Patents

Literature

37results about How to "Reduce the effect of color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

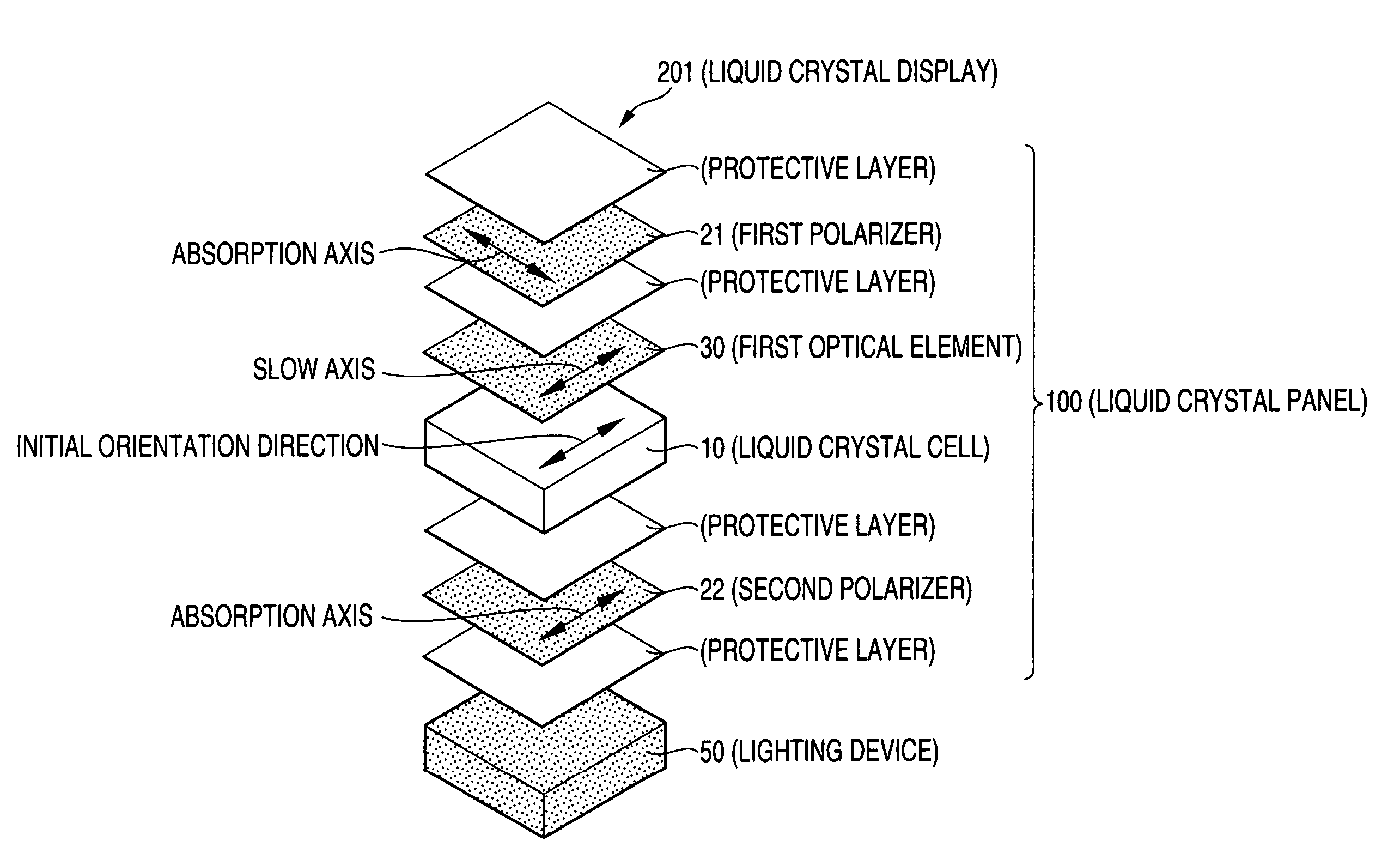

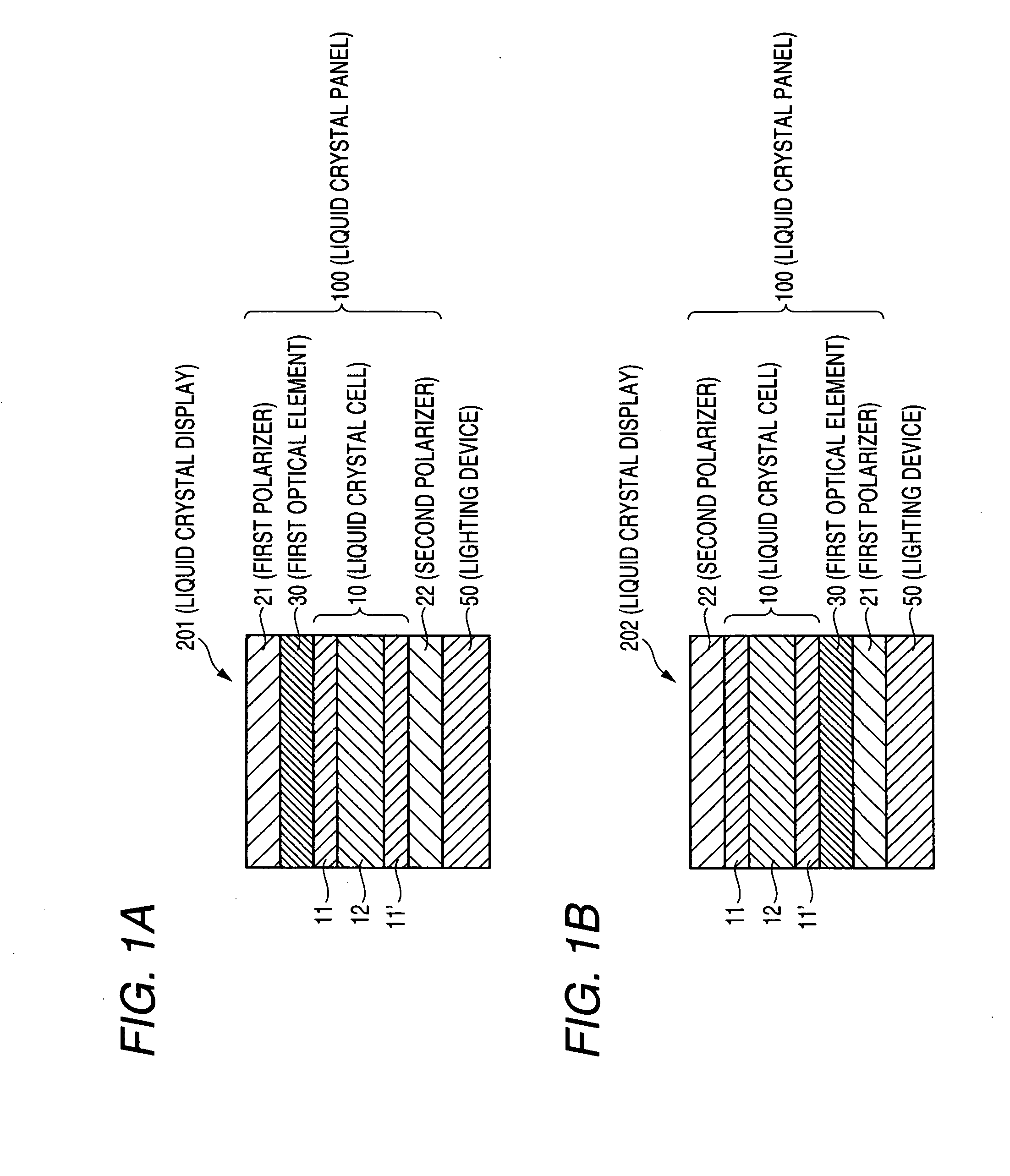

Liquid crystal display

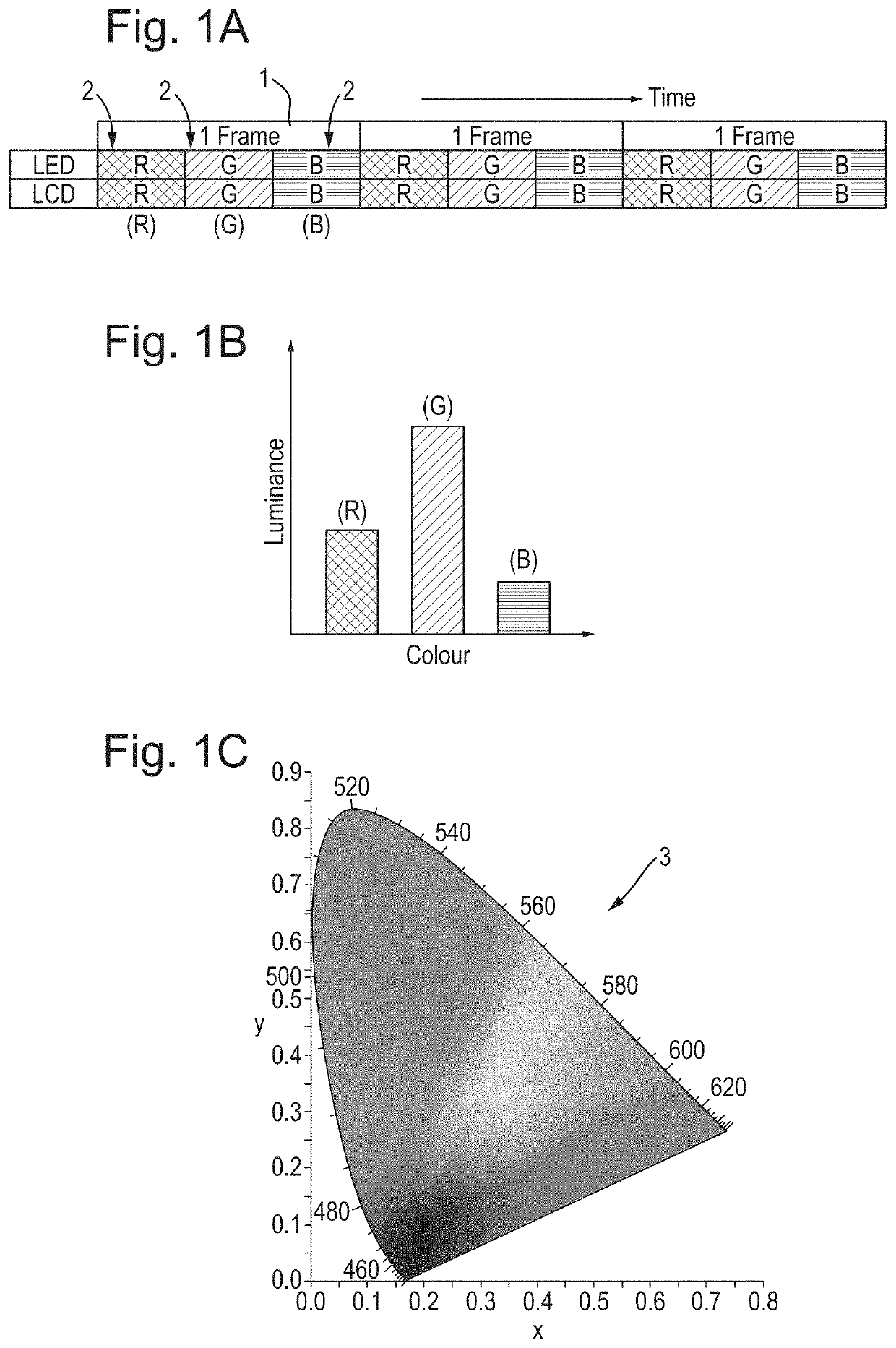

ActiveUS20070211199A1Small color shiftReduce the effect of colorNon-linear opticsEffect lightRelative luminance

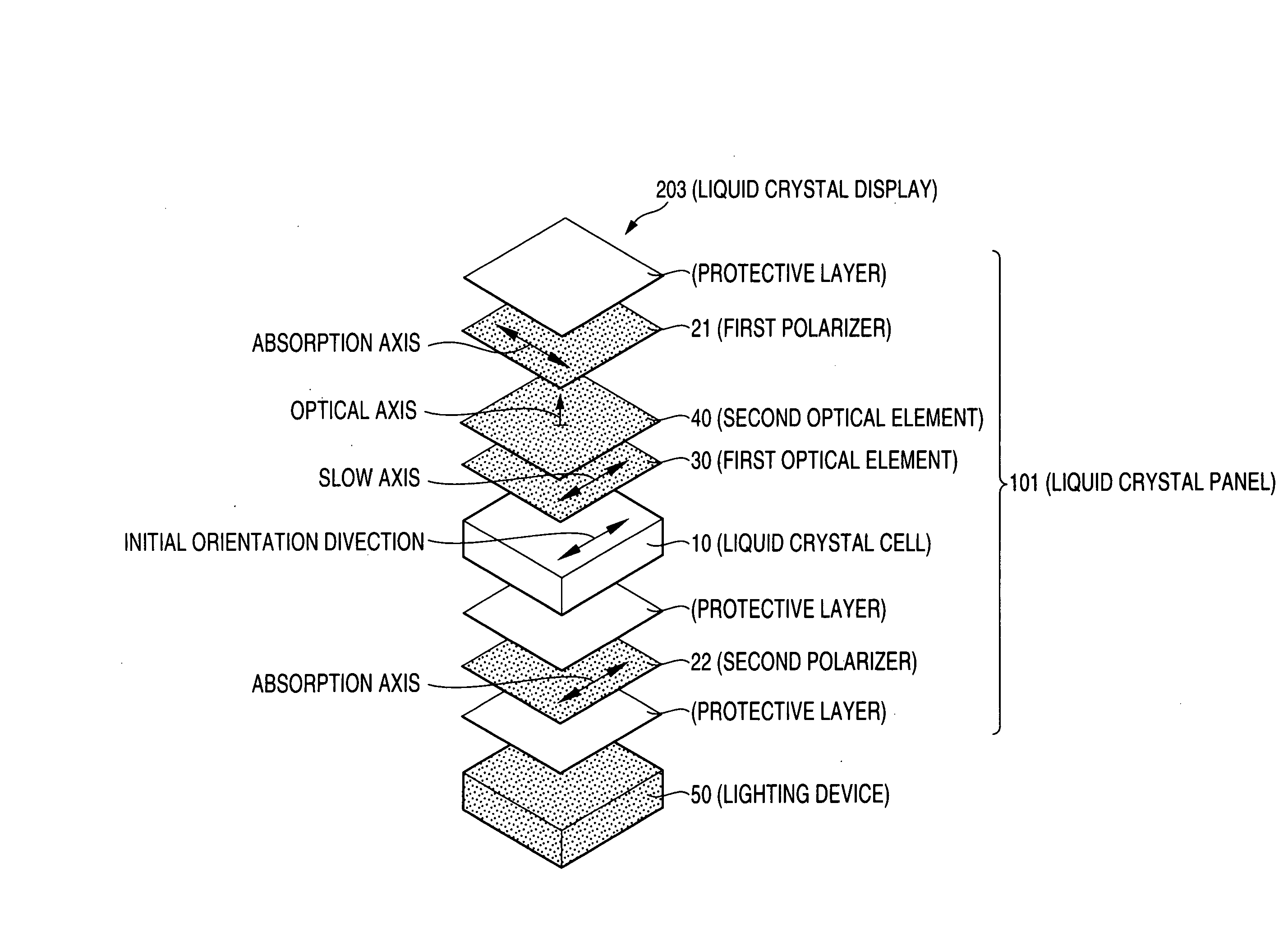

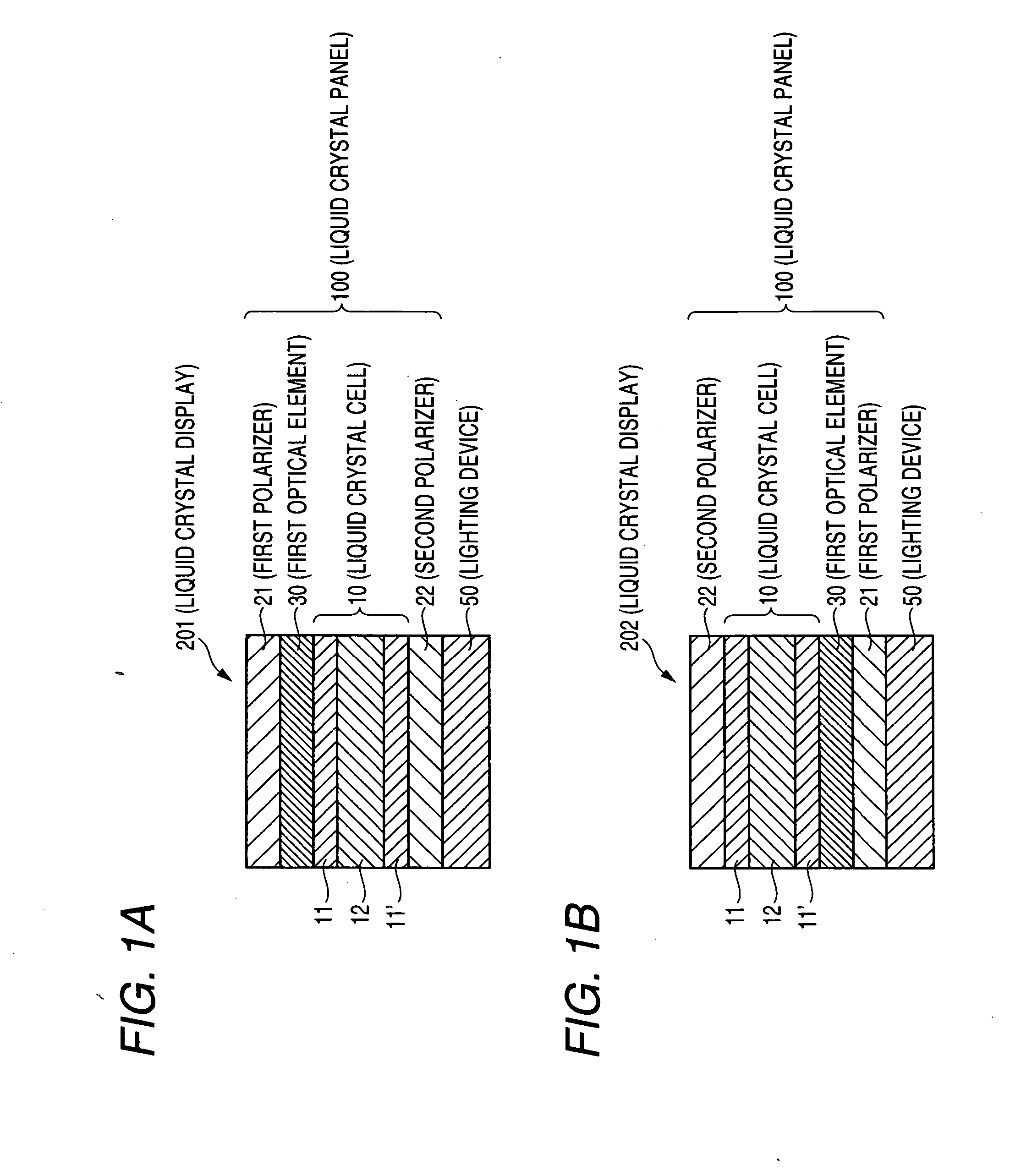

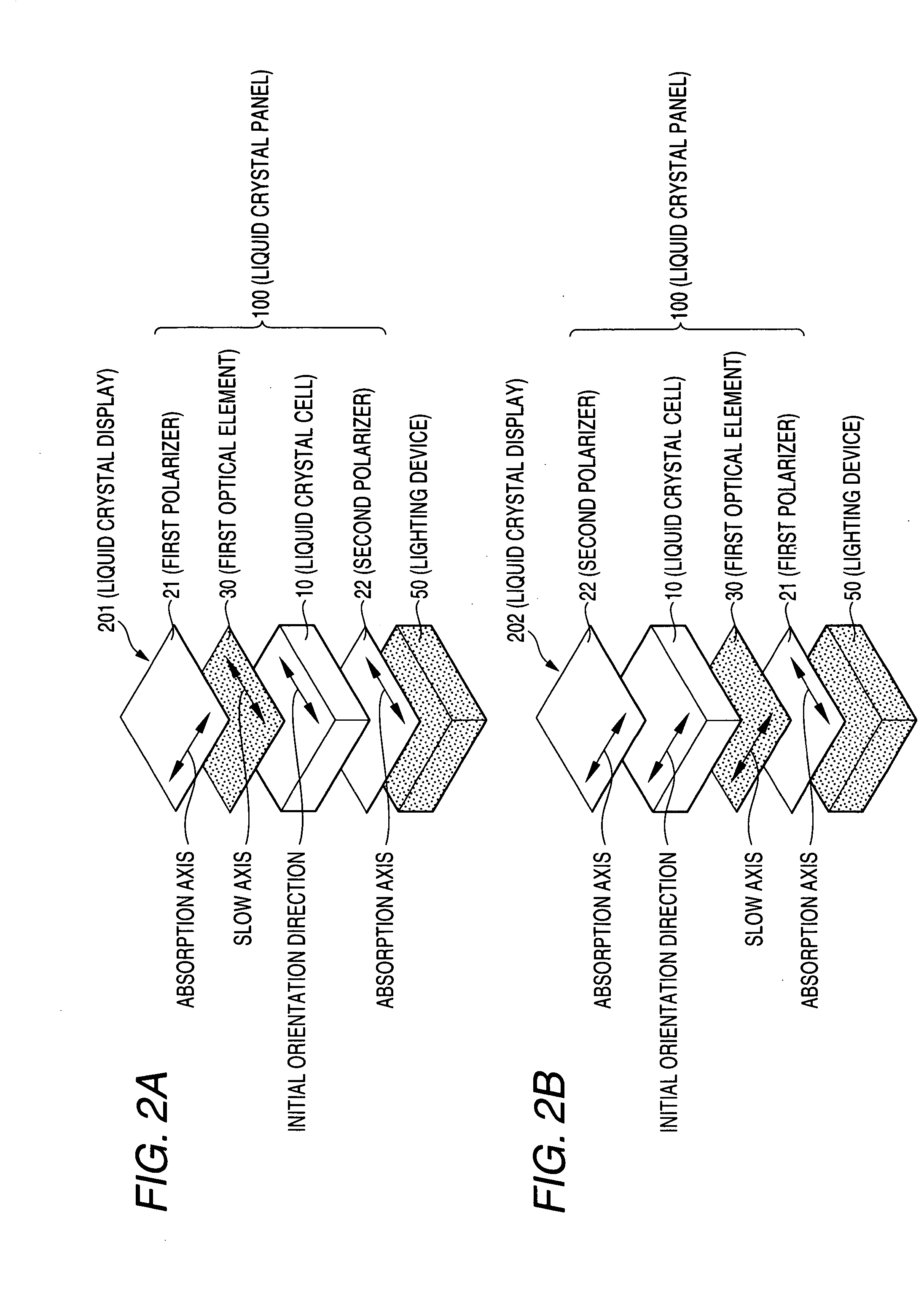

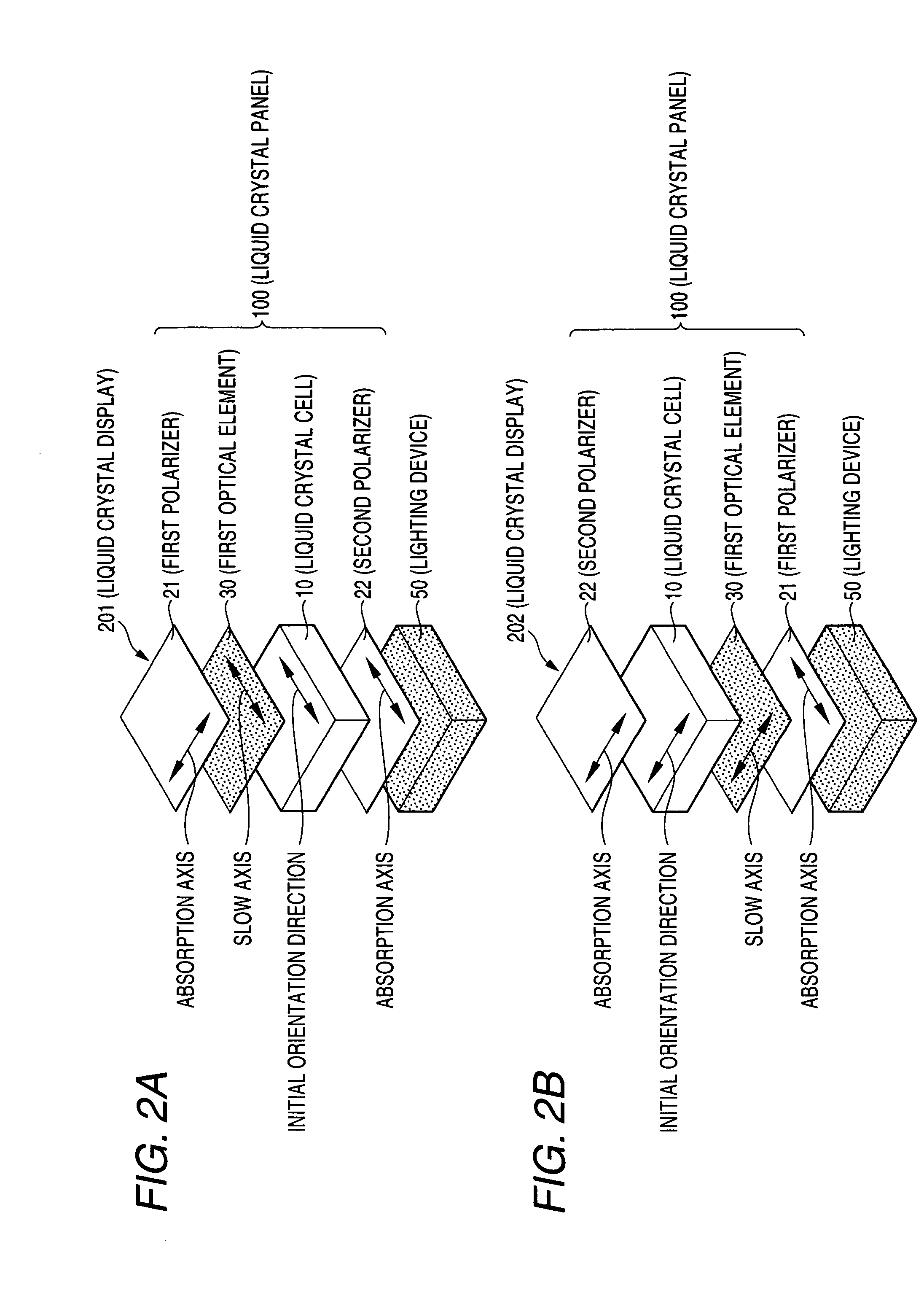

The present invention provides a liquid crystal display including: a liquid crystal panel; and a lighting device disposed on one side of the liquid crystal panel, the liquid crystal panel including: a liquid crystal cell; a first polarizer disposed on one side of the liquid crystal cell; a second polarizer disposed on the other side of the liquid crystal cell; and a first optical element disposed between the liquid crystal cell and the first polarizer; the absorption axis direction of the first polarizer being substantially perpendicular to the absorption axis direction of the second polarizer, the first optical element having an optical indicatrix having a relationship of nx≧nx>ny, the lighting device having: a maximum value of luminance in the wavelength range of 550±50 nm; and a relative luminance at a wavelength of 450 nm is 0.28 or less.

Owner:NITTO DENKO CORP

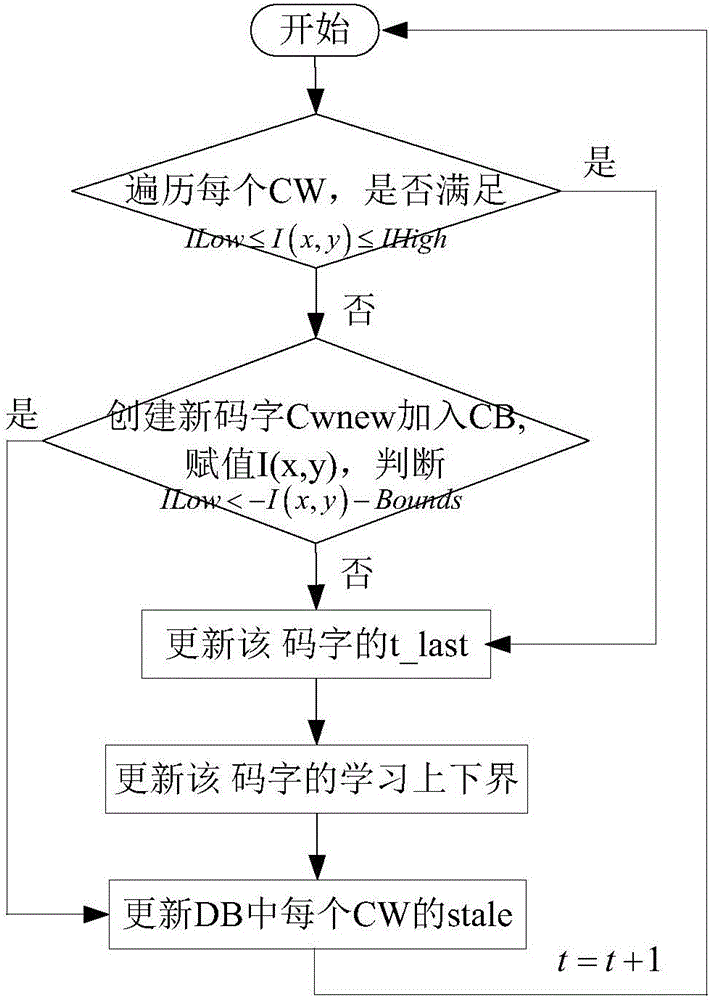

Image processing method based on improved Codebook foreground detection

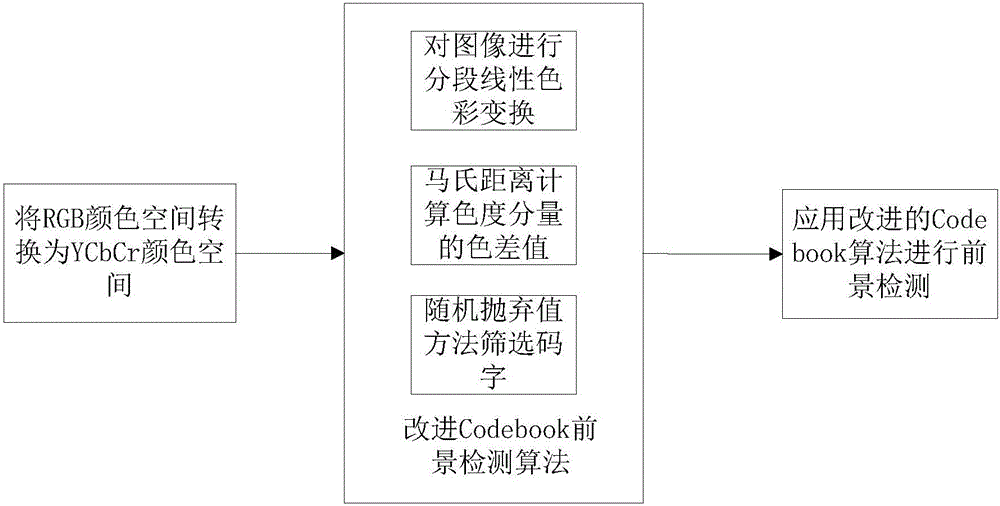

ActiveCN106097366AChroma ConvergenceReduce the effect of colorImage analysisClosed circuit television systemsImaging processingYcbcr color space

The invention discloses an image processing method based on improved Codebook foreground detection. The image processing method is characterized by comprising the following steps that an RGB color space is converted into YCbCr color space; a Codebook foreground detection algorithm is improved; and foreground detection is performed by using the improved Codebook algorithm. With application of the method, foreground detection can be greatly performed, the influence of light change on detection can be reduced in distinguishing of the foreground and the background, memory consumption can be reduced and the performance can be enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

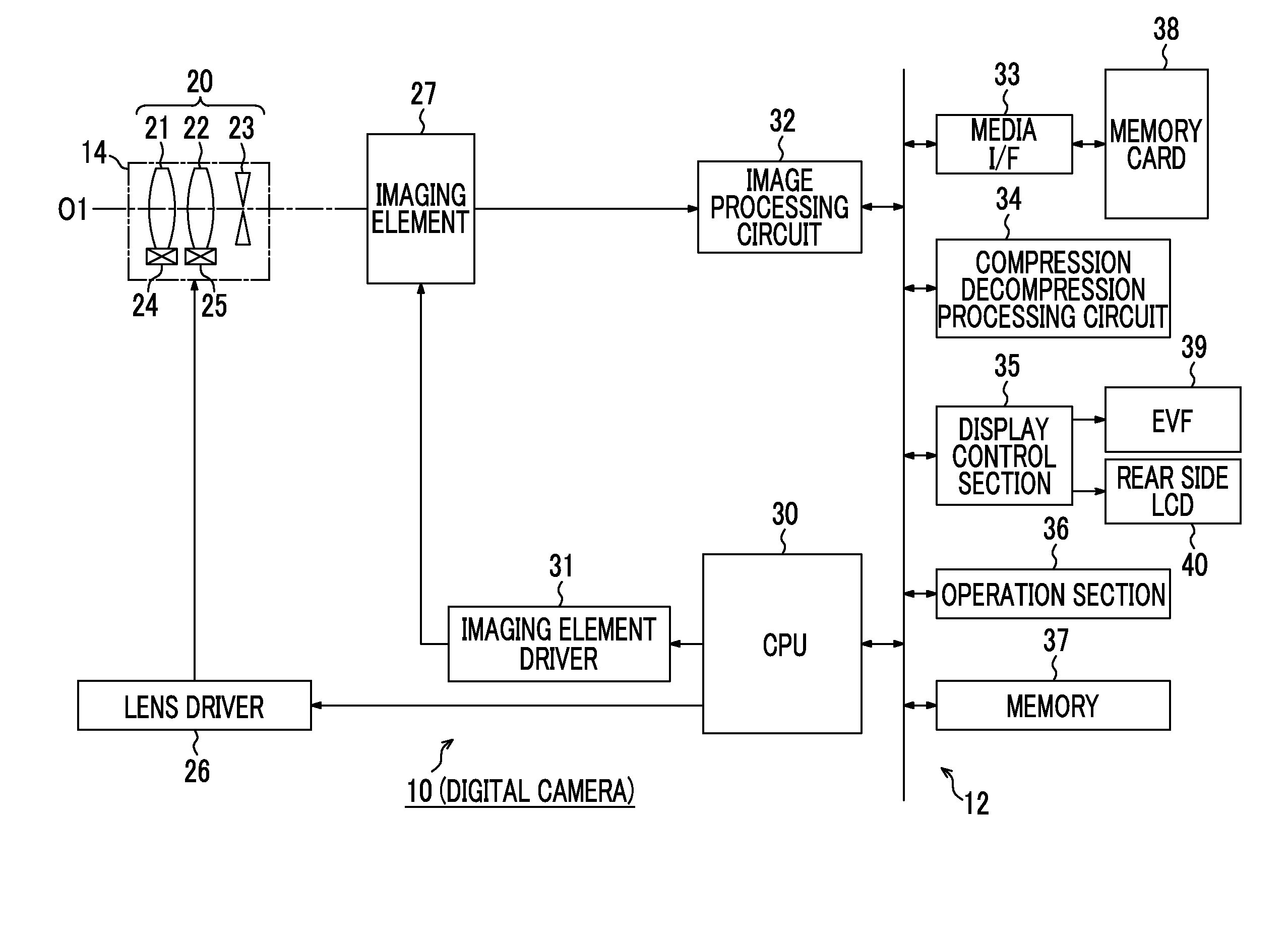

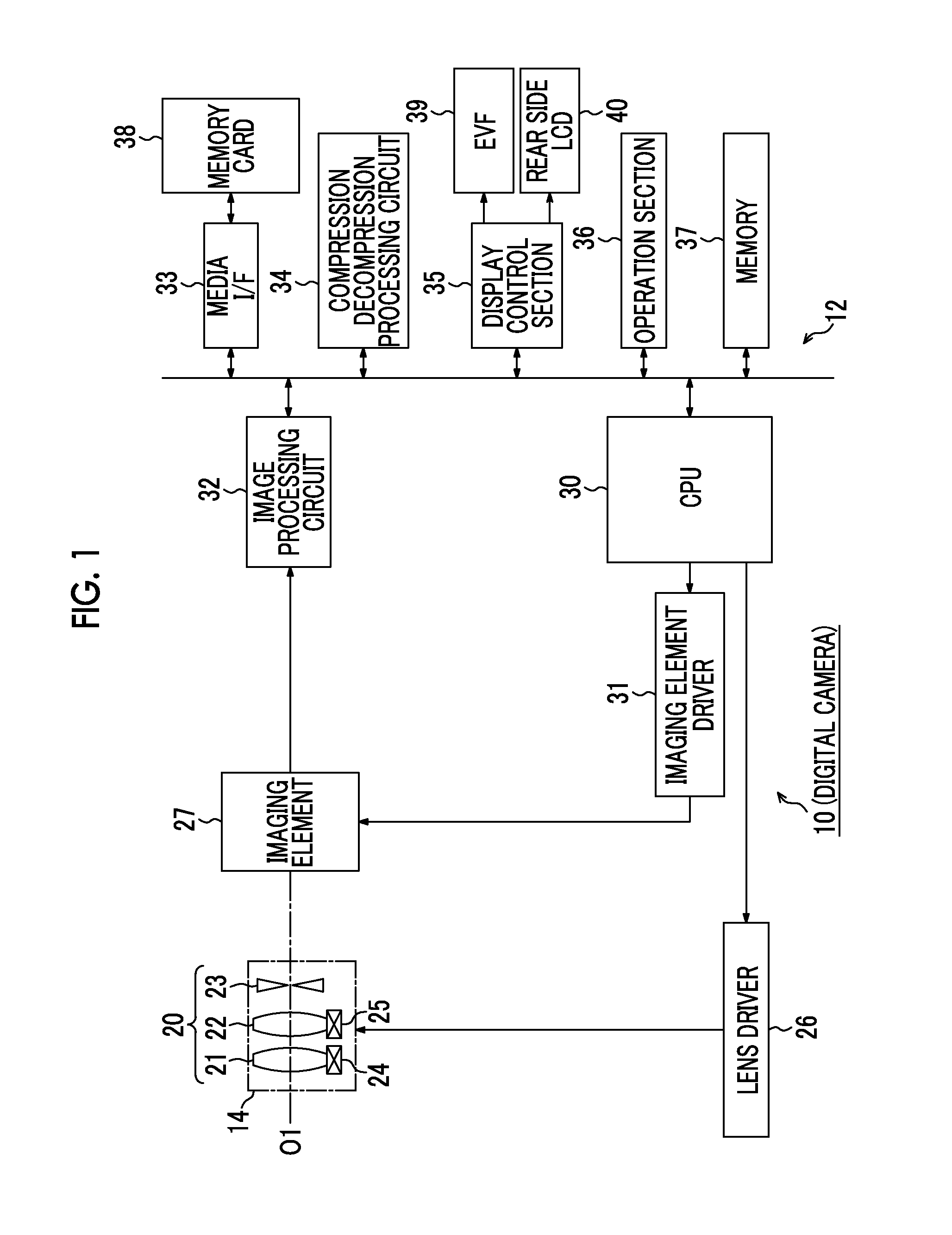

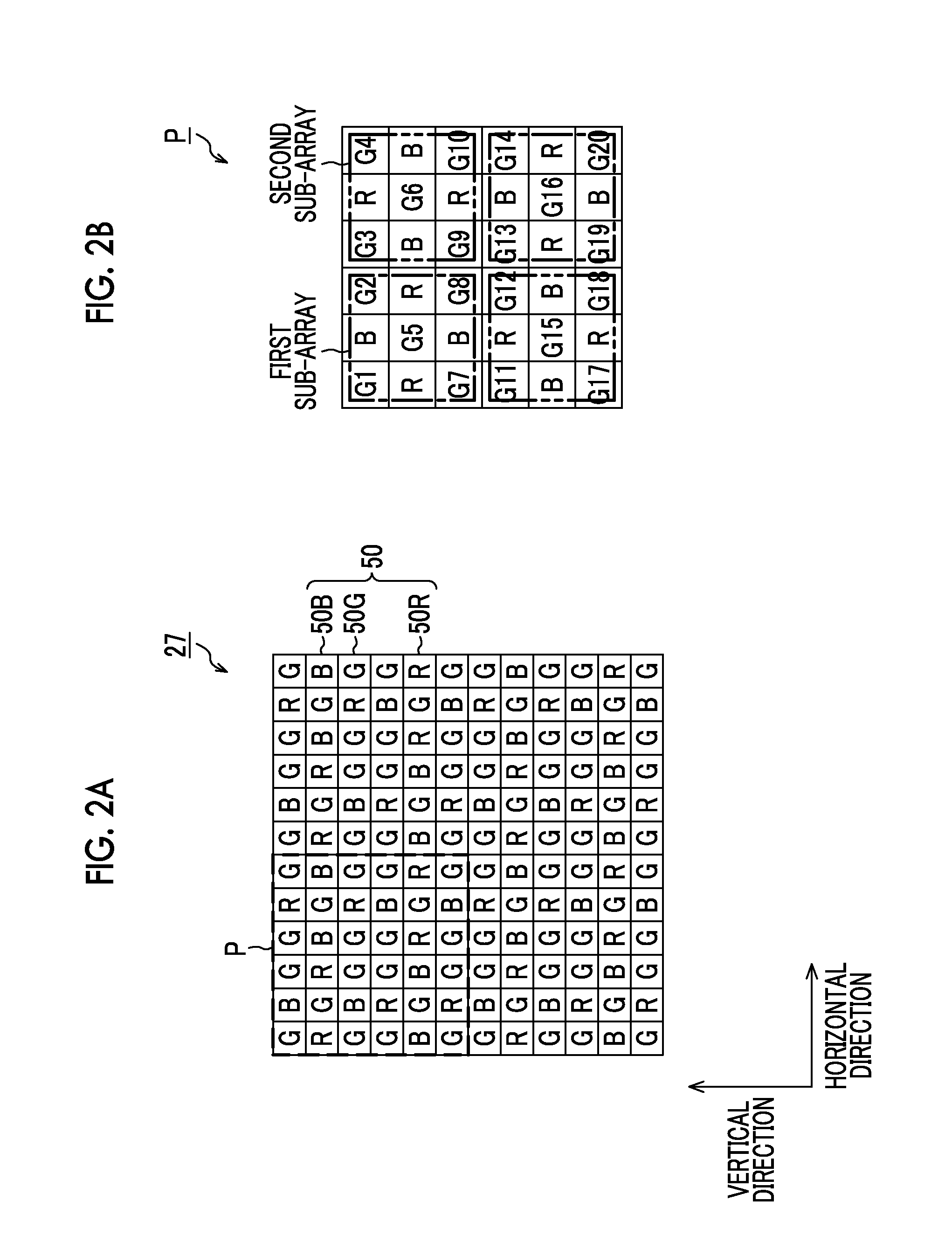

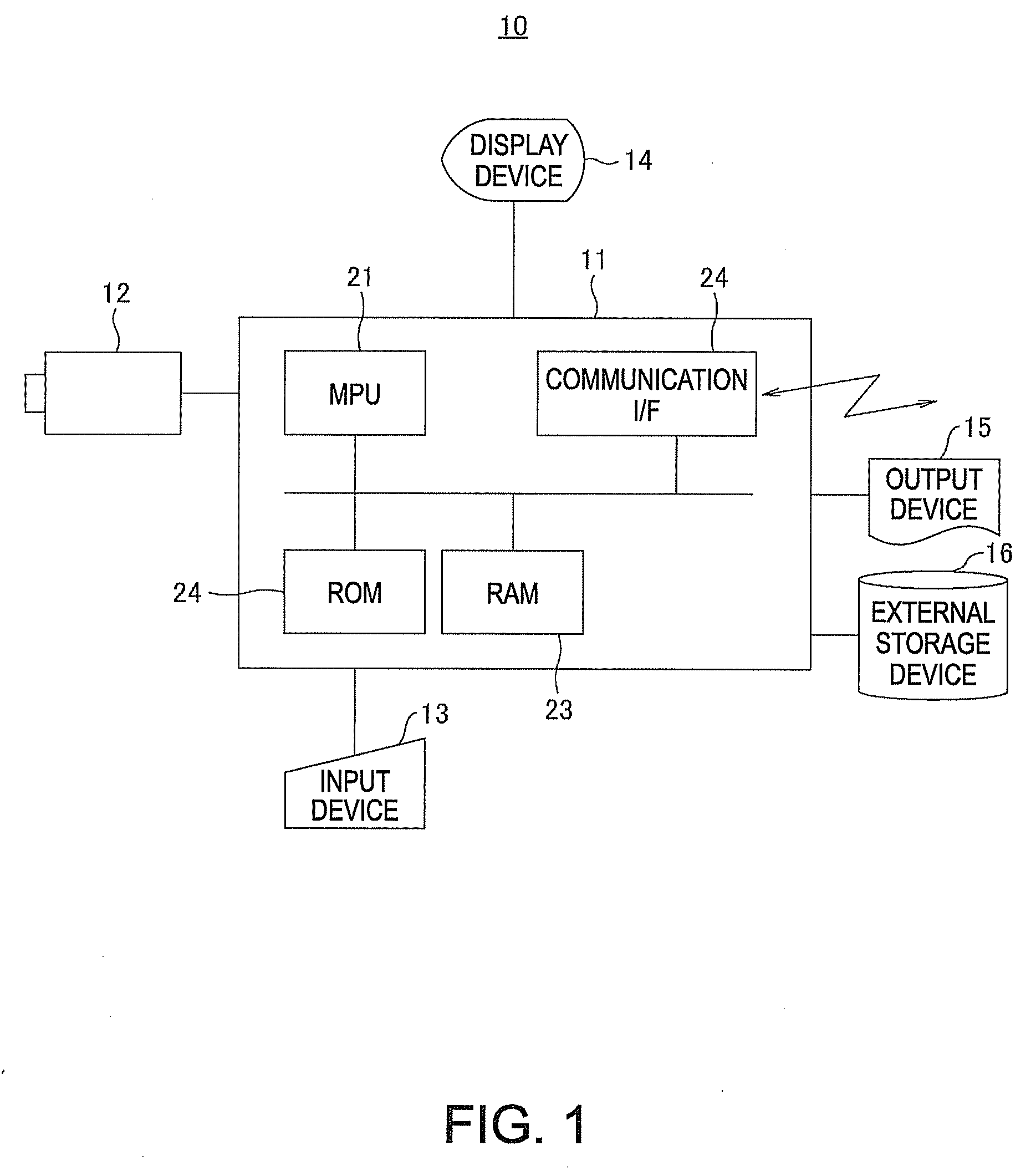

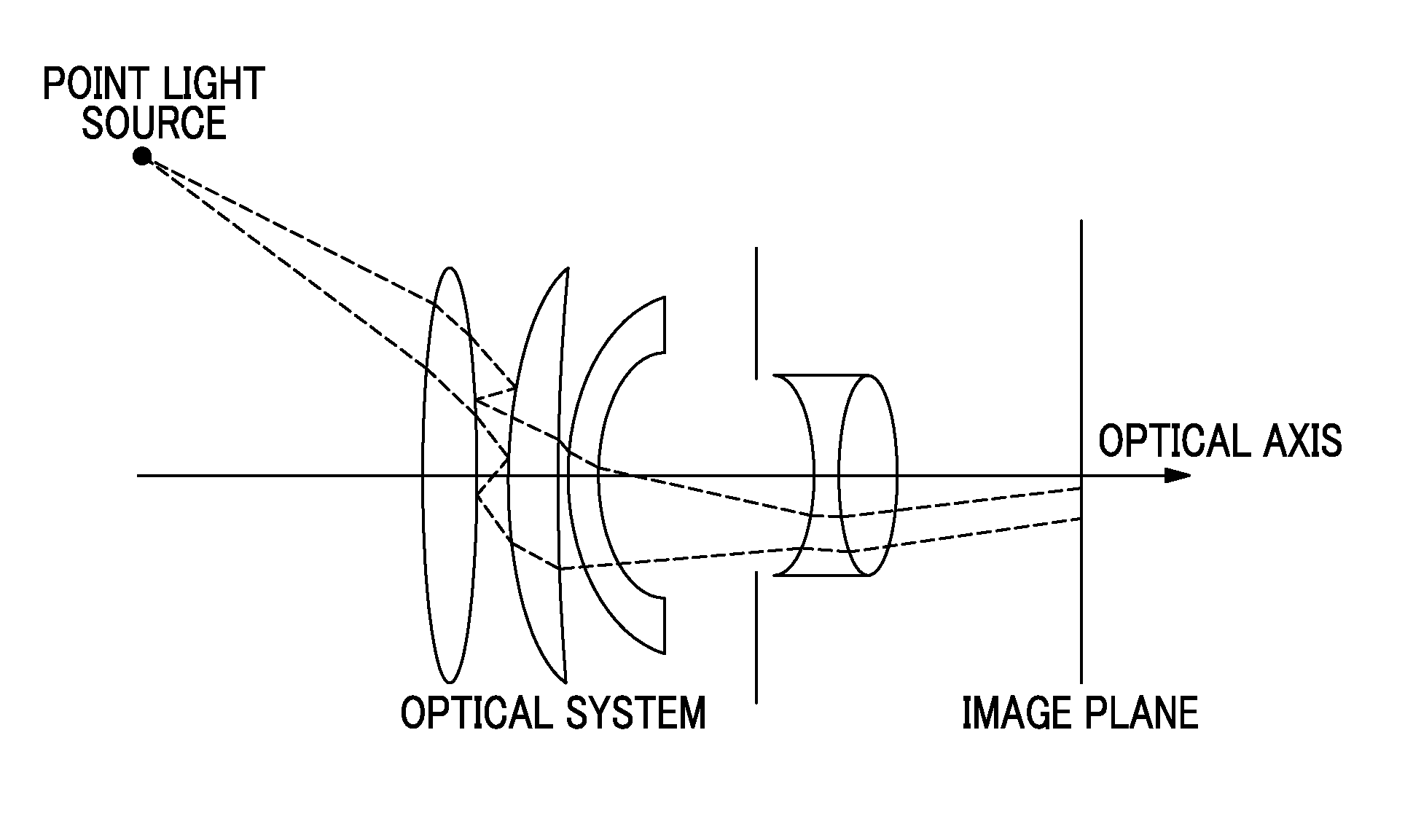

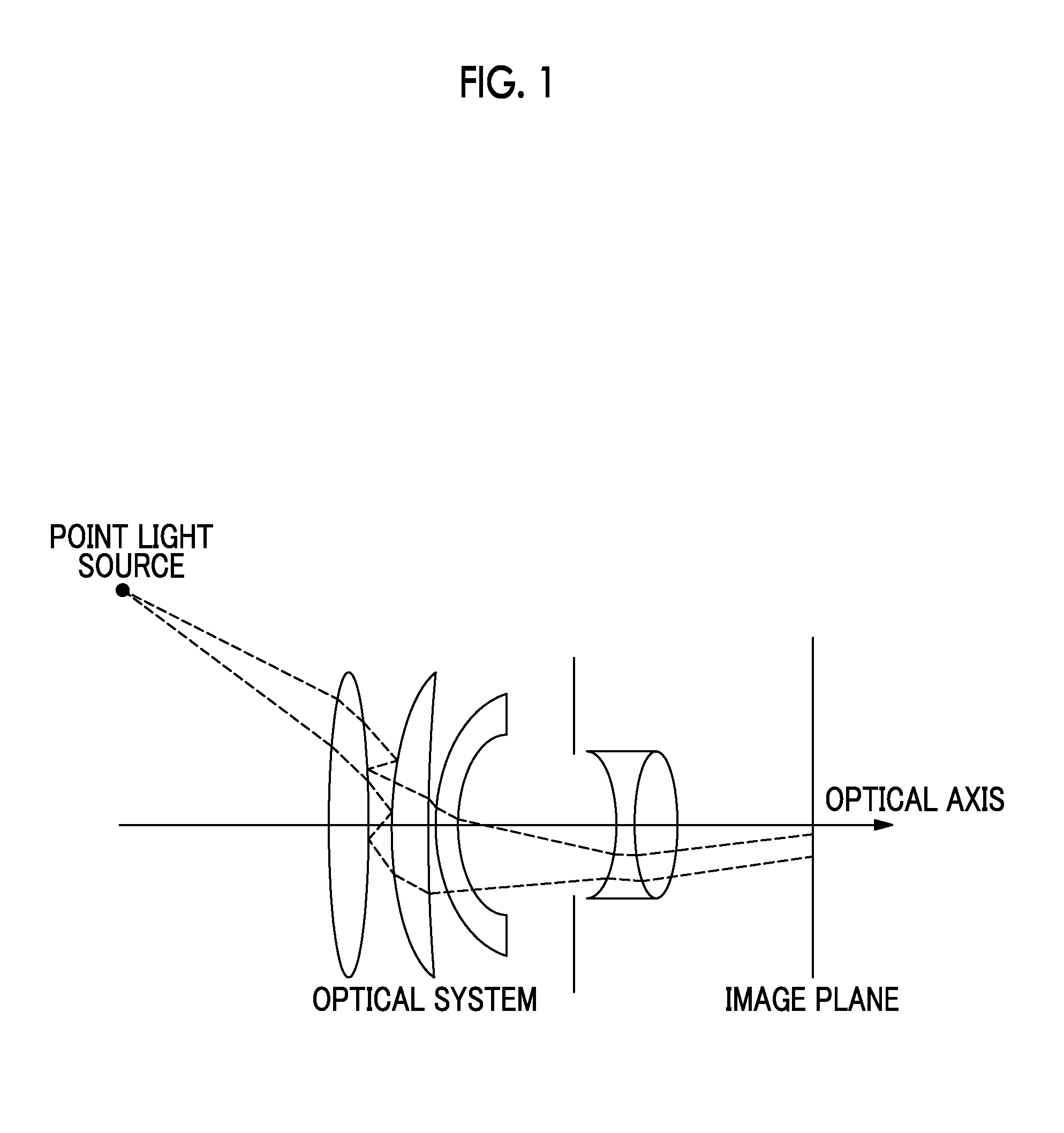

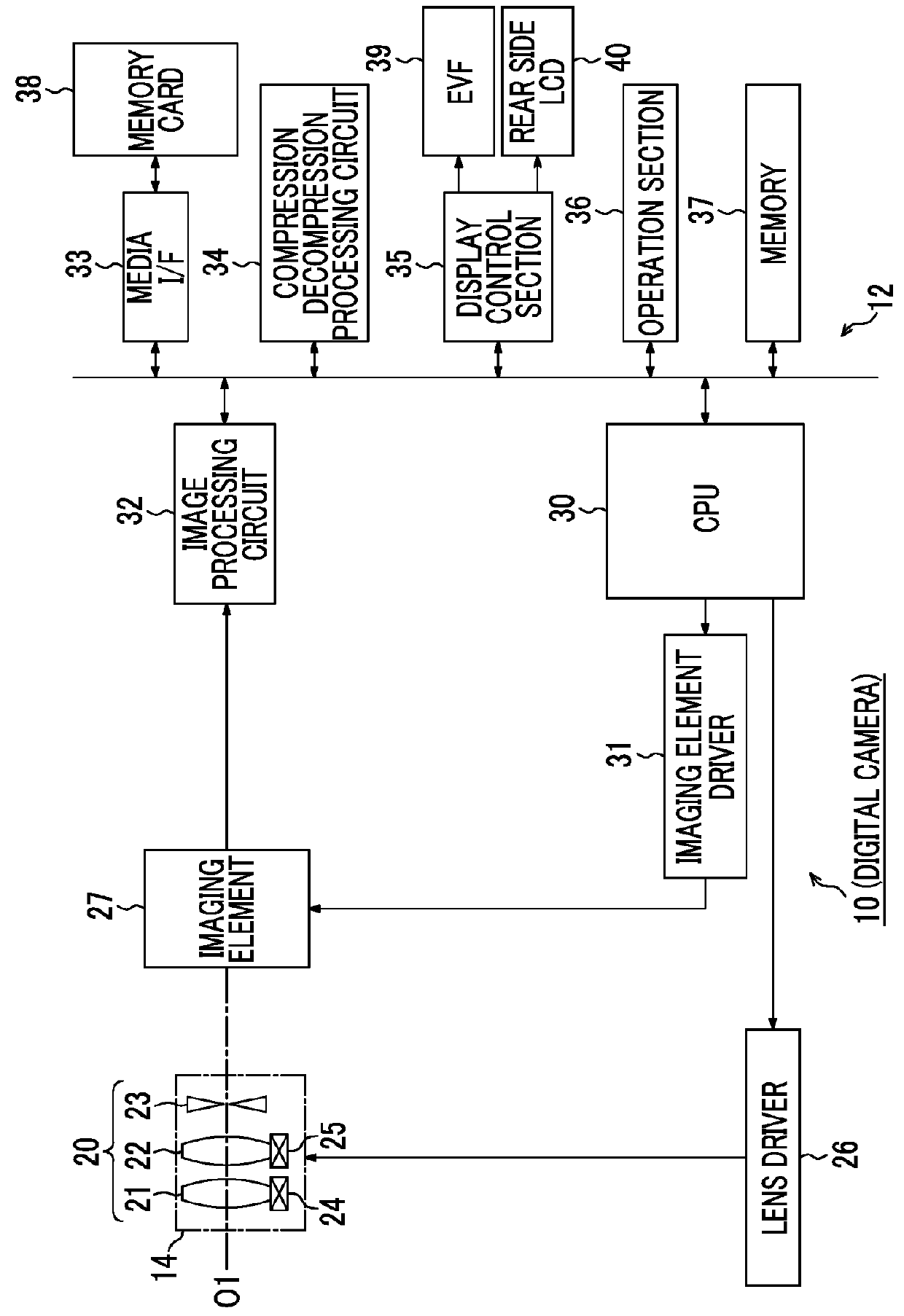

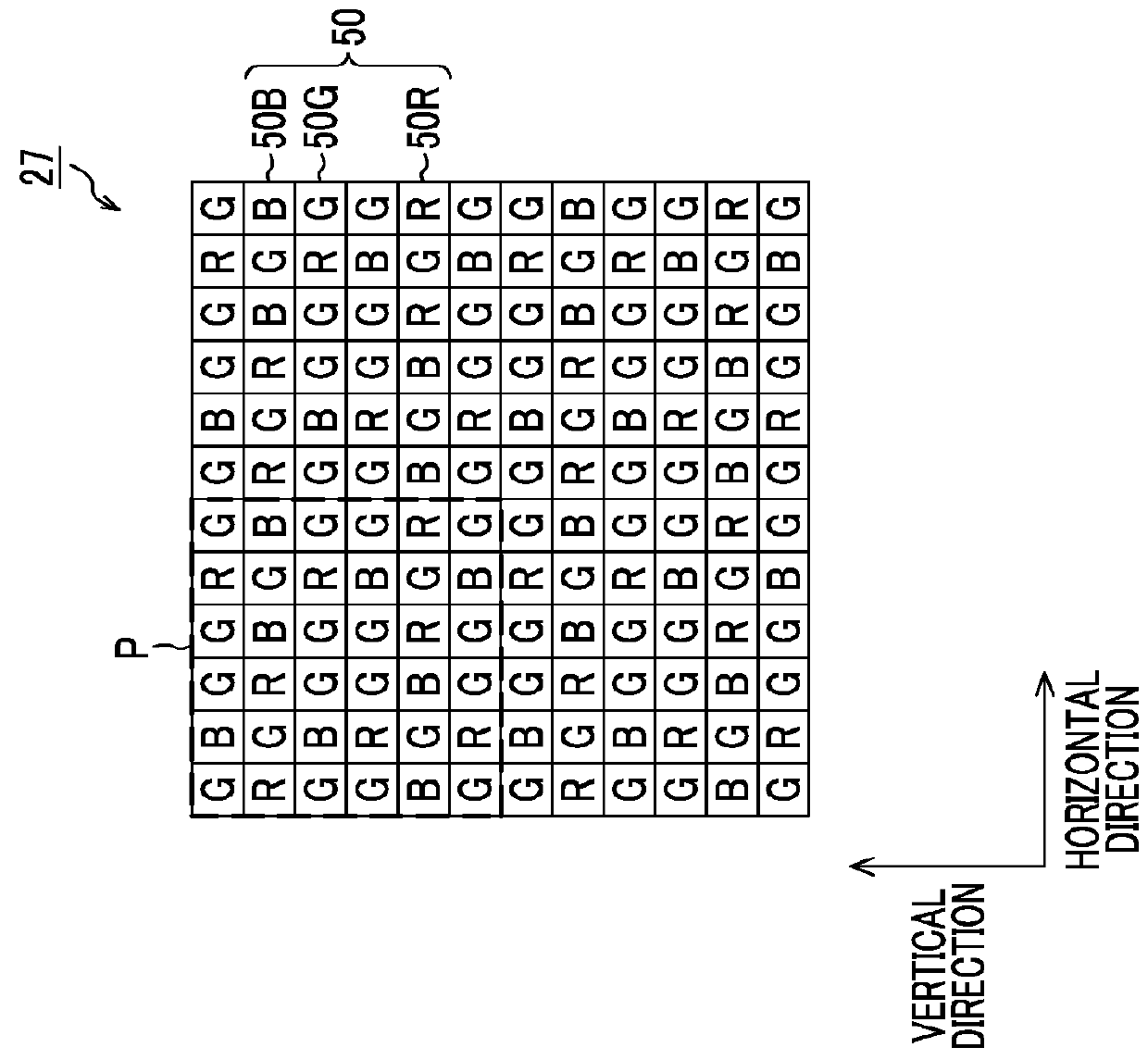

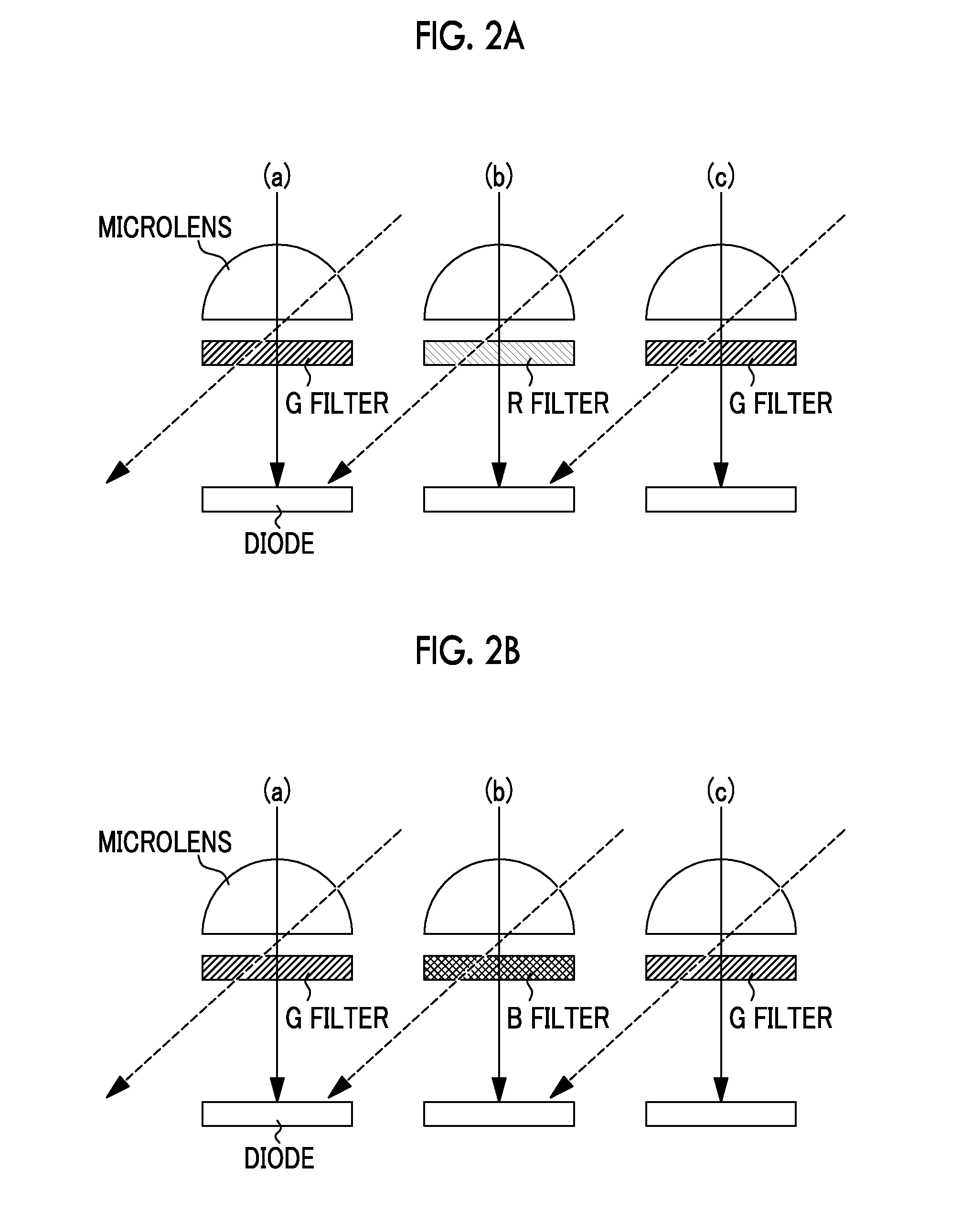

Imaging device, image processing device, image processing method and program

ActiveUS20150326838A1Easy to detectReduce the effect of colorTelevision system detailsTelevision system scanning detailsImaging processing

Owner:FUJIFILM CORP

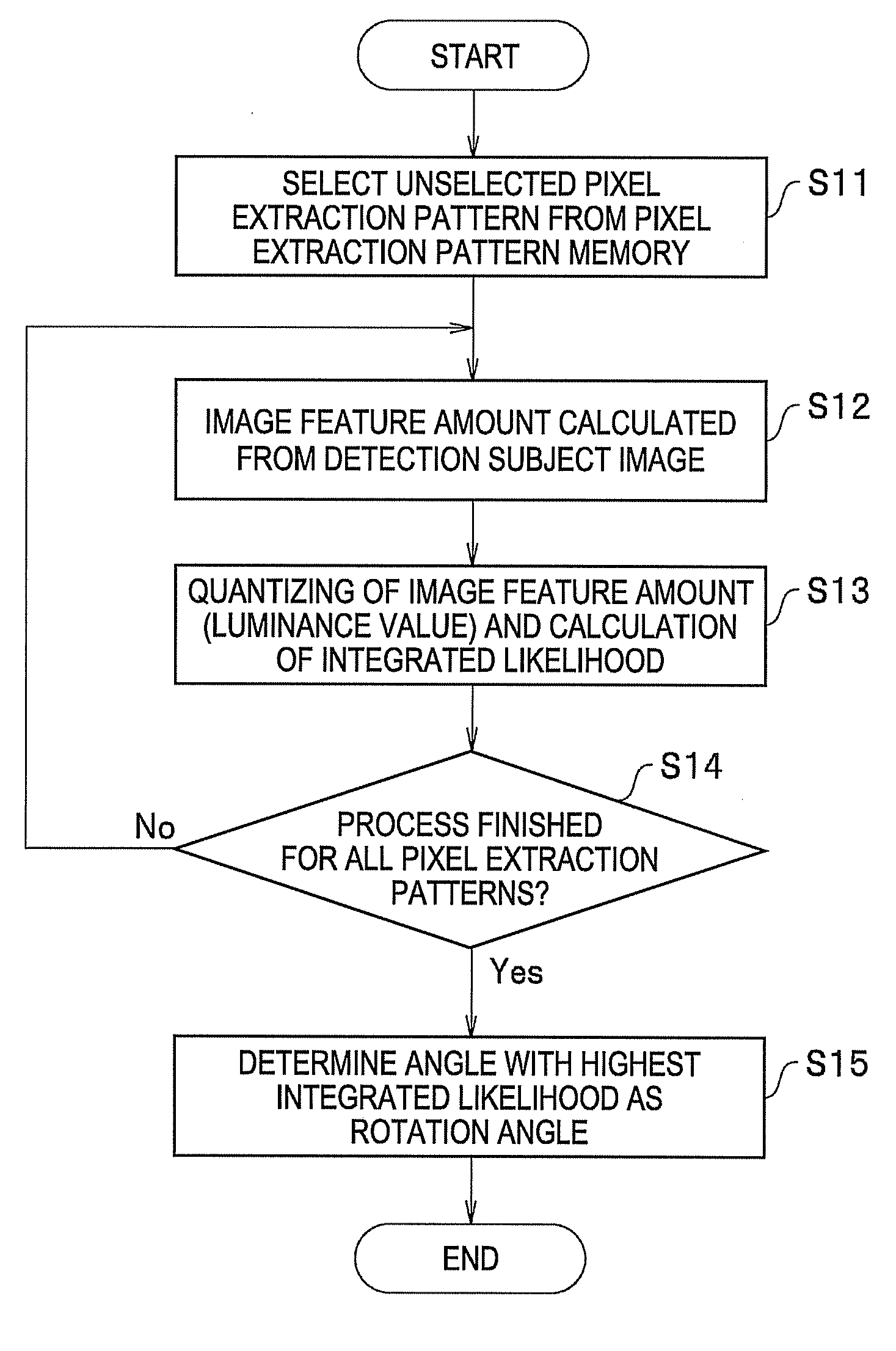

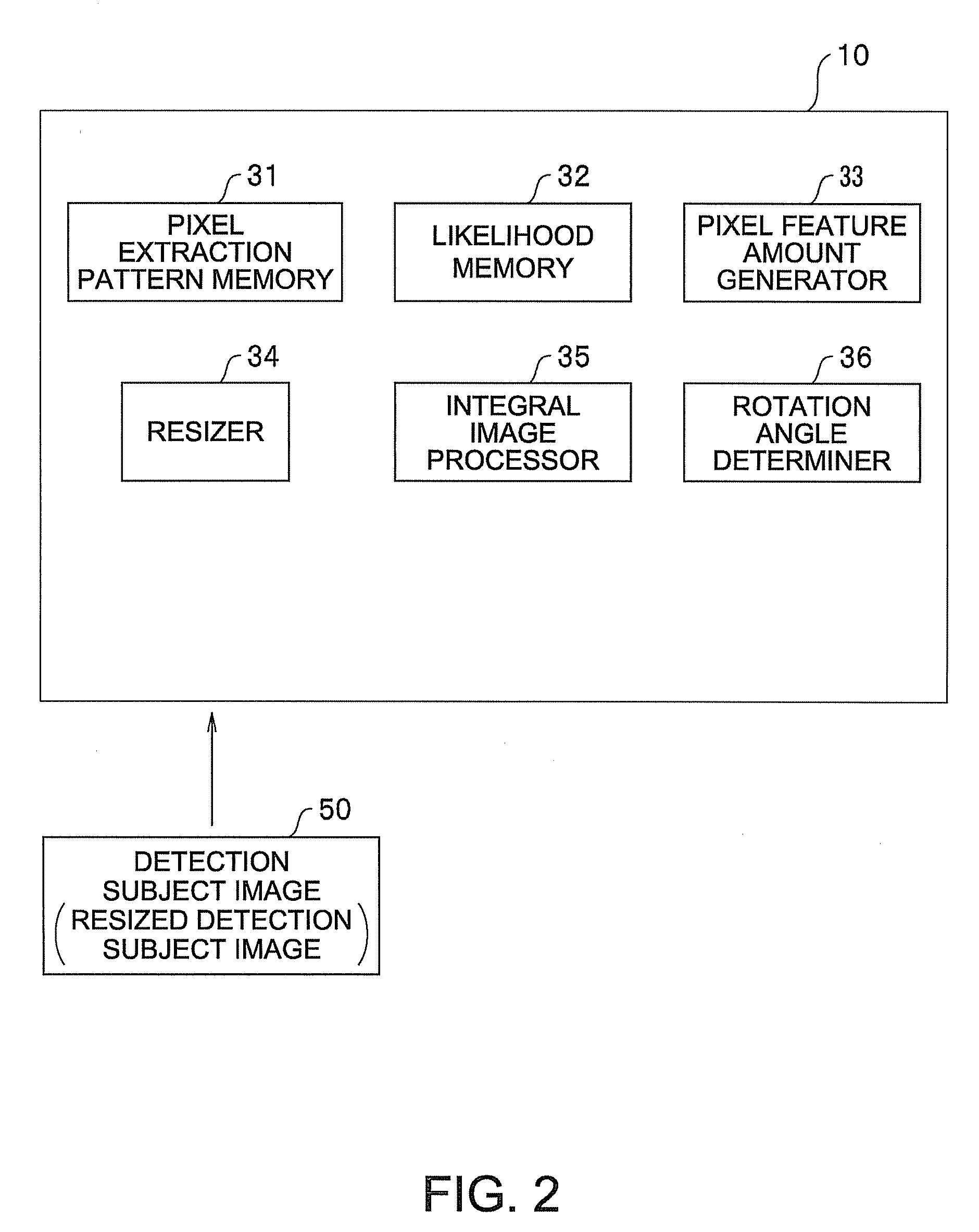

Rotation angle detection apparatus, and control method and control program of rotation angle detection apparatus

InactiveUS20080089588A1Reduce the effect of colorReduce the effect of lightImage analysisCharacter and pattern recognitionImaging FeatureComputer vision

A rotation angle detection apparatus which detects a rotation angle with respect to a reference disposition position of an object included in a detection subject image, includes: a plurality of kinds of pixel extraction pattern for extracting a plurality of pixels which detect an image feature amount from pixels configuring the detection subject image; a feature amount detector which detects, for each pixel extraction pattern, an image feature amount of the extracted plurality of pixels; a likelihood memory which stores a likelihood of the rotation angle, correlated in advance to the image feature amount, for each pixel extraction pattern; and a rotation angle determiner which determines a rotation angle which has a greatest likelihood, based on the image feature amount corresponding to each pixel extraction pattern and on the likelihood, as the rotation angle of the object.

Owner:SEIKO EPSON CORP

Method for making dry white wine through red grape varieties

The invention discloses a method for making dry white wine through red grape varieties. The method is characterized by comprising the process steps of determining of the grape picking period, harvesting of grapes, ear-by-ear selection, peduncle removal, grain-by-grain selection, crushing, low-temperature juice taking, low-temperature clarification, juice separation and temperature increasing, low-temperature alcohol fermentation, tank transferring, ageing or storage, fining, freezing, sterilization, filling and the like. In this way, the produced dry white wine is pale yellow or straw yellow in color, clarified, transparent and glossy. The dry white wine has the pure, active, elegant, fresh and rich fruit aroma; the wine after ageing also has complicated and rich ageing fragrance, and is soft in mouthfeel, fresh, tasty and refreshing.

Owner:YANTAI CHANGYU PIONEER WINE CO LTD

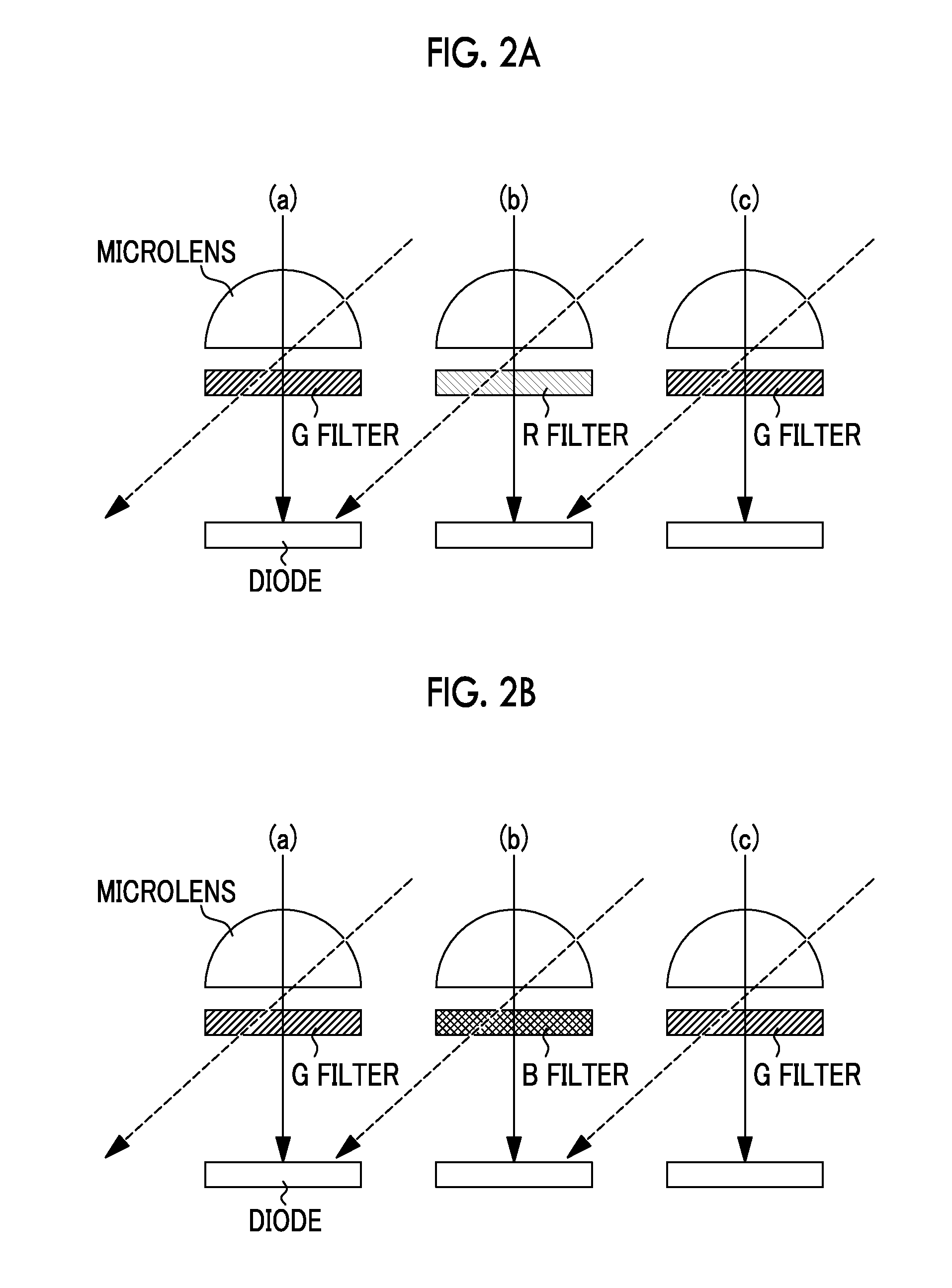

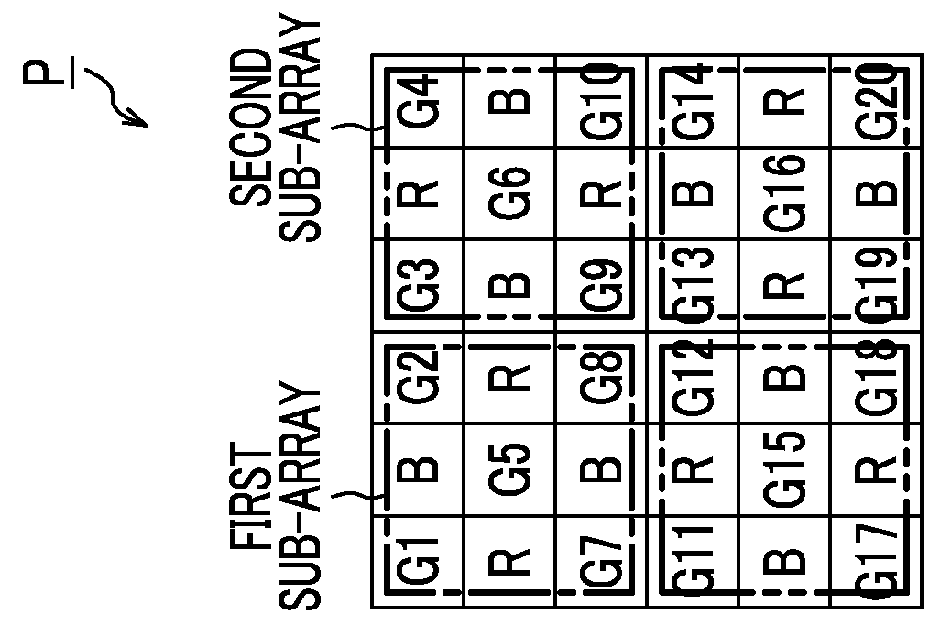

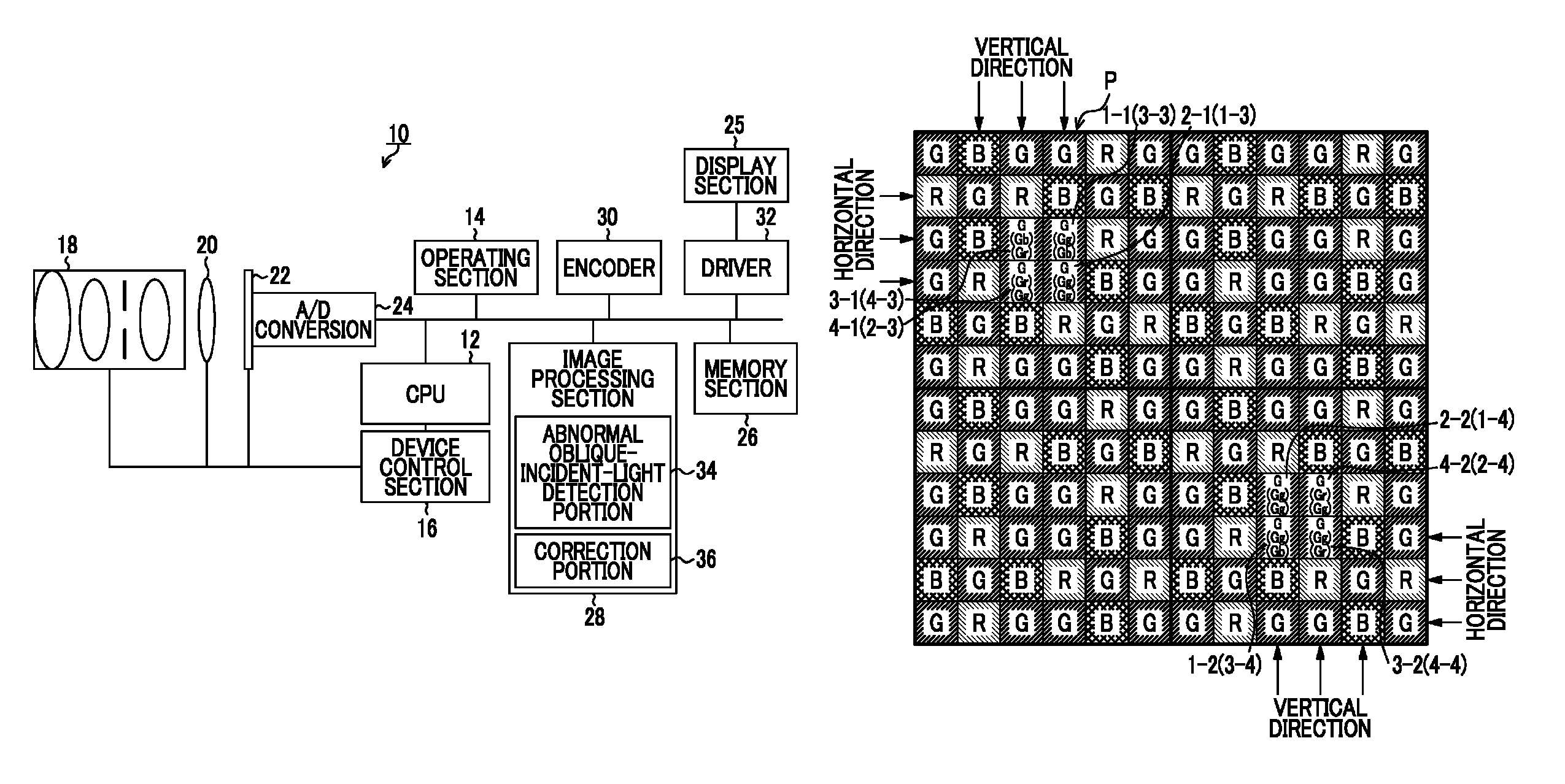

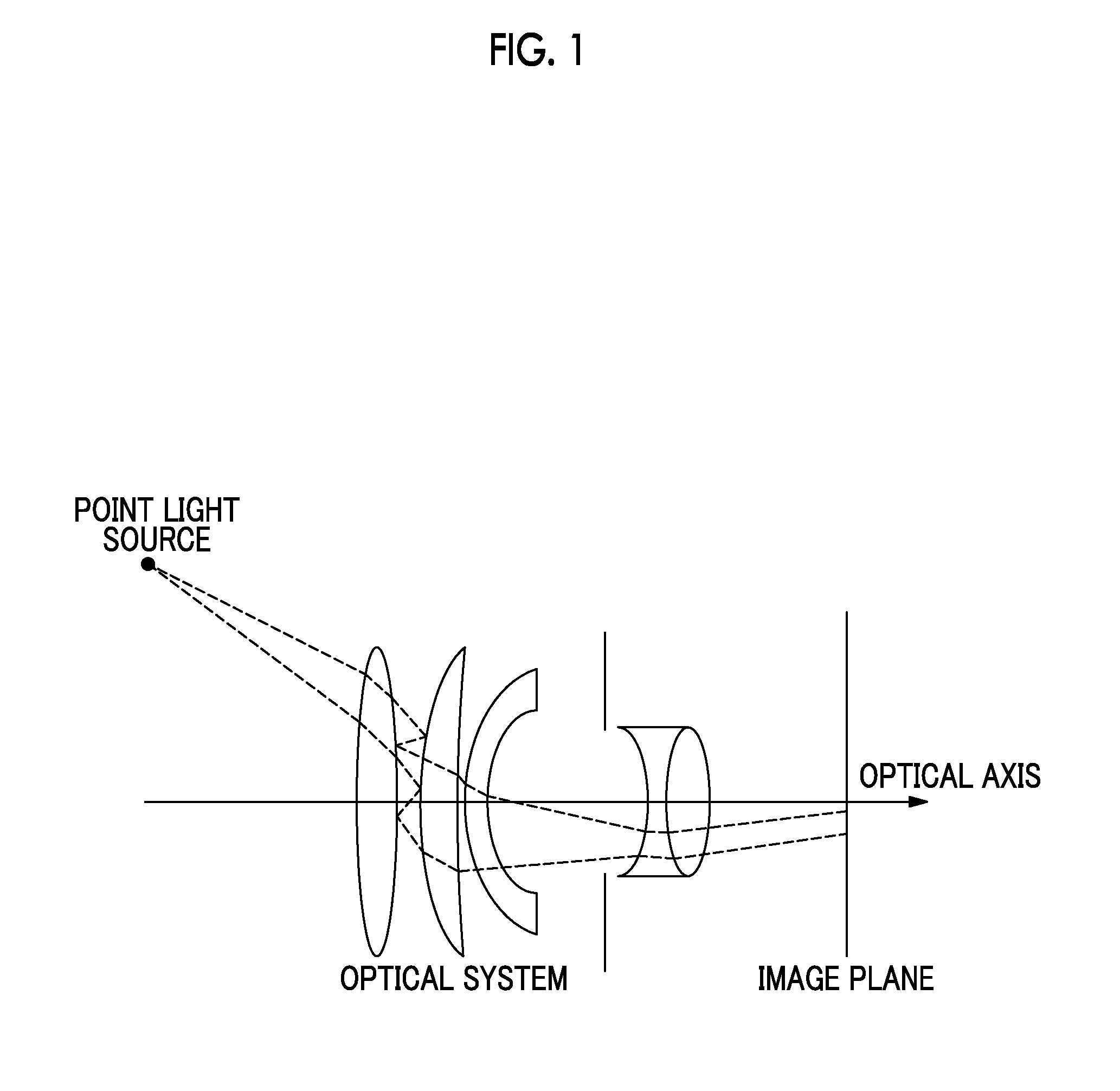

Image capture device, image processing method, and program

ActiveUS20150244955A1Reduce the impactReduce the effect of colorTelevision system detailsTelevision system scanning detailsImaging processingImage capture

According to the present invention, provided is an image capture device, an image processing method, and a non-transitory computer readable medium storing a program capable of detecting a direction of incidence of abnormal oblique incident light and reducing an effect of color mixture caused by the abnormal oblique incident light. An image capture device 10 includes an abnormal oblique-incident-light detection portion 34 and a correction portion 36. An abnormal oblique-incident-light detection portion 34 detects abnormal oblique incident light originated from a first direction by comparing the pixel data of first first-direction same-color adjacent pixels, second first-direction same-color adjacent pixels, first first-direction different-color adjacent pixels, and second first-direction different-color adjacent pixels.

Owner:FUJIFILM CORP

Liquid crystal display

ActiveUS7557882B2Small color shiftReduce the effect of colorNon-linear opticsRelative luminancePolarizer

Owner:NITTO DENKO CORP

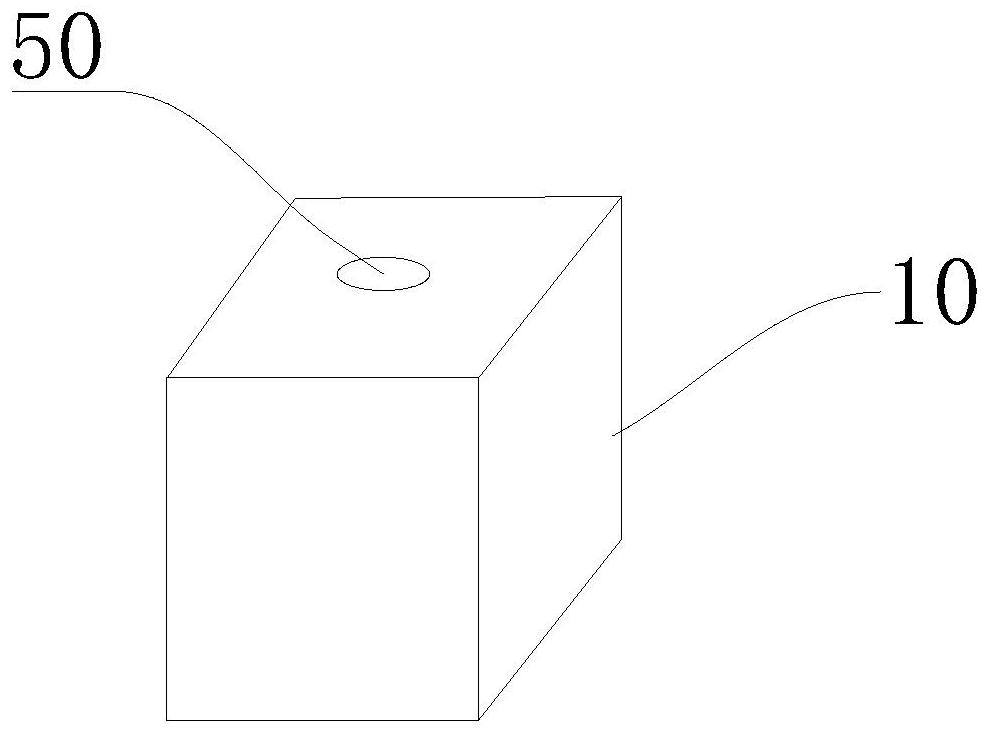

Controlled-release brewing-drinking device and method for Chinese medicine particles

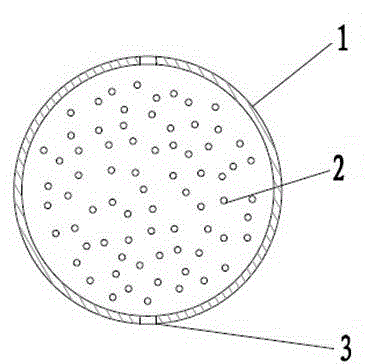

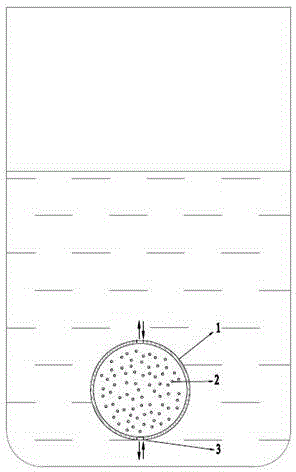

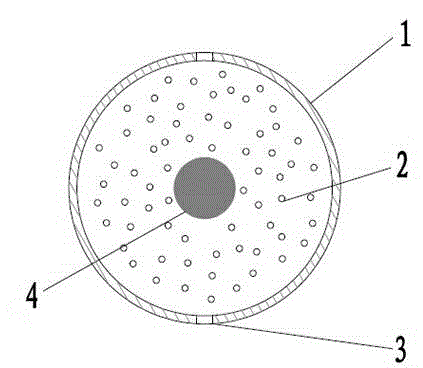

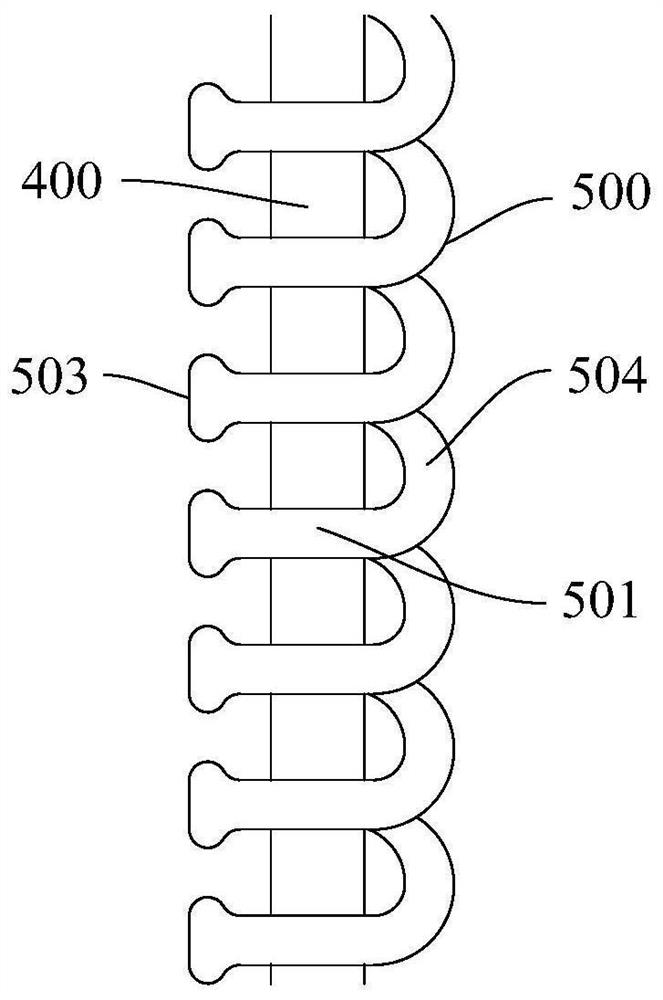

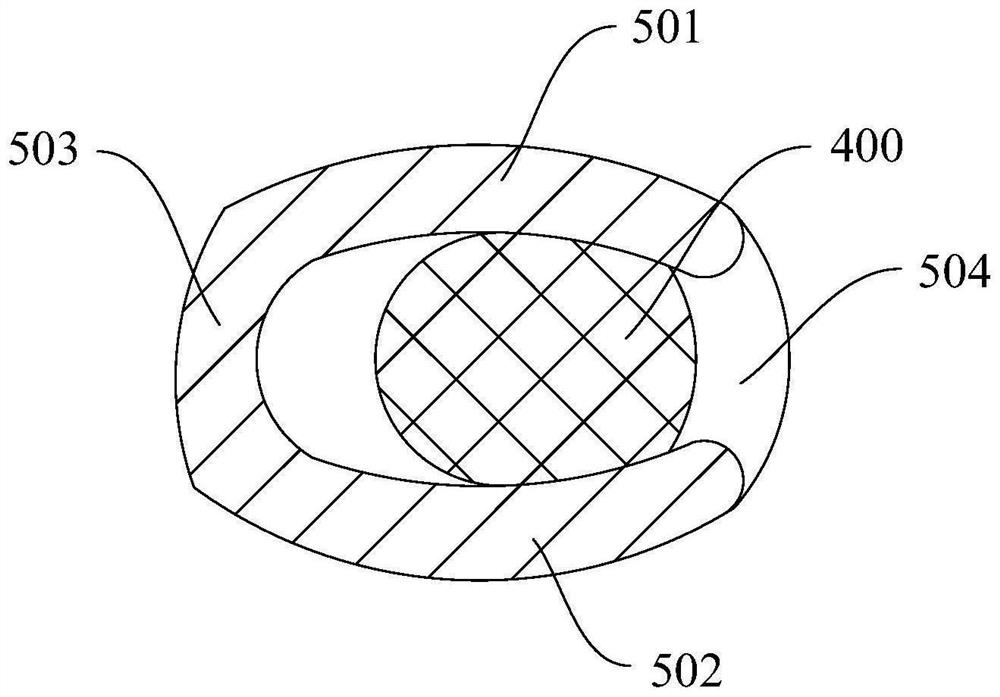

InactiveCN104787501AGuaranteed sealed storageSmall original flavorTransportation and packagingControlled releaseBrewing

The invention discloses a controlled-release brewing-drinking device and method for Chinese medicine particles. The device comprises a container, at least one micro hole is formed in the surface of the container, and the Chinese medicine particles are contained inside the container. In addition, a water-absorbing swelling inner core can be further contained inside the container of the device. Through setting the size and the number of the micro holes in the surface of the container, control over a water and Chinese medicine particle exchanging channel is achieved, and then the speed of dissolving and releasing the Chinese medicine particles in water is controlled. The water-absorbing swelling inner core contained inside the container absorbs the water and swells, so that power capable of pushing and extruding the dissolved Chinese medicine particles outwards is generated; when the water-absorbing swelling inner core swells to occupy the space inside the whole container, the dissolved Chinese medicine particles in the container are completely extruded out, and the water-absorbing swelling inner core and the micro holes are matched so that the speed of releasing the Chinese medicine particles can be further controlled, and the Chinese medicine particles inside the container can be completely released.

Owner:LANZHOU WENHEYUAN MEDICAL TECH

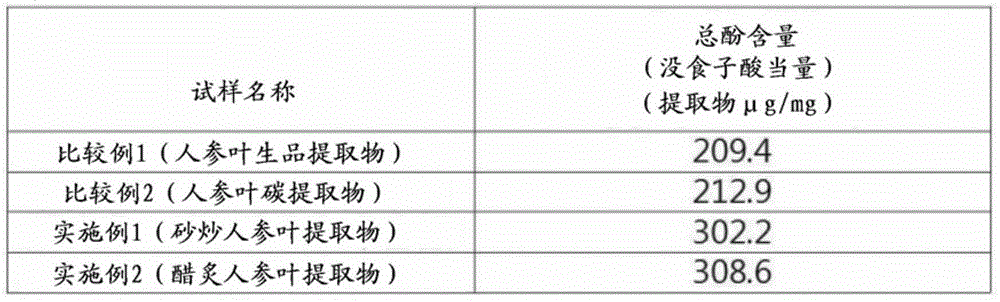

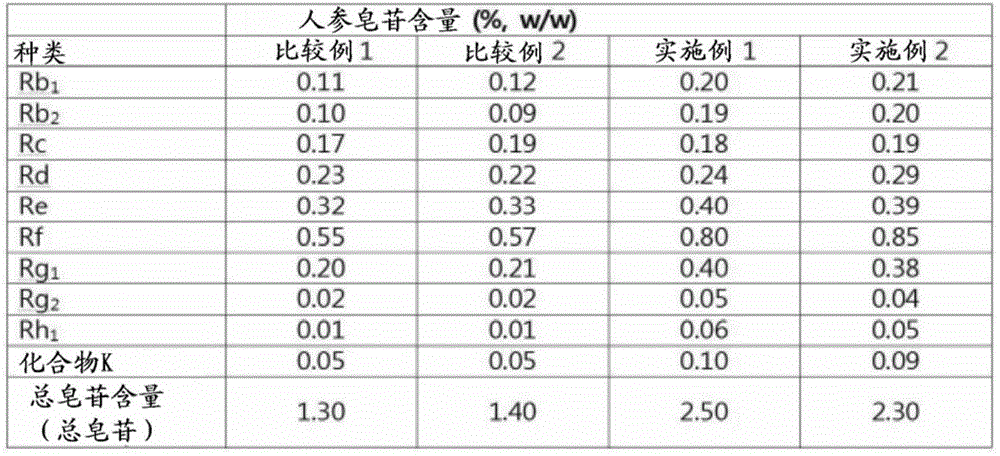

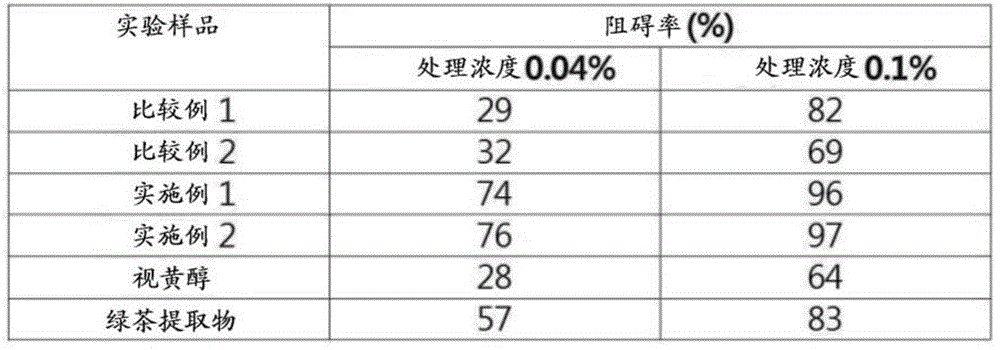

Ginseng leaf extractive manufacturing method and cosmetic composition comprising ginseng leaf extractive serving as effective ingredient

ActiveCN105267268AHigh extraction rateImprove antioxidant capacityCosmetic preparationsToilet preparationsAdditive ingredientMedicine

The invention relates to a ginseng leaf extractive manufacturing method and a cosmetic composition comprising the ginseng leaf extractive serving as an effective ingredient, and discloses a skin external cosmetic composition and a manufacturing method therefor. Compared with a conventional method which takes a pure ginseng leaf extractive as the ginseng leaf extractive of a conventional processed product, the method further improves the antioxidant effect and the activity inhibition and expression inhibition effect of matrix metalloproteinase through the ginseng leaf extractive (0.001-10.0% by weight) produced through a boiling-on-grain method or a method of stir-baking with vinegar. The composition can inhibit the activity of monophenyl oxidase and further improves the darkening skins or prevents the hyperpigmentation of the skin.

Owner:HANKOOK COSMETICS MFG

Polyester resin for building material, and preparation method thereof

InactiveCN102816321AInhibit or reduce thermal oxidationInhibit or reduce the rate of photooxidationPowdery paintsPolyester coatingsAntioxidantAdipic acid

The invention discloses a polyester resin for a building material, which is prepared by esterification and polycondensation reactions of the following components in percentage by weight: 35-40% of neopentyl glycol, 0.1-1% of trimethylolpropane, 50-55% of terephthalic acid, 0.01-1% of esterification catalyst, 58% of isophthalic acid, 23% of adipic acid, 0.01-1% of antioxidant and 0.01-1% of resin additive, wherein the sum of the weight percentages of the components is 100 percent, the acid value of the polyester resin is 28.0-32.0mg KOH / g, the viscosity is 40.0-70.0PA.s by measurement at a temperature of 160 DEG C, the color is 0 to 12, and the glass transition temperature is 60-62 DEG C. The invention also discloses a method for preparing the polyester resin. The antioxidant is added in the first stage of raw material adding instead of the second stage of raw material adding, so that the reaction speed is unexpectedly accelerated, and thus the production efficiency is obviously improved.

Owner:帝兴树脂(昆山)有限公司

Imaging device, image processing device, image processing method and program

ActiveUS9363491B2Reduce the effect of colorGood colorTelevision system detailsColor signal processing circuitsImaging processing

Owner:FUJIFILM CORP

Image capture device, image processing method, and program

ActiveUS9374544B2Reduce the effect of colorRemove variation in the pixel dataTelevision system detailsOptical filtersImaging processingImage capture

Owner:FUJIFILM CORP

Woollen fabric having hand feeling and gloss as cashmere and preparation method thereof

ActiveCN108951142AReduce the effect of colorShrinkproofDry-cleaning apparatus for textilesGrip property fibresWool fiberReducing agent

The invention discloses a woollen fabric having hand feeling and gloss as cashmere and a preparation method thereof. The preparation method includes: chlorinating the woollen fabric with a chlorinating agent; reducing the chlorinated woollen fabric with a reducing agent; alkaline-washing the woollen fabric after the reduction; adding acid to the alkaline-washed woollen fabric for neutralization, and performing softening wet-brushing on a wet-brushing machine. Through the steps of chlorination, reductive cleaning, alkaline washing, neutralization and wet brushing, degraded proteins in a scale layer of denuded wool fibers are removed, so that the fabric has smooth and flat surface and can regularly reflect light beam and shows gloss; therefore, the woollen fabric has a soft hand feeling andis improved in gloss, has an anti-shrinking effect, can solve problems of itching feeling, stiffness, roughness and the like, and has the feeling and gloss as pure cashmere.

Owner:INNER MONGOLIA ORDOS RESOURCE

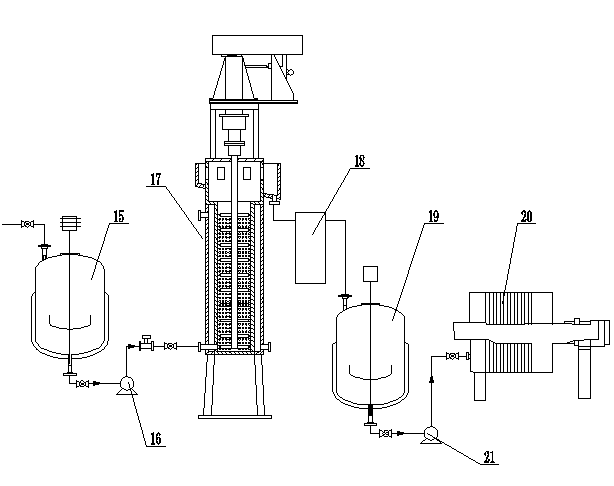

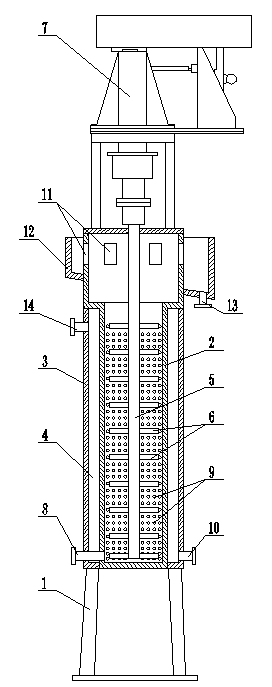

Continuous grinding method for brominated flame retardant and grinding machine for realizing method

InactiveCN103071568AReduce the effect of colorAvoid corrosionGrain treatmentsPulp and paper industryReducing agent

The invention discloses a continuous grinding method for a brominated flame retardant, which comprises the following steps: (1) after uniformly mixing the brominated flame retardant, a reducing agent, a pH regulator and process water, obtaining mixed feed liquid; (2) continuously feeding the mixed feed liquid into a grinding machine for grinding through the bottom of the grinding machine, controlling a feeding speed, and causing the later mixed feed liquid entering into the grinding machine to drive the earlier mixed feed liquid entering into the grinding machine to move upward till flowing out of an overflow port at the top of the grinding machine, wherein the liquid continuously flowing from the overflow port is overflow feed liquid; and (3) after removing ferromagnetic materials from the overflow feed liquid through an iron-removing machine, performing solid-liquid separation, washing the obtained solid material with water and drying, and then obtaining the powdered brominated flame retardant with the grain size in a preset scope. The obtained product has the advantages of good color and luster, uniform grain size of the product, small size distribution scope and stable quality.

Owner:SHANDONG TIANYI CHEM

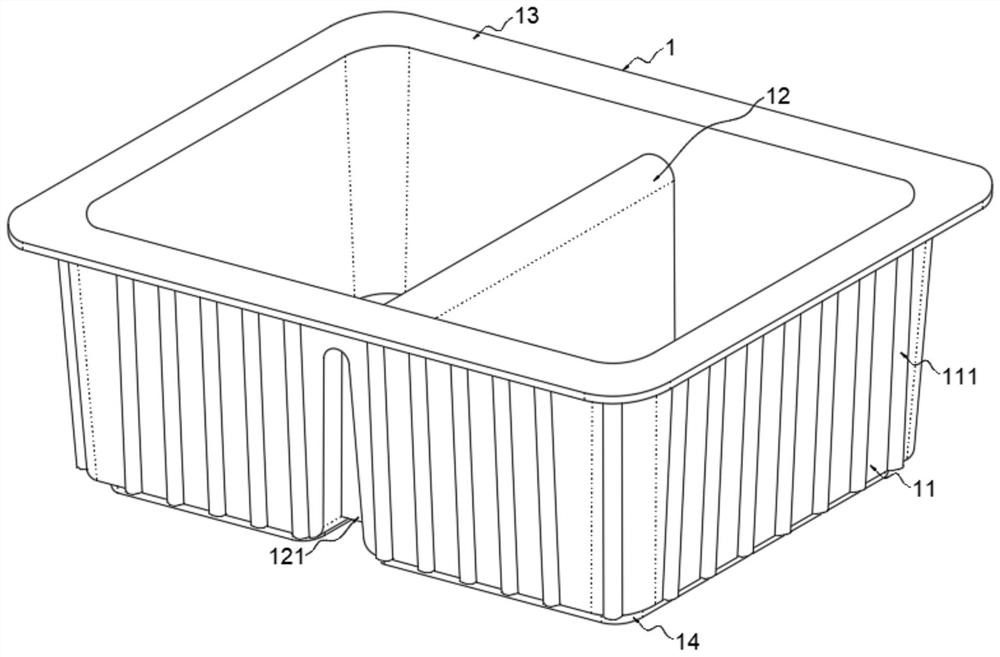

High-stiffness and difficult-to-break degradable environment-friendly lunch box and preparation method thereof

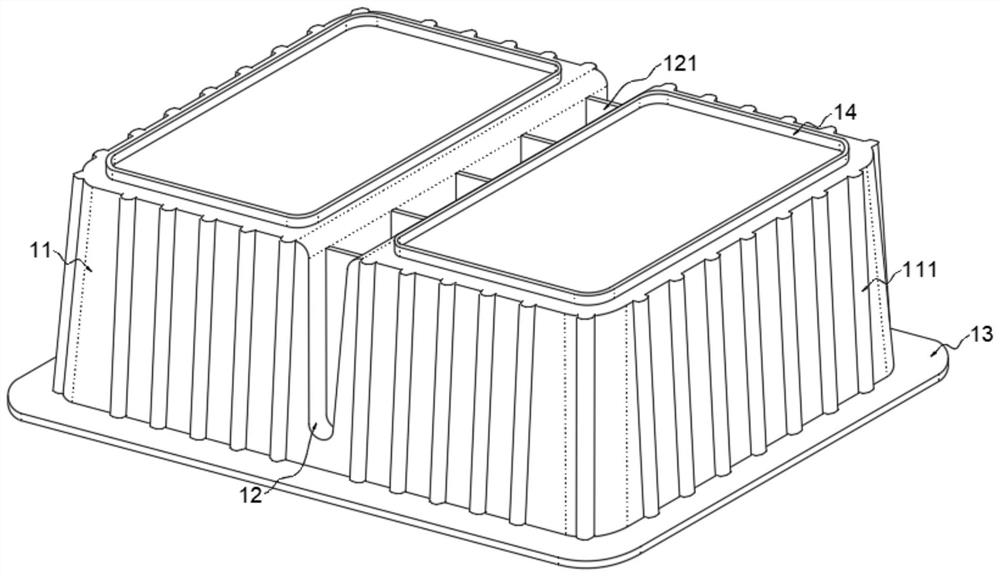

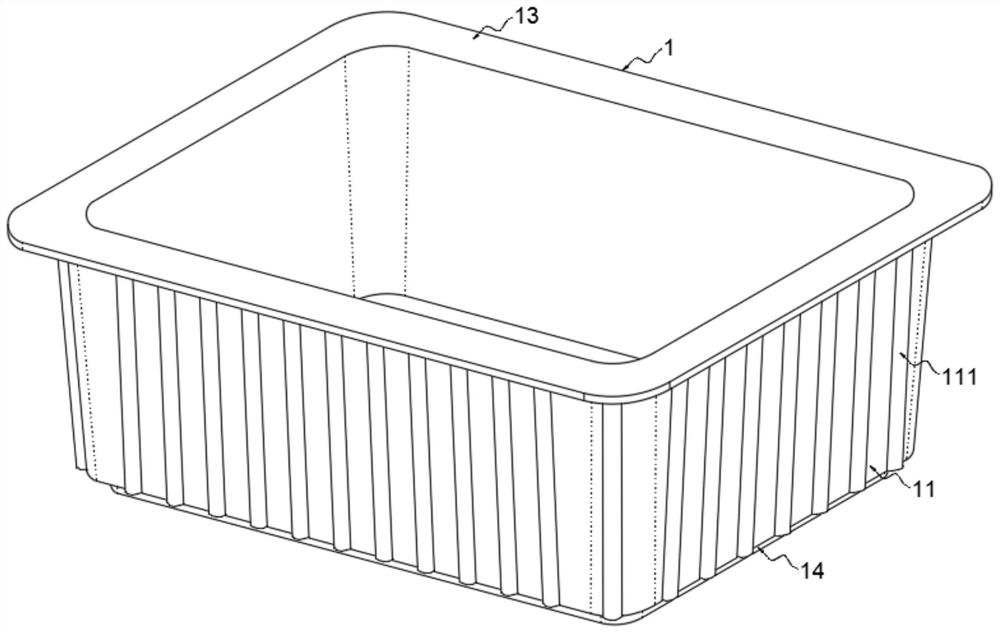

InactiveCN112498890AImprove stabilityImprove stiffnessBio-packagingBoxesEngineeringMechanical engineering

The invention relates to the technical field of lunch box processing, in particular to a high-stiffness and difficult-to-break degradable environment-friendly lunch box and a preparation method thereof. The lunch box comprises a lunch box body, wherein the lunch box body is integrally formed in a high-temperature mold pressing mode, the lunch box body comprises a box body, a plurality of reinforcing strips are integrally formed on the outer side wall of the box body at equal intervals, a plurality of separation grooves are regularly formed in the middle of the box body, a plurality of supporting plates are arranged on the inner sides of the concave surfaces of the separation grooves at equal intervals, an upper edge ring is arranged on the outer side of the top surface of the box body, anda supporting ring is arranged on the bottom surface of the box body. According to the design, the overall stability of the lunch box can be improved, the stiffness of the lunch box is improved, meanwhile, the anti-scalding performance of the lunch box can be enhanced, and better using experiences are brought to a user; and according to the design, the influence of plant fiber pigments on the color of a finished product can be reduced, meanwhile, the use amount of starch and plastic can be reduced, the using cost is reduced, the degradation period is shortened, the degradation rate is improved, and pollution of the disposable lunch box to the environment is relieved.

Owner:彭新星

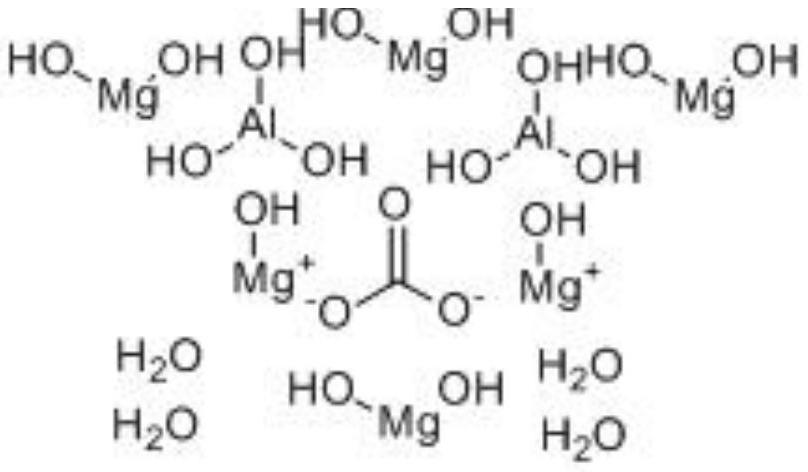

Flame-retardant polypropylene material as well as preparation method and application thereof

The invention discloses a flame-retardant polypropylene material as well as a preparation method and application thereof, and the flame-retardant polypropylene material comprises the following components in percentage by weight: 60%-65% of polypropylene, 13%-15% of a brominated flame retardant, 5%-7% of an antimony trioxide synergist, 11%-13% of superfine talcum powder, 0.5%-1% of a neutralization absorbent LDHs and the balance of a weather-resistant additive. According to the flame-retardant polypropylene material, the problem of poor weather resistance of a flame-retardant material under the condition of high flame retardant content and harmful smoke of the halogen-containing flame retardant can be solved; and the compatibility among the materials is facilitated, the influence of the flame retardant on the color is reduced, and the material performance is improved.

Owner:BEIJING JU LING YAN PLASTIC CO LTD

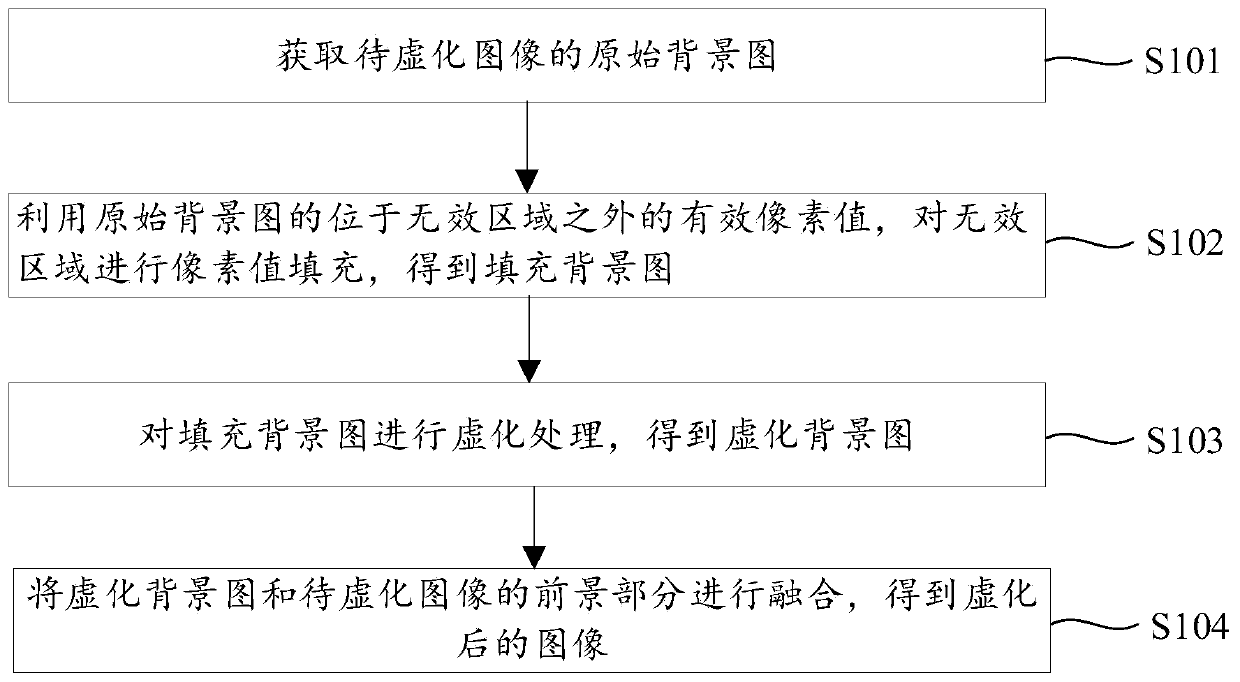

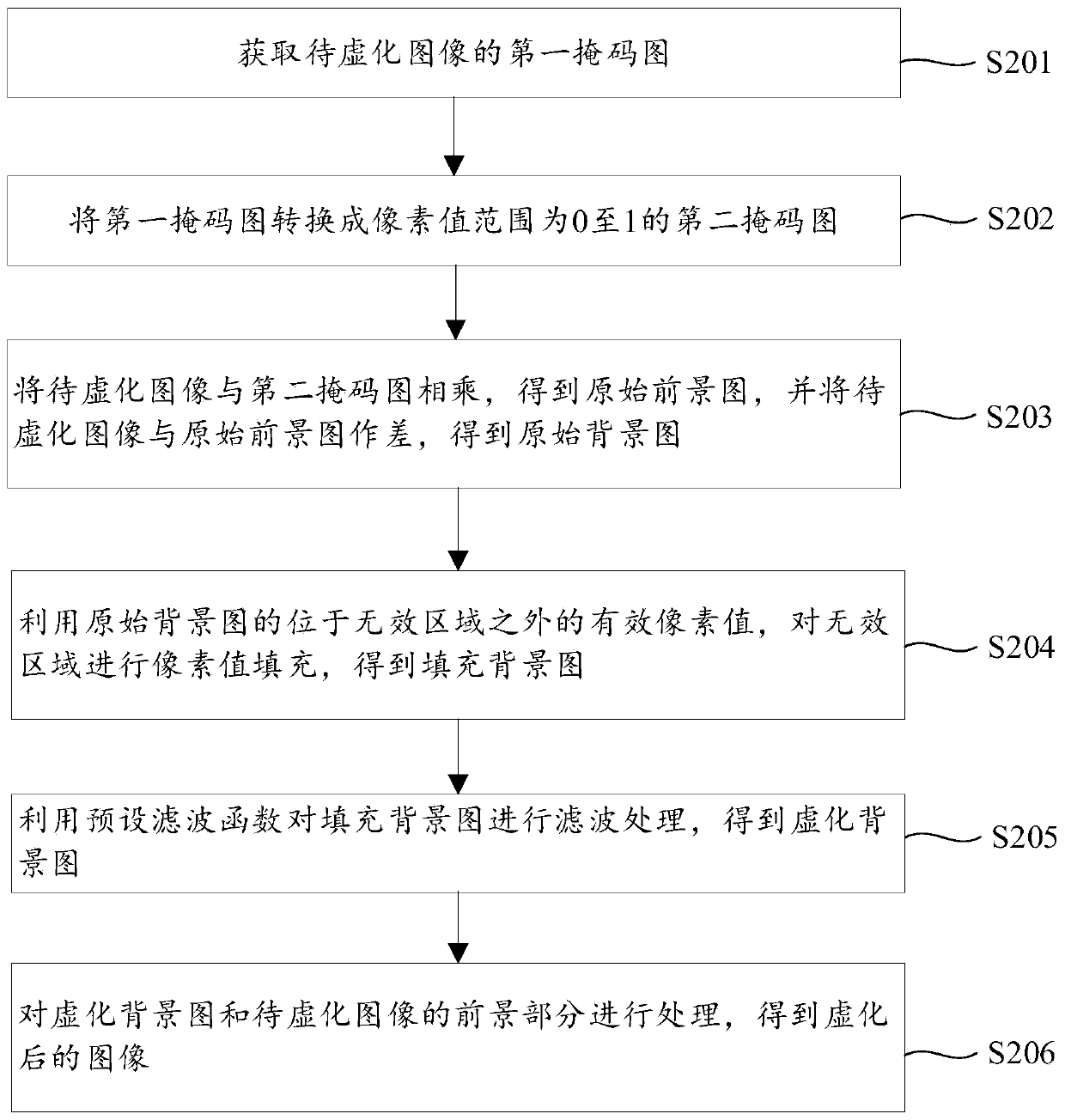

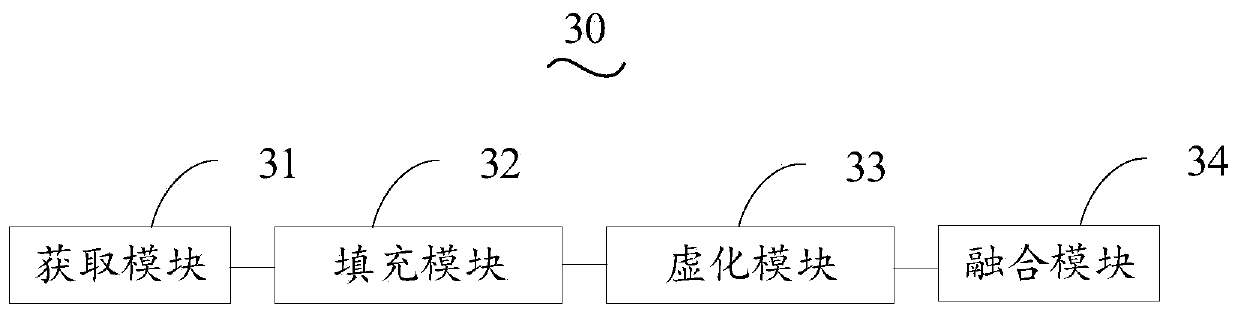

Image blurring method, image blurring device, equipment and storage device

PendingCN111161136AReduce the effect of colorRemove haloGeometric image transformationComputer graphics (images)Radiology

The invention discloses an image blurring method, an image blurring device, equipment and a storage device. The image blurring method comprises the steps: acquiring an original background image of a to-be-blurred image, wherein the original background image comprises an invalid area corresponding to a foreground part of the to-be-blurred image; performing pixel value filling on the invalid area byutilizing an effective pixel value, located outside the invalid region, of the original background image to obtain a filling background image; performing blurring processing on the filling backgroundimage to obtain a blurred background image; and fusing the blurred background image and the foreground part of the to-be-blurred image to obtain a blurred image. According to the scheme, image blurring can be realized, and the halo problem is eliminated.

Owner:SHENZHEN SENSETIME TECH CO LTD

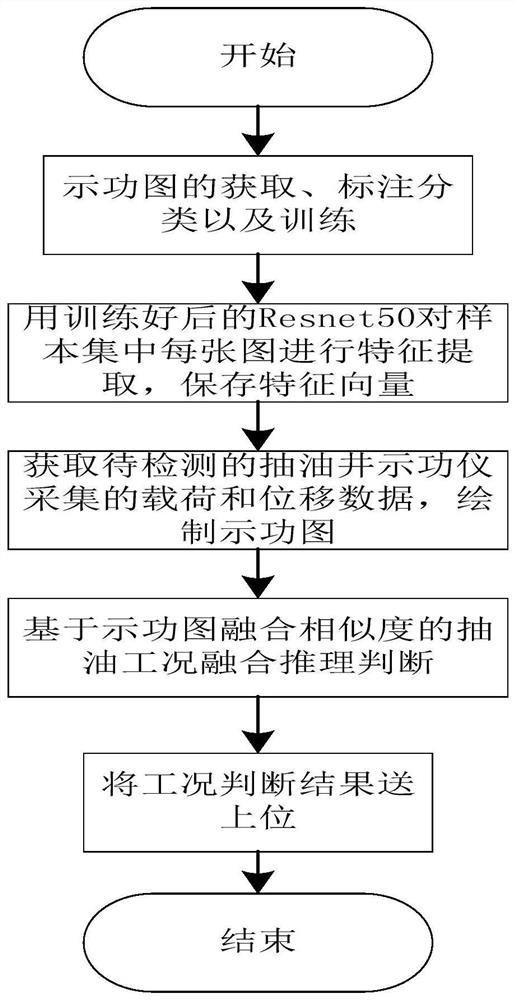

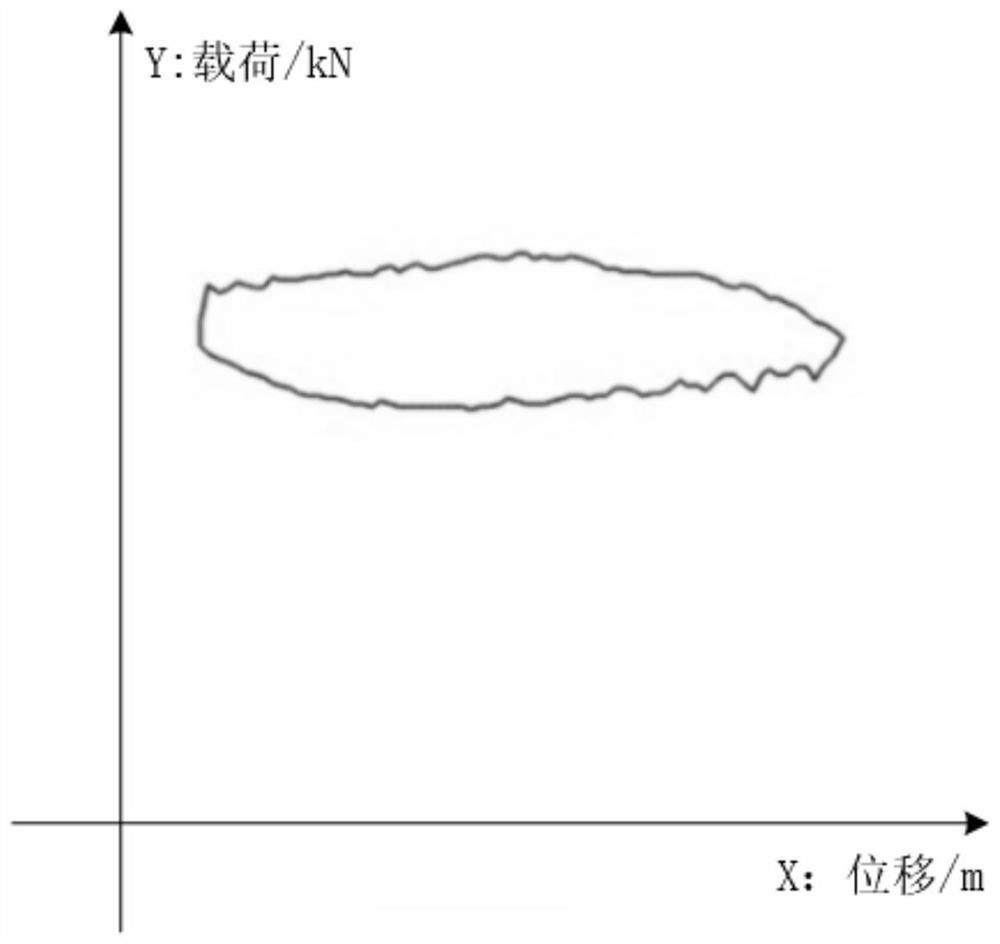

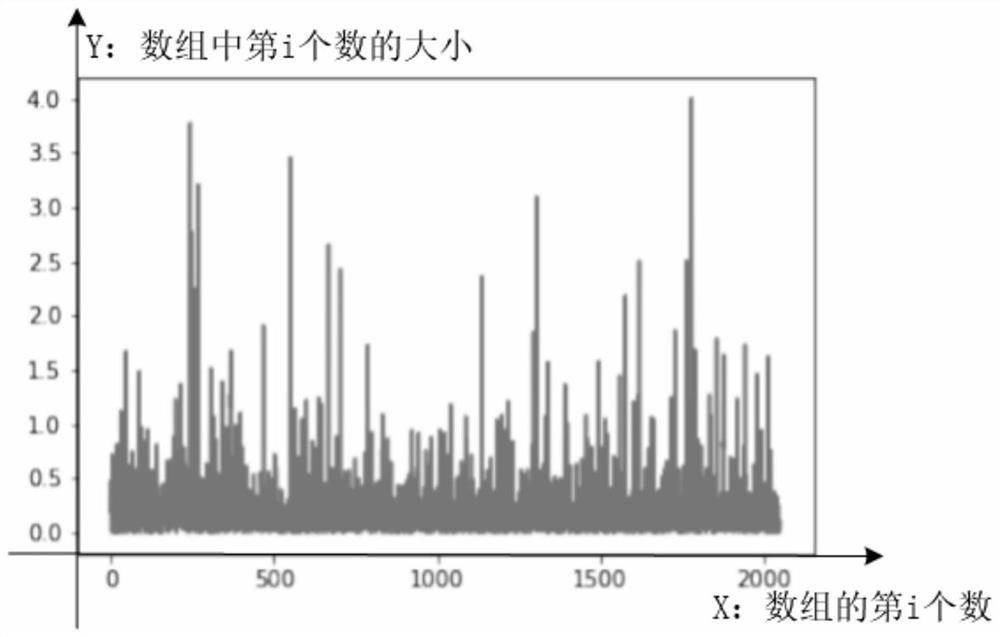

Oil pumping condition fusion reasoning identification method based on indicator diagram fusion similarity

PendingCN114581685AImprove recognition rateImprove recognition accuracyCharacter and pattern recognitionNeural learning methodsSample imageIdentification rate

The invention discloses an oil pumping condition fusion reasoning identification method based on indicator diagram fusion similarity. The method comprises the following steps: (1) indicator diagram acquisition, labeling classification and training; (2) performing feature extraction on each image in the sample set by using the trained Resnet50, and storing a feature vector; (3) acquiring load and displacement data acquired by a pumping well indicator to be detected, and drawing an indicator diagram; (4) oil pumping condition fusion reasoning judgment based on indicator diagram fusion similarity; and (5) sending a working condition judgment result to an upper position for display. A fusion similarity calculation method is provided. The similarity obtained based on the Pearson's correlation coefficient algorithm and the local Hash algorithm is fused according to certain steps, the advantages of the Pearson's correlation coefficient algorithm and the local Hash algorithm are brought into full play, the more reasonable similarity between the to-be-detected image and the sample image is obtained, and finally the recognition rate is effectively improved.

Owner:南京富岛油气智控科技有限公司

Instant pumpkin powder solar-assisted heat pump drying method

InactiveCN107495082AOvercome IntermittentOvercome volatilityFood sciencePretreatment methodDrying time

The invention discloses an instant pumpkin powder solar-assisted heat pump drying method. The method takes fresh pumpkins as a raw material and comprises the following steps: carrying out selection, pretreatment and ultrasonic wave-blanching pretreatment, then achieving safety water content by virtue of a solar-assisted heat pump combined drying method, enabling water content of dry basis to be below 10wt%, and finally carrying out drying kinetic analysis and process optimization study. The method disclosed by the invention applies the ultrasonic wave-blanching pretreatment method and a solar-assisted heat pump combined drying technique and has the advantages of good enzyme deactivation effect, shortened drying time, energy conservation, low cost, easy operation and no pollution, loss of nutrient substances and influence on color of pumpkin powder can be reduced to the utmost extent, related qualities such as color, fragrance and taste of instant pumpkin powder are maintained, large-scale energy-saving processing and production are realized, and the pumpkin powder which is full of nutrients and fine in taste is obtained.

Owner:FUJIAN AGRI & FORESTRY UNIV

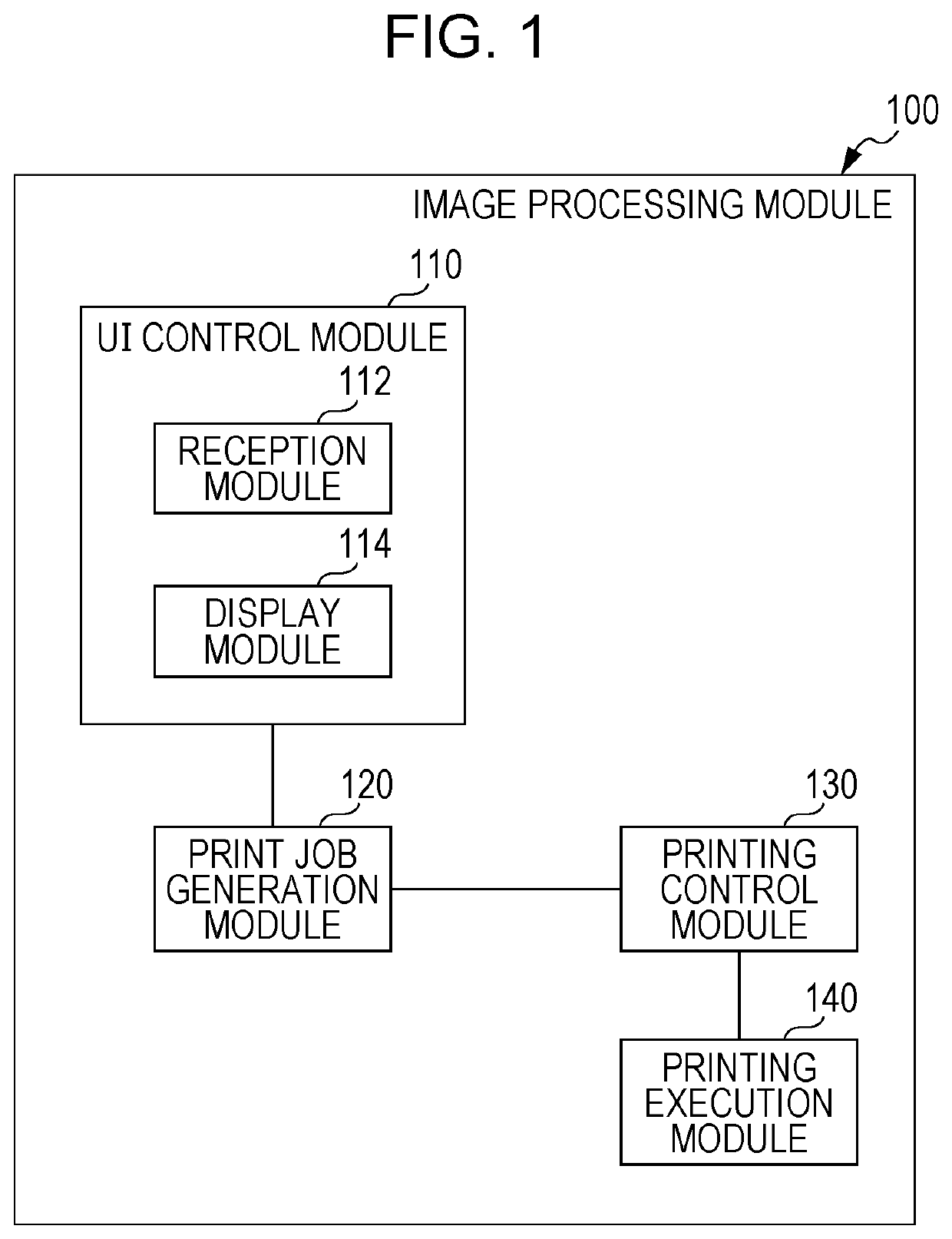

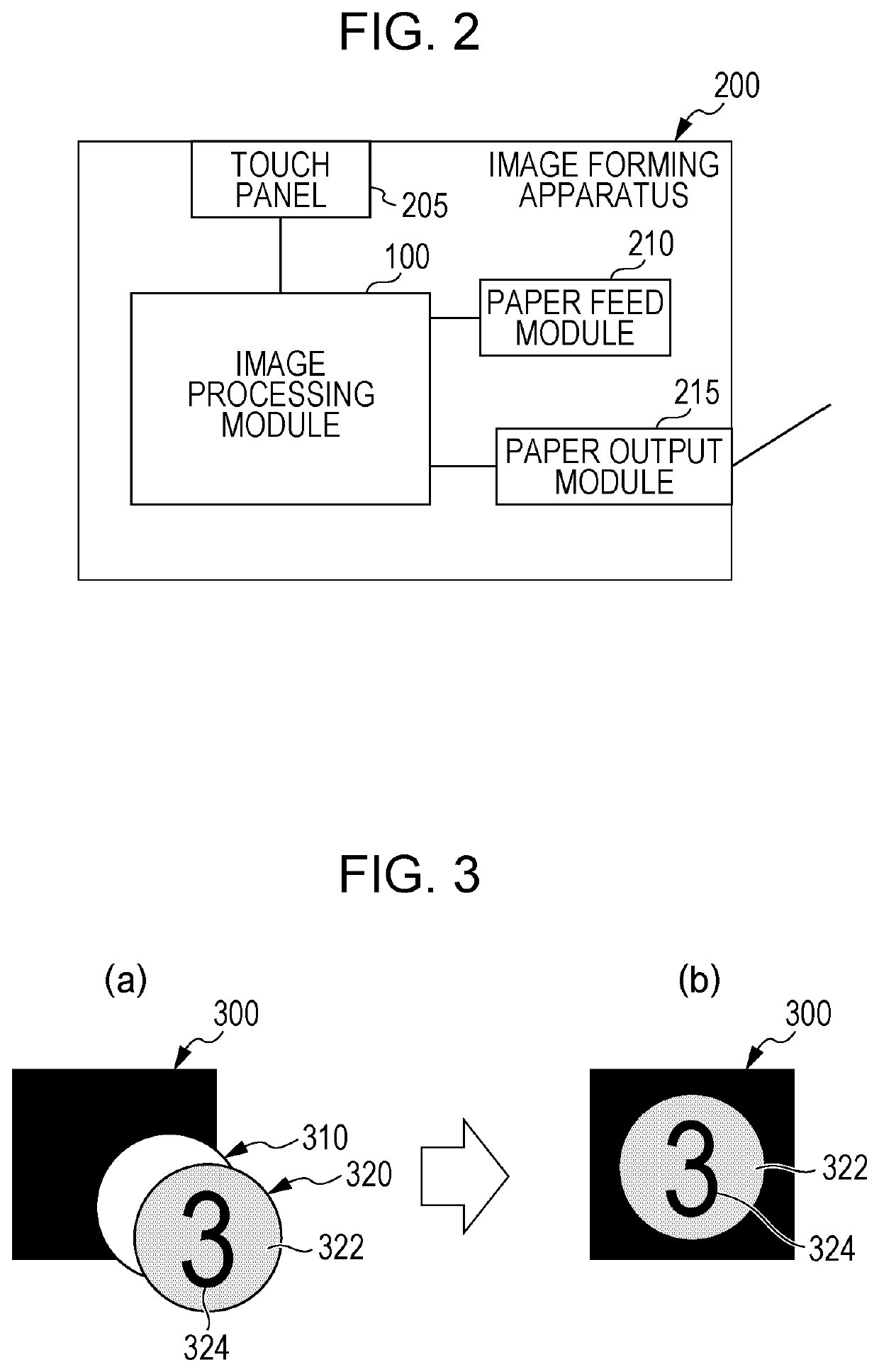

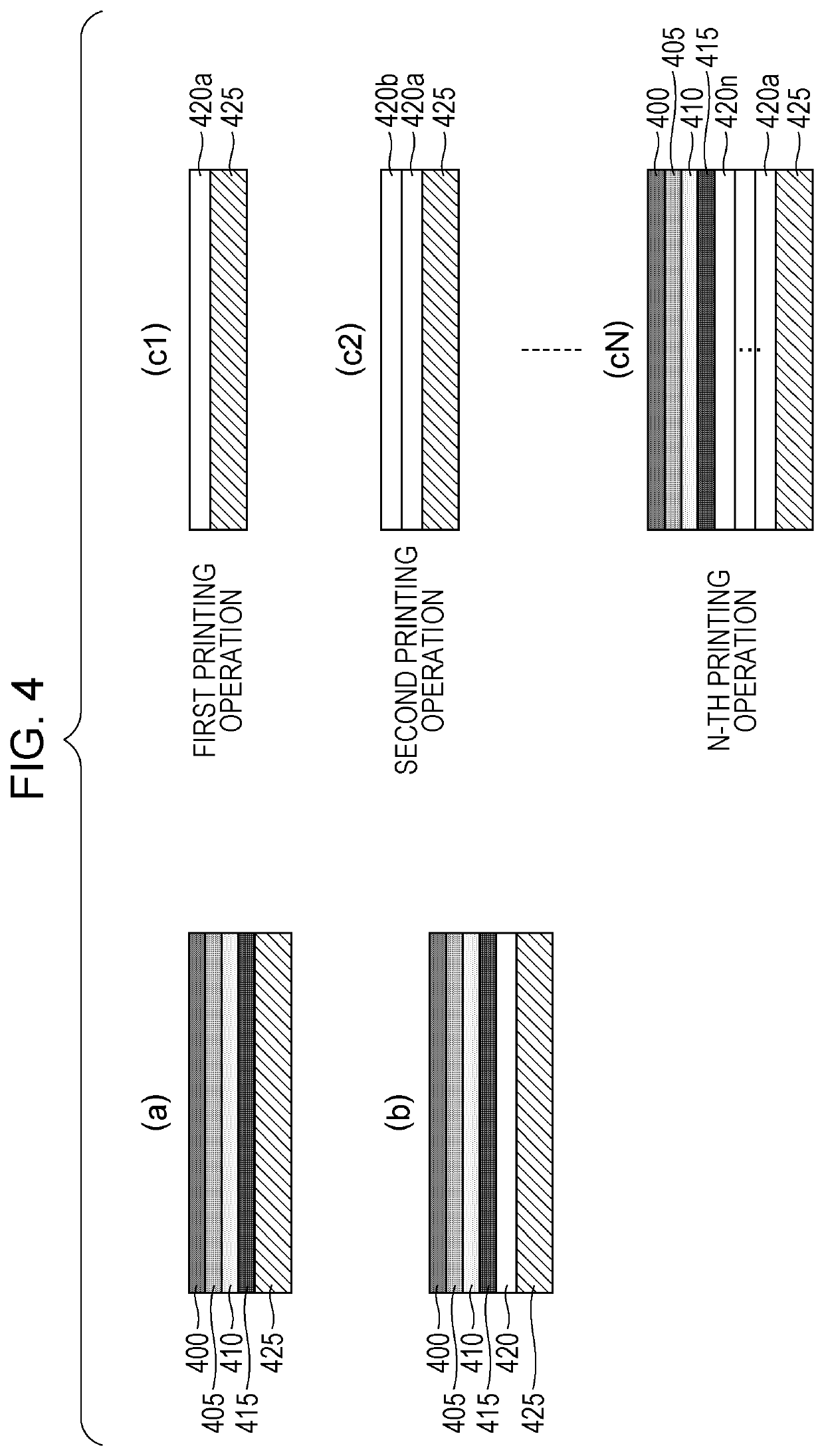

Image processing apparatus, non-transitory computer readable medium, and method for processing image

InactiveUS20190347052A1Reduce the impactReduce the effect of colorDigital output to print unitsImaging processingComputer graphics (images)

An image processing apparatus includes a reception unit that receives specification for covering a color of a medium on which printing is to be performed, a generation unit that generates, using the specification, a print job for additional printing, in which a same color is printed plural times, and a control unit that controls a printing process in accordance with the print job generated by the generation unit.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Yellowing resistant modified acrylic automotive coating

The invention relates to the field of water-based automotive coatings and discloses a yellowing resistant modified acrylic automotive coating. The automotive coating contains the following componentsin parts by weight: 35-45 parts of acrylic resin, 5-10 parts of epoxy resin, 3-5 parts of a hydroxypropyl cycloacrylate, methyl acrylate and lauryl acrylate copolymer, 1-3 parts of an anti-settling agent, 1-2 parts of a flatting agent, 1-2 parts of an antifoaming agent, 2-4 parts of a dry promoter, 0.1-0.5 part of barium sulfate and 20-30 parts of deionized water, wherein the hydroxypropyl cycloacrylate, methyl acrylate and lauryl acrylate copolymer is prepared from a solution polymer; and a weight ratio of the hydroxypropyl cycloacrylate to methyl acrylate to lauryl acrylate is 1:(1-2):(0.2-0.5). The invention aims to provide the yellowing resistant modified acrylic automotive coating with excellent advantages of fullness, glossiness, hardness, solvent resistance, weather resistance and resistance to discoloring and yellowing during high-temperature baking.

Owner:英德市仕曼奇化学工业有限公司

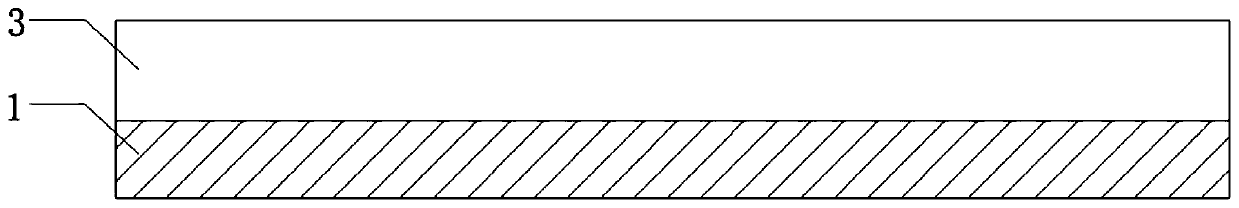

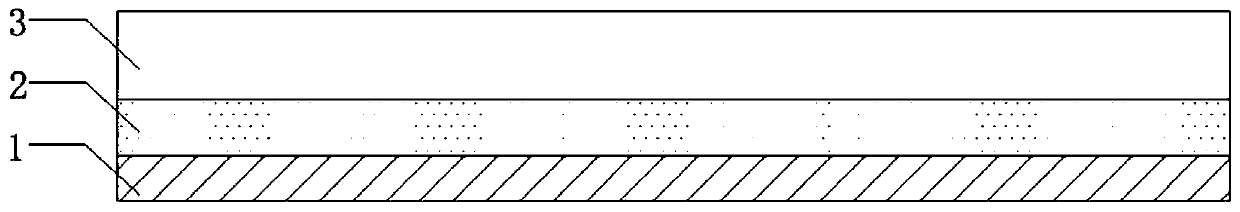

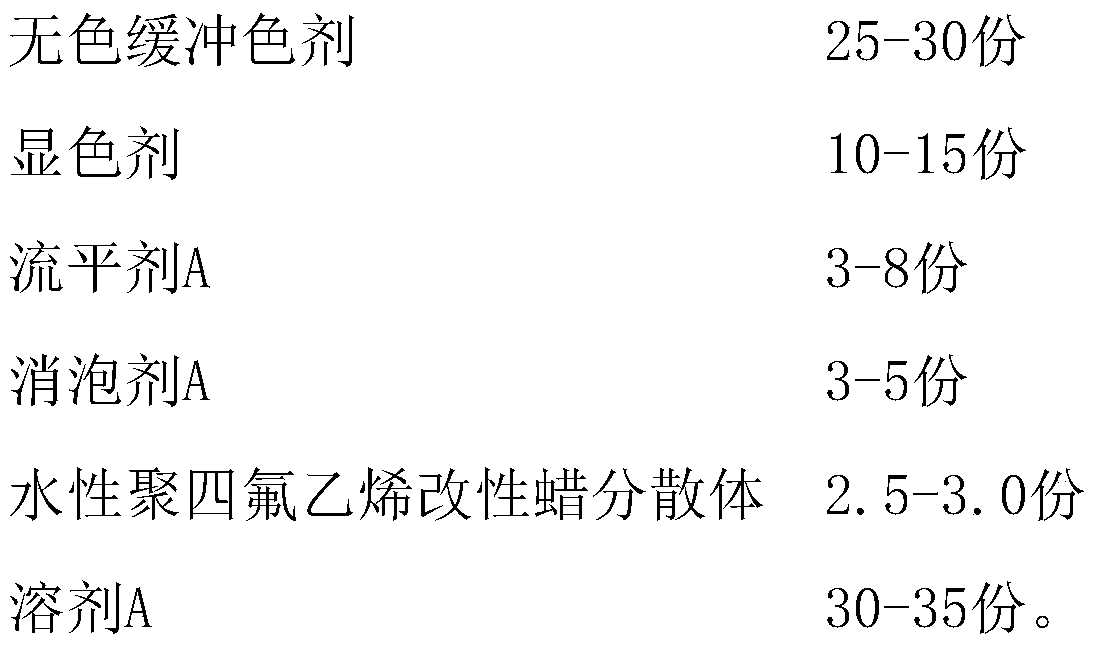

Bottom blue-developing thermosensitive label and preparation method thereof

ActiveCN110379293AGood dispersionBroaden applicationStampsPaper/cardboard articlesHigh volume manufacturingSolvent

The invention relates to the technical field of thermosensitive labels, in particular to a bottom blue-developing thermosensitive label and a preparation method thereof. The bottom blue-developing thermosensitive label comprises a bottom layer and a dye layer which are sequentially arranged from bottom to top, wherein the bottom layer is carbon-source-free paper, and the dye layer is made of developing dye; the color development dye comprises the following raw materials in parts by weight: 25-30 parts of a colorless buffer toner, 10-15 parts of a color developing agent, 3-8 parts of a flattingagent A, 3-5 parts of a defoamer A, 2.5-3.0 parts of an aqueous polytetrafluoroethylene modified wax dispersion, and 30-35 parts of a solvent A. The dye layer of the bottom blue-developing thermosensitive label can change the color developing of the printed characters in a printing state of a thermosensitive printer, can improve the withered monotonous sense of only single black characters at present and can improve the color development effect. The preparation method of the bottom blue-developing thermosensitive label has the advantages of the simple operation, the easy control, the high production efficiency and the stable quality, and can be used for mass production.

Owner:GUANGDONG TENGEN IND GRP CO LTD

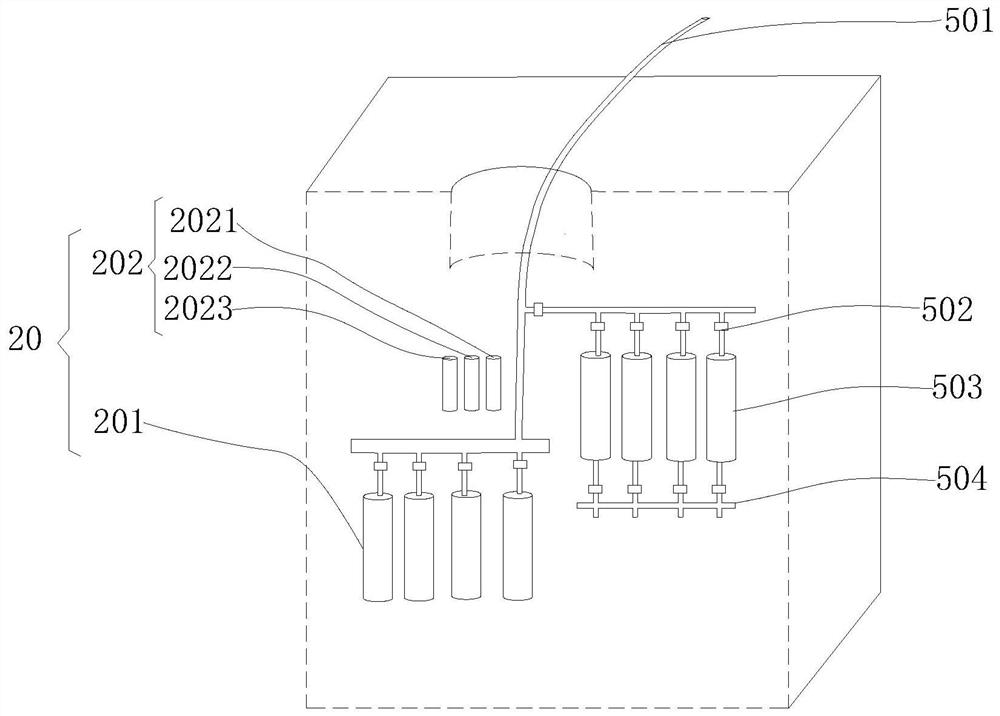

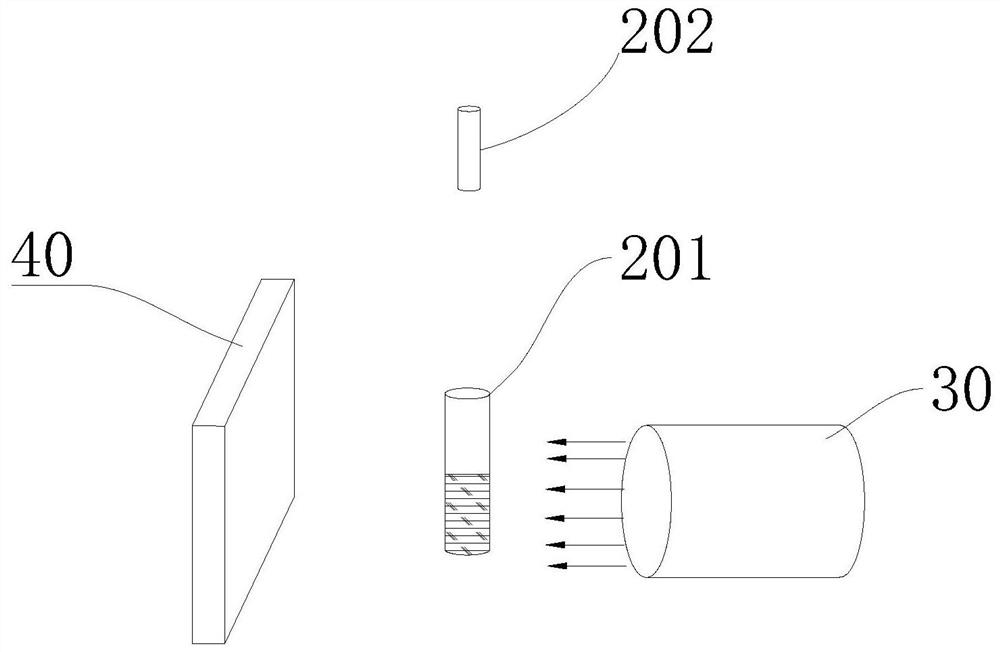

Total phosphorus detection equipment and method

PendingCN113820305ASimplified processing stepsSimple processMaterial analysis by observing effect on chemical indicatorEngineeringColor processing

The invention provides total phosphorus detection equipment. The total phosphorus detection equipment comprises a shell, a reaction module, a lighting module, a detection module and a sampling module, the reaction module and the detection module are arranged in the shell, the sampling module penetrates through the shell and is connected with the reaction module, and the detection module and the illumination module are arranged at the two opposite ends of the reaction module; the reaction module comprises a test tube and a reagent, the illumination module emits light to irradiate the test tube, the light penetrates through the test tube and irradiates the detection module, and the detection module detects the color RGB value of the light at the moment; compared with the prior art, color processing is carried out on the reaction result in the reaction module through the detection module, the color RGB value is obtained, many subsequent processing steps such as high-temperature reaction can be omitted, and the technological process and the equipment structure in the prior art are simplified; the invention further provides a total phosphorus detection method which is suitable for the total phosphorus detection equipment.

Owner:盈奇科技(深圳)有限公司

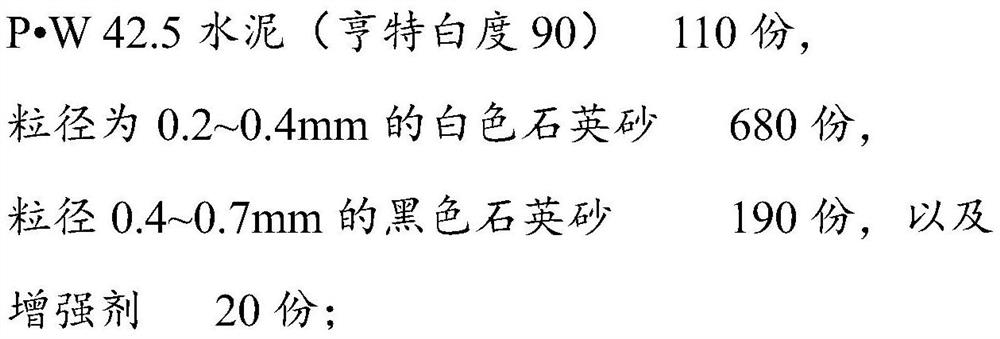

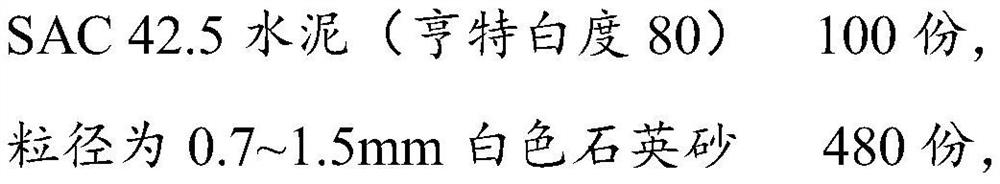

A high-strength water-permeable stone slab and its preparation method

The invention belongs to the field of building materials, and in particular relates to a high-strength water-permeable stone plate and a preparation method thereof. The high-strength water-permeable stone slab provided by the present invention is formed by mixing and pressing various raw materials, and the raw materials include cement, aggregate, and reinforcing agent in specific weight parts; wherein the cement is selected from Hunter whiteness > 70 and strength grade not less than 42.5 Silicate or sulphoaluminate cement; reinforcing agents include limestone powder, vitrified microbeads, mineral powder, thickener, powder polycarboxylate water reducer, coagulation regulator and quartz sand in specific proportions. The colored stone board is formed by pressing and curing after adding a specific reinforcing agent. It does not need to add a surface retarder. The production efficiency is high, and it can improve the wrapping uniformity of the slurry and the aggregate. The grinding performance is better.

Owner:湖北路城建设科技有限公司

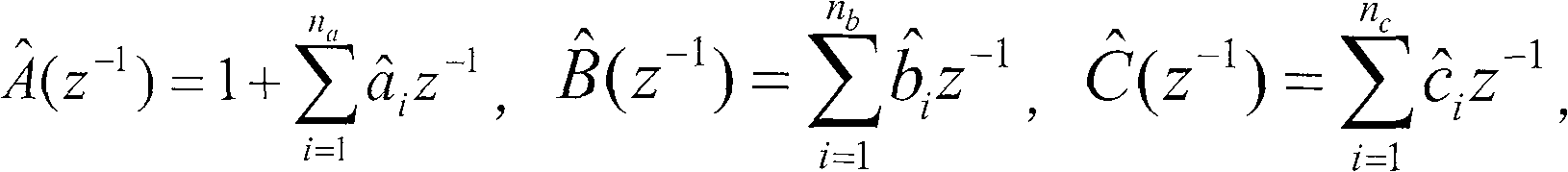

Robust multivariable predicting control method based on uncertain color model

InactiveCN100595701CGuaranteed stabilityReduce the effect of colorTextile treatment machine partsAdaptive controlAlgorithmData acquisition

This invention relates to one dye machine module formula multi-variable prediction robust bar H infinity control method, which determines one dye machine mode formula multiple step prediction robust Hinfinity control method through data collection, process resolution, prediction control, robust H infinity control technique; using the control method to reduce uncertain factors color impact.

Owner:HANGZHOU DIANZI UNIV

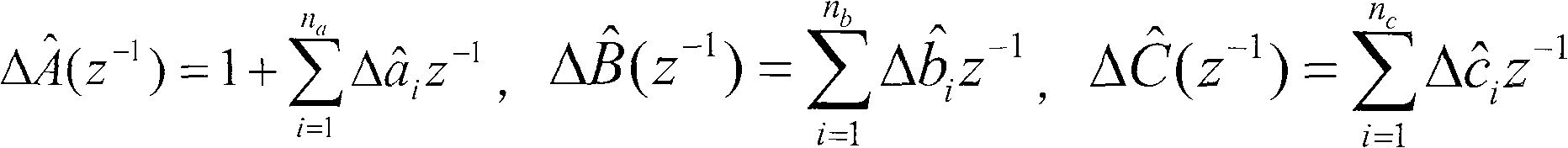

Zipper manufacturing method and zipper

PendingCN112641176AThe printing and dyeing process will not greatly affectReduce manufacturing costSlide fastenersDyeing processDark colorMechanical engineering

The invention provides a manufacturing method of a zipper and the zipper, and the manufacturing method of the zipper comprises the following steps: S1, processing a cloth belt, weaving the cloth belt by using dark-color original lines, and arranging a side edge part on one side of the cloth belt in the width direction of the cloth belt; S2, machining a tooth chain belt; S3, fixing the tooth chain belt to the side edge part of the cloth belt, and obtaining a to-be-machined product; and S4, printing and dyeing the to-be-processed product, wherein the printing and dyeing color is different from the color of the cloth belt. The cloth belt is formed by weaving the dark-color original lines, so that the cloth belt has the same color as the original lines and is also in a dark color, the color of the cloth belt is not greatly influenced by printing and dyeing dyes in the subsequent printing and dyeing process, and meanwhile, the tooth chain belt is printed and dyed into an expected color. Therefore, the finished products of the cloth belts and the tooth chain belts with different colors can be manufactured, compared with the prior art, the manufacturing process is greatly simplified, waste parts do not exist, and then the manufacturing cost of the zipper is greatly reduced.

Owner:DALIAN YKK ZIPPER CO LTD

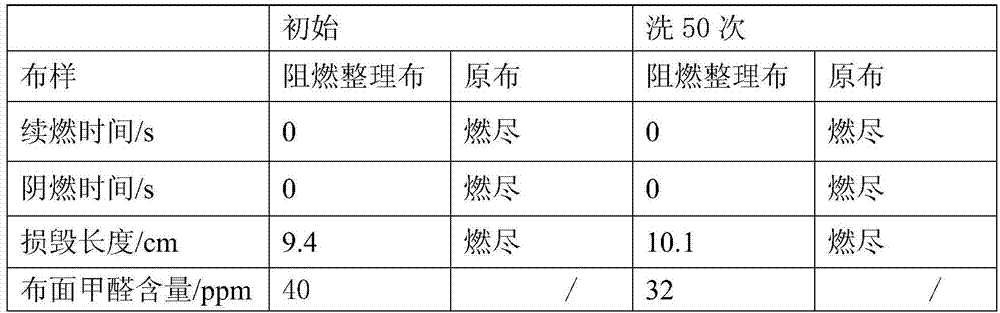

Cotton/nylon blended fabric durable fireproof finishing method and dyeing method

ActiveCN105200768BGood durable fire performanceFeel comfortableDyeing processVegetal fibresNylon materialNylon 6

The invention provides a cotton / nylon blended fabric endurable and fire resistant finishing method and a staining method. The finishing method comprises the following steps: (1) adopting initial bath finishing liquor to perform pad-roll treatment on a cotton / nylon blended fabric, wherein the initial bath finishing liquor comprises at least one type of phosphorus-containing compound, at least one type of nitrogen-containing compound, at least one type of softening agent and at least one type of oxidizing agent; (2) adopting second bath finishing liquor to perform pad-roll treatment on the cotton / nylon blended fabric subjected to the treatment of the initial bath finishing liquor, wherein the second bath finishing liquor comprises at least one type of phosphorus-containing compound, at least one type of nitrogen-containing compound and at least one type of cross-linking agent; (3) adopting third bath finishing liquor to perform pad-roll treatment on the cotton / nylon blended fabric subjected to the treatment of the second bath finishing liquor, wherein the third bath finishing liquor comprises at least one type of oxidizing agent, at least one type of formaldehyde catcher and at least one type of softening agent. The method has the advantages of enabling the fabric to have excellent endurance and fire resistance, comfort hand feeling, and good color consistence.

Owner:DYMATIC CHEM

Low-chromatic-aberration wine red PE color master batch and preparation method thereof

InactiveCN109942948AAchieve color effectReduce the effect of colorBuilding insulationsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a low-chromatic-aberration wine red PE color master batch. The PE color master batch contains the following components in percentage by weight: 25%-35% of PE, 5%-10% of shells,1%-2% of 90# petroleum asphalt, 8%-10% of high-purity ferric oxide, 15%-20% of a dispersing aid and the balance of linear low density polyethylene. By utilizing the combination of the petroleum asphalt and high-purity ferric oxide, the wine red effect is achieved; the petroleum asphalt and shell powder are combined and roasted, and the petroleum asphalt completely penetrates into the shell powderand is melted with the shell powder together, so that the influence caused by the addition amount of the petroleum asphalt to the color can be reduced; and an original petroleum asphalt+high-purity ferric oxide (liquid+solid) mode is adjusted into a shell powder+high-purity ferric oxide (solid+solid) mode, so that the dispersion effect is relatively good, and the chromatic aberration is effectively reduced.

Owner:安徽索克医用科技发展有限公司

Displays

ActiveUS10957279B2Sufficient visibilityImprove visibilityCathode-ray tube indicatorsColor television detailsComputer graphics (images)Radiology

Owner:BAE SYSTEMS PLC

A method for improving the quality of tobacco leaves

The invention provides a method for improving the quality of tobacco leaves, including: the withering period, the yellowing period, the fixed color period, the fermentation period and the dry gluten period, and the withering period, the yellowish period, the fixed color period and the dry tendon period are strictly controlled Air humidity, sugarcane leaf polysaccharide extract was sprayed during the fermentation period. The invention controls the air-drying process in a standardized manner and sprays the sugarcane leaf polysaccharide extract to reduce the bad smell in the air-dried tobacco and improve the sensory quality of the air-dried tobacco.

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com