Patents

Literature

33results about How to "Small color shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid crystal display

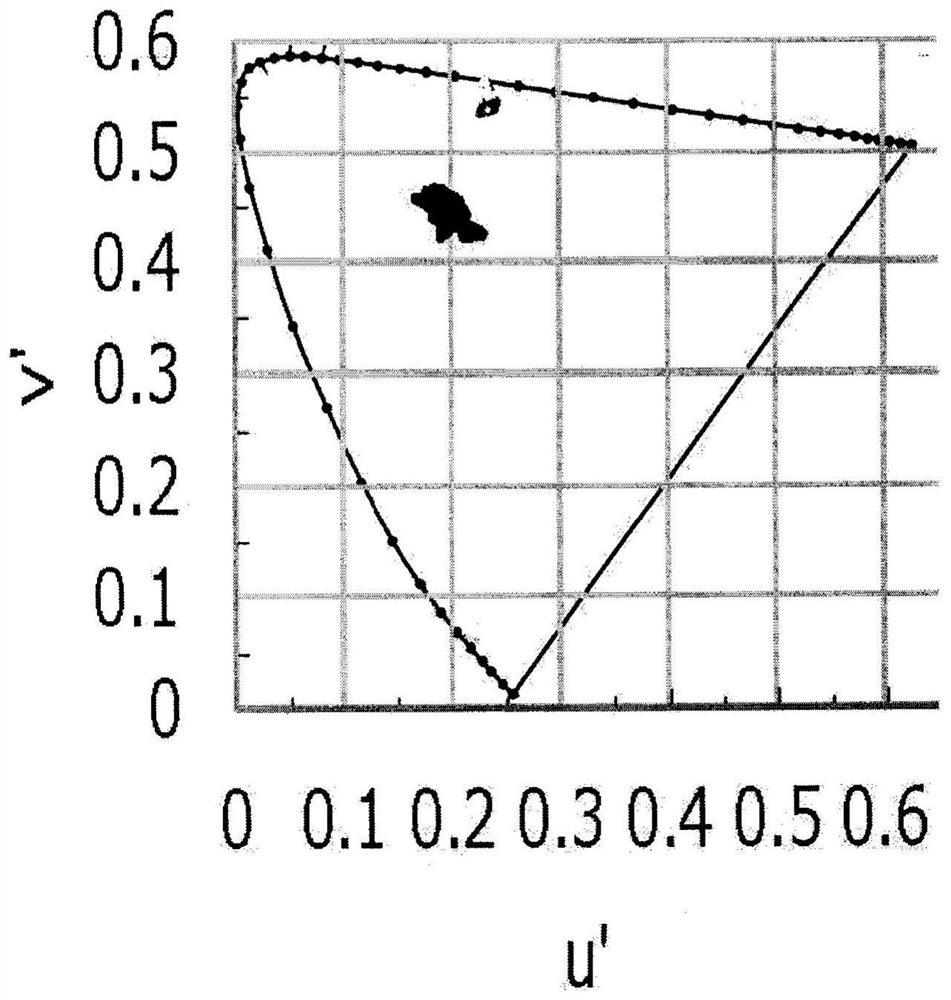

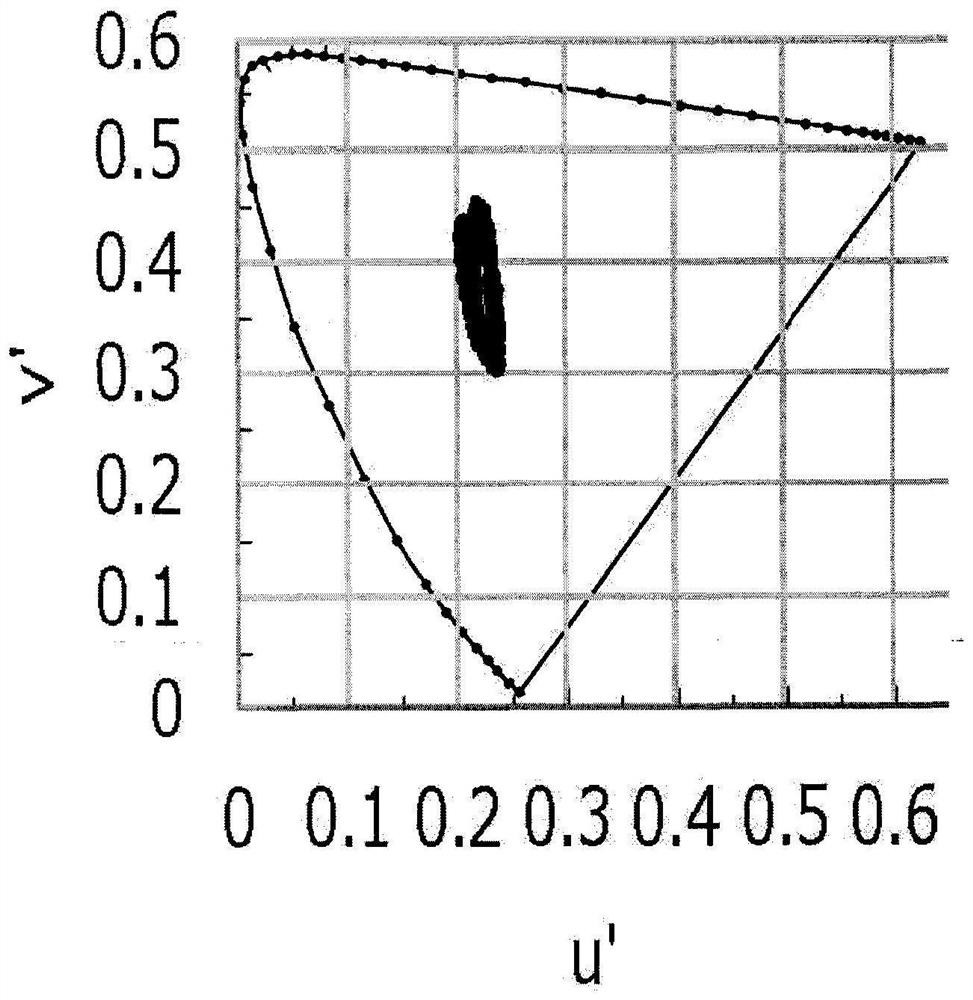

ActiveUS20070211199A1Small color shiftReduce the effect of colorNon-linear opticsEffect lightRelative luminance

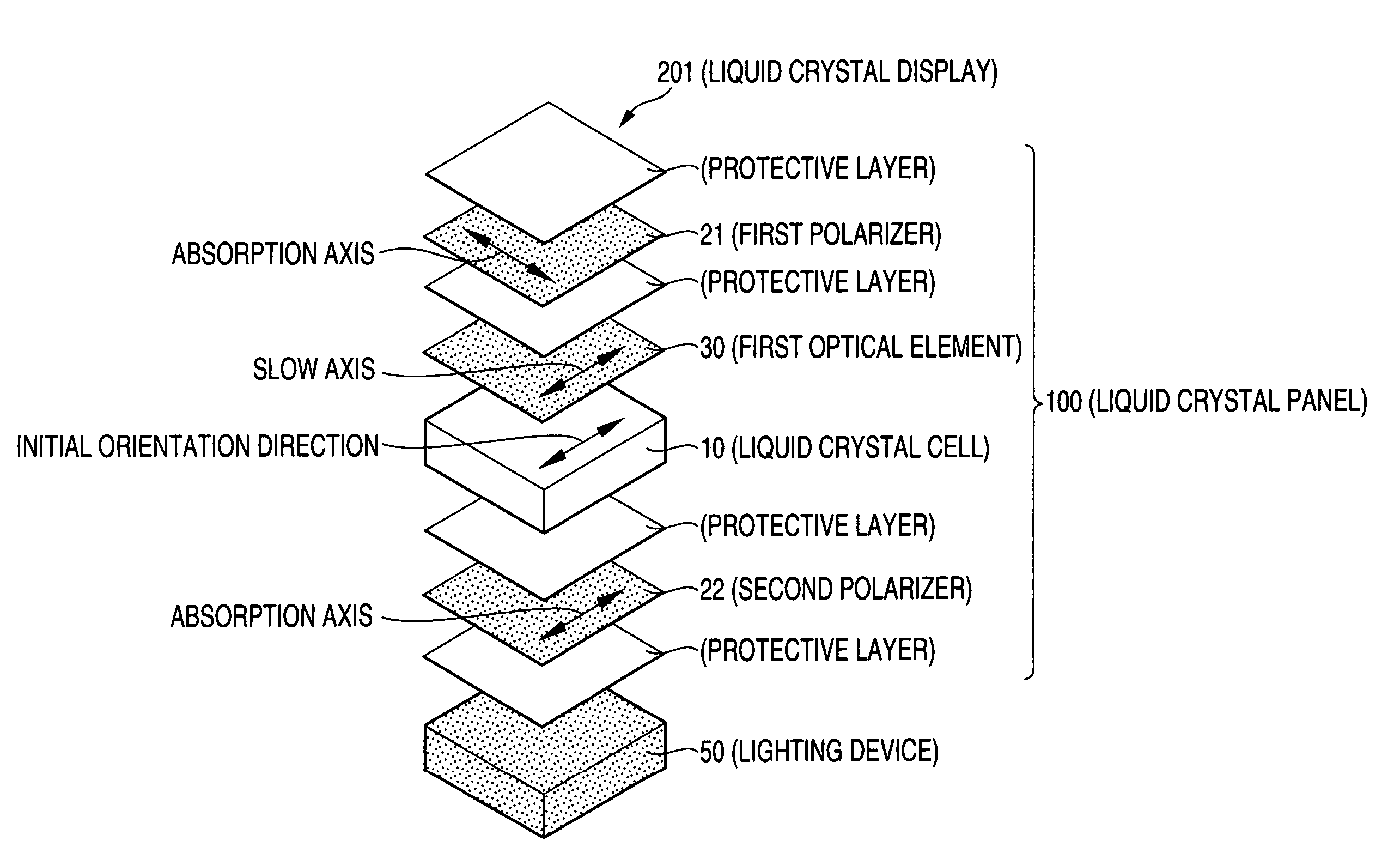

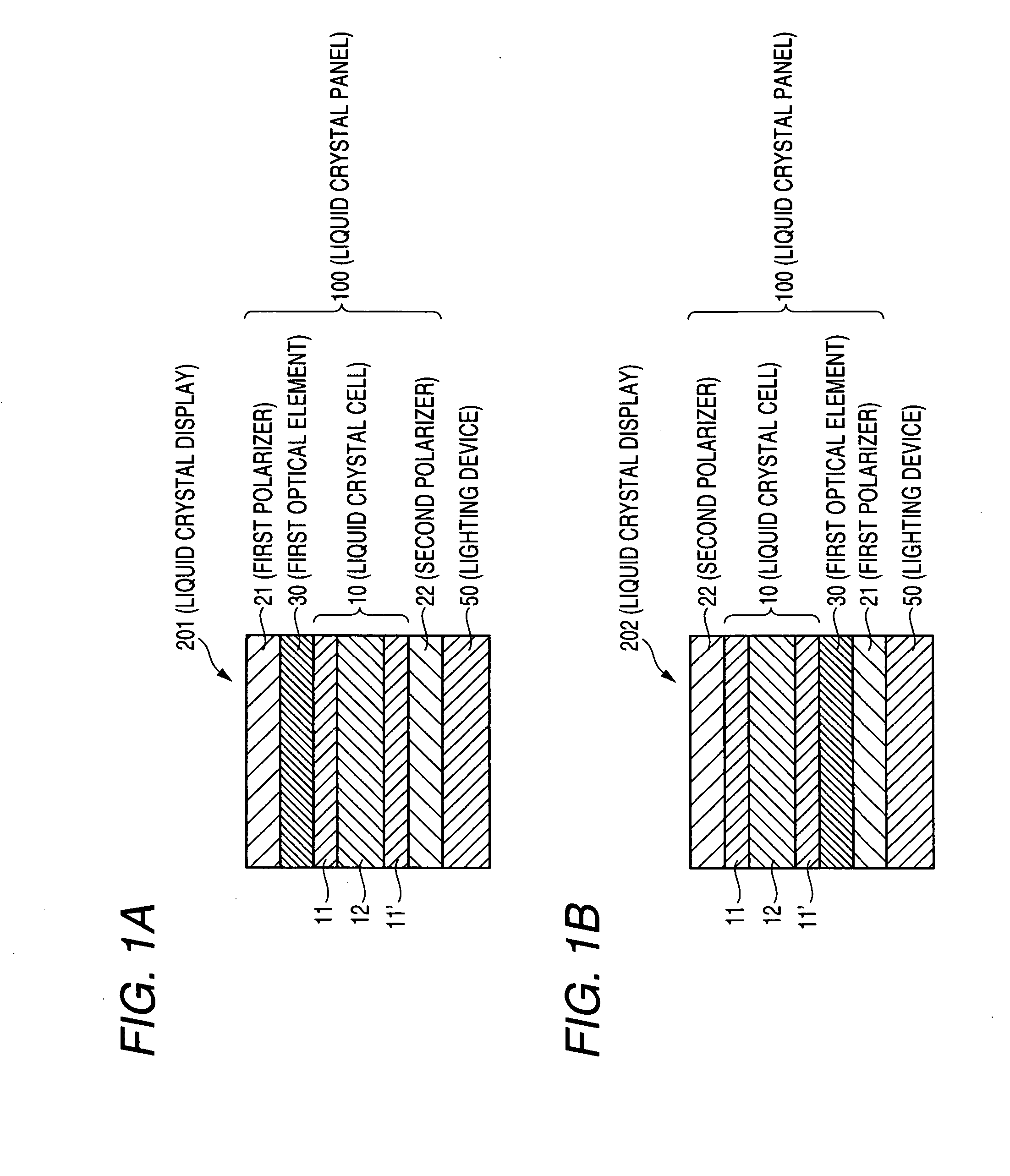

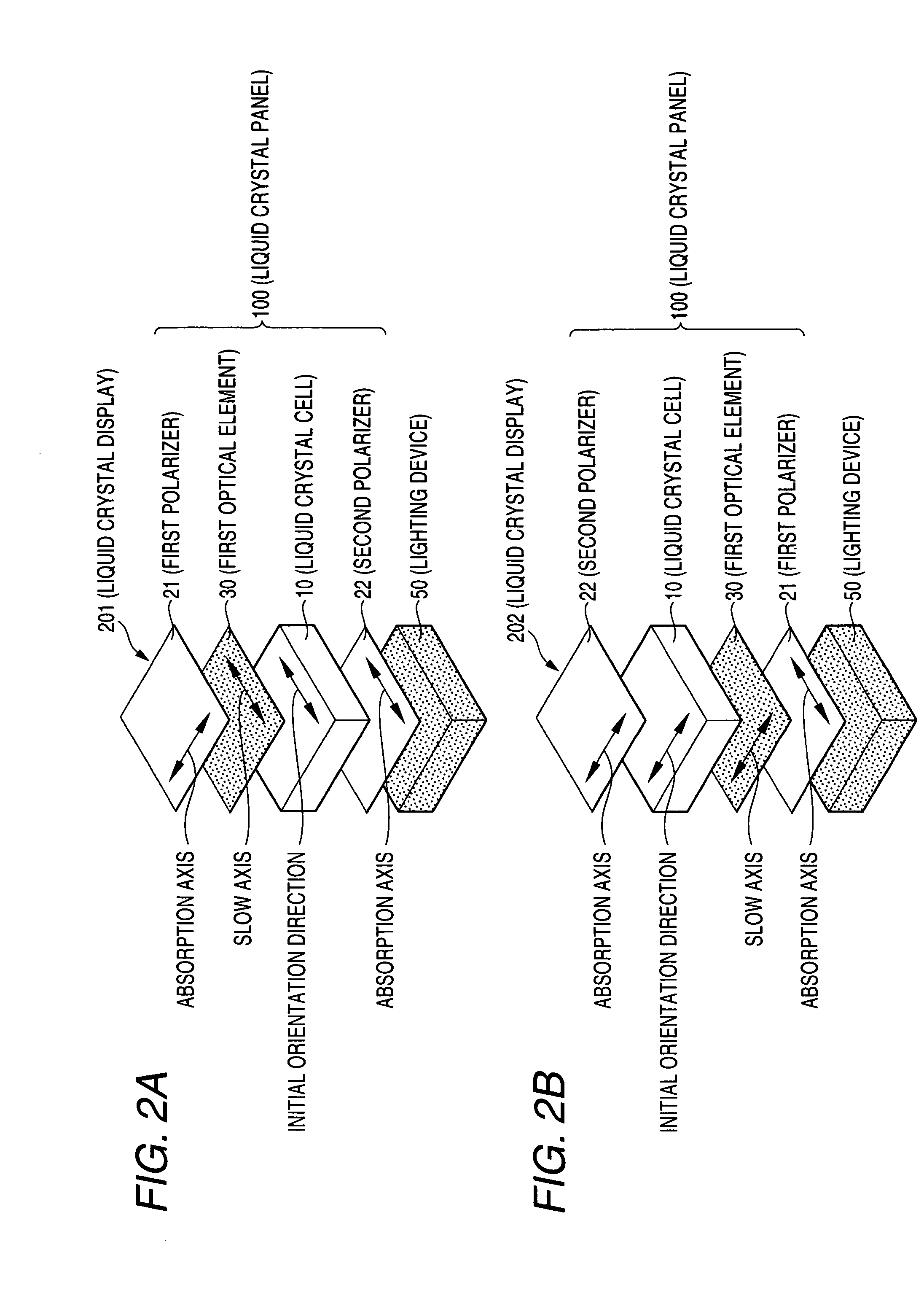

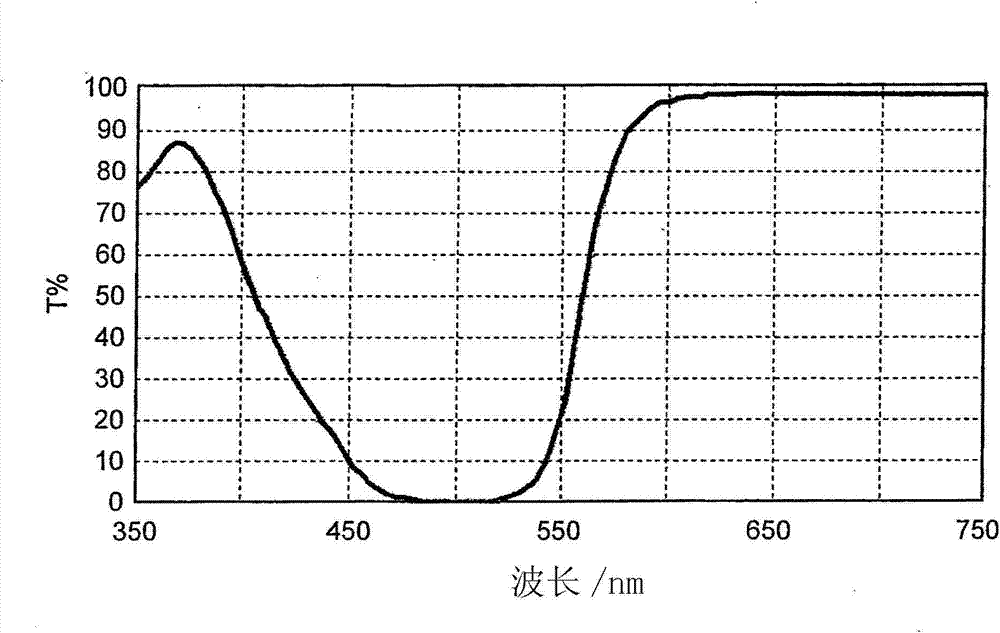

The present invention provides a liquid crystal display including: a liquid crystal panel; and a lighting device disposed on one side of the liquid crystal panel, the liquid crystal panel including: a liquid crystal cell; a first polarizer disposed on one side of the liquid crystal cell; a second polarizer disposed on the other side of the liquid crystal cell; and a first optical element disposed between the liquid crystal cell and the first polarizer; the absorption axis direction of the first polarizer being substantially perpendicular to the absorption axis direction of the second polarizer, the first optical element having an optical indicatrix having a relationship of nx≧nx>ny, the lighting device having: a maximum value of luminance in the wavelength range of 550±50 nm; and a relative luminance at a wavelength of 450 nm is 0.28 or less.

Owner:NITTO DENKO CORP

Weather resistant polyurethane elastomer

This invention relates to polyurethane elastomers and to a process for their production. These elastomers comprise the reaction product of a (cyclo)aliphatic isocyanate component having an NCO group content of about 20 to about 45%, with an isocyanate-reactive component comprising one or more low unsaturation polyether polyols, a low molecular weight organic compound containing two hydroxyl groups and which is free of amine groups, and, optionally, one or more organic compounds having a molecular weight of about 200 to about 500, a hydroxyl functionality of 3 to 4 and comprising an amine-initiated polyether polyol.

Owner:BAYER MATERIALSCIENCE AG

Liquid Crystal Display Device

InactiveUS20090213311A1Widen perspectiveSmall color shiftNon-linear opticsTectorial membranePolarizer

A liquid crystal display device includes: a liquid crystal cell; and a pair of polarizing plates sandwiching the liquid crystal cell and each including a polarizer and a protective film provided on a side of the liquid crystal cell, in which transmission axes of the pair of polarizing plates are orthogonally arranged, wherein Rth(λ) of at least one of the protective films provided on the liquid crystal cell side of the polarizing plates has negative characteristics for ambient temperature, in which Rth(λ) represents a retardation in a thickness direction measured at a wavelength of λ nm.

Owner:FUJIFILM CORP

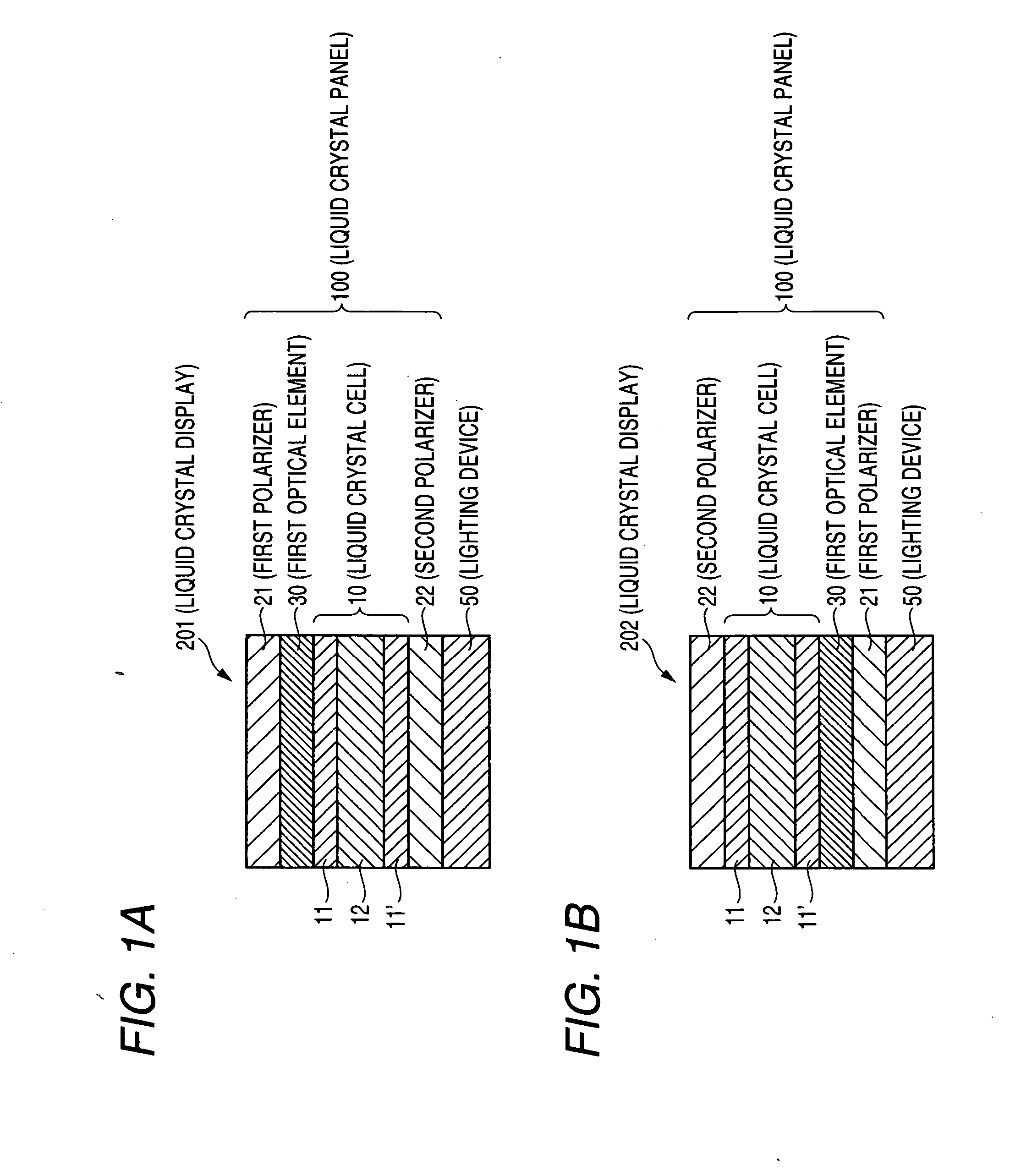

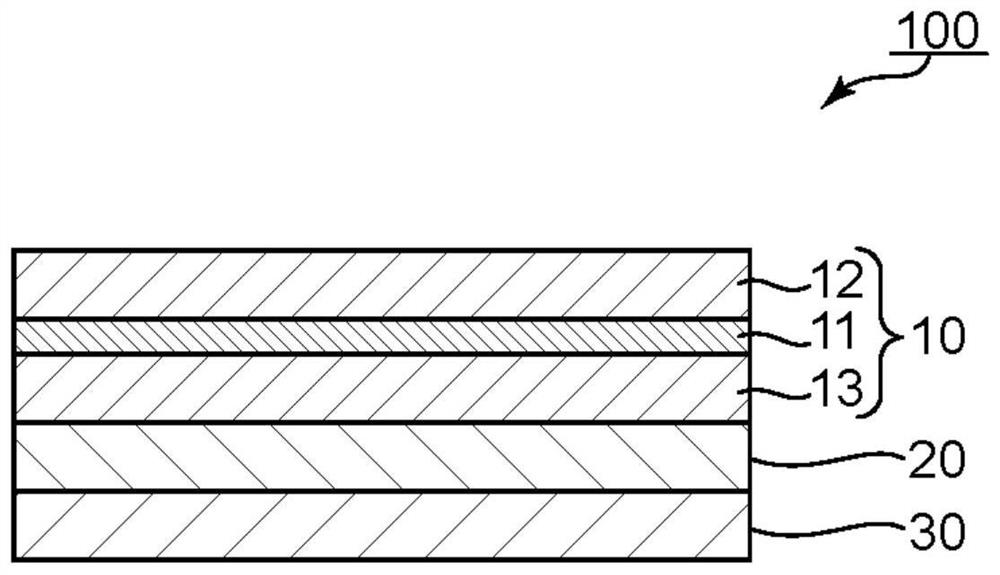

Liquid crystal panel and liquid crystal display

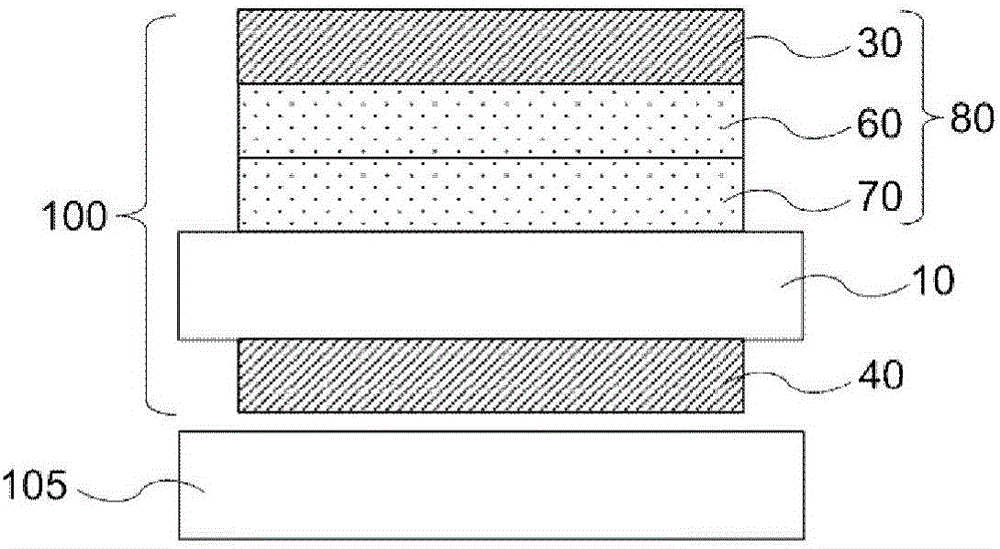

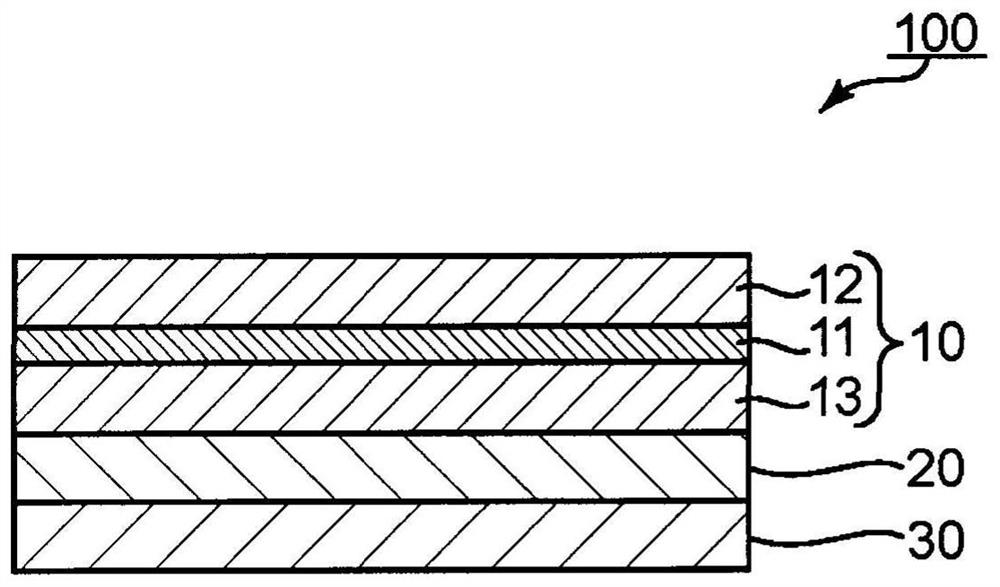

ActiveCN106019684ASmall color shiftLittle color changePolarising elementsNon-linear opticsCrystallographyRefractive index

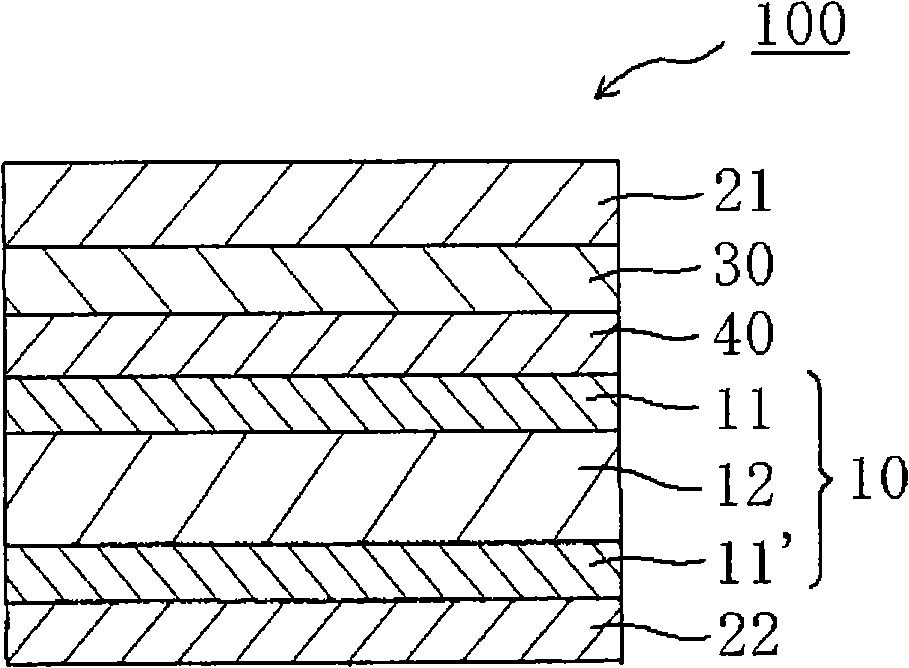

The liquid crystal panel (100) includes a liquid crystal cell (10), a first polarizer (30) on one side of the liquid crystal cell, a second polarizer (40) on the other side of the liquid crystal cell, a first optically anisotropic element (60) having a positive refractive index anisotropy disposed between the liquid crystal cell and the first polarizer, and a second optically anisotropic element (70) having a negative refractive index anisotropy disposed between the first optically anisotropic element and the liquid crystal cell. Liquid crystal molecule in the liquid crystal cell (10) is homogeneously aligned and has a pretilt angle of 0.5 DEG or less in non-electric-field state. At least one of the first optically anisotropic element (60) and the second optically anisotropic element (70) has a ratio R450 / R550 of 1.1 or more, where R550 is a retardation at a wavelength of 550 nm and R450 is a retardation at a wavelength of 450 nm.

Owner:NITTO DENKO CORP

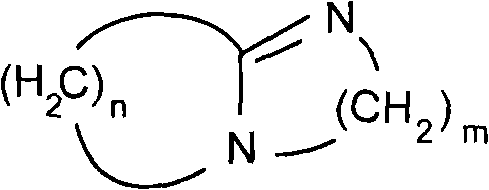

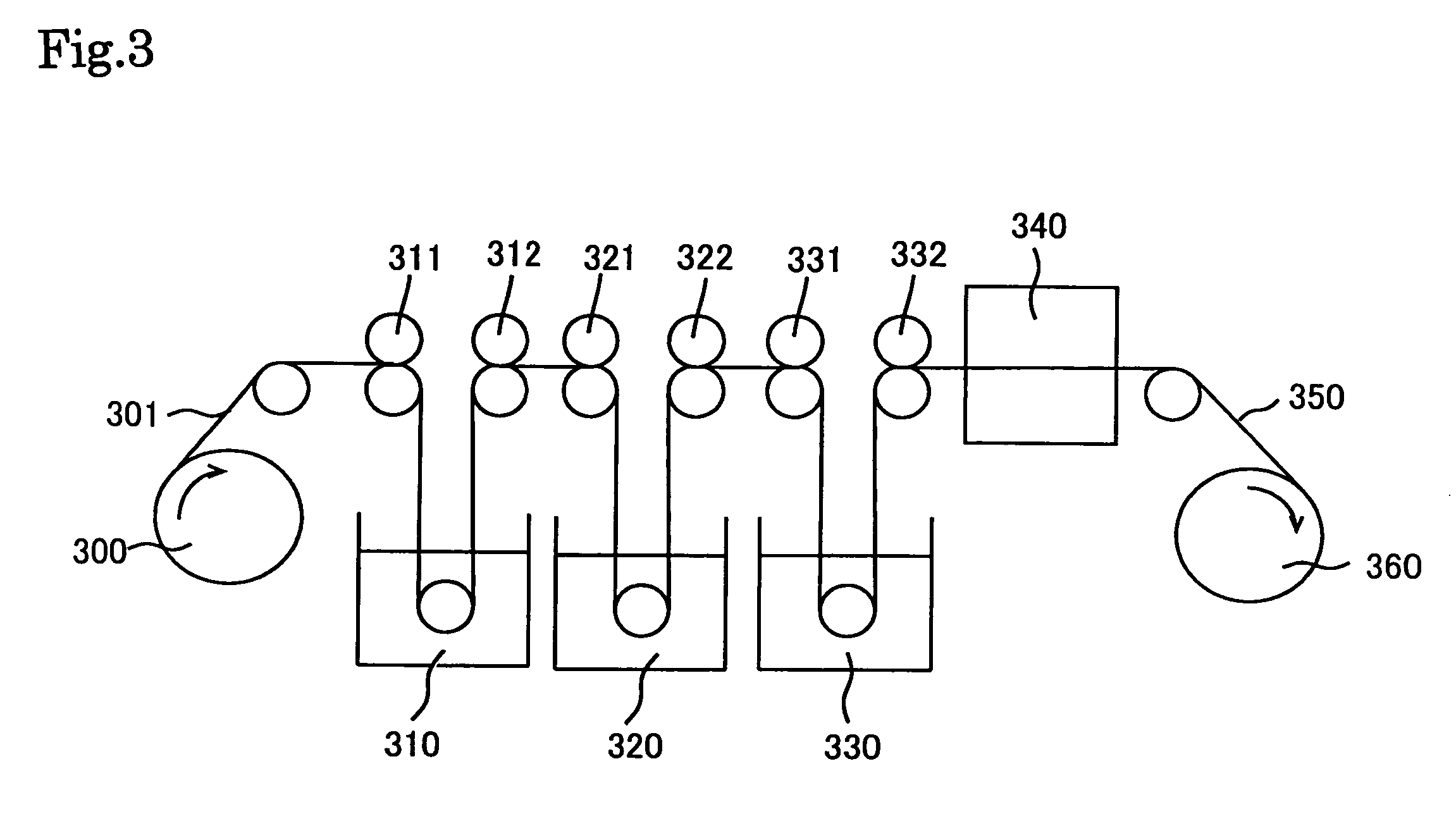

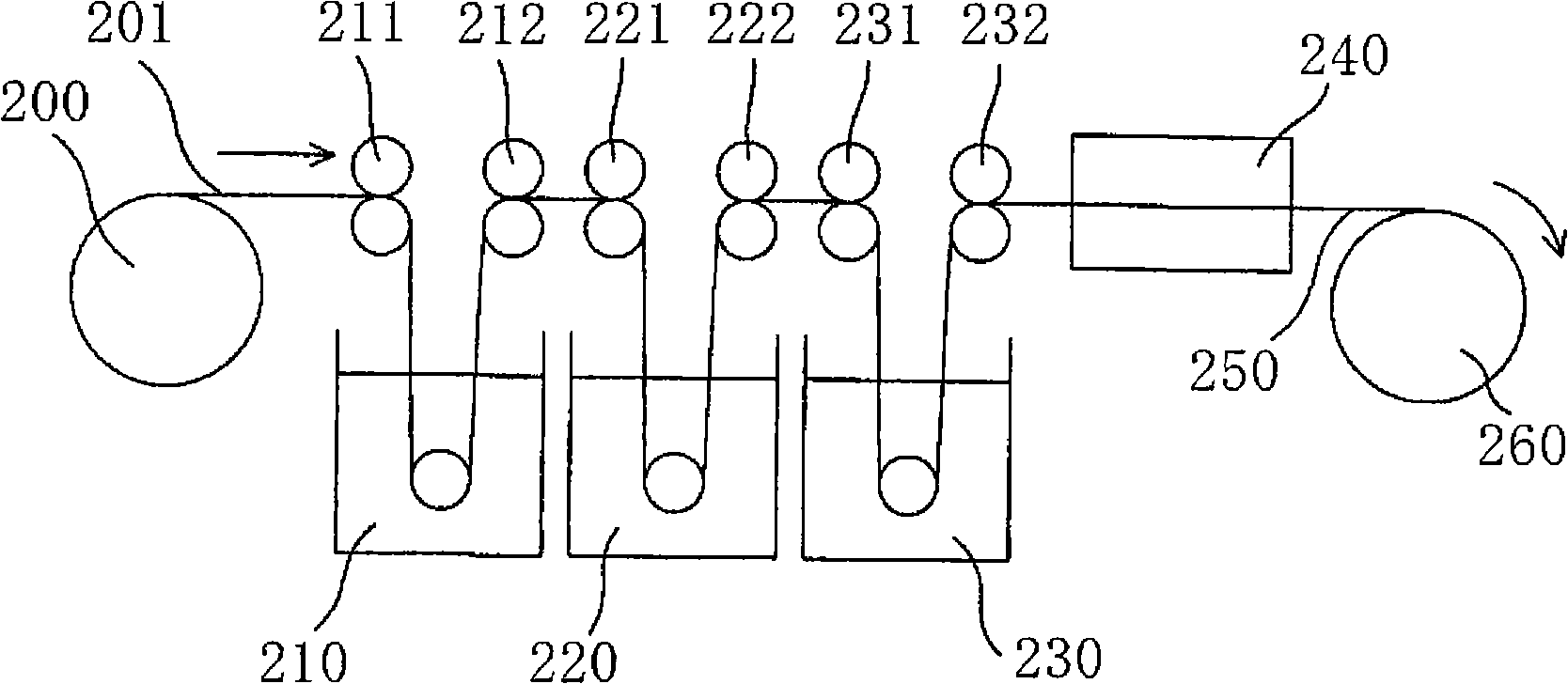

Method of preparing retardation film, polarizing plate, and liquid crystal display

InactiveUS20150114257A1Superior retardation characteristicImprove moisture resistanceOptical articlesOrganic non-macromolecular adhesiveAcetic acidPolymer science

A method of preparing a retardation film includes cellulose acetate having an average degree of acetylation of 2.0 to 2.5 and having a moisture content of 1.0 mass % or less, where the retardation film includes a compound having a Van der Waals volume of 450 to 1000 Å3. The retardation film is prepared by a dope preparing step of dissolving cellulose acetate having an average degree of acetylation within the range of 2.0 to 2.5 to prepare a dope; a film product forming step of casting the dope onto a metal belt to form a film product; a film product peeling step of peeling off the film product from the metal belt; a drawing step of drawing the peeled film product; and a drying step at a drying temperature of 140° C. or more.

Owner:KONICA MINOLTA INC

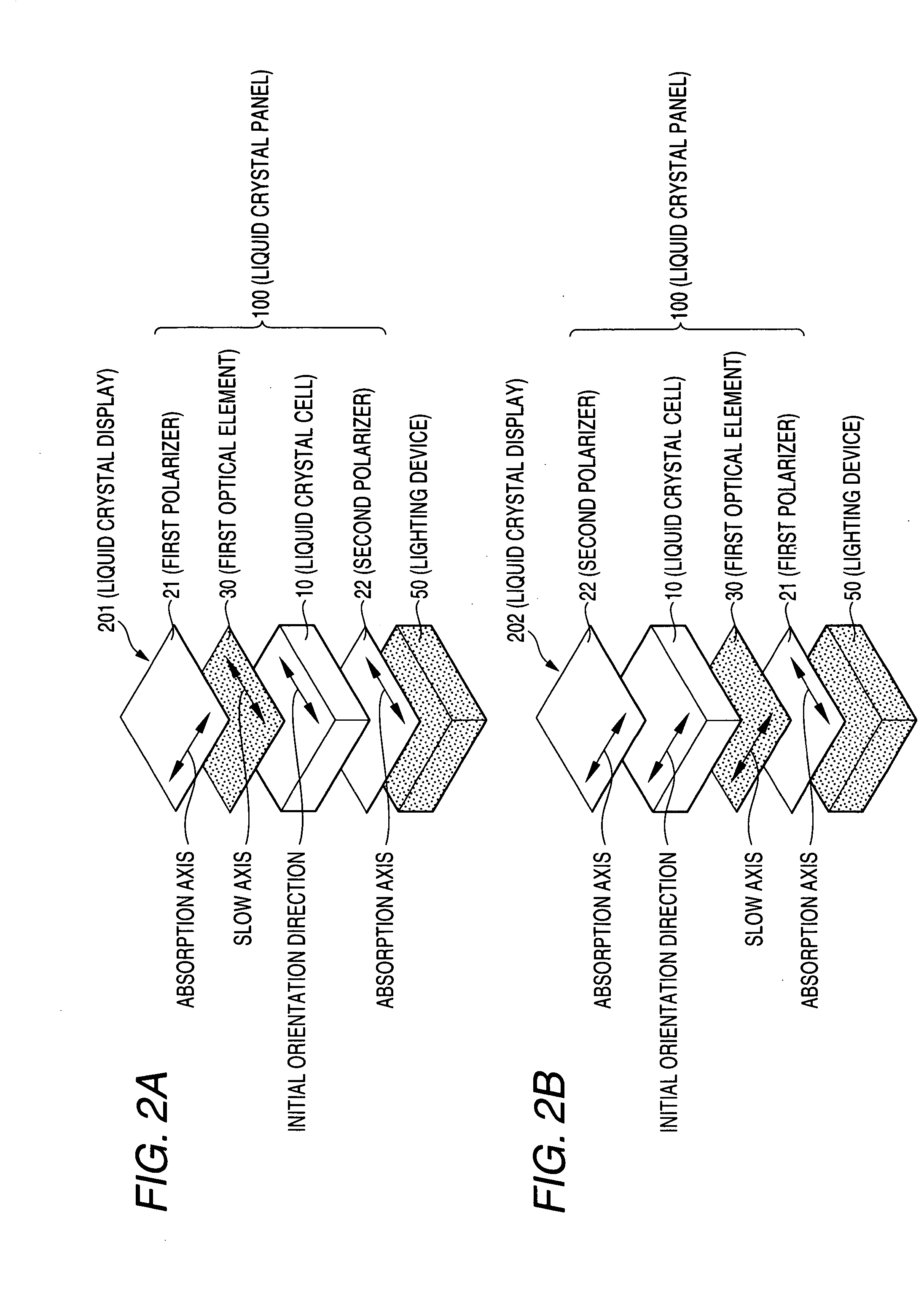

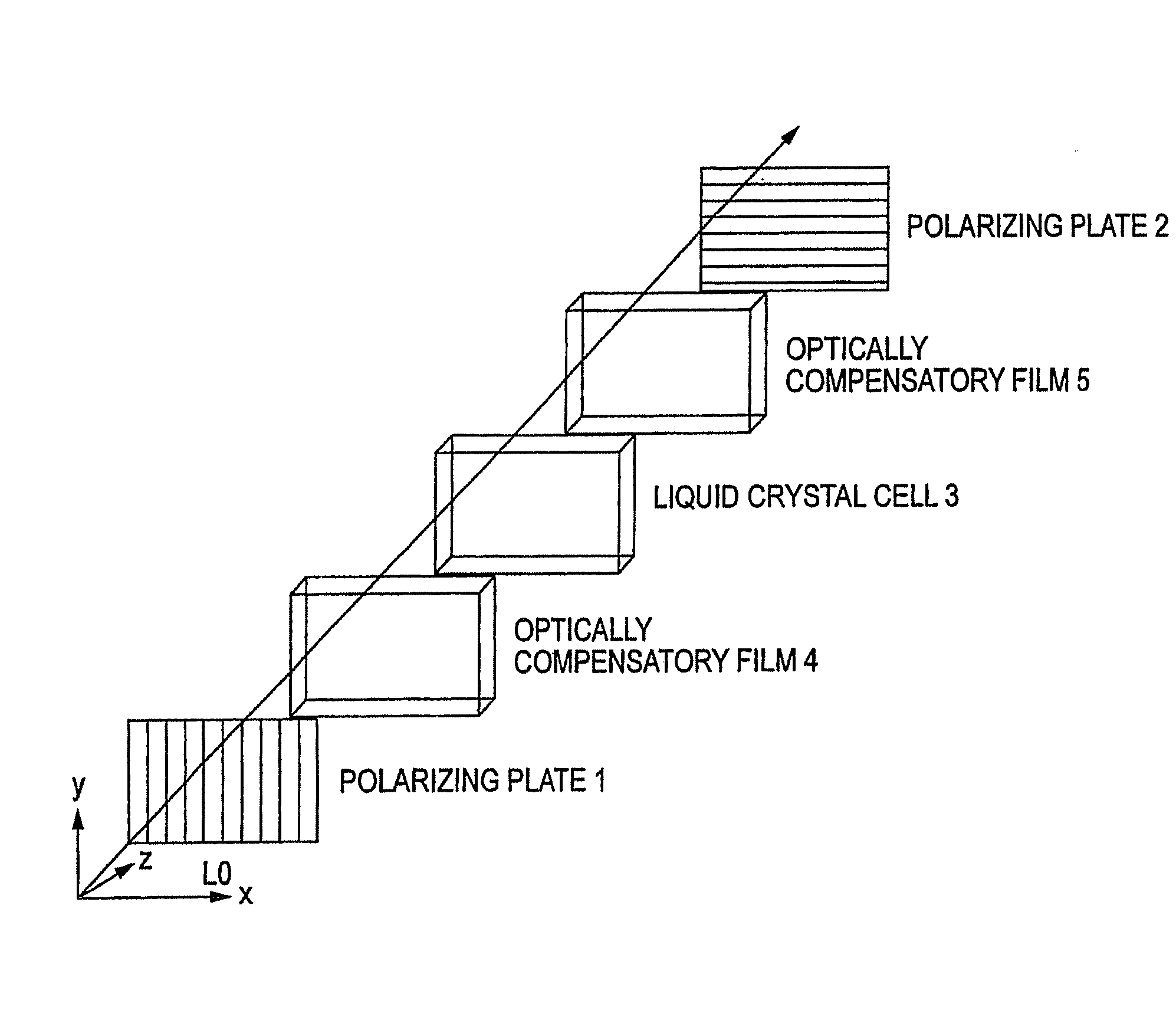

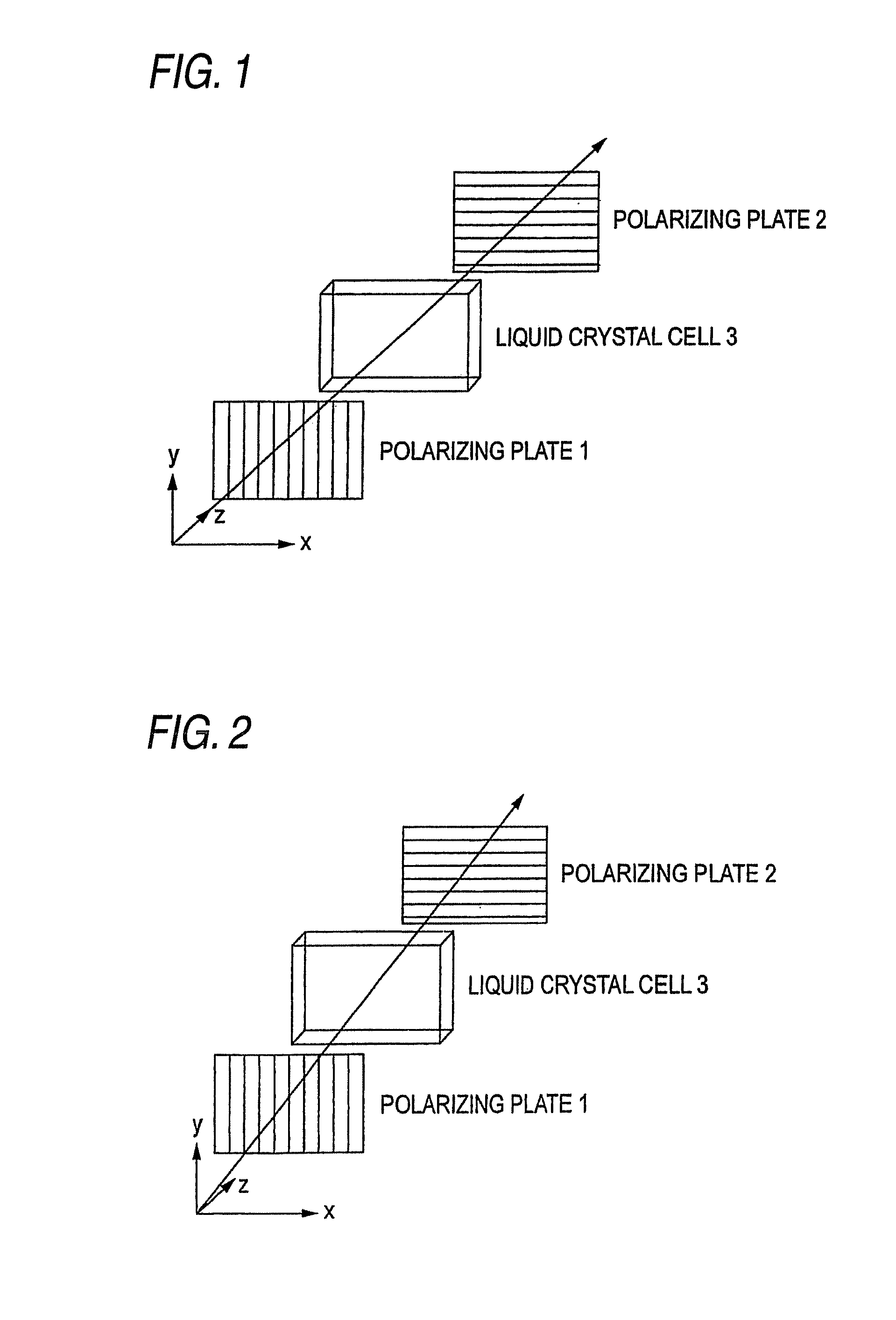

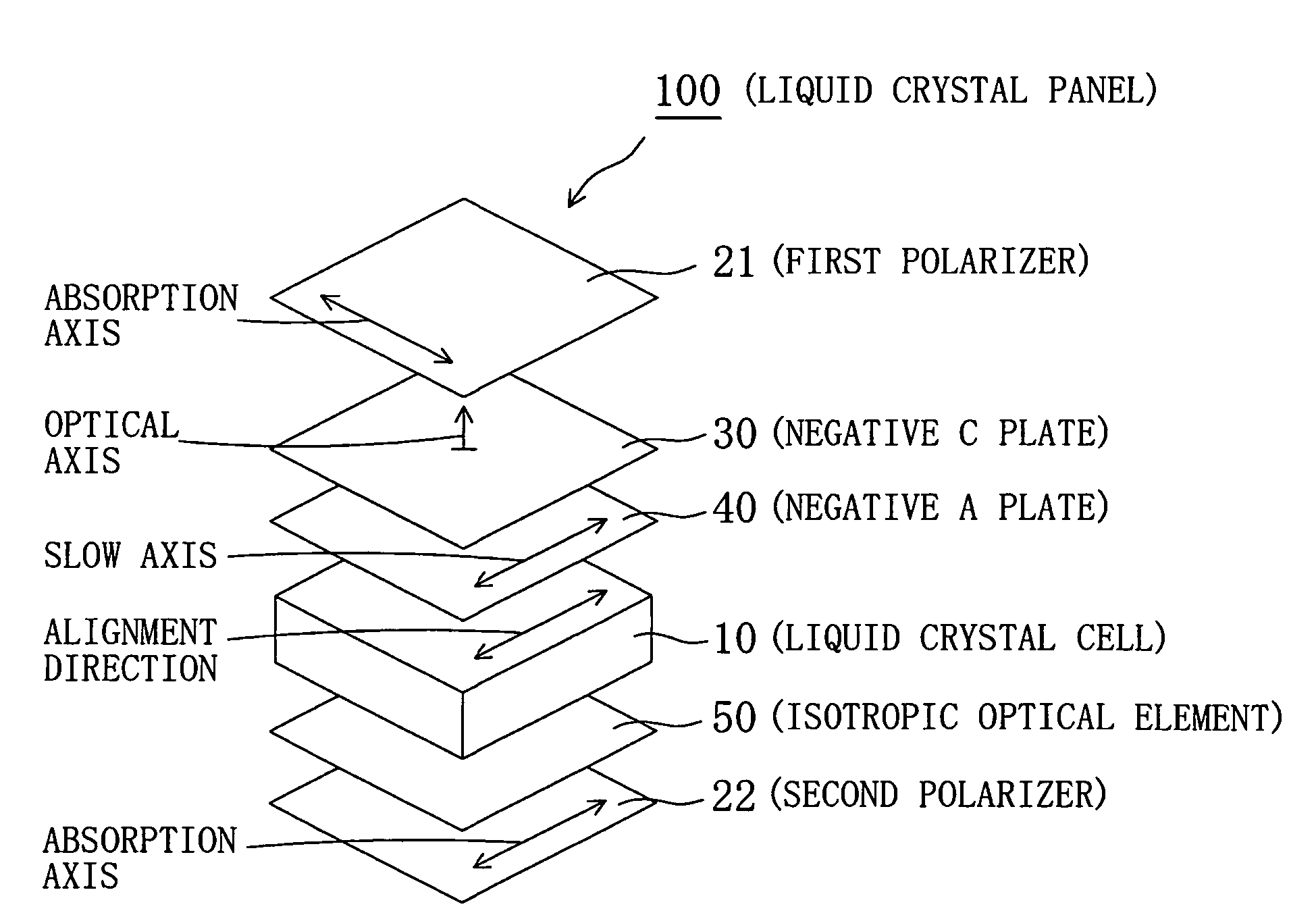

Liquid crystal panel, liquid crystal television, and liquid crystal display apparatus

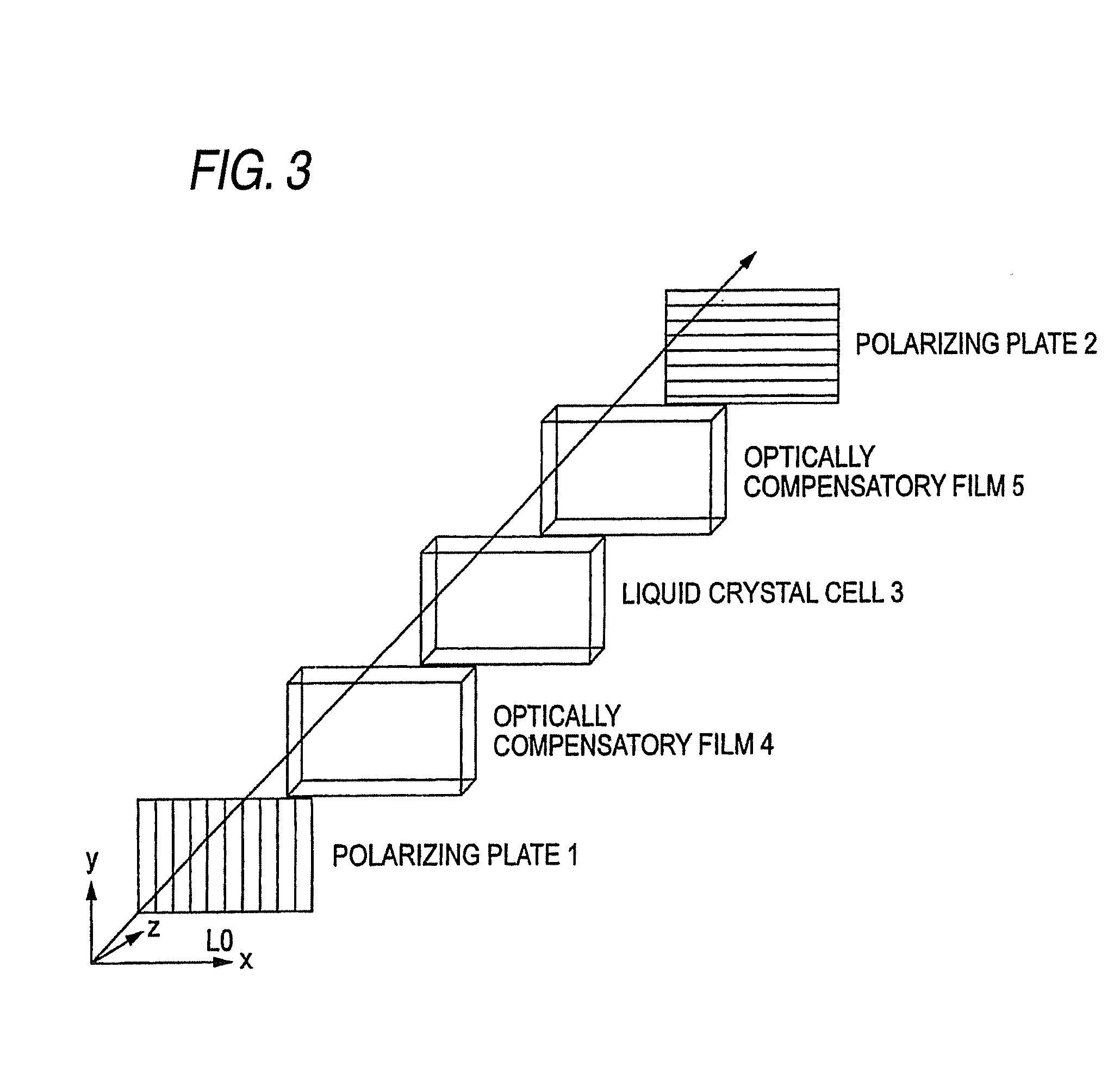

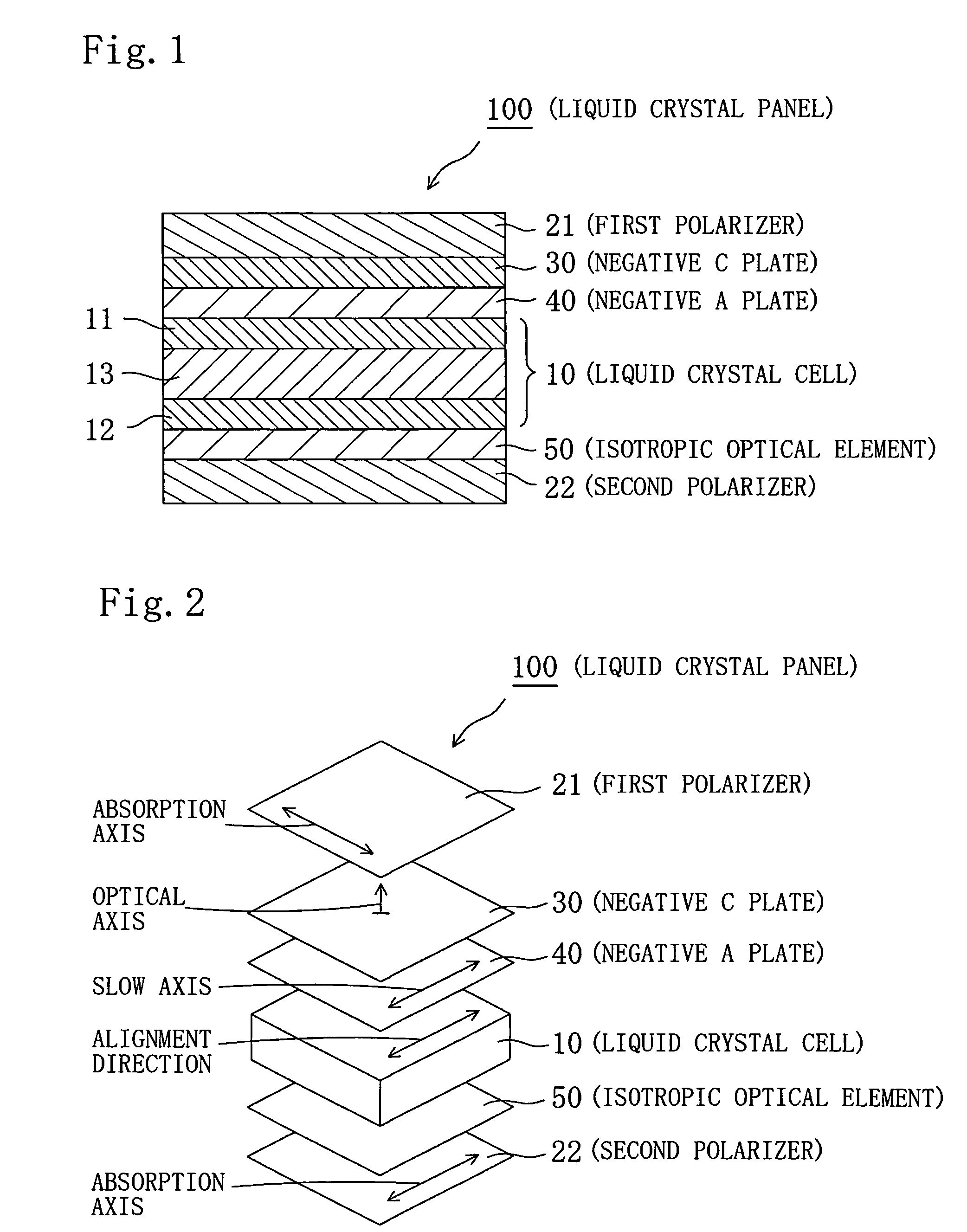

ActiveUS7619706B2Eliminate adverse effects on display propertiesIncrease contrastNon-linear opticsOptical elementsColor shiftPolarizer

A liquid crystal panel including a liquid crystal cell having an improved contrast ratio in an oblique direction and an improved color shift in an oblique direction is provided.A liquid crystal panel according to the present invention includes: a liquid crystal cell; a first polarizer arranged on one side of the liquid crystal cell; a second polarizer arranged on another side of the liquid crystal cell; a negative C plate and a negative A plate arranged between the liquid crystal cell and the first polarizer; and an isotropic optical element arranged between the liquid crystal cell and the second polarizer. The negative C plate is arranged between the first polarizer and the negative A plate.

Owner:NITTO DENKO CORP

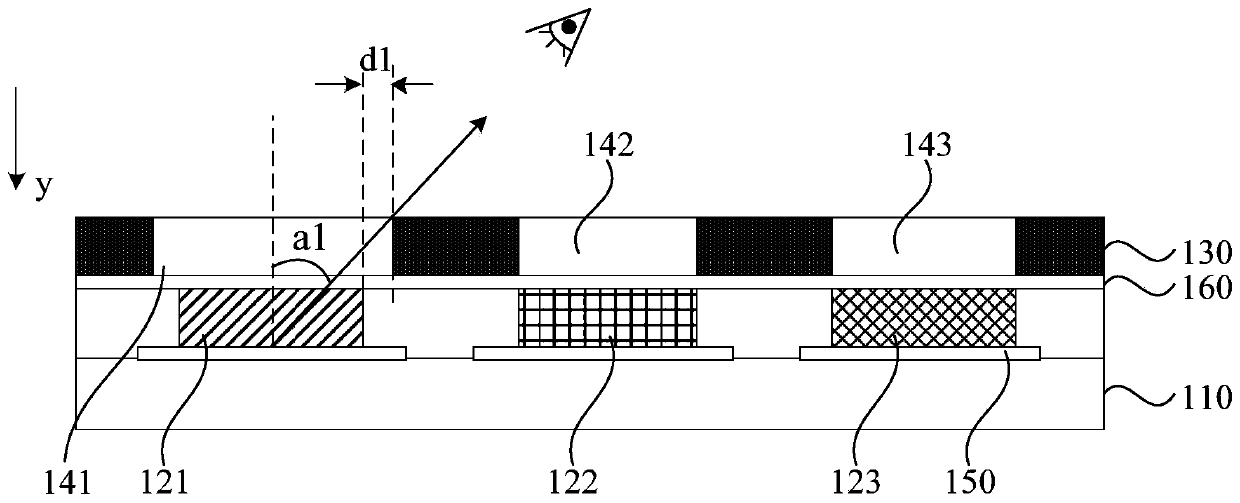

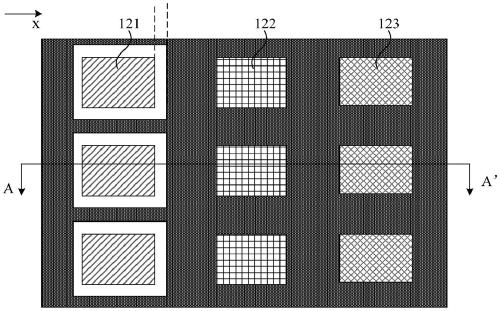

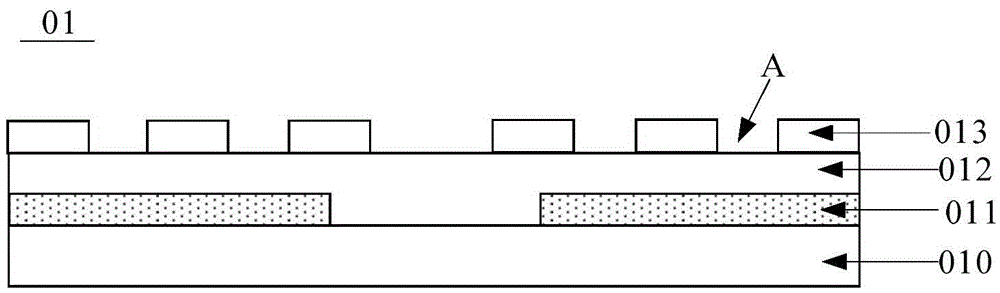

Display panel and display device

ActiveCN111554728ASmall color shiftImprove big view role biasSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

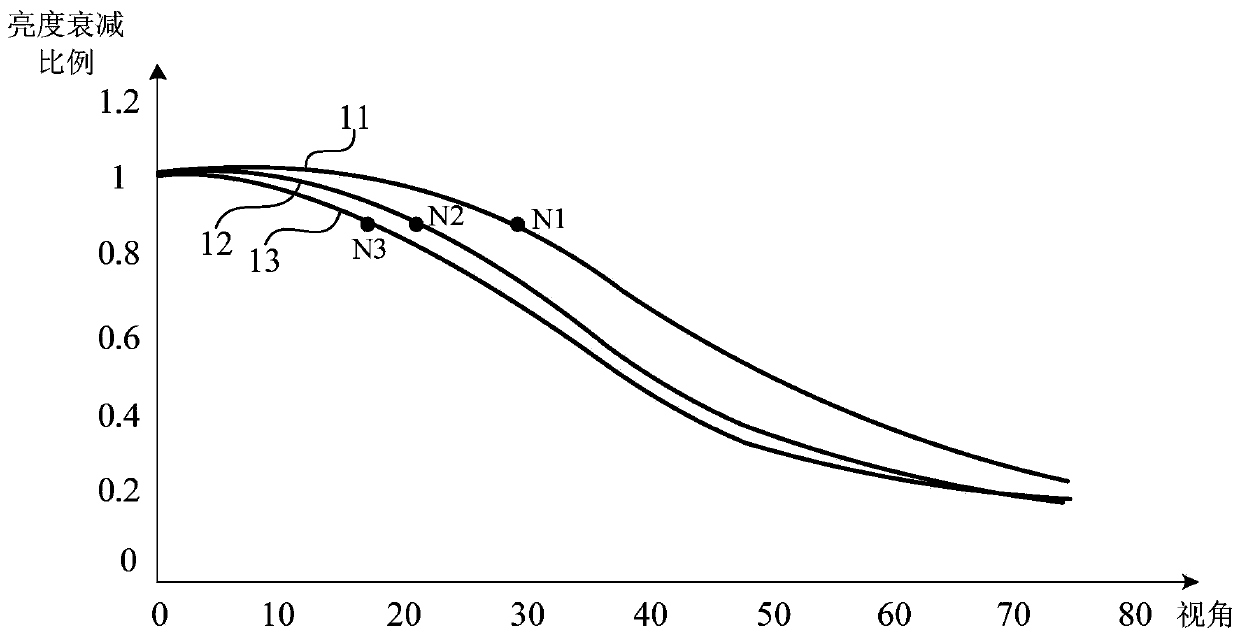

The embodiment of the invention discloses a display panel and a display device. At least an opening corresponding to a first color light-emitting unit is larger than the first color light-emitting unit in size by being arranged in a set direction, and the shortest distance between the first color light-emitting unit and the corresponding opening in the set direction is positively related to a first set visual angle; or in the set direction, the size of the opening corresponding to at least the first color light-emitting unit is smaller than that of the first color light-emitting unit, and theshortest distance between the first color light-emitting unit and the corresponding opening in the set direction is negatively related to the first set visual angle; the first set visual angle is an angle at which the brightness attenuation speed of the first color light-emitting unit is greater than a preset speed in the target brightness attenuation rule; the brightness attenuation of at least the first color light-emitting unit in the display panel along with the increase of the visual angle can meet the target brightness attenuation rule, and it is guaranteed that the color cast degree ofthe display panel under the large visual angle is small.

Owner:HEFEI VISIONOX TECH CO LTD

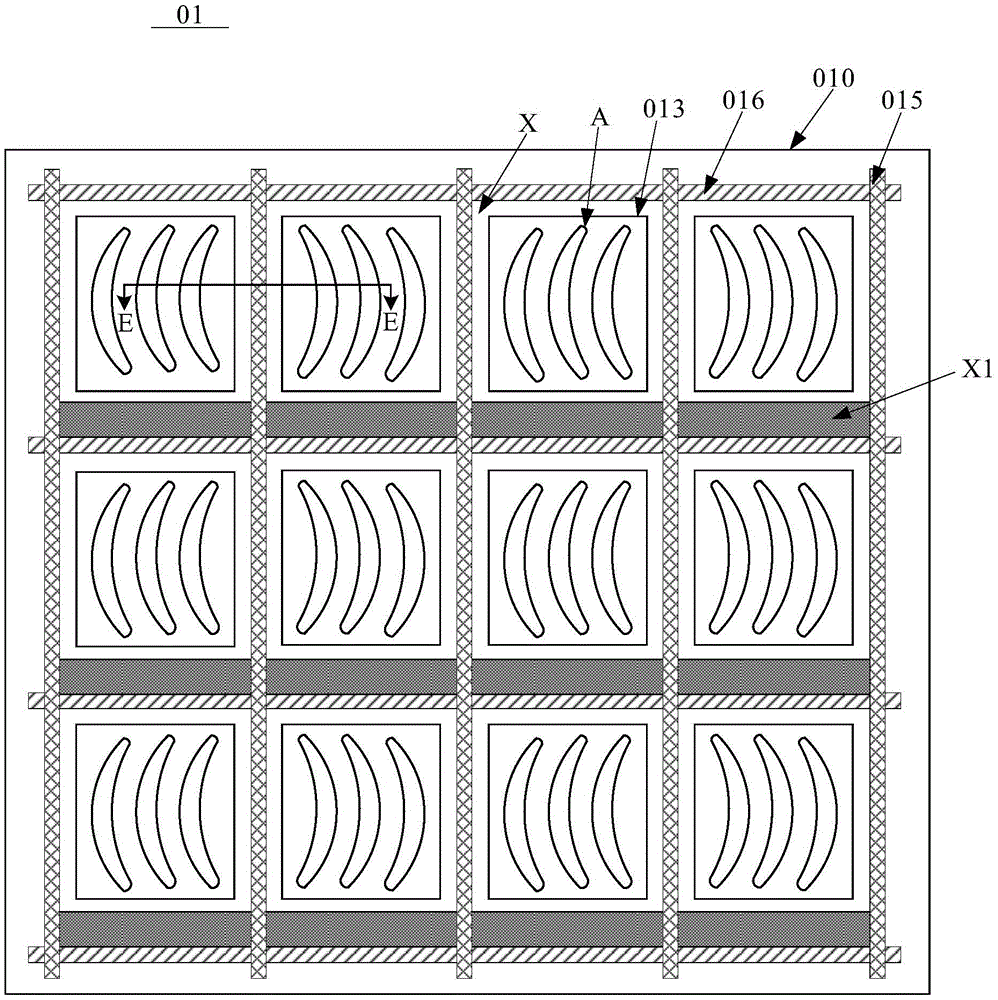

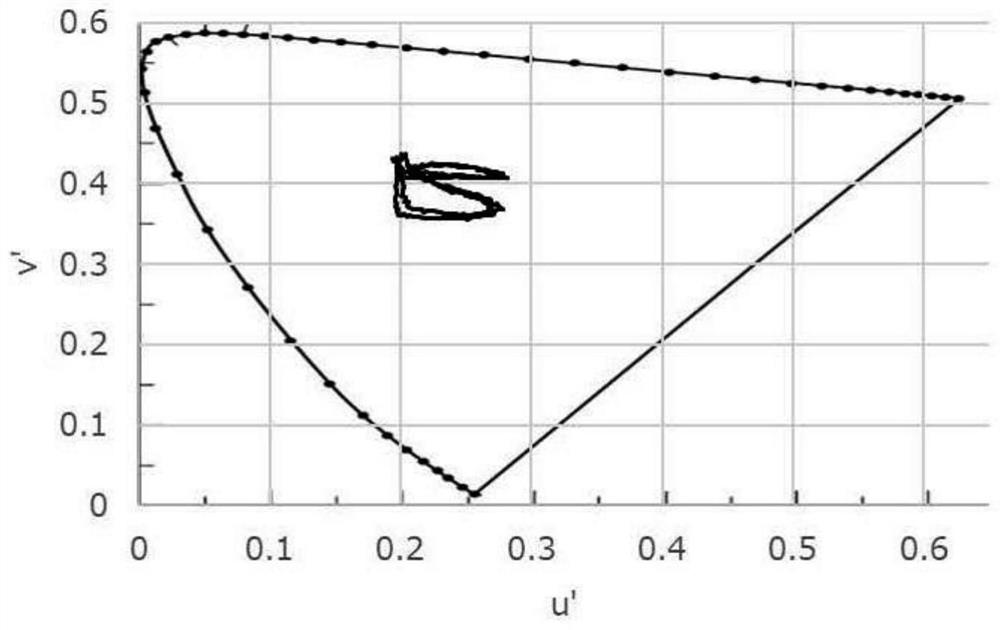

Multi-domain in-plane switching liquid crystal displays

InactiveUS20060244885A1Small color shiftFast in response timeNon-linear opticsPolarizerLiquid-crystal display

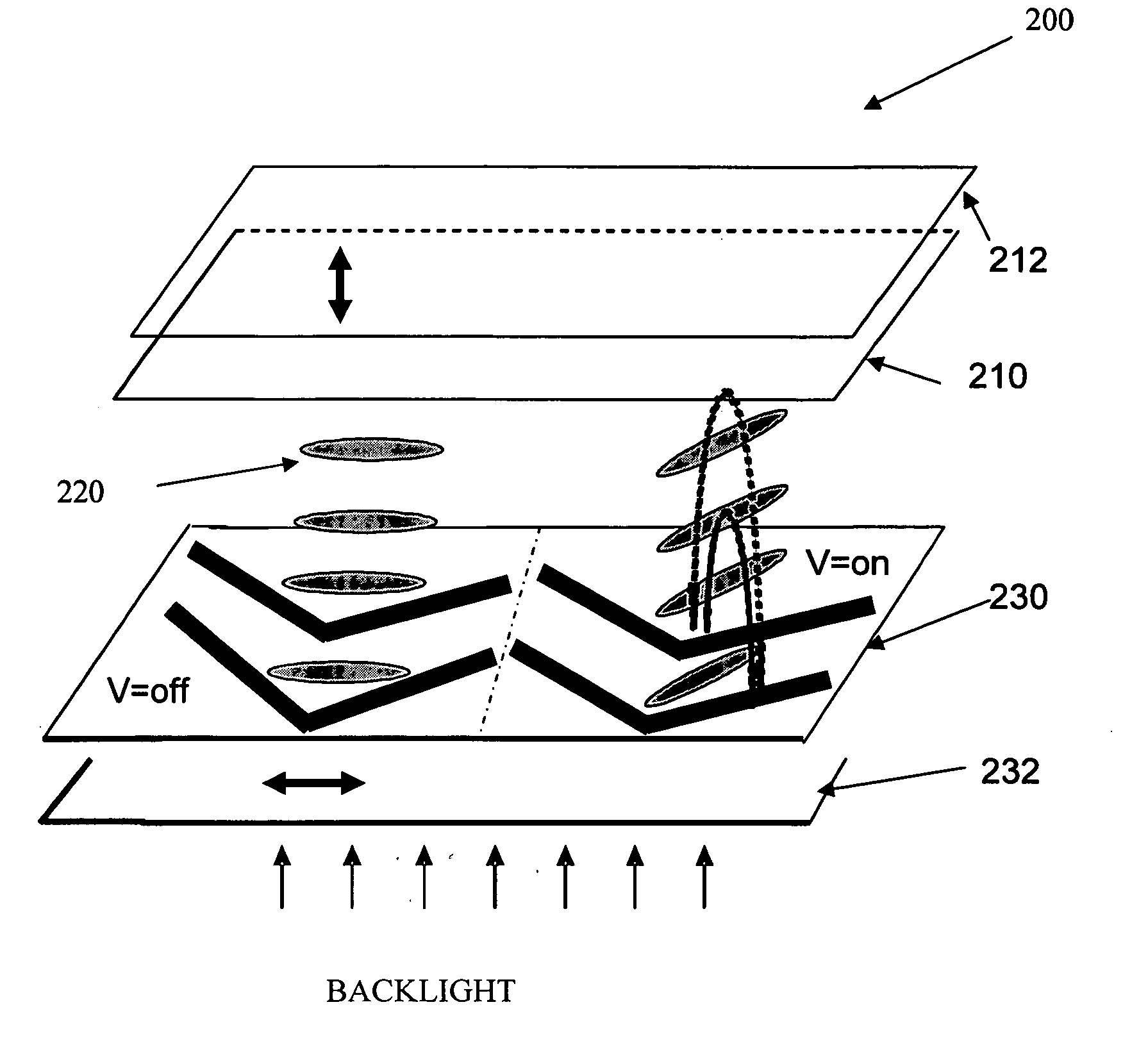

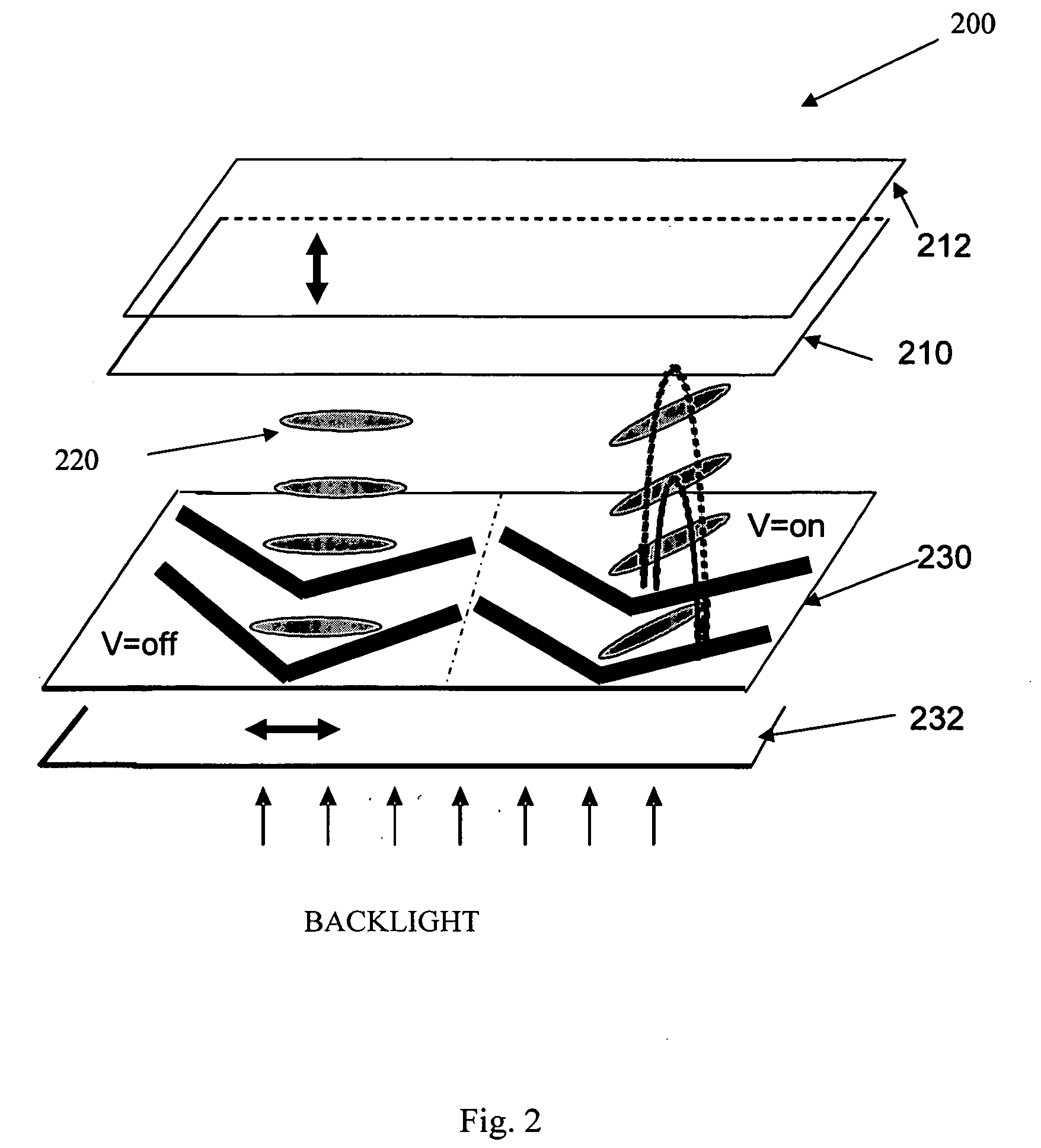

A multi-domain in-plane-switching liquid crystal display with small color shift, wide viewing angle and fast response. The structure of the multi-domain in-plane switching liquid crystal displays comprises plural chevron-shaped common electrodes and chevron-shaped pixel electrodes, arranged alternatingly to form a multi-domain liquid crystal distributions. In an embodiment the structure includes a polarizer and an analyzer and the liquid crystal material is homogenously aligned. In another embodiment the structure includes alignment films for vertically aligning the liquid crystal material and crossed linear polarizers, circular polarizers or a combination of linear polarizers and compensation film. In another embodiment, the multi-domain in-plane switching liquid crystal display provides at least two different uniformly aligned liquid crystal domains, for a double multi-domain-In-plane switching LC display.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Liquid crystal display

ActiveUS7557882B2Small color shiftReduce the effect of colorNon-linear opticsRelative luminancePolarizer

Owner:NITTO DENKO CORP

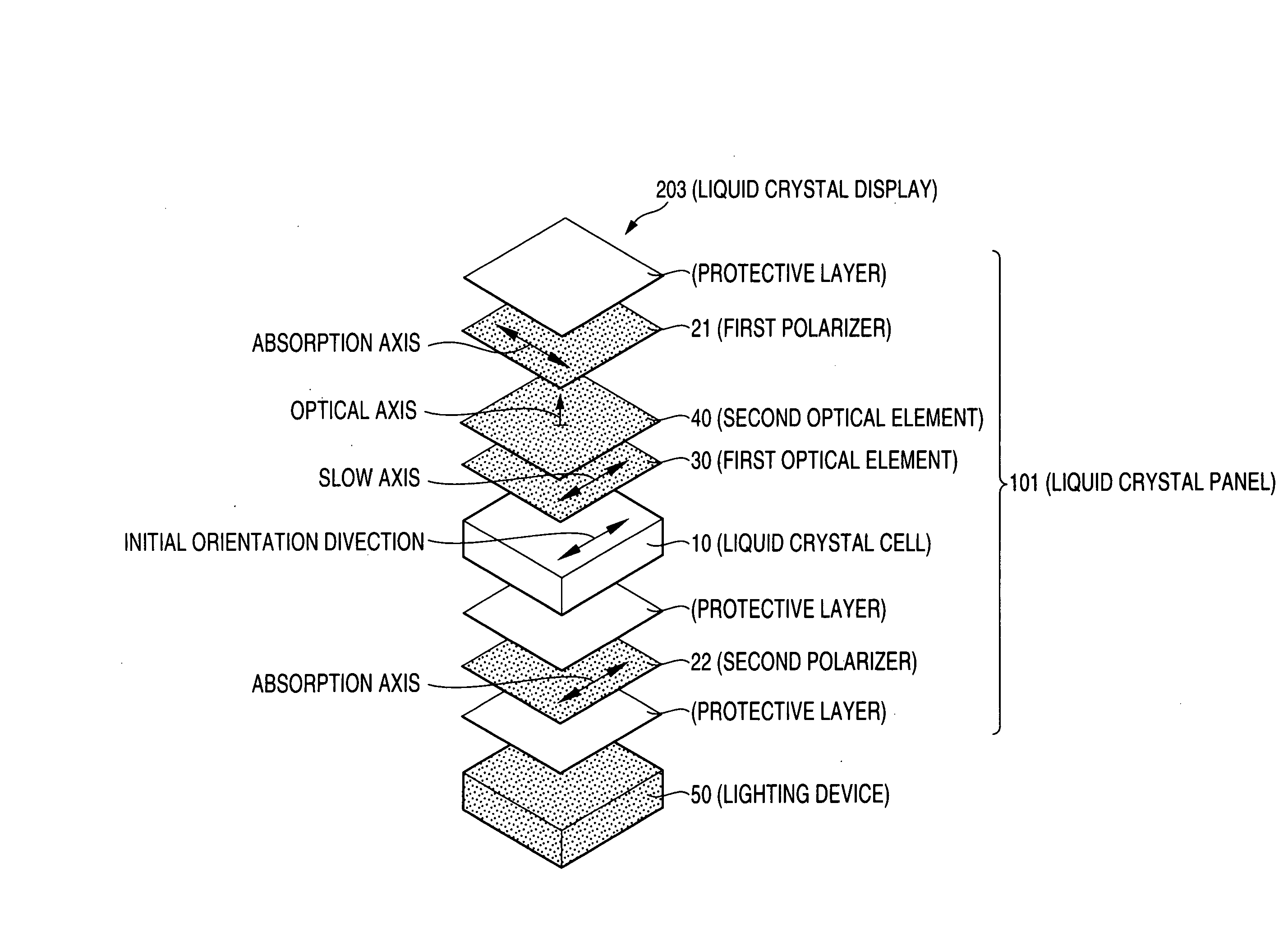

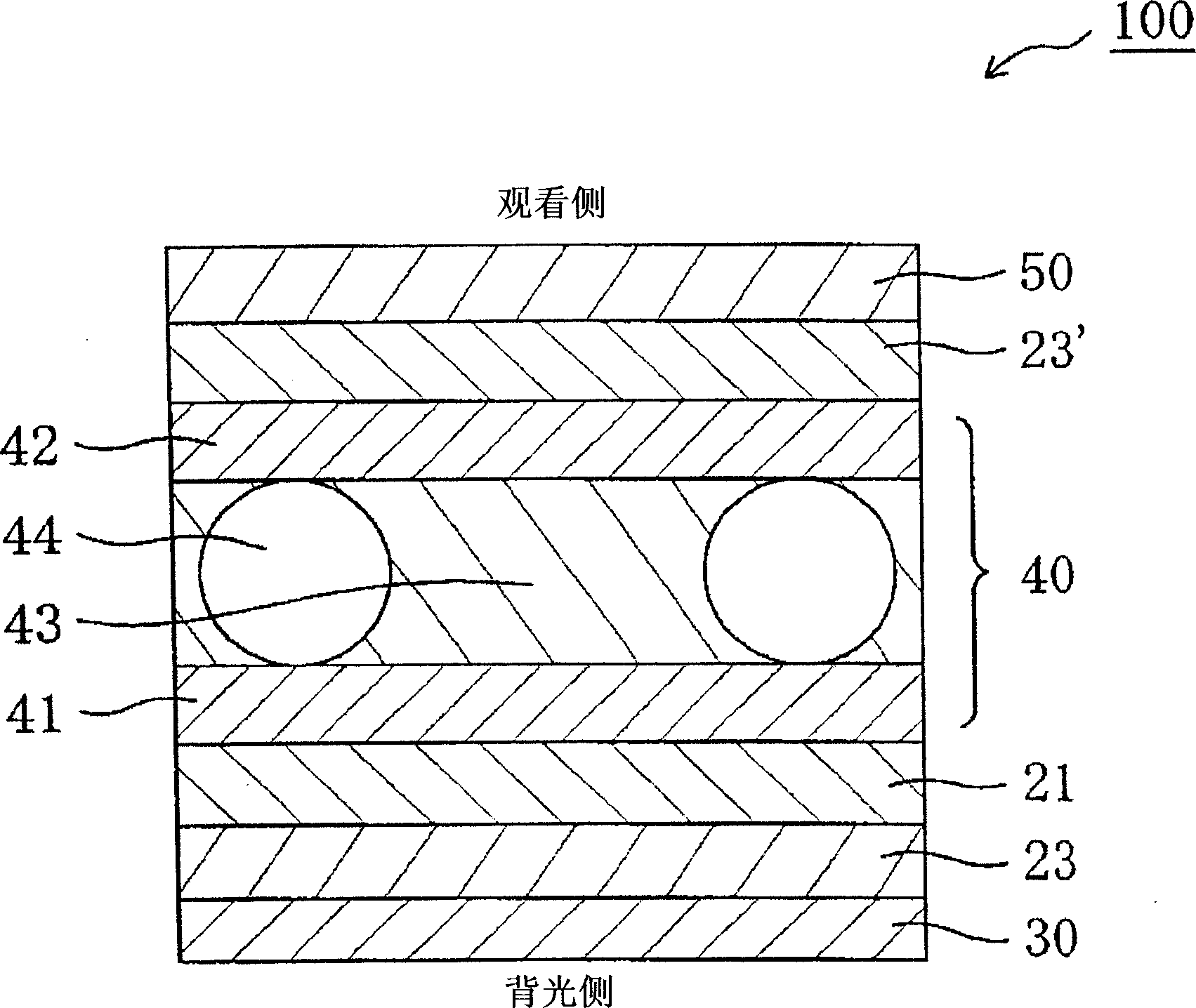

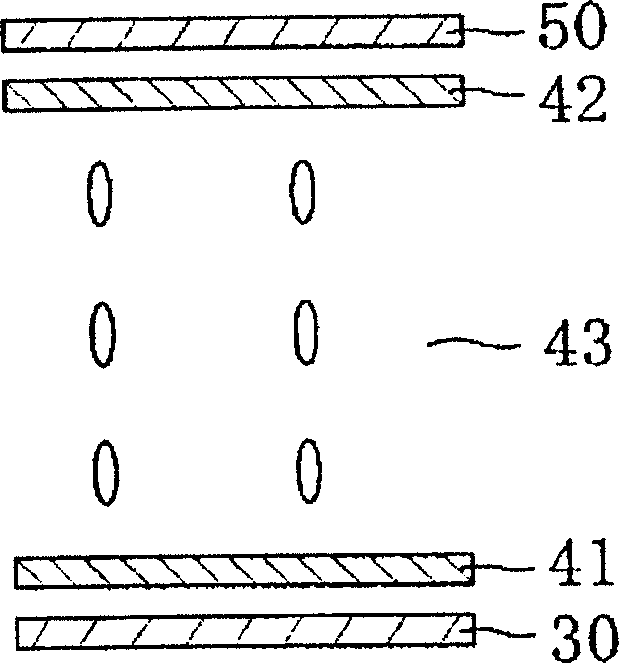

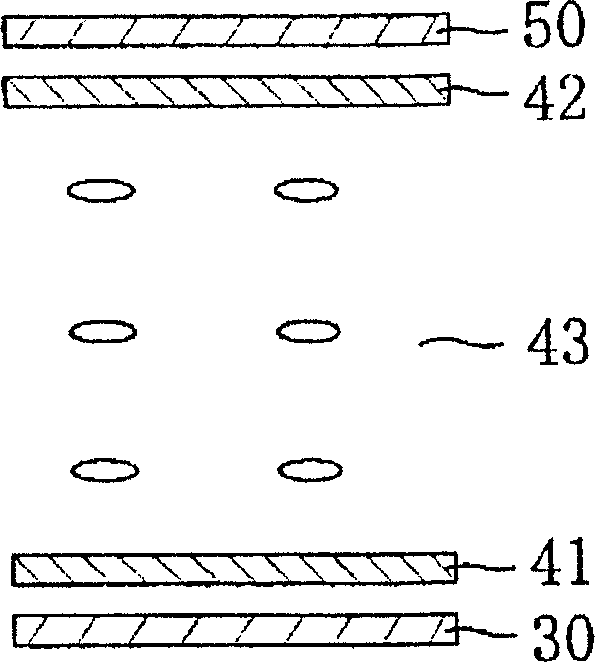

Liquid crystal panel and liquid crystal display device

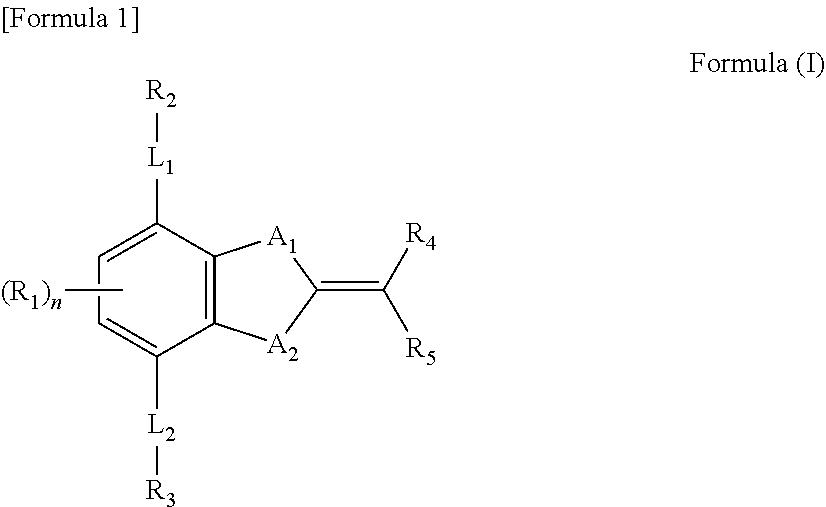

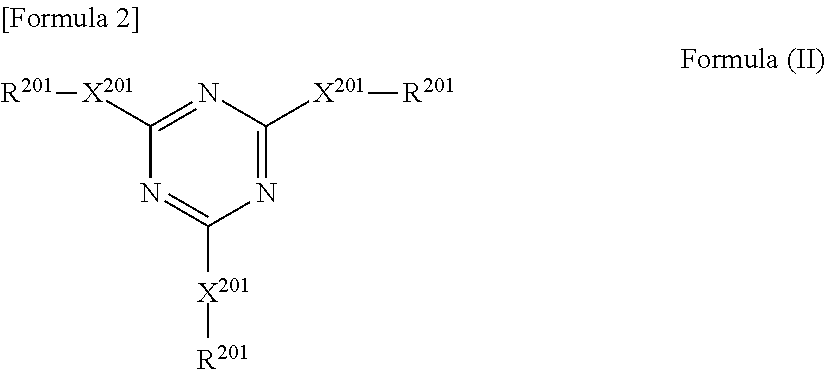

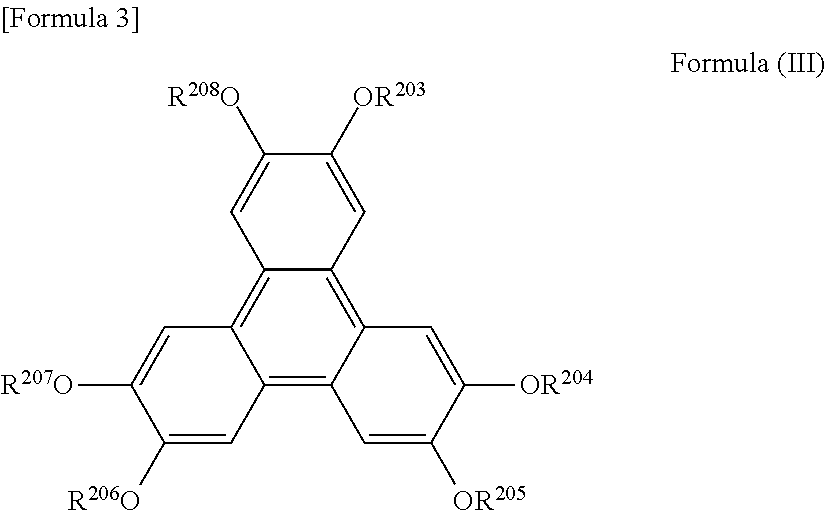

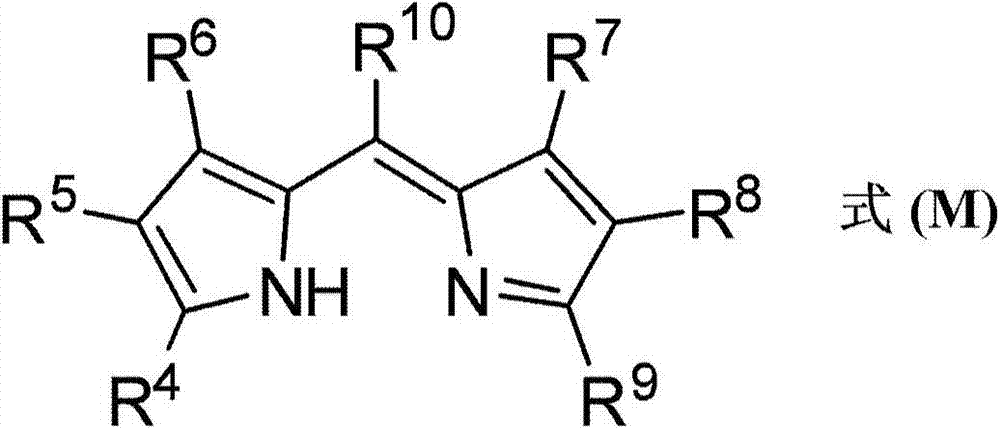

InactiveCN101542367AIncrease contrastSmall color shiftPolarising elementsNon-linear opticsPolycyclic compoundIndex ellipsoid

Provided is very thin liquid crystal panel and liquid crystal display apparatus with a high contrast ratio in an oblique direction, less light leakage, and a small color shift in an oblique direction. The liquid crystal panel of the present invention includes a liquid crystal cell, a first polarizer arranged on one side of the liquid crystal cell, a second polarizer arranged on the other side of the liquid crystal cell, a first optical element arranged between the first polarizer and the liquid crystal cell, and a second optical element arranged between the first optical element and the liquid crystal cell. The first optical element has substantially optically negative uniaxial property, and the second optical element exhibits a refractive index ellipsoid of nx > nz > ny, and is formed of one or more kinds of polycylic compound having a -SO3 M group and / or a -COOM group (M represents a counter ion).

Owner:NITTO DENKO CORP

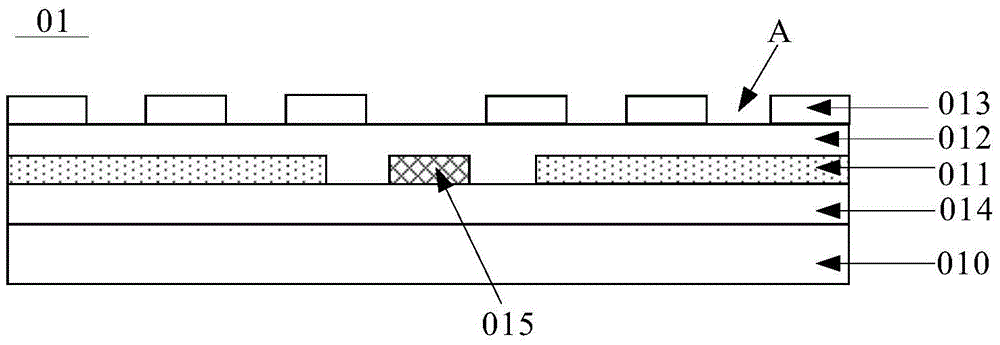

Display substrate and manufacturing method and display device thereof

InactiveCN105467696ALarge viewing angleSmall color shiftSolid-state devicesNon-linear opticsEngineeringDisplay device

The invention discloses a display substrate and a manufacturing method and a display device thereof and belongs to the technical field of display. The display substrate comprises a substrate base plate, wherein first electrodes are formed on the substrate base plate, a first insulation layer is formed on the substrate base plate formed with the first electrodes, second electrodes are formed on the substrate base plate formed with the first insulation layer, and at least one bent slot is formed in each second electrode. The problems of narrower visual angle of the display device and large color offset of the display device are solved, and the effects of enlarging the visual angle of the display device and decreasing the color offset of the display device are achieved. The display substrate is used for display.

Owner:BOE TECH GRP CO LTD +1

Liquid crystal panel and liquid crystal display apparatus

InactiveCN1866098AExcellent oblique contrastSmall color shiftStatic indicating devicesNon-linear opticsCelluloseColor shift

The present invention provides a liquid crystal panel and a liquid crystal display device each giving excellent viewing angle compensation and having excellent oblique contrast and small color shift. The liquid crystal panel of the present invention comprises in a specific order from the backlight side to the viewing side: a first polarizer, a first cellulose-based film, an optical compensation layer having an Nz coefficient represented by the relational formula (1) 2≤Nz≤20, A liquid crystal cell, a second cellulose-based film, and a second polarizer, wherein the retardation (Rth) in the thickness direction of the first cellulose-based film is expressed by relational formula (2), which is less than or equal to 10 nm; and the second cellulose The phase difference (Rth) in the thickness direction of the film-like film is expressed by the relational formula (2), which is less than or equal to 10nm: Nz=(nx-nz) / (nx-ny)...(1) Rth=(nx-nz)× d...(2).

Owner:NITTO DENKO CORP

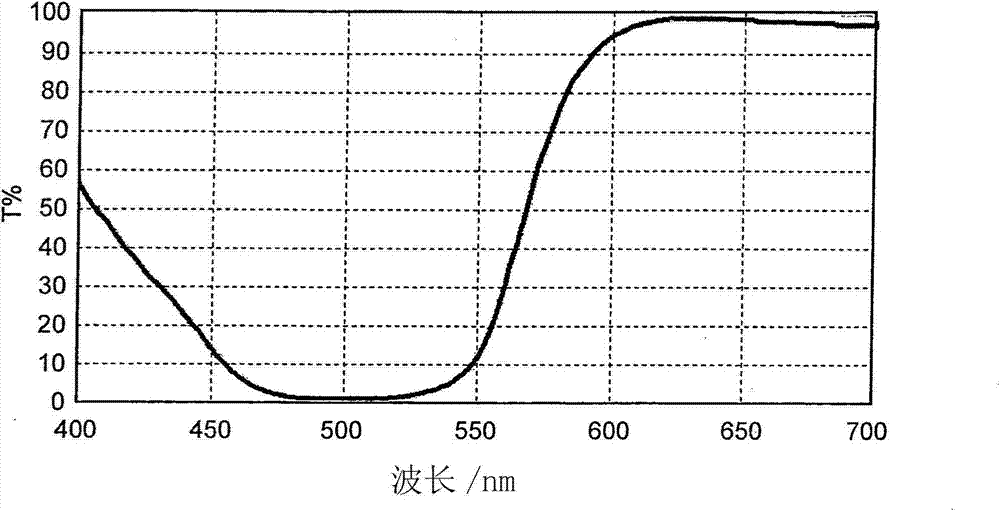

Colored curable composition, color resist, color filter, method for producing the same, solid-state image sensor, and image display device

ActiveCN103589193AHigh color purityGood light fastnessMethine/polymethine dyesElectroluminescent light sourcesPolymer scienceColor gel

Owner:FUJIFILM CORP

Manufacturing method of carboxyl-type solvent-type polyurethane resin artificial leather

InactiveCN106758269AReduce usageGood permeability of the coatingLayered productsTextiles and paperSlurryHigh surface

The invention relates to a manufacturing method of carboxyl-type solvent-type polyurethane resin artificial leather, wherein coating slurry is prepared from carboxyl-type solvent-type polyurethane resin and then is used for coating the surface of an artificial leather basic cloth, and then dyeing treatment is carried out to produce dyed polyurethane artificial leather. The coating slurry includes, by mass, 100 parts of the carboxyl-type solvent-type polyurethane resin, 20-120 parts of dimethylformamide, and 20-120 parts of acetone. The carboxyl-type solvent-type polyurethane resin is used as the coating material for the surface of the artificial leather, so that the dyeing treatment can be carried out by means of a dye. After the dyeing treatment, the artificial leather is dyed, so that the product is colorful, has good coating permeability, has high surface color fastness, and is low in color migration.

Owner:WUXI HUALIAN PLASTIC PROD CO LTD

Manufacturing method of sulfinyl-based solvent type polyurethane resin artificial leather

InactiveCN106758270AReduce usageGood permeability of the coatingLayered productsLiquid/gas/vapor textile treatmentColor effectColour fastness

The invention relates to a manufacturing method of sulfinyl-based solvent type polyurethane resin artificial leather. Coating slurry is prepared from sulfinyl-based solvent type polyurethane resin, then coats the surface of artificial leather base cloth and is dyed to obtain dyed polyurethane artificial leather. The coating slurry comprises the following components in parts by mass: 100 parts of sulfinyl-based solvent type polyurethane resin, 20 to 120 parts of dimethylformamide, and 20 to 120 parts of acetone. The sulfinyl-based solvent type polyurethane resin is used as an artificial leather surface coating material, and can be dyed with dye, and the color effect of dye coloring can be obtained after dyeing, so that the product has the characteristics of bright color, high coating permeability, high surface color fastness and low color transfer performance.

Owner:WUXI HUALIAN PLASTIC PROD CO LTD

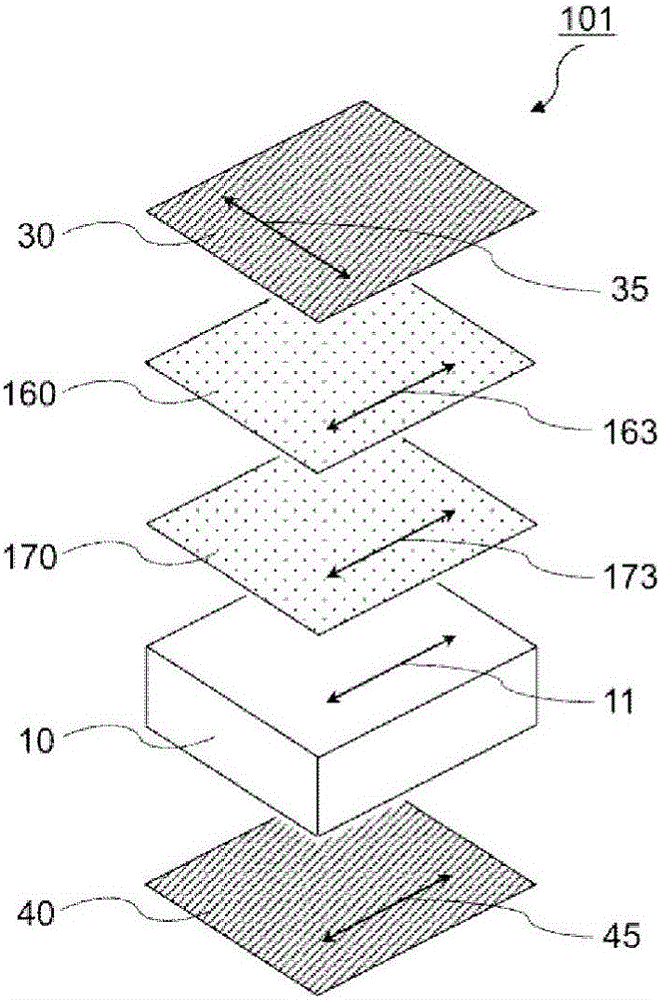

Polarizing plate with phase difference layers and image display device

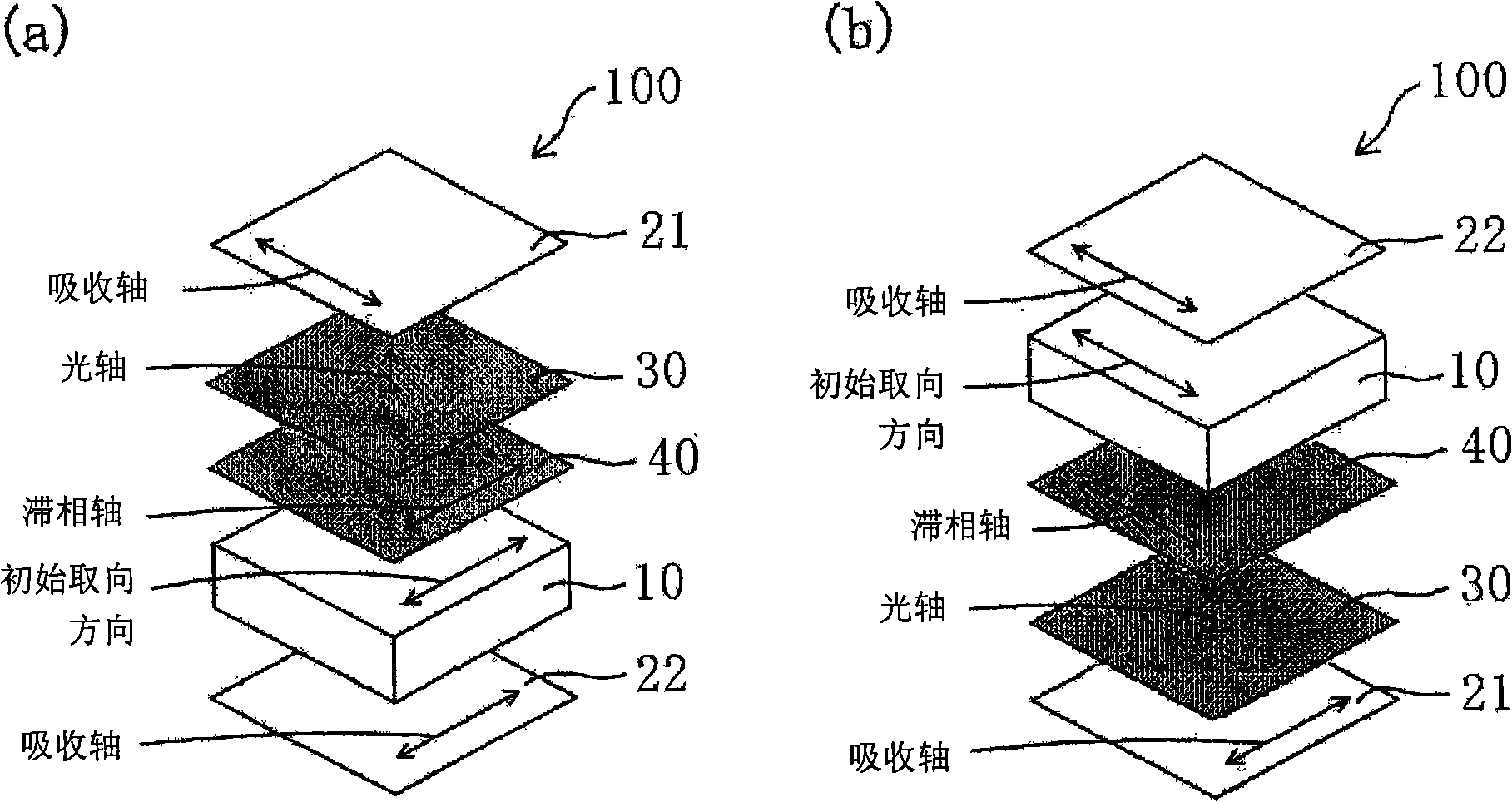

PendingCN113534317ASmall color shiftReduce brightnessPolarising elementsNon-linear opticsPolarizerRefractive index

The invention provides a polarizing plate with phase difference layers and an image display device. Provided is a polarizing plate with phase difference layers capable of realizing an image display device in which the brightness in the tilt direction during black display is small and the color shift in the tilt direction is small. The polarizing plate with phase difference layers according to the present invention is provided with: a polarizing sheet including a polarizer; a first phase difference layer which is disposed adjacent to the polarizing sheet and which has refractive index characteristics exhibiting a relationship of nx > ny = nz; and a second phase difference layer which is disposed adjacent to the first phase difference layer, and which has refractive index characteristics showing a relationship of nz > nx > ny. The absorption axis of the polarizer is substantially orthogonal to the slow axis of the first phase difference layer, and the absorption axis of the polarizer is substantially parallel to the slow axis of the second phase difference layer.

Owner:NITTO DENKO CORP

Manufacturing method for water-soluble nitroxyl polyamide resin artificial leather

InactiveCN106801347AReduce usageGood permeability of the coatingLiquid/gas/vapor open-width material treatmentTextile treatment machine partsColour fastnessPolyamide

The invention relates to a manufacturing method of nitroxyl-based water-soluble polyamide resin artificial leather, which is to use nitroxyl-based water-soluble polyamide resin to prepare coating slurry, then apply the coating slurry to the surface of artificial leather base cloth, and then undergo dyeing treatment to obtain The dyed polyamide artificial leather and the finishing paste include the following components in parts by mass: 100 parts of nitroxyl water-soluble polyamide resin, 20-120 parts of dimethylformamide, and 20-120 parts of acetone. Nitroxyl water-soluble polyamide resin is used as artificial leather surface coating material, which can be dyed with dyes. After dyeing, the color effect of dyeing can be obtained, so that the product has bright colors, good coating permeability, and surface color fastness. High, small color migration characteristics.

Owner:JIANGYIN HUADONG PLASTIC PROD

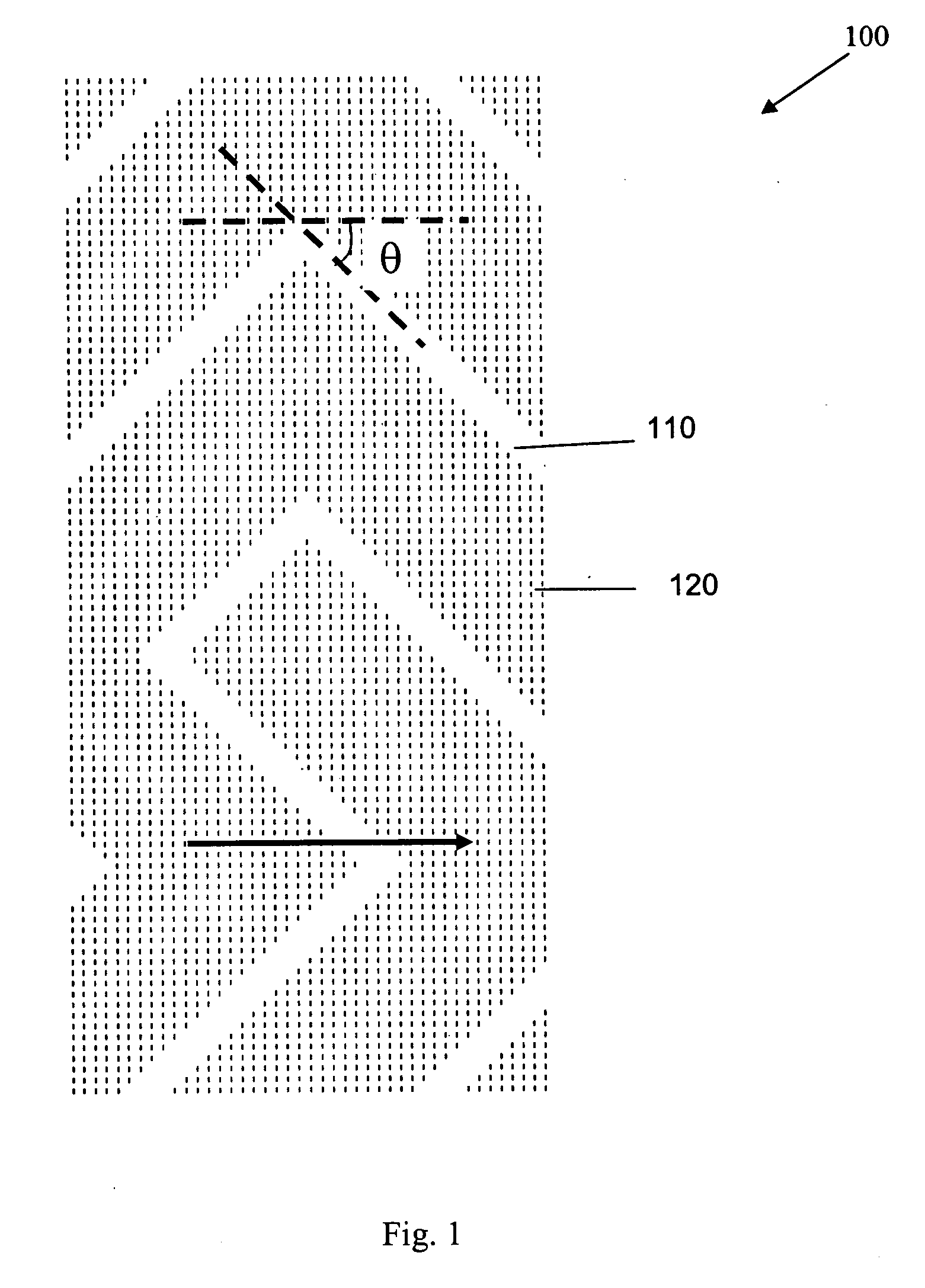

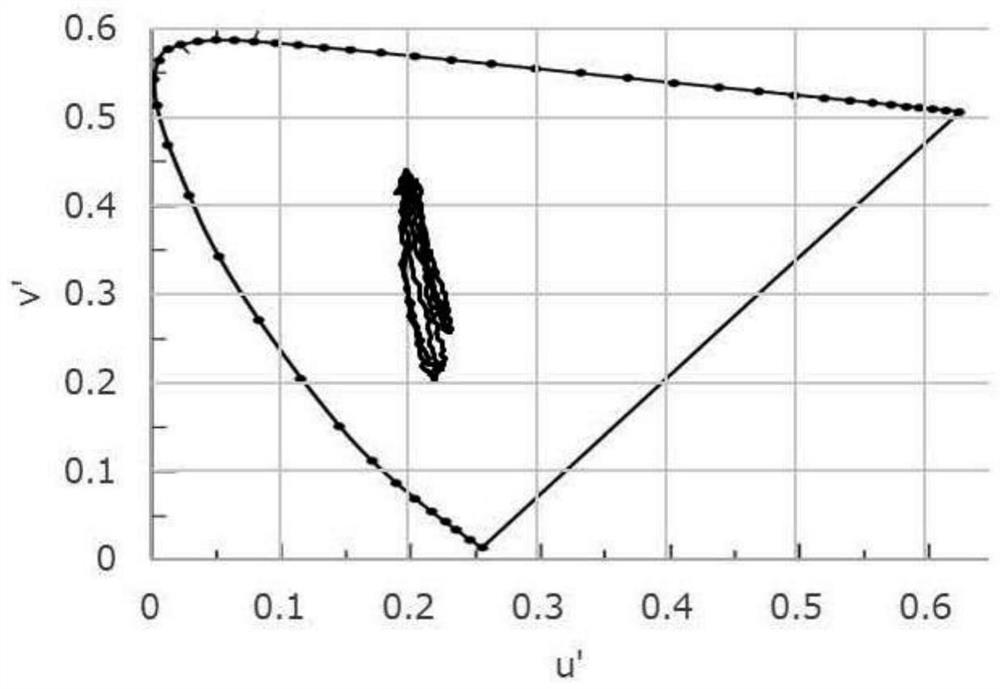

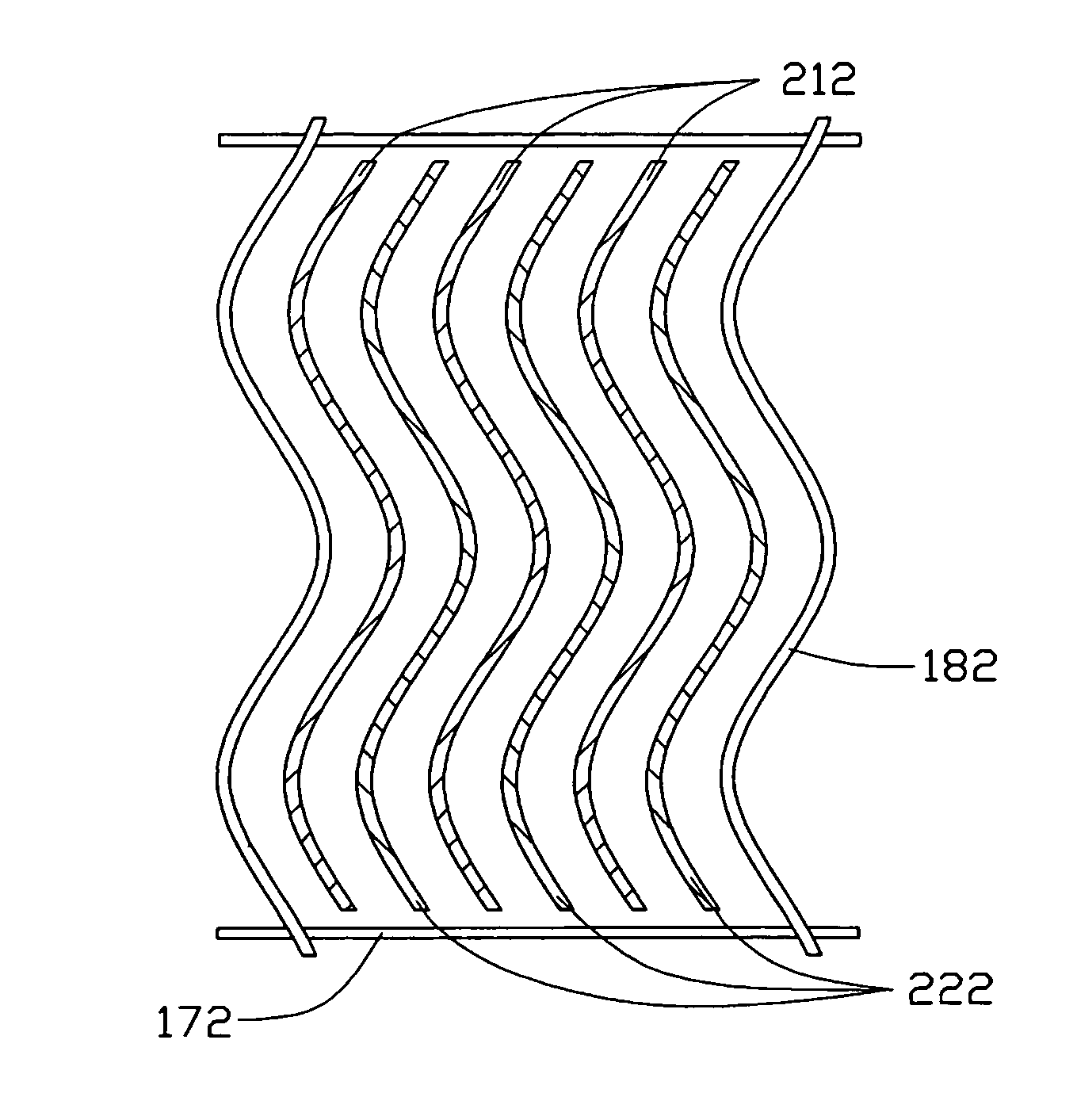

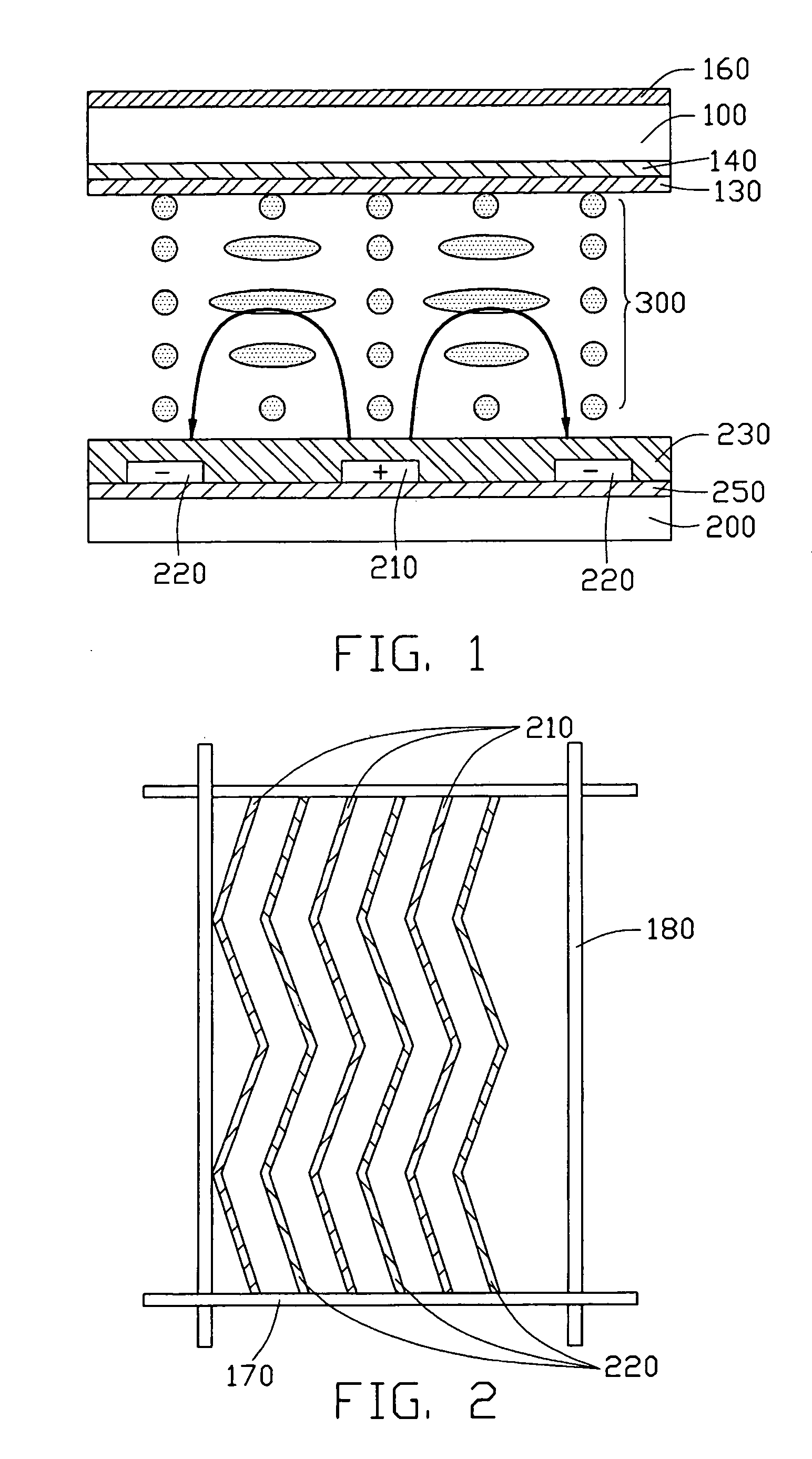

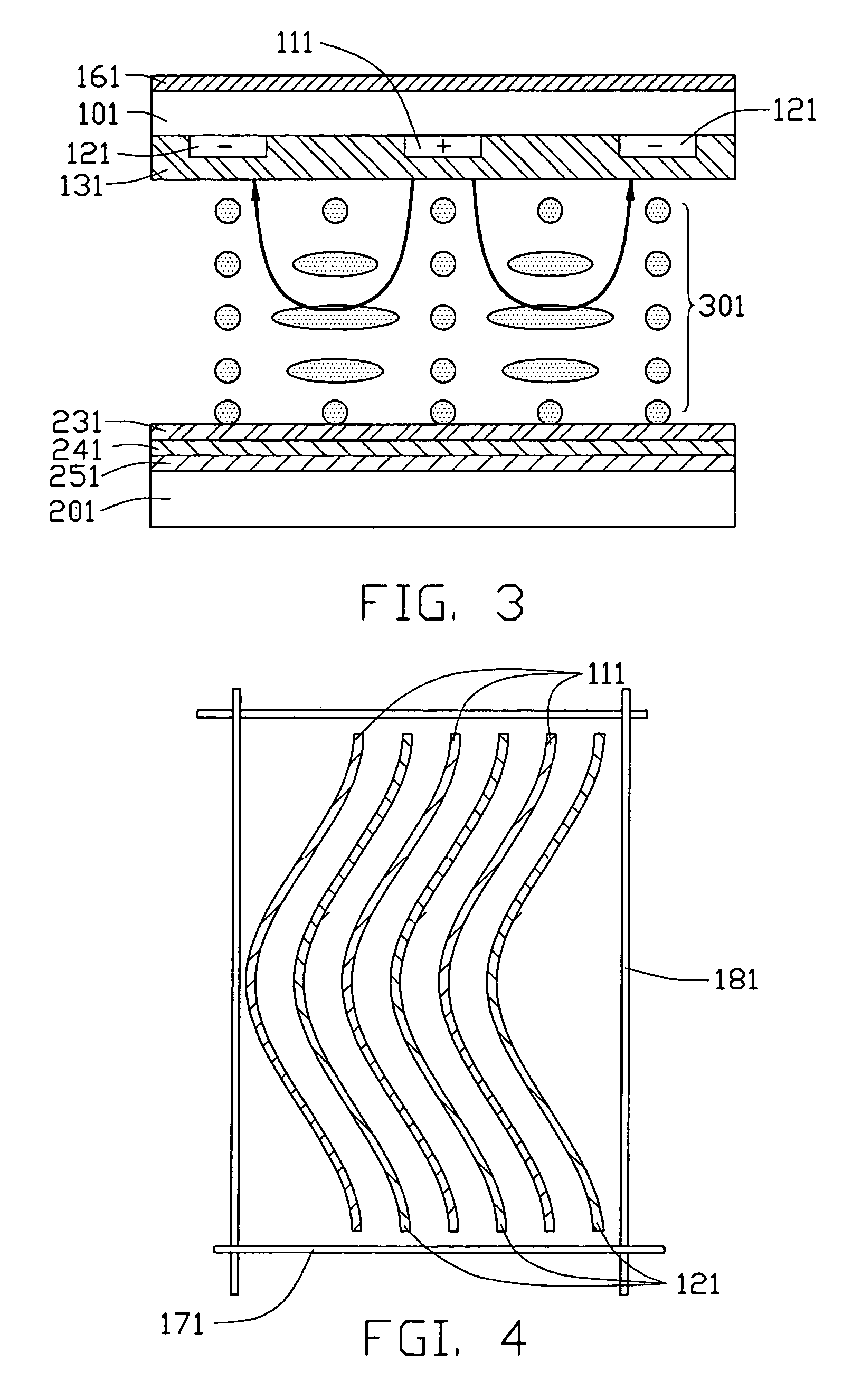

Reflective type continuous domain in-plane switching liquid crystal display

A reflective type IPS LCD includes a transparent upper substrate (100) and a lower substrate (200), and liquid crystal molecules (300) interposed between the substrates. A reflection layer (250) is disposed on the lower substrate. A plurality of gate lines (170) and a plurality of data lines (180) are formed on the upper substrate, thereby defining a plurality of pixel regions arranged in a matrix. Each pixel region includes pixel electrodes (210) and common electrodes (220). The pixel electrodes and the common electrodes have a bent configuration, and are spaced apart from each other. Therefore the electric field generated by them is along two directions, and the LCD exhibits a two-domain display effect. When viewing the LCD display from any oblique angle, the color shifts generated by the two domains counteract, and thus the overall color shift of the display is small.

Owner:INNOLUX CORP

Manufacturing method for water-soluble phosphate polyamide resin artificial leather

InactiveCN106801345AReduce usageGood permeability of the coatingTextiles and paperColour fastnessPhosphate

The invention relates to a manufacturing method for water-soluble phosphate polyamide resin artificial leather. The manufacturing method comprises the following steps: preparing coating slurry from water-soluble phosphate polyamide resin; then coating the surface of artificial leather base cloth with the coating slurry; and carrying out dyeing so as to obtain dyed polyamide artificial leather, wherein the coating slurry comprises, by mass, 100 parts of water-soluble phosphate polyamide resin, 20 to 120 parts of dimethyl formamide and 20 to 120 parts of acetone. Since the water-soluble phosphate polyamide resin is used as a coating material for the surface of artificial leather, dyeing with dyes can be carried out; and after dyeing, dye coloring effect can be obtained, and the produced artificial leather has the characteristics of a brilliant color, good permeability of a coating, high surface color fastness and small color migration.

Owner:JIANGYIN HUADONG PLASTIC PROD

Manufacturing method of nitroxyl-based solvent type polyamide resin artificial leather

InactiveCN106758272AEasy to dyeReduce usageLayered productsTextiles and paperColor effectColour fastness

The invention relates to a manufacturing method of nitroxyl-based solvent type polyamide resin artificial leather. Coating slurry is prepared by using nitroxyl-based solvent type polyamide resin, then coats the surface of artificial leather base cloth and is dyed to obtain dyed polyamide artificial leather. The coating slurry comprises the following components in parts by mass: 100 parts of nitroxyl-based solvent type polyamide resin, 20 to 120 parts of dimethylformamide, and 20 to 120 parts of acetone. The nitroxyl-based solvent type polyamide resin is used as an artificial leather surface coating material, and can be dyed with dye, and the color effect of dye coloring can be obtained after dyeing, so that the product has the characteristics of bright color, high coating permeability, high surface color fastness and low color transfer performance.

Owner:JIANGYIN HUADONG PLASTIC PROD

Dyeing-facilitating sulfonyl polyurethane suede artificial leather manufacturing method

InactiveCN106758291AReduce usageGood permeability of the coatingLiquid/gas/vapor open-width material treatmentTextile treatment machine partsColor effectColour fastness

The invention relates to a dyeing-facilitating sulfonyl polyurethane suede artificial leather manufacturing method. Dyed polyurethane suede artificial leather is obtained by preparing coating slurry by using sulfonyl solvent type polyurethane resin, then coating the surface of suede artificial leather base cloth with the coating slurry, and carrying out dyeing treatment. The coating slurry is prepared from the following components in parts by mass: 100 parts of the sulfonyl solvent type polyurethane resin, 20 to 120 parts of dimethyl formamide and 20 to 120 parts of acetone. As an artificial leather surface coating material, the sulfonyl solvent type polyurethane resin can be dyed through a dye; after being dyed, the sulfonyl solvent type polyurethane resin can achieve a color effect of the dye; therefore, a product has the characteristics of bright color, high coating permeability, high surface color fastness and low color migration property.

Owner:JIANGYIN YONGLONG PLASTICS

Manufacturing method for water-soluble glycol polyurethane resin artificial leather

InactiveCN106758287AReduce usageGood permeability of the coatingLamination ancillary operationsLaminationColour fastnessWater soluble

The invention relates to a manufacturing method for water-soluble glycol polyurethane resin artificial leather. The manufacturing method comprises the following steps: preparing coating slurry from water-soluble glycol polyurethane resin; then coating the surface of artificial leather base cloth with the coating slurry; and carrying out dyeing so as to obtain dyed polyurethane artificial leather, wherein the coating slurry comprises, by mass, 100 parts of water-soluble glycol polyurethane resin, 20 to 120 parts of dimethyl formamide and 20 to 120 parts of acetone. Since the water-soluble glycol polyurethane resin is used as a coating material for the surface of artificial leather, dyeing with dyes can be carried out; and after dyeing, dye coloring effect can be obtained, and the produced artificial leather has the characteristics of a brilliant color, good permeability of a coating, high surface color fastness and small color migration.

Owner:JIANGYIN YONGLONG PLASTICS

Manufacturing method for water-soluble quaternary ammonium polyamide resin artificial leather

InactiveCN106801344AReduce usageGood permeability of the coatingTextiles and paperColour fastnessPolyamide

Owner:JIANGYIN HUADONG PLASTIC PROD

Manufacturing method of amino solvent-type polyurethane resin artificial leather

InactiveCN106758303AReduce usageGood permeability of the coatingPolyurea/polyurethane coatingsTextiles and paperColor effectColour fastness

The invention relates to a manufacturing method of amino solvent-type polyurethane resin artificial leather, comprising the following steps: using amino solvent-type polyurethane resin to prepare coating slurry, coating the surface of an artificial leather substrate with the coating slurry, and carrying out dyeing treatment so as to obtain dyed polyurethane artificial leather. The coating slurry contains the following components (by weight): 100 parts of amino solvent-type polyurethane resin, 20-120 parts of dimethyl formamide and 20-120 parts of acetone. The amino solvent-type polyurethane resin which is used as an artificial leather surface coating material can undergo dyeing processing by the use of dye, and after the dyeing treatment, dyeing color effect can be achieved. Therefore, the product has characteristics of brilliant color, good coating permeability, high surface color fastness and low color transfer performance.

Owner:WUXI HUALIAN PLASTIC PROD CO LTD

Manufacturing method of sulfonyl-like solvent type polyamide resin artificial leather

The invention relates to a manufacturing method of sulfonyl-like solvent type polyamide resin artificial leather. The method is characterized in that coating slurry is prepared through ulfonyl-like solvent type polyamide resin and then coats the surface of a base artificial leather cloth, and then the base artificial leather cloth is subjected to dyeing treatment so as to obtain the dyed polyamide artificial leather, wherein the coating slurry comprises the following components in parts by mass: 100 parts of sulfonyl-like solvent type polyamide resin, 20-120 parts of dimethylformamide, and 20-120 parts of acetone. According to the method, sulfonyl-like solvent type polyamide resin is used as the surface coating material of the artificial leather, and the dyeing processing can be carried out through dye; the dyed color effect can be obtained after the dyeing treatment. Therefore, the product has the characteristics of being bright in color, high in coating permeability, high in surface color fastness, and low in color migration performance.

Owner:JIANGYIN HUADONG PLASTIC PROD

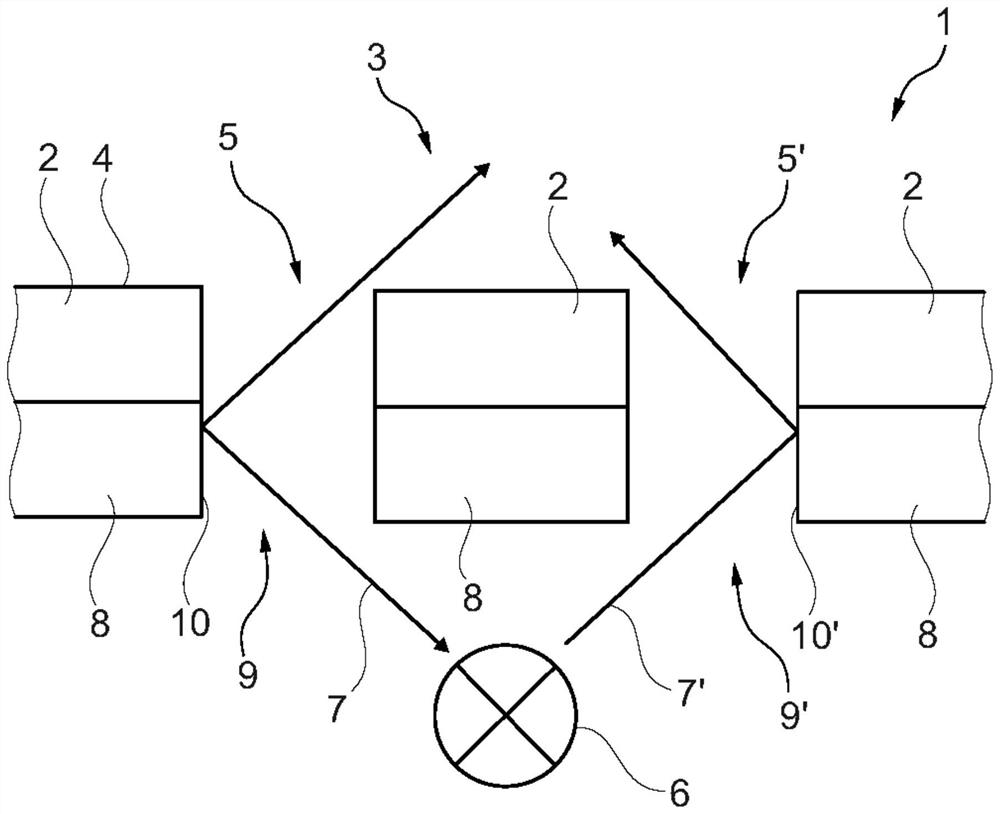

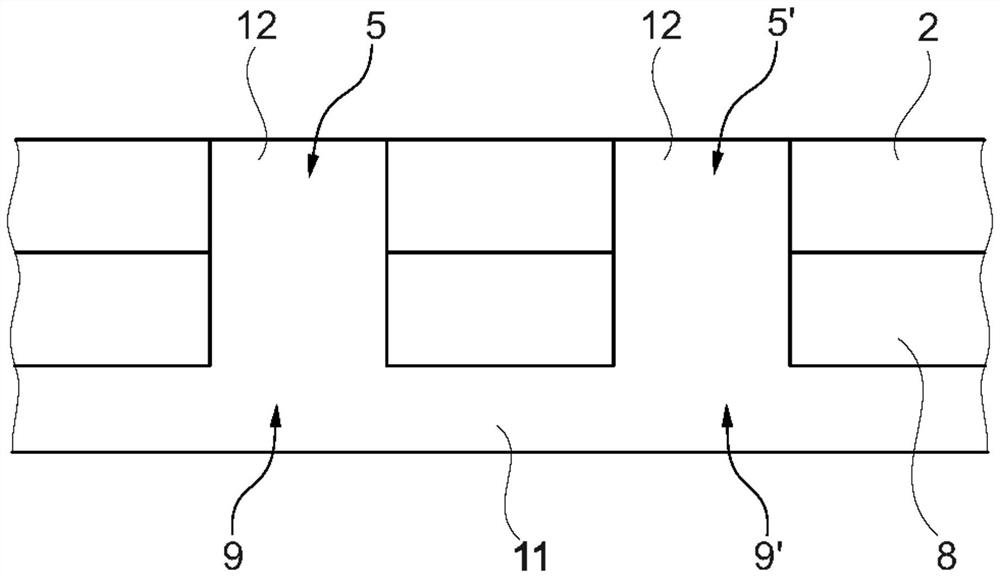

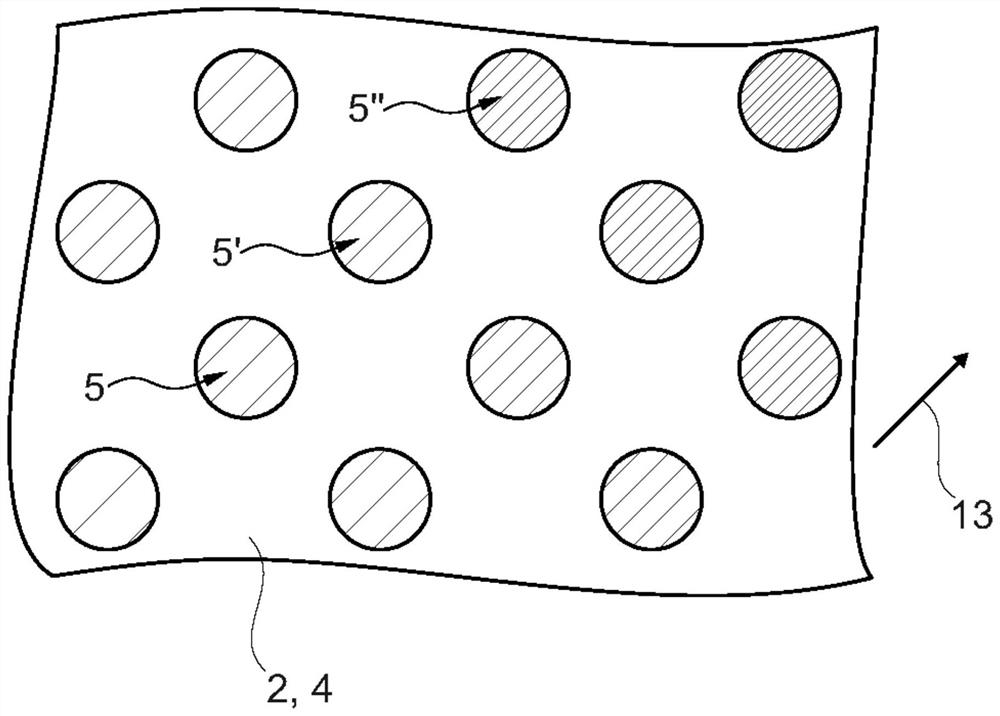

Vehicle interior trim part

PendingCN112298025AImproved light guidanceWide Irradiation CharacteristicsPassenger/driving compartment lightingsLight guidesClassical mechanicsReflective layer

The invention relates to a vehicle interior trim part (1). The proposed vehicle interior trim part (1) comprises a trim layer (2) having through holes (5, 5', 5''). Furthermore, the vehicle interior trim part (1) has a reflective layer (8) with through-openings (9, 9'), the through-openings (9, 9') of which at least partially overlap the through-openings (5, 5', 5'') of the trim layer (2), the reflective layer (8) being arranged in such a way that light is reflected on the inner wall (10, 9', 5'') of the trim layer (2).

Owner:FAURECIA INNENRAUM SYST

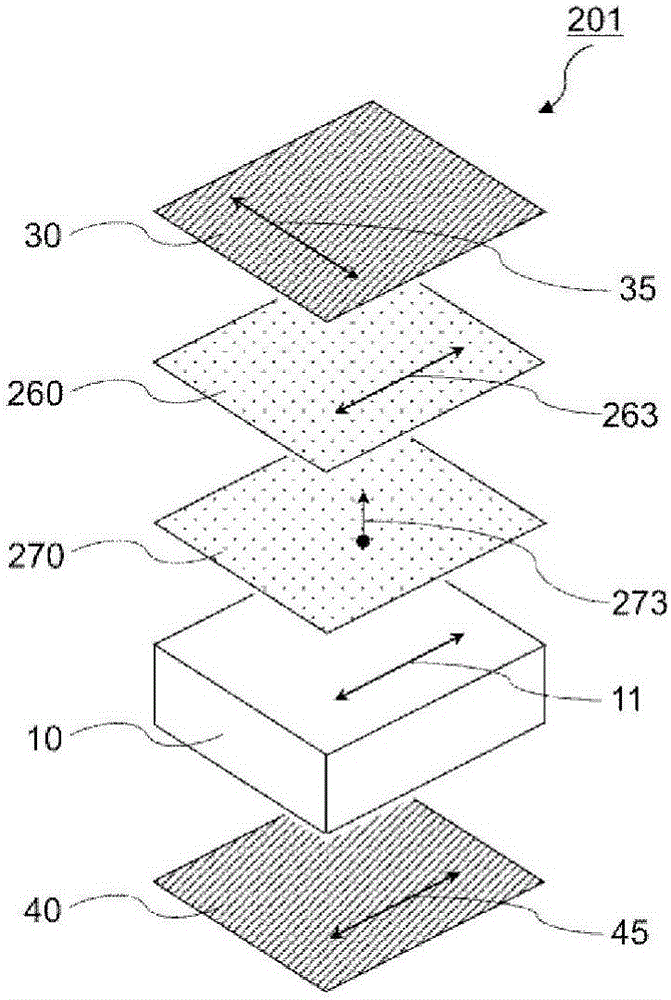

Polarizing plate with phase difference layer and image display device

PendingCN112859421AReduce brightnessSmall color shiftPolarising elementsNon-linear opticsPolarizerRefractive index

The invention provides a polarizing plate with a phase difference layer and an image display device. The invention provides the polarizing plate with the phase difference layer, which can realize the image display device with low brightness in the inclination direction and small color shift in the inclination direction during black display. The polarizing plate with the phase difference layer according to the present invention comprises a polarizing plate including a polarizer; a first phase difference layer which is disposed adjacent to the polarizing plate and has refractive index characteristics showing a relationship of nz > nx > ny; and a second phase difference layer which is disposed adjacent to the first phase difference layer, and has a refractive index characteristic showing a relationship of nx > ny = nz. The absorption axis of the polarizer is substantially orthogonal to the slow axis of the first phase difference layer, and the absorption axis of the polarizer is substantially parallel to the slow axis of the second phase difference layer.

Owner:NITTO DENKO CORP

Method for manufacturing carboxylic solvent type polyamide resin artificial leather

InactiveCN106758296AReduce usageGood permeability of the coatingTextiles and paperColor effectColour fastness

The invention relates to a method for manufacturing carboxylic solvent type polyamide resin artificial leather. The method comprises the following steps: preparing coating slurry with carboxylic solvent type polyamide resin, applying the coating slurry to the surface of an artificial leather substrate and dyeing, and performing dyeing treatment to obtain dyed polyamide artificial leather. The coating slurry comprises the following ingredients in parts by weight: 100 parts of carboxylic solvent type polyamide resin, 20-120 parts of dimethyl formamide and 20-120 parts of acetone. Carboxylic solvent type polyamide resin is taken as a coating material on the surface of the artificial leather, so that carboxylic solvent type polyamide resin can be dyed by a dye, the color effect of dye coloring can be achieved after dyeing, and a product has the characteristics of bright color, good coating permeability, high surface color fastness and small color mobility.

Owner:JIANGYIN YONGLONG PLASTICS

Manufacturing method for glycol polyurethane suede artificial leather convenient for dyeing

InactiveCN106758304AReduce usageGood permeability of the coatingTextiles and paperColor effectColour fastness

The invention relates to a manufacturing method for glycol polyurethane suede artificial leather convenient for dyeing. The manufacturing method comprises the steps of preparing a coating slurry by using glycol solvent type polyurethane resin, applying the coating slurry to the surface of suede artificial leather base cloth, and performing dyeing treatment to obtain dyed polyurethane suede artificial leather, wherein the coating slurry comprises the following components in parts by mass: 100 parts of glycol solvent type polyurethane resin, 20-120 parts of dimethylfomamide, and 20-120 parts of acetone. The glycol solvent type polyurethane resin, as an artificial leather surface coating material, can be dyed by a dye, and can obtain a color effect of dye coloring after the dyeing treatment, thereby endowing a product with the characteristics of bright color, good coating permeability, high surface color fastness and small color migration.

Owner:JIANGYIN HUADONG PLASTIC PROD

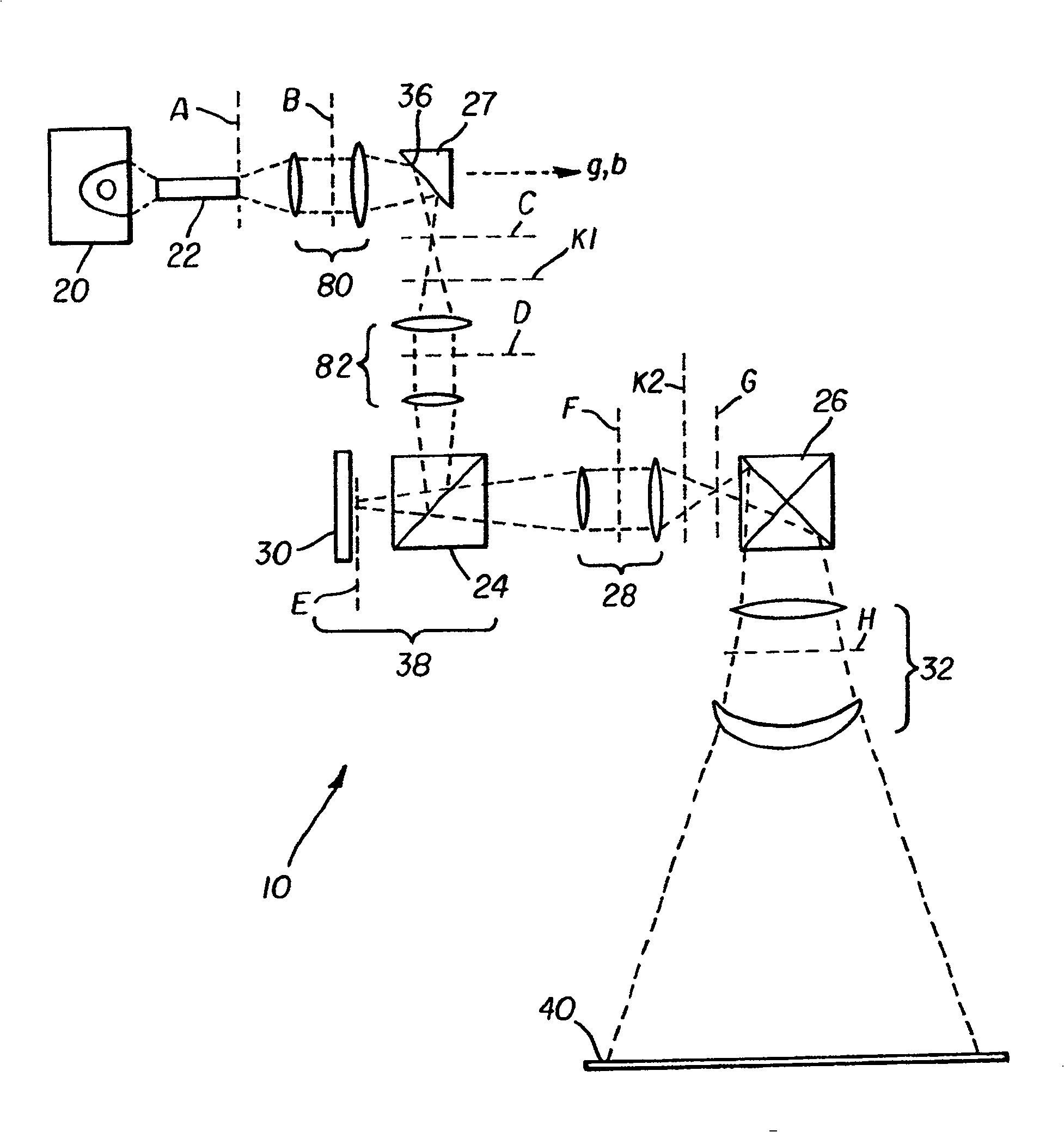

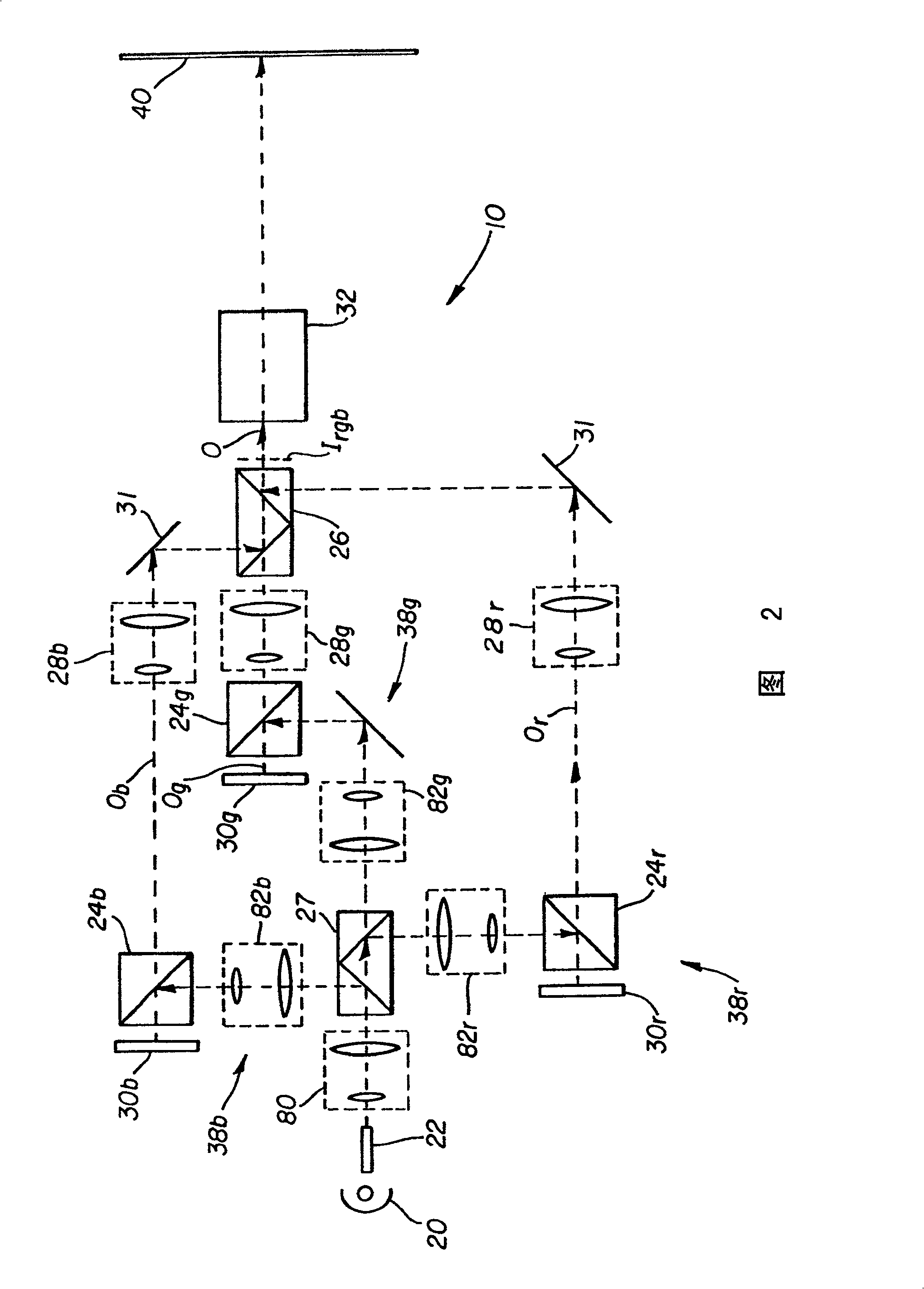

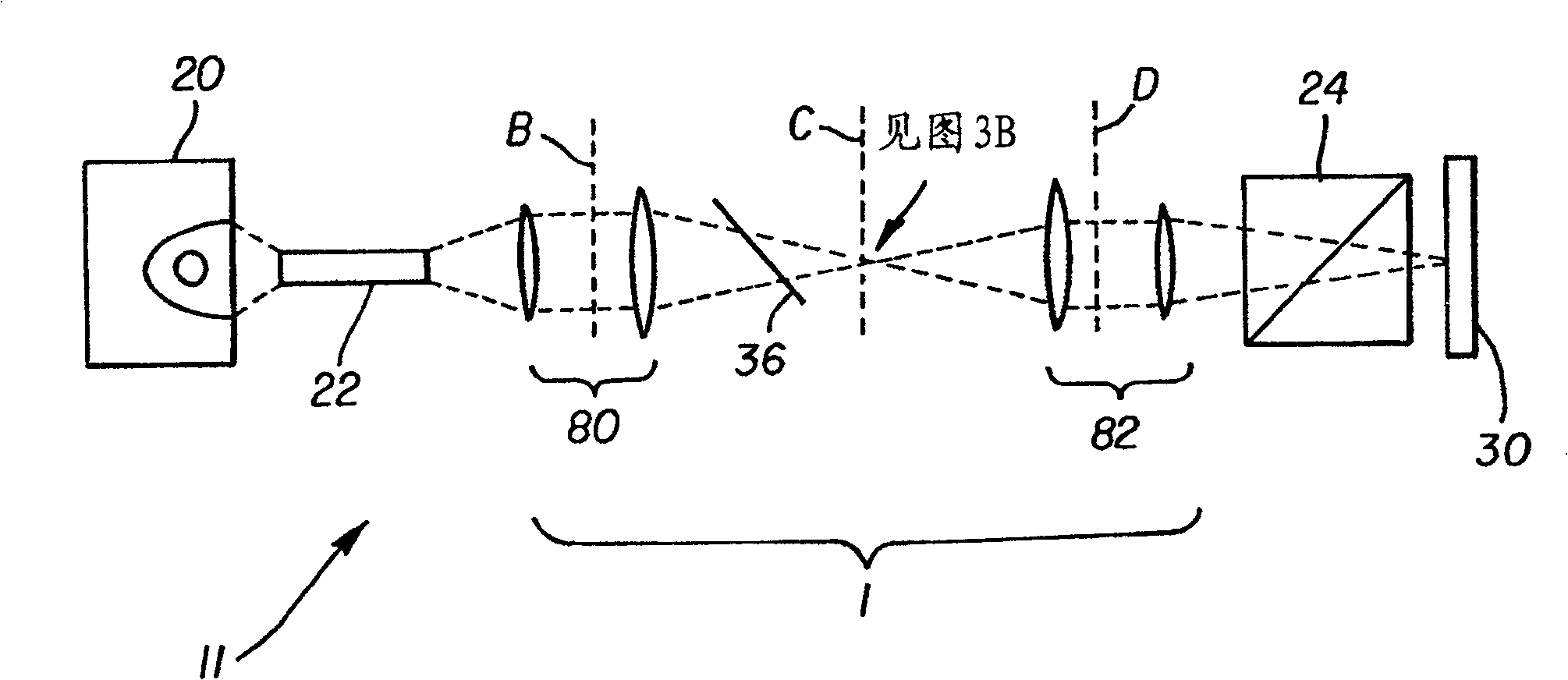

Projector with enhanced security camcorder defeat

InactiveCN100426128CEasy to understandAvoid demolitionTelevision system detailsProjectorsSpatial light modulatorCopy protection

A projector (10) with enhanced security camcorder defeat including a copy protection illumination system (1) for illuminating a spatial light modulator (30) comprises: a polychromatic light source (20); uniformizing optics (22) for homogenizing light from the polychromatic light source to provide a uniform illumination field; relay optics; dichroic optics; an interference modulation element (5) located at a plane in an optical path located between the polychromatic light source and the spatial light modulator; and a detection means for determining the absence of the interference modulation element.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com