High-stiffness and difficult-to-break degradable environment-friendly lunch box and preparation method thereof

A high-stiffness, lunch box technology, applied in sustainable manufacturing/processing, boxes, climate sustainability, etc., can solve problems such as non-compliance with development requirements, consumption of natural resources, insufficient degradation, etc., to shorten the degradation cycle, Improve stability and avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

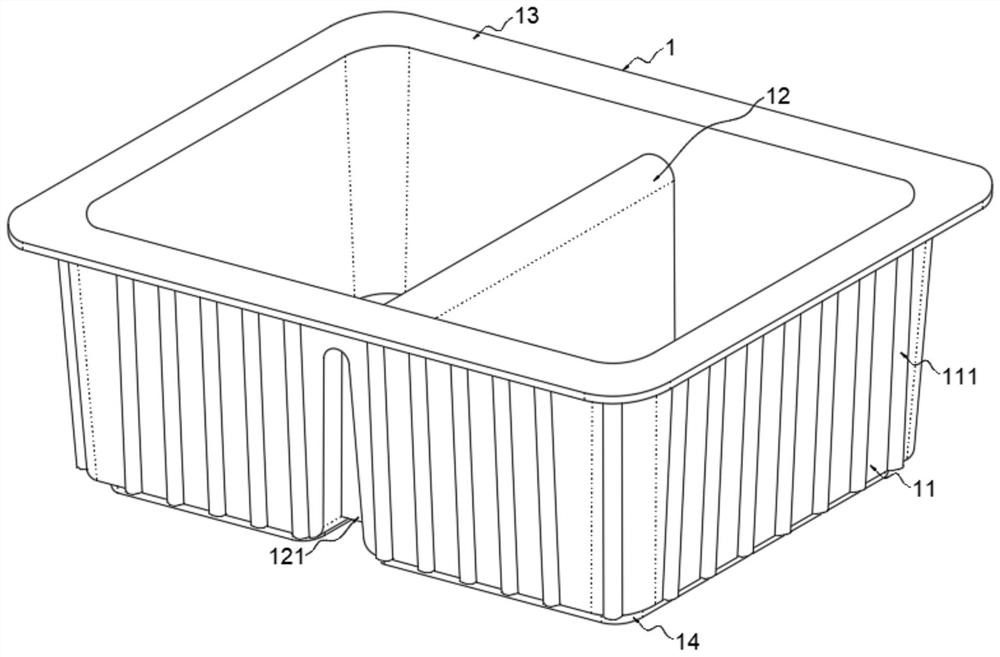

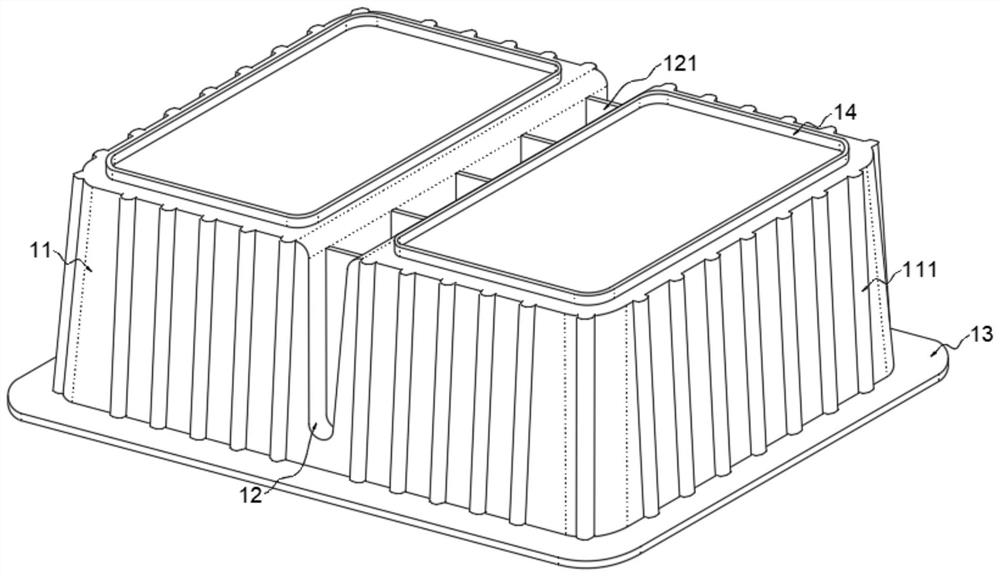

[0054] Such as Figure 1-2 As shown, the purpose of this embodiment is to provide a degradable environmentally friendly lunch box with high stiffness and not easy to break, including a lunch box body 1, which is integrally formed by high temperature molding, and the lunch box body 1 includes a box body 11, a number of reinforcing strips 111 are integrally formed at equal intervals on the outer wall of the box body 11, a number of separation grooves 12 are regularly provided in the middle of the box body 11, and a number of support plates 121 are arranged at equal intervals on the inner side of the concave surface of the separation groove 12, An upper edge ring 13 is provided on the outside of the top surface of the box body 11 , and a support ring 14 is provided on the bottom surface of the box body 11 .

[0055] In this embodiment, the inner side wall of the box body 11 is smooth and flat, which is convenient for storing food and taking food, avoiding small food or liquid foo...

Embodiment 2

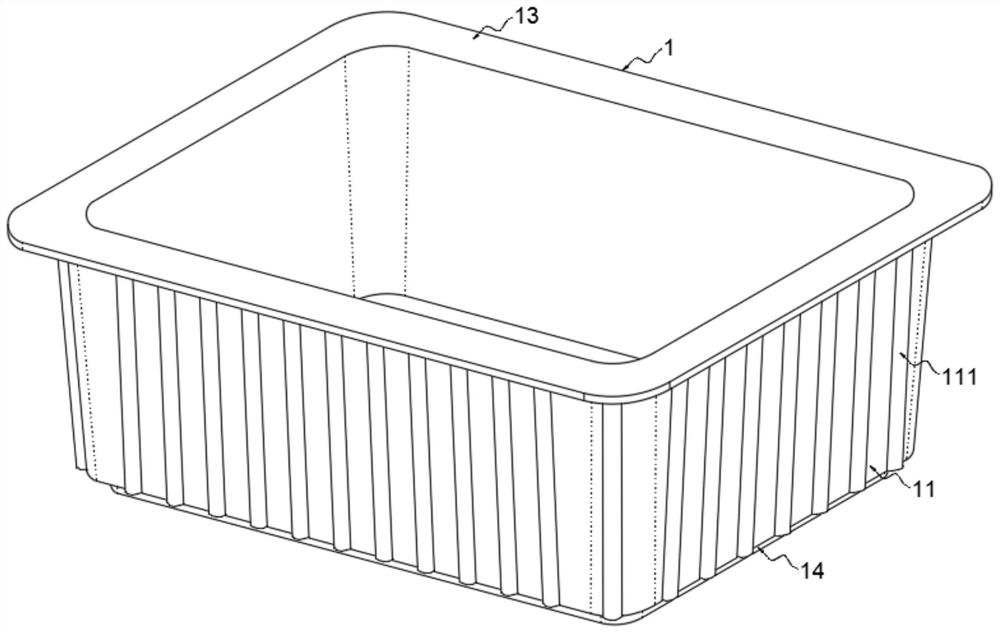

[0067] Such as Figure 3-4 As shown, the purpose of this embodiment is to provide a degradable environmentally friendly lunch box with high stiffness and not easy to break, including a lunch box body 1, which is integrally formed by high temperature molding, and the lunch box body 1 includes a box Body 11, a number of reinforcing strips 111 are integrally formed at equal intervals on the outer wall of the box body 11, an upper edge ring 13 is provided on the outside of the top surface of the box body 11, and a support ring 14 is provided on the bottom surface of the box body 11.

[0068] In this embodiment, the inner side wall of the box body 11 is smooth and flat, which is convenient for storing food and taking food, avoiding small food or liquid food remaining in the lunch box, reducing food waste, and avoiding discarded meals due to food residue. There is mold and odor in the box.

[0069] Furthermore, the reinforcing strips 111 are arranged along the up and down direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com