Patents

Literature

49results about How to "High dimensional control accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Patterning process

ActiveUS20110177462A1High dissolution contrastHigh dimensional control accuracyPhotosensitive materialsPhotomechanical exposure apparatusOrganic solventHigh energy

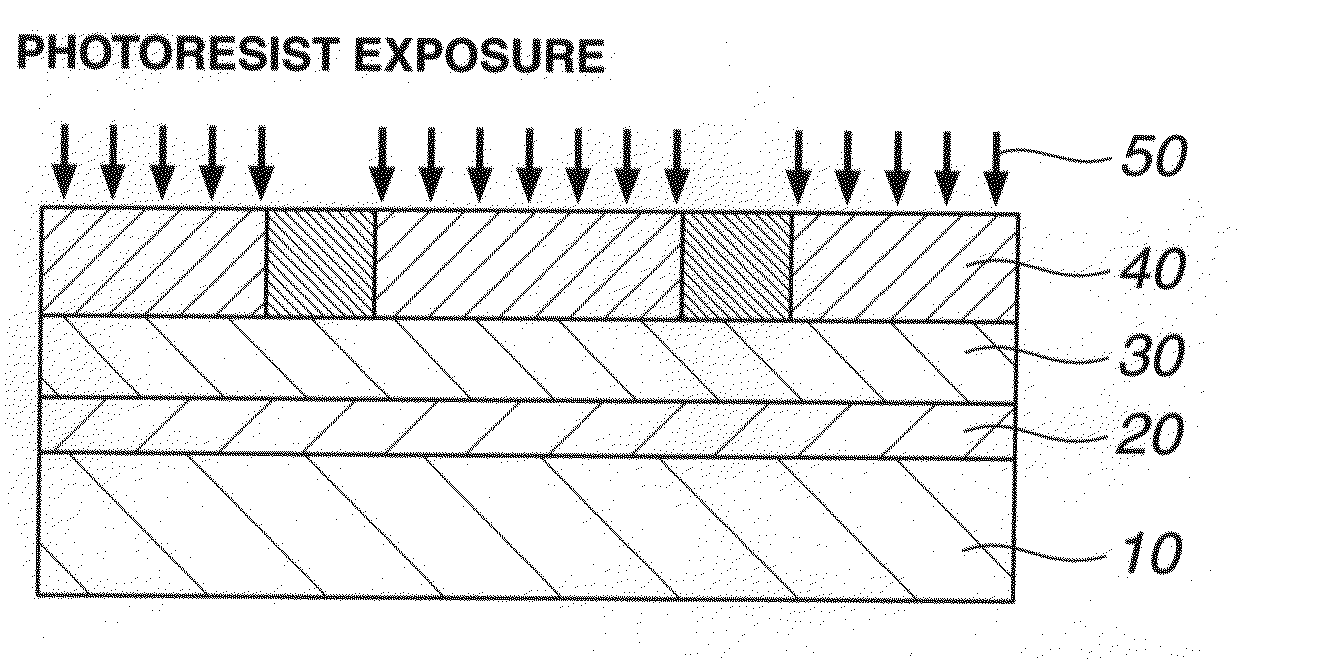

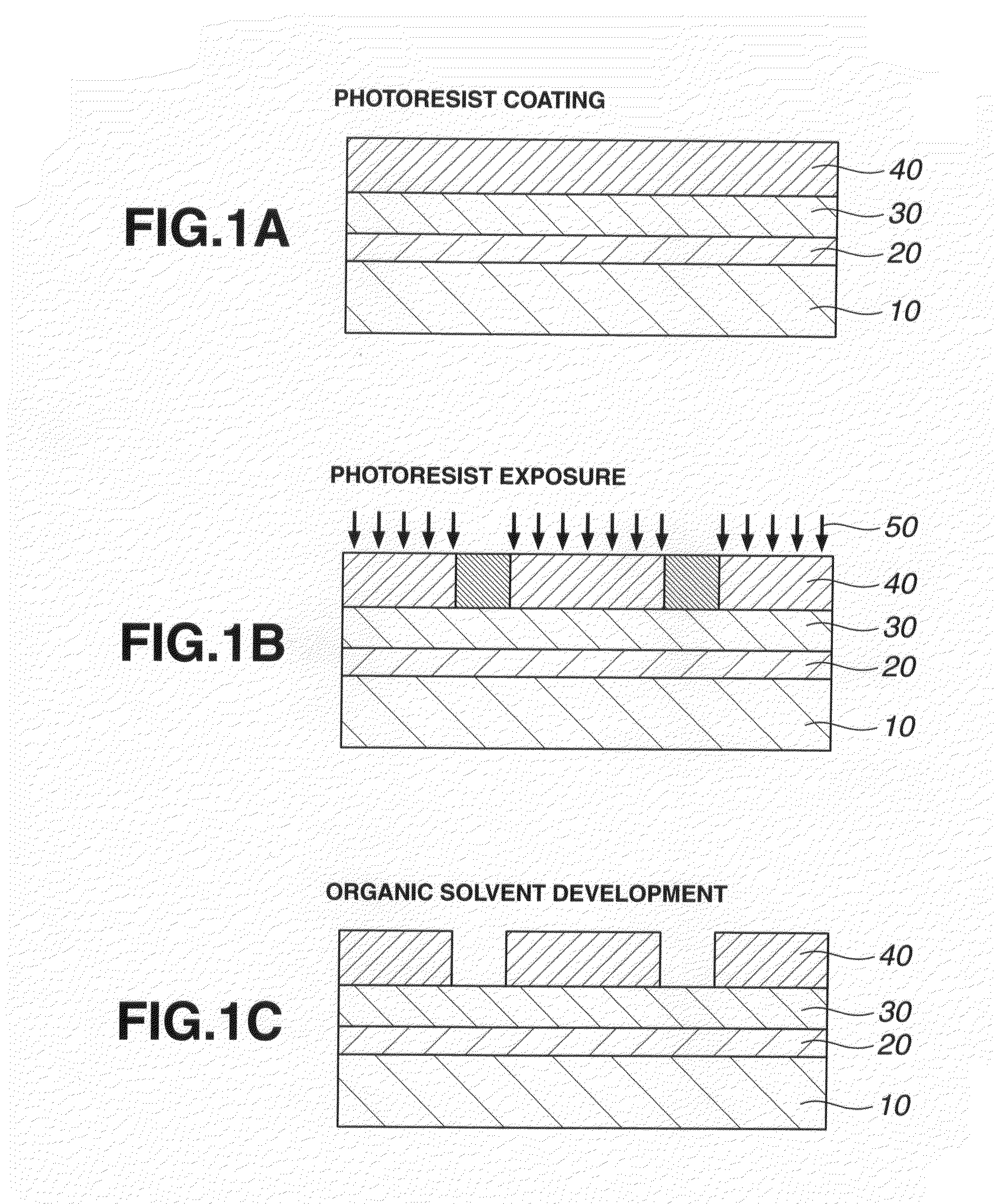

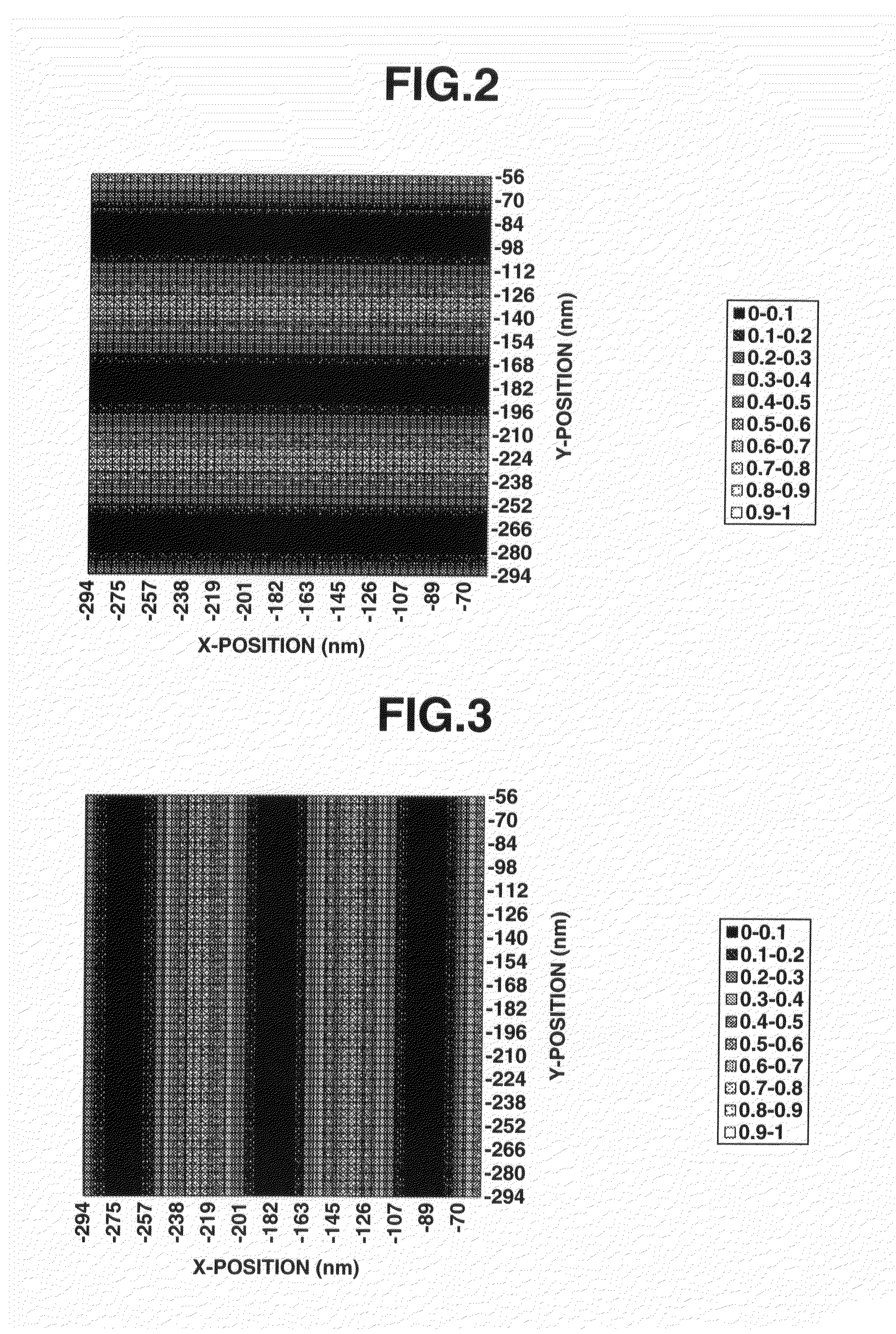

A pattern is formed by coating a resist composition comprising a polymer comprising recurring units having an optionally acid labile group-substituted naphthol group, an acid generator, and an organic solvent onto a substrate, baking to form a resist film, exposing the resist film to high-energy radiation, baking, and developing the exposed film with an organic solvent developer to form a negative pattern wherein the unexposed region of film is dissolved and the exposed region of film is not dissolved. In the process of image formation via positive / negative reversal by organic solvent development, the resist film has a high dissolution contrast and controlled acid diffusion. By subjecting the resist film to exposure through a mask having a lattice-like pattern and organic solvent development, a fine hole pattern can be formed at a high precision of dimensional control.

Owner:SHIN ETSU CHEM IND CO LTD

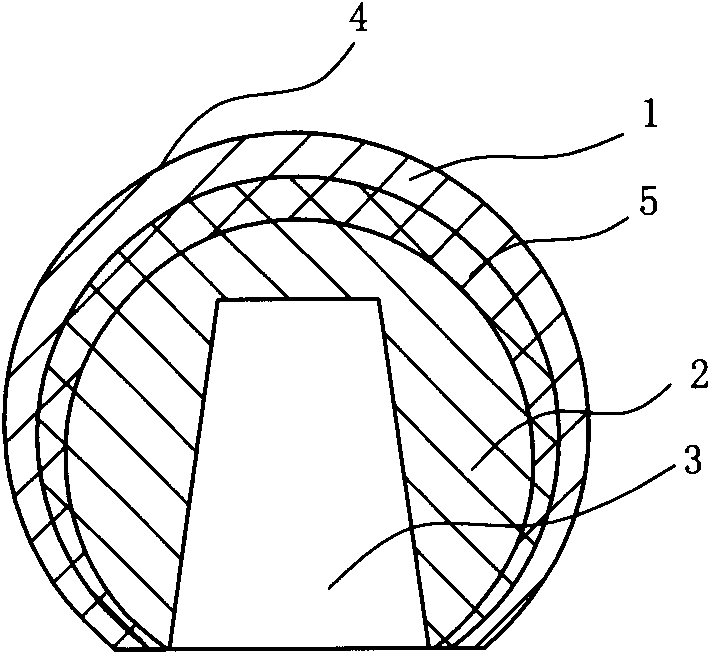

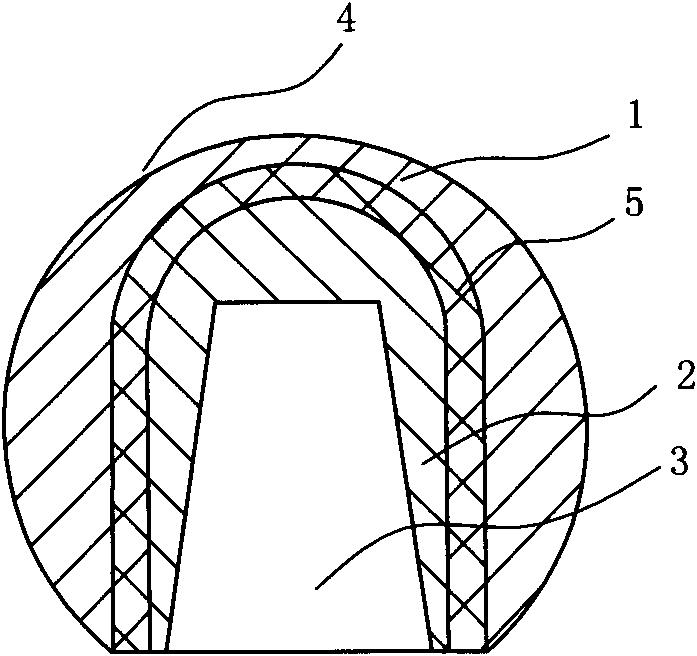

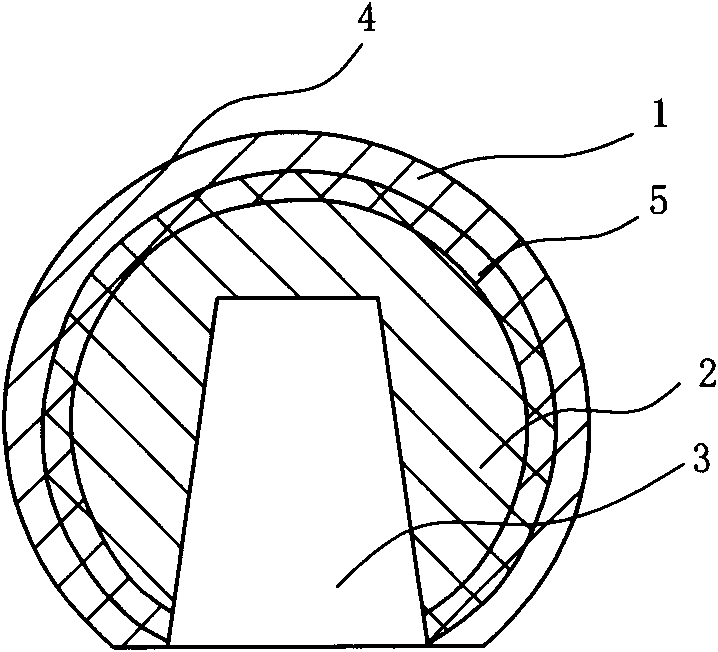

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

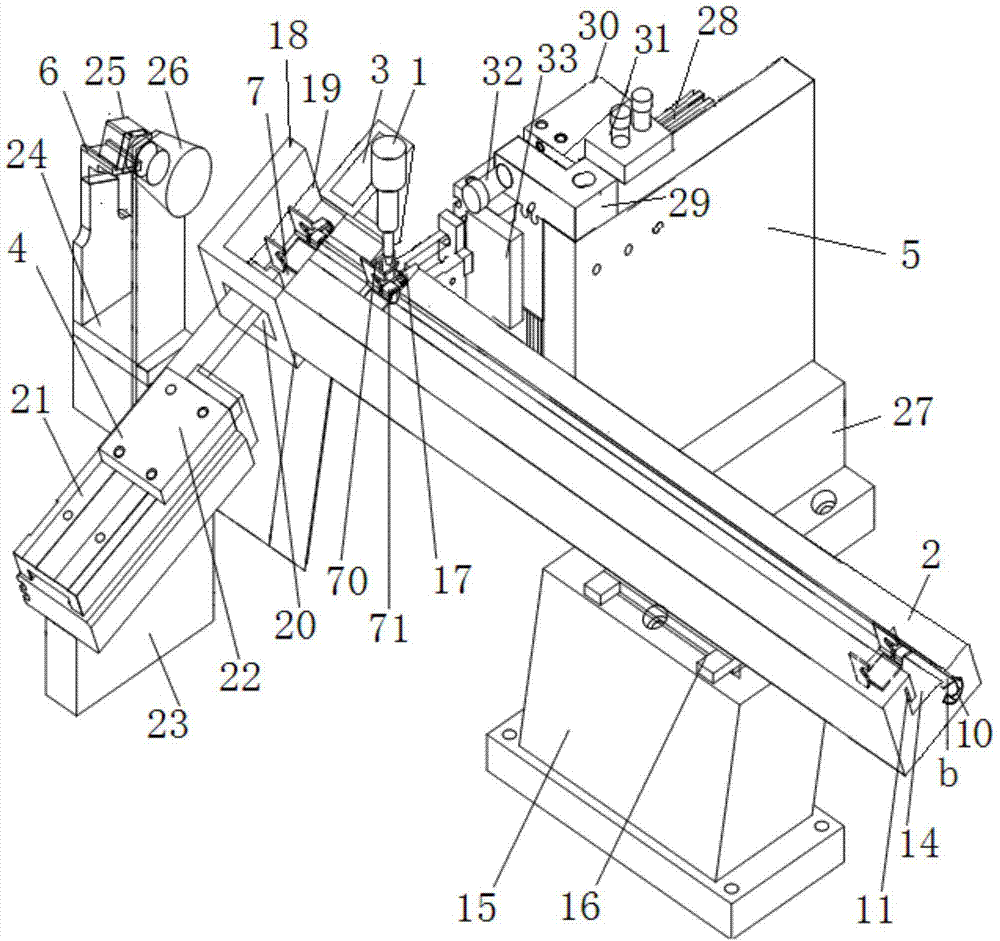

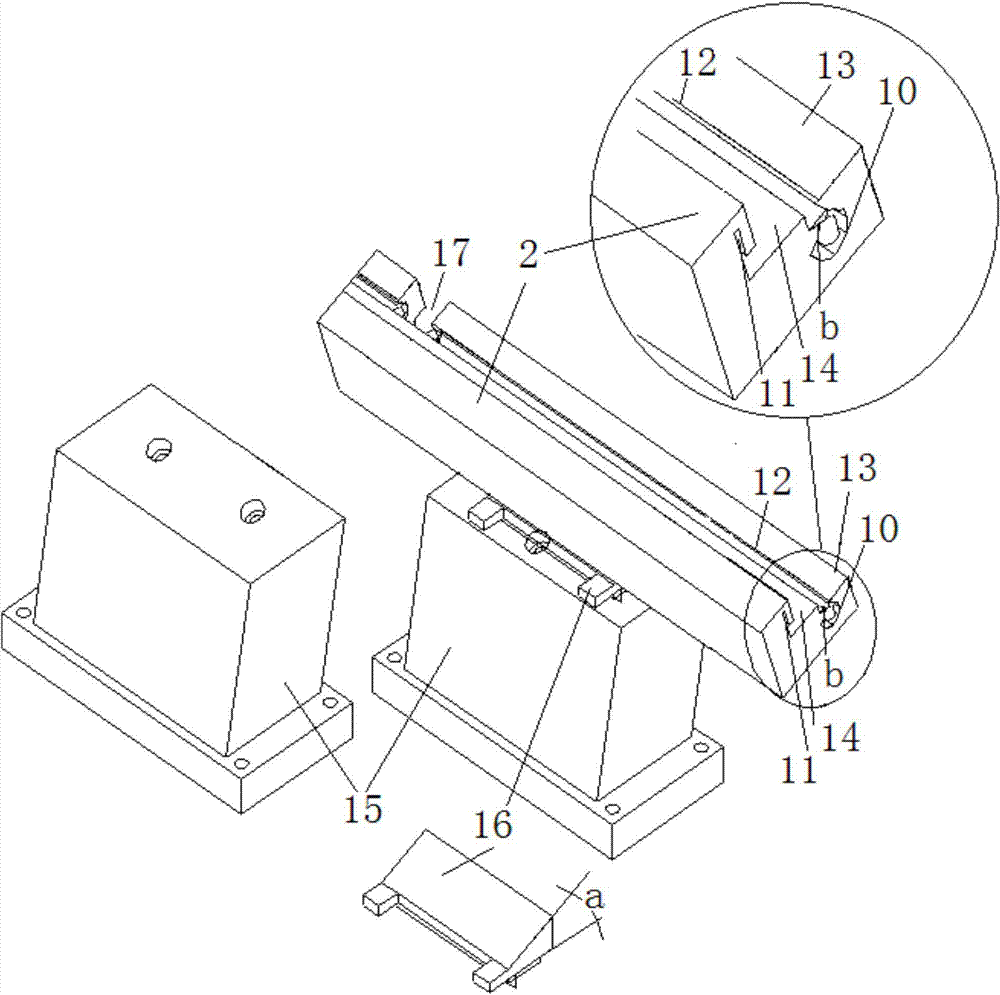

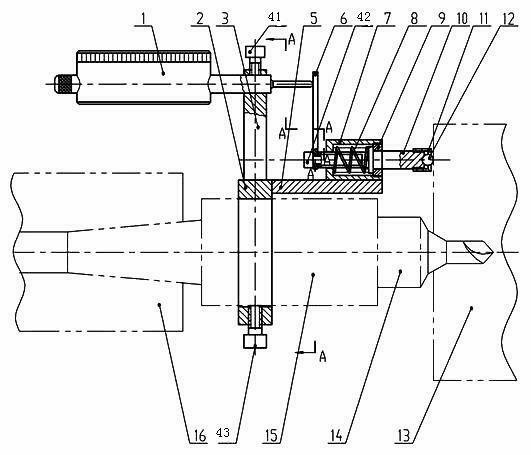

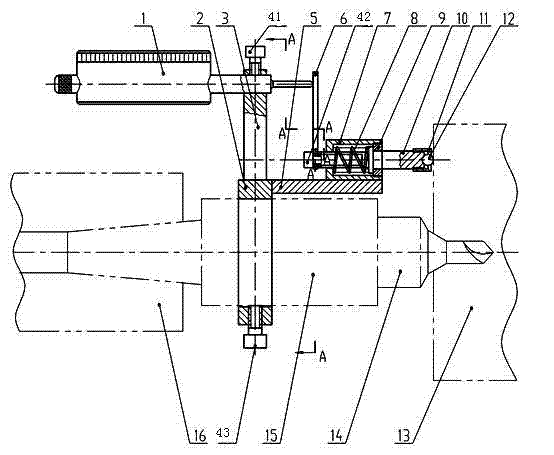

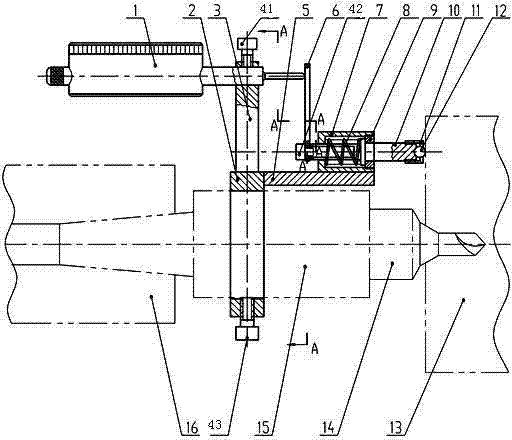

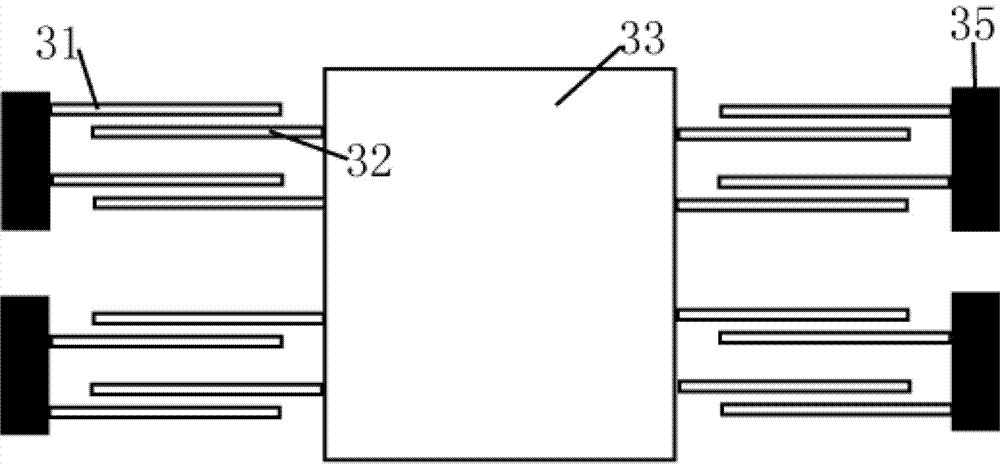

Machining device of large-capacity circuit breaker contact system

ActiveCN104816081AReduce operational riskReduce welding distortionResistance electrode holdersMetal working apparatusForcepsEngineering

The invention discloses a machining device of a large-capacity circuit breaker contact system. The machining device comprises a feeding mechanism, a clamp and a welding mechanism. A linear rail is fixedly arranged on a working table board, and the clamp is arranged on the linear rail; and the welding mechanism is vertically arranged on the inner segment of the linear rail. The machining device is small in operation error, good in operation environment, small in personnel operating risk, low in cost and capable of achieving continuous efficient work; the size control precision of operation clamp forceps is high; the welding deformation of a welding electrode is small, and the welding energy consumption losses are small; hardening of a soft connection and a touch panel is relieved, the welding quality is stable, a step plate area of a welding table is large, and assembling, current bearing capacity, touch on-off synchronization, ultimate breaking capacity, service life, temperature rising, dynamic thermal stability and use safety and performance are obvious facilitated.

Owner:嘉兴彩虹光学膜片科技有限公司

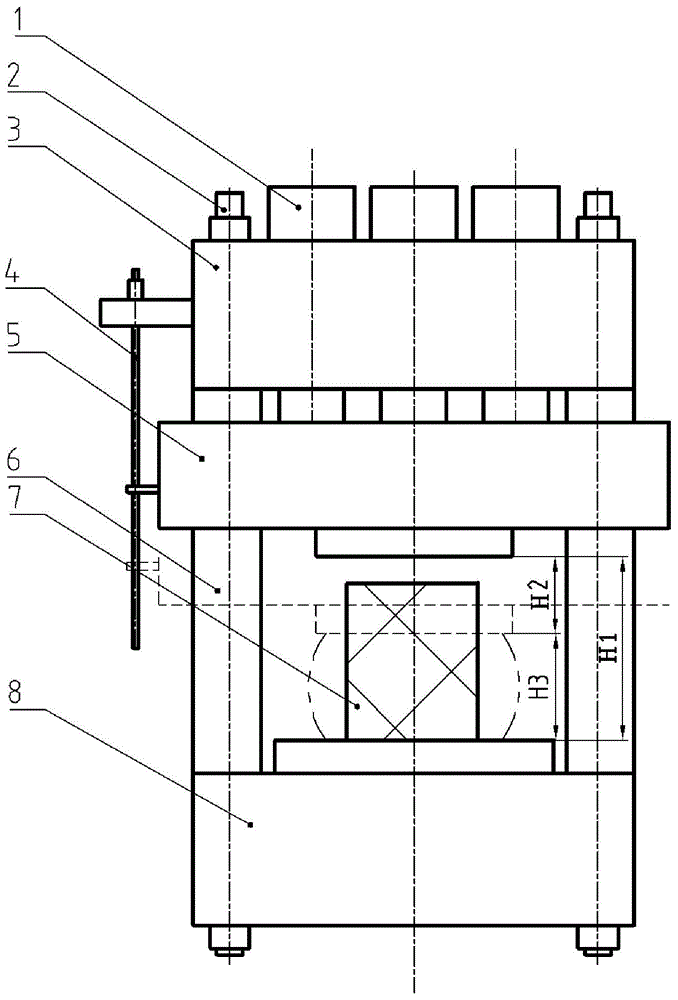

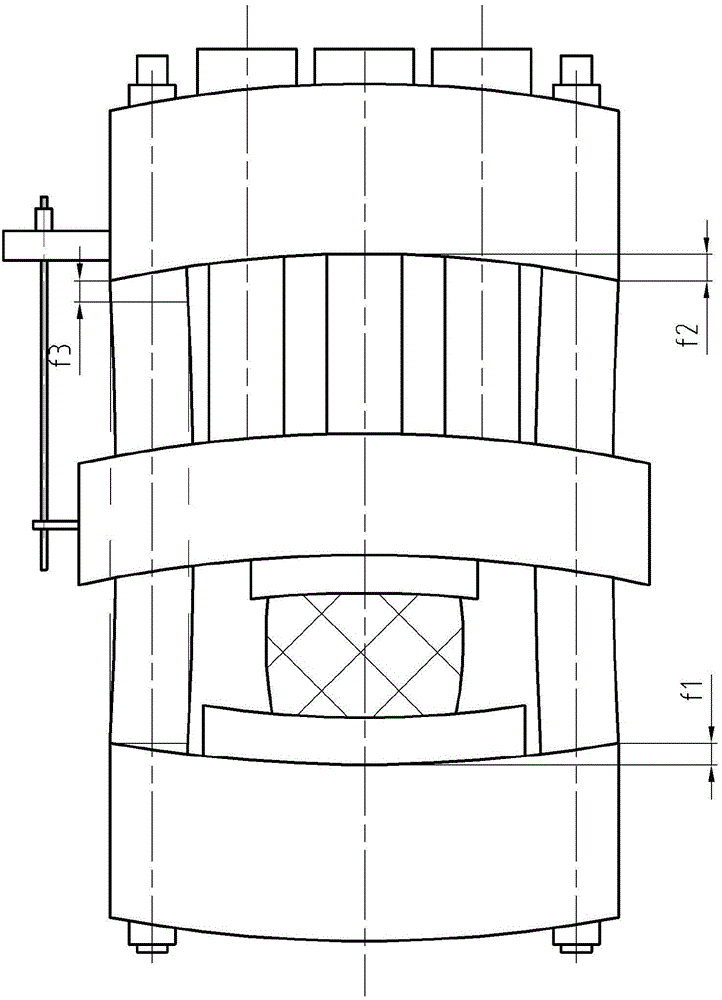

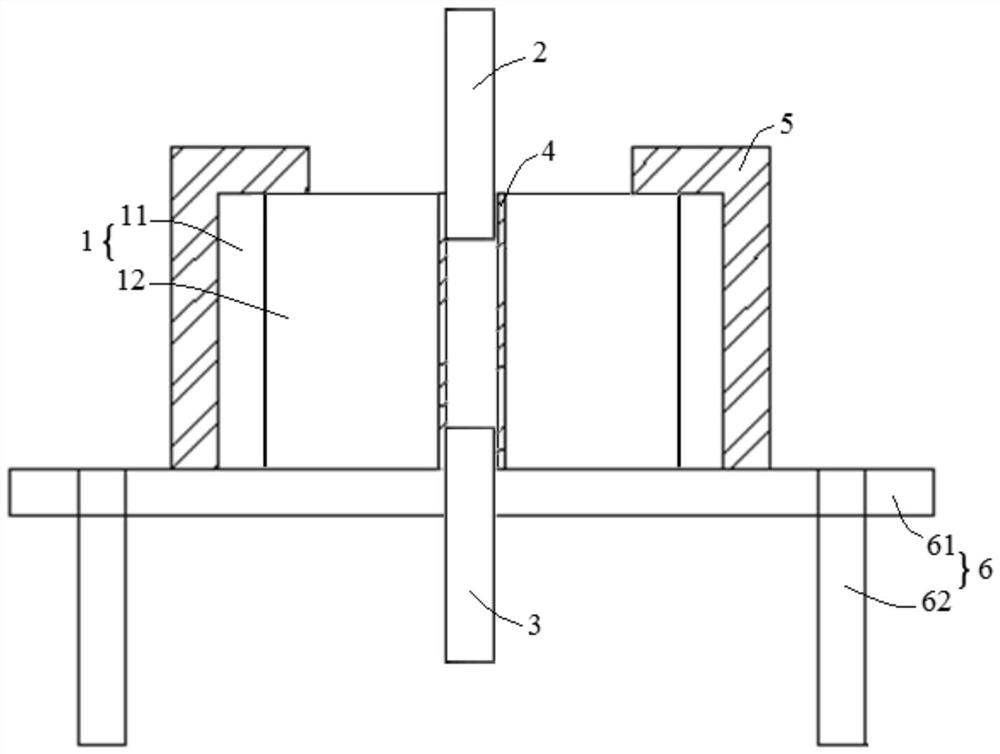

Forged piece size control method based on stand deformation

InactiveCN104550602AEliminate measurement errorsHigh dimensional control accuracyForging press drivesFinal heightPressure load

The invention discloses a forged piece size control method based on stand deformation. The method comprises the following steps: building the relationship between overall press deformation and a pressure load; calculating the final height size of a forged piece. During working of a free forging hydraulic press, a stand is deformed in the vertical direction due to the deformation resistance of the forged piece. The deformation comprises the elastic deformation f1 of a lower transverse beam, the elongation f2 of vertical columns, and the elastic deformation f3 of an upper transverse beam, and f1, f2 and f3 can all lead to the increase of the free height H1 of the press, which is the most important reason of poor size accuracy of the forged piece. Through an operation formula with the deformation value of the stand during working, measuring errors caused by deformation of a press body during working are completely eliminated, the size accuracy of the forged piece is increased from + / -3 millimeters to + / -1 millimeter, the size control accuracy of the forged piece is increased greatly during free forging, the machining balance is lowered, the production efficiency is increased, and the manufacturing cost is lowered.

Owner:CHINA FIRST HEAVY IND +1

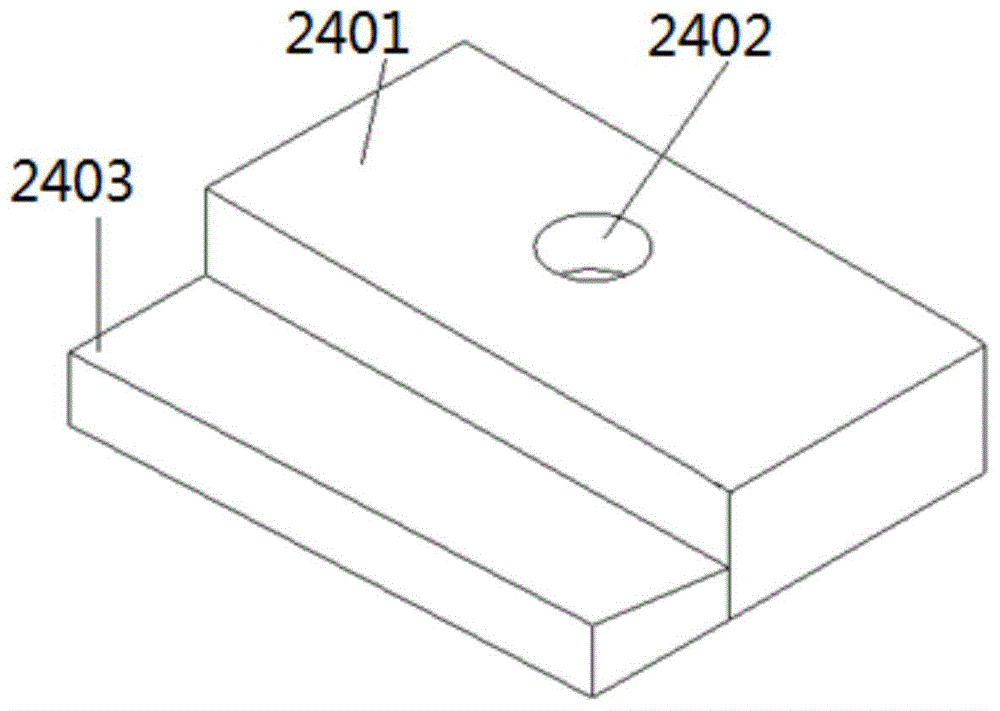

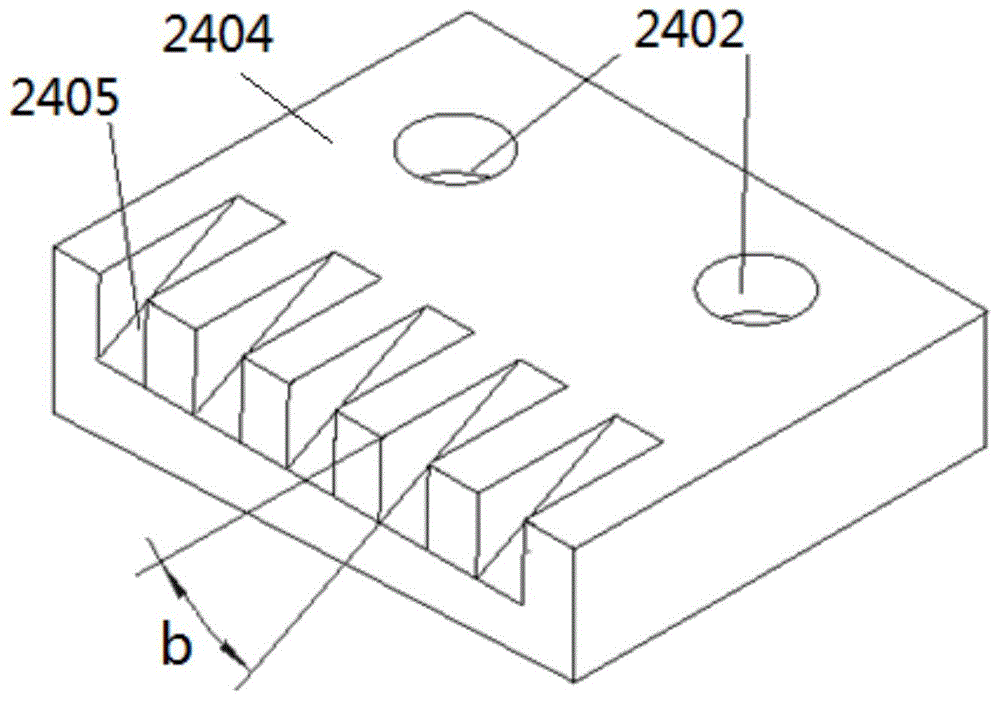

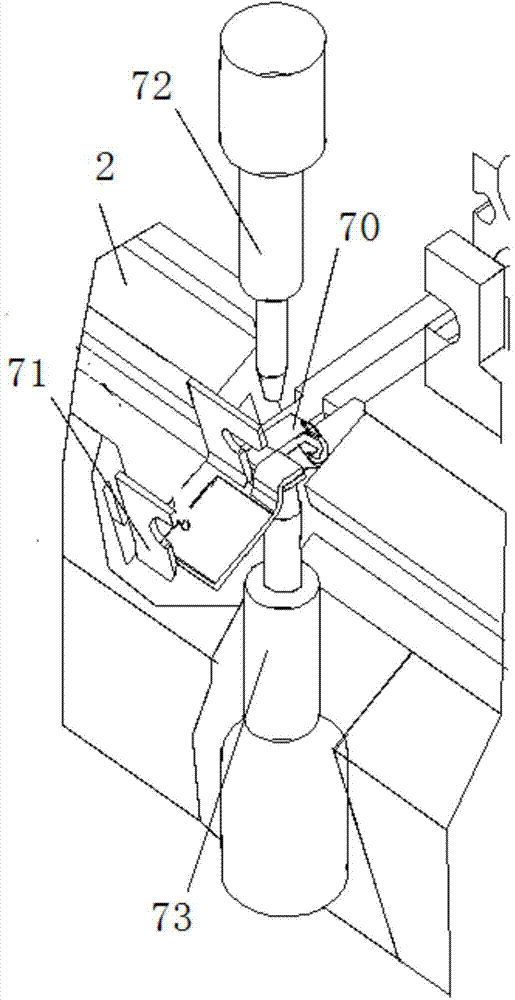

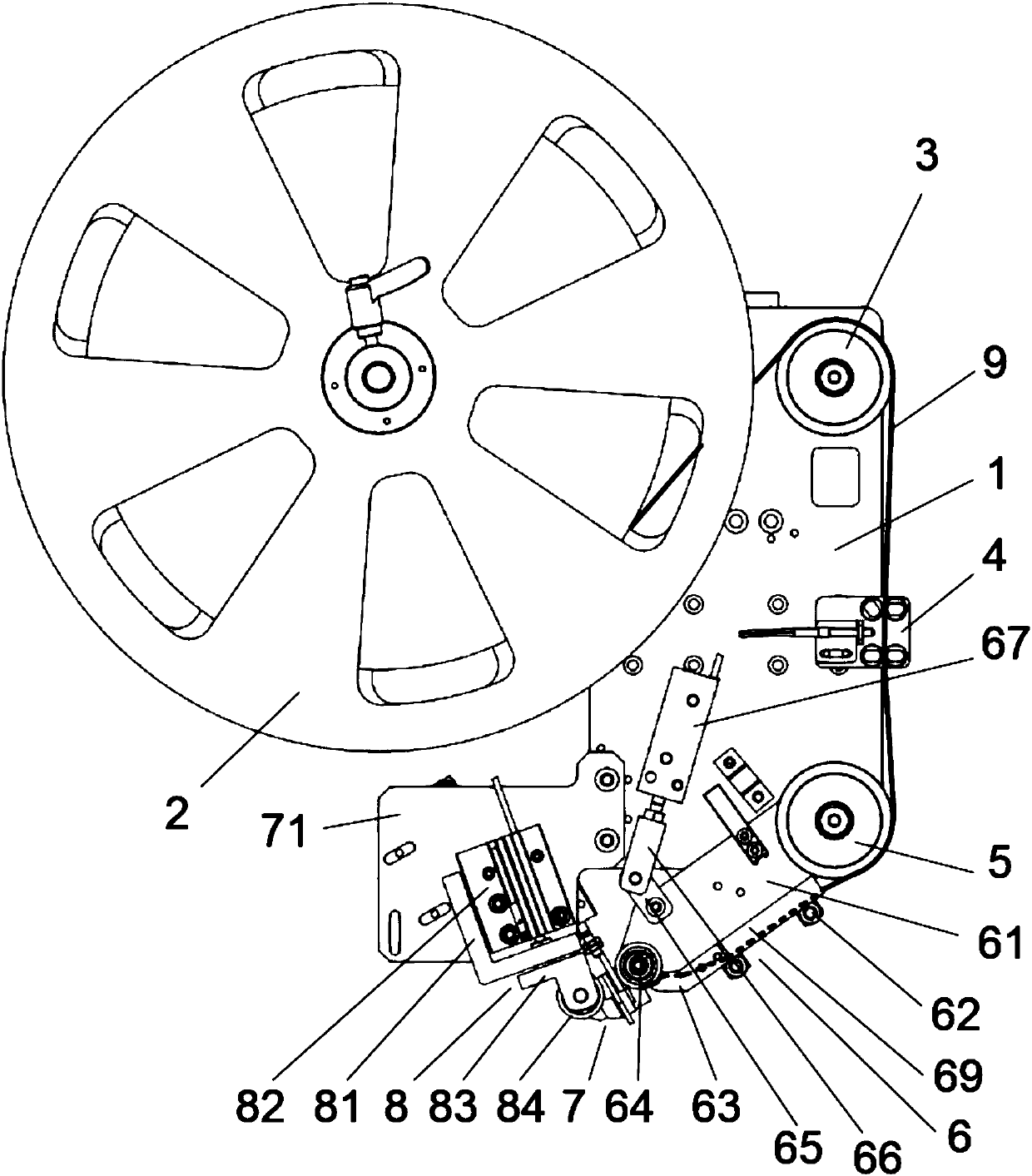

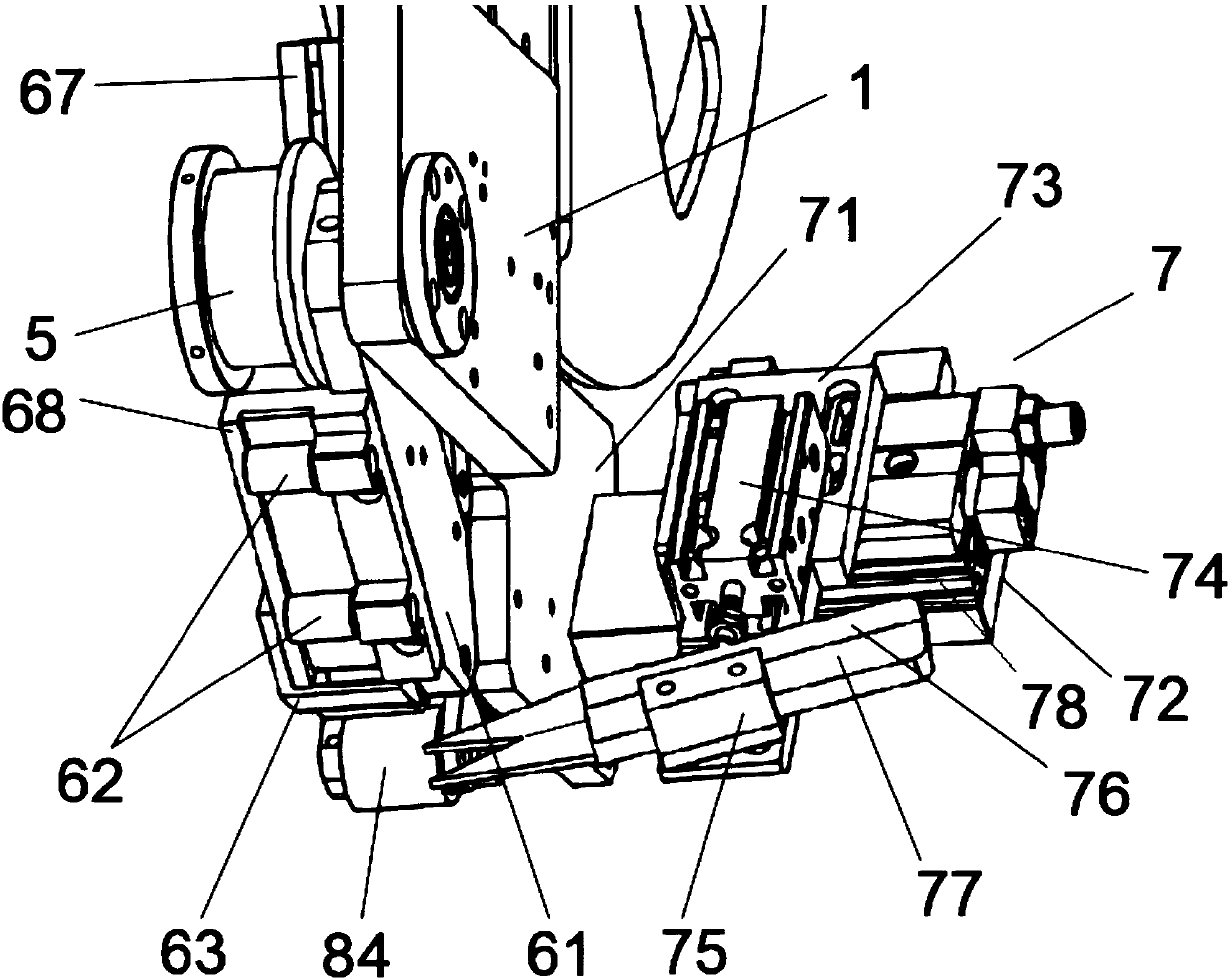

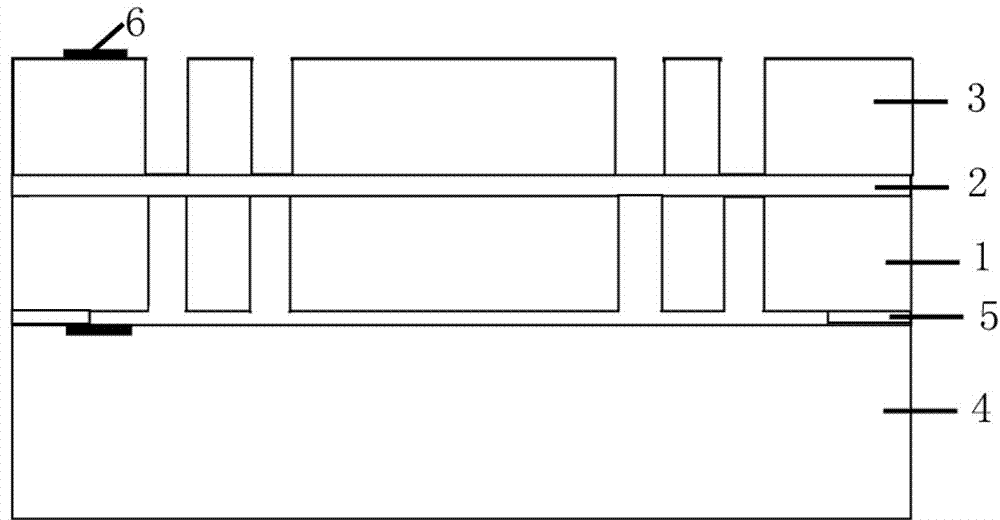

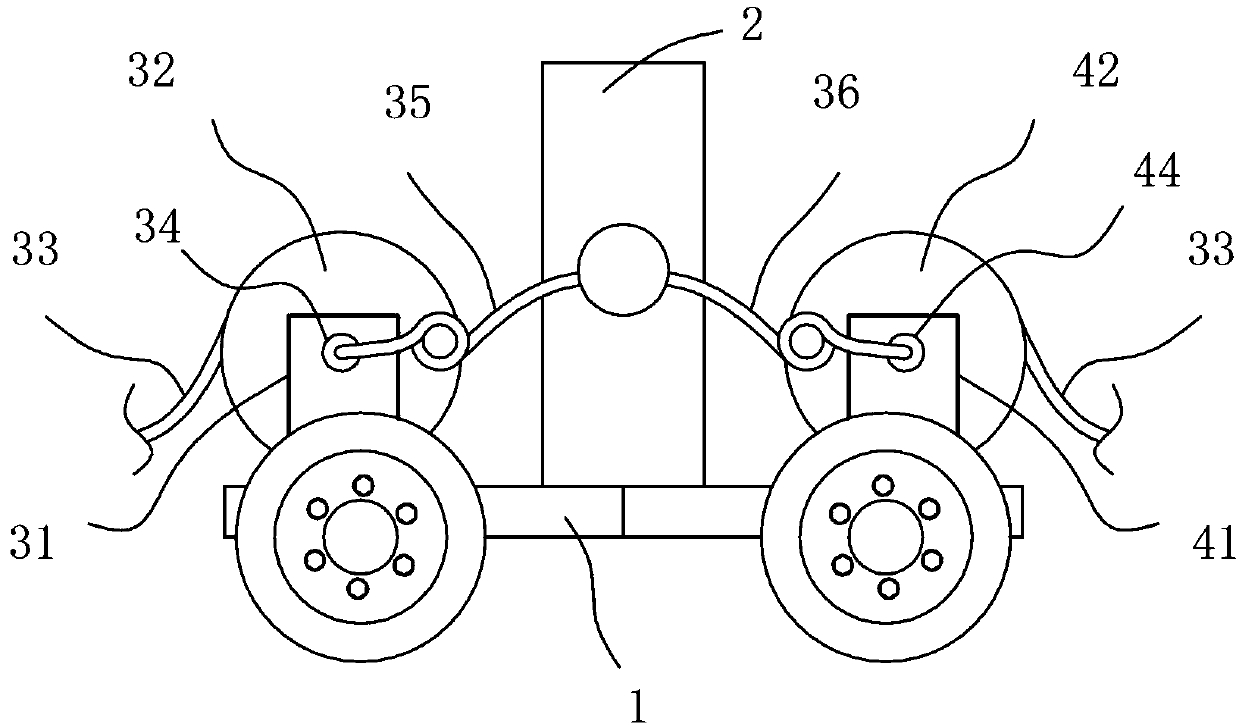

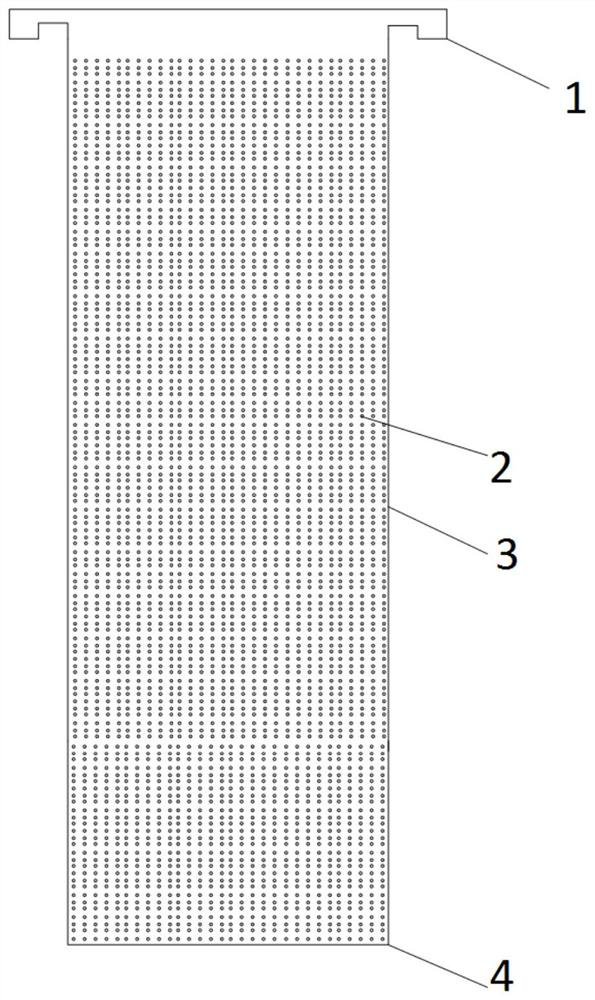

Processing and detecting system for coil bracket of miniature circuit breaker

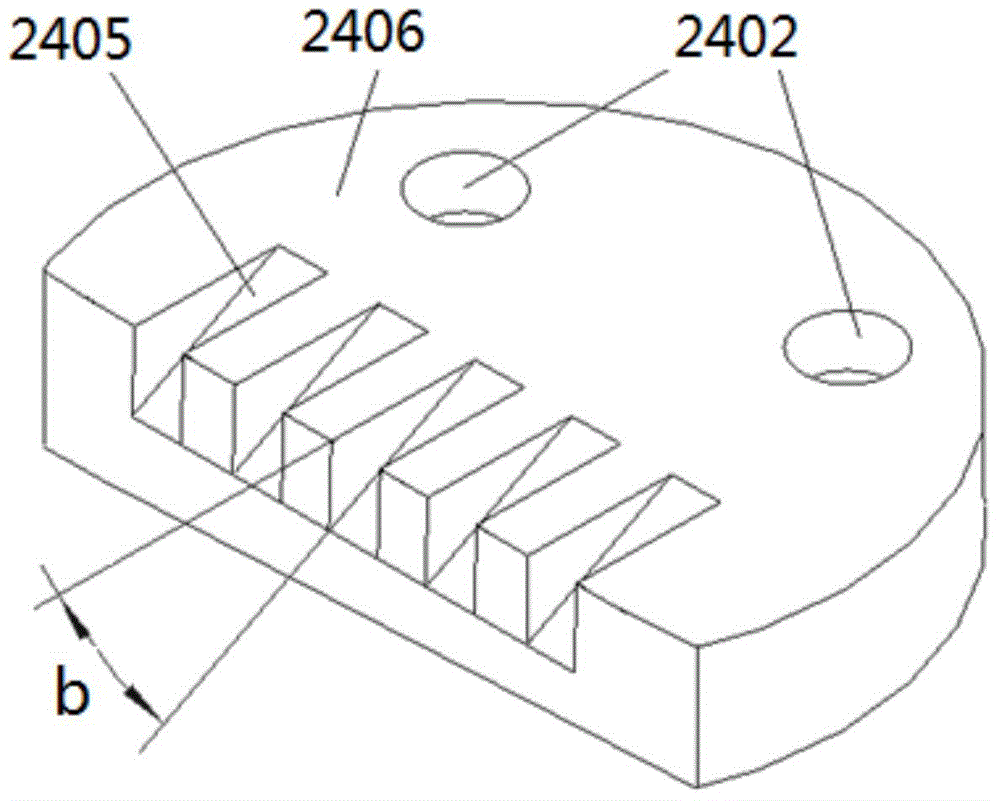

ActiveCN104759419ARealize automatic sortingHigh dimensional control accuracySortingResistance welding apparatusAutomatic processingContact group

The invention discloses a processing and detecting system for a coil bracket of a miniature circuit breaker. The processing and detecting system comprises a track part, wherein an electrode assembly and a feeding mechanism are arranged along the track part; a pushing mechanism and a detection mechanism are arranged at the tail end of the track part; a composite track is fixedly arranged on a work platform through a flat vibration support plate; two layers of steps are arranged on the surface of a long side of the composite track; inverted deep grooves are longitudinally formed in the short side of the composite track; a C-shaped groove is longitudinally formed in the position, close to a high step, of a low step, and is communicated with the surface of the low step; a high edge is arranged on the opening, towards the high step, of the C-shaped groove; and a gap is formed in the inside part at one end of a discharge groove of the composite track. The system disclosed by the invention is capable of replacing an existing manual processing mode, finishing automatic feeding, splitting, positioning, clamping, automatic welding and automatic detection once, realizing automatic sorting of qualified products from unqualified products, and realizing high-speed, convenient and accurate automatic processing and detecting of welding and molding of the coil bracket and a contact group.

Owner:嘉兴彩虹光学膜片科技有限公司

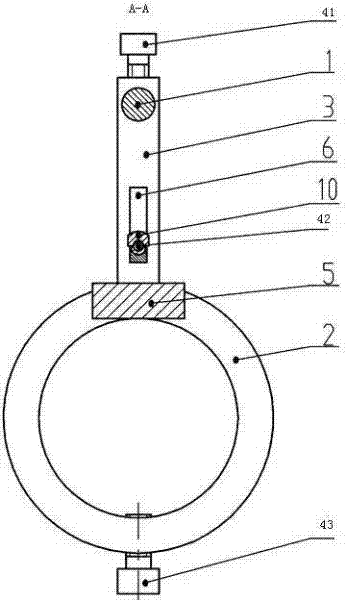

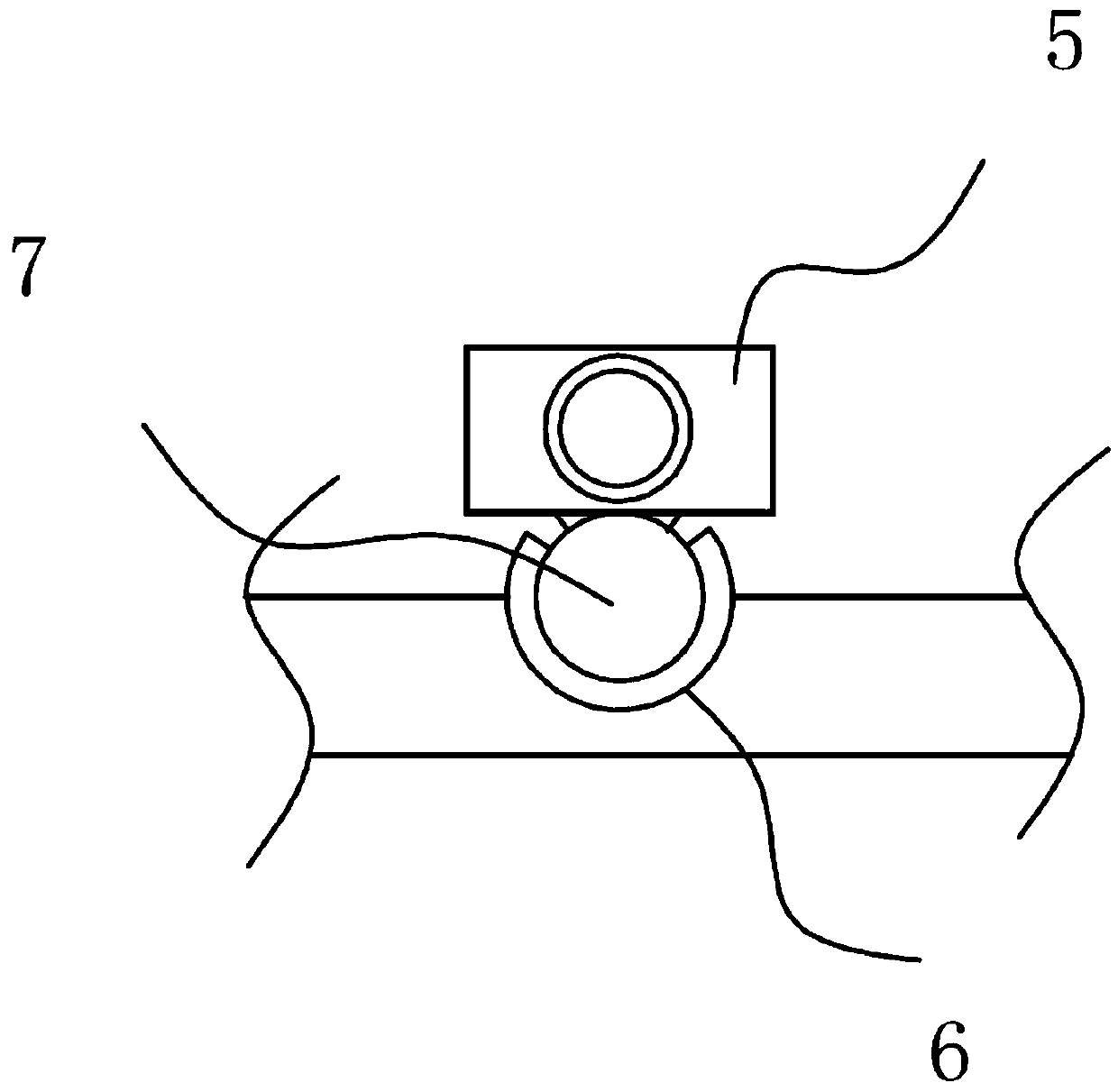

Device for controlling depth of drilled center hole

InactiveCN102126037AReasonable structureEasy to operateDrilling/boring measurement devicesContact padEngineering

The invention relates to a device for controlling the depth of a drilled center hole. A supporting sleeve is arranged and fixed on a taper shank sleeve of a drilling machine. The upper part of the supporting sleeve is provided with a dial indicator through a fixing rod. A guide sleeve is fixed in the horizontal direction of the supporting sleeve through a connection plate. A guide rod capable of axially moving is arranged in the guide sleeve. The front end of the guide rod is contacted with the end face of a part. The rear part of the guide rod is connected with a contact pad. The contact pad is contacted with an indicator head of the dial indicator. In the feeding process of drilling, the guide rod and the contact pad move backwards to contact the indicator head of the dial indicator, so that the depth of the drilled hole is controlled by observing reading on the dial indicator. The device for controlling the depth of the drilled center hole has a reasonable structure, is convenient to operate and use and has high size control precision.

Owner:TIANRUN IND TECH CO LTD

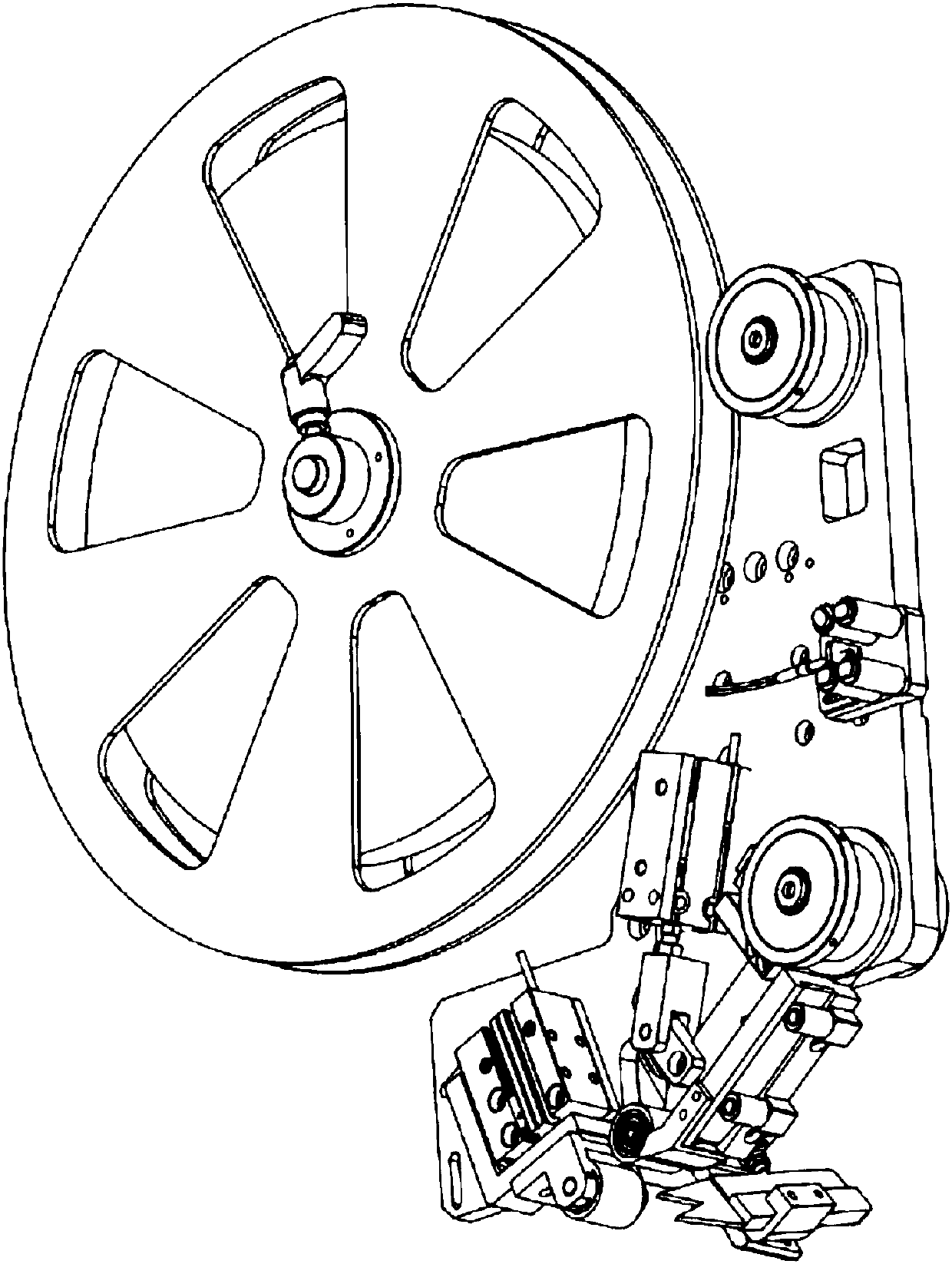

Rolling type flat adhesive tape sticking device

The invention relates to a rolling type flat tape sticking device. A rolling type flat tape sticking device includes a mounting plate; a feeding tray is fixed on the upper left of the mounting plate, a first guide roller is fixed on the upper right, a sensor is fixed on the middle position of the right end, and a lower right is fixed with a A second guide roller; a rolling device is arranged on the left side of the second guide roller, and a shearing device and a leveling device are fixed on the left side of the rolling device. The rolling type flat tape sticking device of the invention has the advantages of simple structure, stable action, high dimensional control precision, compact overall structure and saving processing space; , and then use the flat pressing roller to carry out the side pressing, so that the adhesive tape on the bottom film has a high flatness, good quality of the adhesive, and is very beautiful.

Owner:苏州恒铭达电子科技股份有限公司

Flame cutting technology for thick steel plates

ActiveCN105834548AGuaranteed uptimeAvoid problems such as shootingWelding/soldering/cutting articlesMetal working apparatusEngineeringFlame cutting

The invention discloses a flame cutting technology for thick steel plates. The flame cutting technology comprises the steps of 1, determining the height of a cutting rack before cutting and grinding and polishing rails; 2, setting the cutting speed according to the string formula that V is equal to kD plus d, wherein k is -1.5, d is 350 and the cutting thickness ranges from 10 mm to 120 mm; 3, adopting the mixed gas of oxygen gas and propane, controlling the length of flames to be 10+ / -2 cm and guaranteeing that the proportion of red flames (the head parts) to blue flames (the root parts) of the flames is 1 to 9; 4, carrying out measuring, length-fixed cutting and marking-off on the steel plates, adjusting the positions of cutters to align to the marking-off position and guaranteeing the width of the two cutters of a cutting machine through supporting arms; and 5, after cutting is completed, rechecking the sizes of the steel plates, wherein the width expansion range is 4-8 mm, and the length expansion range is 10-25mm. According to the flame cutting technology, the problem of cutting explosion generated in the cutting process of the thick steel plates can be reduced, the cutting accuracy can be controlled, the cutting quality can be improved, and the product size and the product quality can meet the standard requirements.

Owner:NANJING IRON & STEEL CO LTD

Thermal creeping forming method for machining of titanium alloy cover of weight reduction tank

InactiveCN106271441AHigh dimensional control accuracyReduce stress concentrationShaping toolsThermal creepHot pressing

The invention belongs to the technical field of thermal-press formation of a titanium alloy part and aims at providing a thermal creeping forming method for machining of a titanium alloy cover of weight reduction tank. By means of the method, the precision and performance of the part are improved, the production efficiency is improved, and pollution is avoided. According to the method, a mold matched with the cover part is manufactured firstly so that the outline of the part can be controlled, then the weight reduction tank is pre-machined in a machining mode, and the cover part is formed through the thermal creeping method. The problems that the dimension precision of the weight reduction tank is low and the fatigue performance of components is low due to the traditional mode that thermal creeping forming of the cover is carried out before chemical corrosion machining of the weight reduction tank are solved; the dimension control precision of the weight reduction tank is significantly improved; and the R corners of the arc transitional area of a weight reduction area and a non-weight reduction area are increased from R5 from R2 generated by acid pickling, stress concentration of the transitional area is relieved, and fatigue resistance of the part is improved. The problem of severe chemical corrosion pollution is solved, the physical health of operators is ensured, and the dimension precision and fatigue performance of the components are improved.

Owner:北京普惠三航科技有限公司

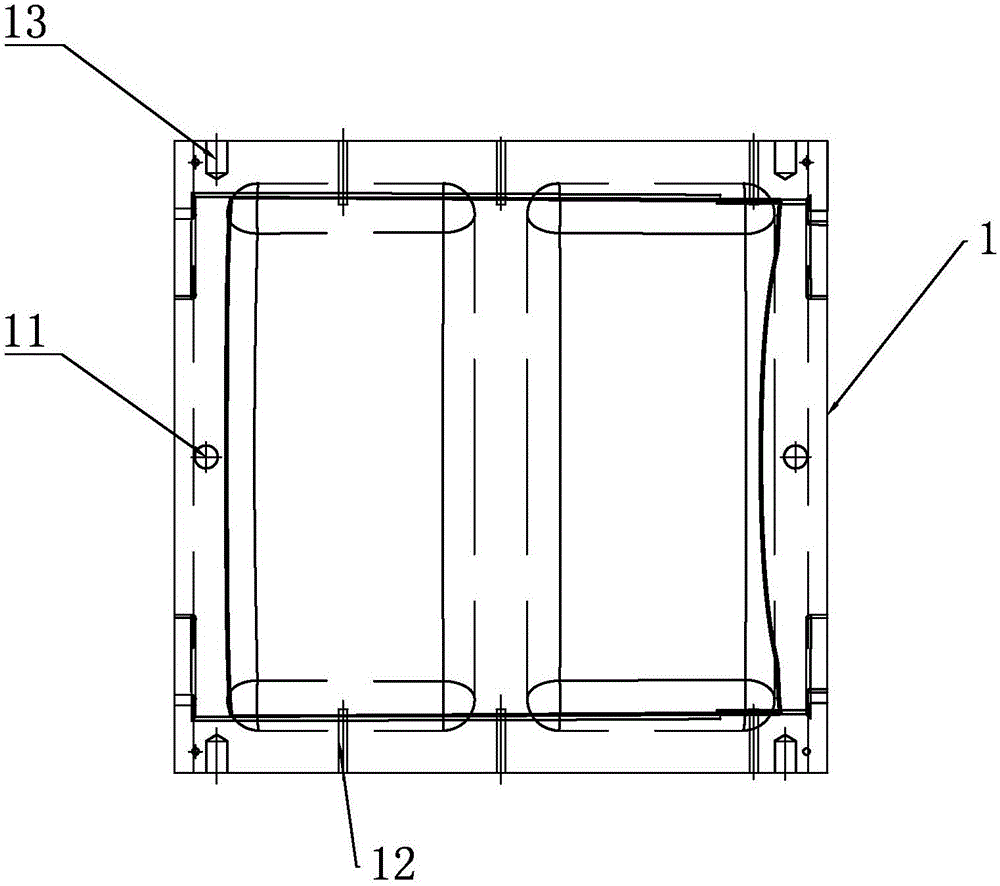

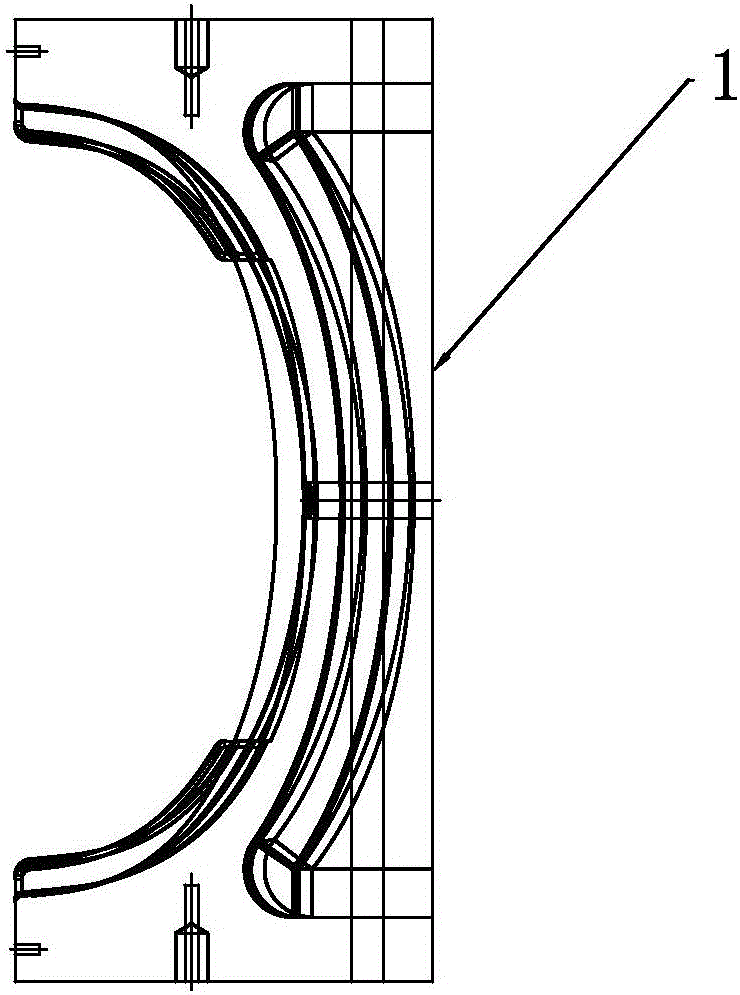

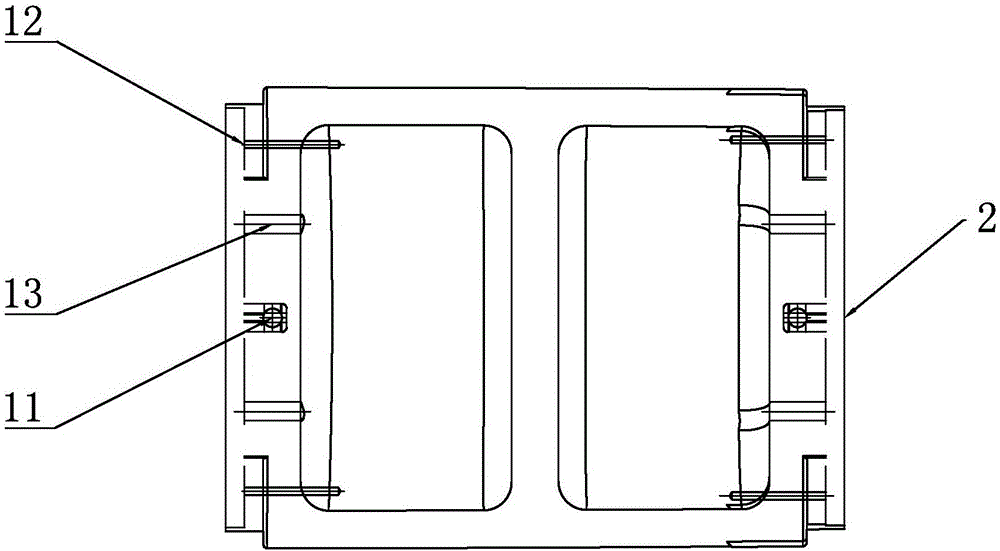

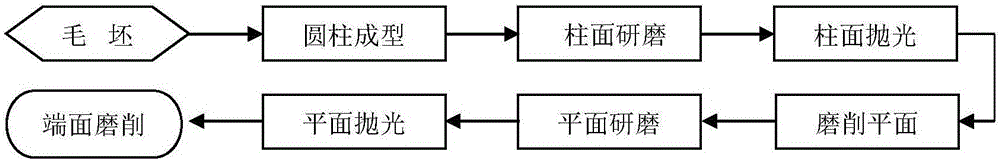

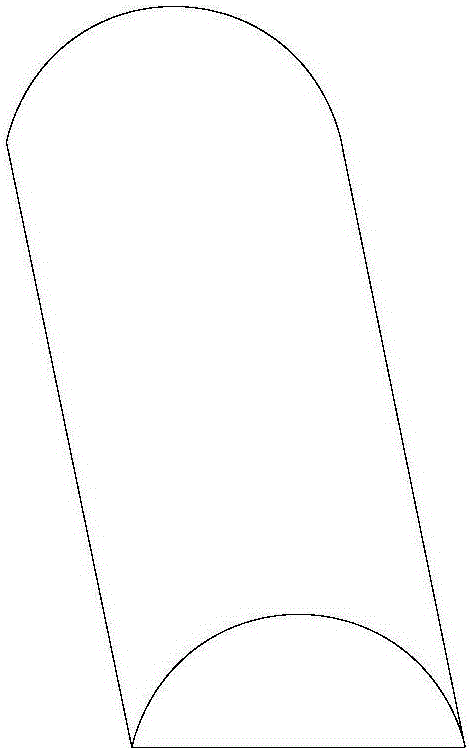

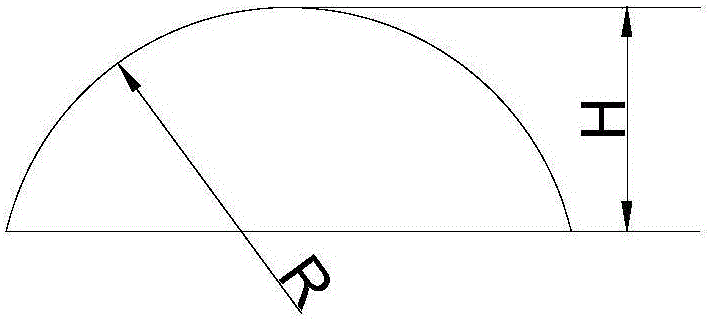

Processing method of plane convex cylindrical mirror

ActiveCN105751031ARealize batch processingImprove general performanceOptical surface grinding machinesLensEngineeringSurface grinding

The invention discloses a processing method of a plane convex cylindrical mirror. The processing method comprises the following steps that a glass blank material is coarsely ground into a cylinder; then, fine grinding and polishing are sequentially performed on the cylinder surface, so that the radius of the polished cylinder is in the radius requirement range of the plane convex cylindrical mirror; the polished cylinder and a plane mold are cast into a dish; the excessive cylinder surface of the cylinder is ground and cut into a plane along the axial direction of the cylinder to form a primary sample of the plane convex cylindrical mirror; the primary sample of the plane convex cylindrical mirror is demoulded; then, the plane of the primary sample of the plane convex cylindrical mirror is ground and polished, so that the arc height of the polished primary sample of the polished plane convex cylindrical mirror is in the arc height requirement range of the plane convex cylindrical mirror; the two ends of the polished primary sample of the polished plane convex cylindrical mirror is subjected to end surface grinding to obtain a finished product of the plane convex cylindrical mirror; the length is in the length requirement range of the plane convex cylindrical mirror. The processing method provided by the invention solves the problems of low precision and low efficiency of the existing processing method of the plane convex cylindrical mirror, and has the advantages that the universality is high; the dimension control precision is high; the mass processing of the plane convex cylindrical mirror can be realized.

Owner:CHINA BUILDING MATERIALS ACAD

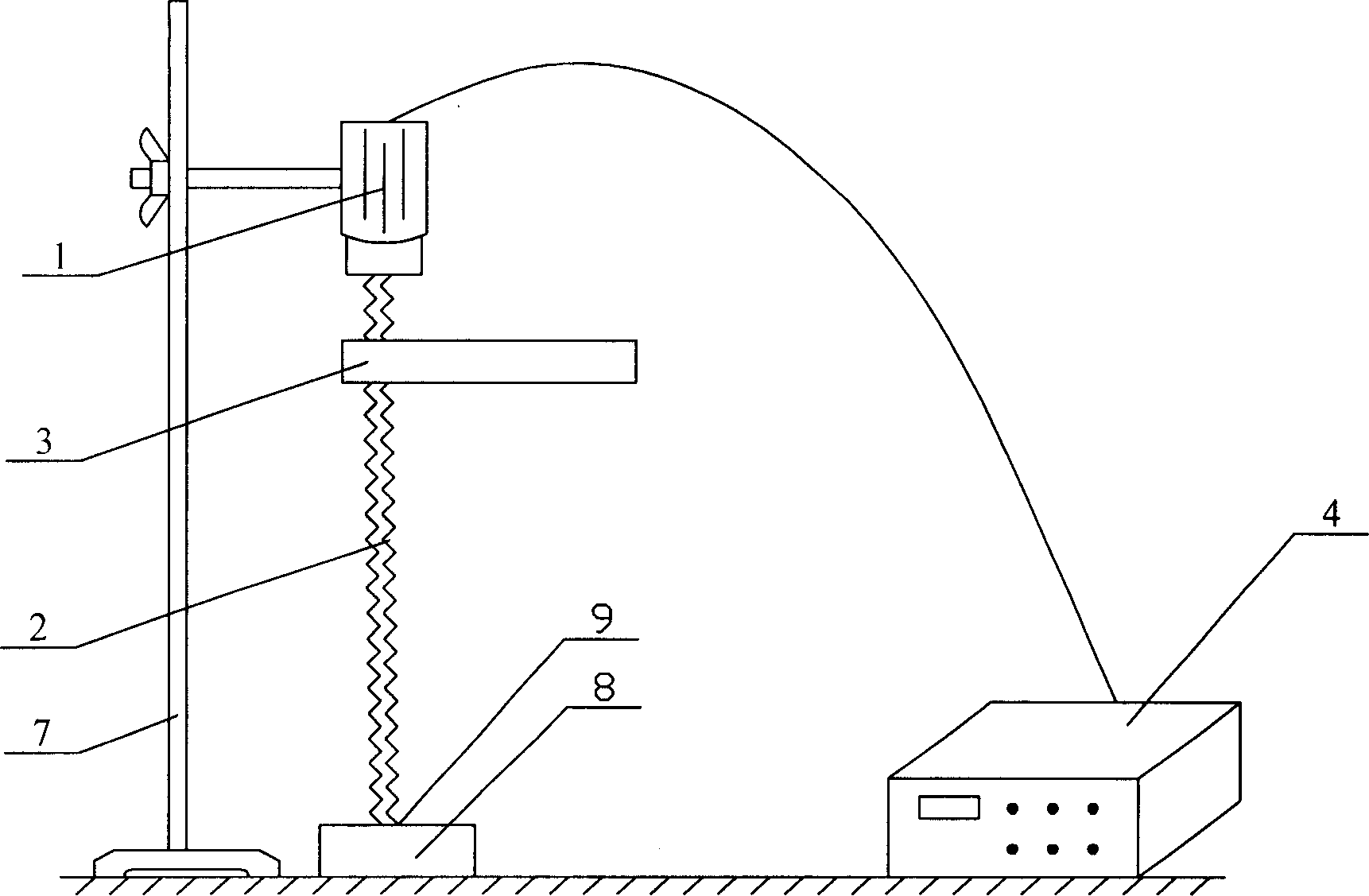

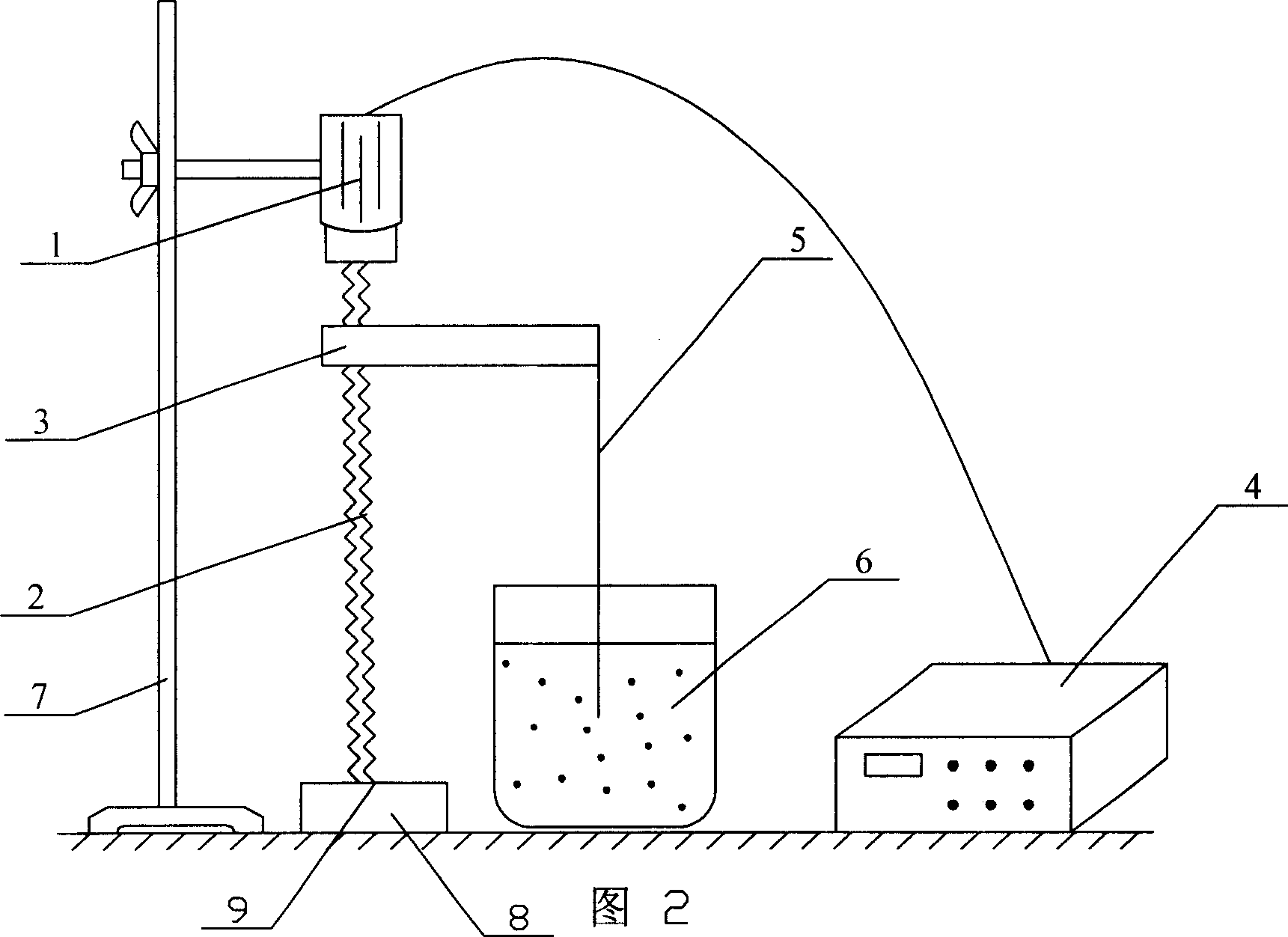

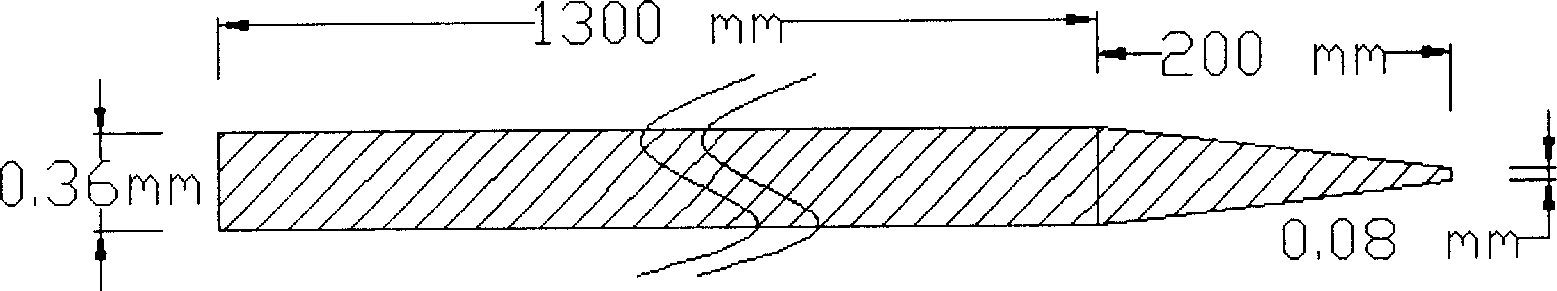

Lifting device and method for processing alloy wire with continuous or step taper at end

InactiveCN1912185AImprove surface roughnessHigh dimensional control accuracyElectricityElectric machine

The invention relates to a mechanics pulling device and the method used it to process superfine metal alloy silk material. The electric machine of the pulling device is fixed on the upper end of the frame whose lower end is fixed on the table board. The electricity input end of the electric machine is connected with the outlet end of the periphery control device. The output end is connected with the upper end of the leading screw whose lower end is fixed in blind hole of the fixing. Pulling moving machine is covered on the leading screw. The invention has low cost, and is good for popularizing and application.

Owner:HARBIN ENG UNIV

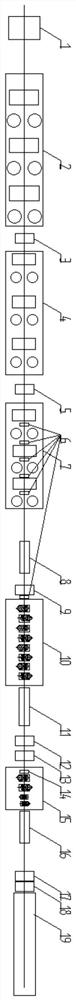

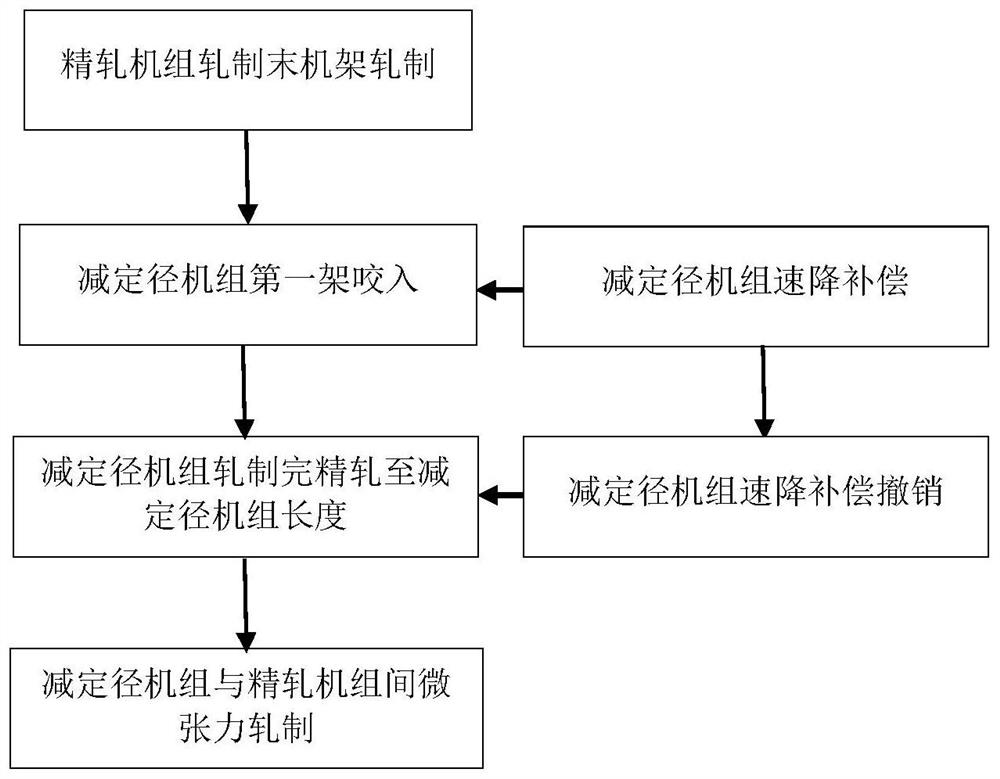

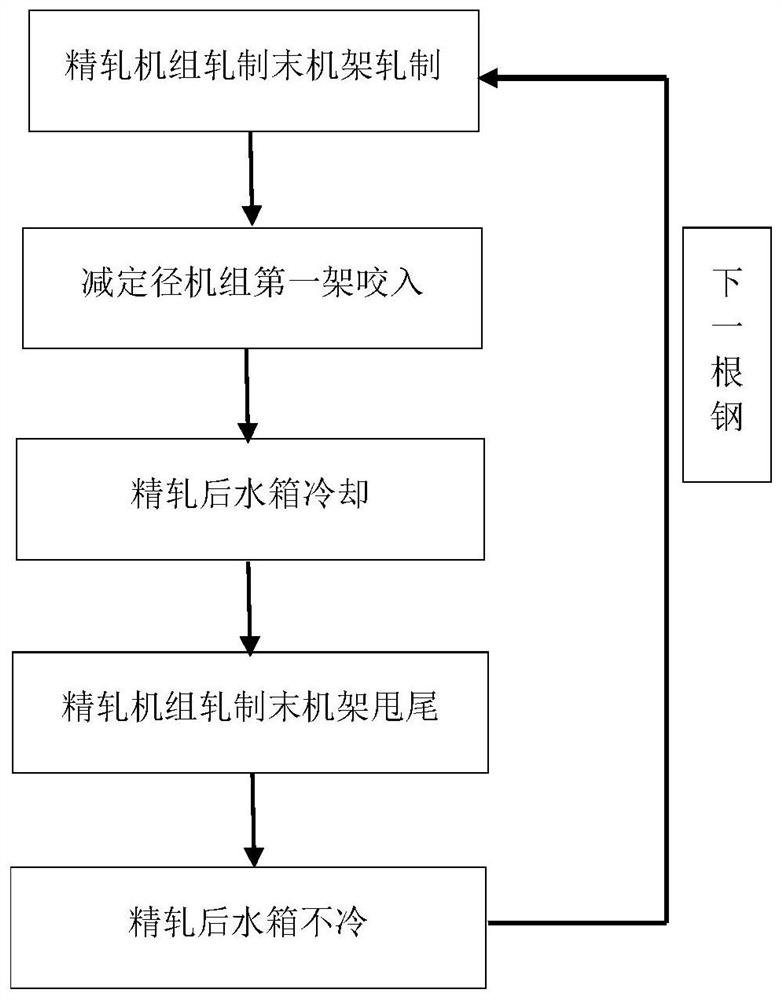

High-speed wire rod production system with reducing and sizing unit and method

PendingCN113070339AHigh dimensional accuracyImprove dimension flowTemperature control deviceWork cooling devicesWire rodProcess engineering

The invention belongs to the field of high-speed wire rod production in the ferrous metallurgical industry, and relates to a high-speed wire rod production system with a reducing and sizing unit and a method. The system comprises a blank heating device, a roughing mill unit, a roughing mill unit rear flying shear, an intermediate mill unit, an intermediate mill unit rear flying shear, a pre-finishing mill unit, a loop between pre-finishing mill units, a pre-finishing mill unit rear flying shear, a finishing mill unit front loop, a finishing mill unit, a finishing mill unit rear water tank, a reducing mill unit front flying shear device, a pinch roll, a cut-off shear, a reducing and sizing mill or a reducing mill, a reducing and sizing unit rear water tank, a silking machine front pinch roll, a silking machine, an air cooling line and a collecting device. According to the method, the size control precision of the free section between the reducing and sizing unit and the finishing mill unit is improved, the size out-of-tolerance of the head and the tail is reduced, the size cleaning performance of a final product is improved, the yield is increased, the accident occurrence probability of the area is reduced, the fault processing time in the production process is shortened, the rolling mill operation rate is increased, and the income is increased.

Owner:CISDI ENG CO LTD +1

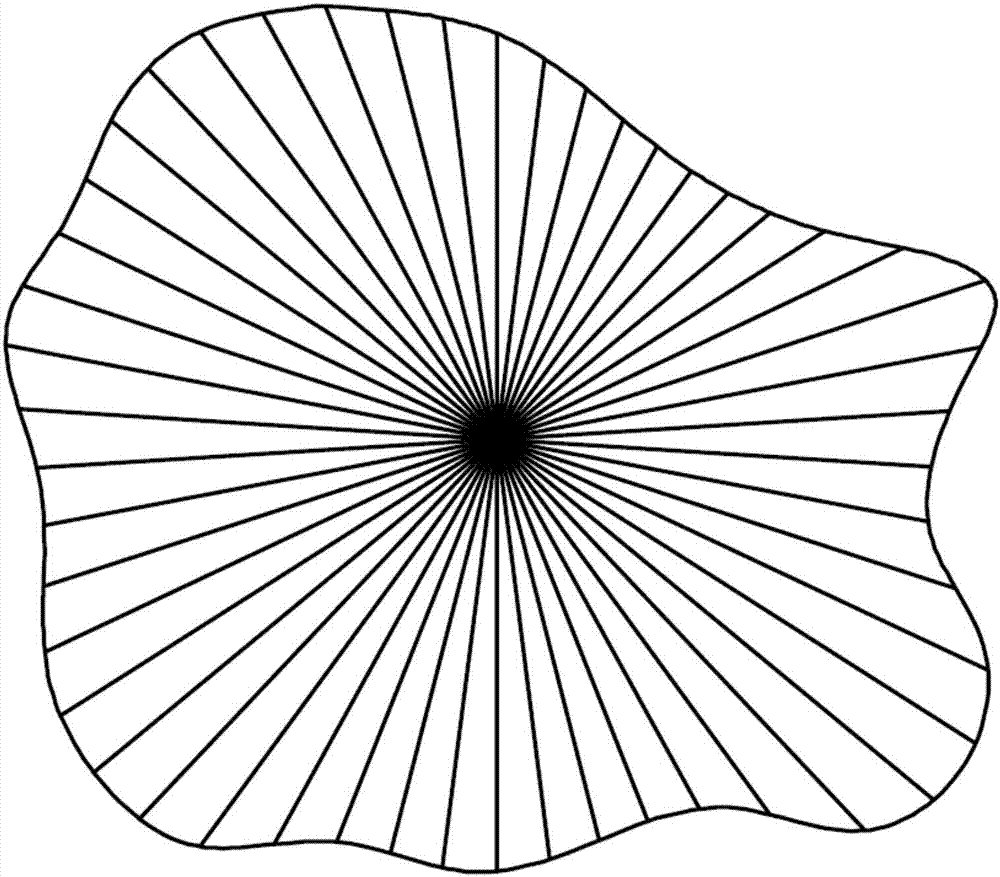

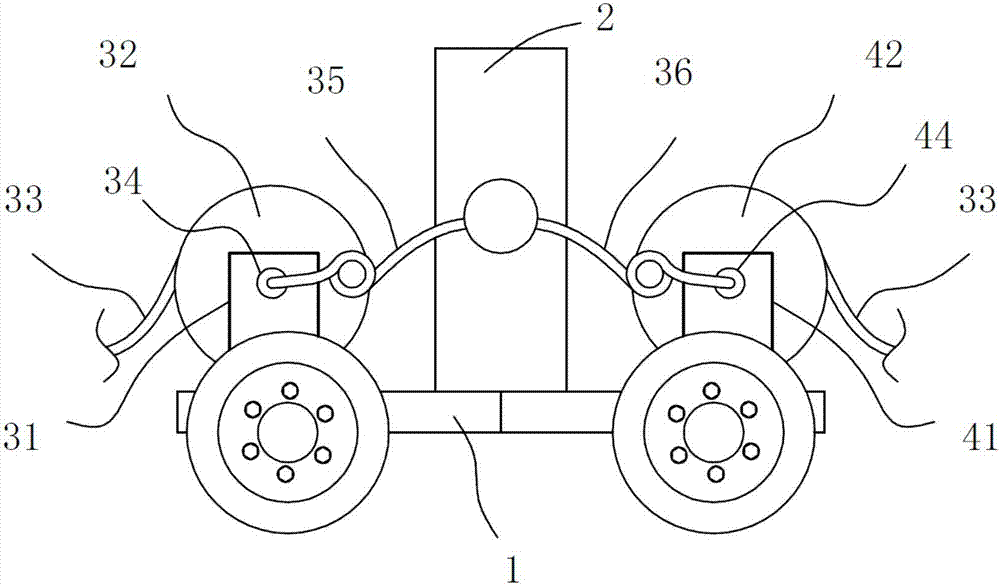

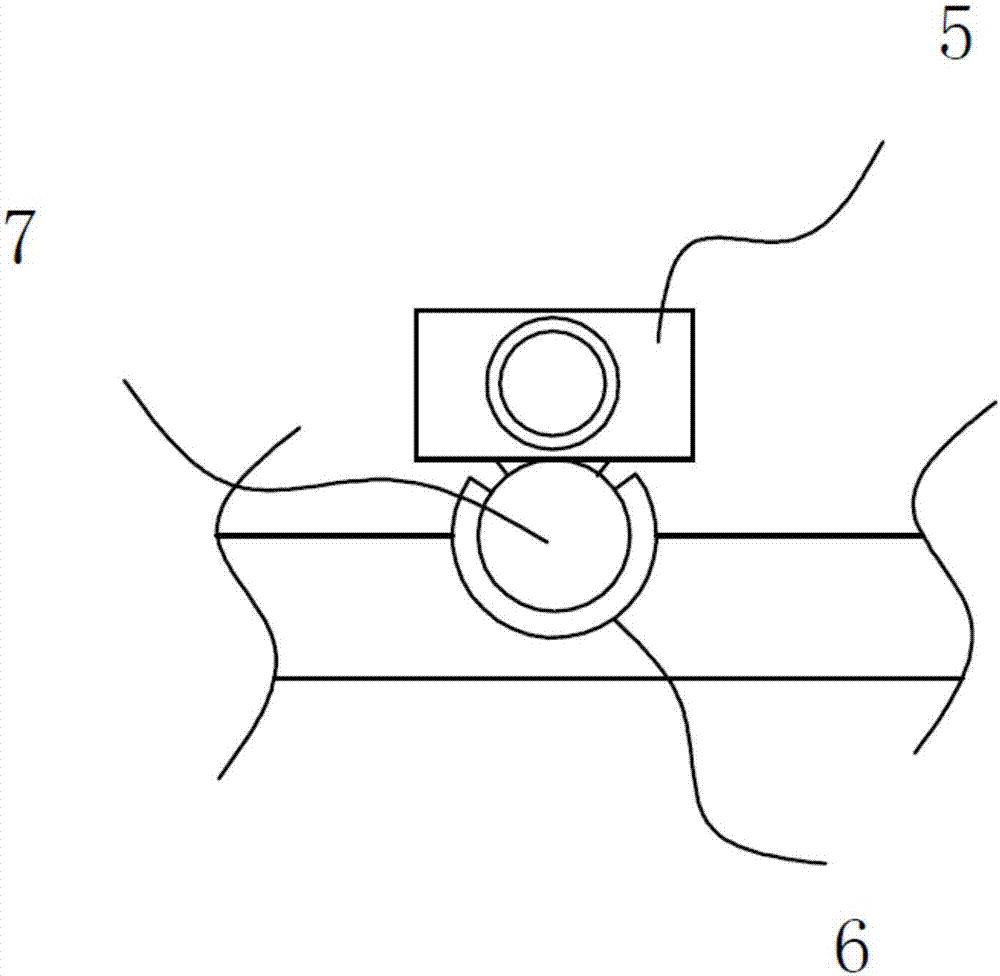

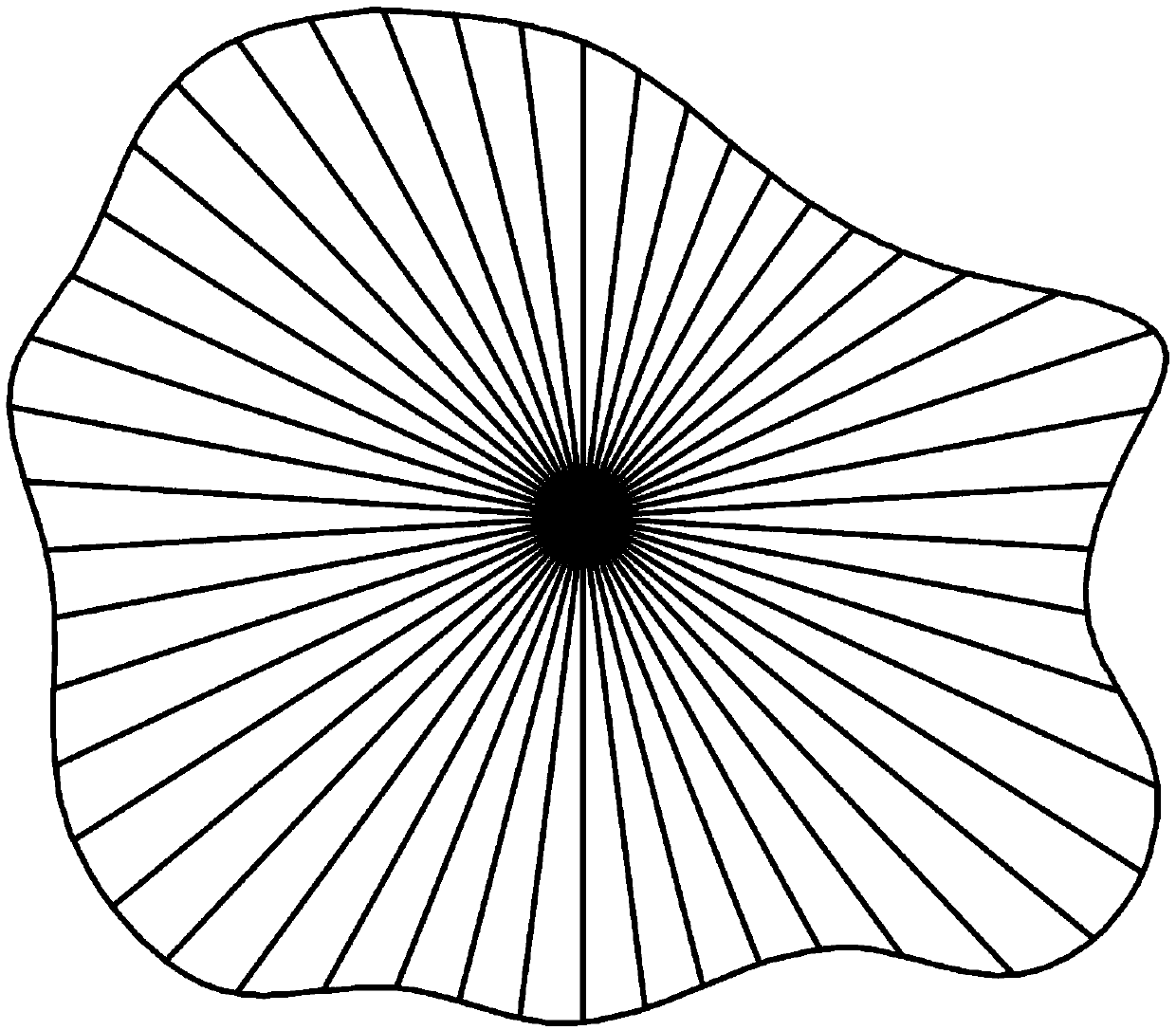

Irregular small-sized land area measuring method based on photoelectric measuring technology

ActiveCN107121098AReduce technical ability requirementsOptimize layoutUsing optical meansGeomorphologyMeasuring instrument

The invention discloses an irregular small-sized land area measuring method based on a photoelectric measuring technology. The irregular small-sized land area measuring method is characterized by comprising the following steps: 1) determining a positioning base point in a land central area; 2) building laser beams which are vertical to one another on the basis of the positioning base point in order to partition a land into four areas; 3) erecting a measuring cable along an outer edge of each area, wherein photoelectric measuring instrument modules are distributed on the measuring cable at equal intervals; 4) acquiring distances between the photoelectric measuring instrument modules and the positioning base point, and transmitting the distances to a control terminal; 5) calculating a land graph and an area according to data acquired through the distances among photoelectric measuring instruments through the control terminal. By adopting the irregular small-sized land area measuring method based on the photoelectric measuring technology, distance information acquired by the photoelectric measuring instruments which are arranged along the edges of the land is utilized in conjunction with equal-interval arrangement of adjacent photoelectric measuring instruments, so that a coordinate graph of the land edges can be drawn, and high boundary annotation accuracy and high size control accuracy are realized; the method is easy and convenient to operate, and contributes to proceeding of outdoor operation.

Owner:NJU OPTOELECTRONICS ENG RES INST CO LTD

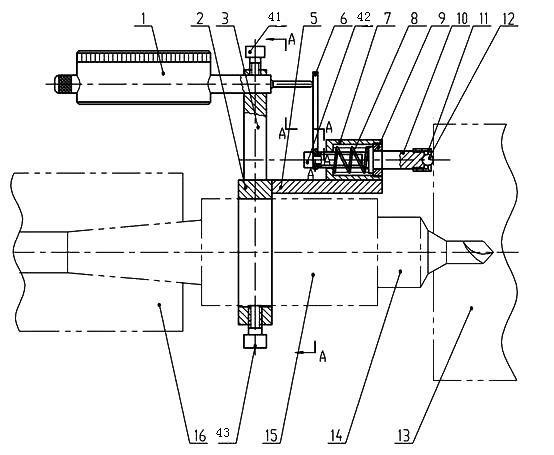

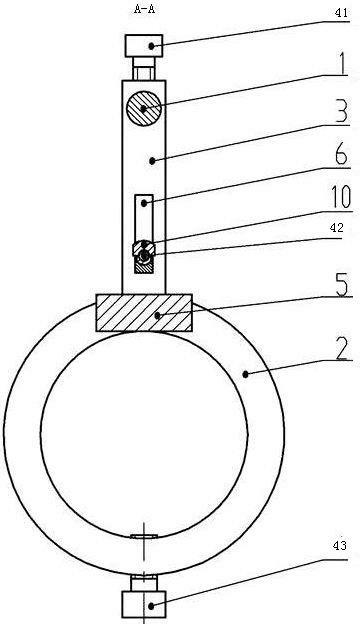

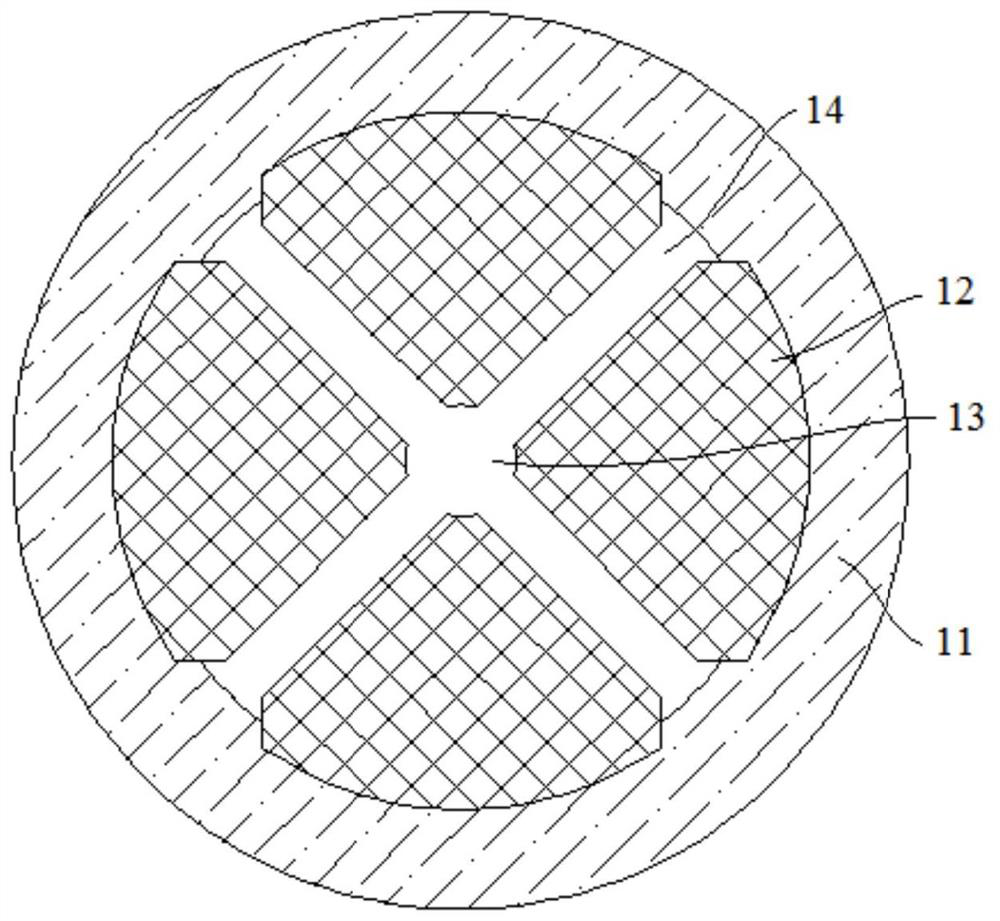

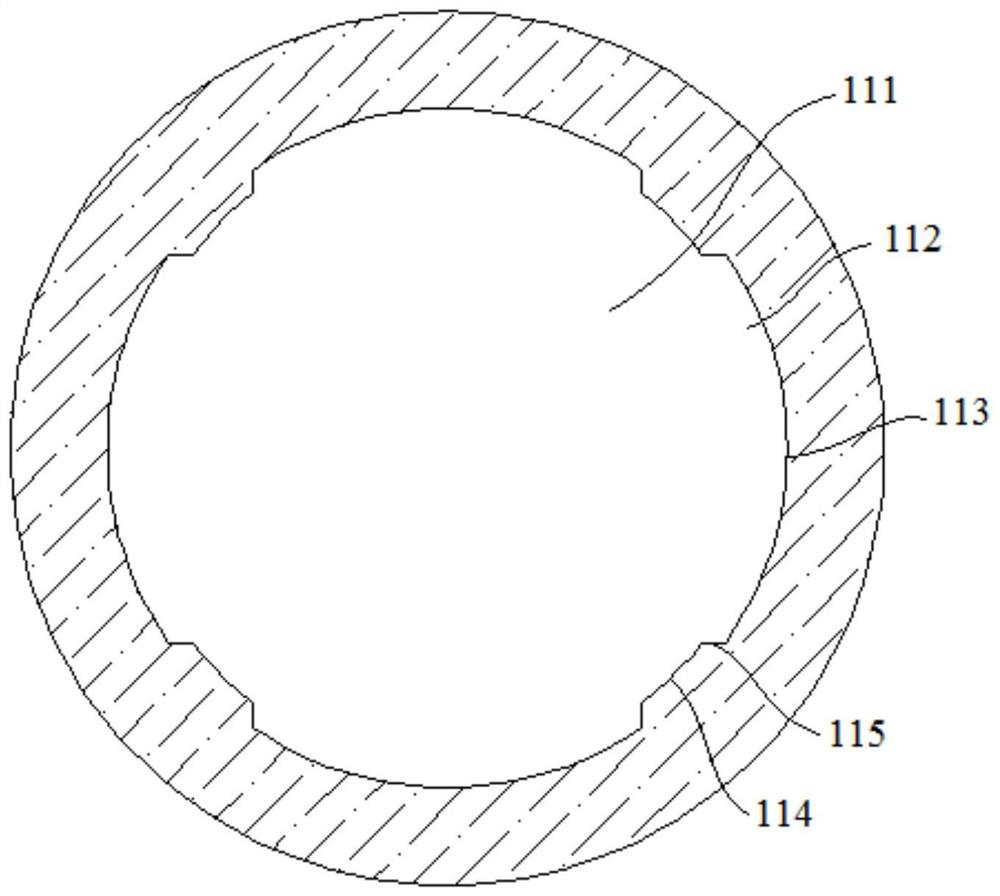

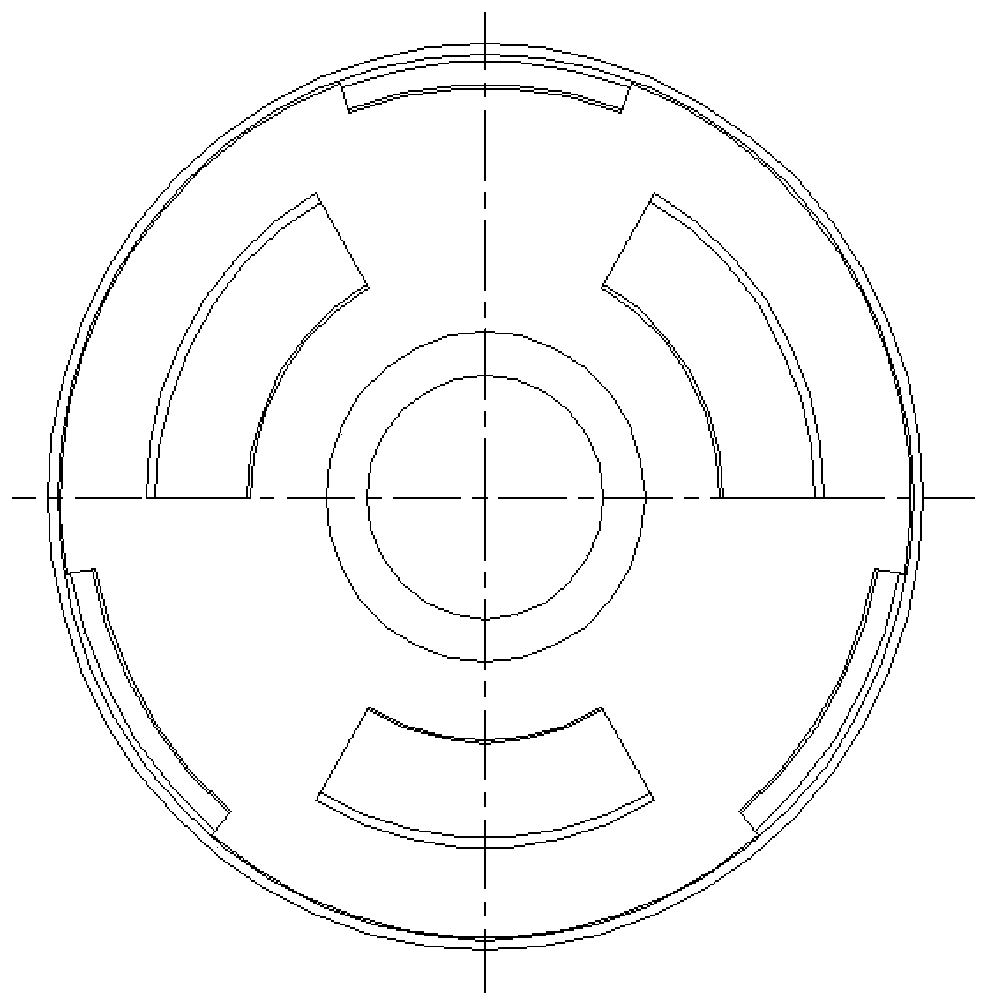

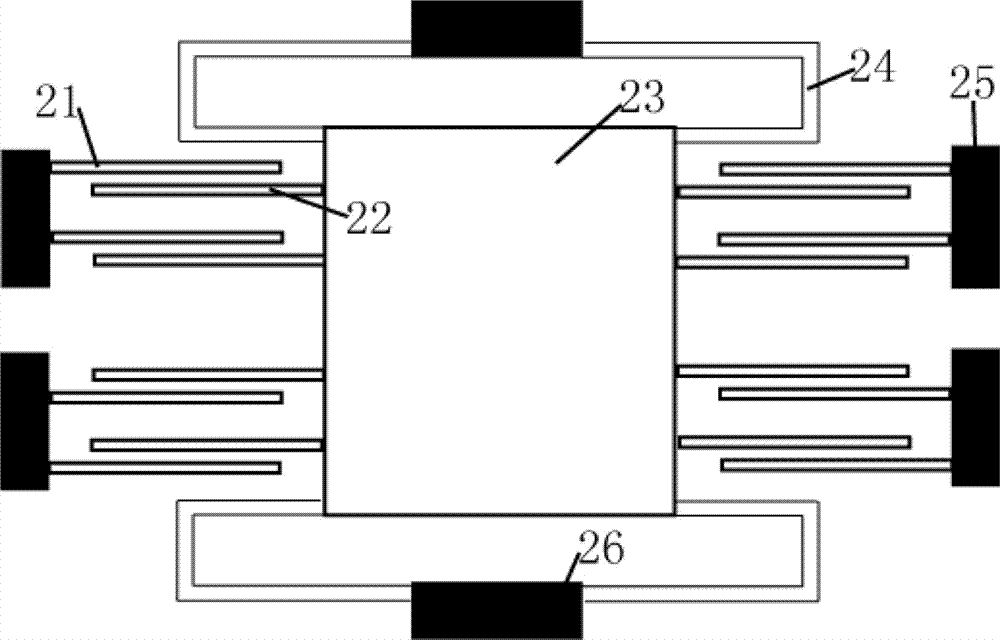

Manufacturing method of small-size sintered NdFeB multi-pole magnetic ring

ActiveCN112164575AEfficient manufacturingImprove magnetic propertiesInductances/transformers/magnets manufactureMagnetic materialsMetallurgyMagnetic loop

The invention discloses a manufacturing method of a small-size sintered NdFeB multi-pole magnetic ring, and belongs to the technical field of permanent magnet material preparation. According to the method, a pneumatic pressing device is adopted for pressing and forming sintered neodymium-iron-boron powder, then a pressed blank is taken out and subjected to isostatic pressing treatment, high-temperature sintering, tempering treatment and trepanning and grinding treatment, and the sintered NdFeB multi-pole magnetic ring is obtained. The pneumatic pressing device comprises an orientation mechanism and a pressing die, the orientation mechanism is composed of an even number of sintered NdFeB magnetic shoes which are evenly distributed in the circumferential direction at intervals, a die installation cavity is formed among the sintered NdFeB magnetic shoes in a surrounding mode, and the pressing die is correspondingly installed in the die installation cavity. By the adoption of the technicalscheme, the small-size sintered NdFeB multi-pole magnetic ring can be effectively manufactured, the manufacturing process is convenient, the equipment investment cost is low, the manufactured multi-pole magnetic ring is good in magnetic performance, and meanwhile the pressing percent of pass and the overall efficiency of the multi-pole magnetic ring are improved.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

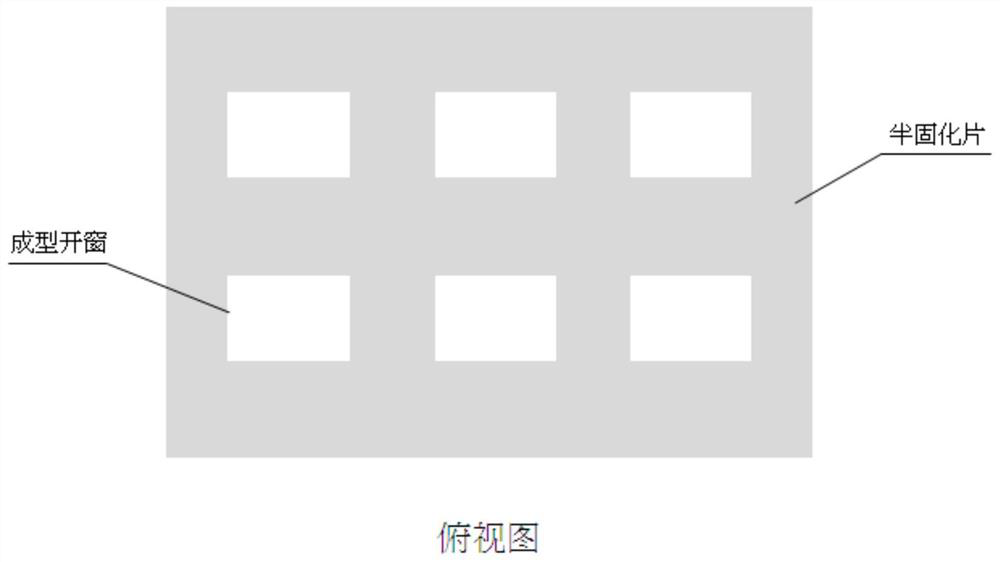

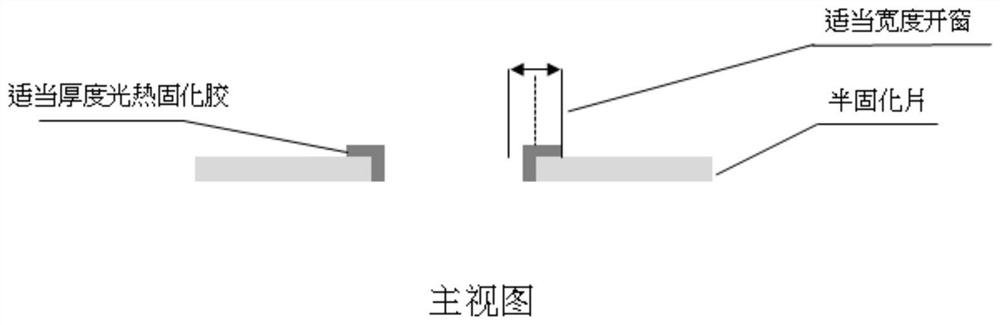

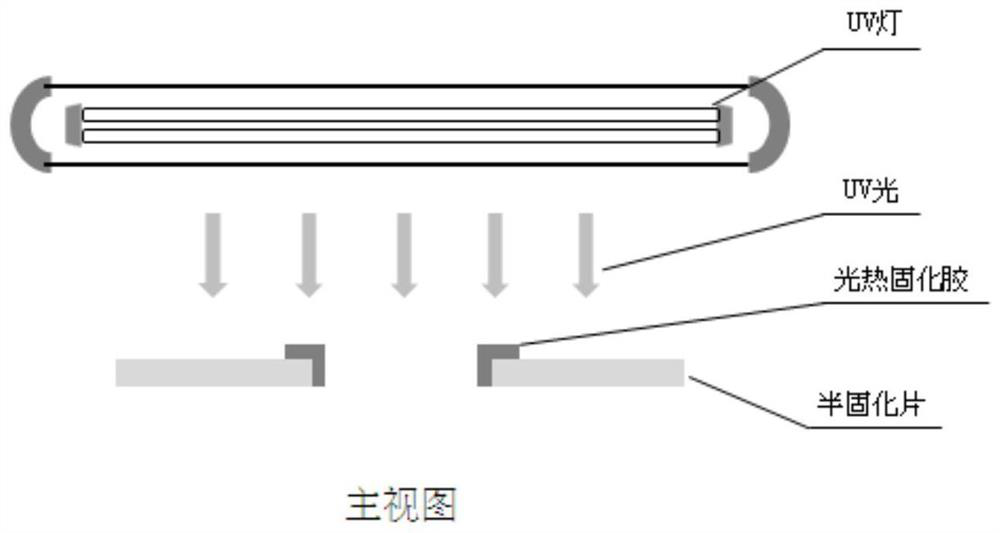

Prepreg glue flowing control method

PendingCN114501861AEffective Control WidthReduce widthCircuit fluid transportMultilayer circuit manufactureAdhesiveMechanical engineering

The invention discloses a prepreg glue flowing control method, which comprises the following steps of: forming a window on a prepreg, jet printing, coating or printing curing glue at the window of the prepreg, and irradiating the curing glue by light to primarily cure the curing glue; and pressing the primarily cured prepregs through a hot press, and completely curing the primarily cured curing glue under the action of heat of the hot press, so that the curing glue and the laminated plate are combined into a whole. According to the invention, the use of low-flow glue or non-flow glue prepregs can be avoided, and the glue overflow of the prepregs in the pressing process can be effectively controlled, so that the flow glue of the prepregs in the pressing process is prevented from flowing to the cavity or the bending groove; the curing adhesive and the PCB are combined into a whole, other special treatment does not need to be carried out on the curing adhesive in the pressing and follow-up processes, no other waste is generated in the operation process, the national and global waste is reduced in cooperation, and environmental protection is achieved.

Owner:KUSN HULI MICROELECTRONICS

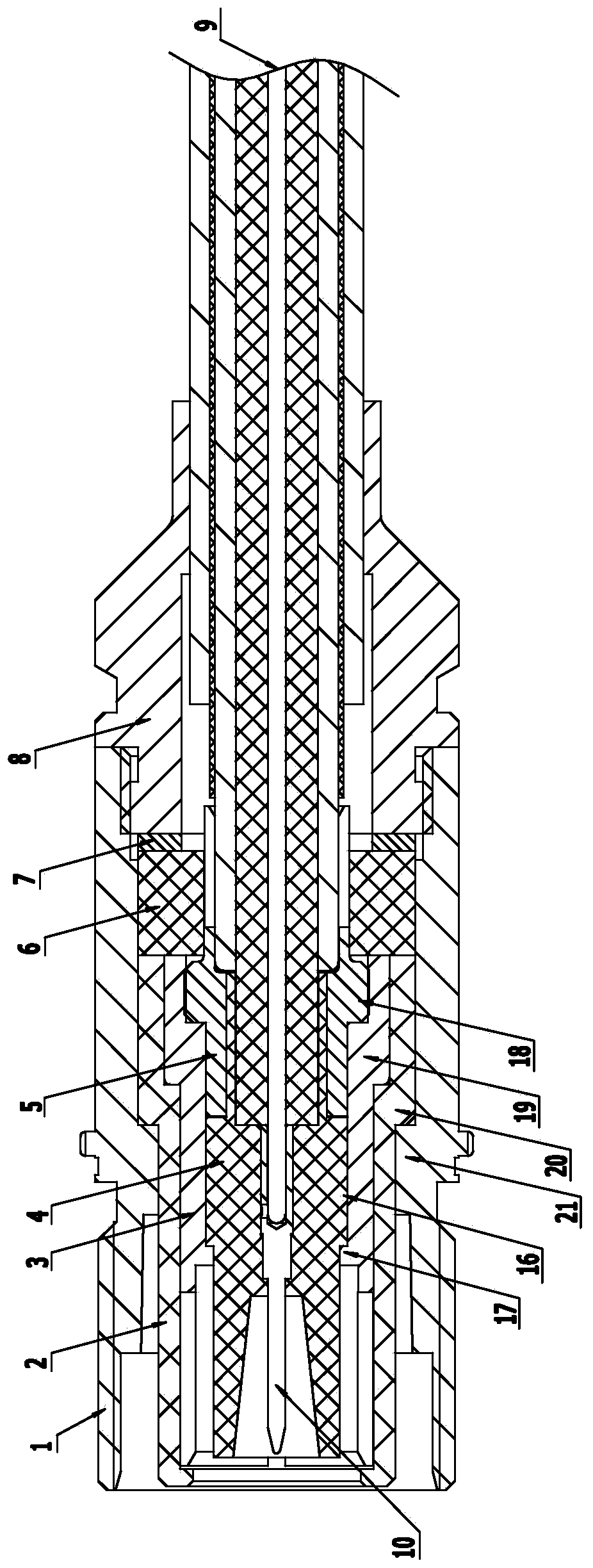

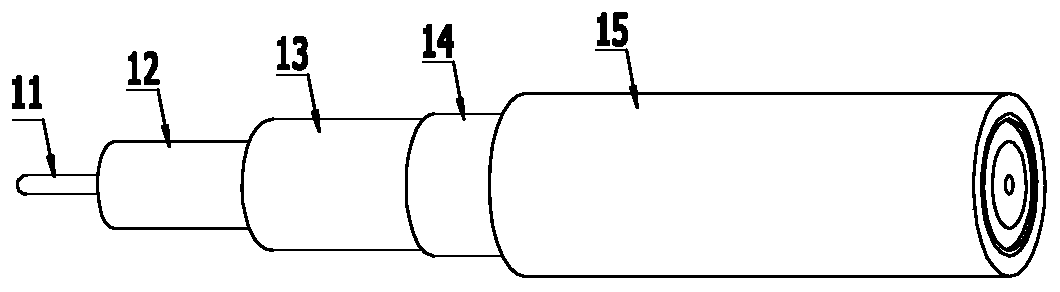

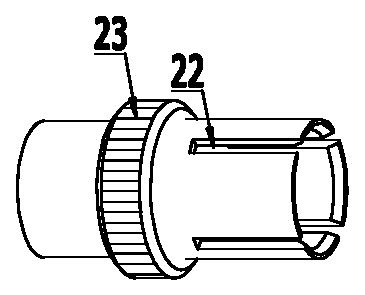

Triaxial hard cable component

ActiveCN110379556APrevent oxidationQuick connectionCoaxial cables/analogue cablesInsulated cablesElectrical conductorEngineering

The invention relates to a triaxial hard cable component. A triaxial hard cable is assembled in a shell at the tail part of a connector, penetrates an inner bushing and an inner insulator in the connector and is welded with a central contact element by adopting a high-temperature soldering tin wire; the periphery of the inner bushing is provided with knurls and is fixed in a middle conductor in aforced mounting mode, the tail end of the inner bushing is provided with an opening to enable the tail end of the inner bushing to be an elastic structure, the cable inner shielding layer is insertedinto the tail end of the elastic structure of the inner bushing to have a fixing effect on the inner shielding layer, the outer shielding layer of the triaxial hard cable is connected with the tail end of the tail shell in an induction brazing mode, and the connection of the periphery of the inner shielding layer and the tail end of the inner bushing is plated with gold; and the connection of theinner wall of the tail portion of the shell and the outer shielding layer is plated with nickel. The triaxial hard cable component can achieve quick and reliable connection of the triaxial hard cableand the connector, is reliable in connection, ensures the reliability and the sealing property of the connection, improves the welding strength and ensures the reliable sealing performance and the good electrical performance of the component under various working conditions.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

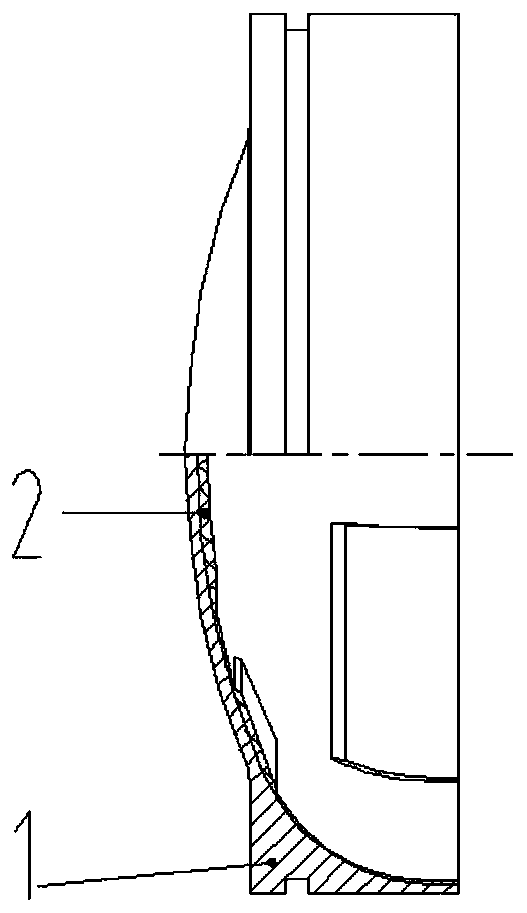

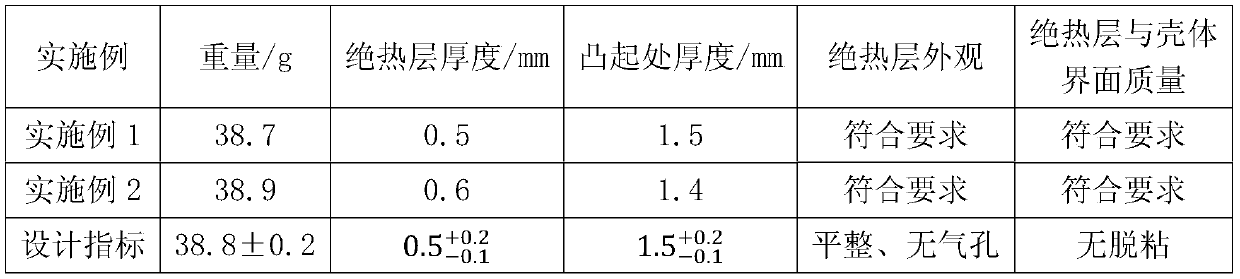

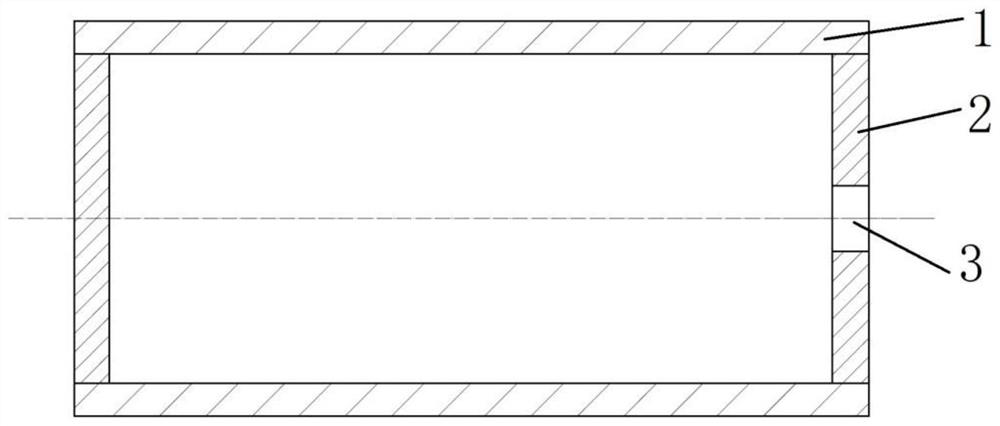

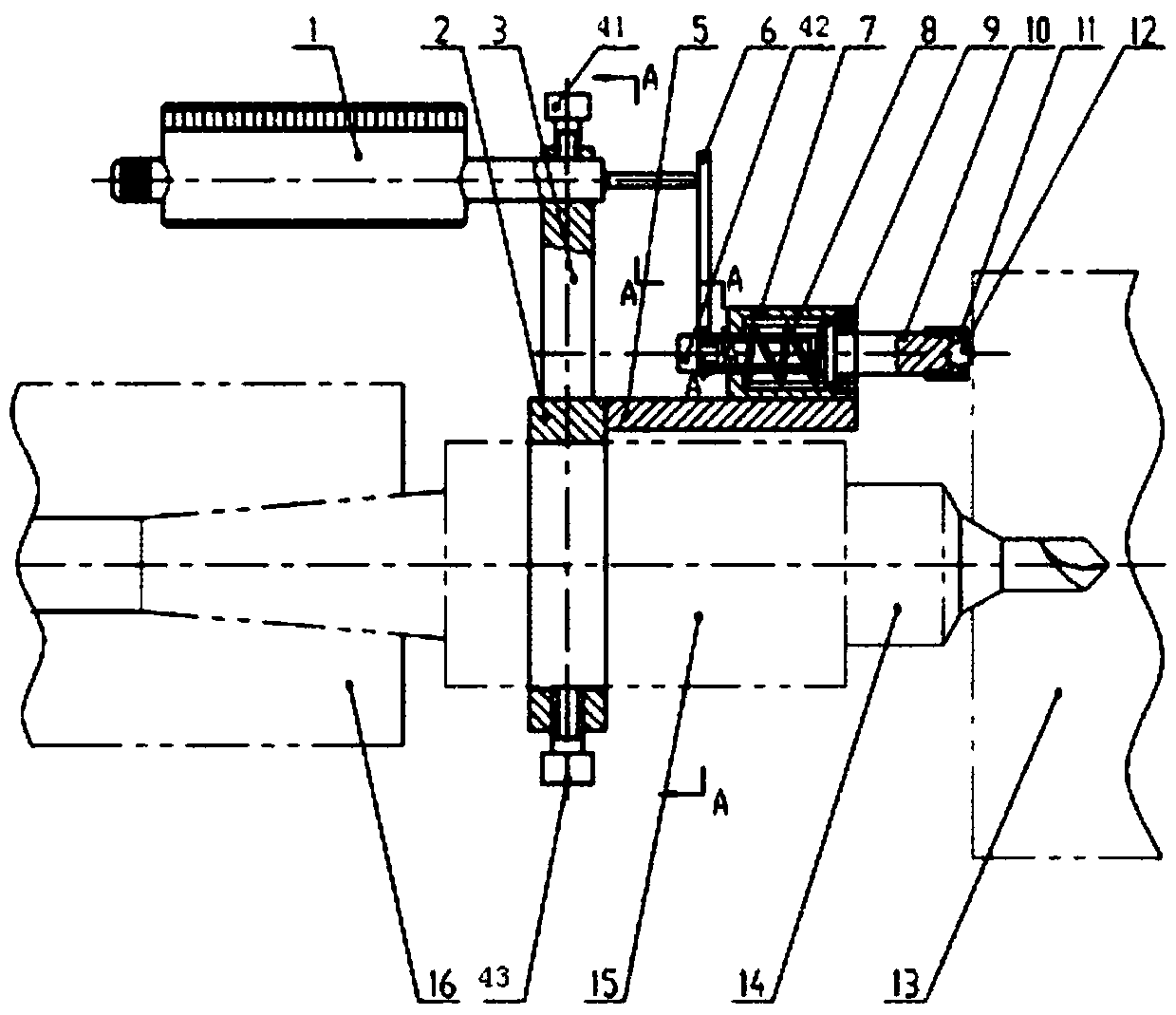

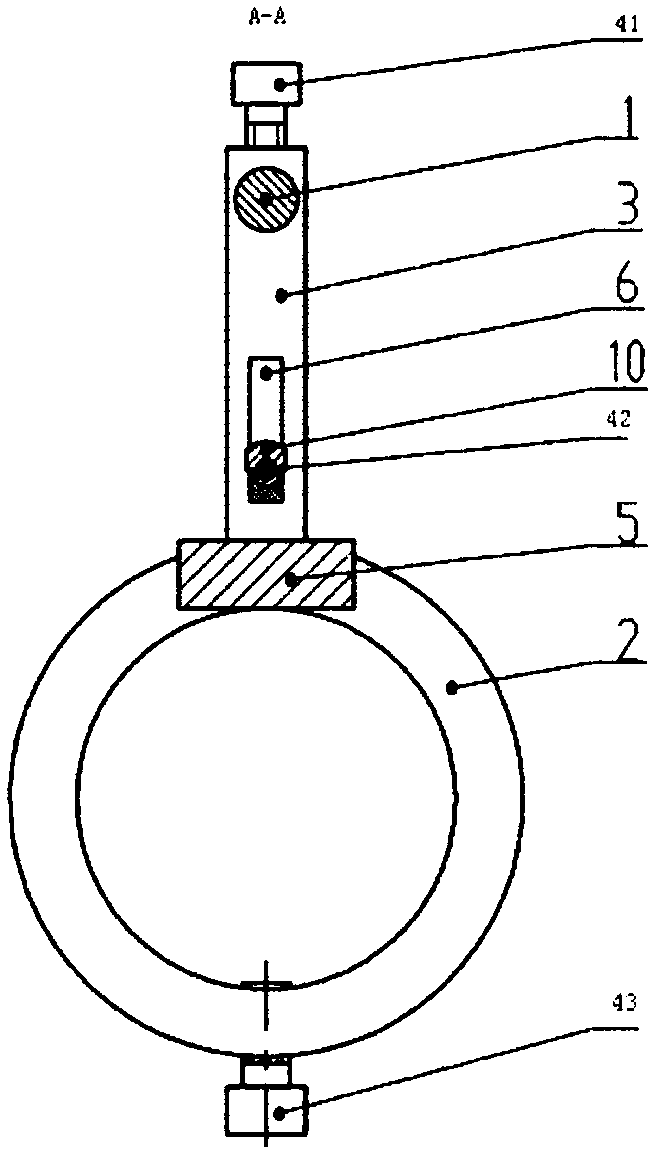

Inner heat insulation layer of front seal head of solid rocket engine and forming method of inner heat insulation layer

ActiveCN110792529AReduce design thicknessReduce negative qualityCoatingsRocket engine plantsInsulation layerSand blasting

The invention discloses an inner heat insulation layer structure of a front seal head of a solid rocket engine and a forming method of the inner heat insulation layer structure. A multi-step structureof an inner profile surface of the inner heat insulation layer is realized. The forming method of the inner heat insulation layer comprises the step 1 of manufacturing a mold according to an inner heat insulation layer structure, the step 2 of sandblasting the inner wall surface of the front seal head, the step 3 of preparing a liquid heat insulation layer, the step 4 of pouring the liquid heat insulation layer with the set mass into the front seal head, the step 5 of assembling the mold and the front seal head to a set position to ensure the designed thickness of the heat insulation layer, the step 6 of putting the product into an oven for curing, and the step 7 of taking out the product after the curing time is met, cooling the product to normal temperature, taking out the mold, and shaping and cutting the heat insulation layer to obtain the designed heat insulation layer. The heat insulation layer is high in size control precision, good in quality consistency and simple in process,and the forming method can meet the forming requirements of inner heat insulation layers in various irregular shapes.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Device for controlling depth of drilled center hole

InactiveCN102126037BReasonable structureEasy to operateDrilling/boring measurement devicesContact padEngineering

The invention relates to a device for controlling the depth of a drilled center hole. A supporting sleeve is arranged and fixed on a taper shank sleeve of a drilling machine. The upper part of the supporting sleeve is provided with a dial indicator through a fixing rod. A guide sleeve is fixed in the horizontal direction of the supporting sleeve through a connection plate. A guide rod capable of axially moving is arranged in the guide sleeve. The front end of the guide rod is contacted with the end face of a part. The rear part of the guide rod is connected with a contact pad. The contact padis contacted with an indicator head of the dial indicator. In the feeding process of drilling, the guide rod and the contact pad move backwards to contact the indicator head of the dial indicator, sothat the depth of the drilled hole is controlled by observing reading on the dial indicator. The device for controlling the depth of the drilled center hole has a reasonable structure, is convenient to operate and use and has high size control precision.

Owner:TIANRUN IND TECH CO LTD

Carbon nanoparticle with high specific surface area and preparation method thereof

ActiveCN107235480AReasonable preparation processEasy to prepareNanotechnologyNano-carbonSolid carbonDispersity

The invention relates to a carbon nanoparticle with a high specific surface area and a preparation method thereof. The method comprises the following steps: firstly, dispersing a hydrophobic initiator and a surfactant into water, injecting a reaction monomer 1 and an acrylonitrile monomer and reacting; and meanwhile, adding the surfactant into a reaction system, reacting and then acquiring compound latex A; treating the compound latex A and coating a protecting layer on the surface thereof, thereby acquiring compound latex B; and drying, pre-oxidizing and carbonizing the compound latex B, thereby acquiring the solid carbon nanoparticle with the high specific surface area. The method disclosed by the invention has the advantages of simpleness and high efficiency; the finally prepared carbon nanoparticle has excellent dispersity, high size control accuracy and high specific surface area; and the diameter of the carbon nanoparticle is within 50-100nm and the specific surface area is within 700-1500m<2> / g.

Owner:DONGHUA UNIV

Comb capacitive micro accelerometer

InactiveCN104133080BIncrease the areaQuality improvementAcceleration measurementCapacitanceAccelerometer

The invention discloses a comb-tooth capacitive micro-accelerometer, which comprises a substrate layer, an insulating layer, a structural layer and a base layer arranged from top to bottom, the insulating layer is arranged between the substrate layer and the structural layer; Both are equipped with metal lead electrodes. The invention doubles the detection capacitance without increasing the area of the device, increases the weight of the mass block, increases the flexibility of the design, can improve the measurement accuracy, and can use dry etching, with good size control and simple process, and can realize Manufactured in high volumes.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Measuring Method of Irregular Small Land Area Based on Photoelectric Measurement Technology

ActiveCN107121098BReduce technical ability requirementsOptimize layoutUsing optical meansGeomorphologyMeasuring instrument

The invention discloses an irregular small-sized land area measuring method based on a photoelectric measuring technology. The irregular small-sized land area measuring method is characterized by comprising the following steps: 1) determining a positioning base point in a land central area; 2) building laser beams which are vertical to one another on the basis of the positioning base point in order to partition a land into four areas; 3) erecting a measuring cable along an outer edge of each area, wherein photoelectric measuring instrument modules are distributed on the measuring cable at equal intervals; 4) acquiring distances between the photoelectric measuring instrument modules and the positioning base point, and transmitting the distances to a control terminal; 5) calculating a land graph and an area according to data acquired through the distances among photoelectric measuring instruments through the control terminal. By adopting the irregular small-sized land area measuring method based on the photoelectric measuring technology, distance information acquired by the photoelectric measuring instruments which are arranged along the edges of the land is utilized in conjunction with equal-interval arrangement of adjacent photoelectric measuring instruments, so that a coordinate graph of the land edges can be drawn, and high boundary annotation accuracy and high size control accuracy are realized; the method is easy and convenient to operate, and contributes to proceeding of outdoor operation.

Owner:NJU OPTOELECTRONICS ENG RES INST CO LTD

Metal powder and method for processing high-performance metal parts using metal powder

Owner:重庆科利得精密机械工业有限公司

Multi-stage rolling device for H-shaped steel

PendingCN113857237AShort rolling timeReduce consumption rateRoll force/gap control deviceMetal rolling stand detailsEngineeringRolling mill

The invention provides a multi-stage rolling device for H-shaped steel, and relates to the technical field of section steel rolling. The multi-stage rolling device comprises a first universal rolling mill, a second universal rolling mill, X-shaped steel and H-shaped steel, the second universal rolling mill comprises a horizontal upper roller, a horizontal lower roller, a rotating side vertical roller and an operation side vertical roller, and a third stroke recording sensor is fixedly arranged on the side, away from the operation side vertical roller, of the rotating side vertical roller. A fourth stroke recording sensor is fixedly arranged on the side, away from the operation side vertical roller, of the rotating side vertical roller, and first stroke recording sensors are fixedly arranged on the two sides of the horizontal upper roller. According to the multi-stage rolling device for the H-shaped steel, a method for controlling the roll gap between the first universal rolling mill and the second universal rolling mill when the H-shaped steel is rolled through an X-H rolling method is provided, a foundation is laid for improving the control precision level of the flange size of the H-shaped steel, and the yield is greatly increased while the product quality is improved.

Owner:北京弥天科技有限公司

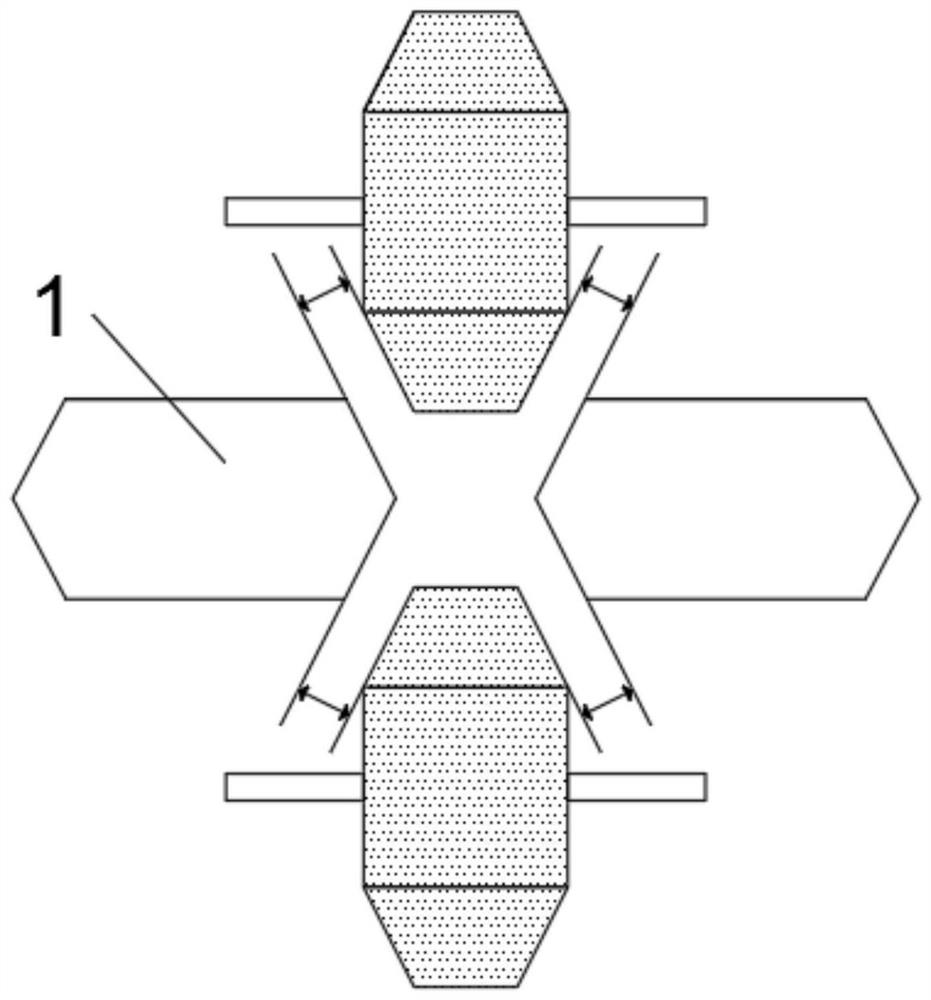

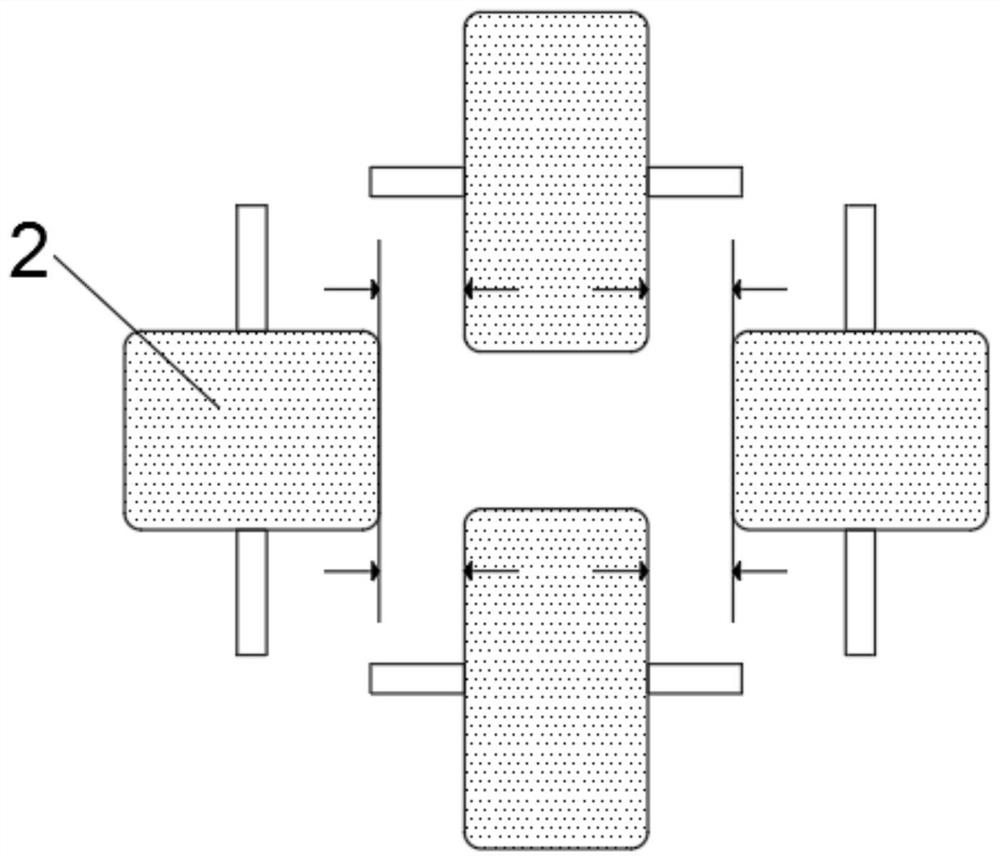

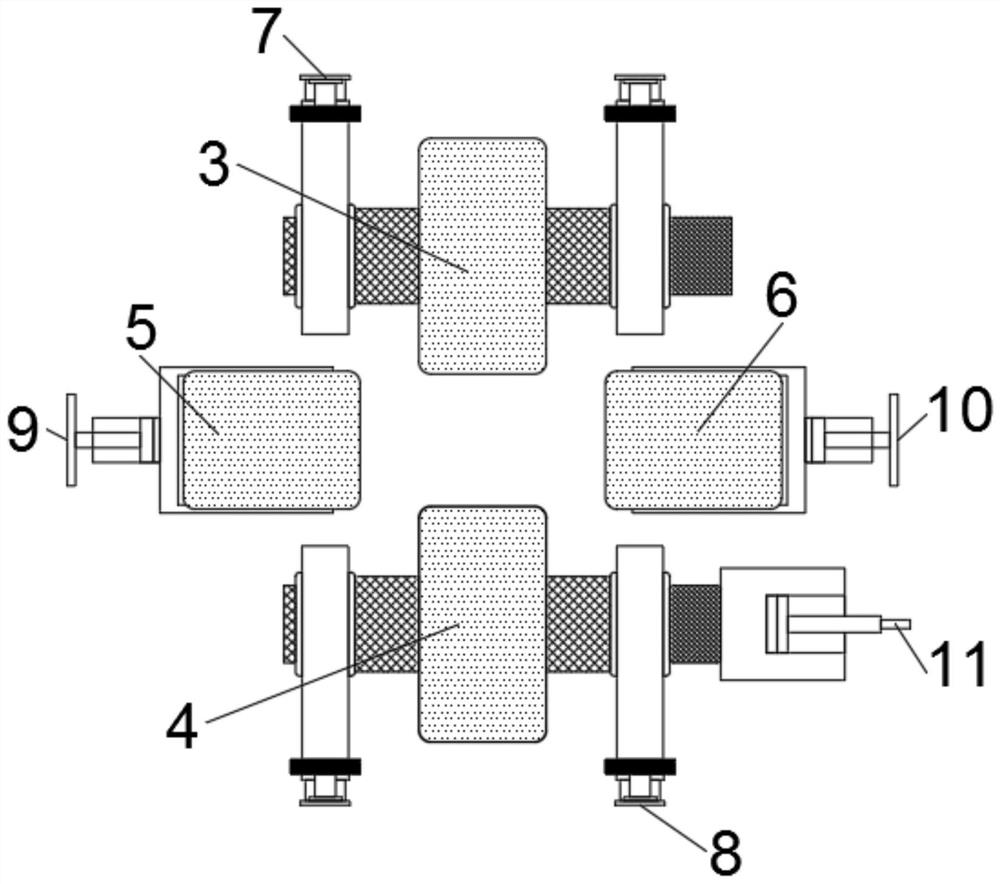

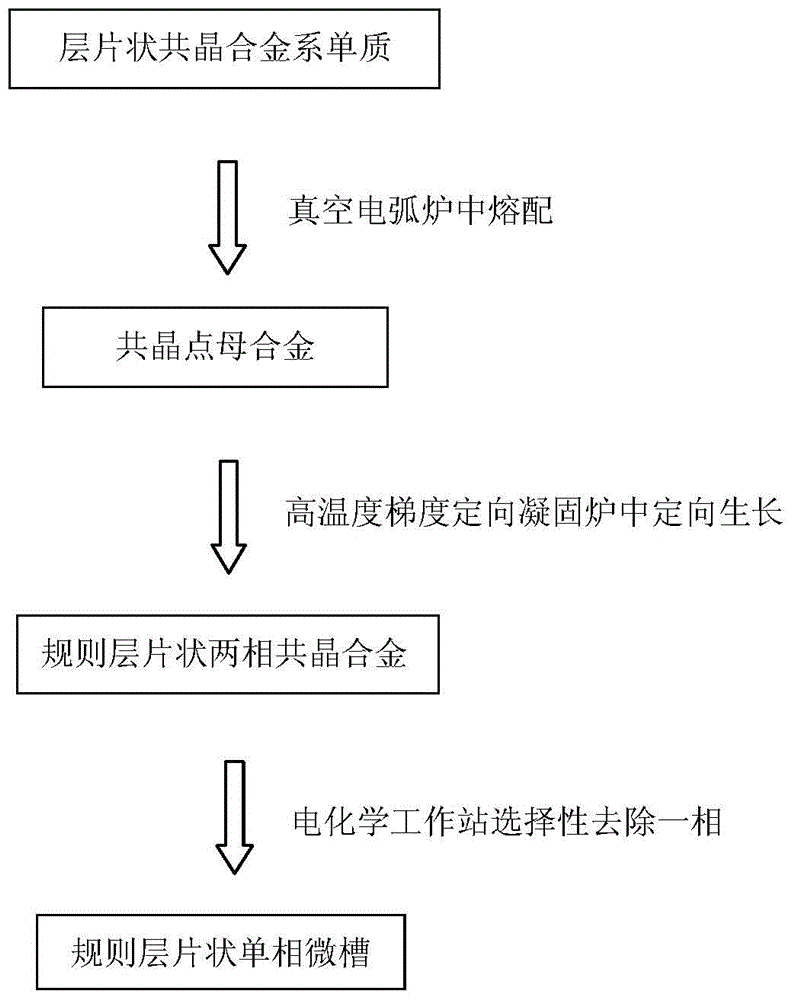

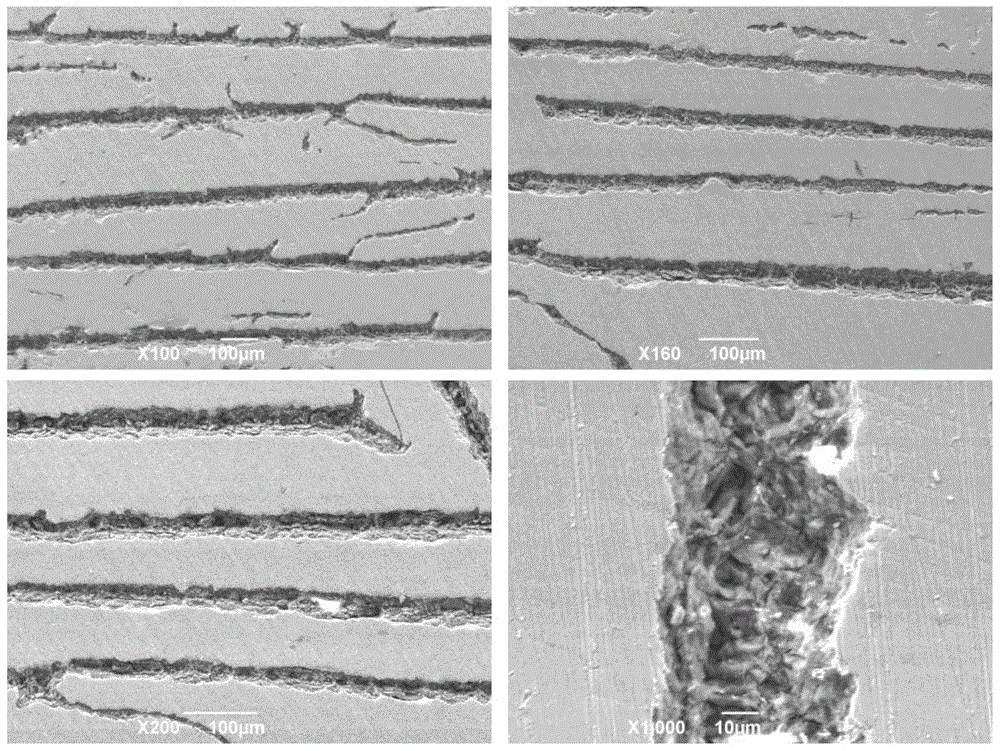

Method for preparing continuous and regular lamellar microgrooves based on lamellar eutectic alloy system

ActiveCN104846430BStructural continuityContinuous rule structurePolycrystalline material growthFrom frozen solutionsElectrode potentialSelective leaching

The invention relates to a method for preparing a continuous regular lamellar microgroove based on a lamellar eutectic alloy system. According to the method, directional solidification technology and selective corrosion technology are combined together; the lamellar eutectic alloy system is used as a base; and lamellar eutectic alloy is prepared by using the directional solidification technology at first, then according to different electrode potentials of composition phases of the eutectic, one of the composition phases is selectively eroded in an appropriate electrolyte, so a continuous regular lamellar single-phase microgroove structure is formed. The preparation process of the method is simple, convenient and controllable; the prepared microgroove is continuous and has more regular morphology, the depth and width of the microgroove are adjustable by adjusting a drawing rate and erosion time, the dimension control accuracy of the microgroove is higher, and the microgroove can be used as a template for preparation of microgroove structures of other metal elements or alloy through a template process; and combination of the directional solidification technology and the selective corrosion technology provides a novel method and thinking for preparation of microgrooves.

Owner:深圳市脑潜能实业发展有限公司

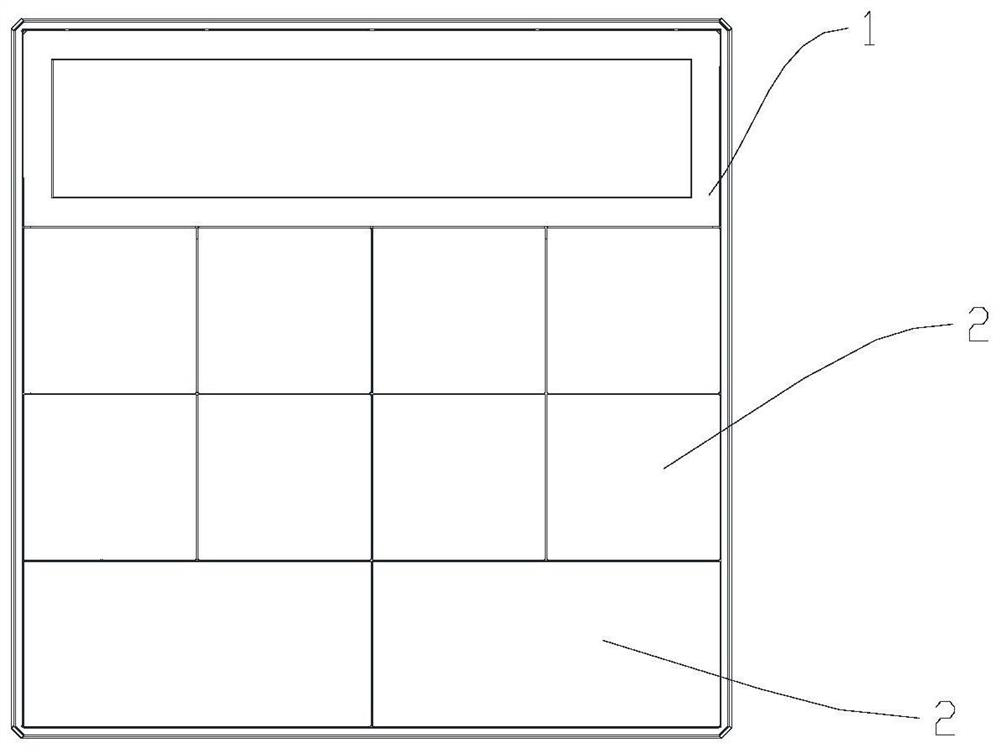

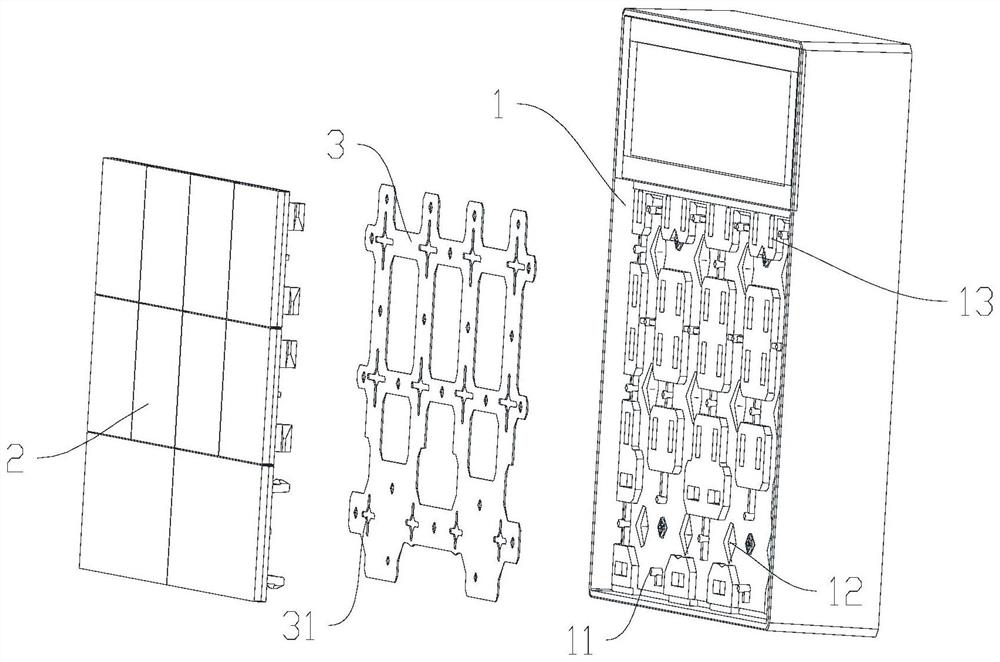

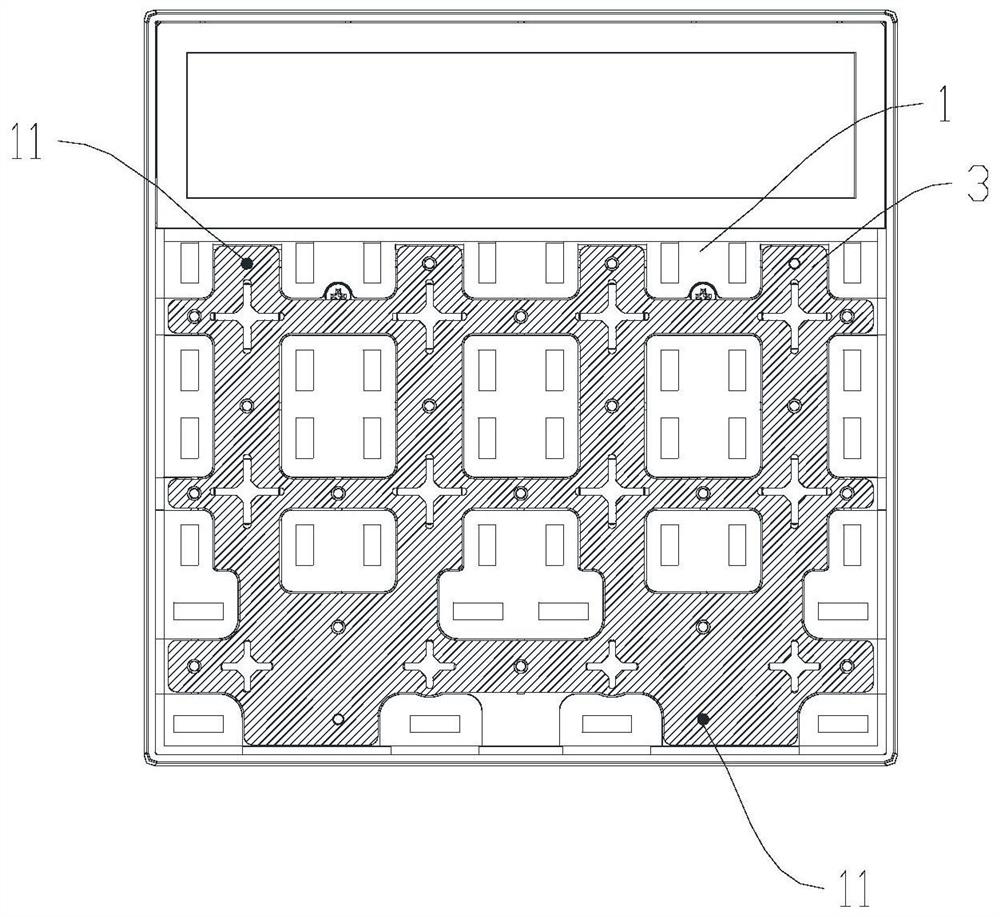

Key gap control structure, wall switch and multi-key product

PendingCN112117152AAvoid mobilityPrevent rotationElectric switchesKey pressingStructural engineering

The invention relates to a key gap control structure, a wall switch and a multi-key product. The key gap control structure comprises a key housing, a plurality of keys, and a positioning layer. The plurality of keys are detachably connected with the key housing, and a cross-shaped rib is arranged on the back surface of each key and is used for triggering a switch elastic sheet; the positioning layer is fixedly arranged between the key and the key housing, a plurality of cross-shaped hole grooves matched with the cross-shaped ribs are formed in the positioning layer, the cross-shaped ribs can penetrate through the cross-shaped hole grooves, and the positioning layer is an integrally-formed metal sheet. By arranging the positioning layer, the positioning ribs and other positioning interfaces, the problem that the key gaps of the multi-key switch controller are not uniform is effectively solved, and the gaps between keys and the use hand feeling of the keys are optimized.

Owner:QINGDAO YEELINK INFORMATION TECH

A Flame Cutting Technology of Thick Steel Plate

ActiveCN105834548BGuaranteed uptimeAvoid problems such as shootingWelding/soldering/cutting articlesMetal working apparatusSheet steelFlame cutting

The invention discloses a flame cutting technology for thick steel plates. The flame cutting technology comprises the steps of 1, determining the height of a cutting rack before cutting and grinding and polishing rails; 2, setting the cutting speed according to the string formula that V is equal to kD plus d, wherein k is -1.5, d is 350 and the cutting thickness ranges from 10 mm to 120 mm; 3, adopting the mixed gas of oxygen gas and propane, controlling the length of flames to be 10+ / -2 cm and guaranteeing that the proportion of red flames (the head parts) to blue flames (the root parts) of the flames is 1 to 9; 4, carrying out measuring, length-fixed cutting and marking-off on the steel plates, adjusting the positions of cutters to align to the marking-off position and guaranteeing the width of the two cutters of a cutting machine through supporting arms; and 5, after cutting is completed, rechecking the sizes of the steel plates, wherein the width expansion range is 4-8 mm, and the length expansion range is 10-25mm. According to the flame cutting technology, the problem of cutting explosion generated in the cutting process of the thick steel plates can be reduced, the cutting accuracy can be controlled, the cutting quality can be improved, and the product size and the product quality can meet the standard requirements.

Owner:NANJING IRON & STEEL CO LTD

A kind of preparation method of micro flow porous metal material

The invention discloses a method for preparing a micro-flow porous metal material. The method comprises: 1. Pressing metal powder through cold isostatic pressing to obtain a porous tube blank, and sintering to obtain a porous metal tube body; 2. The surface of the tube body is machined to obtain a porous metal matrix tube; 3. The dense metal end cap and the dense metal end cap with holes are processed; 4. After the end cap is welded, the surface of the porous metal matrix tube is machined to form a small aperture structure , to obtain a micro-flow porous metal material with a gradient pore structure. In the present invention, part of the particles on the surface of the porous metal pipe body are melted and then solidified through machining, combined with the control of the process parameters of the machining treatment, a small pore structure is formed on the surface of the porous metal pipe body, and a micro-flow porous structure with a gradient pore structure is obtained. The metal material realizes the precise control of micro-flow, and overcomes the difficulties of traditional metal porous materials with large pore size and high porosity, which make it difficult to control micro-flow.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Automobile semi-axle central hole machining depth control device

InactiveCN109158654AReasonable structureEasy to operateMetal working apparatusBoring/drilling machinesEngineering

The invention discloses an automobile semi-axle central hole machining depth control device. A supporting sleeve is fixedly installed on a drilling machine taper shank sleeve, a dial indicator is installed on the upper portion of the supporting sleeve through a fixing rod, a guiding sleeve is fixedly connected to the supporting sleeve through a connecting plate in the horizontal direction, a guiding rod capable of axially moving is installed in the guiding sleeve, the front end of the guiding rod makes contact with the end face of a part, the back portion of the guiding rod is connected with atouch plate, and the touch plate makes contact with the head of the dial indicator. When drilling feeding is conducted, the guiding rod and the touch plate move backwards to make contact with the head of the dial indicator, and the drilling depth is controlled by observing readings of the dial indicator. The automobile semi-axle central hole machining depth control device is reasonable in structure, convenient to operate and use and high in size control precision.

Owner:李达

Metal powder and method for processing high-performance metal parts by using metal powder

The invention discloses metal powder and a method for processing high-performance metal parts by using the metal powder. The metal powder comprises the following raw materials in percentage by weight:3.1-3.4% of electrolytic copper powder, 0.08-0.19% of nickel powder, 0.05-0.15% of molybdenum powder, 0.05-0.15% of cobalt powder, 0.3-0.5% of ferrophosphorus powder, 1.2-1.4% of ferrochrome powder,0.5-0.8% of manganese sulfide powder, 0.3-0.6% of graphite powder, 0.2-0.3% of wax powder, and the balance atomized pure iron powder. The formula of the metal powder is obtained through repeated testsand inspection according to the densification change and the phase change mechanism of a pressed blank in each sintering stage. In addition, the high-performance metal parts meeting the requirementscan be produced through the powder metallurgy method.

Owner:重庆科利得精密机械工业有限公司

Fused deposition modeling 3D printing mercury removal bag cage and preparation method thereof

ActiveCN112519283ALarge specific surface areaIncrease loadGas treatmentAdditive manufacturing apparatus3d printCarbide silicon

The invention discloses a fused deposition modeling 3D printing mercury removal bag cage and a preparation method thereof. The preparation method includes the steps that mercury removal catalytic powder is prepared firstly, and then the mercury removal catalytic powder, polytetrafluoroethylene powder, polyimide powder, nano silicon dioxide, paraffin and silicon carbide powder are mixed to preparefilamentous materials to be used as 3D printing raw materials; the mercury removal bag cage is prepared from the 3D printing raw materials through a fused deposition modeling technology. Compared withthe combination of a conventional bag cage and a mercury removal filter bag, the mercury removal bag cage has the advantages that a catalyst is implanted into the mercury removal bag cage through rawmaterial blending in the preparation process of the bag cage, so that the catalyst is uniformly distributed in the bag cage, the catalytic stability of the whole bag cage is good, and the mercury removal efficiency is high.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com