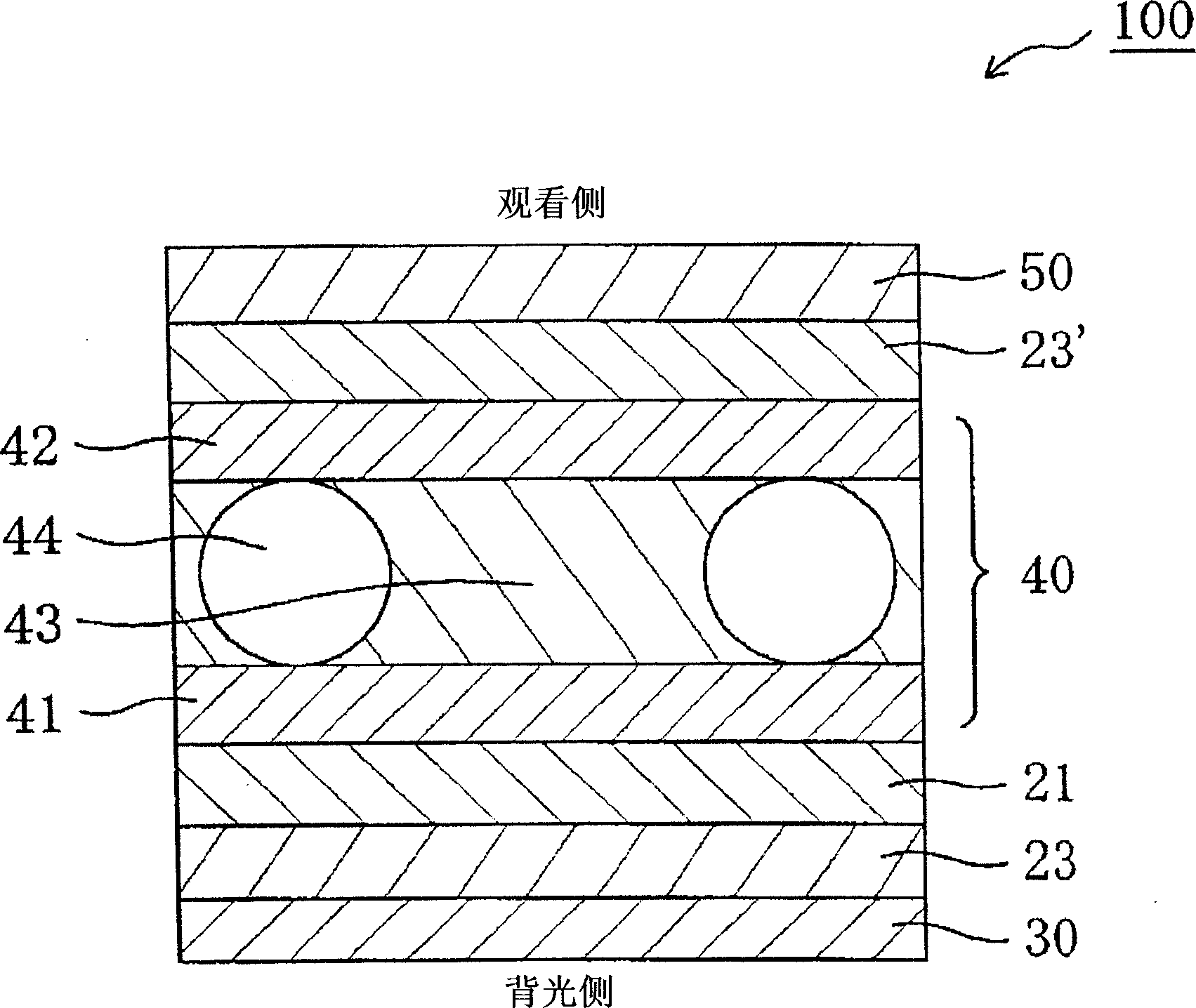

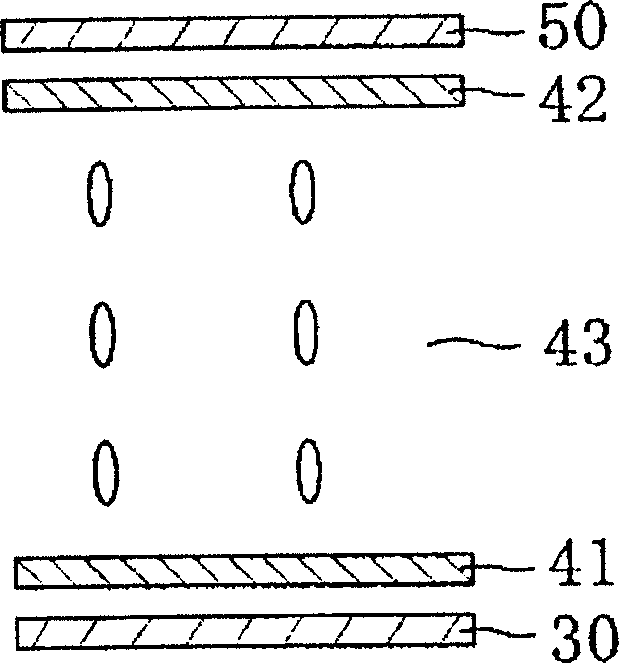

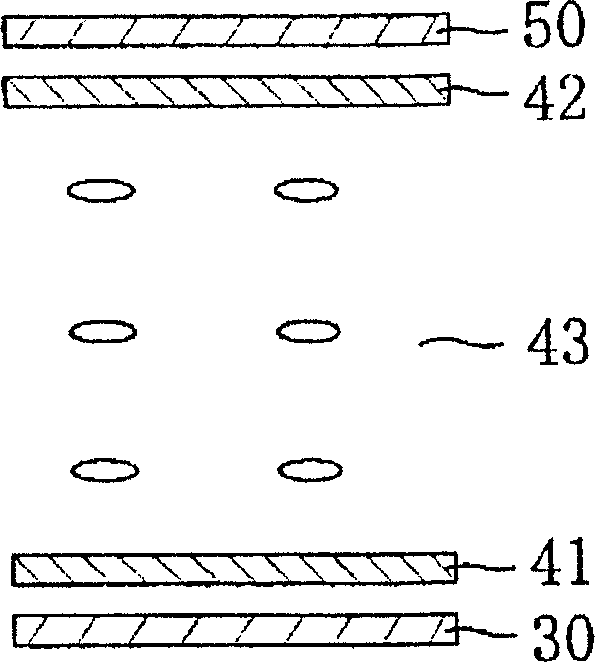

Liquid crystal panel and liquid crystal display apparatus

A liquid crystal panel, cellulose-based technology, applied in the field of liquid crystal panels and liquid crystal display devices, can solve the problems of reduced oblique contrast and increased color shift, and achieve the effects of small color shift, excellent oblique contrast, and excellent viewing angle compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The production method of the polarizer includes subjecting a polyvinyl alcohol-based resin film to a production process including a dyeing step, a crosslinking step, a stretching step, a washing step, and a drying step. In each step except the drying step, each treatment is carried out by immersing a polyvinyl alcohol-based resin in a bath containing a solution to be used in each step. The order and number of dyeing steps, crosslinking steps, stretching steps, washing steps, and drying steps, and implementation and omission of treatments can be appropriately set according to purposes, materials used, conditions, and the like. For example, several processes may be performed simultaneously in one step, or certain processes may be omitted. Specifically, stretching treatment may be performed after, before, or during dyeing treatment and crosslinking treatment, for example. In addition, for example, dyeing treatment is preferably performed before or after stretching treatme...

Embodiment 1

[0239] [Reference Example 1: Production of Cellulosic Film (1)]

[0240] Cyclopentanone was coated on polyethylene terephthalate, and then the whole was attached to a triacetyl cellulose film ("UZ-TAC", trade name, purchased from Fuji Film Industries, Ltd.) with a thickness of 40 μm. Co., Ltd., Re(590)=3nm, Rth(590)=40nm). The resultant was dried at 100° C. for 5 minutes, and after drying, the polyethylene terephthalate film was peeled off. Re(590) of the obtained cellulose-based film (1) was 0.2 nm and Rth(590) was 5.4 nm.

Embodiment 2

[0241] [Reference Example 2: Production of Cellulosic Film (2)]

[0242] The norbornene-based resin was dissolved in cyclopentanone to prepare a solution having a solid content of 20% by weight. This solution was applied to a triacetyl cellulose film ("UZ-TAC", trade name, purchased from Fuji Film Industry Co., Ltd., Re(590)=3 nm, Rth(590)=40 nm) with a thickness of 40 μm) On, the coating thickness is 150 μm. The resultant was dried at 140°C for 3 minutes, and after drying, the norbornene-based resin formed on the surface of the triacetylcellulose film was peeled off. Re(590) of the obtained cellulose-based film (2) was 1.1 nm and Rth(590) was 3.4 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com