Evaporative cooling system

a cooling system and evaporative technology, applied in the field of cooling systems, can solve the problems of affecting the efficiency of evaporation, and the inability to increase the mounting density of heating elements, so as to improve cooling efficiency, efficiently perform evaporative cooling, and increase latent heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

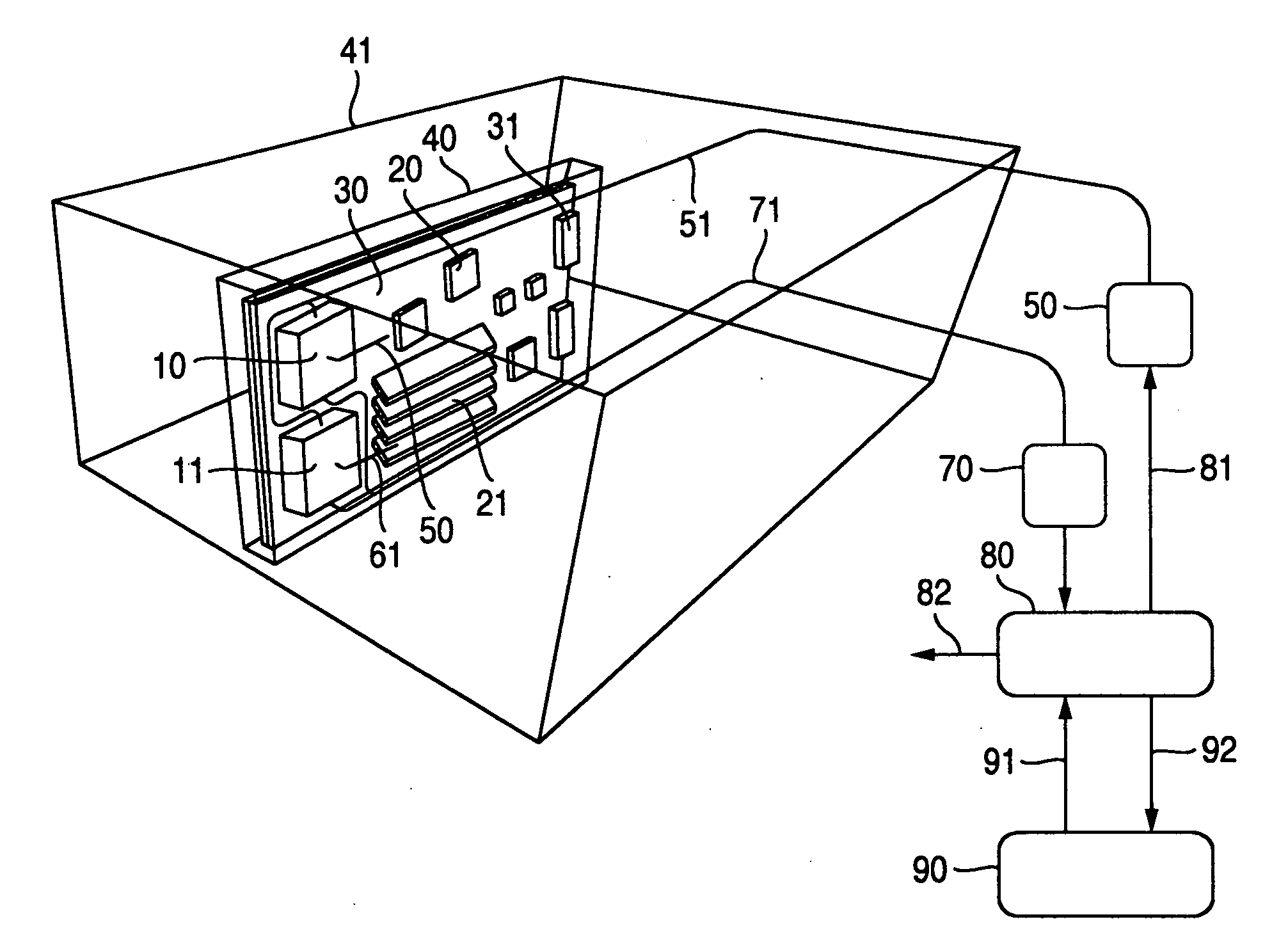

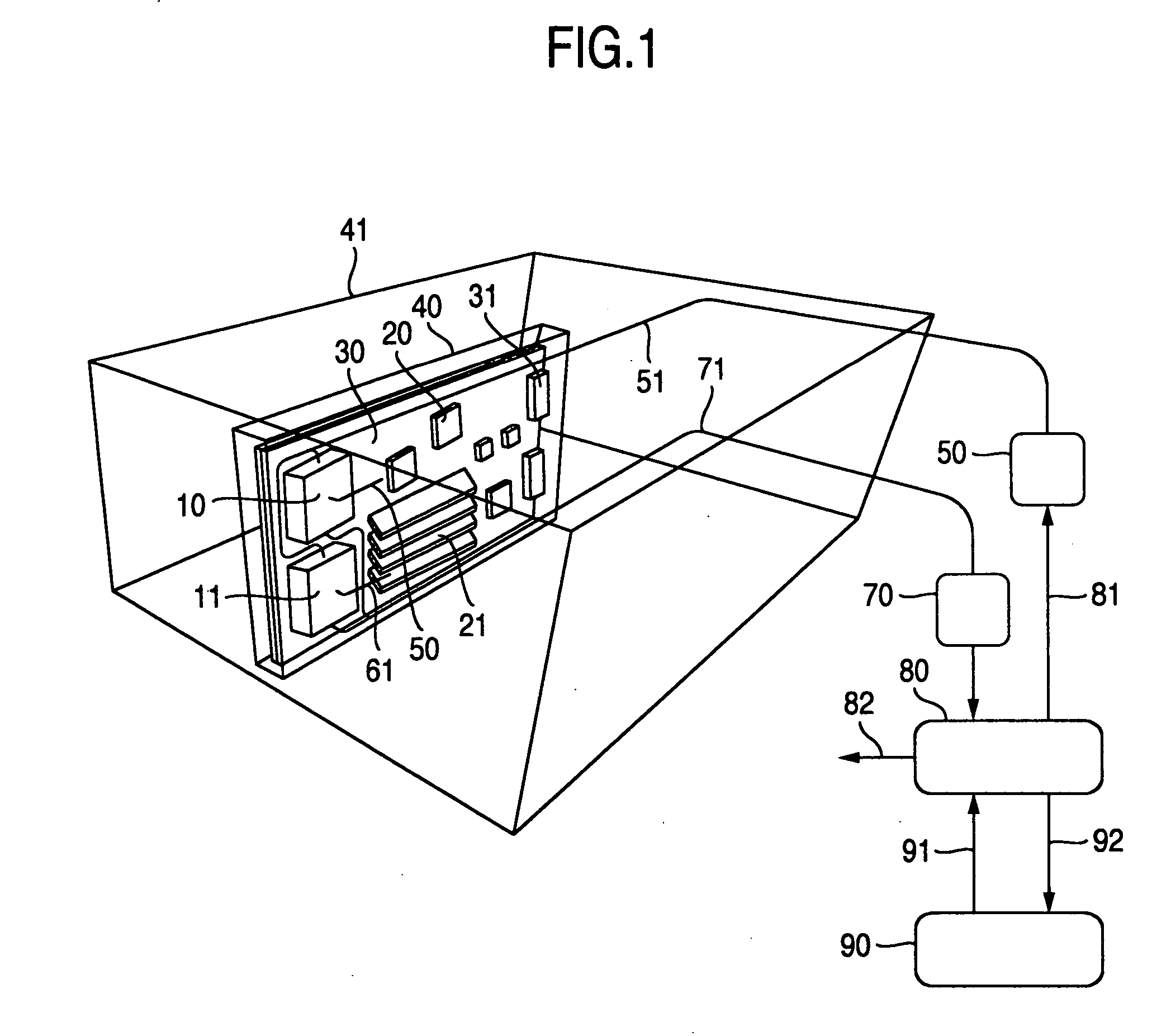

[0052]FIG. 1 is a view showing a configuration of an evaporative cooling system of a first embodiment according to the present invention, and an example in which the present invention is applied to a blade server system. The blade server system comprises a plurality of blade servers 40, a back plane connected to the plurality of blade servers 40, an I / O module, a switch module, a storage module, a management module, a power supply module, an air cooling fan module, and the like, and a server chassis 41 for housing these components. The blade server 40 comprises a processor to which evaporative cooling modules 10 and 11 are attached, a chip set 20, a memory module 21, a mother board 30, a connector 31 for effecting connection with the back plane, and the like, and a case for covering these components.

[0053]The evaporative cooling system comprises the evaporative cooling modules 10 and 11 in contact with the processor which is a heating element, a liquid supply system which includes a...

second embodiment

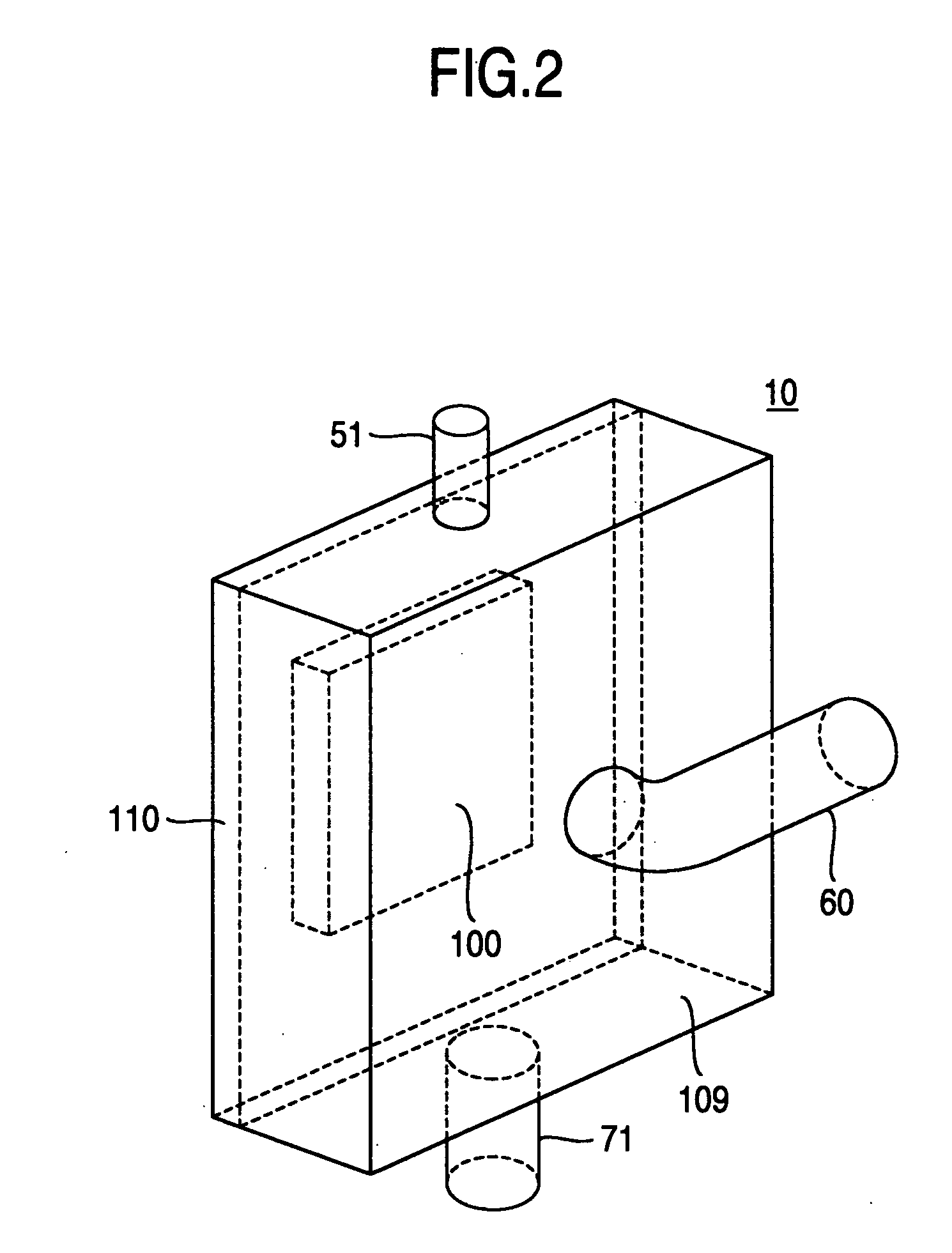

[0065]In the second embodiment, the evaporative cooling modules 10 and 11 are attached to the processor, the refrigerant liquid is evaporated from the vaporizing plate having an area larger than that of the processor chip and having capillaries on the surface thereof. The refrigerant liquid is supplied from an upper part of the evaporative cooling modules 10 and 11 via the liquid supply tube 51. The warm air is supplied to the modules 10 and 11 via the air supply tubes 60 and 61 from the direction different from the direction in which the refrigerant liquid is supplied. The refrigerant vapor and the residual liquid are discharged from a lower part of the modules 10 and 11. The condensed refrigerant liquid collected by the primary heat exchanger 80 is again returned to the modules 10 and 11 through the liquid supply pump 50. The refrigerant is circulated in the closed circuit circulatory system, while the air is passed through in the open circuit system from the warm air blower 62 to...

sixth embodiment

[0075] the liquid supply pump can be eliminated from the liquid supply system by using the exhaust pressure of the exhaust pump and the weight of the refrigerant liquid itself. Thus, it is possible to reduce the power required for the cooling system, and also possible to reduce the size of the blade server system.

[0076]The evaporative cooling system according to the present invention is suitable for information platform devices, such as a server, a network, and a storage which are required to have higher performance and higher density. The evaporative cooling system according to the present invention can be widely applied to cool an apparatus having a heating element, such as, for example, electronic devices such as a PC and a portable telephone, power devices such as a generator and a fuel cell, and dynamic devices such as a motor vehicle and a railroad vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com