Red double-perovskite fluorescent powder for white-light LEDs and preparation method of red double-perovskite fluorescent powder

A technology of red phosphor and double perovskite, which is applied in chemical instruments and methods, luminescent materials, gas discharge lamps, etc., can solve the problem of insufficient intensity of the red light emission area, and achieve good color purity and color rendering , good color rendering and high emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

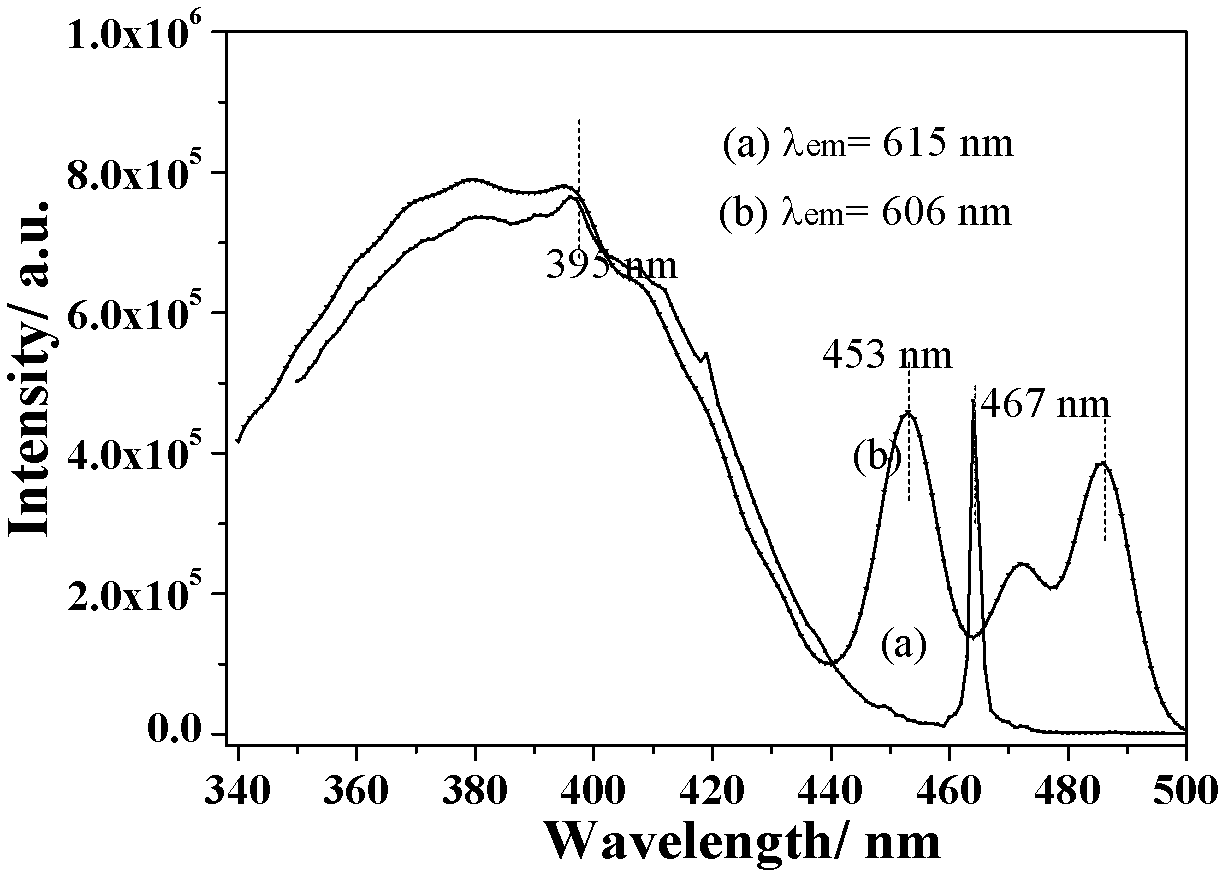

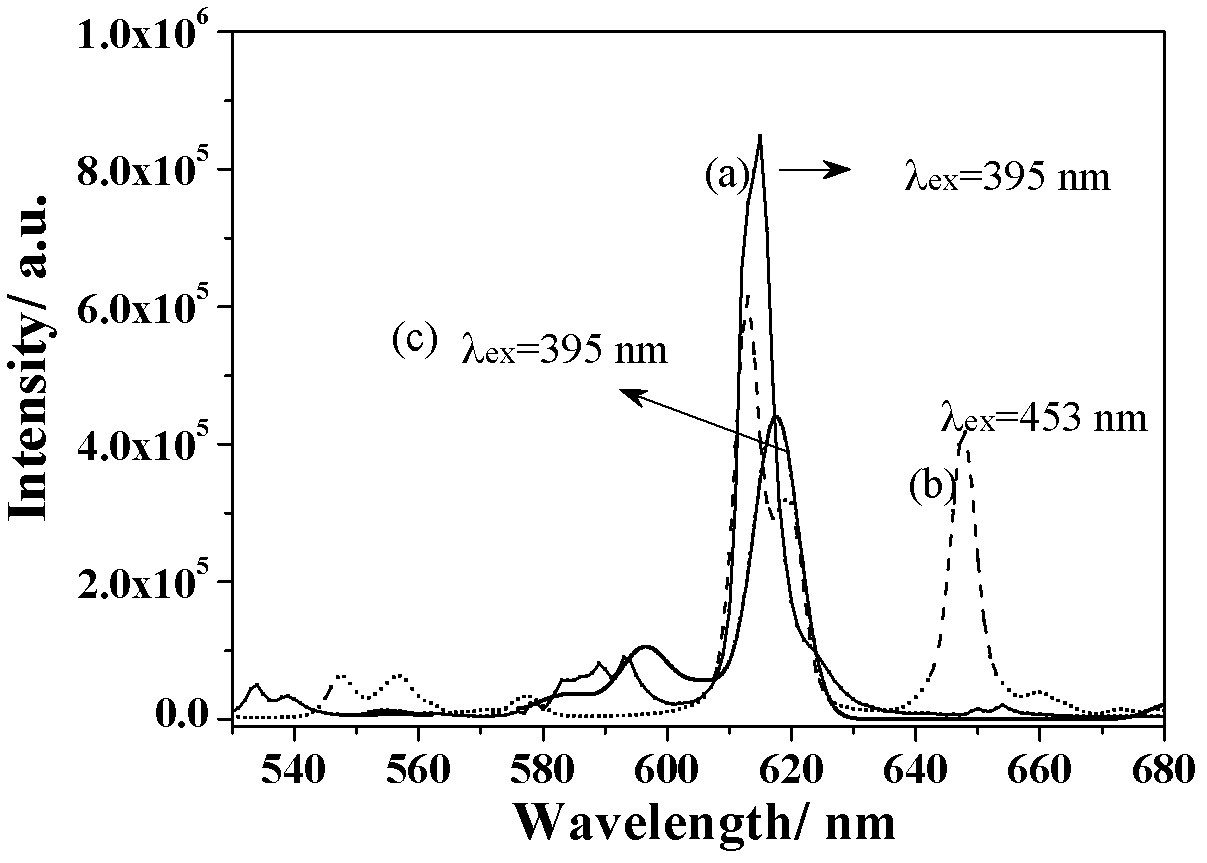

Method used

Image

Examples

Embodiment 1

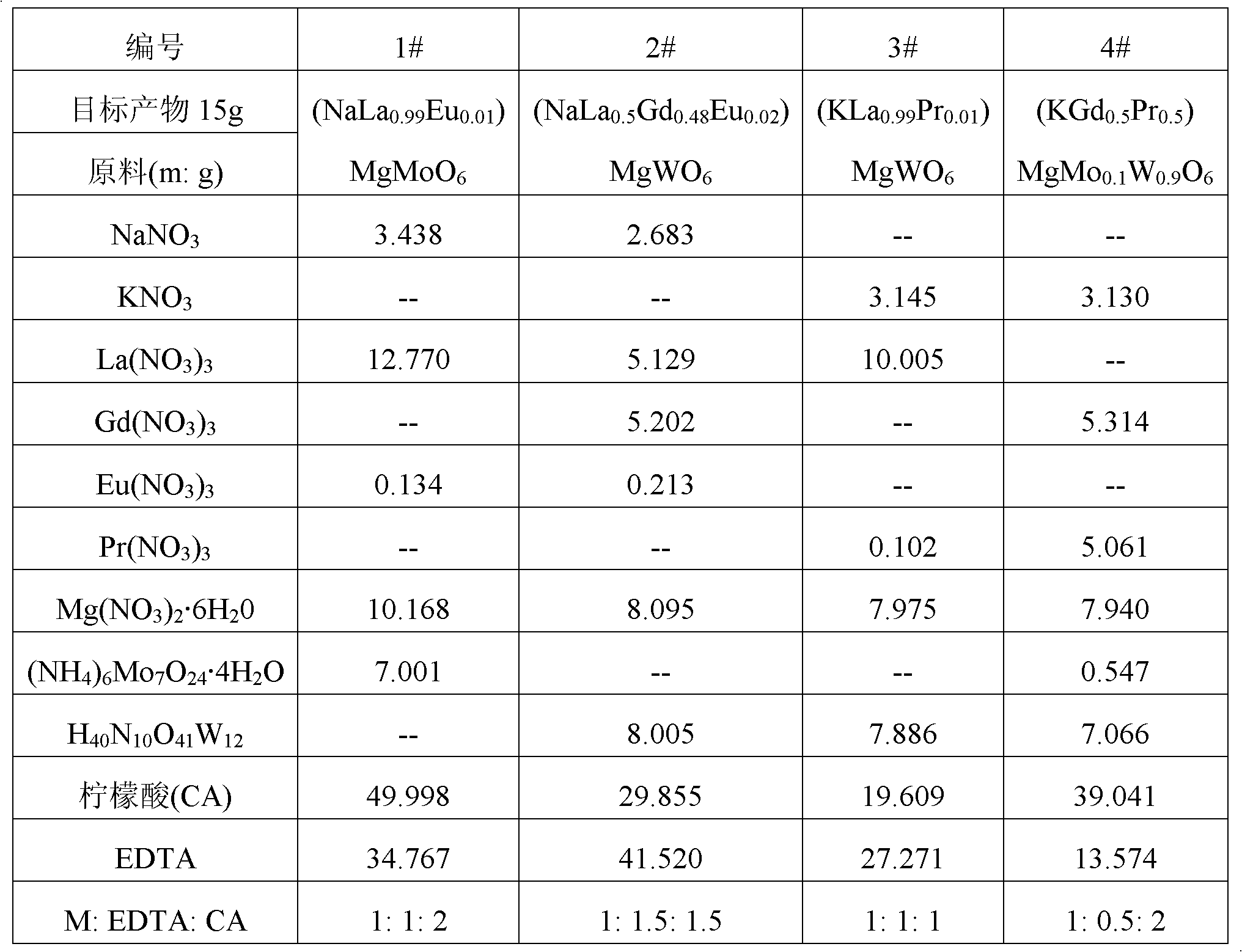

[0032] Example 1 # ((NaLa 0.99 Eu 0.01 )MgMoO 6 ):

[0033] Composition as shown in Table 1 # As shown, the specific preparation method includes the following steps:

[0034] ①Weigh the solid powder raw materials according to the composition in Table 1. First, dissolve ammonium molybdate and EDTA in ammonia solution, and citric acid in deionized water; dissolve ammonium molybdate and EDTA in ammonia solution and metal ion nitrate solution Mix, stir and heat; then adjust the pH of the completely dissolved citric acid solution to 5 with ammonia, then add it to the mixed solution, finally adjust the pH of the solution with ammonia to 7, and the total concentration of all metal ions in the entire solution system is about 1.0 mol / L, the whole process has been stirring and heating, the heating temperature is 35℃;

[0035] ②Place the prepared solution on a magnetic stirrer, stir for 40 minutes and then unpack, heat at 50℃ and keep stirring for about 2.5 hours to form a sol; then increase ...

Embodiment 2

[0041] Example 2 # ((NaLa 0.5Gd0.48 Eu 0.02 )MgWO 6 ):

[0042] Composition as shown in Table 1 2 # As shown, the specific preparation method includes the following steps:

[0043] ①Weigh the solid powder raw materials according to the composition in Table 1. First, dissolve EDTA in the ammonia solution, ammonium tungstate and citric acid in an appropriate amount of deionized water, respectively heat and stir to dissolve; combine the EDTA ammonia solution and metal ion nitric acid Mix the salt solution, stir and heat; then use ammonia to adjust the pH of the completely dissolved citric acid solution to 6 and add it to the mixed solution; finally, use ammonia to adjust the pH of the mixed solution to 8, and add the ammonium tungstate solution. The total concentration of all metal ions in the solution system is about 1.15mol / L, the whole process has been stirred and heated, and the heating temperature is 30℃;

[0044] ②Place the prepared solution on a magnetic stirrer, stir for 30 m...

Embodiment 3

[0048] Example 3 # ((KLa 0.99 Pr 0.01 )MgWO 6 ):

[0049] Composition as shown in Table 1 in 3 # As shown, the specific preparation method includes the following steps:

[0050] ①Weigh the solid powder raw materials according to the composition in Table 1. First, dissolve EDTA in the ammonia solution, ammonium tungstate and citric acid in an appropriate amount of deionized water, respectively heat and stir to dissolve; combine the EDTA ammonia solution and metal ion nitric acid Mix the salt solution, stir and heat; then adjust the pH of the completely dissolved citric acid solution to 7 with ammonia water, then add it to the mixed solution; finally adjust the pH of the solution to 7.5 with ammonia water, and add the ammonium tungstate solution to the mixed solution In the whole solution system, the total concentration of all metal ions is about 1.25mol / L, and the whole process has been stirred and heated at a temperature of 30℃;

[0051] ②Place the prepared solution on a magnetic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com