Polyester resin for TGIC cured high-gloss powder coating and preparation method of polyester resin

A powder coating, polyester resin technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of insufficient surface brightness, low gloss and gloss, and achieve the effect of improving hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

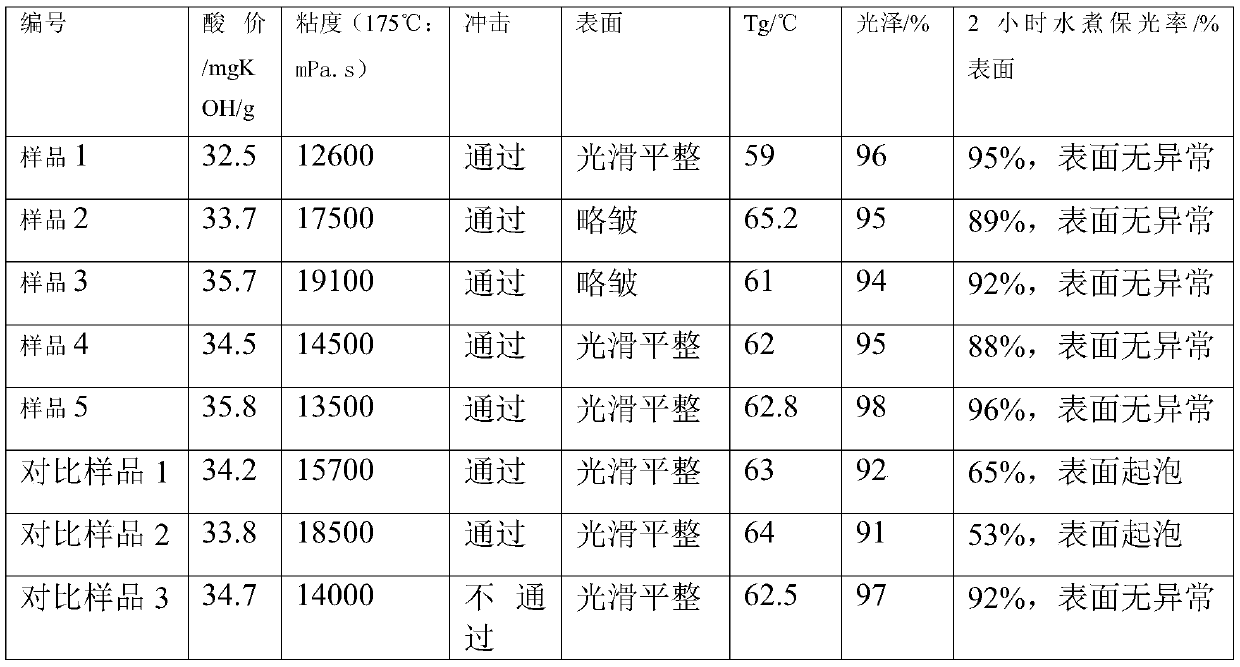

Examples

preparation example Construction

[0029] A kind of preparation method of the high-gloss powder coating polyester resin that TGIC solidifies comprises the steps:

[0030] Step 1, prepare materials according to the formula;

[0031] The formula includes: 25-33% neopentyl glycol, 0.5-1.5% hydroxypivalic acid hydroxy neopentyl glycol monoester, 3-7% ethylene glycol, 2-butyl-2-ethyl-1 ,3-propanediol 1-3%, terephthalic acid 48-61%, isophthalic acid 3-8%, adipic acid 0.5-2%, trimellitic anhydride 0.6-1.4%;

[0032] Step 2: Heat the reactor to 70-100°C, add neopentyl glycol, ethylene glycol, 2-butyl-2-ethyl-1,3-propanediol, hydroxypivalic acid hydroxy neopentyl glycol monoester , add 0.5-1.2% adipic acid, finally add terephthalic acid, esterification catalyst, and gradually heat up to 240-250°C under the protection of nitrogen to maintain until the measured acid value is 5-25mgKOH / g, then cooled to 190-210°C;

[0033] Step 3: Put in the end-capping agent trimellitic anhydride, isophthalic acid and the remaining ad...

Embodiment 1

[0035] Embodiment 1: formula comprises according to mass percentage: neopentyl glycol 25%, hydroxy neopentyl glycol monoester of hydroxypivalate 1.5%, ethylene glycol 7%, 2-butyl-2-ethyl-1,3 - 3% propylene glycol, 59.5% terephthalic acid, 3% isophthalic acid, 0.5% adipic acid, 0.6% trimellitic anhydride, 0.09g monobutyltin oxide for esterification catalyst, 1076, 0.1g, 168 for antioxidant , 0.1g, and the accelerator is 0.09g of triphenylethylphosphorus bromide.

Embodiment 2

[0036] Embodiment 2: formula comprises according to mass percentage: neopentyl glycol 33%, hydroxy neopentyl glycol monoester of hydroxypivalate 0.5%, ethylene glycol 3%, 2-butyl-2-ethyl-1,3 - 1% propylene glycol, 55% terephthalic acid, 8% isophthalic acid, 0.5% adipic acid, 0.6% trimellitic anhydride, 0.09g monobutyltin oxide for esterification catalyst, 1076, 0.1g, 168 for antioxidant , 0.1g, and the accelerator is 0.08g of triphenylethylphosphorus bromide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com