Manufacturing method of small-size sintered NdFeB multi-pole magnetic ring

A technology of multi-pole magnetic ring and manufacturing method, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic materials, magnetic objects, etc., can solve the problems of inconvenient manufacturing, poor magnetic performance, low pressing pass rate and efficiency, and achieve pressing qualified The effects of increased efficiency, uniform magnetic ring density, improved pressing efficiency and pressing qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

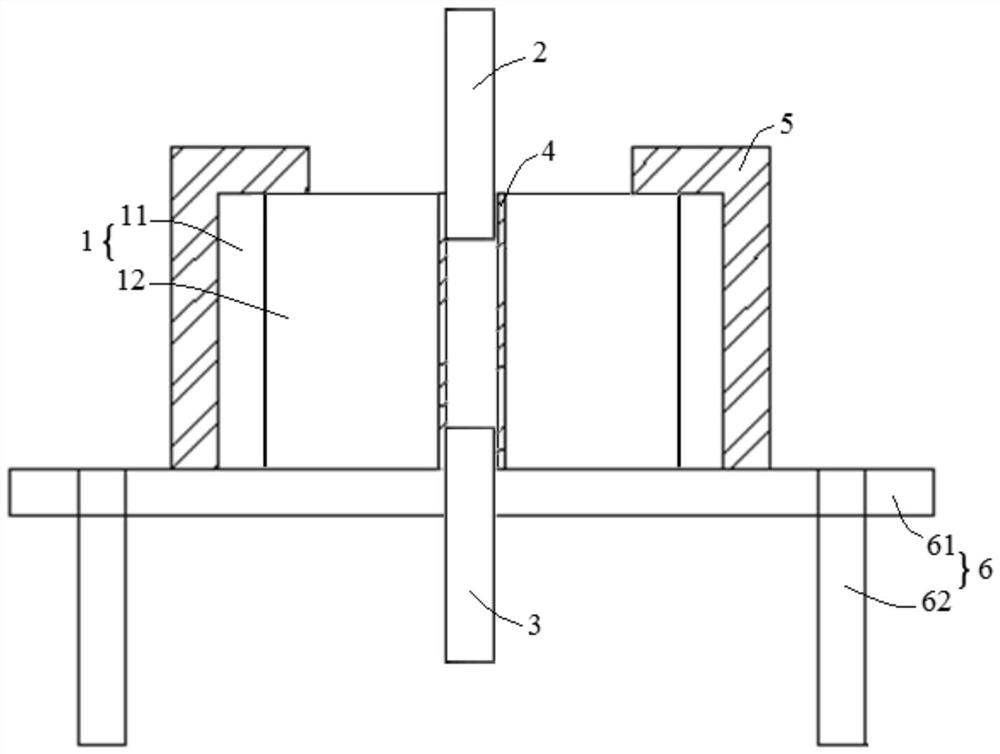

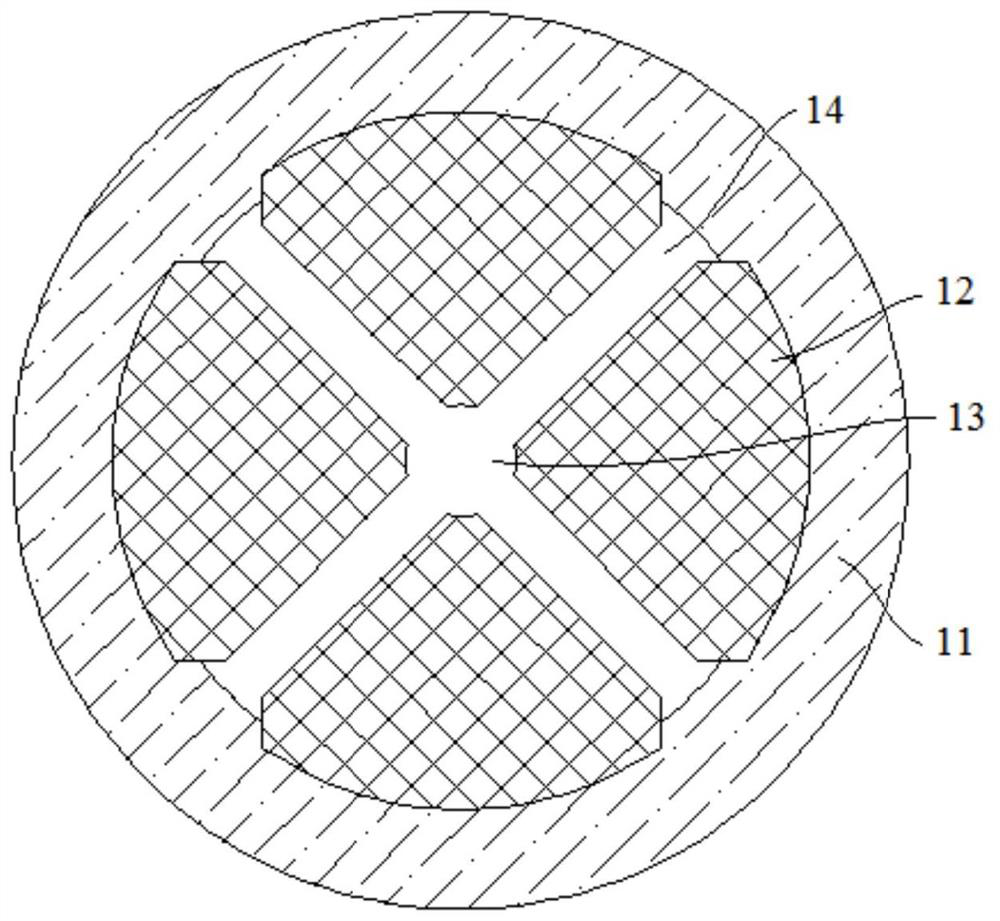

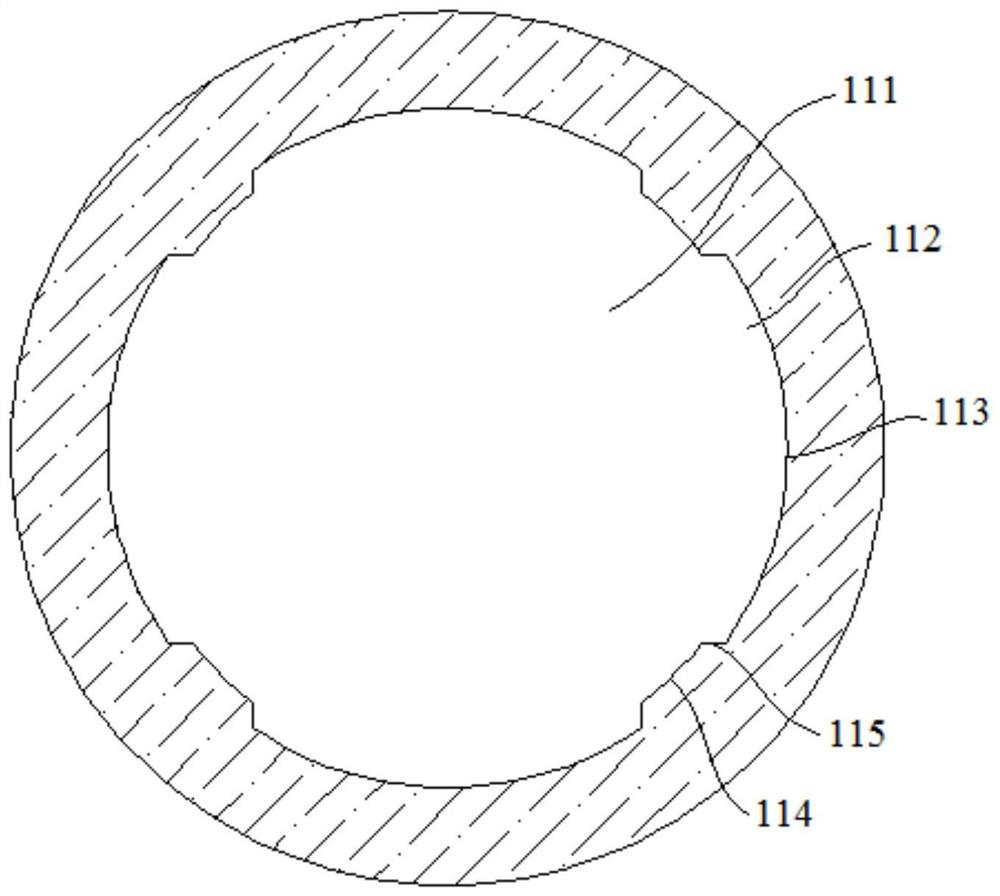

[0048]A pneumatic pressing device for making sintered NdFeB four-stage magnetic rings according to the above structure. Then make the powder with the brand name N35UH, weigh the N35UH powder with a weight of 4.0g in a closed box with an oxygen content lower than 300ppm, and press it with the pneumatic pressing device made according to the above operation. Then take out the compact according to the above operation. Then the obtained compact is subjected to isostatic pressing, high temperature sintering and tempering twice, that is, the sintering temperature is 1050°C during high temperature sintering, and the holding time is 4h; h; during the first tempering treatment, the temperature was raised to 450°C and kept for 5 hours; after the two tempering treatments were completed, a sintered NdFeB quadrupole magnetic column was obtained. Finally, the obtained multi-pole magnetic cylinder is subjected to outer circle machining, inner circle machining (casing, milling), end face grin...

Embodiment 2

[0050] A pneumatic pressing device for making sintered NdFeB four-stage magnetic rings according to the above structure. Then make the powder with the brand name N35UH, weigh a certain amount of N35UH powder in a closed box with an oxygen content of less than 300ppm, and press it with the pneumatic pressing device made according to the above operation. Then take out the compact according to the above operation. Then the obtained compact is subjected to isostatic pressing, high-temperature sintering and tempering twice, that is, the sintering temperature is 1100°C during high-temperature sintering, and the holding time is 3h; h; during the first tempering treatment, the temperature was raised to 520°C and kept for 3 hours; after the two tempering treatments were completed, a sintered NdFeB quadrupole magnetic column was obtained. Finally, the obtained multi-pole magnetic cylinder is subjected to outer circle machining, inner circle machining (casing, milling), end face grindin...

Embodiment 3

[0052] A pneumatic pressing device for making sintered NdFeB four-stage magnetic rings according to the above structure. Then make the powder with the brand name N35UH, weigh a certain amount of N35UH powder in a closed box with an oxygen content of less than 300ppm, and press it with the pneumatic pressing device made according to the above operation. Then take out the compact according to the above operation. Then the obtained compact is subjected to isostatic pressing, high temperature sintering and two tempering treatments, that is, the sintering temperature is 1080°C during high temperature sintering, and the holding time is 3.5h; the temperature is raised to 900°C during the first tempering treatment and kept 2h; during the first tempering treatment, the temperature was raised to 500°C and kept for 4h; after the two tempering treatments were completed, a sintered NdFeB quadrupole magnetic column was obtained. Finally, the obtained multi-pole magnetic cylinder is subject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com