Thin-specification RE700MC steel prepared based on fully headless thin slab continuous casting and rolling process and preparation method thereof

A thin slab continuous casting, thin gauge technology, applied in the field of steelmaking, can solve the problems of limiting the application prospect of 700MC steel, chemical inclusions and segregation, high production cost and energy consumption, and achieves high spheroidization degree and microstructure. The effect of organization, stable product performance, energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

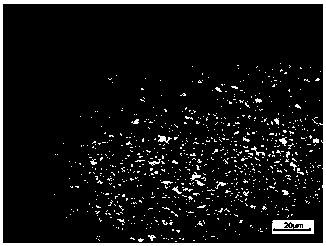

Image

Examples

preparation example Construction

[0026] Aiming at the technical problems existing in the prior art in the background technology, the present invention provides a thin-gauge RE700MC steel prepared based on an all-endless thin slab continuous casting and rolling process and a preparation method thereof. The thin-gauge RE700MC steel of the present invention includes the following qualities Fractional raw material components: C: 0.04%-0.06%, Si: 0.15%-0.50%, Mn: 1.3%-1.8%, Als: 0.02%-0.04%, Nb: 0.010%-0.06%, Ti: 0.04% -0.13%, S: ≤0.0020%, P: ≤0.012%, N: ≤0.005%, and the balance is Fe; the product thickness of RE700MC steel is 1.0mm~3.5mm.

[0027] The preparation method of the thin-gauge RE700MC steel based on the continuous casting and rolling process of the all-endless thin slab of the present invention comprises the following steps in sequence: selecting raw materials, converter smelting, LF refining furnace refining, RH refining furnace refining, continuous casting process, rough Rolling process, induction fu...

Embodiment 1

[0031] The composition design of the thin-gauge RE700MC steel prepared based on the full endless thin slab continuous casting and rolling process is as follows: C: 0.04%, Si: 0.2%, Mn: 1.8%, Als: 0.03%, Nb: 0.010%, Ti: 0.13 %, S: ≤0.0020%, P: ≤ 0.012%, N: ≤0.005%, and the balance is Fe;

[0032] The preparation method of thin gauge RE700MC steel based on the full endless thin slab continuous casting and rolling process is as follows:

[0033] (1) Design and select raw materials according to the above composition;

[0034] (2) The raw materials in the step (1) are sequentially smelted in a converter, refined in an LF refining furnace, and refined in a RH refining furnace to obtain molten steel;

[0035] (3) The molten steel is sequentially passed through the continuous casting process, the rough rolling process, the induction furnace heating process, the finishing rolling process, the laminar flow cooling process, the coiling process, and the flattening coiling process in the ...

Embodiment 2

[0043] The composition design of the thin gauge RE700MC steel prepared based on the full endless thin slab continuous casting and rolling process is as follows: C: 0.05%, Si: 0.2%, Mn: 1.6%, Als: 0.03%, Nb: 0.040%, Ti: 0.09 %, S: ≤0.0020%, P: ≤ 0.012%, N: ≤0.005%, and the balance is Fe;

[0044] The preparation method of thin gauge RE700MC steel based on the full endless thin slab continuous casting and rolling process is as follows:

[0045] (1) Design and select raw materials according to the above composition;

[0046] (2) The raw materials in the step (1) are sequentially smelted in a converter, refined in an LF refining furnace, and refined in a RH refining furnace to obtain molten steel;

[0047] (3) The molten steel is sequentially passed through the continuous casting process, the rough rolling process, the induction furnace heating process, the finishing rolling process, the laminar flow cooling process, the coiling process, and the flattening coiling process in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com