A flame retardant finishing method of cotton/nylon blended fabric

A technology of flame retardant finishing and blended fabrics, applied in textiles and papermaking, plant fibers, fiber processing and other directions, can solve the problems of large odor of finished products, lack of fabric comfort and freedom of movement, and no use value, and achieve comfortable hand feel , the effect of good durable fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

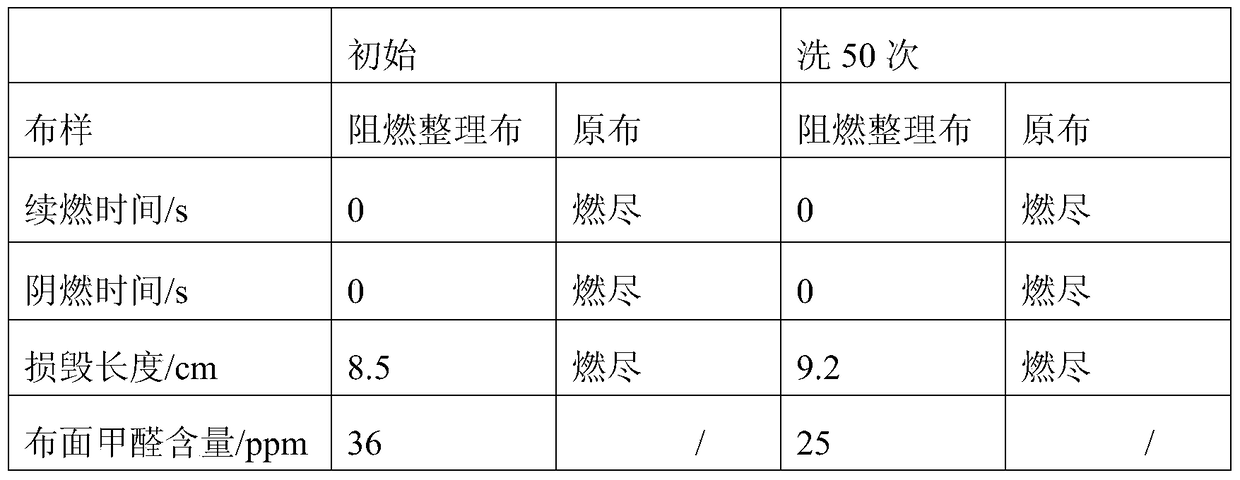

Embodiment 1

[0042] In the present embodiment, the selected fabric is cotton / nylon 6 blended fabric, and the fabric weight per square meter is 232g / m 2 . The content of nylon 66 in the blended fabric is 50%, and the content of cotton is 50%.

[0043] The specific arrangement method is as follows:

[0044](1) The first bath finishing liquid is: 30 g / L of oxidized polyethylene wax emulsion, 20 g / L of hydrophilic polysiloxane emulsion, and 50 g / L of sodium m-nitro-p-toluenesulfonate. The first-bath finishing solution was applied to the above-mentioned blended fabric by padding, and then dried at 60°C.

[0045] (2) The second bath finishing solution is: 350g / L of tetrahydroxymethylphosphonium salt and urea initial shrinkage body (THPS-U), flame retardant DM-307080g / L, cyclic phosphate ester 50g / L, carbamoyl Hydrazine 30g / L, urea 40g / L, etherified 2D resin 20g / L. The second-bath finishing solution was applied to the blended fabric after the first-bath finishing by padding, and then dried at...

Embodiment 2

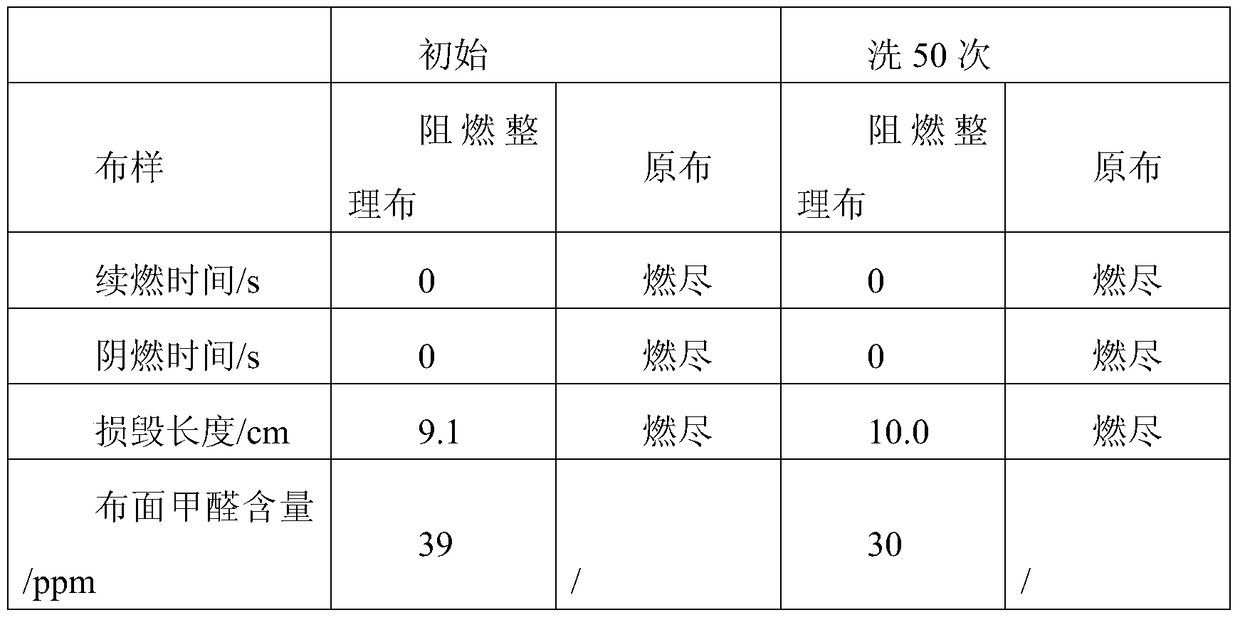

[0053] In the present embodiment, the selected fabric is cotton / nylon 66 blended fabric, and the fabric weight per square meter is 305g / m 2 . In this blended fabric, the content of nylon 66 is 60%, and the content of cotton is 40%.

[0054] The specific arrangement method is as follows:

[0055] (1) The first bath finishing solution is: bis(oleyl carboxyethyl) hydroxyethyl methyl sulfate ammonium salt 20g / L, hydrophilic polysiloxane emulsion 30g / L, m-nitro-p-toluenesulfonic acid Sodium 30g / L, sodium m-nitrobenzenesulfonate 30g / L. The first-bath finishing solution was applied to the above-mentioned blended fabric by padding, and then dried at 60°C.

[0056] (2) The second bath finishing solution is: tetrakis hydroxymethyl phosphonium salt and urea initial contraction body (THPC-U) 400g / L, flame retardant DM-307080g / L, N-hydroxymethyl-3-(dimethyl Oxyphosphono) propionamide 50g / L, cyclic phosphate ester 60g / L, N-methylolacrylamide 20g / L, urea 50g / L, etherified 2D resin 10g / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com