Patents

Literature

31results about How to "Efficiently emits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

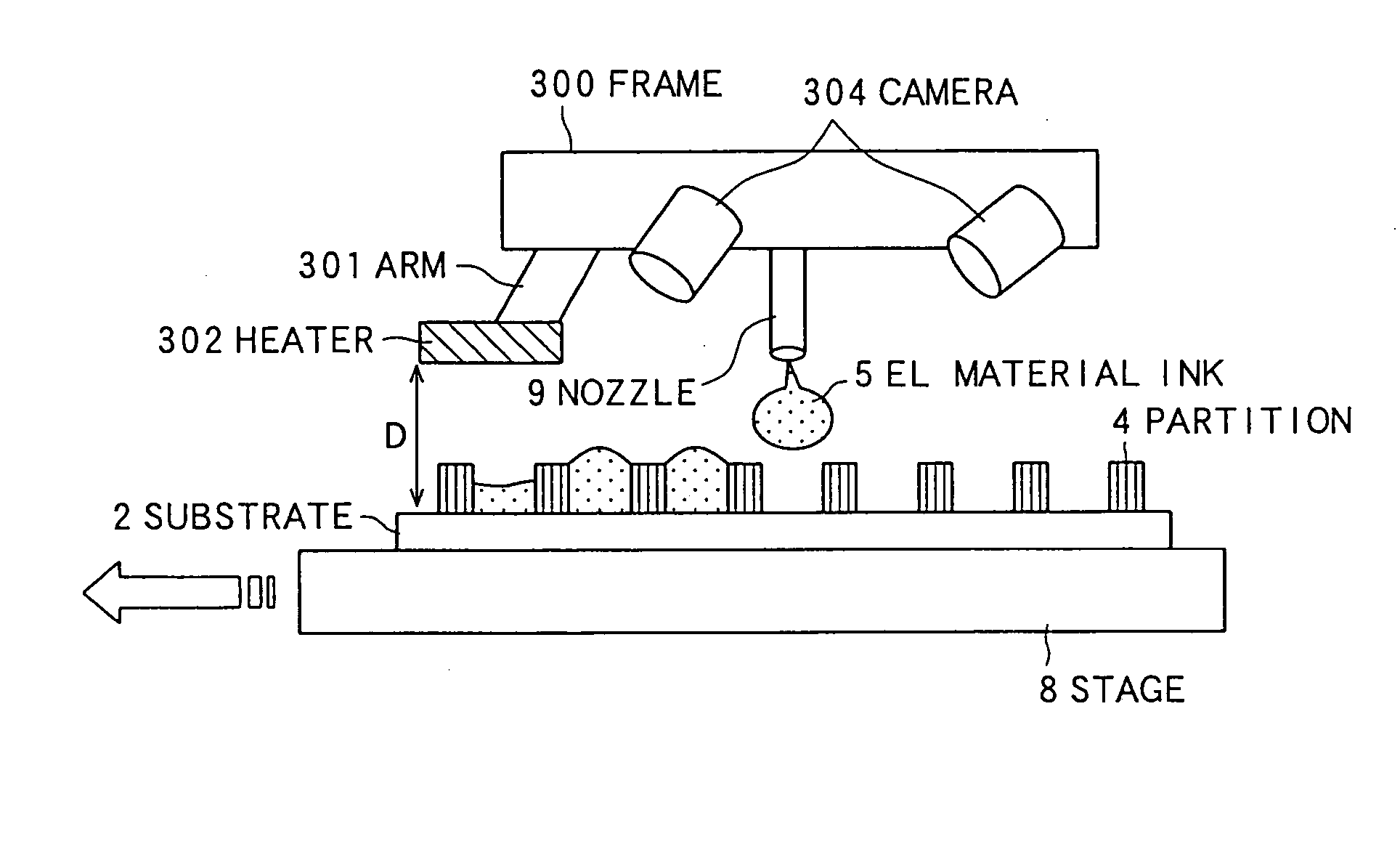

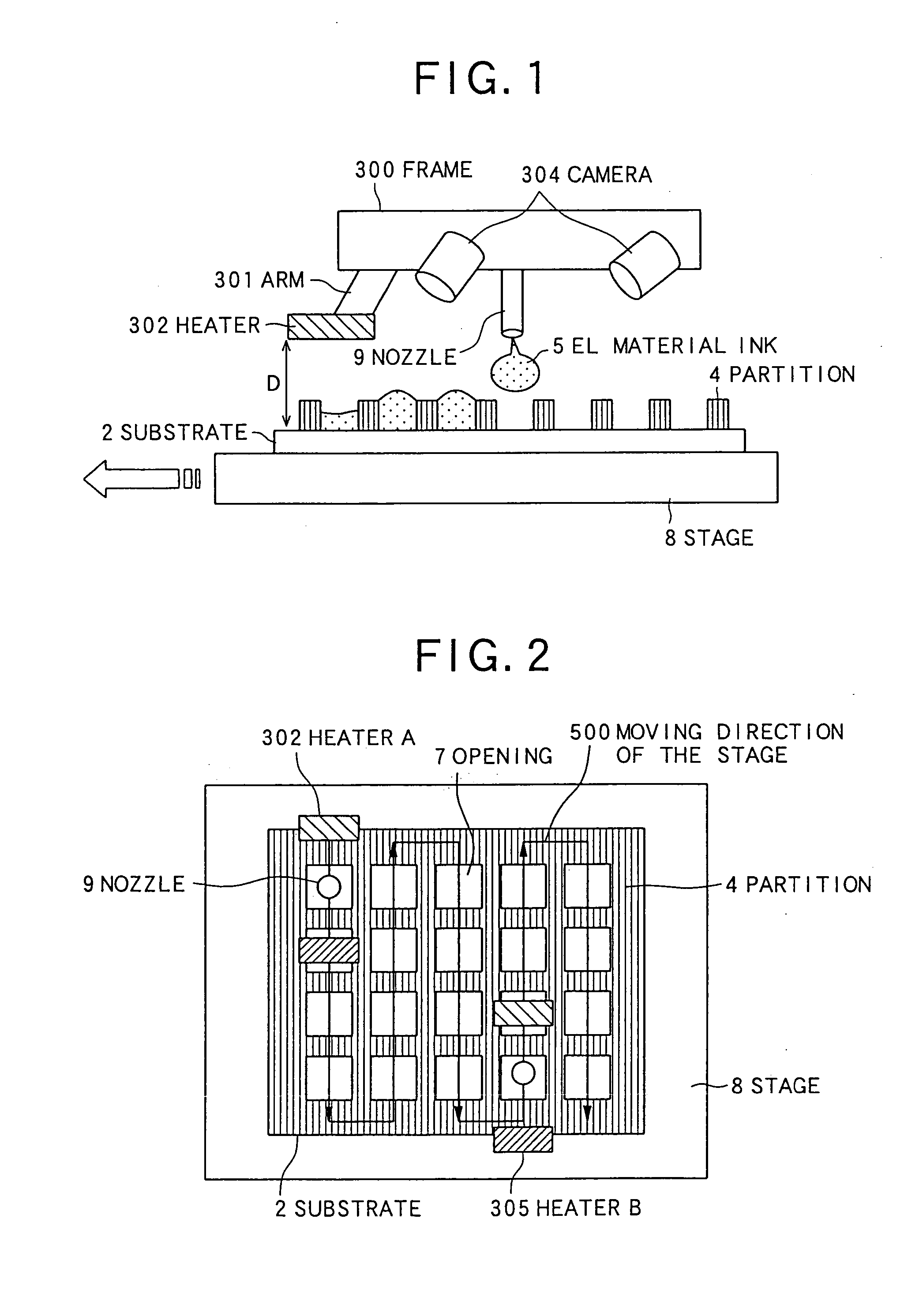

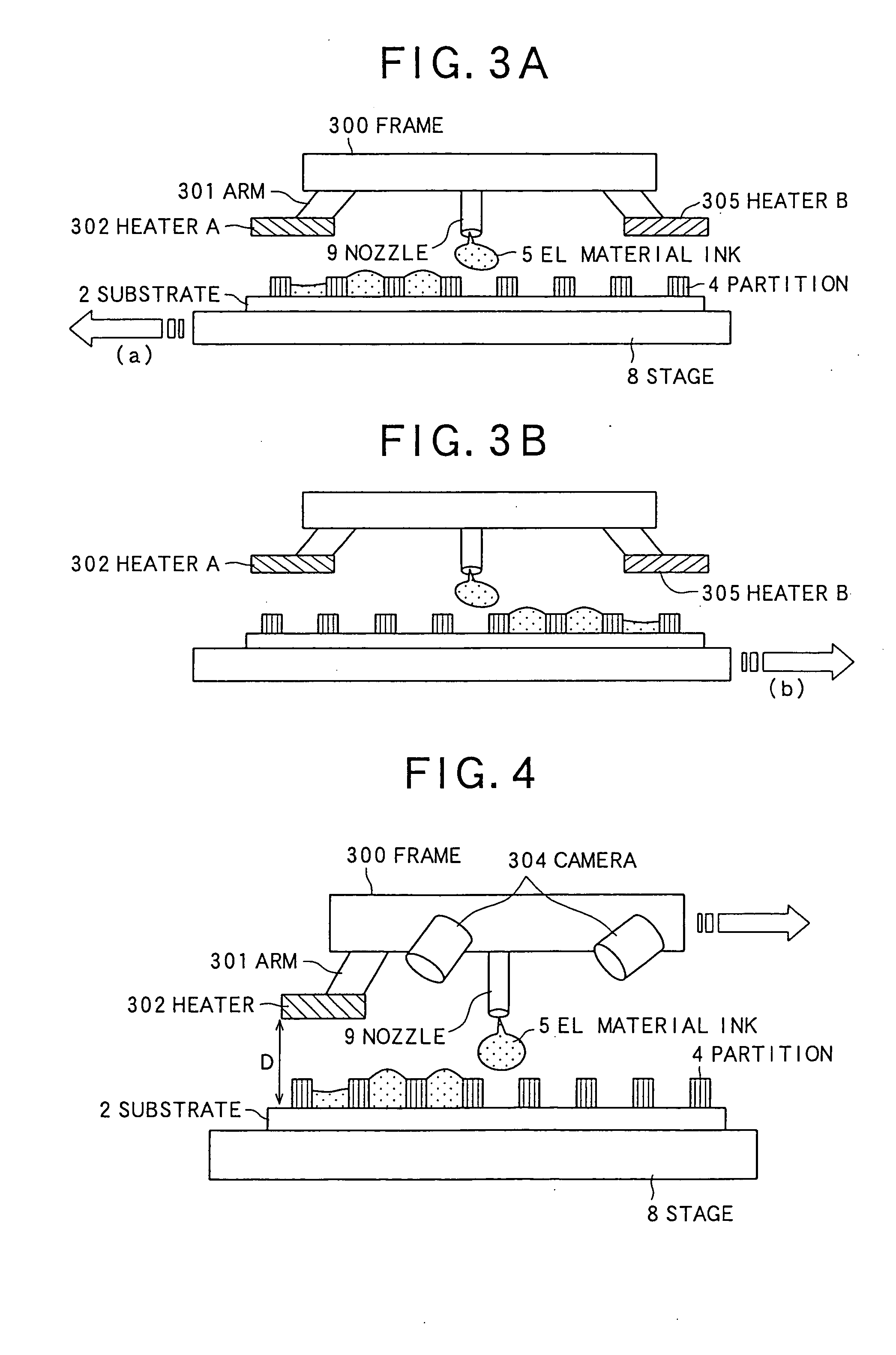

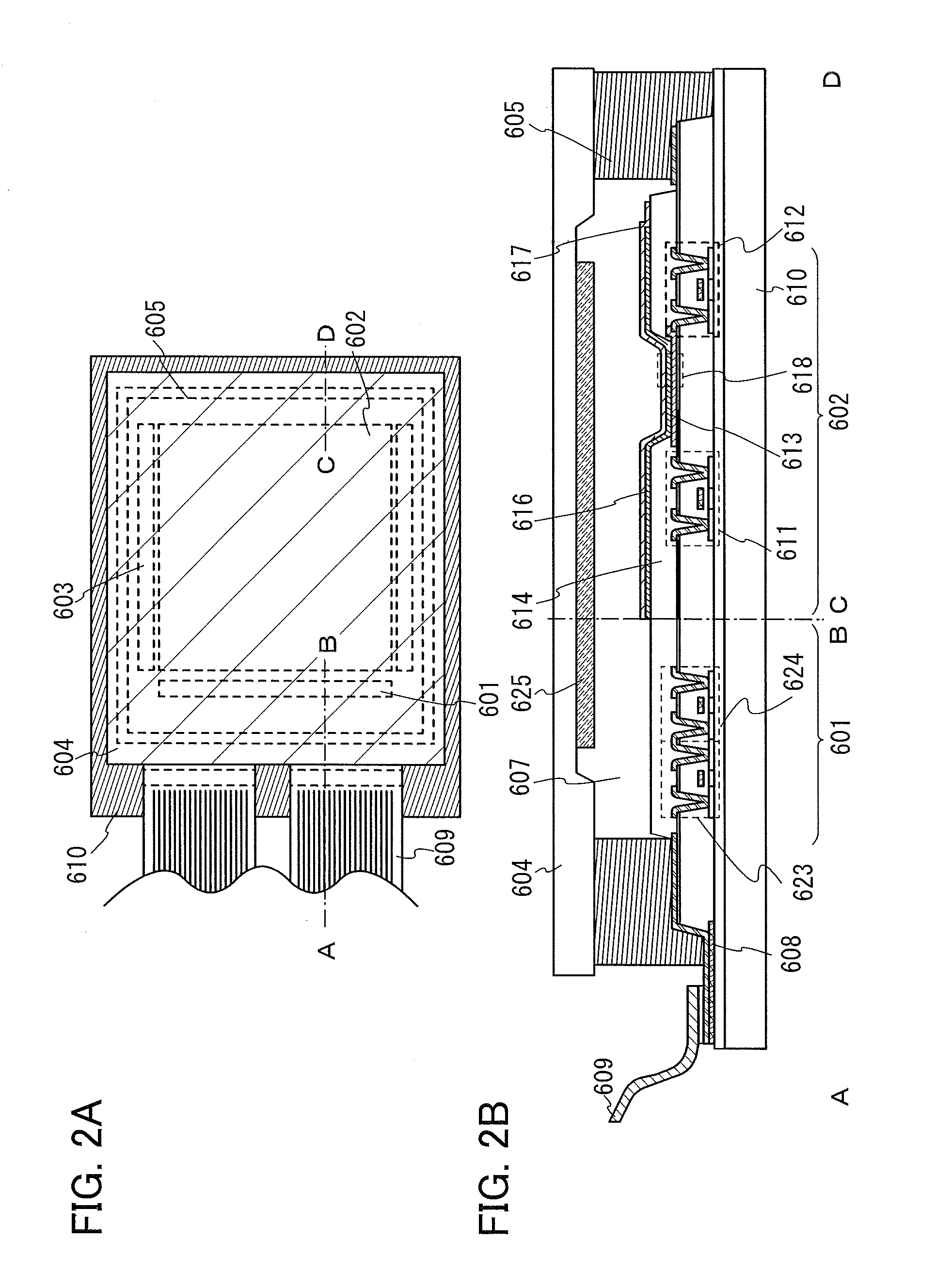

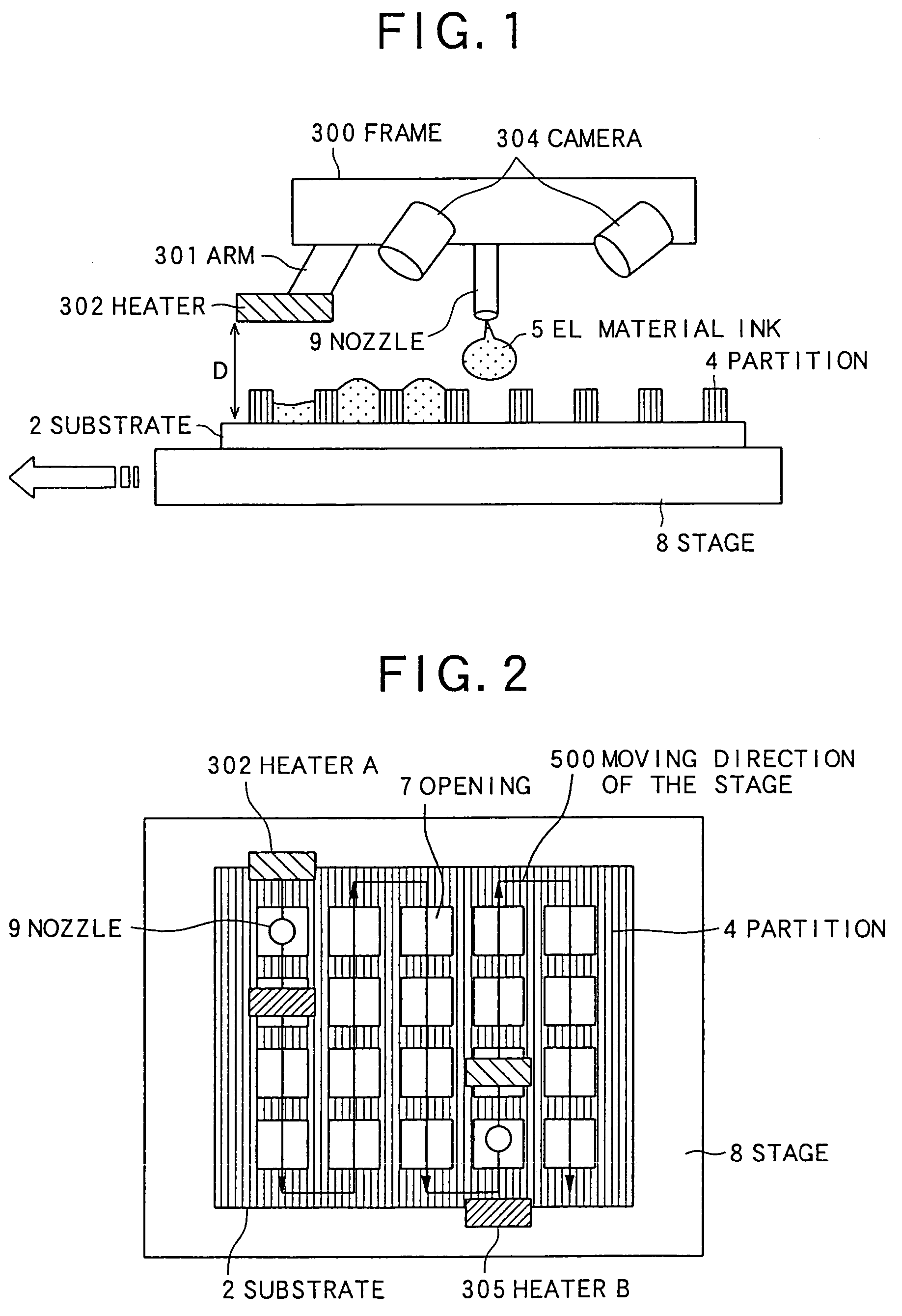

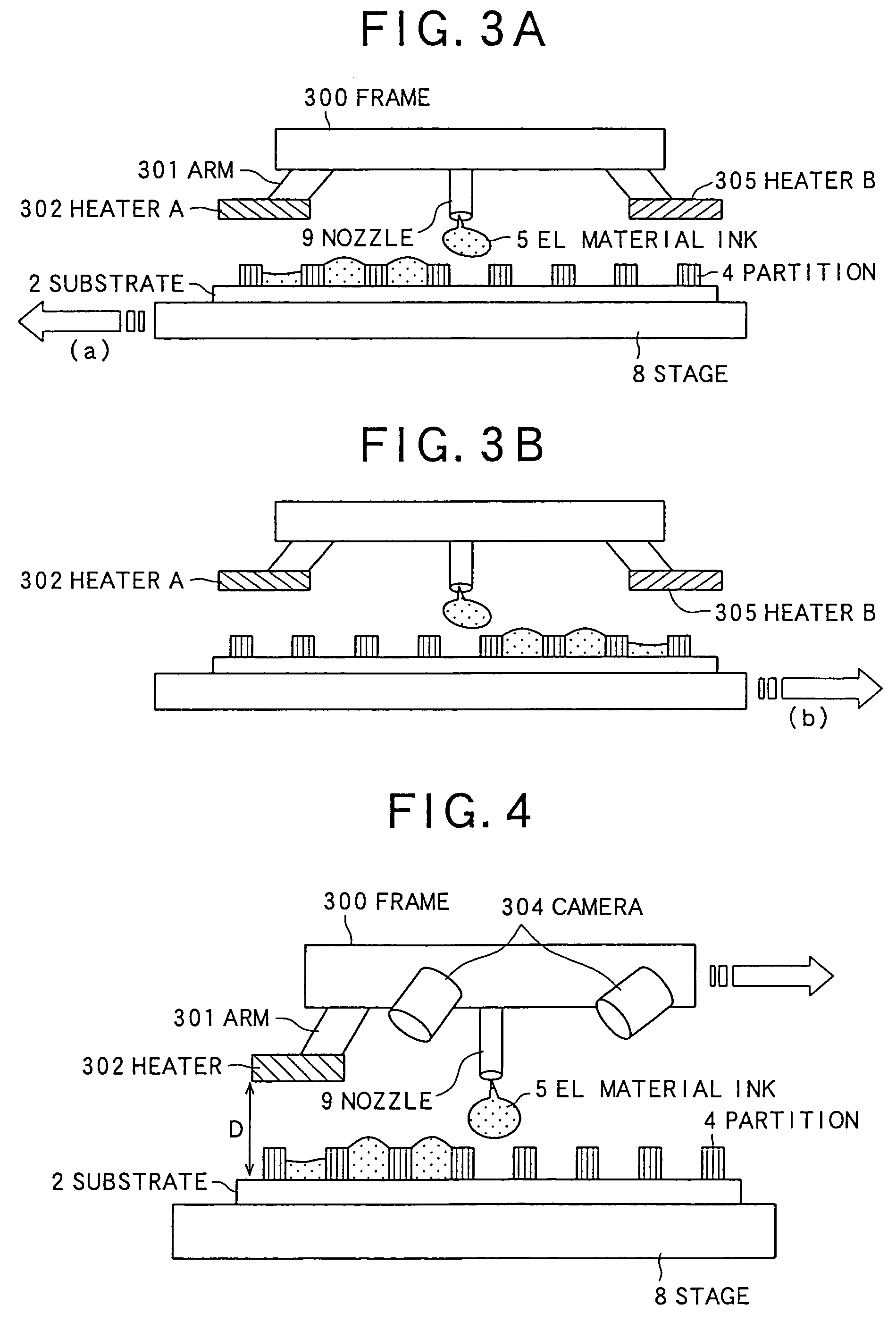

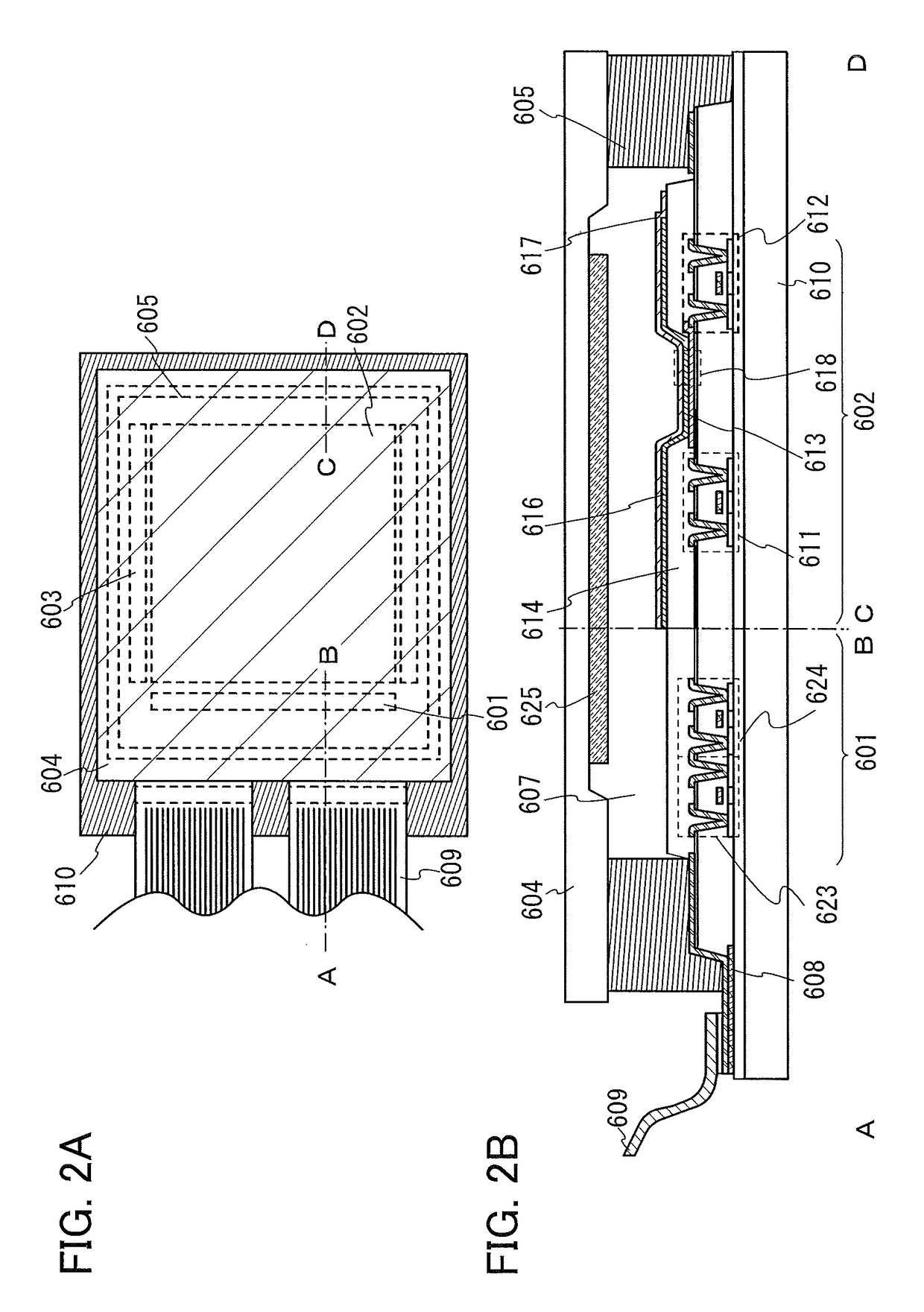

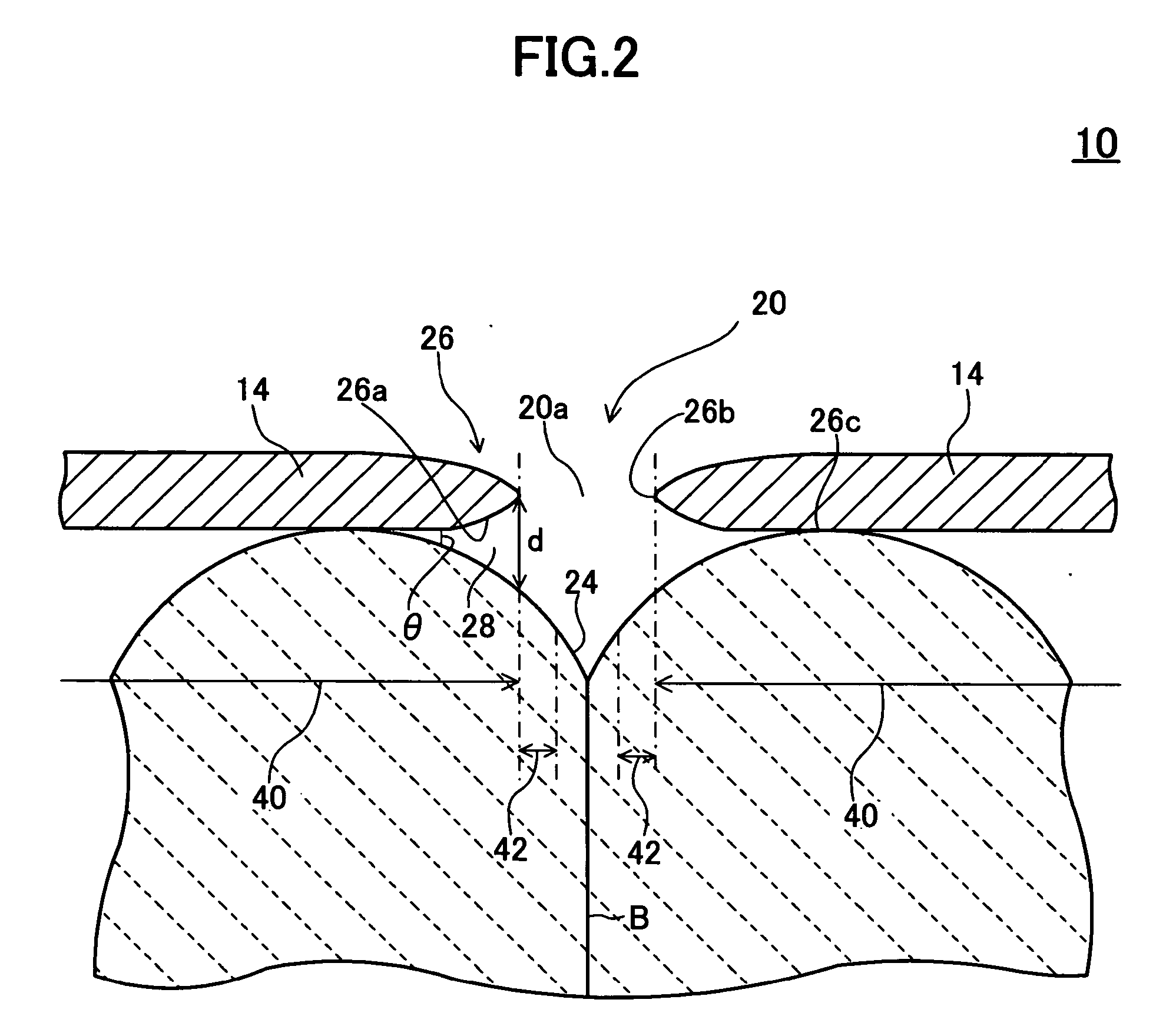

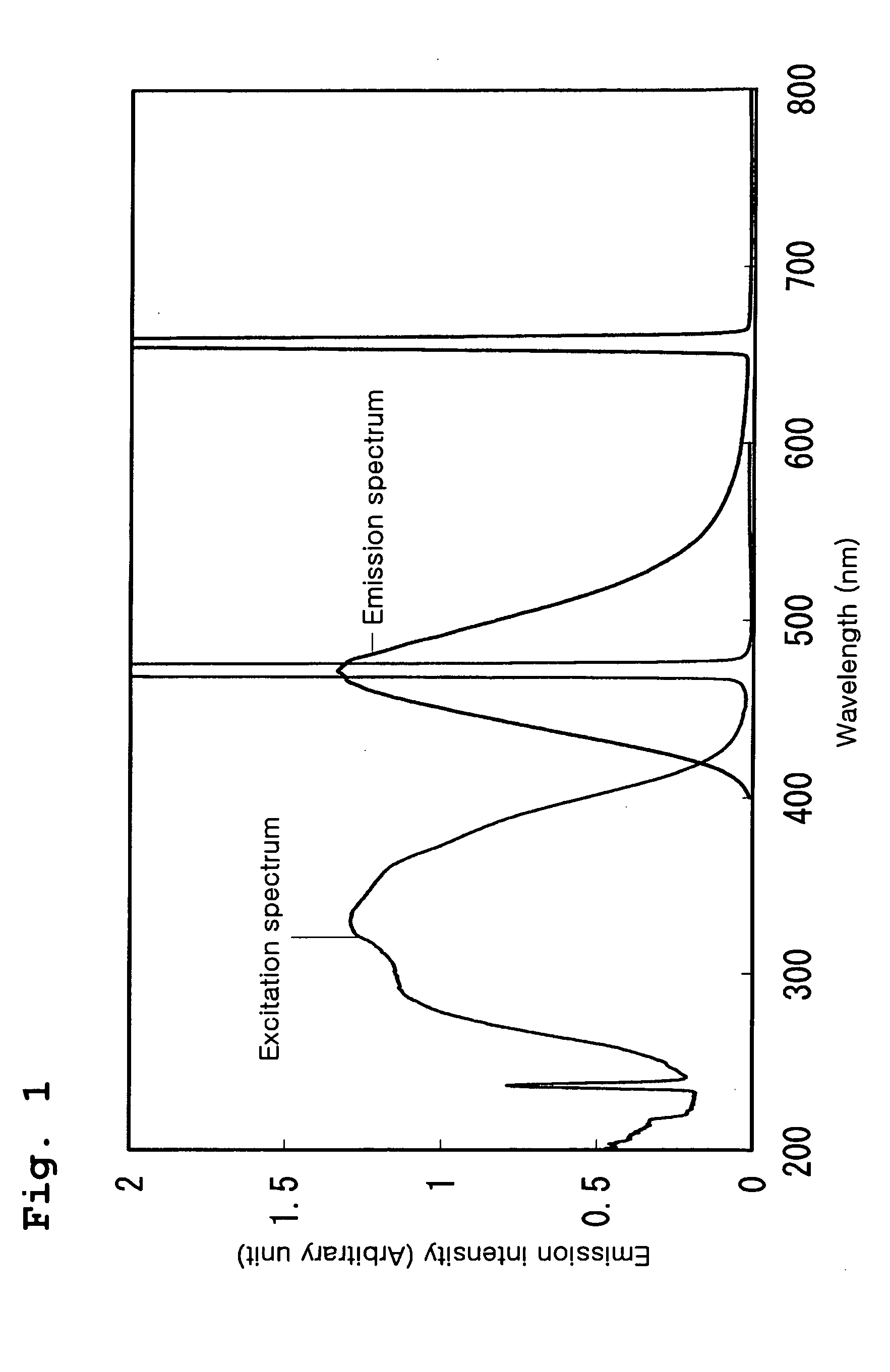

Method and apparatus for manufacturing organic EL display and color filter by ink jet method

InactiveUS20050100660A1Bright enoughPractical and convenientSolid-state devicesSemiconductor/solid-state device manufacturingColor gelEngineering

The object of the present invention is to provide a method and apparatus for manufacturing an EL layer of uniform thickness, causing effective light emission of pixel openings and manufacturing an organic EL display showing sufficient brightness and excellent in practicability, by an ink jet method. Further object is to provide a method and apparatus for manufacturing a color filter excellent in practicability by an ink jet method, in which a dye layer with uniform thickness is formed and optical coloring of uniform tone is conducted at pixel openings. In order to achieve the above object, the present invention is a method for manufacturing an organic EL display by an ink jet method, wherein an uniform organic EL layer is formed by sequentially continuously carrying out: a process of discharge-placing at least an organic EL material in the form of solution on a substrate; and a process of drying the organic EL material in the form of ink placed on the substrate by heating, and the organic EL material is dried by heating over thereof. Further, the placing of the organic EL material on the substrate and drying by heating are sequentially continuously carried out by relatively moving the substrate to a nozzle which discharges the organic EL material and to a device which heats the organic EL material over thereof.

Owner:DAI NIPPON PRINTING CO LTD

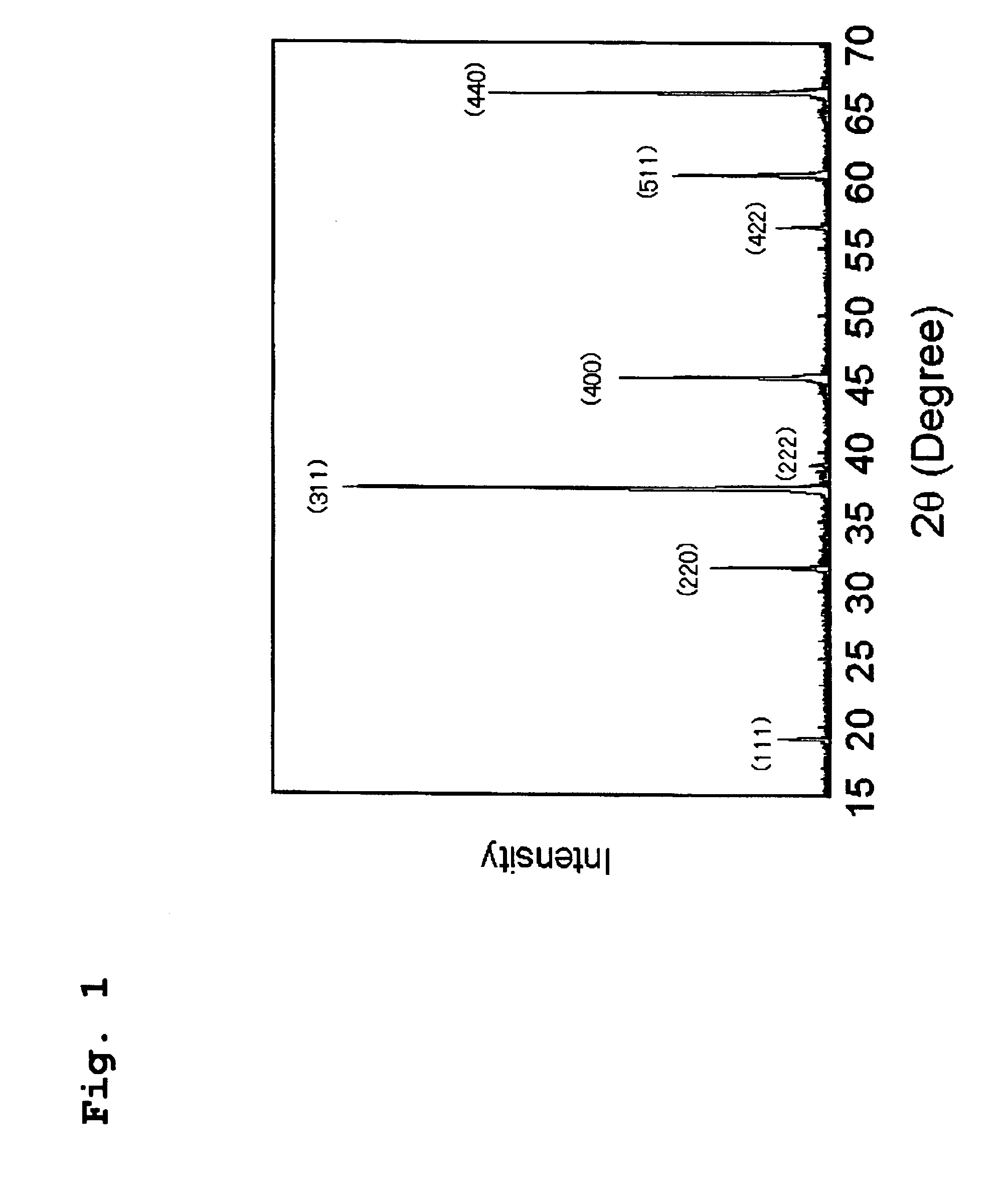

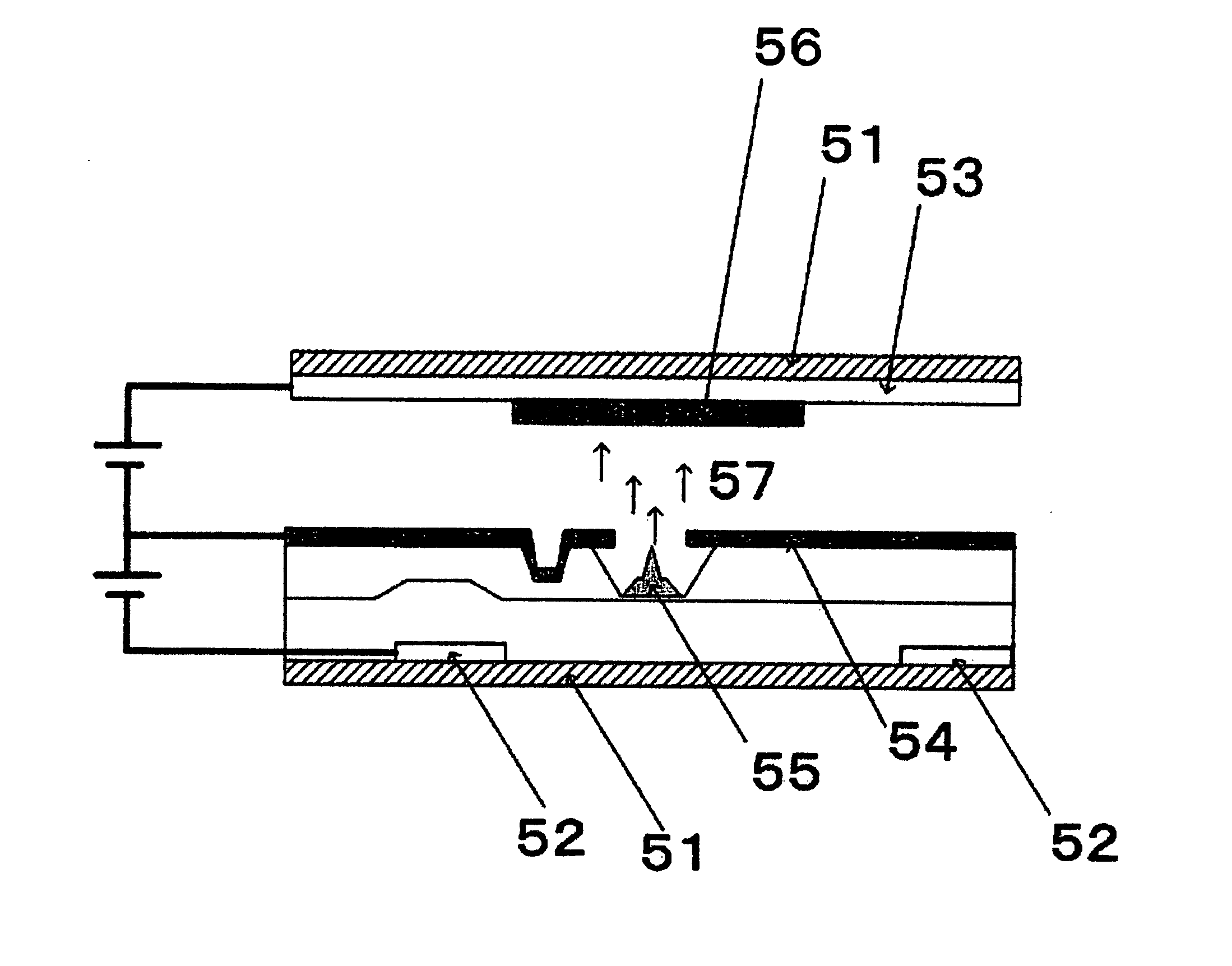

Phosphor and including the same, light emitting apparatus, illuminating apparatus and image display

InactiveUS7608200B2Efficiently emitsIncrease brightnessLaser detailsLaser optical resonator constructionFluorescenceDisplay device

Owner:MITSUBISHI CHEM CORP

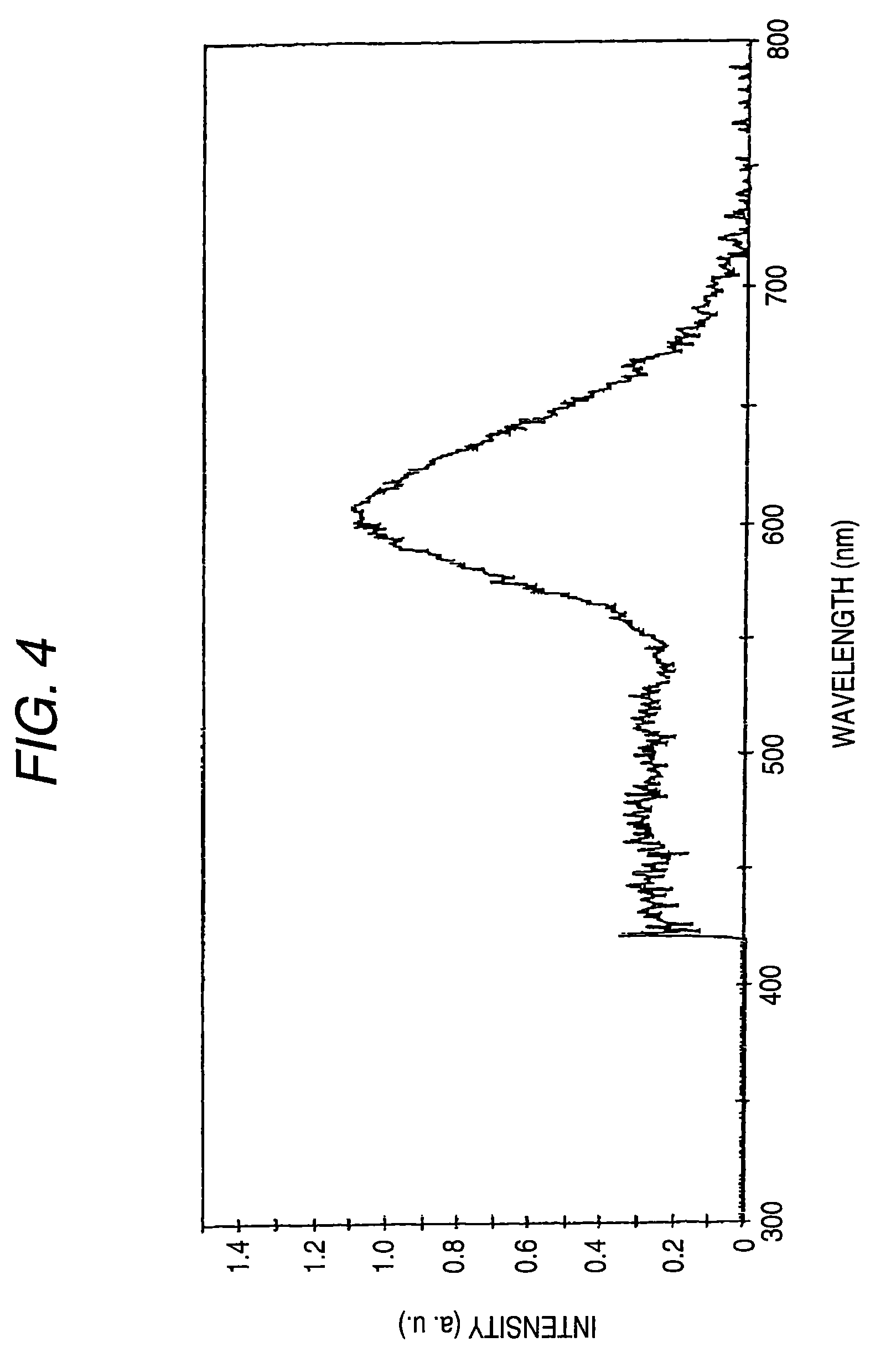

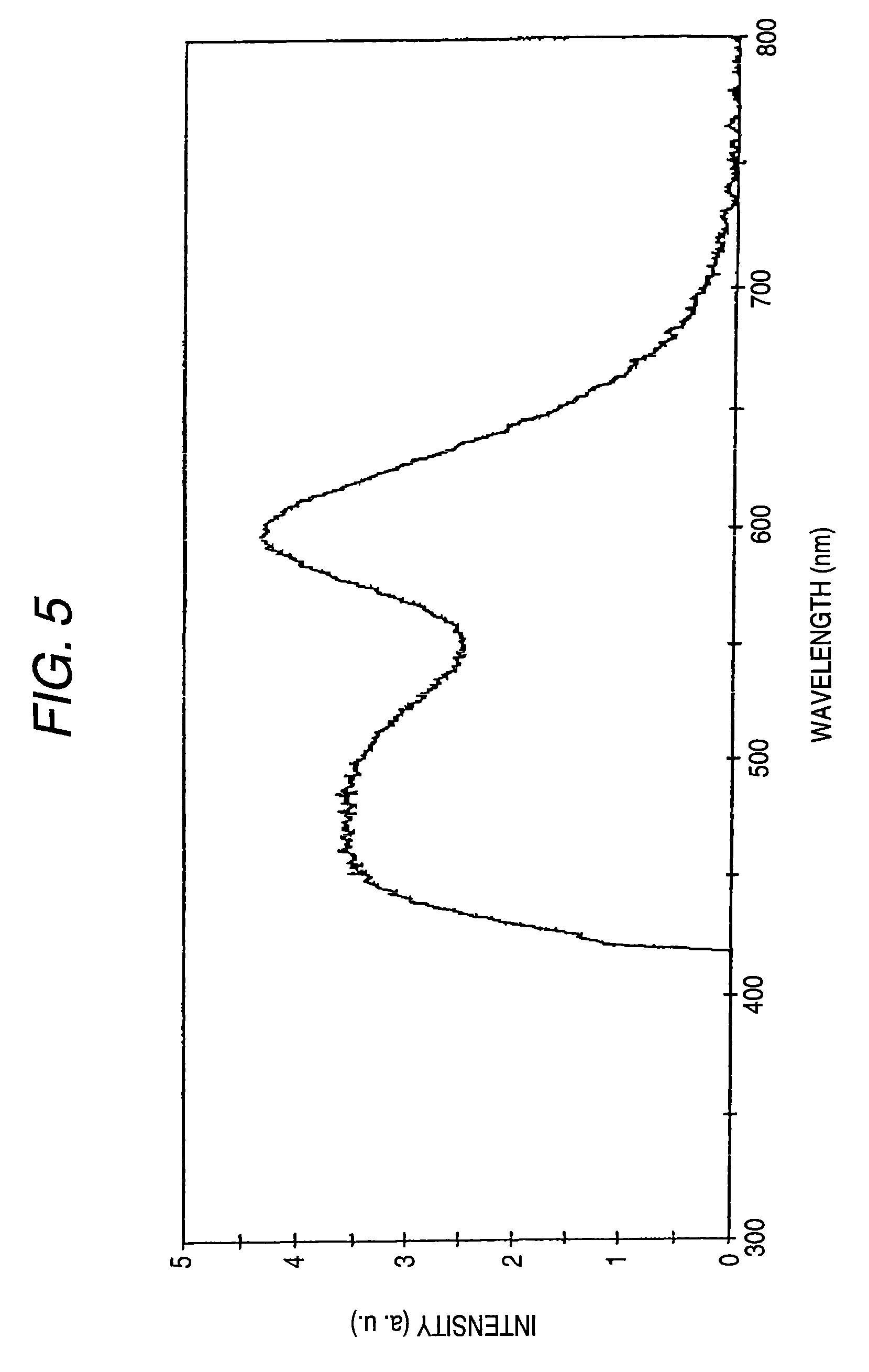

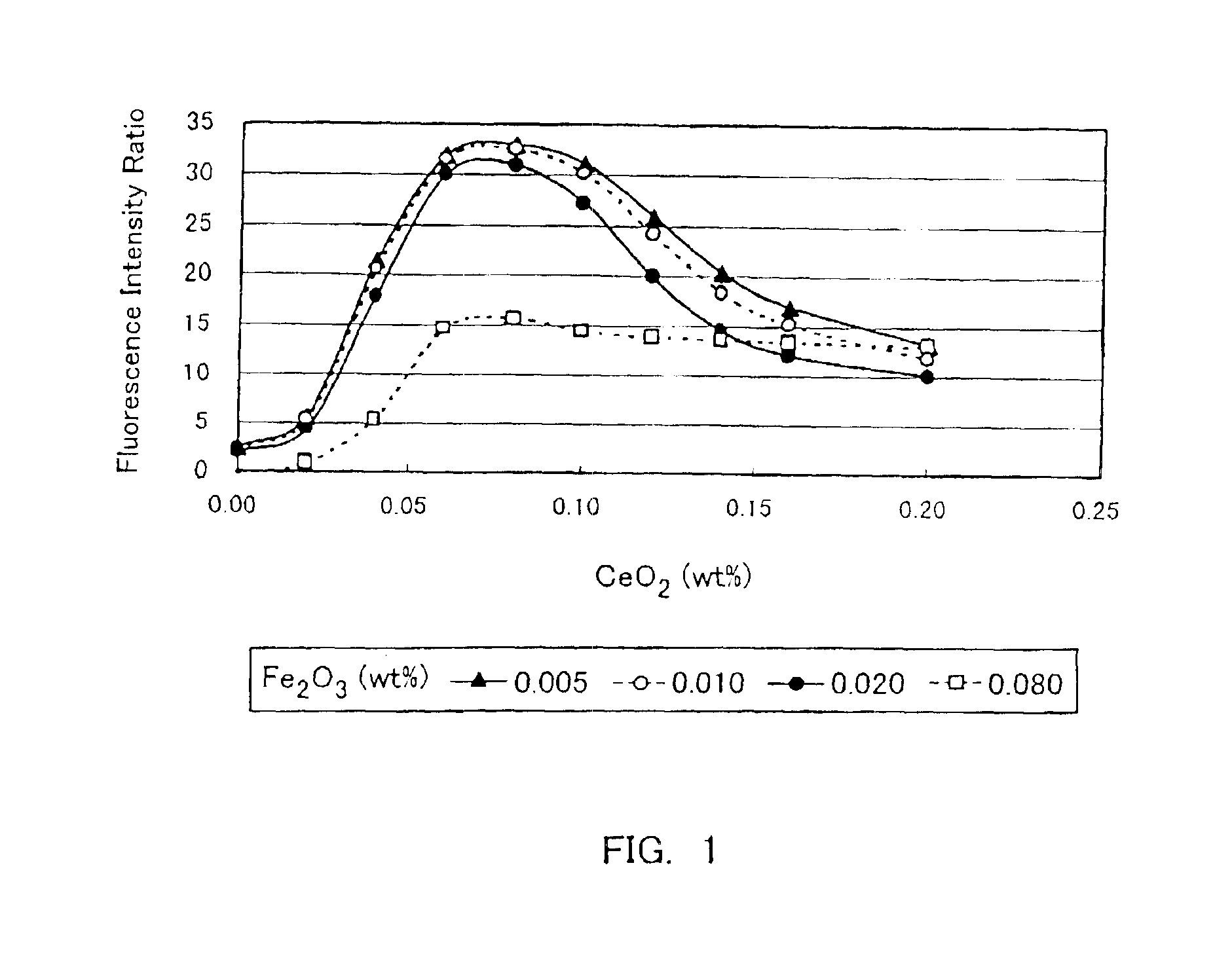

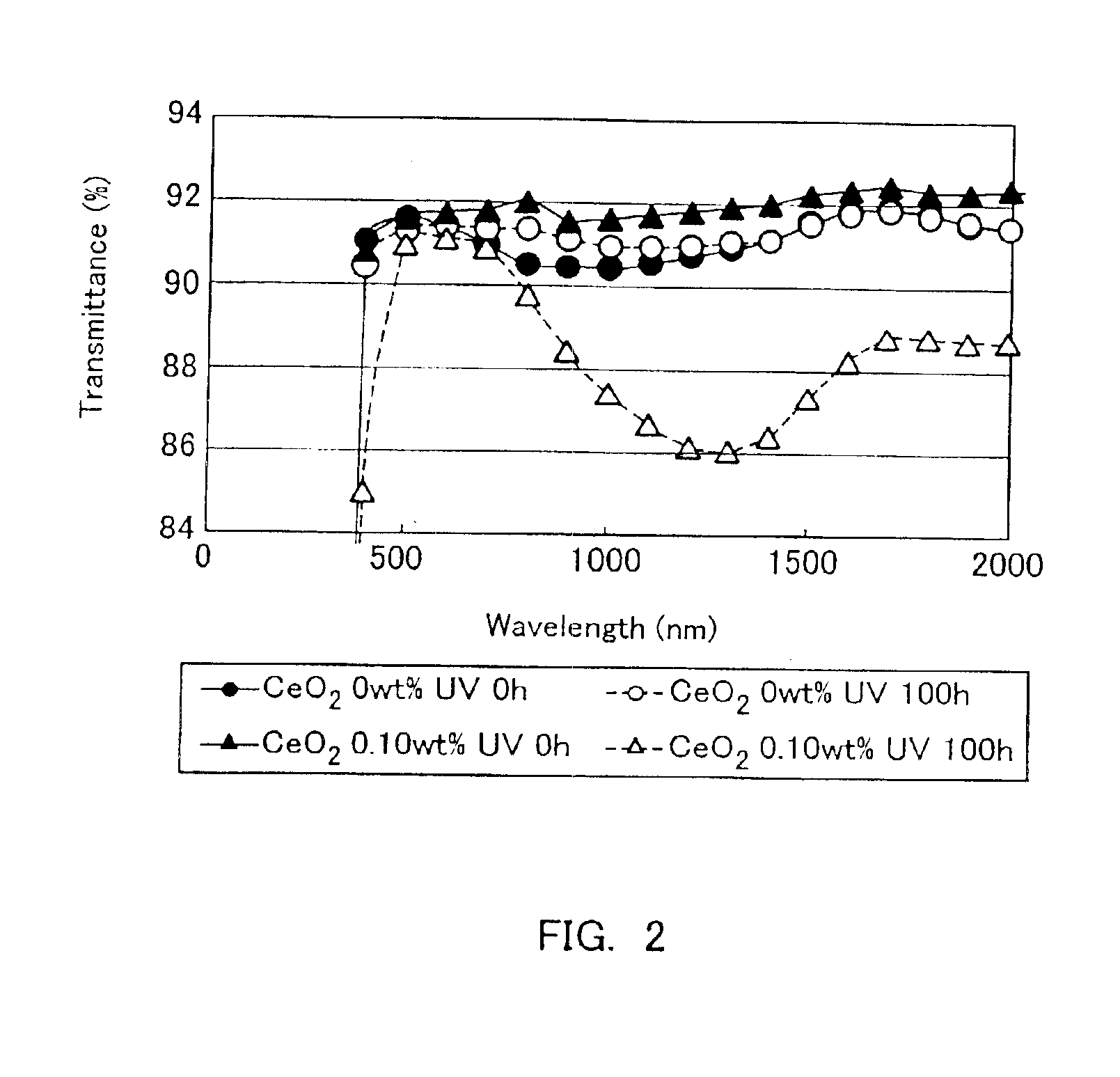

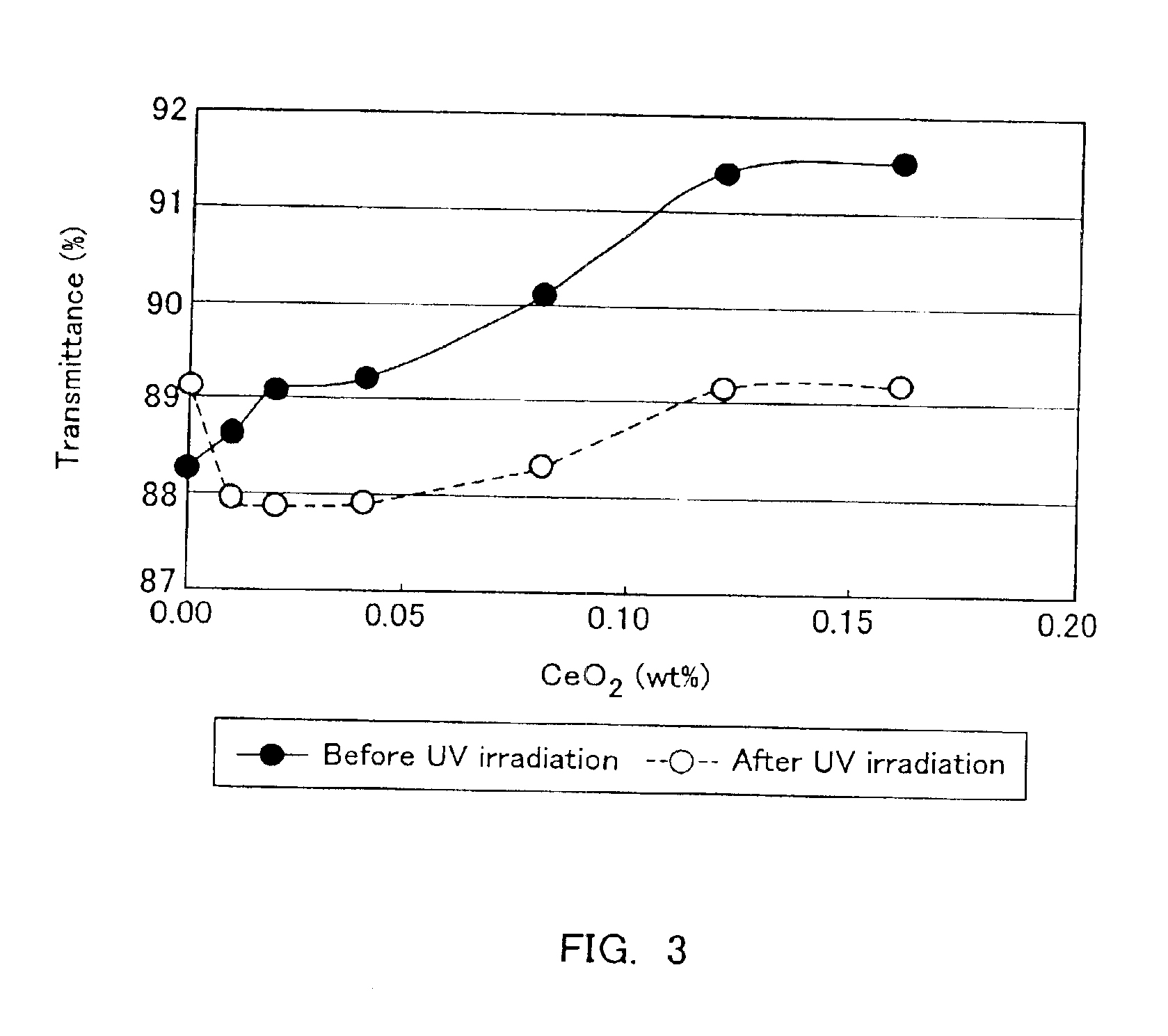

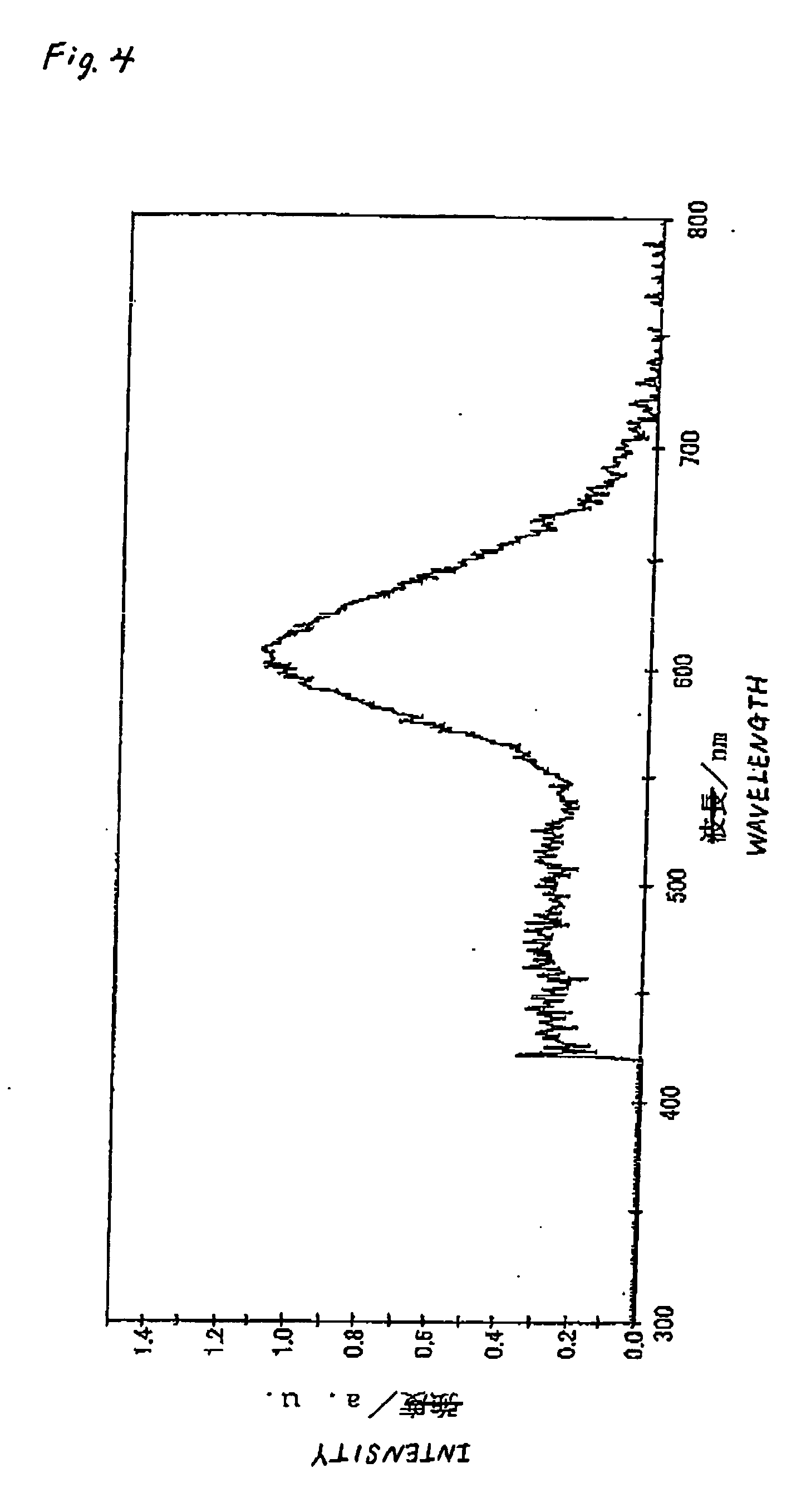

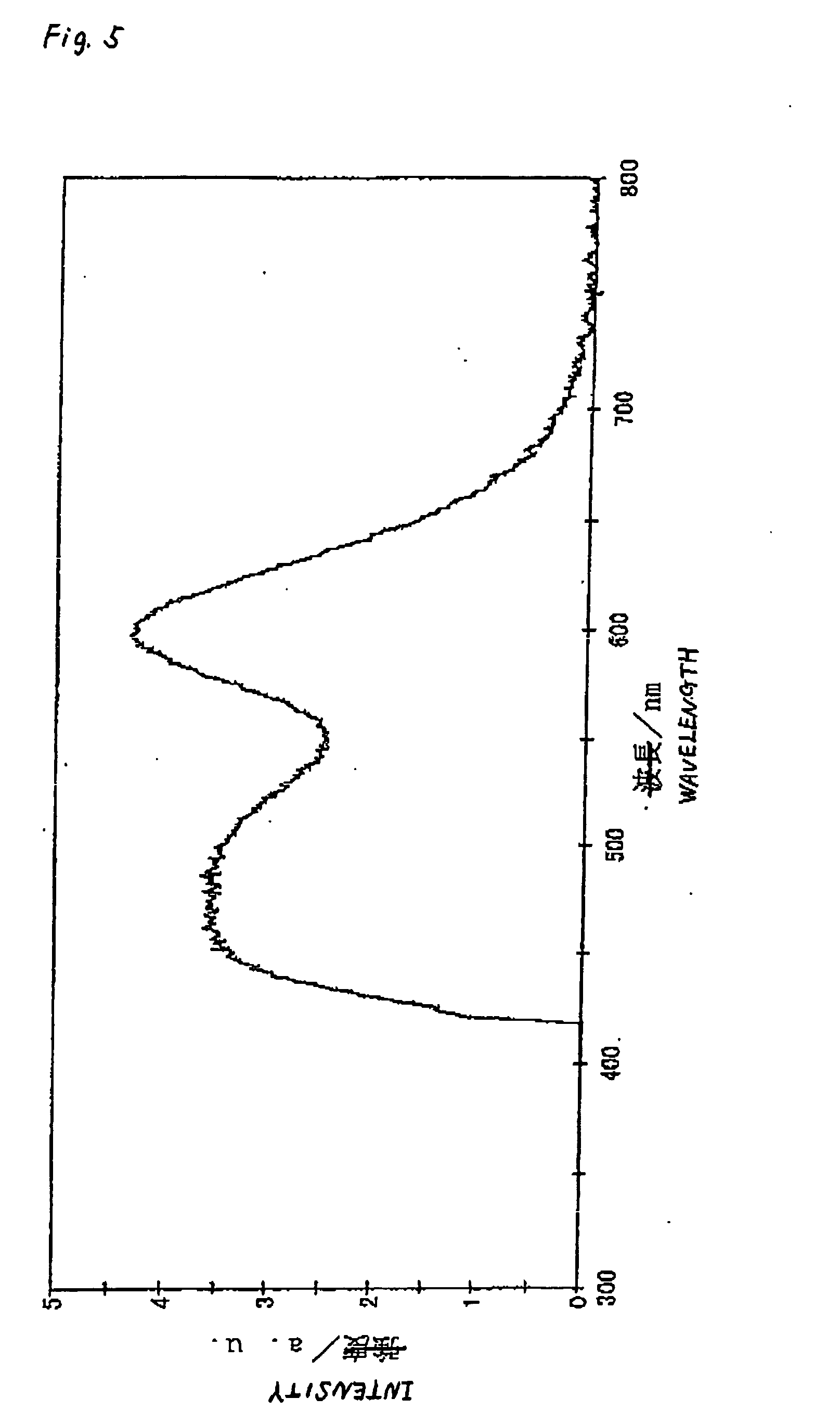

Flat glass having high transmittance

InactiveUS6844280B2High light transmittanceEfficiently emitsSolid-state devicesGlass drawing apparatusFlat glassUltraviolet

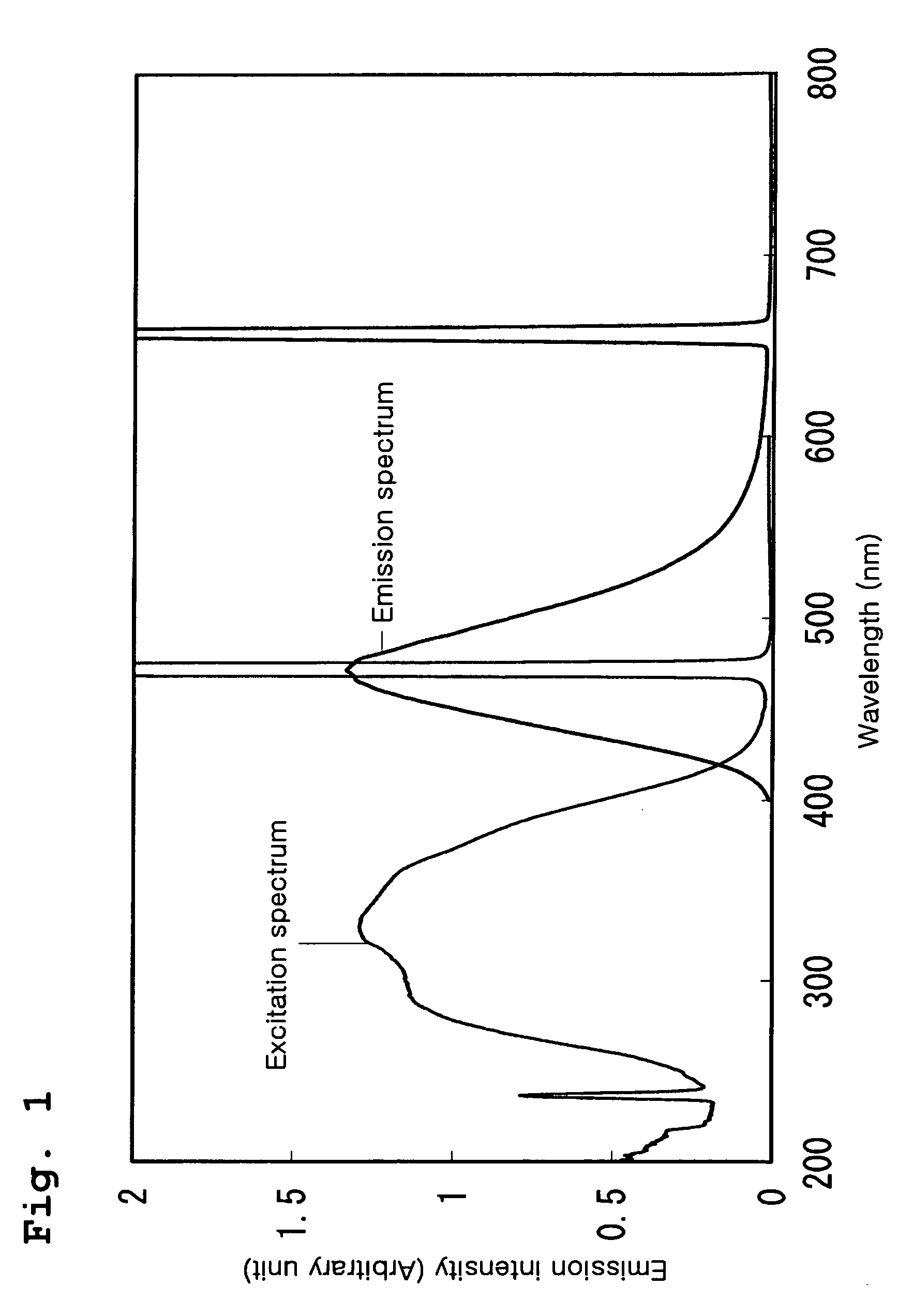

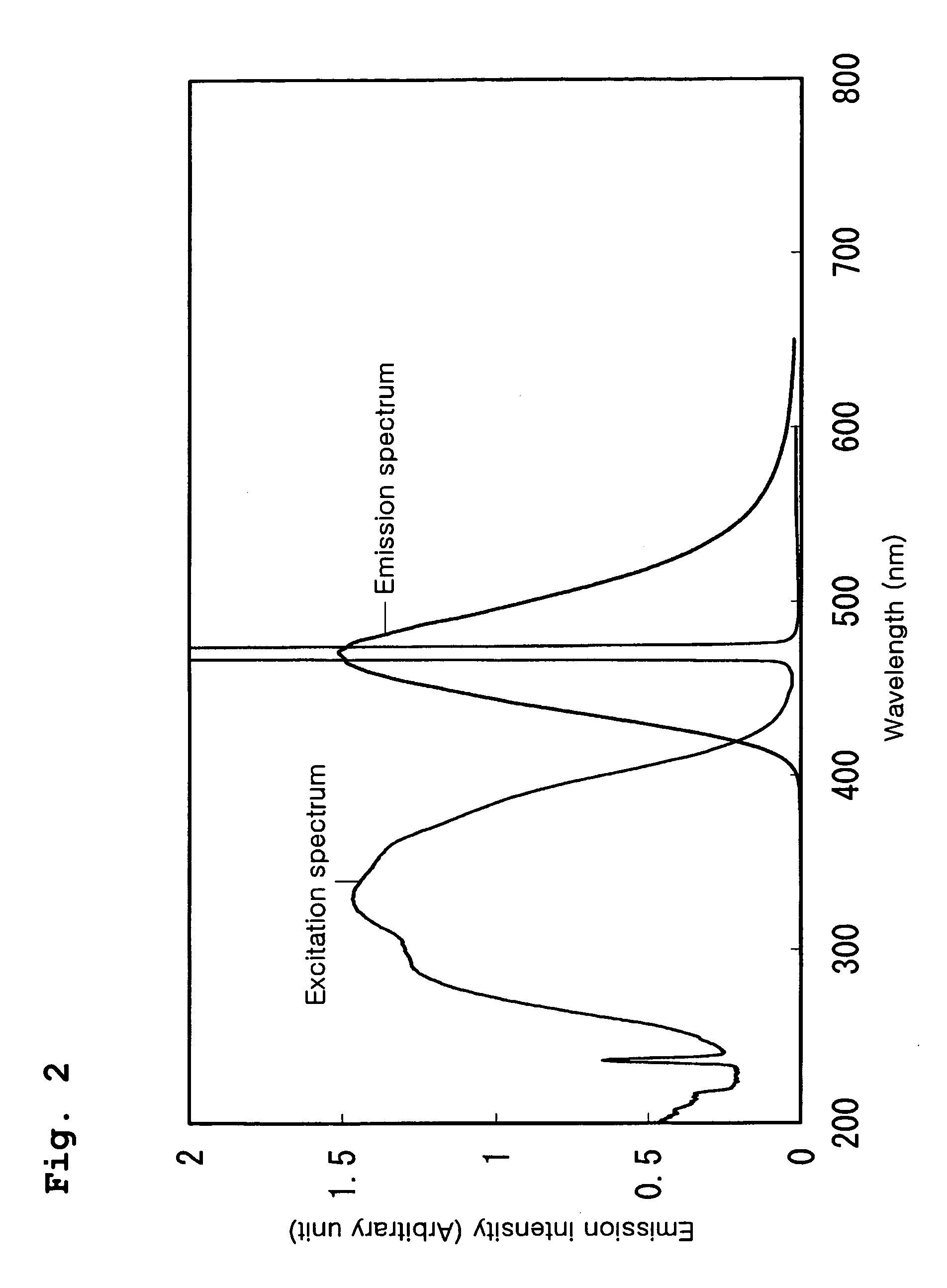

The present invention is to provide a high transmittance glass sheet that has a composition containing as coloring components, expressed in wt. %, 0.005 to less than 0.02% of total iron oxide in terms of Fe2O3, less than 0.008% of FeO, and 0 to 0.25% of cerium oxide and having a ratio of FeO in terms of Fe2O3 to the total iron oxide of lower than 40%, and exhibits high visible light transmittance and solar radiation transmittance. Alternatively, a high transmittance glass sheet is provided that contains not more than 0.06% of total iron oxide and 0.025 to 0.20% of cerium oxide and has a ratio of a fluorescence intensity at 395 nm to a fluorescence intensity at 600 nm of 10% or higher when subjected to ultraviolet irradiation at a wavelength of 335 nm.

Owner:NIPPON SHEET GLASS CO LTD

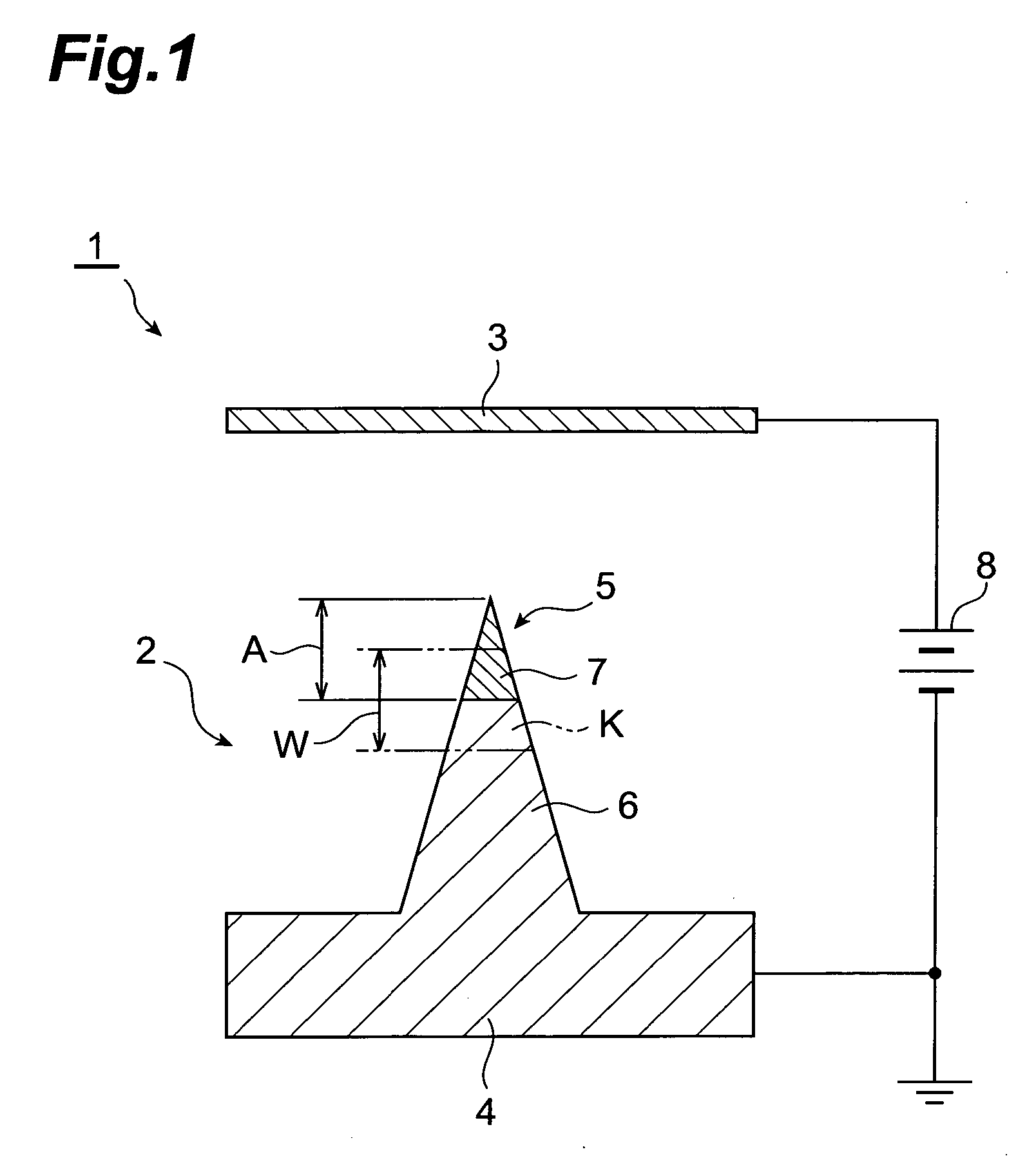

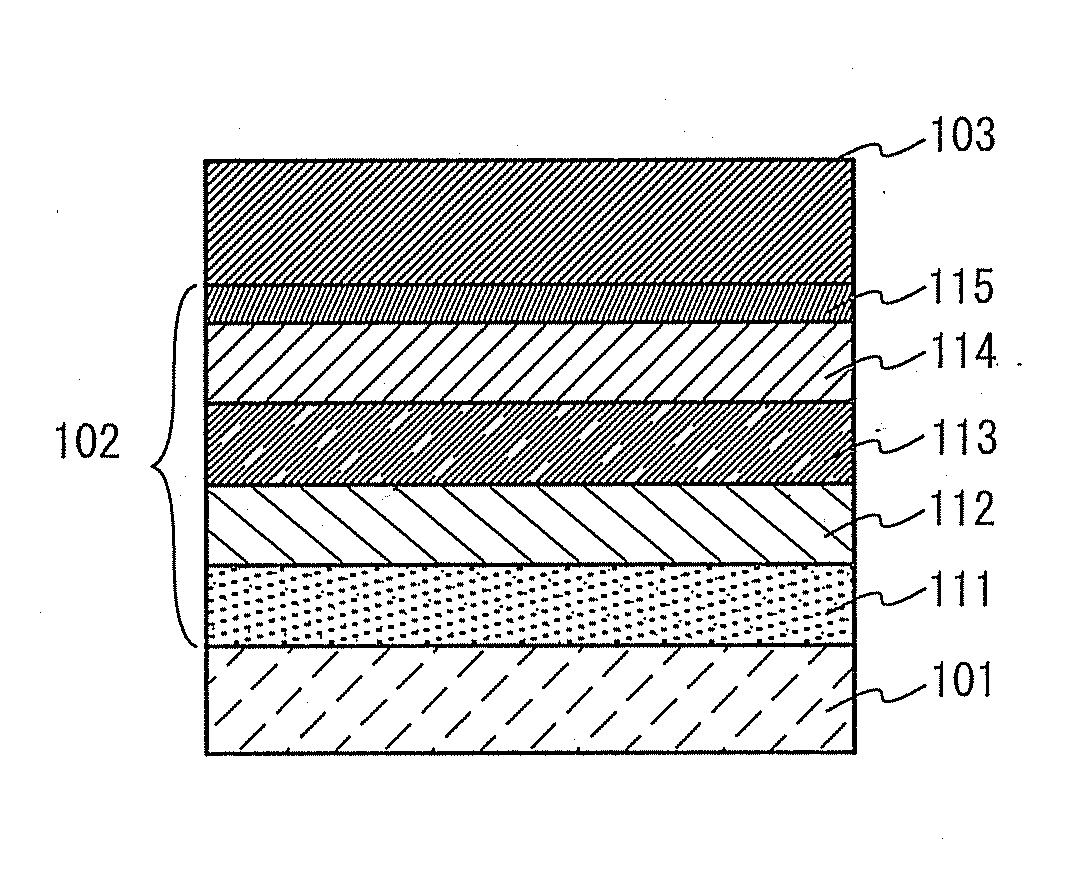

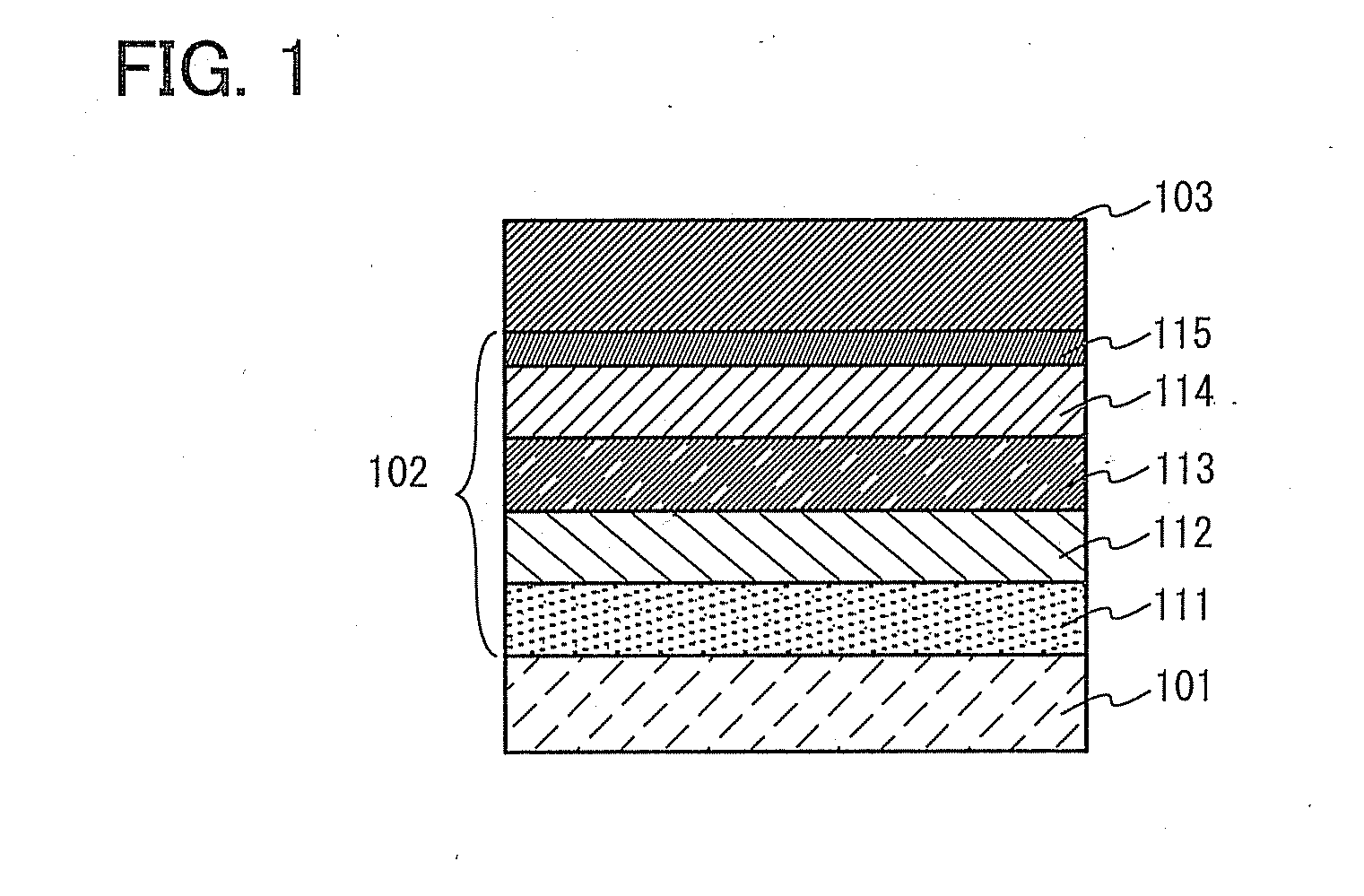

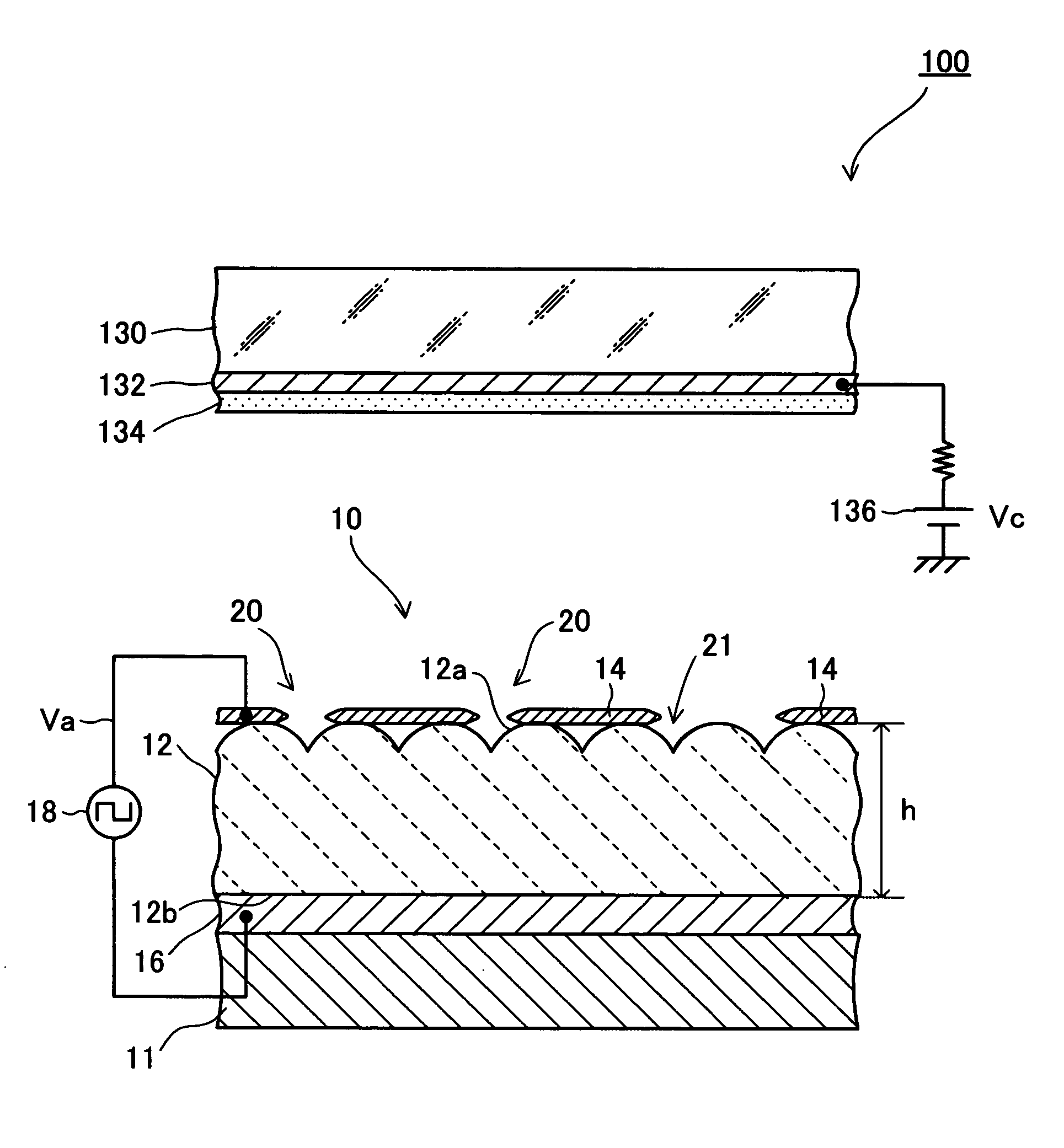

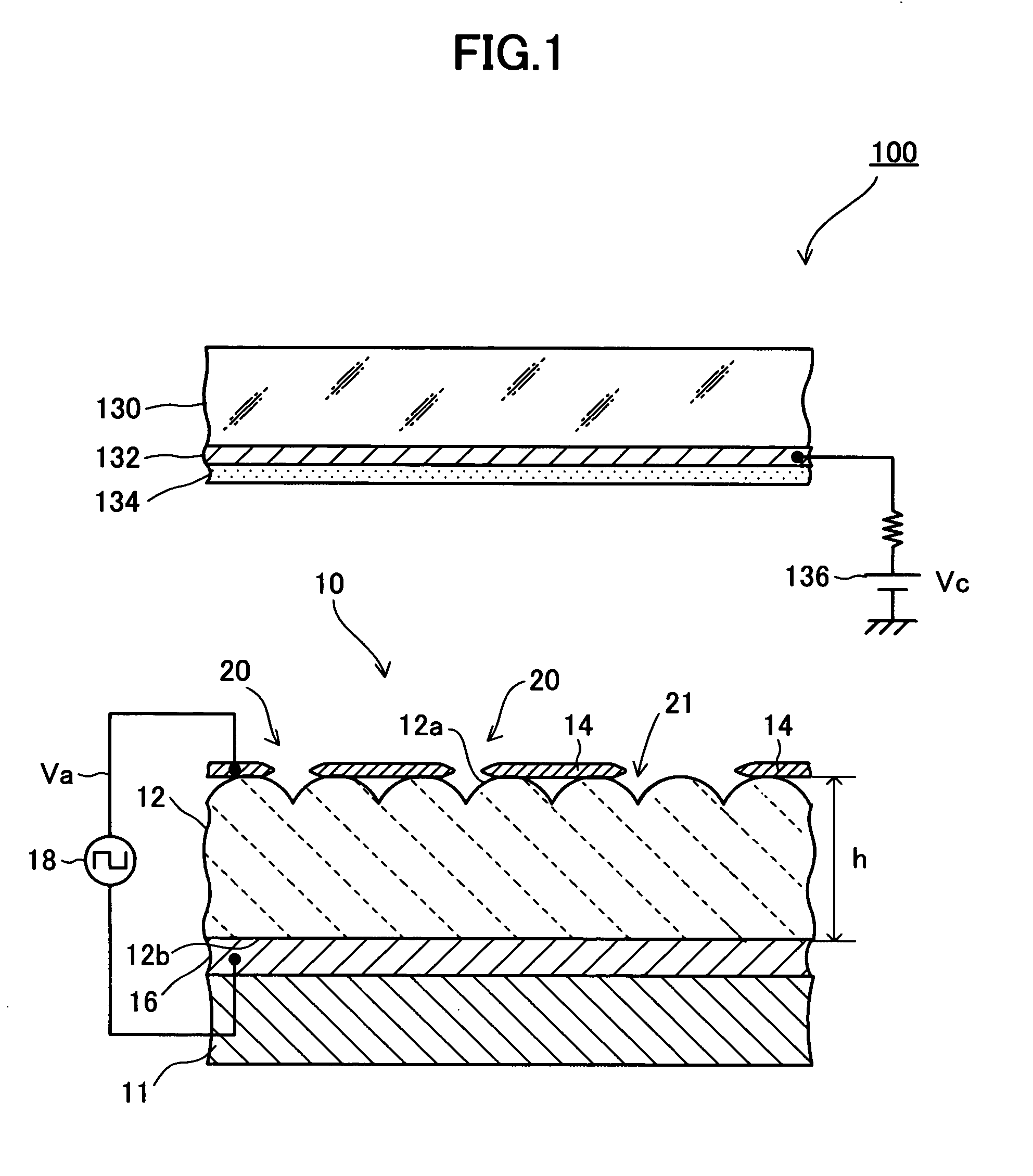

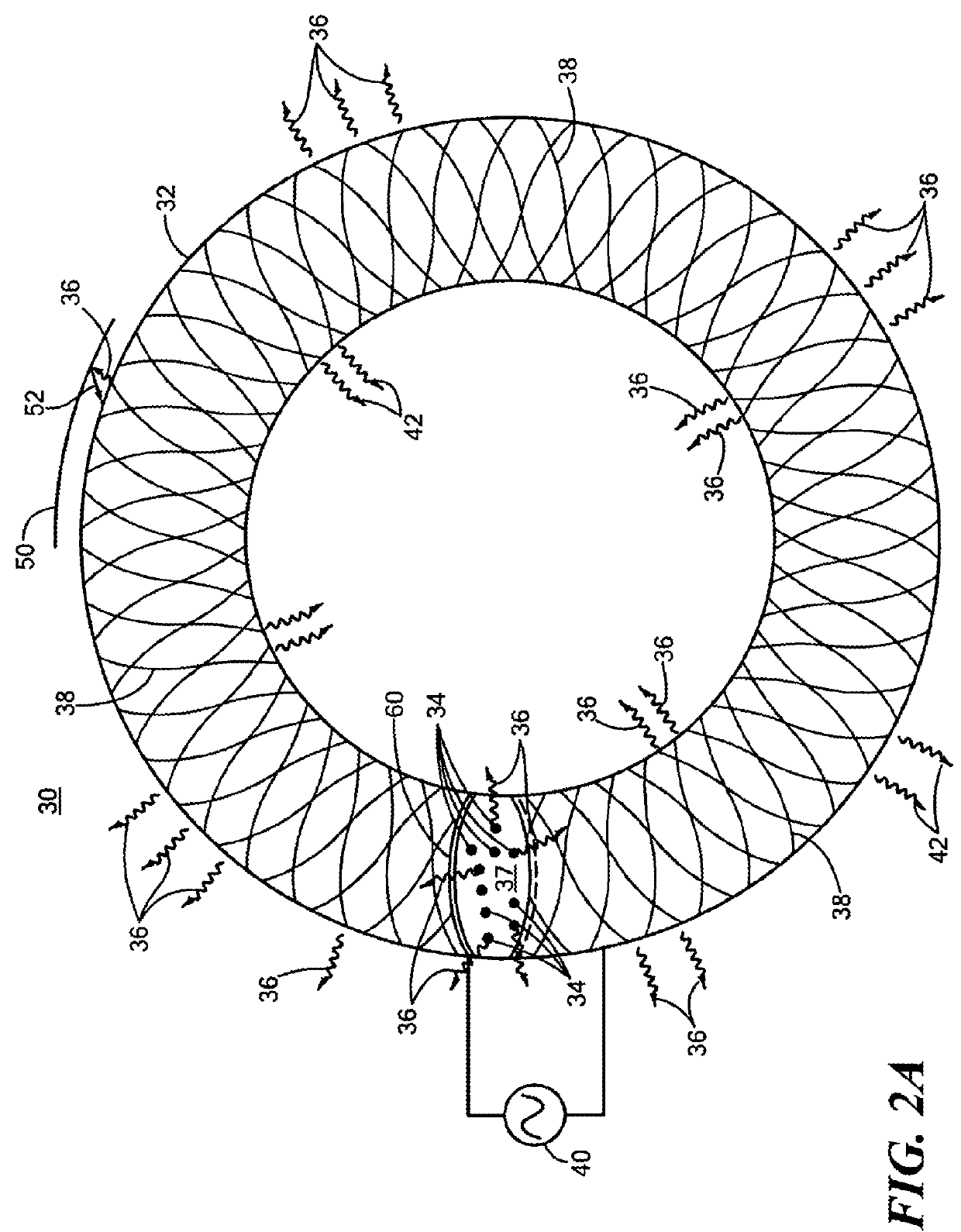

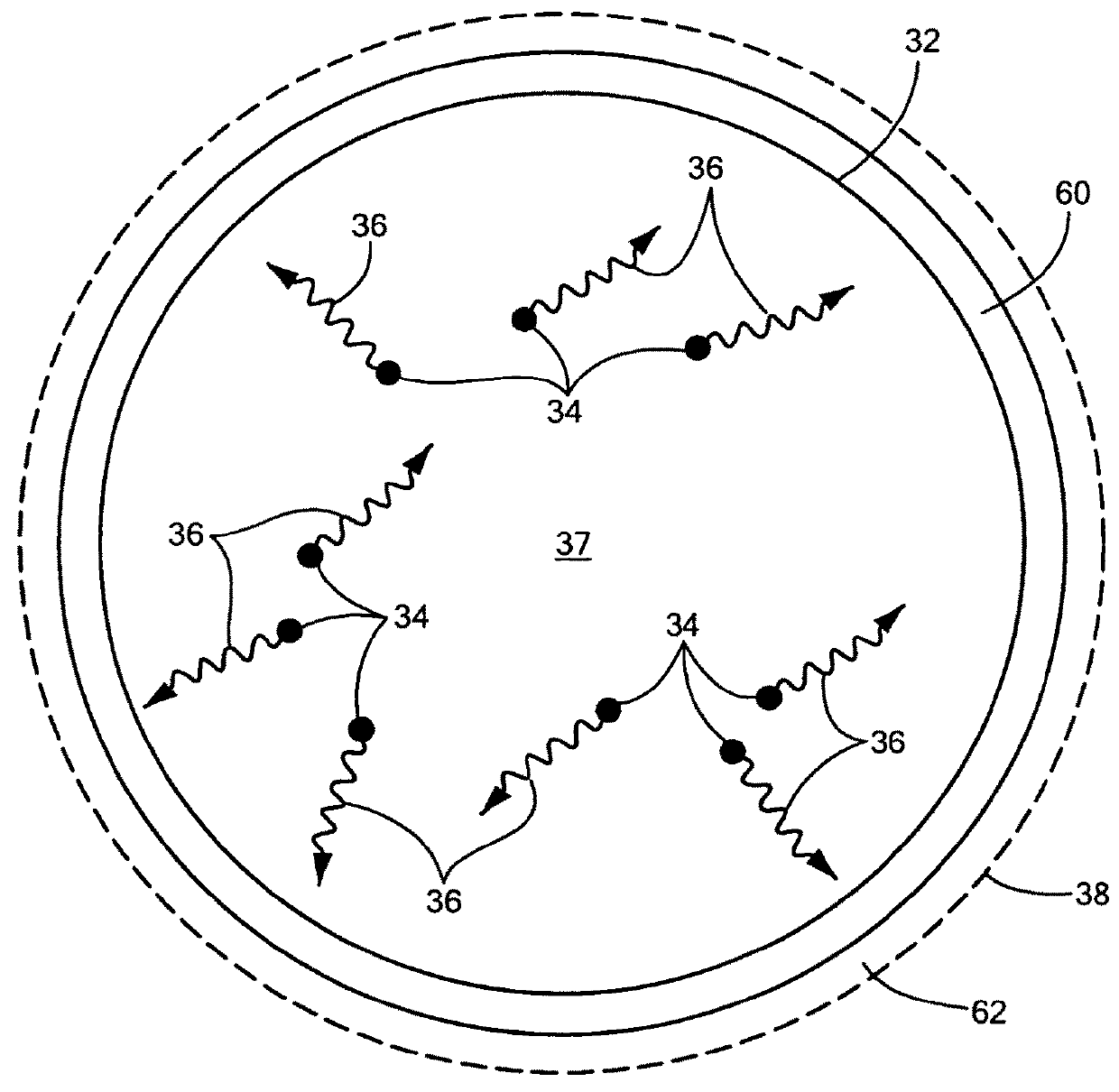

Electron emitter formed of a dielectric material characterized by having high mechanical quality factor

InactiveUS7723909B2Increase productionIncrease speedDischarge tube luminescnet screensNanoinformaticsThin layerElectron

A dielectric-film-type electron emitter includes an emitter section, a first electrode, and a second electrode. The emitter section is formed of a thin layer of a polycrystalline dielectric material. The dielectric material constituting the emitter section is formed of a material having high mechanical quality factor (Qm). Specifically, the dielectric material has a Qm higher than that of a so-called low-Qm material (a material having a Qm of 100 or less). The Qm of the dielectric material is preferably 300 or more, more preferably 500 or more.

Owner:NGK INSULATORS LTD

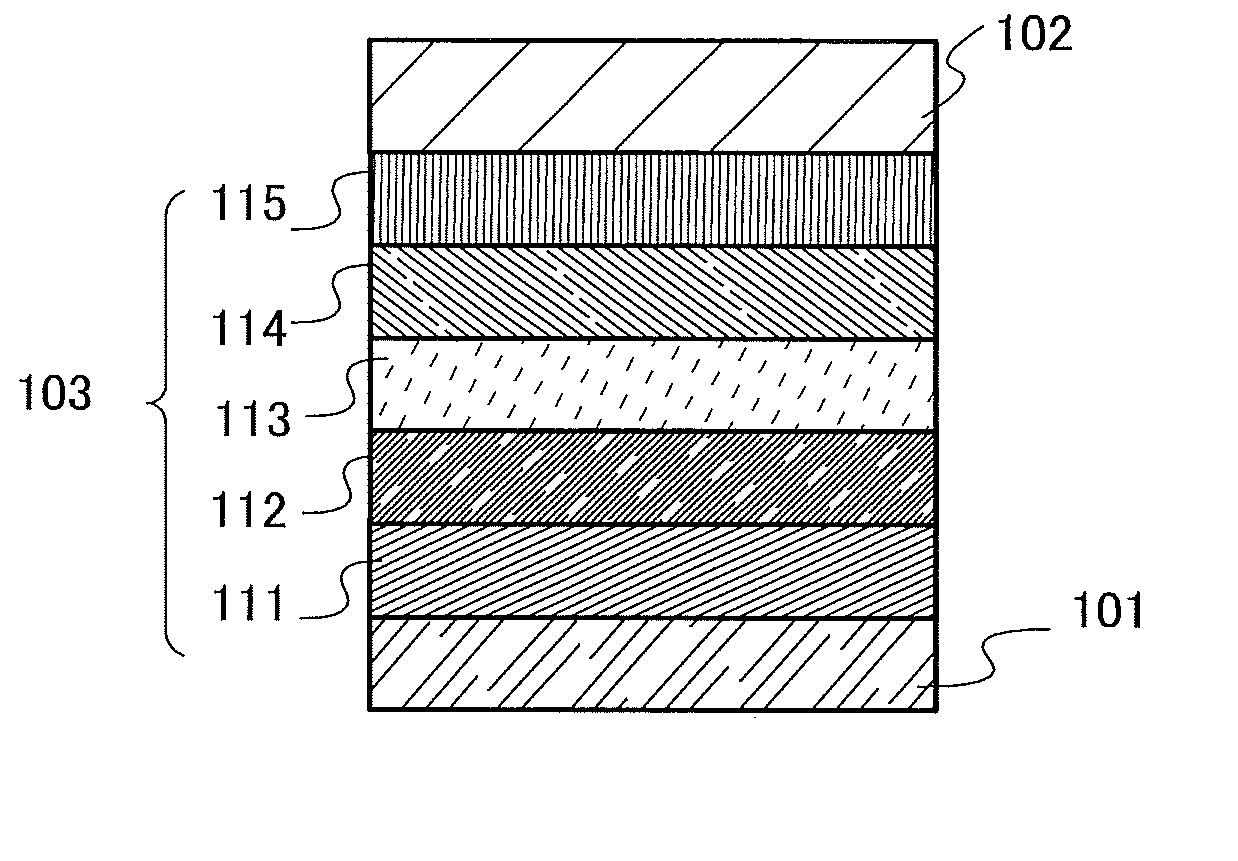

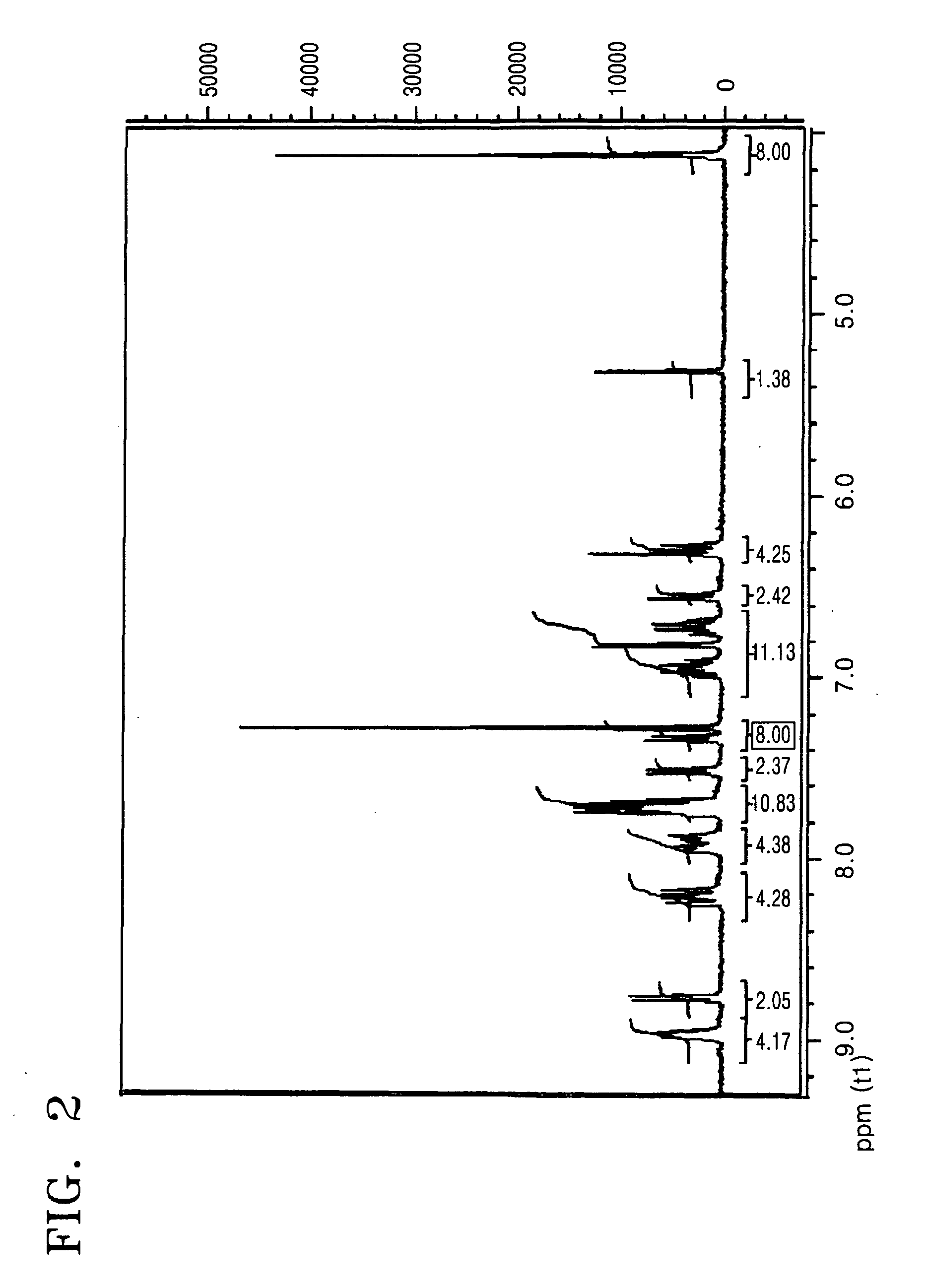

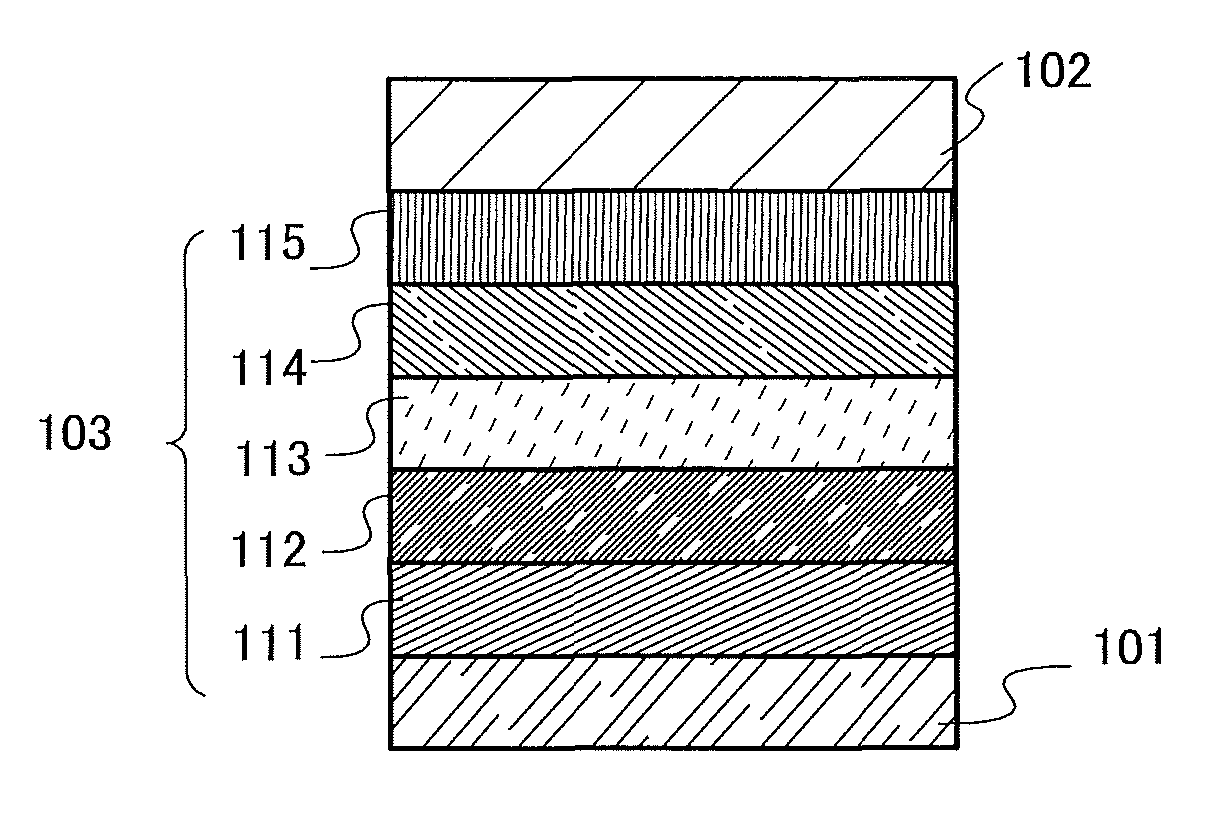

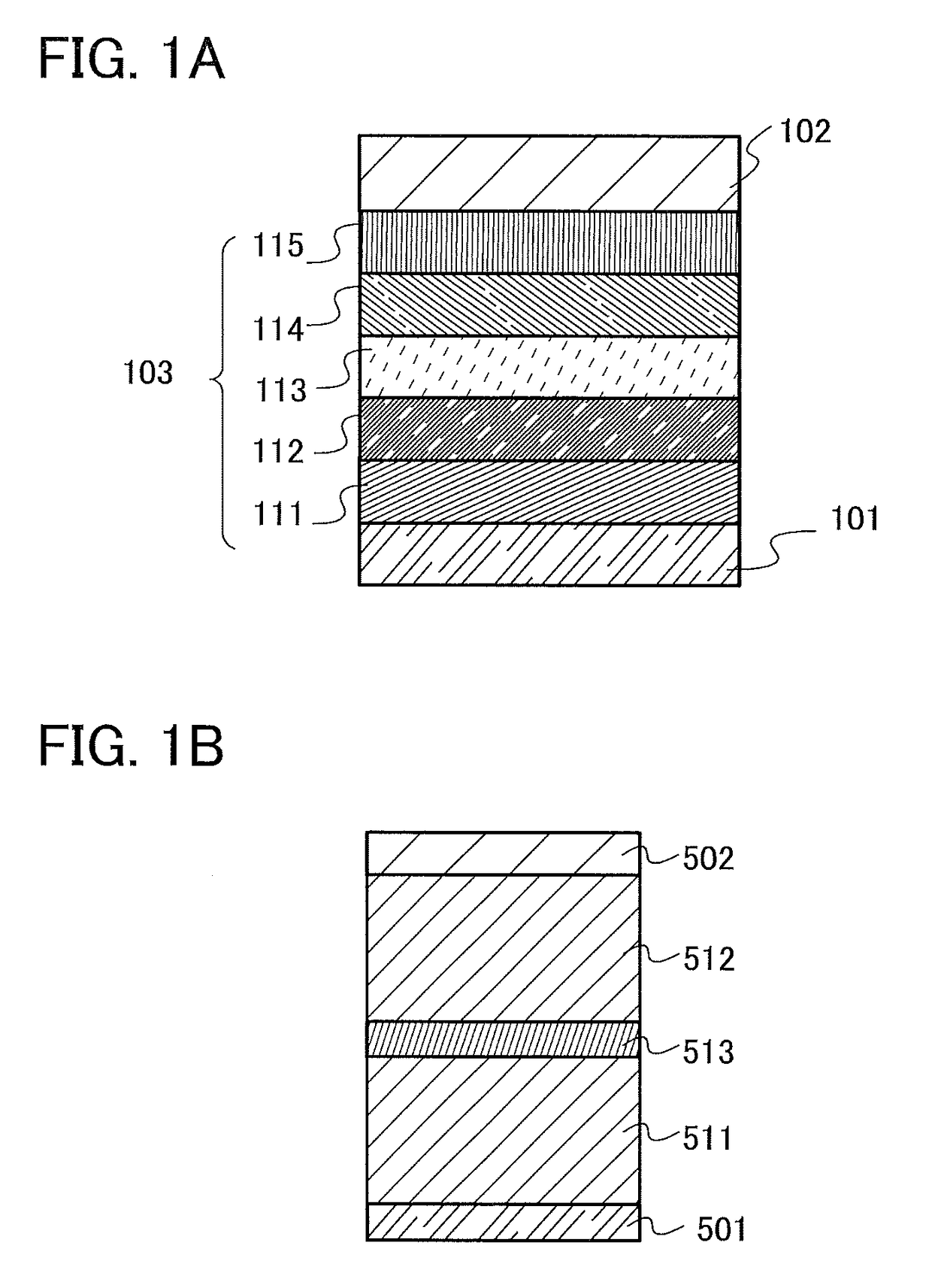

Organic Compound, Light-Emitting Element, Light-Emitting Device, Display Device, Electronic Device, and Lighting Device

ActiveUS20140291643A1Emits light efficientlyImprove emission efficiencyOrganic chemistrySolid-state devicesArylSimple Organic Compounds

A novel organic compound that forms an exciplex emitting light with high efficiency is provided. An organic compound with a triarylamine skeleton in which the three aryl groups of the triarylamine skeleton are a p-biphenyl group, a fluoren-2-yl group, and a phenyl group to which a dibenzofuranyl group or a dibenzothiophenyl group is bonded. By the use of the organic compound and an organic compound with an electron-transport property, an exciplex that emits light with extremely high efficiency can be formed.

Owner:SEMICON ENERGY LAB CO LTD

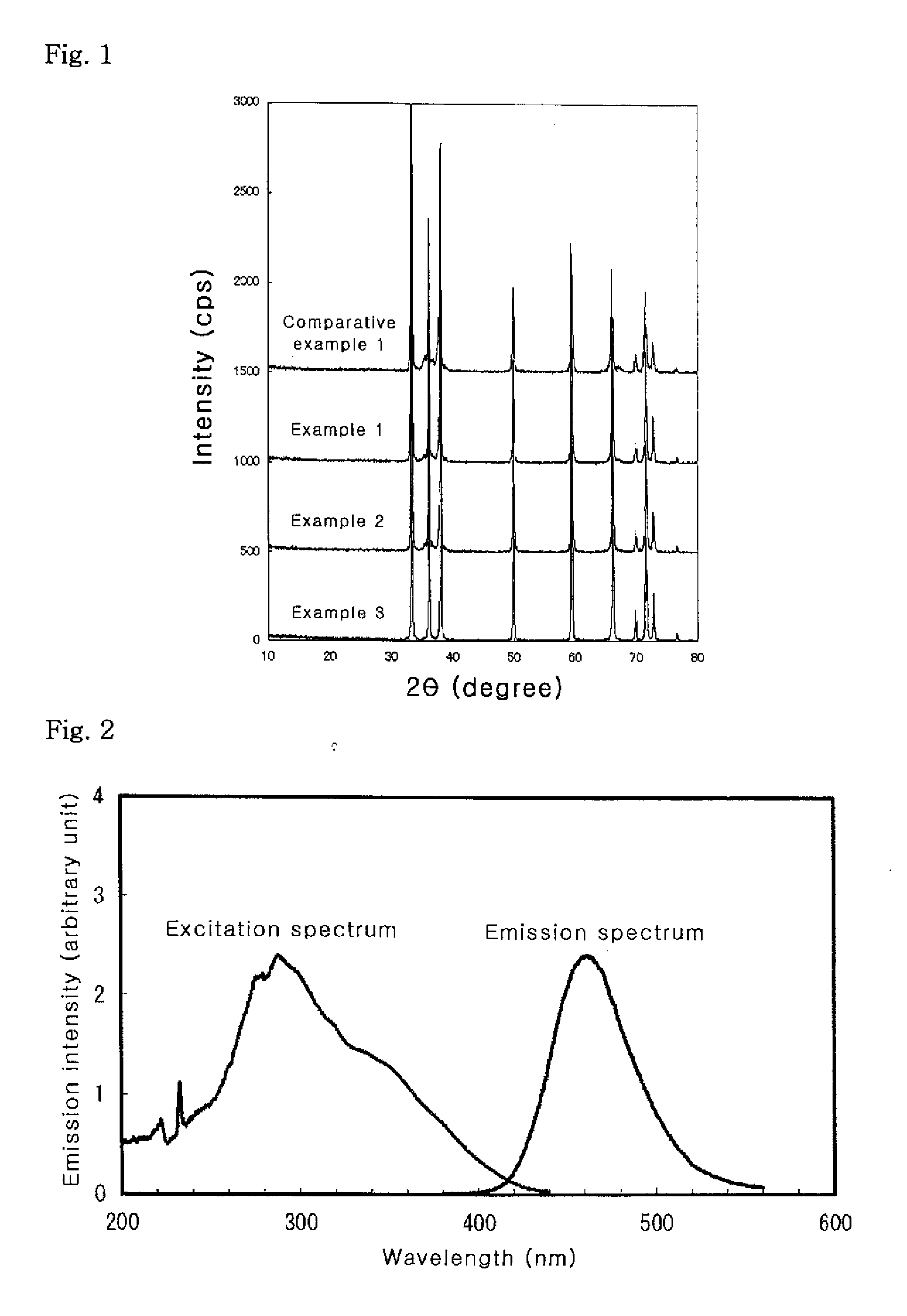

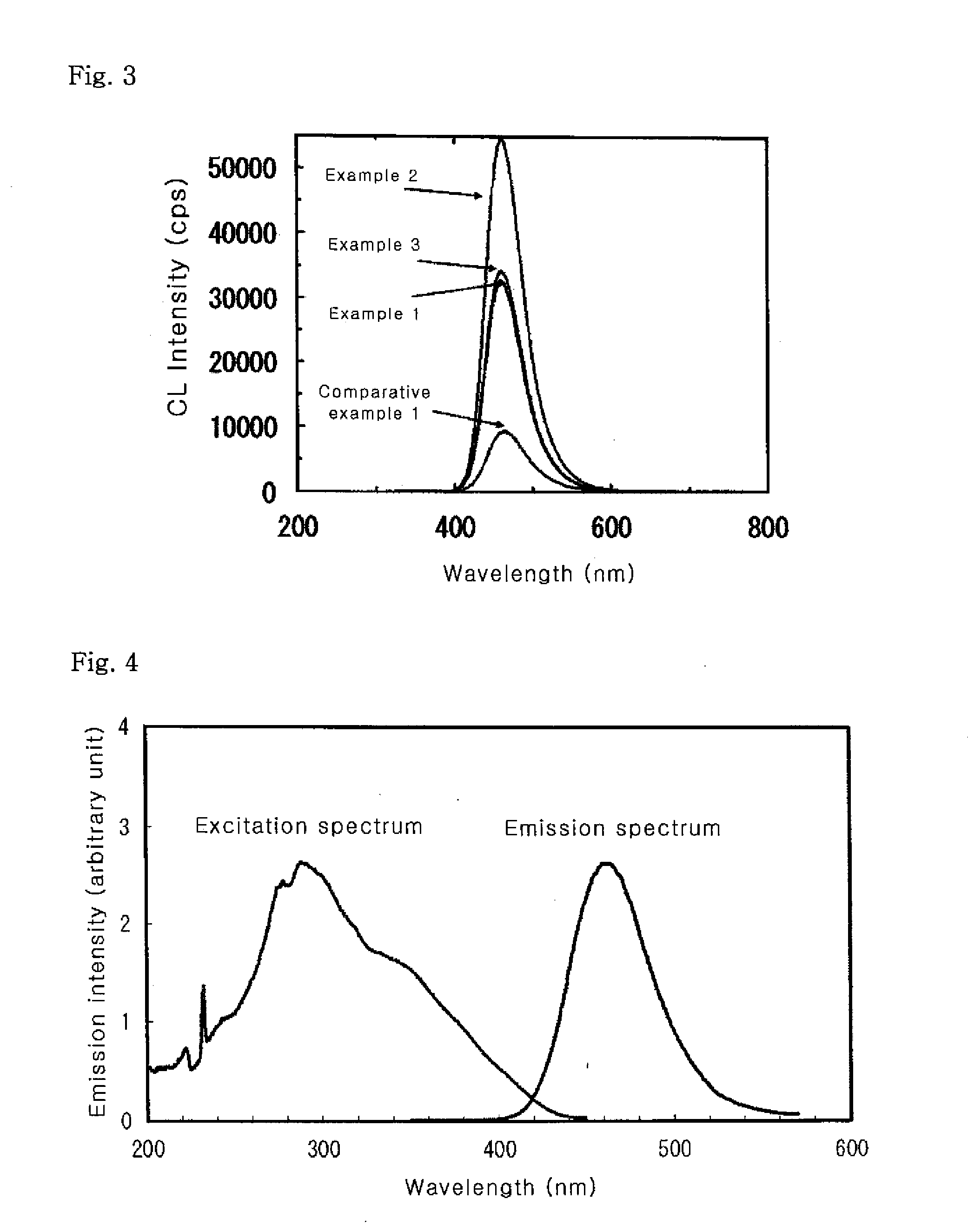

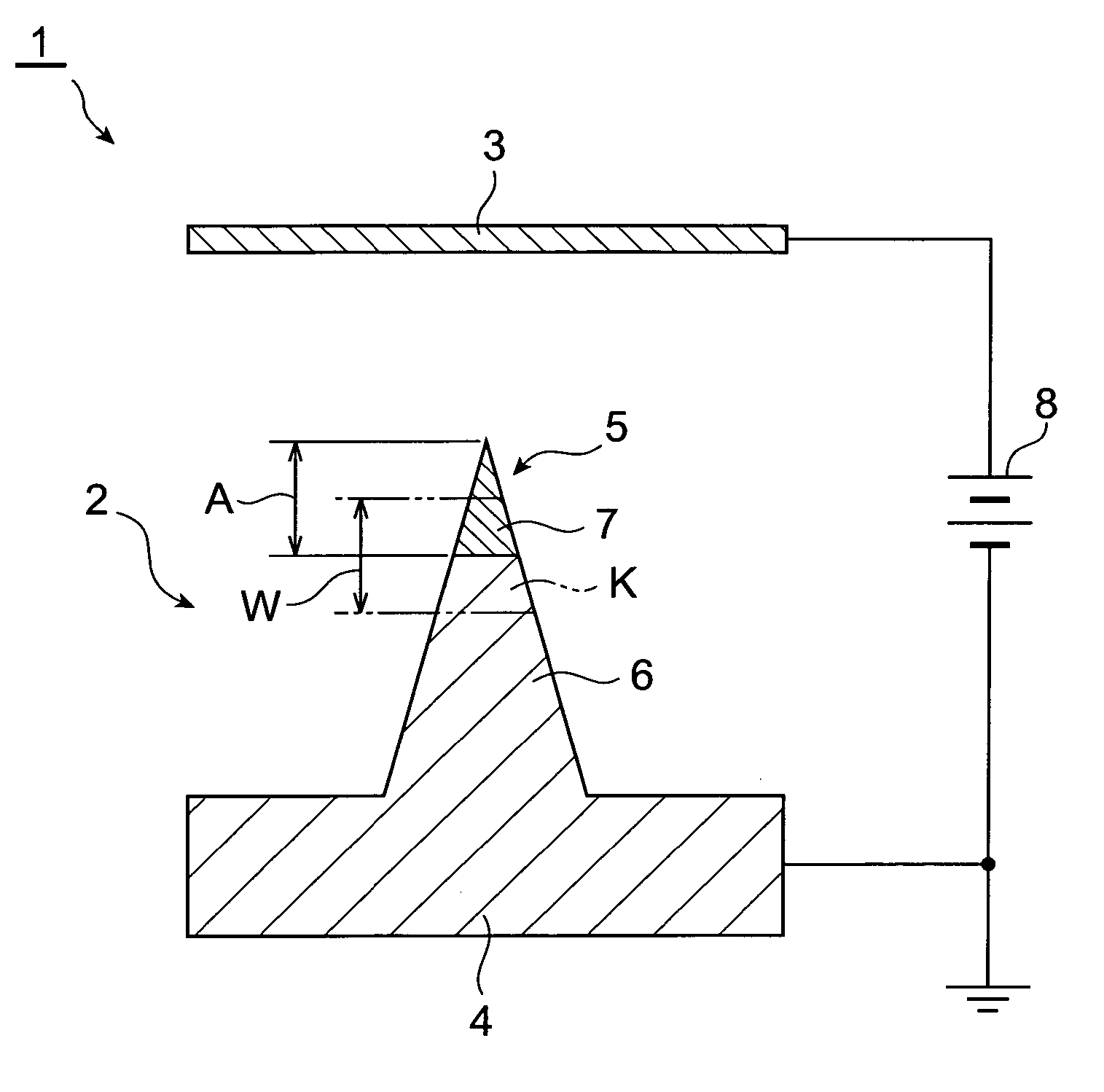

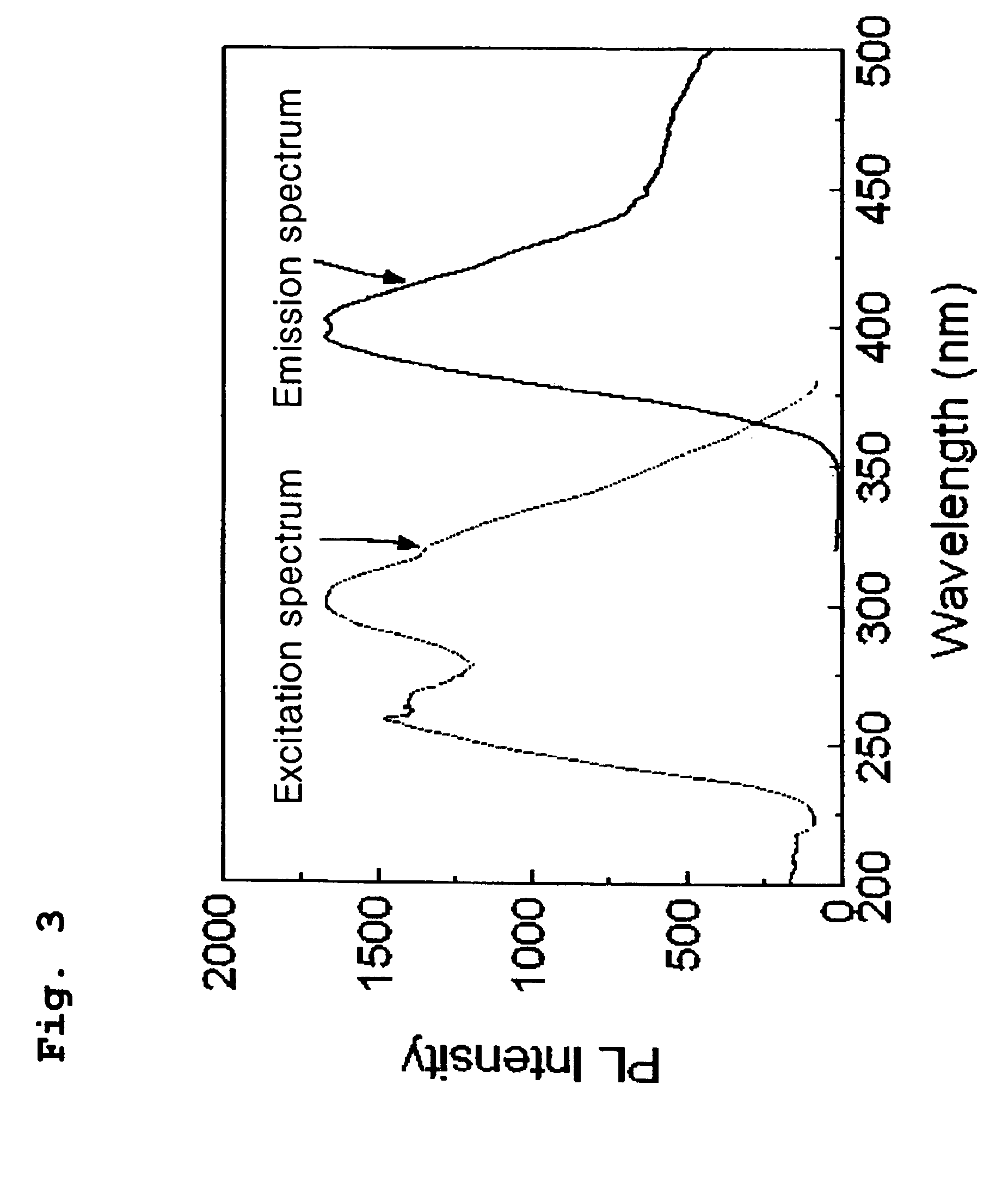

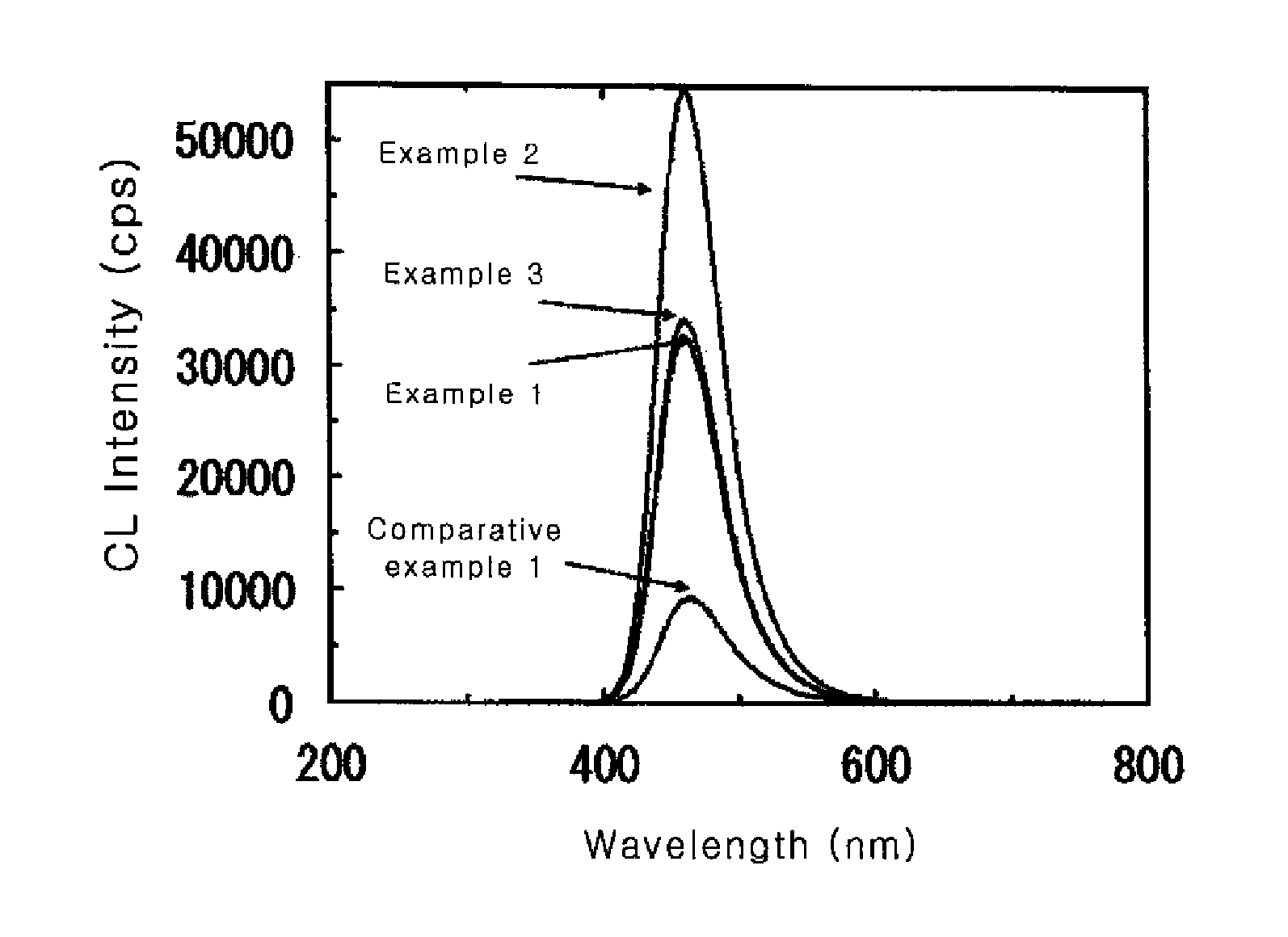

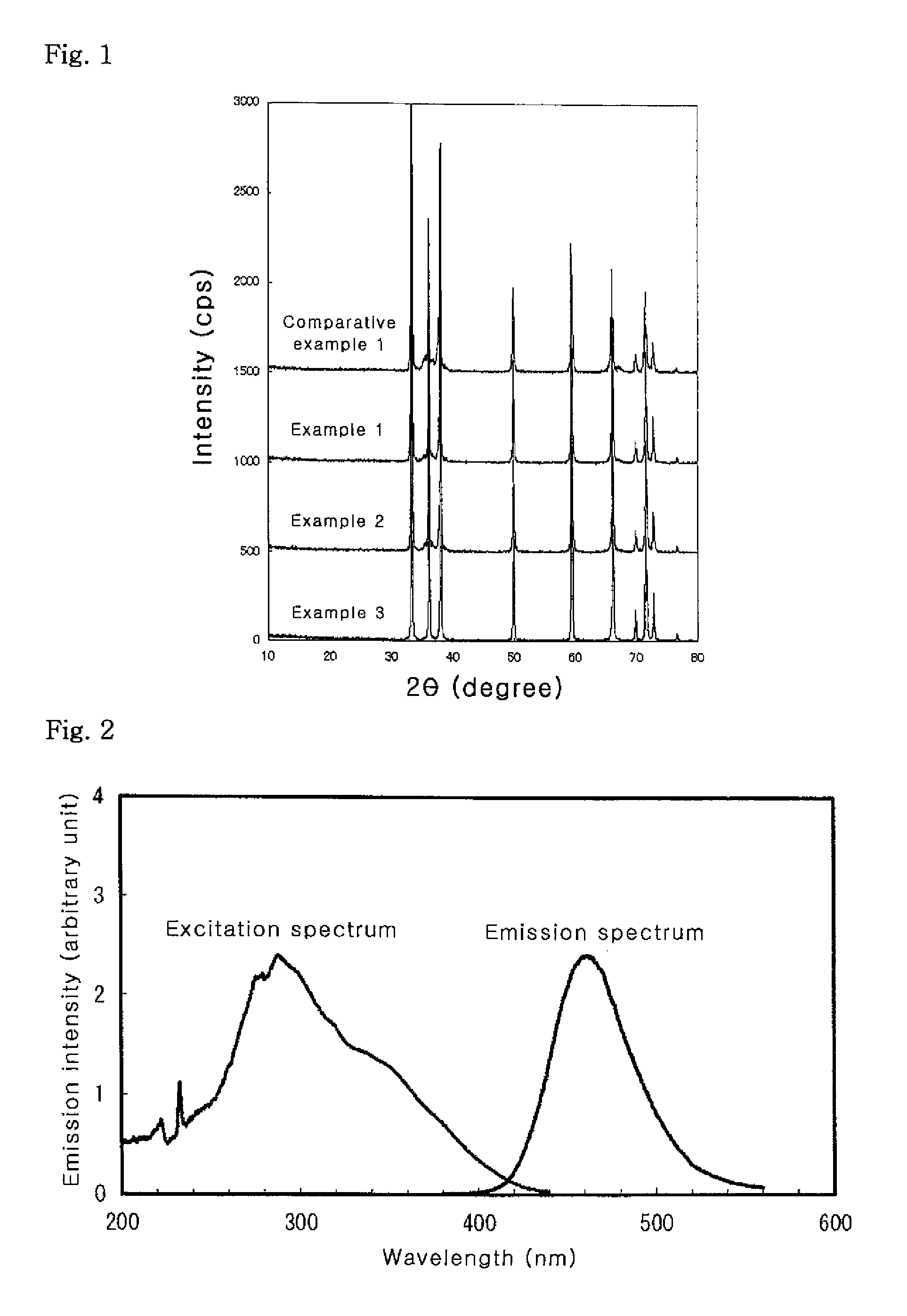

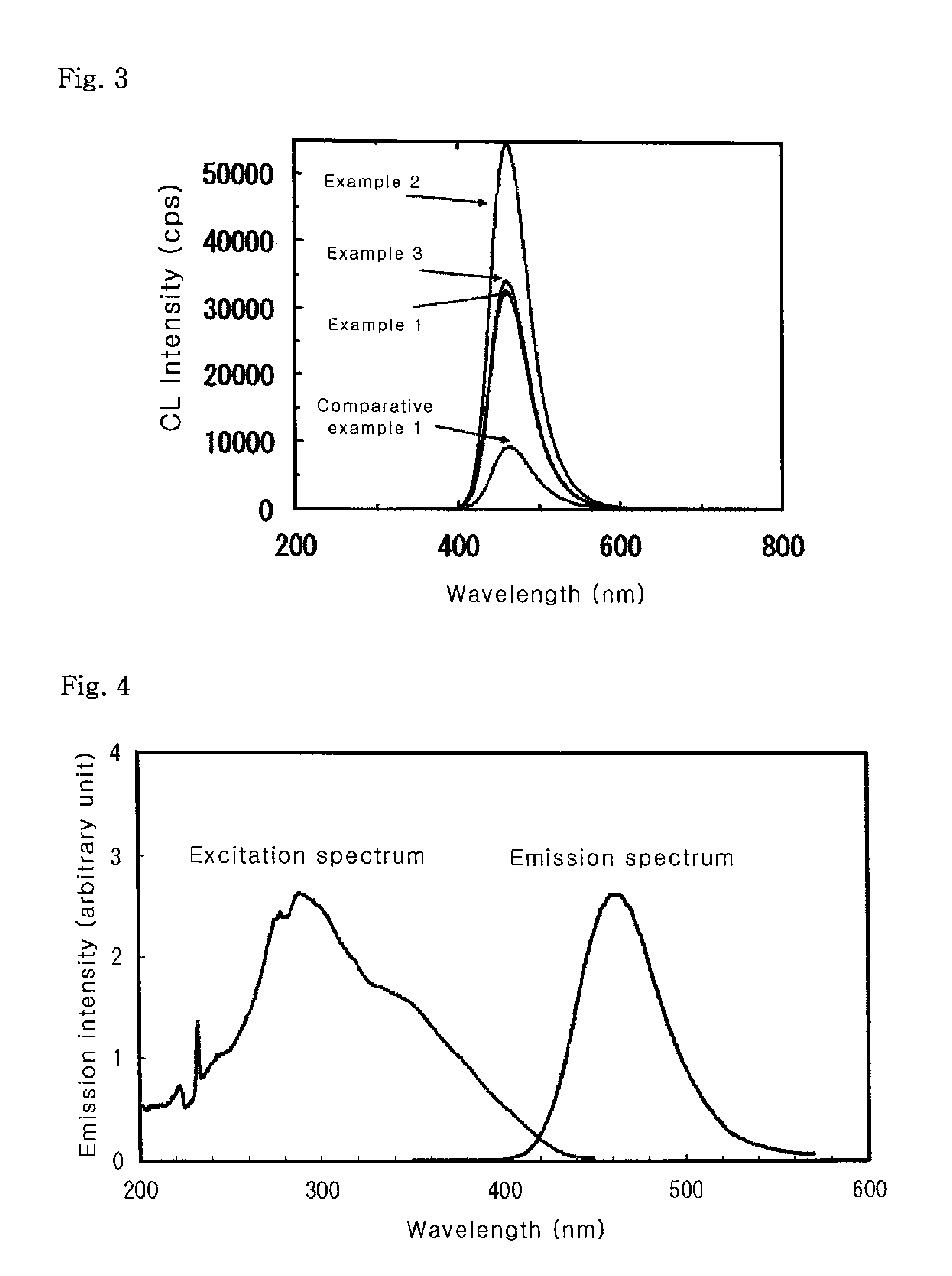

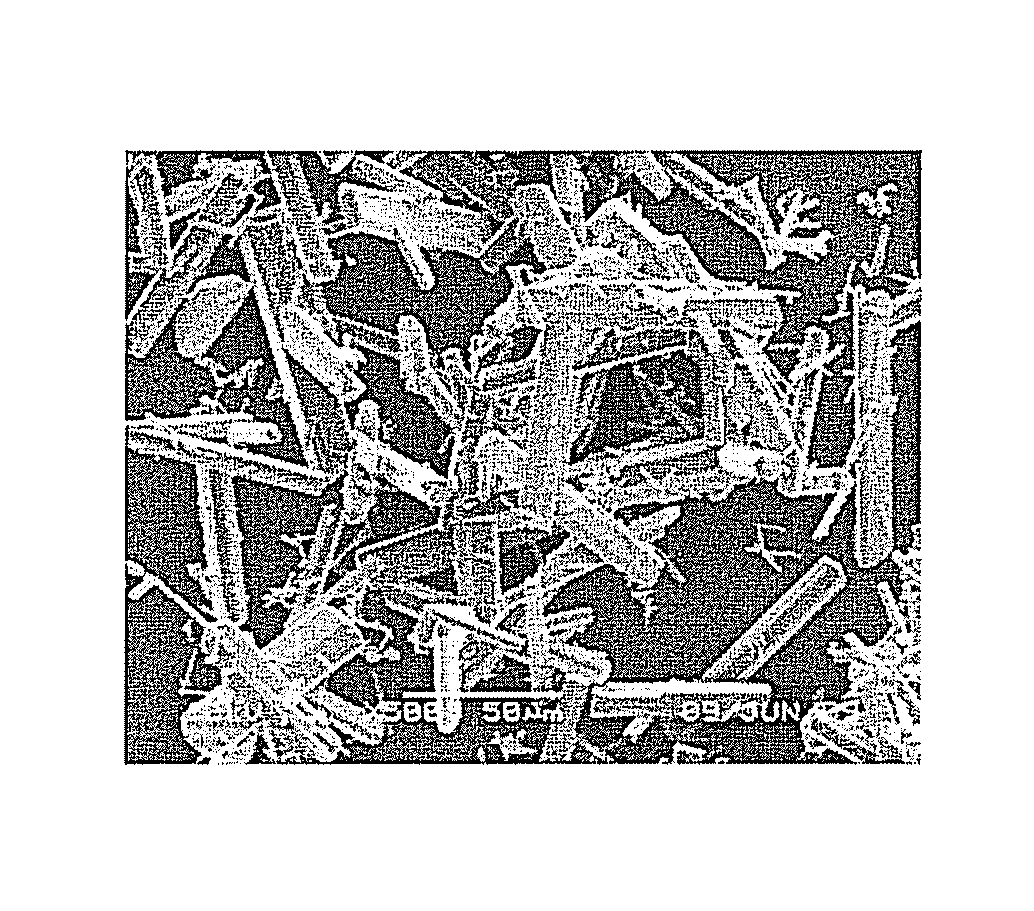

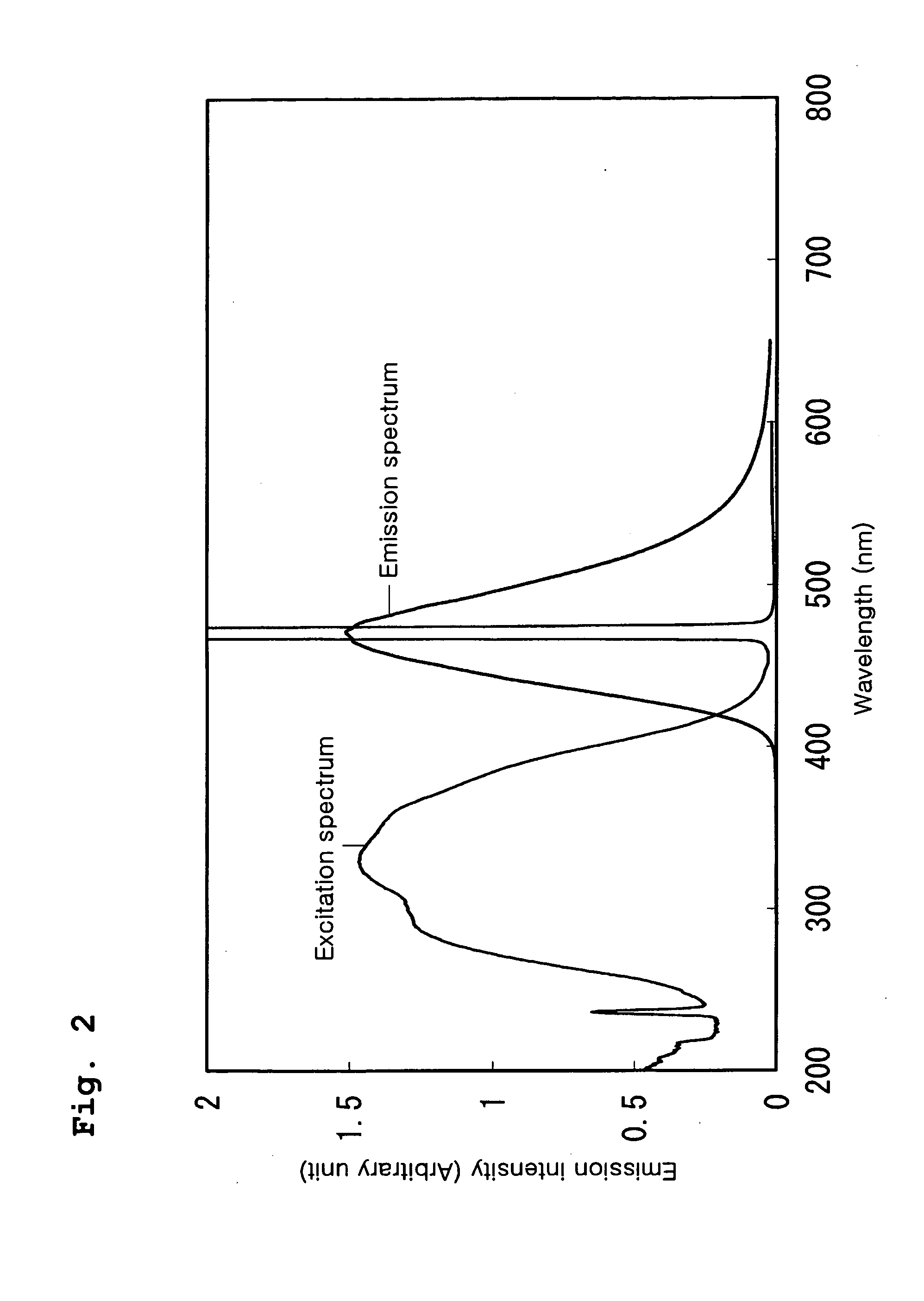

Fluorescent material, process for producing the same, and luminescent device

ActiveUS20100039020A1High emission intensityEfficiently emitsDischarge tube luminescnet screensCathode ray tubes/electron beam tubesLight emitting deviceElectron

A blue fluorescent material having excellent durability and a high luminance, especially one emitting a high-luminance light by the action of electron rays. The fluorescent material comprises inorganic crystals having a crystal structure which is an AlN crystalline, AlN polycrystalline, or AlN solid-solution crystalline structure. It is characterized in that the inorganic crystals contain at least europium in solution and have an oxygen content of 0.4 mass % or lower and that the fluorescent material emits fluorescence derived from divalent europium ions upon irradiation with an excitation source. More preferably, the fluorescent material contains a given metallic element and silicon. Also provided are a process for producing the fluorescent material and an illuminator including the blue fluorescent material.

Owner:NAT INST FOR MATERIALS SCI

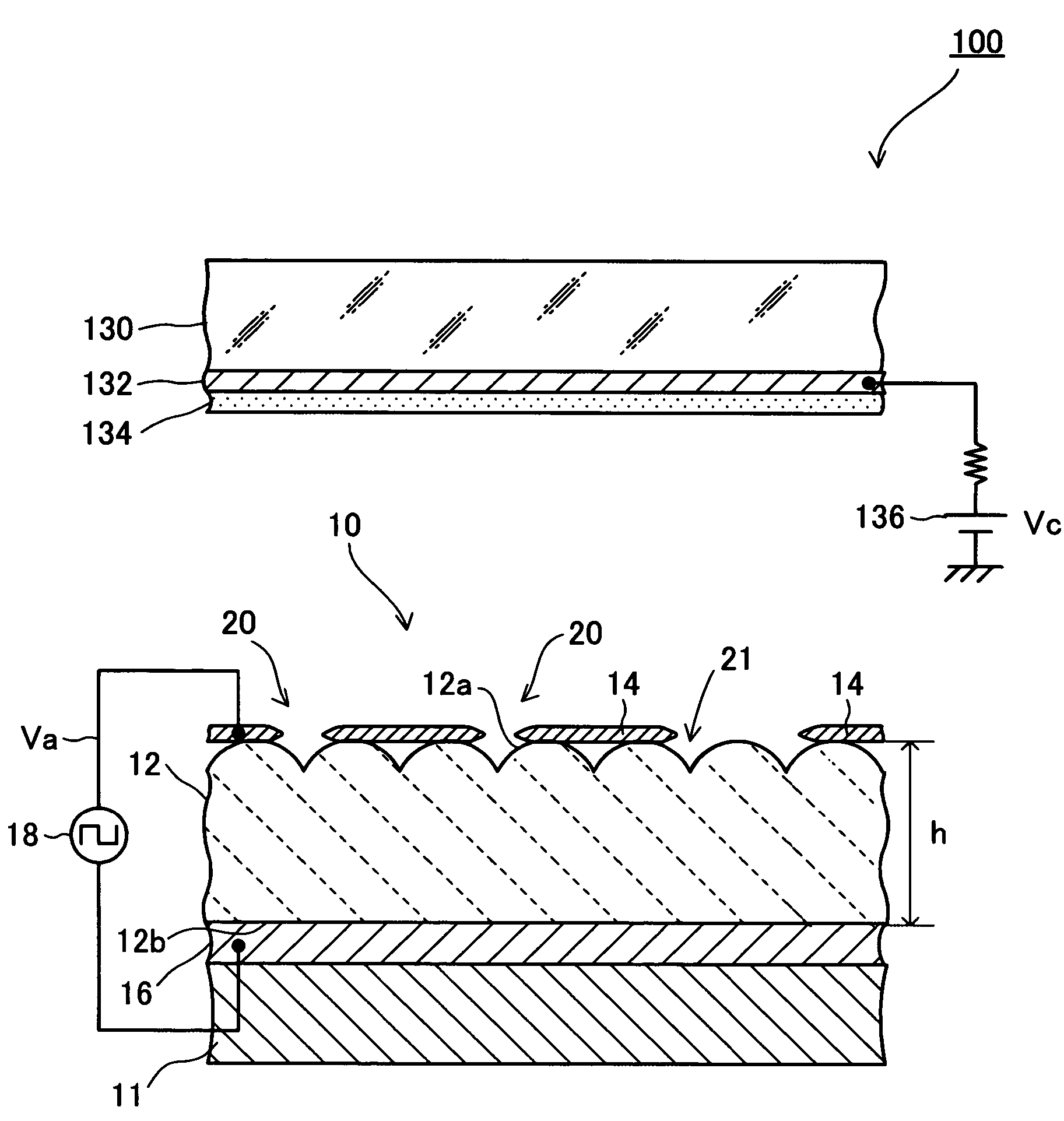

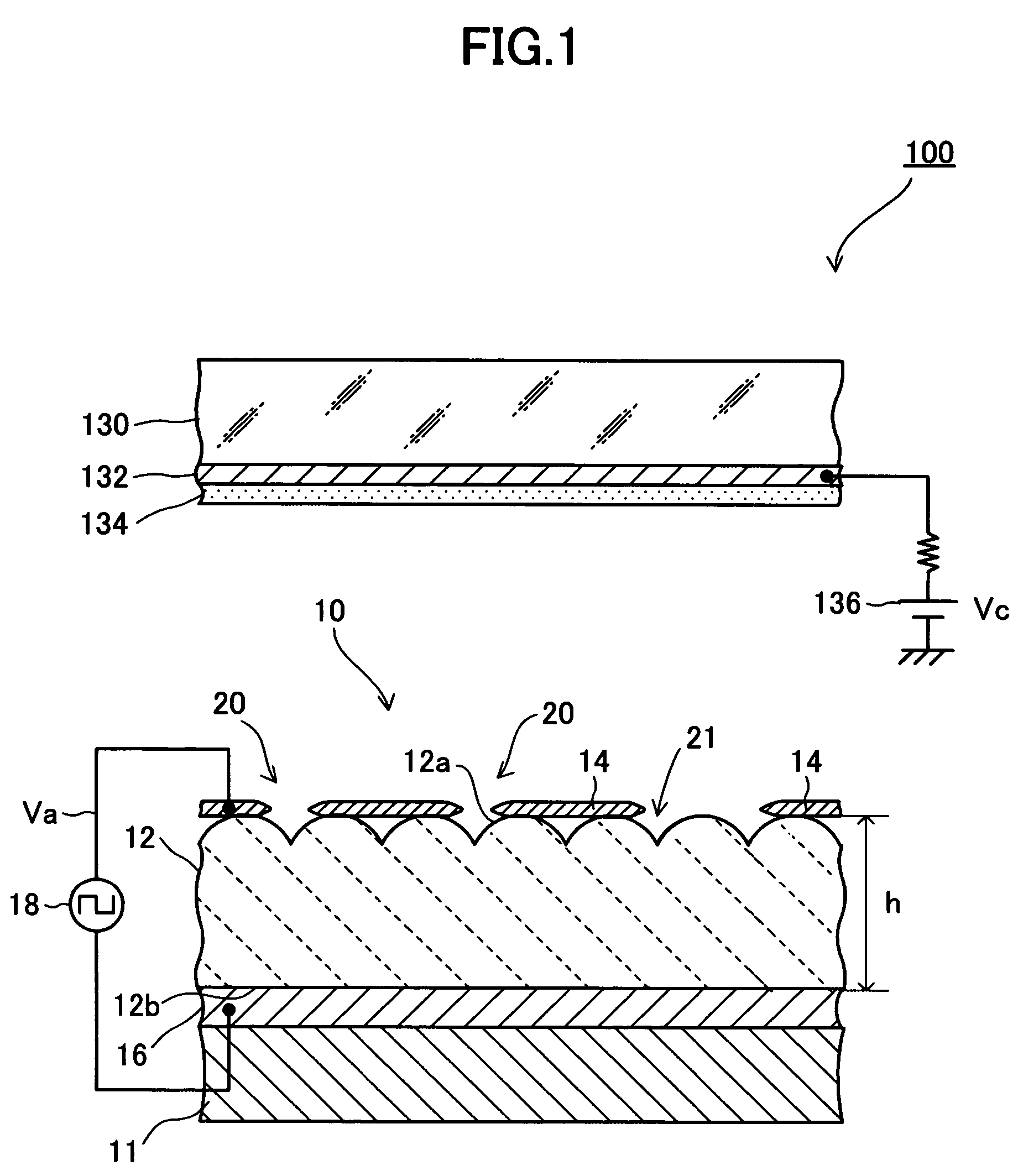

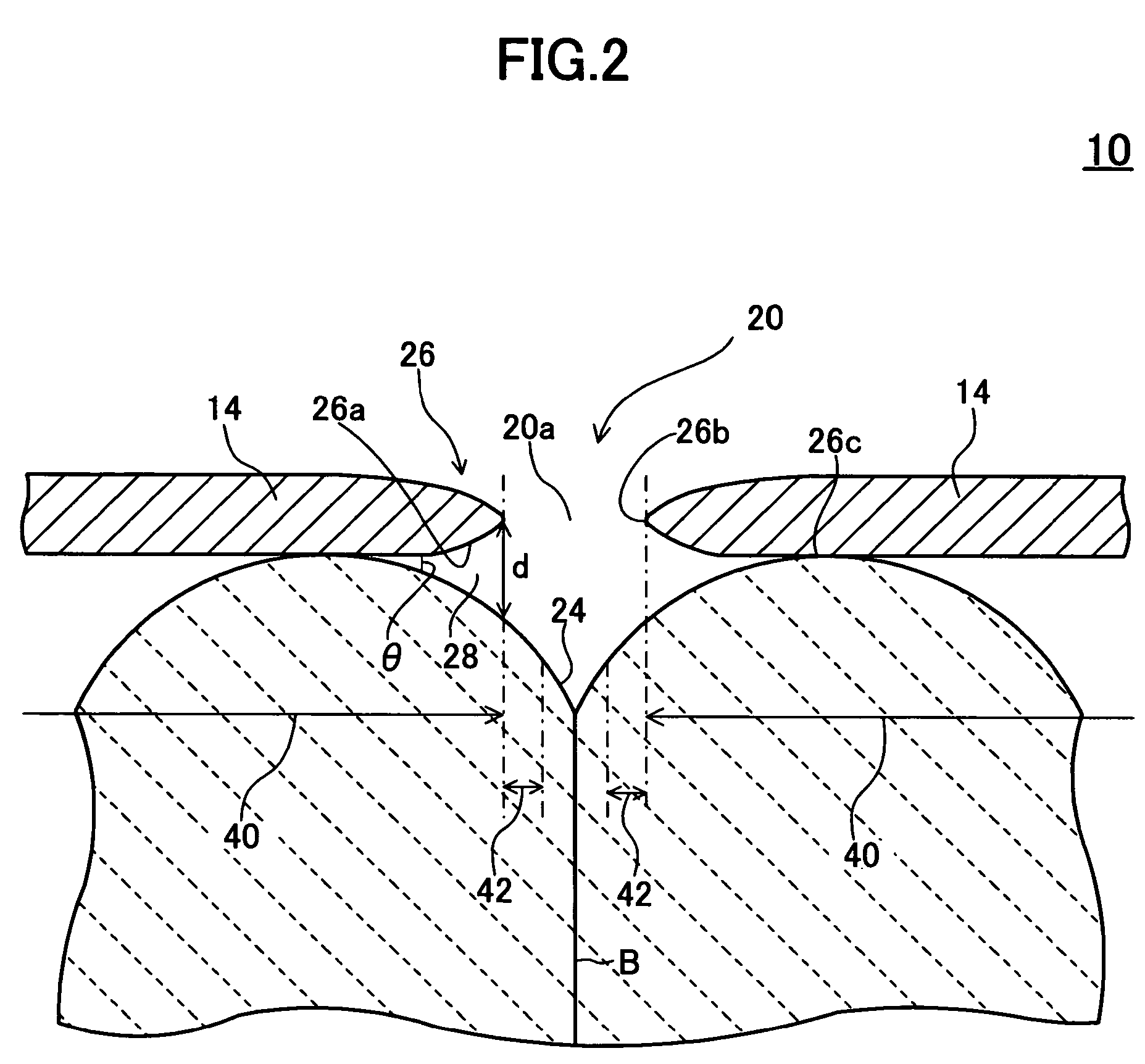

Electron emitting device

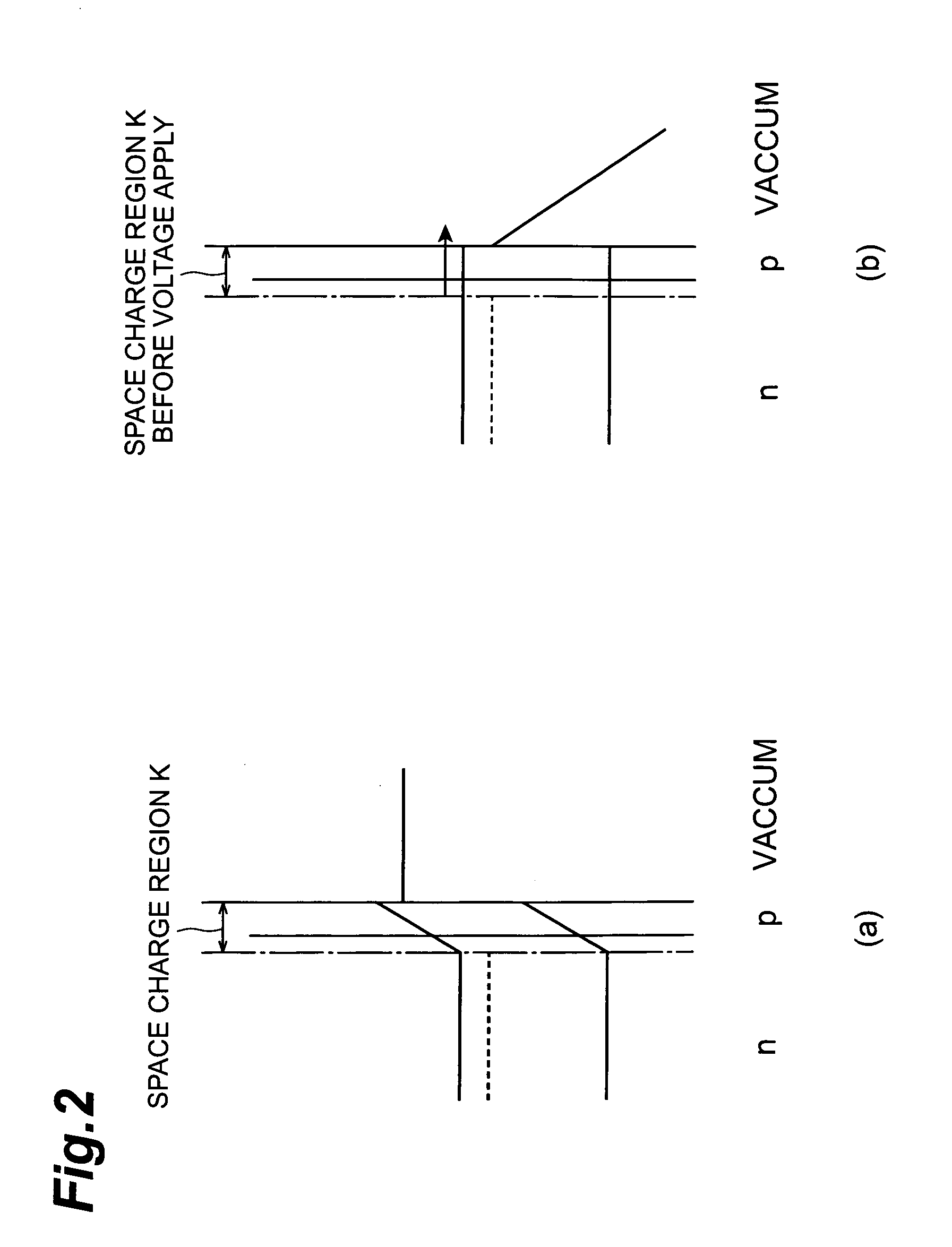

InactiveUS20050133735A1Low energy bandLow stateDischarge tube luminescnet screensLamp detailsElectronAtomic physics

The present invention relates to an electron emitting device having a structure for efficiently emitting electrons. The electron emitting device has a substrate comprised of an n-type diamond, and a pointed projection provided on the substrate. The projection comprises a base provided on the substrate side, and an electron emission portion provided on the base and emitting electrons from the tip thereof. The base is comprised of an n-type diamond. The electron emission portion is comprised of a p-type diamond. The length from the tip of the projection (electron emission portion) to the interface between the base and the electron emission portion is preferably 100 nm or less.

Owner:SUMITOMO ELECTRIC IND LTD

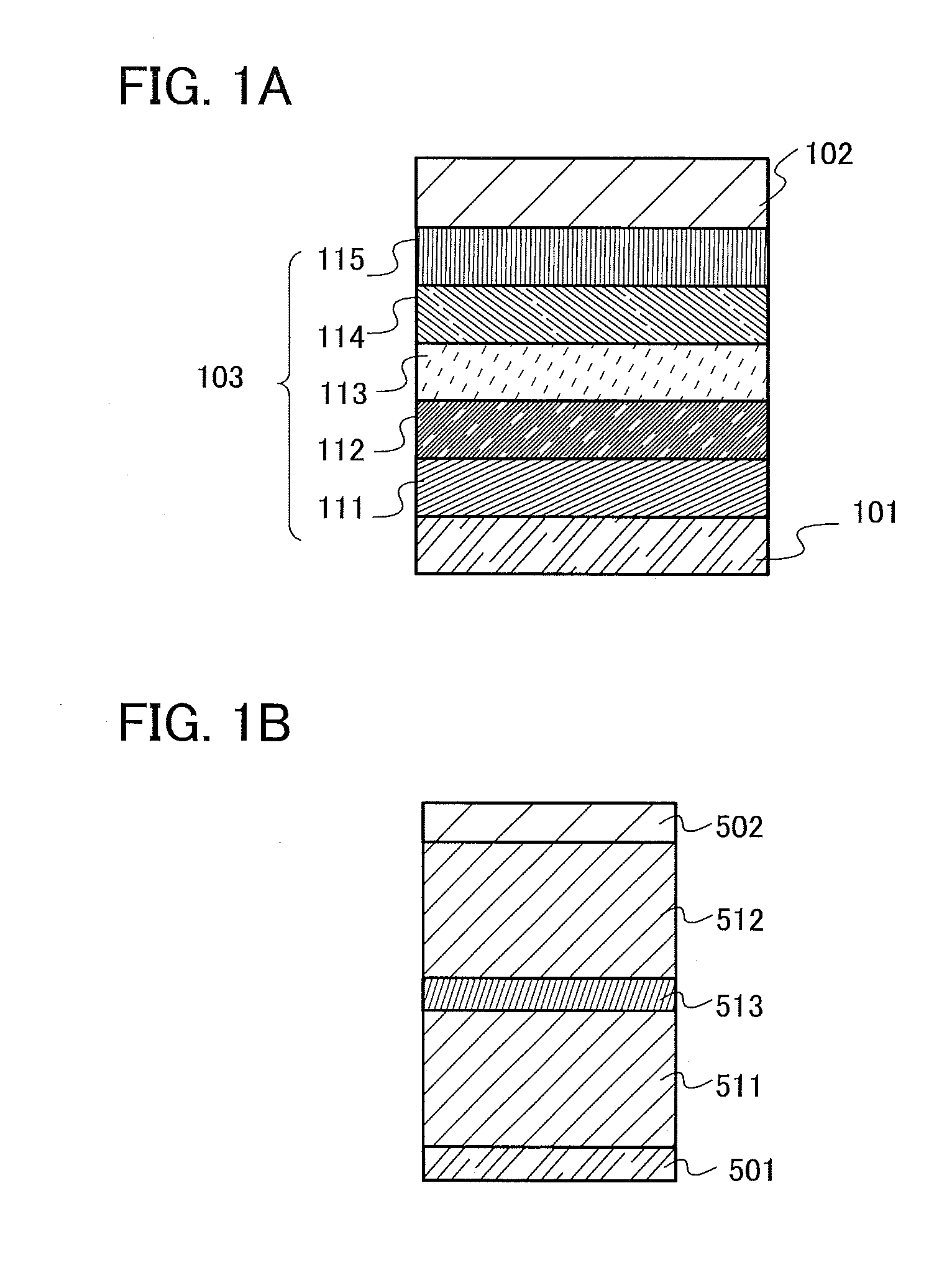

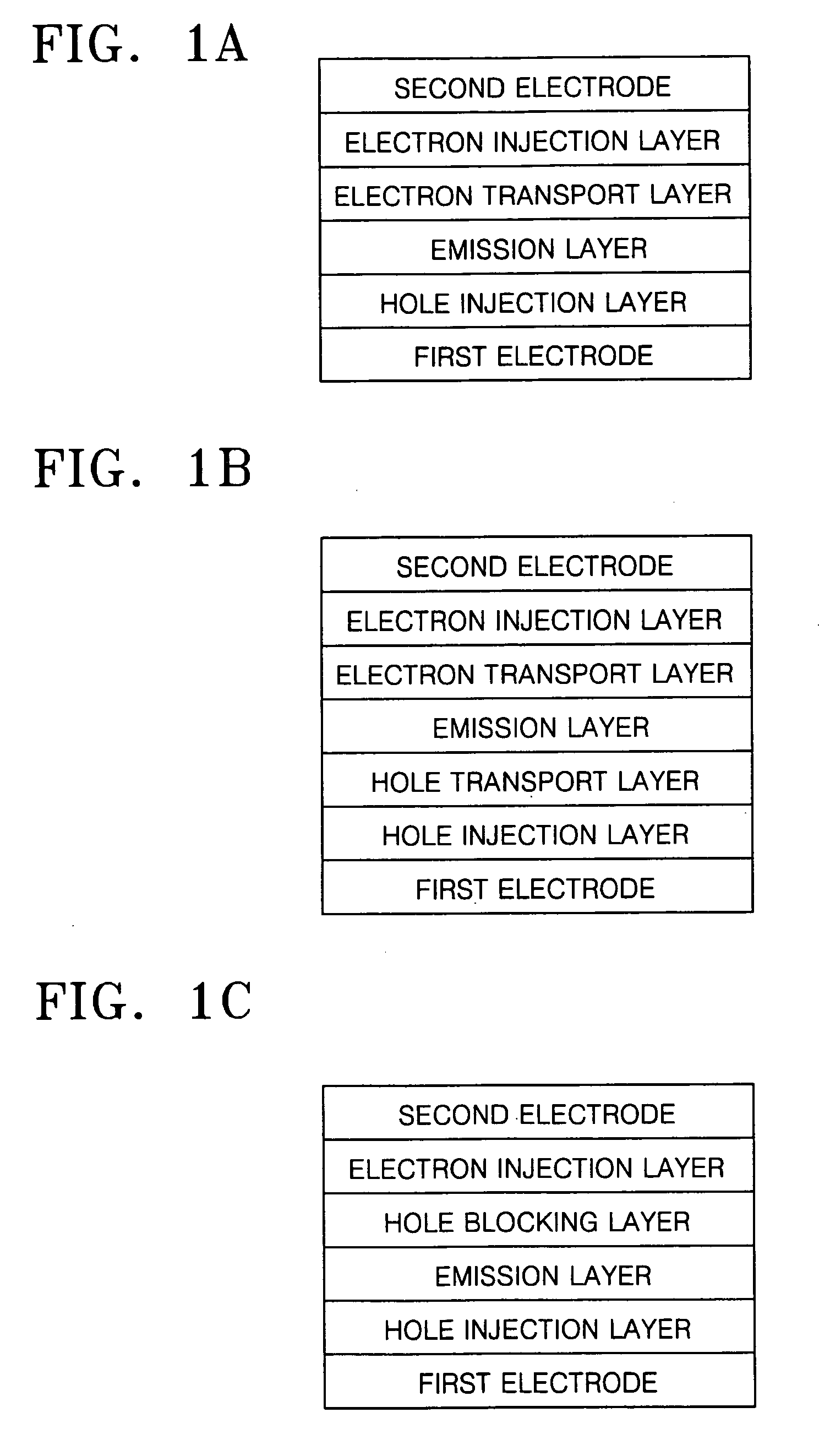

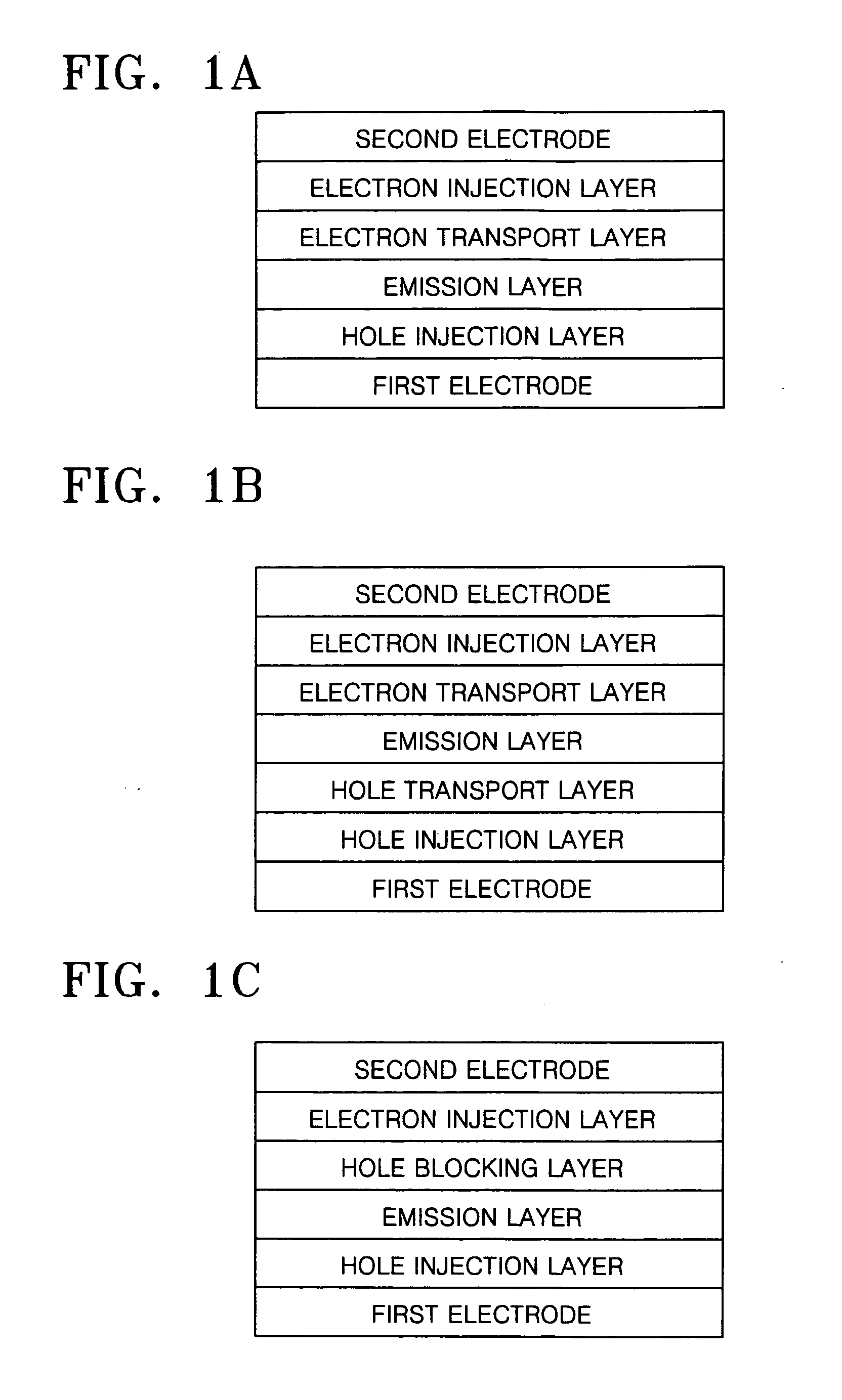

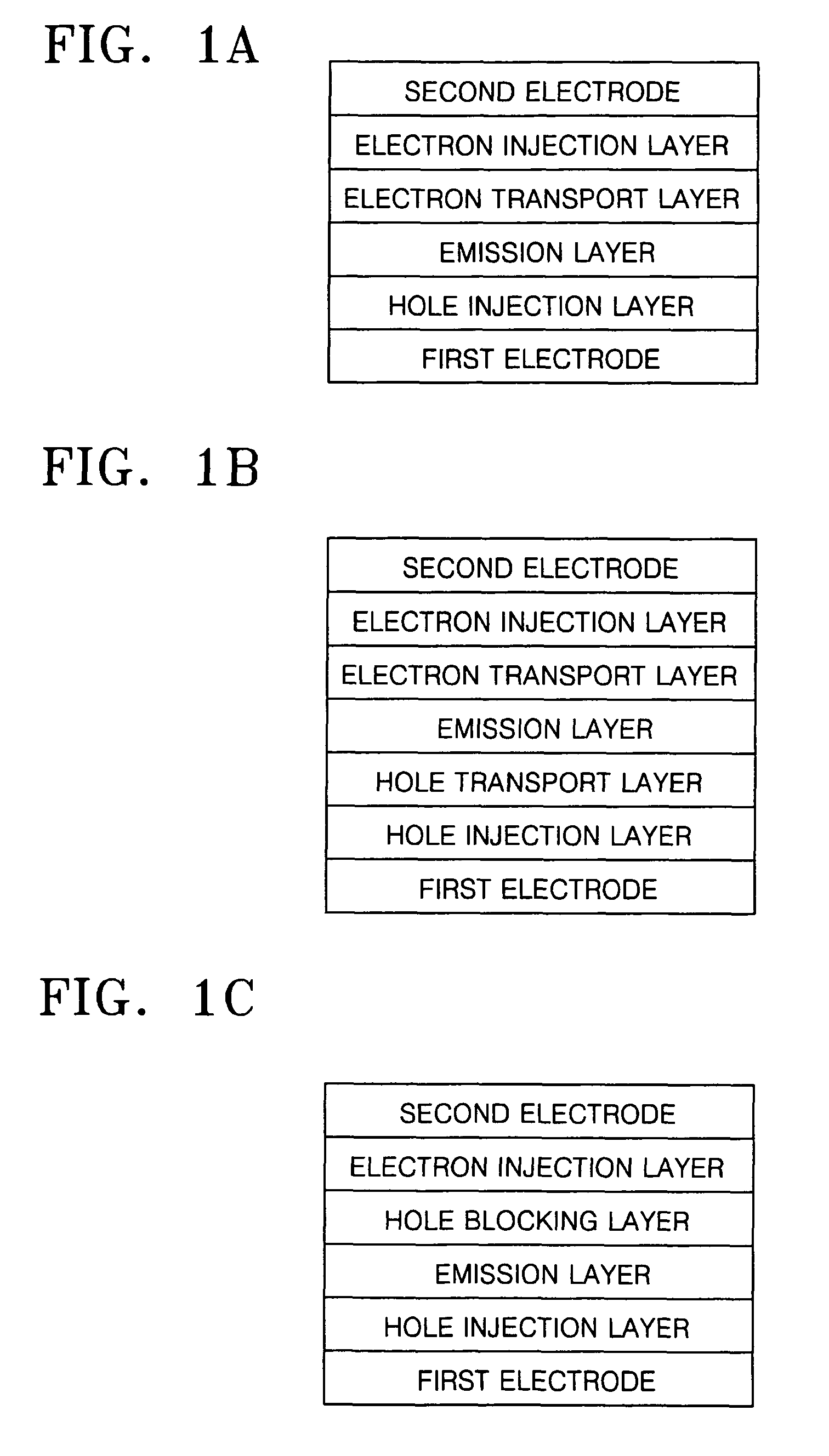

Iridium Complex, Light-Emitting Element, Light-Emitting Device, Electronic Device, and Lighting Device

ActiveUS20130161598A1Reduce power consumptionQuality improvementIndium organic compoundsSolid-state devicesArylIridium

Owner:SEMICON ENERGY LAB CO LTD

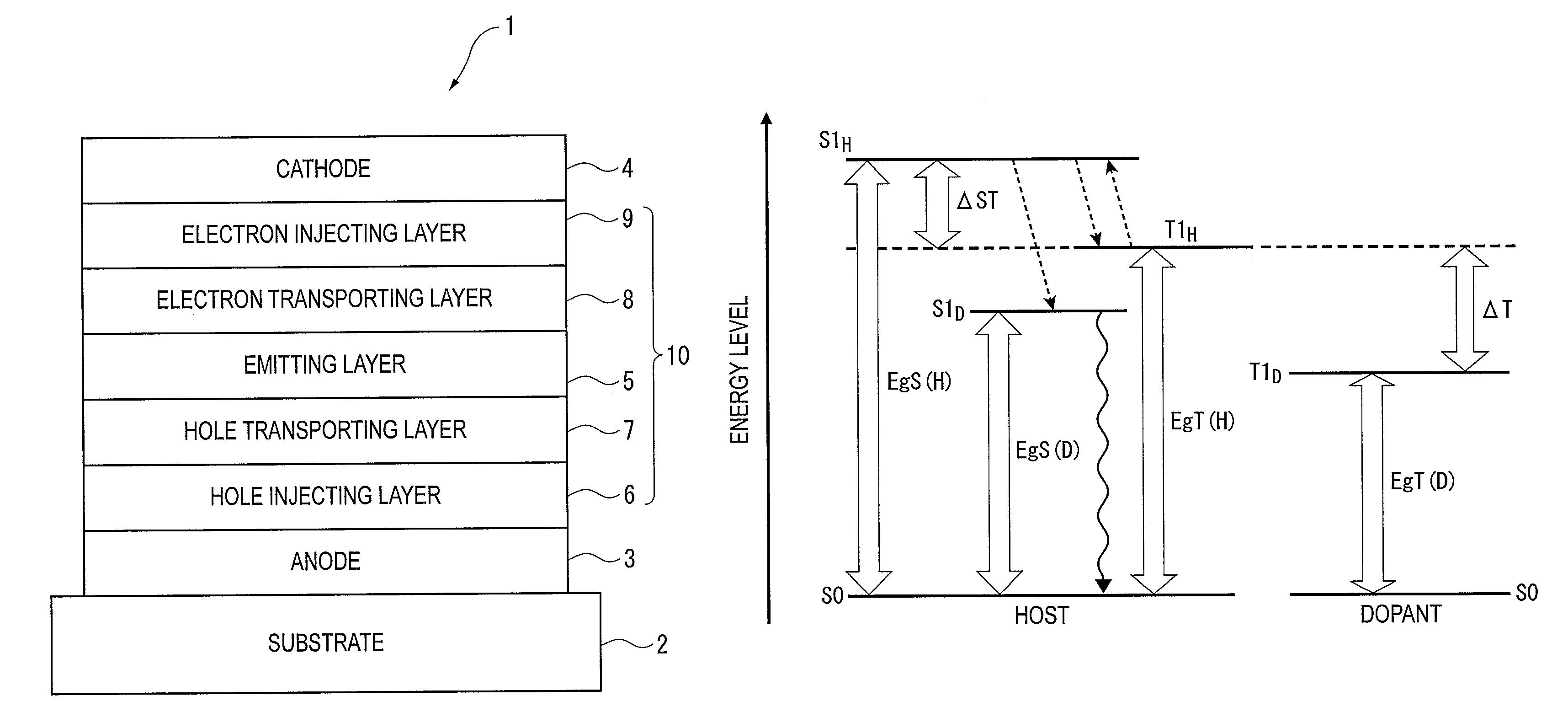

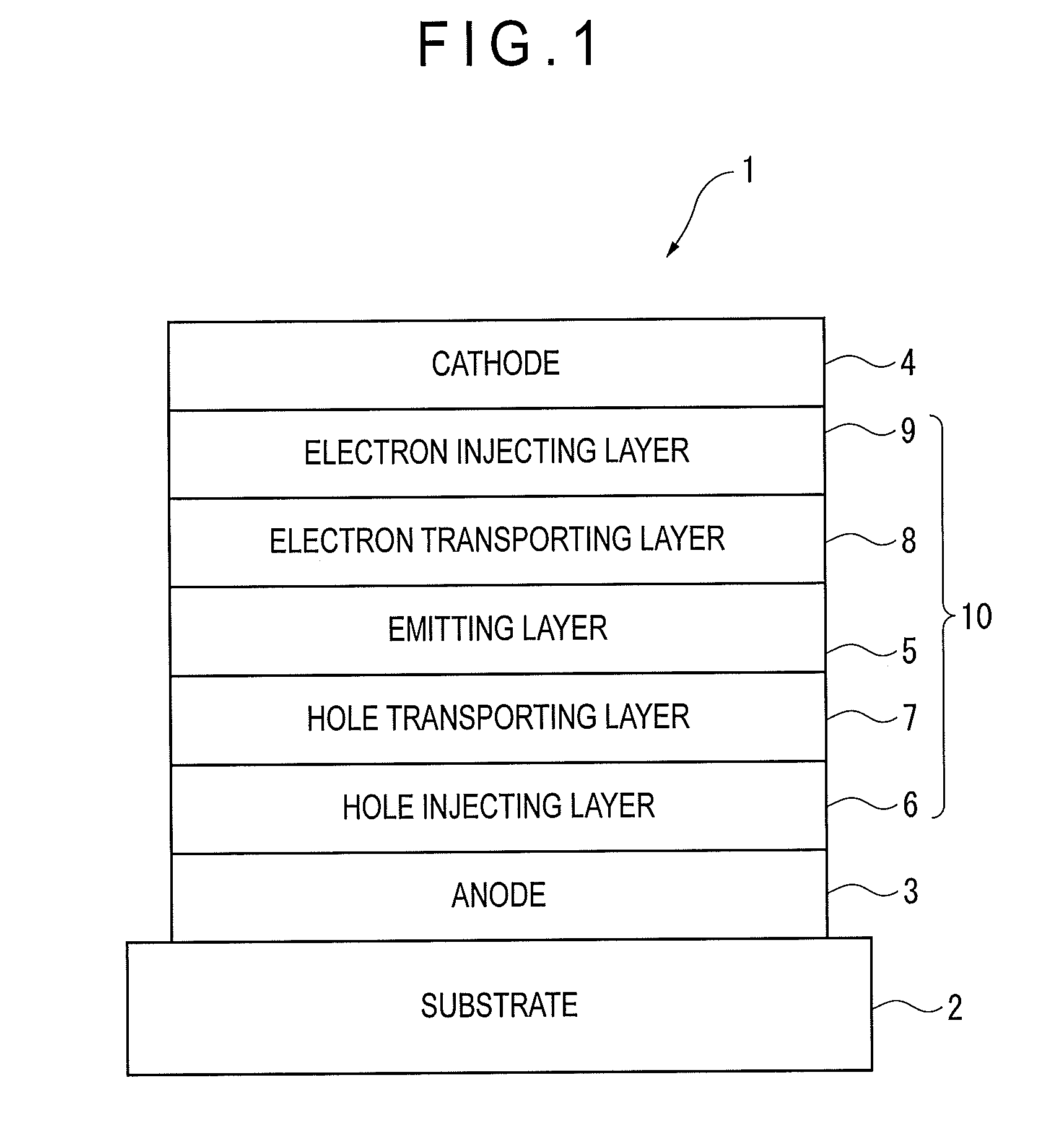

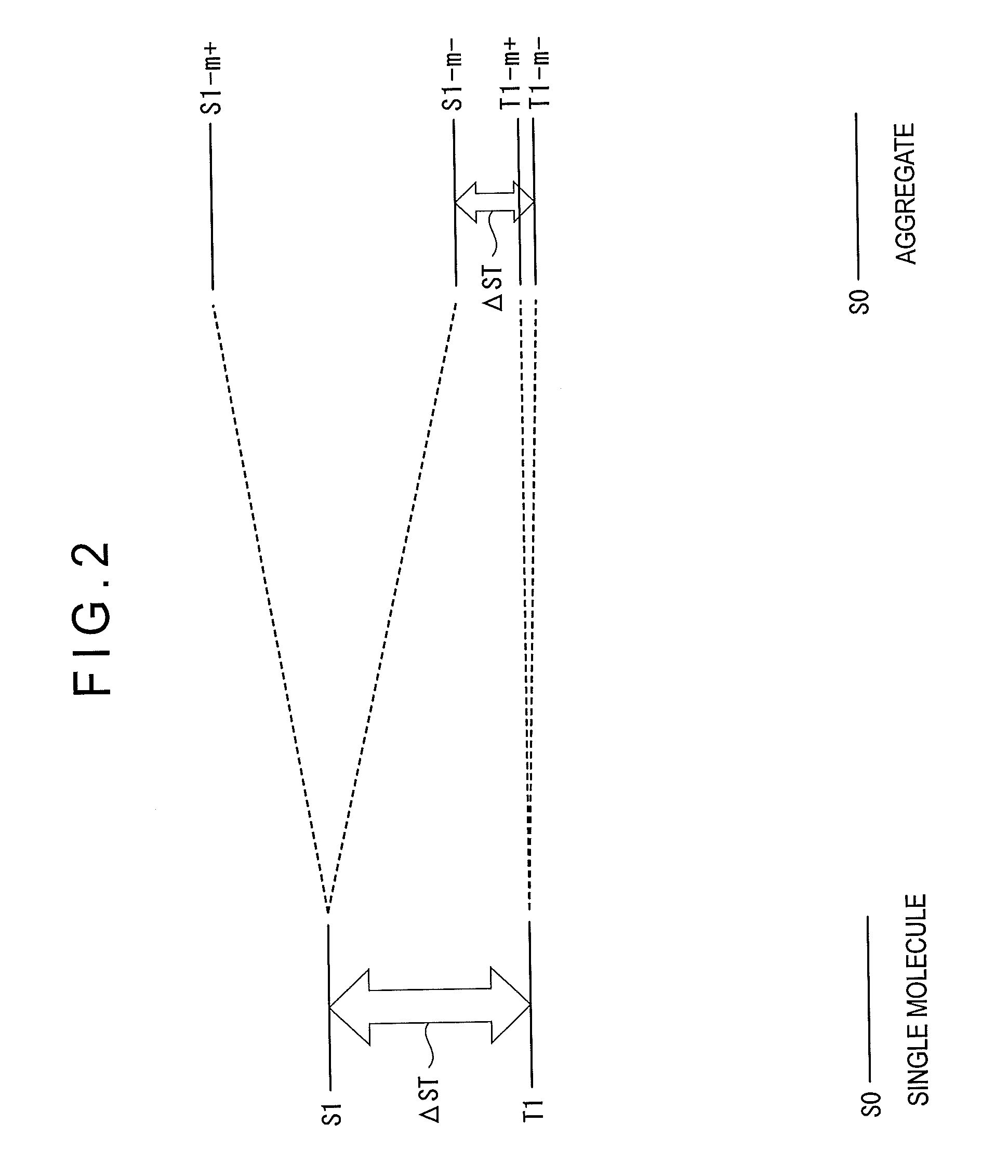

Organic electroluminescence device

An organic electroluminescence device includes: a cathode; an anode; and an organic thin-film layer disposed between the cathode and the anode, the organic thin-film layer having one or more layers including an emitting layer, in which the emitting layer includes a first material represented by the following formula (1) and a second material in a form of a fluorescent dopant material.

Owner:IDEMITSU KOSAN CO LTD

Phosphor and including the same, light emitting apparatus, illuminating apparatus and image display

InactiveUS20070158614A1Efficiently emitsIncrease brightnessLaser detailsLaser optical resonator constructionLight equipmentChemical composition

An object of the present invention is to provide a high-efficiency red light emitting phosphor and white light emitting phosphor for using in a display or lighting which high-efficiently emits light in combination with a light source which emits light in the region from near-ultraviolet light to visible light. The present invention relates to a phosphor having a crystal phase having a specified chemical composition.

Owner:MITSUBISHI CHEM CORP

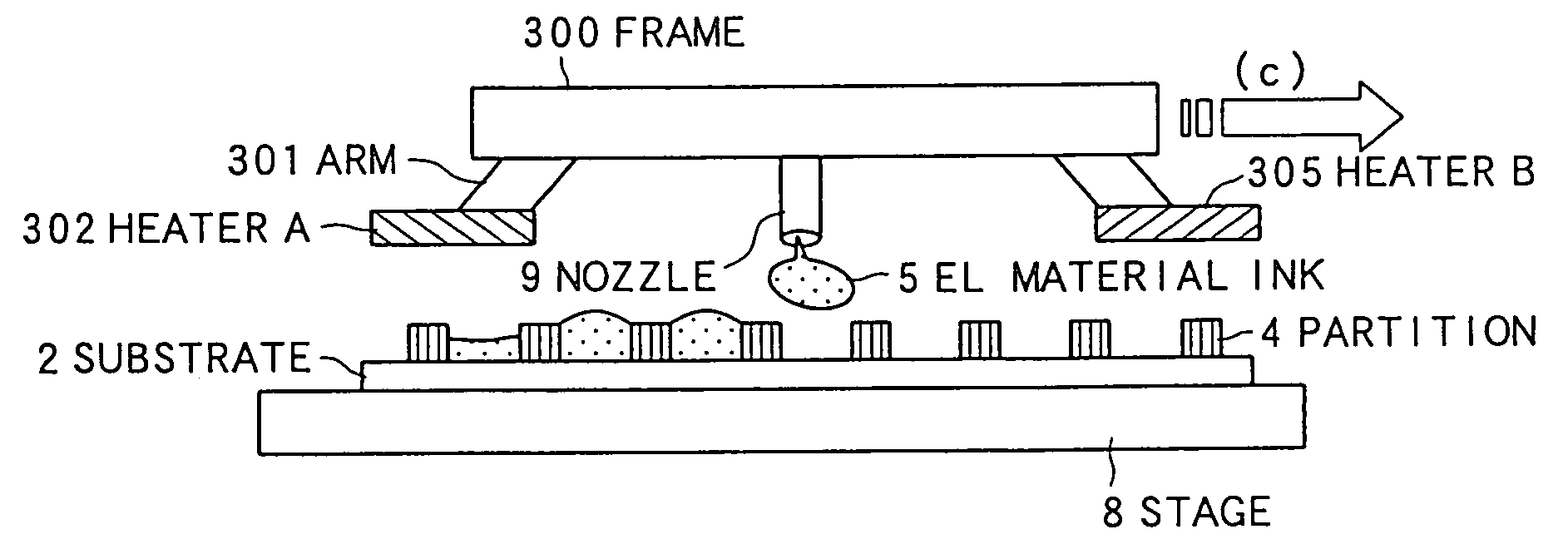

Method and apparatus for manufacturing organic EL display and color filter by ink jet method

InactiveUS7368145B2Bright enoughPractical and convenientVacuum evaporation coatingSolid-state devicesEngineeringColor filter array

A method and apparatus for manufacturing an EL layer of uniform thickness, causing effective light emission of pixel openings and manufacturing an organic EL display showing sufficient brightness and excellent in practicability, by an ink jet method. A method and apparatus for manufacturing a color filter excellent in practicability by an ink jet method, in which a dye layer with uniform thickness is formed and optical coloring of uniform tone is conducted at pixel openings. The method includes: a process of discharge-placing at least an organic EL material in the form of solution on a substrate; and a process of drying the organic EL material in the form of ink placed on the substrate by heating, and the organic EL material is dried by heating over thereof.

Owner:DAI NIPPON PRINTING CO LTD

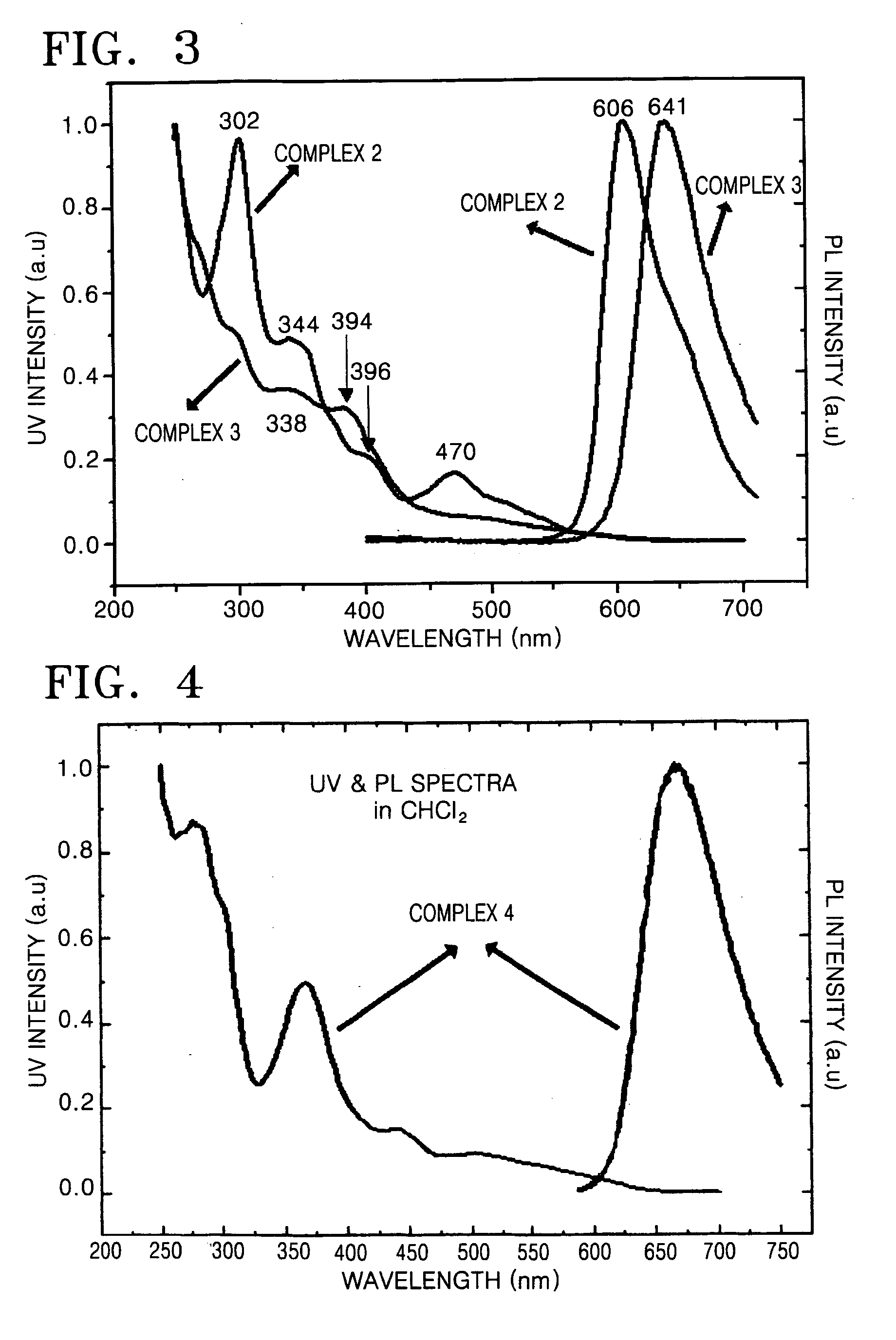

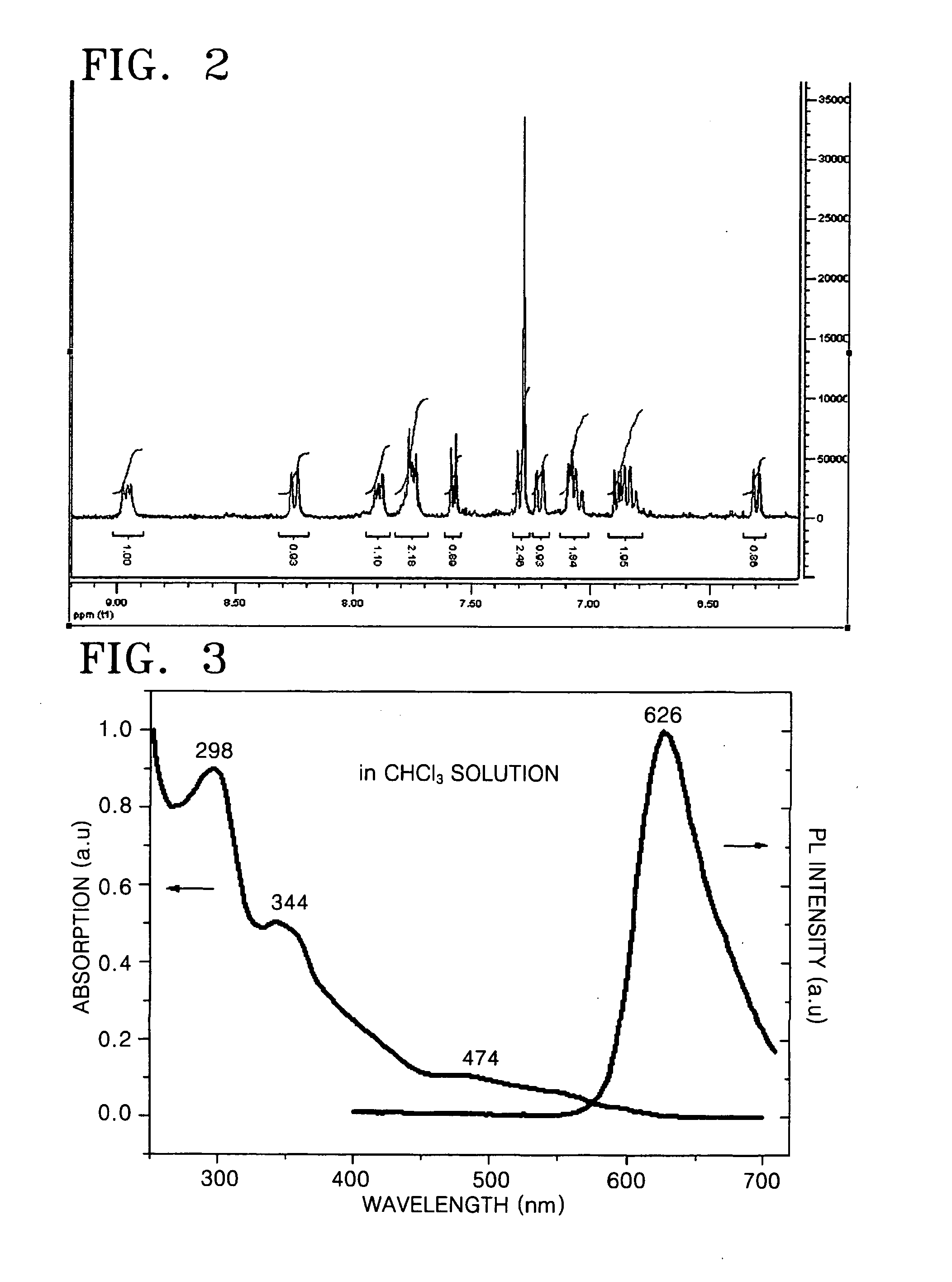

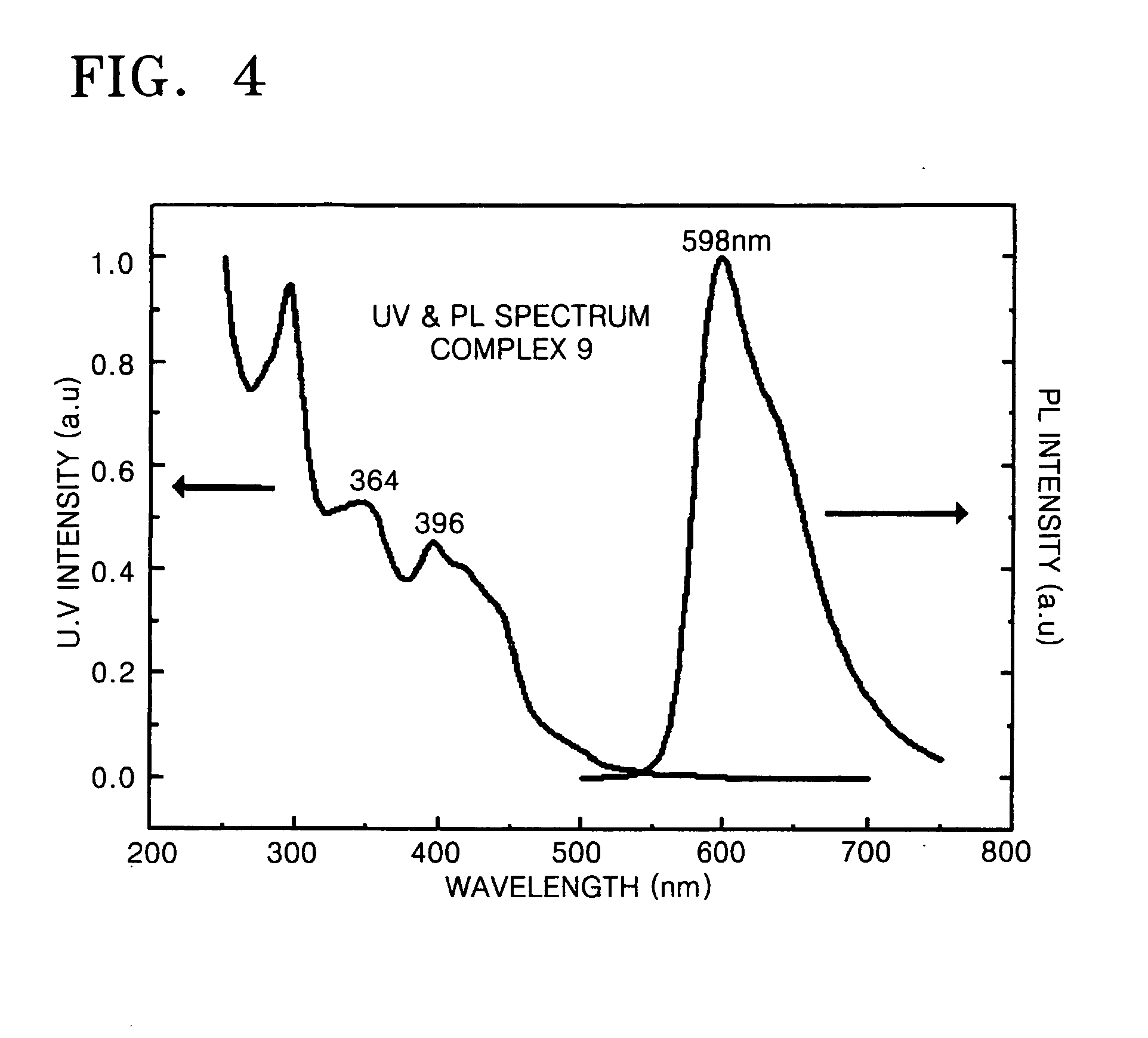

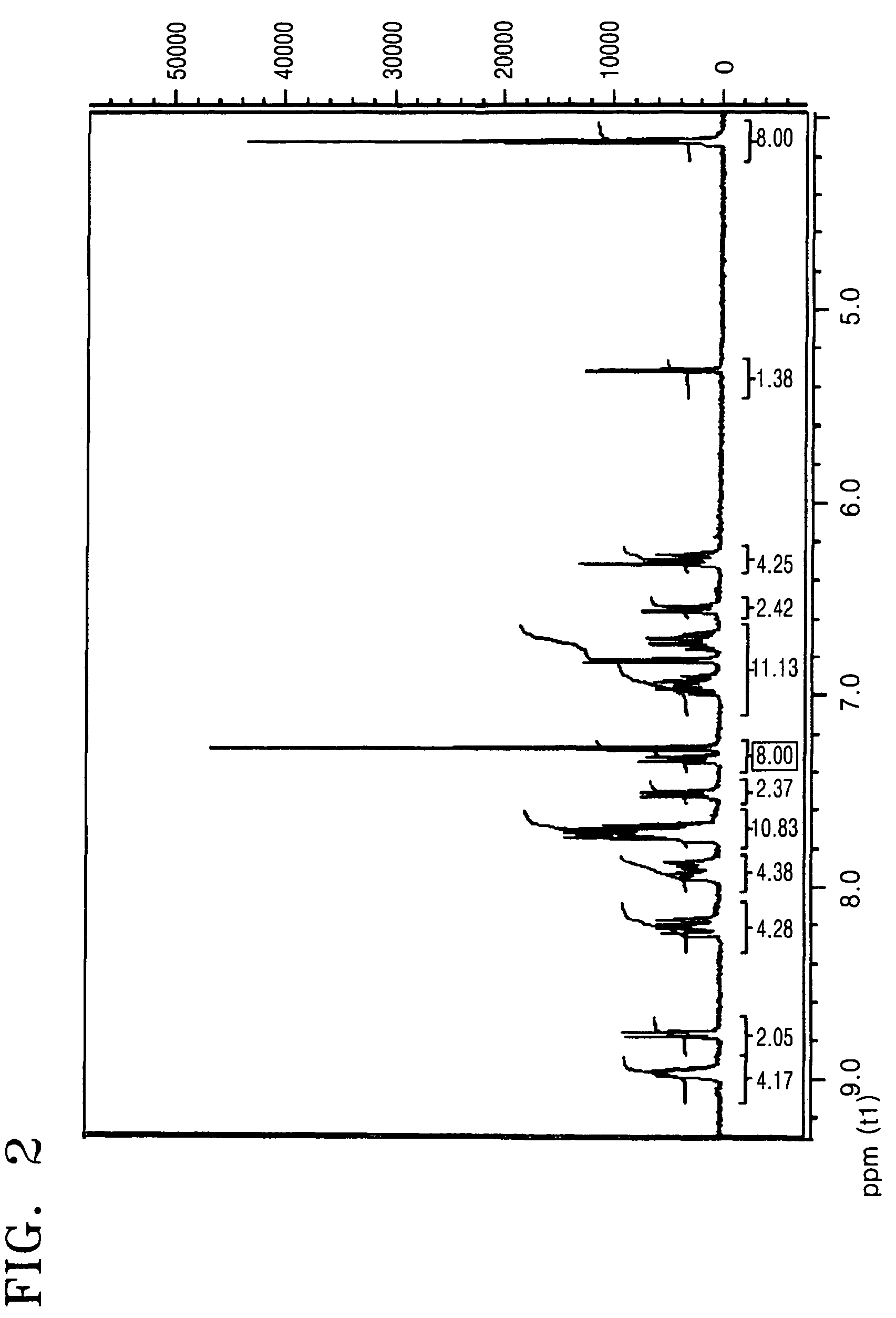

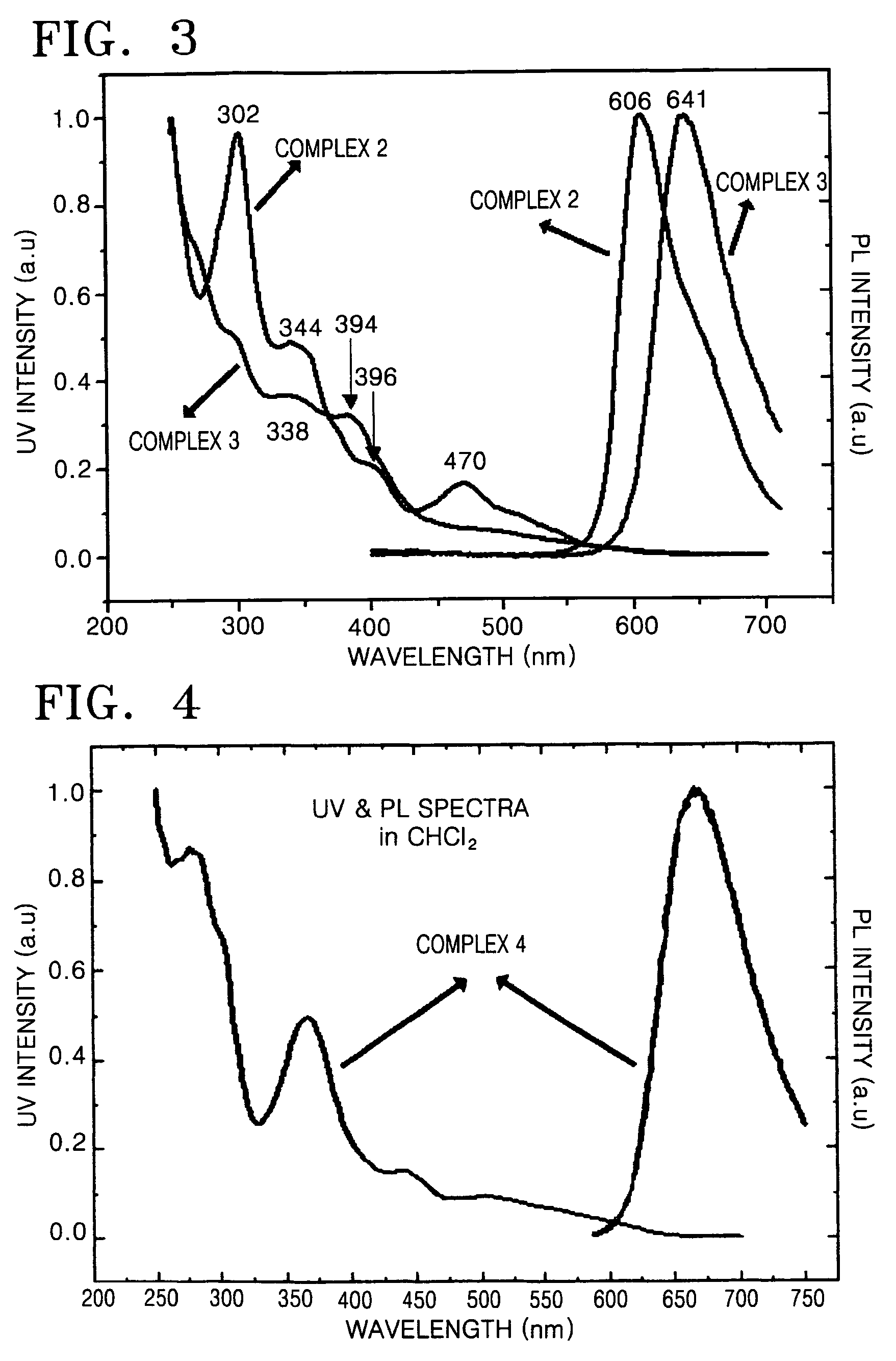

Cyclometalated transition metal complex and organic light emitting device using the same

ActiveUS20070184303A1Solve low luminous efficiencyImprove external quantum efficiencyGroup 5/15 element organic compoundsSolid-state devicesCarboxylic acidAte complex

Provided is a cyclometalated transition metal complex represented by Formula 1:The cyclometalated transition metal complex contains a new ancillary ligand having a carboxylate acid or the like connected to a hetero ring, so that it can efficiently emit red light from a phosphorous material through intersystem crossing (ISC) to form triplet excitons and then metal to ligand charge transfer (MLCT). An organic light emitting device manufactured using the transition metal complex shows excellent luminous efficiency and external quantum efficiency.

Owner:SAMSUNG DISPLAY CO LTD

Cyclometalated transition metal complex and organic electroluminescence device using the same

ActiveUS20070190358A1Efficiently emitsEfficient emissionsIndium organic compoundsDischarge tube luminescnet screensTriplet stateRed light

Provided is a cyclometalated transition metal complex represented by Formula 1, Formula 2 or Formula 3:By including a new ancillary ligand, the cyclometalated transition metal complex can efficiently emit red light using a phosphor by intersystem crossing (ISC) of excitons to triplet states and then metal to ligand charge transfer (MLCT). An organic light emitting device prepared using the transition metal compound shows high luminous efficiency and high external quantum efficiency.

Owner:SAMSUNG DISPLAY CO LTD

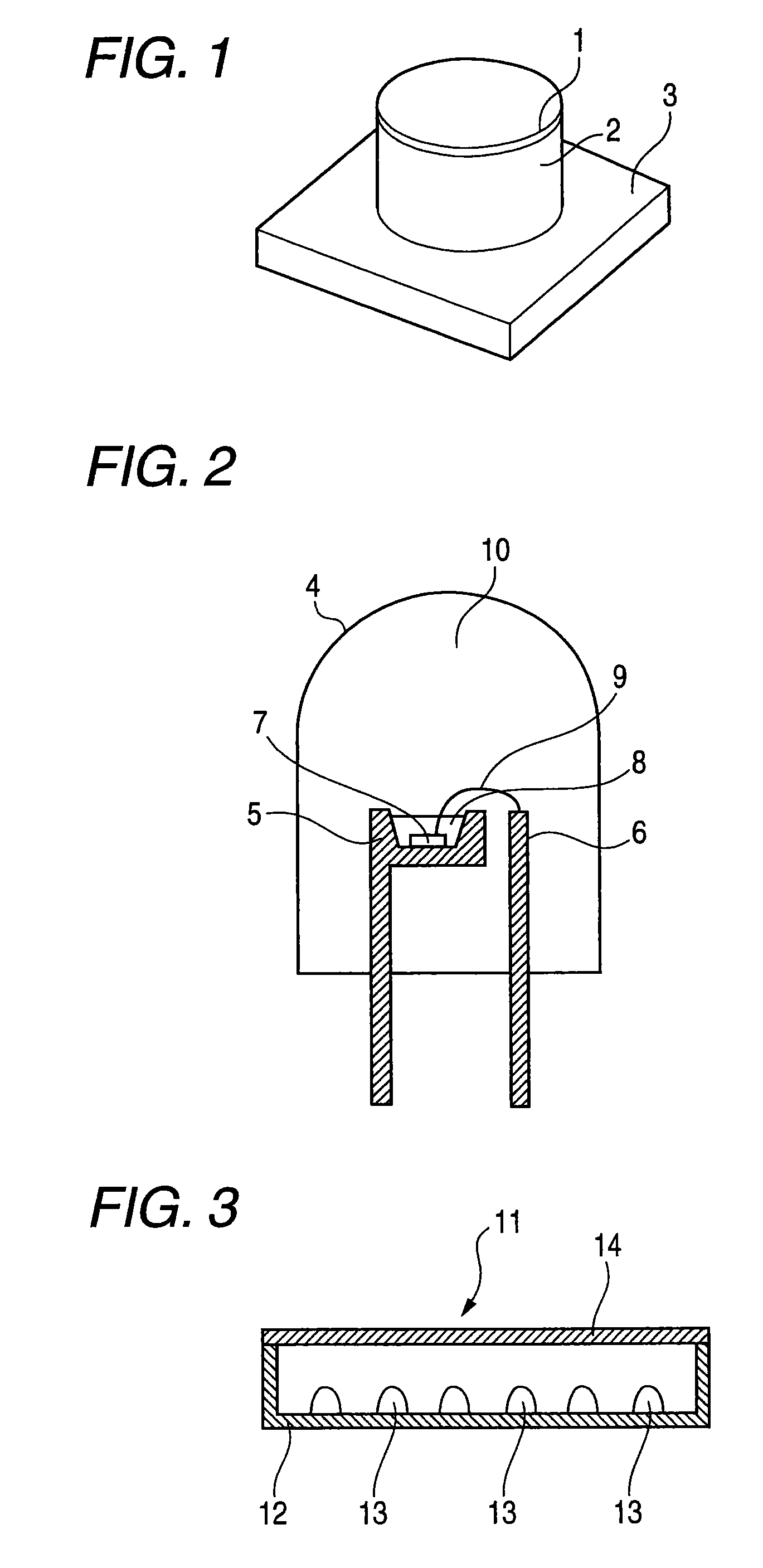

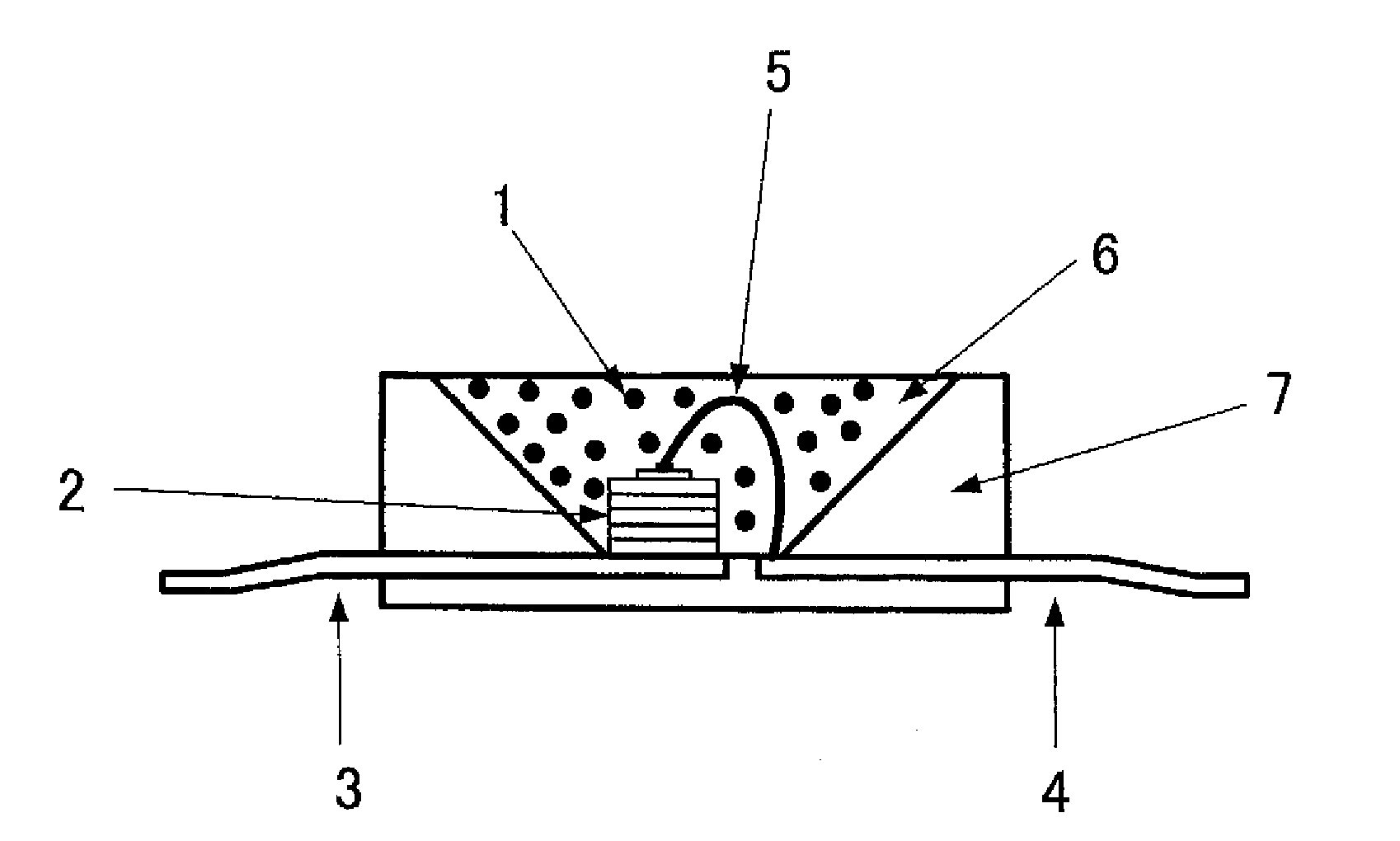

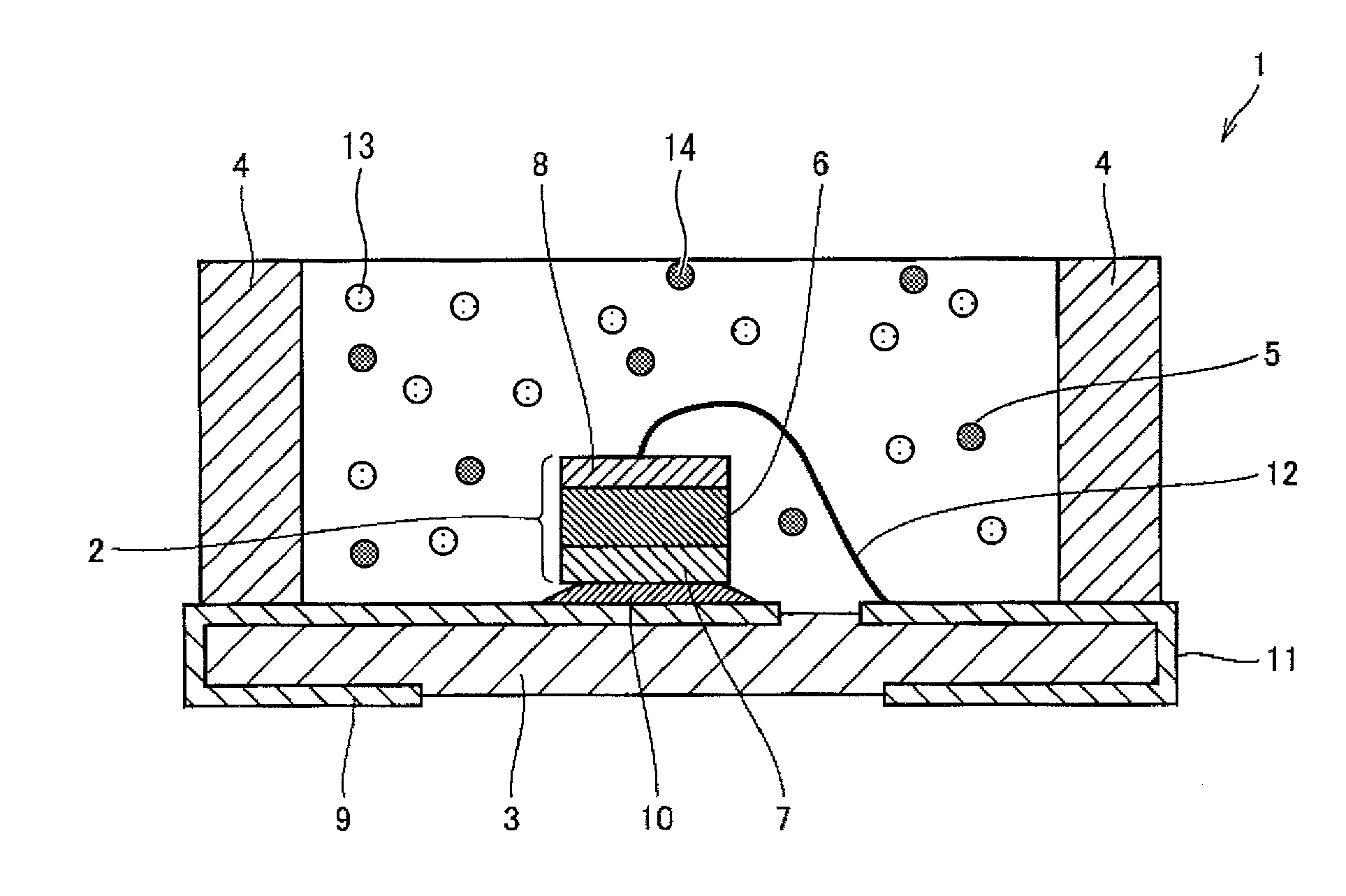

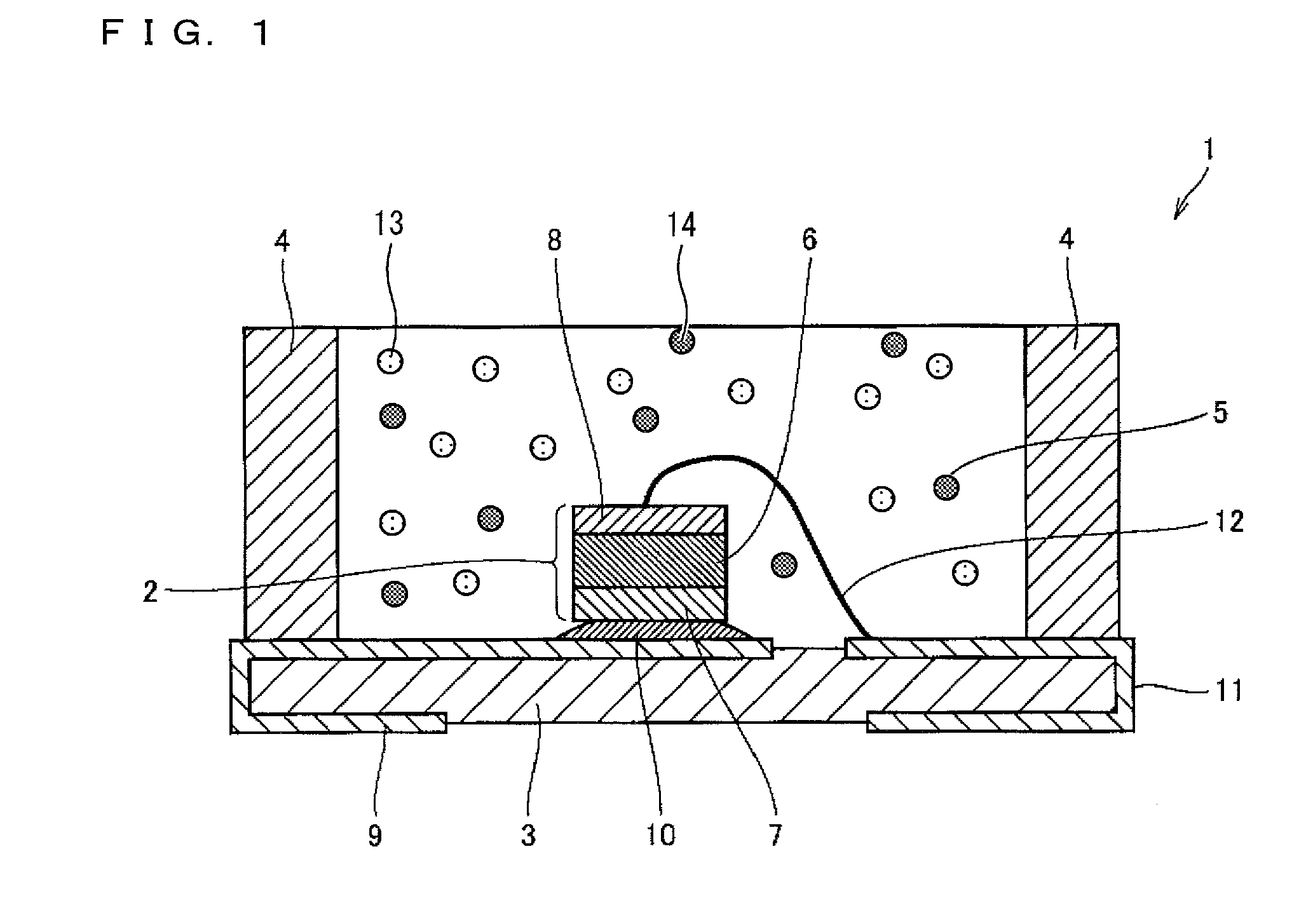

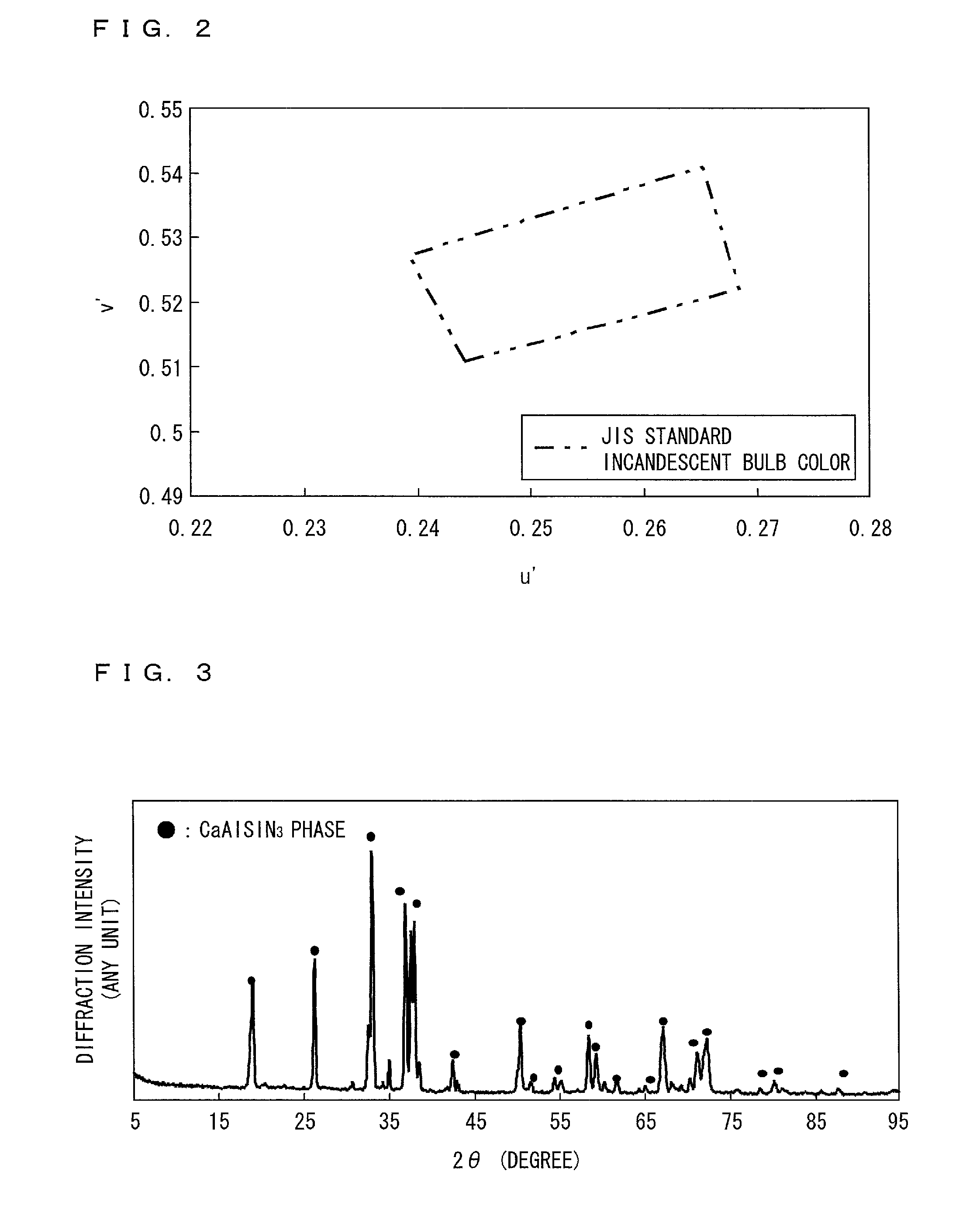

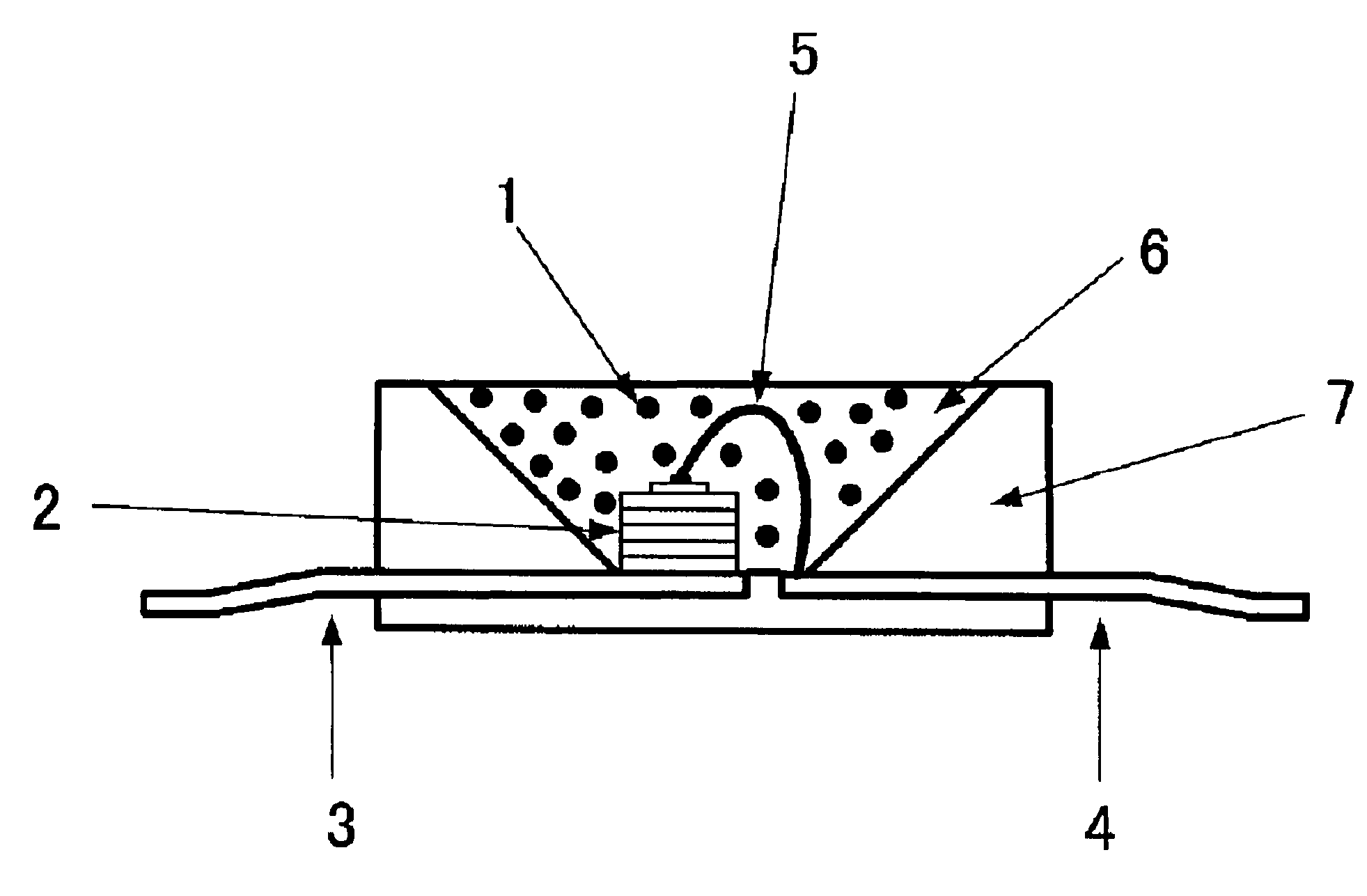

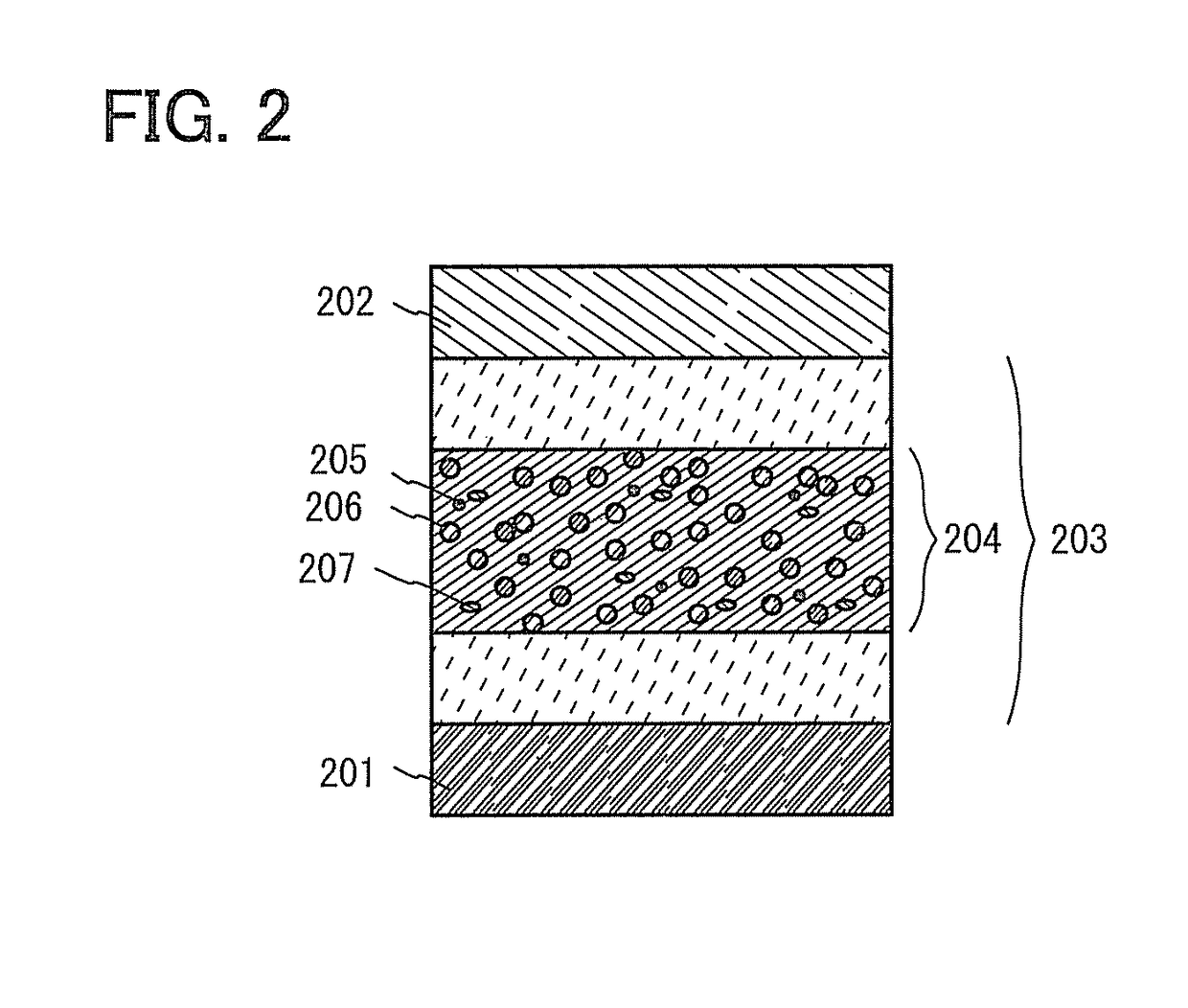

Light-emitting device

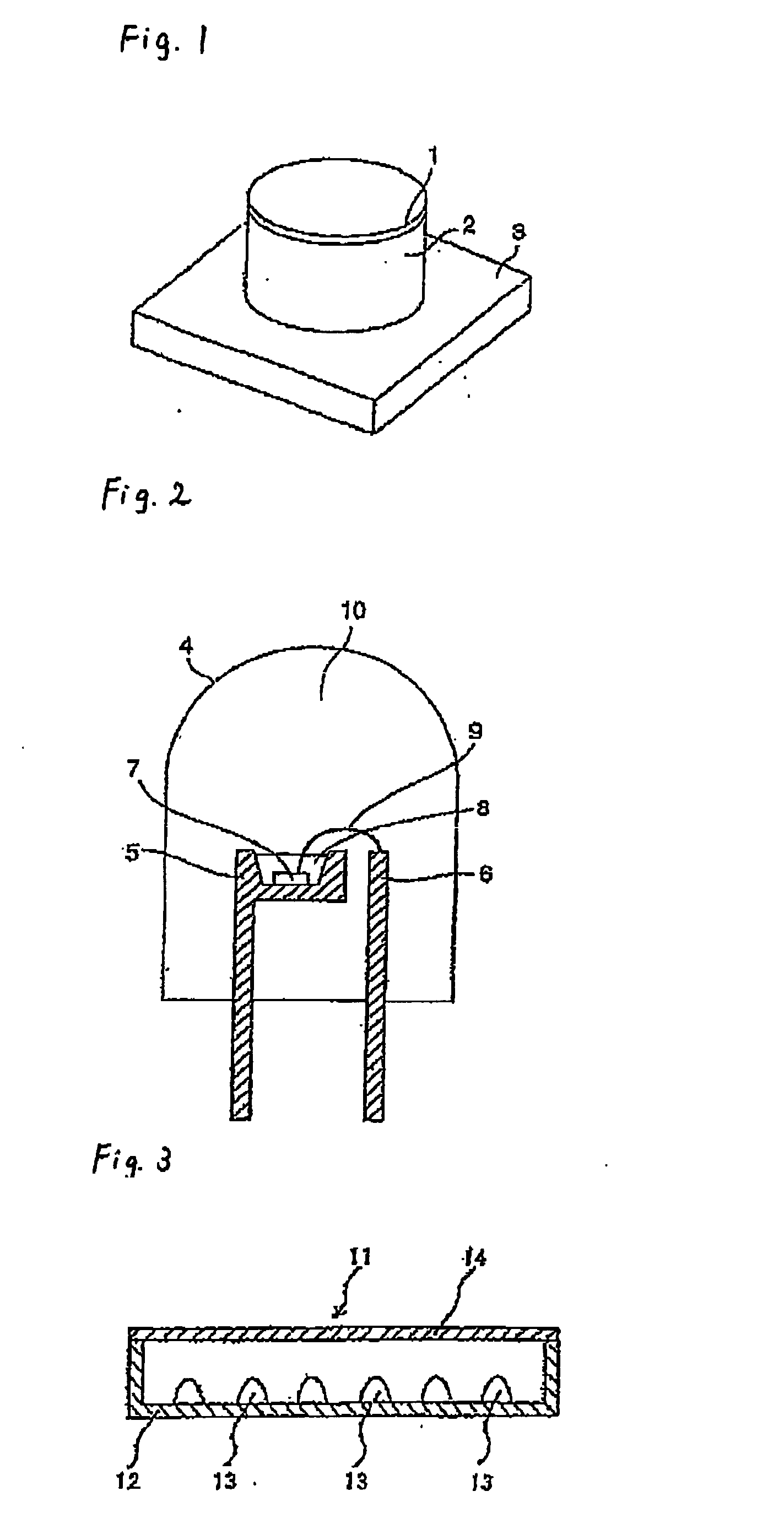

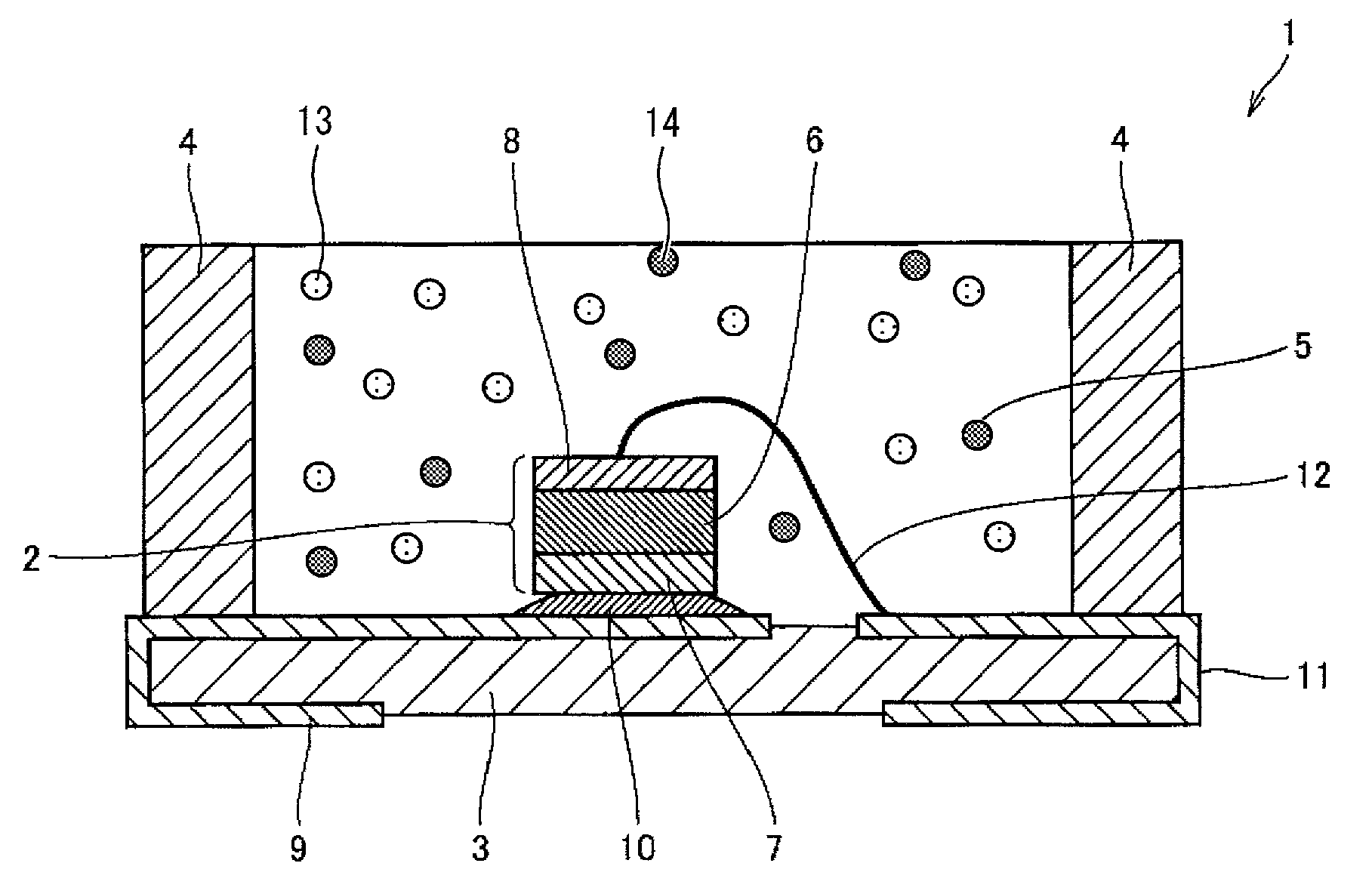

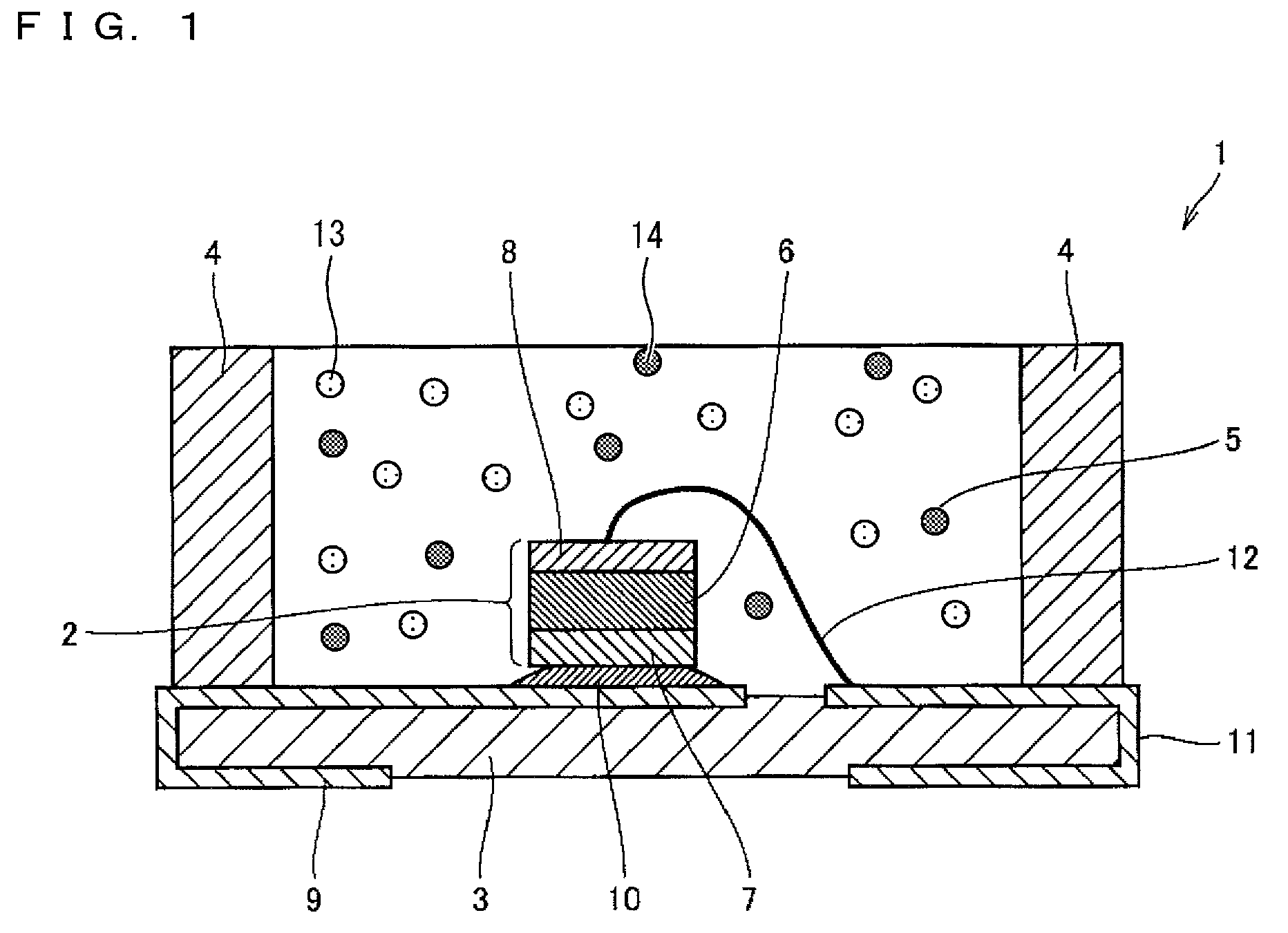

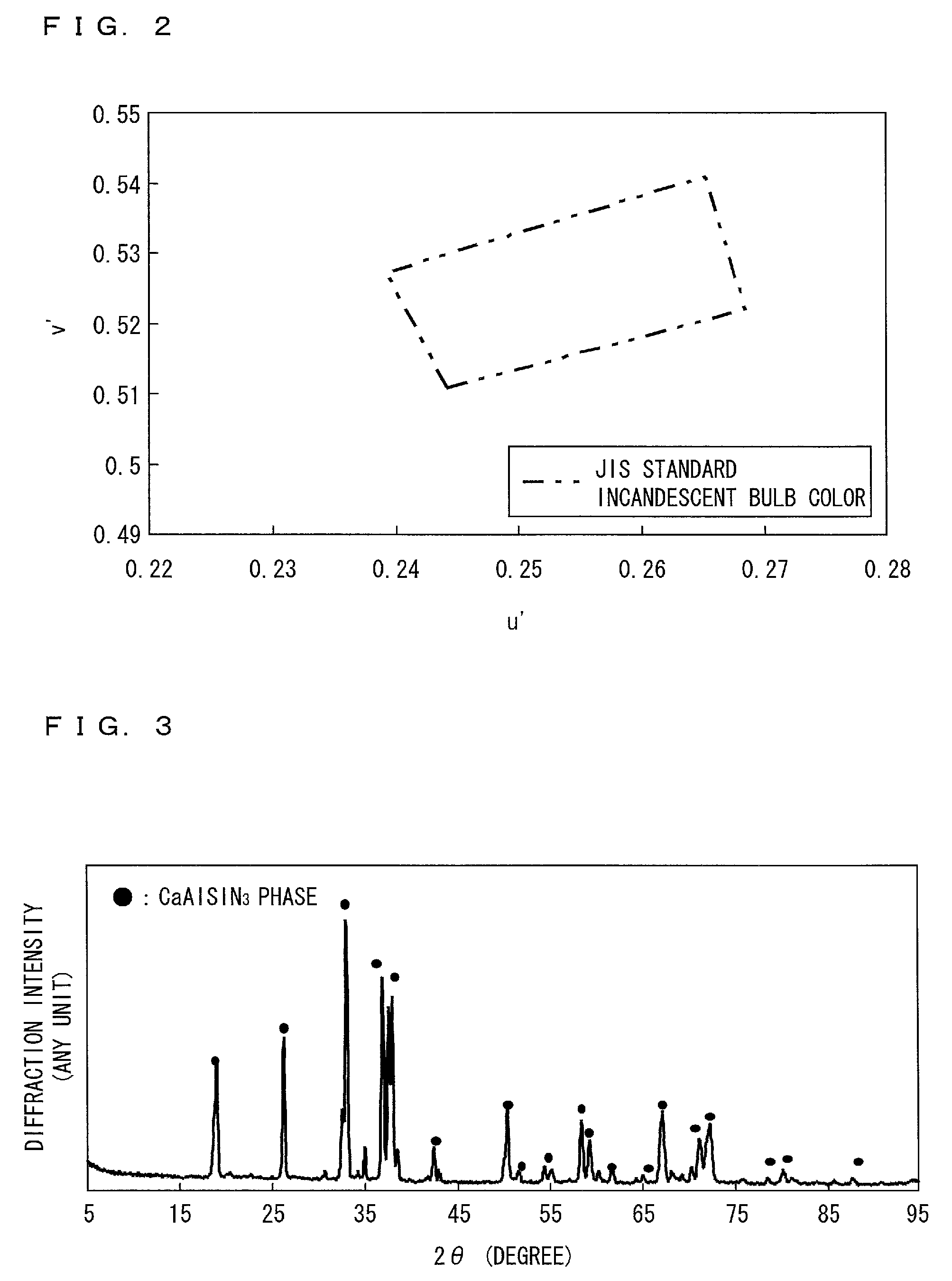

ActiveUS20120319155A1Efficient emissionsWithout degrading color renderingElectroluminescent light sourcesSolid-state devicesPhosphorFull width at half maximum

Disclosed is a light-emitting device that exhibits good color rendering and highly efficiently emits white light in an incandescent bulb color range. The semiconductor light-emitting device (1) of the present invention includes: a semiconductor light-emitting element (2) that emits blue light; a green phosphor (14) that absorbs the blue light and emits green light; and an orange phosphor (13) that absorbs the blue light and emits orange light. The orange phosphor (13) produces an emission spectrum having a peak at a wavelength of equal to or greater than 590 nm but equal to or less than 630 nm and having a full width at half maximum of 130 nm or greater at the peak, the full width at half maximum of the emission spectrum of the orange phosphor (13) being broader than a full width at half maximum of an emission spectrum of the green phosphor (14). The orange phosphor (13) exhibits an absorptance having a peak wavelength of 420 nm or greater. ABS(530) and ABS(MAX) satisfy a relation, ABS(530) / ABS(MAX)<0.60, where ABS(MAX) is an absorptance of the orange phosphor (13) at the peak wavelength thereof, and ABS(530) is an absorptance of the orange phosphor (13) at a wavelength of 530 nm.

Owner:NAT INST FOR MATERIALS SCI

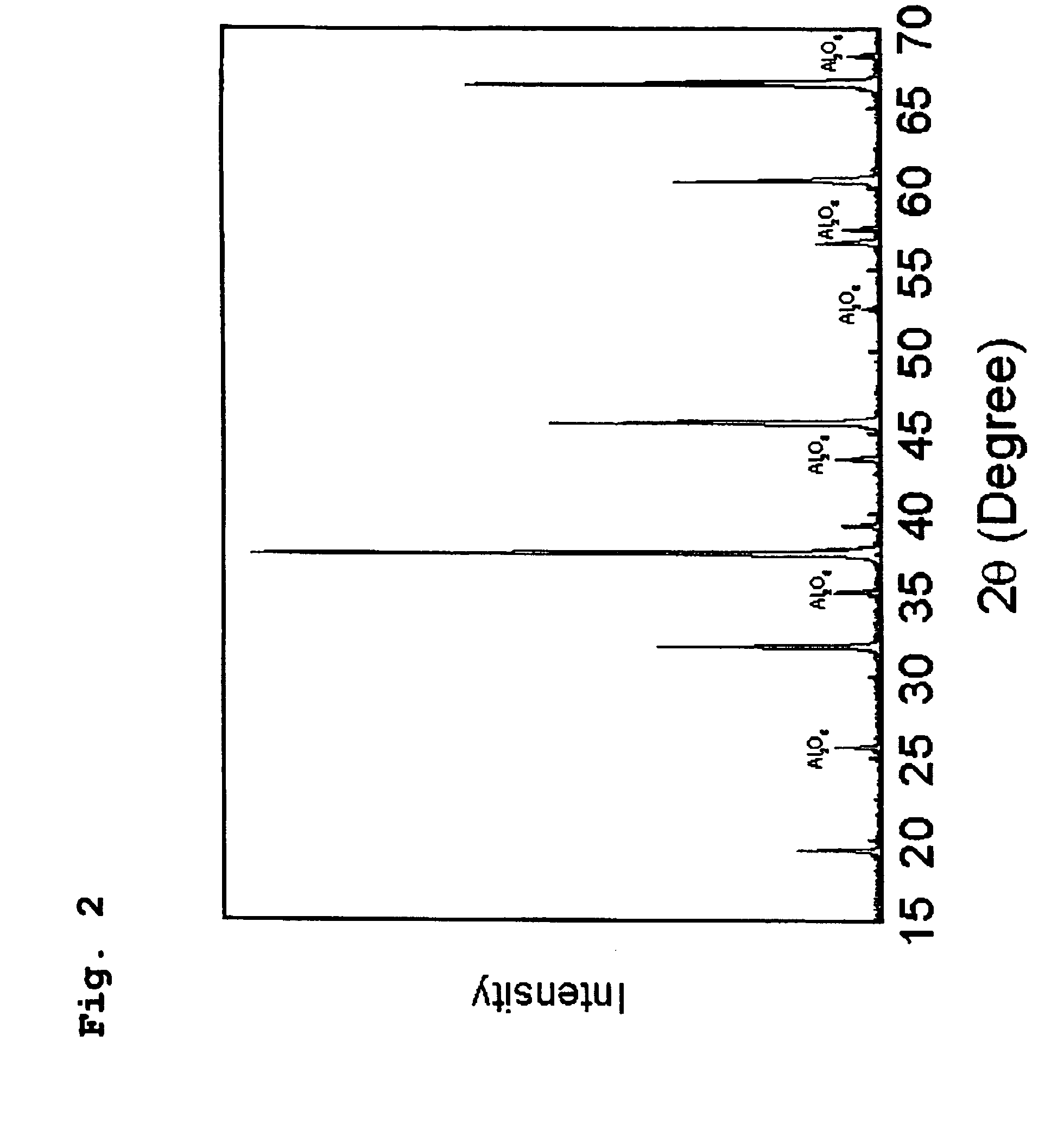

Phosphor, method for producing same, and light-emitting device

ActiveUS8057704B2Increase intensityReduce emission intensityLaser detailsDischarge tube luminescnet screensFluorescencePhosphor

Disclosed are violet, blue, and green phosphors having excellent durability and high luminance. Specifically disclosed is a phosphor which contains a metal element M (M is at least one element selected from among Mn, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Tm and Yb) for constituting a metal ion, which is solid-solubilized in an AlON crystal, an AlON solid solution crystal or an inorganic crystal having the same crystal structure as AlON. The phosphor is capable of emitting fluorescence having a peak in the wavelength range from 300 nm to 700 nm. Also disclosed is a method for producing such a phosphor. Further disclosed are an illuminating device and an image display each containing such a phosphor.

Owner:NAT INST FOR MATERIALS SCI

Fluorescent material, process for producing the same, and luminescent device

ActiveUS8142685B2High emission intensityEfficiently emitsDischarge tube luminescnet screensCathode ray tubes/electron beam tubesLight emitting deviceElectron

A blue fluorescent material having excellent durability and a high luminance, especially one emitting a high-luminance light by the action of electron rays. The fluorescent material comprises inorganic crystals having a crystal structure which is an AlN crystalline, AlN polycrystalline, or AlN solid-solution crystalline structure. It is characterized in that the inorganic crystals contain at least europium in solution and have an oxygen content of 0.4 mass % or lower and that the fluorescent material emits fluorescence derived from divalent europium ions upon irradiation with an excitation source. More preferably, the fluorescent material contains a given metallic element and silicon. Also provided are a process for producing the fluorescent material and an illuminator including the blue fluorescent material.

Owner:NAT INST FOR MATERIALS SCI

Organic compound, light-emitting element, light-emitting device, display device, electronic device, and lighting device

ActiveUS9634263B2Efficient emissionsLow efficiencyOrganic chemistrySolid-state devicesArylSimple Organic Compounds

A novel organic compound that forms an exciplex emitting light with high efficiency is provided. An organic compound with a triarylamine skeleton in which the three aryl groups of the triarylamine skeleton are a p-biphenyl group, a fluoren-2-yl group, and a phenyl group to which a dibenzofuranyl group or a dibenzothiophenyl group is bonded. By the use of the organic compound and an organic compound with an electron-transport property, an exciplex that emits light with extremely high efficiency can be formed.

Owner:SEMICON ENERGY LAB CO LTD

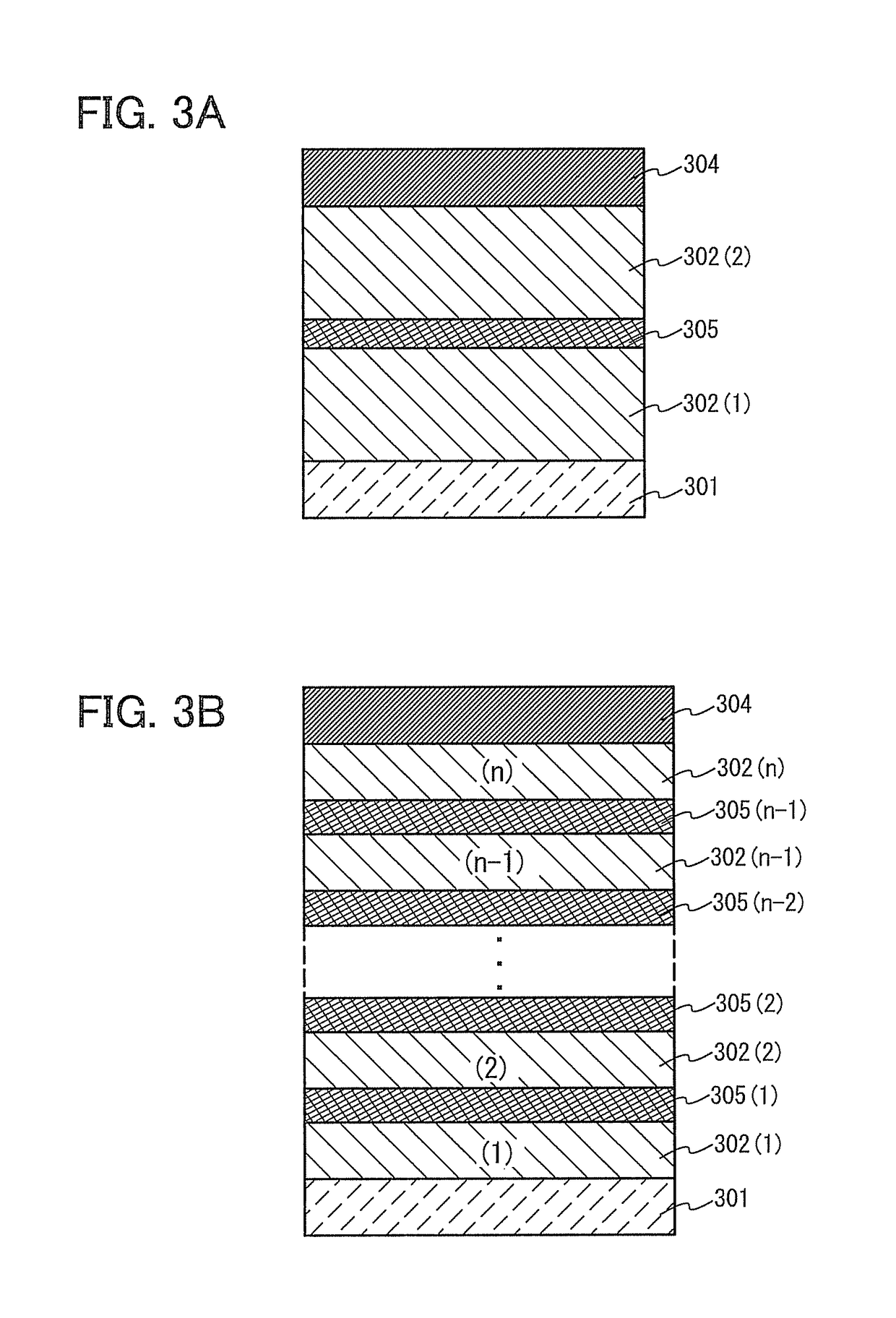

Beta-sialon, method for producing same and light-emitting device using same

ActiveUS9139769B2Efficiently emitsImprove launch performanceElectroluminescent light sourcesLuminescent compositionsFluorescenceSilicon oxide

β-Sialon comprising Eu2+ that is present in a solid solution form in β-sialon represented by Si6-zAlzOzN μm [wherein z is 0.3-1.5], which shows, when excited with light of 450 nm in wavelength, a peak wavelength of fluorescent spectrum of 545-560 nm, a half-value breadth of 55 nm or greater, and an external quantum efficiency of 45% or greater. The β-sialon can be produced by blending at least one kind of oxide selected from aluminum oxide and silicon oxide with silicon nitride and aluminum nitride in such a manner as to give z of 0.3-1.5, further adding thereto a europium compound and a β-sialon powder having an average particle diameter of 5 μm or greater and an average degree of circularity of 0.7 or greater, each in a definite amount, and baking the mixture.

Owner:DENKA CO LTD

Electron emitter

InactiveUS20060290255A1Increase productionIncrease speedDischarge tube luminescnet screensNanoinformaticsThin layerElectron

A dielectric-film-type electron emitter includes an emitter section, a first electrode, and a second electrode. The emitter section is formed of a thin layer of a polycrystalline dielectric material. The dielectric material constituting the emitter section is formed of a material having high mechanical quality factor (Qm). Specifically, the dielectric material has a Qm higher than that of a so-called low-Qm material (a material having a Qm of 100 or less). The Qm of the dielectric material is preferably 300 or more, more preferably 500 or more.

Owner:NGK INSULATORS LTD

Cyclometalated transition metal complex and organic light emitting device using the same

ActiveUS8048537B2Efficiently emitsEfficient emissionsGroup 5/15 element organic compoundsSolid-state devicesQuantum efficiencyOrganic light emitting device

Provided is a cyclometalated transition metal complex represented by Formula 1:The cyclometalated transition metal complex contains a new ancillary ligand having a carboxylate acid or the like connected to a hetero ring, so that it can efficiently emit red light from a phosphorous material through intersystem crossing (ISC) to form triplet excitons and then metal to ligand charge transfer (MLCT). An organic light emitting device manufactured using the transition metal complex shows excellent luminous efficiency and external quantum efficiency.

Owner:SAMSUNG DISPLAY CO LTD

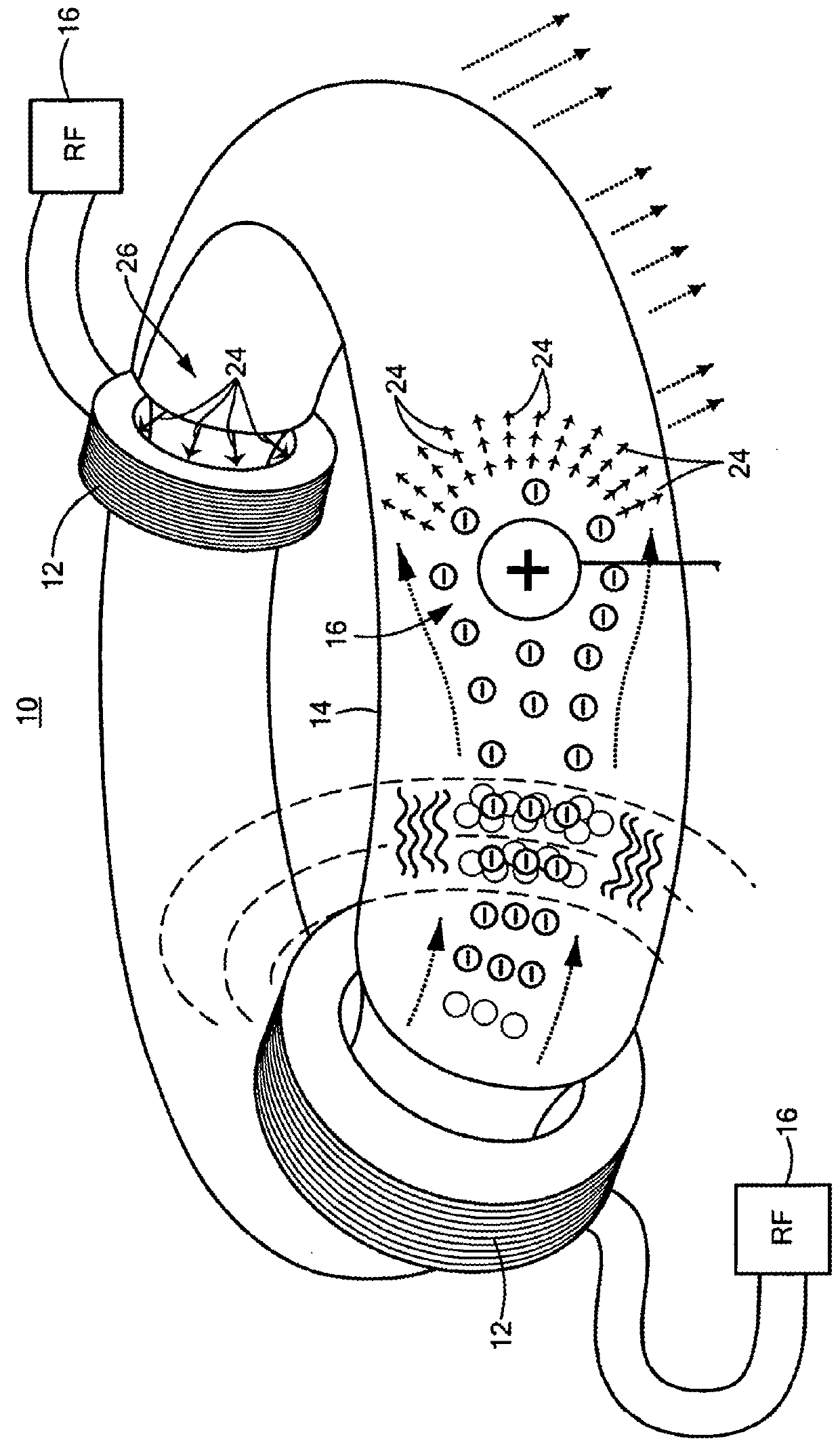

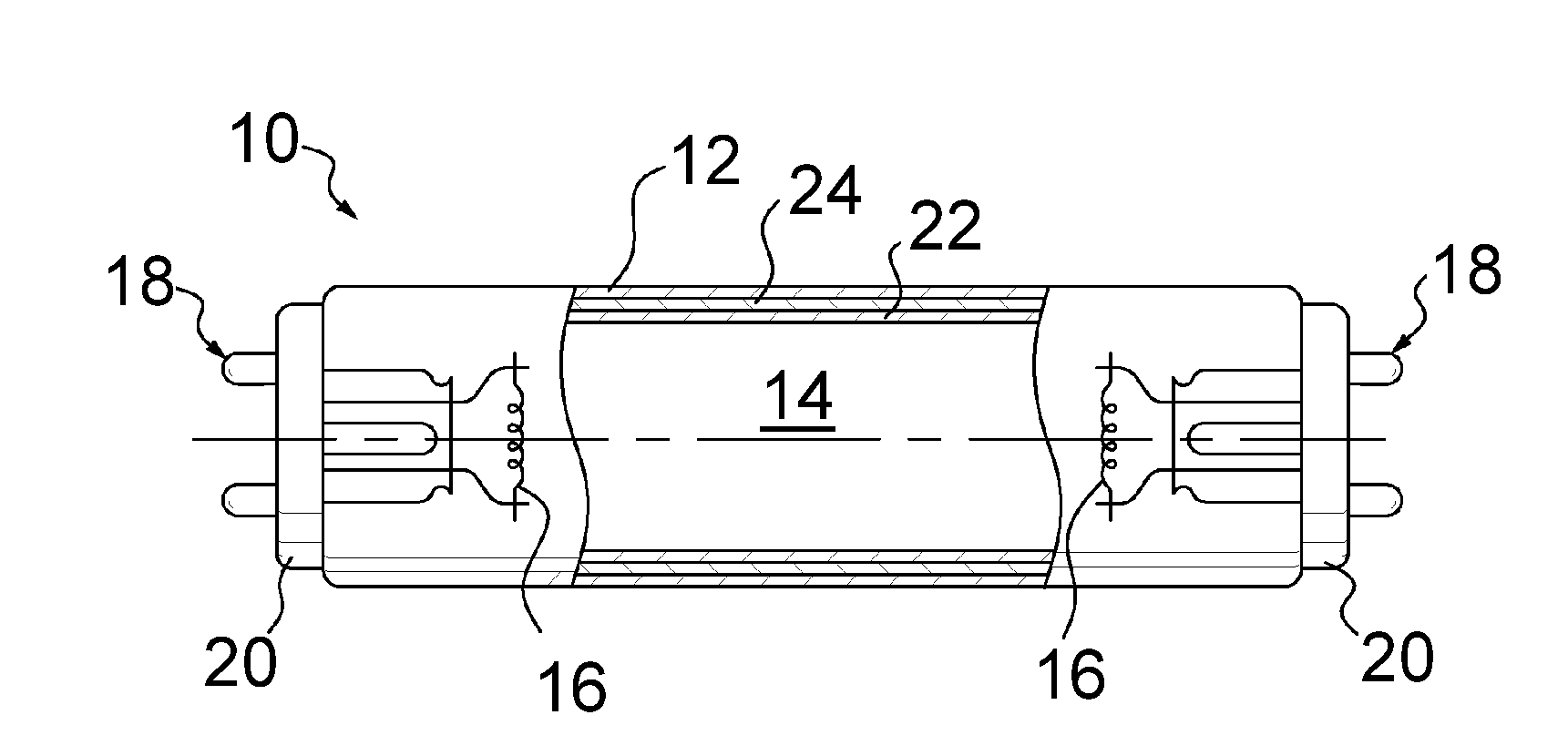

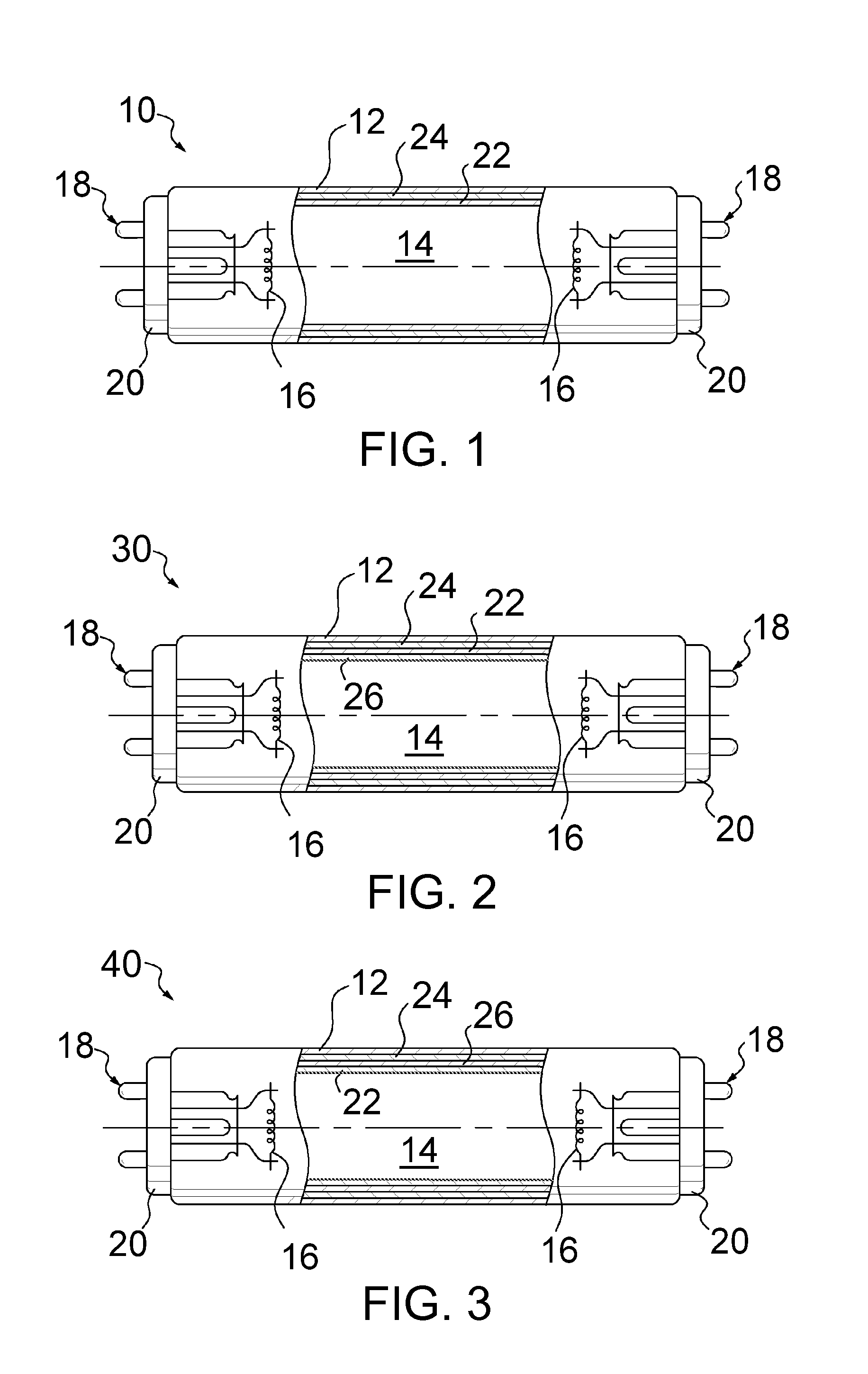

Coreless transformer UV light source system

InactiveUS9334177B1Effective lightingEfficiently emitsWater/sewage treatment by irradiationX-ray tube with very high currentRadio frequencyLight source

A coreless transformer ultra-violet (UV) light source system comprising a bulb including a predetermined amount of an element which efficiently emits UV light when exposed to a high current plasma state and a predetermined amount of a buffer gas therein. An optically thin mesh primary surrounds a portion of the bulb. A pulsed radio frequency (RF) oscillator is coupled to the primary configured to drive high current pulses into the primary causing the light emitting element to form a conducting secondary comprised of the element in a plasma state thereby causing the element to efficiently emit UV light.

Owner:DIVERSIFIED TECH INC

Phosphor, process for producing the same, and luminescent device

ActiveUS8114313B2Emission intensity unlikelyEfficiently emitsDischarge tube luminescnet screensCathode ray tubes/electron beam tubesFluorescenceLight emitting device

Owner:NAT INST FOR MATERIALS SCI

Light-emitting device

ActiveUS8674392B2Efficient emissionsWithout degrading color renderingElectroluminescent light sourcesSolid-state devicesPhosphorFull width at half maximum

Disclosed is a light-emitting device that exhibits good color rendering and highly efficiently emits white light in an incandescent bulb color range. The semiconductor light-emitting device (1) of the present invention includes: a semiconductor light-emitting element (2) that emits blue light; a green phosphor (14) that absorbs the blue light and emits green light; and an orange phosphor (13) that absorbs the blue light and emits orange light. The orange phosphor (13) produces an emission spectrum having a peak at a wavelength of equal to or greater than 590 nm but equal to or less than 630 nm and having a full width at half maximum of 130 nm or greater at the peak, the full width at half maximum of the emission spectrum of the orange phosphor (13) being broader than a full width at half maximum of an emission spectrum of the green phosphor (14). The orange phosphor (13) exhibits an absorptance having a peak wavelength of 420 nm or greater. ABS(530) and ABS(MAX) satisfy a relation, ABS(530) / ABS(MAX)<0.60, where ABS(MAX) is an absorptance of the orange phosphor (13) at the peak wavelength thereof, and ABS(530) is an absorptance of the orange phosphor (13) at a wavelength of 530 nm.

Owner:NAT INST FOR MATERIALS SCI

Pressure regulator

ActiveUS20090267482A1Emission intensity unlikelyLow emission intensityDischarge tube luminescnet screensCathode ray tubes/electron beam tubesInorganic crystalsMetal

A blue phosphor, which has excellent durability and high brightness, and in particular a blue phosphor in a powder state, which can realize high-brightness luminescence upon exposure to an electron beam, are provided. The phosphor being characterized by comprising at least europium incorporated as a solid solution into an inorganic crystal having a crystal structure of an AlN crystal or an AlN solid solution crystal, wherein the phosphor emits divalent europium-derived fluorescence having a peak at a wavelength in the range of 430 nm to 500 nm upon exposure to an excitation source, is provided. In this case, it is more preferable that a predetermined metal element and silicon are incorporated therein. And a manufacturing method to manufacture such phosphor is also provided. Further, a lighting device comprising such blue phosphor is provided.

Owner:NAT INST FOR MATERIALS SCI

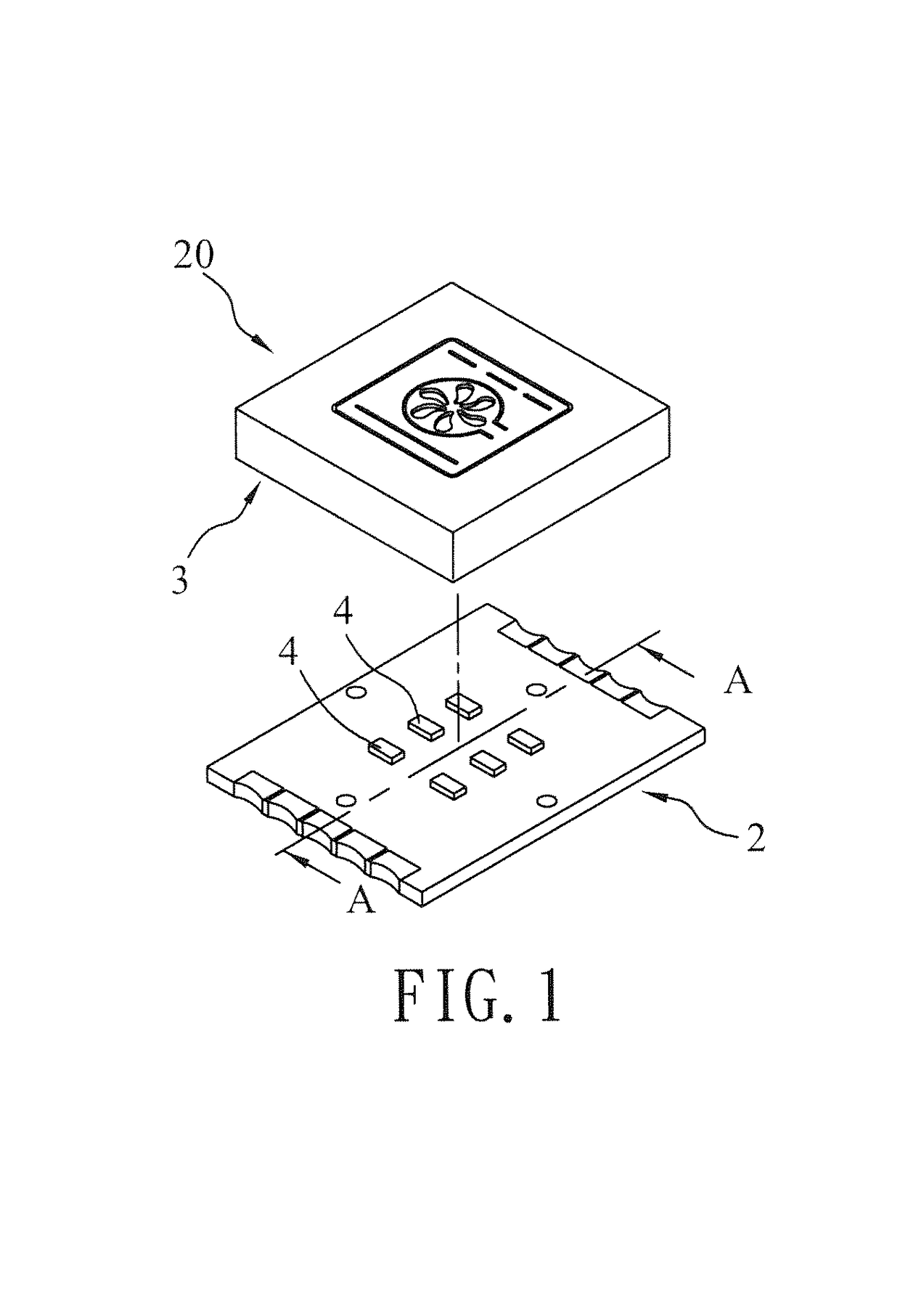

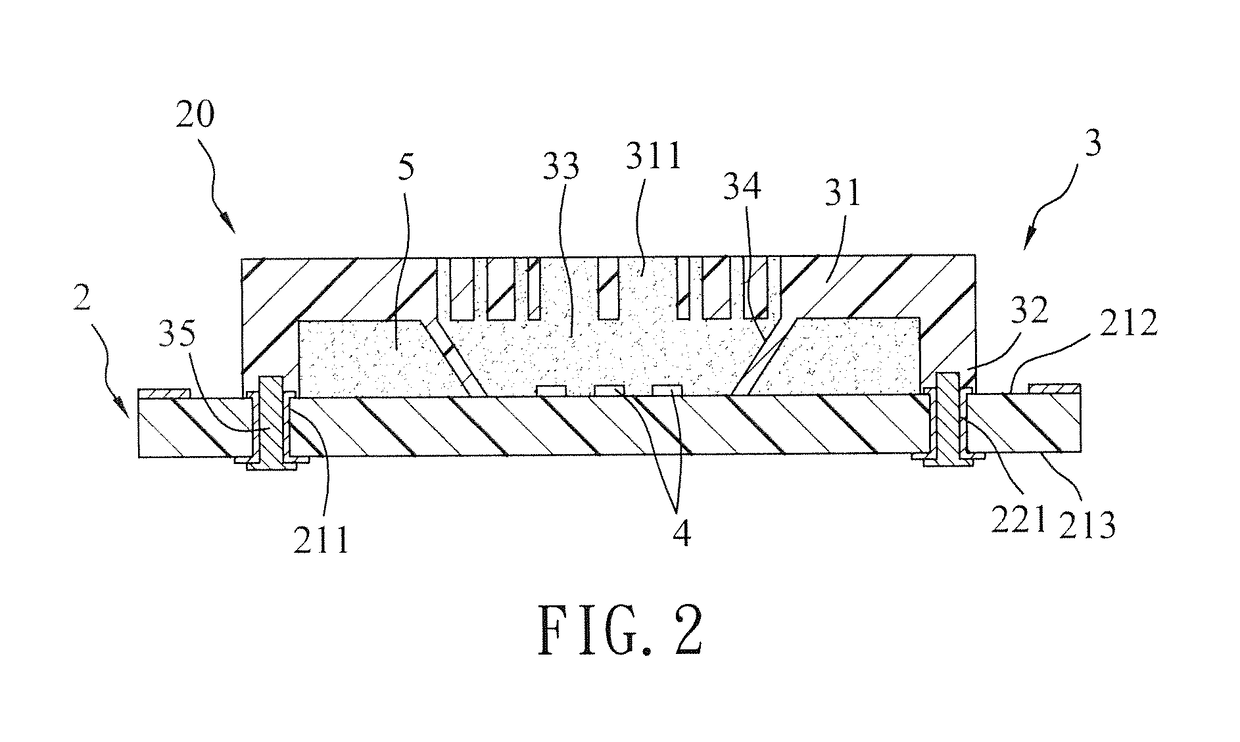

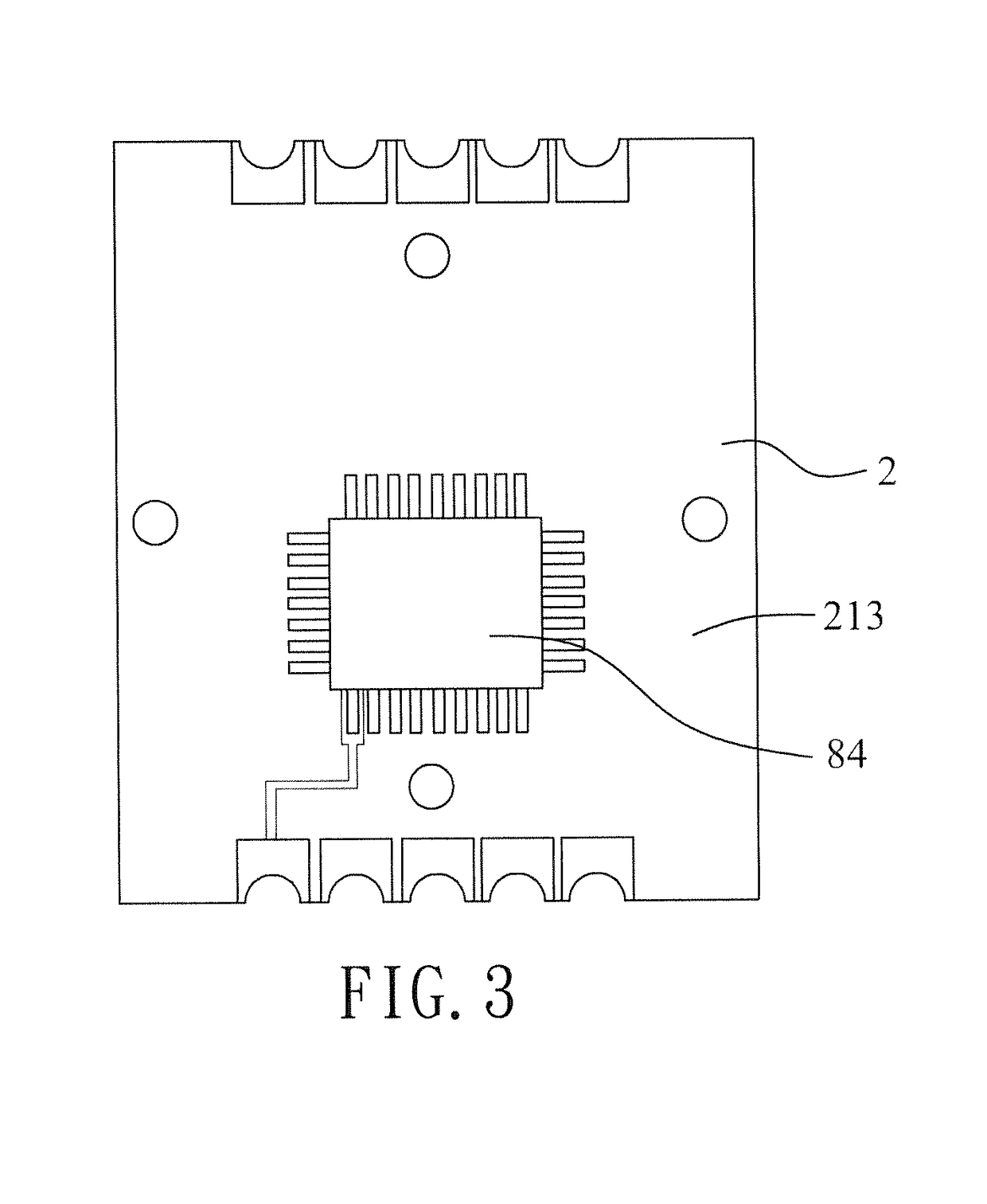

Light-emitting touch-switch device and light-emitting touch-switch module

ActiveUS10187059B2Increase the areaEffective lightingElectronic switchingElectricityPlastic materials

A light-emitting touch-switch device includes a first circuit board, a cap unit and a light-emitting element. The first circuit board is electrically coupled to a sensing chip. The cap unit is disposed on the first circuit board and that is at least partially made of an electrically conductive plastic material having a resistance of equal to or smaller than 1×105Ω. The cap unit and the first circuit board cooperate to define a receiving space. The light-emitting element is disposed in the receiving space and is electrically coupled to the first circuit board. A light-emitting touch-switch module including the light-emitting touch-switch device is also disclosed.

Owner:LITE ON OPTO TECH (CHANGZHOU) CO LTD +1

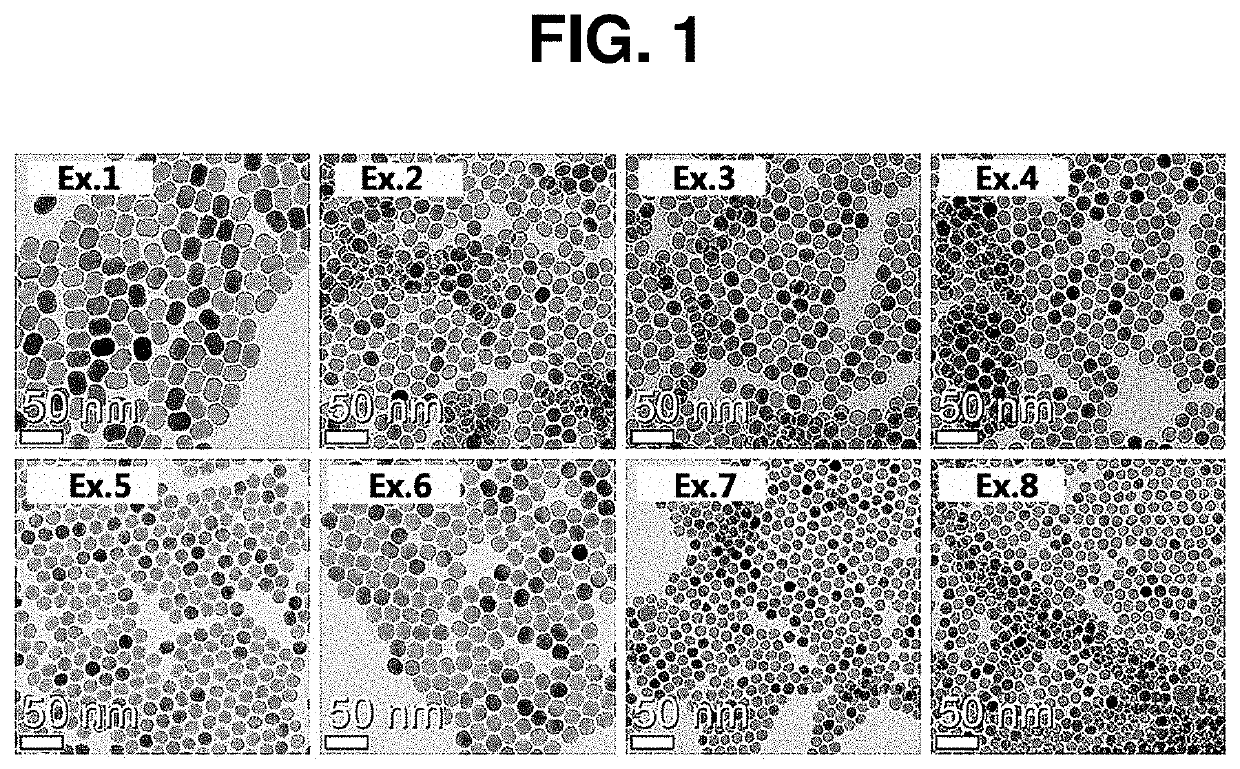

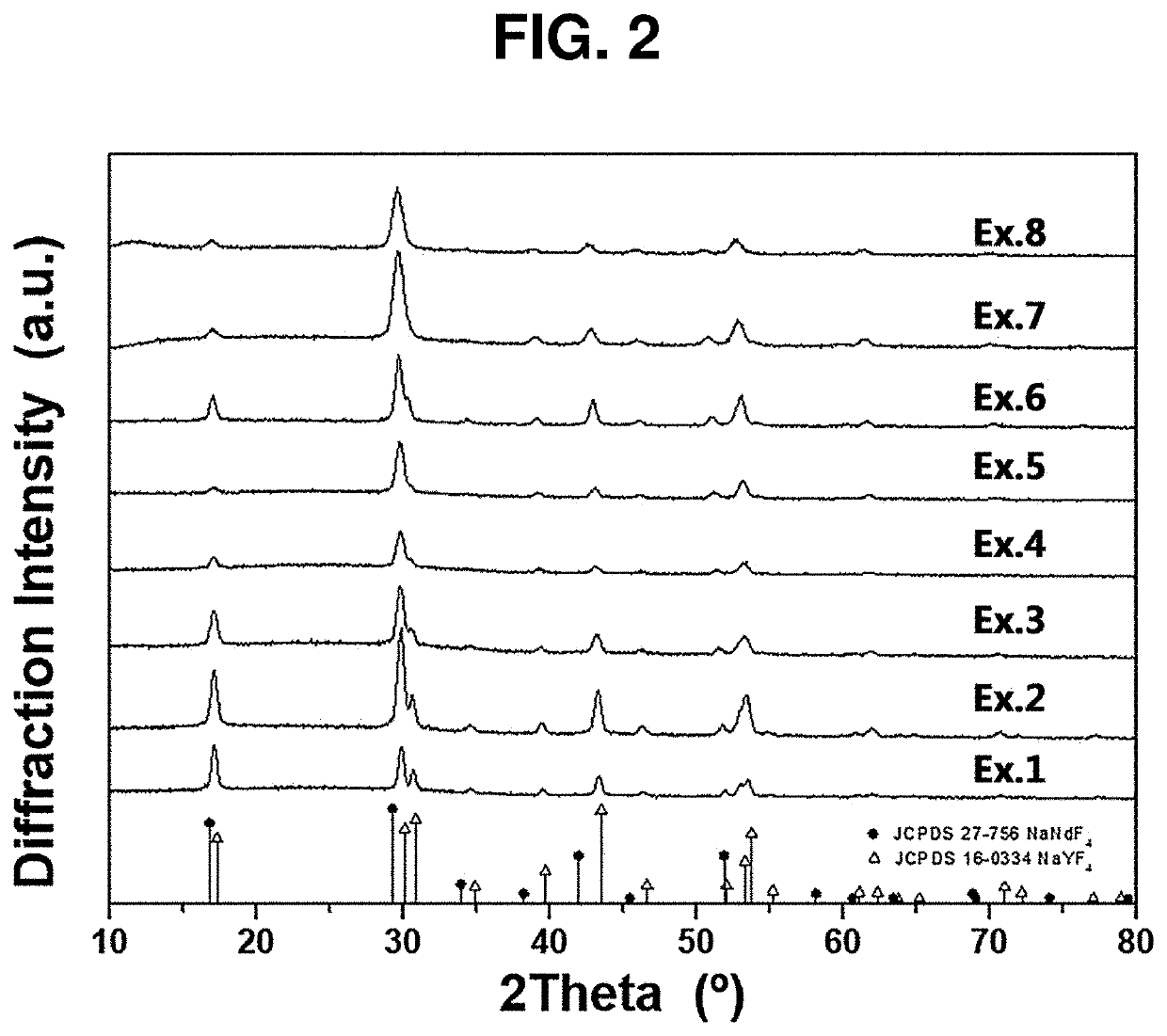

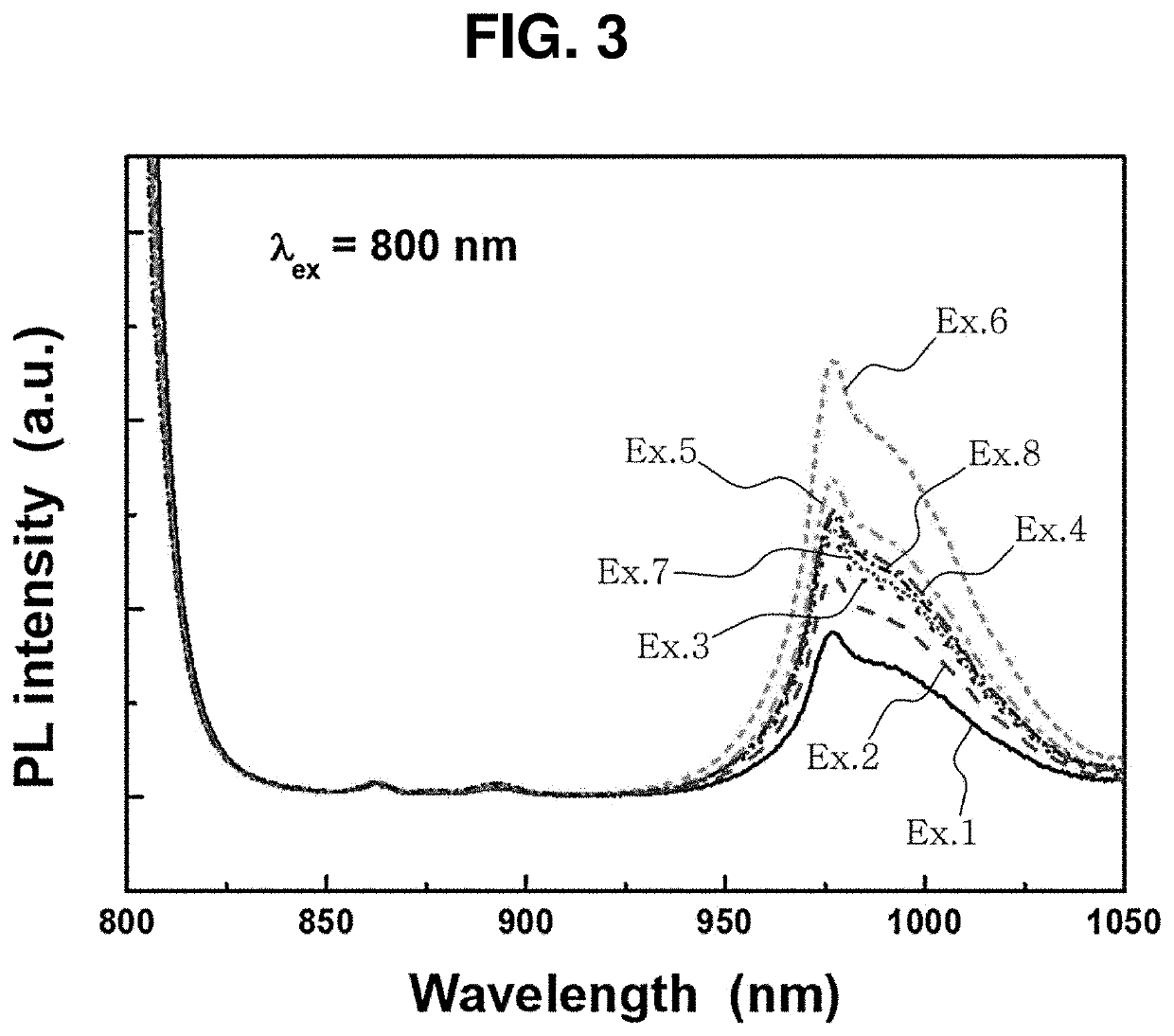

Down-shifting nanophosphors, method for preparing the same, and luminescent solar concentrator using the same

ActiveUS20210332293A1Efficient emissionsHigh near infrared ray shifting efficiencyMaterial nanotechnologySolar heating energyInfraredFluorescence

The present disclosure relates to down-shifting nanophosphors, a method for preparing the same, and a luminescent solar concentrator (LSC) using the same. The down-shifting nanophosphors according to an embodiment of the present disclosure include a core including NaYF4 nanocrystals doped with neodymium (Nd) and ytterbium (Yb), and further include a neodymium (Nd)-doped crystalline shell surrounding the core, or further include a NaYF4 crystalline shell surrounding the crystalline shell. Therefore, the down-shifting nanophosphors efficiently absorb near infrared rays with a wavelength range of 700-900 nm and efficiently emit near infrared rays with a wavelength range of 950-1050 nm. In addition, the down-shifting nanophosphors according to an embodiment of the present disclosure has a size of 60 nm or less, and thus can be applied to manufacture transparent LSC films with ease and can realize transparent solar cell modules having high near infrared ray shifting efficiency.

Owner:KOREA INST OF SCI & TECH

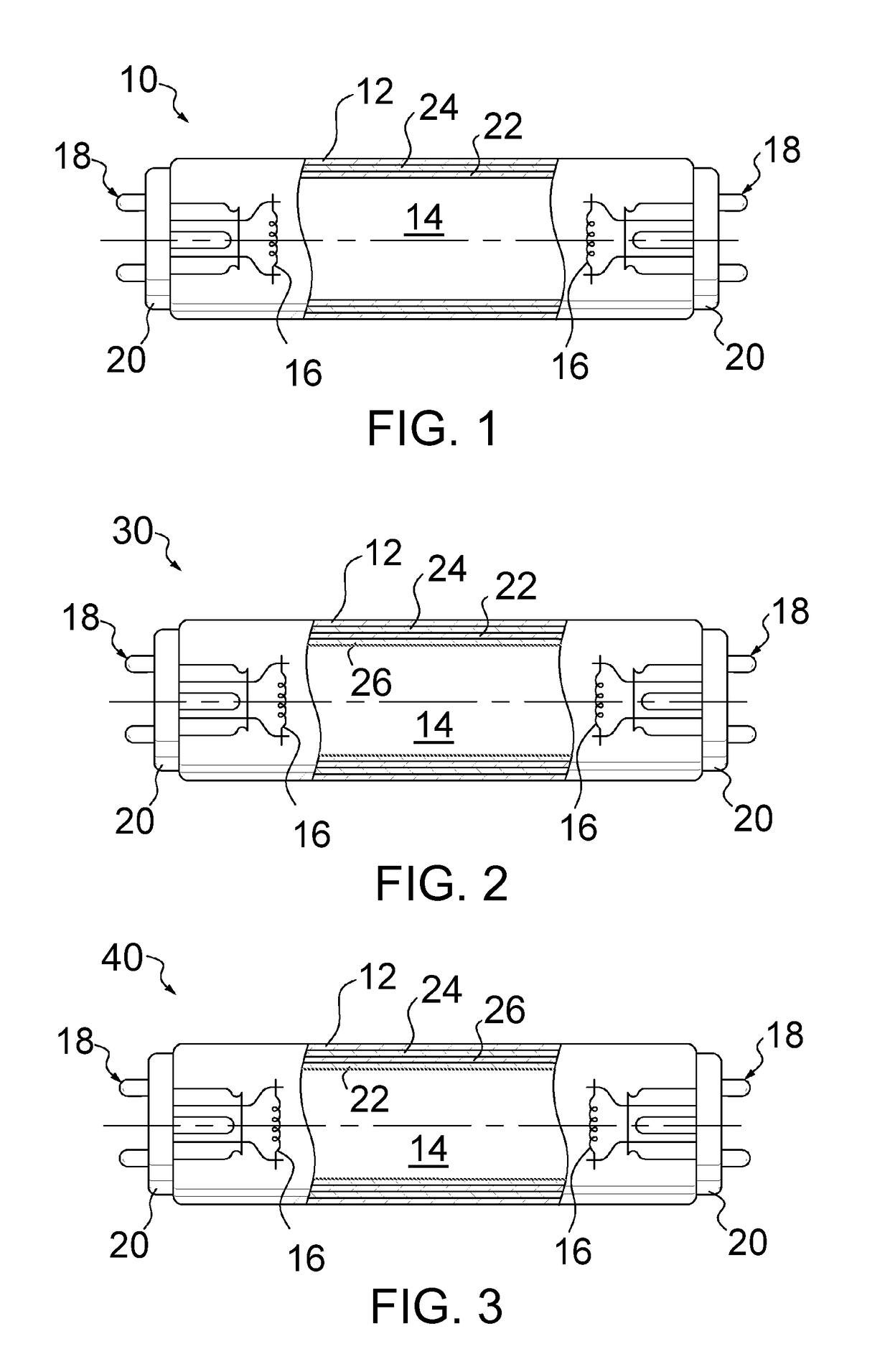

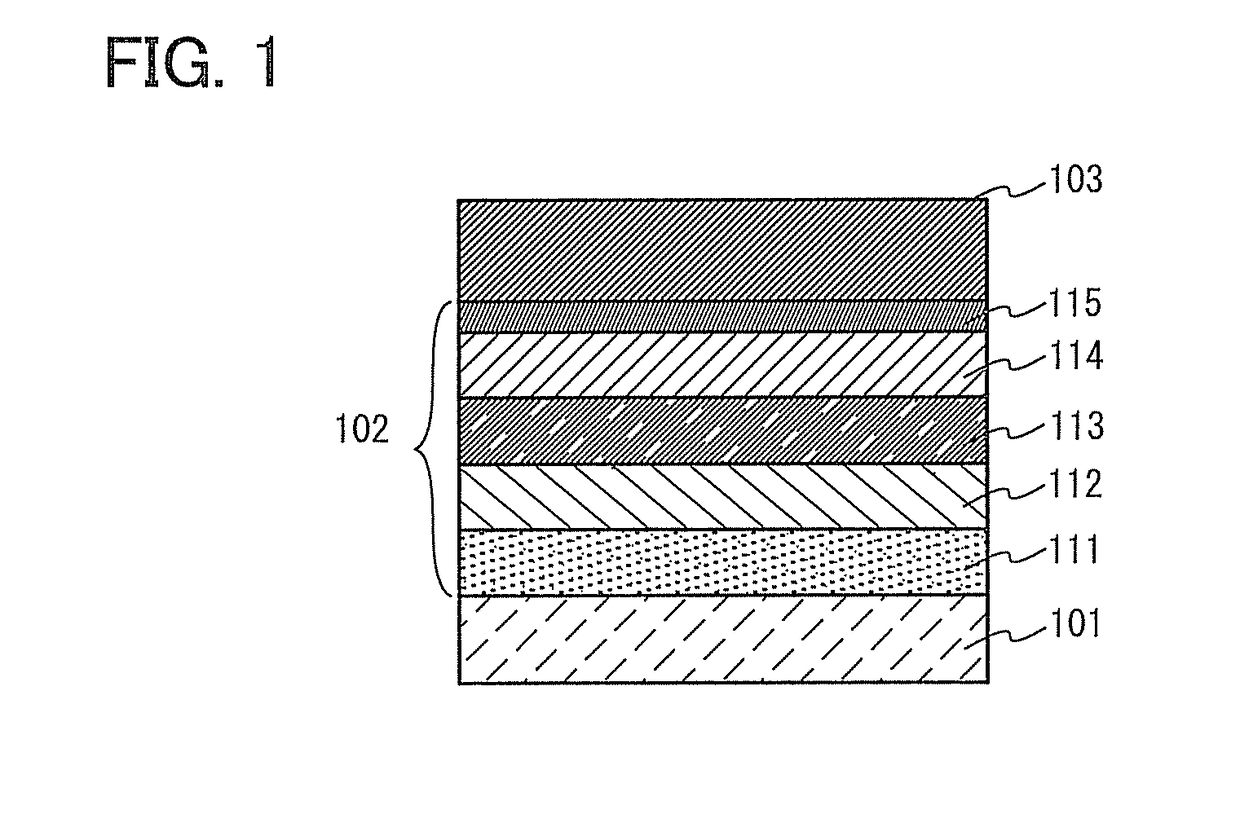

Phosphor-containing coating systems and fluorescent lamps equipped therewith

InactiveUS9633830B2Improve performanceEfficiently emitsLuminescent paintsLuminescent compositionsCoating systemPhosphor

Coating systems suitable for use in generating fluorescent visible light, and lamps provided with such coating systems. The coating systems includes a phosphor-containing coating that contains at least a first phosphor that is predominantly excited by ultraviolet radiation of a first wavelength to emit visible light and absorbs but is less efficiently excited by ultraviolet radiation of a second wavelength. The coating system further includes a second phosphor that absorbs the ultraviolet radiation of the second wavelength and little if any of the ultraviolet radiation of the first wavelength.

Owner:GENERAL ELECTRIC CO

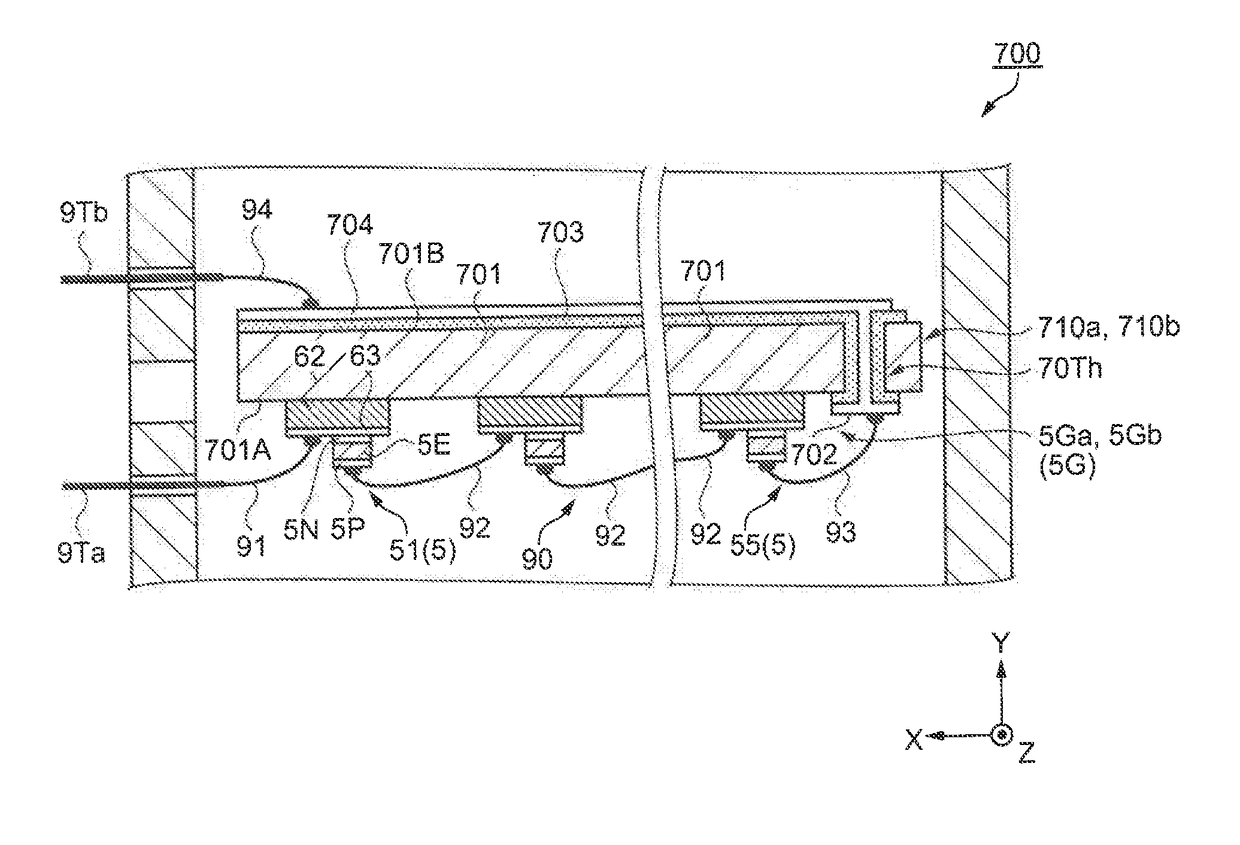

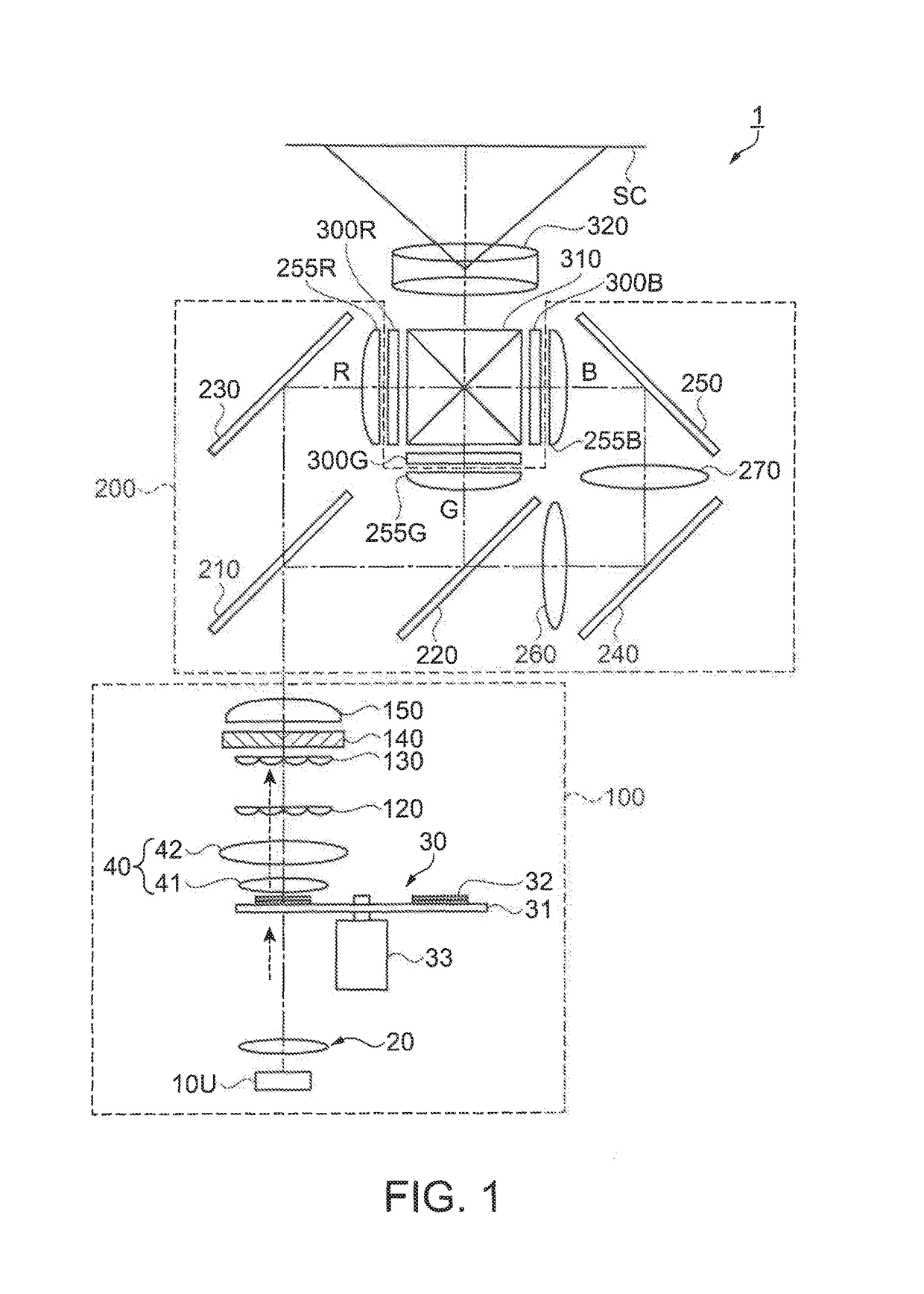

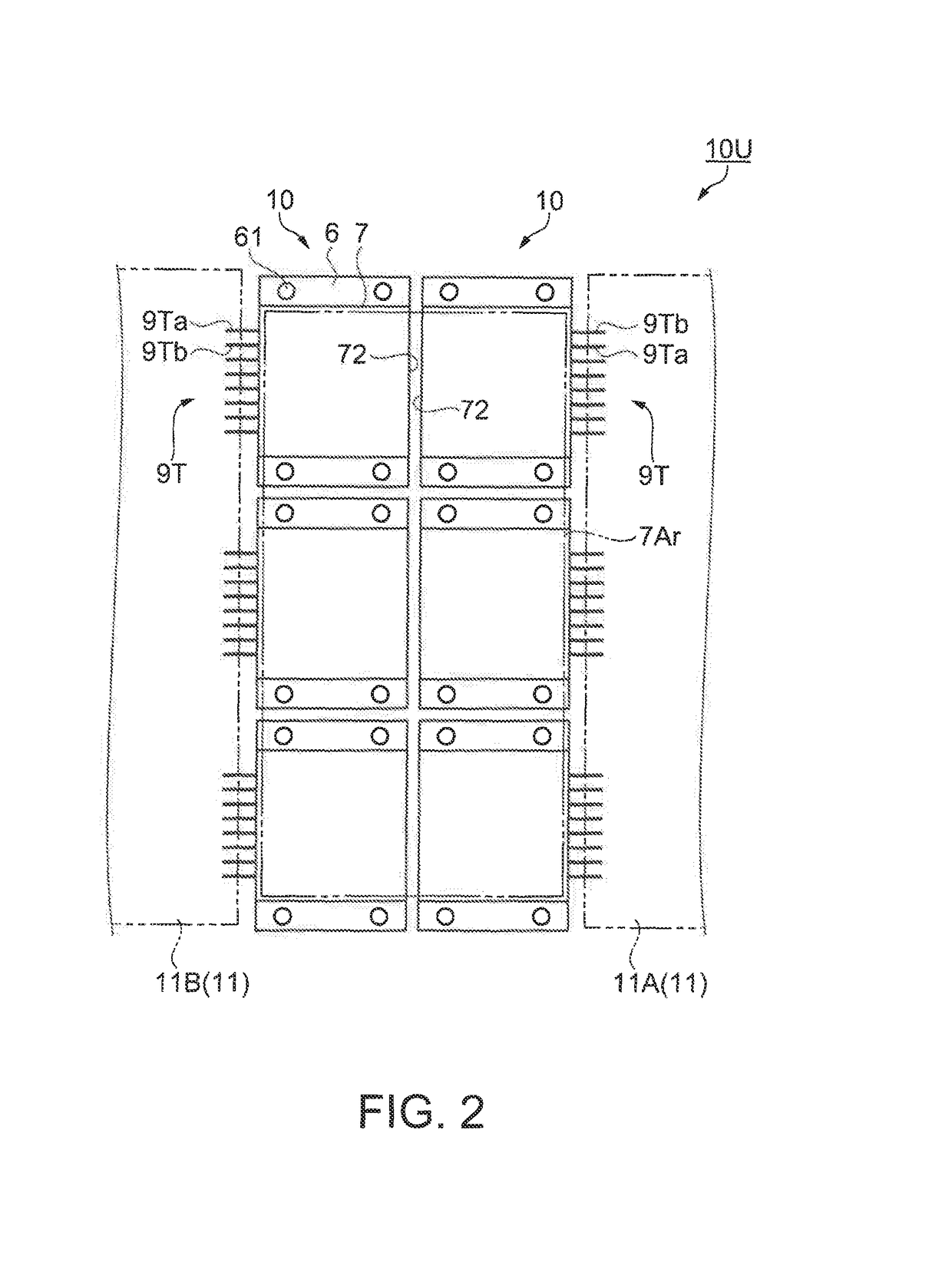

Light source device and projector

ActiveUS10054849B2Avoid low lightSmall sizePlanar light sourcesElectric circuit arrangementsElectrical polarityOptoelectronics

A light source device includes: a base substrate; a plurality of light emitting elements disposed on the base substrate along each of an X-direction and a Y-direction crossing the X-direction; and a first polarity terminal and a second polarity terminal for supplying power to the plurality of light emitting elements. The first polarity terminal and the second polarity terminal project from one side of the base substrate in the X-direction as viewed in a Z-direction orthogonal to the X-direction and the Y-direction.

Owner:SEIKO EPSON CORP

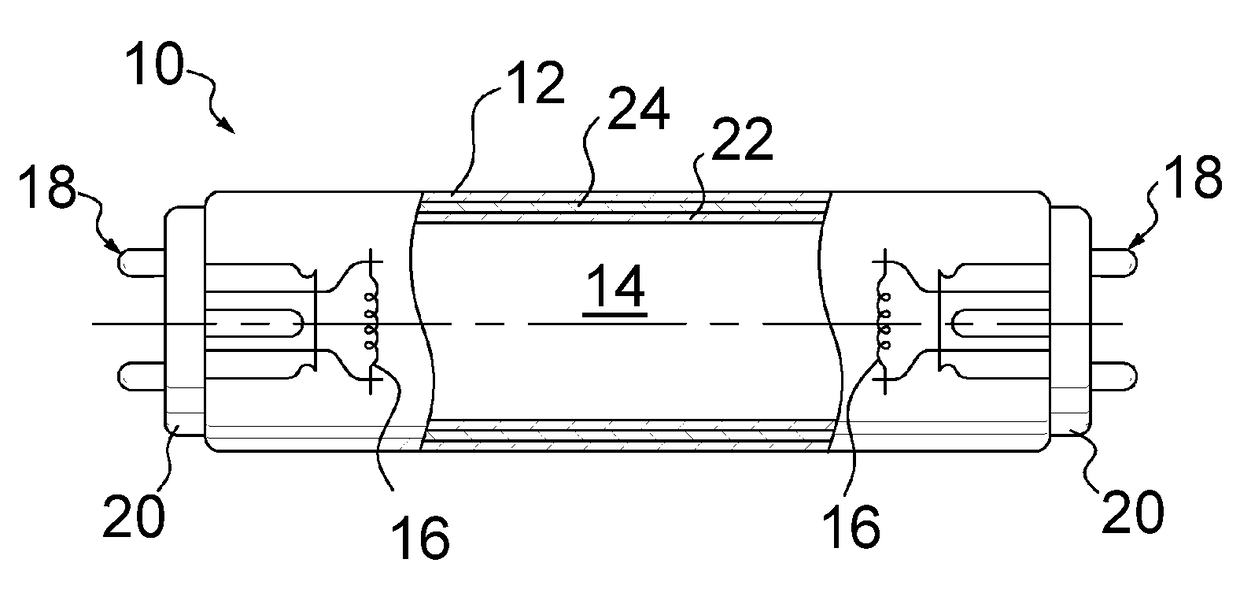

Phosphor-containing coating systems and fluorescent lamps equipped therewith

InactiveUS20160064203A1Efficiently emitsImprove performanceDischarge tube luminescnet screensLuminescent paintsPhosphorFluorescence

Coating systems suitable for use in generating fluorescent visible light, and lamps provided with such coating systems. The coating systems includes a phosphor-containing coating that contains at least a first phosphor that is predominantly excited by ultraviolet radiation of a first wavelength to emit visible light and absorbs but is less efficiently excited by ultraviolet radiation of a second wavelength. The coating system further includes a second phosphor that absorbs the ultraviolet radiation of the second wavelength and little if any of the ultraviolet radiation of the first wavelength.

Owner:GENERAL ELECTRIC CO

Iridium complex, light-emitting element, light-emitting device, electronic device, and lighting device

ActiveUS9768396B2Reduce power consumptionQuality improvementIndium organic compoundsSolid-state devicesArylIridium

A tris-type iridium complex in which a ligand having a distinctive nitrogen-containing five-membered heterocyclic skeleton is coordinated is provided. The ligand has a nitrogen-containing five-membered heterocyclic skeleton composed of 2 to 4 nitrogen atoms and one or more carbon atoms. In the skeleton, an aryl group is bonded to a carbon atom on both sides of which nitrogen atoms are positioned, and a tricycloalkyl group having a bridge structure and having 9 or 10 carbon atoms is bonded to one of the two nitrogen atoms positioned on both the sides of the carbon atom. The tricycloalkyl group having a bridge structure and having 9 or 10 carbon atoms may be an adamantyl group or a noradamantyl group.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com