Cotton/nylon blended fabric durable fireproof finishing method and dyeing method

A technology for blended fabrics and fire-resistant finishing, applied in dyeing, textile and papermaking, fiber processing, etc., can solve the problems of limiting the application scope of fire-resistant cotton/nylon blended fabrics, poor fire-resistance durability, and poor hand feel. Effect of fabric color impact, comfortable hand, good color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

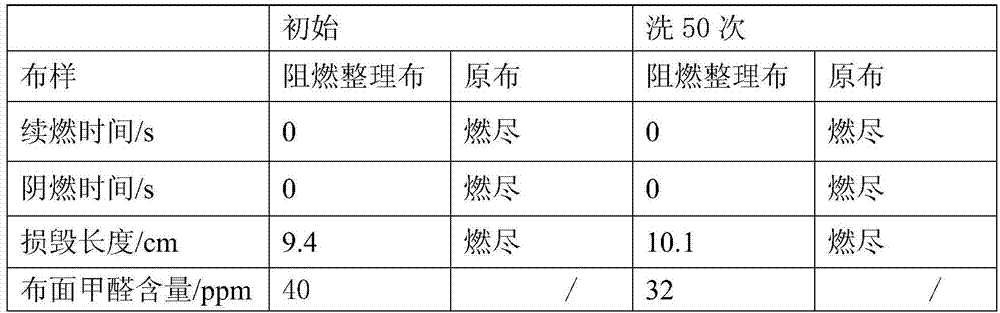

Examples

Embodiment 1

[0044] The selected cotton / nylon blended fabric is cotton / nylon 6 blended fabric, and the weight per square meter of the fabric is 273g / m 2 . In this blended fabric, the content of nylon 6 is 45%, and the content of cotton is 55%.

[0045] The first bath finishing liquid is: tetrahydroxymethyl phosphonium salt and urea initial contraction (THPC-U) 308g / L, N-hydroxymethyl-3-(dimethoxyphosphono)propionamide (Pyrovatex CP) 62g / L, flame retardant DM-3070107g / L, cyclic phosphate ester 33g / L, N-methylolacrylamide 31g / L, urea 88g / L, polysiloxane emulsion 30g / L, nitro-p-toluene Sodium sulfonate 55g / L. The first-bath finishing solution was applied to the above-mentioned cotton / nylon blended fabric by padding, dried at 100° C., and baked at 160° C. for 2.5 minutes.

[0046] The second bath finishing solution is: tetrahydroxymethyl phosphonium salt and ammonia precondensate (THPN) 234g / L, flame retardant DM-307092g / L, cyclic phosphate (that is, bicyclic phosphite and phosphonate conde...

Embodiment 2

[0055] The selected cotton / nylon blended fabric is cotton / nylon 66 blended fabric, and the weight per square meter of the fabric is 298g / m 2 . In this blended fabric, the content of nylon 66 is 65%, and the content of cotton is 35%.

[0056] The first bath finishing solution is: pre-condensed product of tetrahydroxymethyl phosphonium salt and ammonia (THPN) 315g / L, tetrahydroxymethyl phosphonium salt (THPC) 55g / L, flame retardant DM-307090g / L, cyclic Phosphate ester 20g / L, N-methylolacrylamide 25g / L, urea 62g / L, polysiloxane emulsion 30g / L, sodium nitro-p-toluenesulfonate 50g / L. The first-bath finishing solution was applied to the above-mentioned cotton / nylon blended fabric by padding, dried at 100° C., and baked at 160° C. for 2.5 minutes.

[0057] The second bath finishing solution is: the initial contraction body (THPS-U) of tetrahydroxymethylphosphonium salt and urea (THPS-U) 245g / L, flame retardant DM-307085g / L, N-hydroxymethyl-3-(dimethoxy Phosphono) propionamide (Pyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com