Piezoelectret structure and preparation method thereof

A piezoelectric electret, electret technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices Equal direction, can solve the problem of injection, to avoid the loss of internal charge, improve the internal charge storage density and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

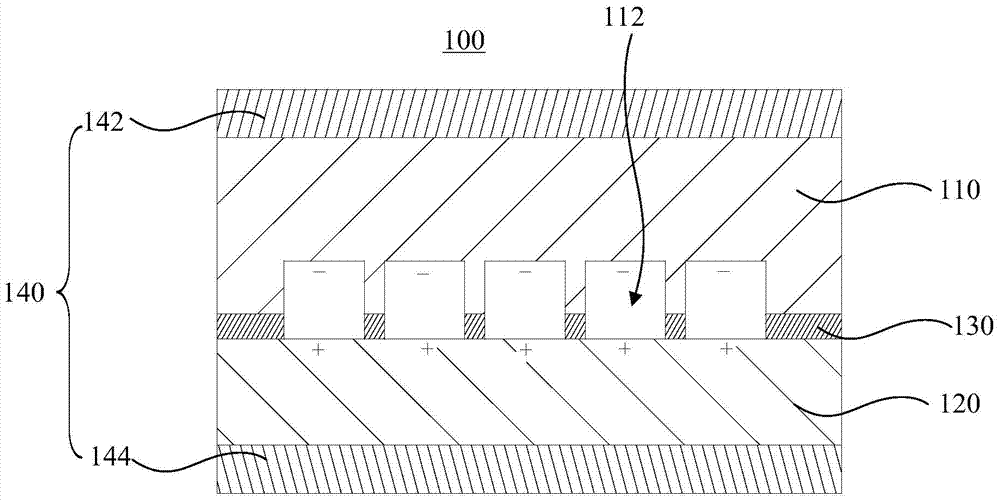

[0056] see Figure 4 , is the preparation method of the piezoelectric electret structure in one embodiment, it comprises the following steps:

[0057] Step S110, providing a first electret film. The first electret film can be formed by an electret material with a strong ability to store negative charges. For example, the material of the first electret film can be selected from polytetrafluoroethylene (Polytetrafluoroethene, PTFE), fluorinated ethylene propylene copolymer ( Fluorinated ethylene propylene, FEP), perfluoroalkoxy resin (Polyfluoroalkoxy, PFA), or polyethylene naphthalate (polyethylene naphthalate, PEN). The thickness of the first electret film may range from 0.1 μm to 2000 μm, for example, may be 25 μm.

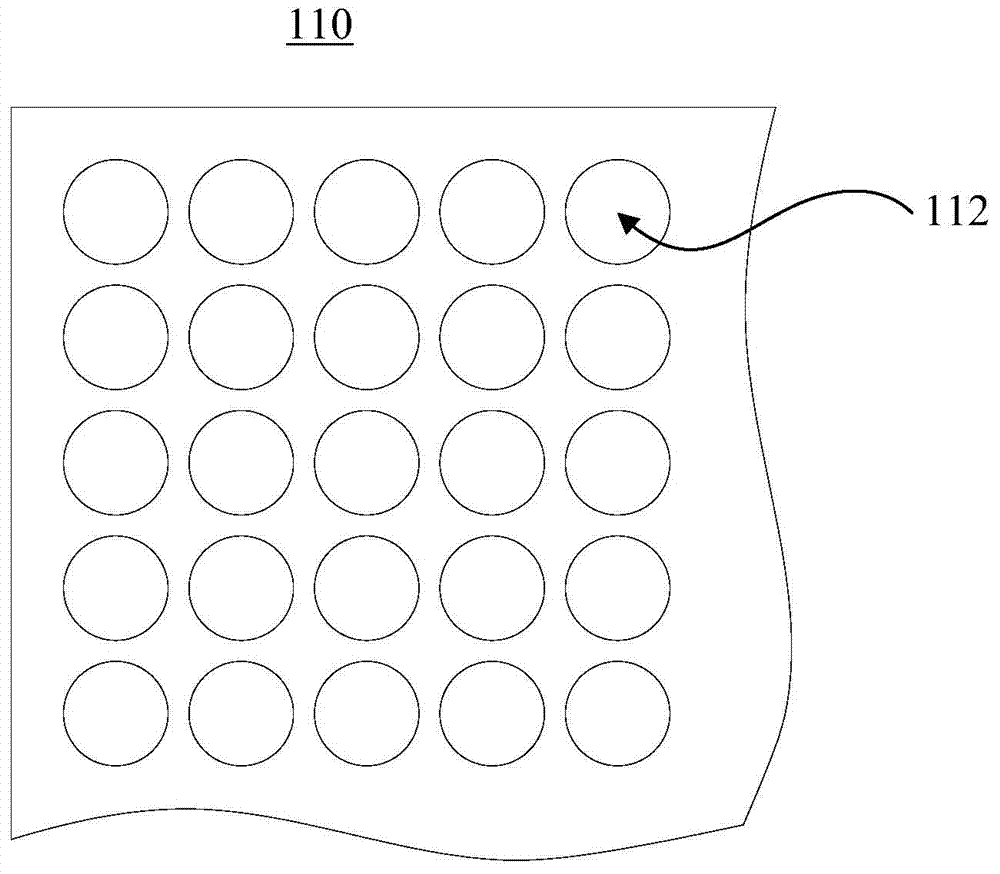

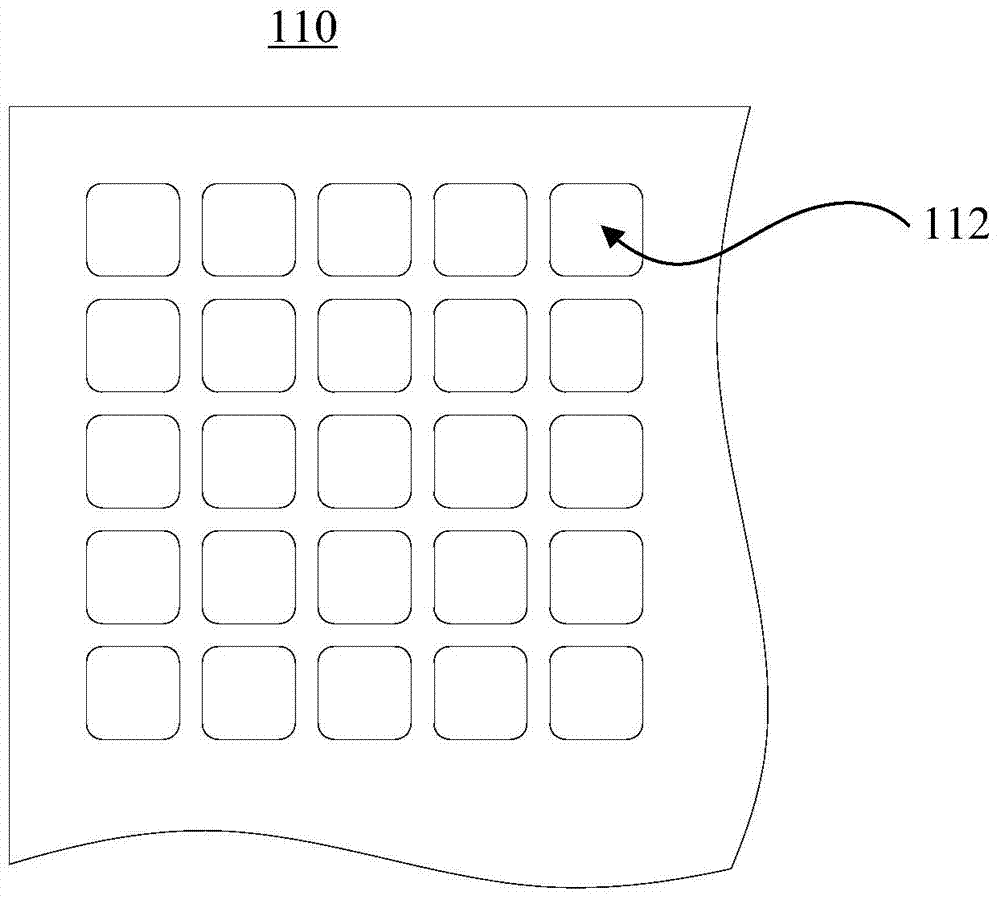

[0058] Step S120, forming a plurality of first grooves distributed in an array on the surface of the first electret film. Air pressure forming or thermocompression forming can be used.

[0059] Specifically, when using the air pressure forming method, first d...

Embodiment 1

[0098] Preparation of Porous PTFE / FEP Piezoelectret Structure

[0099] Provide a FEP film with a thickness of 12.5μm, adopt a molding fixture with a specification of 10*10*0.8cm, and use the air pressure molding method, the molding pressure is 0.8MPa, and the working temperature is 170°C, forming an array of circles on the surface of the FEP film. Shaped groove, the size of the circular groove is Φ1.5mm, the distance between two adjacent grooves is 0.3mm, and the depth of the groove is 0.5mm. Provide a porous PTFE film with a thickness of 25 μm, and use the corona polarization method to polarize the FEP film and the porous PTFE film. When polarizing the FEP film, the polarization voltage is -15kV, and the polarization time is 1min; , the polarization voltage was 13kV, and the polarization time was 1min. The circular groove is sealed with a barrier layer, and the FEP film is fixed on a device with negative pressure, and glue is coated on the surface of the FEP film adjacent to...

Embodiment 2

[0101] Preparation of porous PTFE film / PET mesh / porous PTFE film

[0102]A 60-mesh PET mesh film with a thickness of 50 um is provided, and a porous PTFE film with a thickness of 25 um is used for both the first electret film and the second electret film. Use the corona polarization method to polarize the PET mesh and the porous PTFE film, use the -13kV polarization voltage corona method to polarize one of the unformed porous PTFE films, and use the 15kV polarization voltage corona method to polarize the other unformed Type porous PTFE membrane, polarization time 1min. Glue was coated on the opposite surfaces of the PET film respectively, and then a pressure of 5KPa was applied, the glue curing temperature was 80°C, and the time was 50min to form the first glue layer and the second glue layer. Brush silver glue to a thickness of 200 nm on the surfaces of the first electret film and the second electret film respectively to form the first electrode and the second electrode. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com