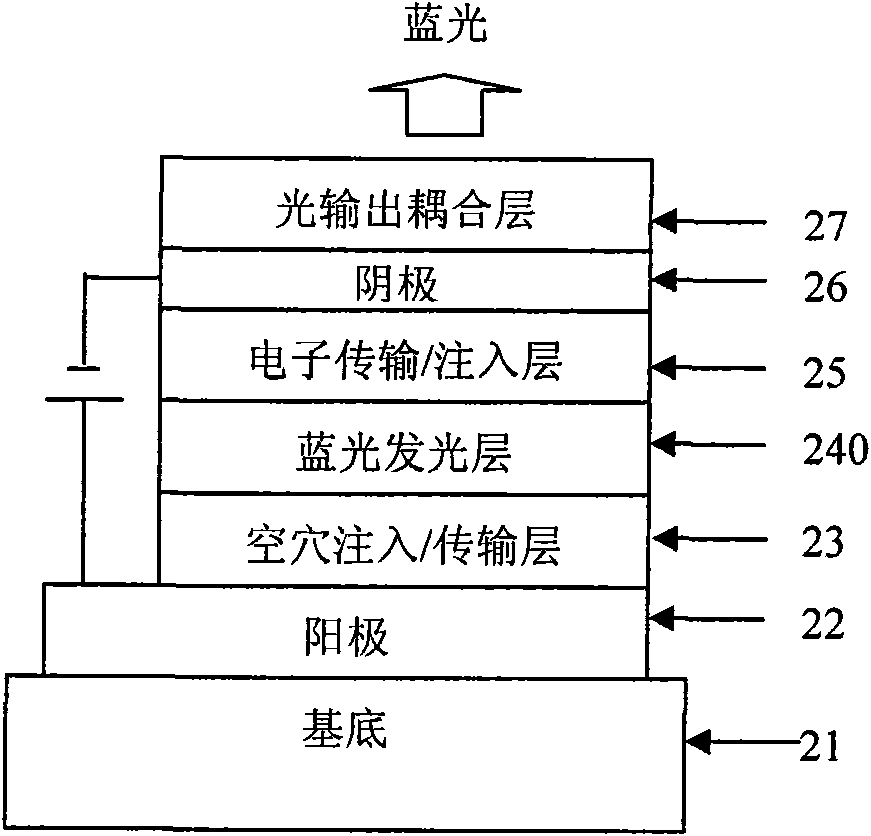

Blue-light top luminous organic diode structure and fabricating method thereof

InactiveCN101540373AEliminate complex plate-checking proceduresEliminate the version control programSolid-state devicesSemiconductor/solid-state device manufacturingCouplingLight beam

The invention provides a blue-light top luminous organic diode structure and a fabricating method thereof. The blue-light top luminous organic diode structure comprises a substrate, a reflection electrode (anode) positioned on the substrate, a hole injection / transmitting layer positioned on the reflection layer, a blue-light luminous layer positioned on the hole injection / transmitting layer, an electronic transmitting / injection layer positioned on the blue-light luminous layer, a semitransparent metal electrode (cathode) positioned on the electronic transmitting / injection layer, and a light output coupling layer positioned on the electronic transmitting / injection layer. The invention realizes the transmission of blue light through using the light output coupling layer to inhibit the microcavity effect (multiple beam interference effect), and realizes the strengthened blue light transmission by utilizing the wide-angle interference effect. The method can conveniently realize the coherent enhancement of the blue light strength through controlling the thickness of the hole injection / transmitting layer, and has potential application value.

Owner:NANJING UNIV OF POSTS & TELECOMM

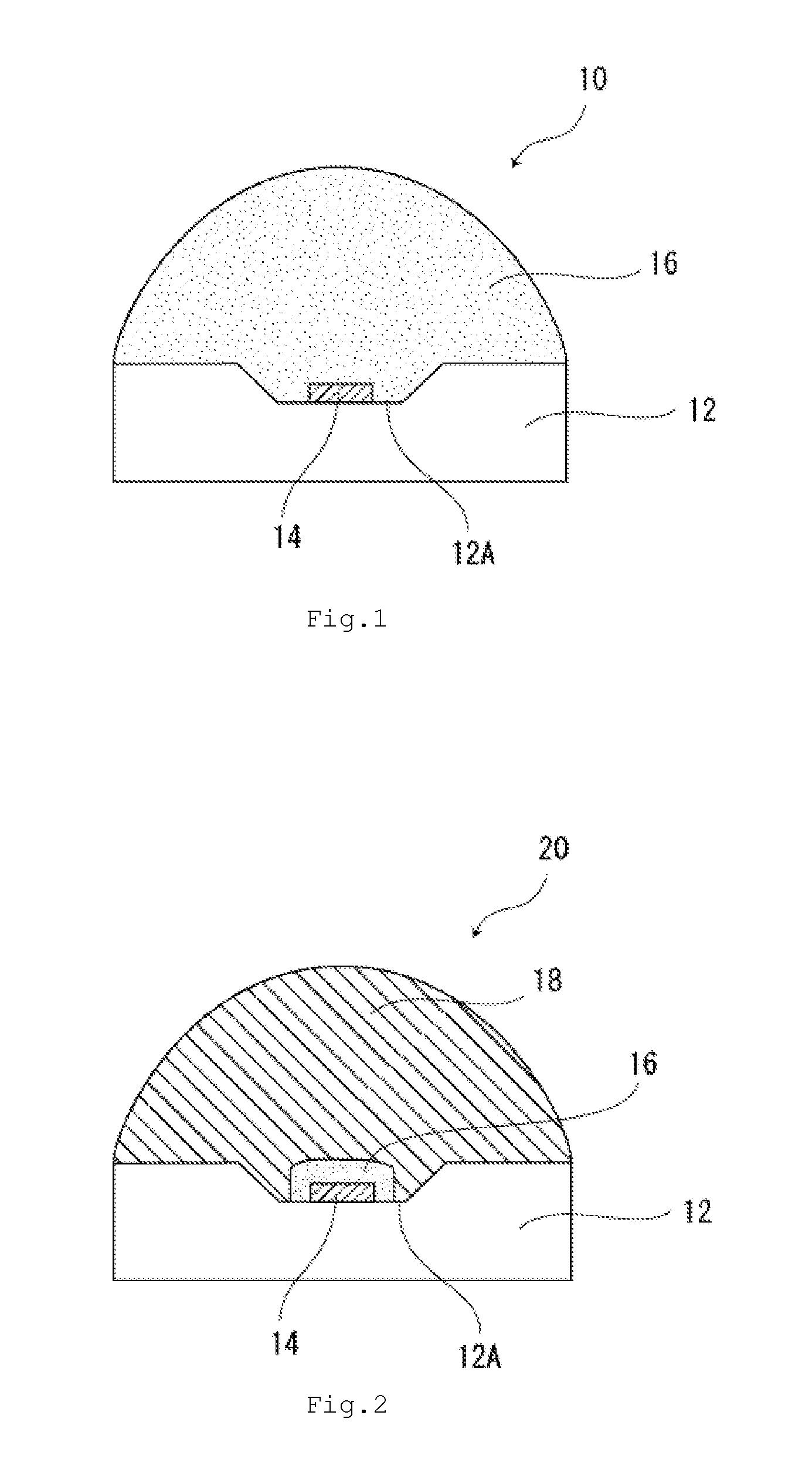

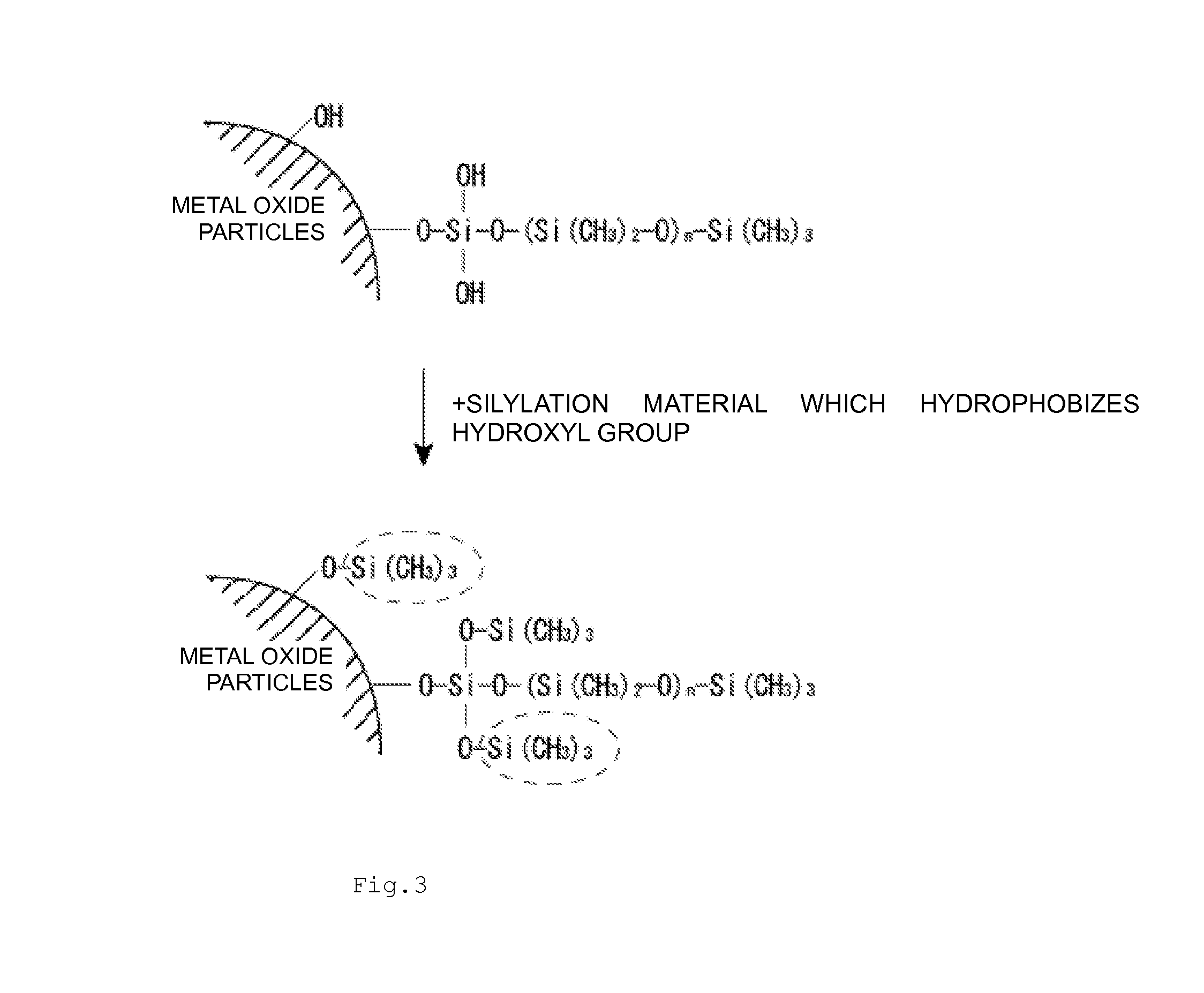

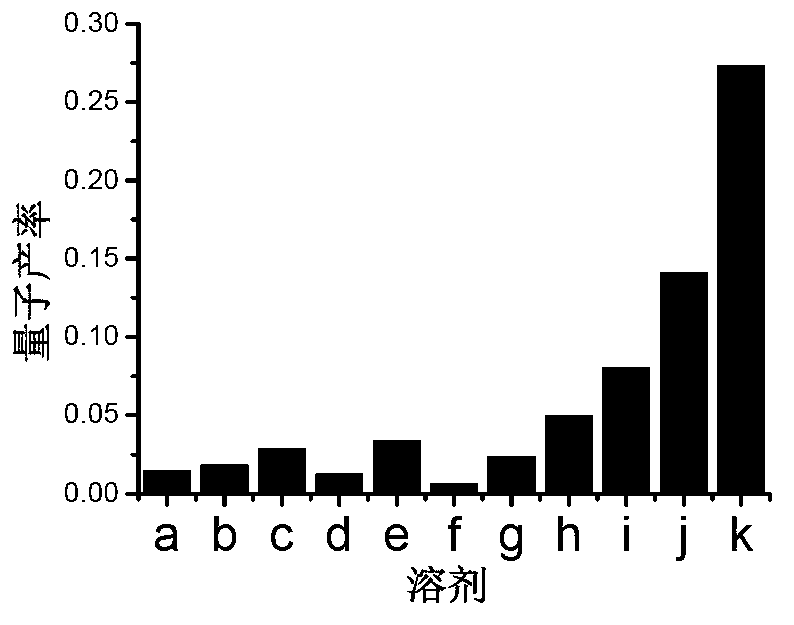

Surface-modified-metal-oxide-particle material, composition for sealing optical semiconductor element, and optical semiconductor device

ActiveUS20150021643A1Low viscosityImprove featuresPigmenting treatmentMaterial nanotechnologyTransmittanceLength wave

There is provided a surface-modified-metal-oxide-particle material including surface-modified-metal-oxide-particles obtained by performing surface modification on metal oxide particles with a surface-modifying material, in which the surface-modifying material includes a predetermined silicone compound, an average primary particle diameter of the metal oxide particles is 3 nm to nm, viscosity at 25° C. is 1000 Pa·s or less, and transmittance of light at a wavelength of 400 nm to 800 nm and a thickness of 1 mm is 60% or greater, a composition for sealing optical semiconductor element, and an optical semiconductor device using the same.

Owner:SUMITOMO OSAKA CEMENT CO LTD

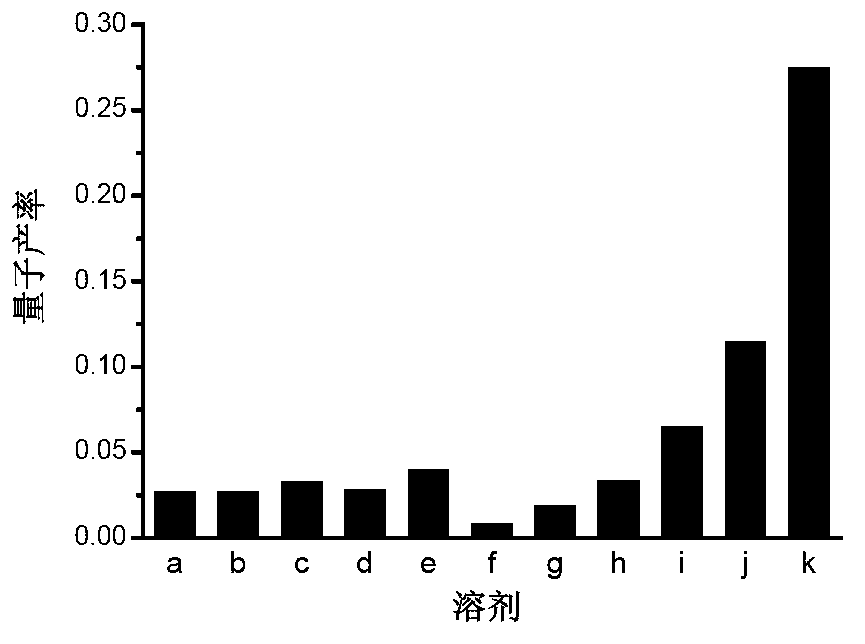

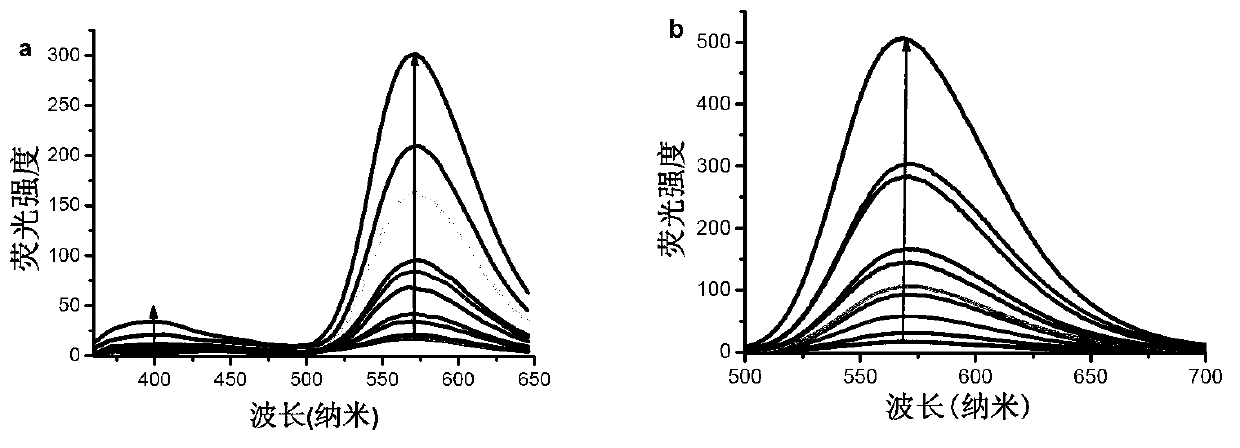

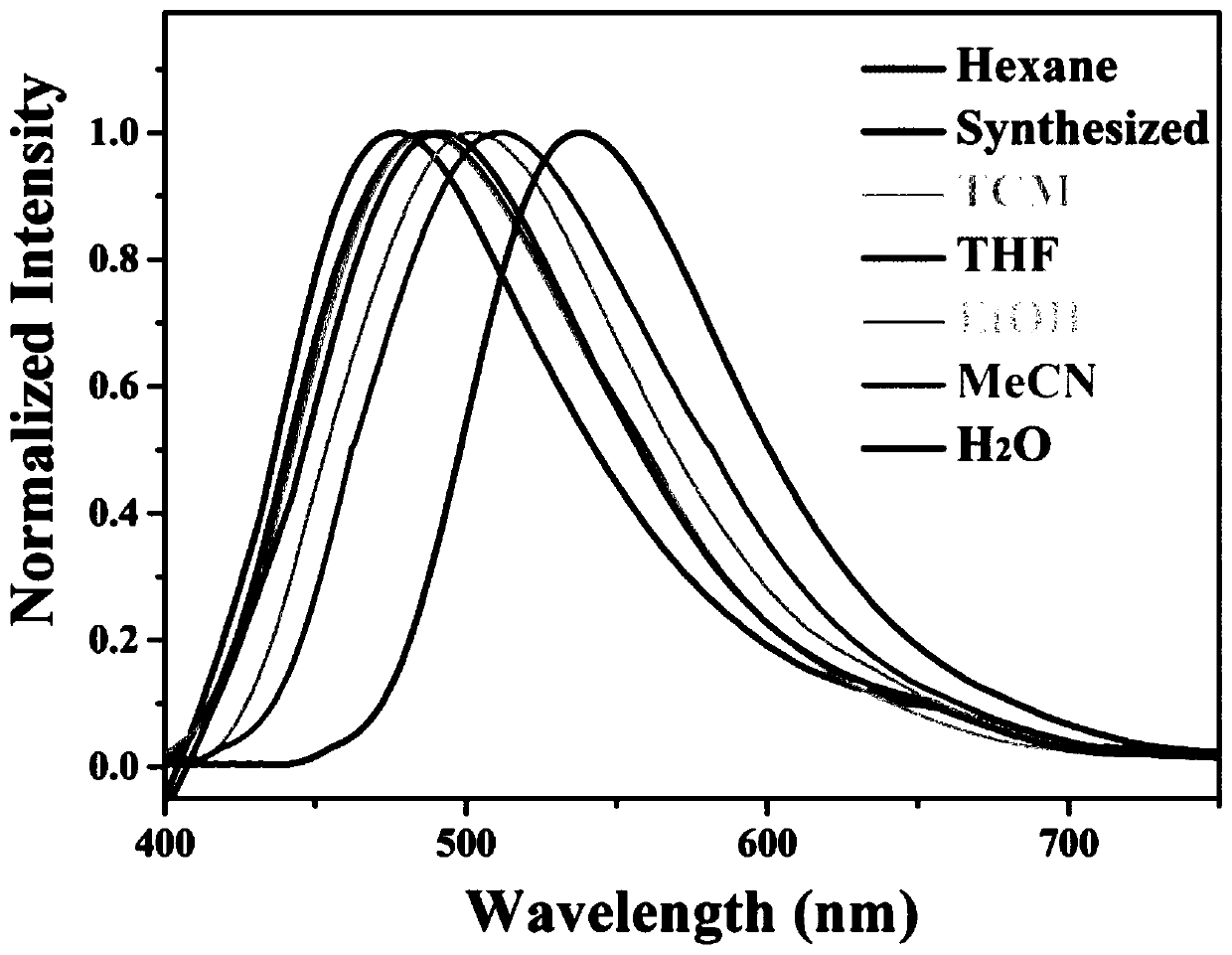

Carbazole hemicyanine fluorescent dye and application thereof

ActiveCN102757659AHigh emission intensityHigh viscosityMethine/polymethine dyesFlow propertiesIonHalogen

The invention relates to a carbazole hemicyanine fluorescent dye and application thereof. The carbazole hemicyanine fluorescent dye has a structural general formula I, in which R1 and R2 are independently slected from hydrogen and C1-6 alkyl, C1-6 hydroxy instead of alkyl and C1-6 alkoxy; R3 is H or a formaldehyde radical; and Y is a halogen negative ion. The dye provided by the invention has sensitive response to the change of environment viscosity, the influence on the fluorescent property caused by solvent polarities is very little, and the dye has a two-photon property and can detect the environment viscosity by a ratio method. Therefore, the dye provided by the invention can be used for detecting the change of microenvironment viscosity of cells and tissues.

Owner:DALIAN UNIV OF TECH +1

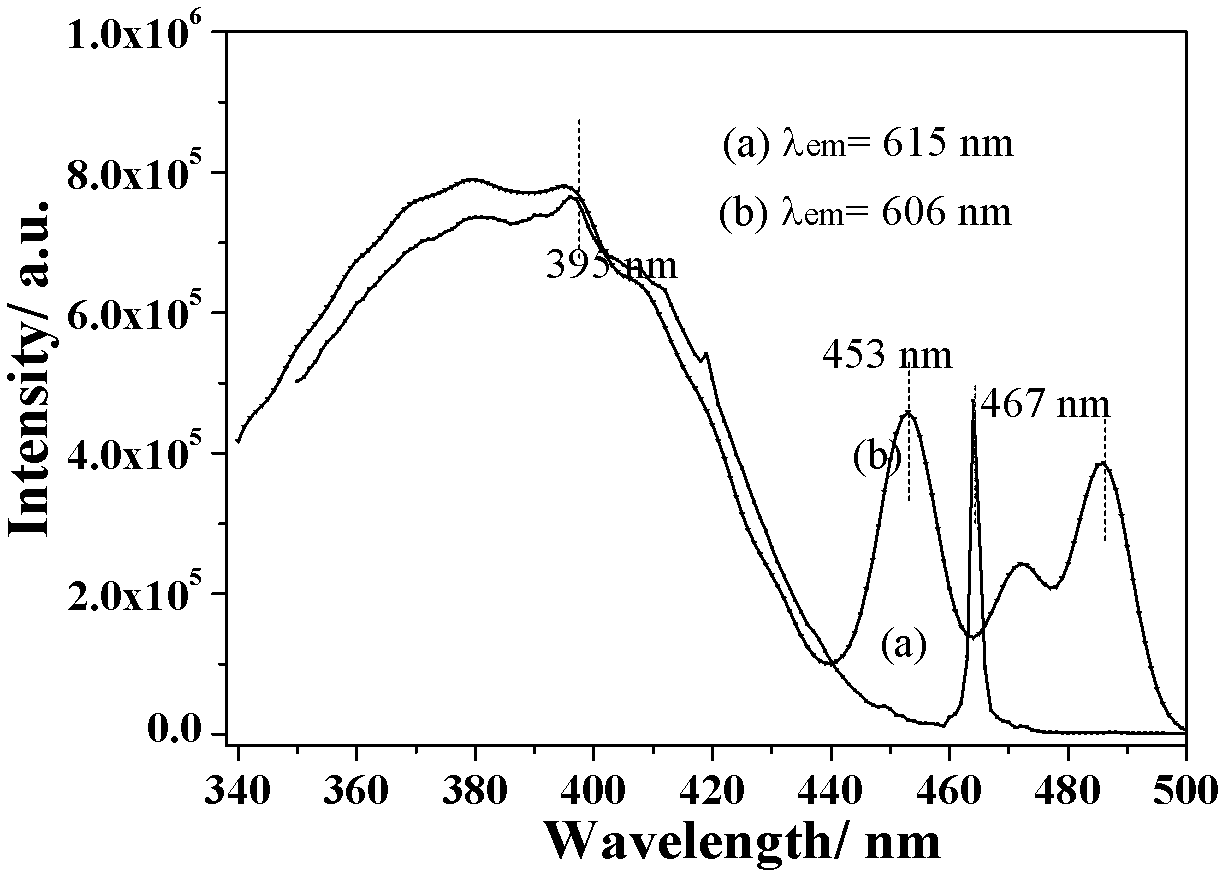

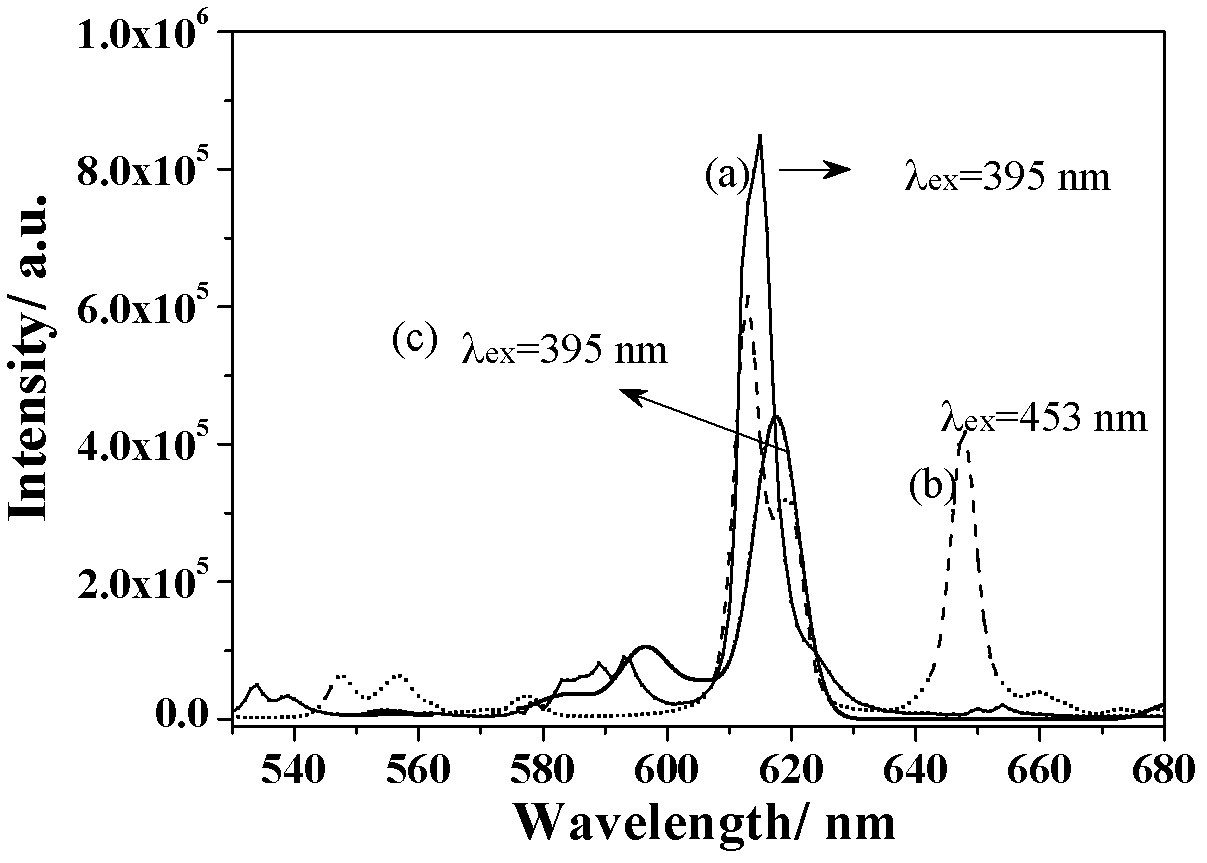

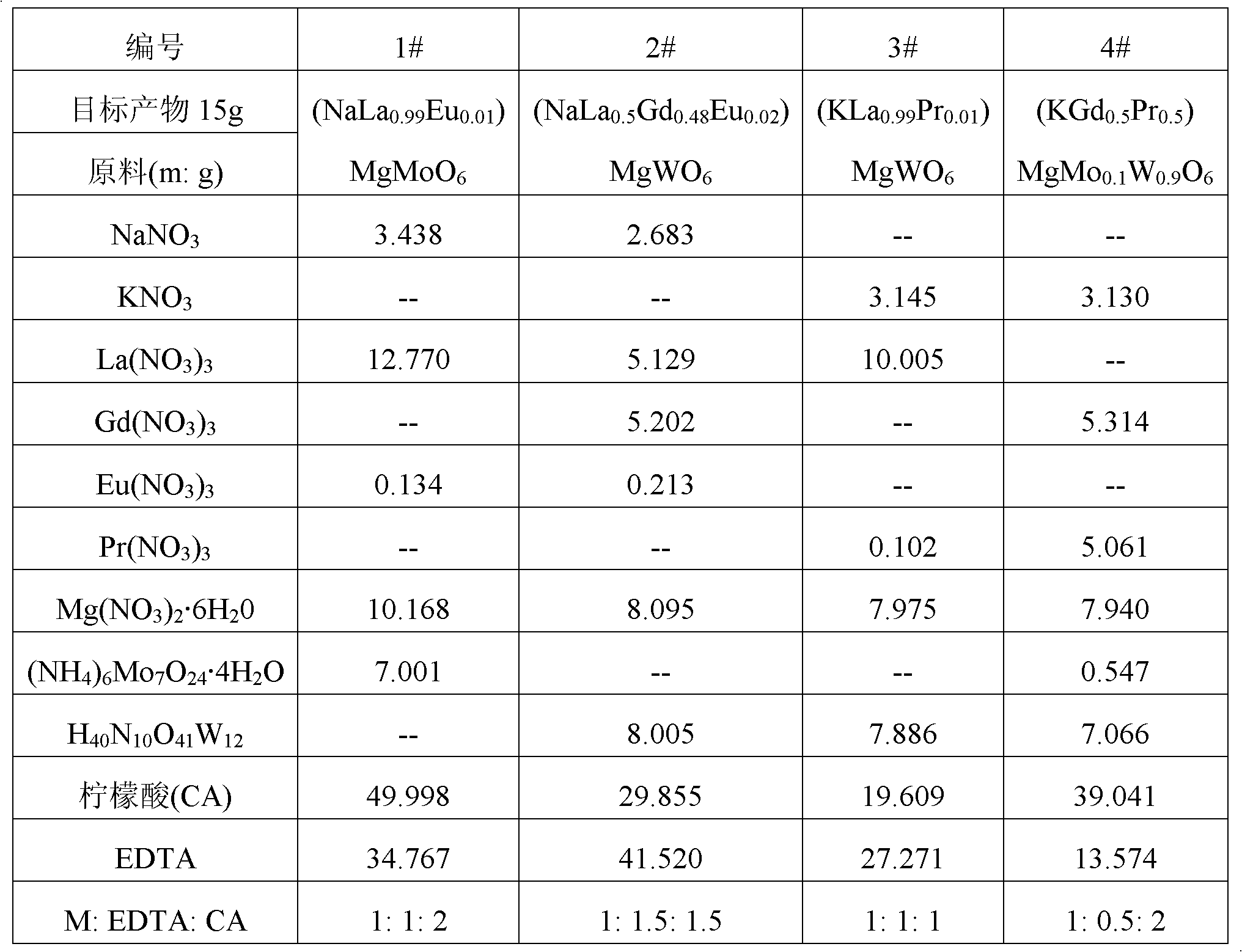

Red double-perovskite fluorescent powder for white-light LEDs and preparation method of red double-perovskite fluorescent powder

ActiveCN102634340AGood color renderingHigh emission intensityGas discharge lamp usageLuminescent compositionsRare-earth elementIon

The invention relates to a red double-perovskite fluorescent powder for white-light LEDs and a preparation method of the red double-perovskite fluorescent powder. The red double-perovskite fluorescent powder is characterized by comprising double-perovskite components shown in the following formula: (AA'1-xMex)MgMO<6>, wherein the A is one of Na or K, the A' is one of La or Gd or composition of the La and the Gd, the M is one of W or Mo or composition of the W and the Mo, the Me is one of rare-earth element Eu or Pr, and the x is larger than or equal to 0.005 and is smaller than or equal to 0.5. The fluorescent powder is prepared by means of sol-gel, single-phase double-perovskite oxide powder can be obtained at the lower temperature and in shorter time, mixing of ions or atoms can be realized by active ions of rare earth, test period is short and stability is fine.

Owner:武汉视美乐激光显示发展有限公司

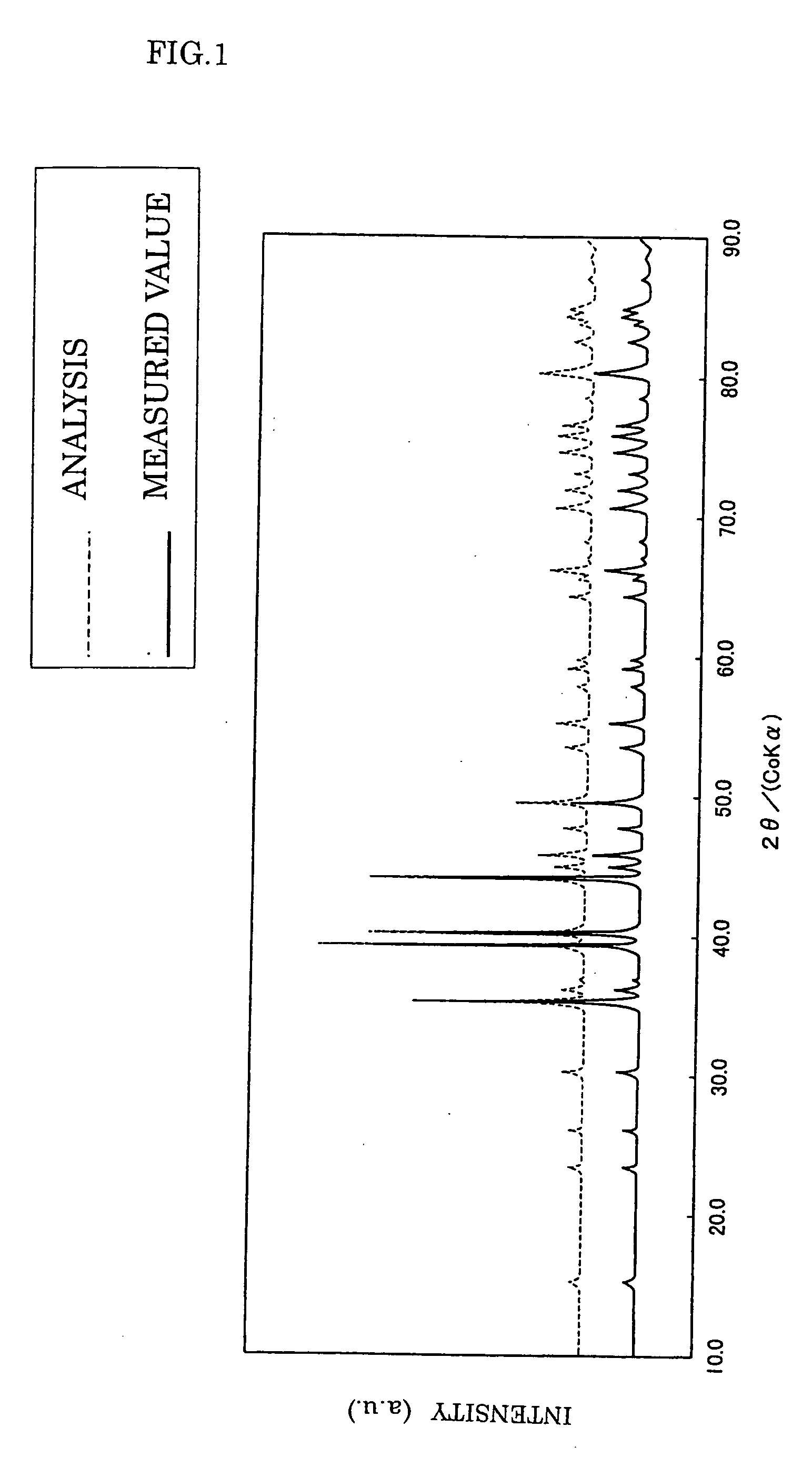

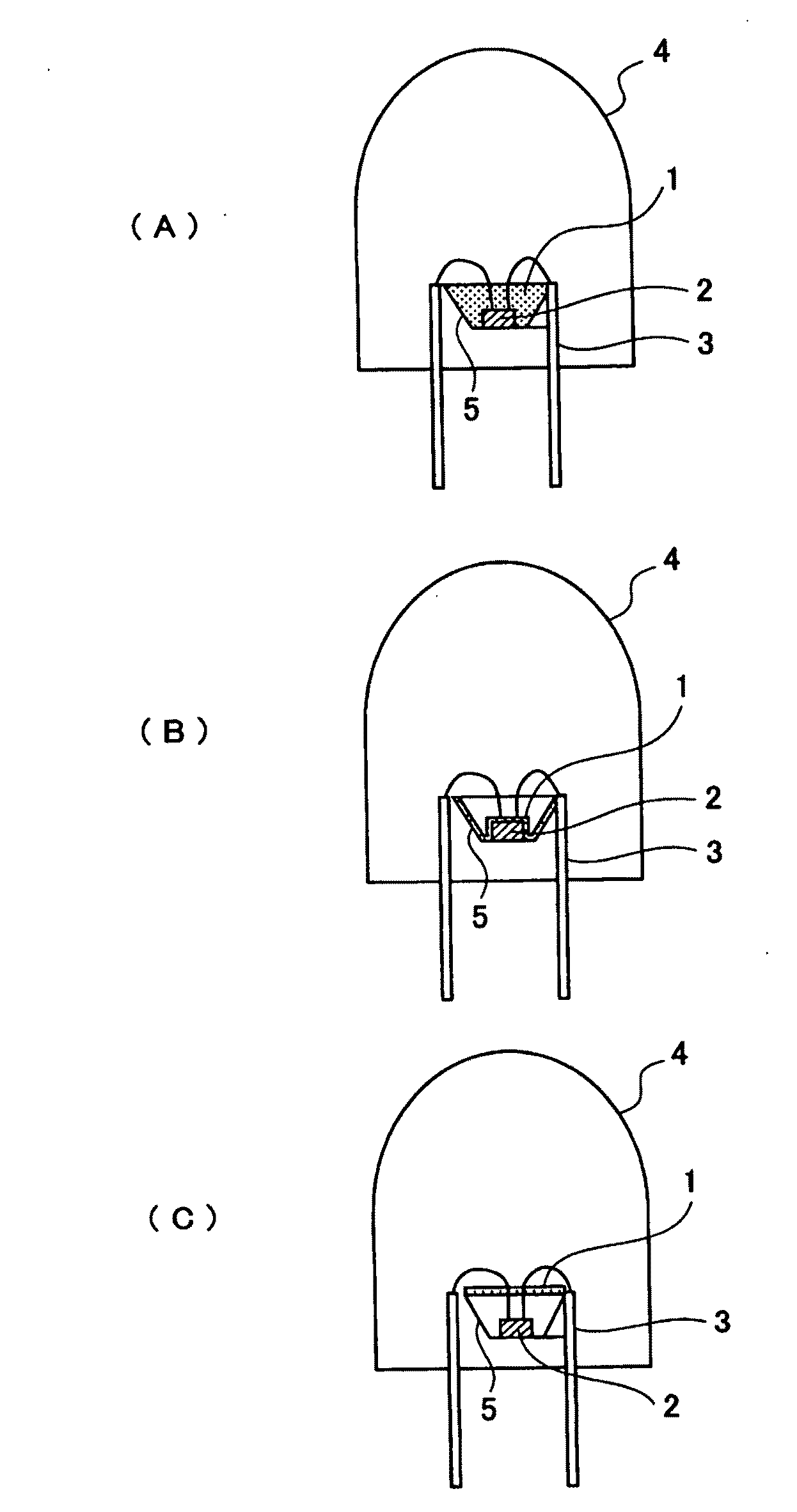

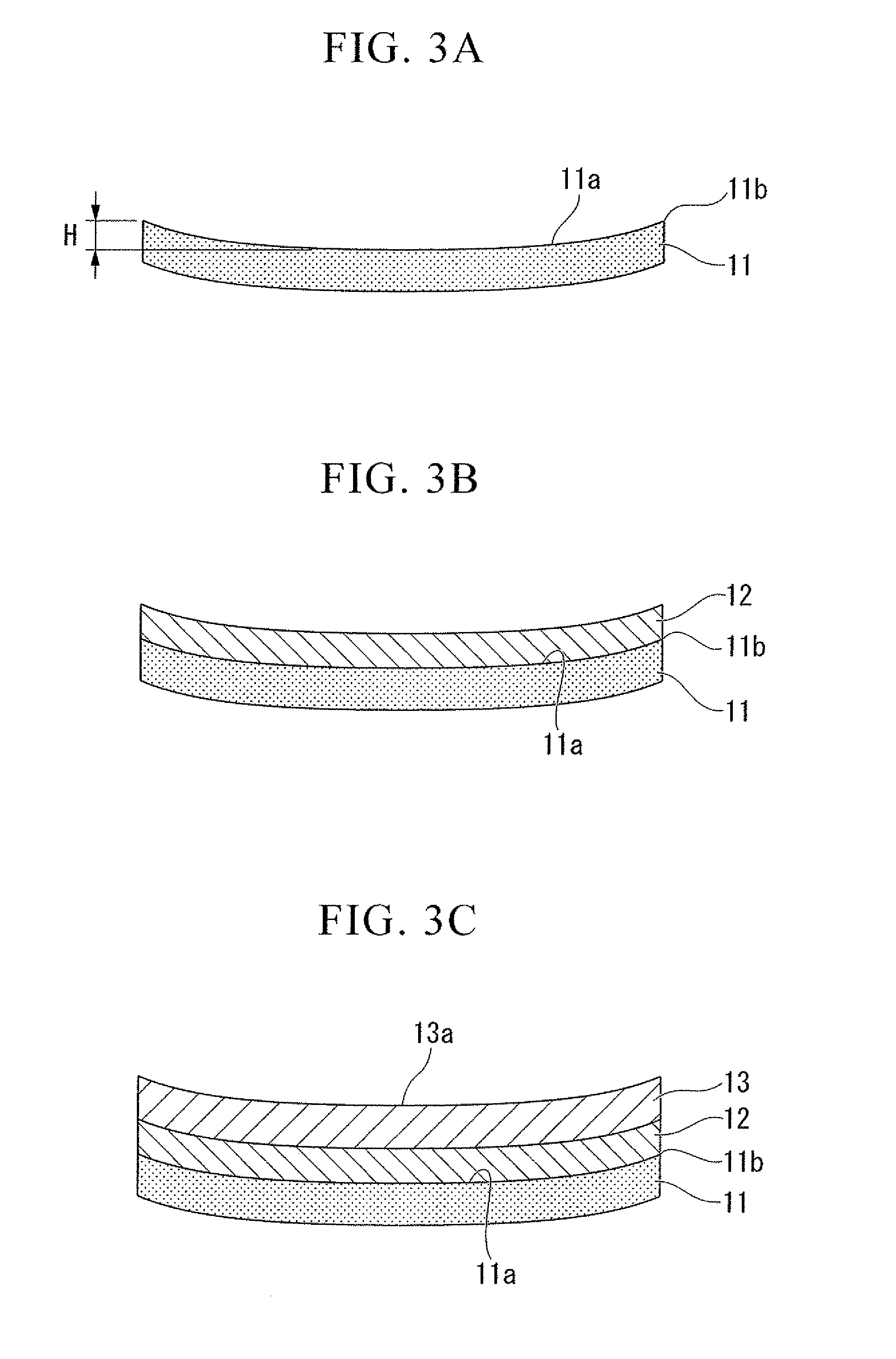

Method for manufacturing group iii nitride semiconductor light emitting element, group iii nitride semiconductor light emitting element and lamp

ActiveUS20110163349A1High crystallinityStable emission wavelengthSolid-state devicesSemiconductor/solid-state device manufacturingRocking curveX-ray

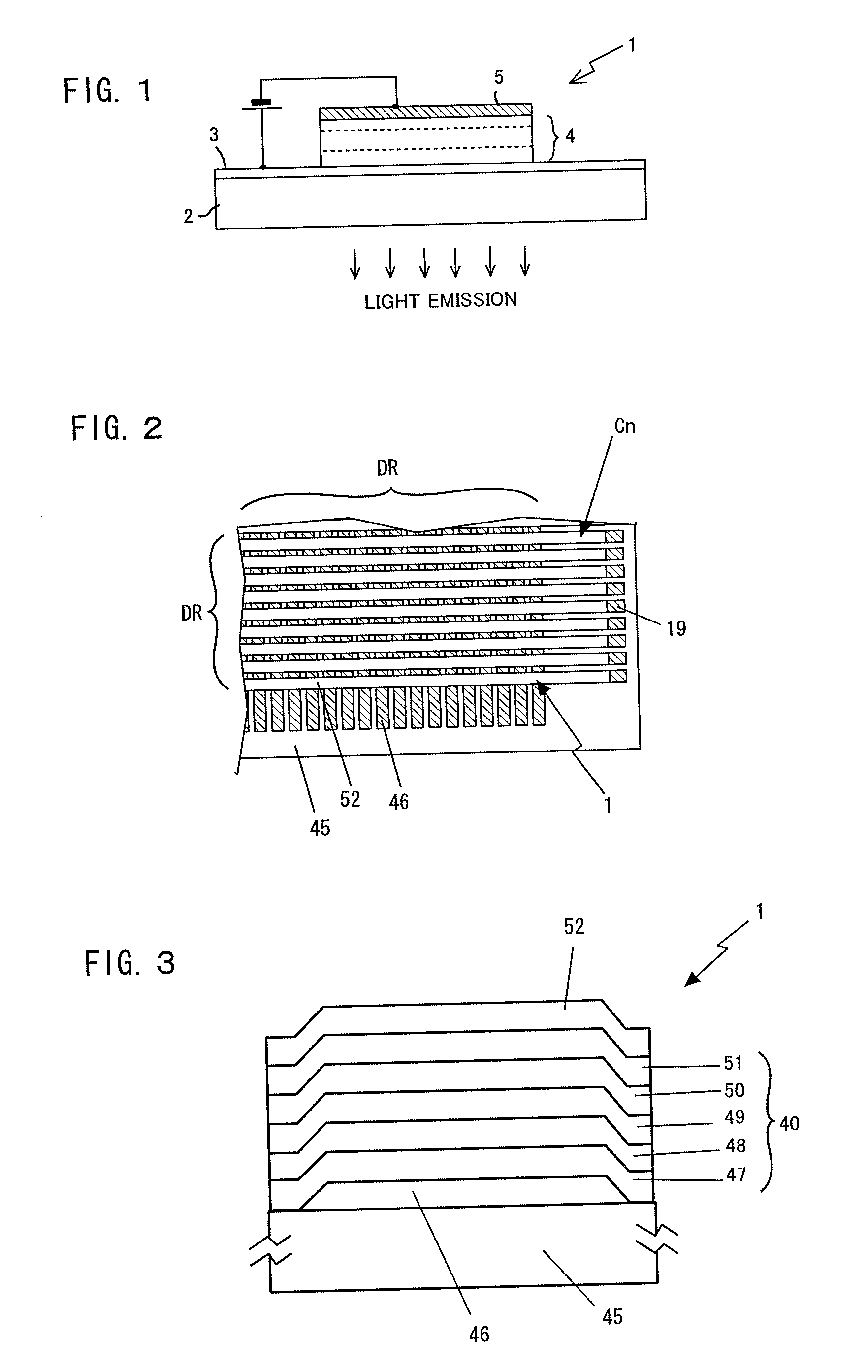

The present invention provides a method for manufacturing a group III nitride semiconductor light emitting element, with which warping can be suppressed upon the formation of respective layers on the substrate, a semiconductor layer including a light emitting layer of excellent crystallinity can be formed, and excellent light emission characteristics can be obtained; such a group III nitride semiconductor light emitting element; and a lamp. Specifically disclosed is a method for manufacturing a group III nitride semiconductor light emitting element, in which an intermediate layer, an underlayer, an n-type contact layer, an n-type cladding layer, a light emitting layer, a p-type cladding layer, and a p-type contact layer are laminated in sequence on a principal plane of a substrate, wherein a substrate having a diameter of 4 inches (100 mm) or larger, with having an amount of warping H within a range from 0.1 to 30 μm and at least a part of the edge of the substrate warping toward the principal plane at room temperature, is prepared as the substrate; the X-ray rocking curve full width at half maximum (FWHM) of the (0002) plane is 100 arcsec or less and the X-ray rocking curve FWHM of the (10-10) plane is 300 arcsec or less, in a state where the intermediate layer has been formed on the substrate and where thereafter the underlayer and the n-type contact layer are formed on the intermediate layer; and furthermore the n-type cladding layer, the light emitting layer, the p-type cladding layer, and the p-type contact layer are formed on the n-type contact layer.

Owner:TOYODA GOSEI CO LTD

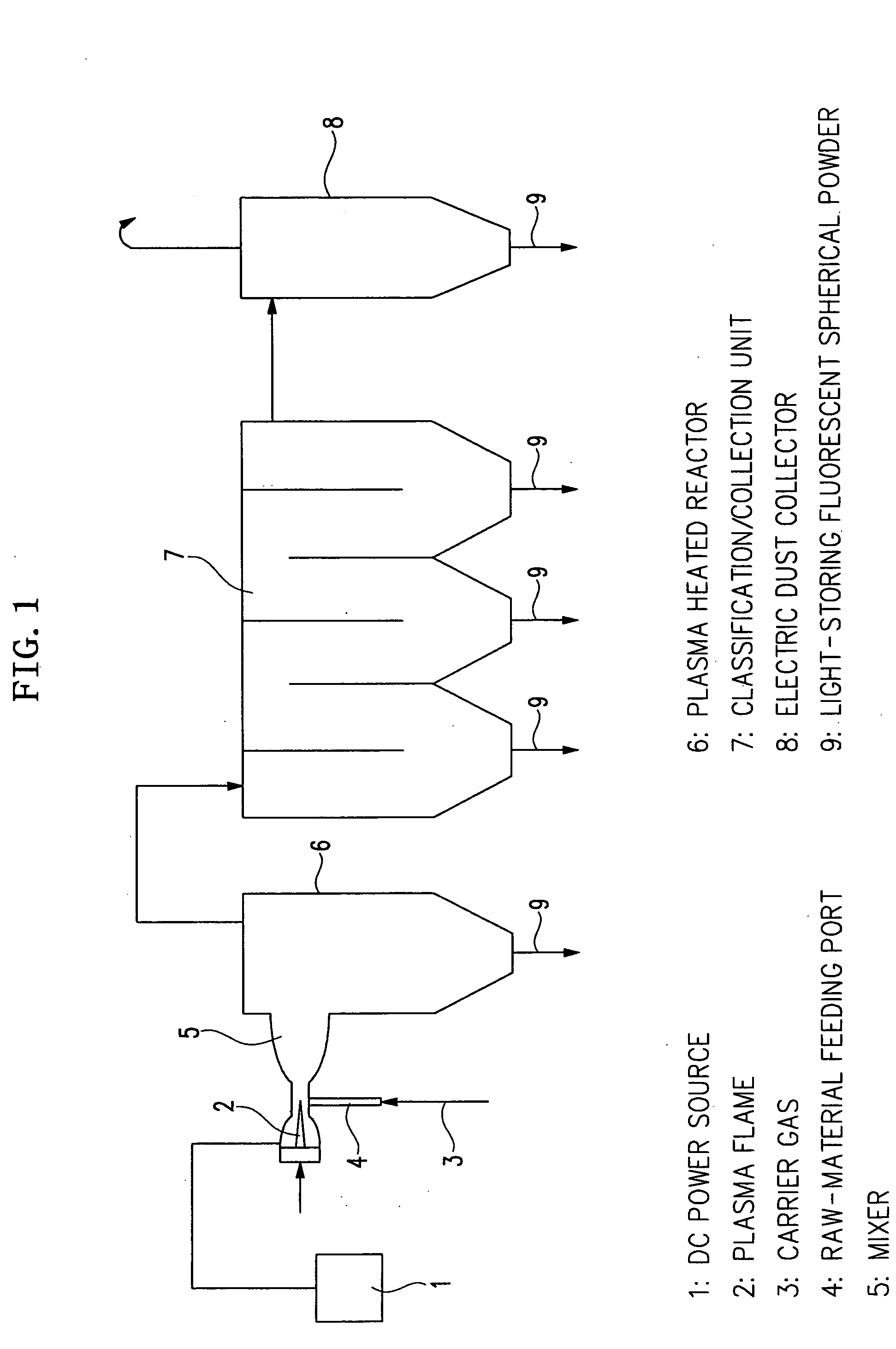

Spherical light storing phosphor powder and process for producing the same

InactiveUS20060001007A1Increased durabilityHigh emission intensityLuminescent compositionsAluminateAlkaline earth metal

An object of the present invention is to provide a light-storing fluorescent spherical powder that exhibits a high emission intensity, emits light for a prolonged time, and has an excellent workability even when it is added to synthetic resin or the like. There is provided a light-storing fluorescent spherical powder that contains an alkaline earth metal aluminate as a main component and a transition metal element such as lanthanoid as an activator, in which the powder comprises a spherical powder. There is further provided a process of manufacturing a light-storing fluorescent spherical powder that includes preparing as a raw material a light-storing fluorescent powder that has been previously synthesized or a light-storing fluorescent precursor powder that has been produced by pre-reaction of a synthetic raw material of a light-storing fluorescent material, and passing the prepared raw material through a region heated to a temperature higher than a melting point of a light-storing fluorescent material, thereby forming the raw material into spherical shape.

Owner:EZ BRIGHT CORP +1

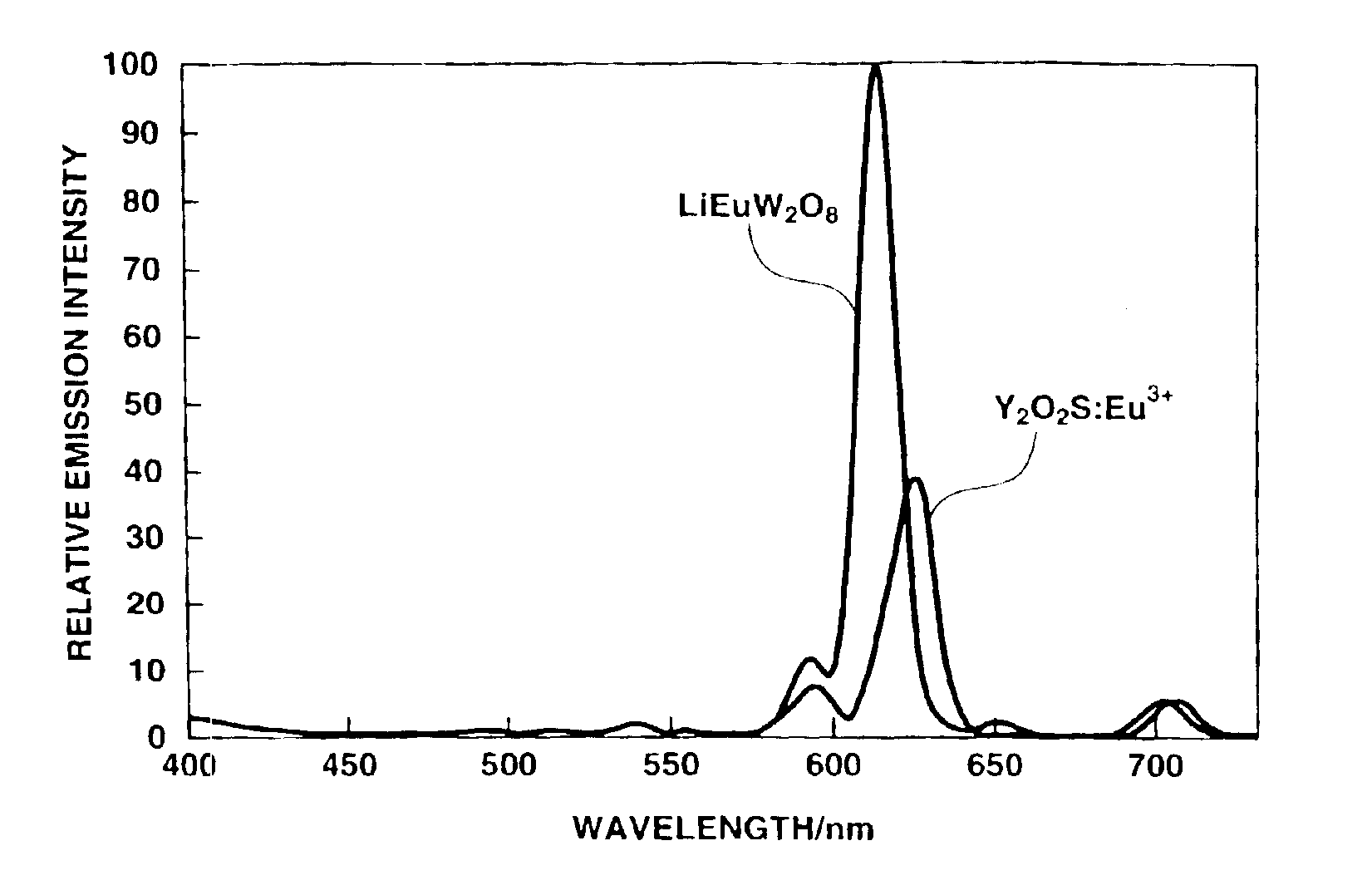

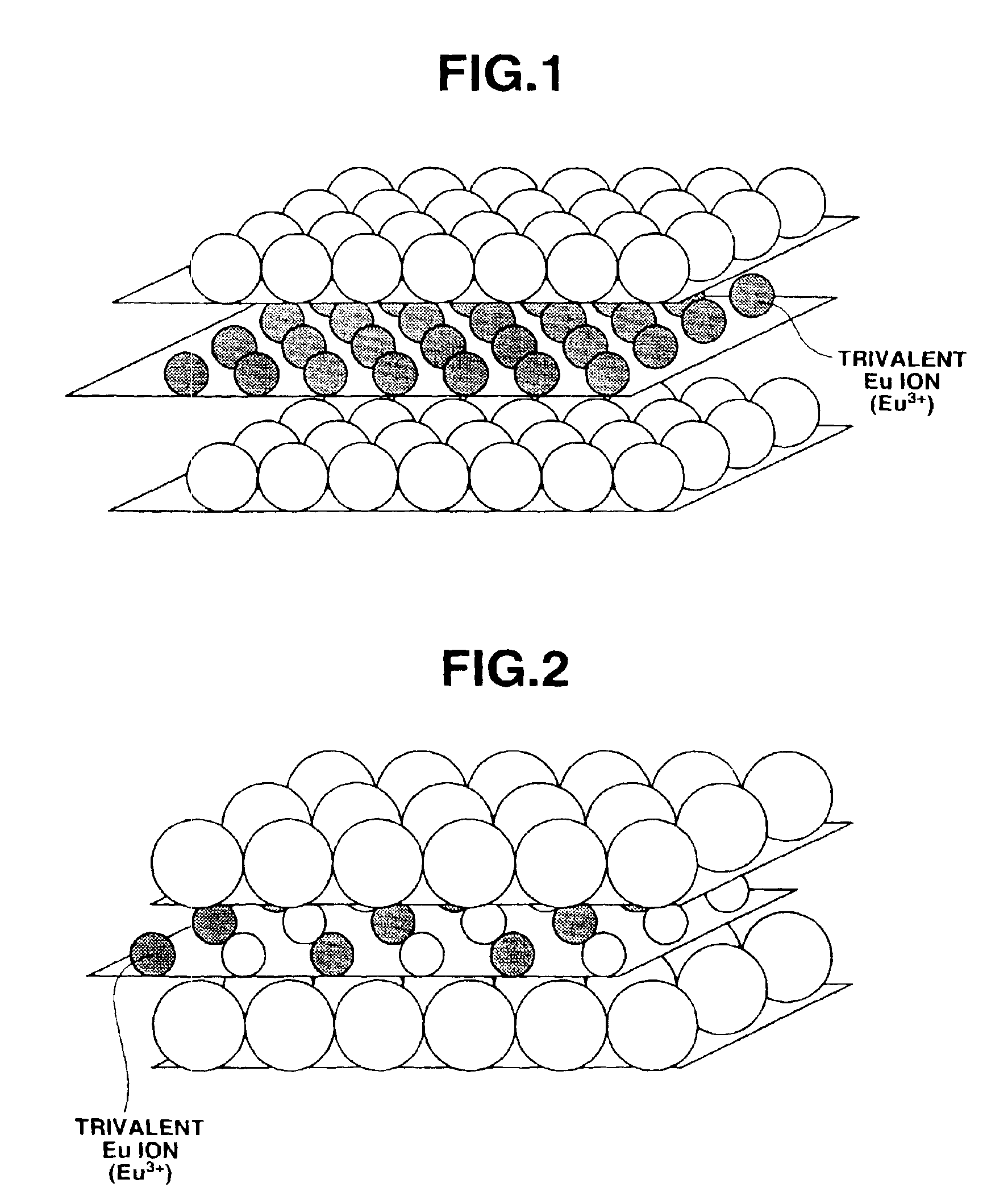

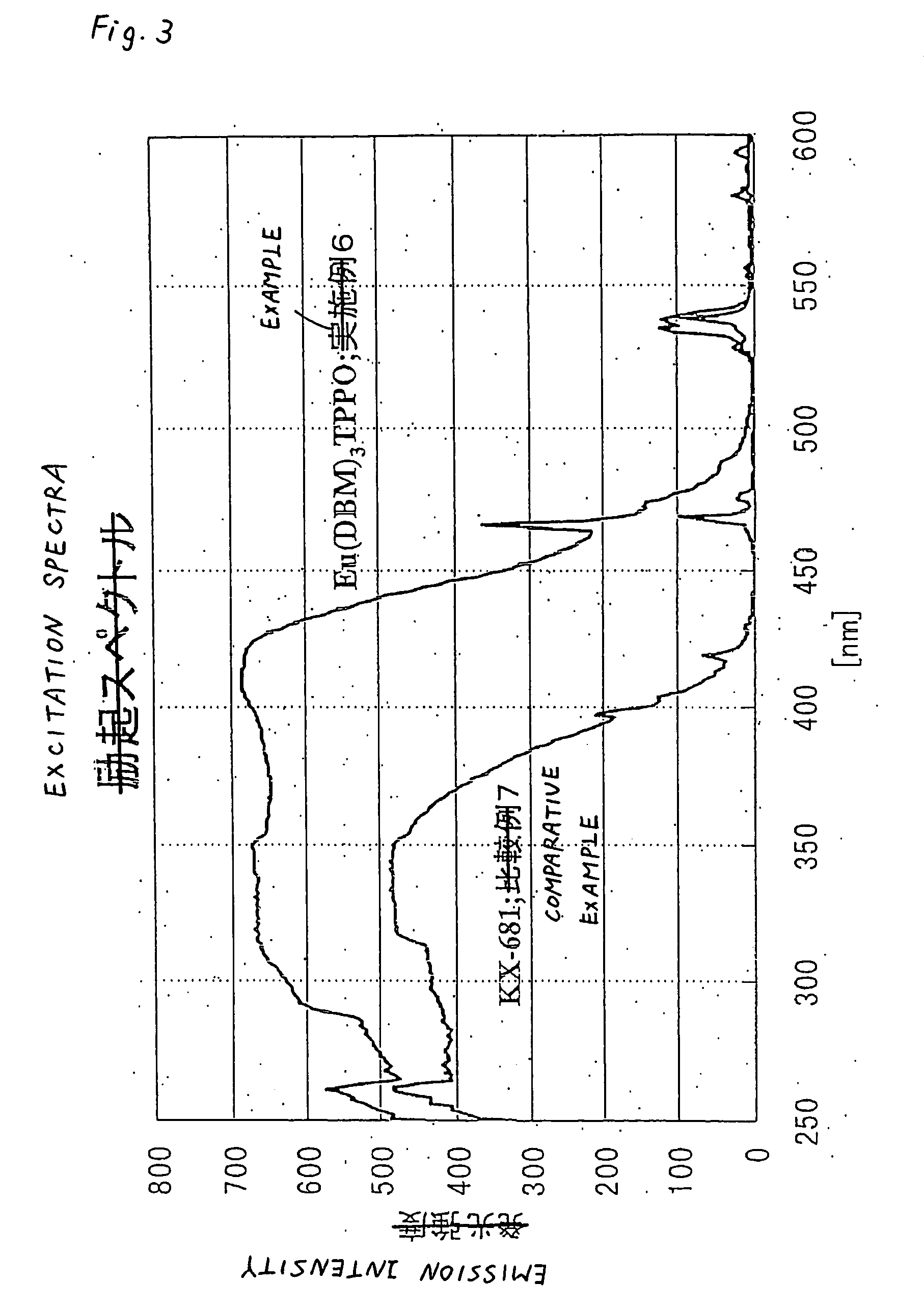

Red light emitting phosphor, its production and light emitting device

InactiveUS6982523B2Improve efficiencyIncrease brightnessDischarge tube luminescnet screensMolybdeum compoundsRare-earth elementDisplay device

As a red light emitting phosphor capable of efficiently emitting red light at a high luminance in response to exciting light having a wavelength of 350-420 nm, and practically used in a light emitting device for red display or a light emitting device for white or intermediate color display in combination with green and blue light emitting phosphors, the invention provides a red light emitting phosphor capable of emitting red light upon excitation with light having a wavelength of 350-420 nm and having compositional formula (1):AEuxLn(1-x)M2O8 (1)wherein A is at least one element selected from among Li, Na, K, Rb and Cs, Ln is at least one element selected from among Y and rare earth elements exclusive of Eu, M is at least one element selected from among W and Mo, and x is a positive number satisfying 0<x≦1; and a red light emitting phosphor having compositional formula (2):D0.5EuyLn(1-y)M2O8 (2)wherein D is at least one element selected from among Mg, Ca, Sr and Ba, Ln is at least one element selected from among Y and rare earth elements exclusive of Eu, M is at least one element selected from among W and Mo, and y is a positive number satisfying 0<y≦1. Methods for preparing the red light emitting phosphors, and light emitting devices using the red light emitting phosphors are also provided.

Owner:FINE RUBBER KENKYUUSHO

Wavelength-converting member

ActiveUS20080035887A1High emission intensityImprove reliabilityLuminescent compositionsSemiconductor devicesPhosphorLength wave

A wavelength-converting member with high emission intensity and that is superior in weather resistance and reliability is obtained. There is provided a phosphor on which a cleaning treatment and / or a coating treatment are / is performed is contained in a glass material having a composition of SiO2: 30 to 50%, Li2O: 0 to 15%, Na2O: 0 to 10%, K2O 0 to 10%, Li2O+Na2O+K2O: 20 to 30%, B2O3:5 to 15%. MgO: 0 to 10%, BaO: 0 to 10% , CaO: 0 to 10%, SrO: 0 to 10%, Al2O3: 0 to 10%, ZnO: 0 to 15%, TiO2: 10 to 20%, Nb2O5: 1 to 5%, La2O3: 0 to 5%, and TiO2+Nb2O5+La2O3: 11 to 20% by mole percentage.

Owner:NIPPON ELECTRIC GLASS CO LTD

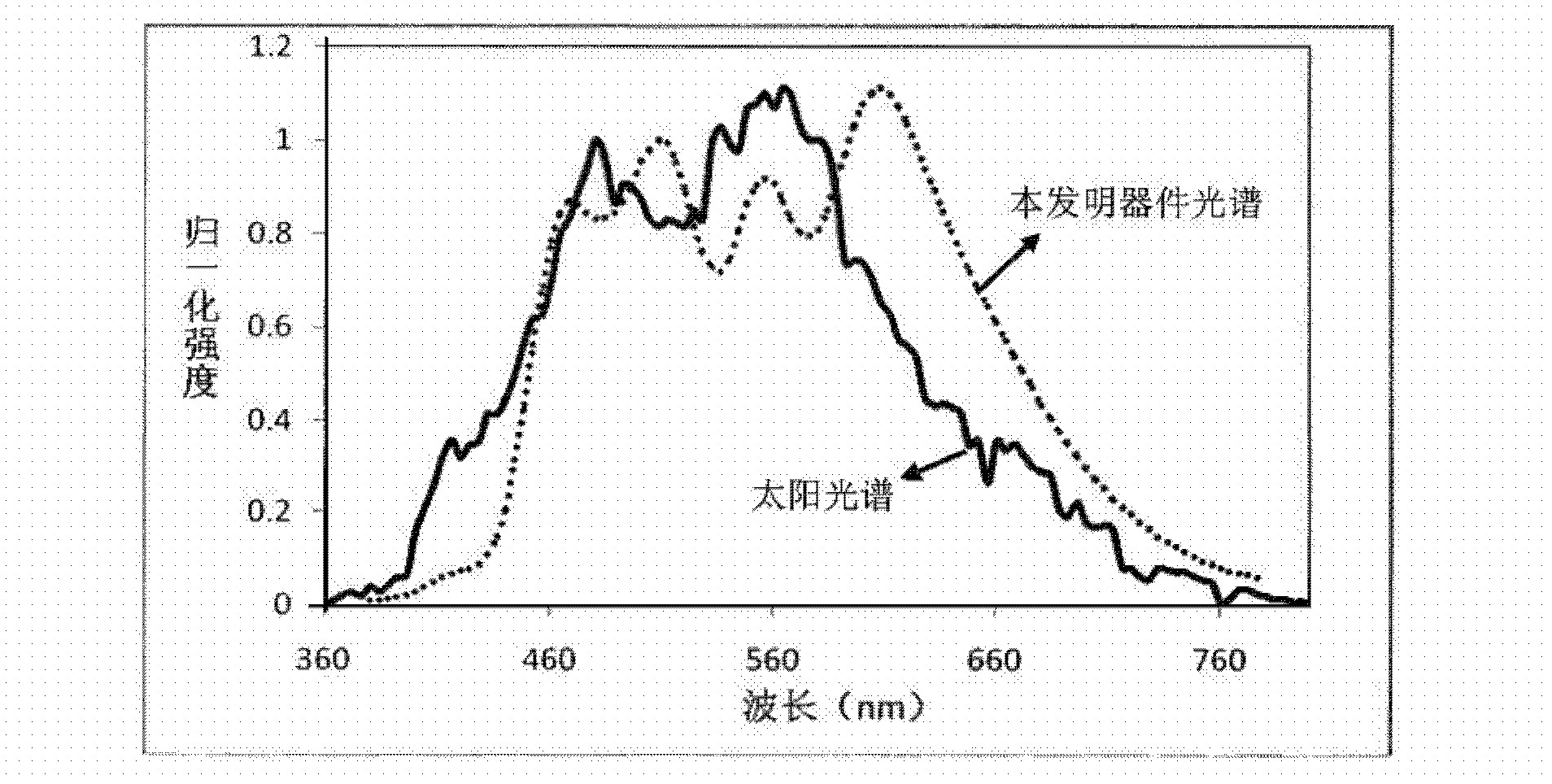

White light luminescence device

ActiveCN108630794AGood chemical stabilityImprove thermal stabilitySemiconductor devicesLuminescenceWave band

The invention provides a novel white light luminescence device. The device comprises an excitation light source and a fluorescent layer configured to the upstream of the excitation light source. The fluorescent layer comprises a fluorescent powder group and a transparent material. The fluorescent powder group comprises a first fluorescent powder which is excited by the excitation light source to emit white light or visible light, and a second fluorescent powder which is simultaneously excited by the excitation light source to emit infrared light. In the invention, a white light color with highphotosynthetic efficiency can be provided, simultaneously, a high-efficient infrared wave band can be provided, and a new application characteristic is provided for an LED illumination light source.

Owner:JIANGSU BREE OPTRONICS CO LTD

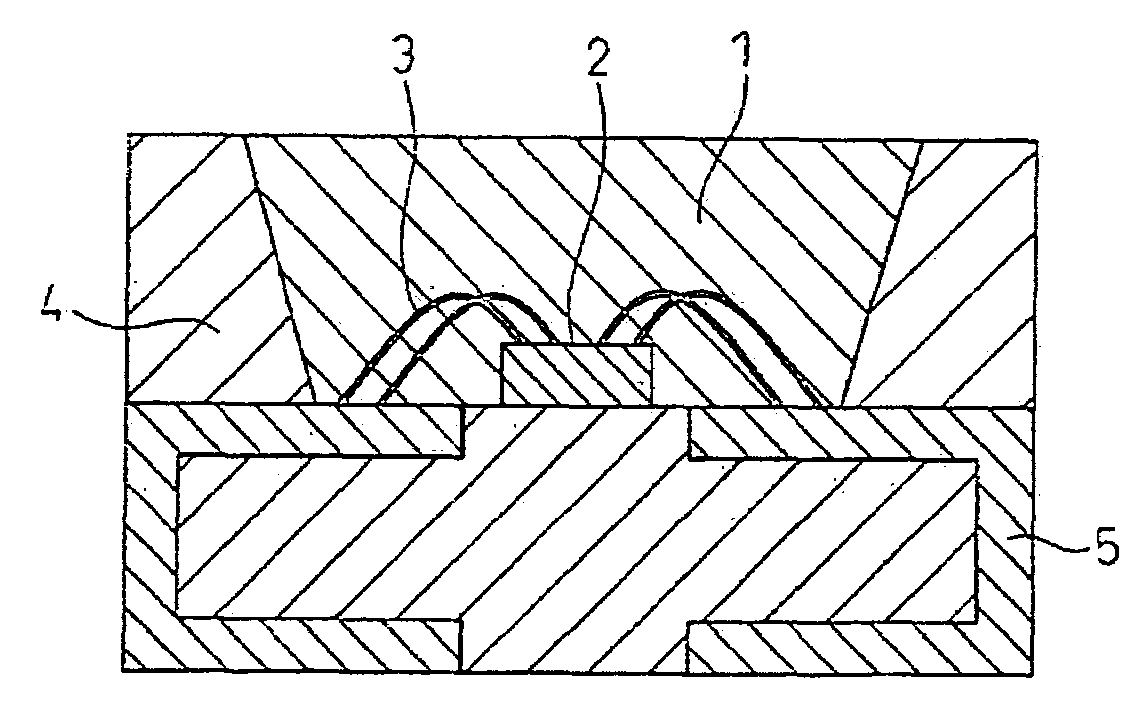

Liquid crystal display device

InactiveUS6853416B2Increase contrastLow purityStatic indicating devicesNon-linear opticsLiquid-crystal displayFilter material

In a liquid crystal display device comprising color filters therein, the present invention provides a color-converting material in at least one of the color filters which converts a part of an incident light of the at least one of the color filters into a light in a specific wavalength range together with a filter material passing the light in the specific wavelength range, so as to prevent deterioration of color purity of the light emitted thereby and to improve efficiency of optical utilization therein.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Preparing method for organic white LED illumination light source with high color-rendering index and adjustable color temperature

InactiveCN103000822AAvoid concentration quenchingHigh emission intensitySolid-state devicesSemiconductor/solid-state device manufacturingChemistryColor temperature

Disclosed is a preparing method for organic white LED illumination light source with high color-rendering index and adjustable color temperature. Four dyes, including blue, green, yellow and red dyes, are selected. Either two dyes are capable of forming into a complementary color. Blue and yellow dyes are mixed in a light-emitting layer of one host material while green and red dyes are mixed in a light-emitting layer of another host material. By utilizing a preparation of a blue fluorescent material collocating with green and red phosphor materials, the host materials of the two color-complementing light-emitting layers are consistent. The host material selected for the light-emitting layer close to a positive pole has good hole-transmission capability while the host material selected for the light-emitting layer close to a negative pole has good electronic transmission capacity. The host material selected by the blue and yellow light layers is of a hole type, while the host material selected by the green and red light layers is of an electronic type. Manufactured is a white illumination light source with high color-rendering index and adjustable color temperature. Specific technical parameters are provided for manufacturing the illumination light source with high color-rendering index and adjustable color temperature.

Owner:江苏广发光电科技有限公司

Fluorescent material, process for producing the same, and luminescent device

ActiveUS20100039020A1High emission intensityEfficiently emitsDischarge tube luminescnet screensCathode ray tubes/electron beam tubesLight emitting deviceElectron

A blue fluorescent material having excellent durability and a high luminance, especially one emitting a high-luminance light by the action of electron rays. The fluorescent material comprises inorganic crystals having a crystal structure which is an AlN crystalline, AlN polycrystalline, or AlN solid-solution crystalline structure. It is characterized in that the inorganic crystals contain at least europium in solution and have an oxygen content of 0.4 mass % or lower and that the fluorescent material emits fluorescence derived from divalent europium ions upon irradiation with an excitation source. More preferably, the fluorescent material contains a given metallic element and silicon. Also provided are a process for producing the fluorescent material and an illuminator including the blue fluorescent material.

Owner:NAT INST FOR MATERIALS SCI

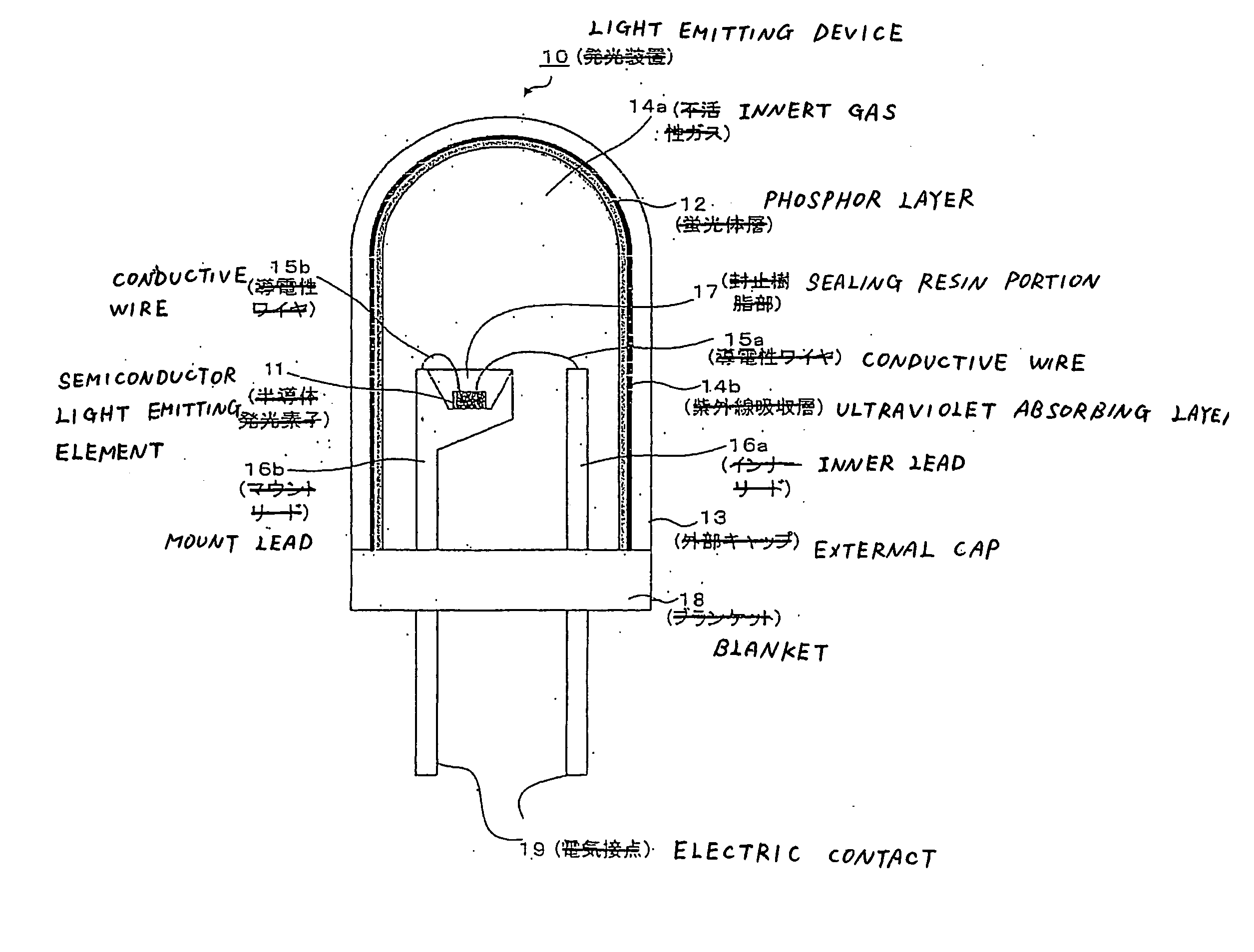

Light emitting device and lighting device using it, image display unit

InactiveUS20070132366A1High emission intensityImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesLuminous intensityEffect light

An object of the present invention is to provide a light emitting device which is high in emission intensity and stable, that is to say, a light emitting device in which when an LED or LD having an emission peak at 380 nm to 410 nm is used as an excitation light source of the light emitting device, the emission intensity of a red phosphor does not largely change to some deviation of the emission wavelength of the LED or LD to maintain not only brightness but also a balance at the time when mixed with a blue and green phosphors. The present invention relates to a light emitting device characterized in that the device comprises a phosphor which has Eu3+ as a luminescent center ion, in which a minimum emission intensity within the excitation wavelength range of 380 nm to 410 nm in an excitation spectrum is 65% or more of a maximum emission intensity, and which has an emission efficiency at 400 nm of 20% or more, and a semiconductor light emitting element which emits light in the region from near-ultraviolet light to visible light.

Owner:MITSUBISHI CHEM CORP

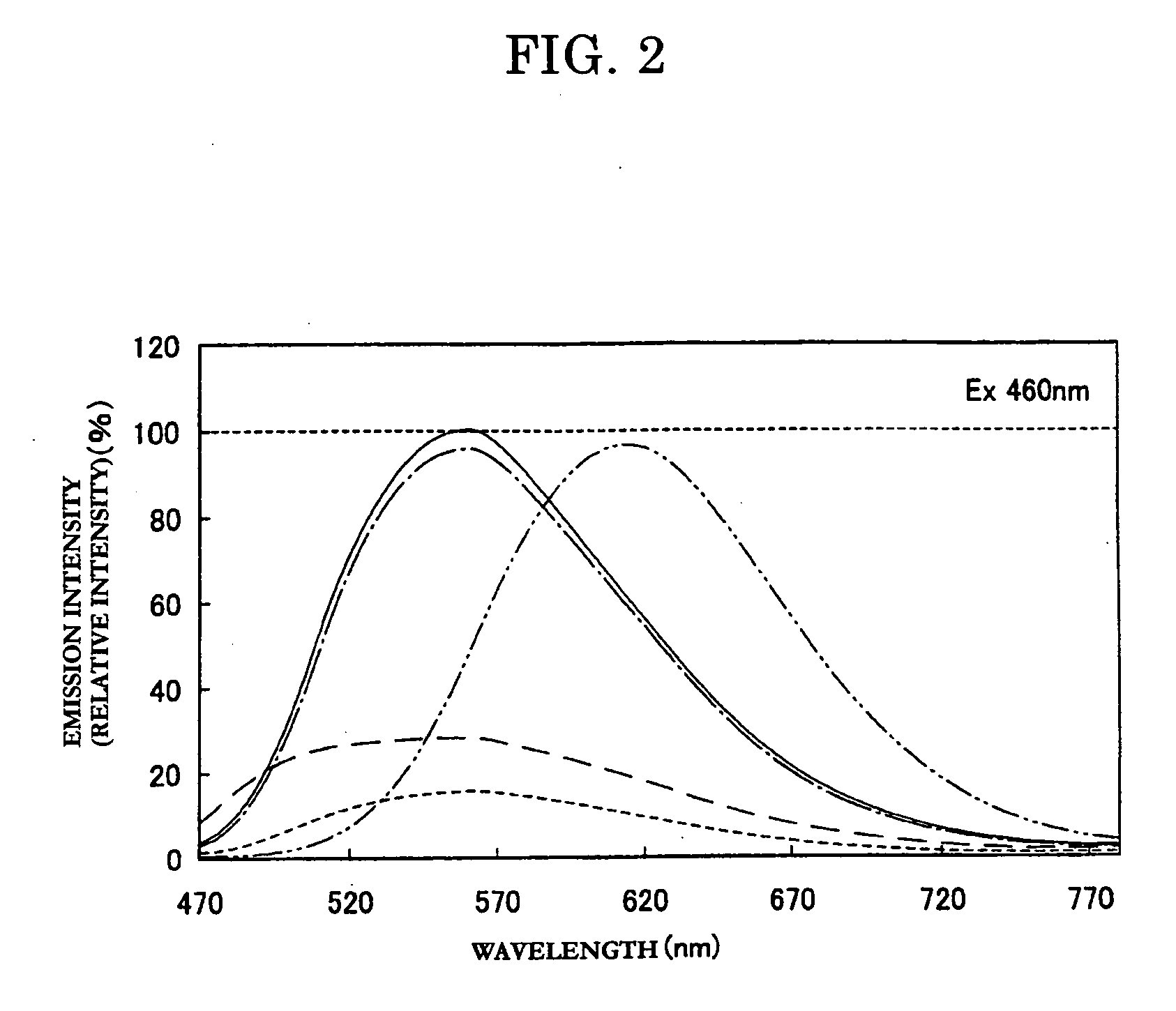

Phosphor, Manufacture Thereof; Light-Emitting Device, and Image Display Device Utilizing Phosphor

ActiveUS20130207538A1Increase brightnessSmall temperature fluctuationsDischarge tube luminescnet screensElectroluminescent light sourcesPhosphorLight emitting device

Provided is a chemically and thermally stable phosphor having different emission characteristics than the conventional phosphor and exhibiting high emission intensity if combined with an LED of 470 nm or less. The phosphor of the present invention is represented by a composition formula: MdAeDfEgXh (d+e+f+g+h=1; M is one or more kinds of elements selected from Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, and Yb; A is one or more kinds of elements selected from Mg, Ca, Sr, and Ba; D is one or more kinds of elements selected from Si, Ge, Sn, Ti, Zr, and Hf; E is one or more kinds of elements selected from B, Al, Ga, In, Sc, Y, and La; and X is one or more kinds of elements selected from O, N, and F) and parameters d, e, f, g, and h satisfy the predetermined condition.

Owner:NAT INST FOR MATERIALS SCI

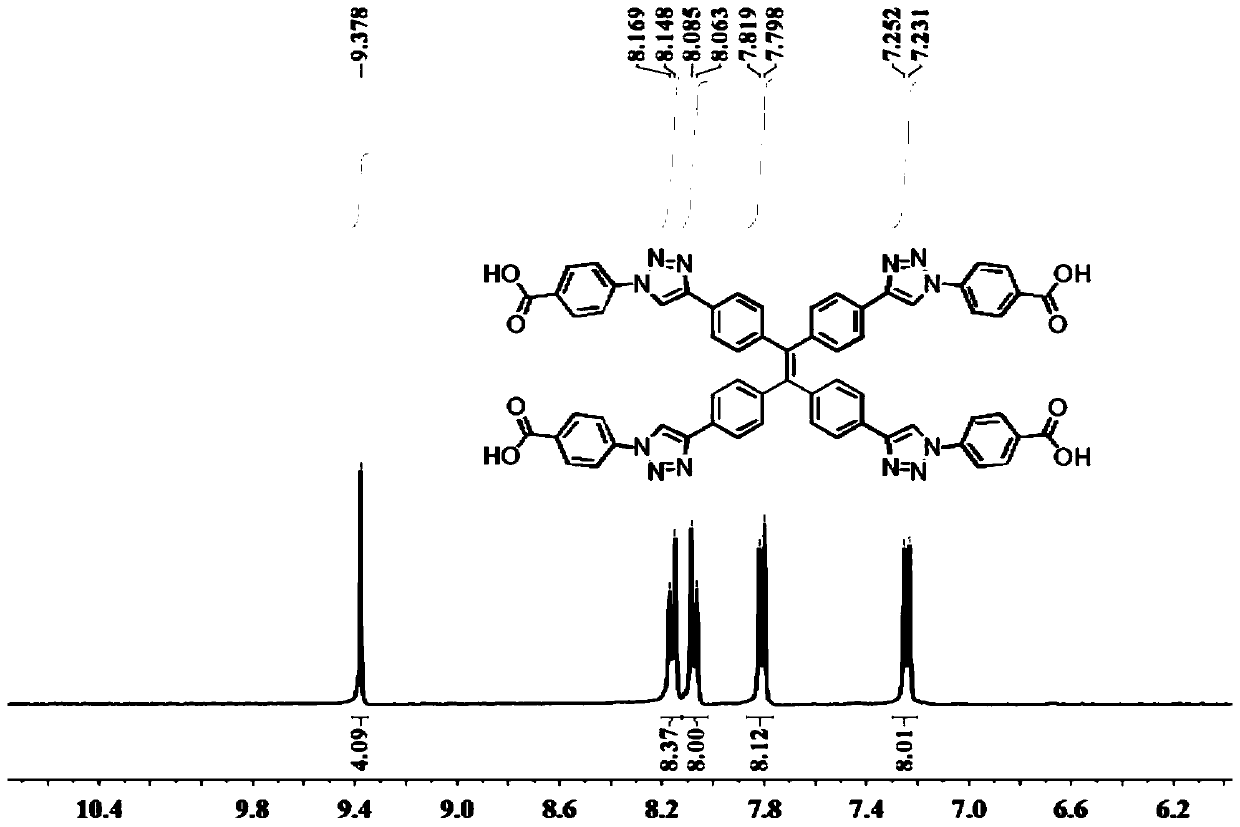

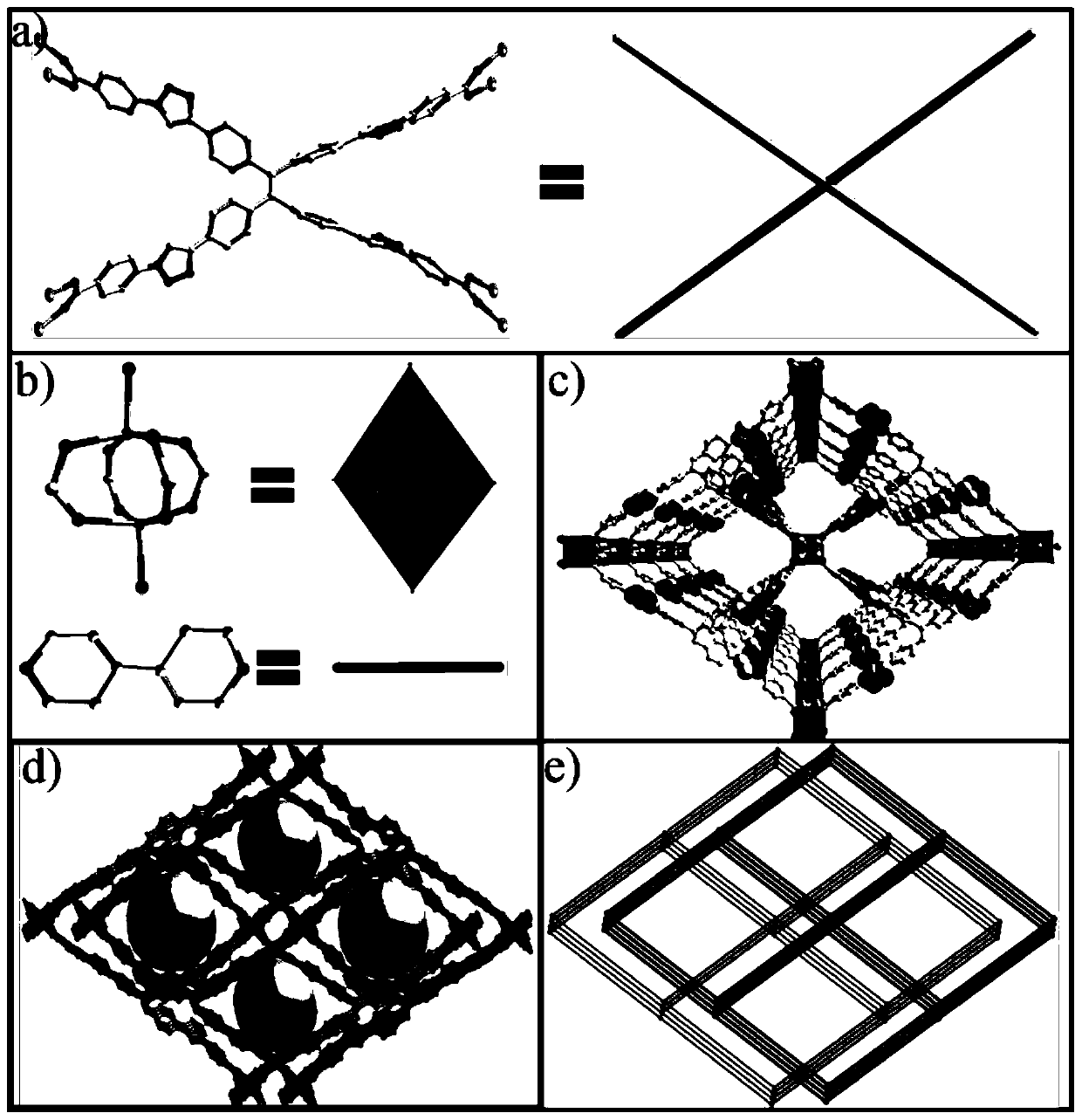

Functionalized metal-organic framework compounds, complexes formed therefrom, and methods of preparation and use thereof

ActiveCN110218220AEnvironmentally friendlyHigh fluorescence quantum yieldOther chemical processesOrganic chemistry methodsQuantum yield4,4'-Bipyridine

The invention discloses a functionalized metal-organic framework compounds, complexes formed therefrom, and methods of preparation and use thereof, wherein the molecular formula of the functionalizedmetal-organic framework compound is C36H22N7O4Zn, and the complex is formed by self-assembling tetra(4-(3-(4-carboxyphenyl)-2,3,4-triazole)-phenyl)ethylene as the main ligand, 4-4'-bipyridine as an auxiliary ligand and zinc nitrate. A LIFM-WZ-6 has high fluorescence quantum yield and two-photon absorption cross section, and has the advantages of high emission intensity and stable luminescence performance. A large amount of small cationic dyes can be adsorbed to achieve the purpose of adjusting the luminescence properties by single-photon and two-photon excitation and realize the emission of white light. The LIFM-WZ-6 does not mercury, is non-toxic, non-volatile, easy to recycle, and environmentally friendly; the composite can adsorb different kinds of cationic dyes with different contentsto obtain light emitting complexes with different light colors and luminosity, so that the light colors of the light emitting complexes can be more easily adjusted and the light color conversion can be realized.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com