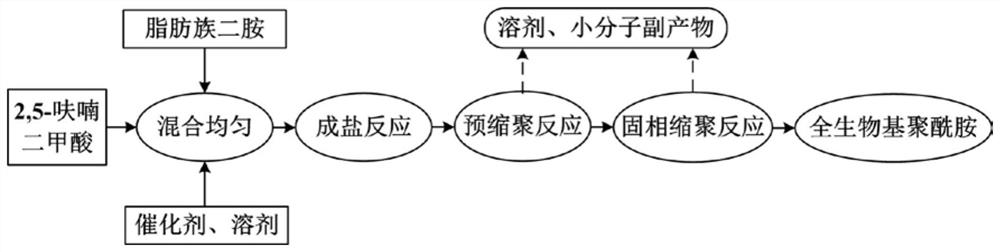

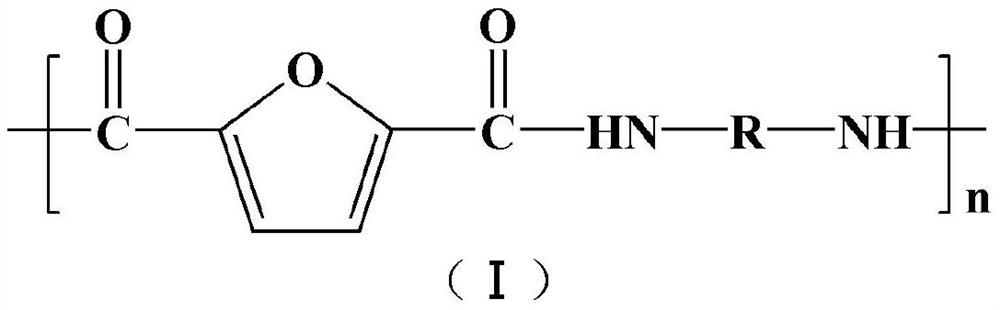

Full-bio-based polyamide and preparation method thereof

A bio-based polyamide and polyamide salt technology, which is applied in the field of chemical engineering, can solve the problems of increasing reaction steps and synthesis costs, the reaction rate and yield need to be improved, etc., and achieves abundant reserves, good reactivity and thermal stability, The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

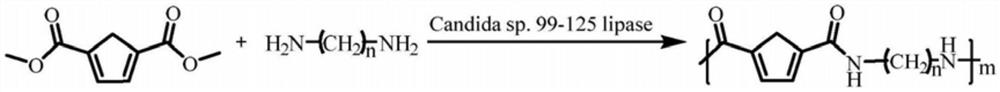

Method used

Image

Examples

Embodiment 1

[0053] The air in the stainless steel salt-forming reactor was replaced three times by vacuuming and nitrogen gas. Under the protection of nitrogen, 1 mol of bio-based monomer 2,5-furandicarboxylic acid and 1.15 mol of bio-based monomer 1,4 -Butanediamine, 258mg of phosphorous acid catalyst and 400mL of deionized water were added to the salt-forming reactor to obtain a mixture; start stirring to mix the above mixture evenly, set the stirring speed to 300rpm, and heat the above mixture to 60 °C, reacted for 60 minutes, and the pH of the solution was 7.7 after the reaction, and a polyamide salt solution with a mass fraction of 36% was obtained.

[0054] Then check the air tightness of the stainless steel polymerization kettle. After the inspection is complete, replace the air in the stainless steel reaction kettle three times. Under the protection of nitrogen, transfer the polyamide salt solution obtained before to the polymerization kettle, and first heat it to 195°C. The react...

Embodiment 2

[0058] The air in the stainless steel salt-forming reactor was replaced three times by vacuuming and nitrogen gas. Under the protection of nitrogen, 1 mol of bio-based monomer 2,5-furandicarboxylic acid and 1.10 mol of bio-based monomer 1,5 - Add pentamethylenediamine, 536mg of phosphorous acid catalyst and 500mL of ethanol into the salt-forming reactor to obtain a mixture; start stirring to mix the above mixture evenly, set the stirring speed to 350rpm, and heat the above mixture to 72°C under normal pressure, After 75 minutes of reaction, the pH of the solution was 7.4 after the reaction, and a polyamide salt solution with a mass fraction of 38% was obtained.

[0059] Then check the air tightness of the stainless steel polymerization kettle. After the inspection is complete, replace the air in the stainless steel reaction kettle three times. Under the protection of nitrogen, transfer the polyamide salt solution obtained before to the polymerization kettle, and first heat it t...

Embodiment 3

[0063] The air in the stainless steel salt-forming reactor was replaced three times by vacuuming and nitrogen gas. Under the protection of nitrogen, 1 mol of bio-based monomer 2,5-furandicarboxylic acid and 1.08 mol of bio-based monomer 1,6 - Add hexamethylenediamine, 145mg of sodium phosphite catalyst and 350mL of deionized water into the salt-forming reactor to obtain a mixture; start stirring to mix the above mixture evenly, set the stirring speed to 200rpm, and heat the above mixture to 90° C., reacted for 120 minutes, and the pH of the solution was 7.2 after the reaction, thereby obtaining a polyamide salt solution with a mass fraction of 42%.

[0064] Then check the air tightness of the stainless steel polymerization kettle. After the inspection is complete, replace the air in the stainless steel reaction kettle three times. Under the protection of nitrogen, transfer the polyamide salt solution obtained before to the polymerization kettle, and first heat it to 225 ° C. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com