Patents

Literature

72results about How to "Reduce emission intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

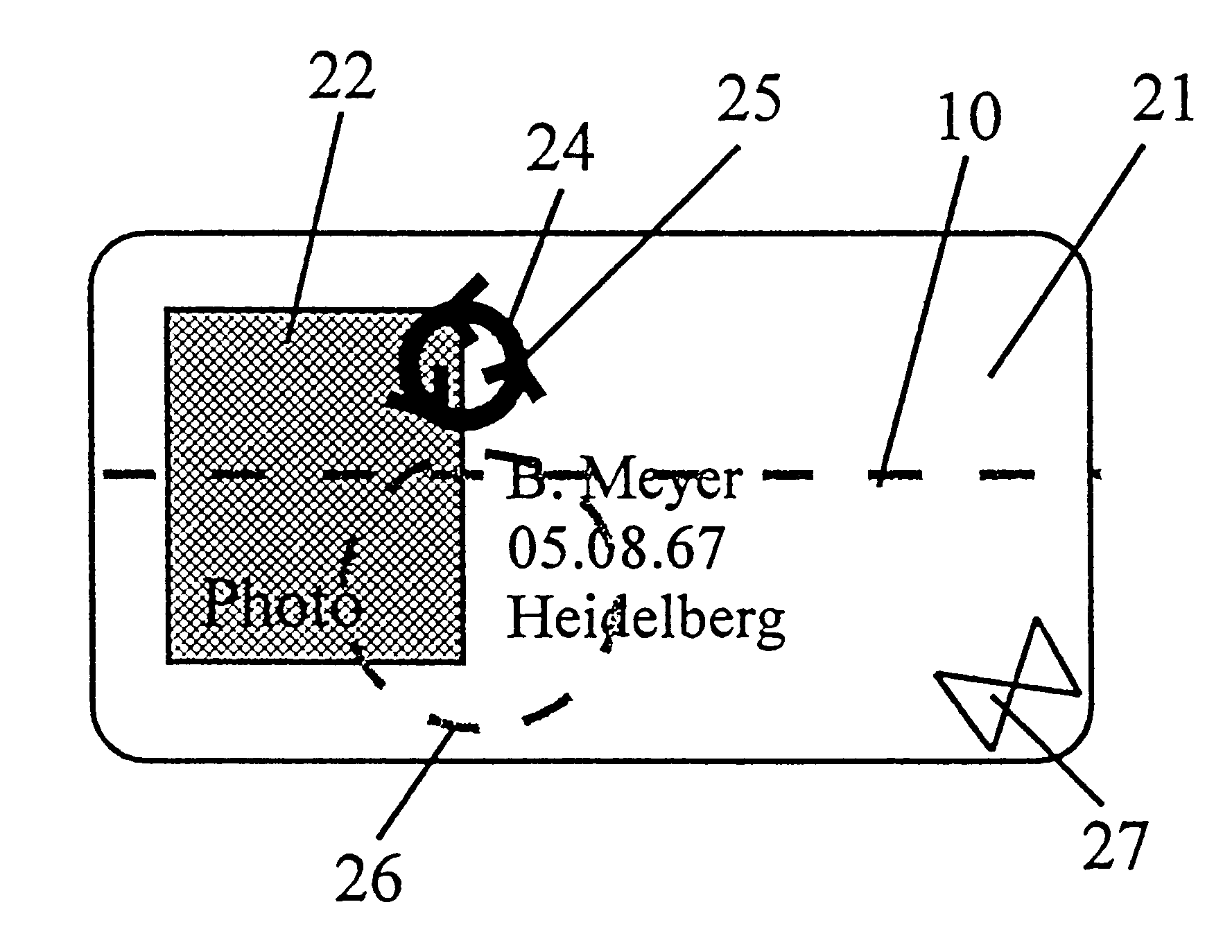

Security document with optically excitable dyes for authenticity check

InactiveUS6234537B1Reduce emission intensityIncrease intensityOther printing matterDuplicating/marking methodsEngineeringLaser

A security document with optically excitable dyes for authenticity checking. Dyes are applied to or embedded in the security documents. The dyes are advantageously embedded in a carrier material which in conjunction with the dyes forms a laser-active element. Certain optically excitable dyes are incorporated in a security document in such a way that when the security and / or sensitive document is optically excited, the dyes embedded in the security and / or sensitive document resonate with the material of the securities and secure documents, so that a well-defined narrow spectrum of all excited materials is emitted.

Owner:BUNDESDRUCKEREI GMBH

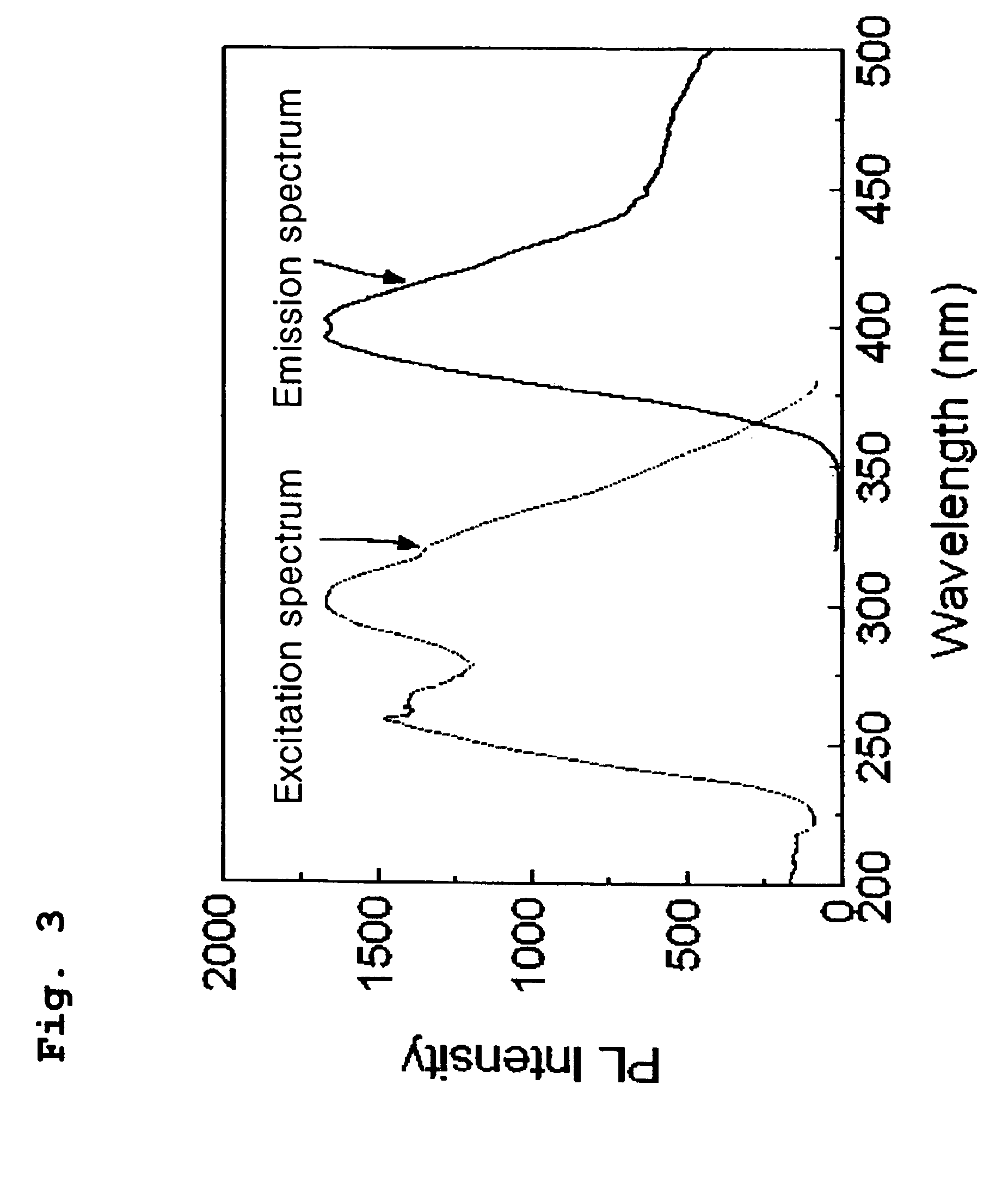

Phosphor mixture and light emitting device

ActiveUS20060197432A1Good color propertiesSmall color shiftDischarge tube luminescnet screensLamp detailsColor shiftPhosphor

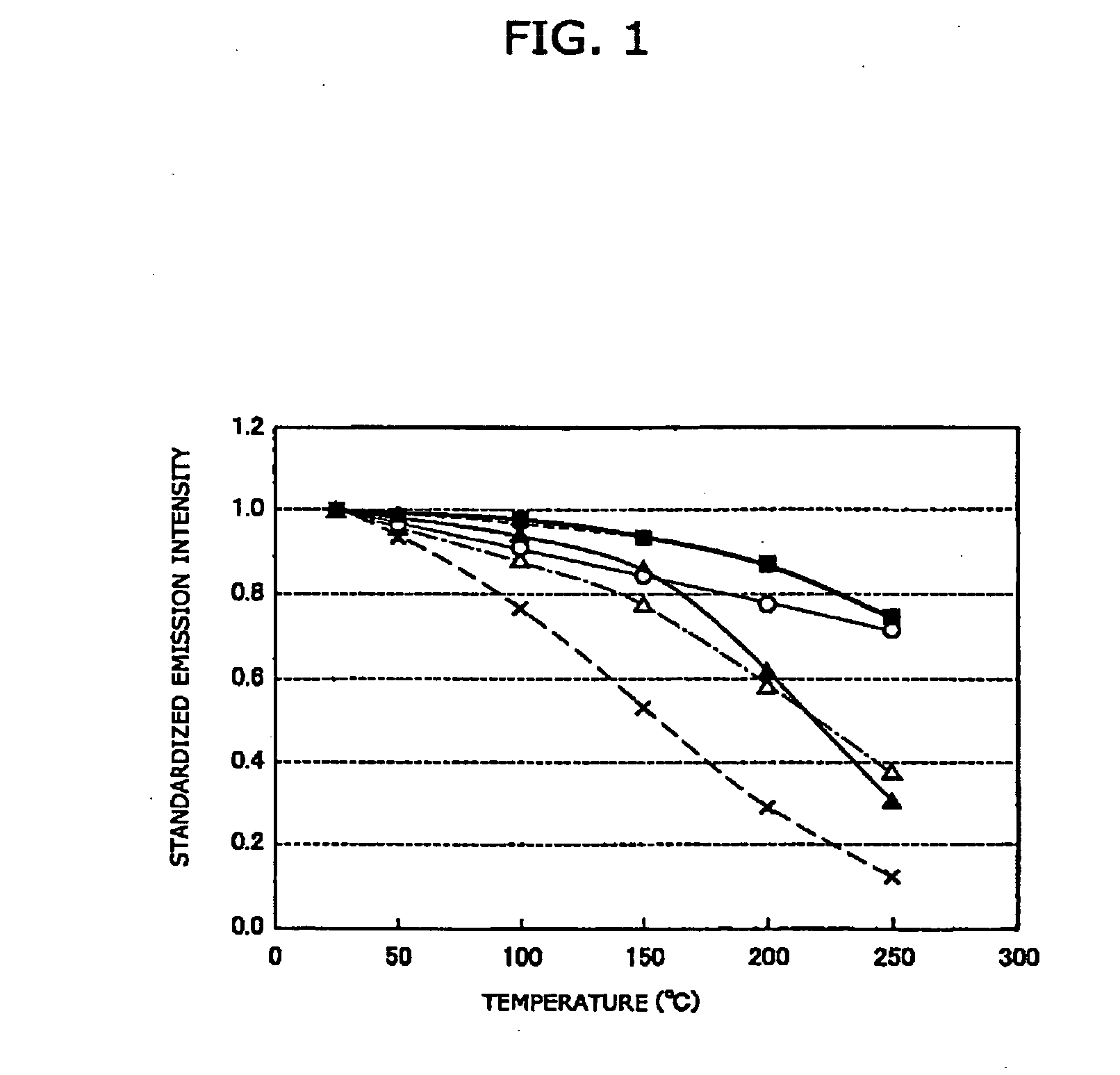

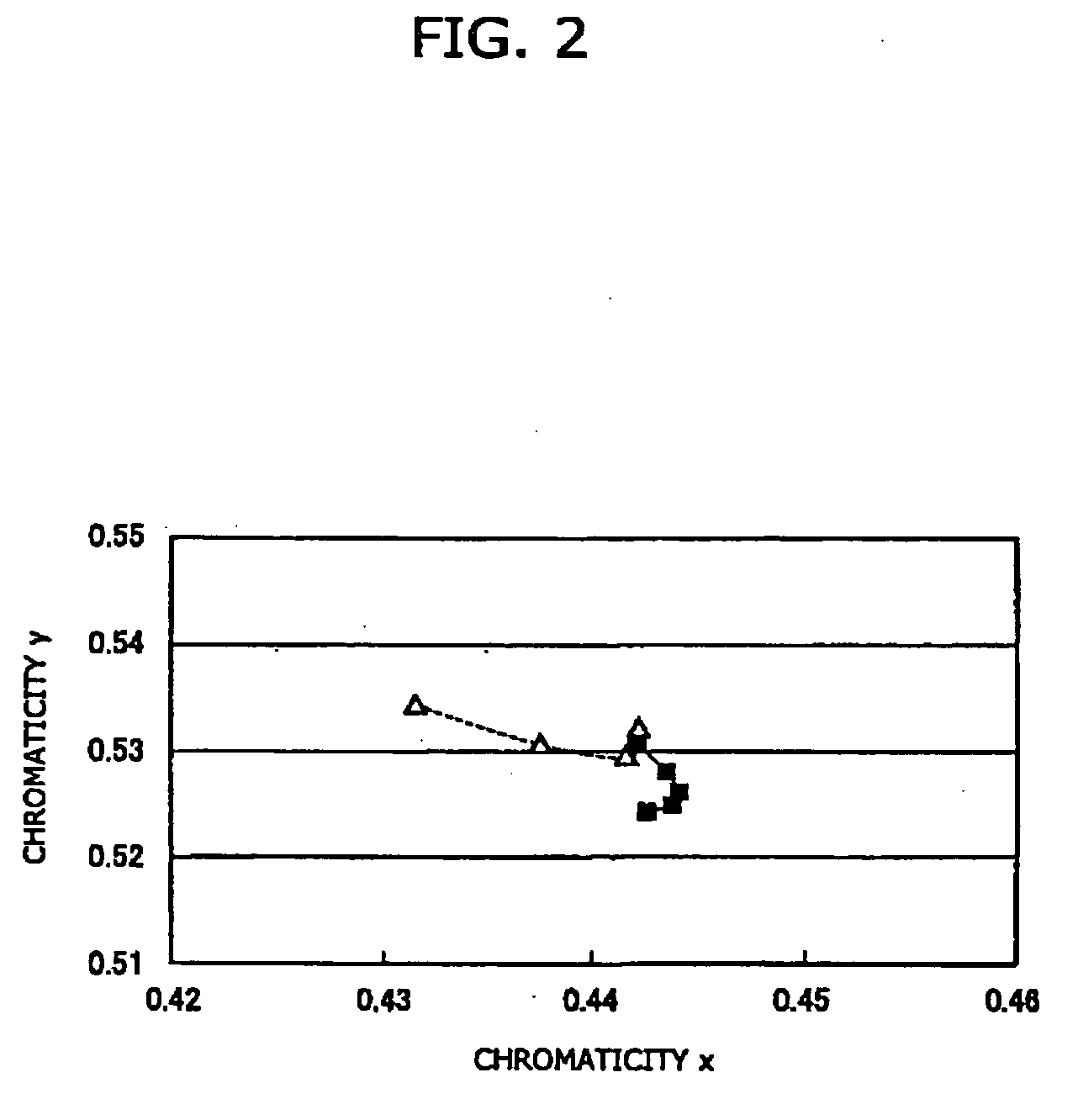

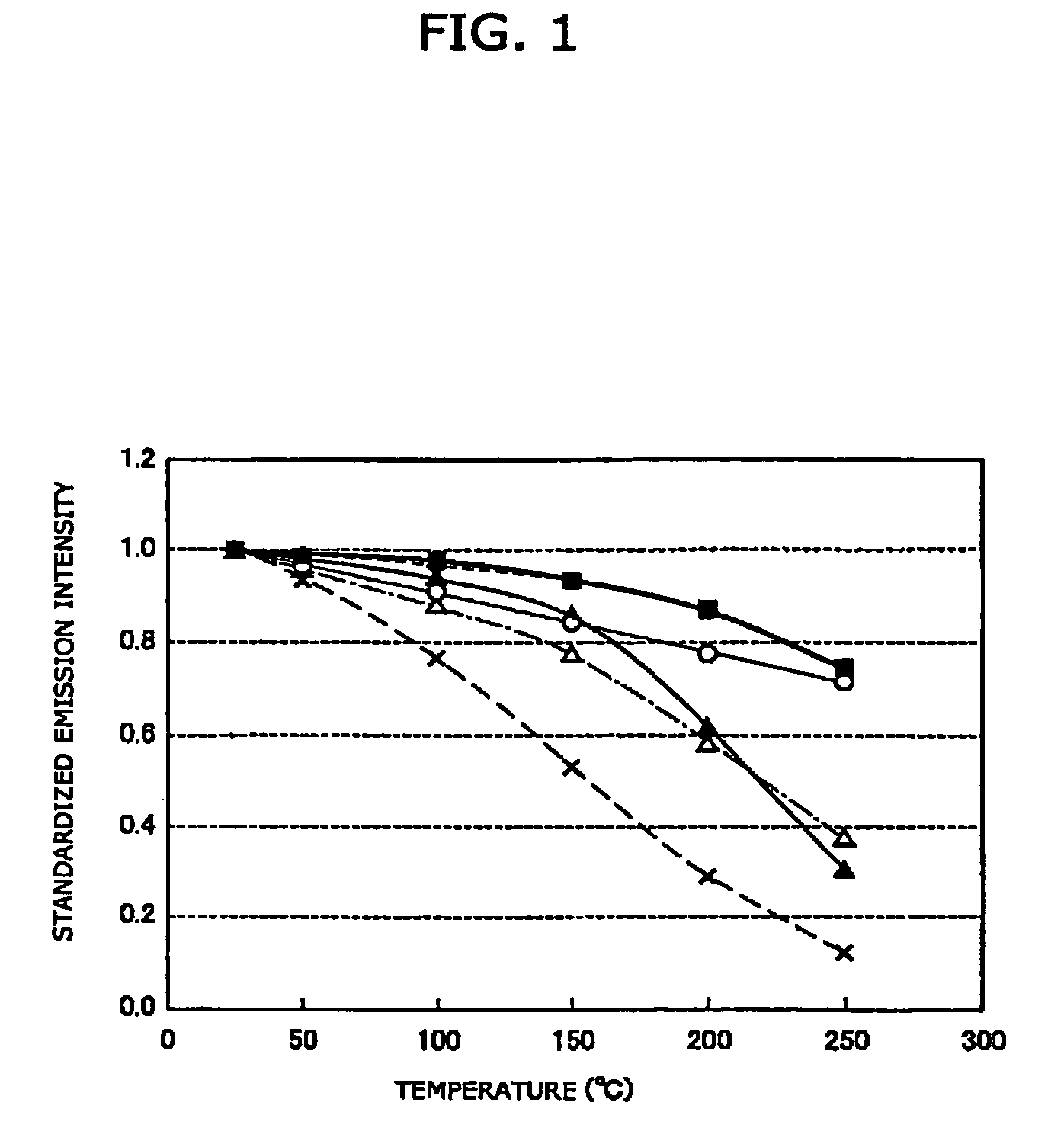

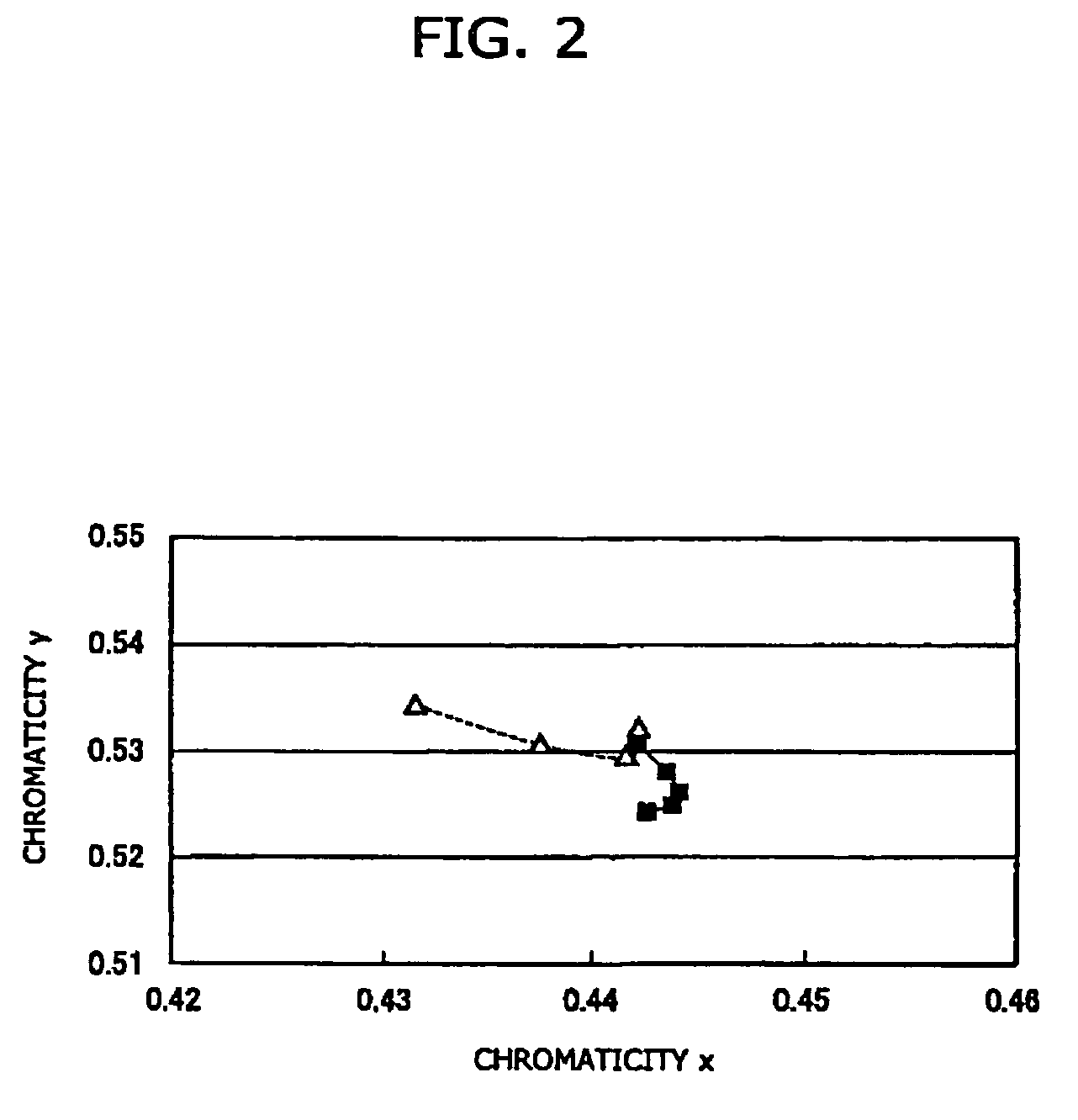

To provide a phosphor mixture realizing a light emitting device having a phosphor and a light emission element, by which light emission is performed, with a small color shift due to a feeding current and having an excellent color rendering properties. CaAlSin3:Eu as a red phosphor and YAG:Ce as a yellow phosphor are manufactured, and emission spectra thereof are obtained. Meanwhile, the emission spectrum of an excitation light emitted by a light emitting part is obtained. From the emission spectra thus obtained, a relative mixing ratio of each phosphor is obtained by simulation, so that a correlated color temperature of the light emitting device becomes a target temperature. Then, based on the relative mixing ratio thus obtained, each phosphor is measured and mixed, and a phosphor mixture is thereby obtained.

Owner:NICHIA CORP +1

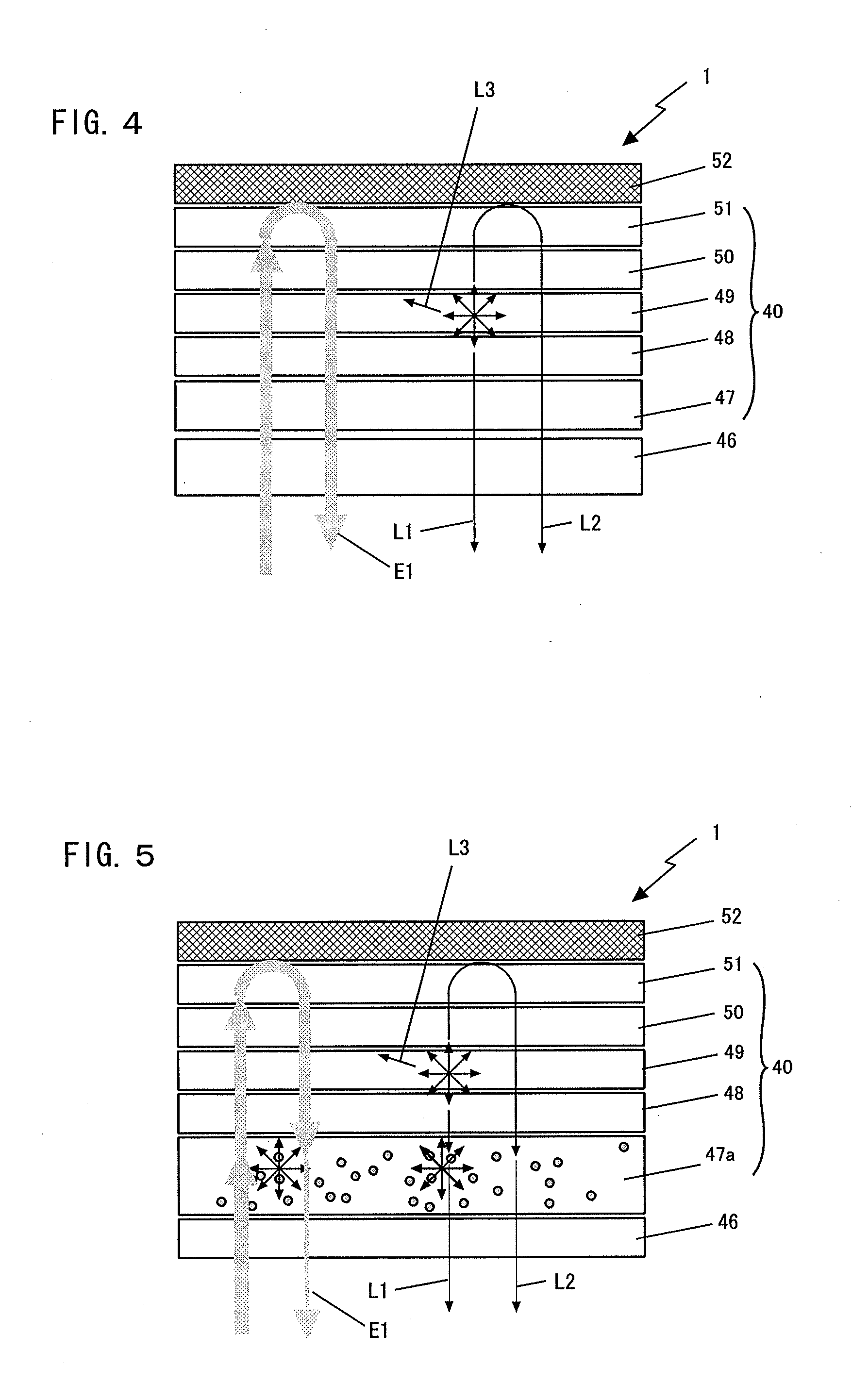

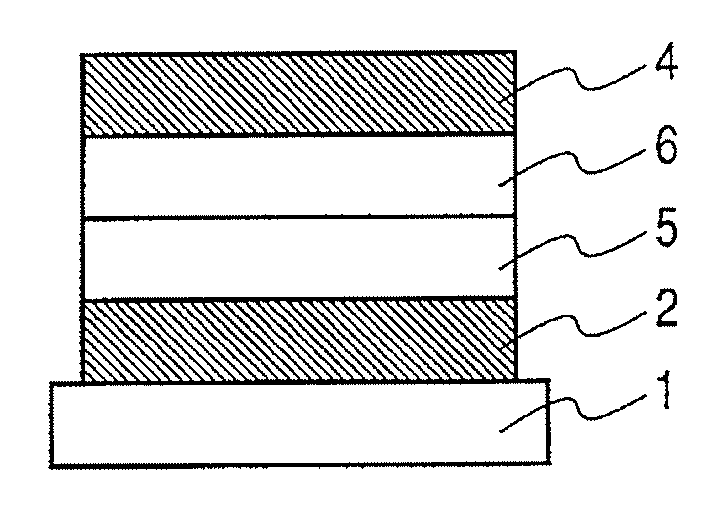

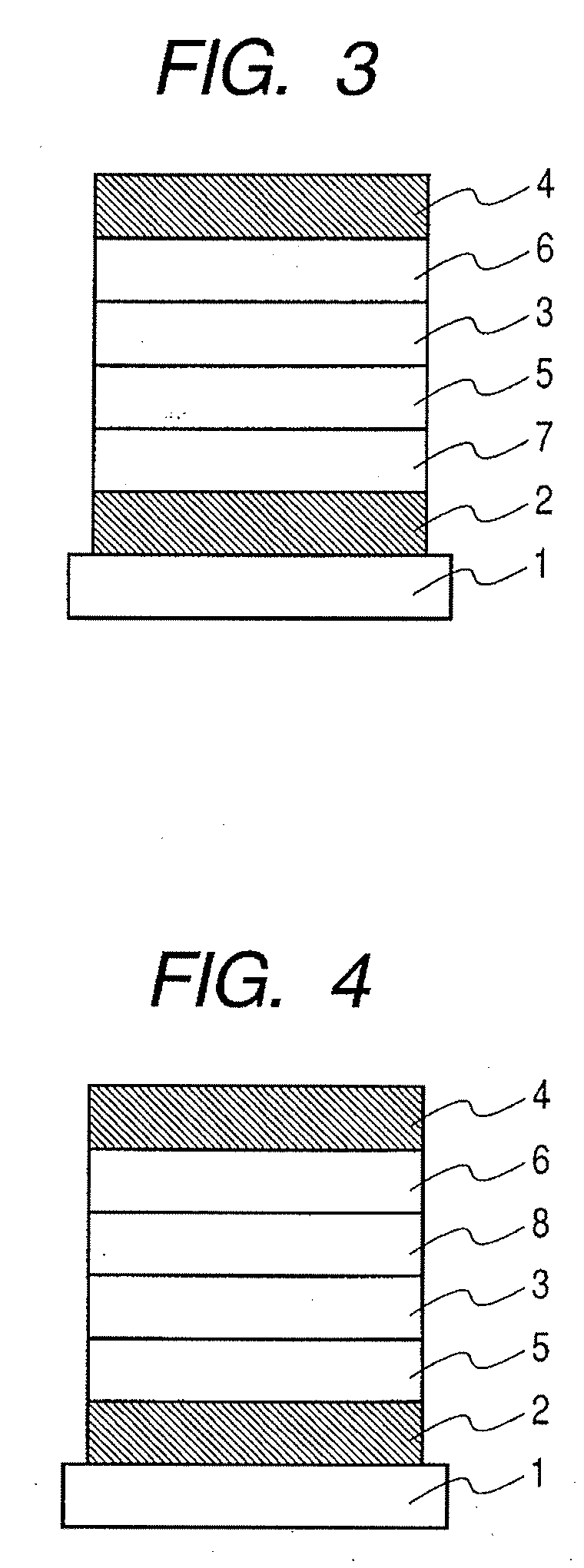

Organic light-emitting device

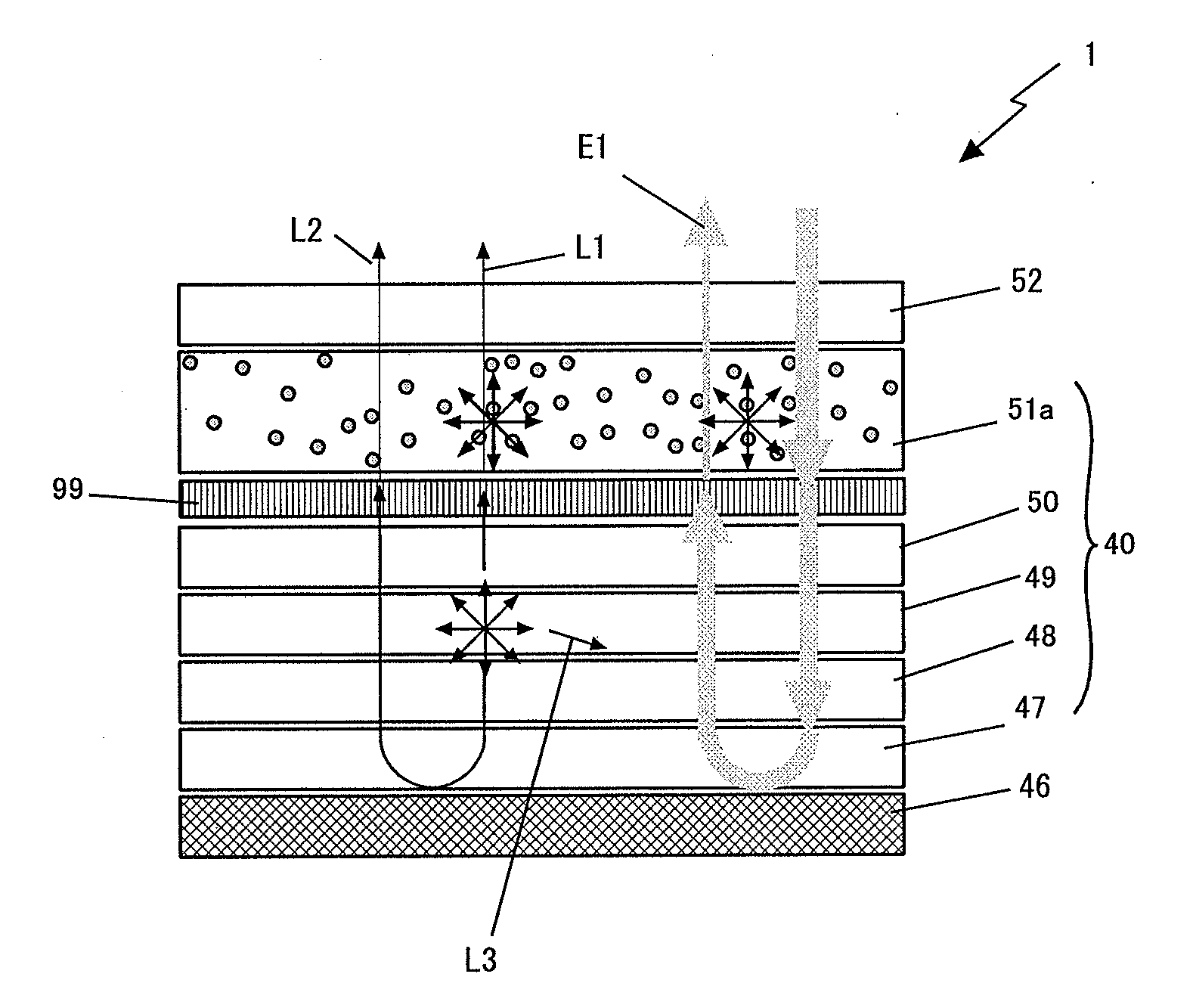

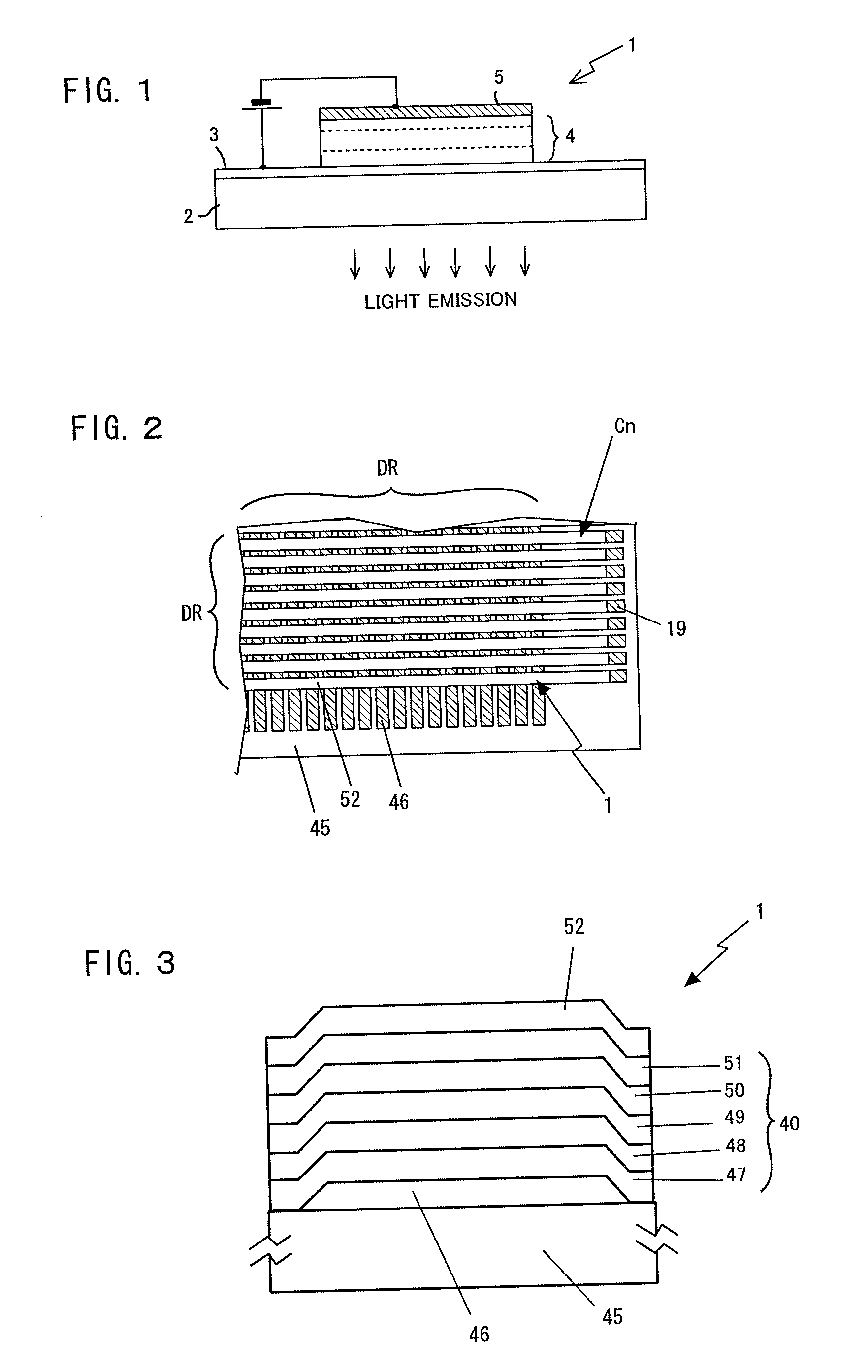

InactiveUS20110062481A1Reduce the impact of interferenceHigh yieldMaterial nanotechnologyElectroluminescent light sourcesLuminous intensityOrganic light emitting device

An organic light-emitting device cutting off ambient light while keeping emission intensity includes a pair of first and second electrodes opposed to each other; and a plurality of organic semiconductor layers layered and disposed between the first and second electrodes, wherein the organic semiconductor layers include an organic light-emitting layer, the organic semiconductor device further comprising a light-scattering layer layered and disposed between the organic light-emitting layer and at least one of the first and second electrodes. The light-scattering layer includes: organic materials having carrier injection and transport characteristics of transporting electrons and / or holes; and plural particles dispersed among the organic materials so that light emitted from the organic light-emitting layer is passed therethrough.

Owner:PIONEER CORP

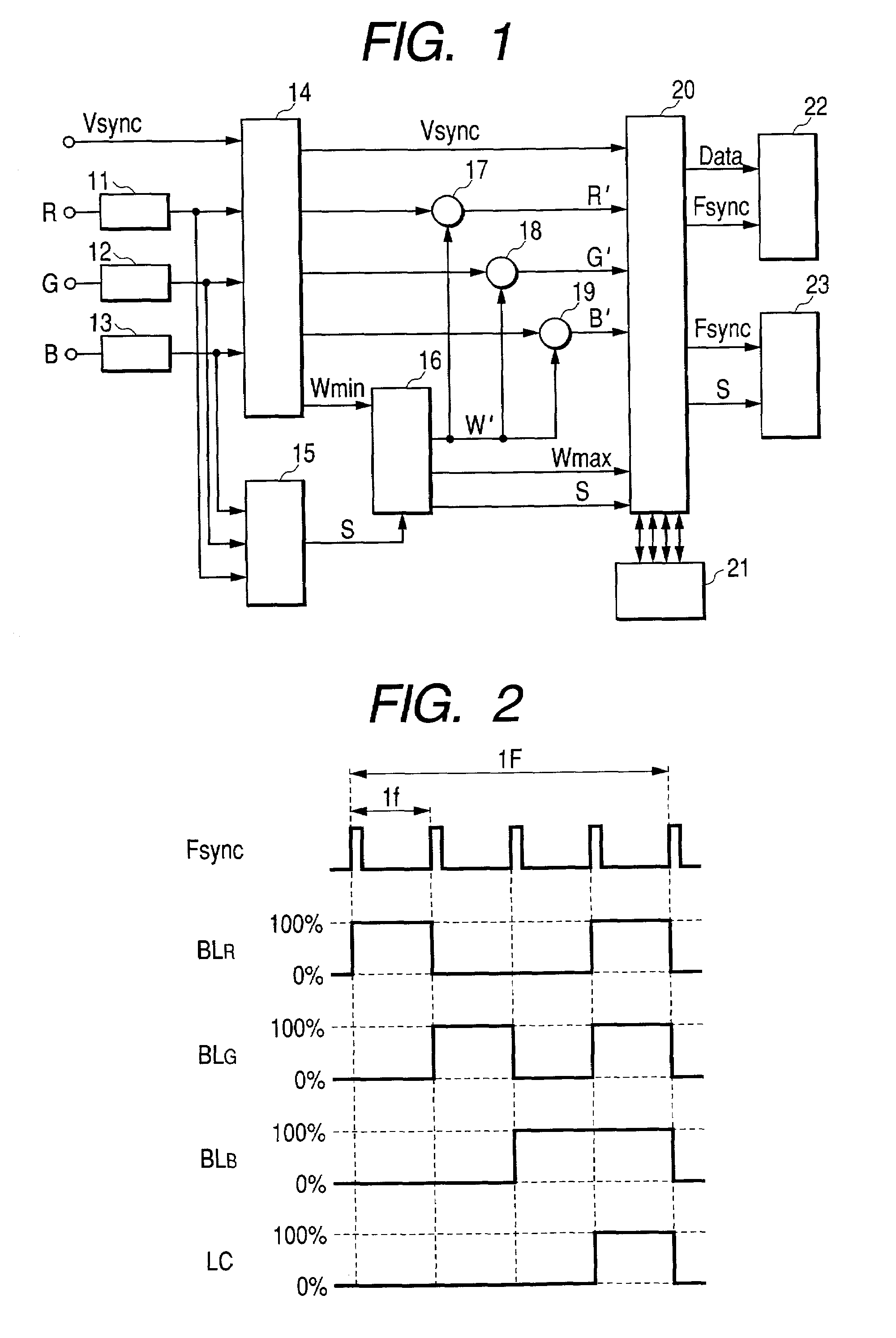

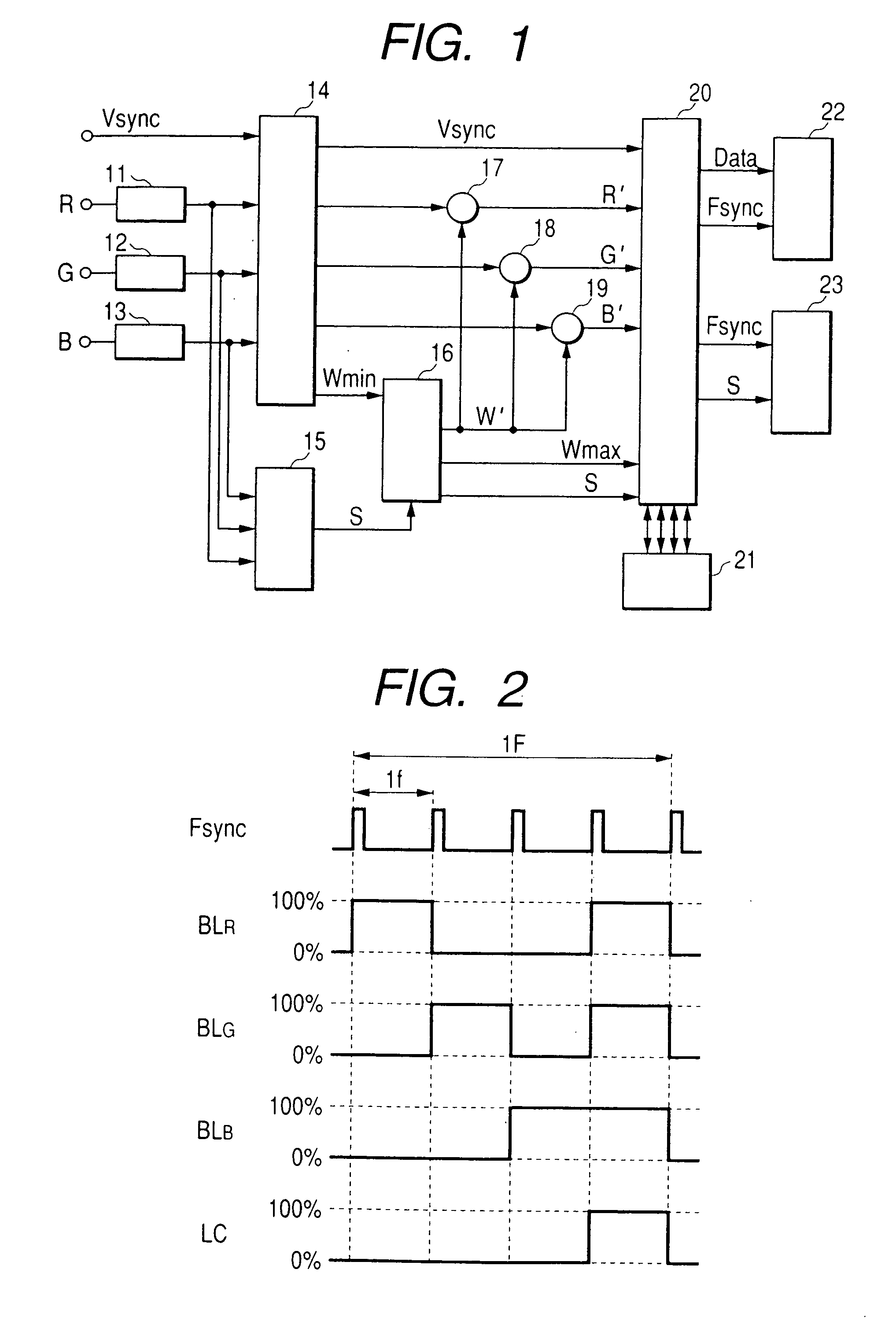

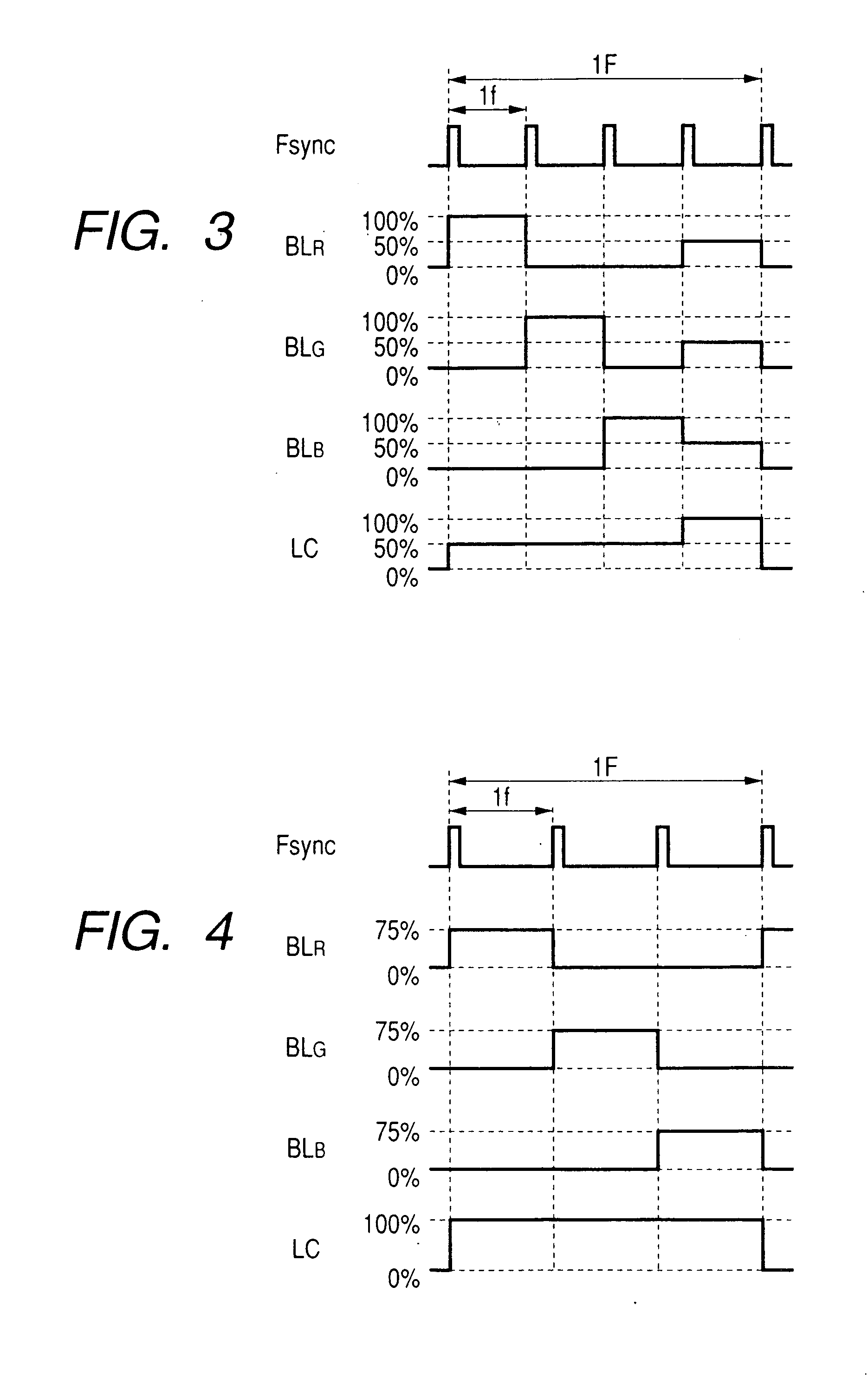

Color liquid crystal display device

InactiveUS6961038B2Reduce power consumptionReduce emission intensityStatic indicating devicesPicture reproducers using solid-state color displayLiquid-crystal displayComputer science

Owner:CANON KK

Electronic devices including dual-function electronic components, radiation-emitting components, radiation-sensing components, or any combination thereof

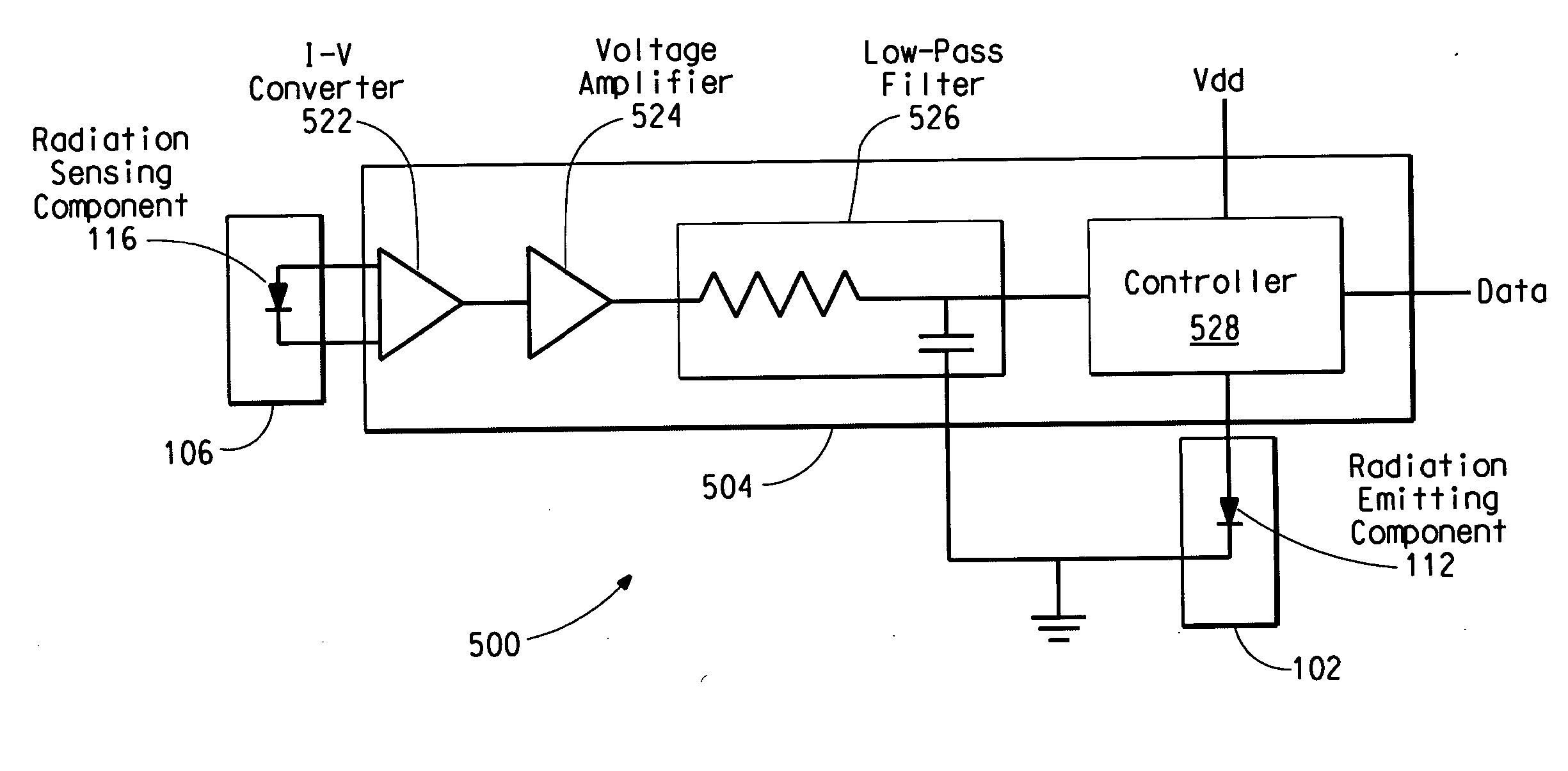

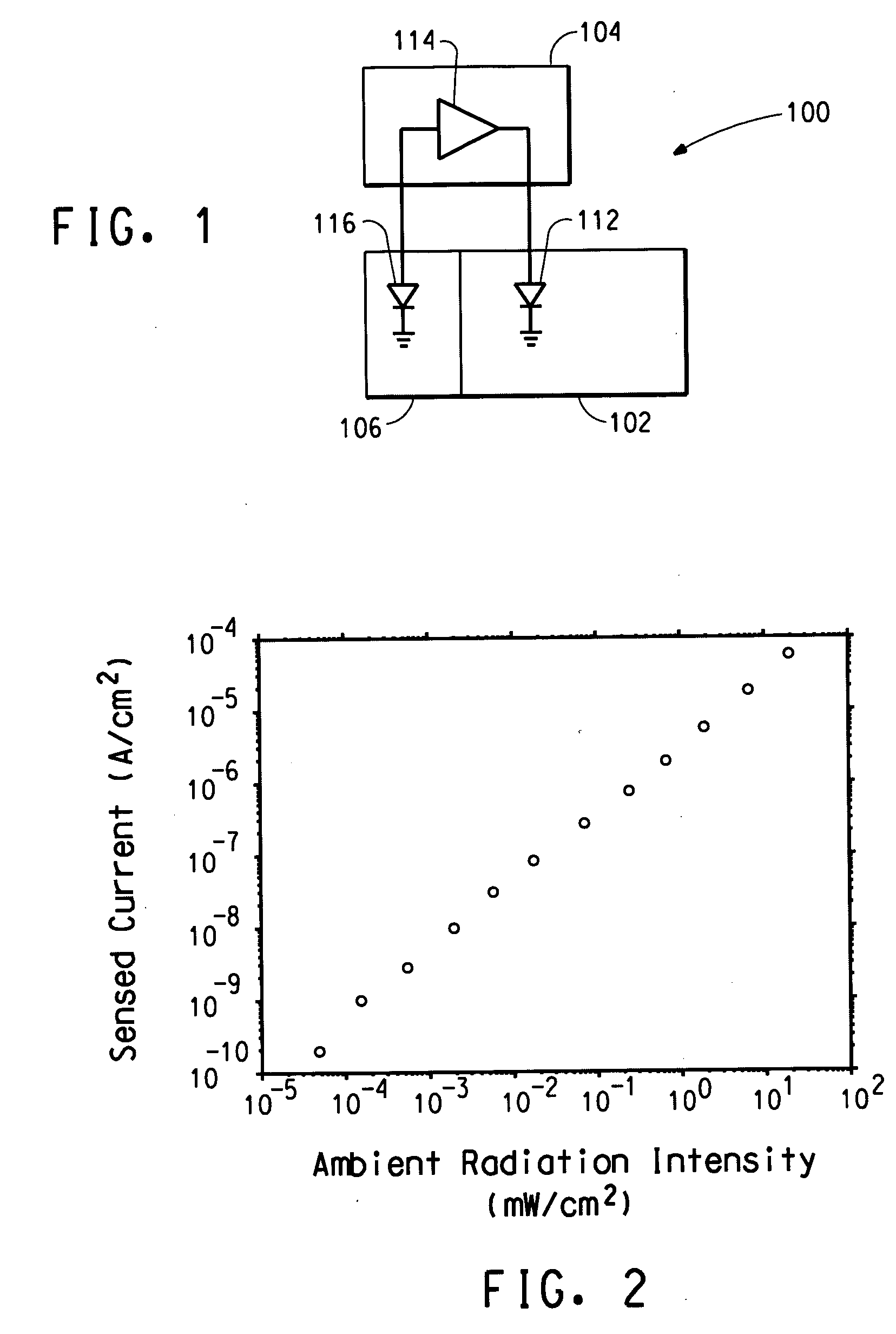

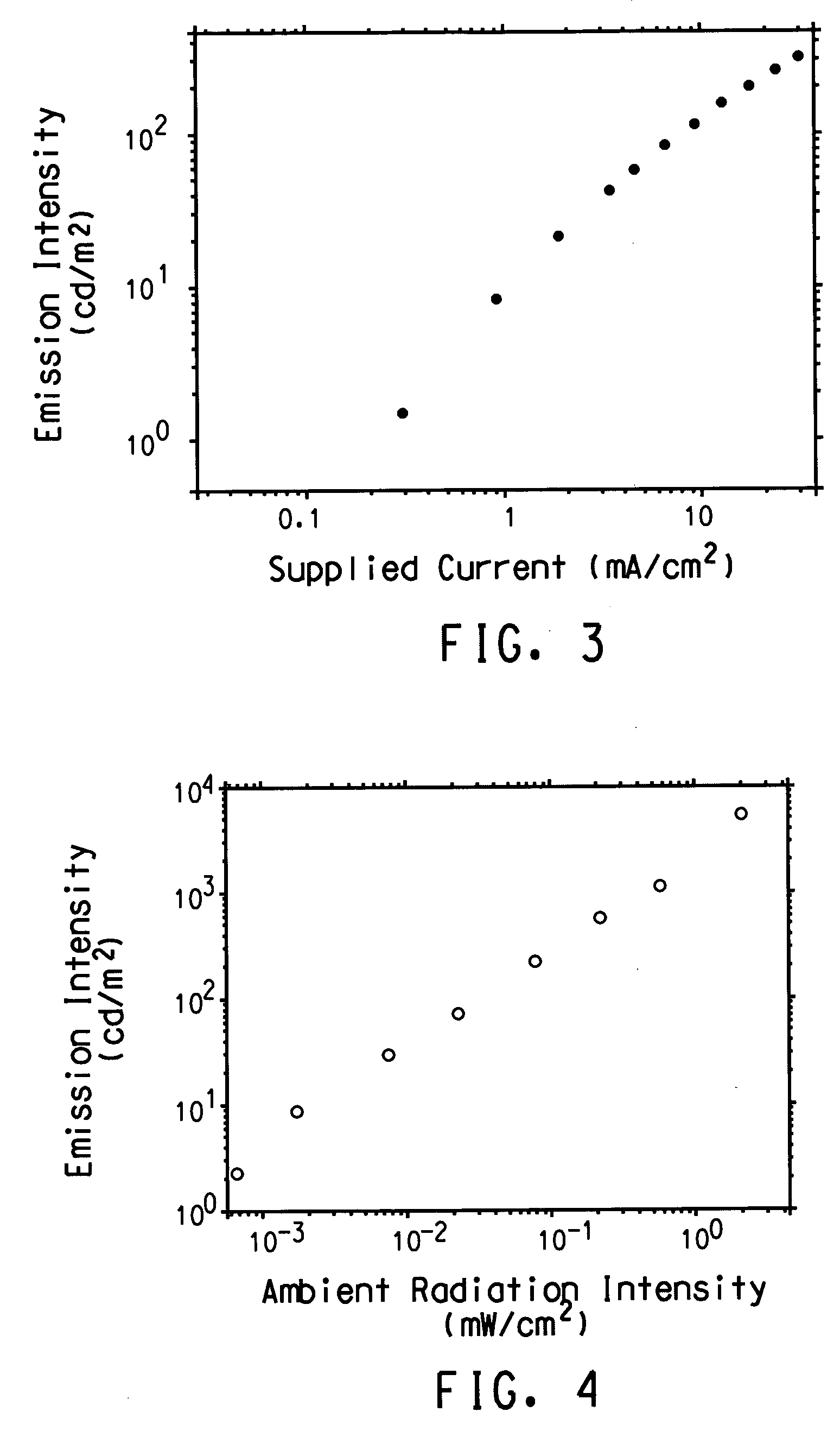

InactiveUS20060145053A1Good power conservation characteristicLess power consumptionPhotometry using reference valueMaterial analysis by optical meansLow-pass filterDisplay device

An electronic device can include circuitry that compensates for the emission intensity of a display, including a radiation-emitting component, in response to ambient radiation. In one embodiment, the circuitry includes a low-pass filter that can help to reduce the effect of quick changes in intensity of ambient radiation. In another embodiment, an electronic device includes a dual-function electronic component and a switch. The switch is configured to be closed at least during a portion of time while the dual-function electronic component is between an emission mode and a sensing mode. In still another embodiment, the circuitry includes a current amplifier that is configured to amplify a current from a radiation-sensing component to produce an amplified current. In yet another embodiment, the circuitry includes an I-V converter and a voltage amplifier. The I-V converter converts a current from a sensor to a voltage, and the voltage amplifier amplifies that voltage.

Owner:EI DU PONT DE NEMOURS & CO

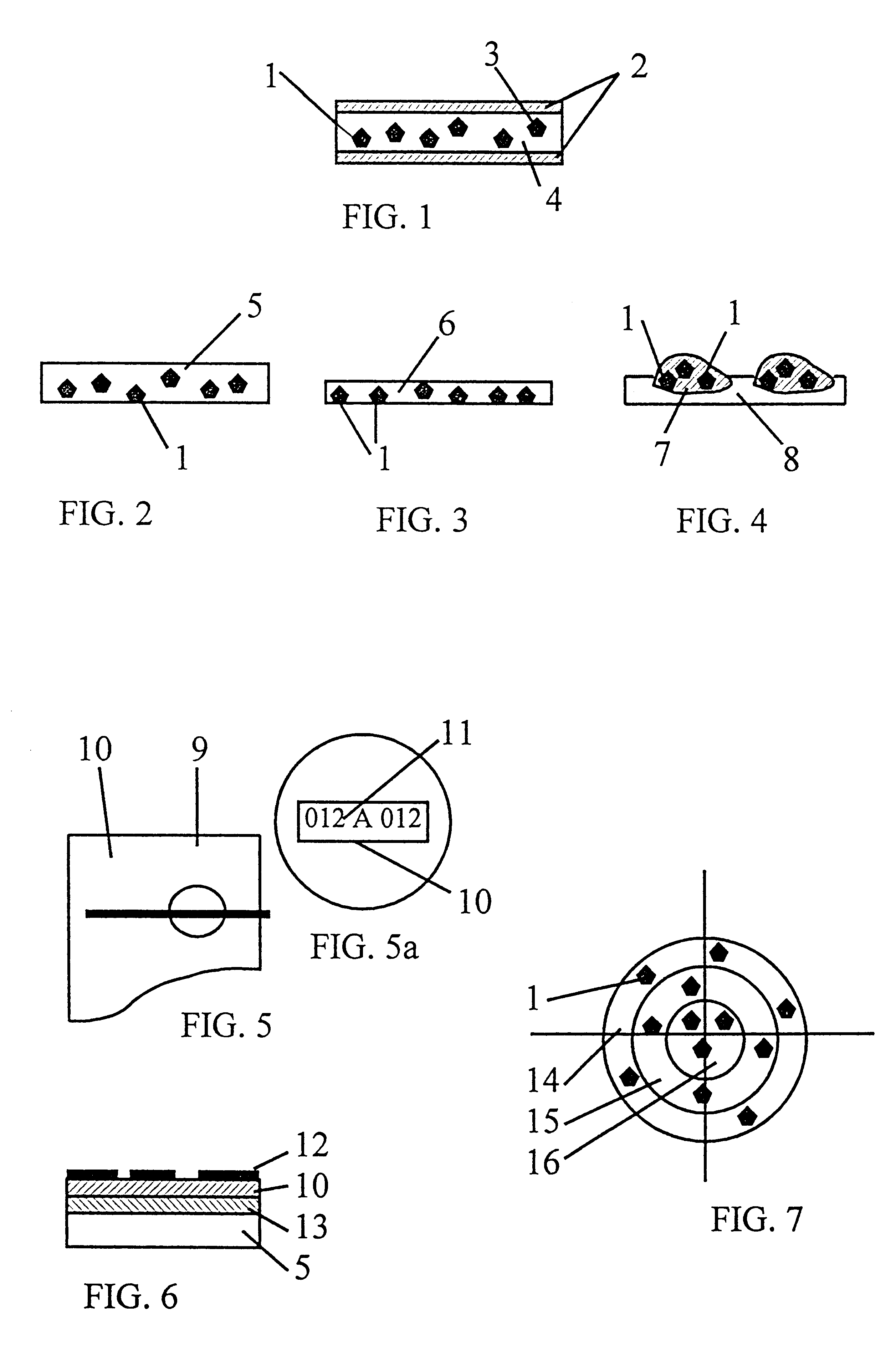

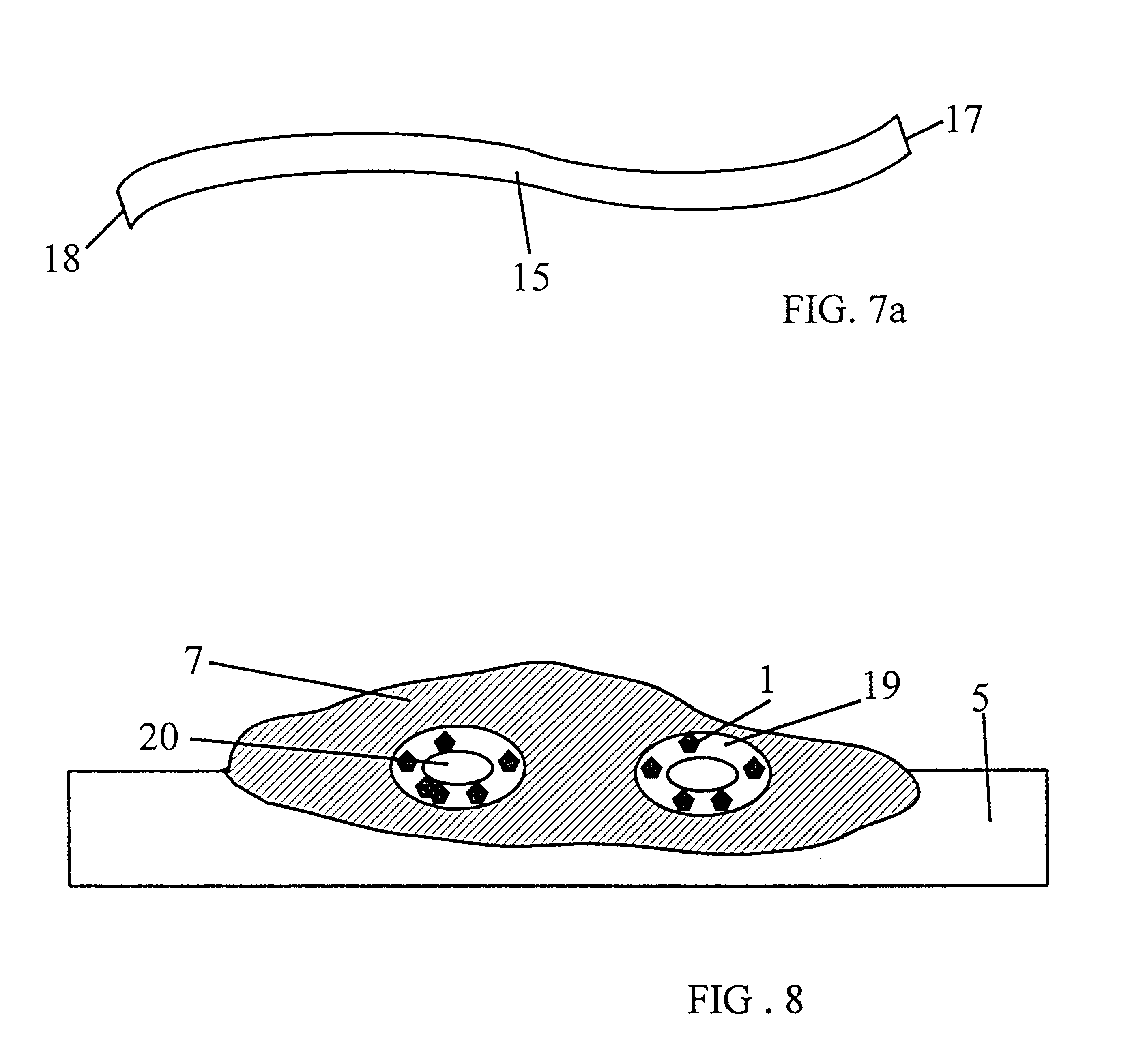

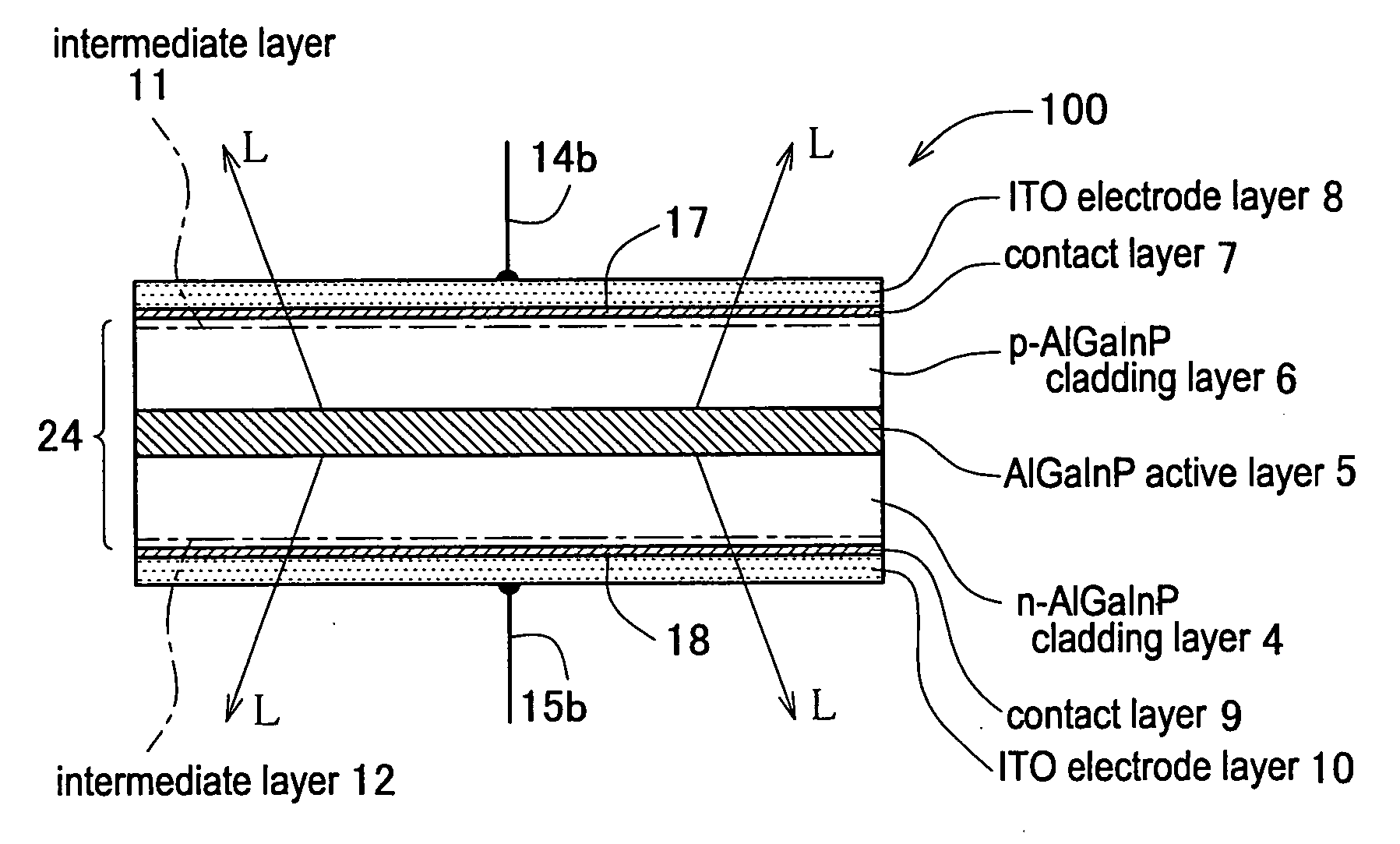

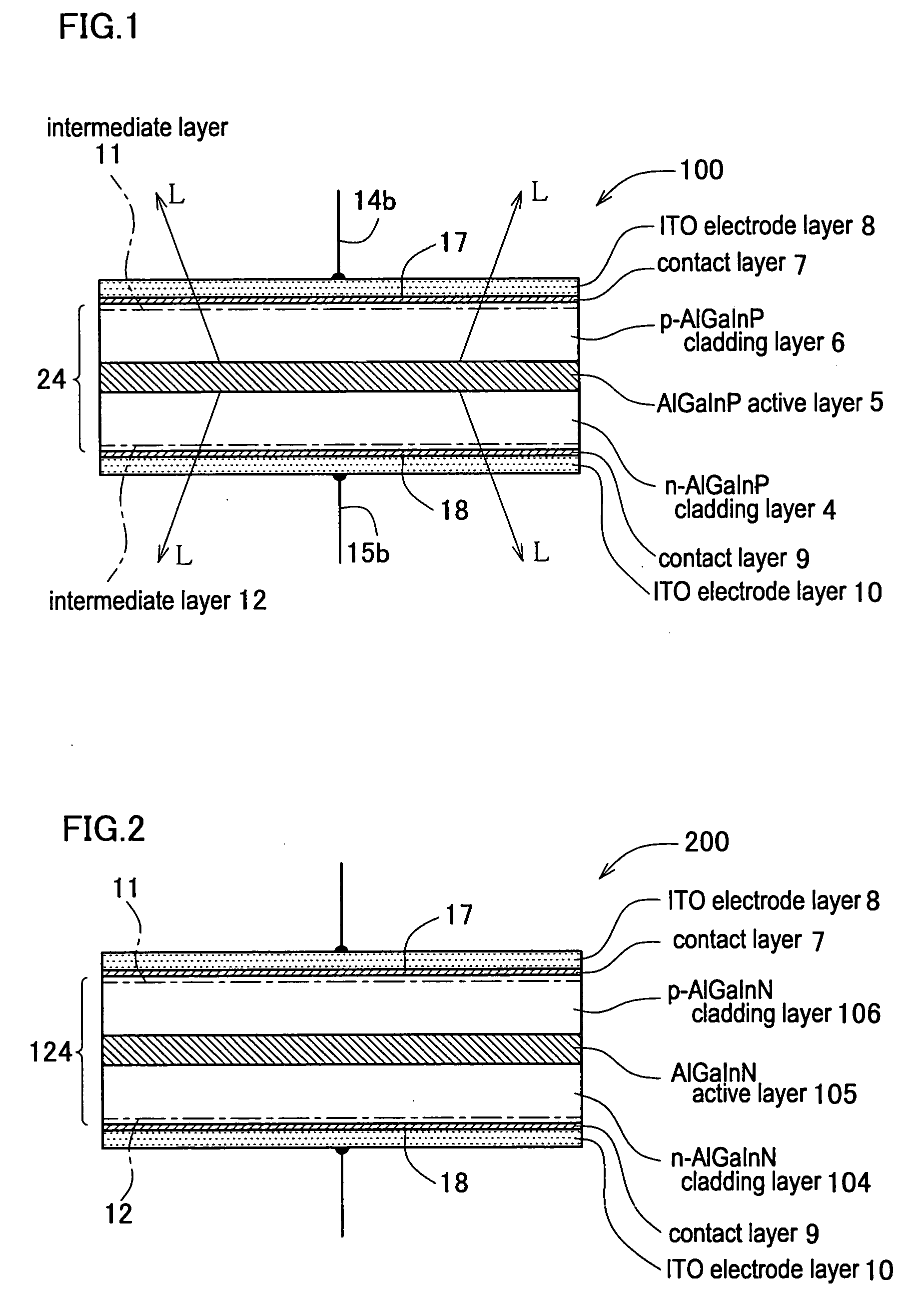

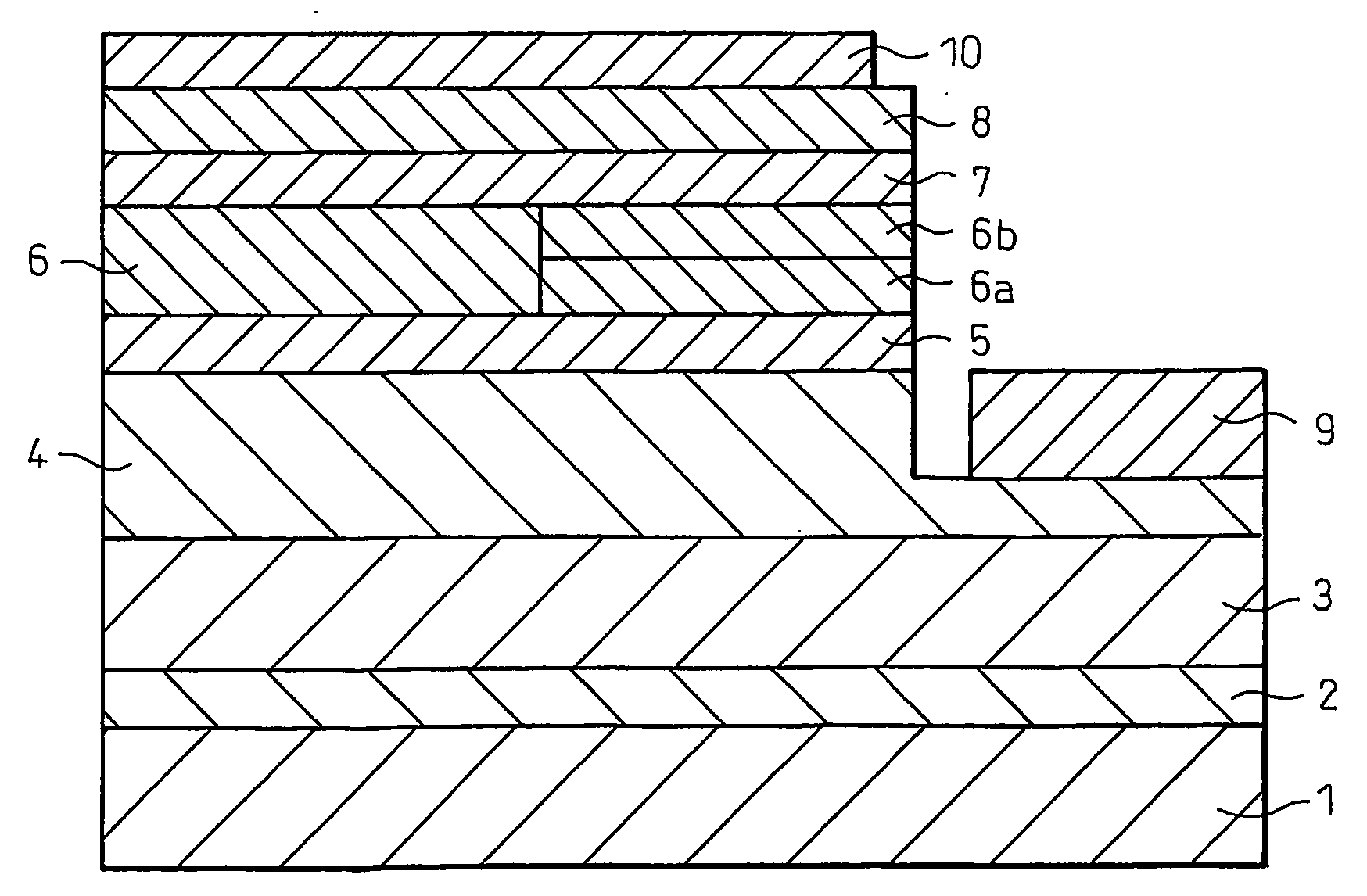

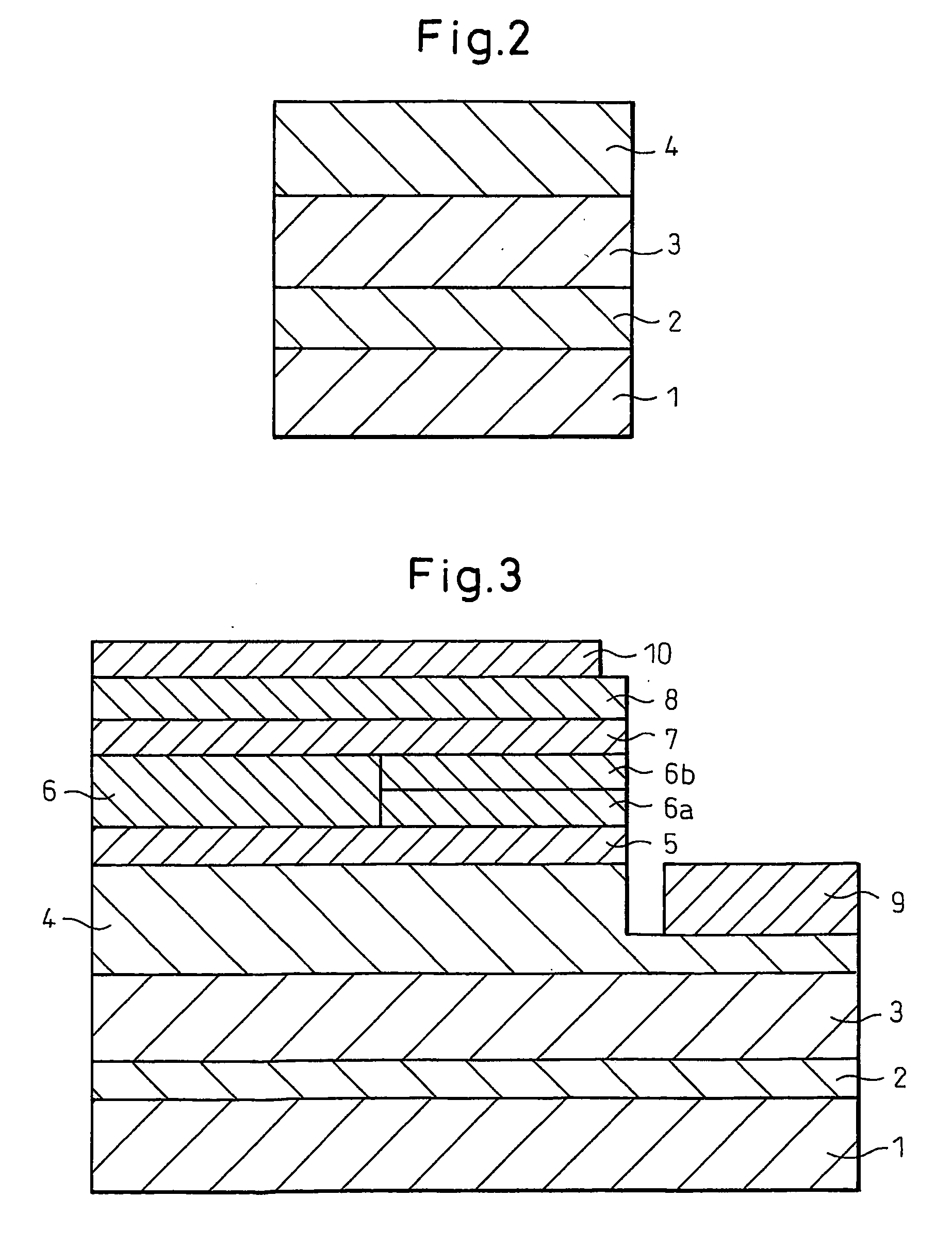

Method of fabricating light-emitting device and light-emitting device

InactiveUS20050285127A1Enhance carrier confinement effectImprove internal quantum efficiencySemiconductor/solid-state device detailsSolid-state devicesContact layerLattice constant

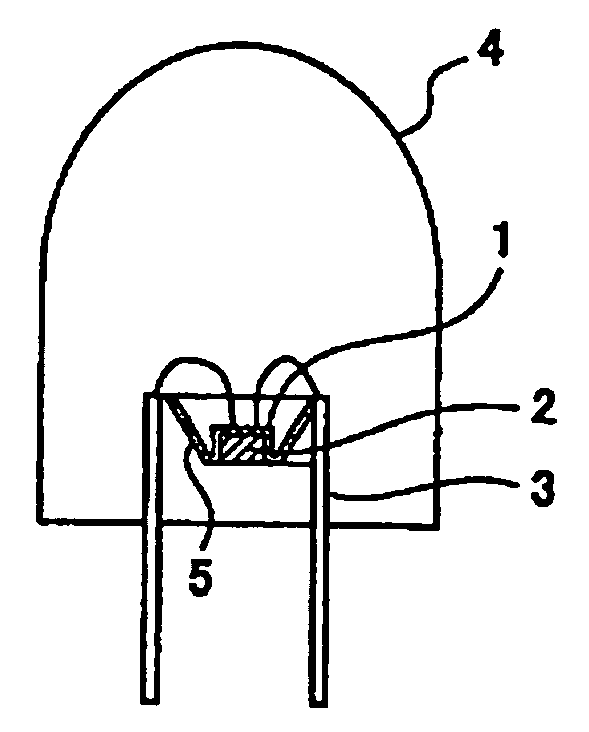

A light-emitting device 100 has ITO transparent electrode layers 8, 10 used for applying drive voltage for light-emission to a light-emitting layer section 24, and is designed so as to extract light from the light-emitting layer section 24 through the ITO transparent electrode layers 8, 10. The light-emitting device 100 also has contact layers composed of In-containing GaAs, formed between the light-emitting layer section 24 and the ITO transparent electrode layers 8, 10, so as to contact with the ITO transparent electrode layers respectively. The contact layers 7, 9 are formed by annealing a stack 13 obtained by forming GaAs layers 7′, 9′ on the light-emitting layer section, and by forming the ITO transparent electrode layers 8, 10 so as to contact with the GaAs layers 7′, 9′, to thereby allow In to diffuse from the ITO transparent electrode layers 8, 10 into the GaAs layers 7′, 9′. This provides a method of fabricating a light-emitting device, in which the ITO transparent electrode layers as the light-emission drive electrodes are bonded as being underlain by the contact layers, to thereby reduce contact resistance of these electrodes, and to thereby make the contact layers less susceptible to difference in the lattice constants with those of the light-emitting layer section during the formation thereof.

Owner:SHIN-ETSU HANDOTAI CO LTD

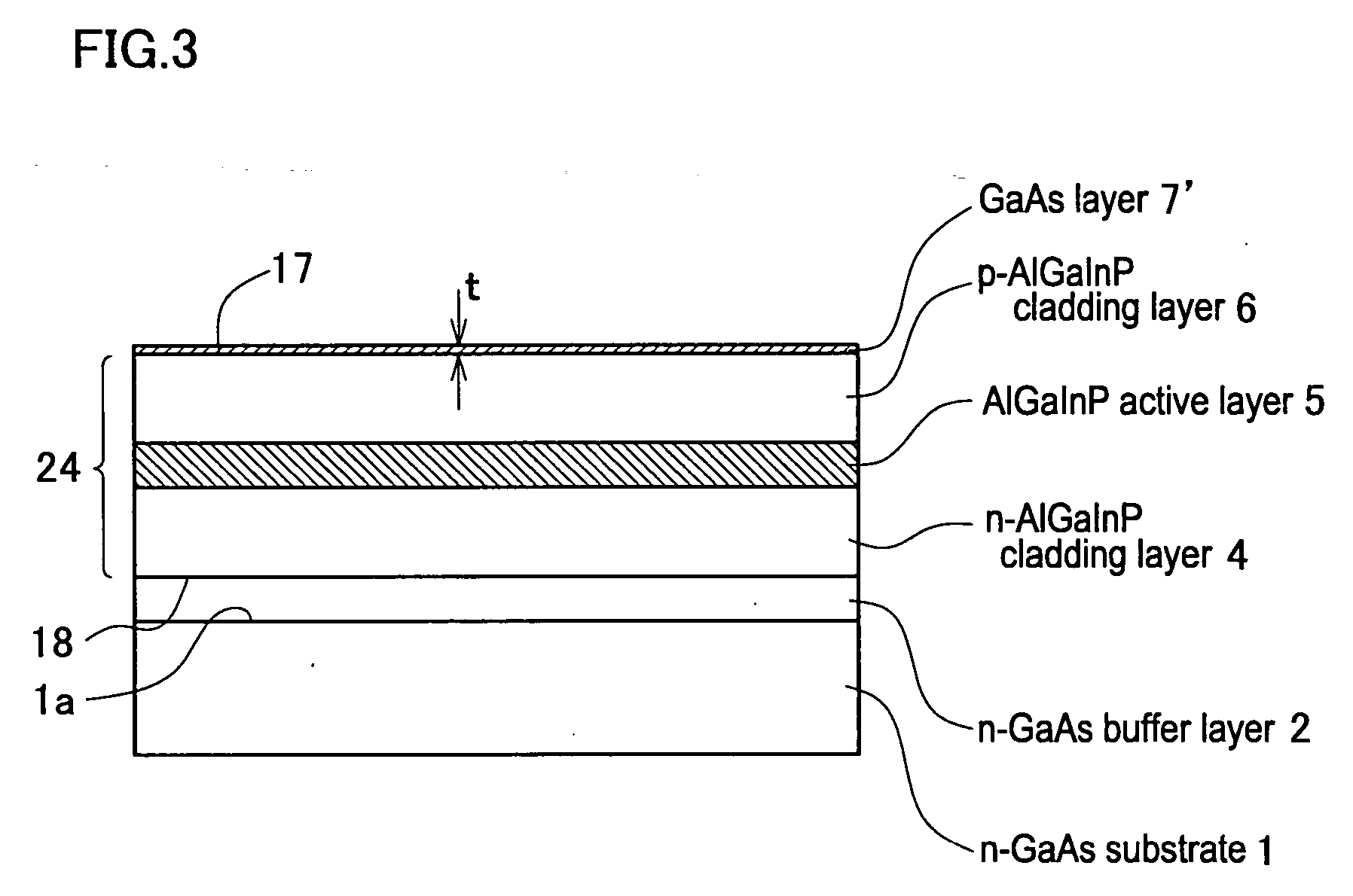

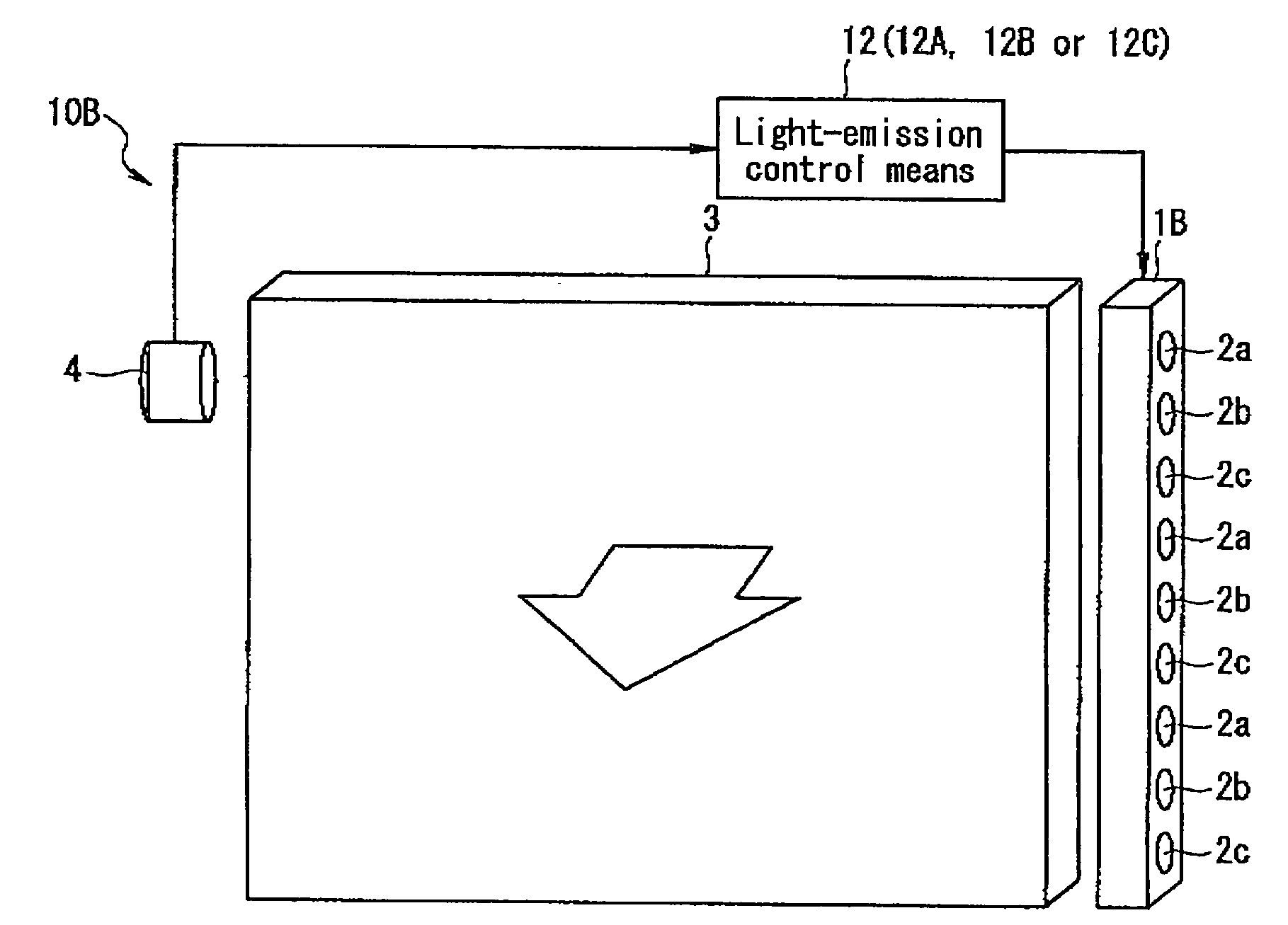

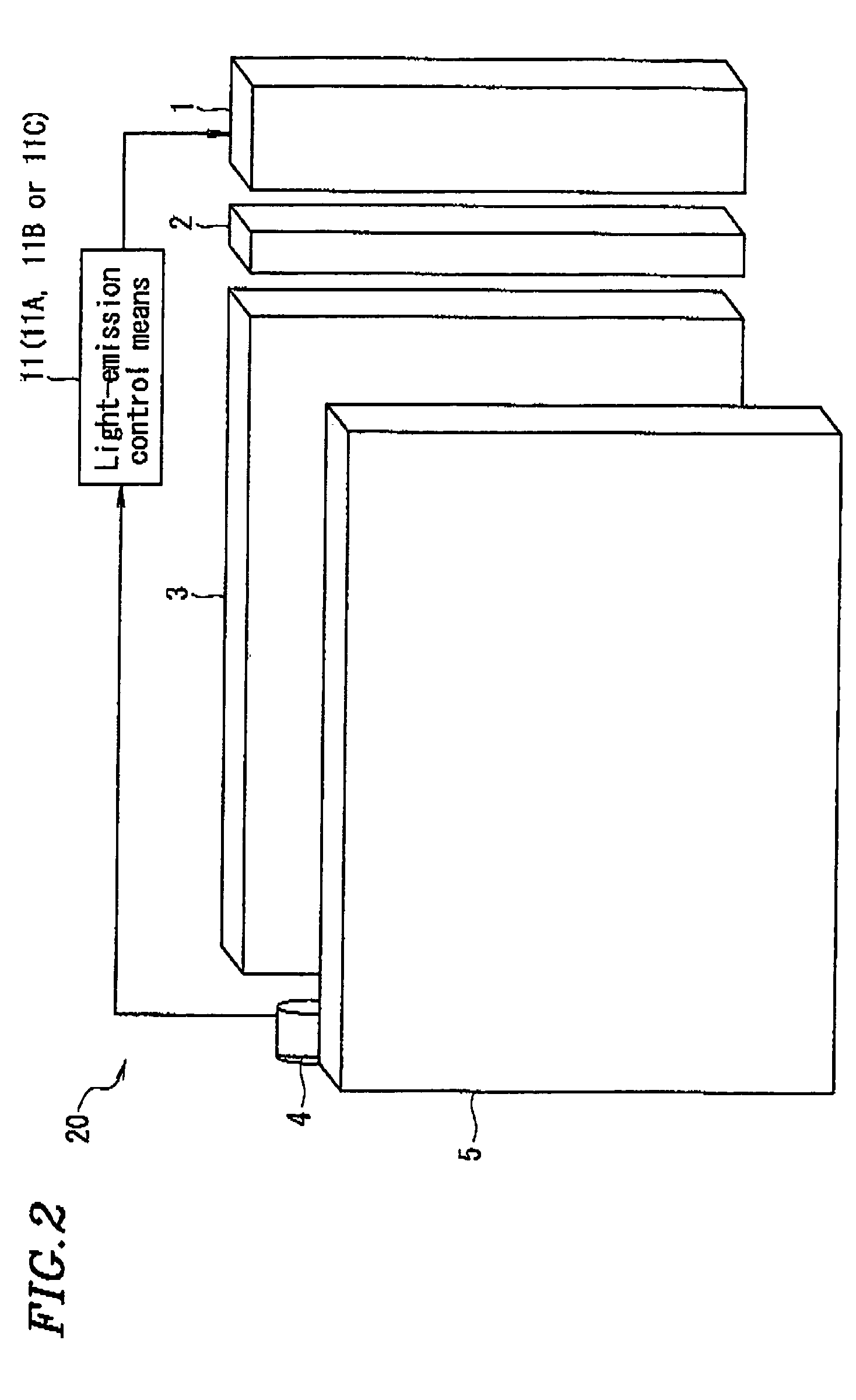

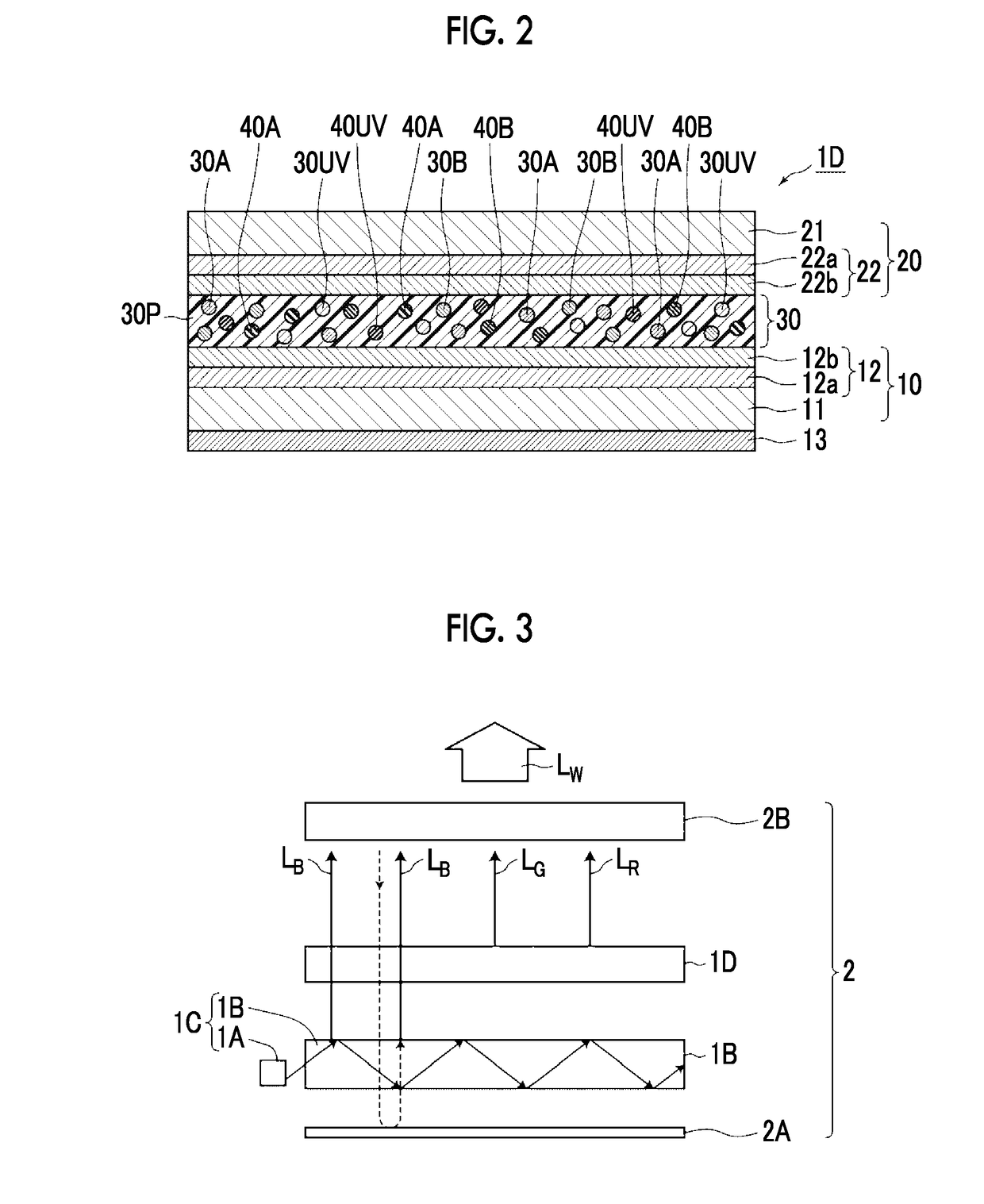

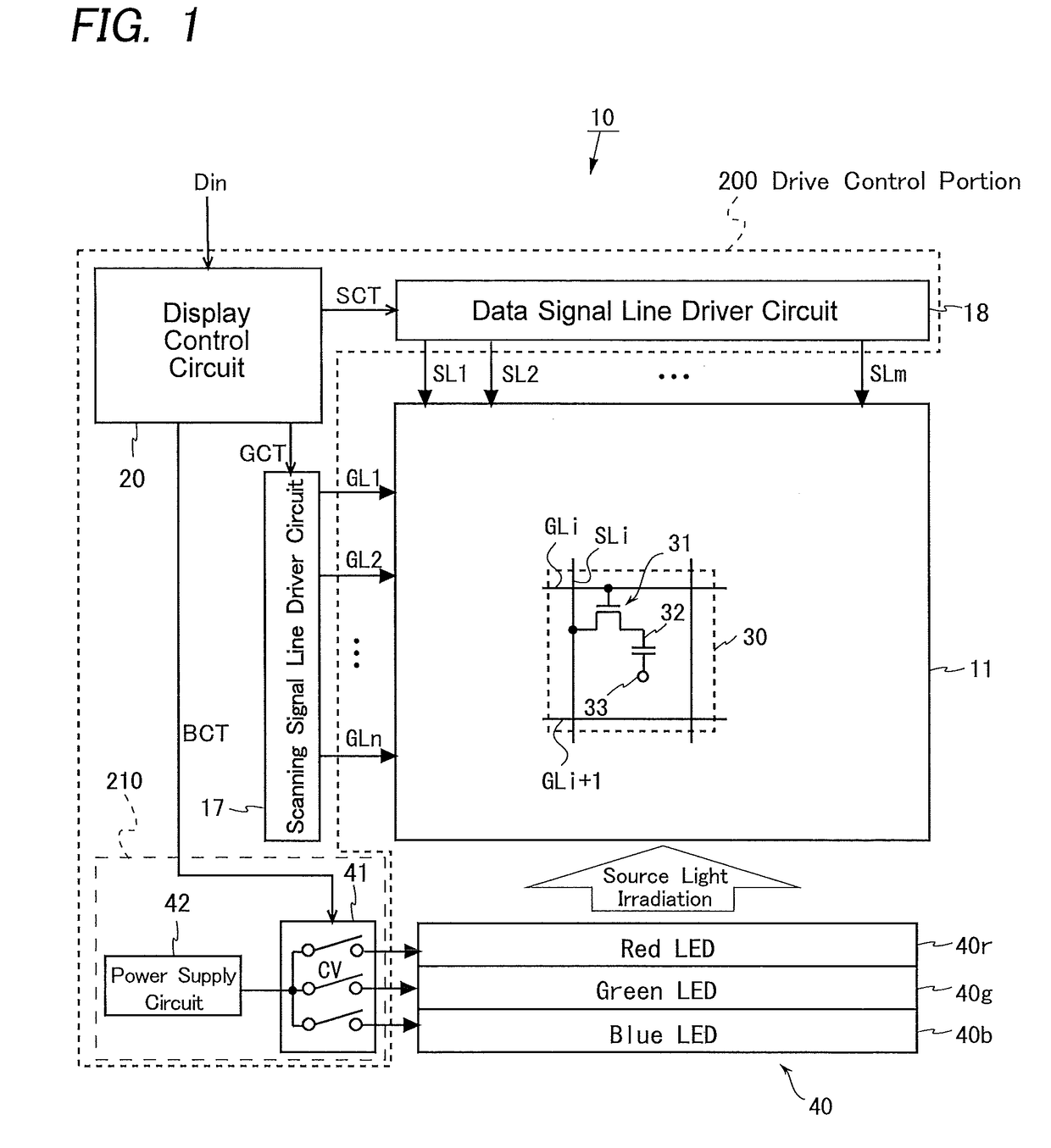

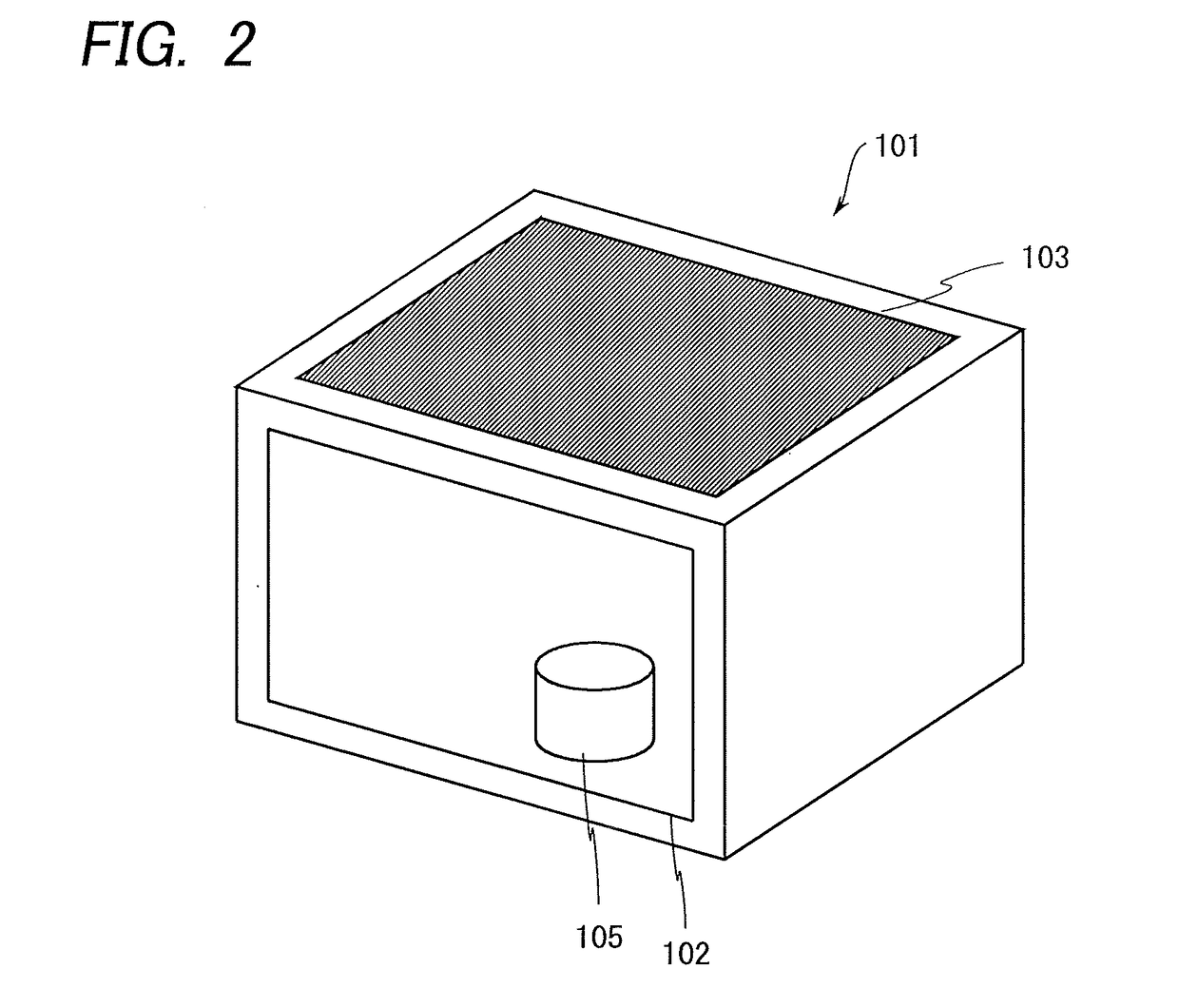

Light emitting device and display apparatus and read apparatus using the light emitting device

InactiveUS7510300B2Reduce emission intensityIncrease intensityElectrical apparatusStatic indicating devicesLuminous intensityLight emission

A light emitting device provided with a plurality of types of light sources having different light emitting colors and with a light emission control means for allowing light to emit, during a specified period of monitoring a light emitting intensity, from at least one light source out of the plurality of types of light sources at a light emitting intensity different from that available outside the specified period. Accordingly, when a plurality of types of light sources are used, the light emitting intensities of a plurality of types of light sources can be monitored with light sensors of types fewer than the types of light sources to control while points and a brightness characteristics.

Owner:SHARP KK

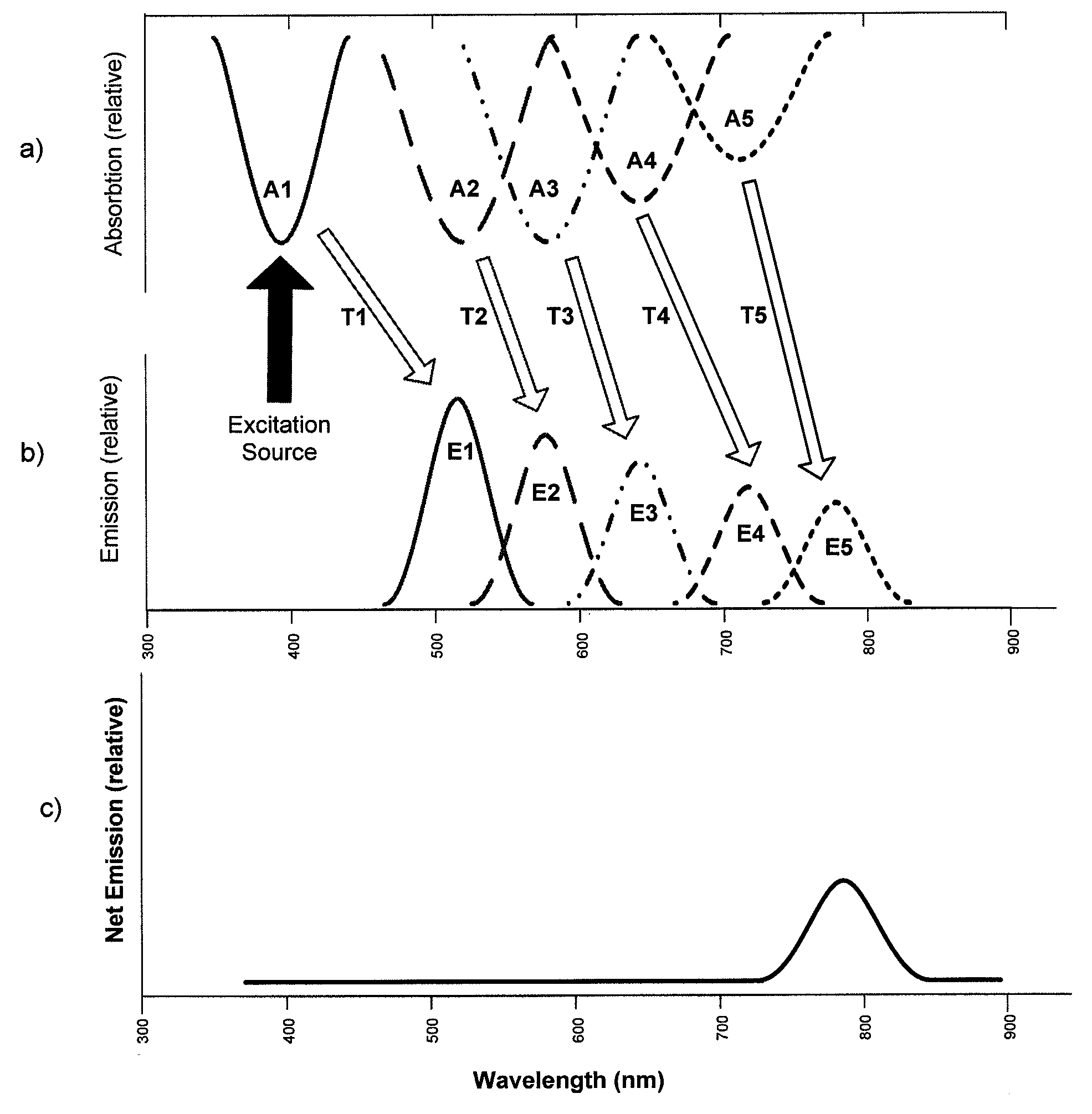

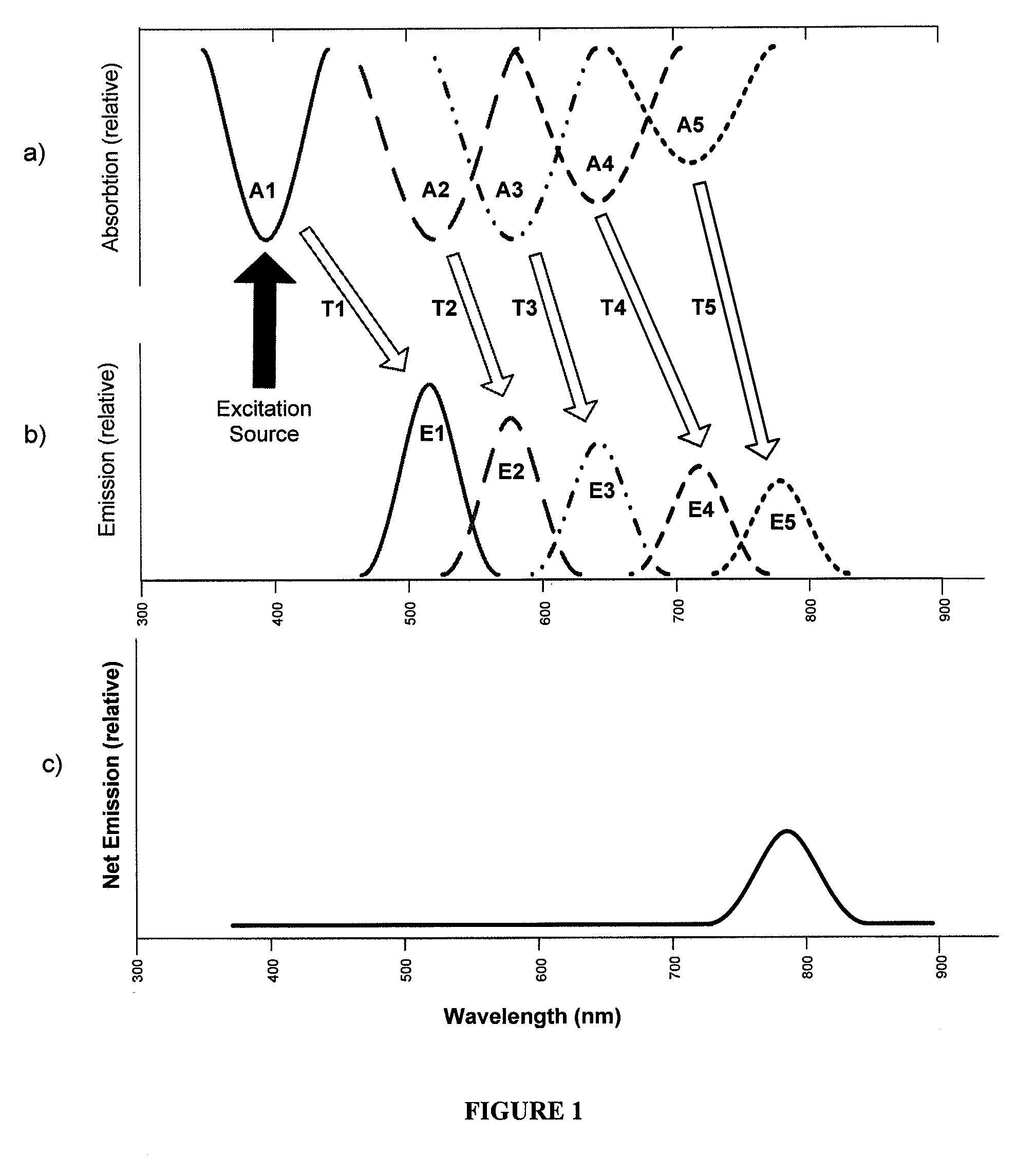

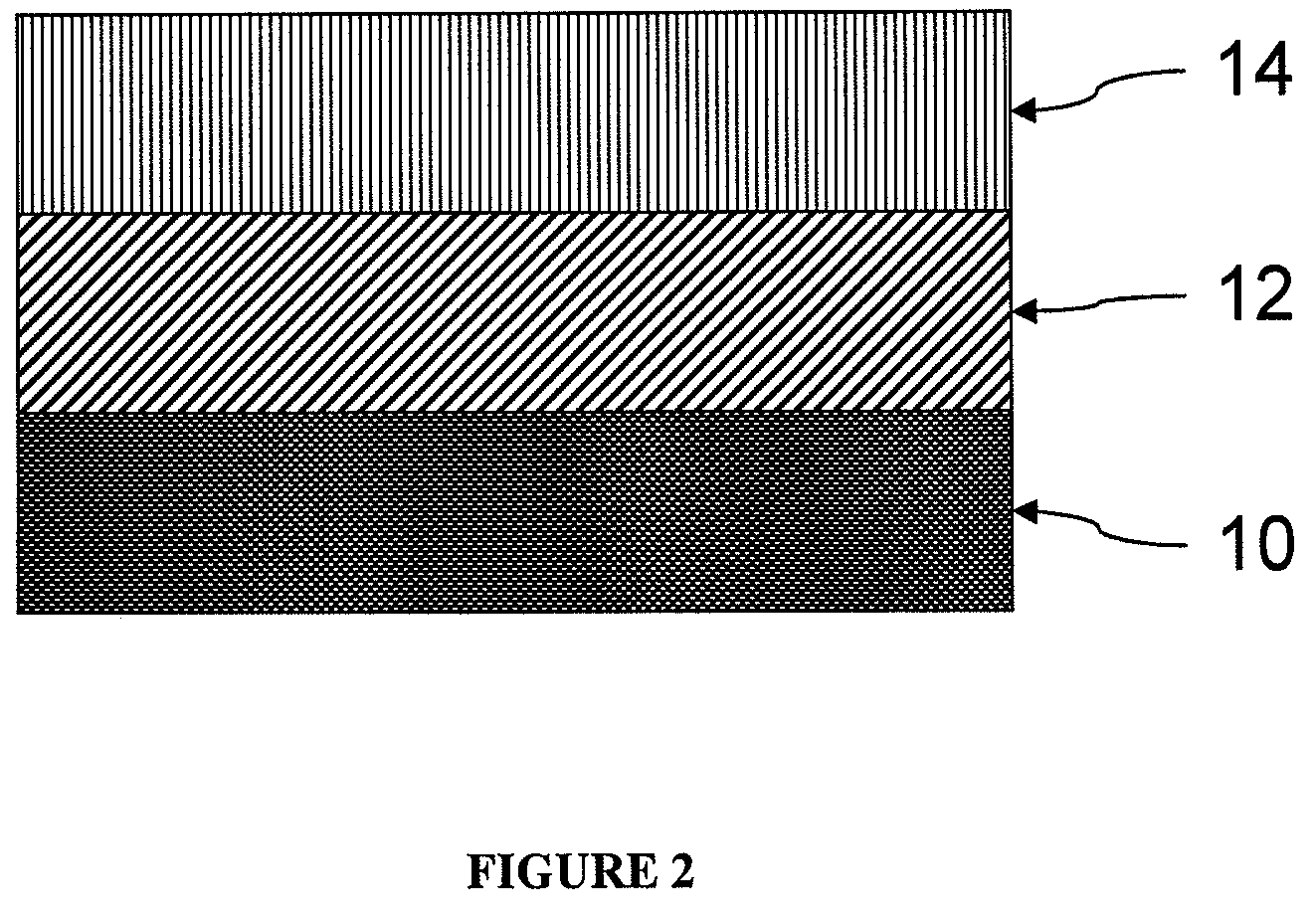

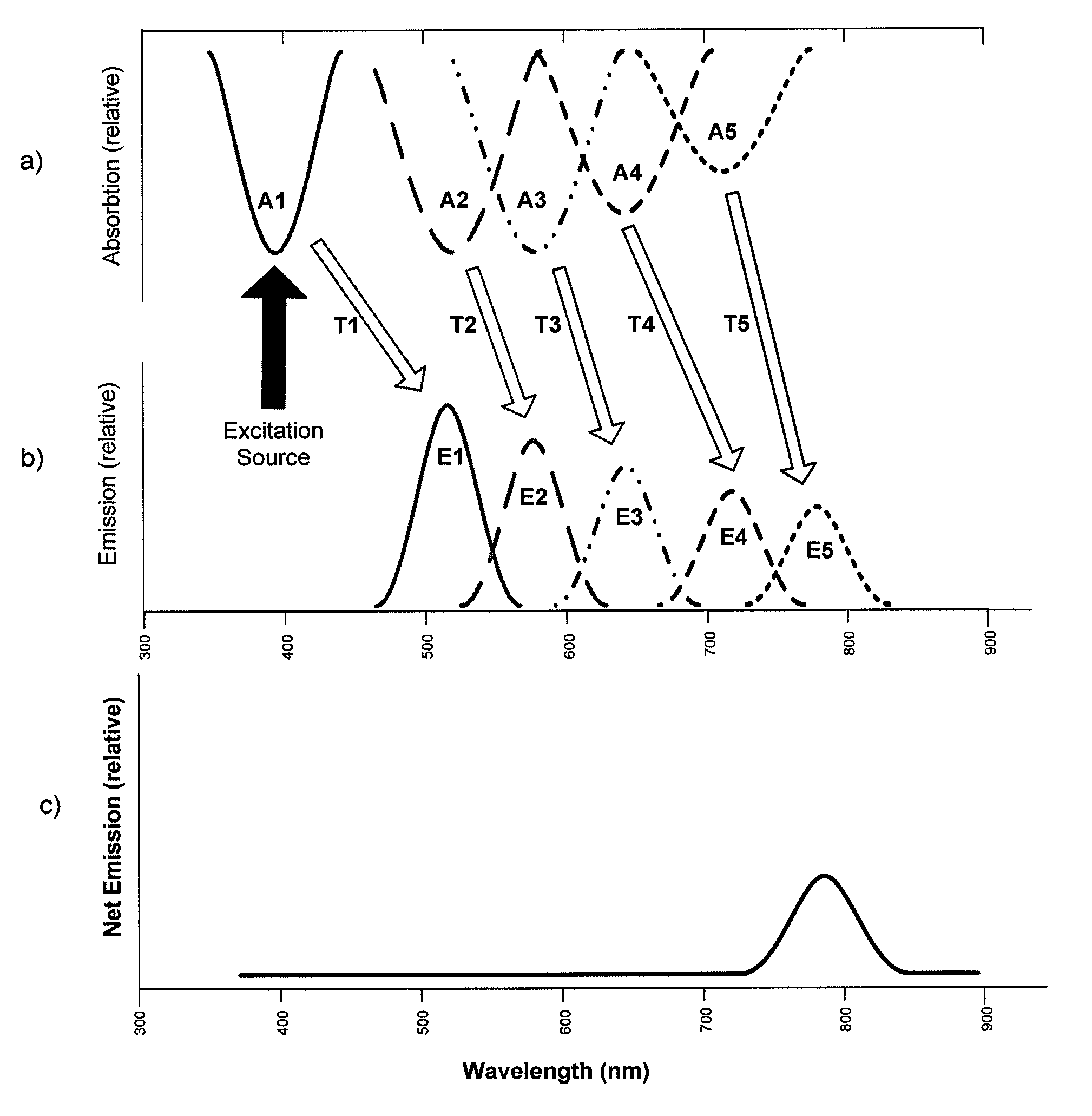

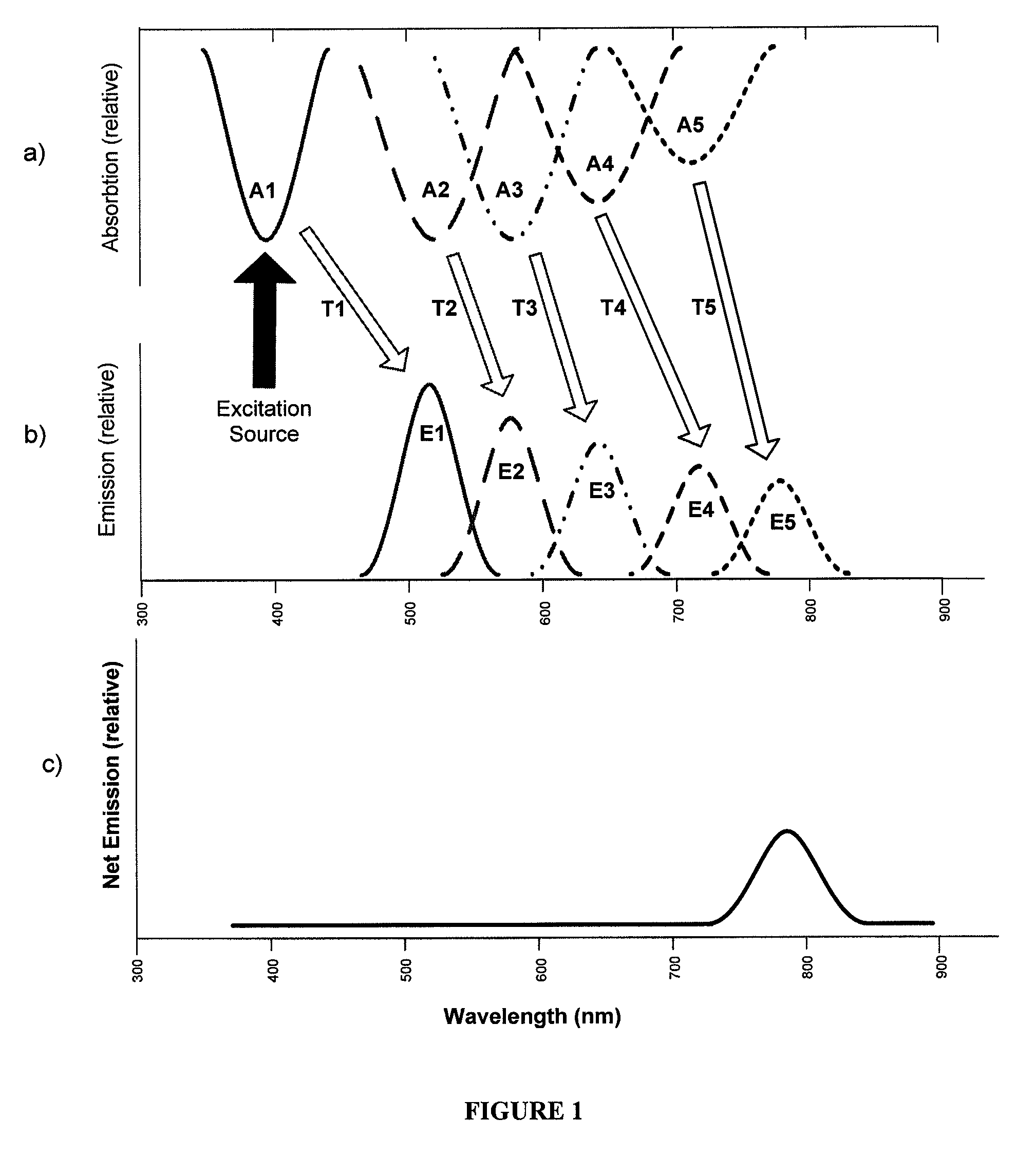

Photoluminescent markings with functional overlayers

InactiveUS20100320371A1Increase rangeEasy to usePaper-money testing devicesPattern printingLuminous intensityPhotoluminescence

Provided are photoluminescent markings that contain a photoluminescent layer and one or more functional overlayers wherein the photoluminescent marking has an emission signature that lies partly or fully in the infrared region of the electromagnetic spectrum. One functional overlayer conceals the photoluminescent layer and blends into the background or blends with marks that are normally present, without significantly reducing the luminescent intensity of the photoluminescent layer. Another functional overlayer provides photolytic stability to the underlying photoluminescent layer. The invention also includes functional overlayers that enhance the daytime observability of the infrared emissions. A further functional overlayer prevents the observability of a printed message with the naked eye. A combination of functional overlayers each providing a different function is also included. As well, the present invention includes a multifunctional overlayer. The present invention also relates to methods of creating and using the inventive photoluminescent markings as well as objects containing the inventive photoluminescent markings.

Owner:PERFORMANCE INDICATOR LLC

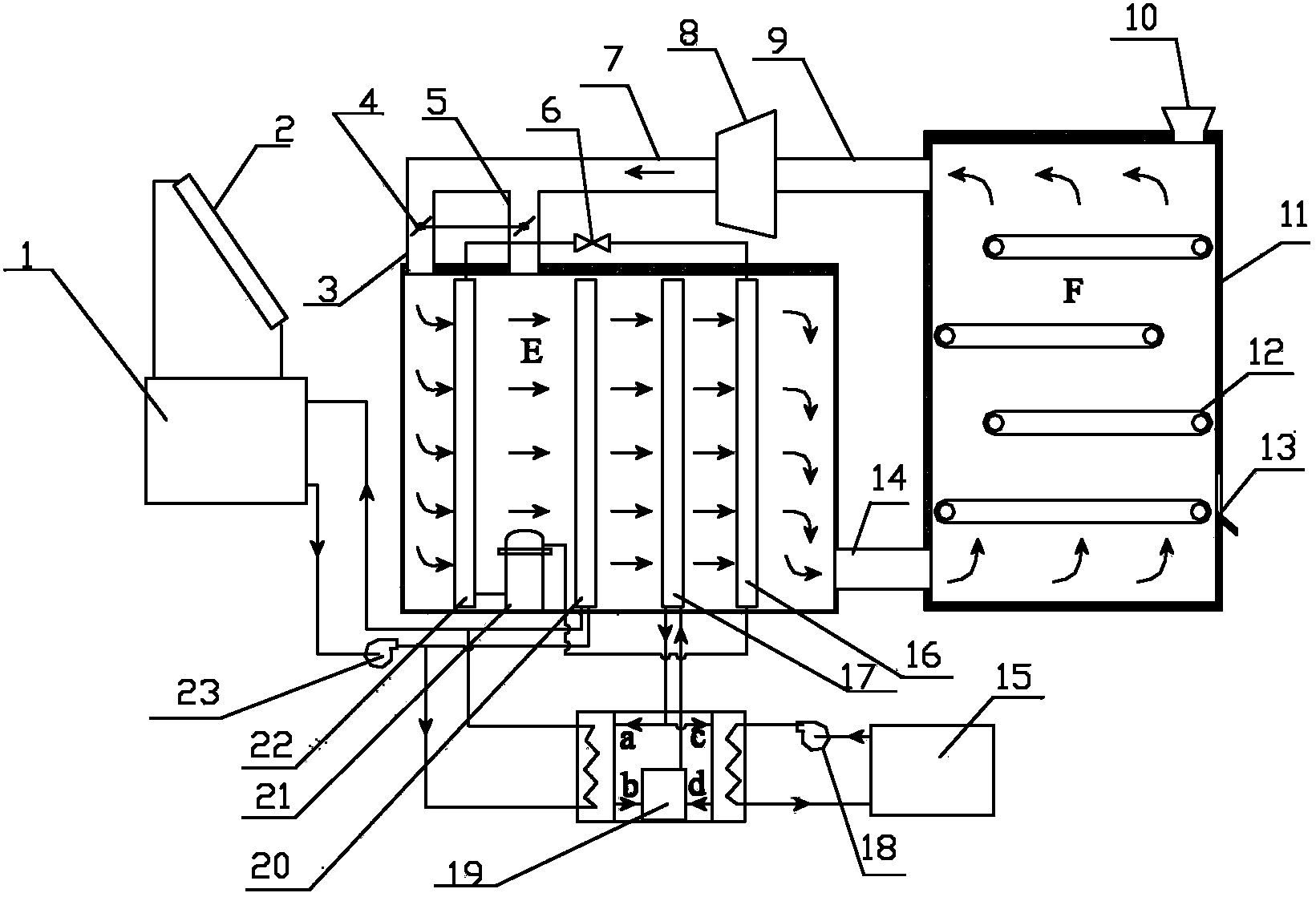

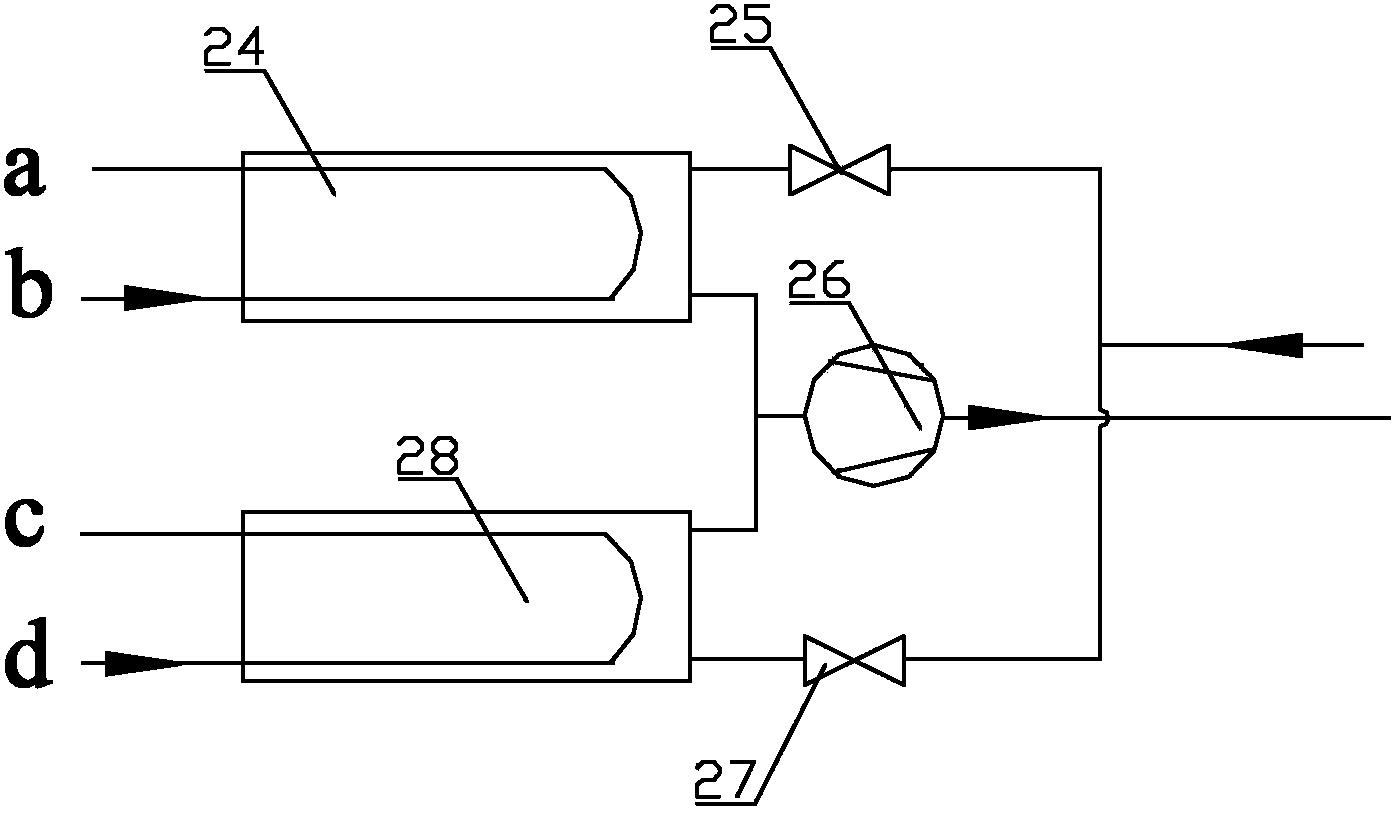

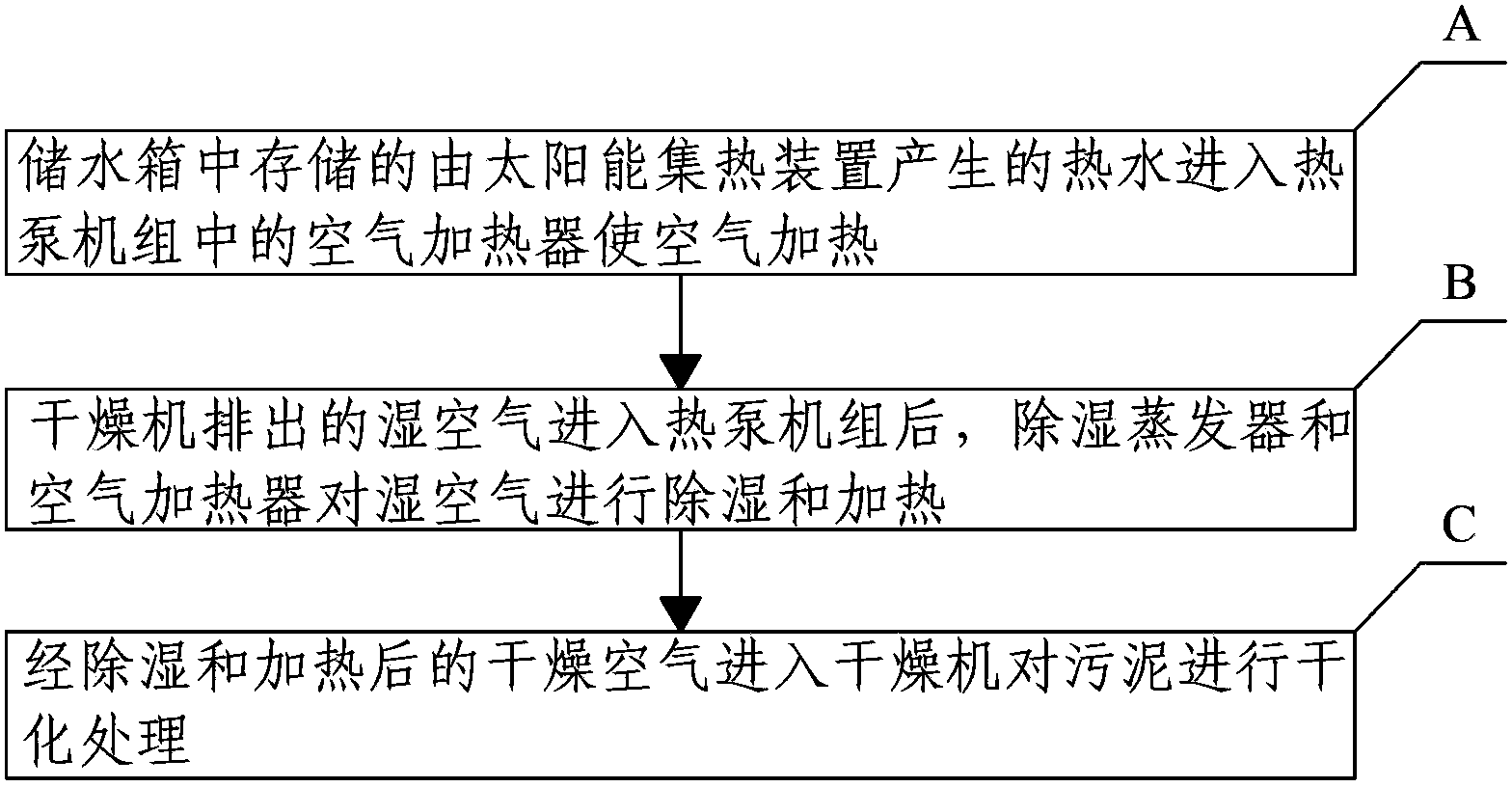

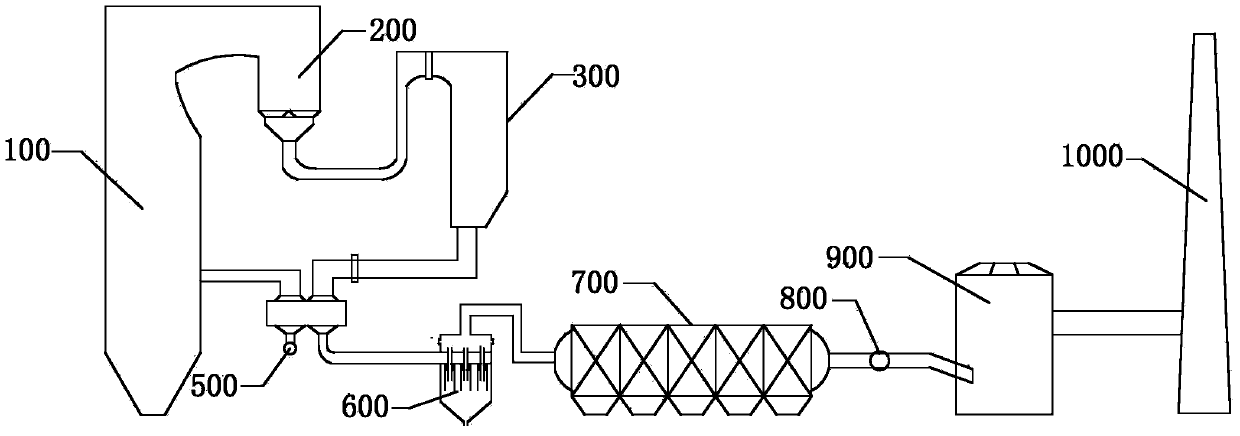

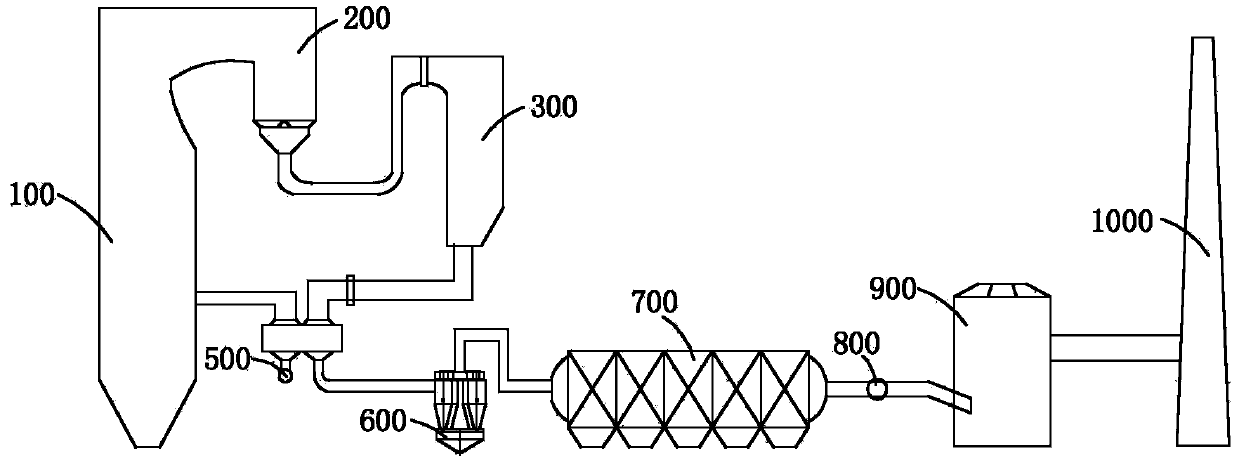

Solar energy heat pump combined sludge drying system and drying method

ActiveCN103482838AReduce emission intensityReduce consumptionSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentWater circulationReclaimed water

The present invention discloses a solar energy heat pump combined sludge drying system, which comprises a solar energy heat supply subsystem, a heat pump subsystem and a drying device subsystem, wherein the heat pump subsystem comprises an air source heat pump subsystem and a reclaimed water source heat pump subsystem, the solar energy heat supply subsystem comprises a heat collection device for collecting solar radiation energy, a hot water storage tank, a first water pump and a hot water coil pipe, and the hot water storage tank, the first water pump and the hot water coil pipe are connected through pipelines to form a sealed water circulation system. According to the present invention, solar energy heat can be effectively utilized, water vapor latent heat in wet air can be recovered, and energy required by sludge drying at night or in case of insufficient solar energy can be ensured with the solar energy heat supply subsystem and the reclaimed water source heat pump subsystem.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

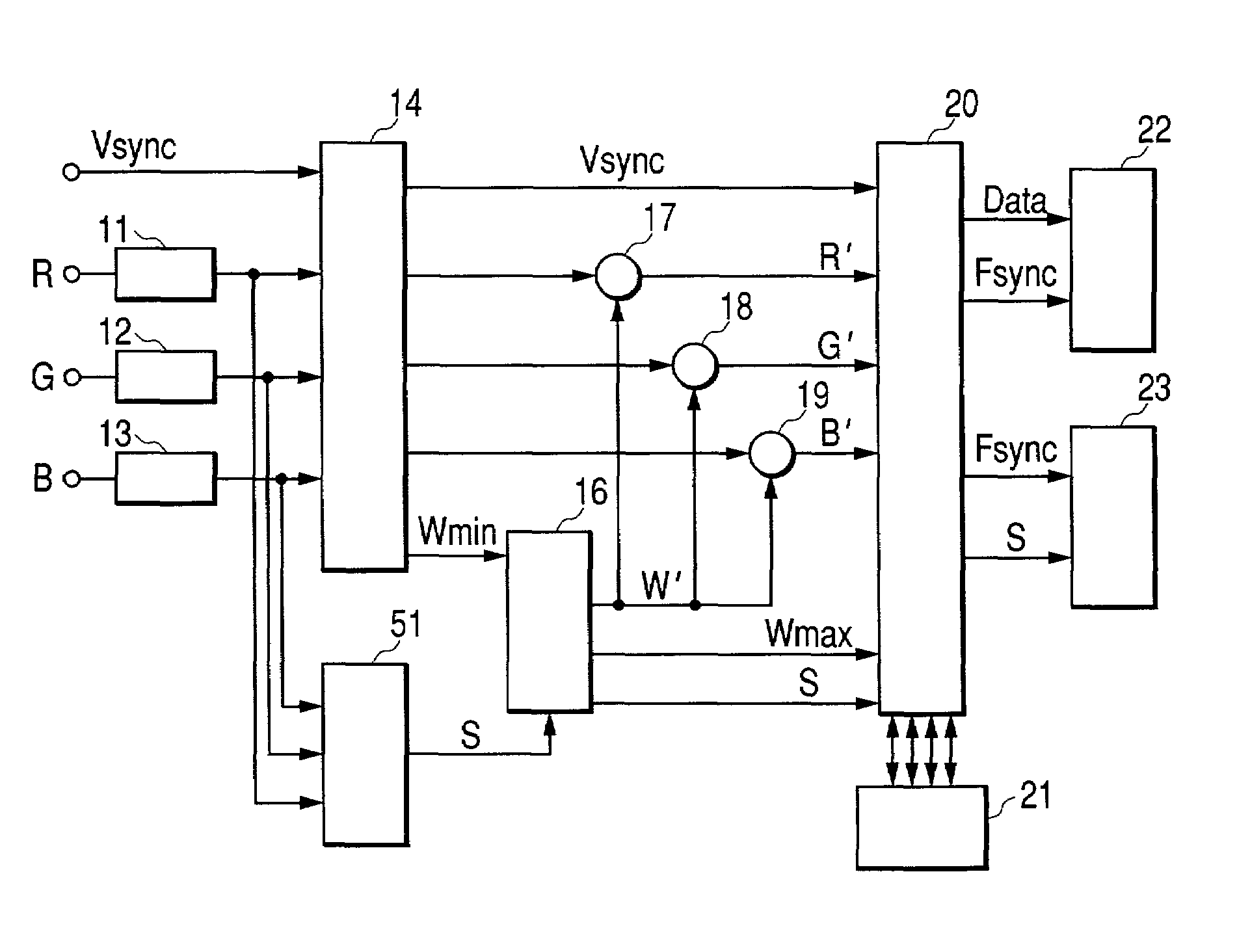

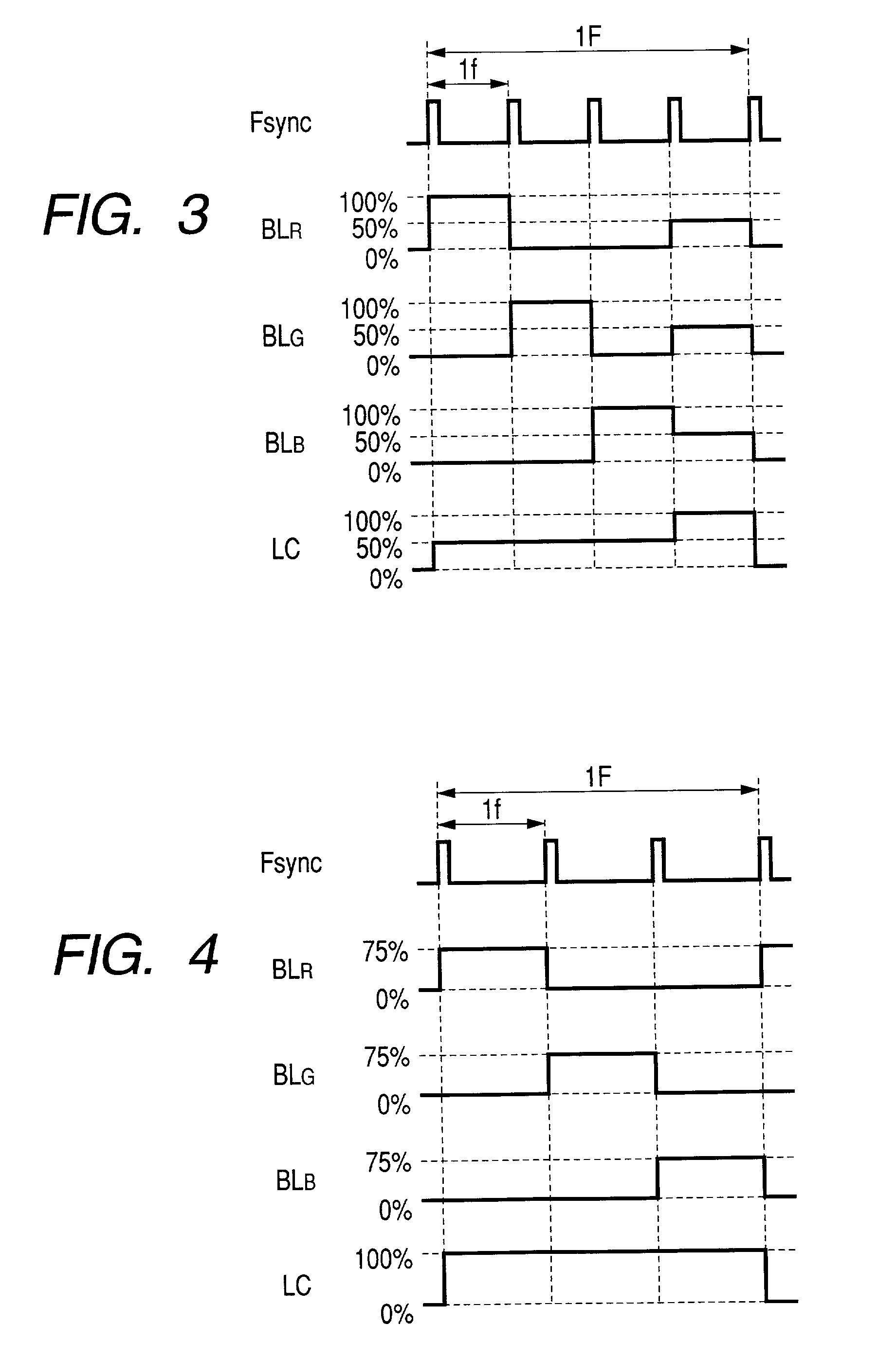

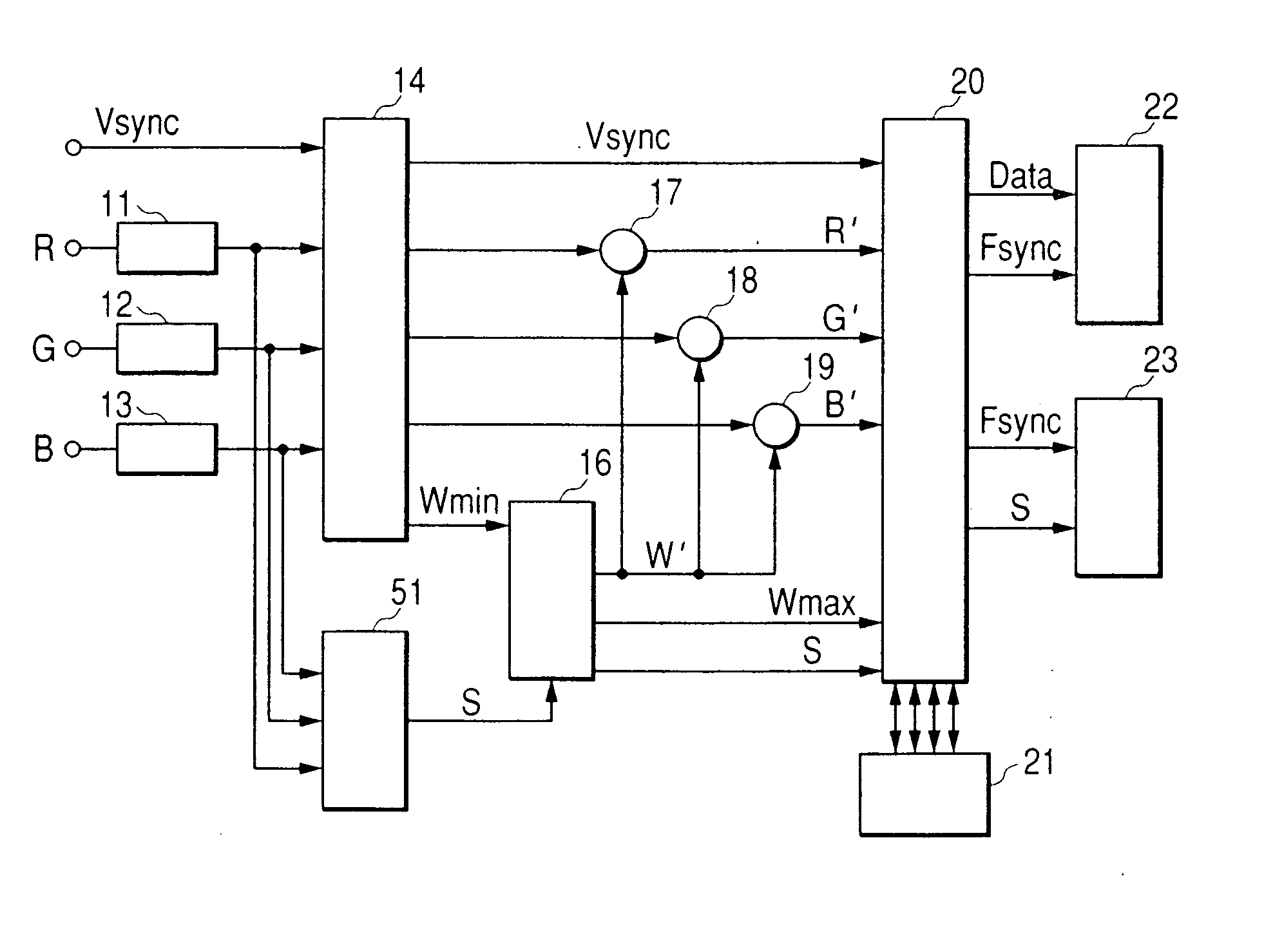

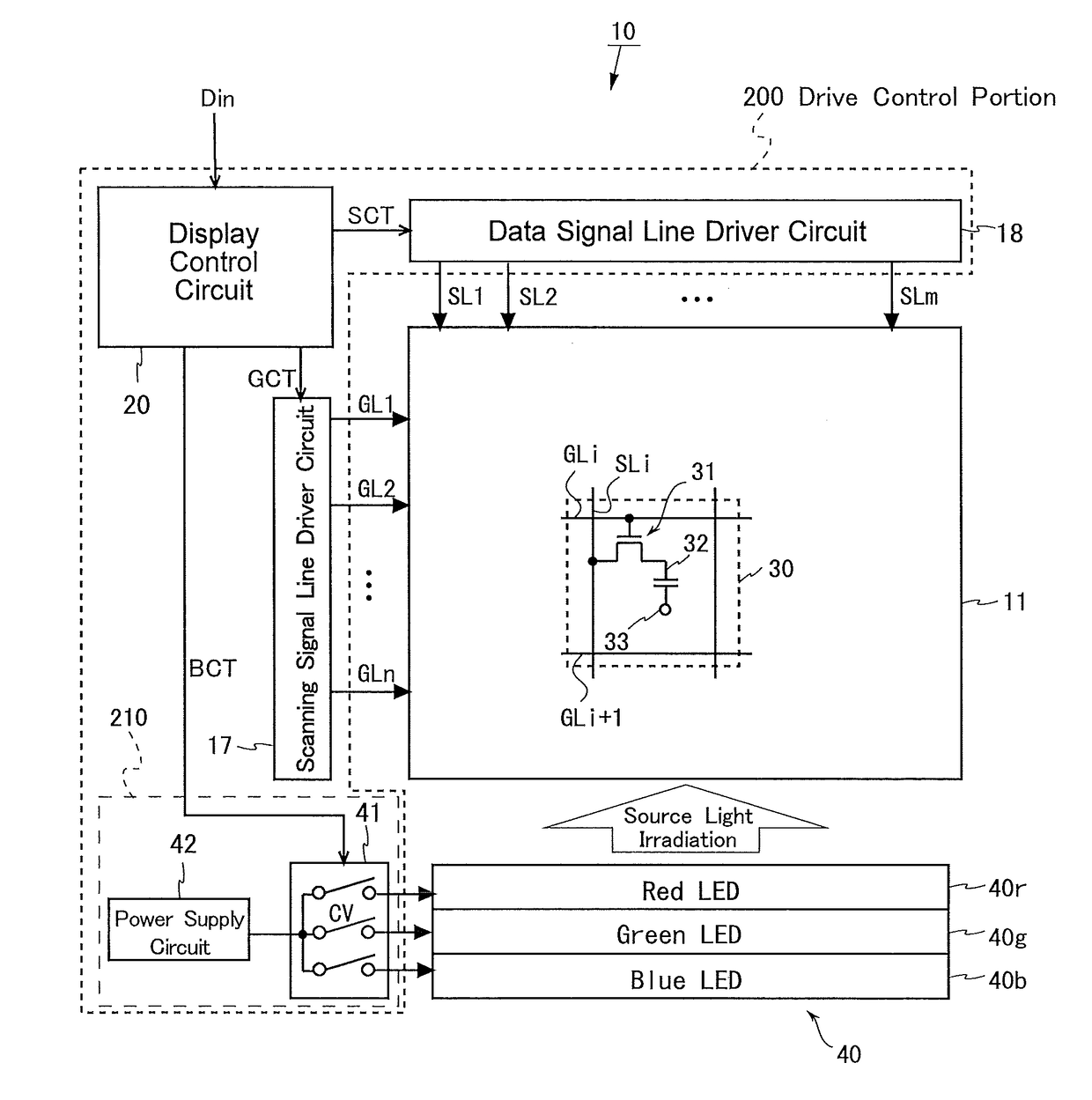

Color liquid crystal display device

InactiveUS20050237288A1Reduce power consumptionReduce emission intensityStatic indicating devicesPicture reproducers using solid-state color displayLiquid-crystal displayLight source

A color liquid crystal display device includes at least a liquid crystal display part, and light sources for irradiating the liquid crystal display part with lights of three primary colors, respectively, and performs display of one frame by respective fields of three primary colors and a white field displayed with a mixture of the three primary colors in the liquid crystal display part. The device further includes a circuit for comparing brightness levels of inputted three primary color signals for one frame with each other to define a maximum value thereof as a brightness level of a white signal for one frame; a circuit for setting a proportion of the brightness level of the white signal to be displayed in the white field; and a light source driving part for driving the light sources of the three primary colors so that the white field emits light depending on the brightness level of the white signal and the proportion.

Owner:CANON KK

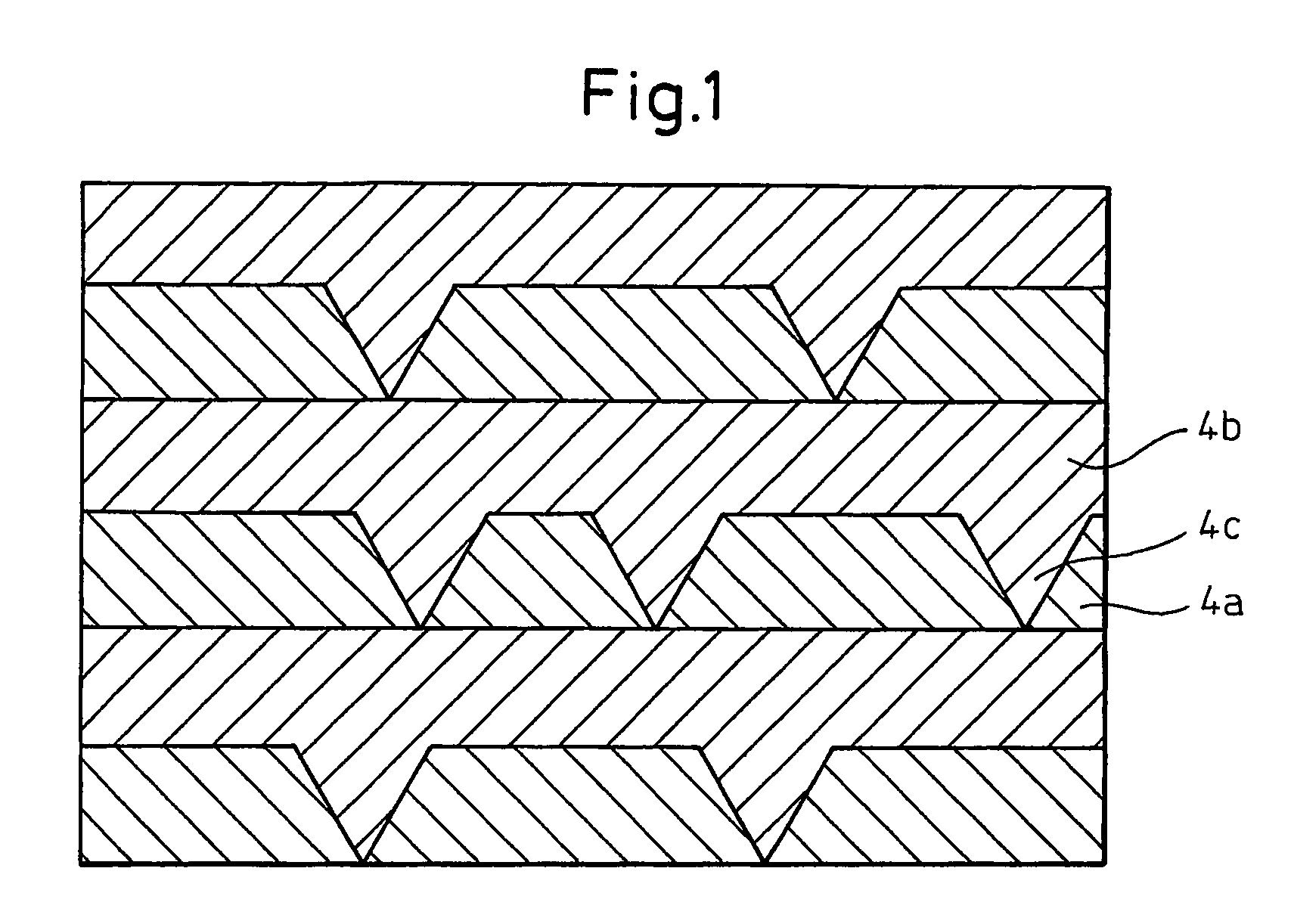

N-Type Group III Nitride Semiconductor Layered Structure

InactiveUS20080230800A1Improve flatnessLess pittingSolid-state devicesSemiconductor/solid-state device manufacturingHigh concentrationImpurity

An object of the present invention is to provide a low-resistance n-type Group III nitride semiconductor layered structure having excellent flatness and few pits. The inventive n-type group III nitride semiconductor layered structure comprises a substrate and, stacked on the substrate, an n-type impurity concentration periodic variation layer comprising an n-type impurity atom higher concentration layer and an n-type impurity atom lower concentration layer, said lower concentration layer being stacked on said higher concentration layer.

Owner:TOYODA GOSEI CO LTD

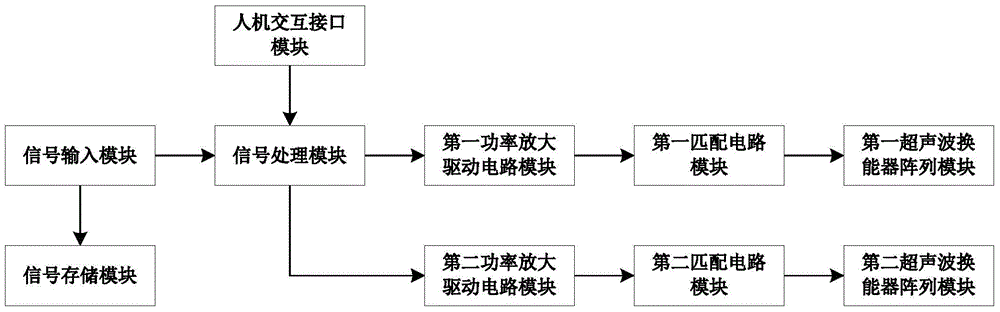

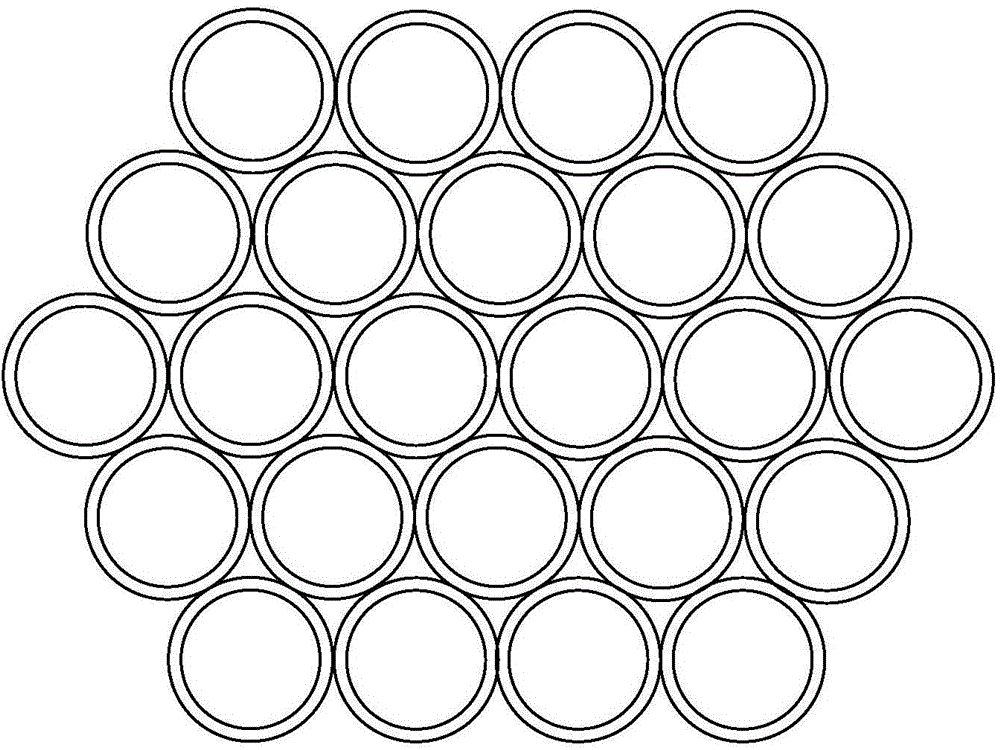

Anti-eavesdropping device

InactiveCN104601784AReduce emission intensityImprove interference effectEavesdropping prevention circuitsInteraction interfaceComputer module

The invention discloses an anti-eavesdropping device which comprises a signal input module, a signal processing module, a signal storage module, a human-computer interaction interface module, two or more than two power amplifying driving circuit modules, two or more than two matching circuit modules and two or more than two ultrasonic transducer array modules. An audio frequency fixed point propagation technology is innovatively used to transmit a record interference signal, a conversion signal based on an original voice signal is adopted as an interference signal, the interference is only conducted on the target area requiring anti-eavesdropping recording interference, other areas are not affected, transmission strength of the interference signals is reduced, and a good interference effect is obtained. Effective interference on the anti-eavesdropping recording of a recording device in different application scenes is achieved, and the device has important practical significance and wide use value.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Phosphor mixture and light emitting device

ActiveUS7477009B2Low efficiencyReduce emission intensityDischarge tube luminescnet screensLamp detailsColor shiftPhosphor

To provide a phosphor mixture realizing a light emitting device having a phosphor and a light emission element, by which light emission is performed, with a small color shift due to a feeding current and having an excellent color rendering properties. CaAlSin3:Eu as a red phosphor and YAG:Ce as a yellow phosphor are manufactured, and emission spectra thereof are obtained. Meanwhile, the emission spectrum of an excitation light emitted by a light emitting part is obtained. From the emission spectra thus obtained, a relative mixing ratio of each phosphor is obtained by simulation, so that a correlated color temperature of the light emitting device becomes a target temperature. Then, based on the relative mixing ratio thus obtained, each phosphor is measured and mixed, and a phosphor mixture is thereby obtained.

Owner:NICHIA CORP +1

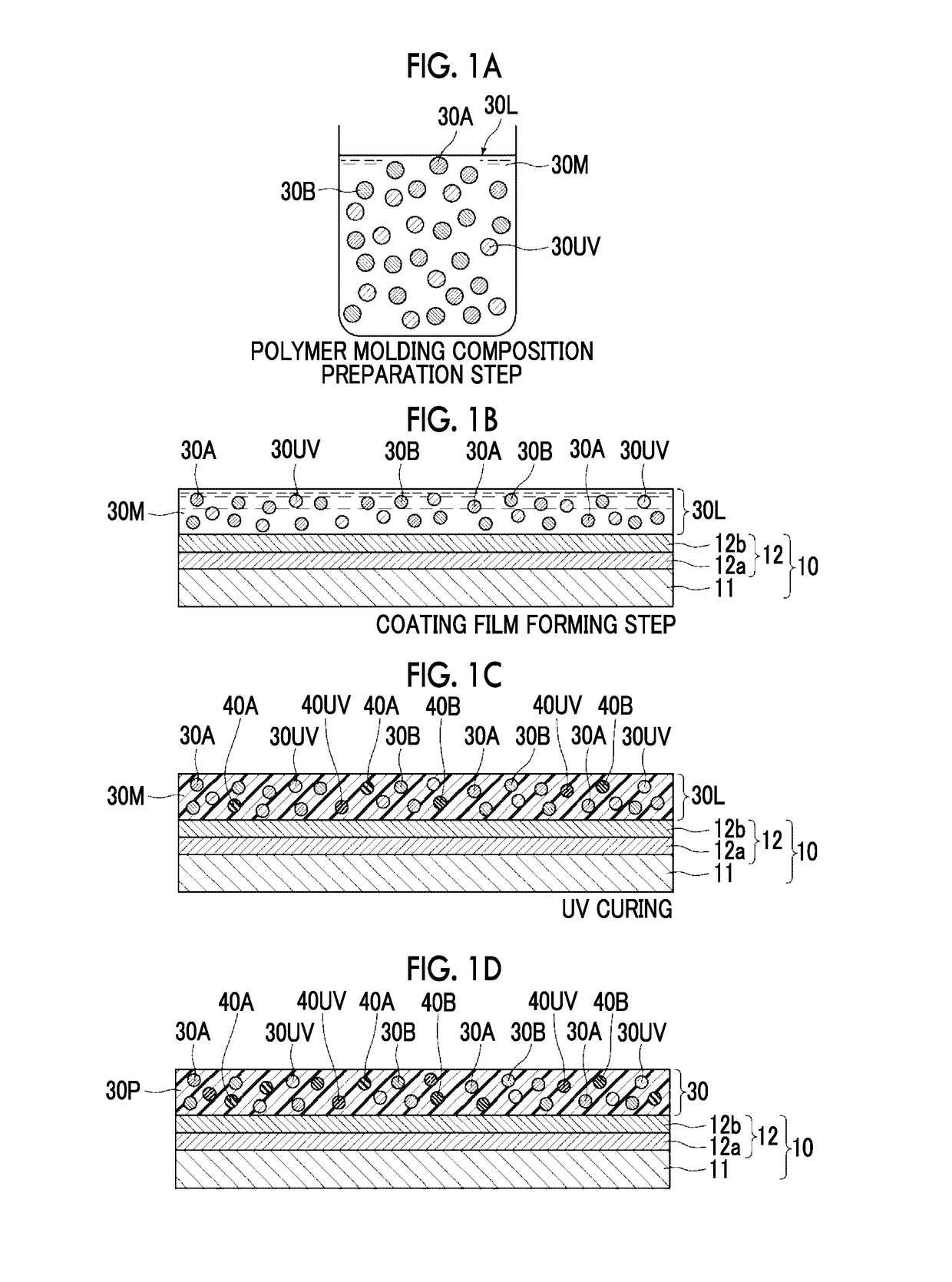

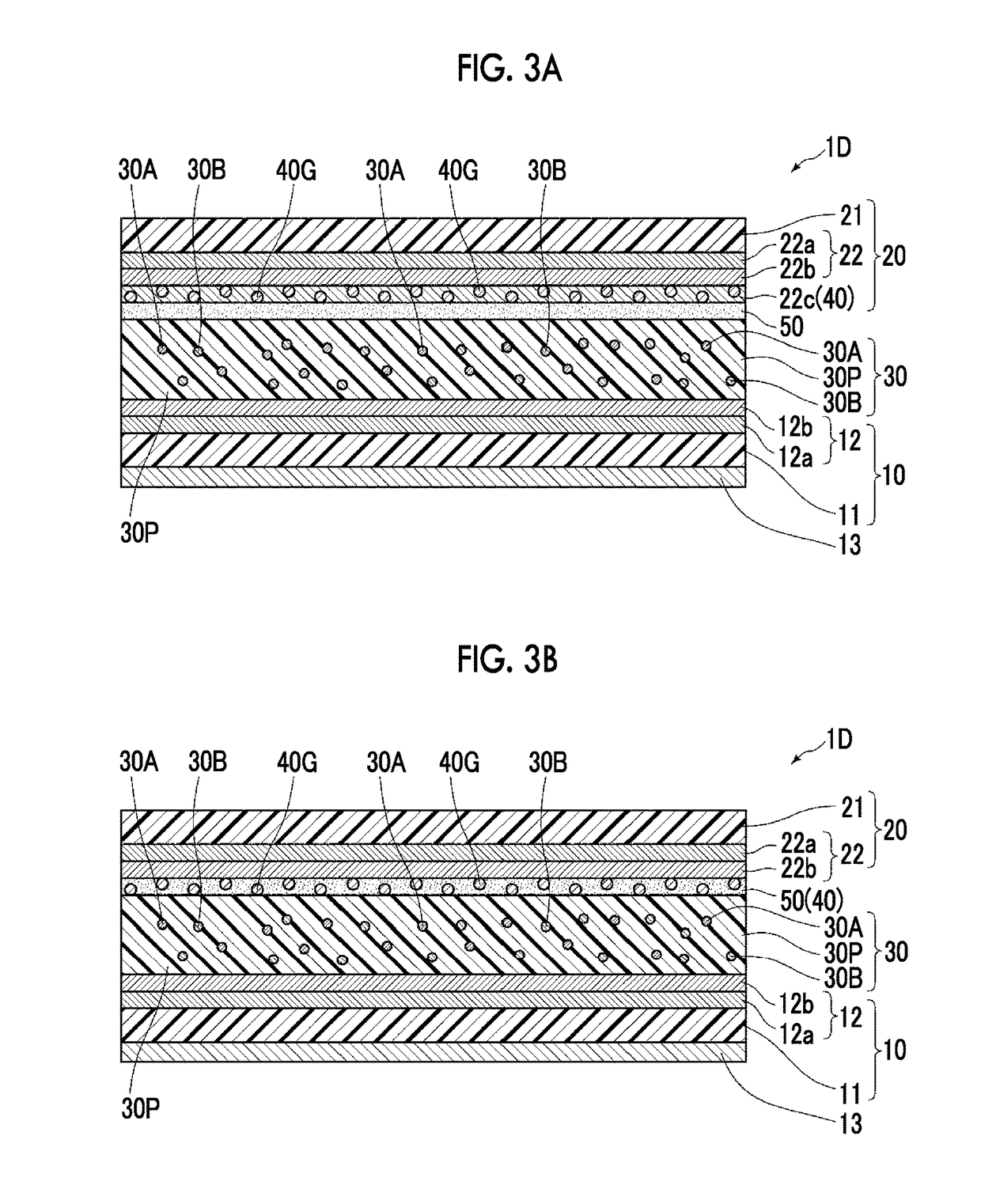

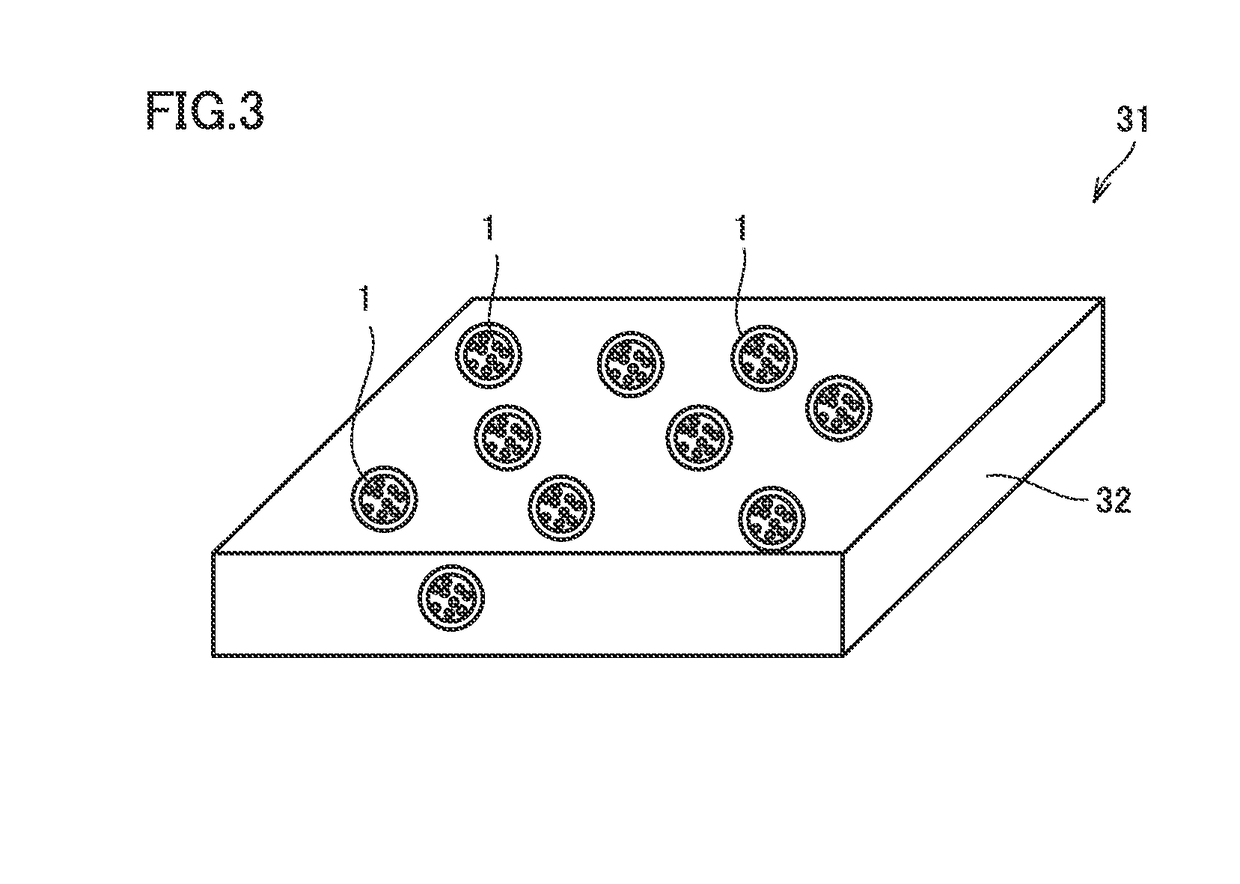

Composition and polymer molding composition, wavelength converter obtained using the same, wavelength conversion member, backlight unit, and liquid crystal display device

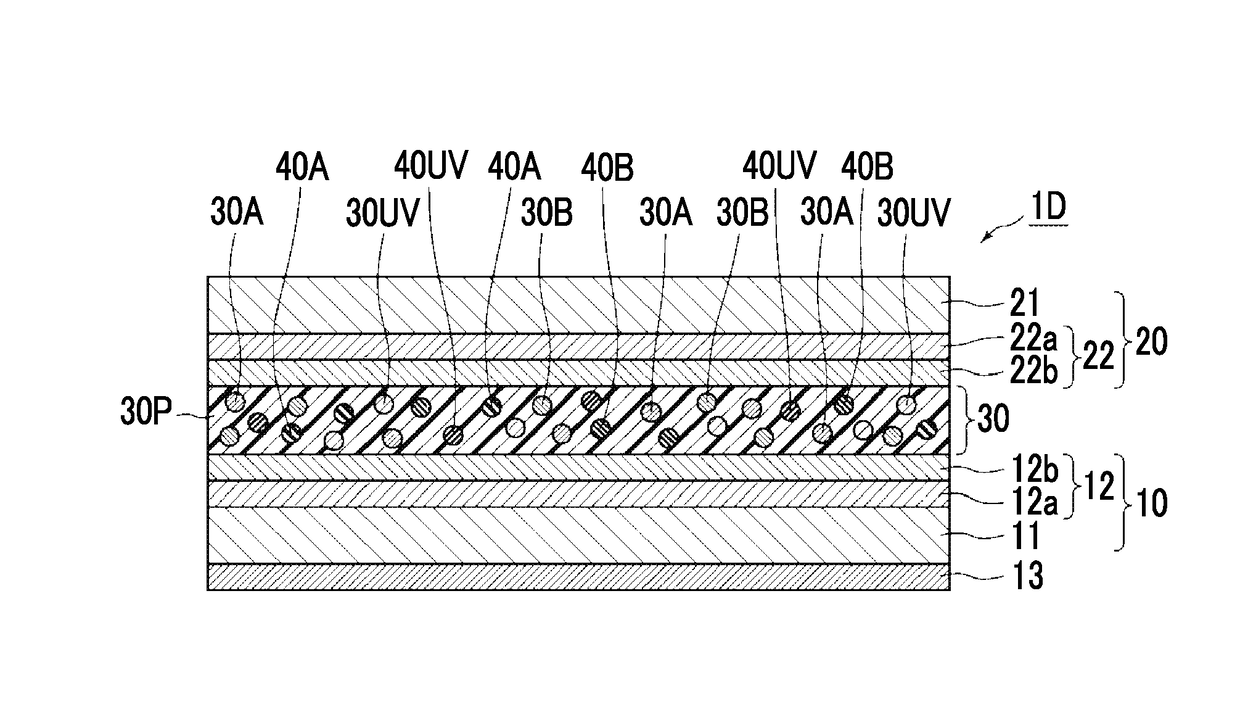

ActiveUS20180072942A1Increase intensityIncreased durabilityMechanical apparatusLuminescent paintsLiquid-crystal displayQuantum dot

A composition and a wavelength converter are provided. The composition includes at least: quantum dots having an emission peak wavelength in a visible light region; and quantum dots having an emission peak wavelength in an ultraviolet region or in a near-ultraviolet region. The wavelength converter includes, in a polymer: quantum dots having an emission peak wavelength in a visible light region; quantum dots having an emission peak wavelength in an ultraviolet region or in a near-ultraviolet region; and an oxide formed by oxidizing at least a part of the quantum dots having an emission peak wavelength in an ultraviolet region or in a near-ultraviolet region.

Owner:FUJIFILM CORP

Organic light-emitting device

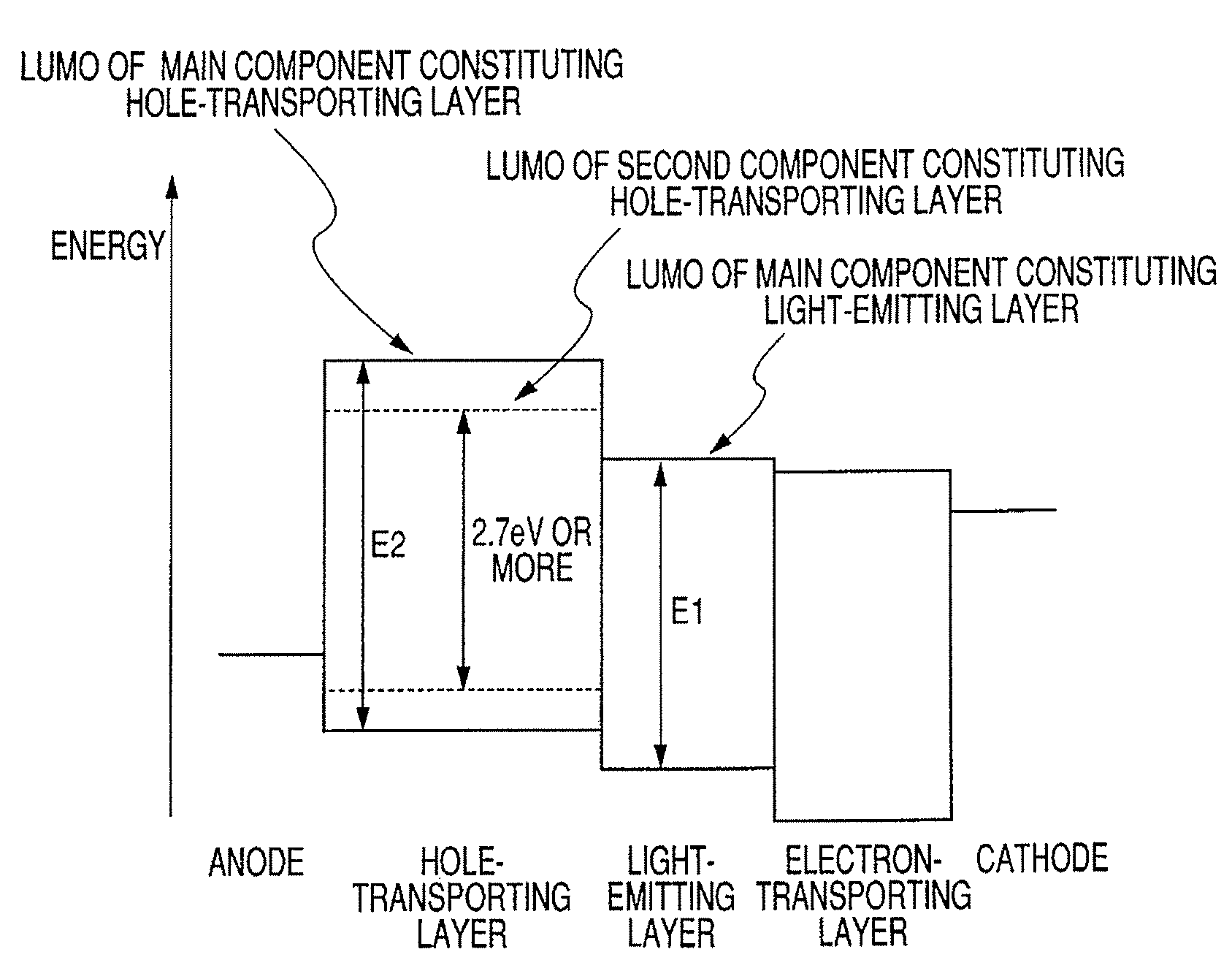

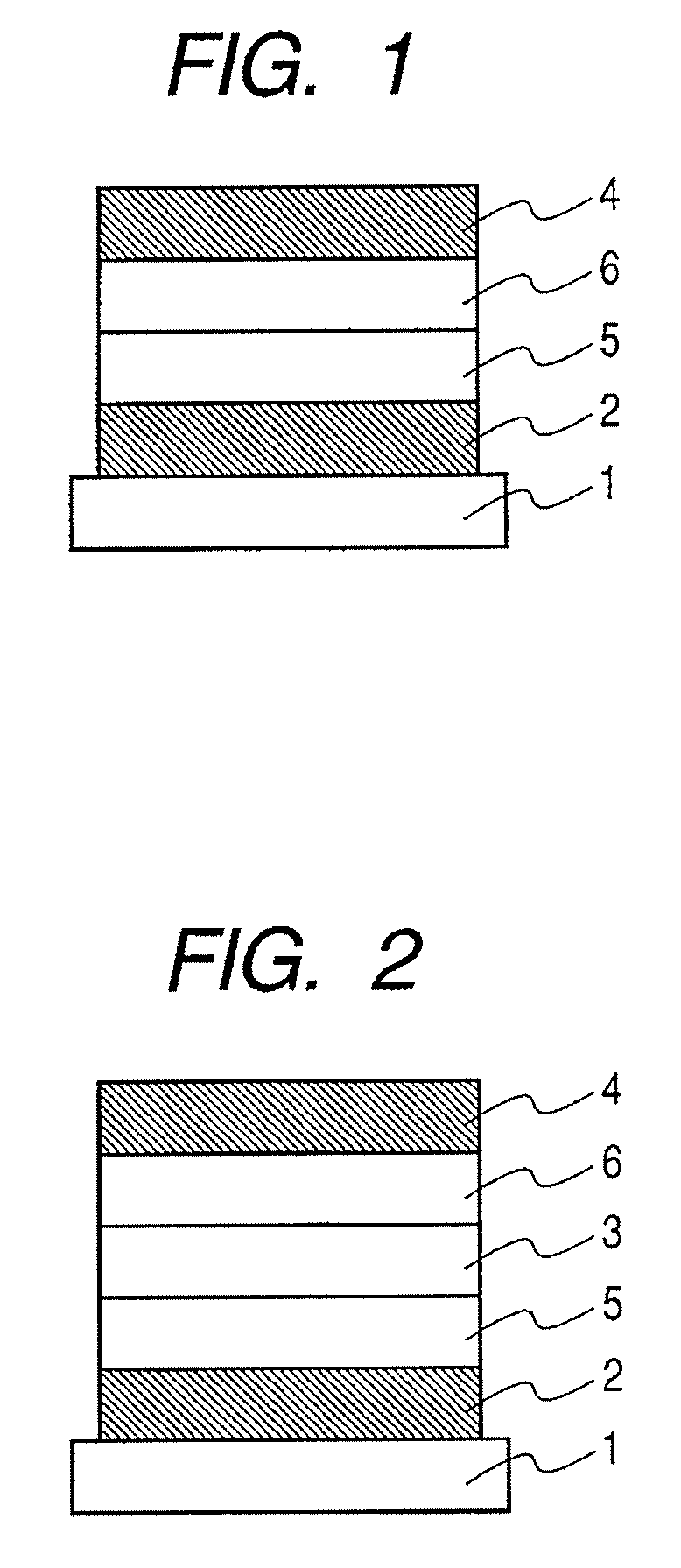

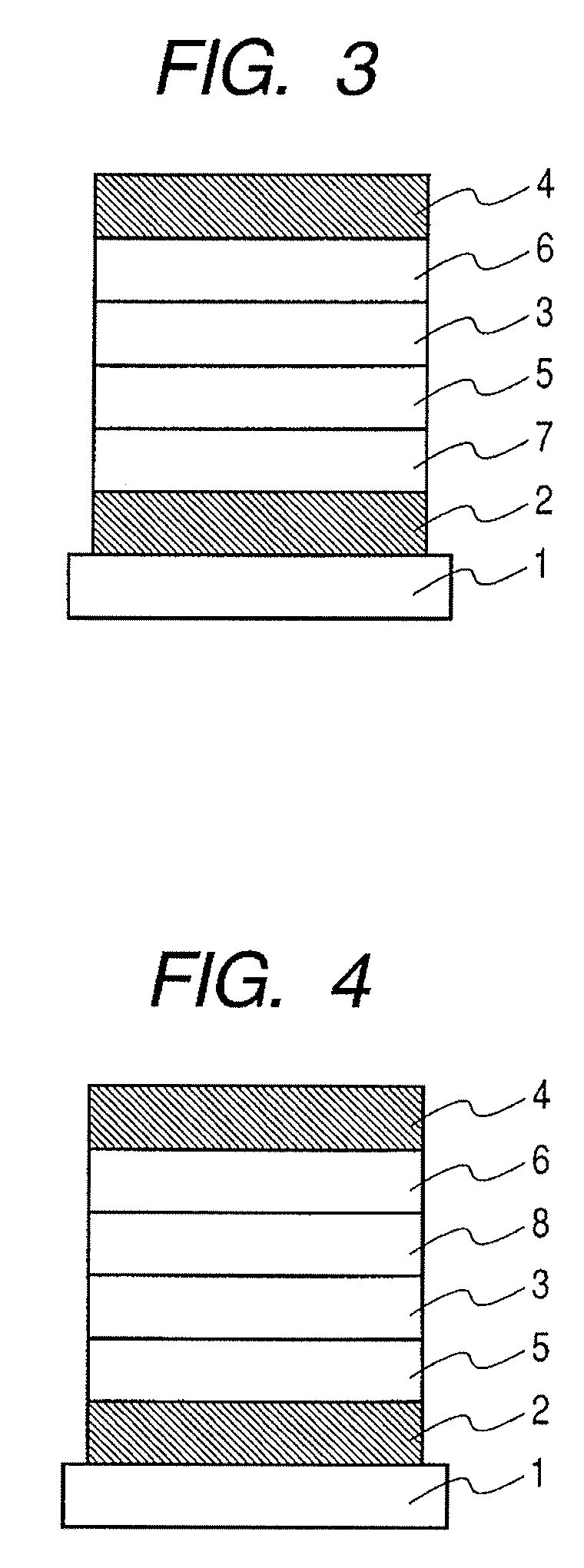

ActiveUS20070205713A1Alleviate lowering in emission intensityWide bandgapDischarge tube luminescnet screensElectroluminescent light sourcesMolecular orbital energyExcited state

In an organic light-emitting device which uses, in particular, a light-emitting layer material having a wide band gap, a lowering in emission intensity due to continuous driving is alleviated while maintaining a high emission efficiency. There is provided an organic light-emitting device in which a hole-transporting layer contains a second component in addition to a main component; an energy of a lowest triplet excited state of the second component is less than an energy of a lowest triplet excited state of the main component of the hole-transporting layer; a lowest unoccupied molecular orbital energy of the second component is higher than a lowest unoccupied molecular orbital energy of the main component of a light-emitting layer; and the second component has an energy gap of 2.7 eV or more.

Owner:CANON KK

Photoluminescent markings with functional overlayers

InactiveUS7960688B2Increase rangeEasy to usePaper-money testing devicesPattern printingPhotoluminescenceElectromagnetic spectrum

Disclosed are photoluminescent markings that contain a photoluminescent layer and one or more functional overlayers wherein the photoluminescent marking has an emission signature that lies partly or fully in the infrared region of the electromagnetic spectrum. One functional overlayer conceals the photoluminescent layer and blends into the background or blends with marks that are normally present, without significantly reducing the luminescent intensity of the photoluminescent layer. Another functional overlayer provides photolytic stability to the underlying photoluminescent layer. Also disclosed are functional overlayers that enhance the daytime observability of the infrared emissions. A further functional overlayer prevents the observability of a printed message with the naked eye. A combination of functional overlayers each providing a different function is also included. Also disclosed are a multifunctional overlayer and methods of creating and using the inventive photoluminescent markings as well as objects containing the inventive photoluminescent markings.

Owner:PERFORMANCE INDICATOR LLC

Organic light-emitting device

ActiveUS7466074B2Alleviate lowering in emission intensityWide bandgapDischarge tube luminescnet screensLamp detailsMolecular orbital energyExcited state

Owner:CANON KK

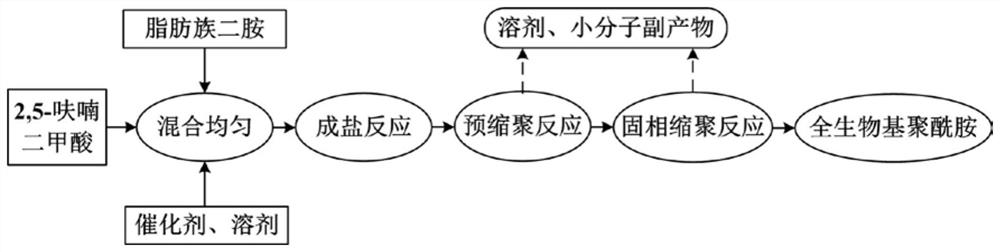

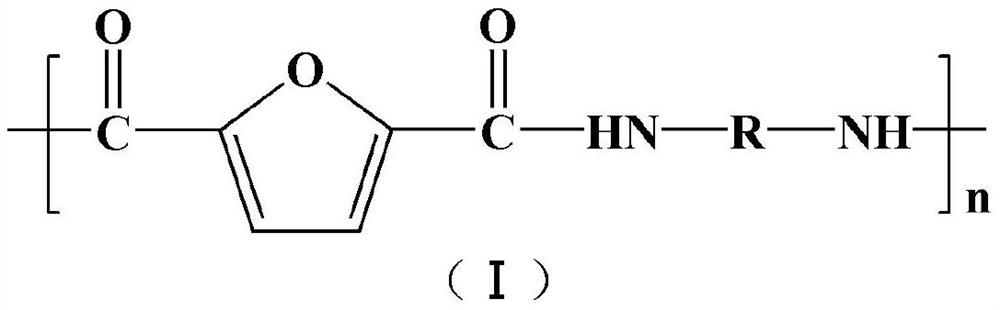

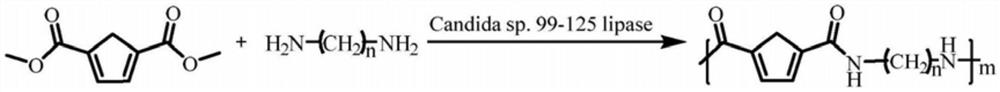

Full-bio-based polyamide and preparation method thereof

The invention discloses 2,5-furan dicarboxylic acid based polyamide with a full biomass source and a preparation method thereof, and belongs to the technical field of bio-based polyamide. The structural formula of the 2,5-furan dicarboxylic acid based polyamide is shown as (I), and in the formula, R is alkylene of C4, C5, C6 and C10. According to the method, 2,5-furan dicarboxylic acid and aliphatic diamine are used as raw materials, and 2,5-furan dicarboxylic acid based polyamide is prepared through a salt forming-pre-polycondensation-solid phase polycondensation process. 2,5-furan dicarboxylic acid and aliphatic diamine monomers are derived from biomass resources. The raw materials are wide in source, rich in reserves and renewable, and can be used as supplementation and partial substitution of non-renewable fossil raw material monomers, so that the high-performance environment-friendly polyamide is synthesized, is used in the fields of fibers, high-performance engineering plastics and the like, and has important scientific significance and application value.

Owner:PETROCHINA CO LTD

Germanium nanoparticles and biosubstance labeling agent by use thereof

InactiveUS20070178308A1Reduced biotoxityReduce environmental loadLiquid surface applicatorsSynthetic resin layered productsNanoparticleInorganic materials

Nanoparticles are disclosed, comprising a core and a shell, wherein the core comprises germanium (Ge) and the shell comprises an inorganic material, and the nanoparticles exhibit an average core size of 1 to 50 nm. A biosubstance labeling agent by use thereof is also disclosed.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

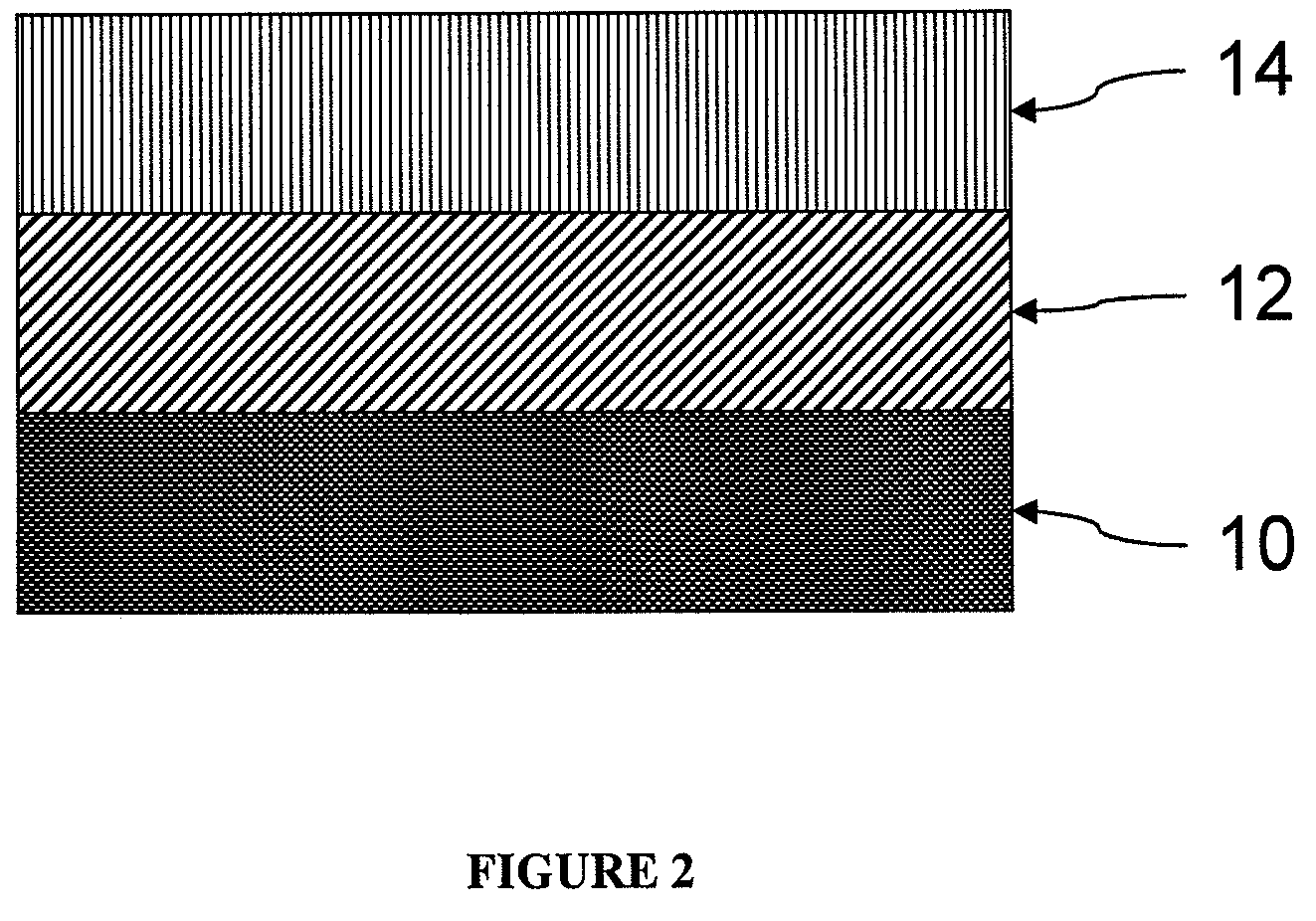

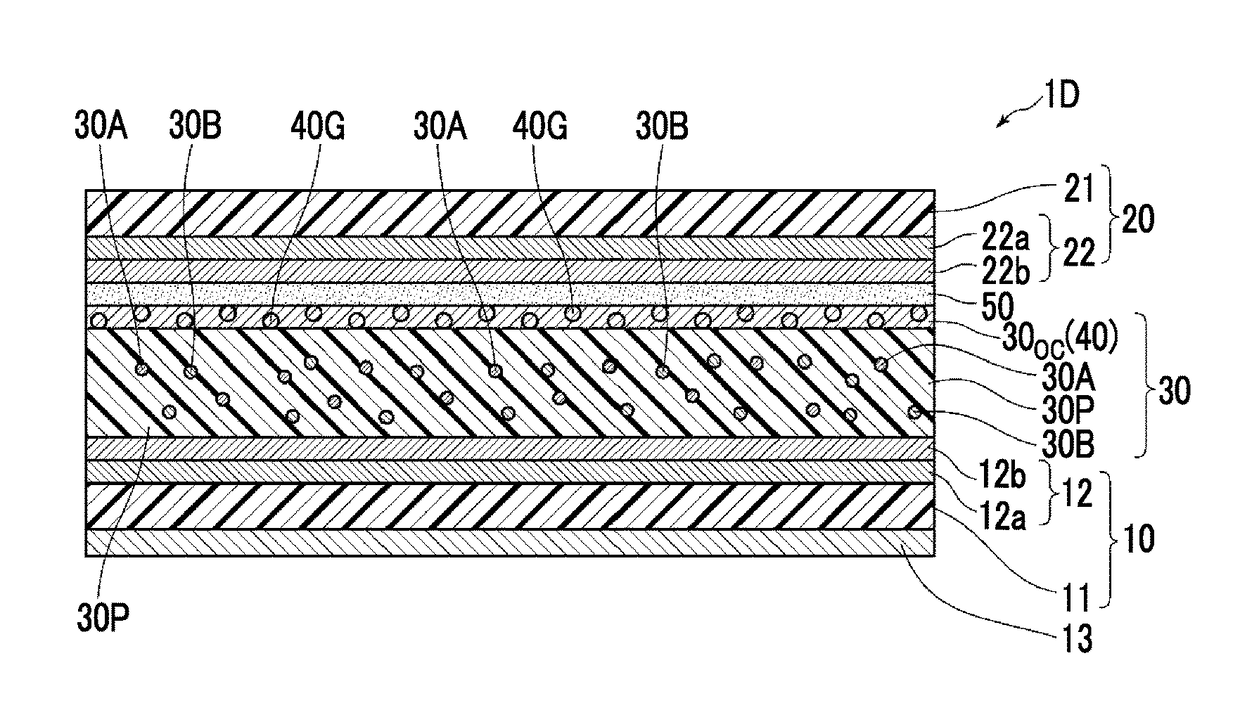

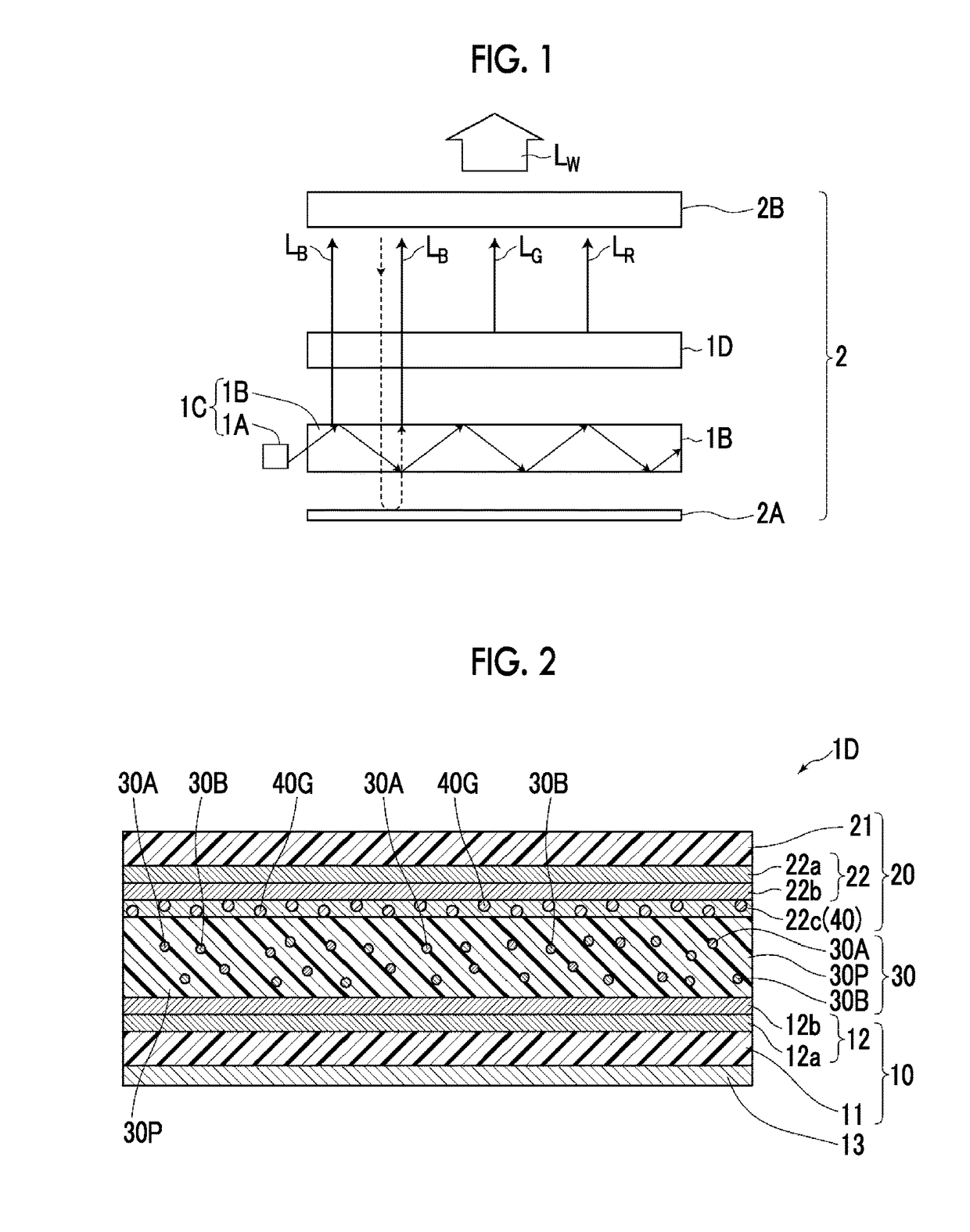

Wavelength conversion member, backlight unit including wavelength conversion member, and liquid crystal display device

InactiveUS20170242179A1Reduce emission intensityEmission intensity is not to decreaseMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayFluorescence

The wavelength conversion member includes: a wavelength conversion layer obtained by curing a polymerizable composition including quantum dots that emit fluorescence when excited by excitation light; a barrier layer having a moisture permeability of 0.1 g / (m2·day·atm) or lower that is formed over at least one surface of the wavelength conversion layer; and at least one intermediate layer that is interposed between the wavelength conversion layer and the barrier layer. The at least one intermediate layer includes a gettering agent-containing layer that includes a gettering agent for trapping at least one of water or oxygen.

Owner:FUJIFILM CORP

Color image display device and color image display method

InactiveUS20180240418A1SuppressionReduction in display color saturationStatic indicating devicesNon-linear opticsColor imageLiquid-crystal display

The present invention provides a field-sequential color image display device inhibiting color breakup and a reduction of the range of color reproduction while achieving enhanced transparency of a transparent display area.In the field-sequential liquid crystal display device, a light source data computation portion (206) obtains drive light source data Ek by modifying initial light source data on the basis of a transparent color, which is a target color TCk, and a target color display area proportion TPk, which is obtained from input data Din, such that transparency of a transparent display area in an image to be displayed increases. On the basis of the drive light source data Ek, a light source driver portion (210) drives red, green, and blue LEDs of a light source portion (120) for respective frame periods within a frame period during which the image represented by the input data is to be displayed. A spatial light modulation drive portion (214) controls transmittance through a liquid crystal panel in a pixel array portion (110), for each pixel so as to maximize transmittance through the transparent display area.

Owner:SHARP KK

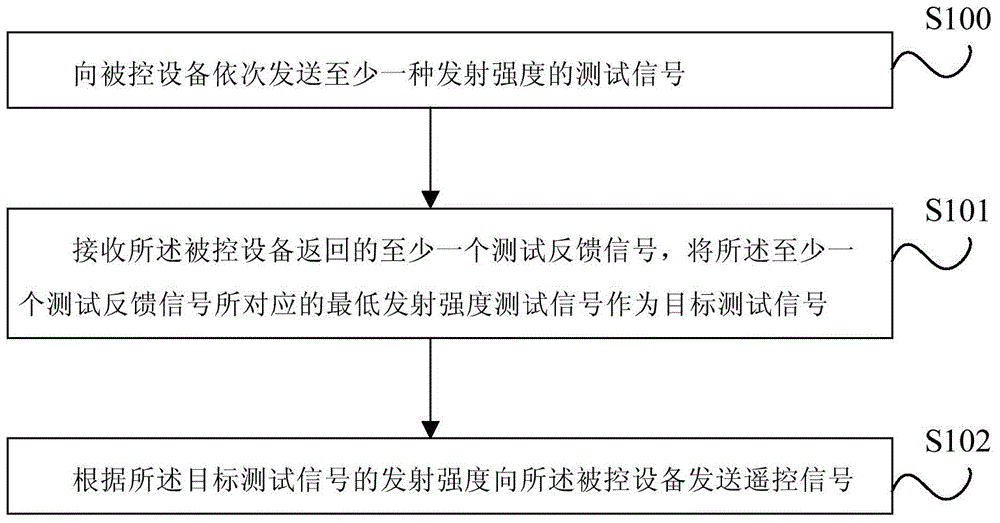

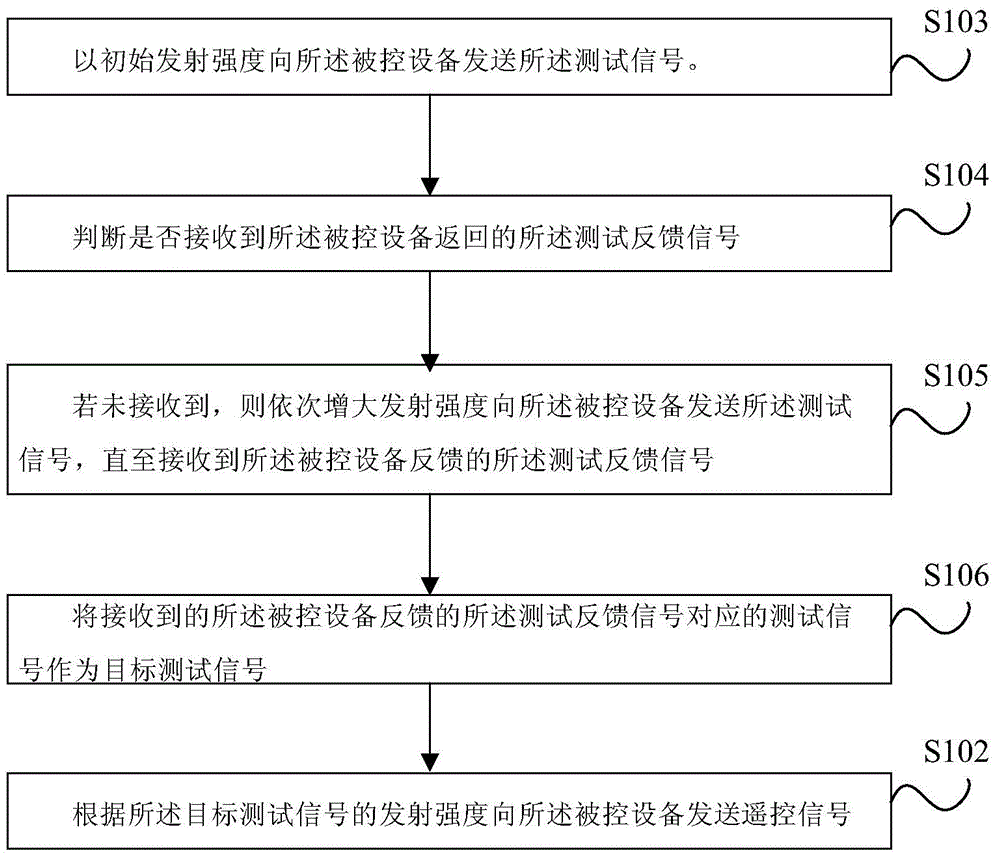

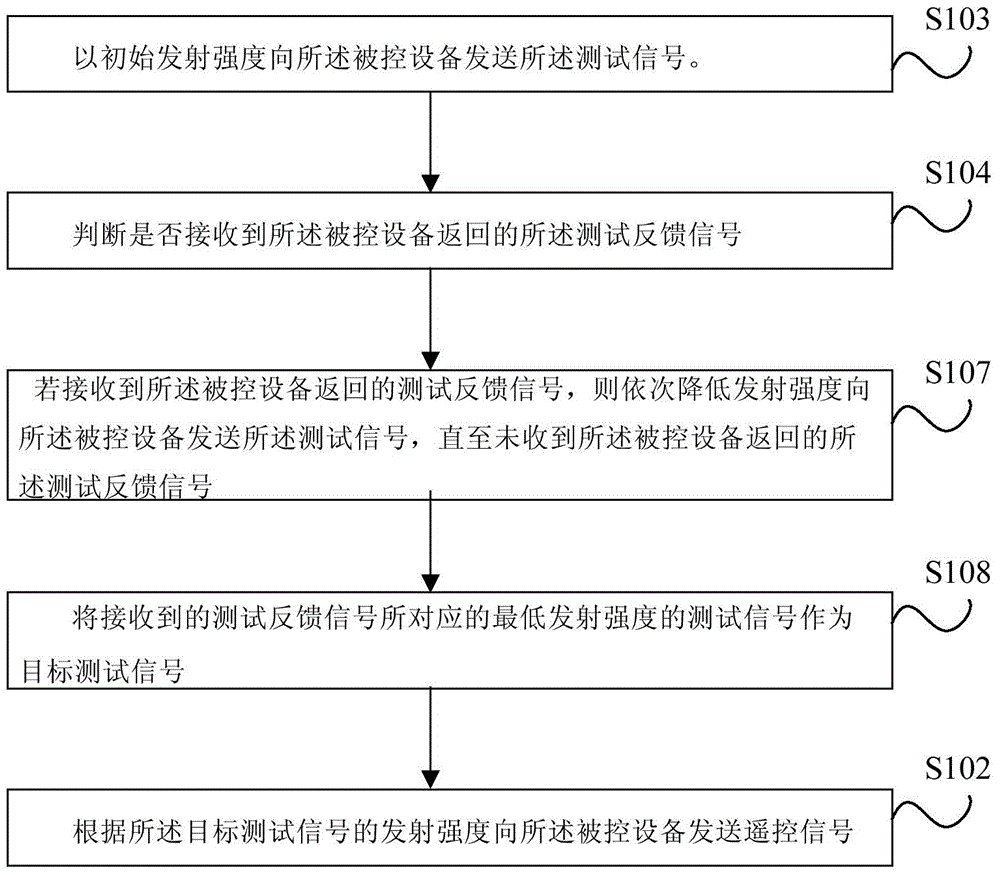

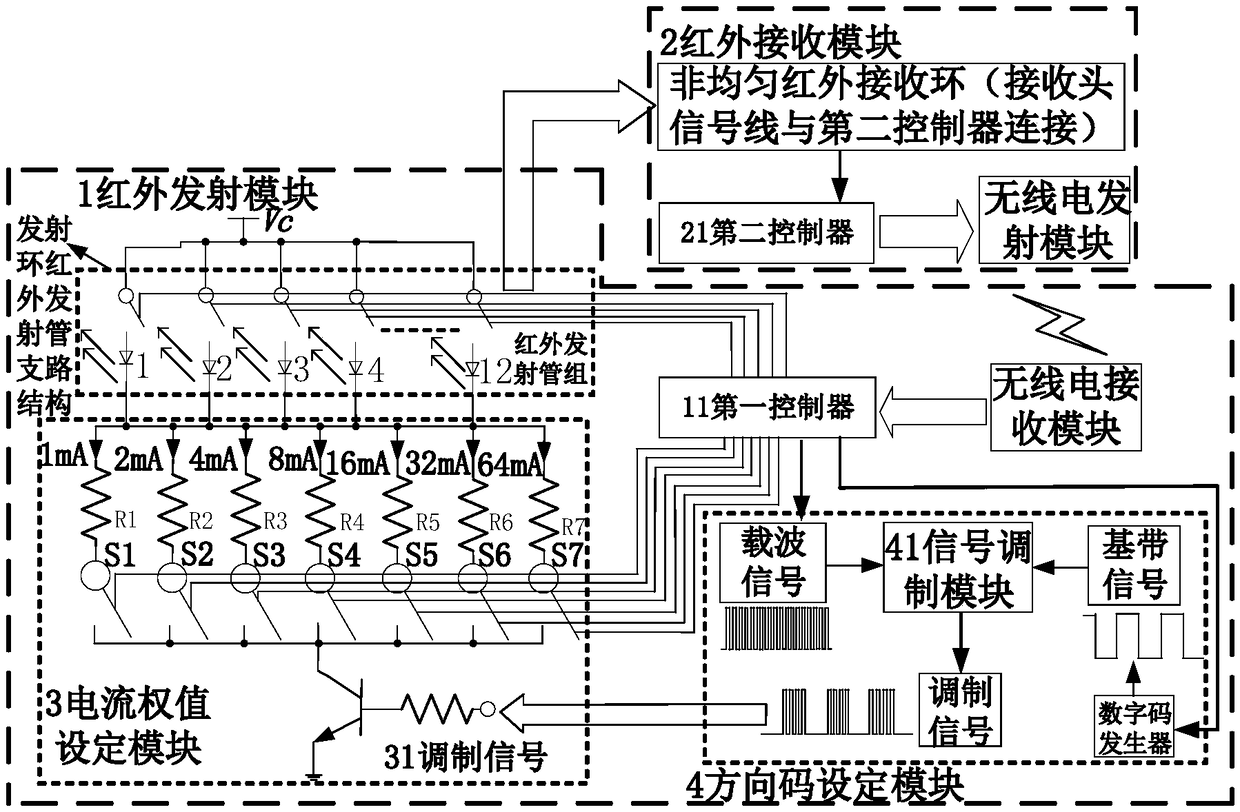

Infrared remote control method and device

ActiveCN104867316AEnsure effective controlExtended use timeNon-electrical signal transmission systemsShortest distanceElectrical battery

The invention provides an infrared remote control method and device. When infrared remote control equipment provided by the invention is used for remotely controlling controlled equipment, firstly, at least one testing signal of emission intensity is sequentially sent to the controlled equipment, and the current lowest emission intensity capable of being received by the controlled equipment is determined according to a testing feedback signal returned back by the controlled equipment; then, a remote control signal is sent to the controlled equipment according to the lowest emission intensity capable of being received by the controlled equipment so that the emission intensity can be increased when the infrared remote control equipment has low electric quantity or is in a long distance, and the emission intensity can be reduced when the infrared remote control equipment has high electric quantity or is in a short distance; and the effective control on the controlled equipment by an infrared remote controller is guaranteed, and the service time of a battery in the infrared remote controller is prolonged, so that energy sources are saved.

Owner:HISENSE VISUAL TECH CO LTD

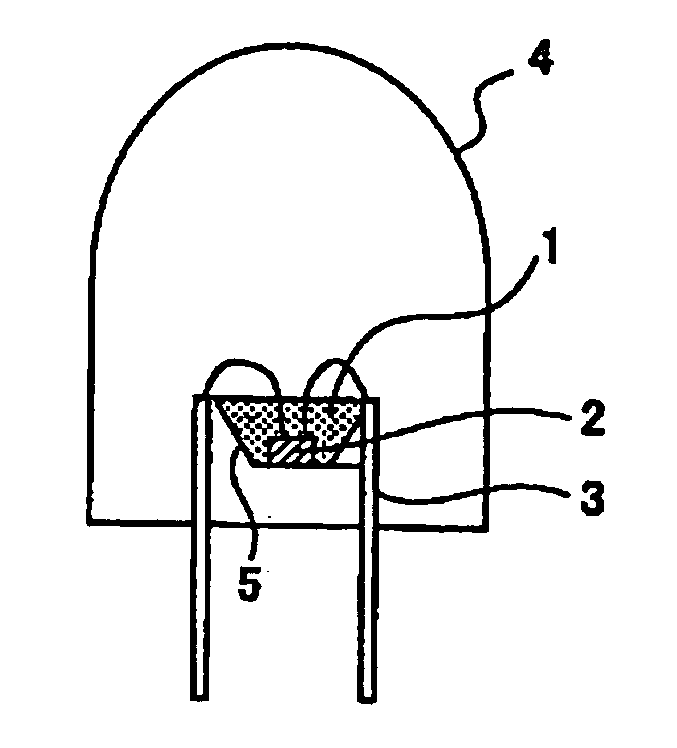

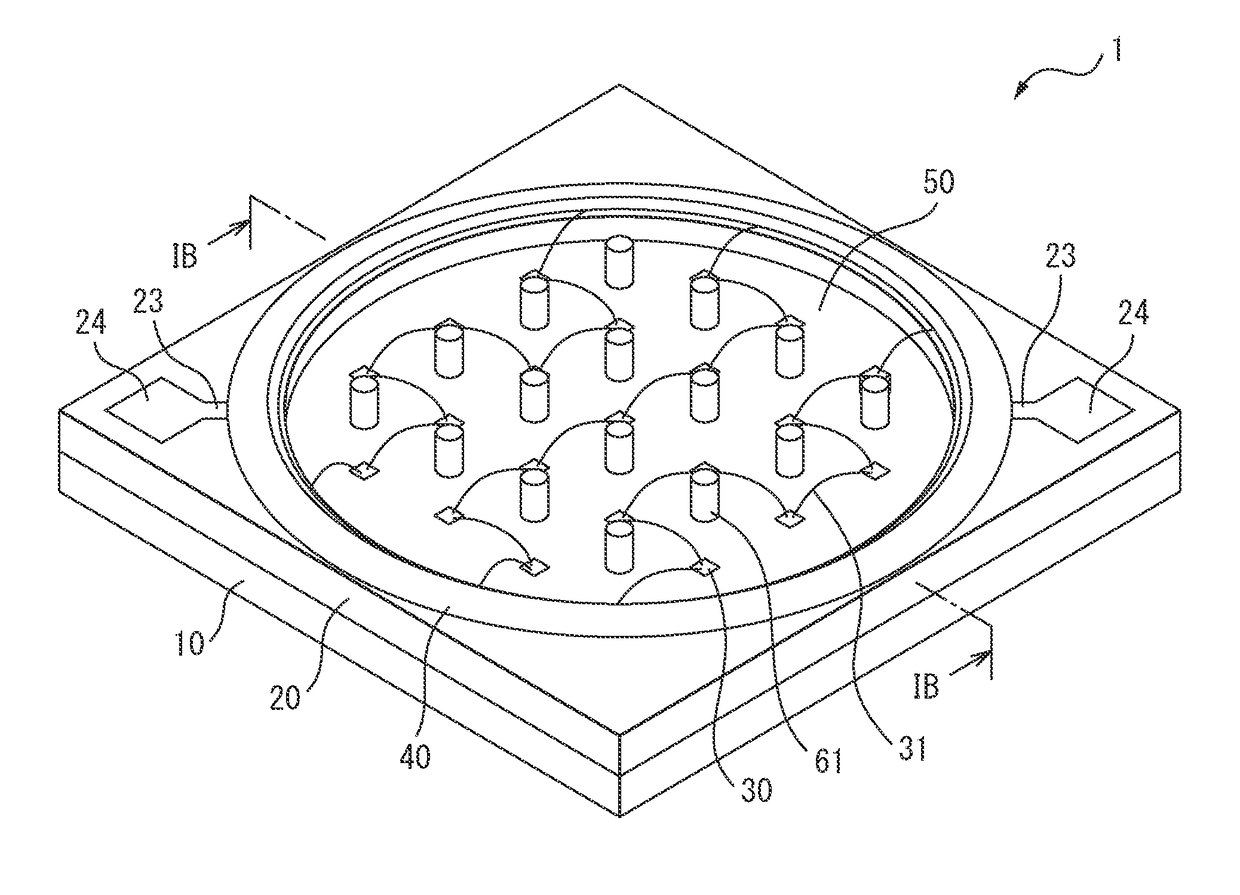

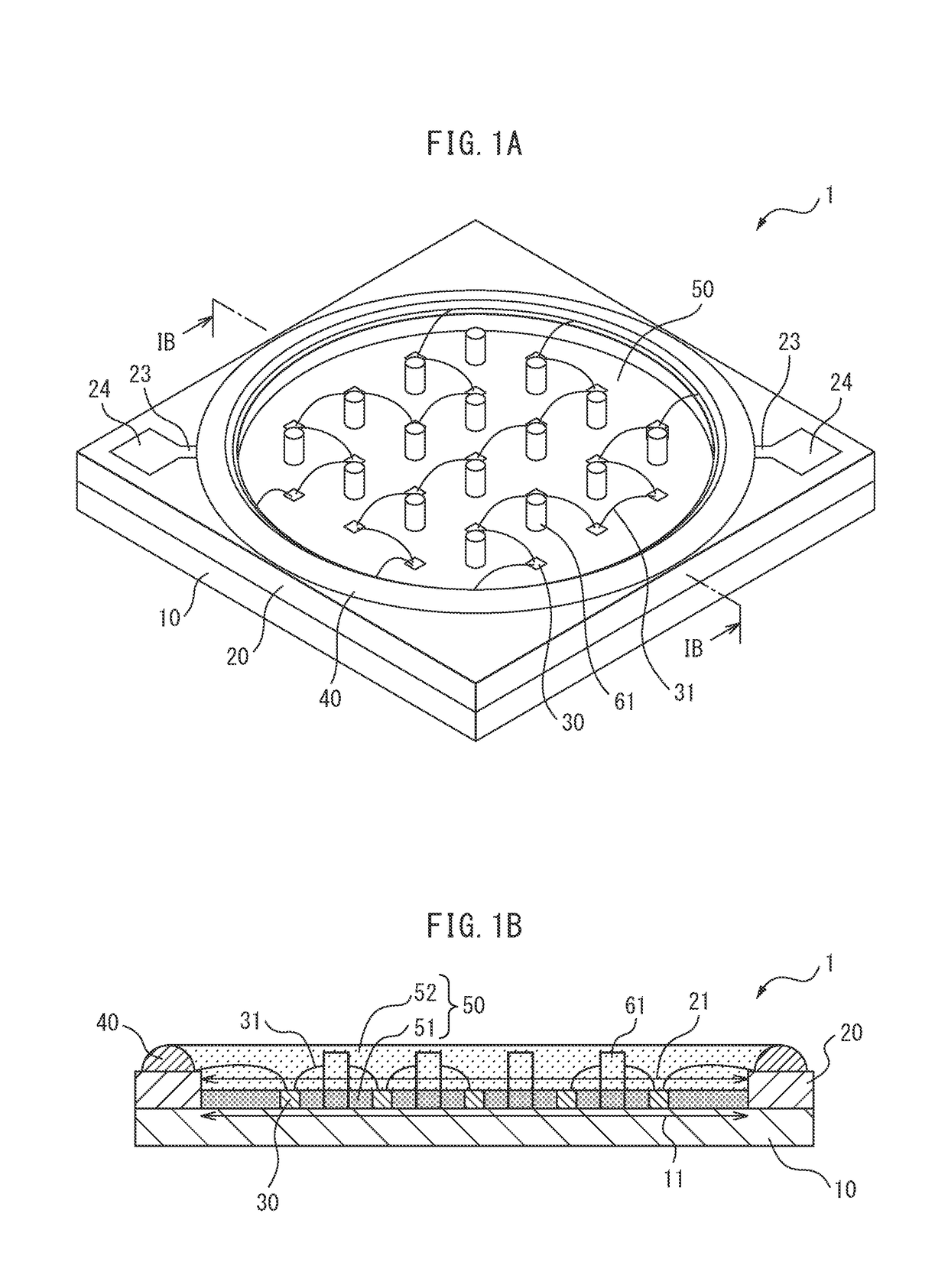

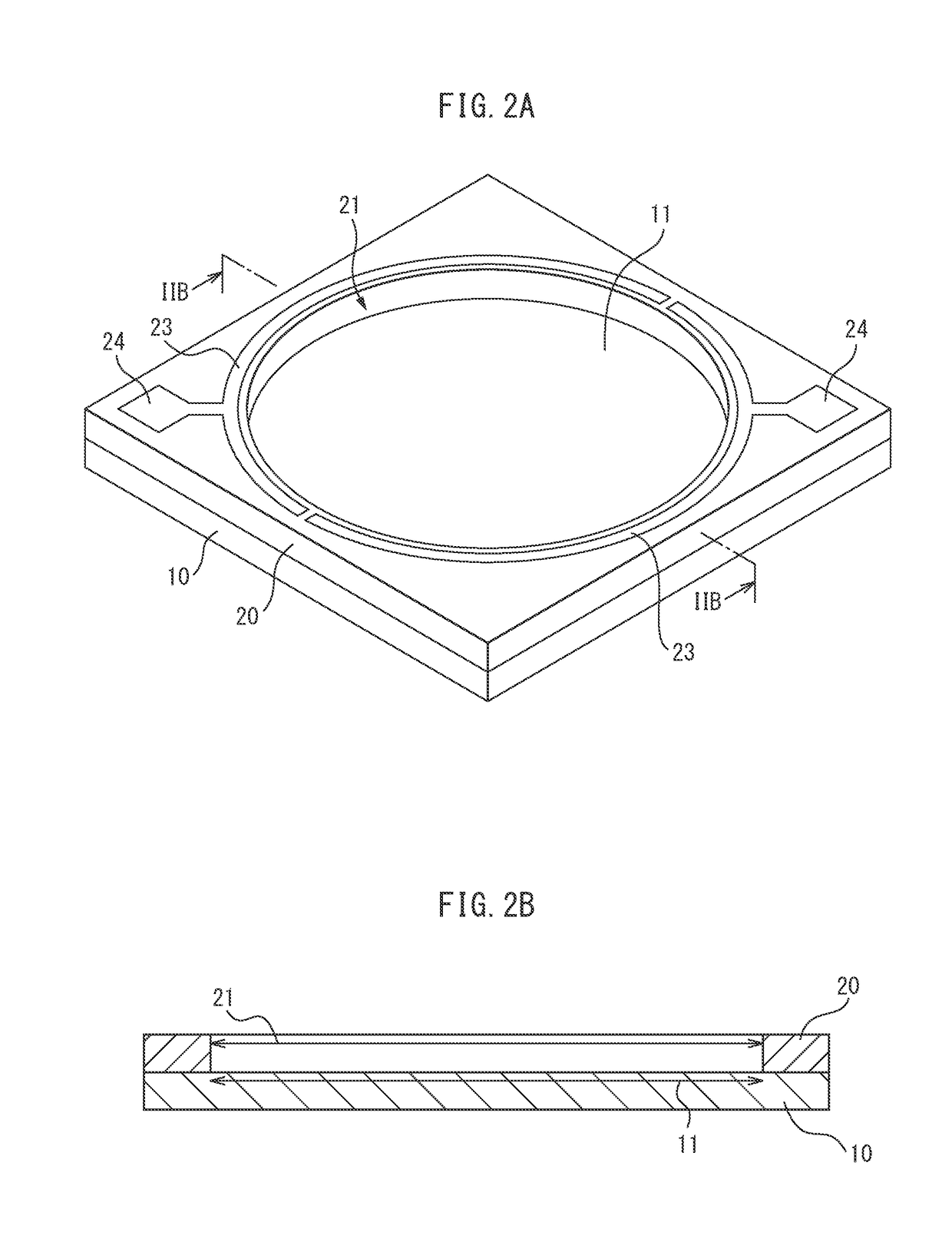

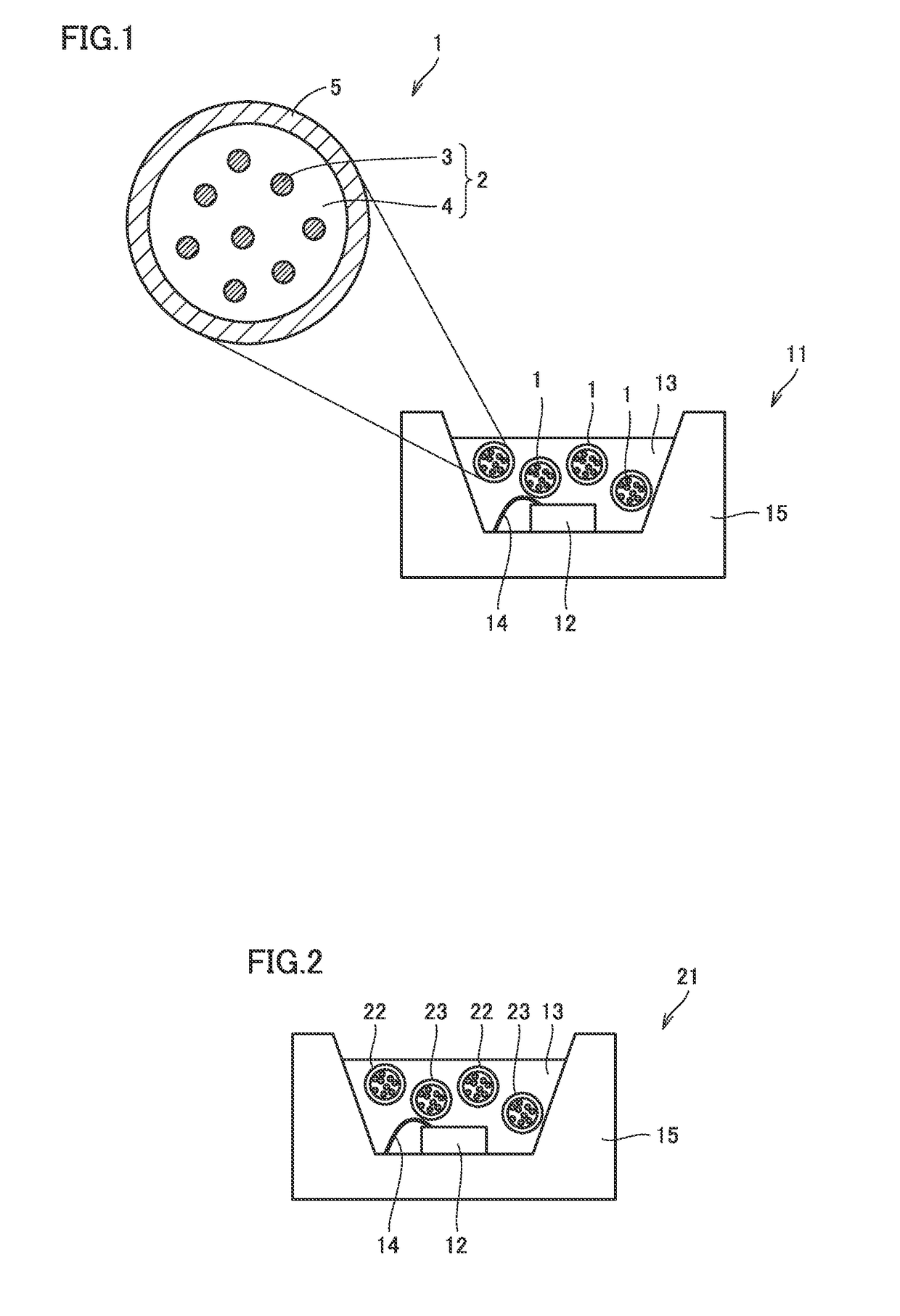

Light emitting device

ActiveUS20170365754A1Reduce intensityReduce emission intensityElectric circuit arrangementsSolid-state devicesPhosphorLight emitting device

A light-emitting device in which the emission intensity of light-emitting elements is improved by making heat generated by light emission of the light-emitting elements be effectively released is provided. The light-emitting device includes a mounting substrate including a mounting region, light-emitting elements mounted on the mounting region, a sealing resin which contains a phosphor and integrally seals the light-emitting elements, and at least one heat transfer member which is arranged among the light-emitting elements on the mounting region, is embedded in the sealing resin, and has a higher thermal conductivity than the sealing resin.

Owner:CITIZEN ELECTRONICS CO LTD +1

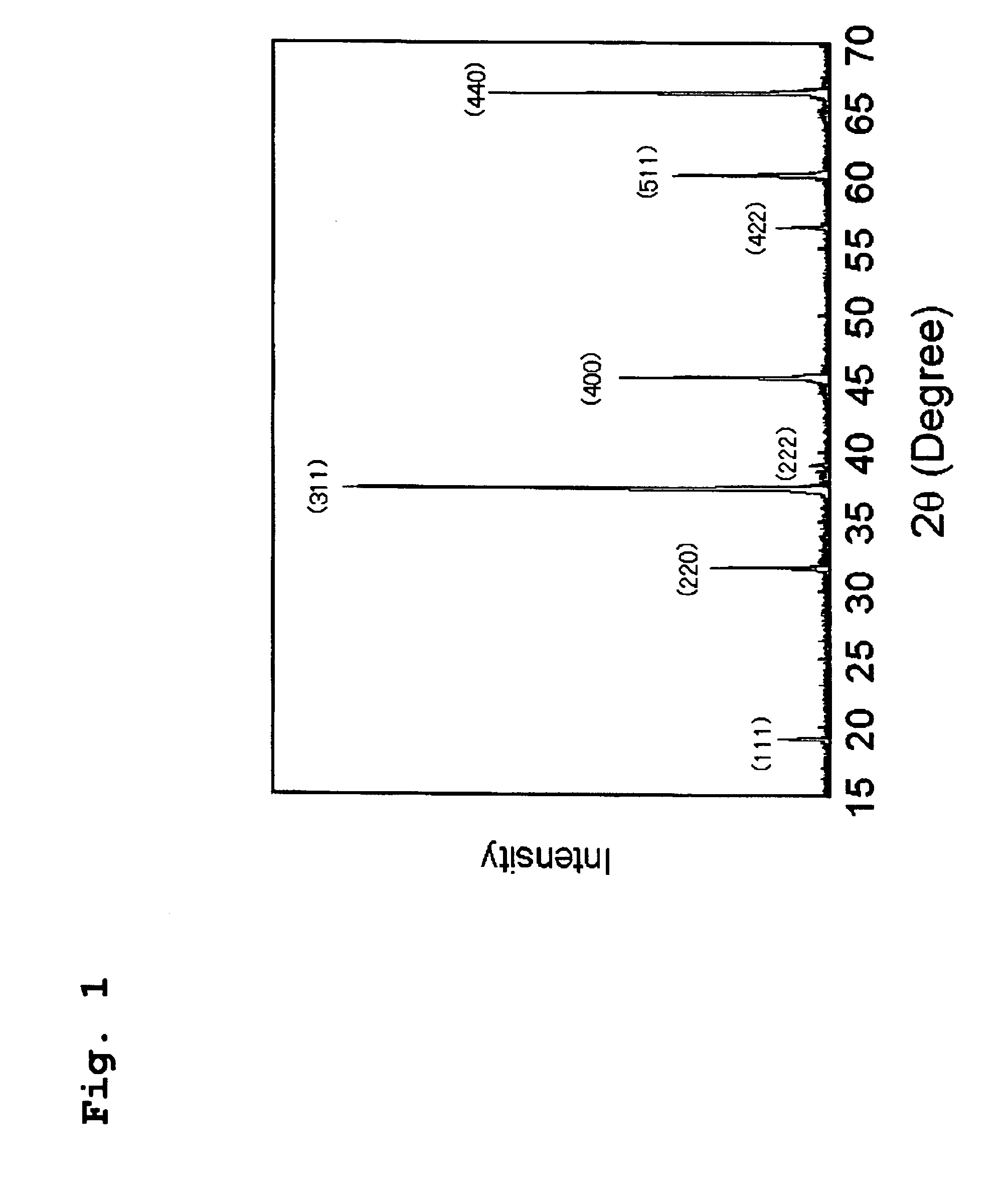

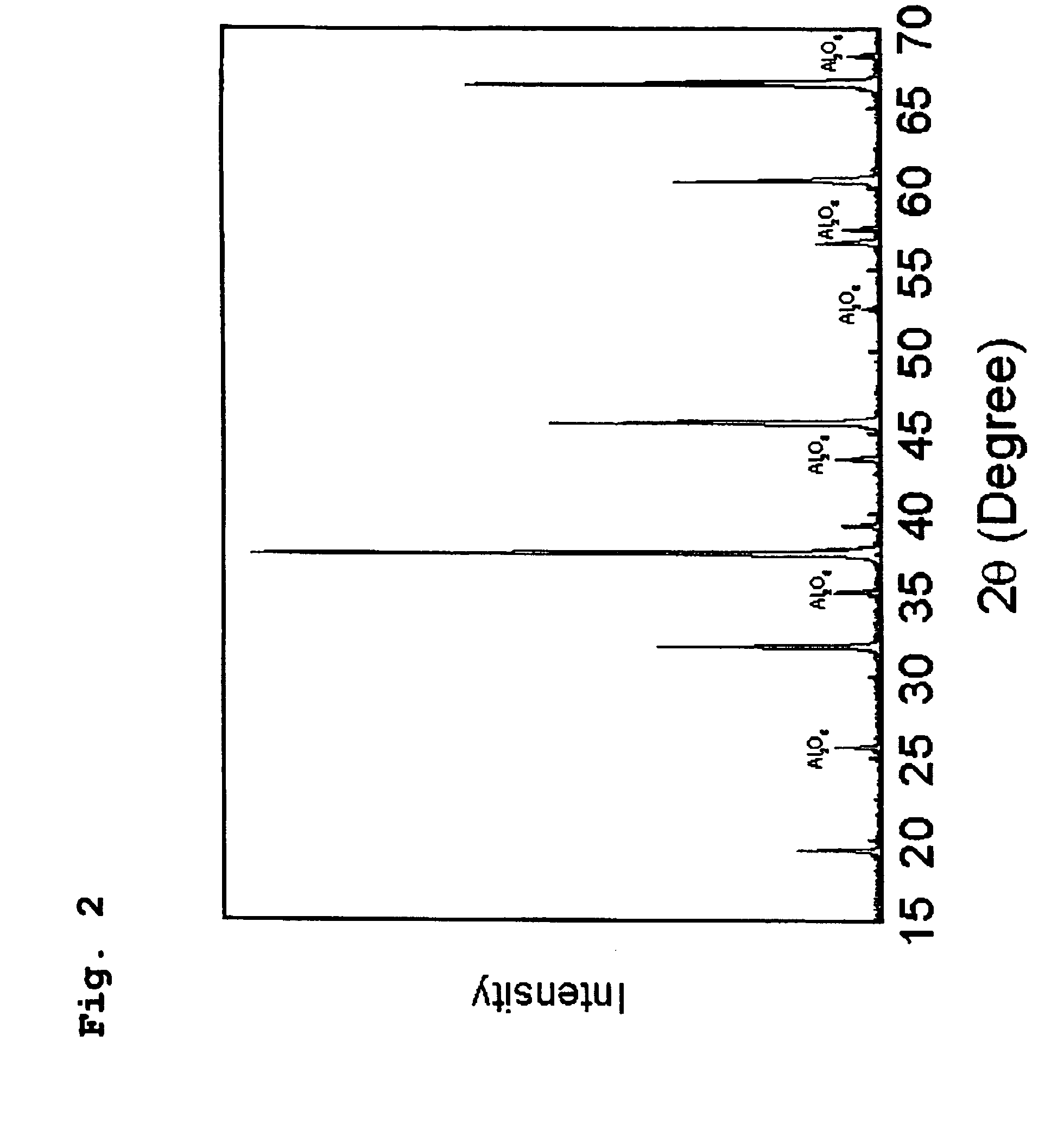

Phosphor, method for producing same, and light-emitting device

ActiveUS8057704B2Increase intensityReduce emission intensityLaser detailsDischarge tube luminescnet screensFluorescencePhosphor

Disclosed are violet, blue, and green phosphors having excellent durability and high luminance. Specifically disclosed is a phosphor which contains a metal element M (M is at least one element selected from among Mn, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Tm and Yb) for constituting a metal ion, which is solid-solubilized in an AlON crystal, an AlON solid solution crystal or an inorganic crystal having the same crystal structure as AlON. The phosphor is capable of emitting fluorescence having a peak in the wavelength range from 300 nm to 700 nm. Also disclosed is a method for producing such a phosphor. Further disclosed are an illuminating device and an image display each containing such a phosphor.

Owner:NAT INST FOR MATERIALS SCI

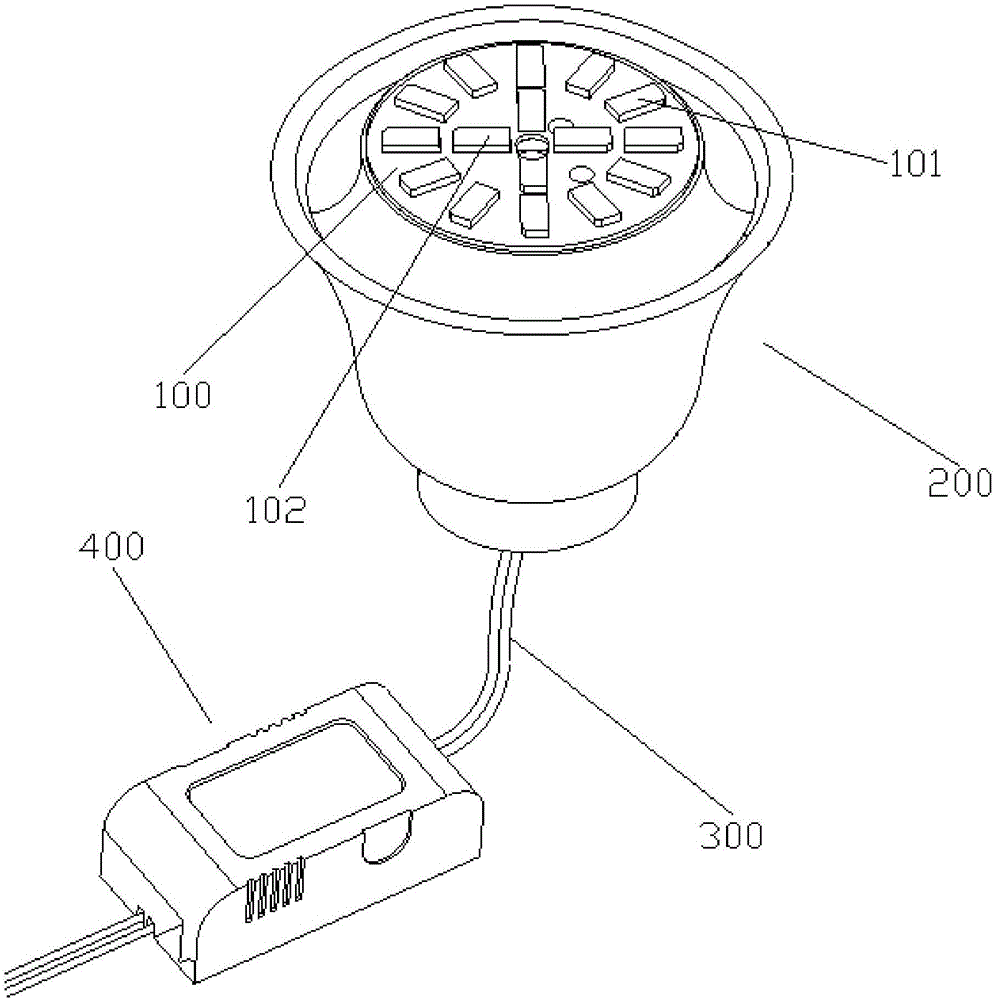

LED illuminating device and preparation method thereof

ActiveCN106764483ANot suitable for chippingIncrease productivityElectric circuit arrangementsLuminescent compositionsEngineeringLED circuit

The invention relates to an LED illuminating device and a preparation method thereof. The device is characterized by comprising an LED apparatus, an LED circuit board, a heat dissipator and a power supply controller. The LED apparatus is arranged on the LED circuit board, the LED circuit board is arranged above the heat dissipator, and the power supply controller is connected to the LED circuit board through a wire. The LED illuminating device can emit approximate natural light.

Owner:SHENZHEN YMH INTELLIGENT TECH CO LTD +1

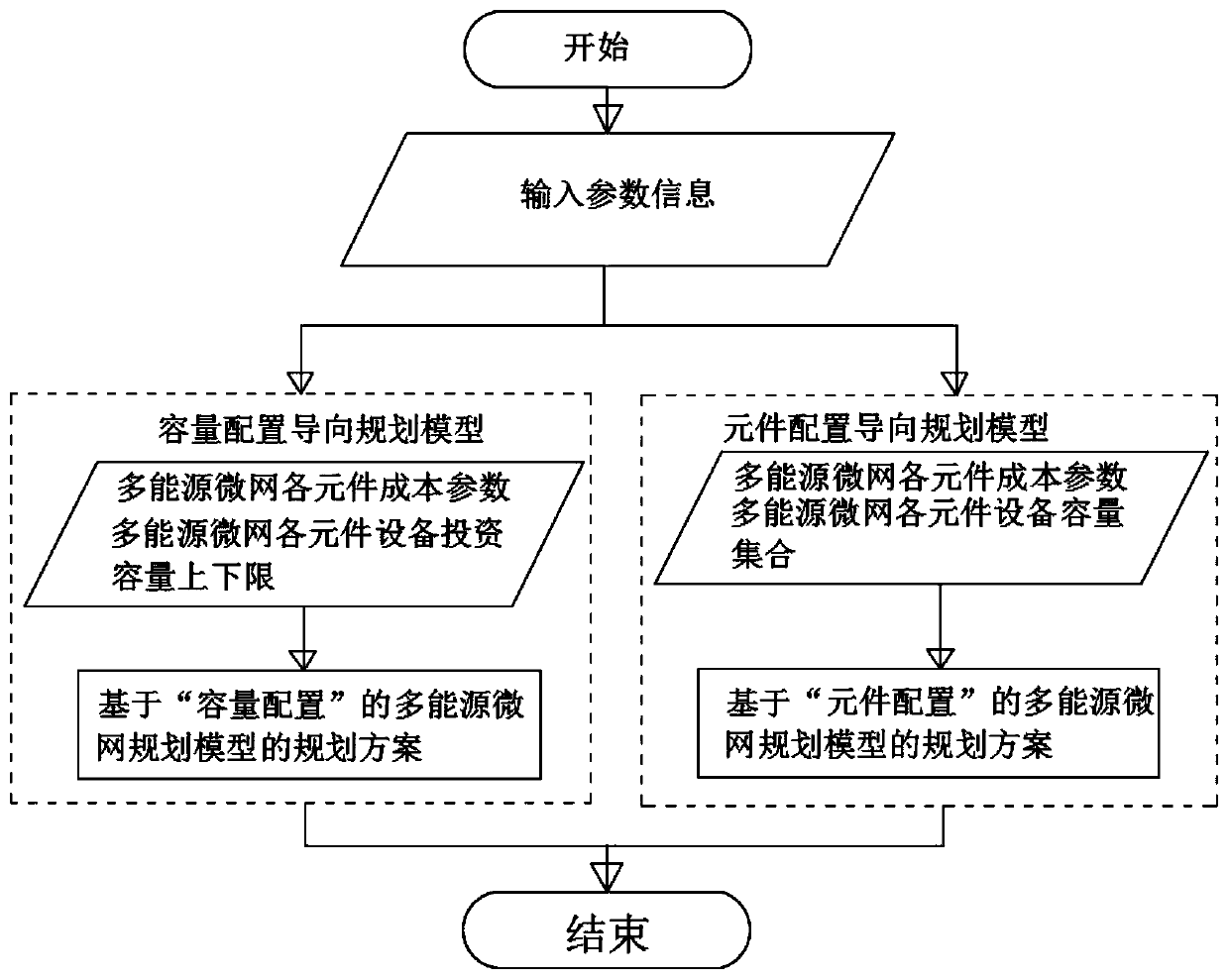

Intelligent park multi-energy microgrid configuration method based on multi-target random optimization

The invention discloses an intelligent park multi-energy microgrid configuration method based on multi-target random optimization. The intelligent park multi-energy microgrid configuration method comprises the following steps: S1, constructing a multi-energy microgrid configuration optimization model based on capacity configuration guidance by taking the economical efficiency of investment and operation of a multi-energy microgrid configuration system in an intelligent park as a target and taking investment decisions and investment capacities of thermoelectric replacement equipment, a renewable distributed power supply and electric energy storage equipment as constraint conditions; and S2, aiming at reducing the solving difficulty of a nonlinear objective function and a constraint condition in the mode, optimizing corresponding configuration decision schemes of the thermoelectric replacement equipment with fixed capacity, the renewable distributed power supply and the electric energy storage equipment, constructing a multi-energy microgrid configuration optimization model based on element configuration guidance, wherein the model constructed by the method has better economical efficiency and emission reduction advantages, and reduces the dependence degree on a traditional single energy supply system, so that renewable energy sources are better and more efficiently consumed andutilized, and the overall carbon emission intensity of the system is reduced.

Owner:GUANGDONG POWER GRID CO LTD +1

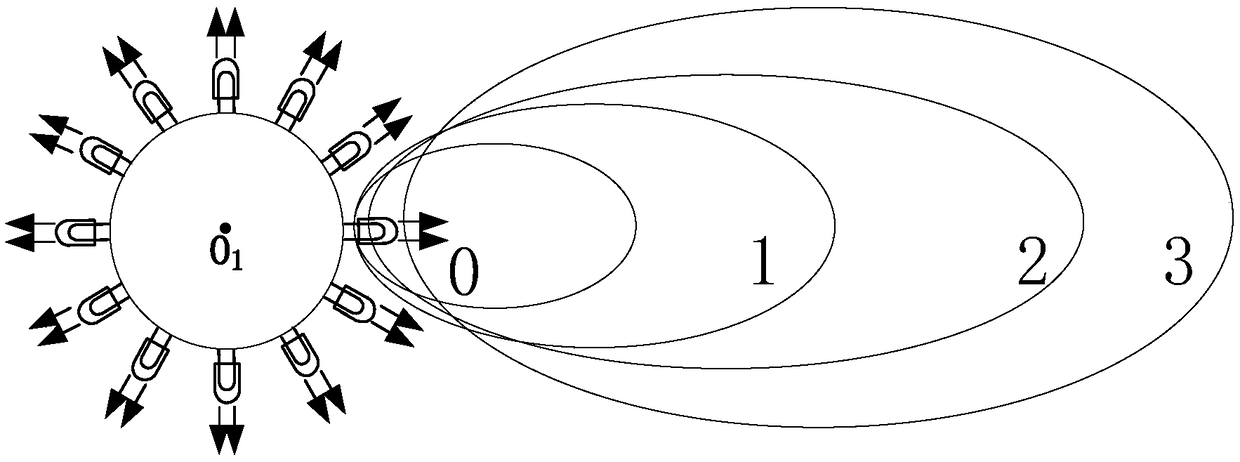

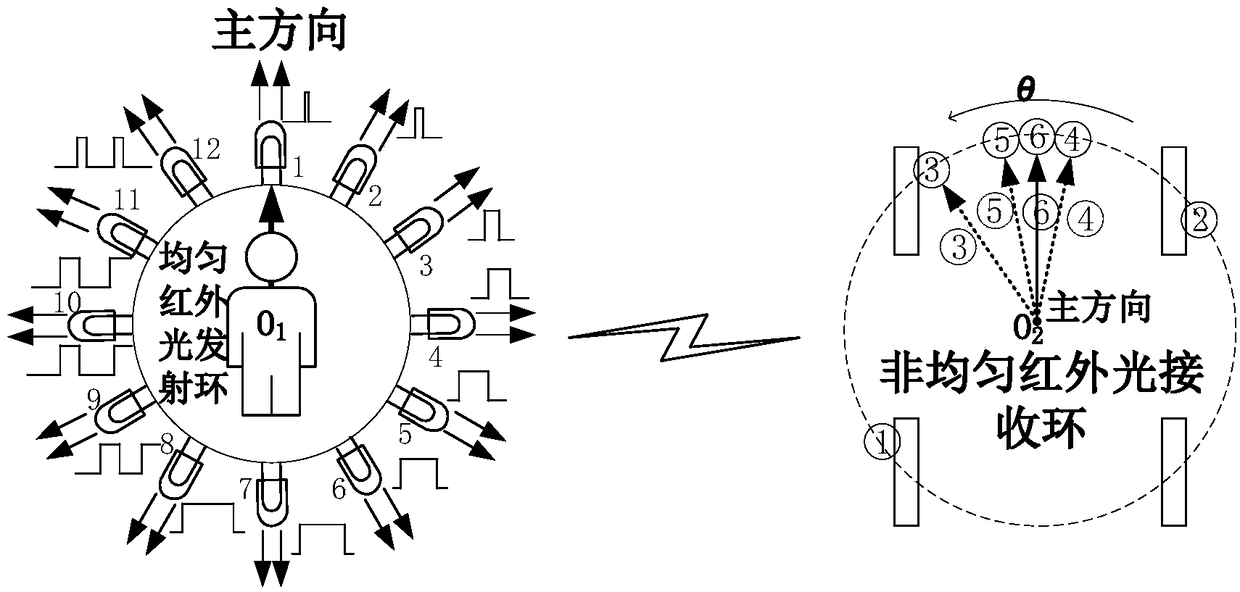

Automatic follow-up control method and system based on infrared signal

ActiveCN109360406ASolve the technical problem that the direction of the receiving end relative to the transmitting end cannot be measuredReduce intensityNon-electrical signal transmission systemsControl unitElectrical and Electronics engineering

The invention discloses an automatic follow-up control method and system based on infrared signal. The invention is provided with an asymmetrically distributed infrared receiving tube on the infraredreceiving module. The infrared signal from the infrared transmitting module is received through the asymmetrically distributed infrared receiving tube. According to the regional orientation of the received infrared signal, the main direction of the infrared receiving module is gradually aligned with the infrared transmitting module. At the same time, during the alignment process, the intensity ofthe infrared signal is gradually reduced to obtain the critical strength of the infrared signal transmitted to the receiving module. Therefore, the automatic follow-up control method and system basedon infrared signal can calculate the distance between the infrared transmitting module and the receiving module according to the intensity of the infrared signal, while performing high-precision fastdirection finding, and drive the infrared receiving module to achieve follow-up control. The automatic follow-up control method and system based on infrared signal can reduce the precision requirementof the infrared device by the cooperation of the hardware circuit and the control unit, and achieve high-precision direction finding and fast following under the premise of a small number of infraredreceiving modules, thereby reducing the hardware cost.

Owner:SOUTHEAST UNIV

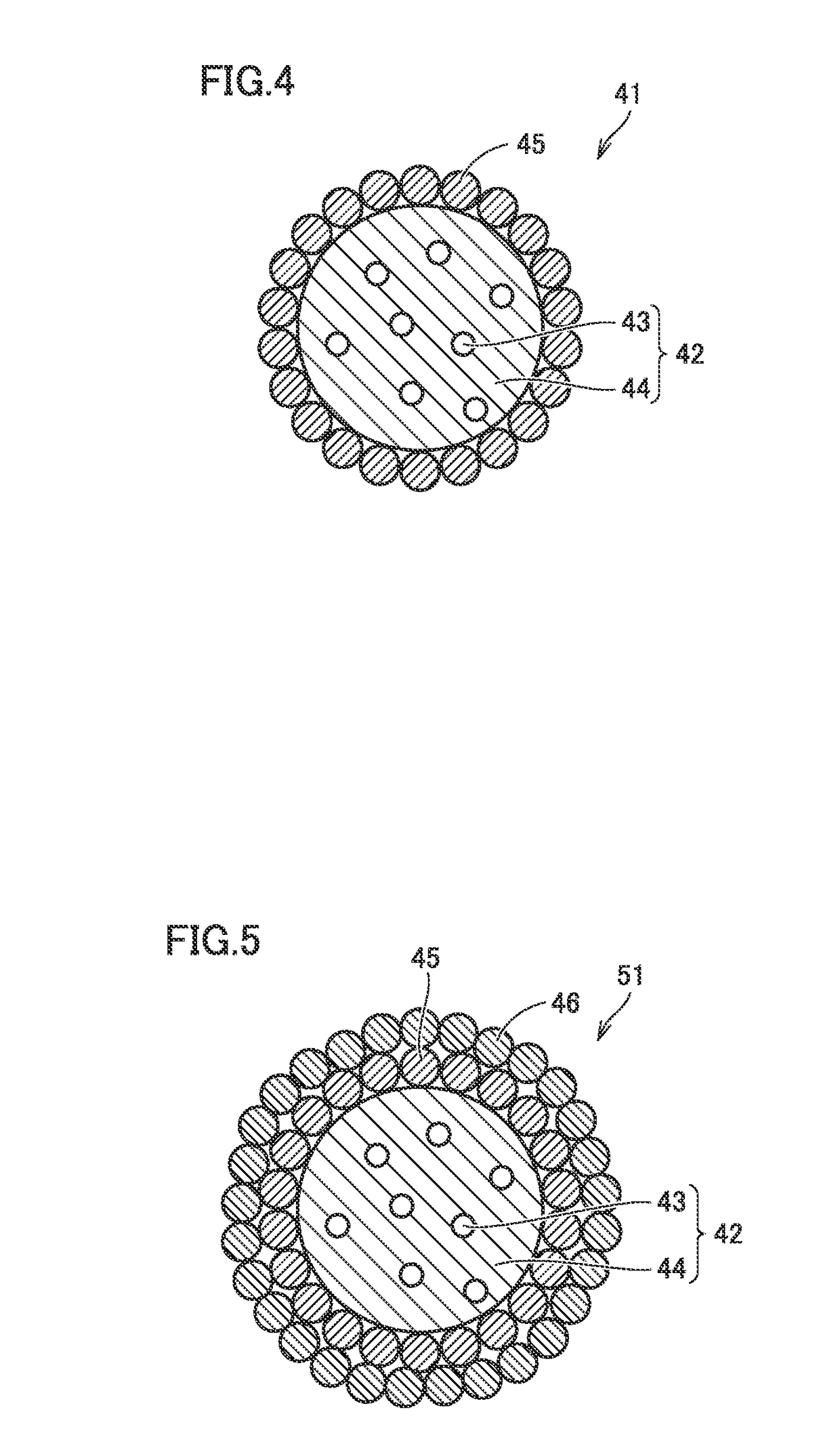

Phosphor containing particle, and light emitting device and phosphor containing sheet using the same

ActiveUS20180358517A1Improve light emission efficiencyGood chemical stabilityLuminescent compositionsSemiconductor devicesParticulatesSemiconductor Nanoparticles

A phosphor containing particle including a core portion which is a particulate matter of resin including a constitutional unit derived from an ionic liquid with a semiconductor nanoparticle phosphor dispersed therein and a shell portion which is a matter in a form of a layer of resin which includes a constitutional unit derived from an ionic liquid and coats at least a portion of the core portion, and a phosphor containing particle including a particulate matter of resin including a constitutional unit derived from an ionic liquid with a semiconductor nanoparticle phosphor dispersed therein and a metal oxide layer coating at least a portion of the particulate matter of resin. A light emitting device including a light source and a wavelength converter in which phosphor containing particles are dispersed in a translucent medium, and a phosphor containing sheet in which phosphor containing particles are dispersed in a sheet-shaped translucent medium.

Owner:SHARP KK

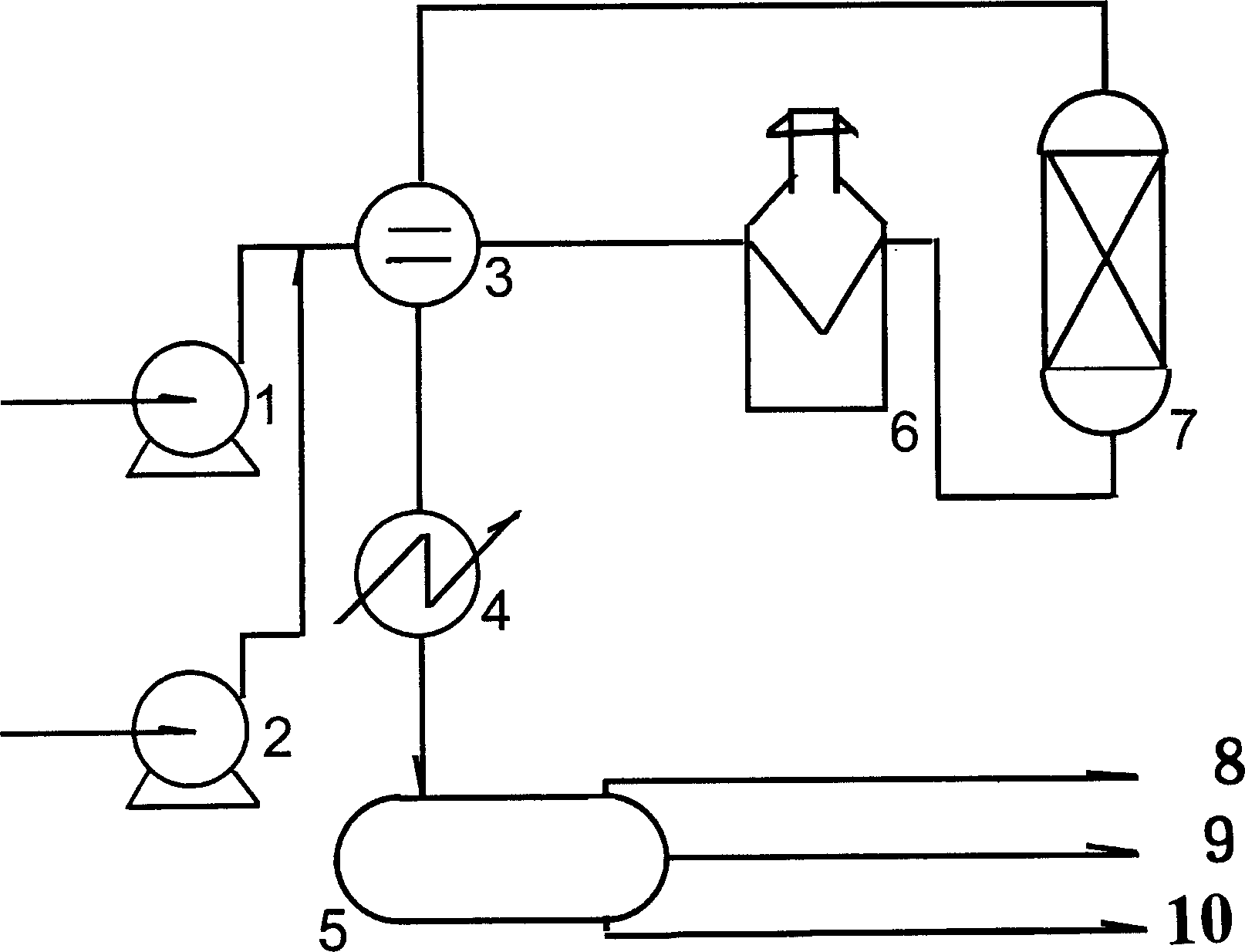

Method for low-pressure continuous hydrolysis preparation of fatty acid

InactiveCN1544595AReduce partial pressureIncrease hydrolysis rateFatty acid chemical modificationIodo fatty acidDecomposition

The invention provides a process for preparing fatty acid through low pressure continuous hydrolytic decomposition, wherein the water-oil weight ratio is 5-30:100, the pump output pressure is controlled between the range of 0.02-0.5MPa, preferably between 0.1-0.4MPa, the raw materials are subjected to heat transfer through heat exchanger and are charged into heating-furnace to be heated to 250-500 deg. C and enter reactor, reacting for 2-30 minutes and the reaction product is led out, the fatty acid is obtained by straight distillation of separated crude fatty acid or fuel gas.

Owner:陈天晓

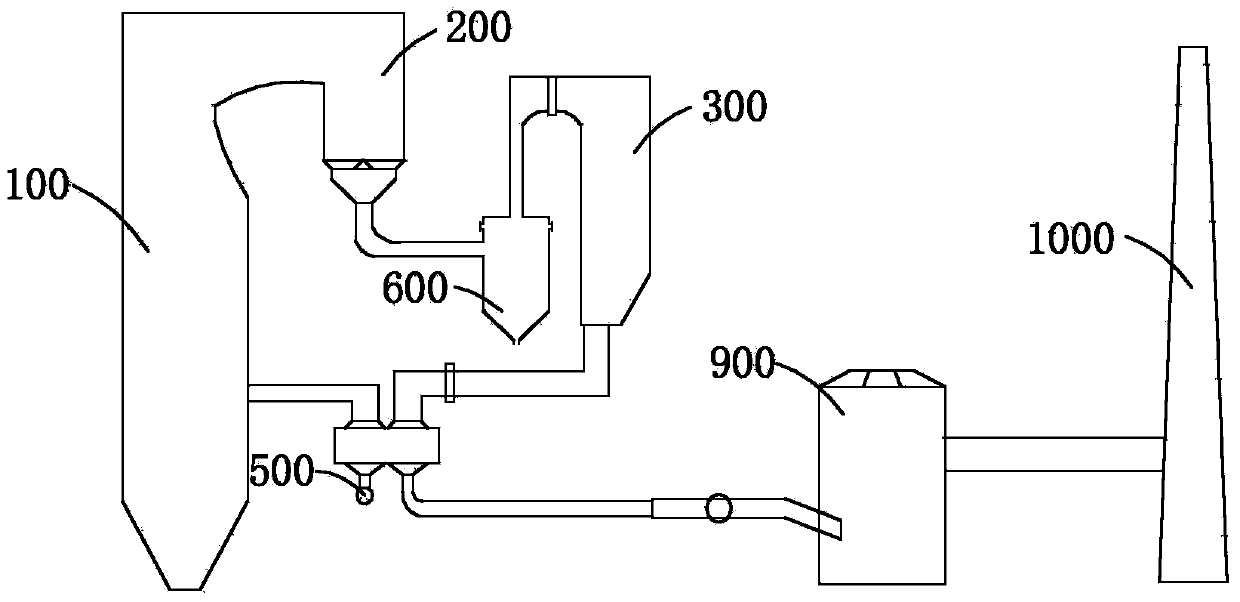

System and method for efficiently removing dust in flue gas of coal-fired power plant

InactiveCN103994455AReasonable designMeet emission standardsLighting and heating apparatusAir preheaterCyclone

The invention provides a system for efficiently removing dust in flue gas of a coal-fired power plant. The system is arranged between a boiler and a chimney of the coal-fired power plant, and used for removing dust in the flue gas discharged from the coal-fired power plant. The system comprises an economizer, a denitration reactor, an air preheater and a desulfurizing tower which are communicated sequentially, wherein the economizer is communicated with the boiler, and the desulfurizing tower is communicated with the chimney. The system further comprises a multi-tube type cyclone separator, wherein the multi-tube type cyclone separator is arranged between the economizer and the chimney and used for removing dust in the flue gas of the coal-fired power plant. The invention further provides a method for efficiently removing dust in the flue gas of the coal-fired power plant. The system for efficiently removing dust in the flue gas of the coal-fired power plant is reasonable in design, and for the flue gas discharged from the coal-fired power plant, the multi-tube type cyclone separator is arranged between the economizer and the chimney to remove dust from the flue gas; moreover, the multi-tube type cyclone separator can meet the requirement for purification efficiency of the system, and the flue gas discharged from the coal-fired power plant can reach the corresponding discharging standard.

Owner:彭维明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com