Multi-stage rolling device for H-shaped steel

A technology of H-shaped steel and shaped steel, which is applied in the direction of metal rolling, metal rolling, metal rolling rack, etc., can solve the problem of affecting the control accuracy of the flange size of H-shaped steel products, the difficulty of calculating the roll gap of vertical rolls, and the inaccurate calculation Problems such as the vertical roll gap, etc., to achieve the effect of short rolling time, low roll consumption rate, and improved control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

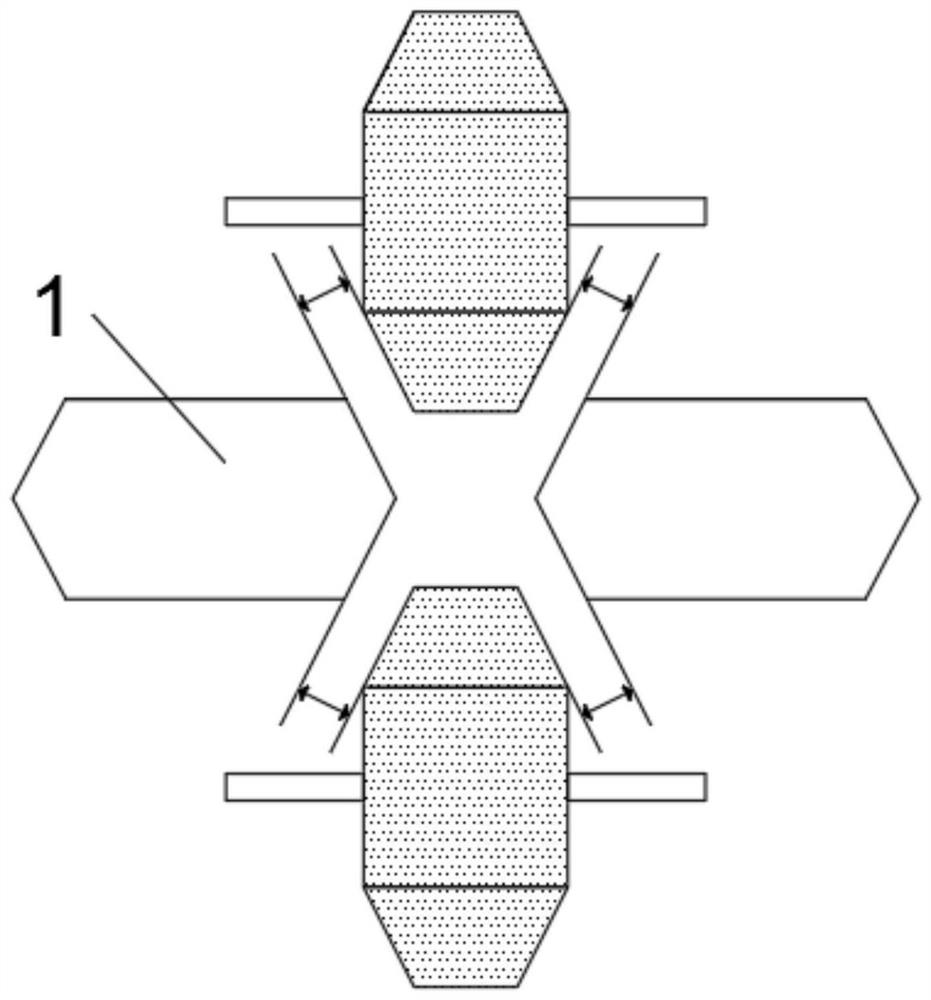

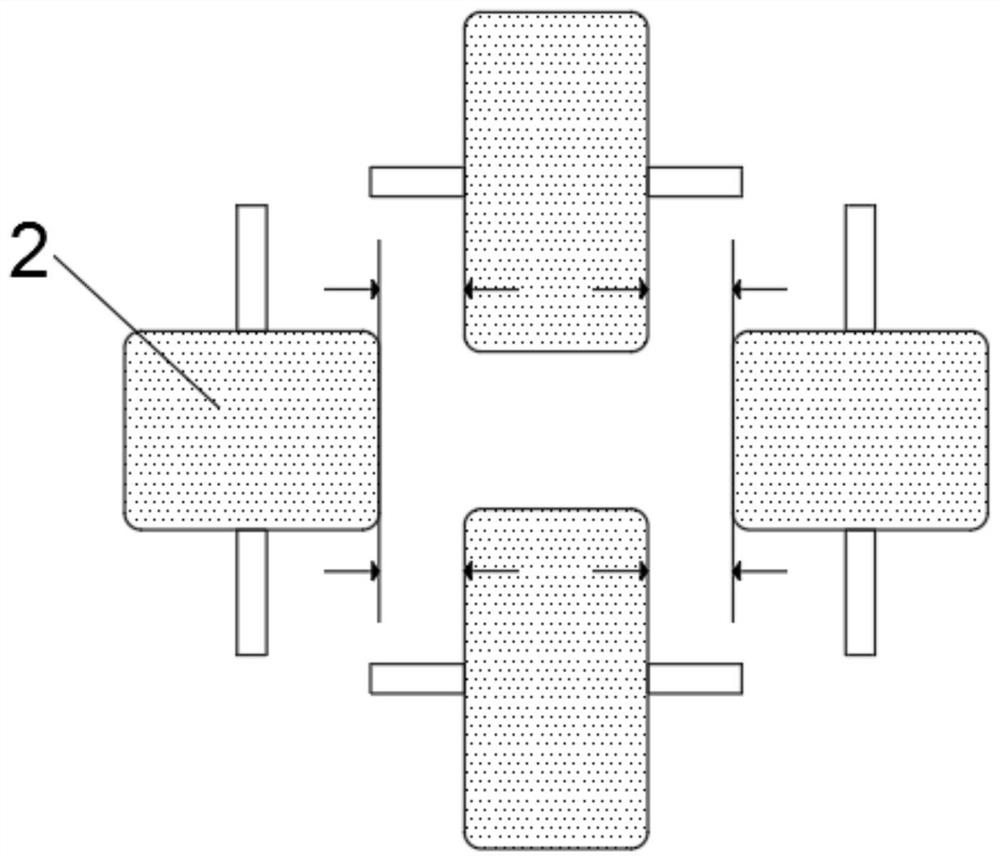

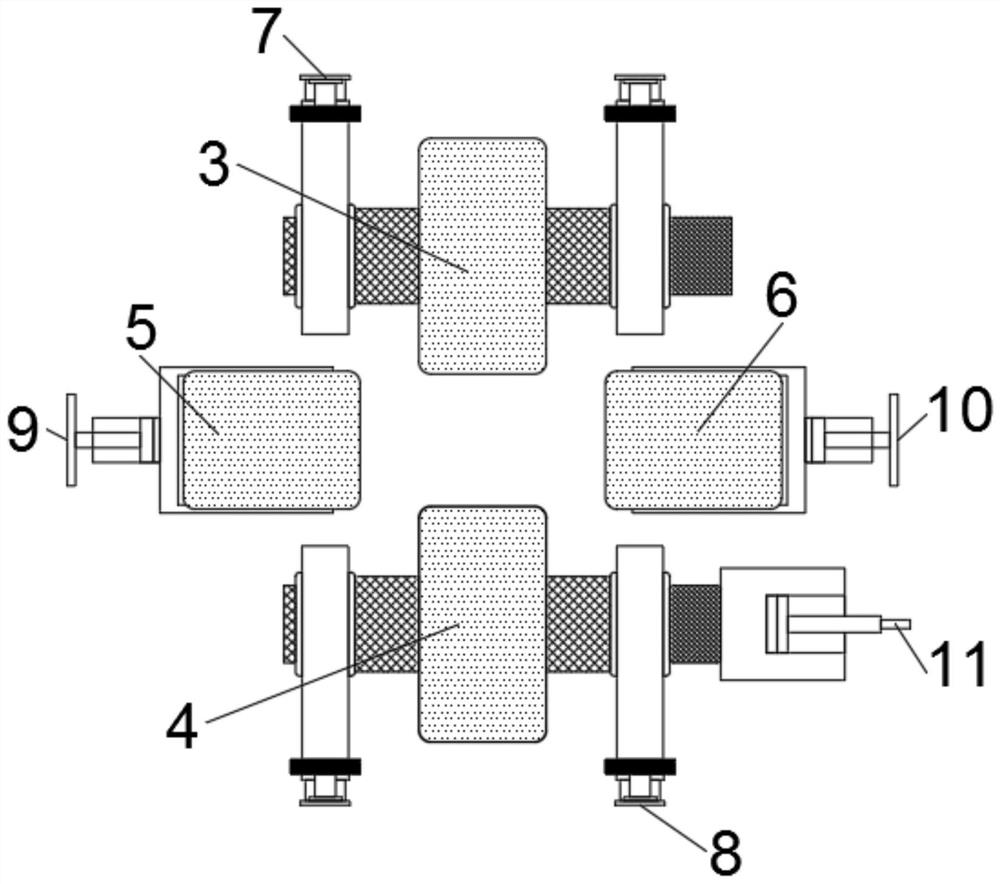

[0052] Such as Figure 1-5 As shown, the embodiment of the present invention provides a multi-stage rolling device for H-beams, including No. 1 universal rolling mill 1, No. 2 universal rolling mill 2, X-shaped steel 12 and H-shaped steel 13, and No. 2 universal rolling mill 2 includes horizontal upper roll 3, The horizontal lower roller 4, the rotating side vertical roller 5 and the operating side vertical roller 6, the side of the rotating side vertical roller 5 far away from the operating side vertical roller 6 is fixedly provided with No. No. 4 travel recording sensor 10 is fixedly installed on one side of roller 5, No. 1 travel recording sensor 7 is fixedly installed on both sides of horizontal upper roller 3, and No. 2 travel recording sensor 8 is fixedly installed on both sides of horizontal lower roller 4.

[0053] No. 1 universal rolling mill 1 adopts X-shaped hole design, and its vertical roll is waist drum-shaped. No. 2 universal rolling mill 2 adopts H-shaped hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com