A kind of forging method of special-shaped ring of alloy material for aviation

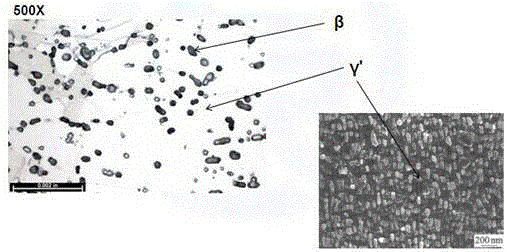

A technology of alloy materials and special-shaped rings, which is applied in the field of metal forging, can solve the problems of sudden change in grain size, accelerated oxidation of coarse grains, and short ring forging time, so as to achieve uniform and fine grain size, slow down the growth tendency, and fine grain size. and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

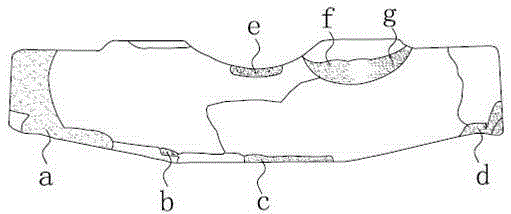

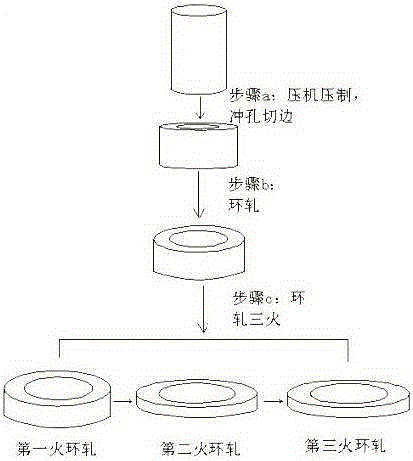

[0043] Example 1: Please refer to the attached figure 2 To attach Figure 5 , the invention discloses a method for forging a special-shaped ring of an alloy material for aviation, comprising the following steps:

[0044] a. Preheat the Inco783 bar material cut according to the specification at 1100°C for 2 hours, press it with a 3,000-ton press, punch and trim to obtain a round billet with an inner diameter of 125mm, and the final rolling temperature of this step is 900°C;

[0045] b. Preheat the round billet obtained in step a at 1040°C for 2 hours, then ring roll it until the inner hole is 352mm, and the final rolling temperature of this step is 900°C;

[0046]c. Preheat the billet obtained in step b at 996°C for 1 hour, then continuously ring-roll three fires, and the ring-rolling ratio of each fire is 9%, 14%, and 19% in turn; obtain a special-shaped ring with an inner hole of 733mm , the finishing temperature of this step is 900°C;

[0047] d. Aging: annealing the s...

Embodiment 2

[0056] Example 2: The invention discloses a method for forging a special-shaped ring of an alloy material for aviation, which comprises the following steps:

[0057] a. Preheat the nickel-based superalloy bar material blanked according to the specification at 1070°C for 3 hours, press it with a press, punch and trim the edges to obtain a round billet with a certain inner diameter, and the final rolling temperature of this step is 980°C;

[0058] b. Preheat the round billet obtained in step a at 1020°C for 2 hours, and then ring roll until the inner hole increases to a certain requirement. The final rolling temperature of this step is 900°C;

[0059] c. Preheat the billet obtained in step b at 1020°C for 2 hours, then continue ring rolling for three fires, and the ring rolling ratio of each fire is 7%, 12%, and 16% in turn; to obtain a special-shaped ring, the final step of this step The rolling temperature is 850°C;

[0060] d. Aging: annealing the special-shaped ring obtai...

Embodiment 3

[0063] Example 3: The invention discloses a method for forging a special-shaped ring of an alloy material for aviation, which comprises the following steps:

[0064] a. Preheat the nickel-based superalloy rods cut according to the specifications at 1180°C for 1.5 hours, press them with a press, punch holes and trim the edges to obtain a round billet with a certain inner diameter, and the final rolling temperature of this step is 900°C ;

[0065] b. Preheat the round billet obtained in step a at 1100°C for 2 hours, and then ring roll until the inner hole increases to a certain requirement. The final rolling temperature of this step is 850°C;

[0066] c. Preheat the billet obtained in step b at 1100°C for 2 hours, then continue ring rolling for three fires, and the ring rolling ratio of each fire is 8%, 14%, and 19% in turn; to obtain a special-shaped ring, the final step of this step The rolling temperature is 850°C;

[0067] d. Aging: annealing the special-shaped ring obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com