Bracket material for bone tissue engineer and preparation method thereof

A technology of bone tissue engineering and scaffold materials, applied in medical science, prostheses, etc., can solve the problems of expensive scaffolds, destruction of the natural structure between collagen bundles, high antigenicity, etc., and achieve good mechanical properties and biocompatibility, The preparation process is green and environmentally friendly, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

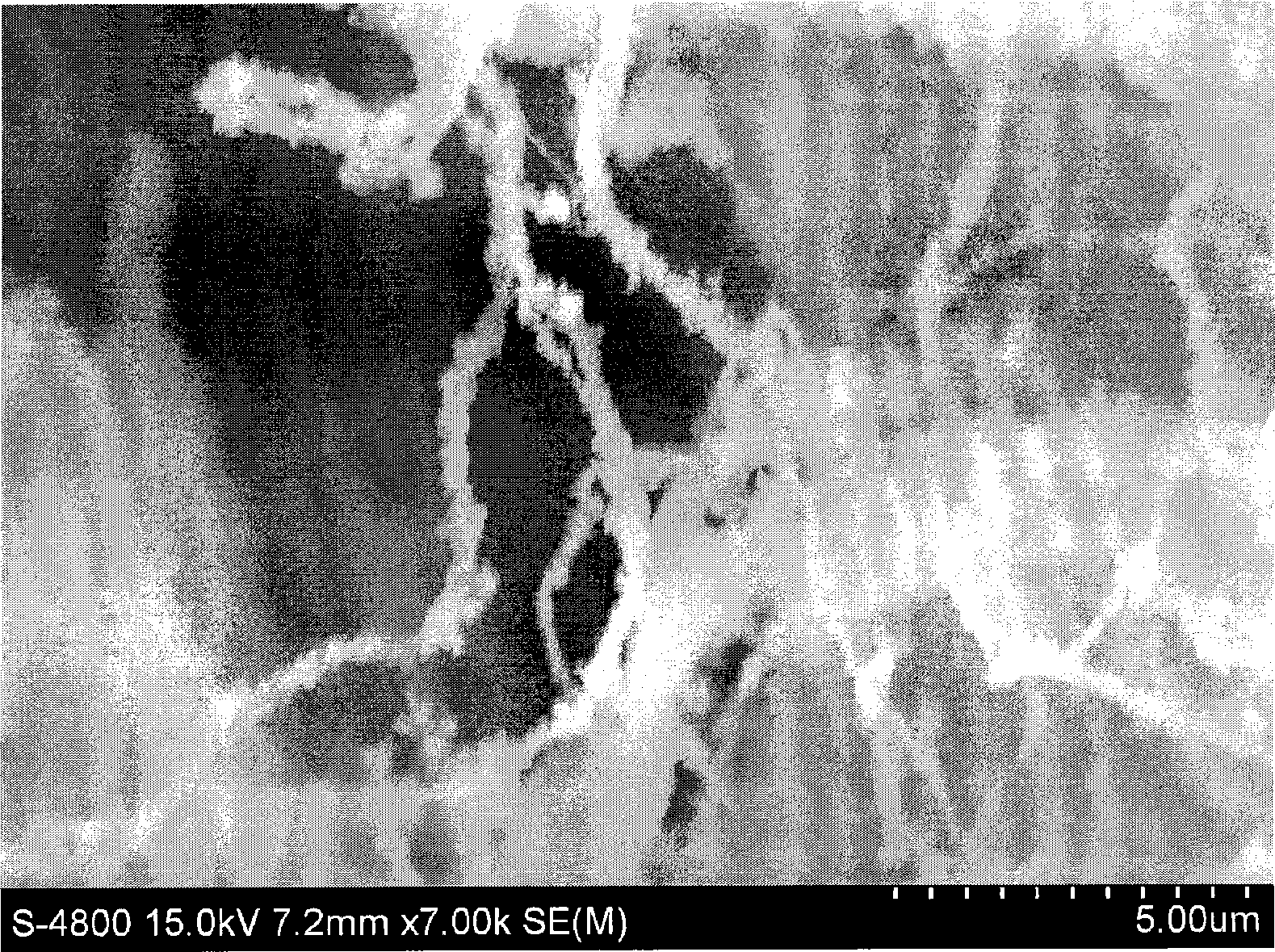

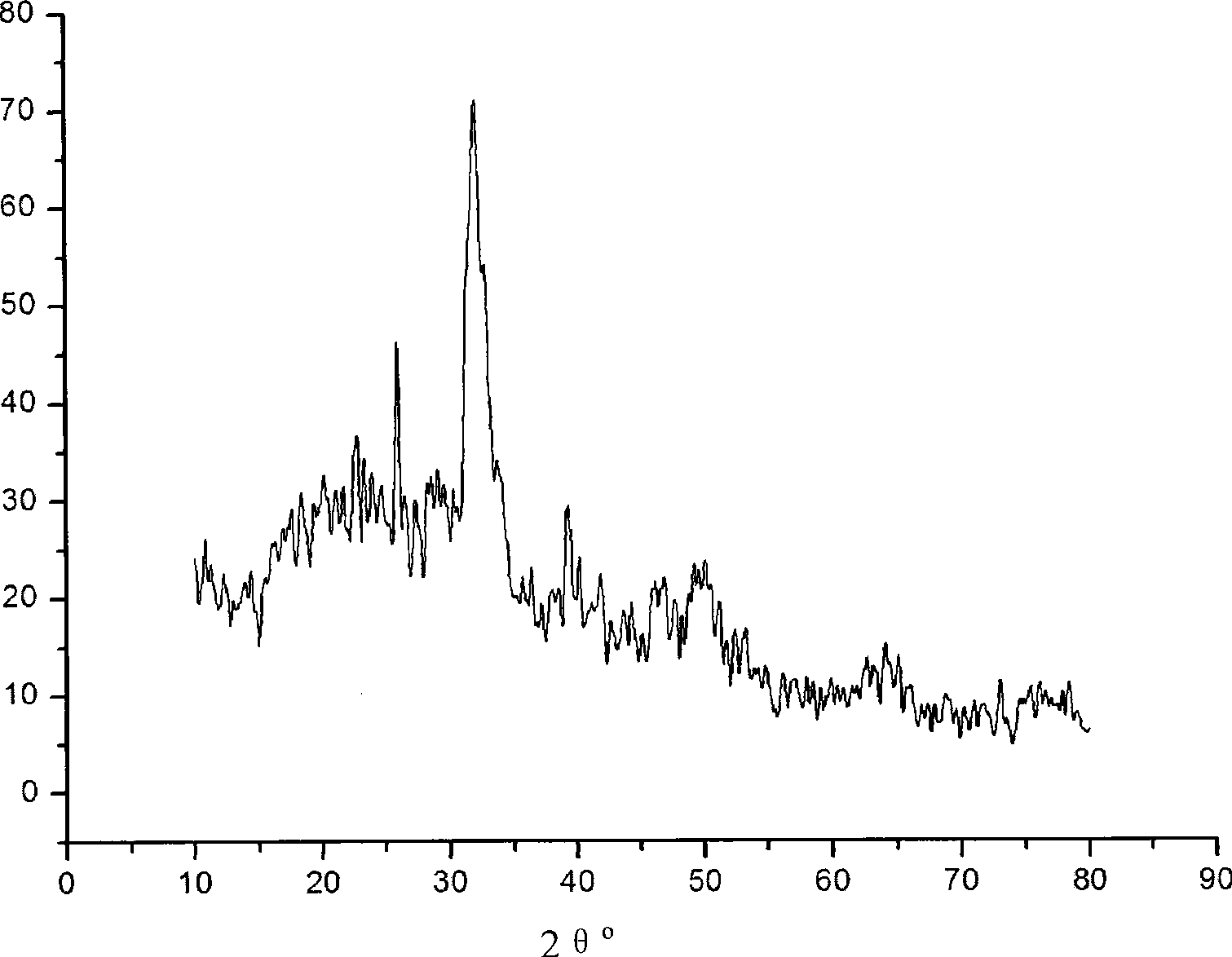

[0027] The extracted pigskin collagen with a purity of up to 96% was cut into a block frame of length: width: height = 1 cm × 1 cm × 0.2 cm with a stainless steel blade. Soak the stent in Tris buffer solution with pH=8.8 (the preparation method is to dissolve 121.1g Tris base in 800ml water at 25°C, add concentrated HCL to adjust the pH value to 8.8, and continue to add water to 1 liter), and place it at 37°C Make it fully swell in a shaker for 24 hours, take it out and rinse it with deionized water for 3 times, 20 minutes each time. Take out the bulk collagen, wipe off the surface moisture with filter paper, put it into a liquid nitrogen bucket to freeze for 2 hours, freeze-dry at -80°C for 8 hours, and obtain fully expanded pure collagen scaffold A. Prepare 0.25M CaCl separately 2 Solution B and 0.25M (NH 4 ) 2 HPO 4Solution C 1L each. Soak A in 25ml of B solution, and shake in a shaker at 37°C at a speed of 120 rpm for 2 hours, take it out and wash it with deionized wa...

Embodiment 2

[0030] The extracted pigskin collagen with a purity of up to 96% was cut into a block frame of length: width: height = 1 cm × 1 cm × 0.2 cm with a stainless steel blade. Soak the scaffold in Tris buffer solution with pH=8.8, put it in a shaker at 37°C to fully swell for 24 hours, take it out and wash it with deionized water for 3 times, 20 minutes each time. Take out the bulk collagen, wipe off the surface moisture with filter paper, put it into a liquid nitrogen bucket for 2 hours, and then freeze it at -80°C for 8 hours to obtain a fully expanded pure collagen scaffold. At 37°C, prepare a standard simulated body fluid (in which: Na + 142.0,K + 5.0, Mg 2+ 1.5, Ca 2+ 2.5, Cl - 148.8, HCO 3 - 4.2, HPO 4 3- 1.0, SO 4 2- 0.5(mM)) 1L, adjust the pH=7.4 with Tris buffer solution of pH=8.8 and 0.1M HCl, immerse the collagen scaffold in the simulated body fluid, and shake at a speed of 120 rpm in a shaker at 37°C After 6 days (the mineralization solution was changed every ...

Embodiment 3

[0033] The extracted pigskin collagen with a purity of up to 96% was cut into a block frame of length: width: height = 1 cm × 1 cm × 0.2 cm with a stainless steel blade. Soak the scaffold in Tris buffer solution with pH=8.8, put it in a shaker at 37°C to fully swell for 24 hours, take it out and wash it with deionized water for 3 times, 20 minutes each time. Take out the bulk collagen, wipe off the surface moisture with filter paper, put it into a liquid nitrogen bucket and freeze it for 2 hours, and freeze-dry it at -80°C for 80 hours to obtain fully expanded pure collagen scaffold A. Prepare 9mM CaCl separately 2 Solution B and 4.2mM (NH 4 ) 2 HPO 4 For solution C, mix B and C at a volume ratio of 1:1. At 37°C, adjust the pH to 7.4 with Tris buffer at pH 8.8 and 0.1M HCL. Soak A in the mixed solution of B and C, and shake it in a shaker at 37°C at a speed of 120 rpm for 6 days (change the mineralization solution every two days), take it out and wash it with deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com