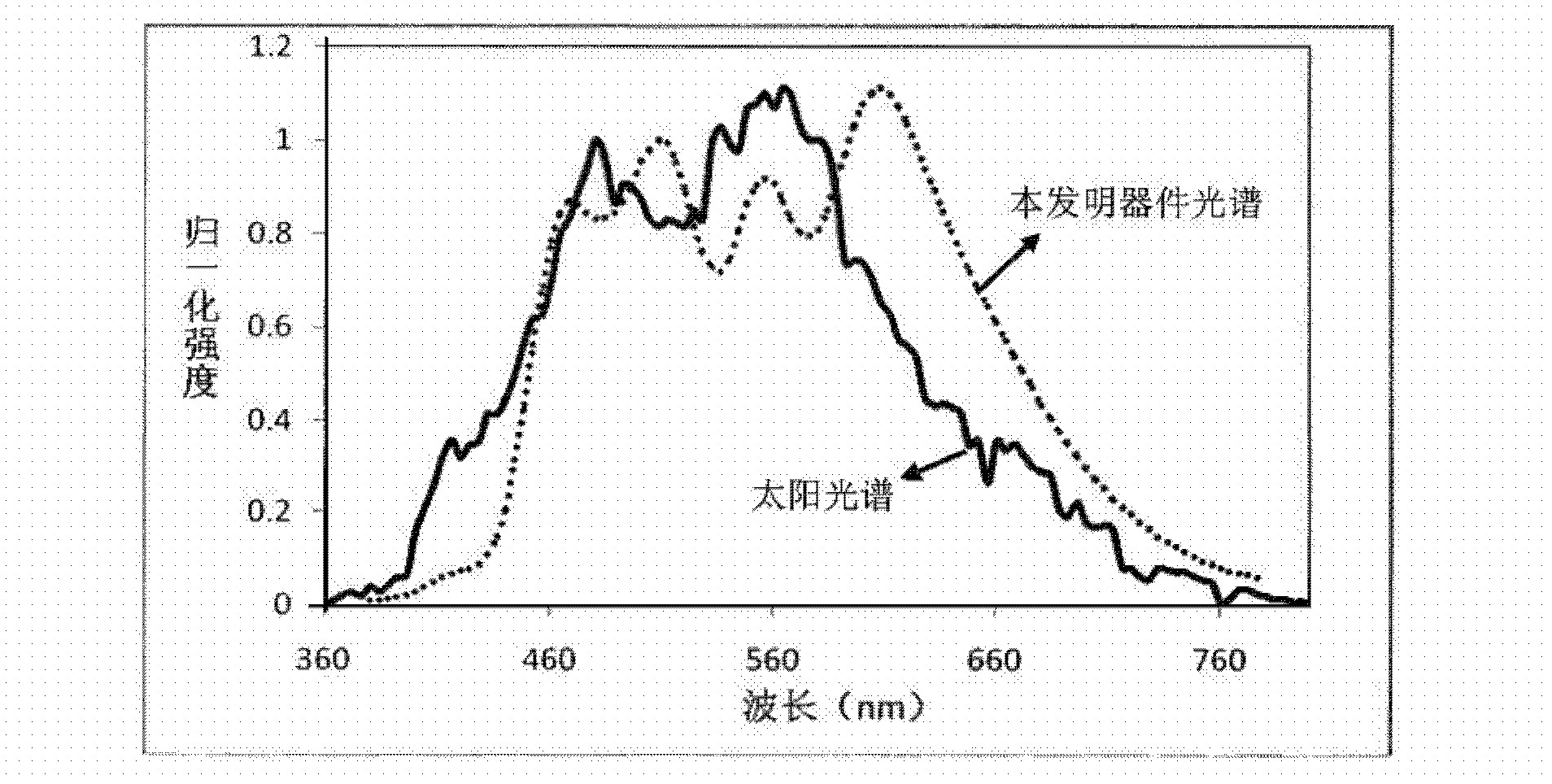

Preparing method for organic white LED illumination light source with high color-rendering index and adjustable color temperature

A LED lighting and high color rendering technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as inability to achieve white light, poor heat dissipation, and uneven light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

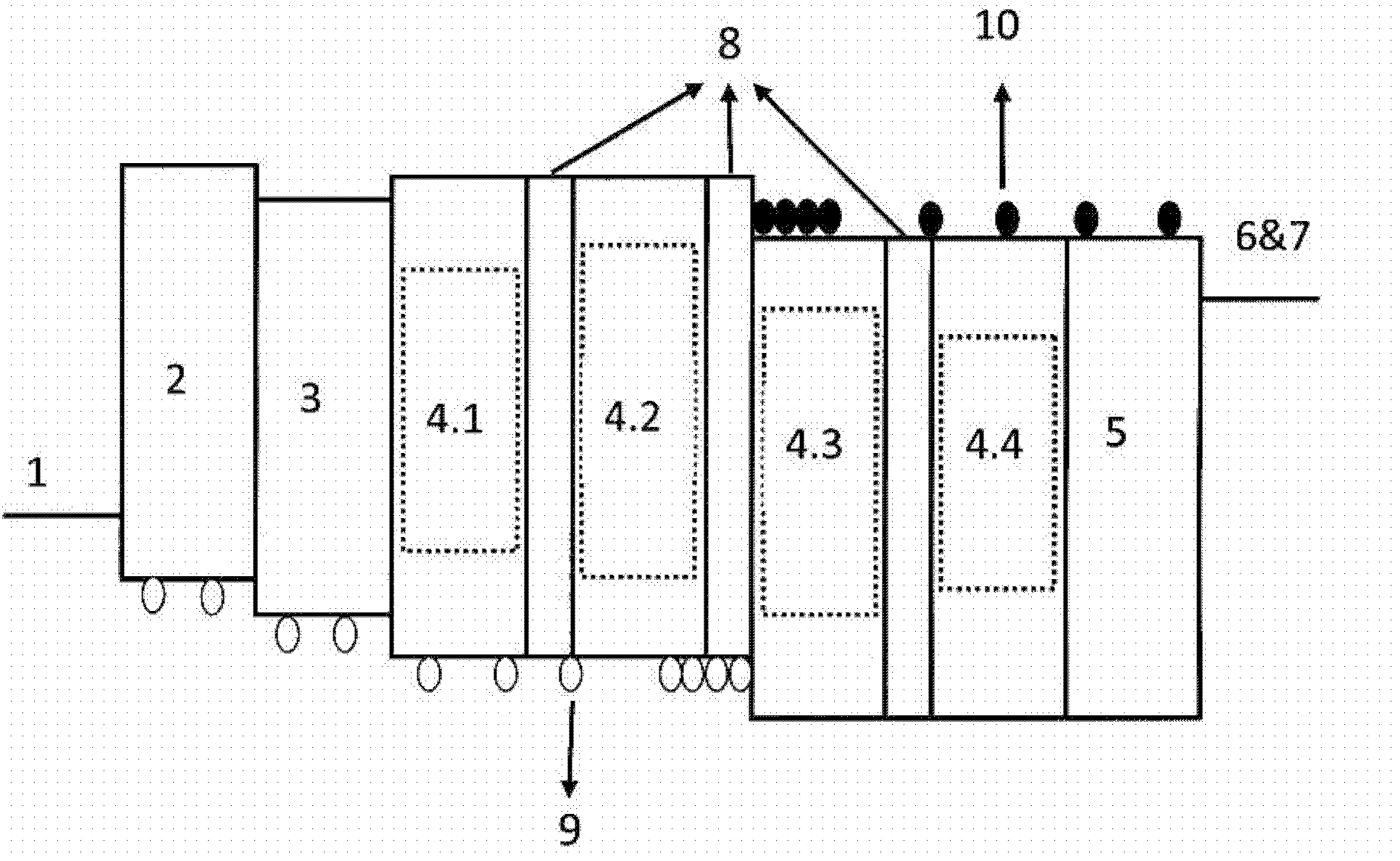

[0035] An imitation embodiment of the present invention is described as follows with reference to the drawings:

[0036] See figure 2 As shown, the preparation method of the four-band high color rendering index white organic LED lighting source with adjustable color temperature is as follows:

[0037] a). Select an ITO glass substrate 1 that meets the required size and surface resistance, clean it with deionized water, and then use deionized water and alcohol for ultrasound respectively. The ultrasound time is 30min and 20min, respectively. After ultrasound, dry and treat with a UV-ozone cleaner. 15 minutes;

[0038] b) Using a vacuum evaporation method, the hole injection layer 2 and the hole transport layer 3 are prepared by evaporation on the ITO substrate 1 at a rate of 0.06-0.1 nm / s and a thickness of 40 nm and 10 nm, respectively.

[0039] c). Above the hole transport layer 3, the light-emitting layer 4 is prepared by a dual-source co-evaporation method. The light-emitting laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com