Device for controlling depth of drilled center hole

A technology of depth control and center hole drilling, applied in drilling/drilling equipment, positioning measurement in boring machine/drilling machine, manufacturing tools, etc. Reasonable structure, high dimensional control precision and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

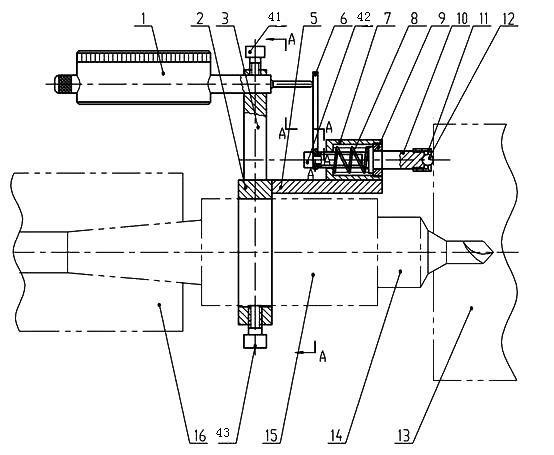

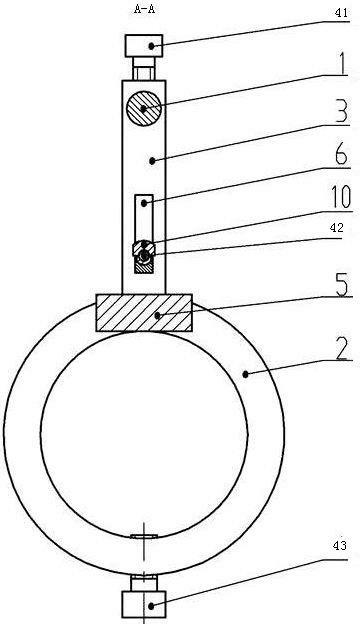

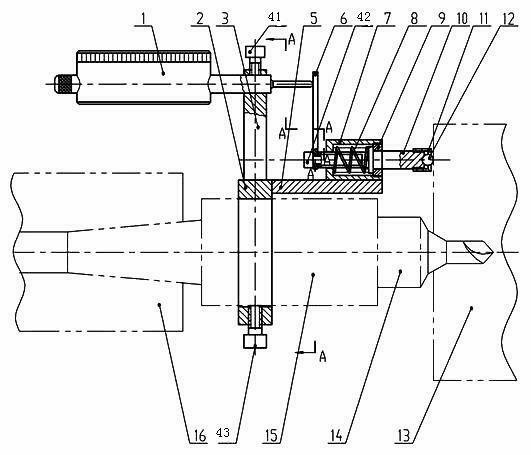

[0013] From figure 1 , figure 2 It can be seen that a drilling center hole depth control device installs and fixes a support sleeve 2 on the taper shank sleeve 15 of the drilling rig, and compresses the screw holes on the support sleeve 2 with screws 43 . Said bracing sleeve 2 tops install dial indicator 1 by fixed rod, and said dial indicator 1 table rod inserts in the hole of fixed rod 3 tops, presses fixed table rod by side screw hole with screw 41. The lower part of the fixed rod 3 is welded on the support sleeve 2. The specific composition and structure of the dial gauge 1 belongs to the prior art. The support sleeve 2 is fixedly connected with a guide sleeve 7 through the connecting plate 5 in the horizontal direction, the left end of the connecting plate 5 is welded with the support sleeve 2, and the right end is welded with the guide sleeve 10. An axially movable guide rod 10 is installed in the guide sleeve 7, the front end of the guide rod 10 is in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com