Solar energy heat pump combined sludge drying system and drying method

A solar heat pump and sludge drying technology, which is applied in dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve problems such as inoperability, heat pump performance degradation, evaporator tube wall and air heat transfer coefficient are small, etc. , to achieve the effect of reducing primary energy consumption and carbon emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

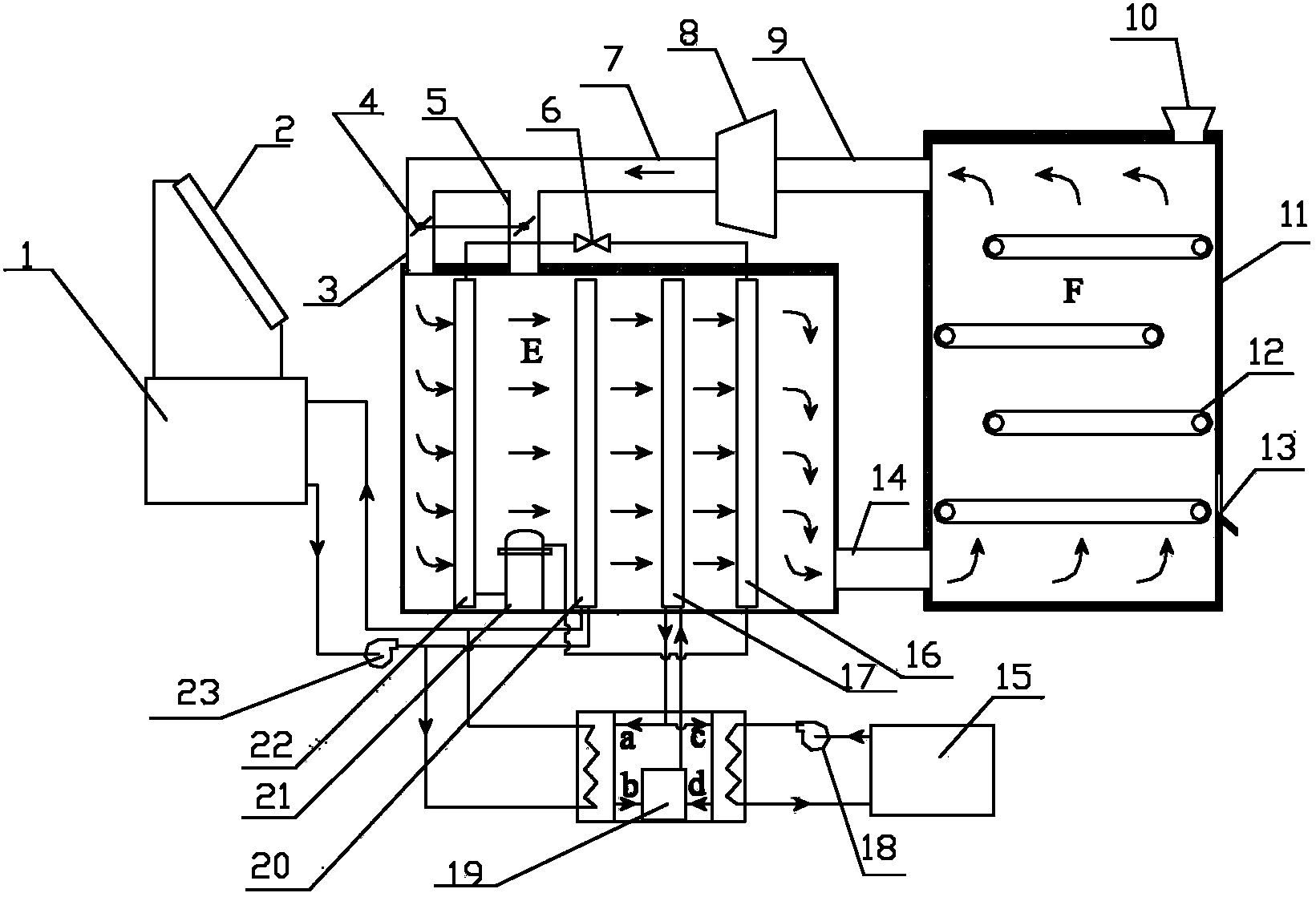

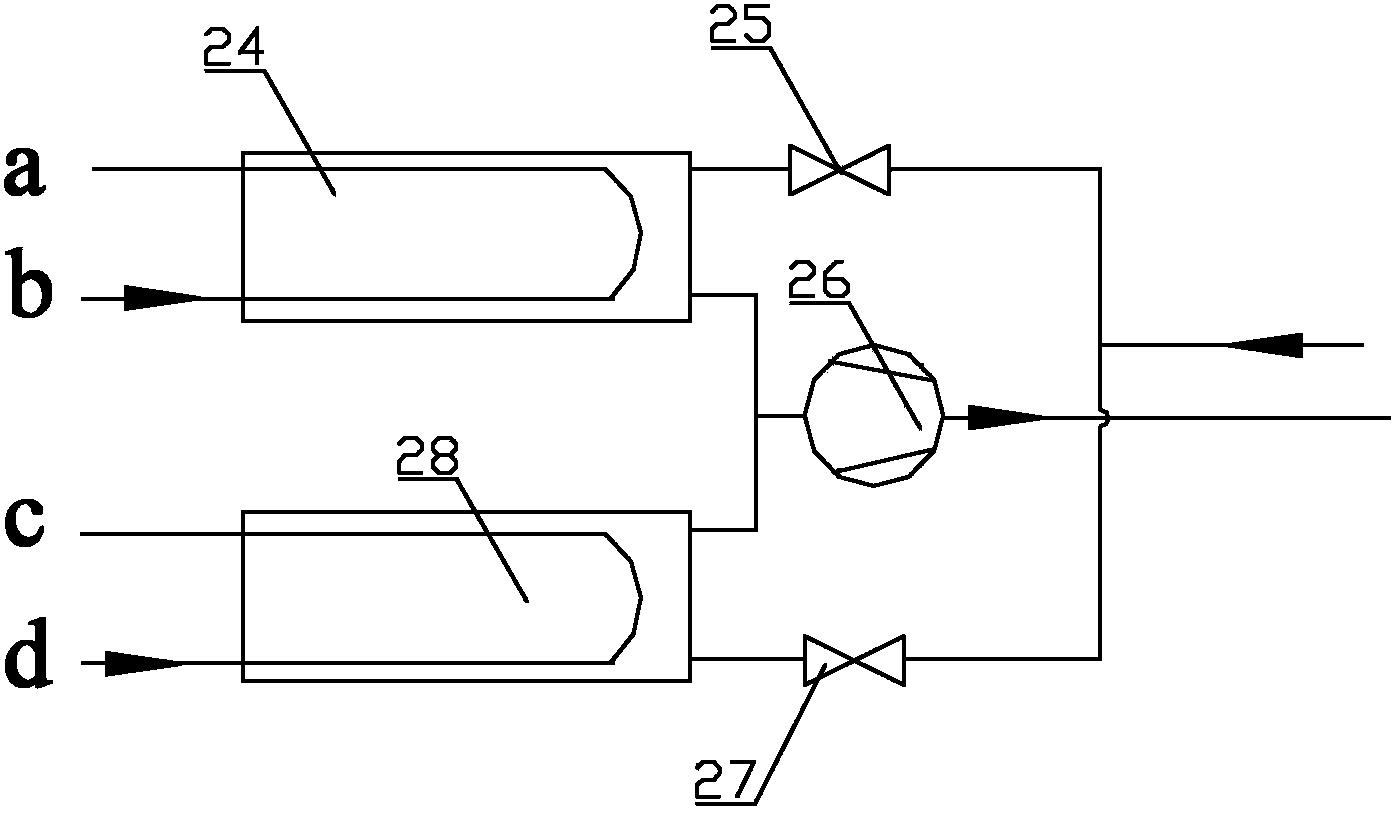

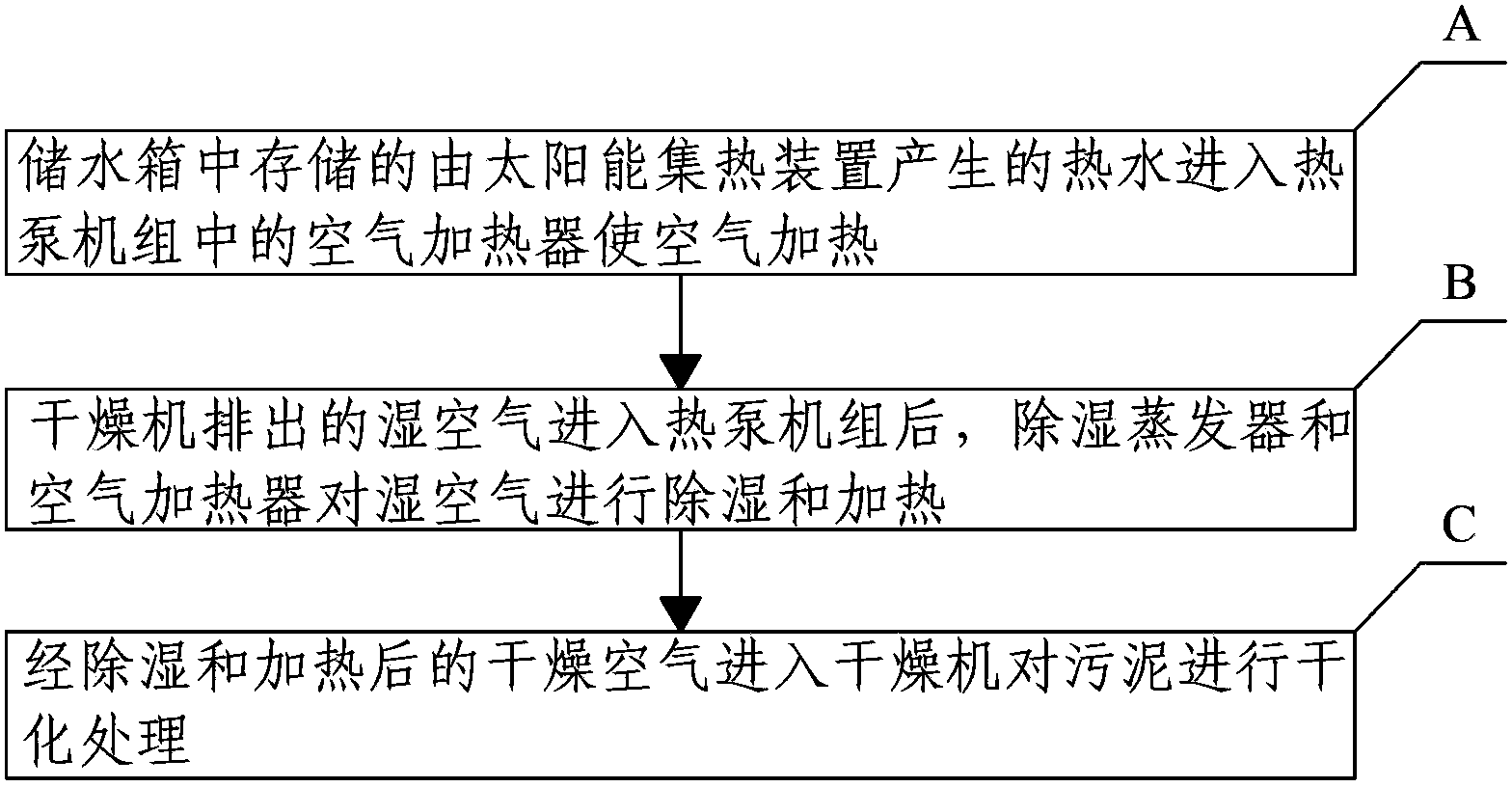

[0029] Such as figure 1 As shown, a solar heat pump combined with sludge drying system according to the present invention includes a solar heating subsystem, a heat pump subsystem and a drying device subsystem, and the heat pump subsystem includes an air source heat pump subsystem and a reclaimed water source heat pump subsystem. The solar heating subsystem includes a heat collector 2 for collecting solar radiation energy, a hot water storage tank 1, a first water pump 23 and a hot water coil 20; the hot water storage tank 1 and the first The water pump 23 and the hot water coil 20 are connected through pipelines to form a closed water circulation system. The water in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com