Patents

Literature

212results about How to "Improve installation density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

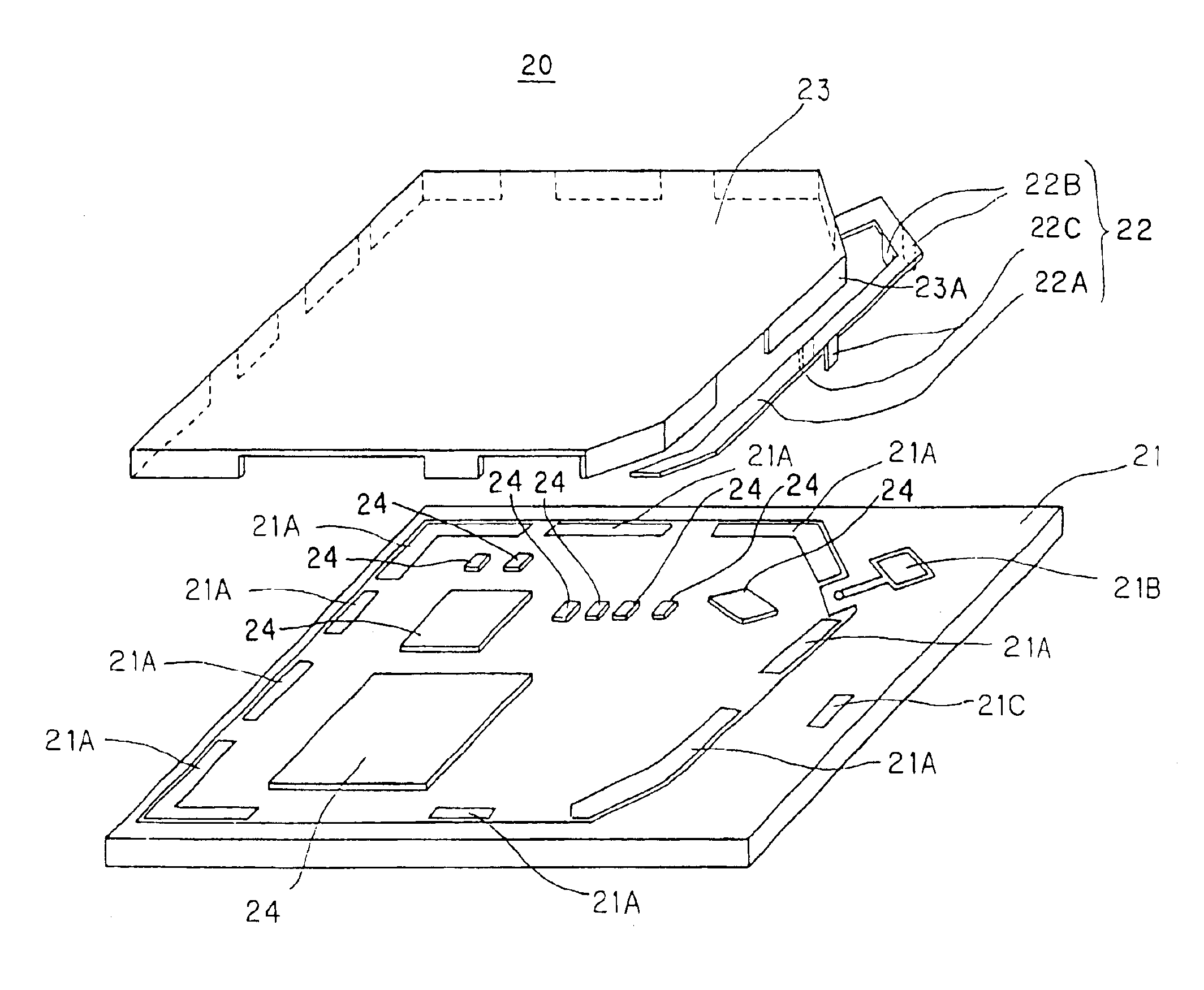

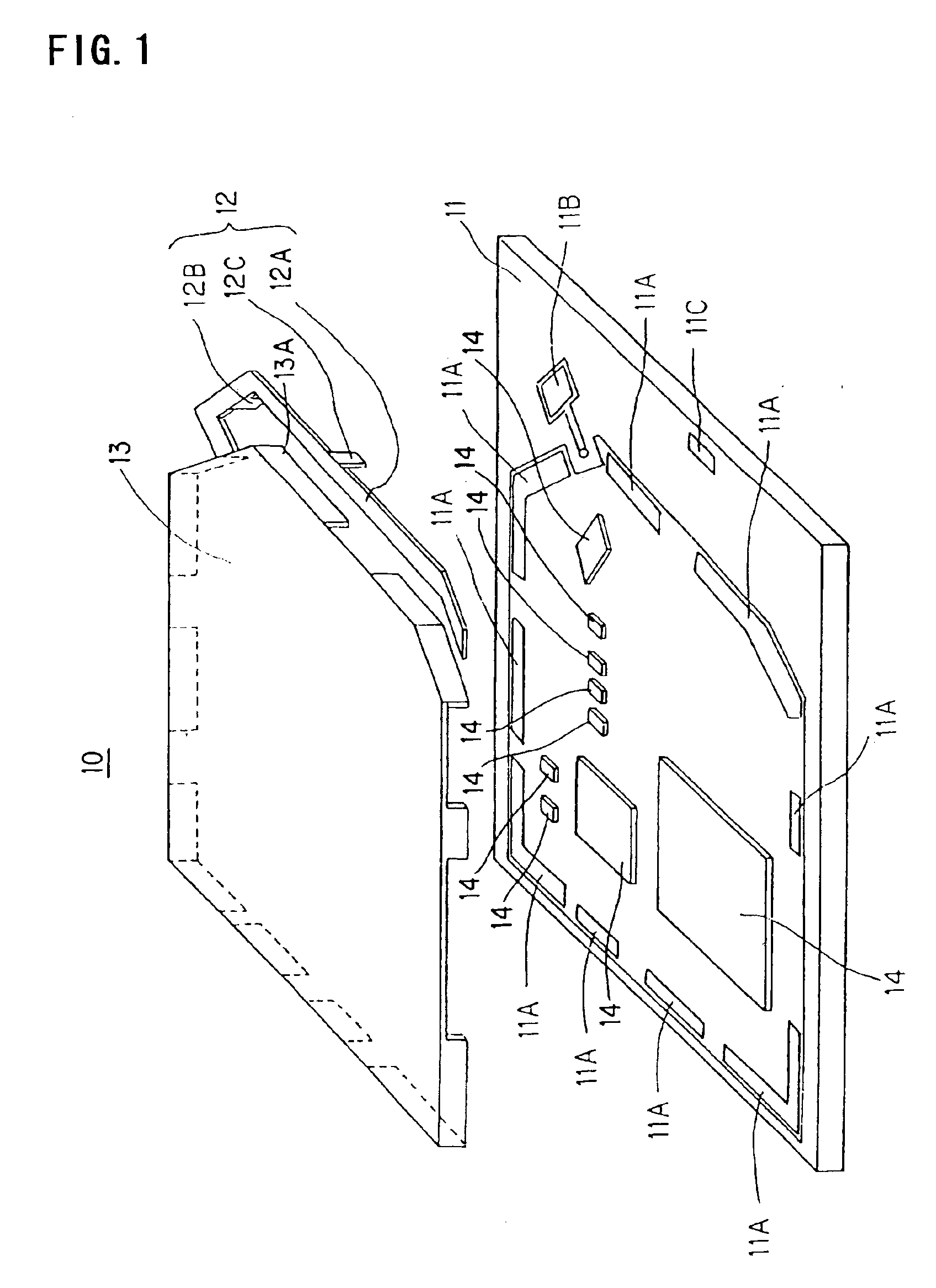

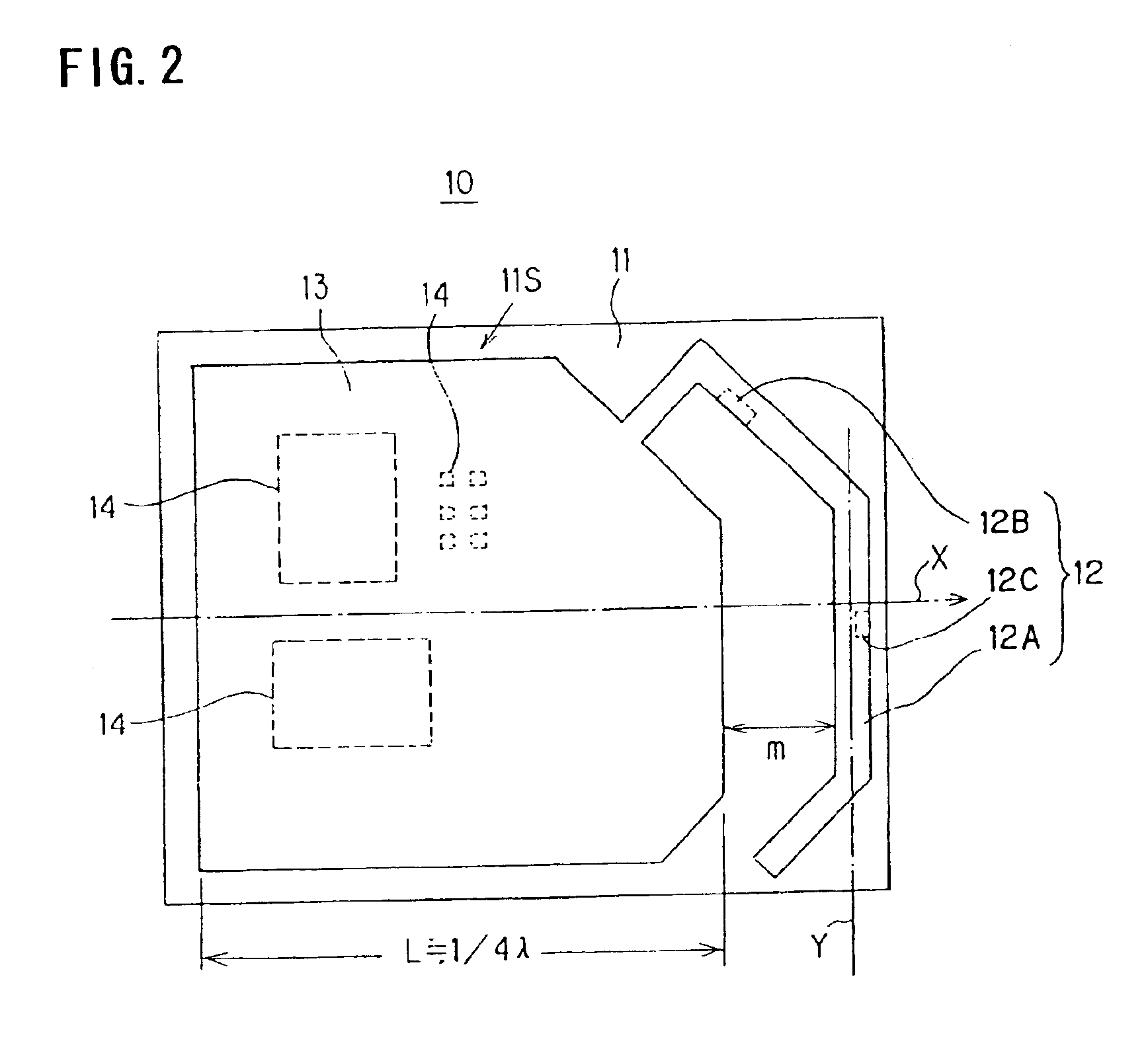

Antenna apparatus, printed wiring board, printed circuit board, communication adapter and portable electronic equipment

ActiveUS6946996B2Improve installation densitySmaller printed wiringSimultaneous aerial operationsAntenna supports/mountingsLength waveElectronic component

An antenna apparatus is provided that includes a printed wiring board, electronic components disposed on the printed wiring board, a shielding member (ground member) that is disposed on the printed wiring board. The shielding member has a length along a predetermined directional axis X set substantially to ¼λ or more, the wavelength of an electromagnetic wave used for communication being λ. An antenna element extends in a direction crossing the directional axis X and is grounded to the shielding member (ground member).

Owner:SEIKO EPSON CORP

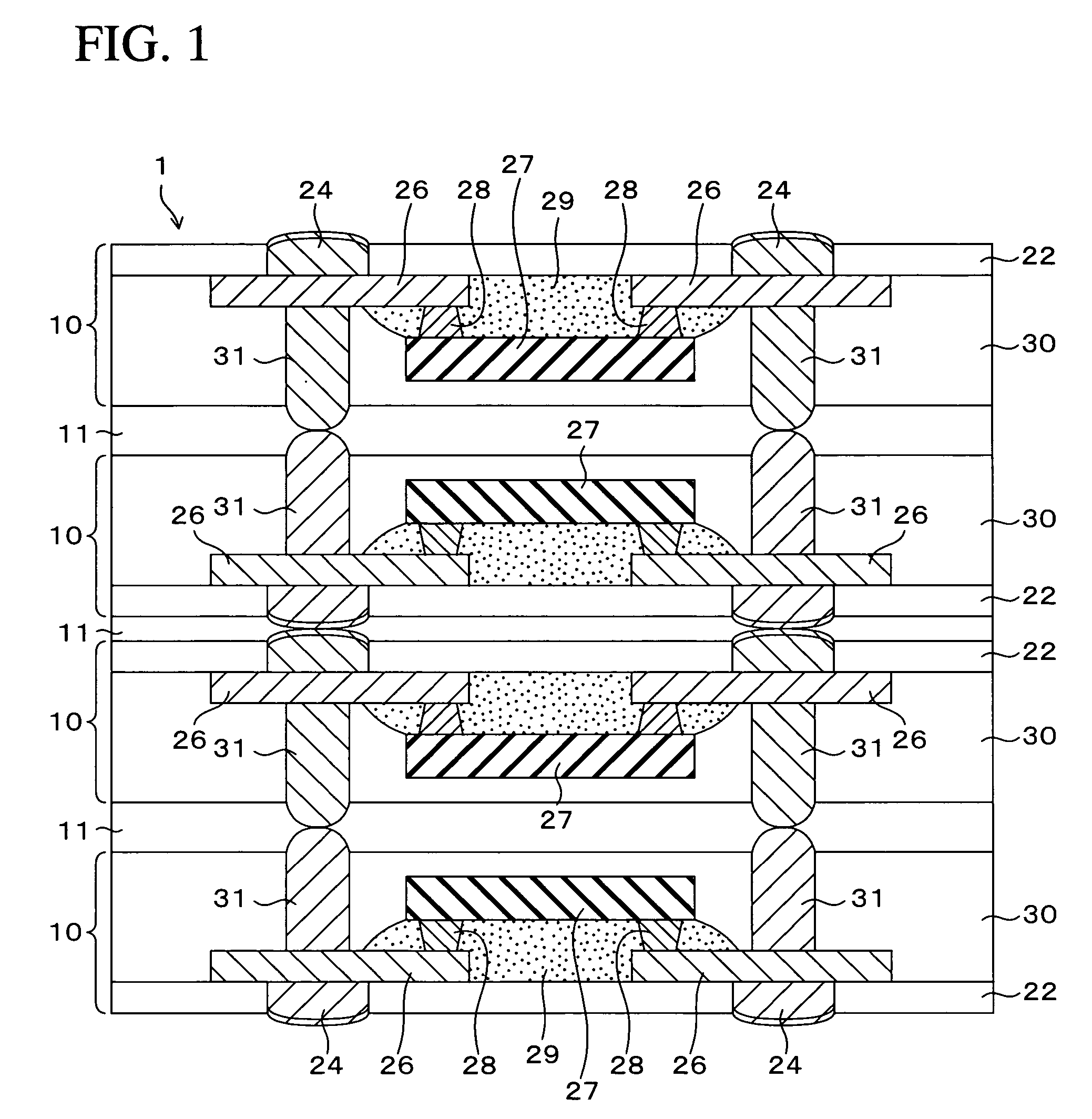

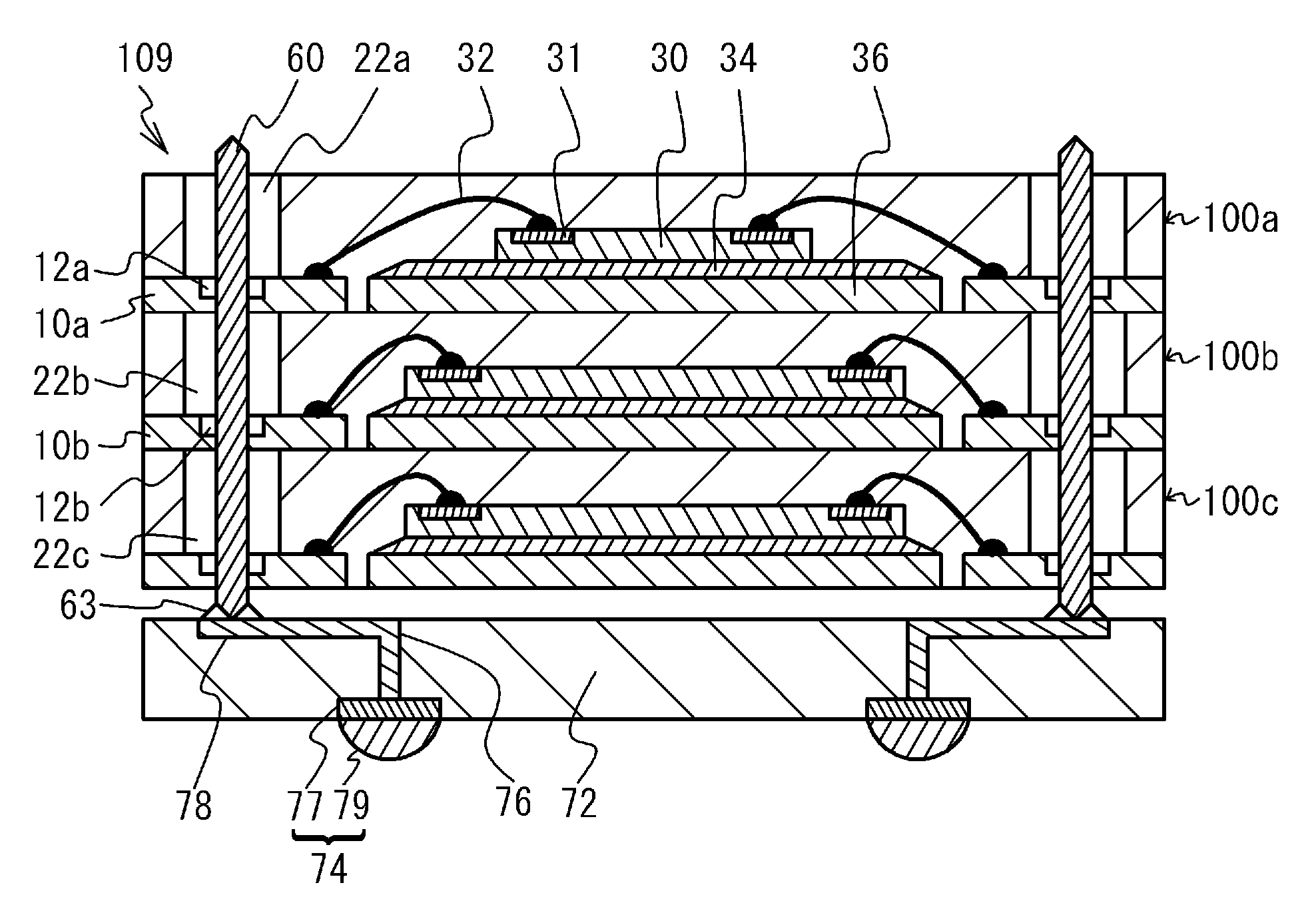

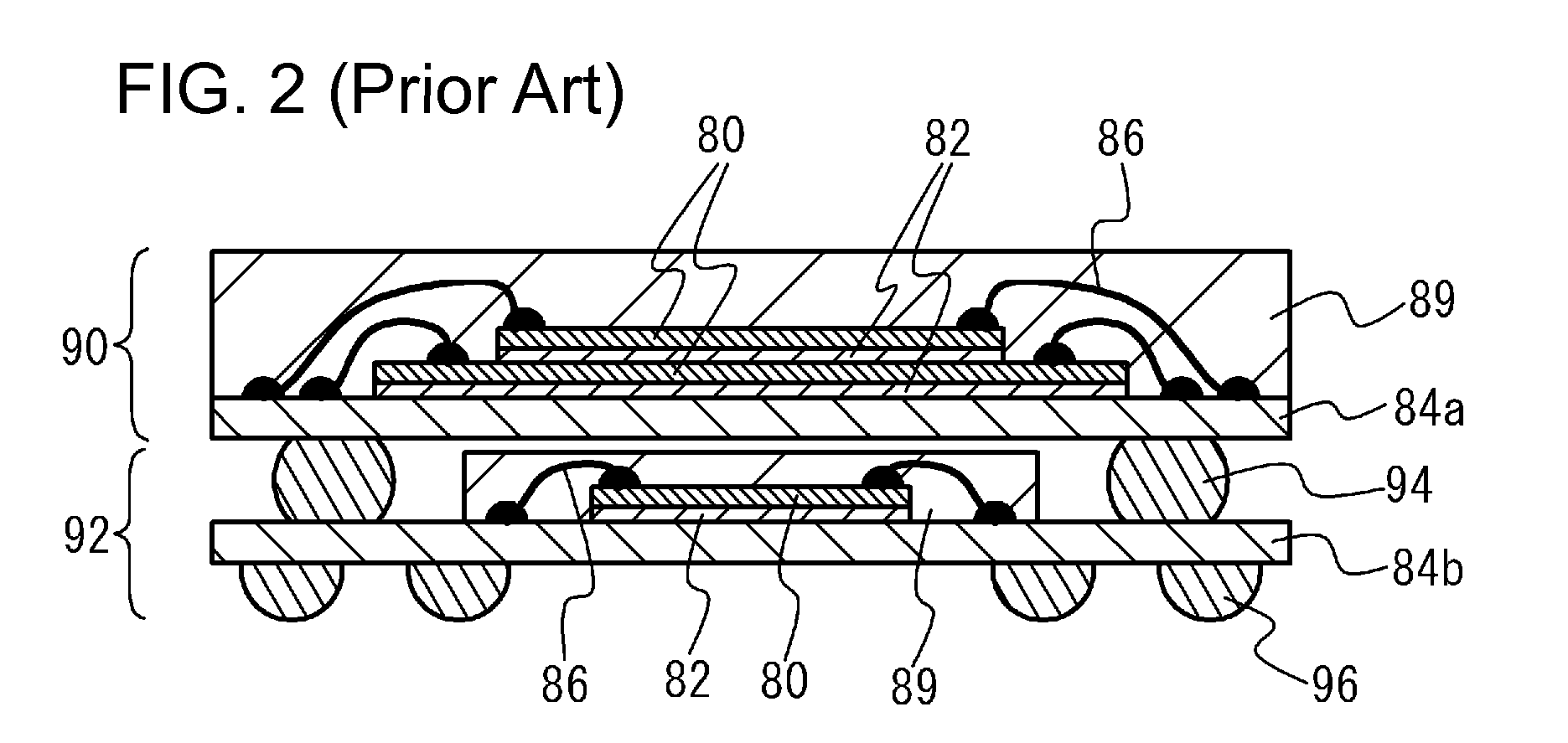

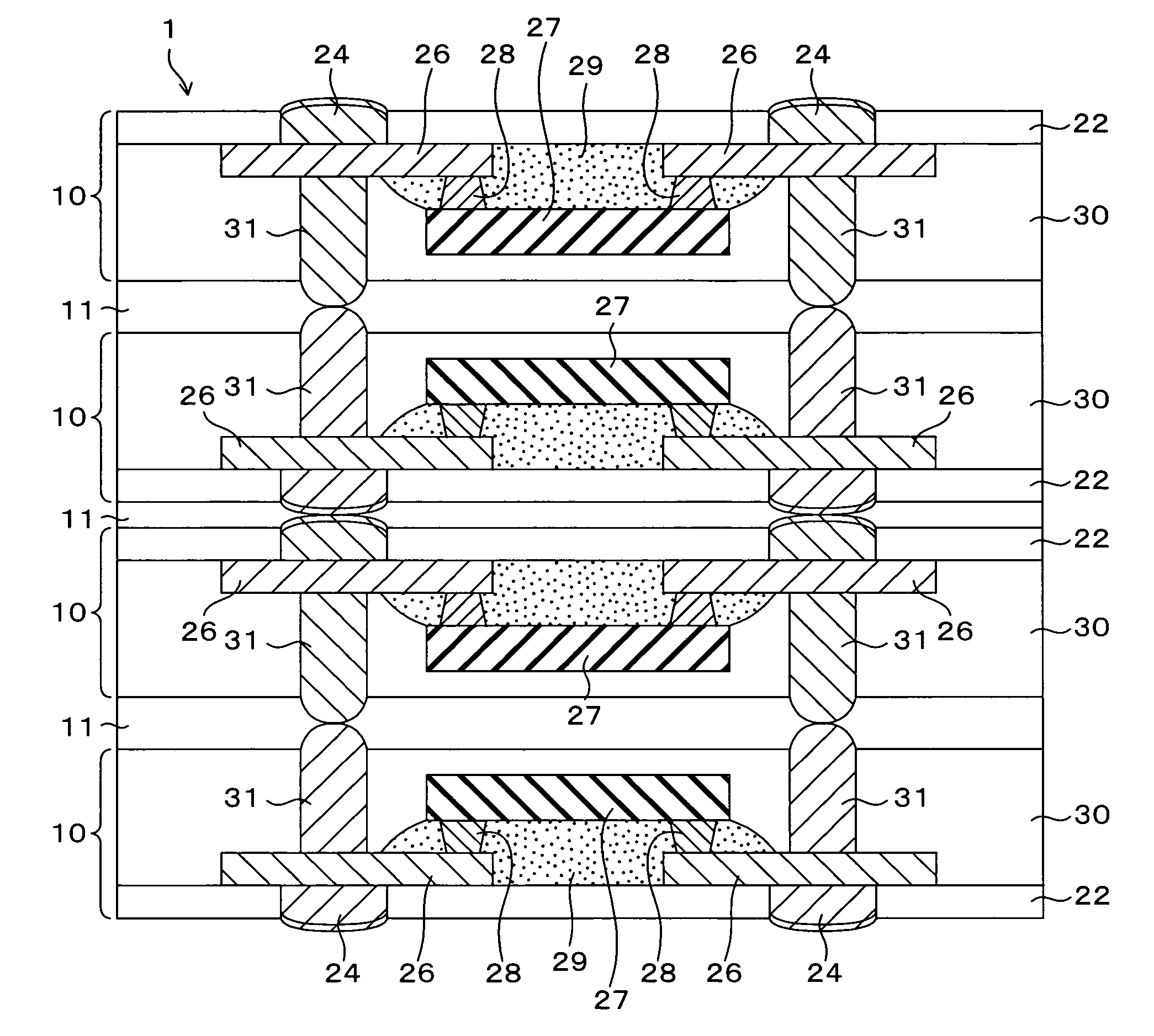

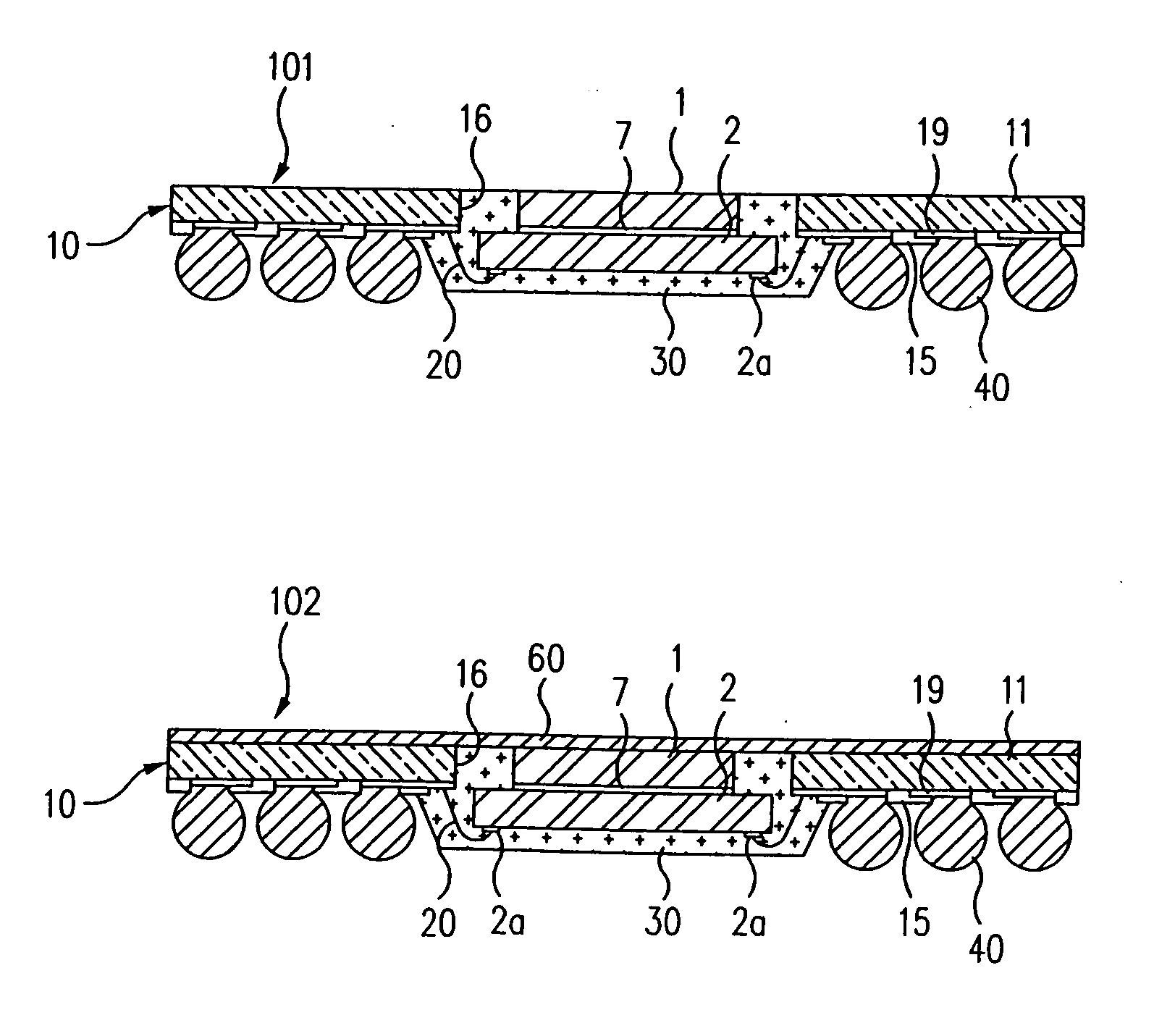

Electronic parts packaging structure and method of manufacturing the same

InactiveUS20070018313A1Improve installation densityAvoid it happening againSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

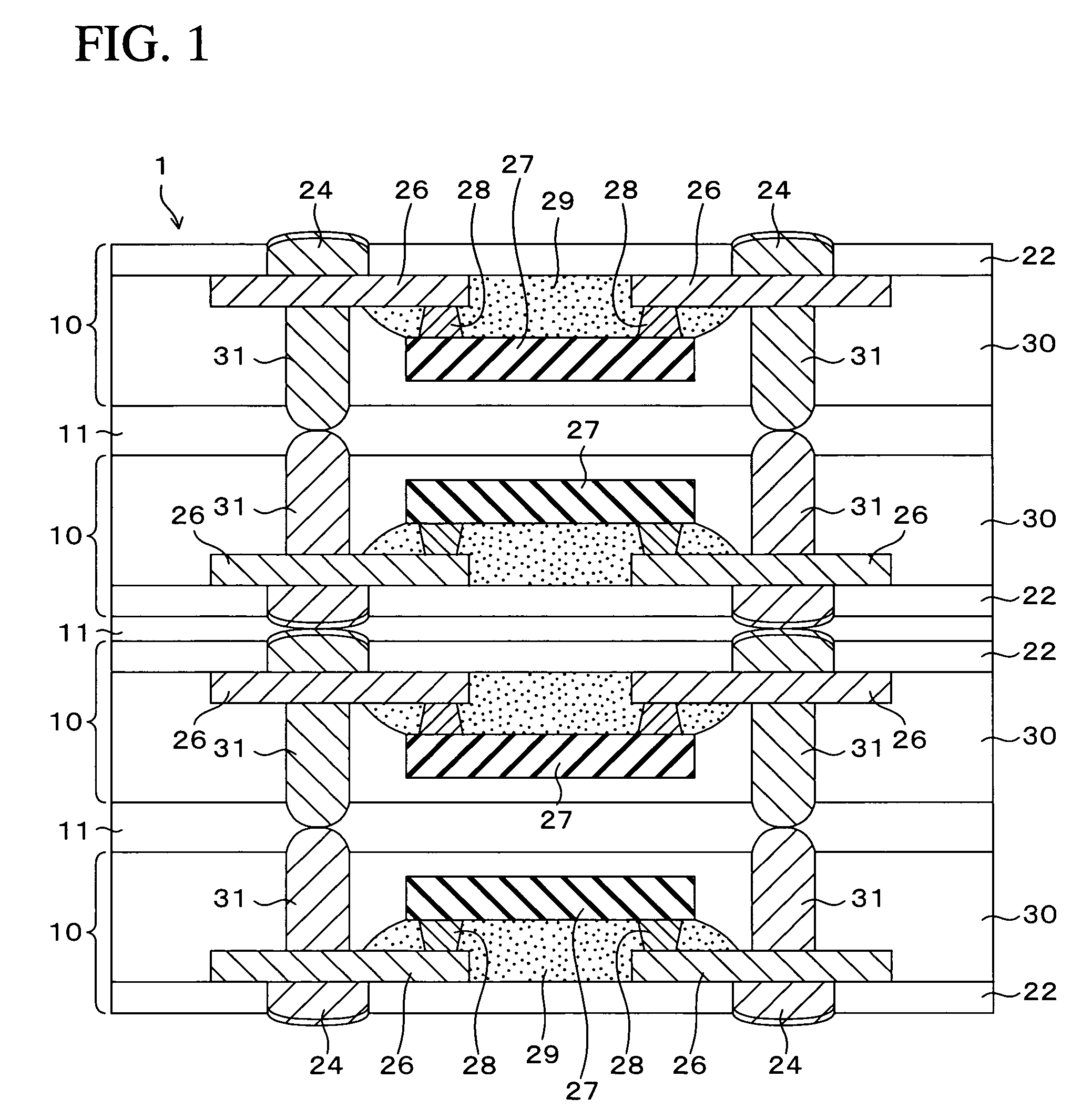

In an electronic parts packaging structure of the present invention constructed by stacking a plurality of sheet-like units in a thickness direction, each of the units includes a first insulating layer, wirings formed on one surface of the first insulating layer, a semiconductor chip (electronic parts) connected to the wirings, a second insulating layer formed on an one surface side of the first insulating layer to cover the semiconductor chip, and connecting portions (terminals and contact vias) for connecting electrically the wirings and wirings of other unit, wherein arrangement of the first insulating layer, the semiconductor chip, the wirings, and the second insulating layer is symmetrical between units adjacent in a thickness direction.

Owner:SHINKO ELECTRIC IND CO LTD

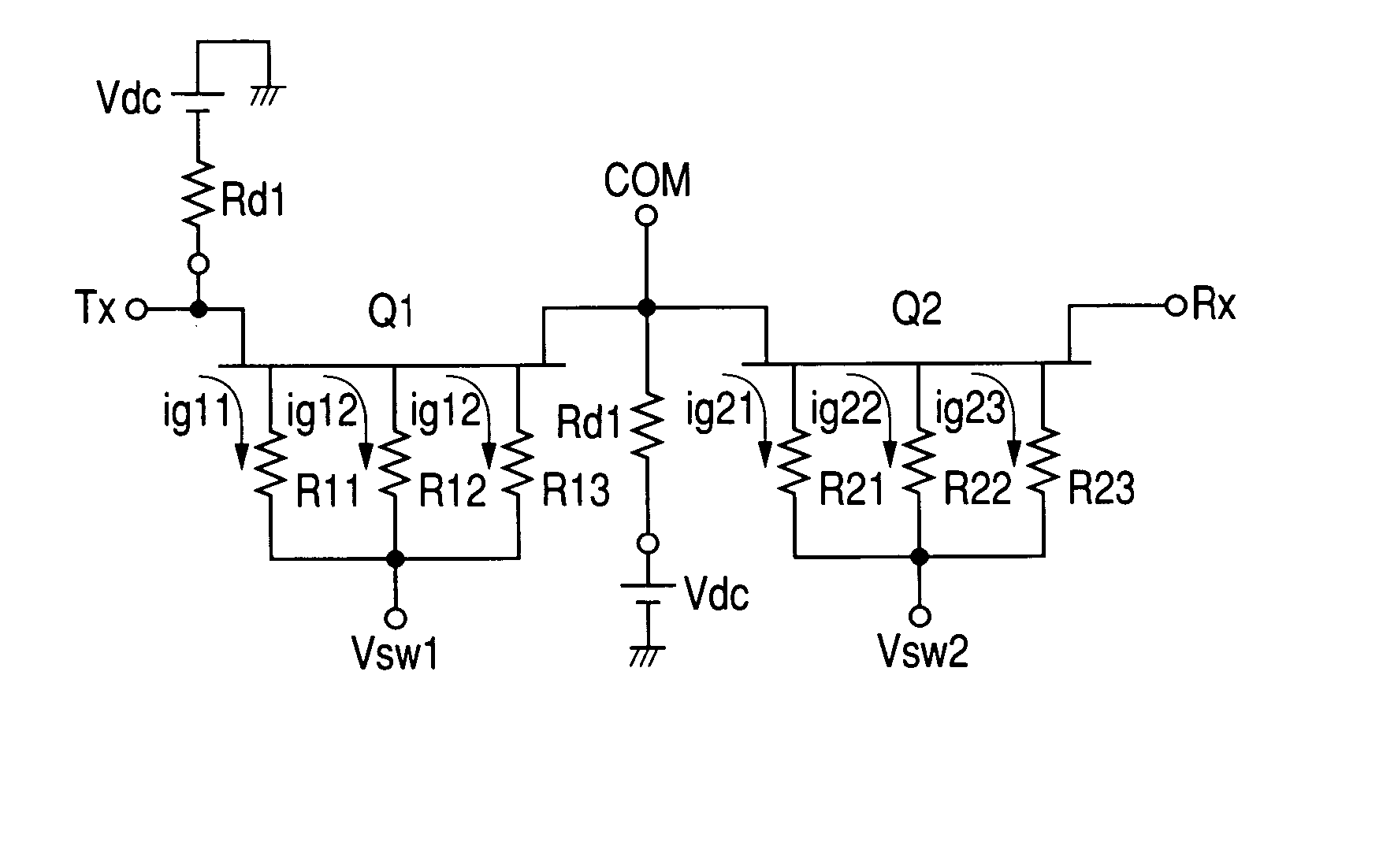

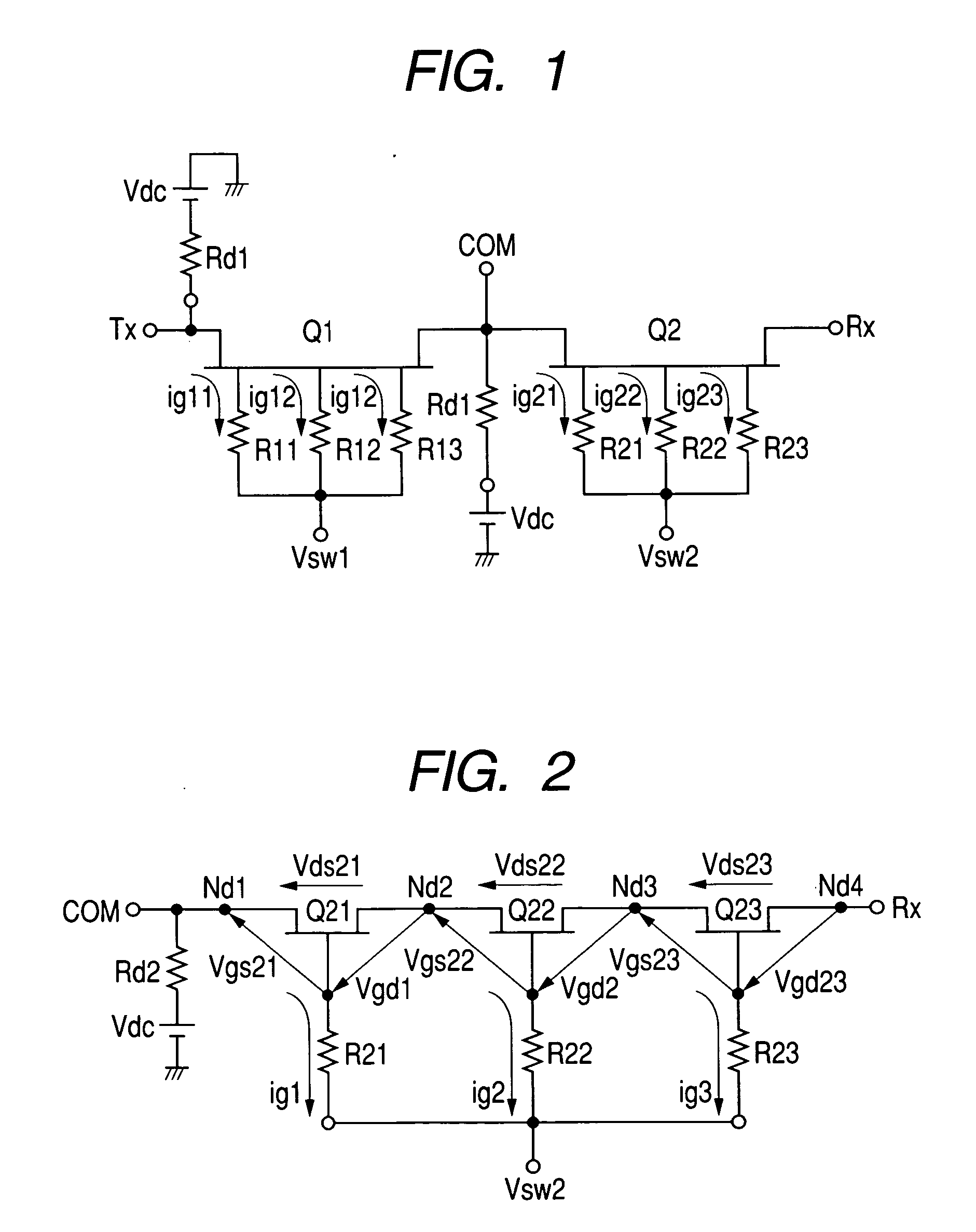

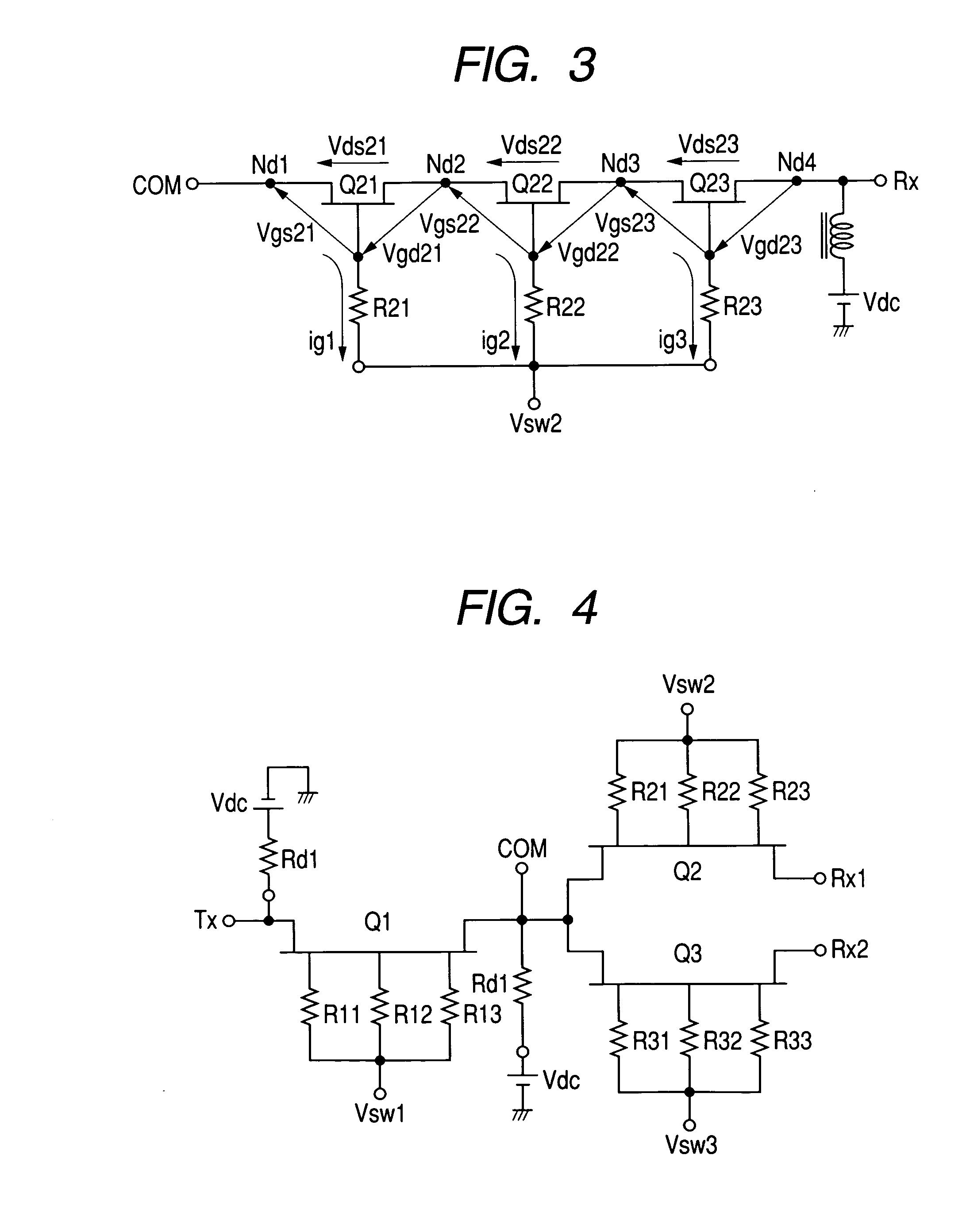

Electric component for communication device and semiconductor device for switching transmission and reception

ActiveUS20050047038A1Reduce component countImprove installation densityAmplifier modifications to reduce non-linear distortionGated amplifiersAudio power amplifierCommunications system

There are provided a transmission / reception switching circuit which is small in insertion loss and harmonic distortion and allows an increase in the output power of a power amplifier and an electronic component for communication on which the transmission / reception switching circuit is mounted. As an element composing a transmission / reception switching circuit in a wireless communication system, series-connected FETs or a multi-gate FET are used in place of a diode. Gate resistors connected between the individual gate terminals and a control terminal are designed to have resistance values which become progressively smaller from the gate to which a highest voltage is applied toward the gate to which a lowest voltage is applied.

Owner:MURATA MFG CO LTD

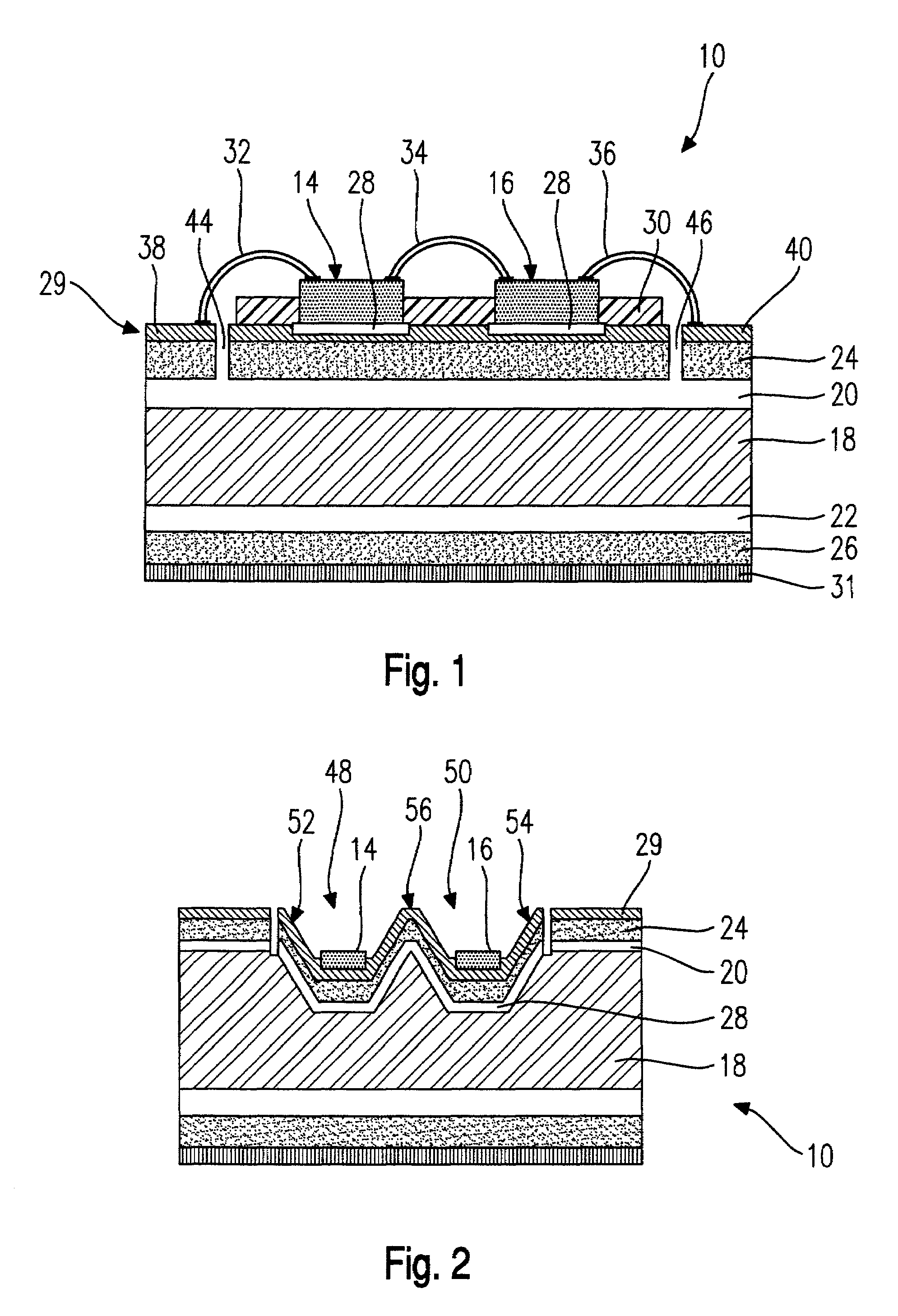

Interconnection element for electric circuits

ActiveUS8299368B2Efficient heat transferImprove installation strengthLine/current collector detailsSemiconductor/solid-state device detailsElectrical conductorInterconnection

Owner:INVENSAS CORP

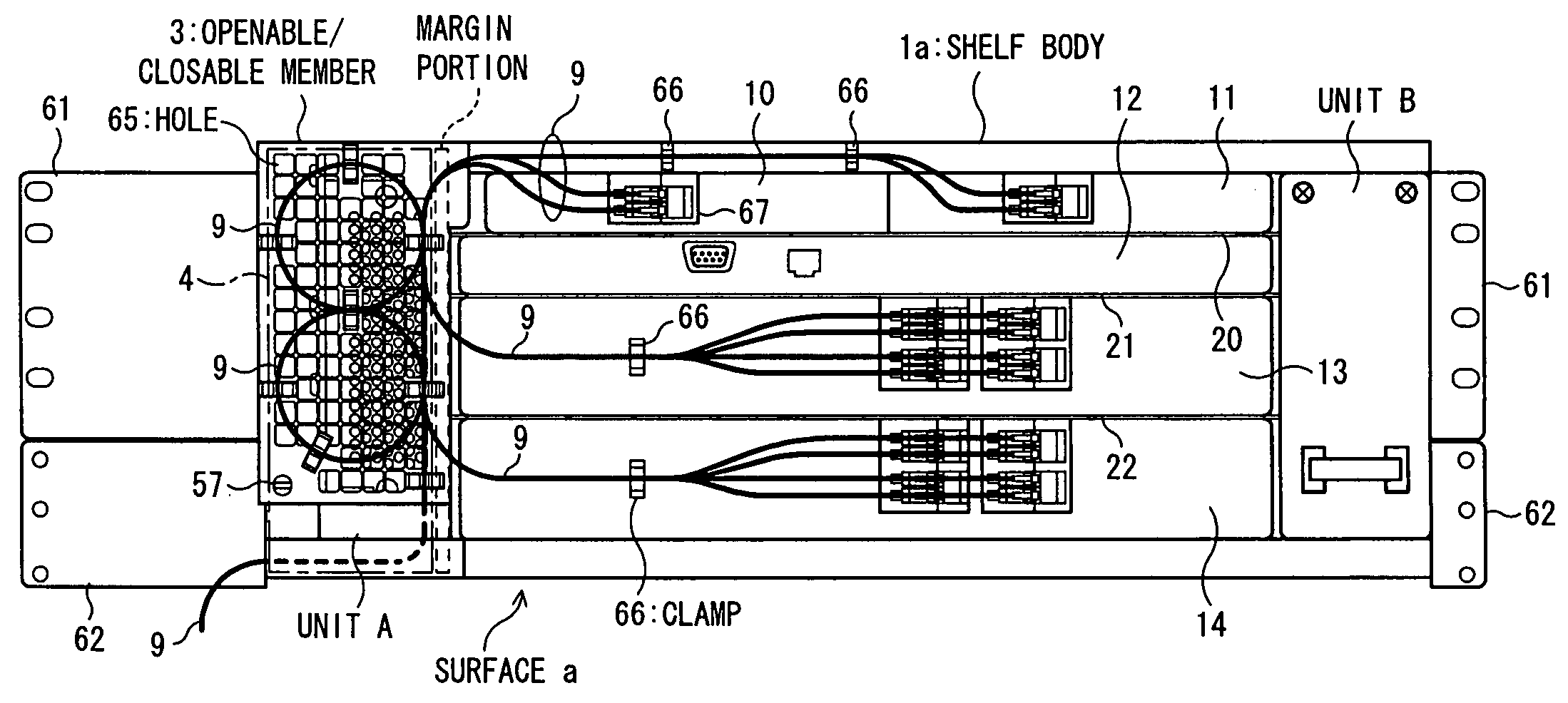

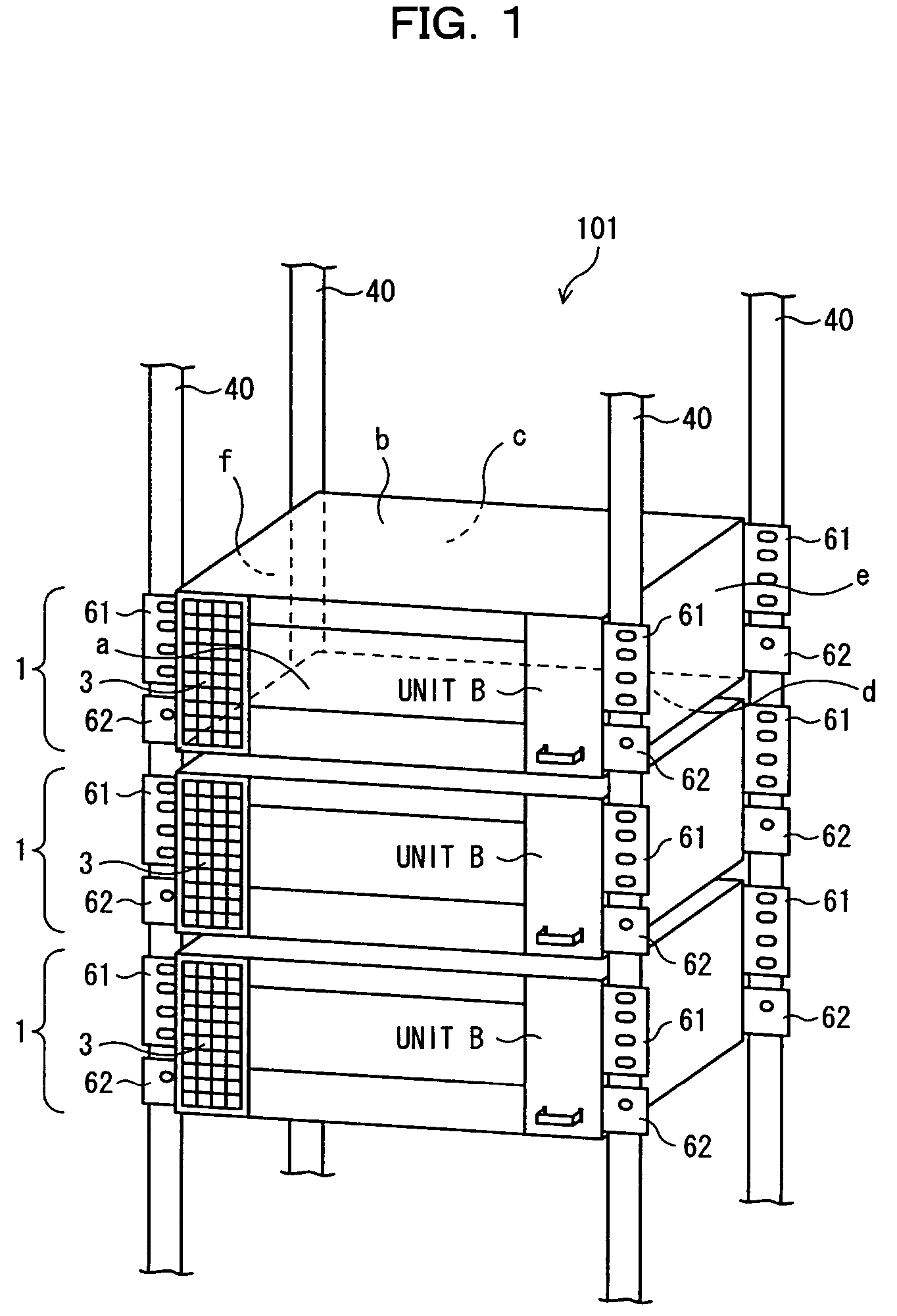

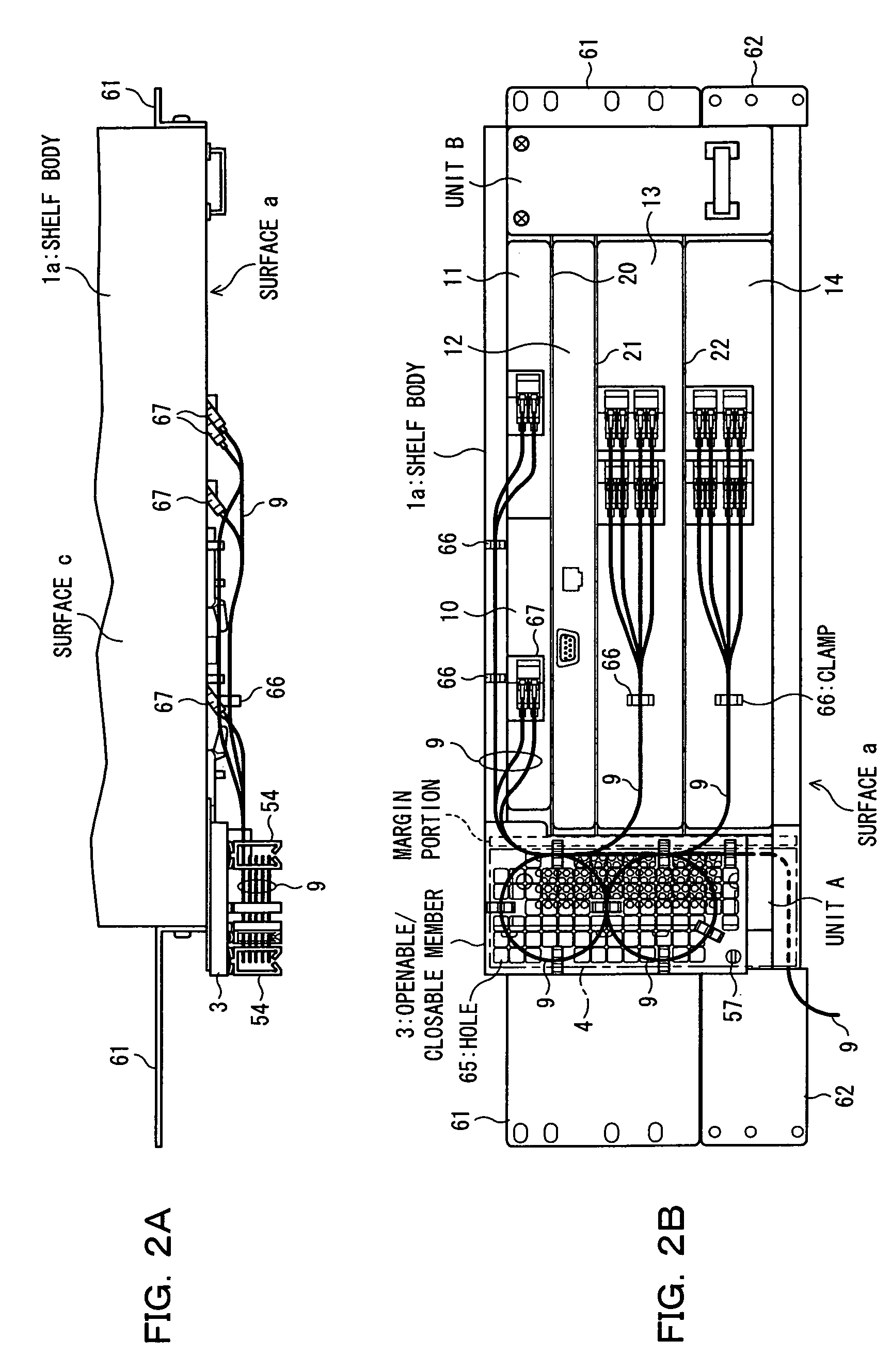

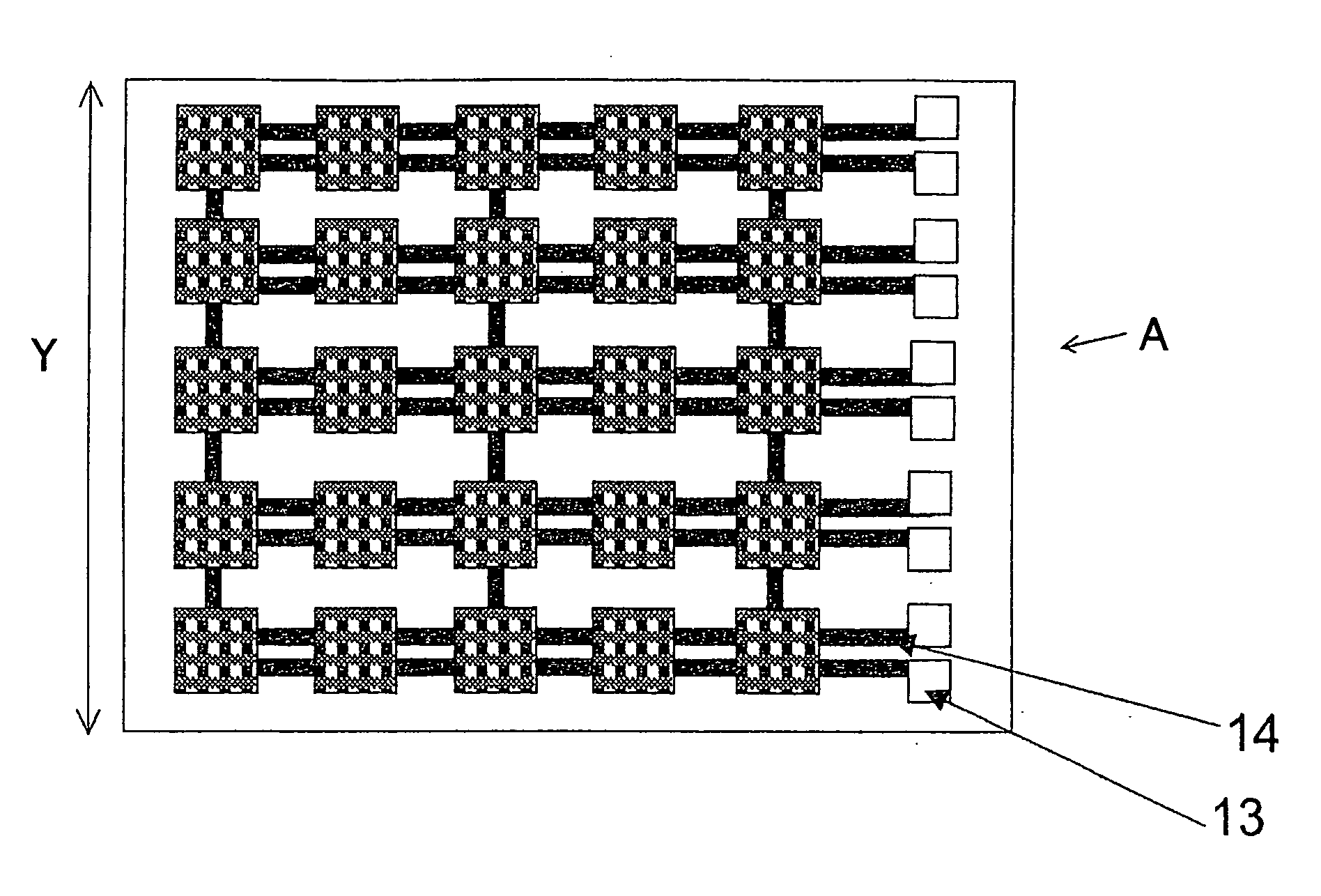

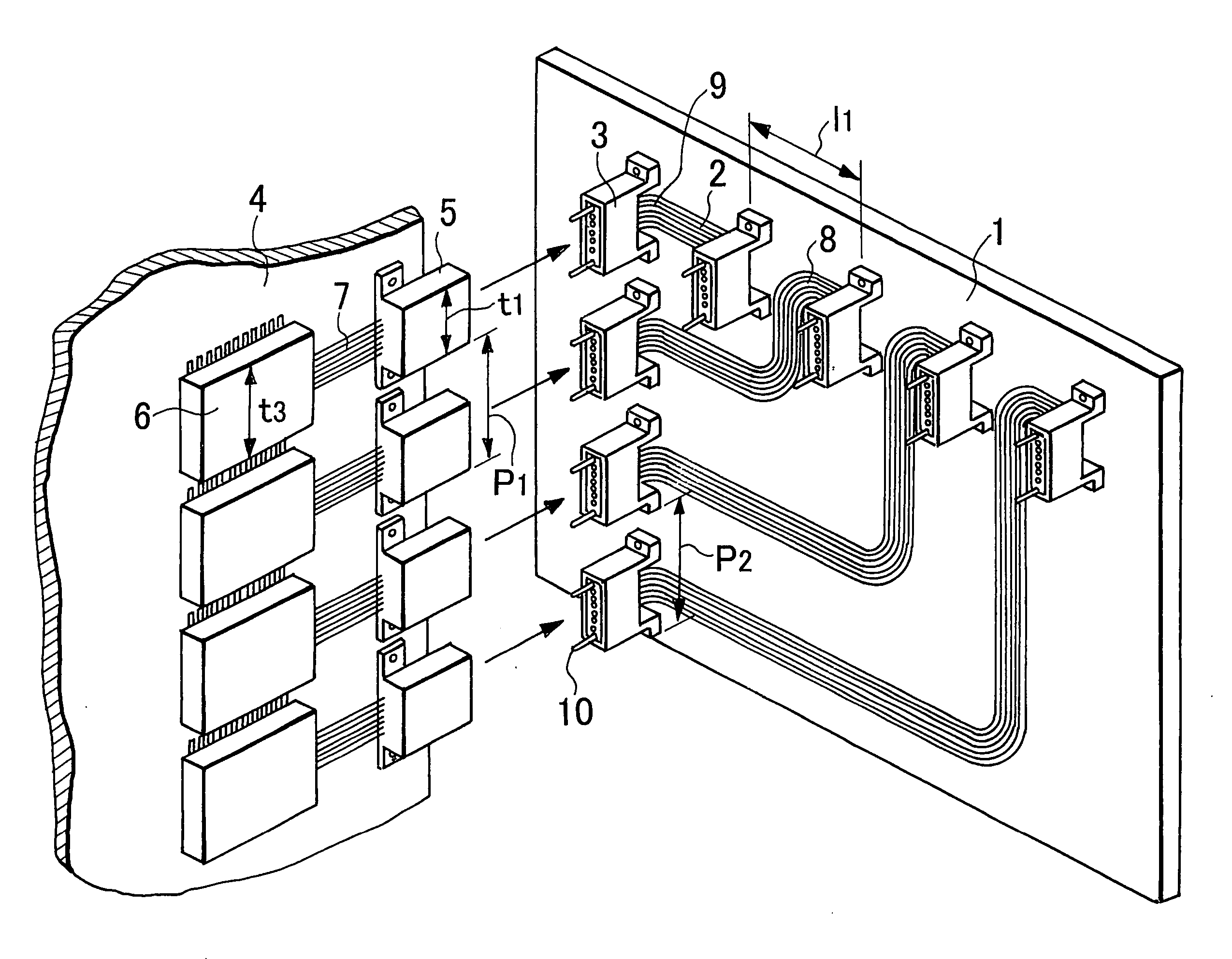

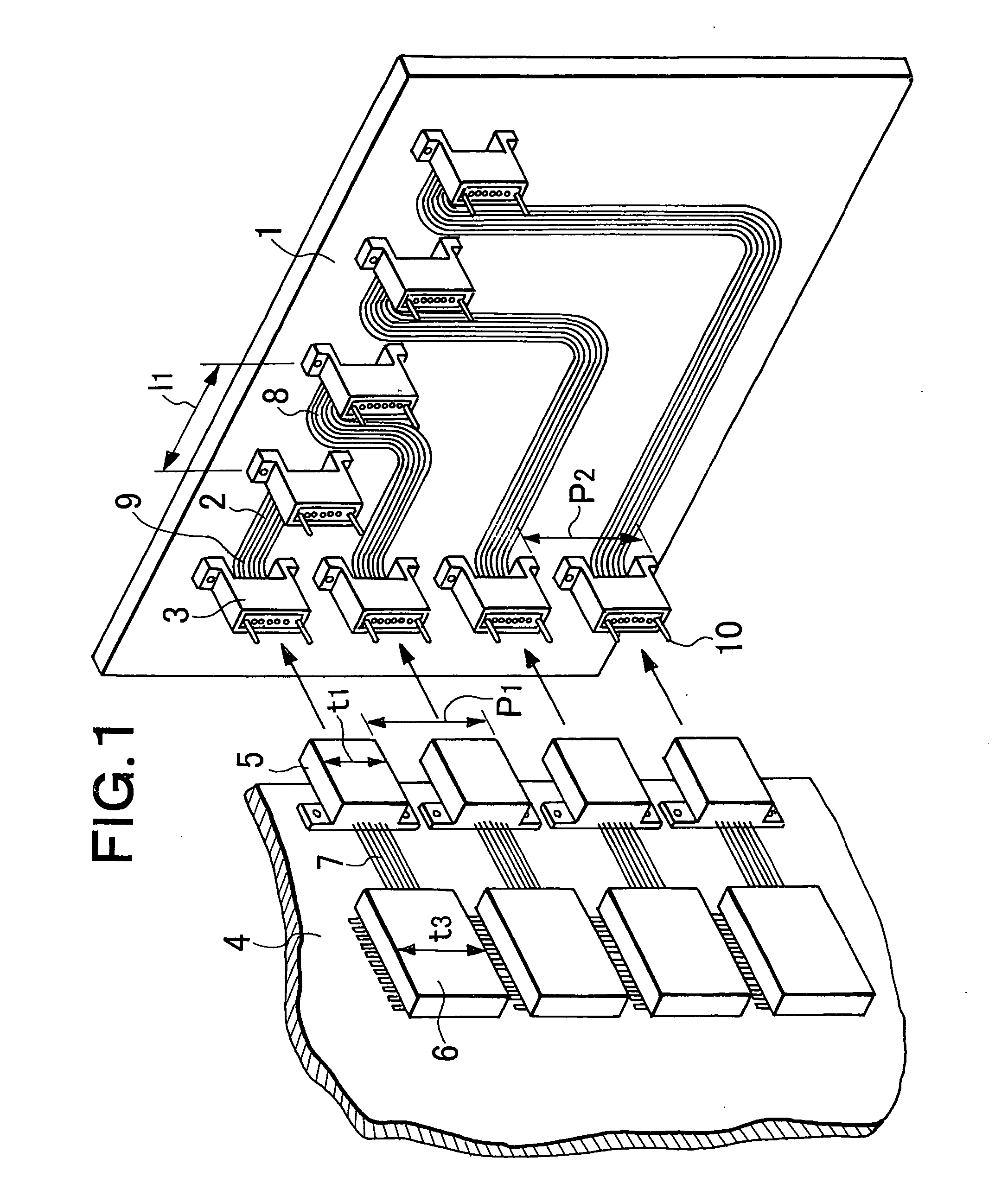

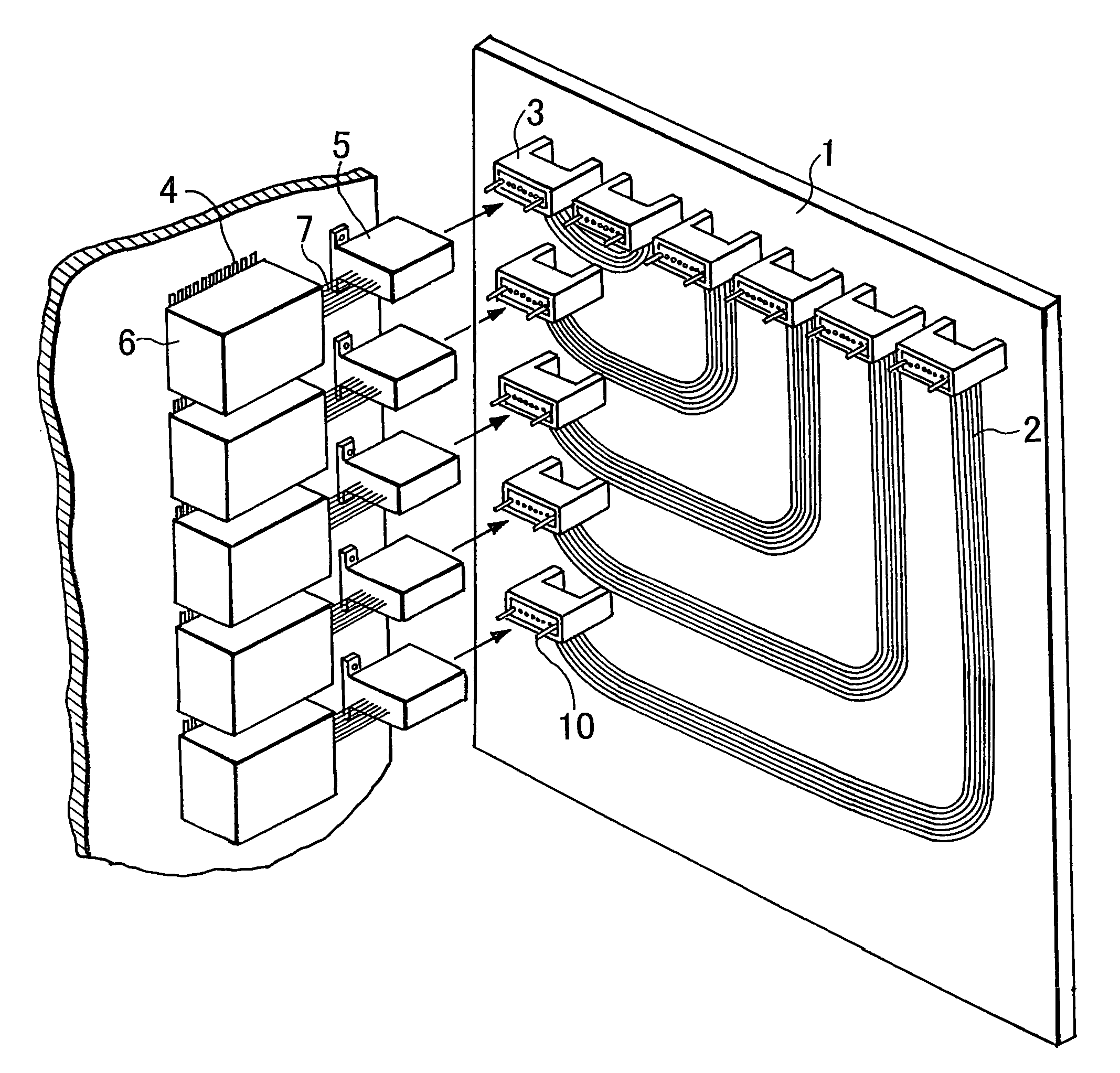

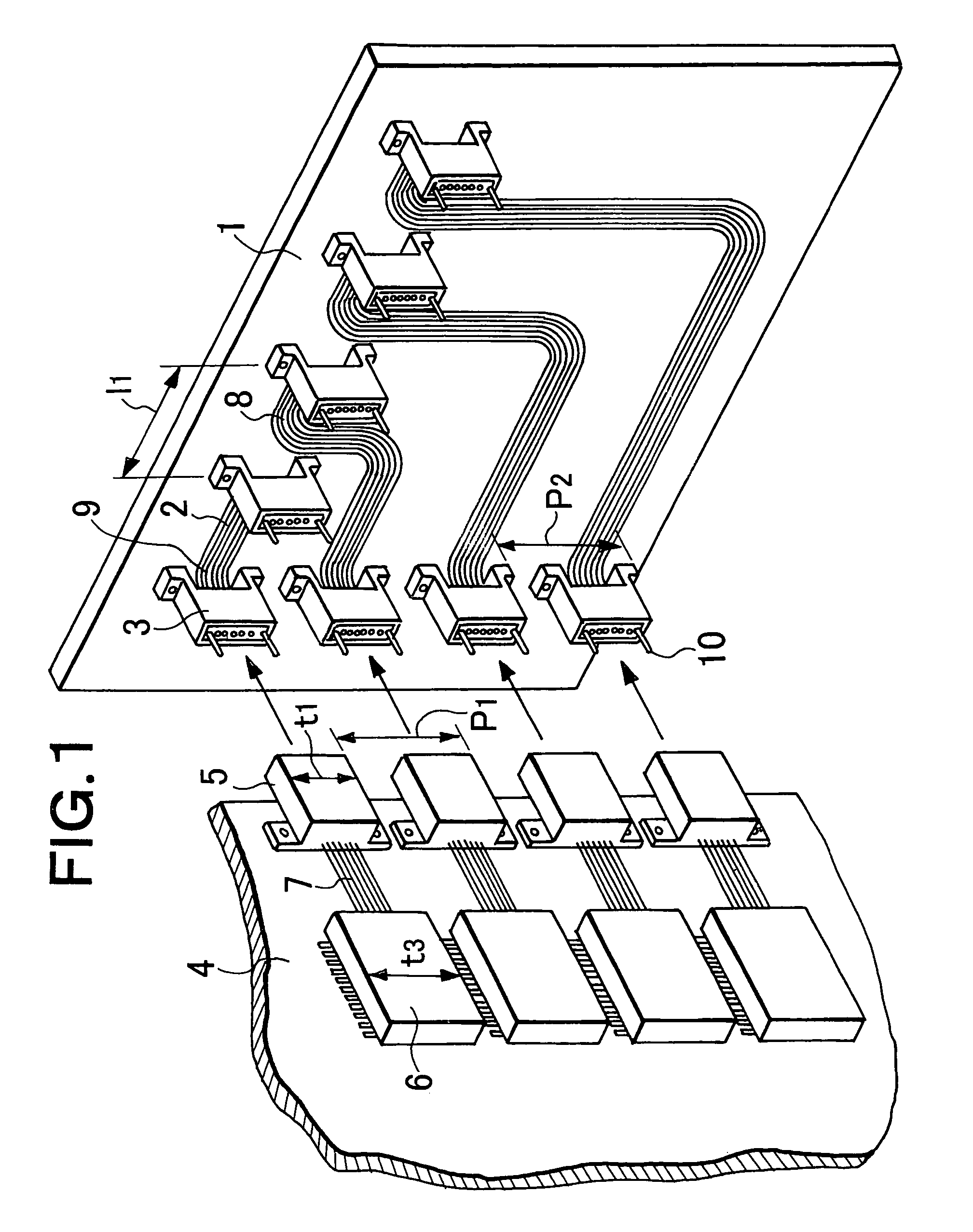

Structured shelf

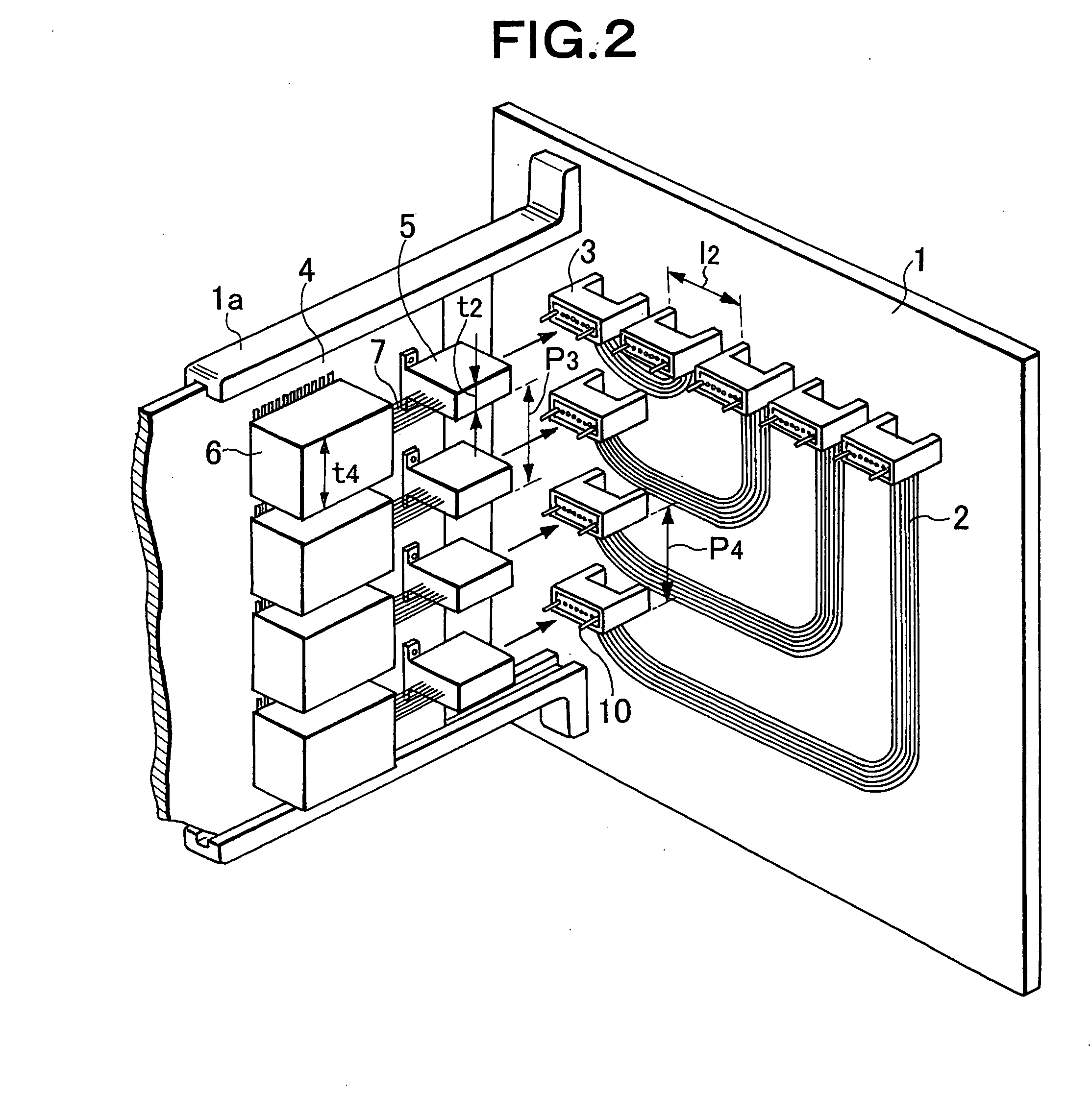

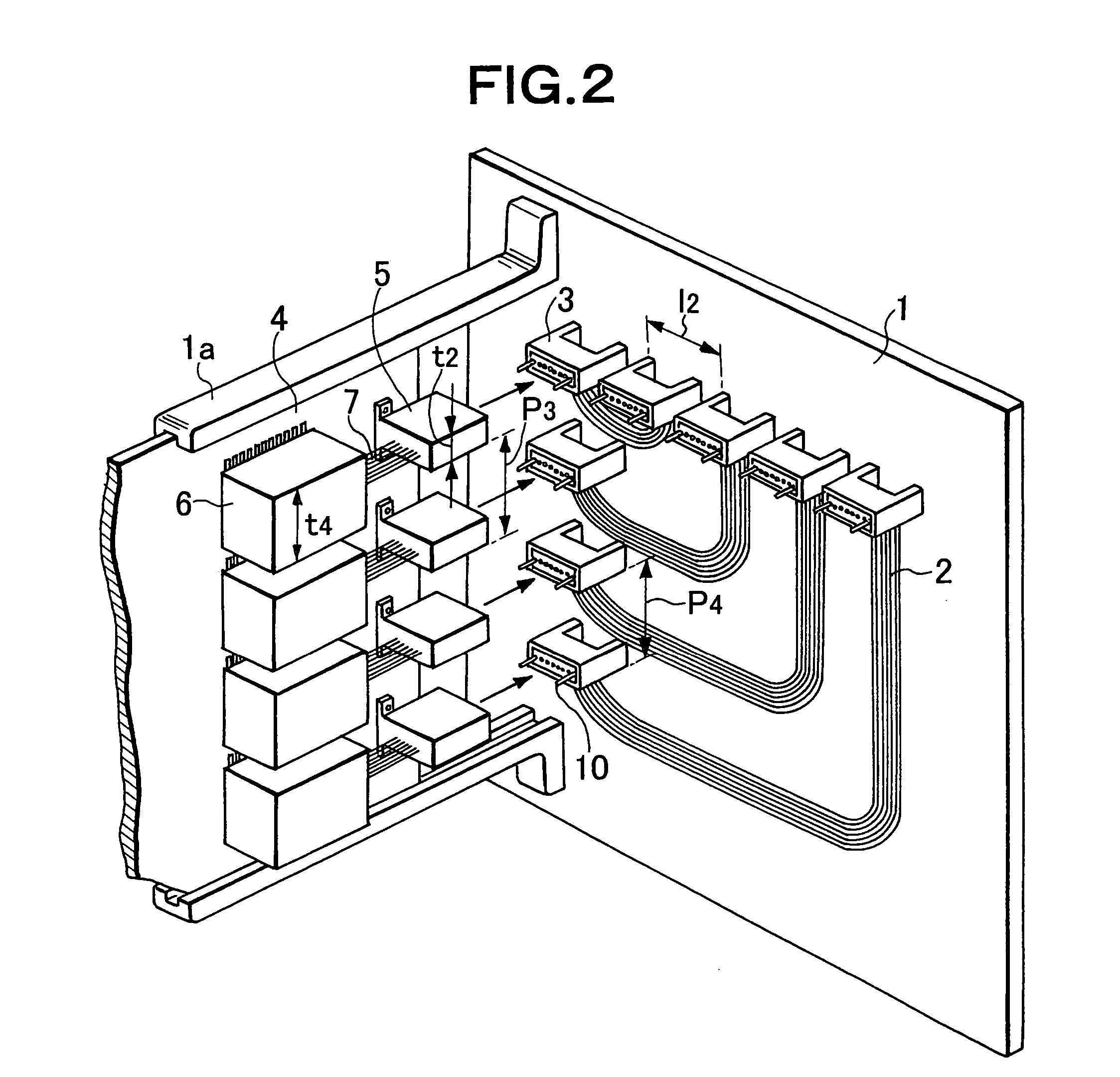

In an optical transmission node, a plurality of shelves, respectively connected to a plurality of optical cables having limitations on bending radius, are stored in one rack of the node. In a shelf body thereof, the first and second opening portions are made in a front surface, and an extra-cable looping device loops an extra portion of the optical cable, further a moving mechanism is provided for moving the extra-cable looping device to avoid a space occupied by the units in a state removed from the second opening portion, this enables extra-cable handling within a limited spatial range and the insertion / removal of the units having various functions from the shelf in a state where the cable is active and further the improvement of a shelf mounting density per rack.

Owner:FUJITSU LTD

Semiconductor device and semiconductor device unit

InactiveUS20060071349A1Increase the number ofSmall sizeSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device, comprising: a flexible substrate; at least one semiconductor element; at least one electrode for external connection, the element and the electrode being formed on a front surface of the flexible substrate; and at least one wire formed on the front surface to electrically connect the element to the electrode, wherein at least a part of the flexible substrate has a curved form.

Owner:SHARP KK

Optical connection structure of optical backplane to circuit substrate

InactiveUS20070086723A1Increased circuit densityImprove installation densityCoupling light guidesFibre transmissionEngineeringOptical backplane

An optical backplane includes an optical connector which receives juxtaposed optical signals transmitted in nonparallel to the main surface of a circuit substrate from the circuit substrate or transmits juxtaposed optical signals in nonparallel to the main surface of the circuit substrate to the circuit substrate. The optical connector disposes and accommodates edge portions of a plurality of optical fibers and the disposing direction of the optical fibers in the optical connector is in nonparallel to the main surface of the circuit substrate.

Owner:NEC CORP +3

Connection structure and a connection method for connecting a differential signal transmission cable to a circuit board

ActiveUS8758051B2Improve installation densityLine/current collector detailsElectrically conductive connectionsElectrical conductorDifferential signaling

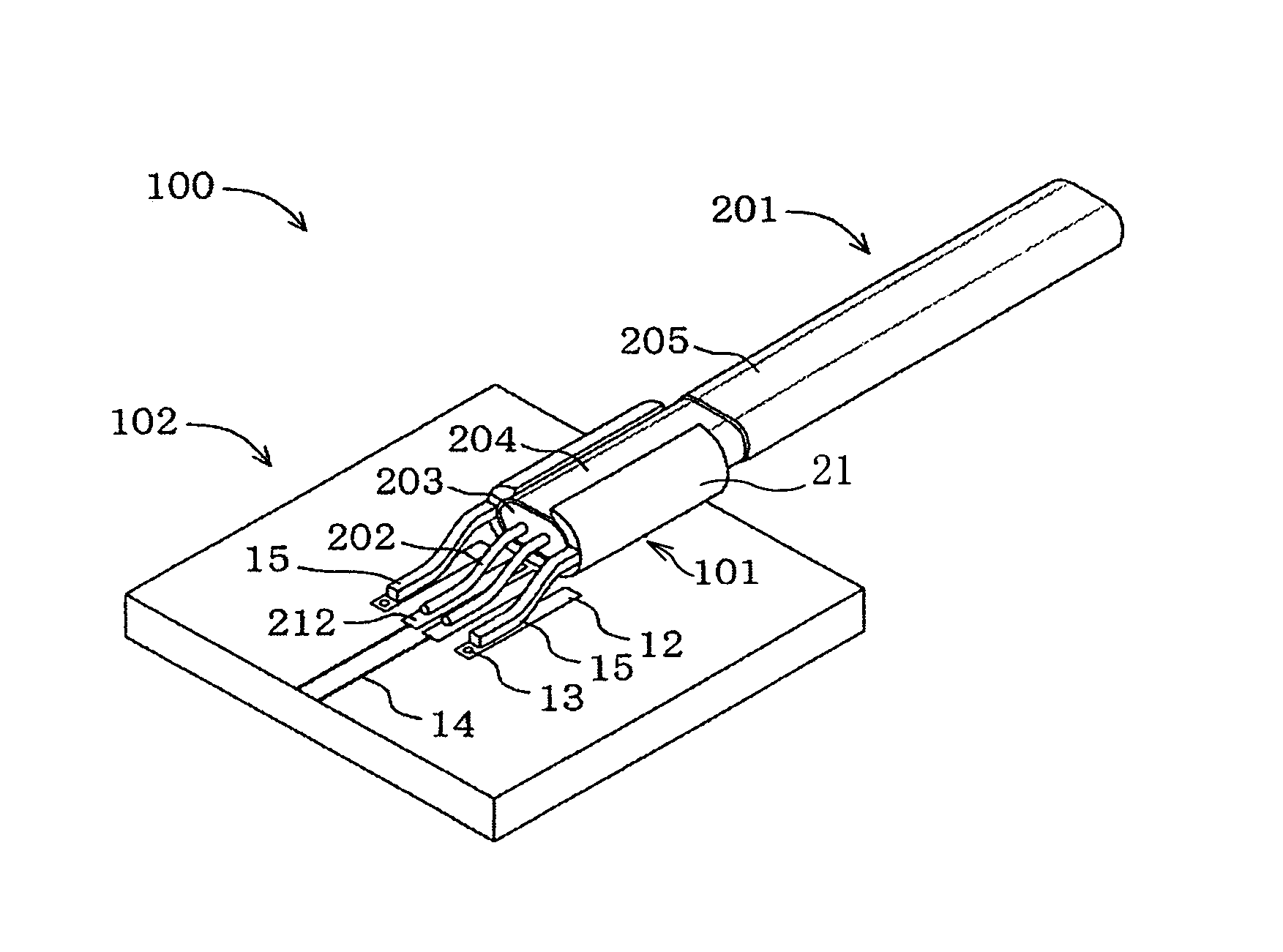

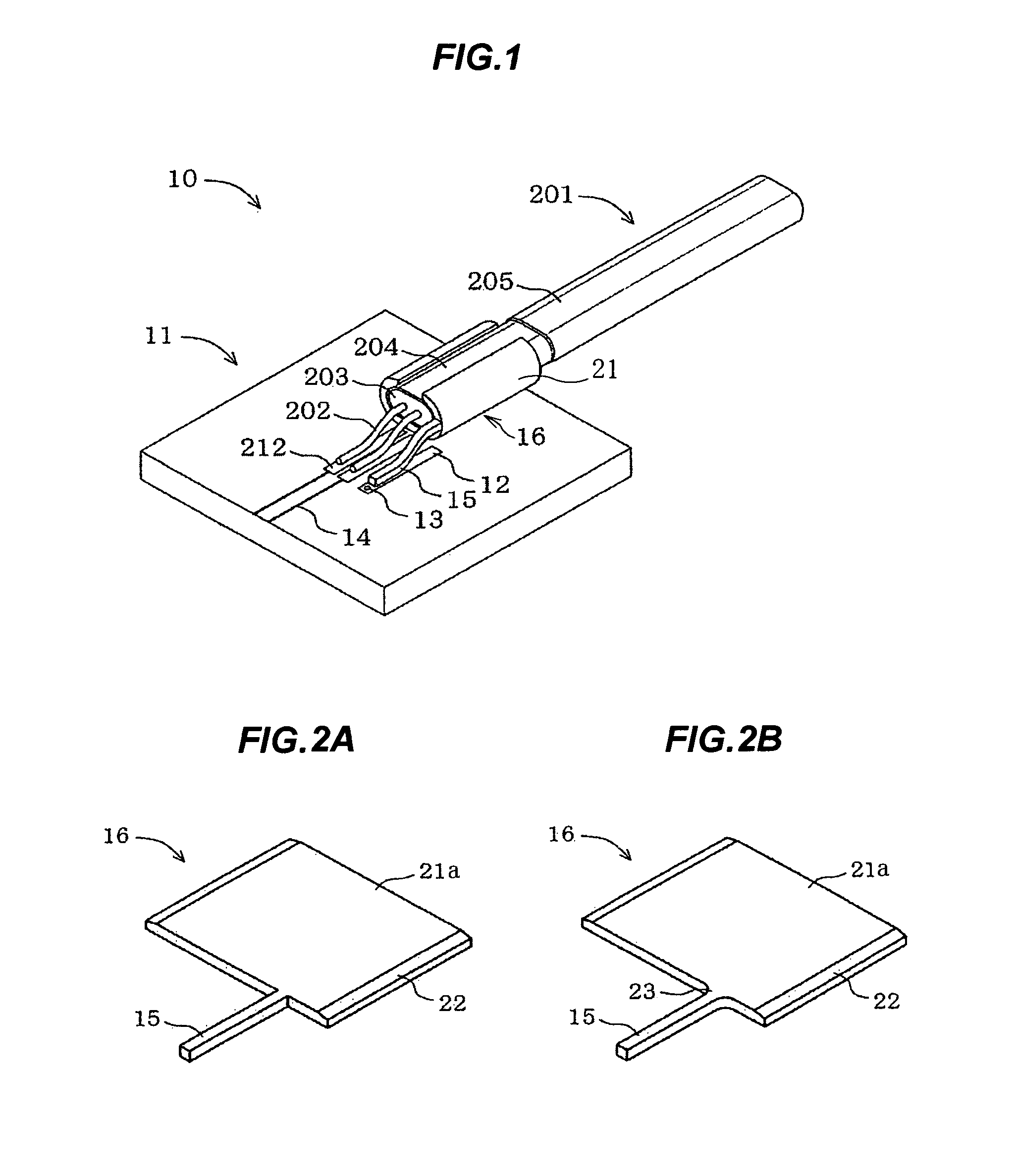

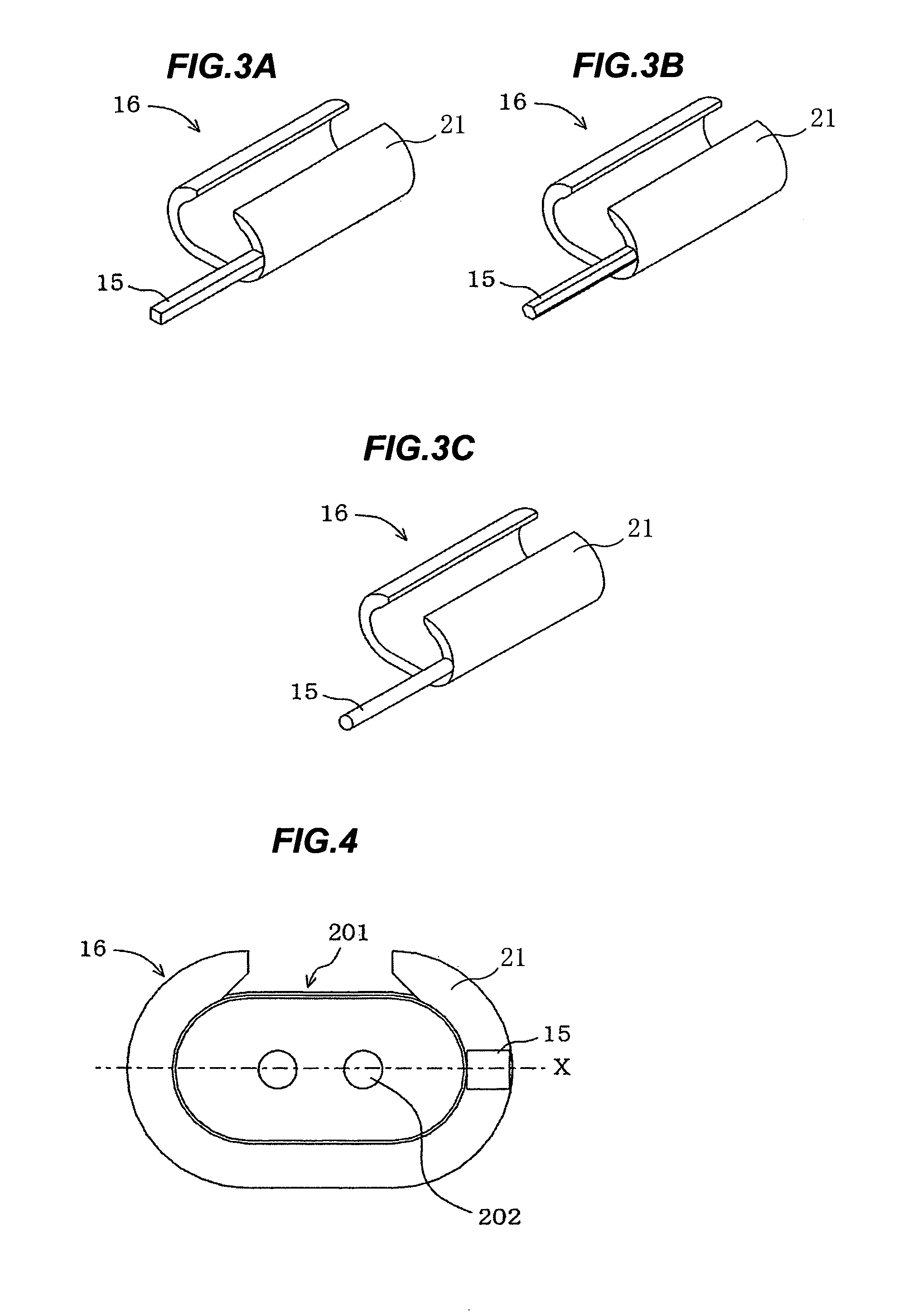

A connection structure for connecting a differential signal transmission cable to a circuit board. A differential signal transmission cable includes an outer conductor provided around a pair of signal line conductors via an insulator. Parts of the signal line conductors are exposed from a tip of the differential signal transmission cable. A circuit board is provided with a pair of signal pads and a ground pad. A shield-connecting terminal includes a main body which is crimp-connected to the outer conductor and a solder-connecting pin which is solder-connected to the ground pad. The exposed parts of the signal line conductors are solder-connected to the signal pads, respectively, and the outer conductor is solder-connected to the ground pad via the solder-connecting pin of the shield-connecting terminal.

Owner:HITACHI METALS LTD

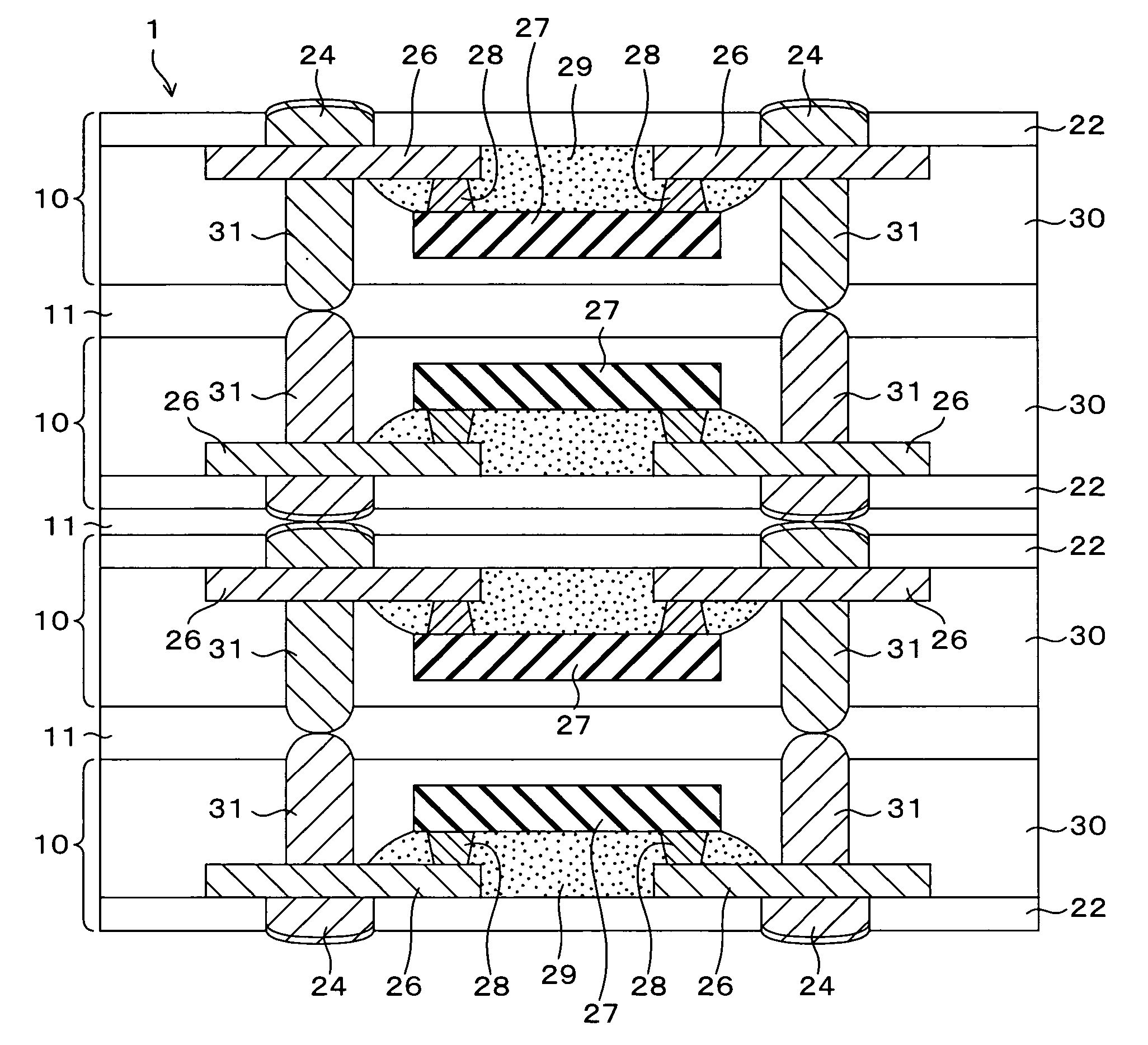

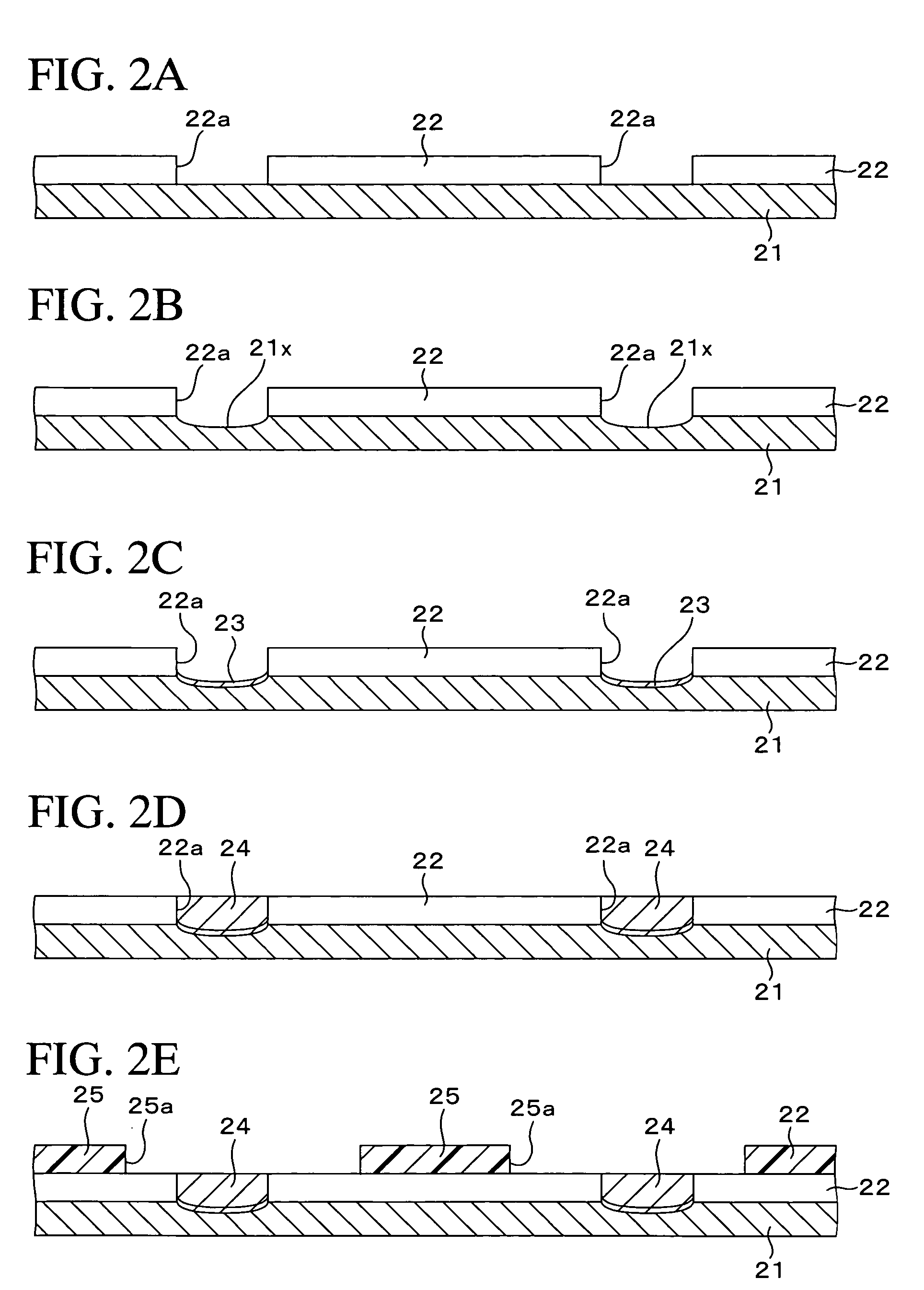

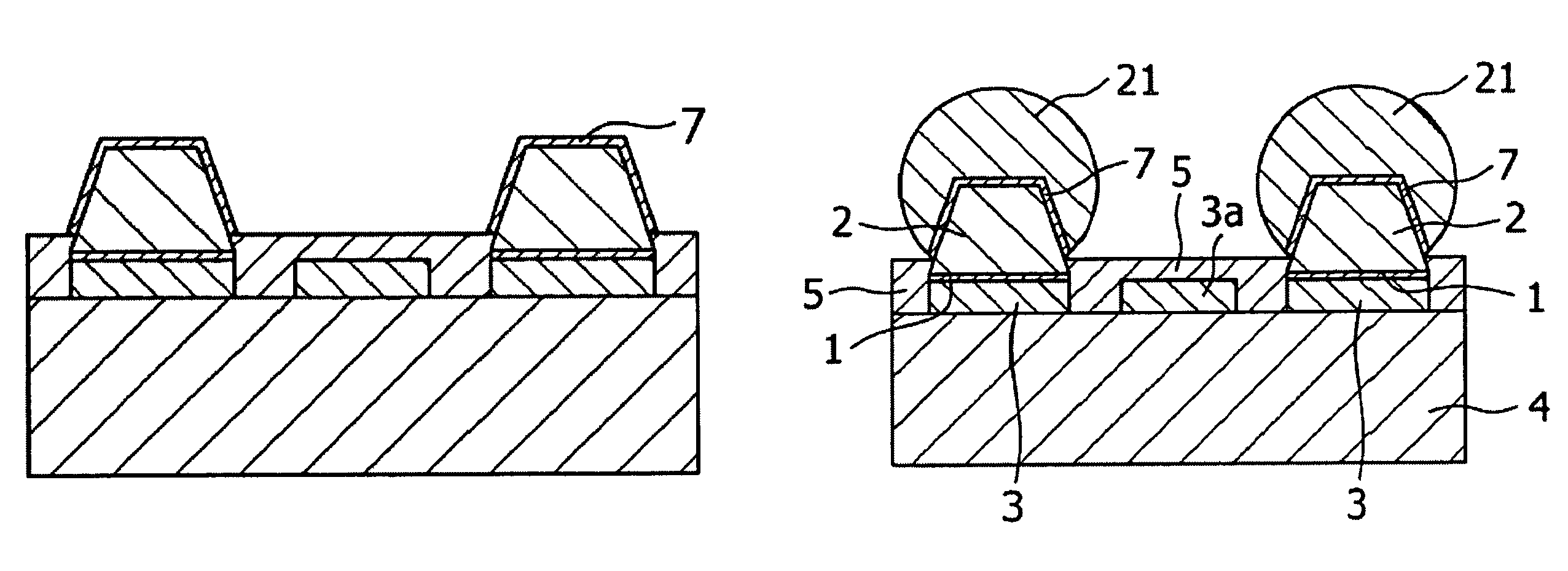

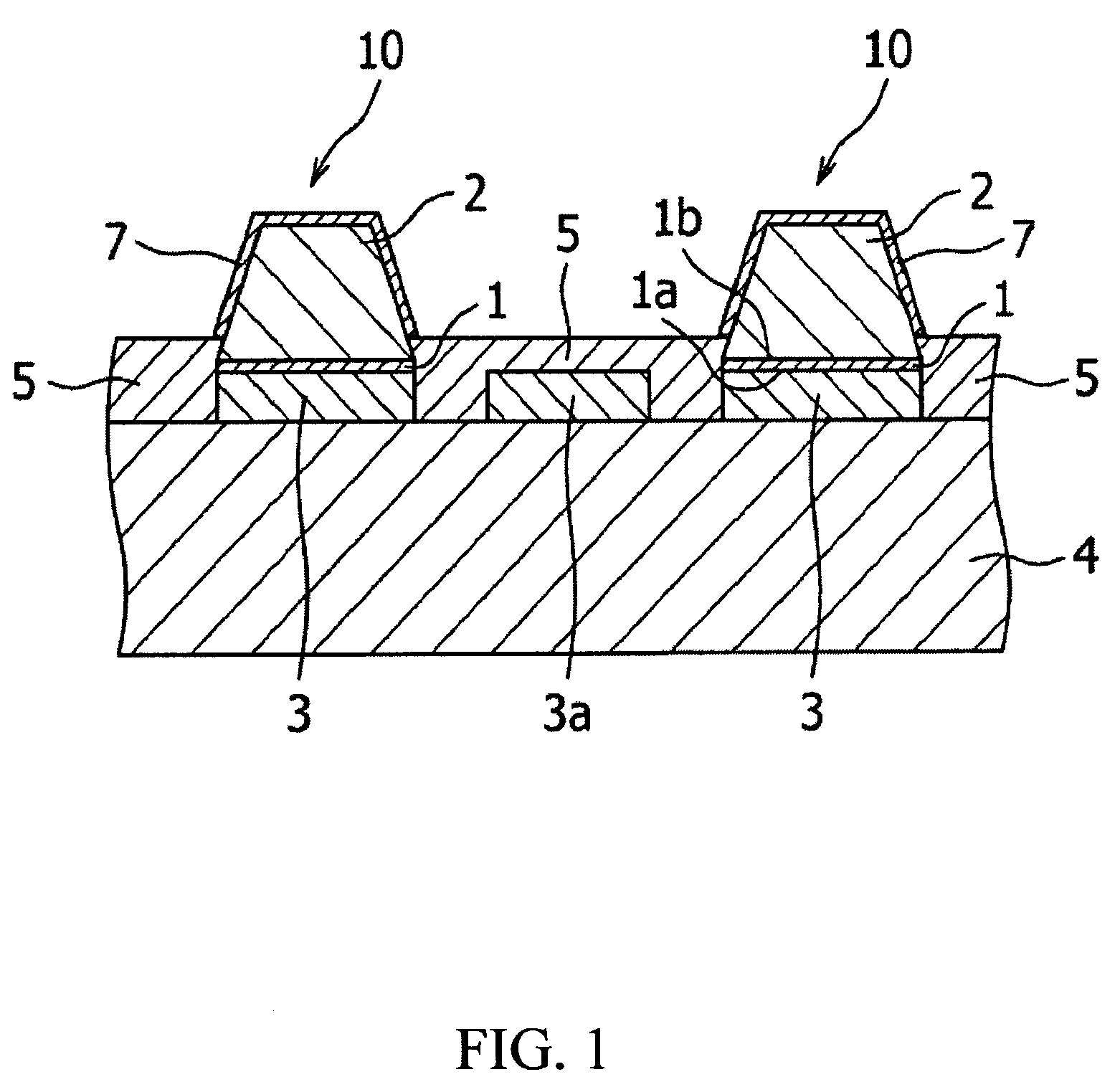

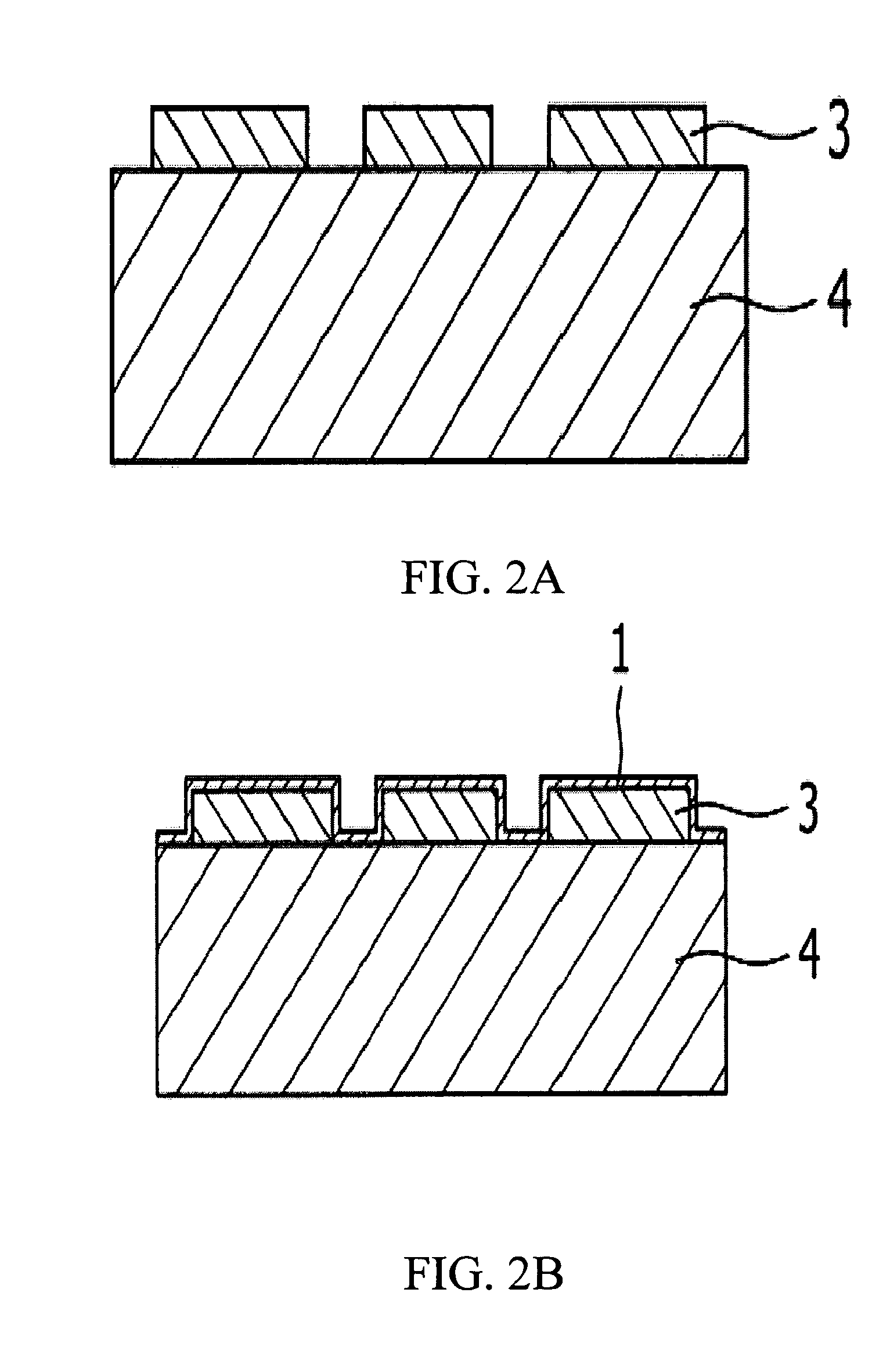

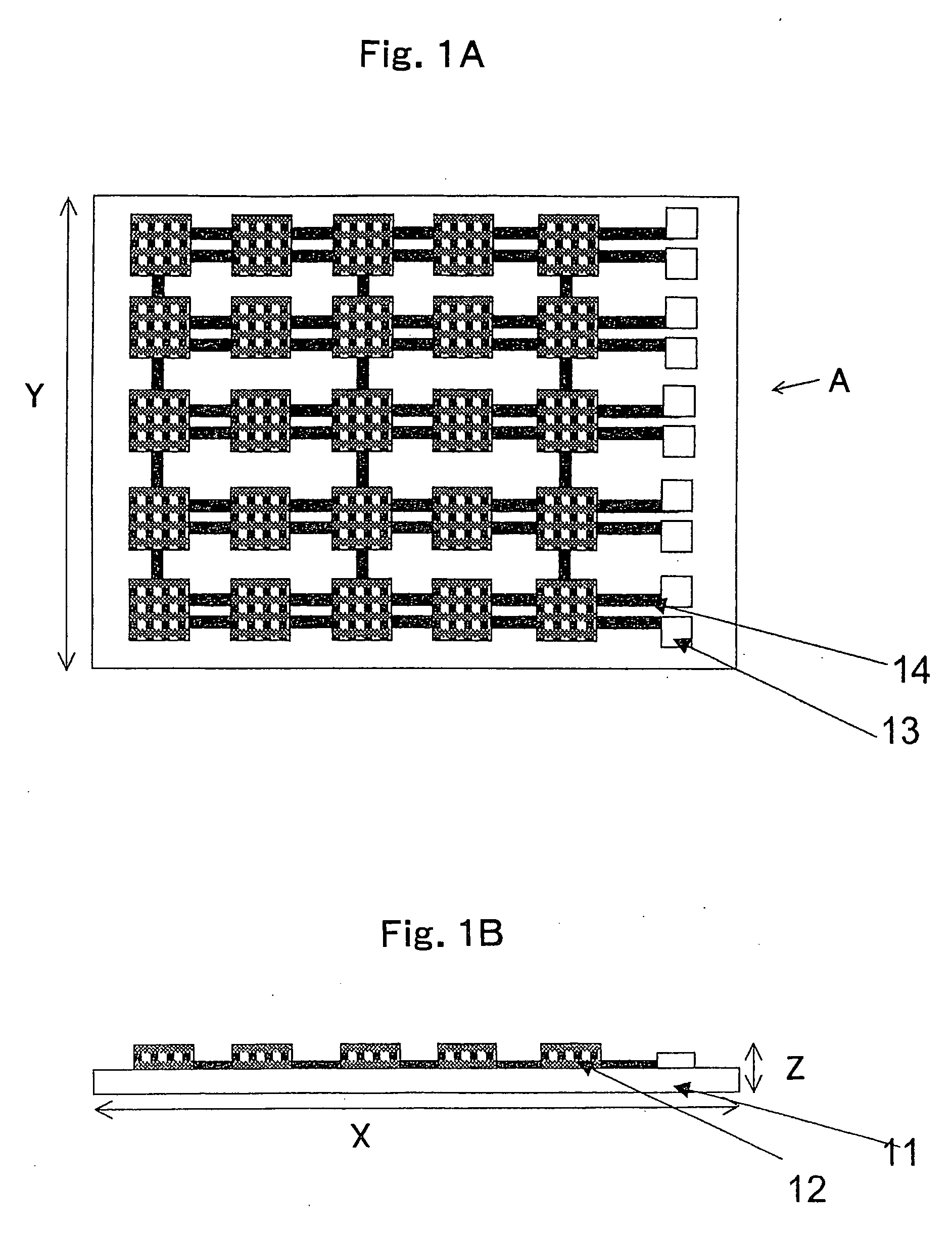

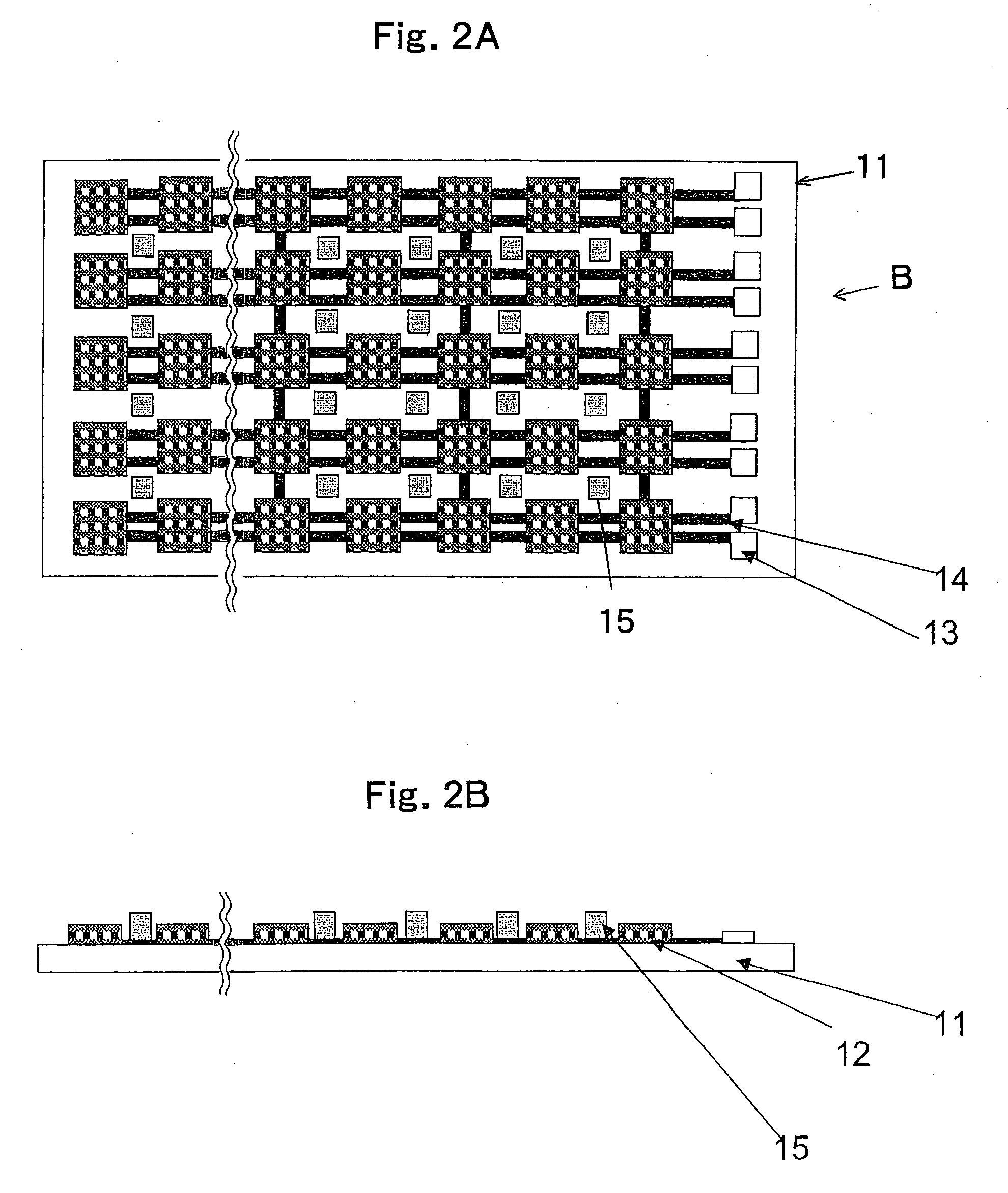

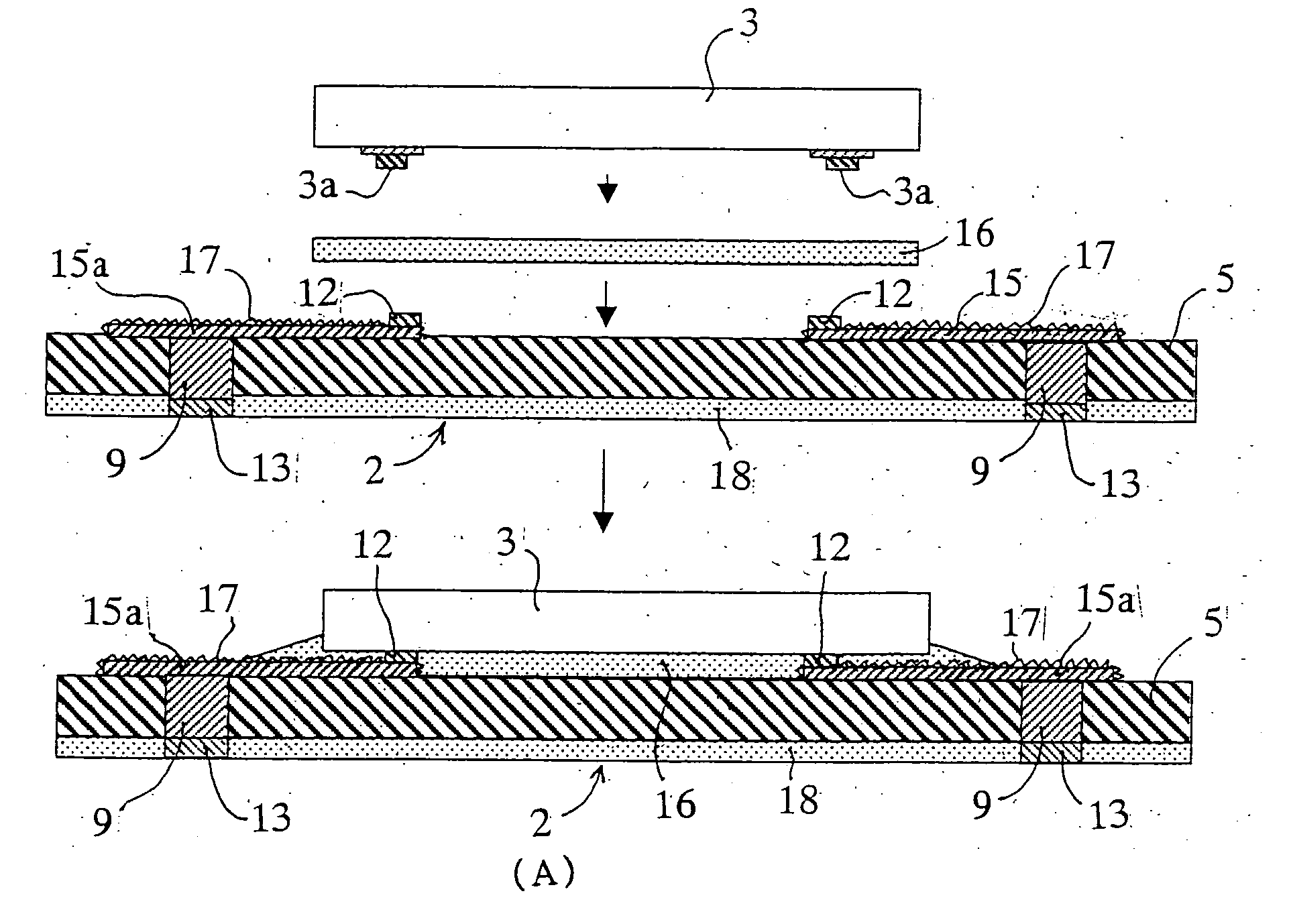

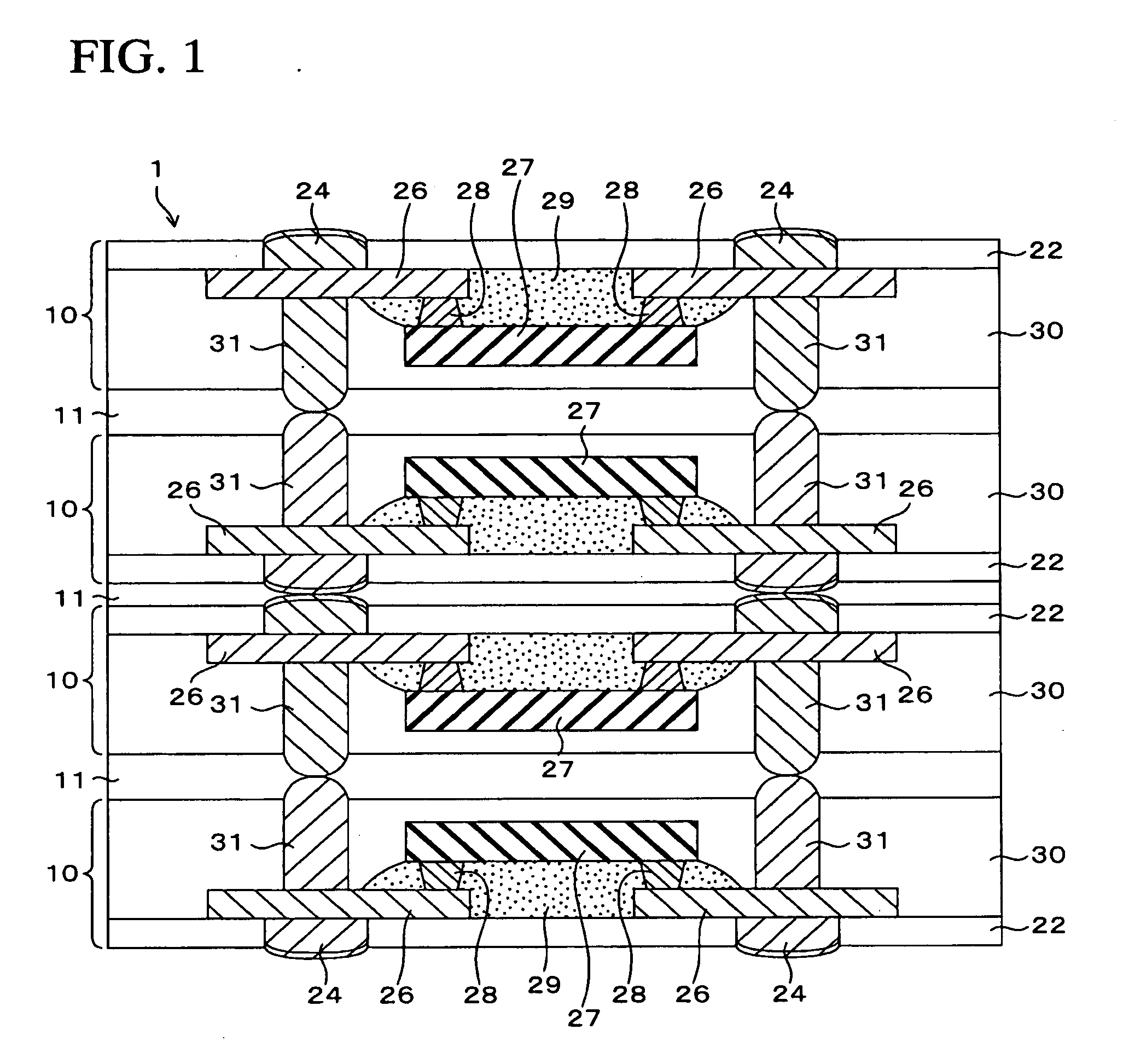

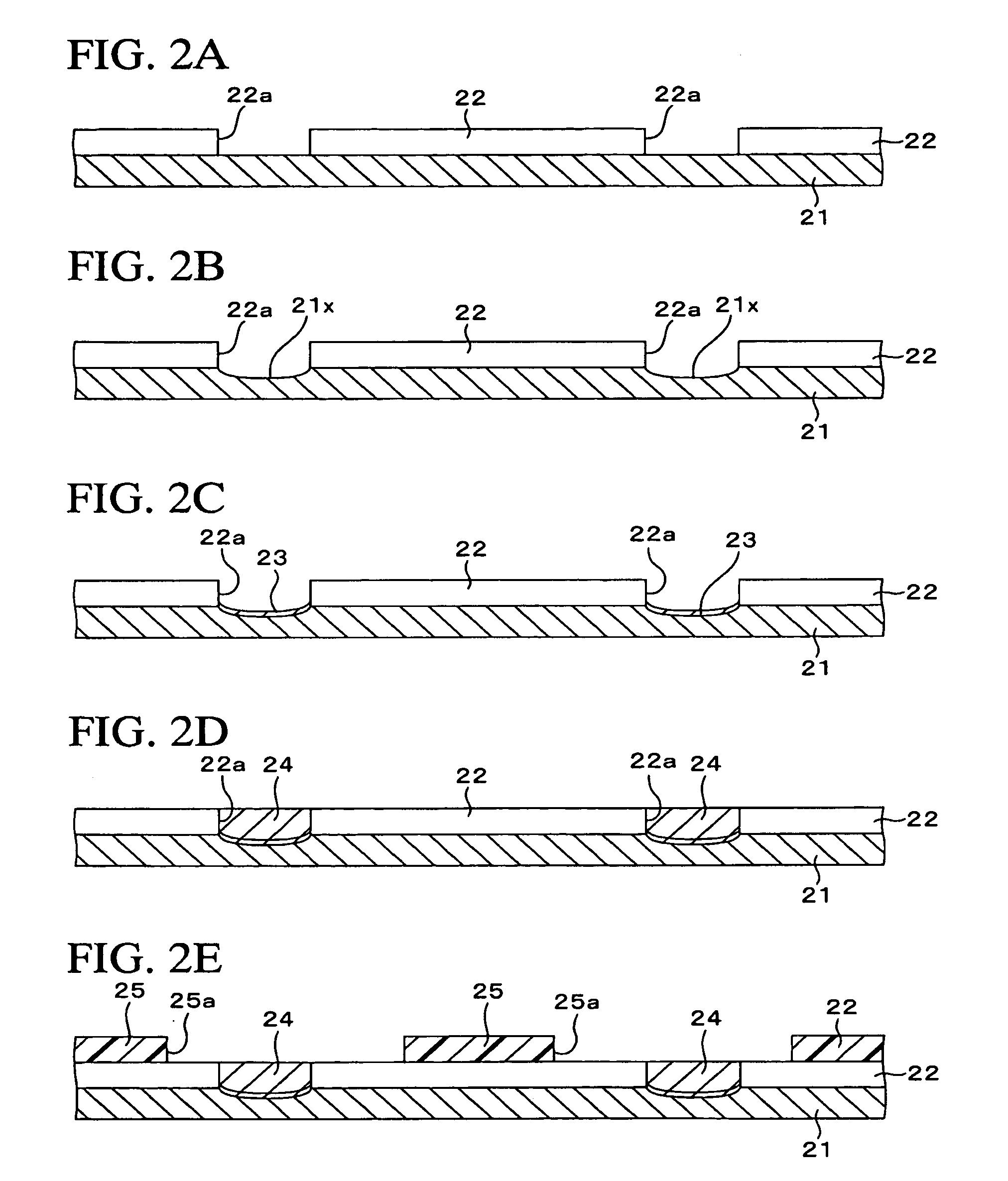

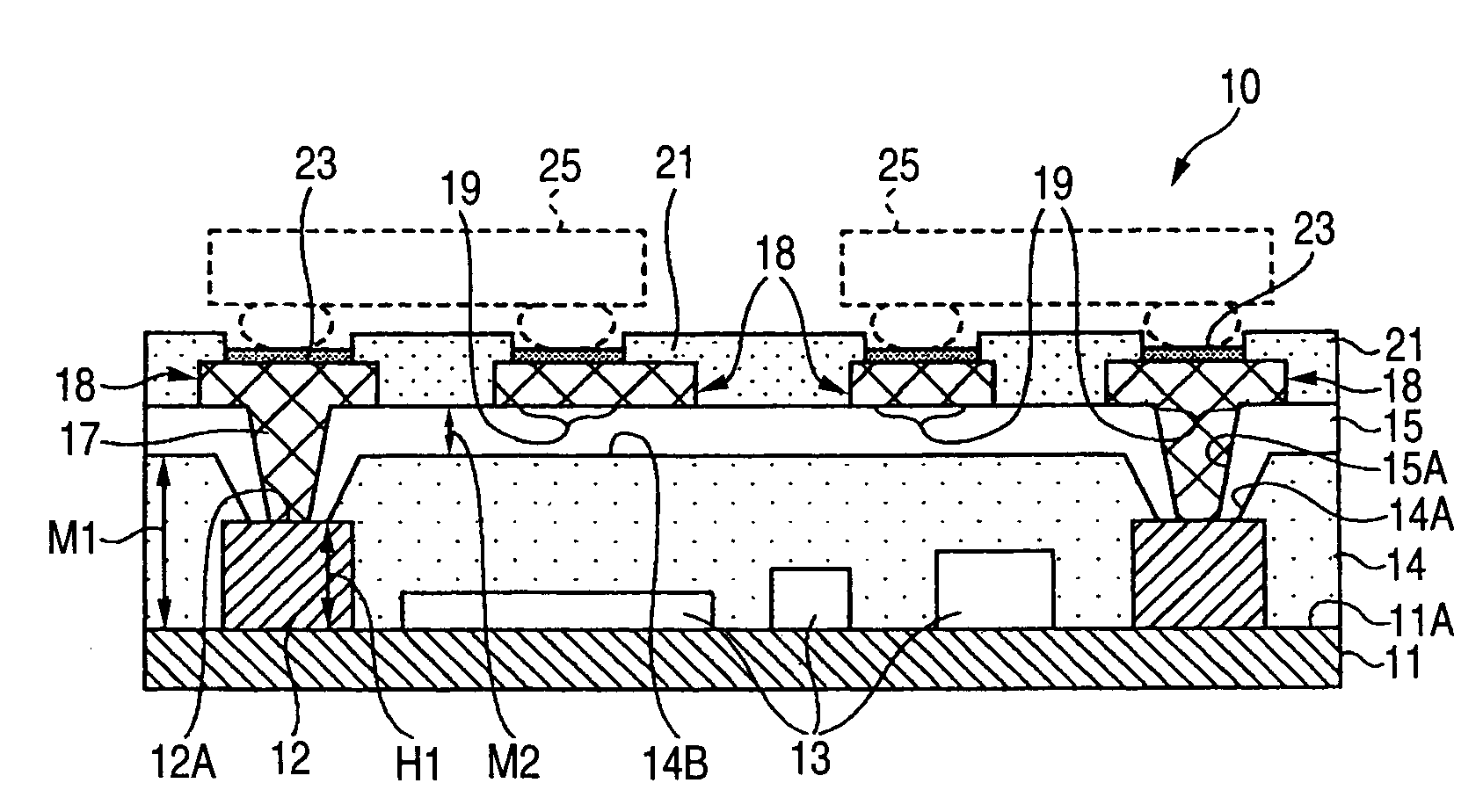

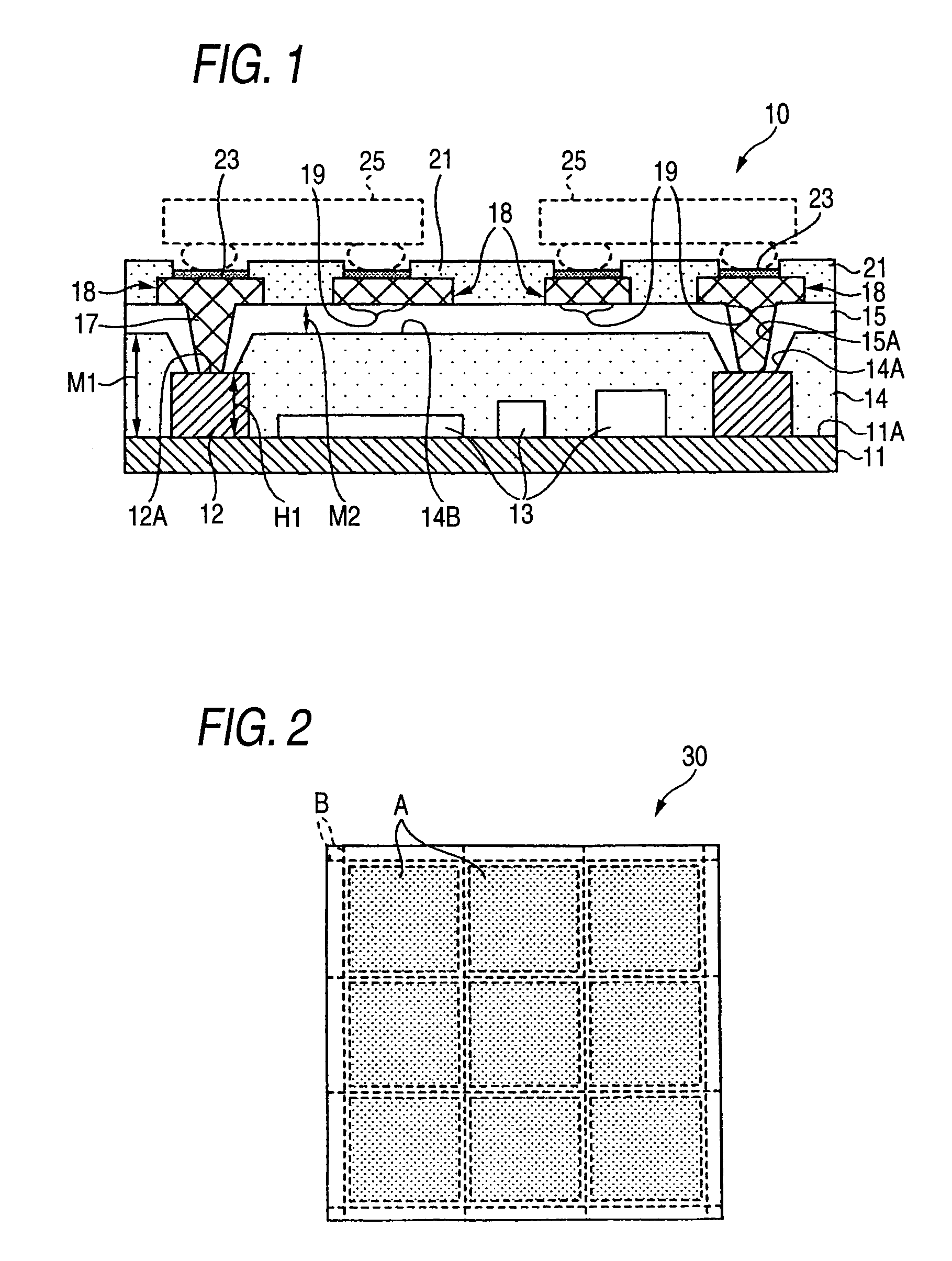

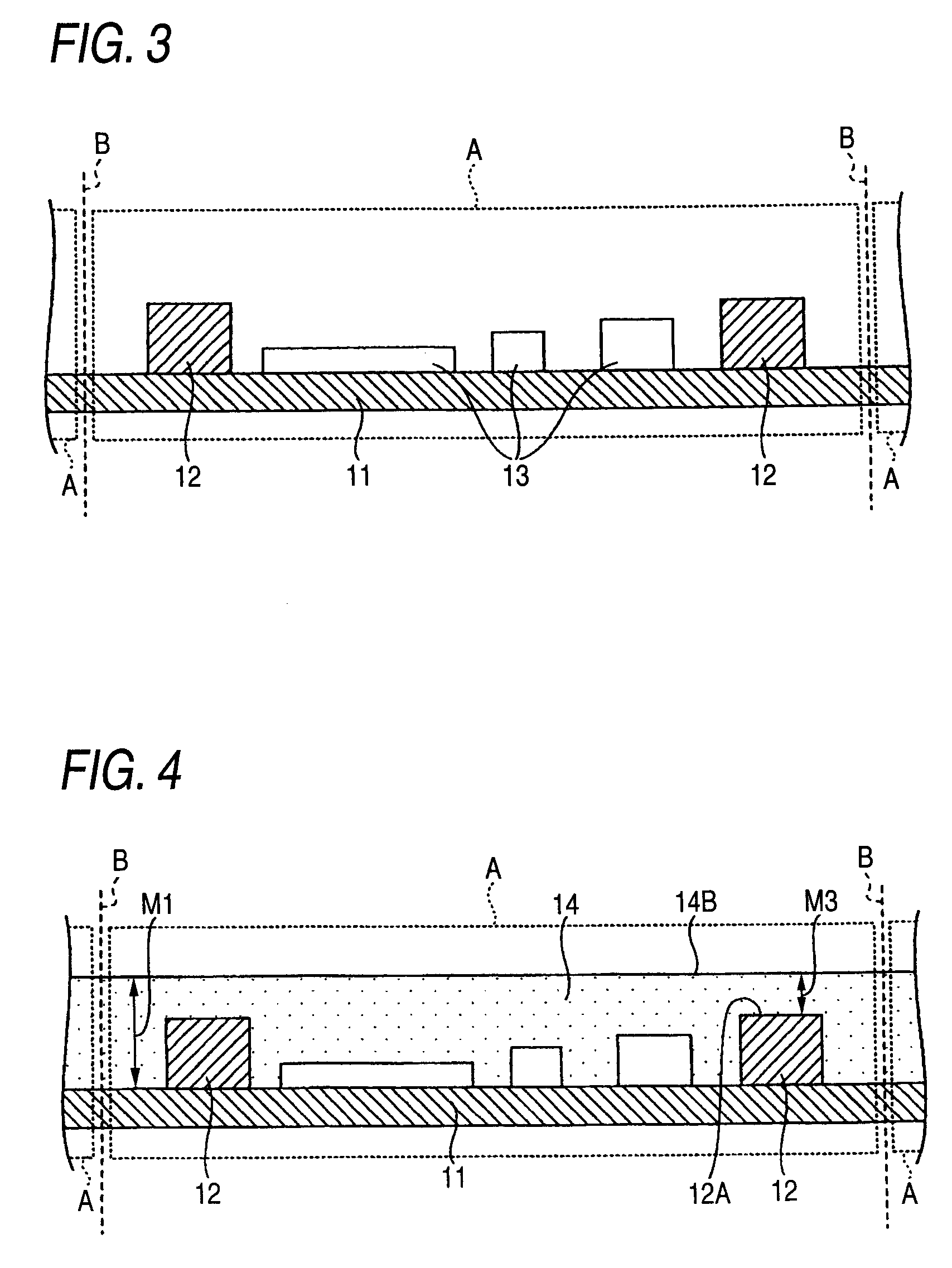

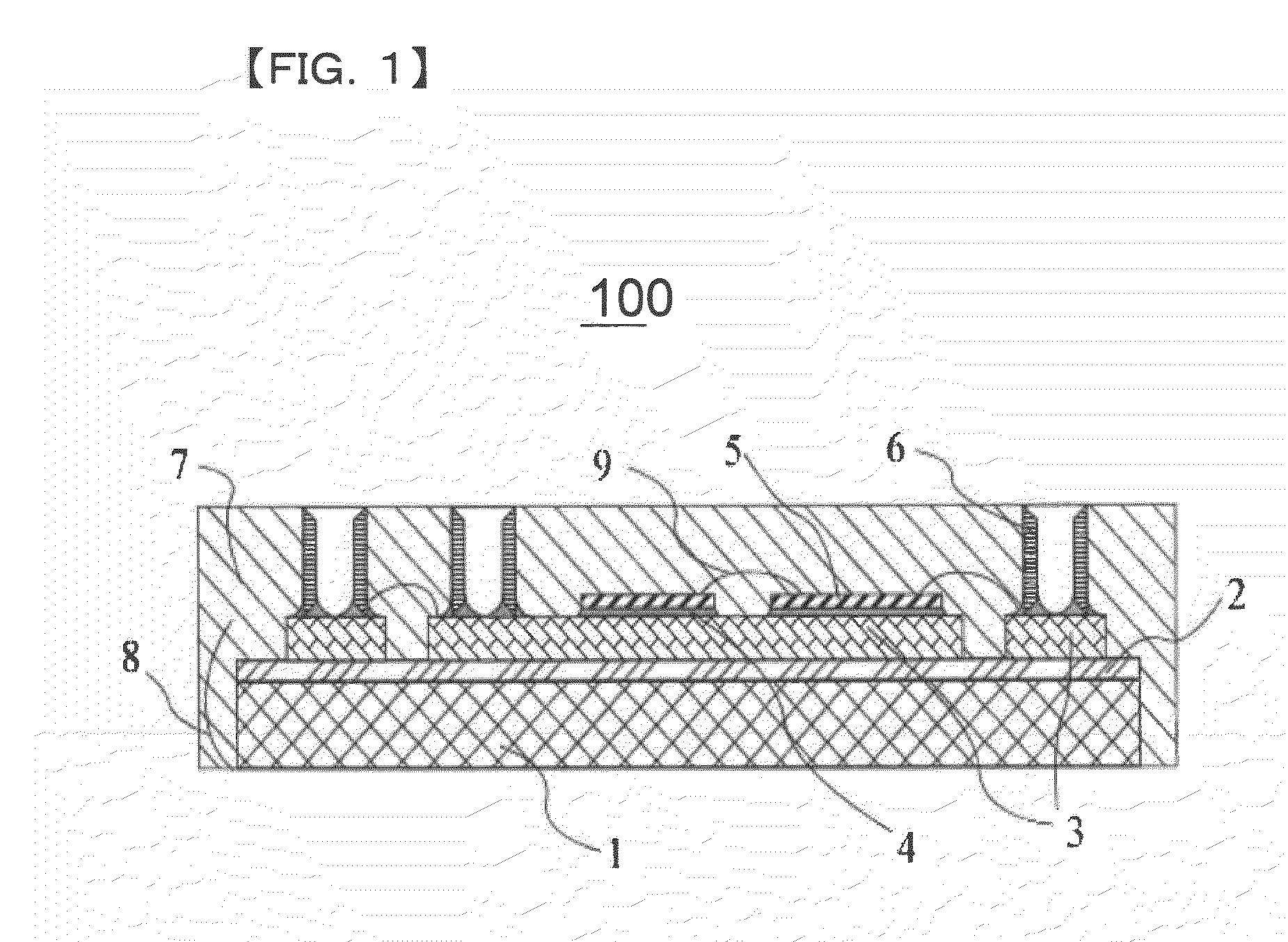

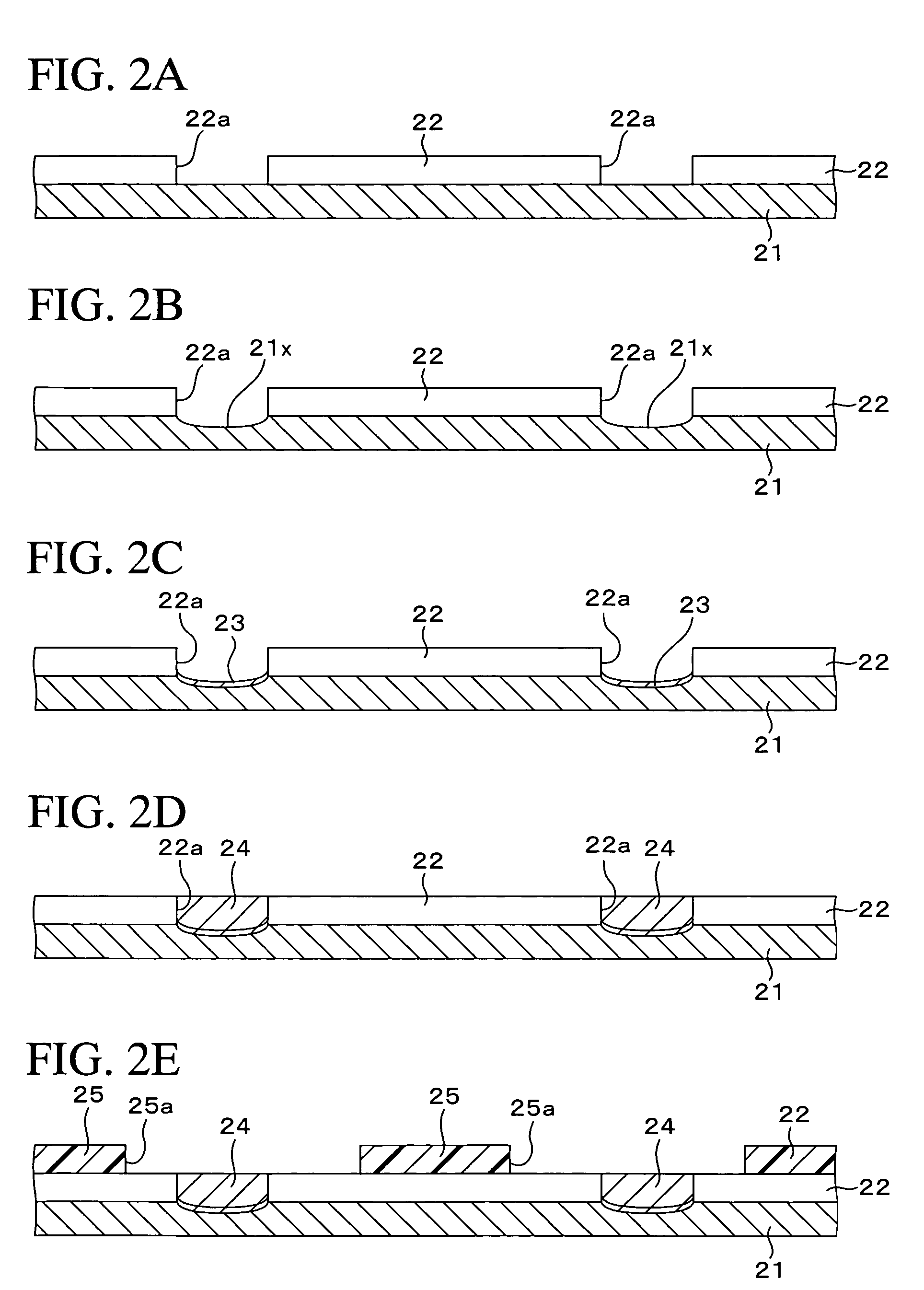

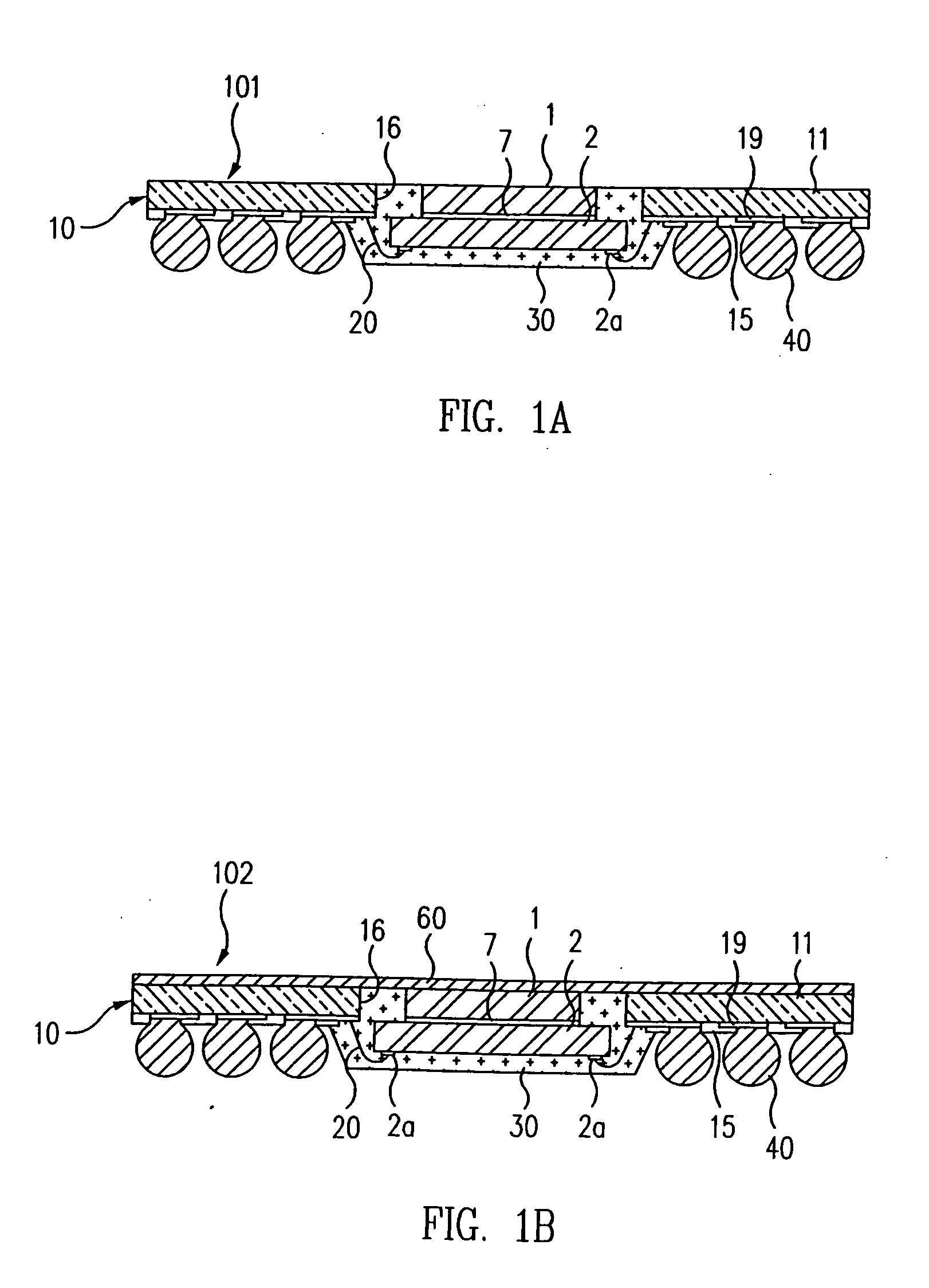

Semiconductor chip mounting wiring board, manufacturing method for same, and semiconductor module

InactiveUS20060076671A1Small diameterImprove installation densitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

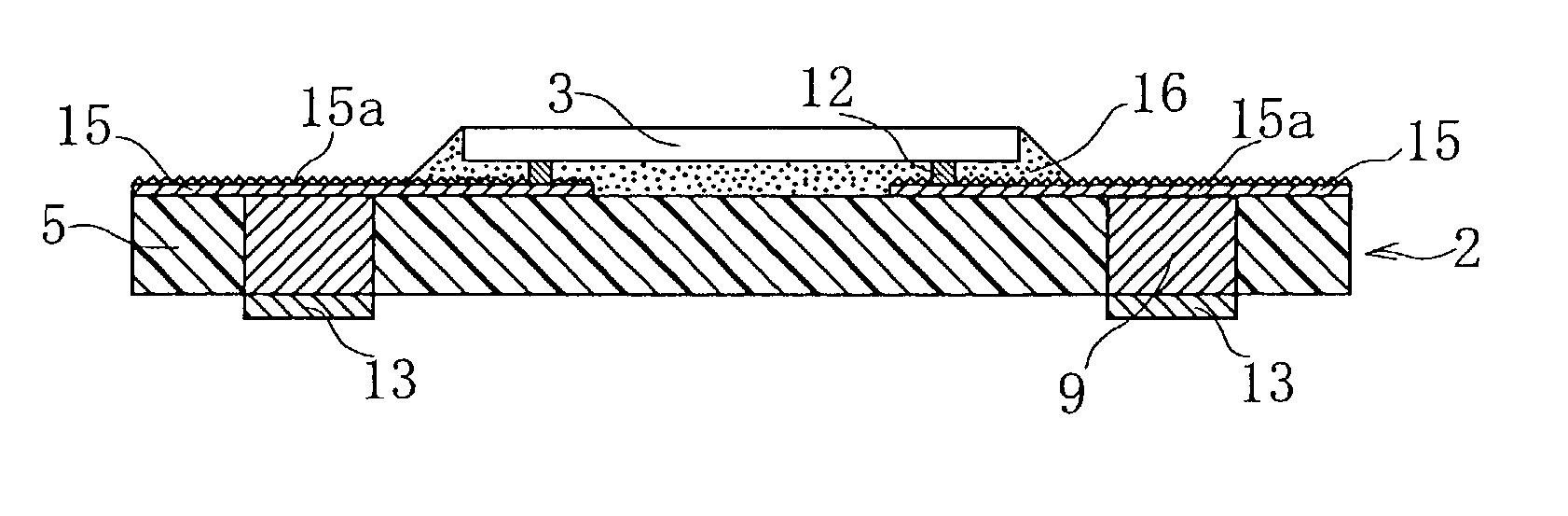

A semiconductor chip mounting wiring board 2 includes an insulating resin substrate 5, a first conductive bump 12 formed on one side of the insulative resin substrate 5 to mount a semiconductor chip 3, a wiring pattern 15 extending from the first conductive bump 12 toward the periphery of the insulating resin substrate 5, a filled viahole 9 leading from the other side of the insulating resin substrate 5 to the wiring pattern 15, and a second conductive bump 13, or a conductive pad 19, positioned just above the filled viahole 9 and electrically connected to the viahole 9. A semiconductor module is produced by mounting the semiconductor chip 3 in advance on the first conductive bump 12 on the semiconductor chip mounting wiring board 2 and stacking a plurality of the wiring boards 2 and interlayer members 20 each having an opening 27 to receive the semiconductor chip 3 and a conductive post 26 or conductive pad connected to the second conductive bump 13 of the wiring board 2 alternately on each other with an adhesive applied between them, placing another interconnecting circuit board such as an I / O wiring board 30 or the like on an outermost layer, and by applying hot-pressing to the stack. The semiconductor module thus produced has a high connection reliability and can be designed for a high mounting density and a lower profile.

Owner:IBIDEN CO LTD

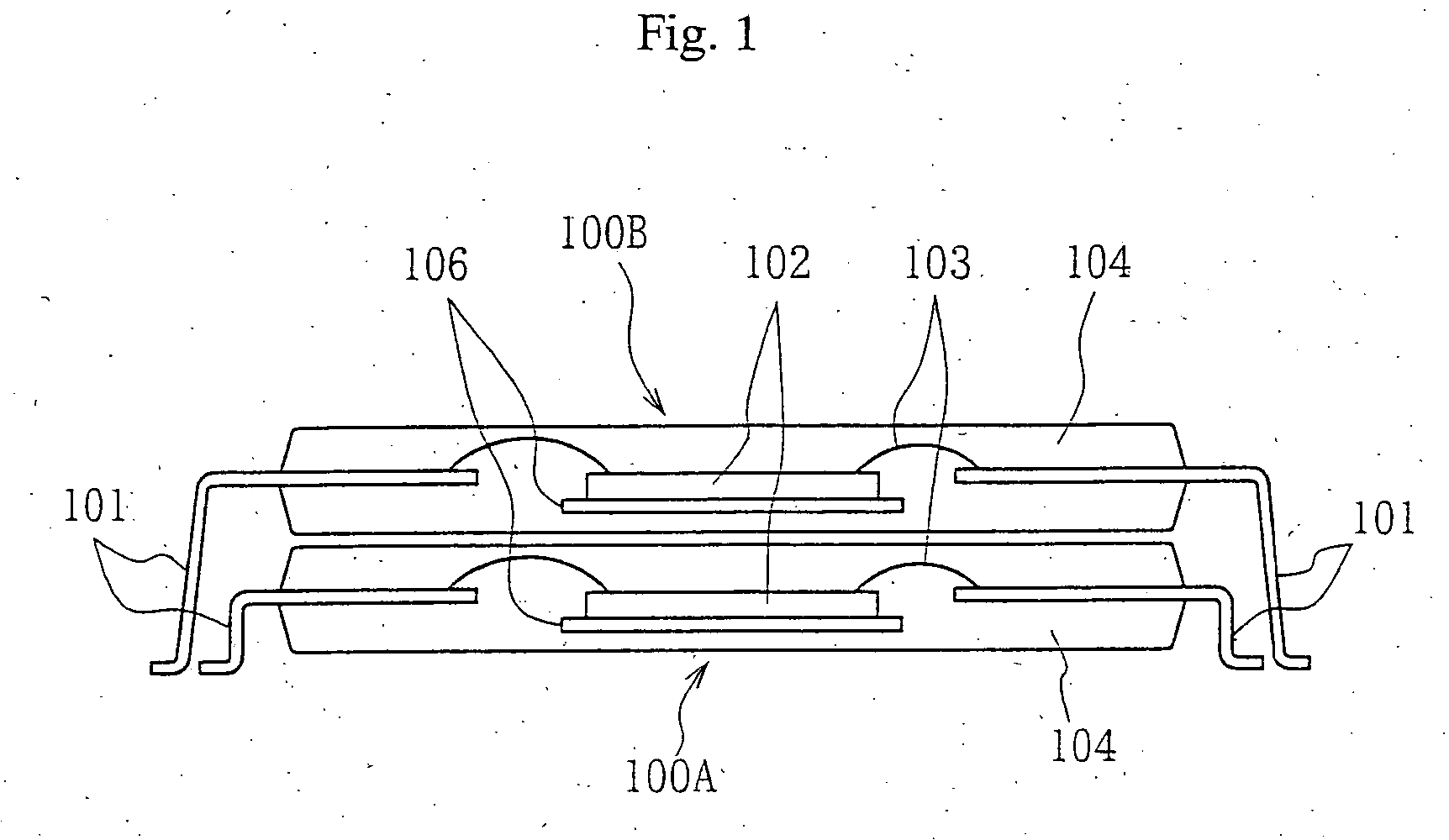

Semiconductor light emitting device

InactiveUS20100163920A1More compact in sizeImprove installation densitySolid-state devicesSemiconductor devicesIn planeLight emitting device

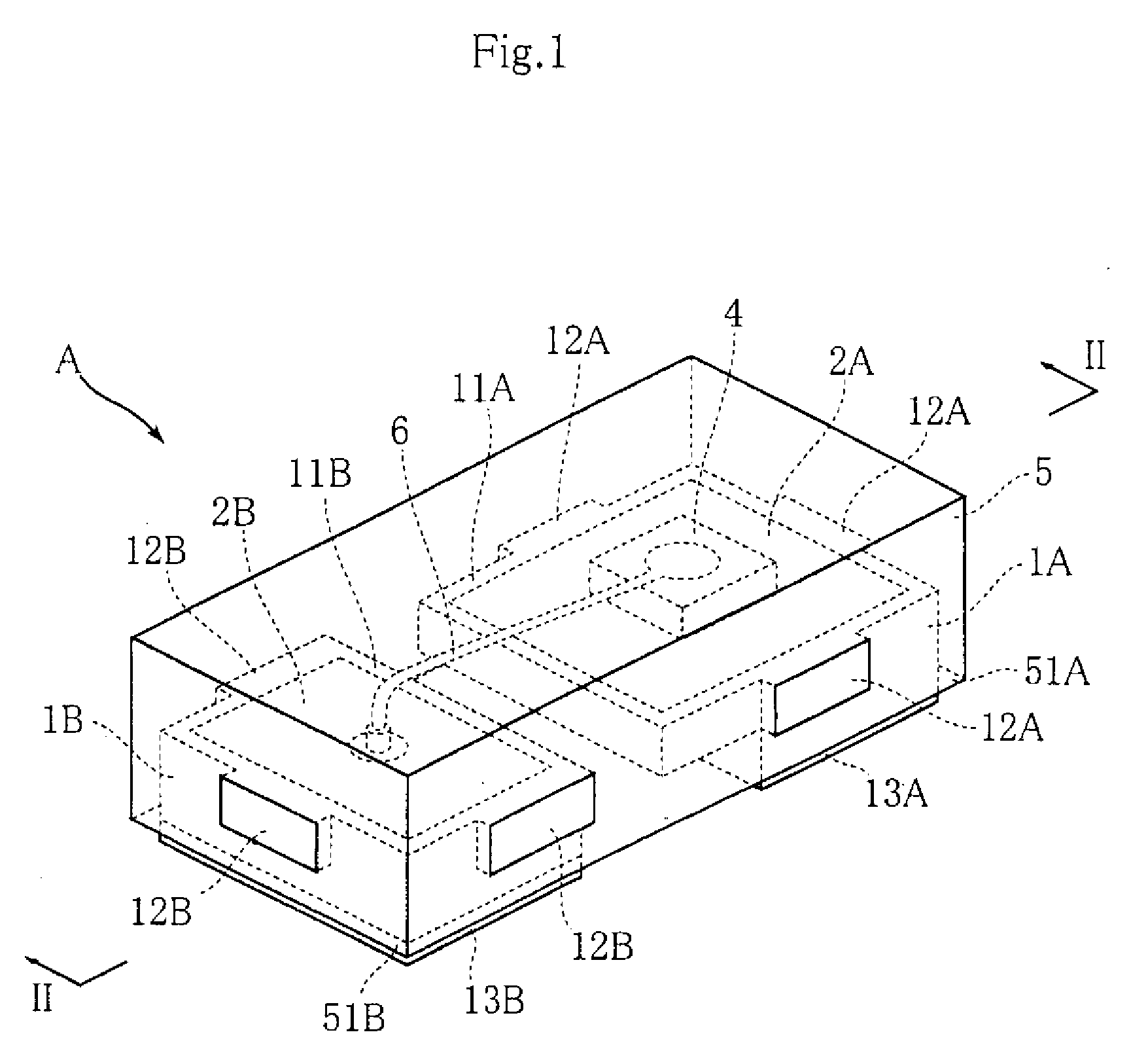

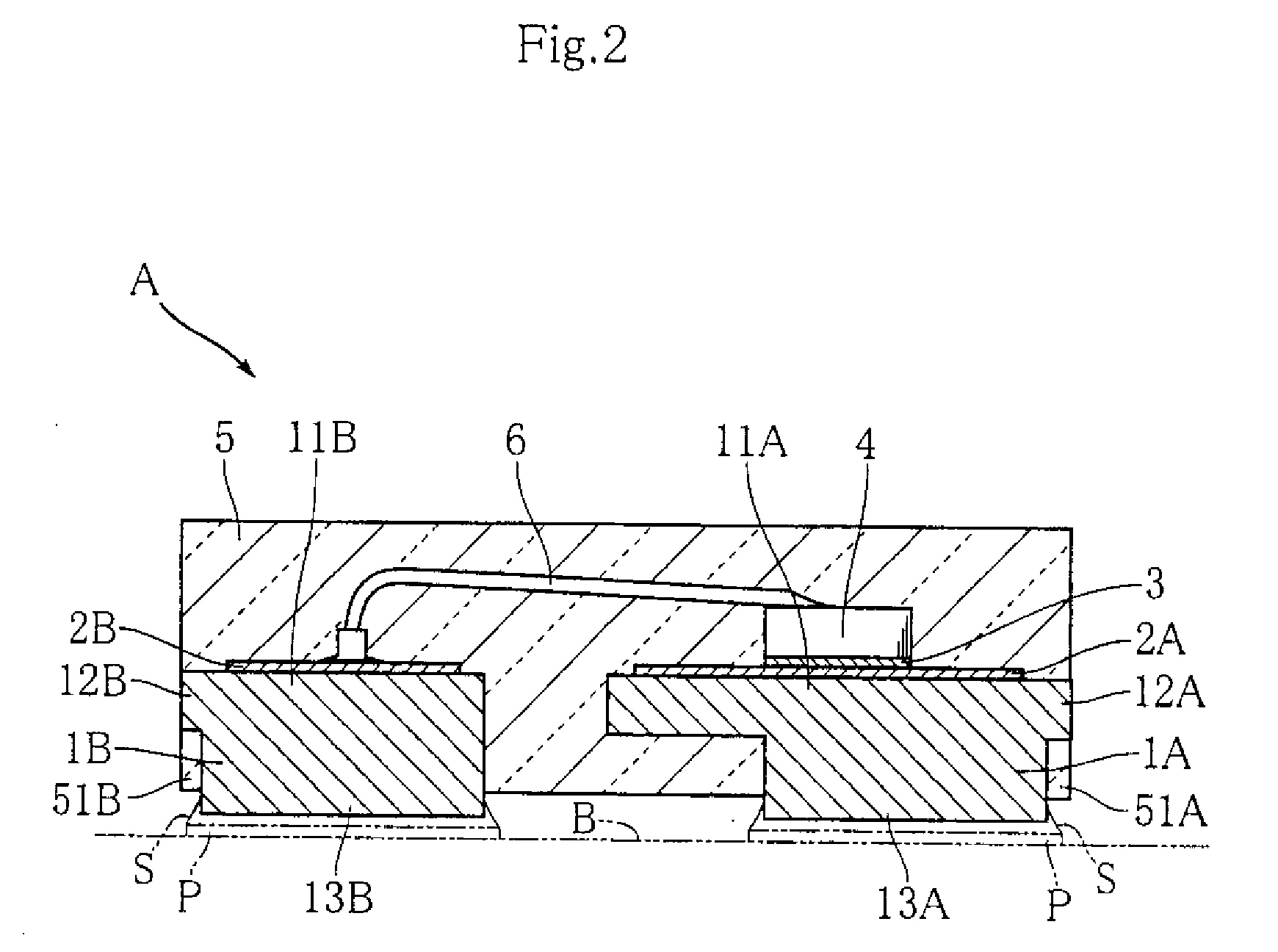

A semiconductor light emitting device (A) includes a resin package (5), a semiconductor light emitting element (4), a first lead (1A) and a second lead (1B). The resin package (5) has an upper surface and a bottom surface, and has translucency. The semiconductor light emitting element (4) is covered with the resin package (5) in a state where the semiconductor light emitting element faces the upper surface of the resin package (5). The first lead (1A) includes a bonding pad (11A) which supports the semiconductor light emitting element (4). The second lead (1B) is separated from the first lead (1A), and is electrically connected to the semiconductor light emitting element (4) via a wire (6). The leads (1A, 1B) have mounting terminals (13A, 13B) which are exposed from the bottom surface of the resin package (5). The mounting terminals (13A, 13B) are surrounded by the resin package (5) in an in-plane direction perpendicular to the thickness direction of the resin package.

Owner:ROHM CO LTD

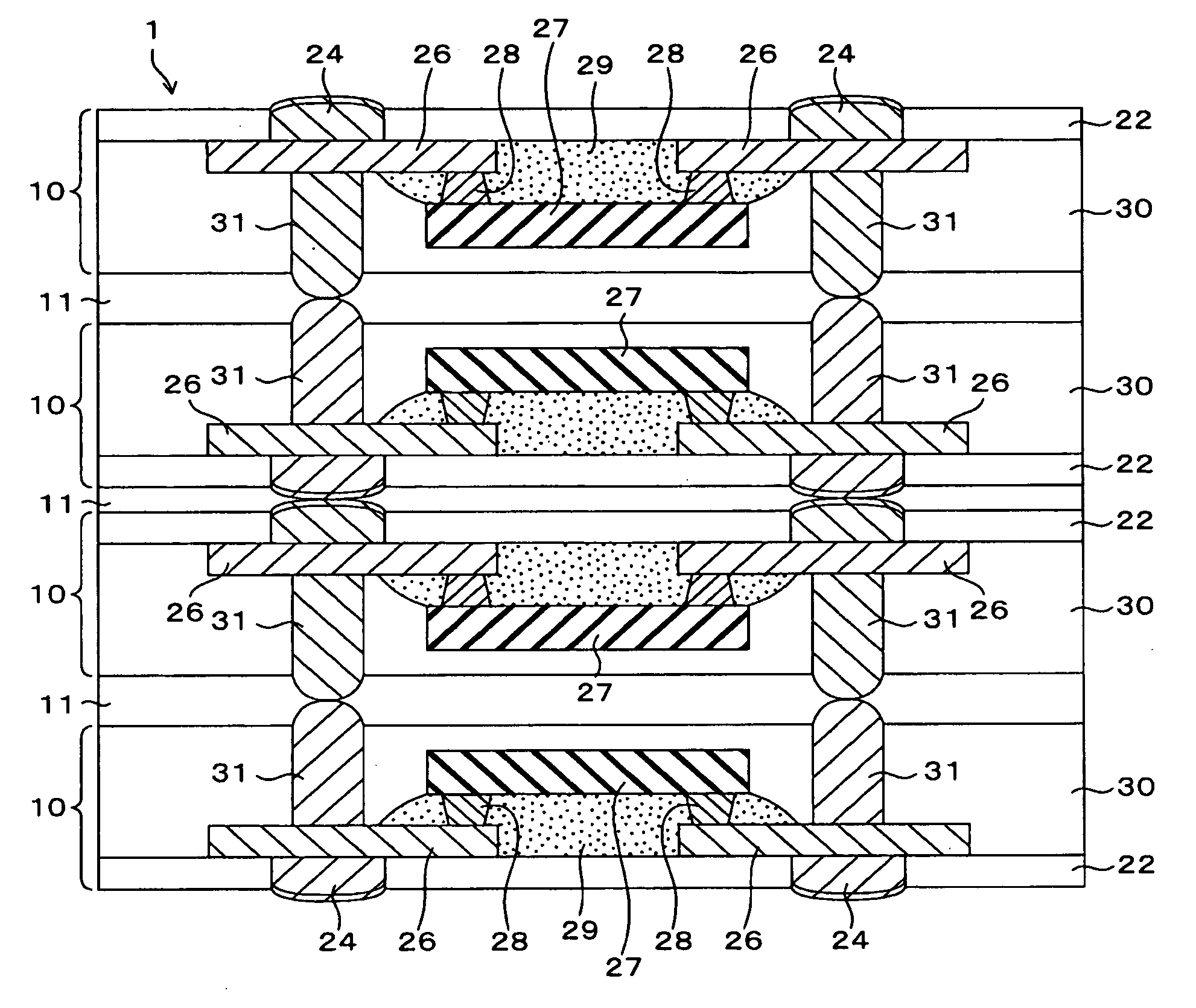

Semiconductor chip mounting wiring board, manufacturing method for same, and semiconductor module

InactiveUS7049528B2Improve installation densityLow profile typePrinted circuit assemblingSemiconductor/solid-state device detailsSemiconductor chipHot pressing

A semiconductor chip mounting wiring board 2 includes an insulating resin substrate 5, a first conductive bump 12 formed on one side of the insulative resin substrate 5 to mount a semiconductor chip 3, a wiring pattern 15 extending from the first conductive bump 12 toward the periphery of the insulating resin substrate 5, a filled viahole 9 leading from the other side of the insulating resin substrate 5 to the wiring pattern 15, and a second conductive bump 13, or a conductive pad 19, positioned just above the filled viahole 9 and electrically connected to the viahole 9. A semiconductor module is produced by mounting the semiconductor chip 3 in advance on the first conductive bump 12 on the semiconductor chip mounting wiring board 2 and stacking a plurality of the wiring boards 2 and interlayer members 20 each having an opening 27 to receive the semiconductor chip 3 and a conductive post 26 or conductive pad connected to the second conductive bump 13 of the wiring board 2 alternately on each other with an adhesive applied between them, placing another interconnecting circuit board such as an I / O wiring board 30 or the like on an outermost layer, and by applying hot-pressing to the stack. The semiconductor module thus produced has a high connection reliability and can be designed for a high mounting density and a lower profile.

Owner:IBIDEN CO LTD

Electronic parts packaging structure and method of manufacturing the same

InactiveUS20110039370A1Improve installation densityAvoid it happening againPrinted circuit assemblingLine/current collector detailsSemiconductor chipElectron

In an electronic parts packaging structure of the present invention constructed by stacking a plurality of sheet-like units in a thickness direction, each of the units includes a first insulating layer, wirings formed on one surface of the first insulating layer, a semiconductor chip (electronic parts) connected to the wirings, a second insulating layer formed on an one surface side of the first insulating layer to cover the semiconductor chip, and connecting portions (terminals and contact vias) for connecting electrically the wirings and wirings of other unit, wherein arrangement of the first insulating layer, the semiconductor chip, the wirings, and the second insulating layer is symmetrical between units adjacent in a thickness direction.

Owner:SHINKO ELECTRIC IND CO LTD

Method of manufacturing a semiconductor apparatus

ActiveUS7514772B2Improve installation densitySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

Owner:SHINKO ELECTRIC IND CO LTD

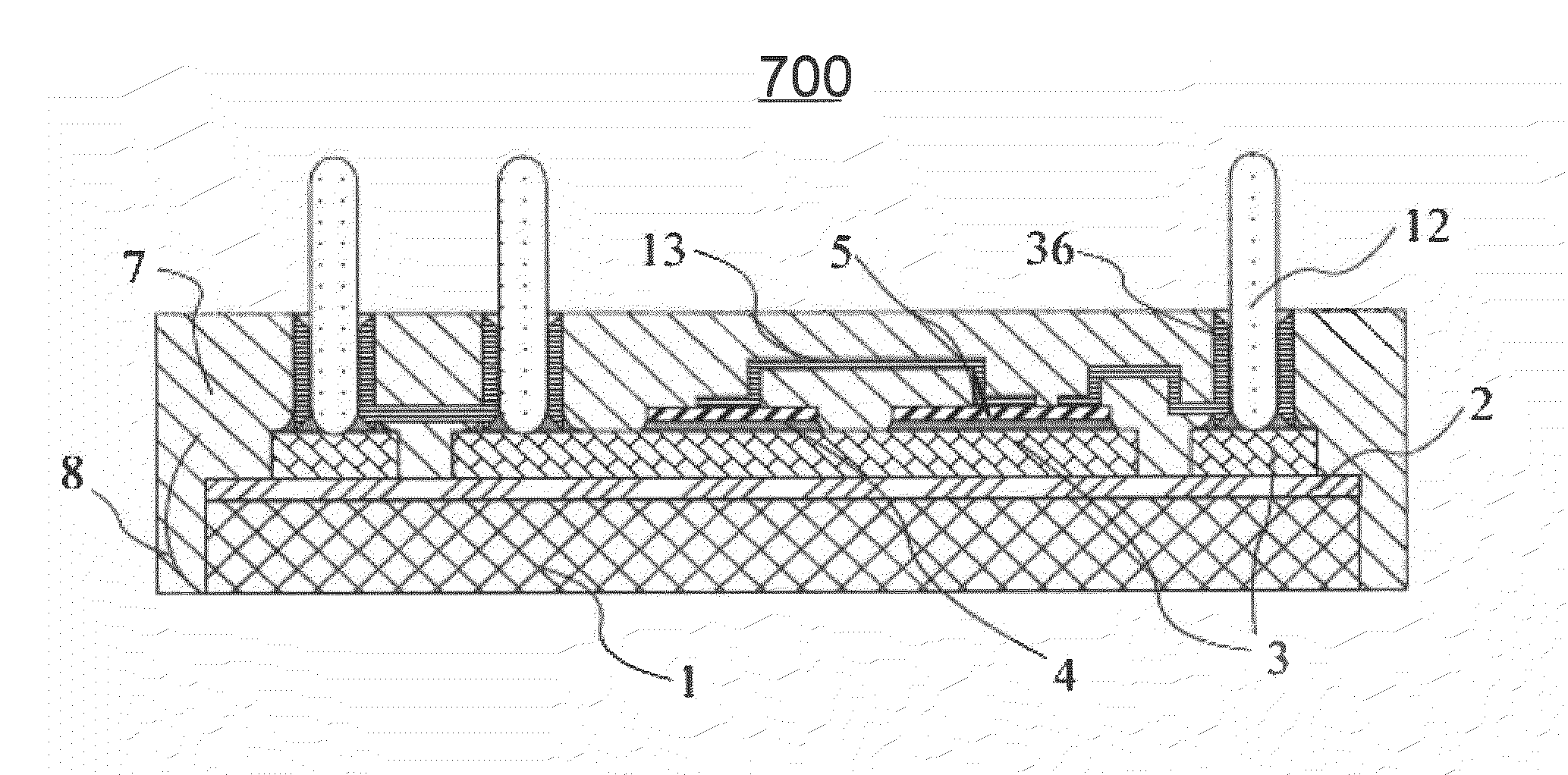

Power semiconductor device

ActiveUS20100013086A1Improve productivitySmall sizeSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceProduction rate

A power semiconductor device with improved productivity, reduced size and reduction of amounting area therefore is provided. In the provided power semiconductor device, an external terminal does not limit an increase in current. The power semiconductor device is sealed with transfer molding resin. In the power semiconductor device, a cylindrical external terminal communication section is arranged on a wiring pattern so as to be substantially perpendicular to the wiring pattern. An external terminal can be inserted and connected to the cylindrical external terminal communication section. The cylindrical external terminal communication section allows the inserted external terminal to be electrically connected to the wiring pattern. A taper is formed at, at least, one end of the cylindrical external terminal communication section, which one end is joined to the wiring pattern.

Owner:ROHM CO LTD

Semiconductor device and method for manufacturing thereof

ActiveUS20090289336A1Improve installation densitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipLead frame

The present invention provides a semiconductor device including: a semiconductor chip; a lead frame provided with a recessed portion on at least one of an upper surface or a lower surface thereof, and electrically coupled to the semiconductor chip; and a resin section that molds the semiconductor chip and the lead frame, and is provided with an opening above the recessed portion. By inserting a conductive pin (not shown) into the recessed portion through the opening, a plurality of semiconductor devices can be mechanically and electrically coupled to each other.

Owner:MONTEREY RES LLC

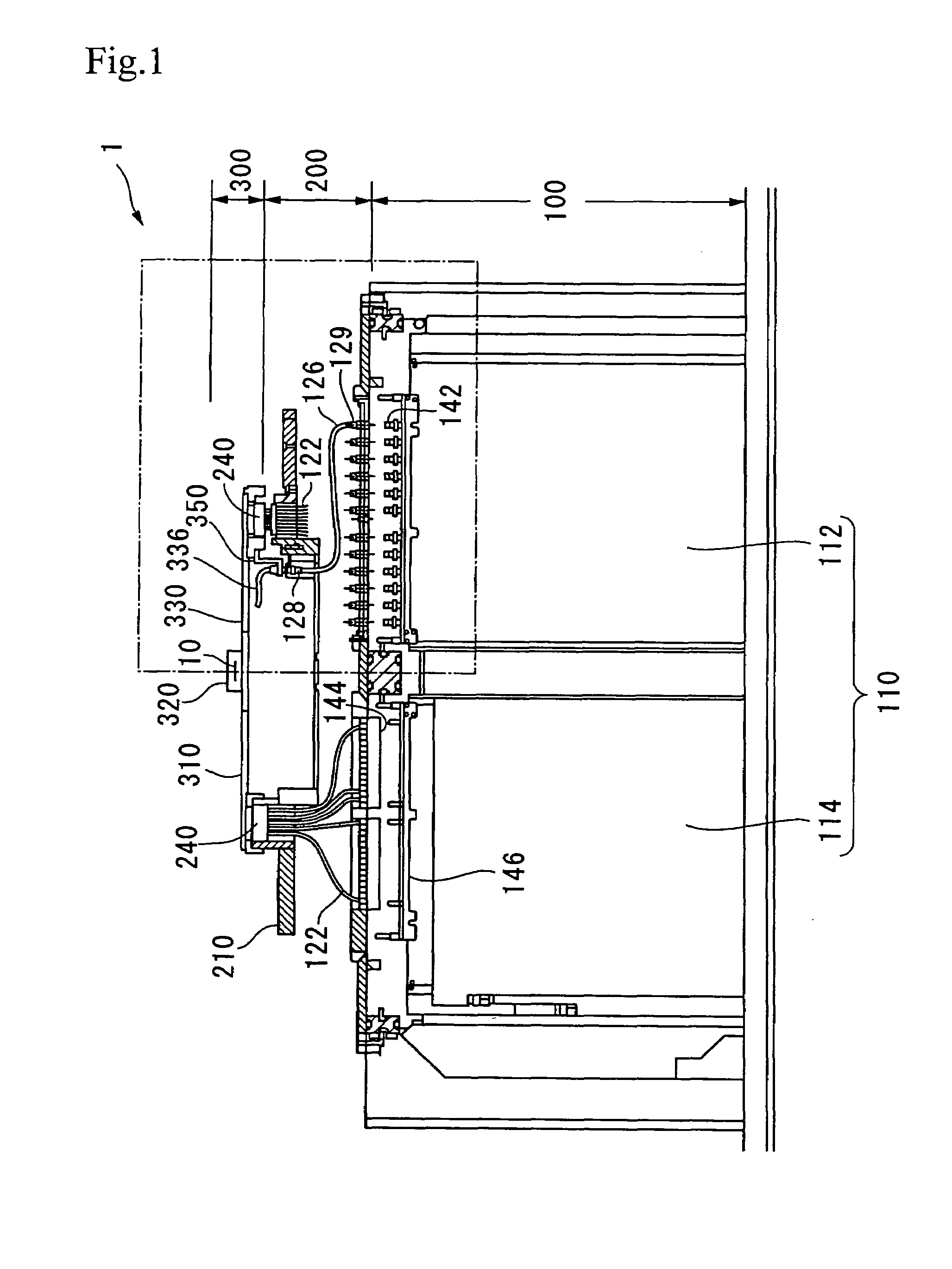

Connector housing block, interface member and electronic device testing apparatus

InactiveUS7458837B2Reduce in quantityHigh densityElectric discharge tubesIncorrect coupling preventionElectricityCoil spring

Owner:ADVANTEST CORP

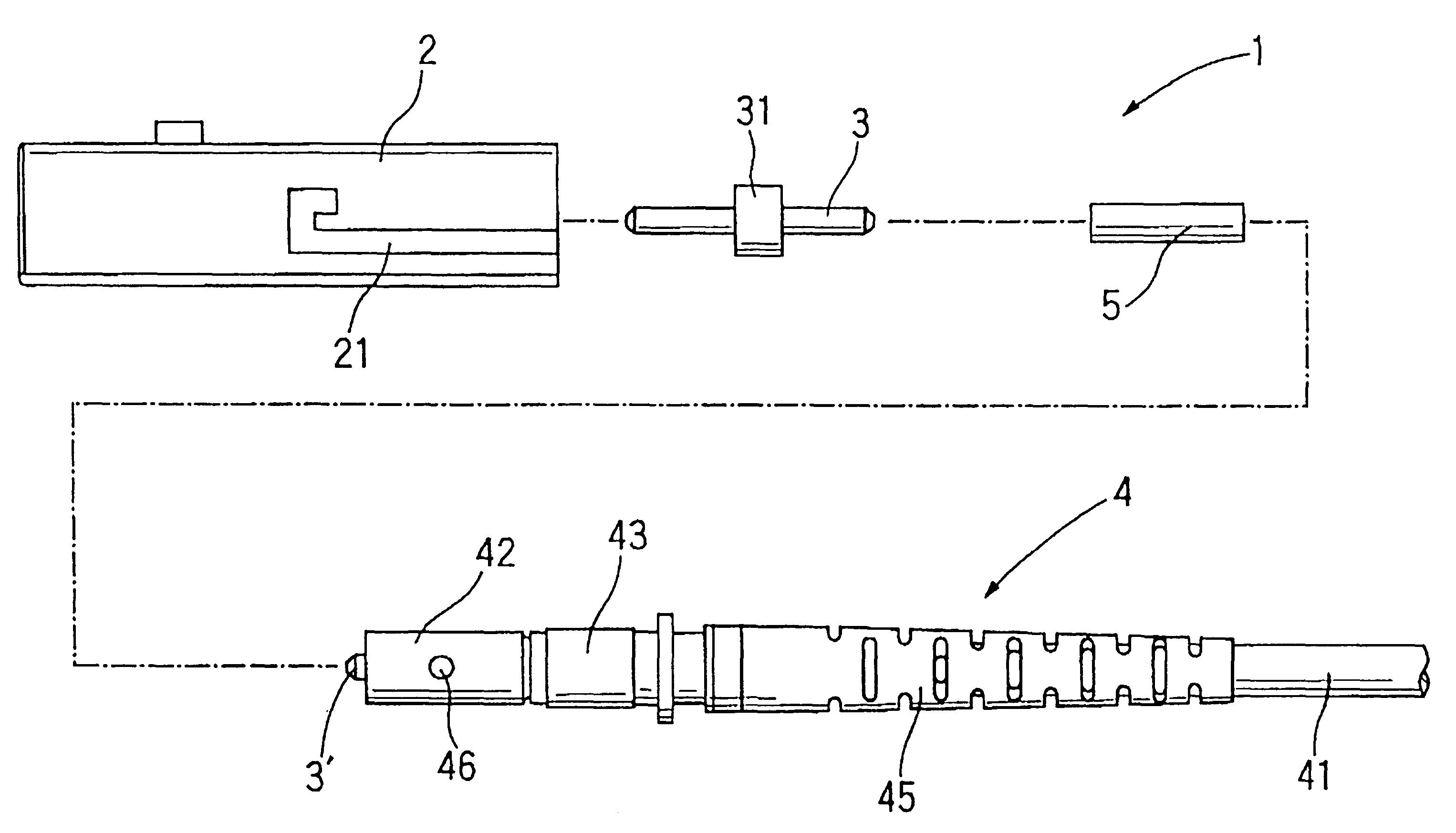

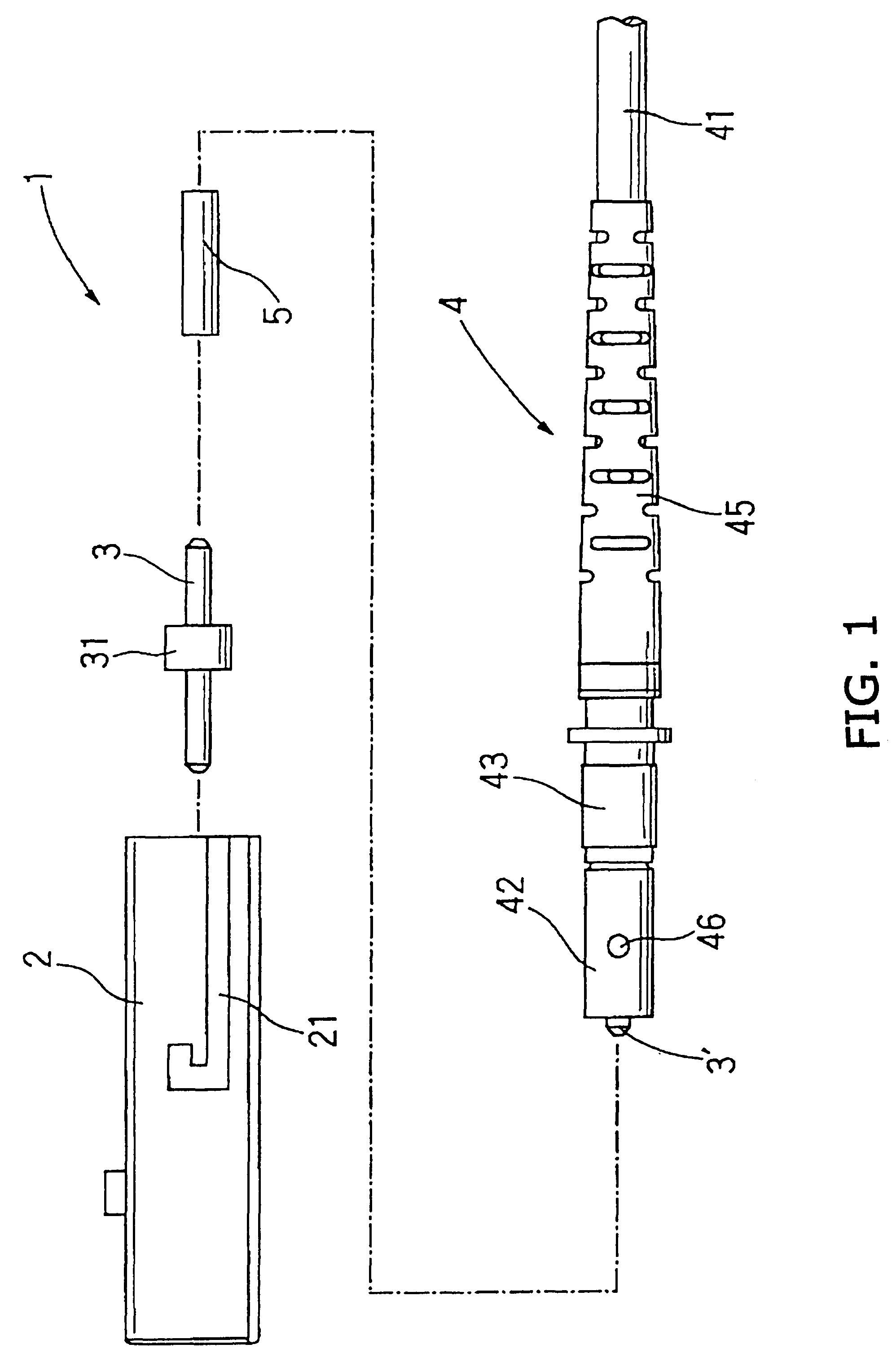

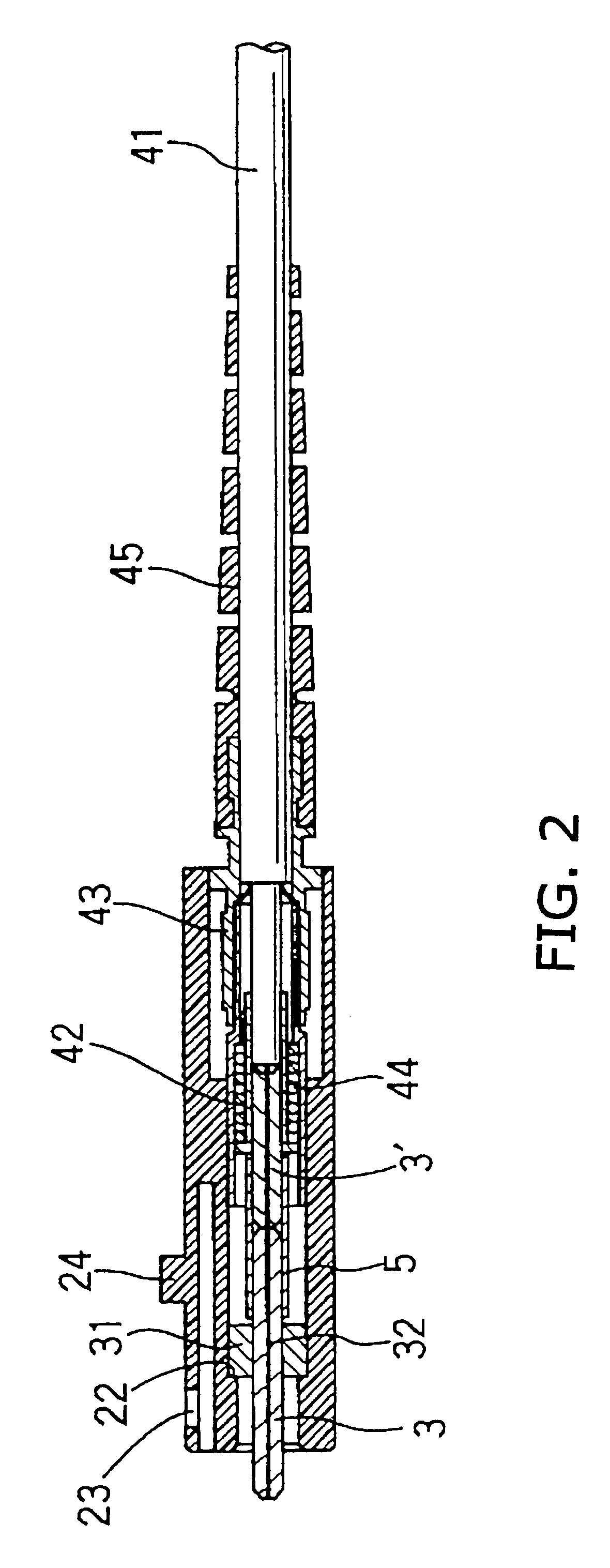

Optical connector

InactiveUS6450695B1Improve installation densitySatisfactory mechanical strengthCoupling light guidesAbutmentEngineering

The optical connector comprising a housing (2), a first ferrule section (3) for holding an optical fiber having a damping or filtering function, a second ferrule section (3') for holding an ordinary optical fiber, and an aligning sleeve (5) for aligning the first and second ferrule sections (3, 3') for detachable abutment.

Owner:HIROSE ELECTRIC GROUP

Lighting apparatus for guiding light onto a light polymerizable piece to effect hardening thereof

InactiveUS7001057B2Increase the areaFocusPoint-like light sourcePortable electric lightingLight equipmentLight guide

A lighting apparatus for dental purposes having plurality of light sources supported on semi-conductor bases, which are mounted on a substrate is provided. The lighting apparatus includes a reflective over surface encircling the light sources which reflects visible light. The lighting apparatus may be deployed in a light hardening device as a light source unit with the emitted light beams being conducted, in particular, by a prismatic body, to a light guiding conduit.

Owner:IVOCLAR VIVADENT AG

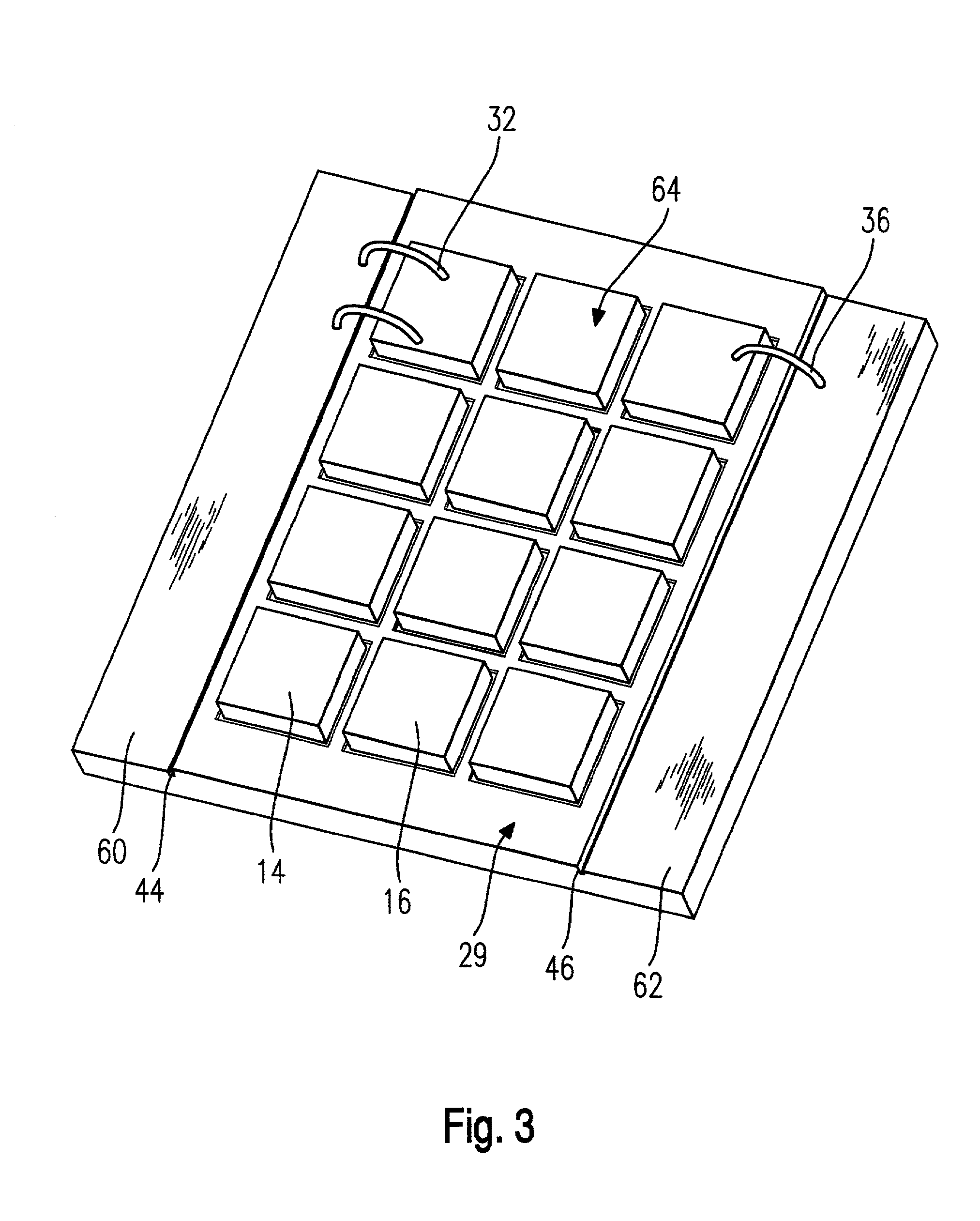

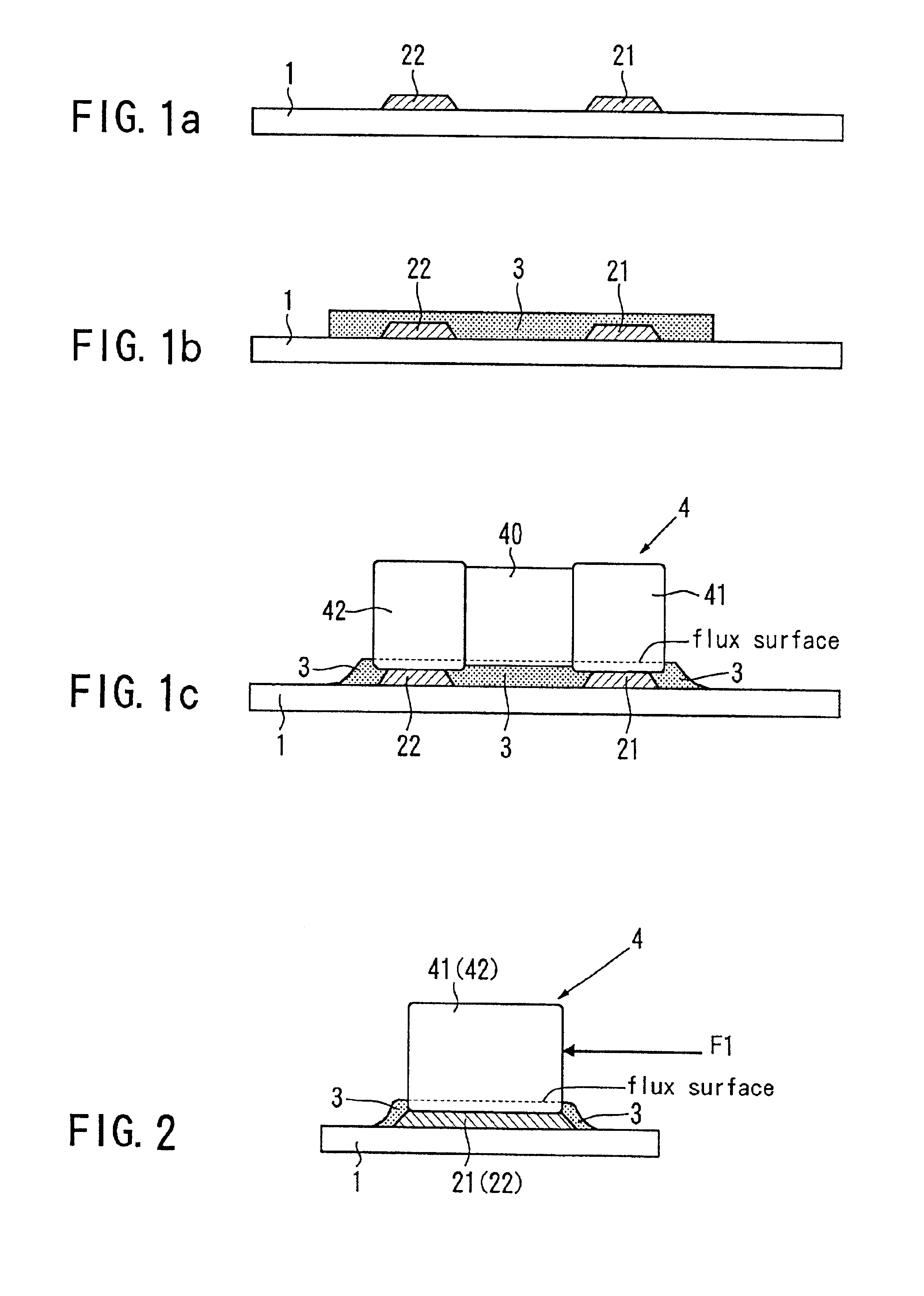

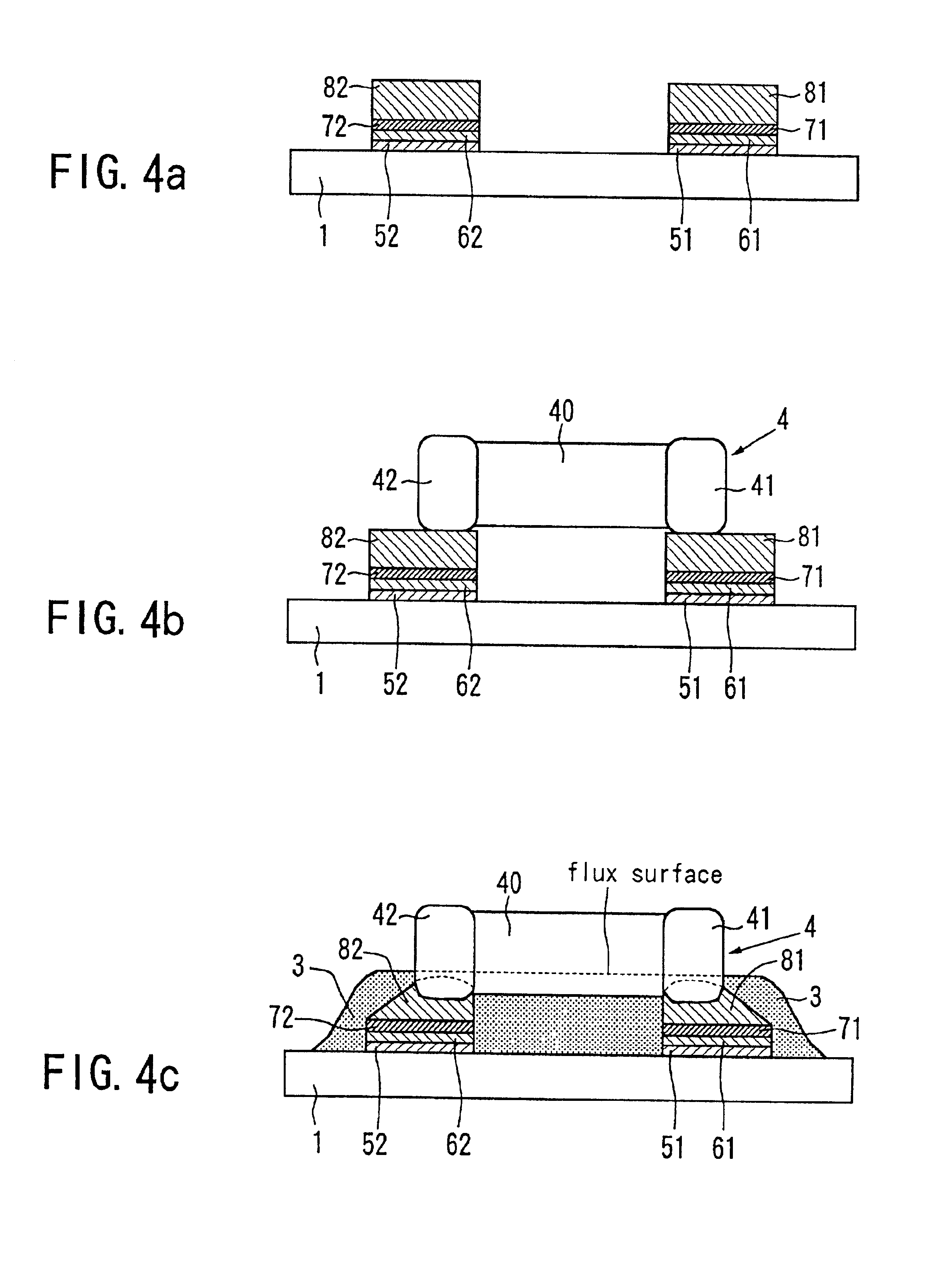

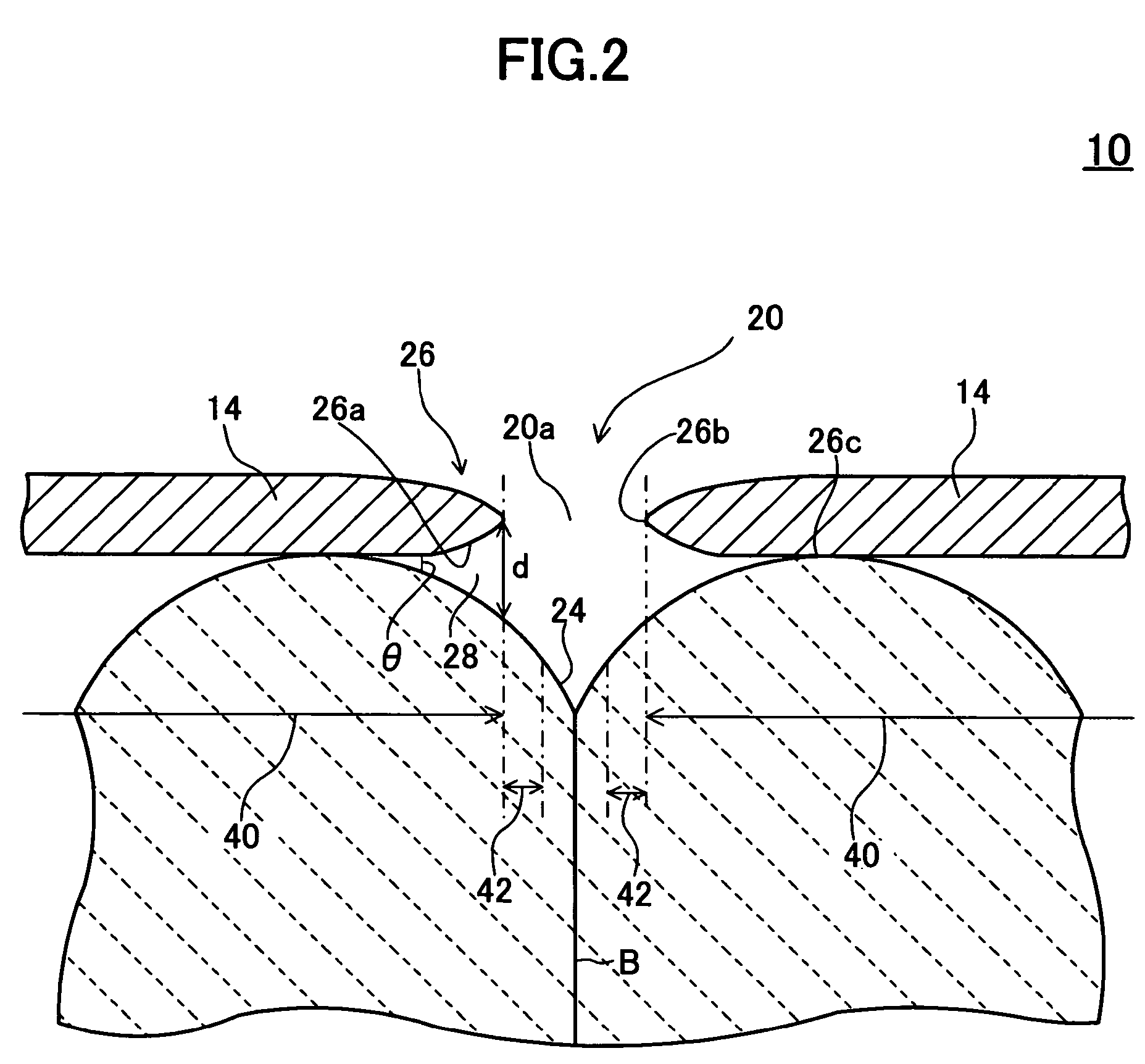

Soldering flux, solder paste and method of soldering

InactiveUS6915944B1High mounting densityReduce pitchPrinted circuit assemblingFinal product manufactureSolder pasteBonding strength

The present invention relates to a soldering flux, a soldering paste and a soldering method that achieve a sufficient degree of bonding strength even when components are mounted at a higher density, components are further miniaturized or components are mounted with a smaller pitch. A flux 3 contains an adhesive resin and a hardening agent. This flux or a soldering paste containing the flux is applied onto a component mounting board 1, and then, an electronic component 4 is mounted and soldered onto the component mounting board 1.

Owner:TDK CORPARATION

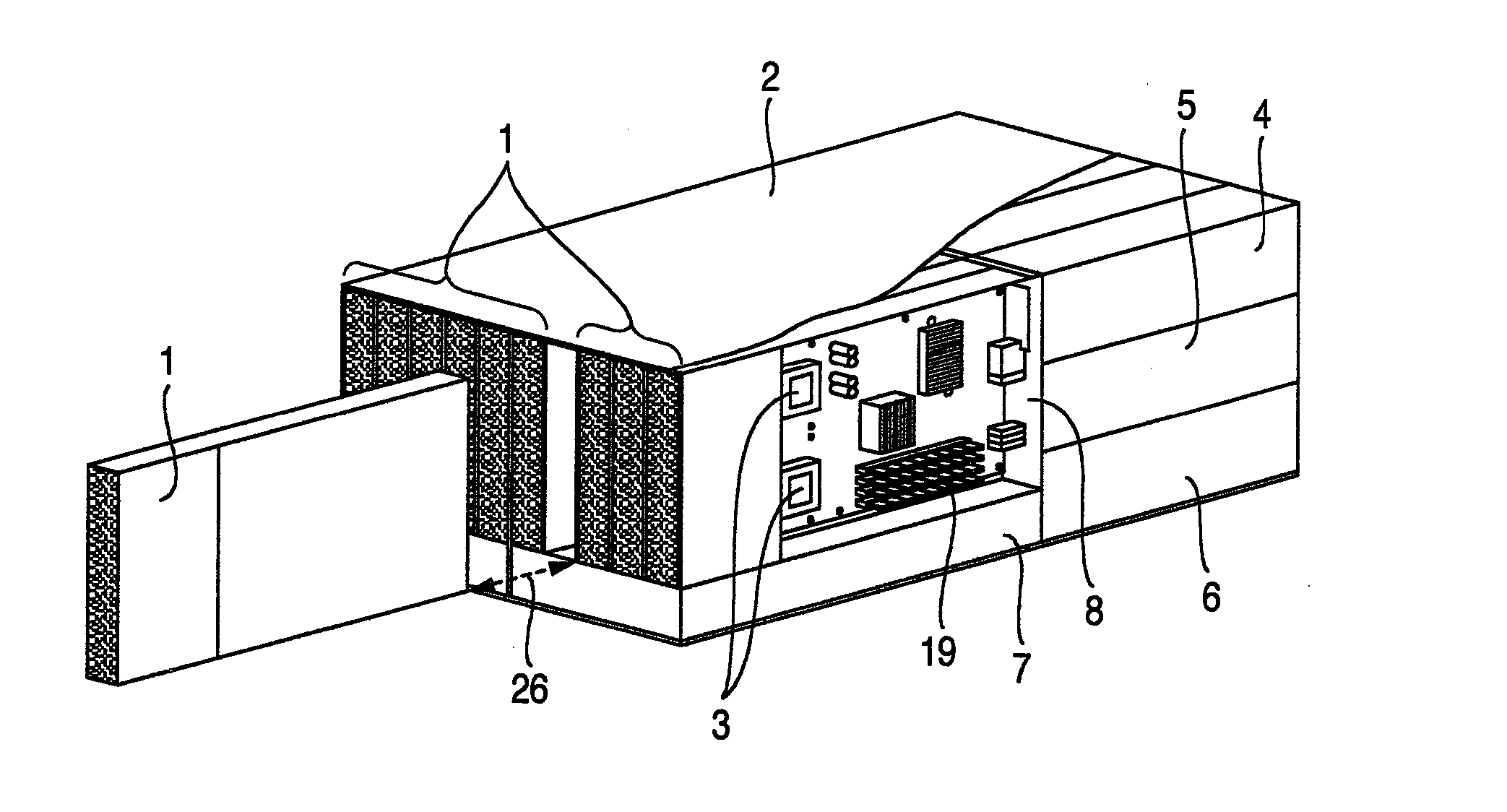

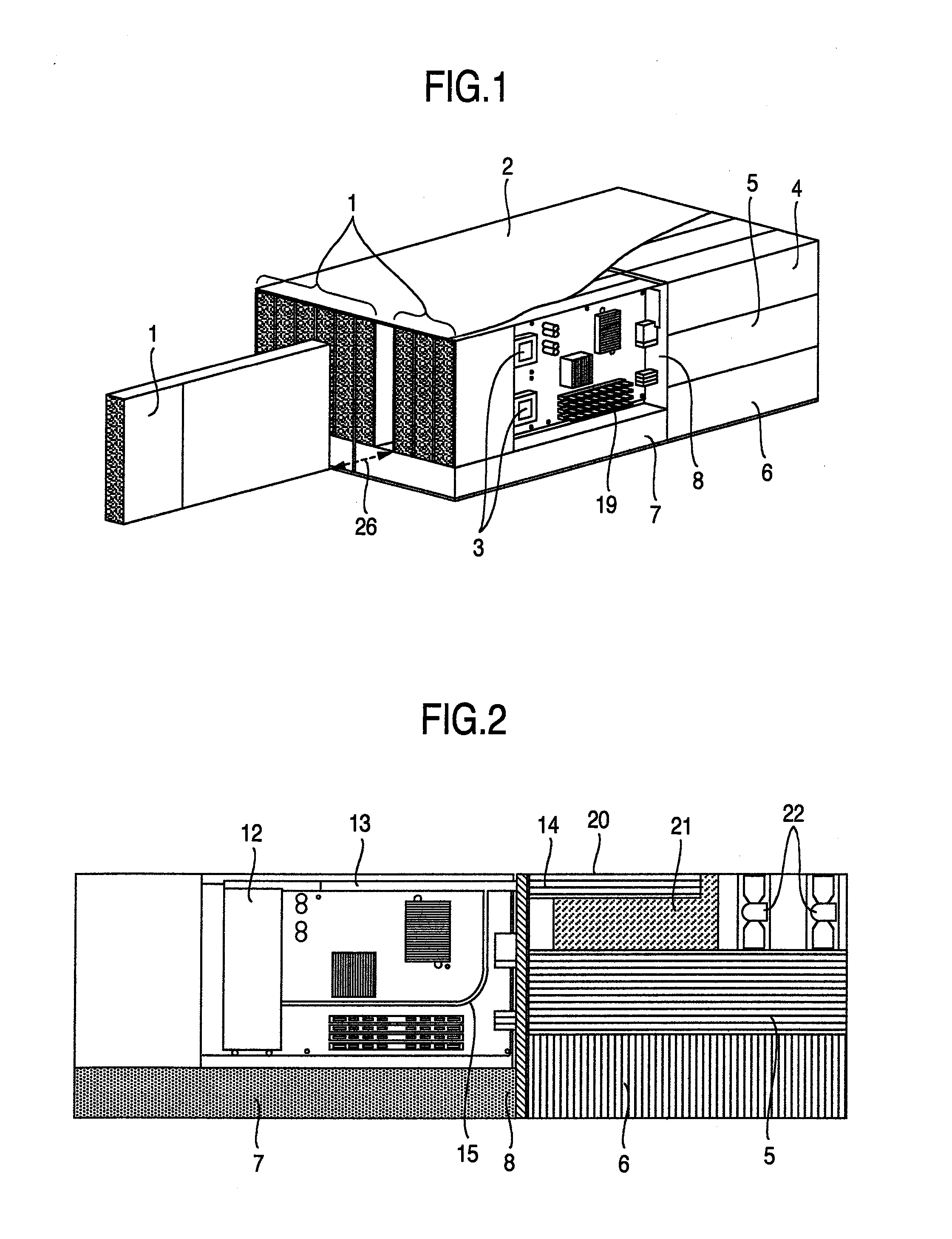

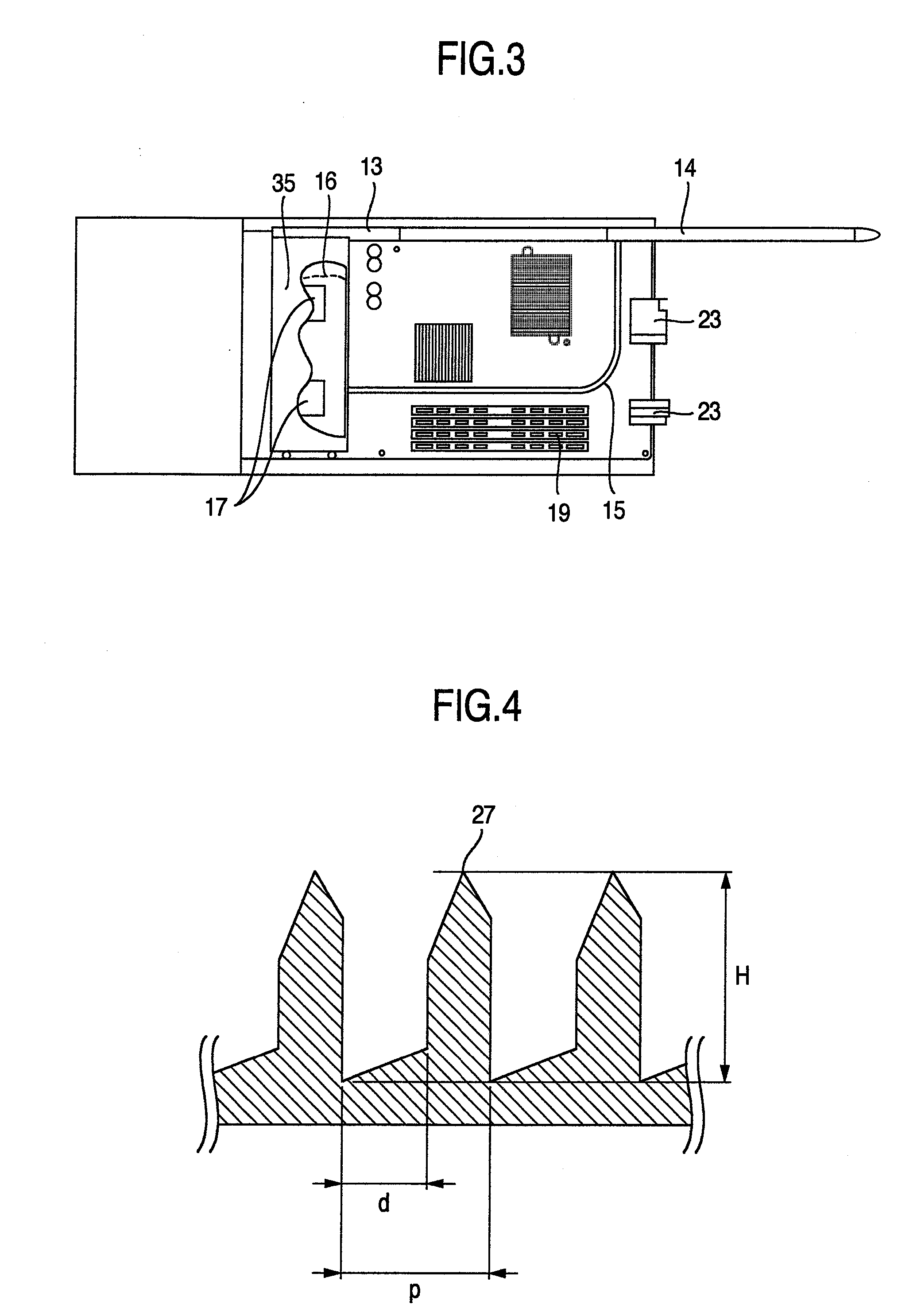

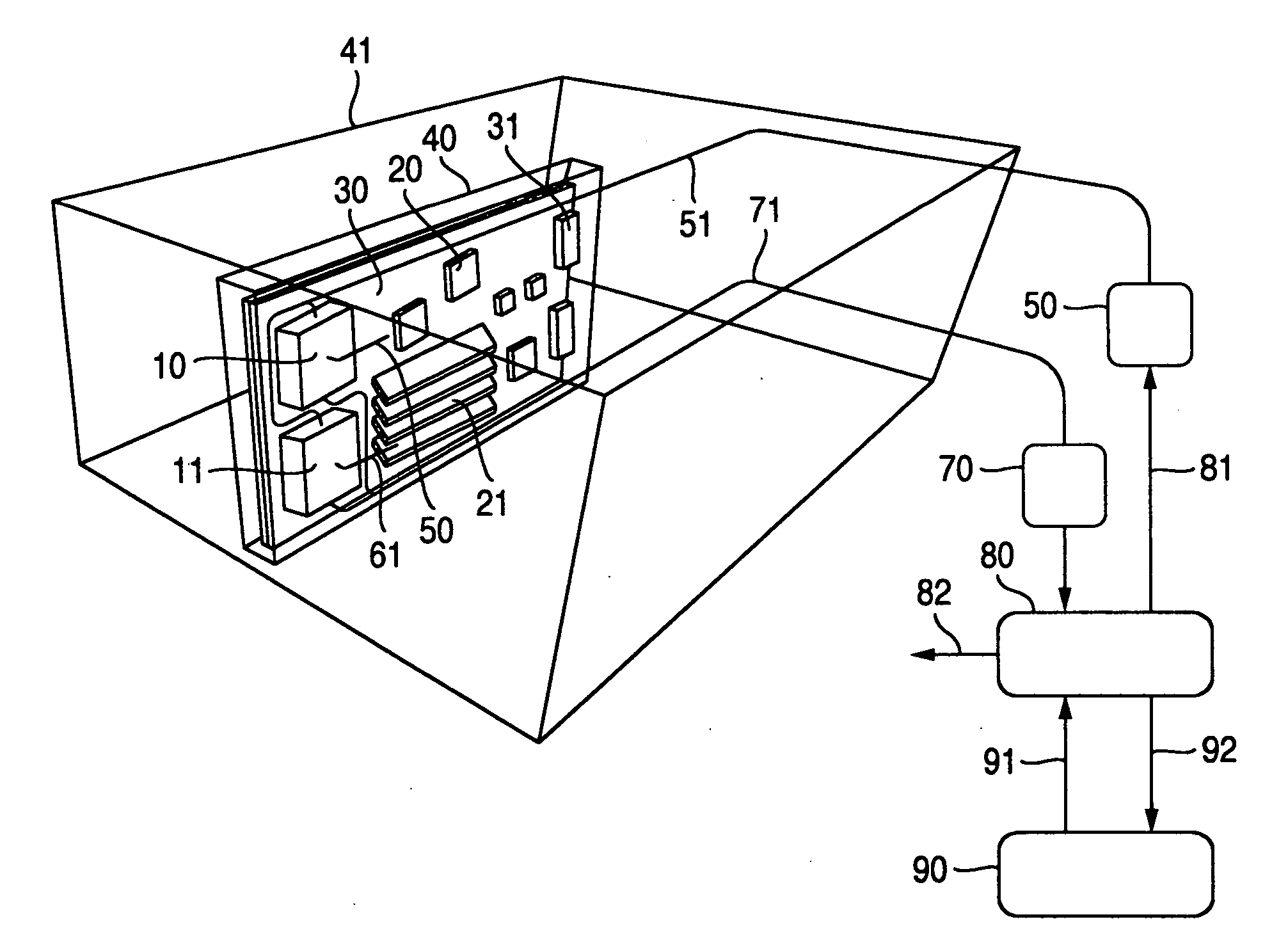

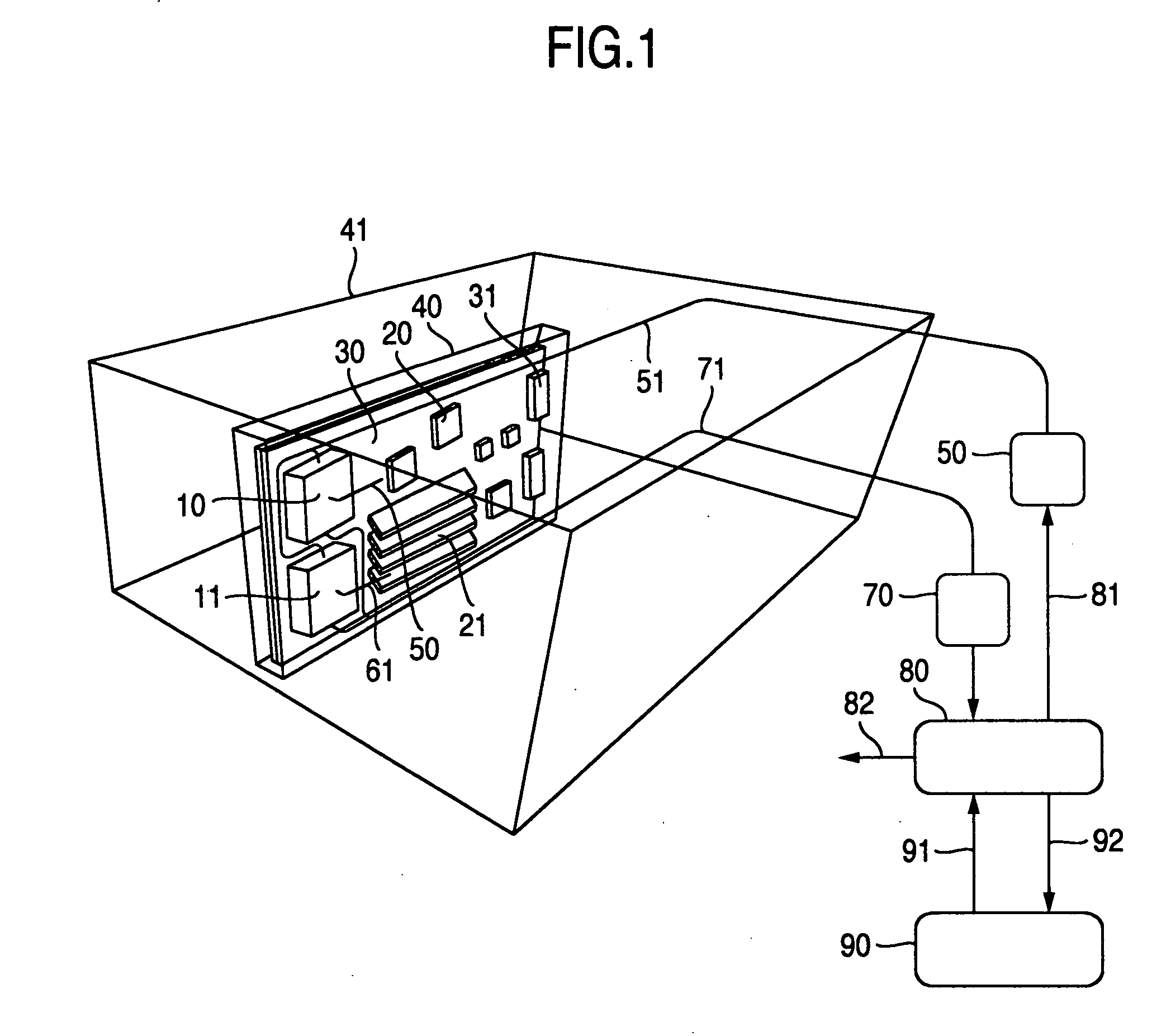

Cooling device and electronic equipment including cooling device

InactiveUS20100073866A1Improve installation densityReduce spacingDigital data processing detailsSolid-state devicesWorking fluidEngineering

A blade server including a cooling structure to be loaded with a CPU of high performance is provided. In order to enhance draining performance of a condensed working fluid which stays between fins, a vapor condensing pipe is used, in which grooves are formed in a direction substantially parallel direction with a pipe axis direction on the above described pipe inner surface, a section of a row of the above described fins is exposed on a side surface of the above described groove, the above described groove is disposed at a lower side in the vertical direction from the center line in the pipe axis direction of the vapor condensing pipe when the above described groove is installed in the above described vapor condensing pipe, and a wick with a wire space smaller than the fin space of the above described fin row is filled inside the above described groove.

Owner:HITACHI LTD

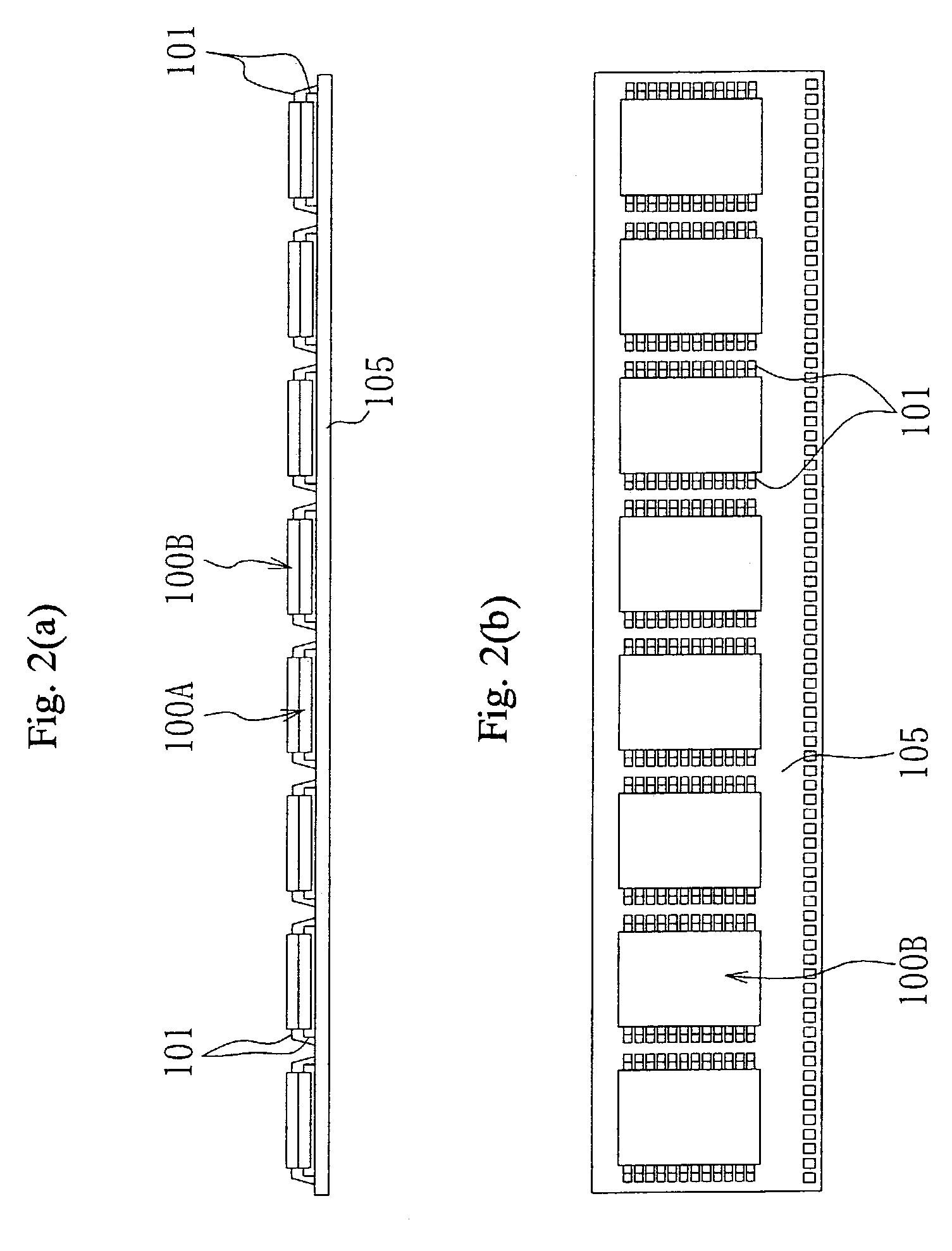

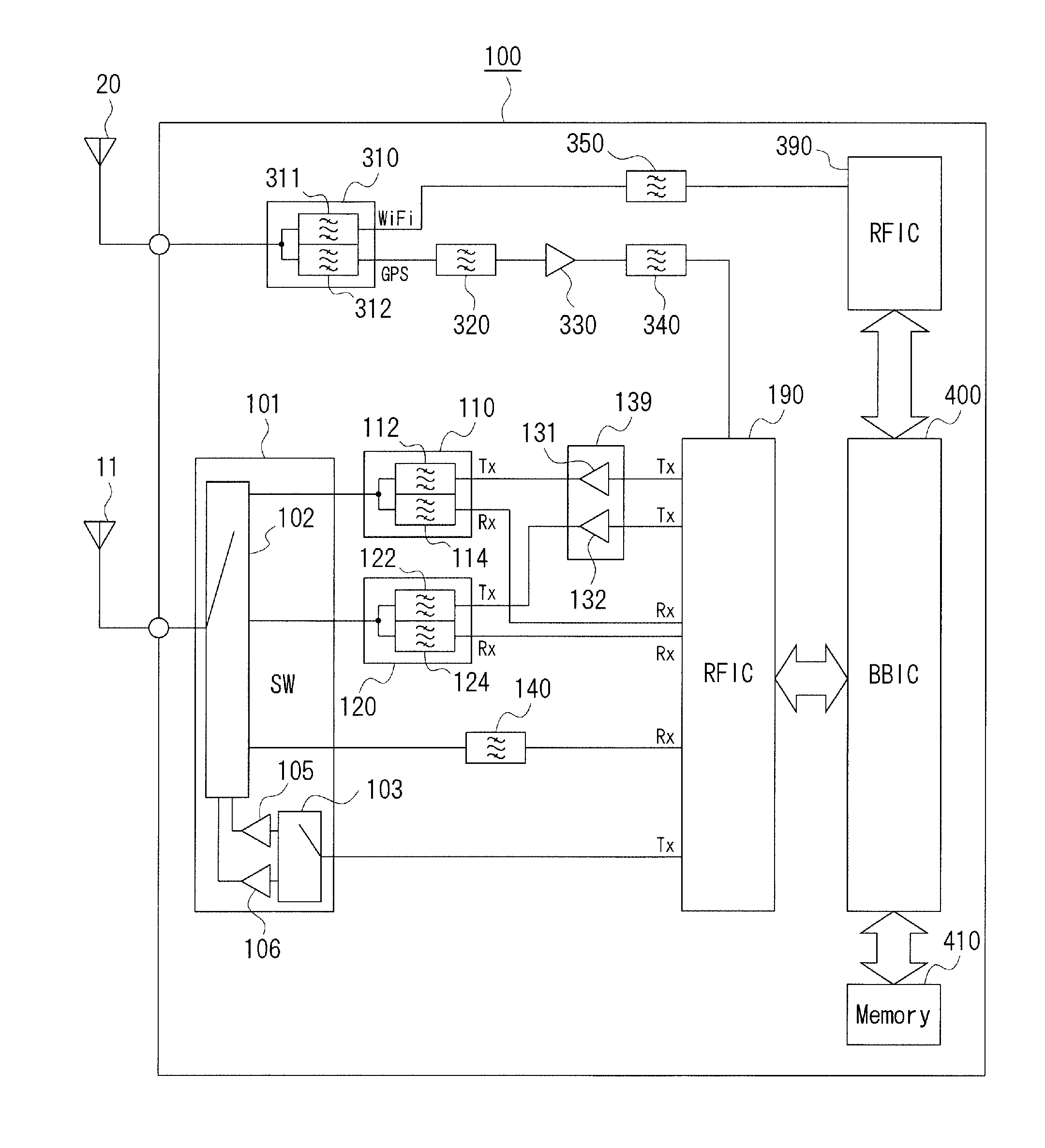

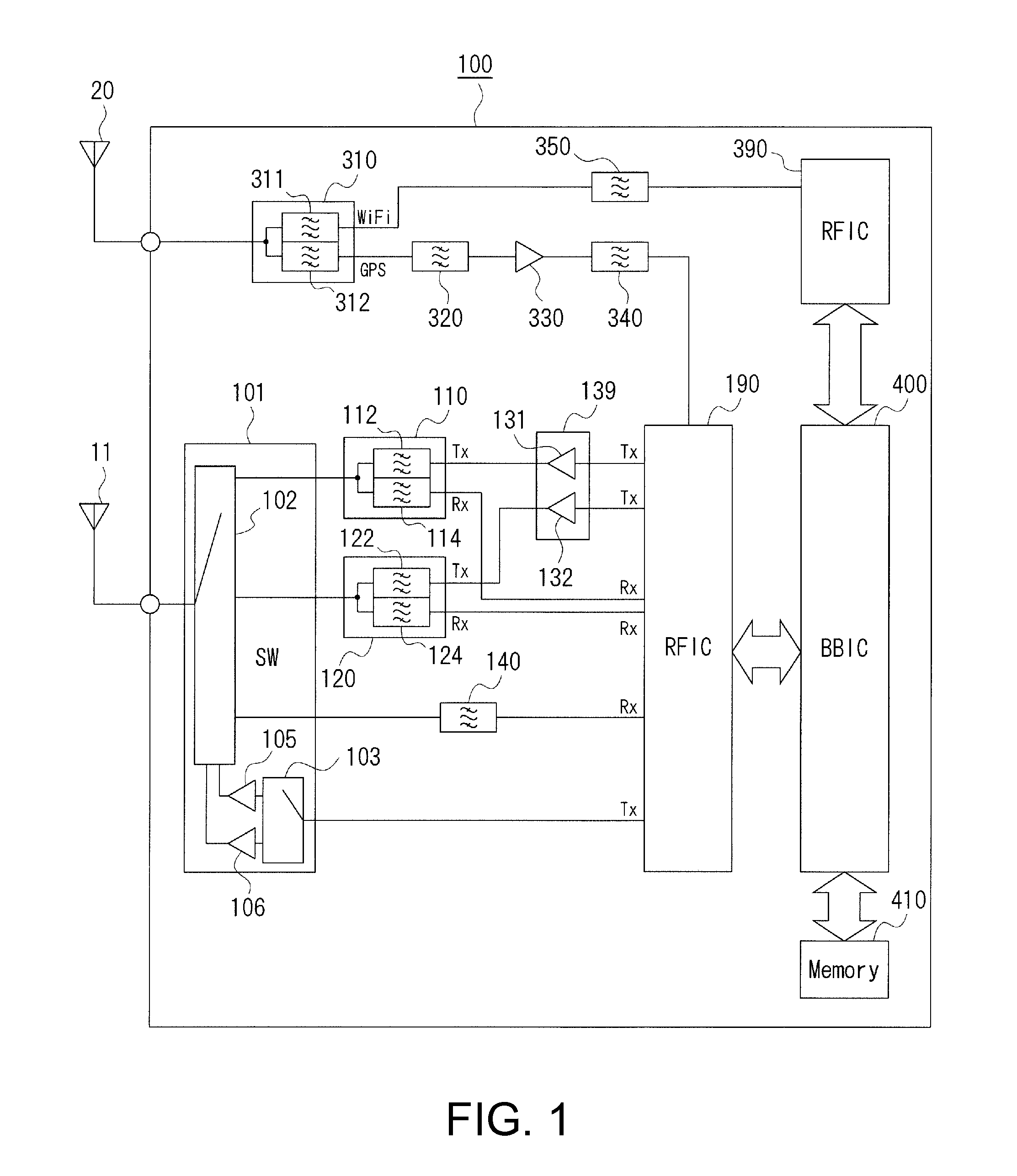

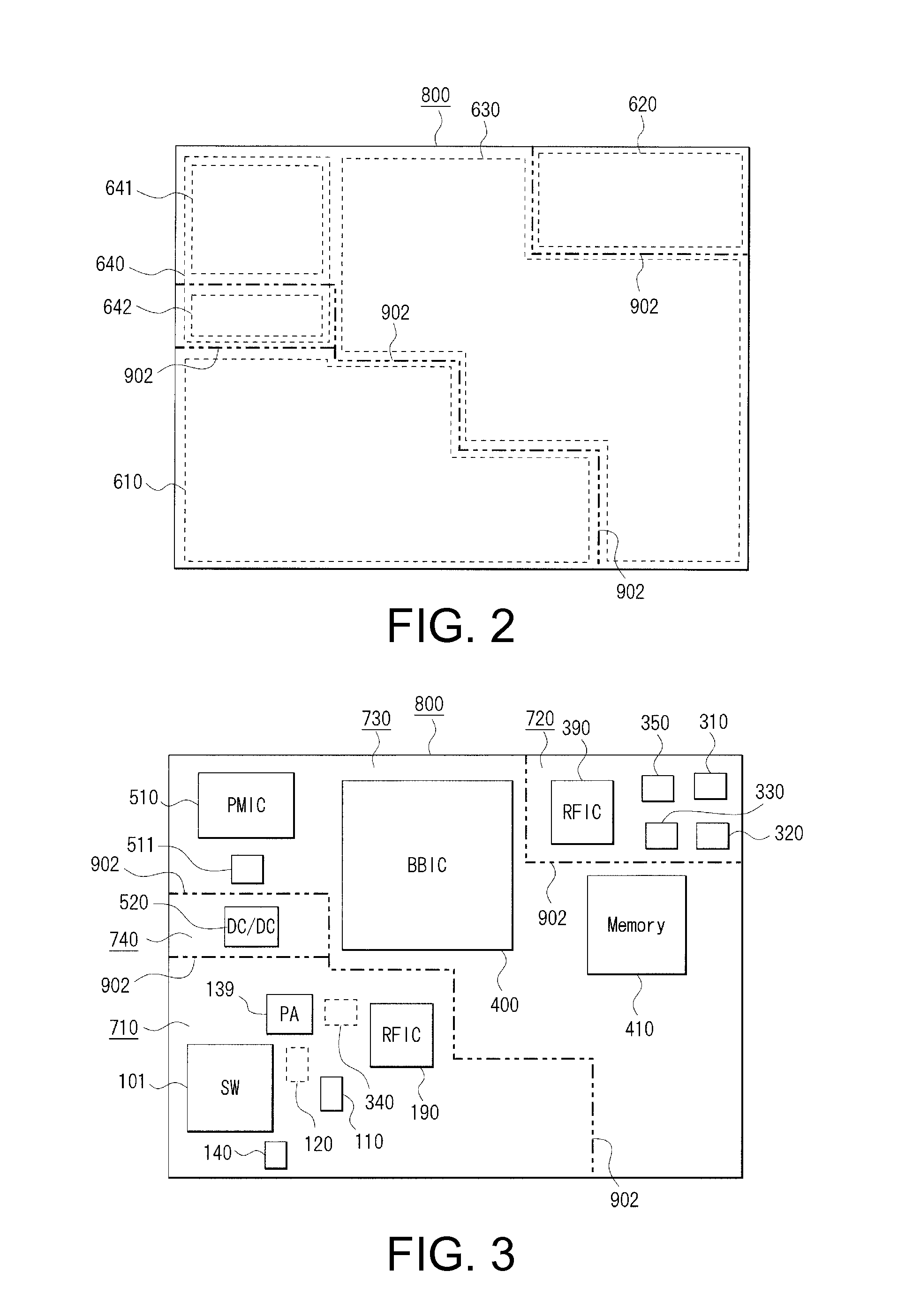

Communication module

ActiveUS20150119102A1Improve installation densityImprove cooling efficiencySemiconductor/solid-state device detailsCross-talk/noise/interference reductionComputer moduleElectronic component

A communication module includes a circuit substrate having a first high-frequency processing section related to mobile phone communication, a second high-frequency processing section that processes reception signals related to satellite positioning systems, a system section having a baseband processing section and application processing section, and a power circuit section, a sealing member covering the electronic components mounted on the circuit substrate, a conductive shield layer formed on a surface of the sealing member, and a shield wall formed in the sealing member so as to demarcate a mounting area of the first high-frequency processing section and a mounting area of the second high-frequency processing section.

Owner:TAIYO YUDEN KK

Electronic parts packaging structure

InactiveUS7843059B2Improve installation densityAvoid it happening againSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

In an electronic parts packaging structure of the present invention constructed by stacking a plurality of sheet-like units in a thickness direction, each of the units includes a first insulating layer, wirings formed on one surface of the first insulating layer, a semiconductor chip (electronic parts) connected to the wirings, a second insulating layer formed on an one surface side of the first insulating layer to cover the semiconductor chip, and connecting portions (terminals and contact vias) for connecting electrically the wirings and wirings of other unit, wherein arrangement of the first insulating layer, the semiconductor chip, the wirings, and the second insulating layer is symmetrical between units adjacent in a thickness direction.

Owner:SHINKO ELECTRIC IND CO LTD

Optical connection structure between optical backplane and circuit substrate

ActiveUS7585119B2Easy to processMounting density of the circuit substrate to the optical backplanePrinted circuit detailsFibre transmissionInformation processingComputer module

Information processing equipment includes a photoelectric conversion module disposed on a circuit substrate, a first optical connector connected to the photoelectric conversion module through a plurality of first optical fibers and disposed to an edge portion of the circuit substrate, and a second optical connector disposed on an optical backplane and optically connected to the first optical connector. The disposing direction of the optical fibers in the photoelectric conversion module is in nonparallel with the main surface of the circuit substrate and the disposing direction of the optical fibers in the first optical connector and the disposing direction of the optical fibers in the second optical connector are in nonparallel with the main surface of the circuit substrate.

Owner:NEC CORP

Evaporative cooling system

InactiveUS20080302505A1Increase latent heat flux LaImprove cooling efficiencySemiconductor/solid-state device detailsElectric propulsion mountingRefluxNuclear engineering

The evaporative cooling system comprises: evaporative cooling modules, a liquid supply system which comprises a liquid supply pump and a tube, and which supplies a refrigerant liquid to the evaporative cooling modules; an air supply system which comprises air supply tubes, and which supplies warm air to the evaporative cooling modules; an exhaust system which comprises an exhaust pump and a tube, and which exhausts air containing a refrigerant vapor from the evaporative cooling modules; a reflux system which comprises a primary heat exchanger and a reflux tube, and which condenses the refrigerant vapor to return the condensed refrigerant liquid to the liquid supply system; and a heat exhaust system which comprises a secondary heat exchanger and tubes, and which discharges heat absorbed from the primary heat exchanger.

Owner:HITACHI LTD

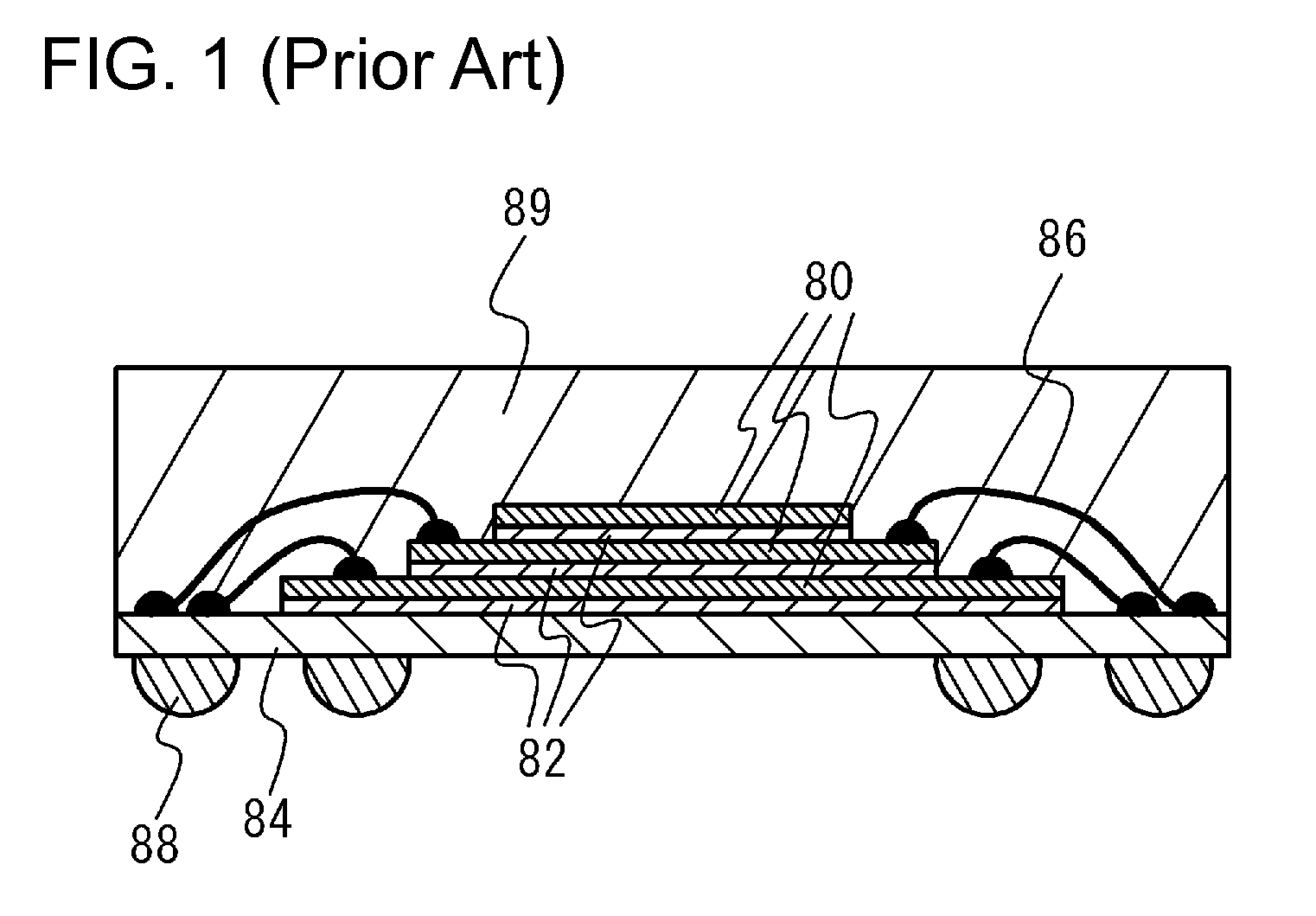

Semiconductor package and method for fabricating the same

InactiveUS20050205979A1Improve installation densityFunctionalSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package and method for fabricating the same is disclosed. In one embodiment, the semiconductor package includes a circuit board, at least two semiconductor chips, electric connection means, an encapsulant, and a plurality of conductive balls. The circuit board has a resin layer and a circuit pattern. The resin layer is provided with an opening at its center portion. The circuit pattern is formed on at least one of upper and lower surfaces of the resin layer and includes one or more bond fingers and ball lands exposed to the outside. The semiconductor chips have a plurality of input / output pads on an active surface thereof. The semiconductor chips are stacked at a position of the opening of the circuit board, with at least one of the chips being within the opening. Alternatively, both chips are in the opening. The electric connection means connects the input / output pads of the semiconductor chips to the bond fingers of the circuit board. The encapsulant surrounds the semiconductor chips so as to protect the chips from the external environment. The conductive balls are fusion-bonded on the ball lands of the circuit board.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Method for preparing highly heat-conductive copper-clad plate

ActiveCN101767481AHigh thermal conductivityImprove installation densityLamination ancillary operationsPolyureas/polyurethane adhesivesSolventPrinted circuit board

The invention relates to a method for preparing a highly heat-conductive copper-clad plate, which is realized by the following steps of: preparing gluewater; preparing a gluewater solution with the solid content of 60-90% by using a mixture of polyfunctional epoxy resin and polyurethane; taking an inorganic filler which adopts a mixture of aluminium nitride and aluminium oxide as the main contents, wherein aluminium nitride content accounts for 40-60 wt% of the total weight of the mixture, and aluminium oxide content accounts for 40-60 wt% of the total weight of the mixture; using the inorganic filler after being fully and uniformly mixed as the filler of the gluewater solution; using dicyandiamide as a curing agent, imidazole as an accelerating agent and acetone as a solvent to prepare the gluewater solution with the solid content of 60-80% and the gel time of 150-450 seconds for application; putting the gluewater solution into a glue mixer and then conveying the gluewater solution to a heating medium oil vertical gluing machine; and preparing a single-surface or double-surface copper-clad plate. The prepared copper-clad plate has high heat conductivity, capability of holding a higher installation density and excellent dimension stability, and can be used for preparing printed circuit boards with finer wiring and more layers.

Owner:SHANGHAI GUOJI ELECTRONICS MATERIALS CO LTD

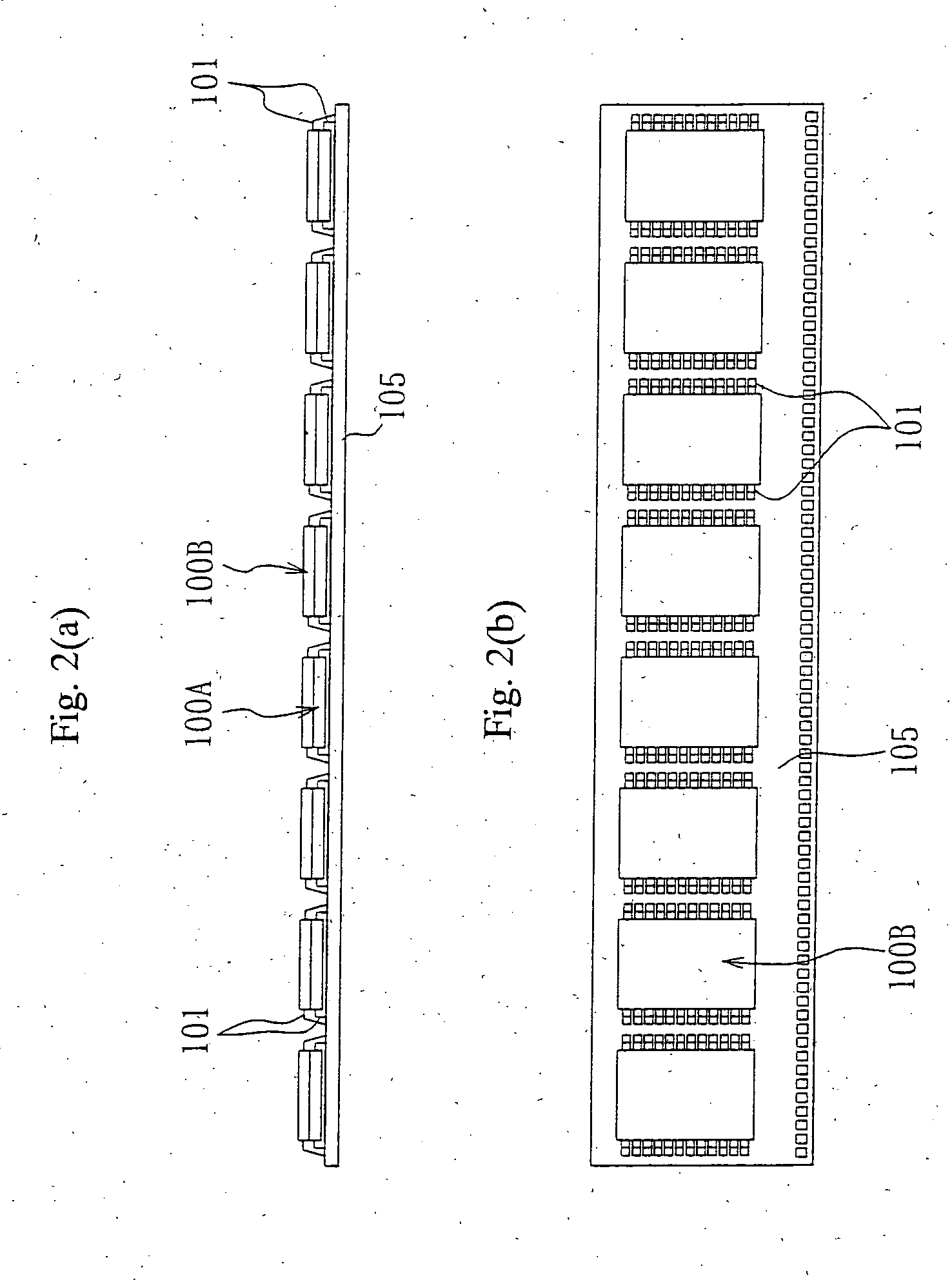

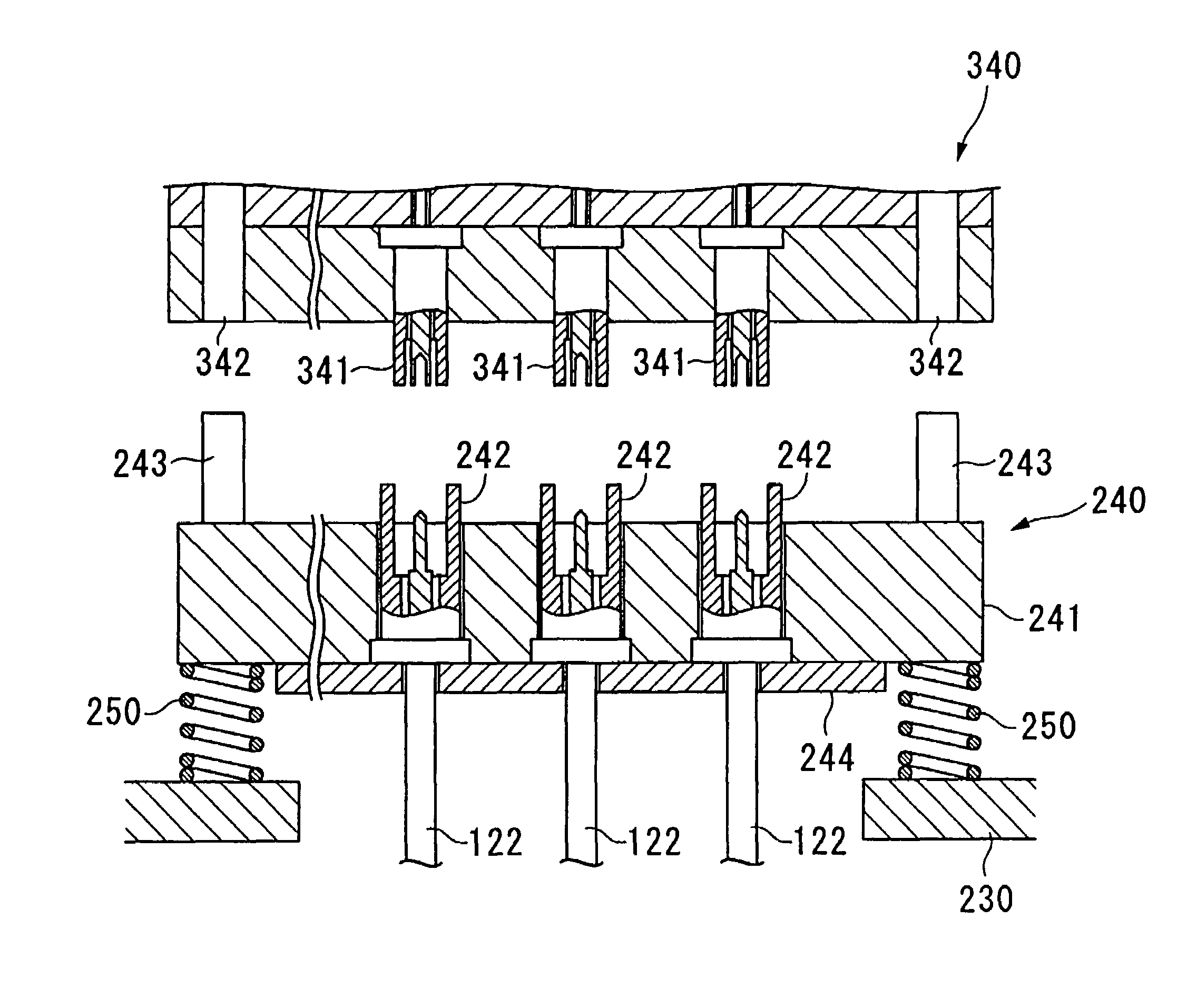

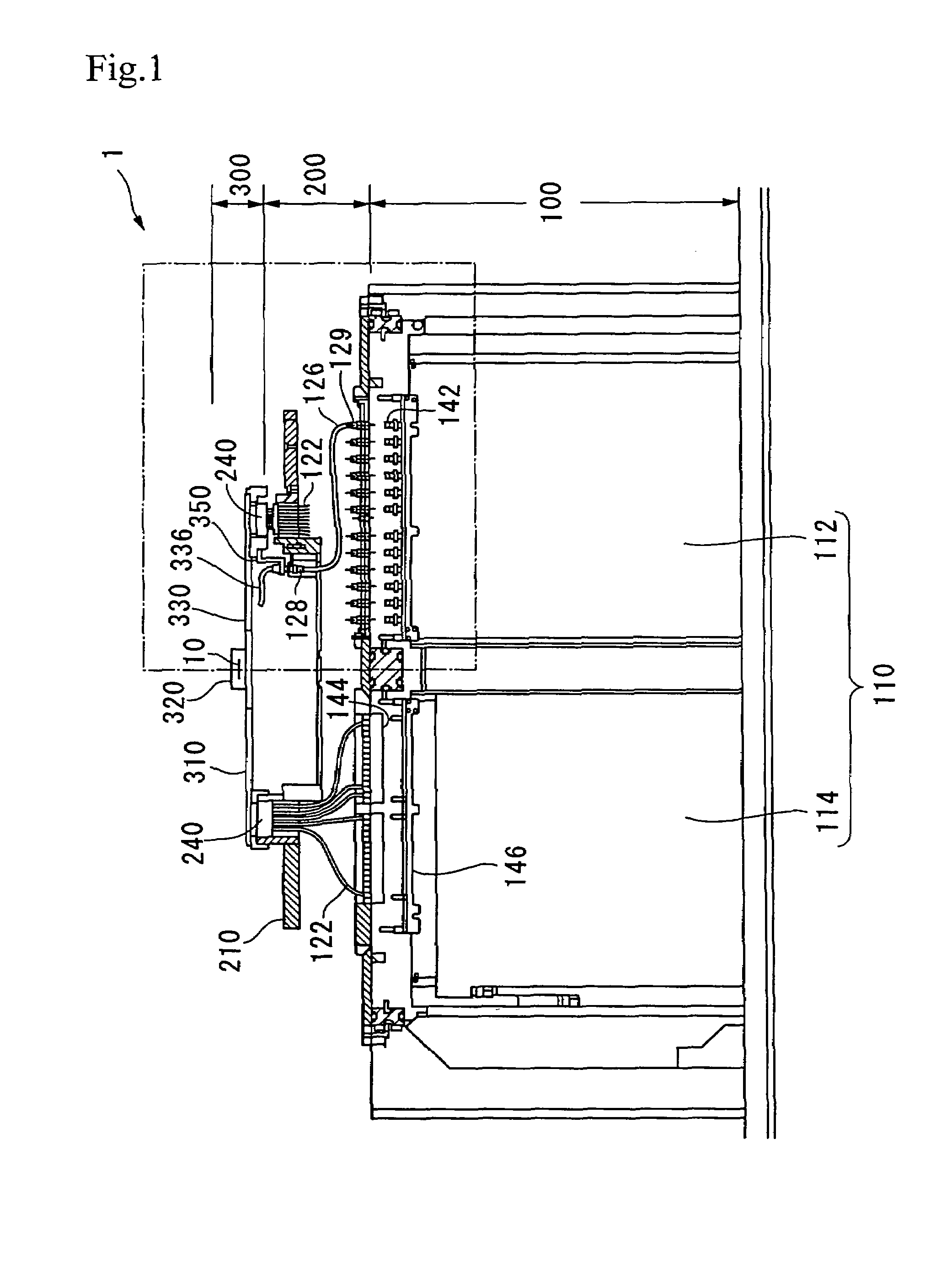

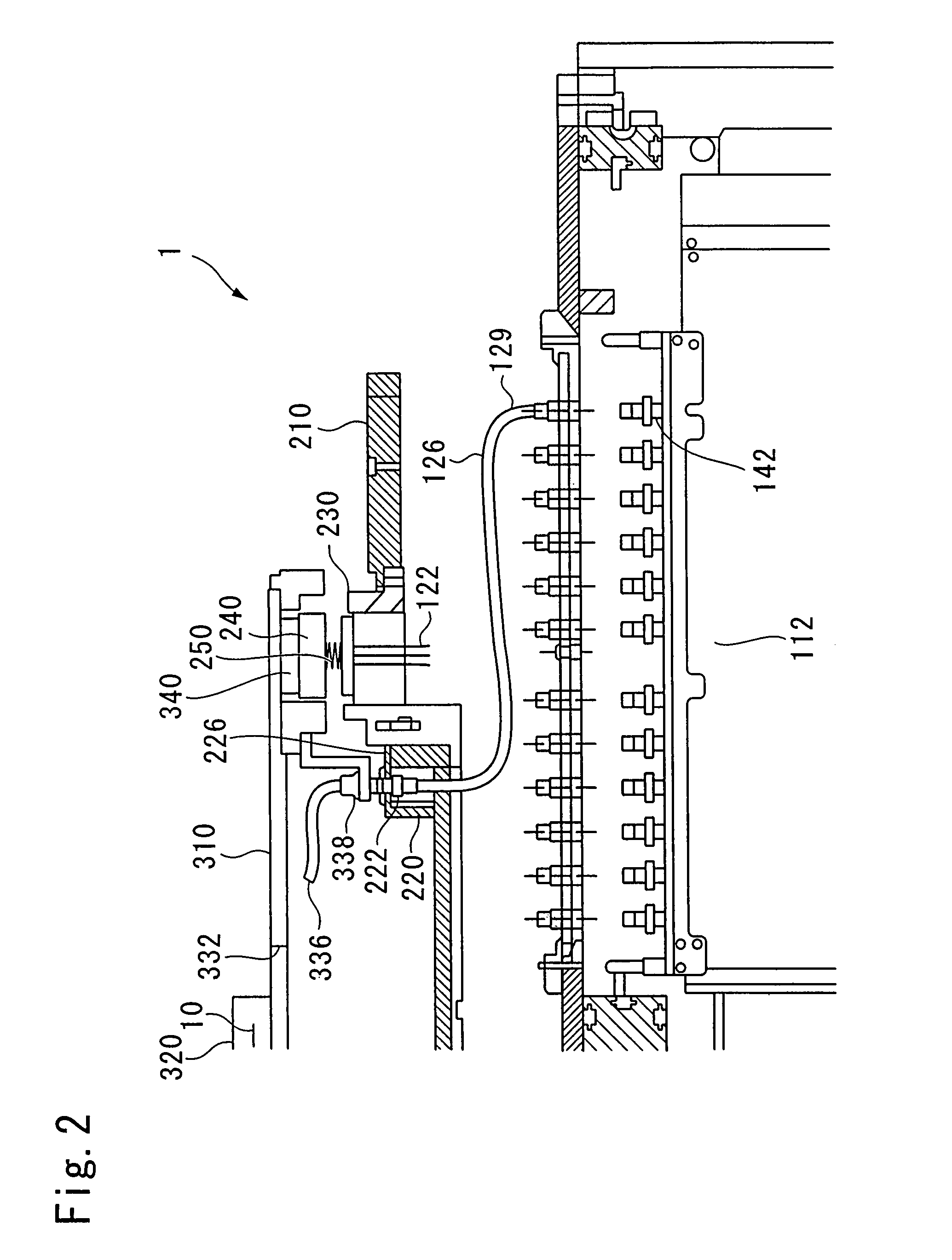

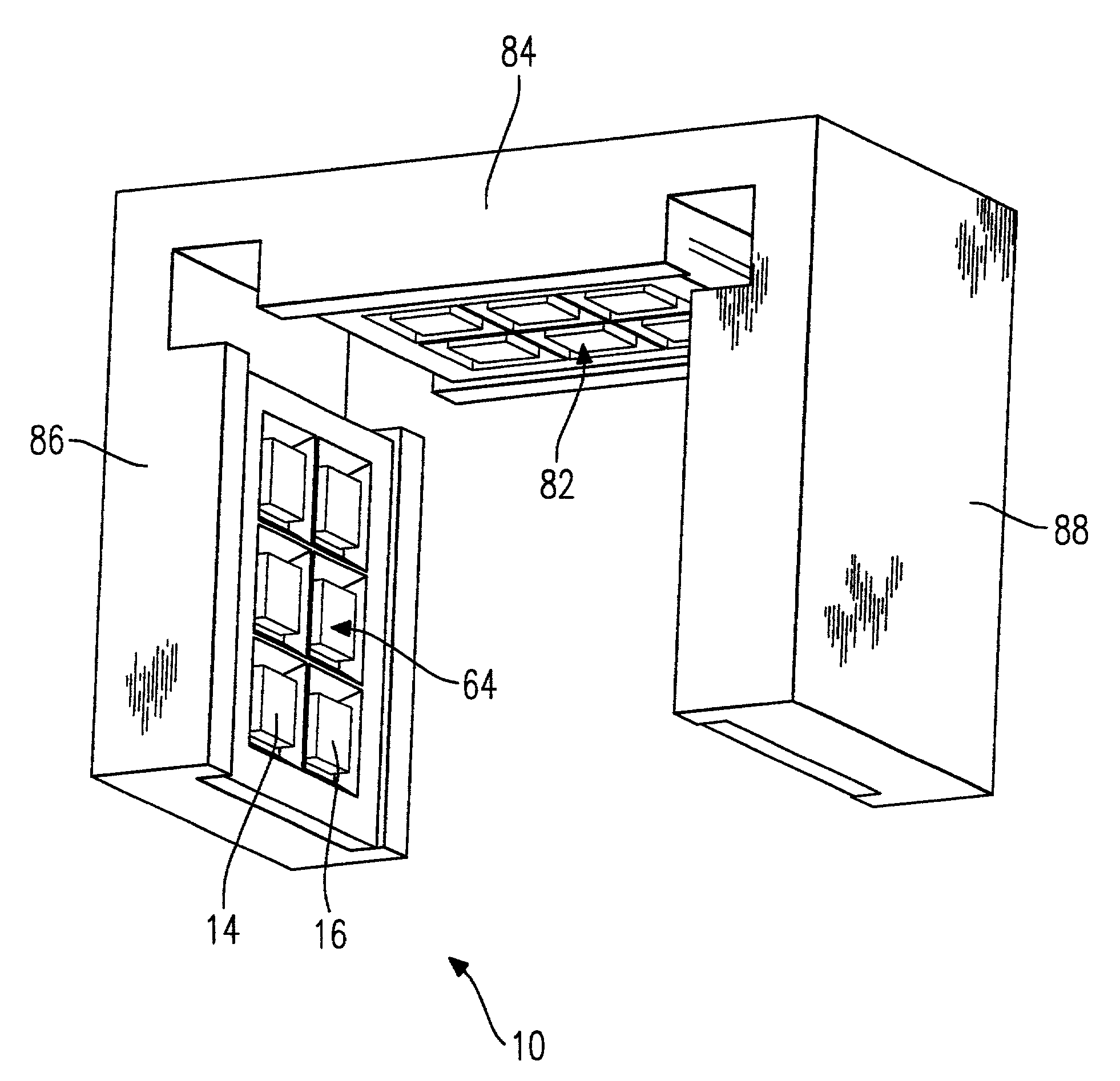

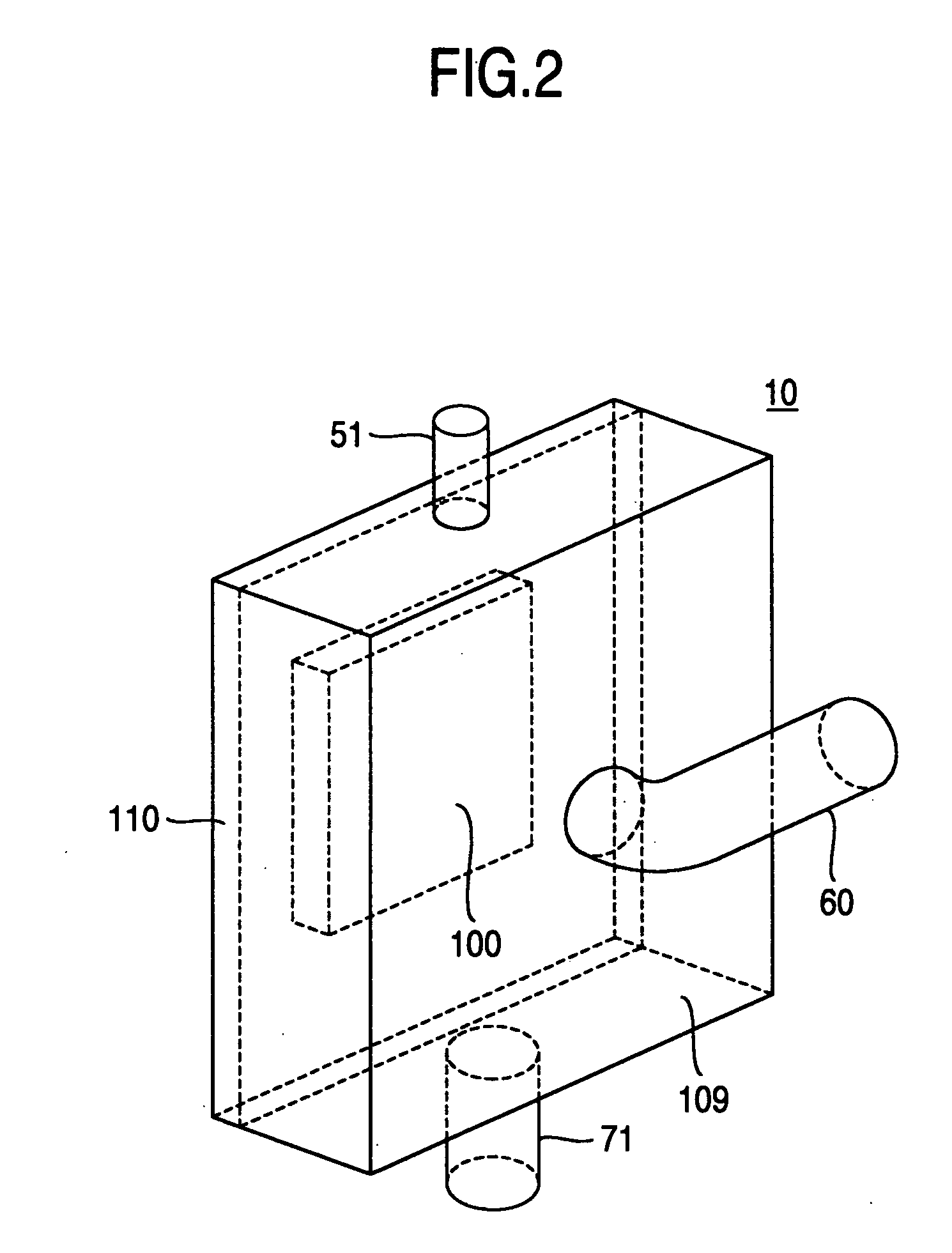

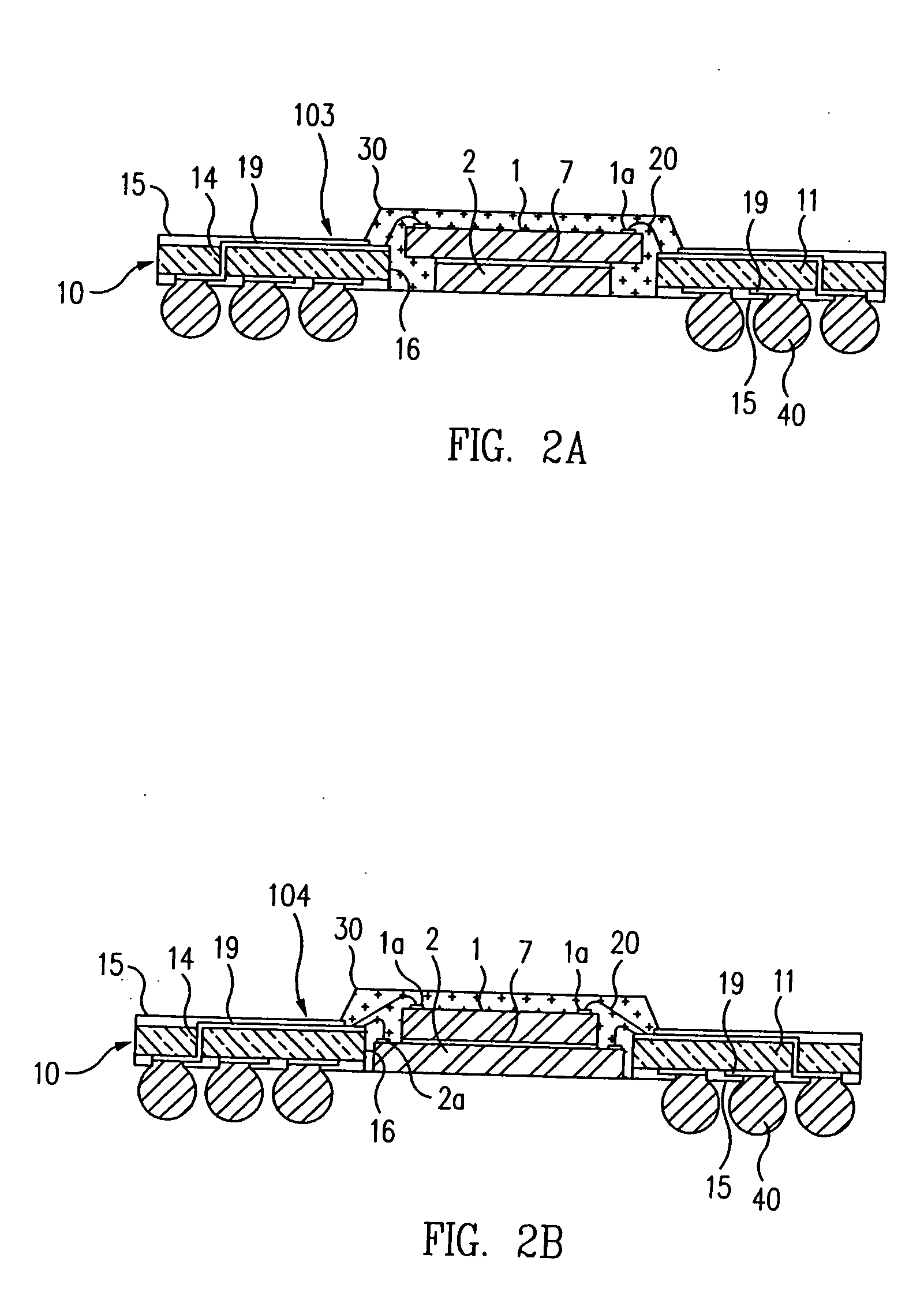

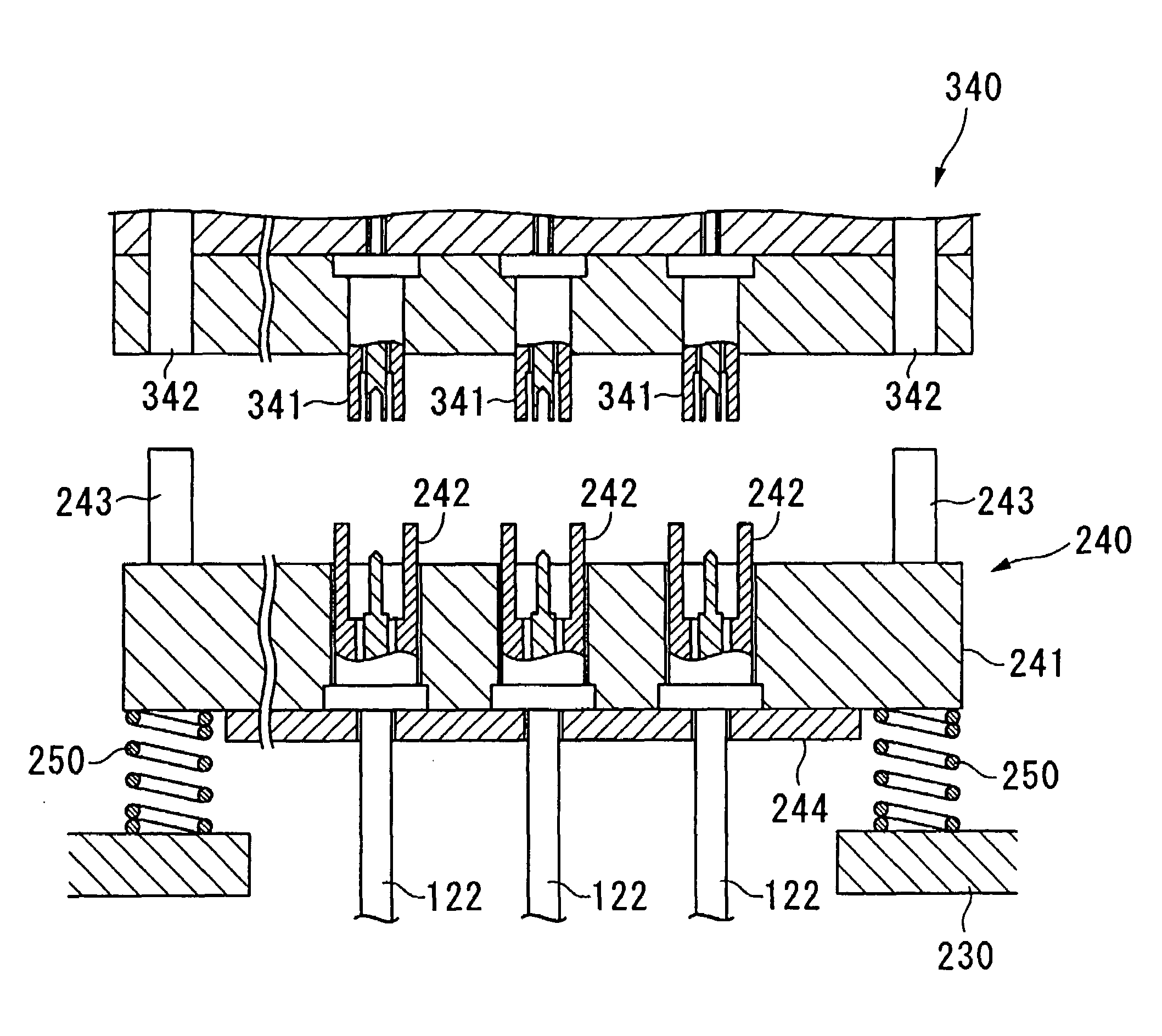

Connector housing block, interface member and electronic device testing apparatus

InactiveUS20070167083A1Reduce in quantityHigh densityElectric discharge tubesIncorrect coupling preventionCoil springEngineering

In a connector housing block 260 comprising an interface member 200 for electrically connecting a test head body 100 with sockets 320 in an electronic device testing apparatus, a connector housing 240 provided with a plurality of connector pins 242 in a non-floating state is attached to a block base 230 in a floating state via a coil spring 250. Due to the configuration, the number of parts of the connector housing 240 can be reduced, mounting density of the connector pins 242 can be improved, and a positional error of the connector housing 240 can be absorbed.

Owner:ADVANTEST CORP

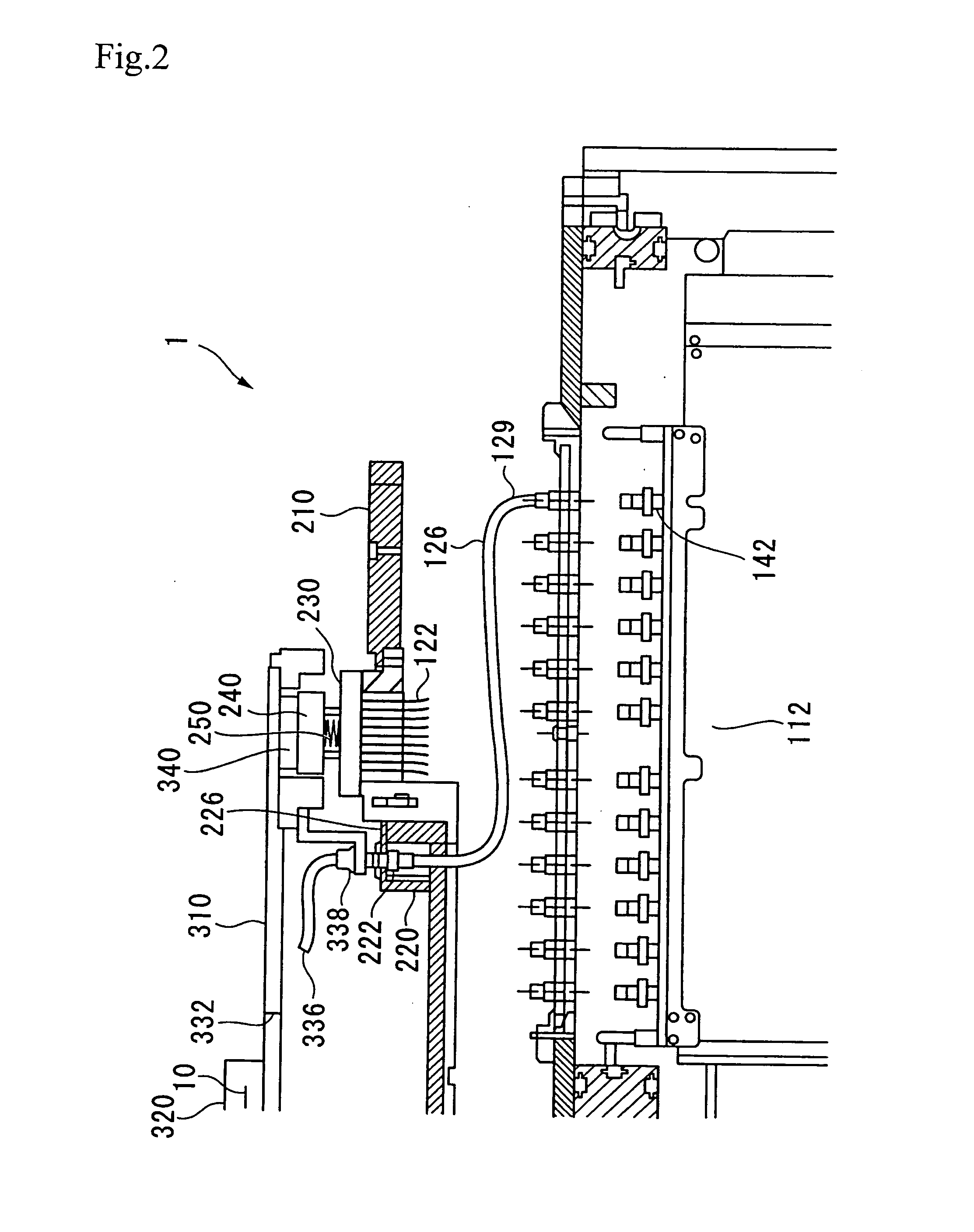

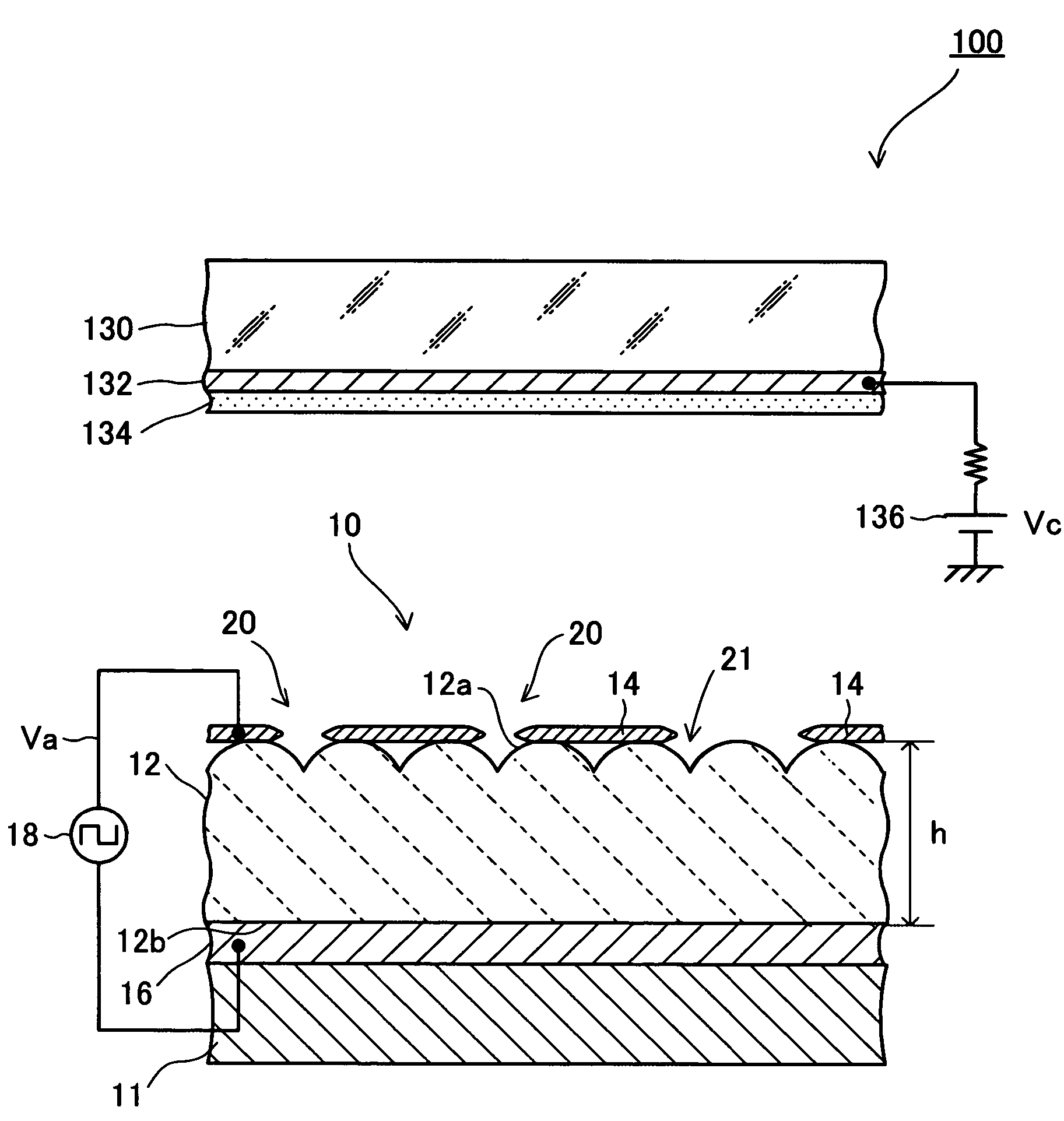

Electron emitter formed of a dielectric material characterized by having high mechanical quality factor

InactiveUS7723909B2Increase productionIncrease speedDischarge tube luminescnet screensNanoinformaticsThin layerElectron

A dielectric-film-type electron emitter includes an emitter section, a first electrode, and a second electrode. The emitter section is formed of a thin layer of a polycrystalline dielectric material. The dielectric material constituting the emitter section is formed of a material having high mechanical quality factor (Qm). Specifically, the dielectric material has a Qm higher than that of a so-called low-Qm material (a material having a Qm of 100 or less). The Qm of the dielectric material is preferably 300 or more, more preferably 500 or more.

Owner:NGK INSULATORS LTD

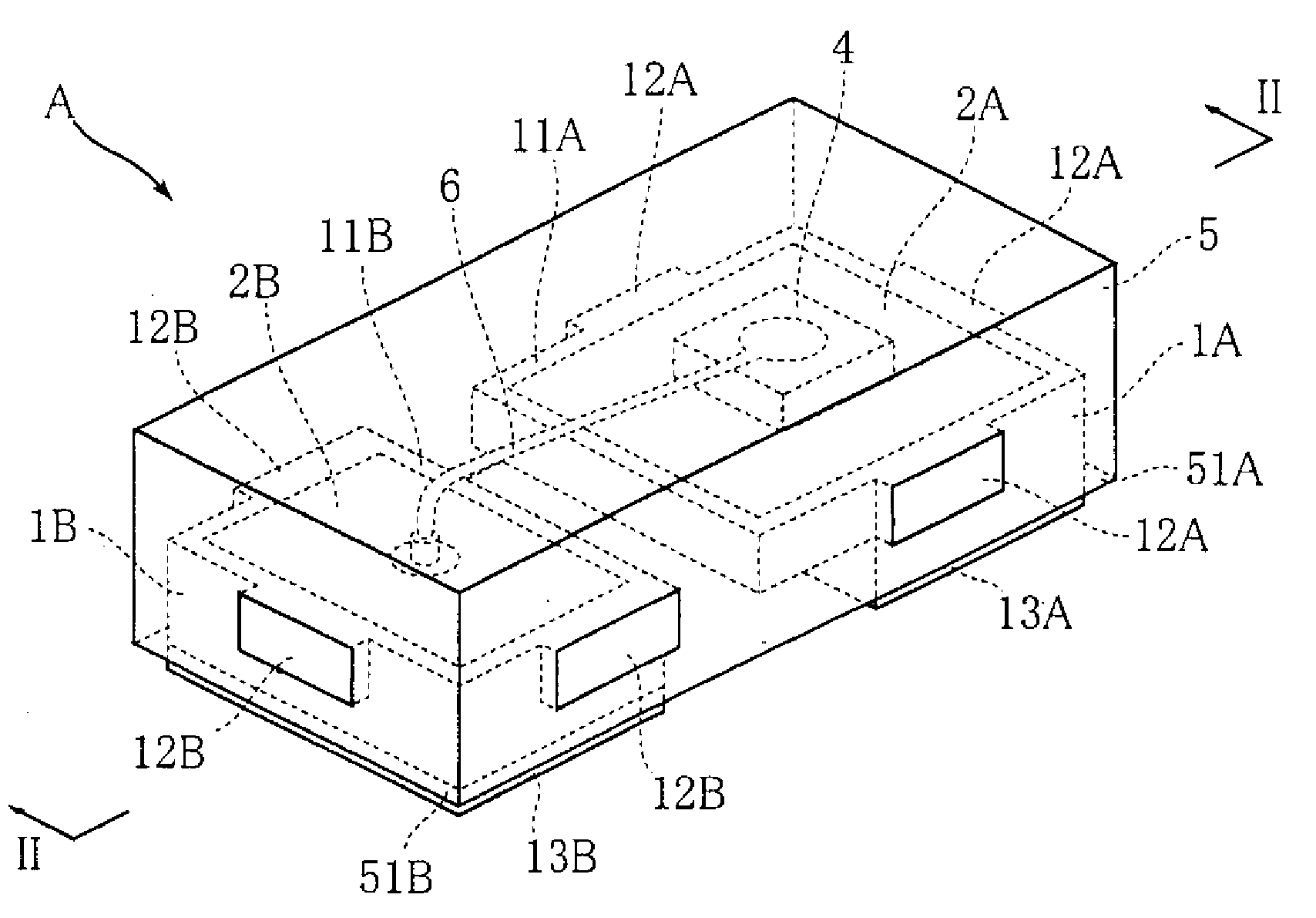

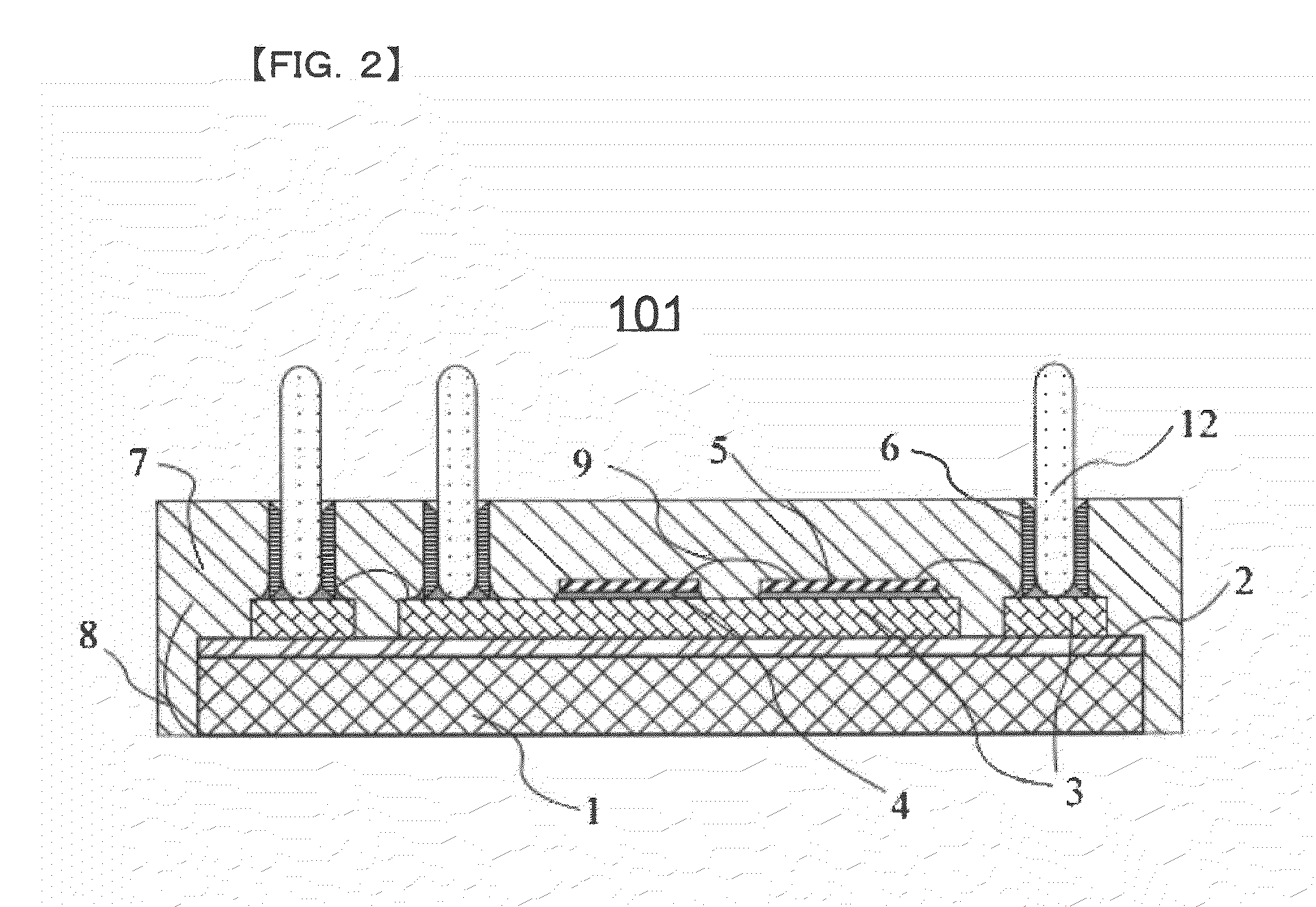

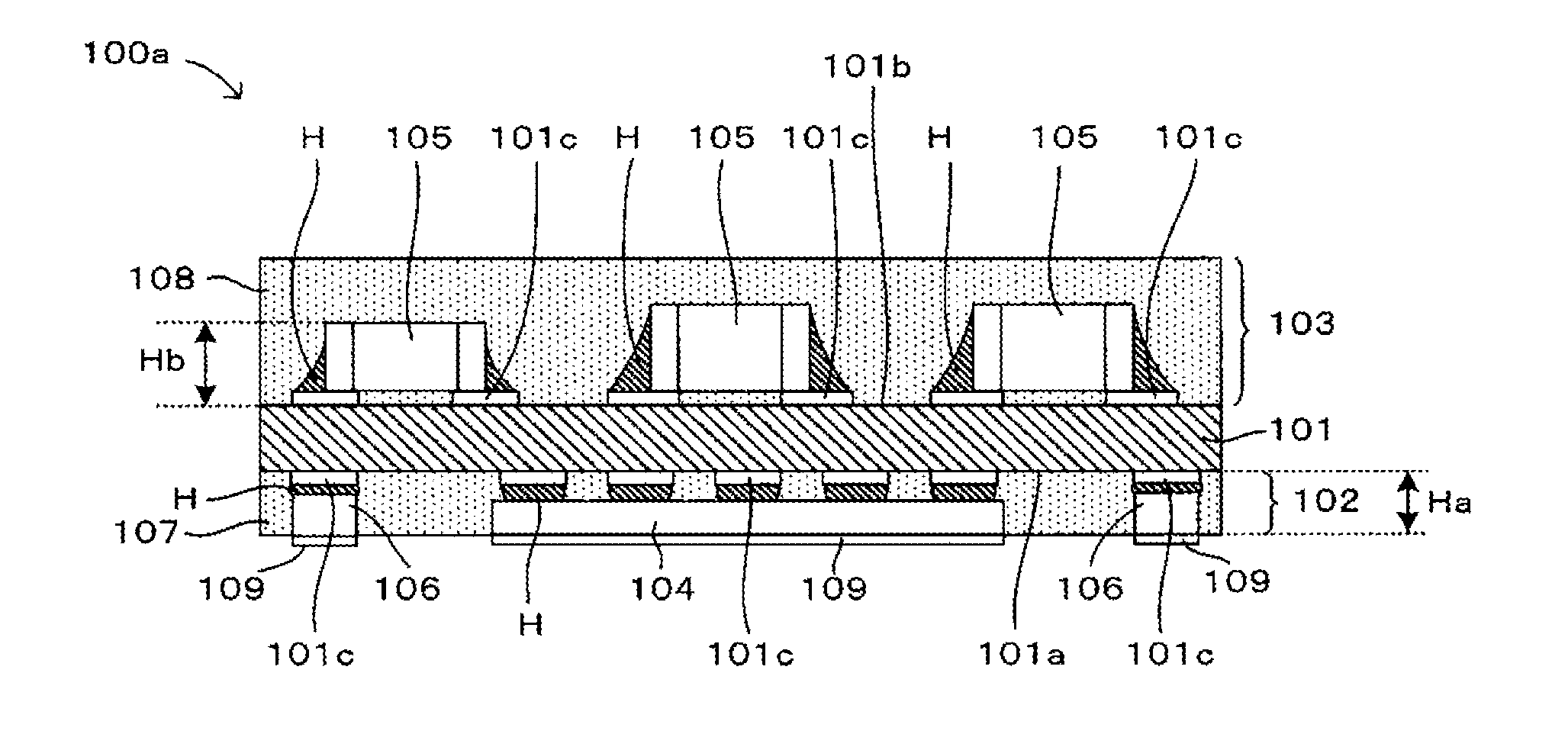

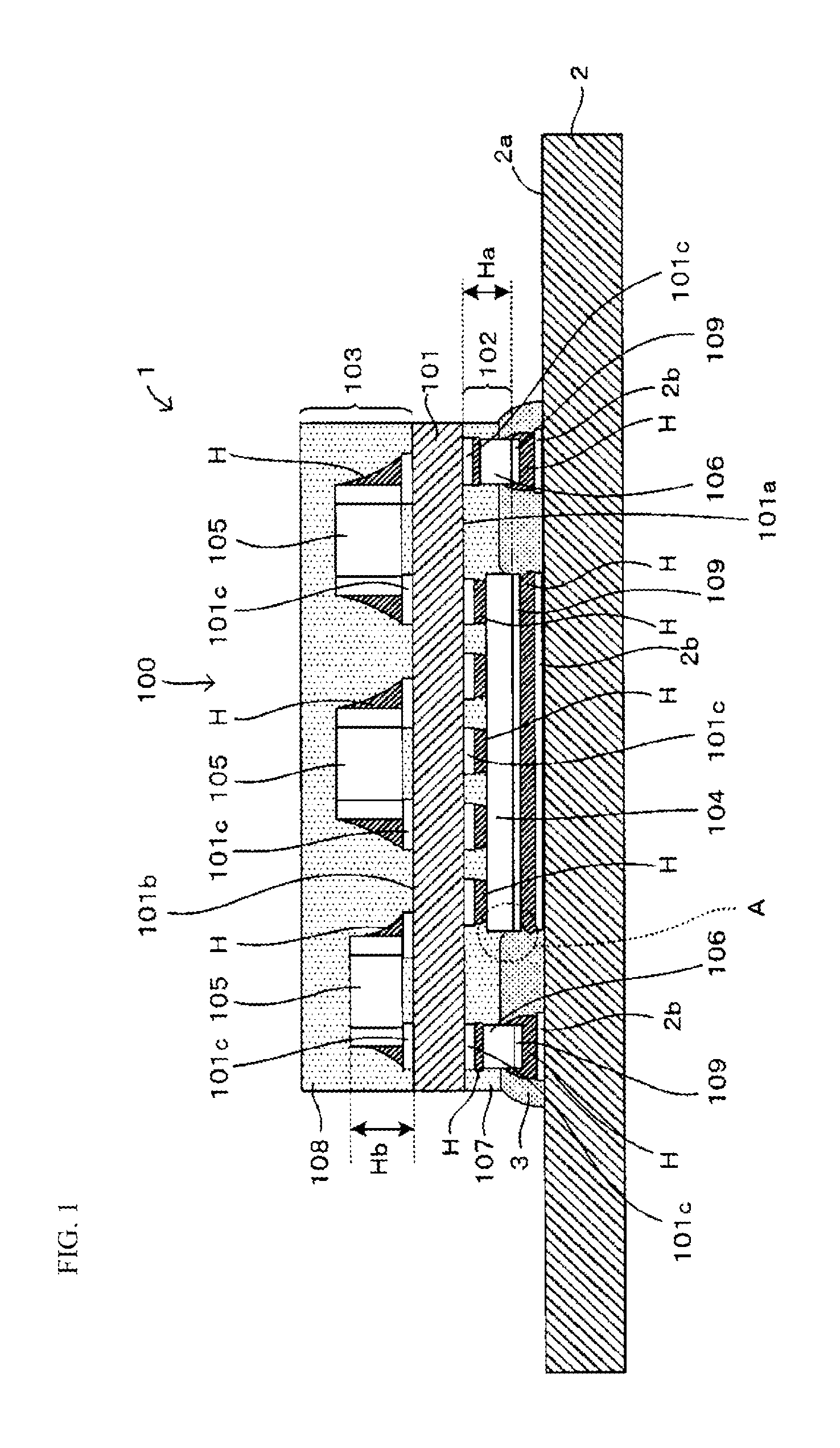

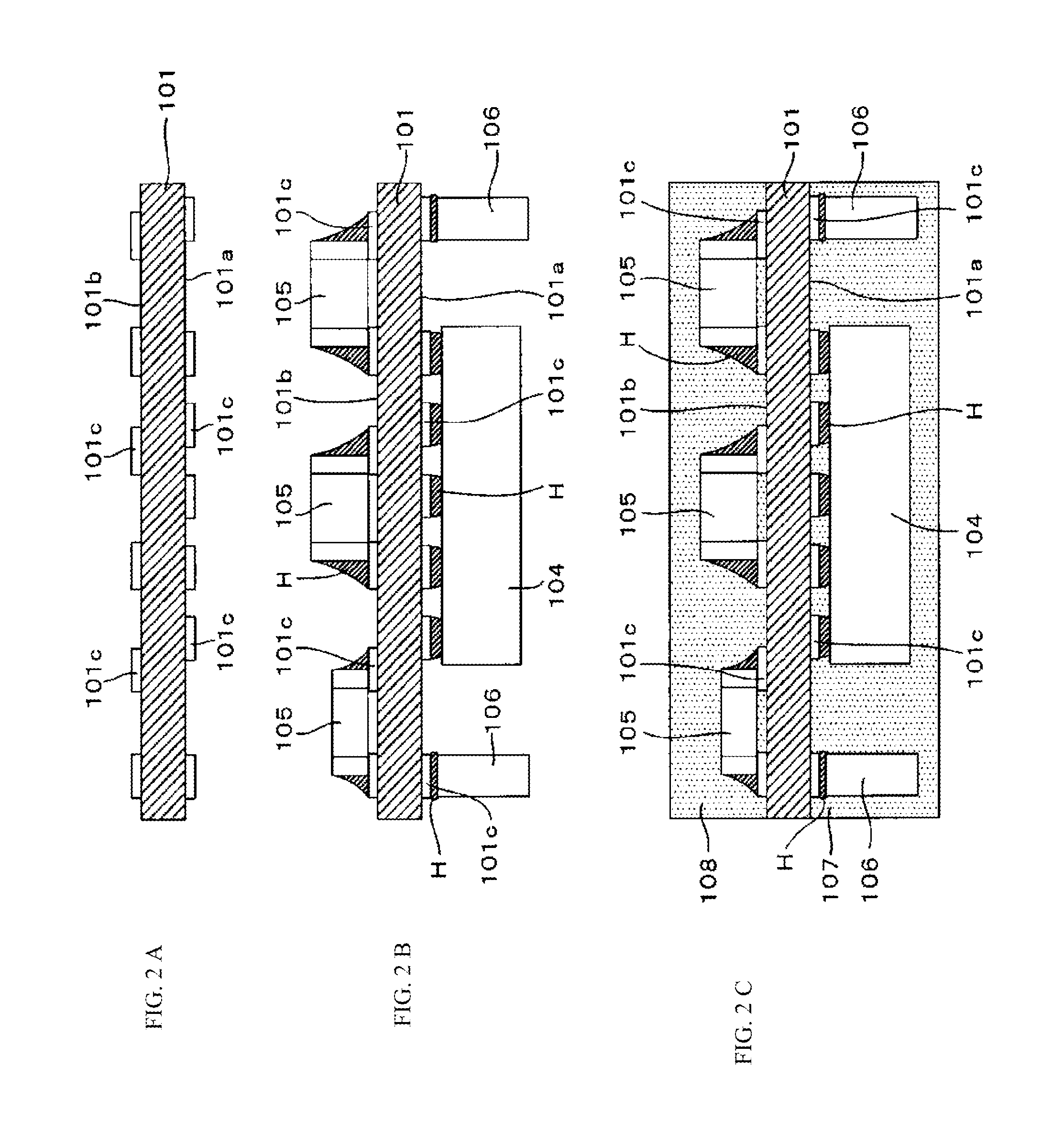

Module

ActiveUS20150179621A1Function increaseImprove installation densitySemiconductor/solid-state device detailsSolid-state devicesSpiteSemiconductor

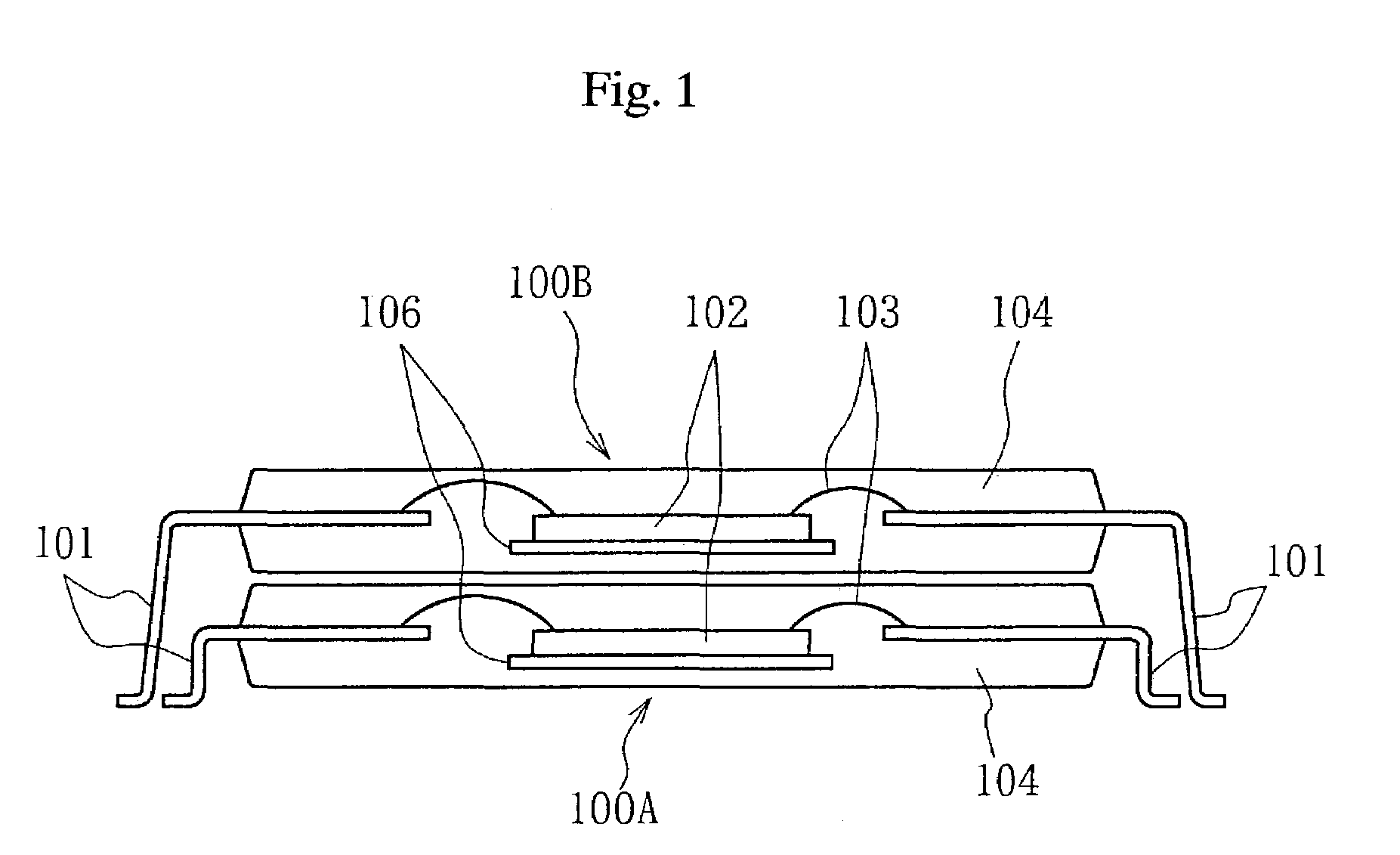

A low profile module is provided that has a high functionality achieved by increasing the component mounting density. In spite of achieving high functionality in a module 100 by respectively mounting components such as a semiconductor substrate 104 and chip components 105 on the two main surfaces 101a and 101b of a wiring substrate 101, the low-profile module 100 can be provided which has a high functionality as a result of increasing its component mounting density by forming a thickness Ha of a first component layer 102 formed by mounting only the semiconductor substrate 104 face down on one main surface 101a of the wiring substrate 101 so as to be smaller than the thickness of a second component layer 103 formed by mounting a plurality of chip components 105 on the other main surface 101b of the wiring substrate 101.

Owner:MURATA MFG CO LTD

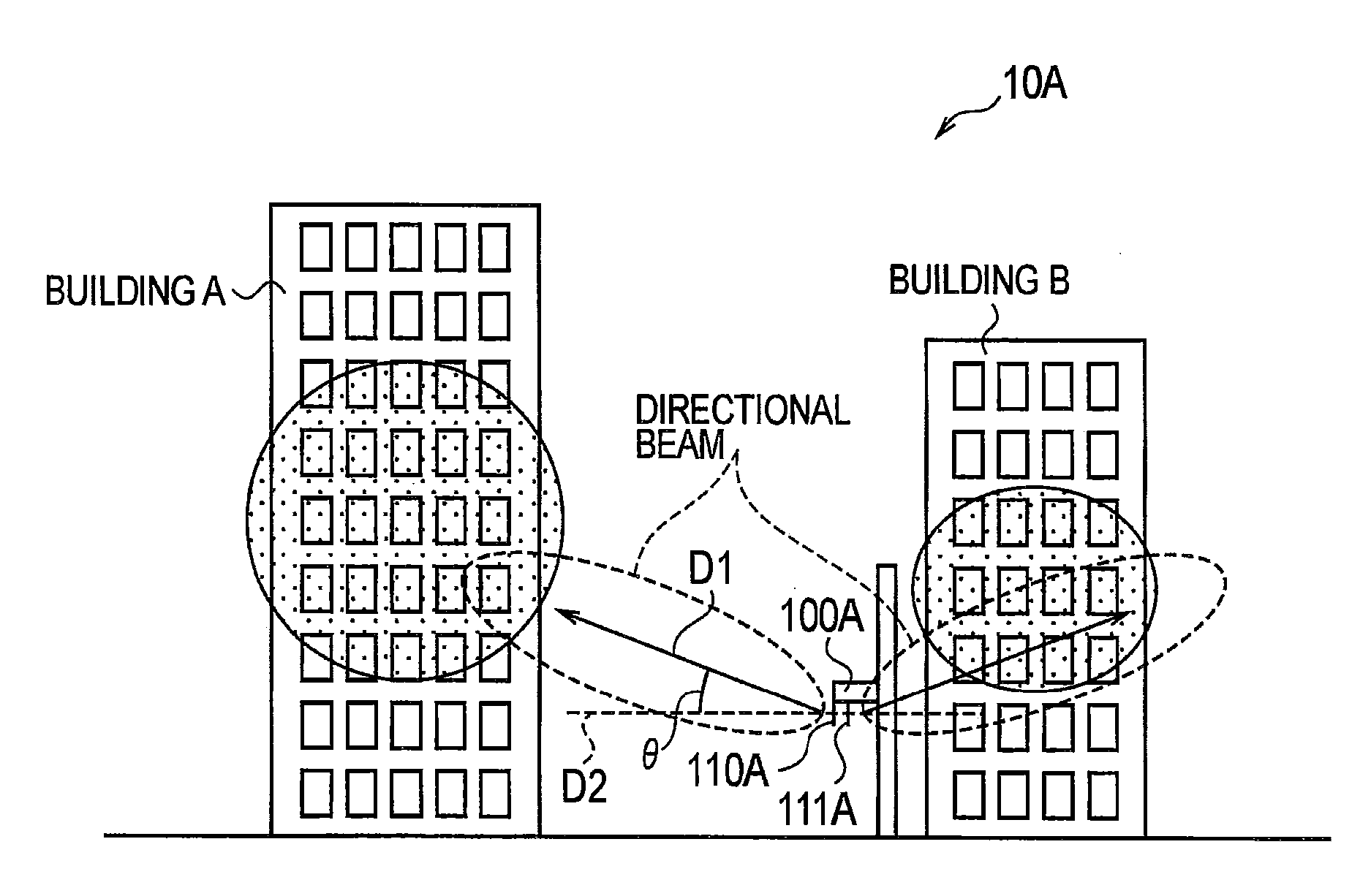

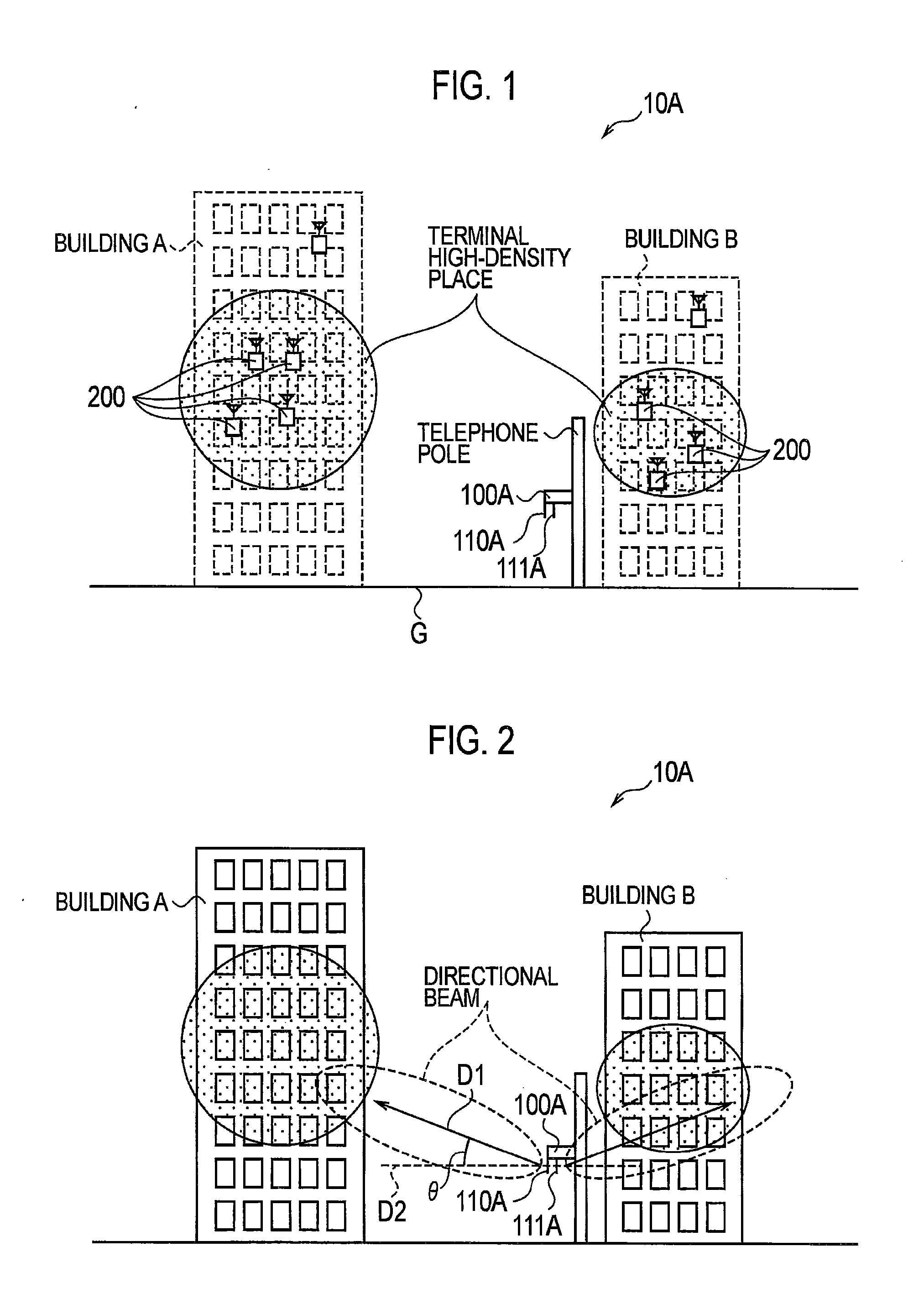

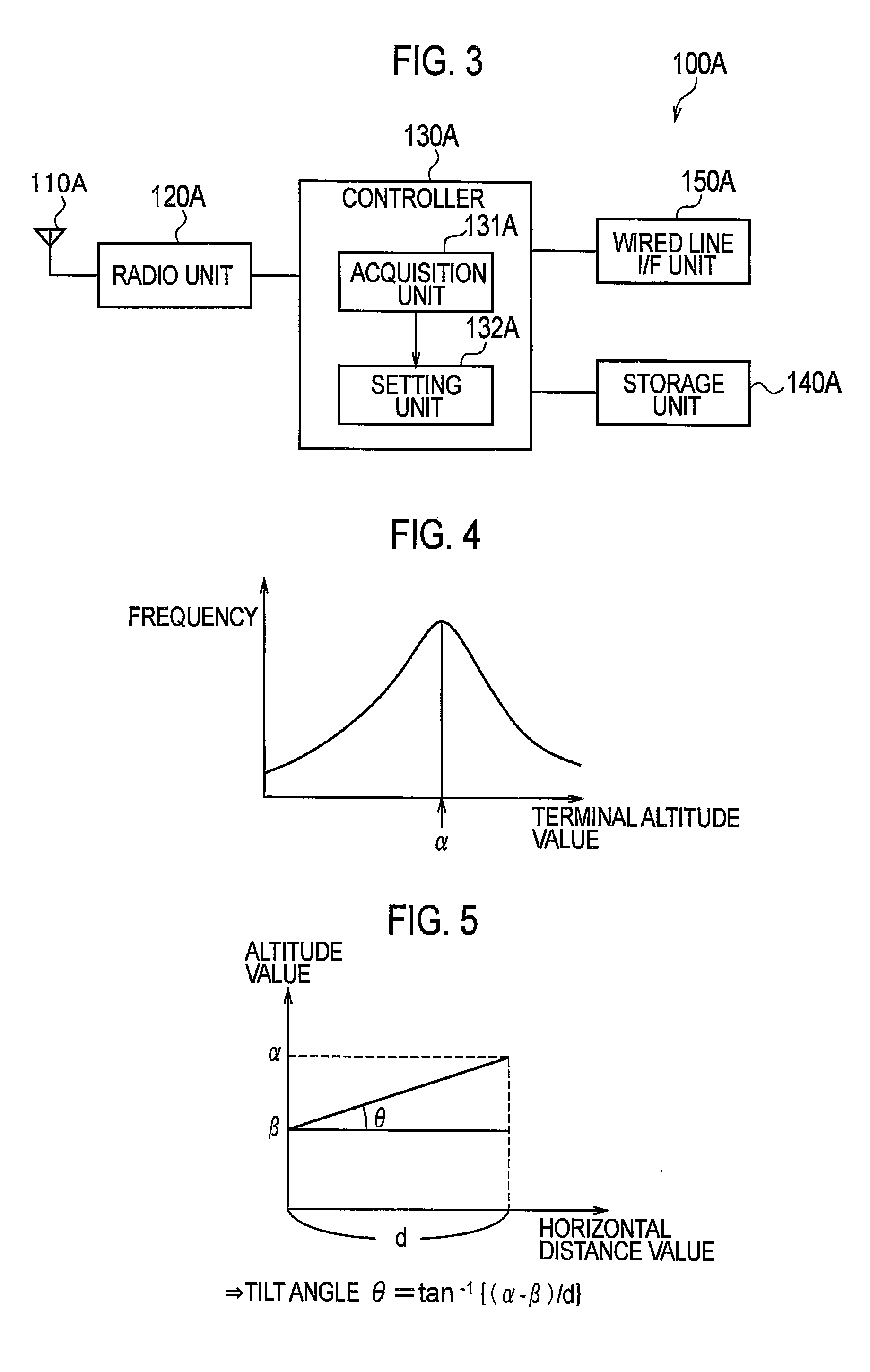

Antenna controller device, radio communication system, and antenna controlling method

InactiveUS20120015684A1High-quality communication serviceAppropriate settingSpatial transmit diversityNetwork planningCommunications systemVertical plane

A radio base station (100A) has a directional antenna (110A) by which the beam direction (D1) which is a direction to which a directional beam is directed can be changed in a vertical plane. The radio base station (100A) acquires a terminal altitude value indicating the altitude of a radio terminal connected to the radio base station (100A), and sets a tilt angle (θ) which is an angle made by the beam direction (D1) and the horizontal direction by use of the acquired terminal altitude value.

Owner:KYOCERA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com