Patents

Literature

213results about How to "Realize batch processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

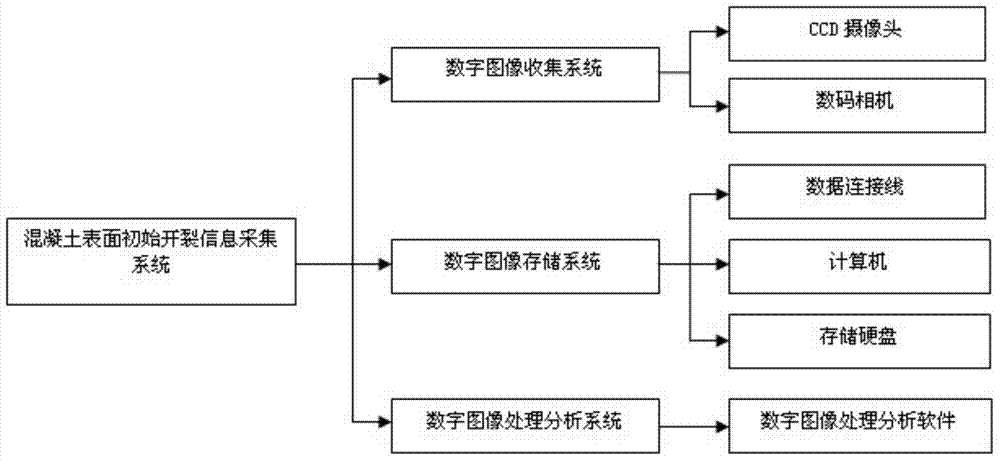

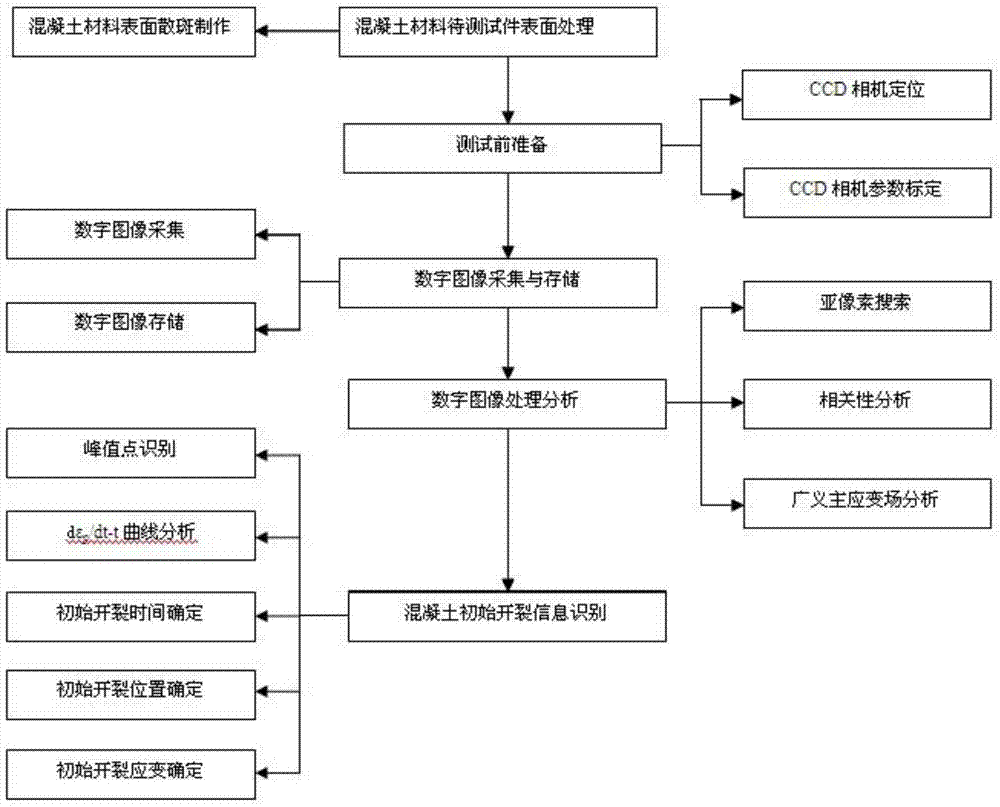

Acquisition system and identification method of concrete surface initial crack information

ActiveCN104330023AEasy to handleSimple and fast operationUsing optical meansBatch processingTime changes

The invention relates to the technical field of construction material detection and aims to provide an acquisition system and identification method of concrete surface initial crack information. According to the method, the image of the surface of a concrete material piece to be tested is shot by a digital camera, then the digital image is processed and analyzed through a digital image matching method, finally the initial crack position of concrete is identified through a main strain distribution map peak point, and the initial crack time of the concrete is judged through the time change rule of the peak point strain. According to the acquisition system and identification method of concrete surface initial crack information, the influence of a strain gauge size effect can be effectively avoided, a strain gauge is not pasted to the surface of the concrete, and the initial crack position of the concrete surface can be accurately determined. All test equipment of the method is reproducible, the initial crack information of the concrete material can be objectively, accurately and reasonably identified, according to the method, the concrete sample treatment is simple, the operation is simple, the batch processing can be realized, a lot of manpower cost is saved, and the test cost is low.

Owner:ZHEJIANG UNIV

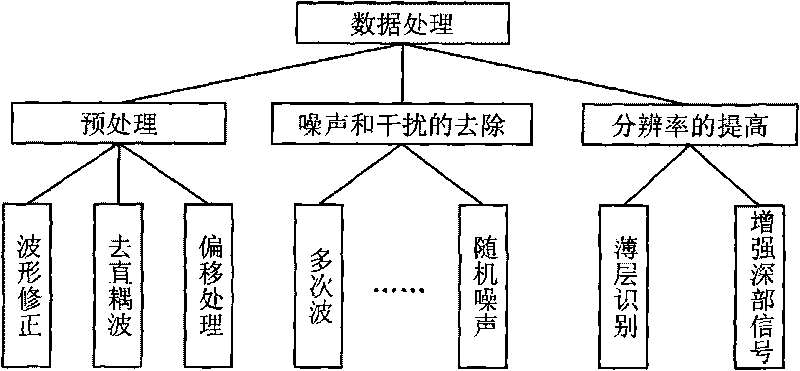

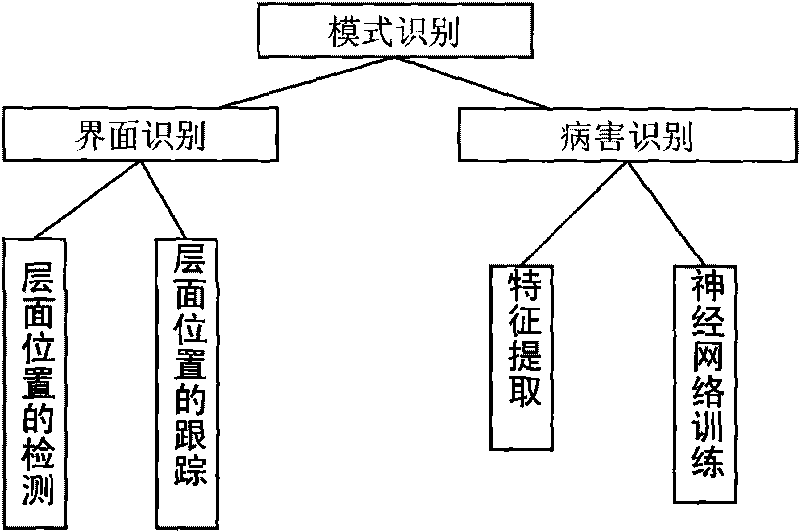

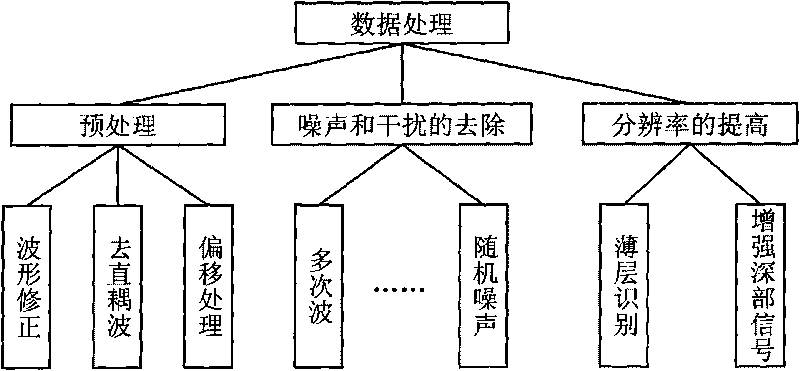

Method for processing ground penetrating radar data

InactiveCN101738642ARealize batch processingElectric/magnetic detectionAcoustic wave reradiationParallel computingMATLAB

The invention relates to a method for processing ground penetrating radar data. The method chooses Visual C++2005 as RAILGPR1.0 interface development environment, adopts MATLAB 7.1 as a calculation kernel language, calls MATLAB engine through foreground VC, and uses MATLAB in the background for calculation. Compared with the prior art, the method has a read display function, a data processing function, an automatic interpretation function and a plurality of other functions.

Owner:TONGJI UNIV

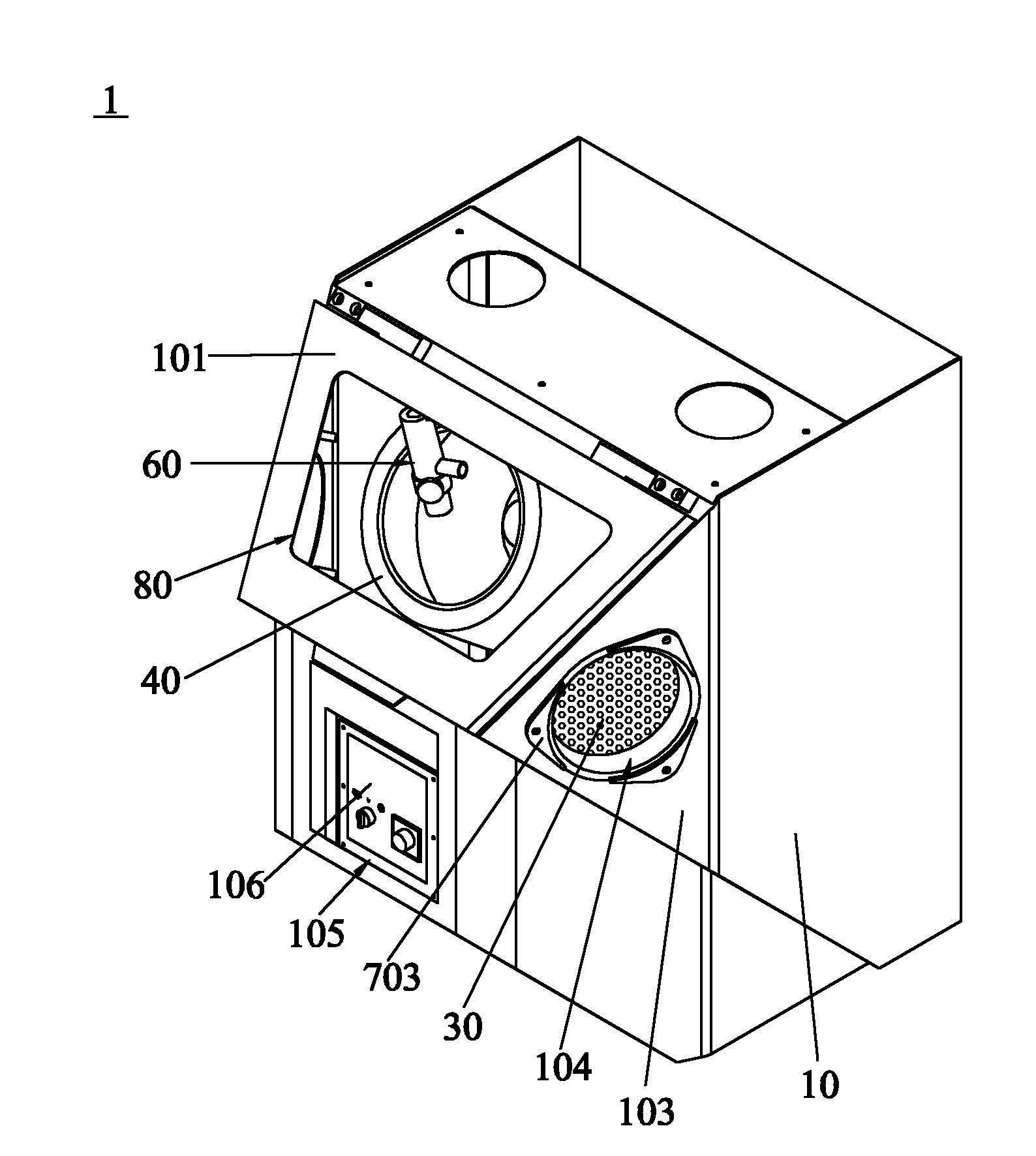

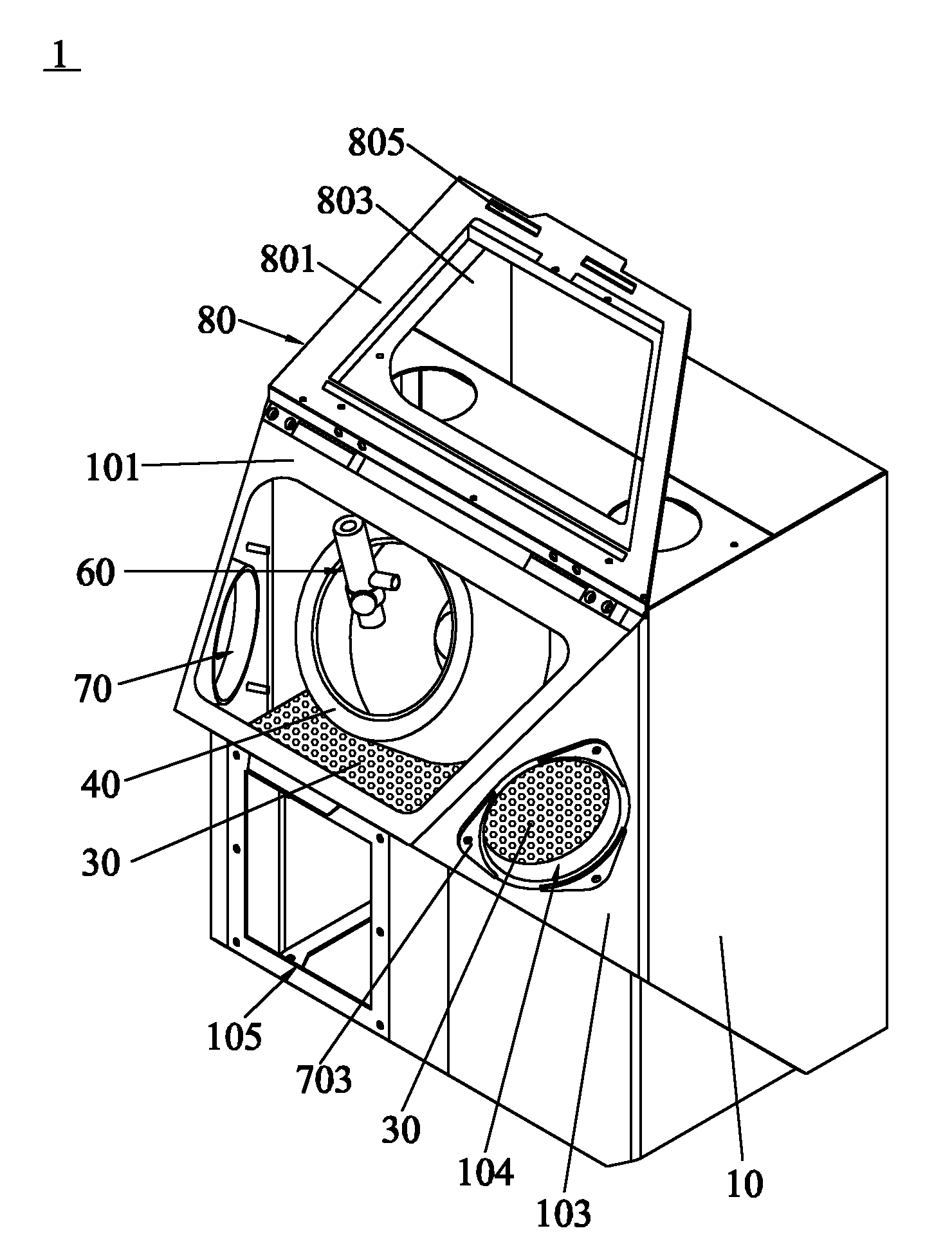

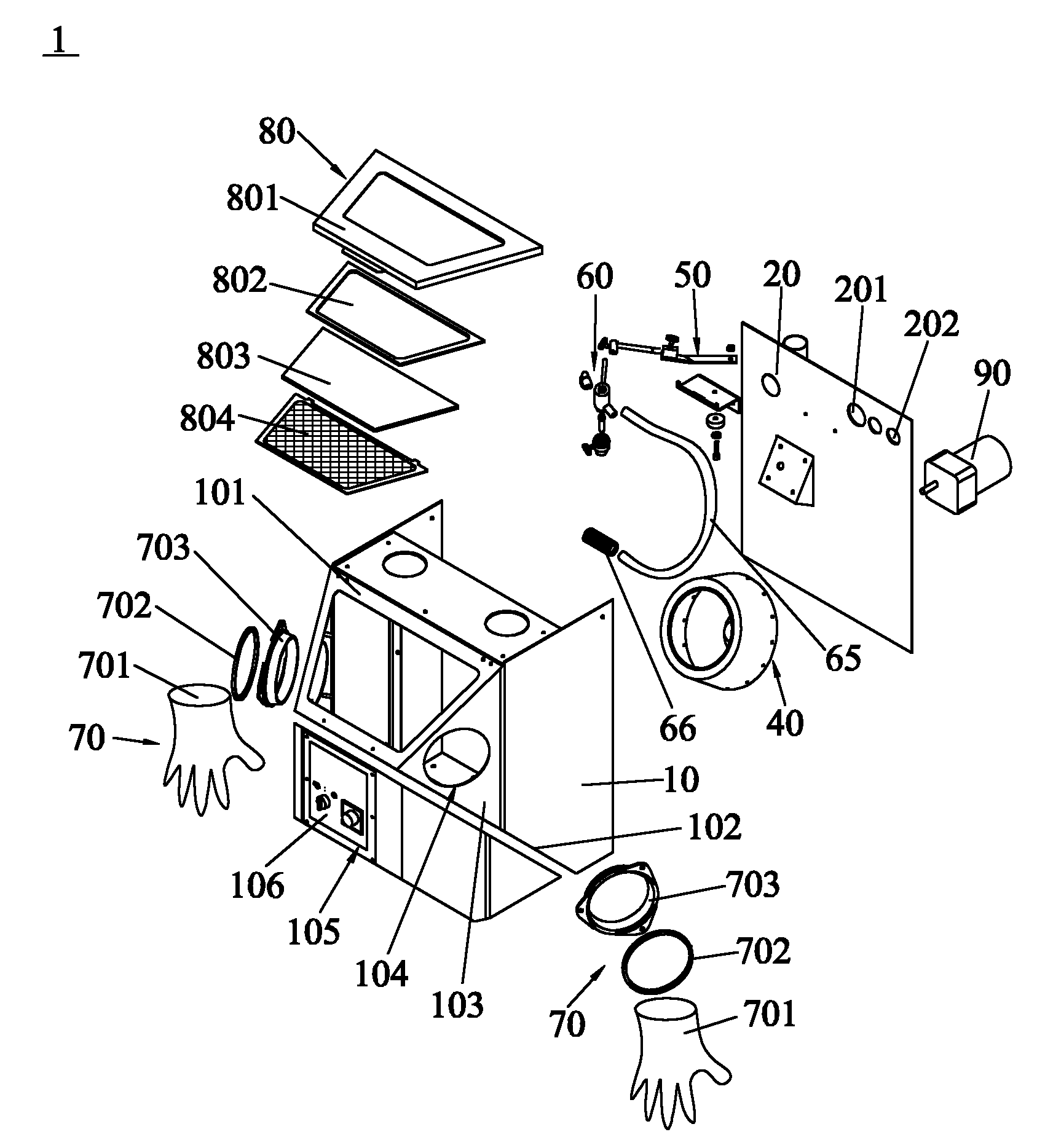

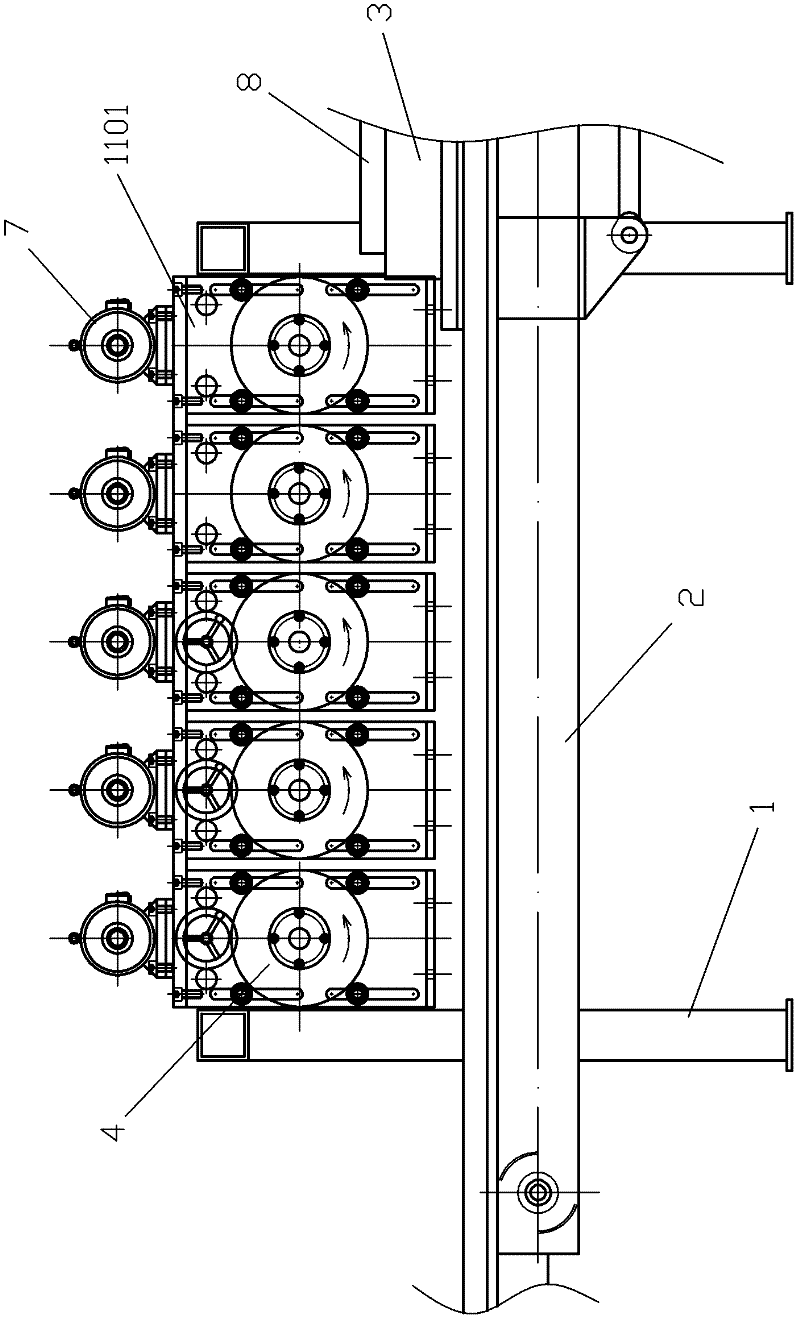

Sand blasting machine

InactiveCN102133738ARealize batch processingReduce labor intensityBlast gunsAbrasive blasting machinesBatch processingSand blasting

The invention discloses a sand blasting machine. The sand blasting machine comprises a basal body, a back plate, a filter hole plate, a drum, a swinging mechanism, a nozzle mechanism, a glove mechanism and a driving mechanism, wherein the basal body has a hollow structure; a front side plate of the basal body is provided with a viewing window; the back plate is arranged at the rear end of the basal body; the filter hole plate with through holes is arranged in the basal body and partitions the basal body into a working region and an abrasive material storage region; the drum of which the wall is provided with through holes is arranged inside the back plate and is positioned in the working region; the driving mechanism is arranged outside the back plate and is connected with the drum; the swinging mechanism is arranged inside the back plate and is positioned above the drum; the nozzle mechanism is movably connected with the swinging mechanism; and the glove mechanism is arranged on the two sides of the basal body and is positioned in the working region. Thus, switching of a manual mode and an automatic mode can be realized, labor intensity of operating personnel and harm to health of the operating personnel are reduced, batch processing of workpieces is realized, efficiency of cleaning the workpieces is greatly improved, safety and stability are high, and quality and yield of the workpieces are further improved.

Owner:广东创捷机械设备有限公司

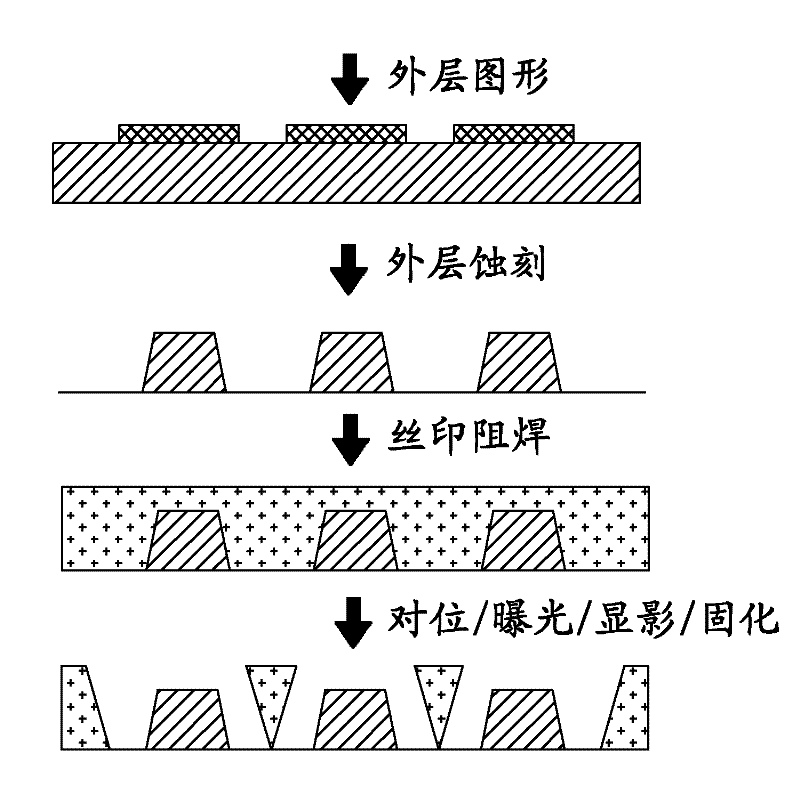

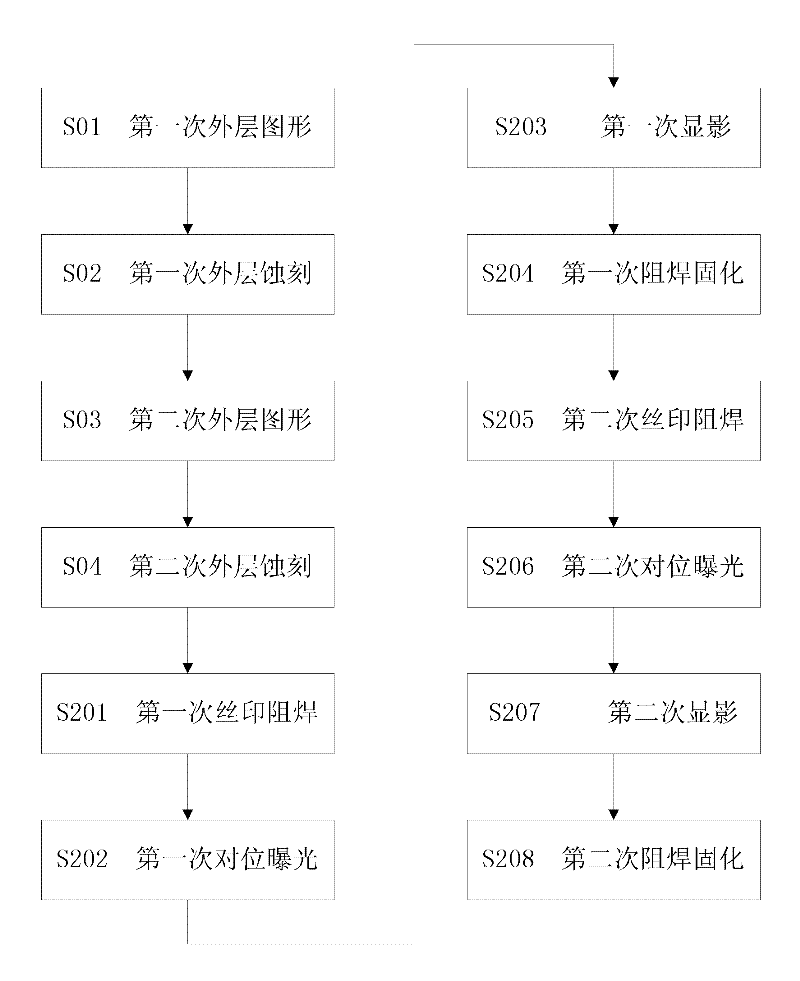

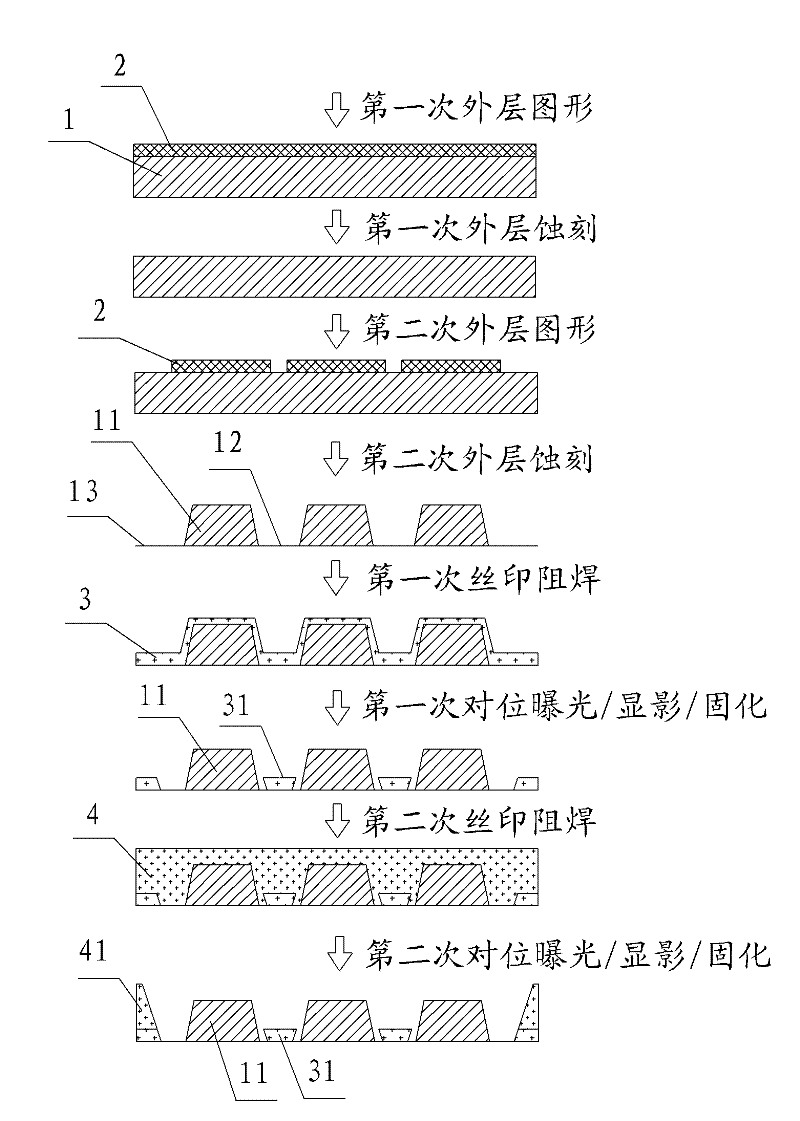

Processing method of surface-mounted pads on thick copper circuit board

ActiveCN102244985ABig sizeMeet the design size requirementsConductive material chemical/electrolytical removalSolder maskCopper

The invention discloses a processing method of surface-mounted pads on a thick copper circuit board. The processing method comprises the following steps: S01. patterning an external layer for the first time; 2. etching the external layer for the first time; 3. patterning the external layer for the second time; 4. etching the external layer for the second time; and 5. manufacturing a solder mask bridge among the surface-mounted pads by a fractional solder resisting method. The processing method has the beneficial effects that the surface-mounted pads are manufactured by a partitioned etching method, which strengthens size control of the surface-mounted pads and meets the design requirements; and the solder mask bridge among the surface-mounted pads are manufactured by utilizing the fractional solder resisting method so that the solder mask bridge and the circuit board are firmly connected together and are not easily separated from each other.

Owner:WUXI SHENNAN CIRCUITS CO LTD

Process for treating phosphate coating wastewater of steel pipes

InactiveCN102020373ARealize batch processingLess one-time investmentWaste water treatment from metallurgical processMultistage water/sewage treatmentChemical treatmentPhosphate

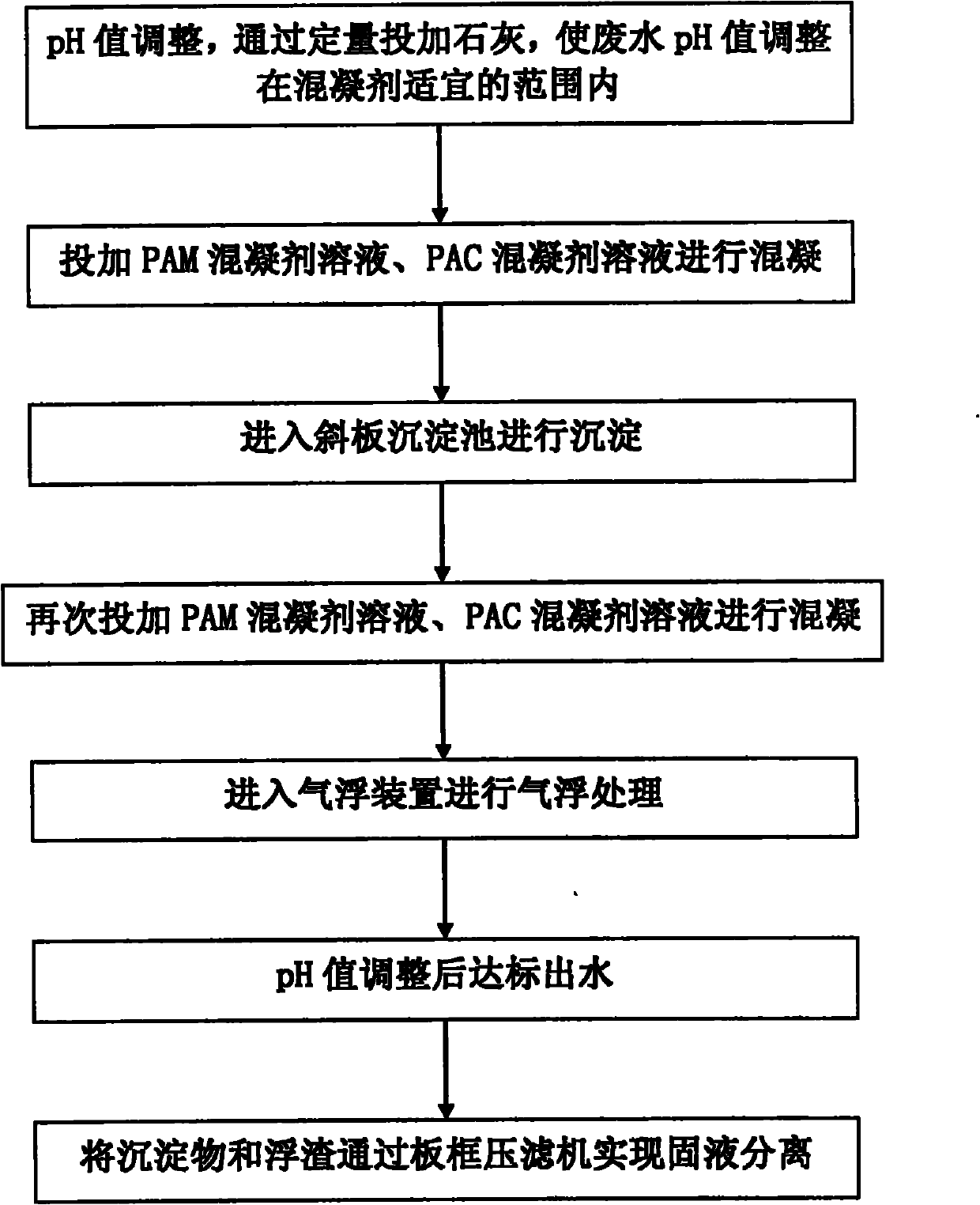

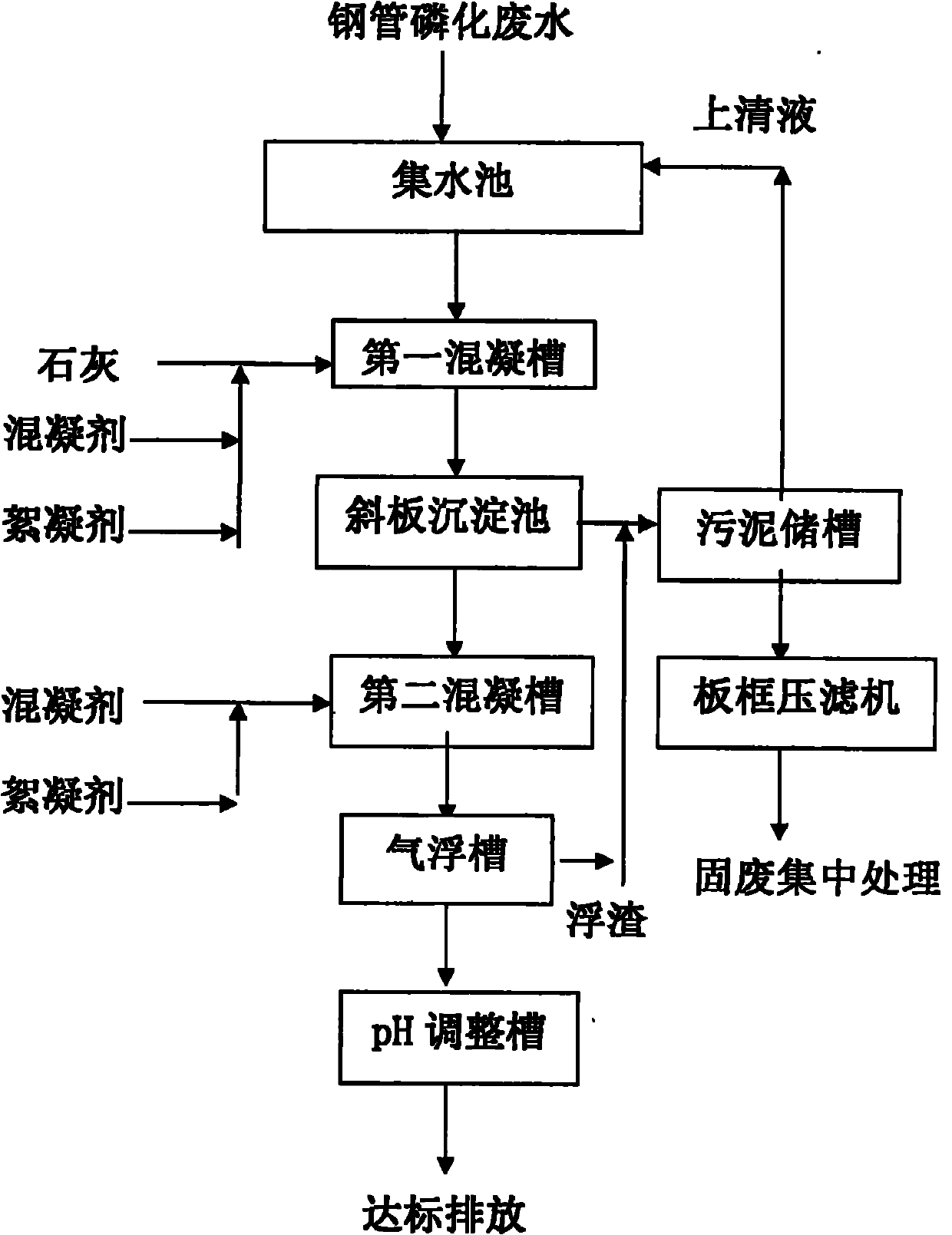

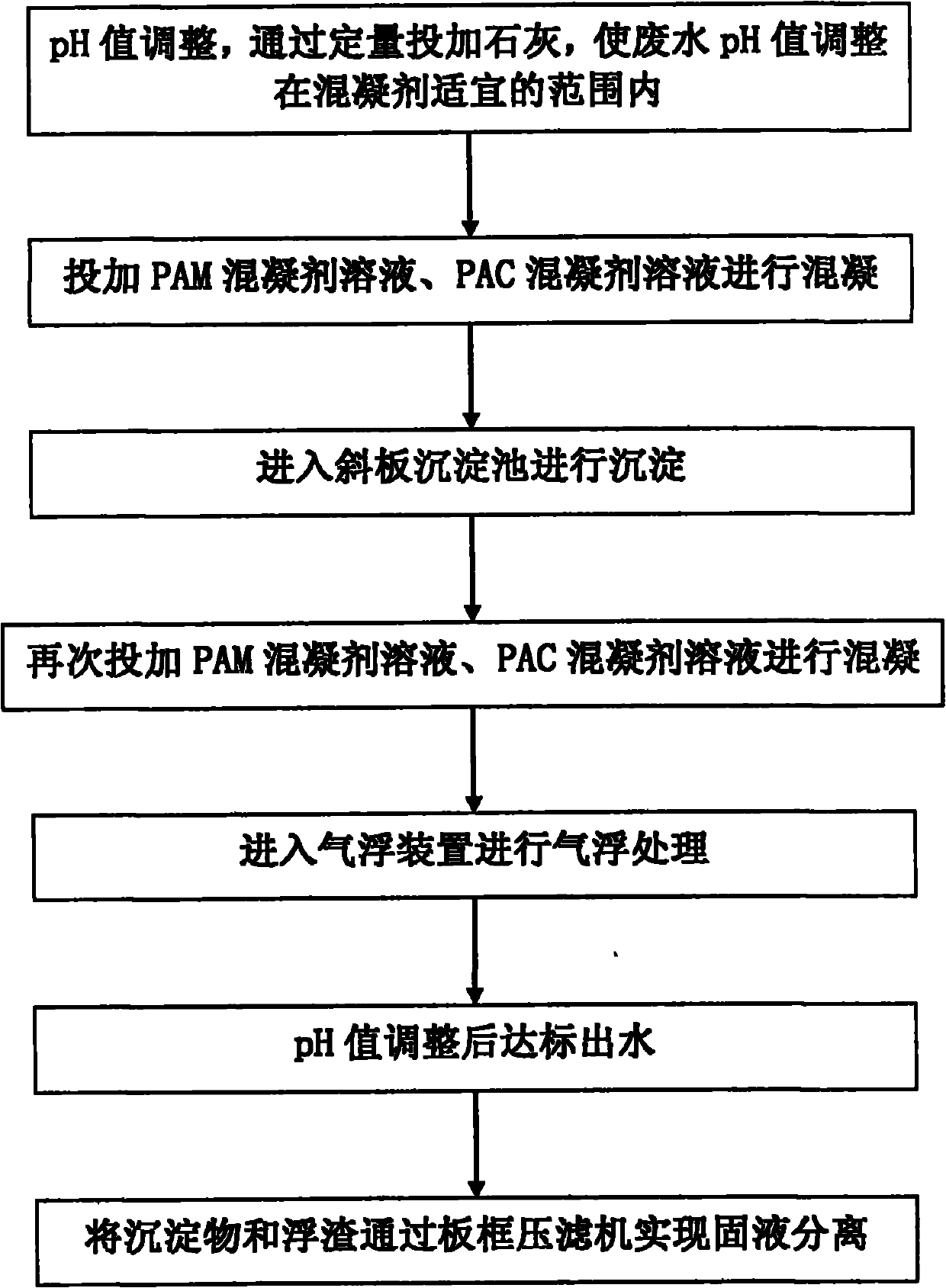

The invention relates to a process for treating phosphate coating wastewater of steel pipes, which comprises the following steps of: (1) regulating the pH value, namely regulating the pH value of the wastewater to be in a coagulant applicable range by quantitatively adding lime; (2) adding PAM coagulant solution and PAC coagulant solution for coagulation; (3) introducing into a sloping plate settling tank for settlement; (4) adding the PAM coagulant solution and PAC coagulant solution again for coagulation; (5) introducing into a floatation device for floatation treatment; (6) meeting the standard and discharging water after the pH value is regulated; and (7) performing solid-liquid separation on sediments in the sloping plate settling tank and dross in the floatation device by using a plate-and-frame filter press. According to the process for treating the phosphate coating wastewater of the steel pipes, physical and chemical treatment technology and a production process are closely combined, and the batch treatment of the phosphate coating wastewater of the steel pipes is realized. The process has the advantages that: one-time investment is low, the treatment effect is stable, the production running cost is low, the process is easy and convenient to implement and the like.

Owner:BAOSTEEL ENG & TECH GRP

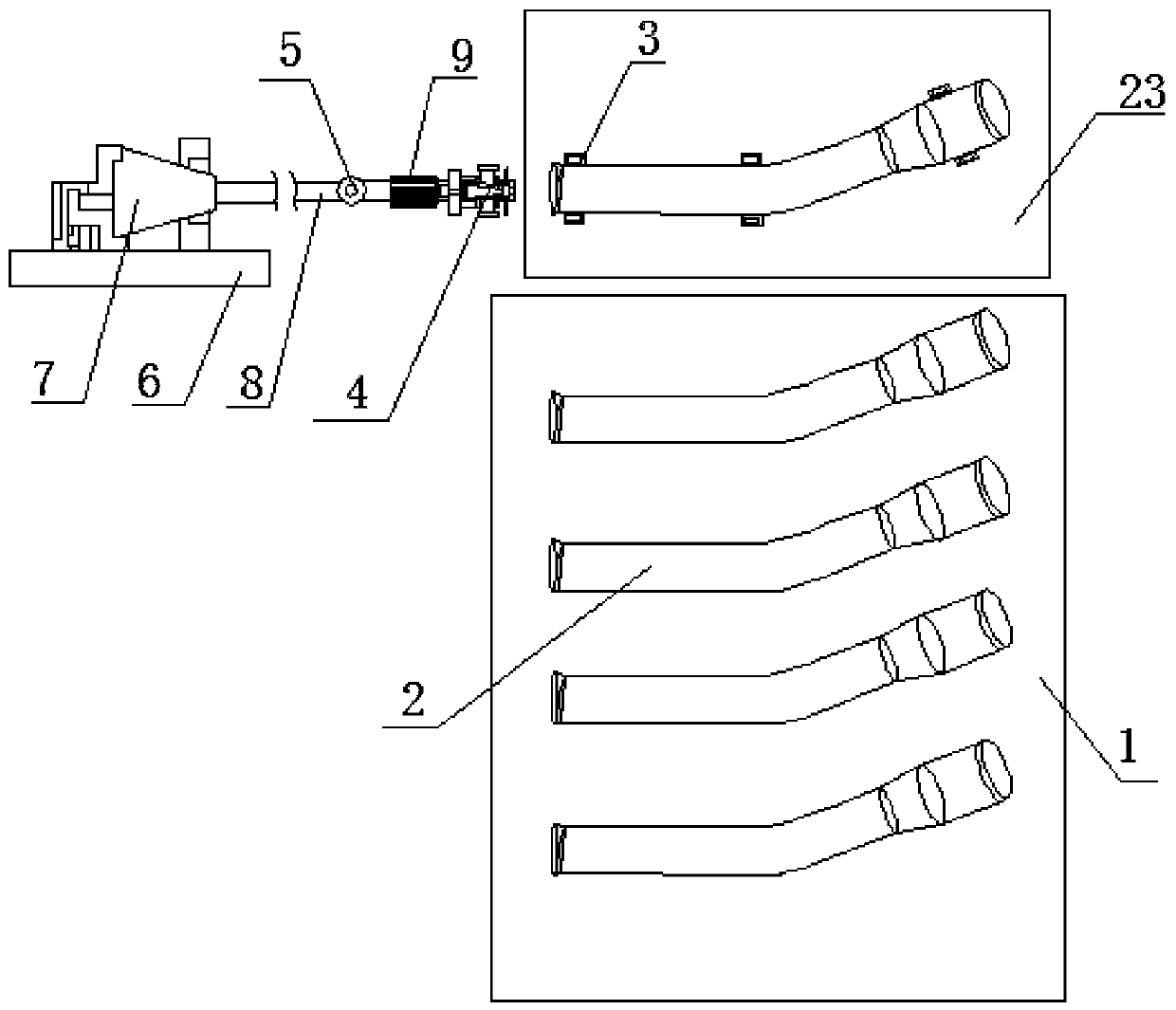

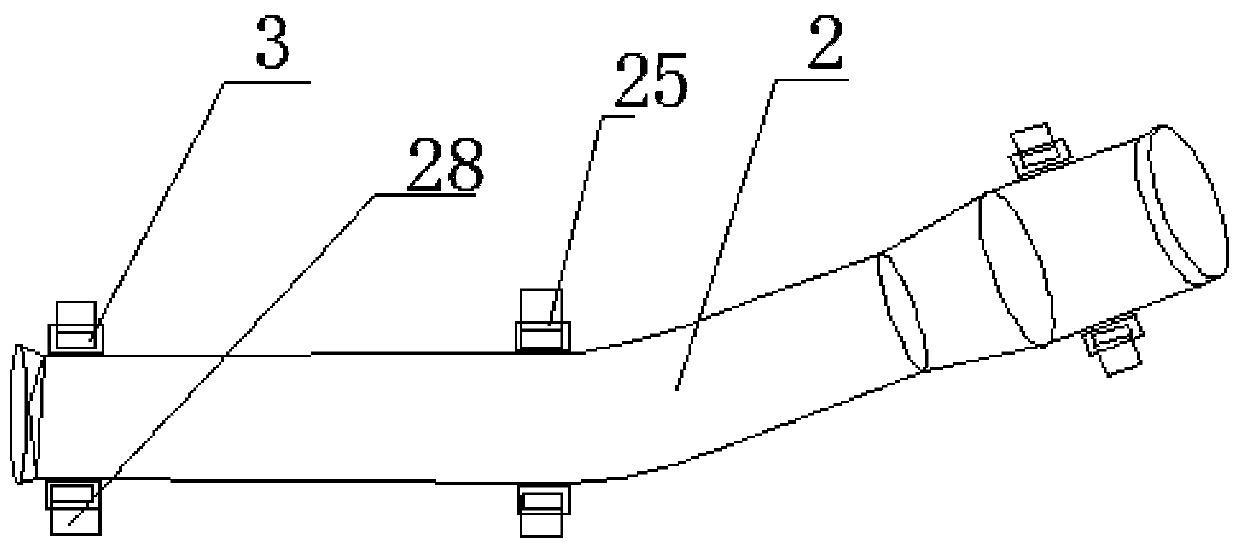

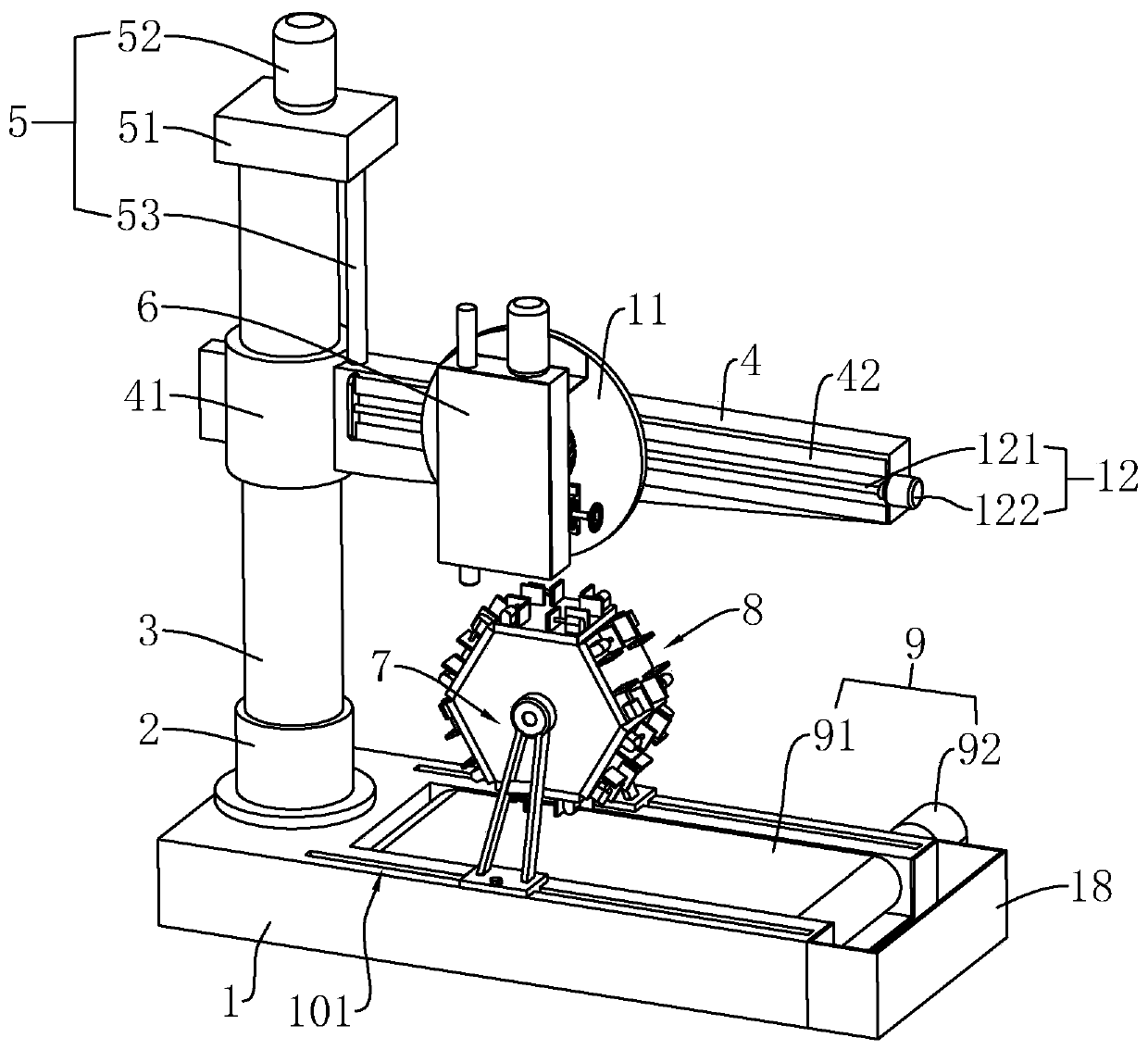

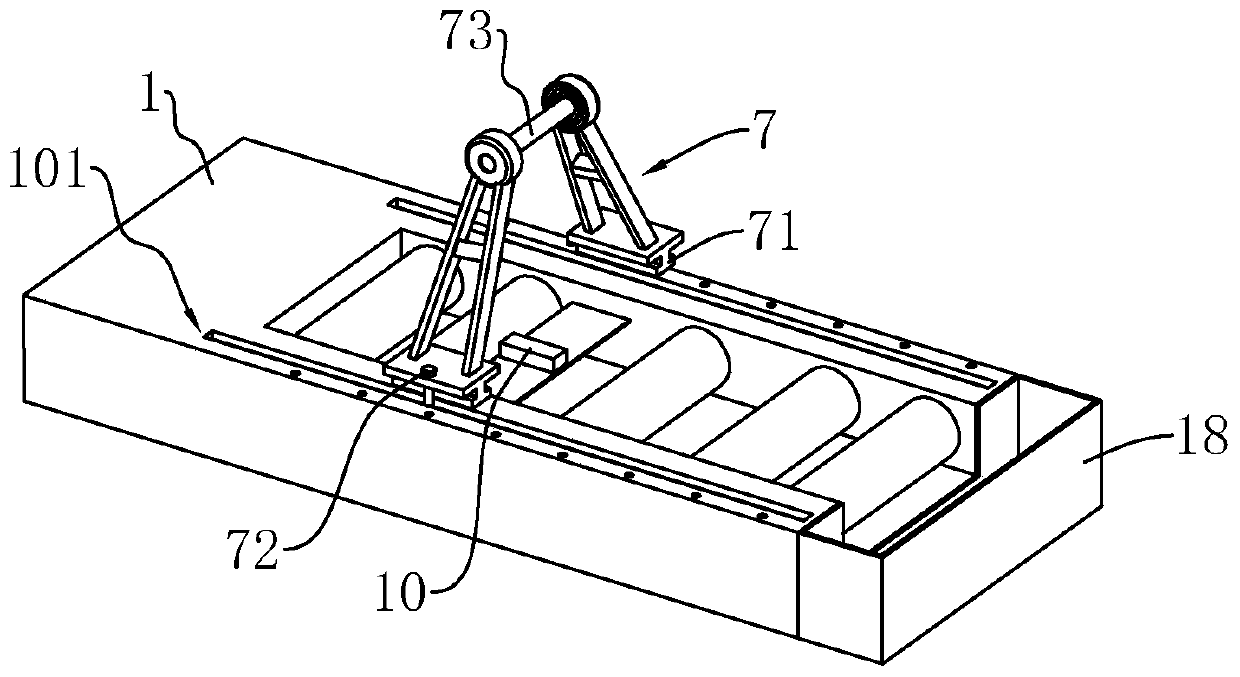

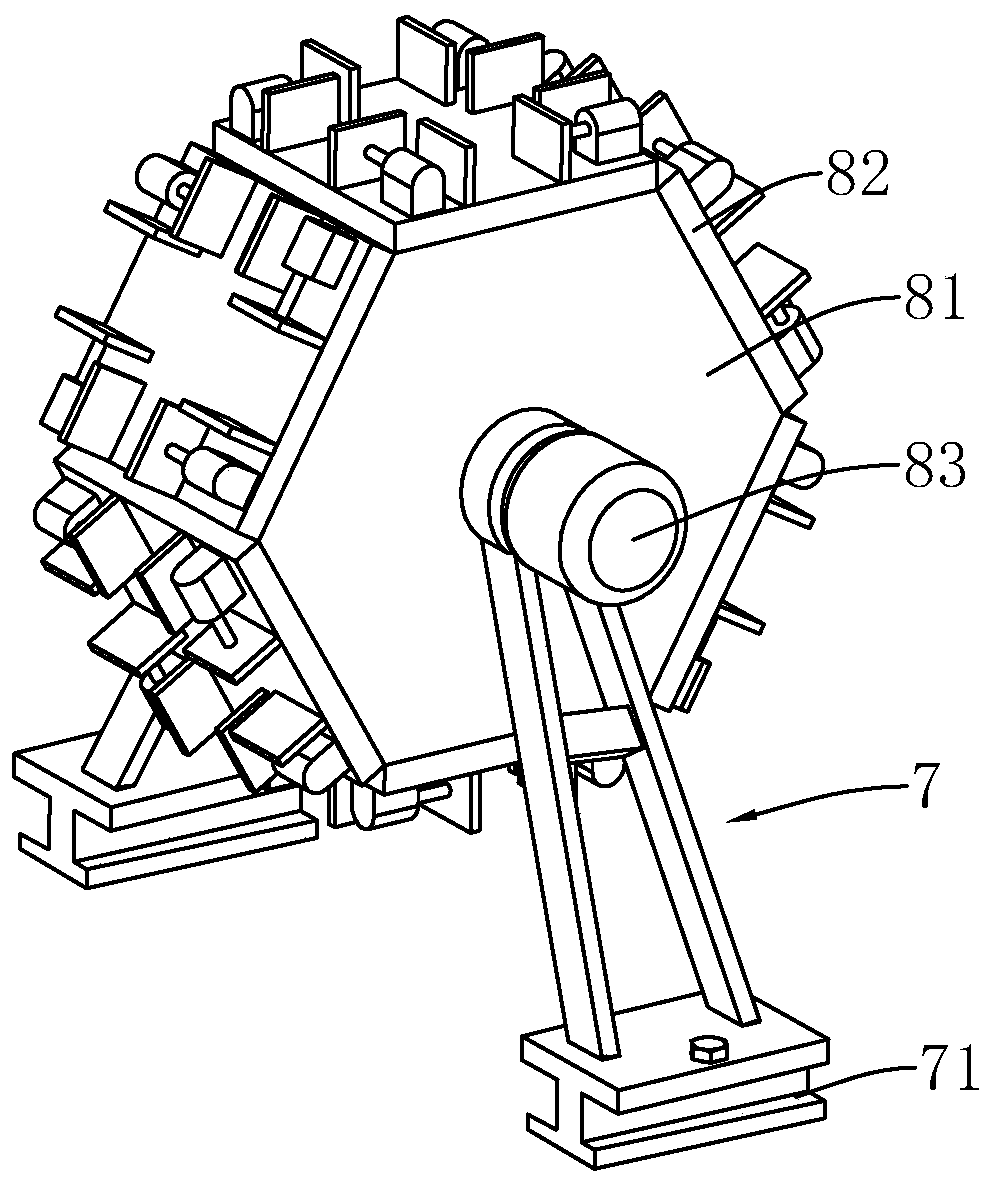

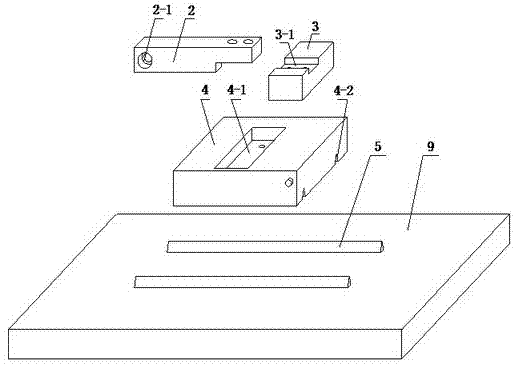

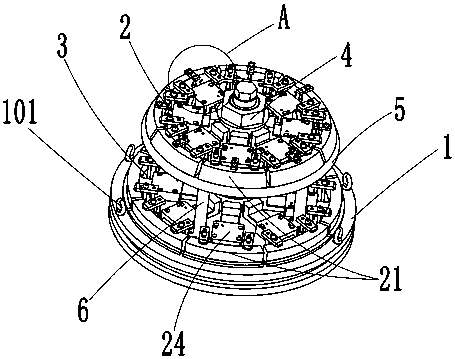

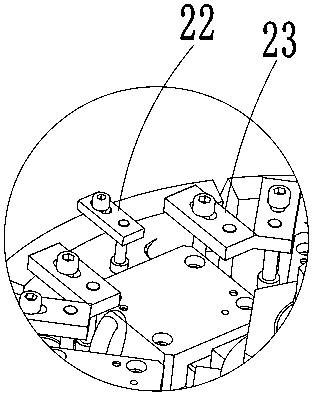

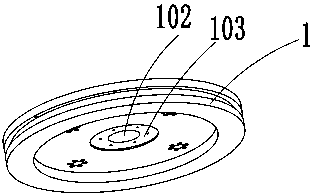

Intake pipe processing equipment for engine air intake system

InactiveCN110497284AImprove processing efficiencyImprove grinding efficiencyEdge grinding machinesGrinding carriagesAerospace engineeringBatch processing

The invention discloses an intake pipe processing equipment for an engine air intake system. According to the invention, the batch processing of intake pipes can be effectively realized. The intake pipe is placed on a positioning and locking mechanism on a processing table, and can be automatically positioned by a positioning mechanism of the positioning and locking mechanism and locked by the locking mechanism, and a grinding processing mechanism is started to extend and grind the inner wall of the intake pipe; a grinding head assembly is arranged at the end of a flexible feeding rod of an axial feeding mechanism in a way that the angle of an universal ball hinge can be adjusted, so as to effectively enable the grinding head assembly and the flexible feeding rod to adapt to the arc of theintake pipe; the intake pipe processing equipment can adapt to the grinding of different inner wall diameters of different parts of the intake pipe, the grinding is thorough, and the versatility is high; at the same time, the pressing force of the grinding can be controlled by an ejector cylinder, which is simple and convenient; and by utilizing the design of an elastic positioning piece of the locking mechanism, the intake pipe can be positioned and locked under the pressing effect of a locking pressing seat.

Owner:GUILIN UNIV OF AEROSPACE TECH

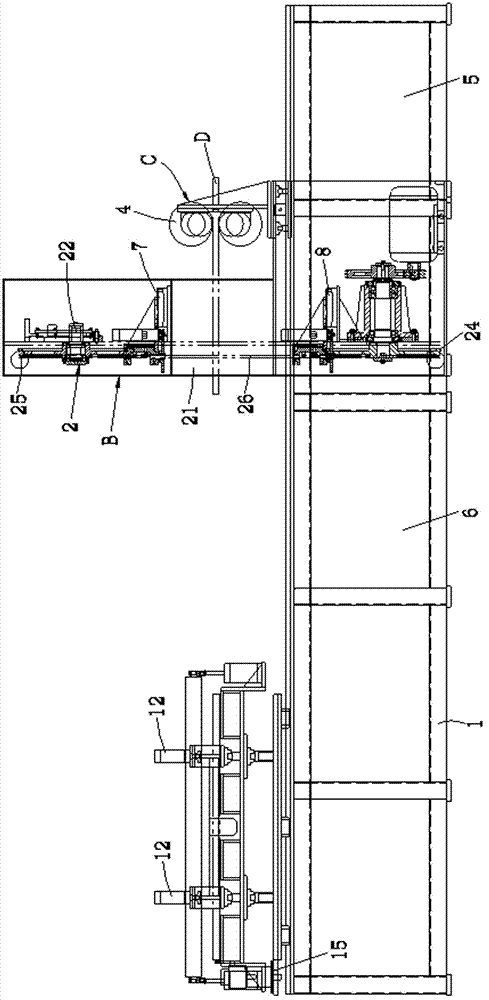

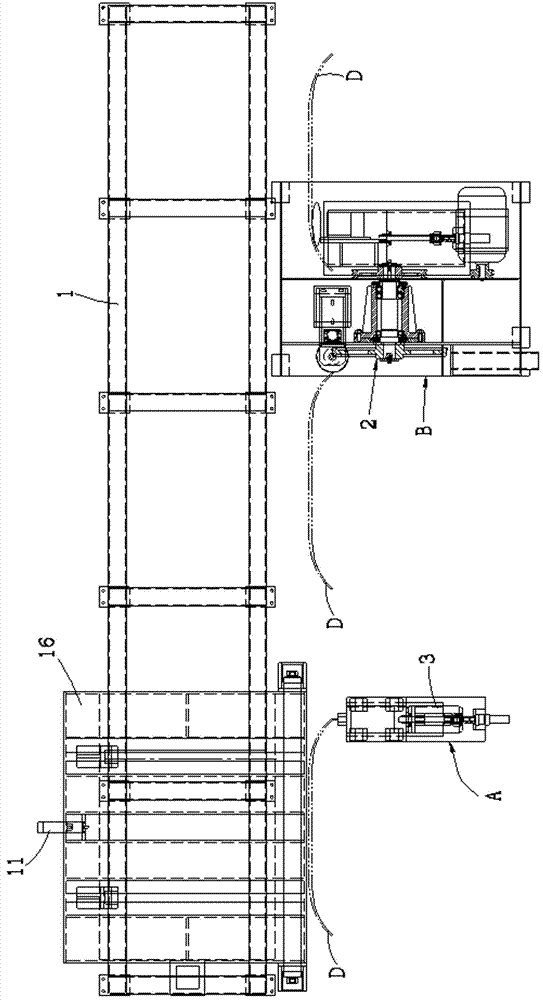

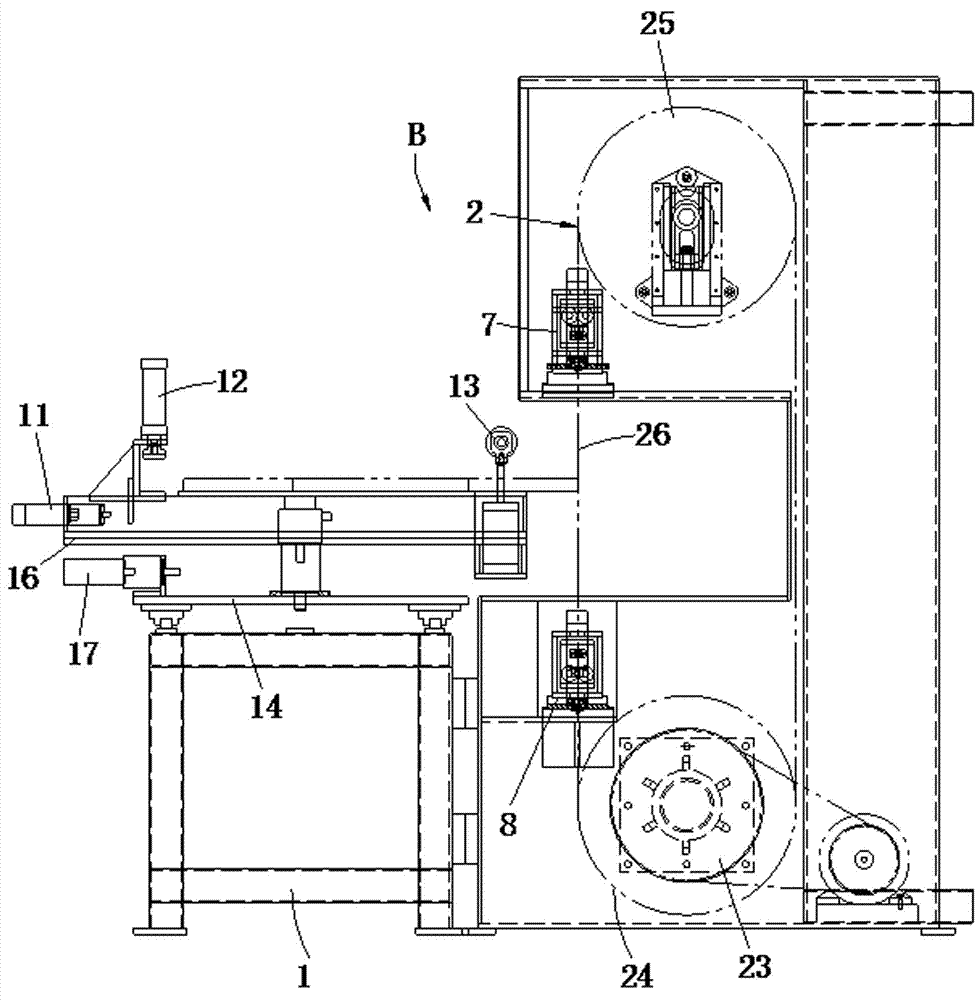

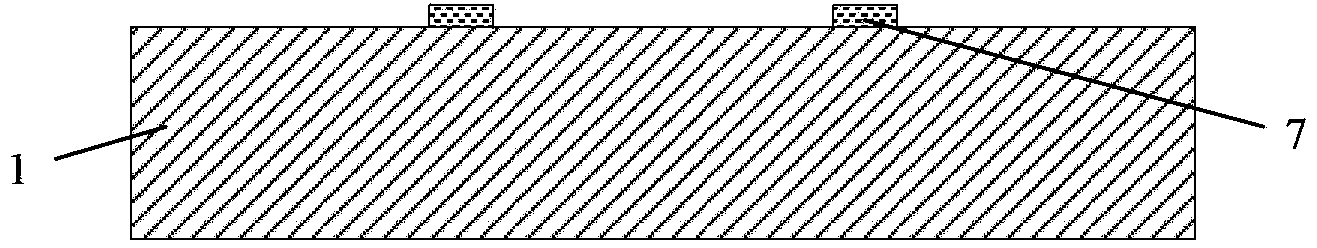

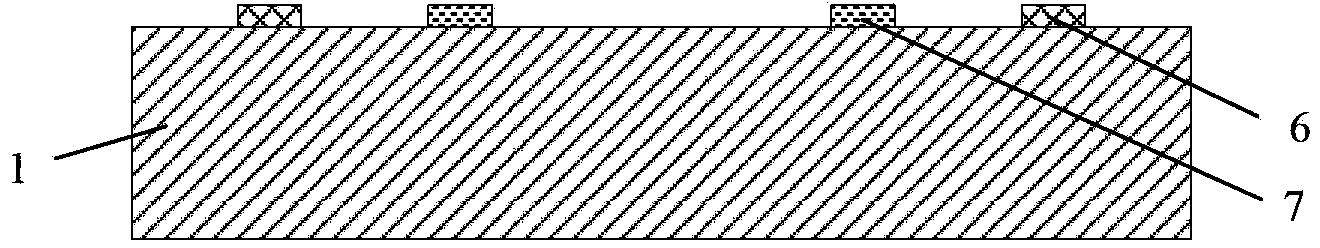

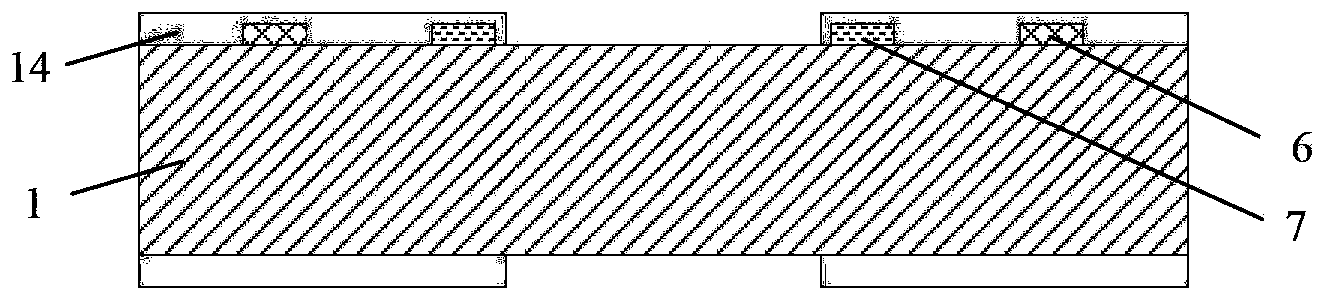

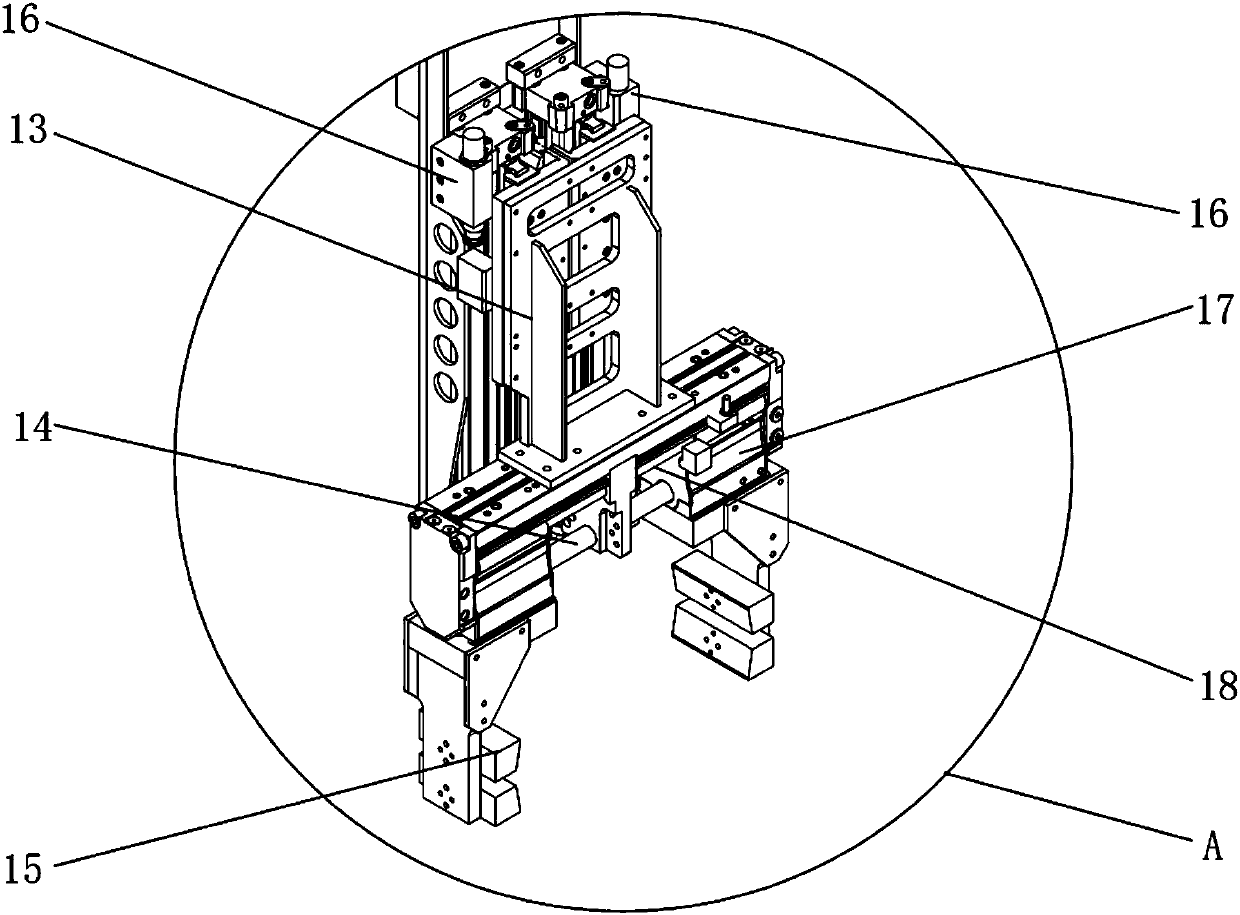

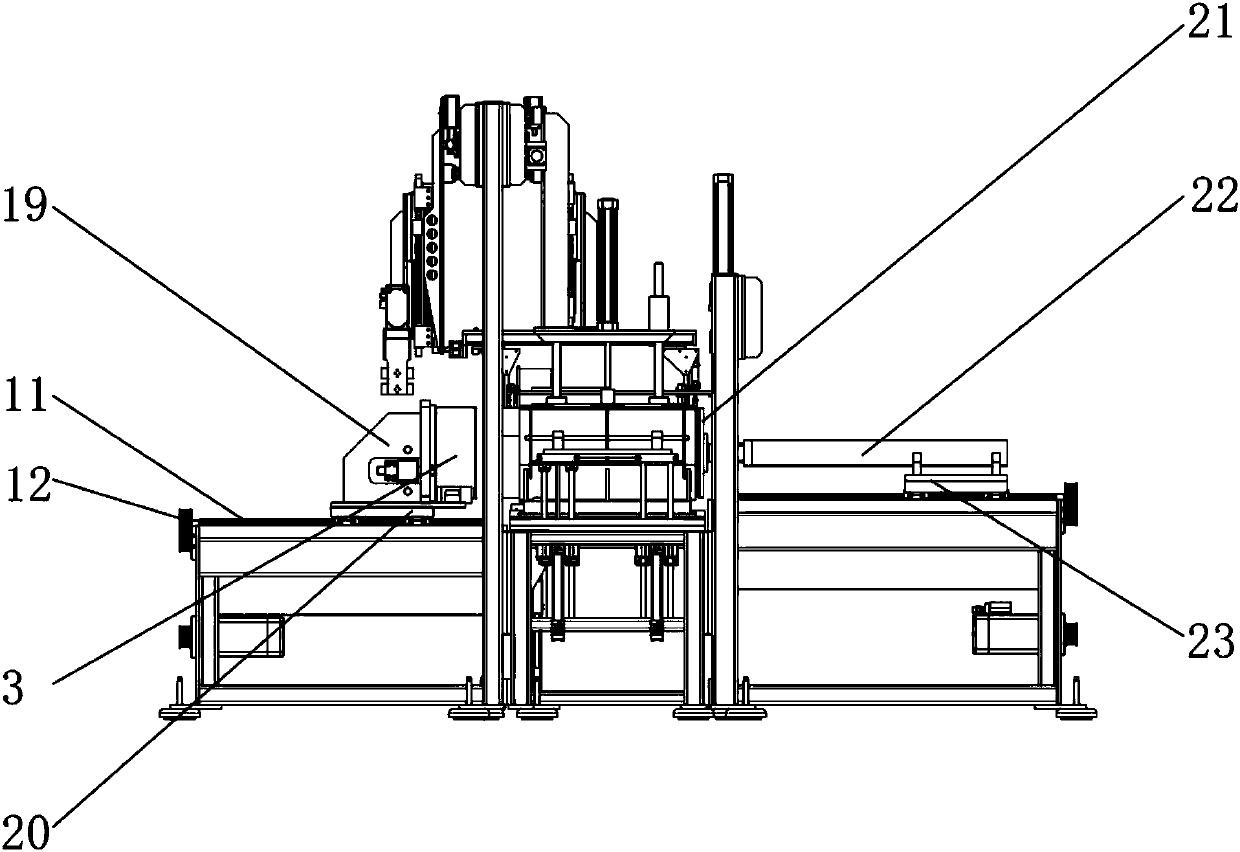

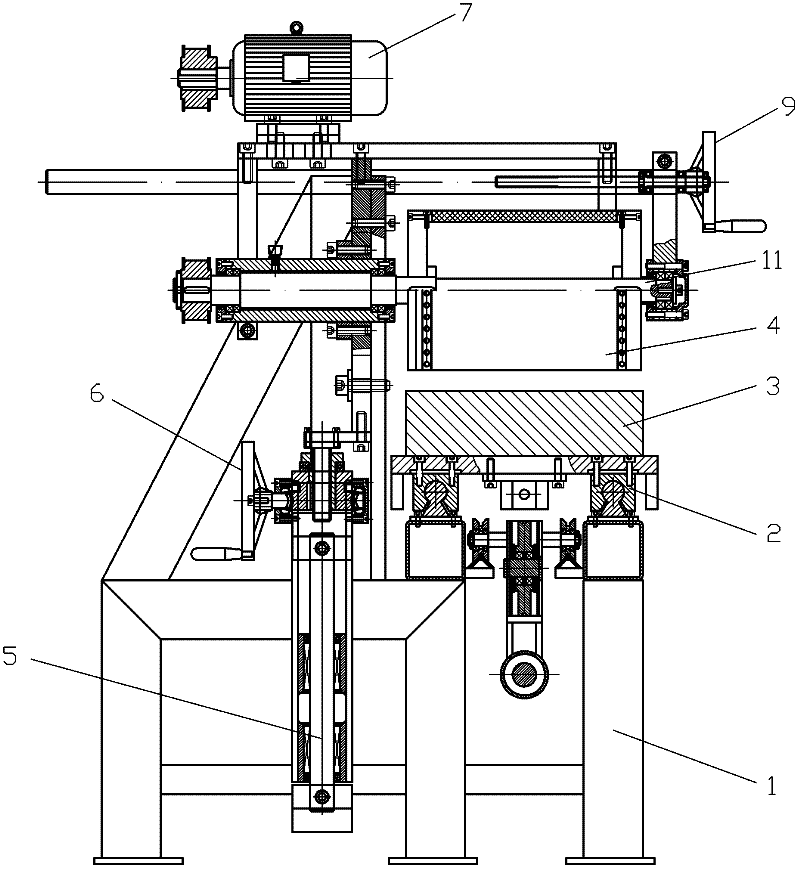

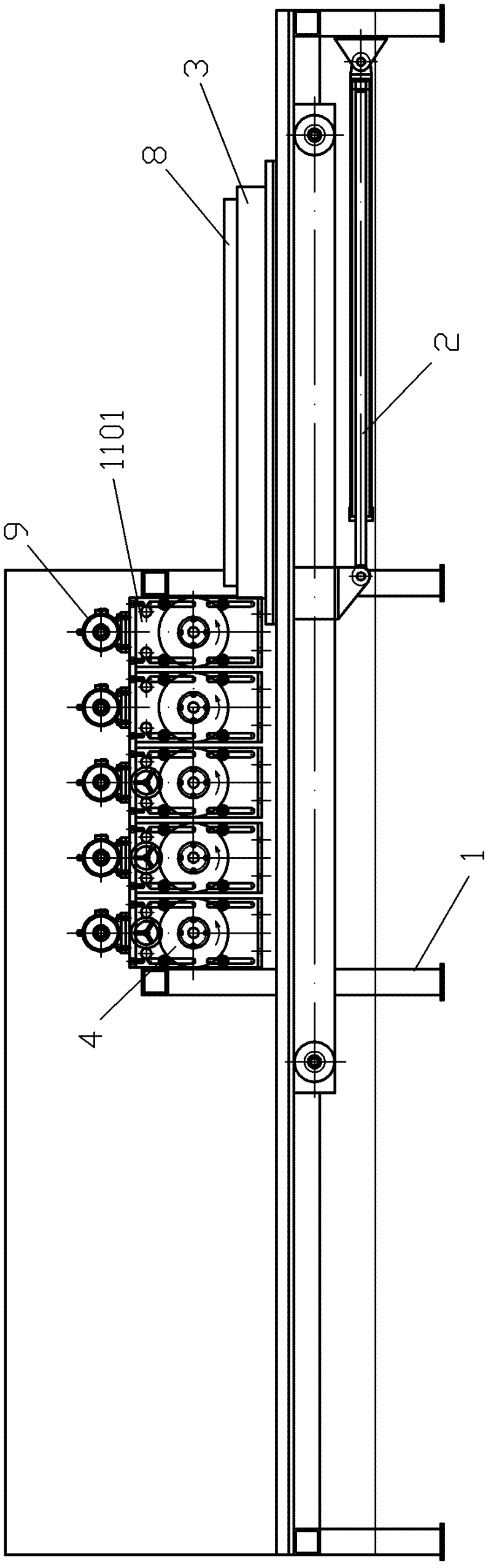

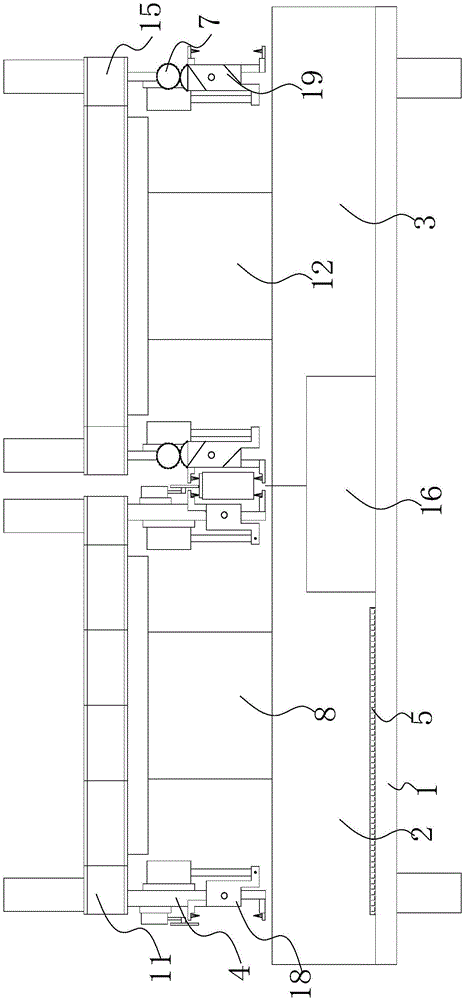

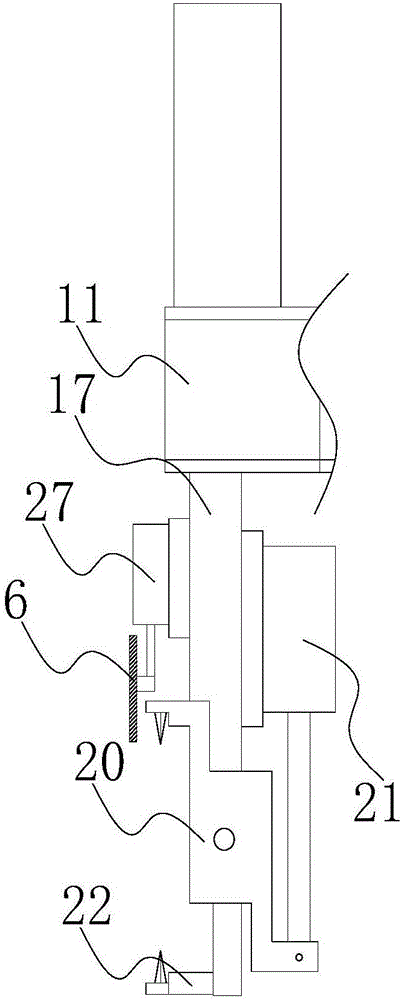

Automatic machining equipment and machining method for pantograph carbon slide plate of high-speed rail

ActiveCN104772827AChange the production processGuaranteed machining accuracyMetal sawing devicesRailway vehiclesNumerical controlEngineering

The invention relates to automatic machining equipment and a machining method for a pantograph carbon slide plate of a high-speed rail. The automatic machining equipment is sequentially provided with a milling station, a sawing station and a chamfering station and comprises a machine stand, a band sawing machine, a workpiece milling device, a workpiece chamfering device, a CNC (Computer Numerical Control) system and a pneumatic system; a carbon slide plate workpiece to be machined is arranged on the machine stand and is sequentially subjected to milling, sawing and chamfering machining; a saw frame of the band sawing machine is also provided with a saw band upper guide servo rotating device and a saw band lower guide servo rotating device which are capable of freely, synchronously and correspondingly rotating a band saw blade within a certain range. According to the automatic machining equipment and the machining method disclosed by the invention, the carbon slide plate can be machined in a sawing manner, and the working procedures, namely sawing, milling and chamfering are integrated on one equipment and can be automatically finished after once clamping, so that materials are saved and the working efficiency is improved.

Owner:ZHE JIANG CHENLONG SAWING MACHINE CO LTD

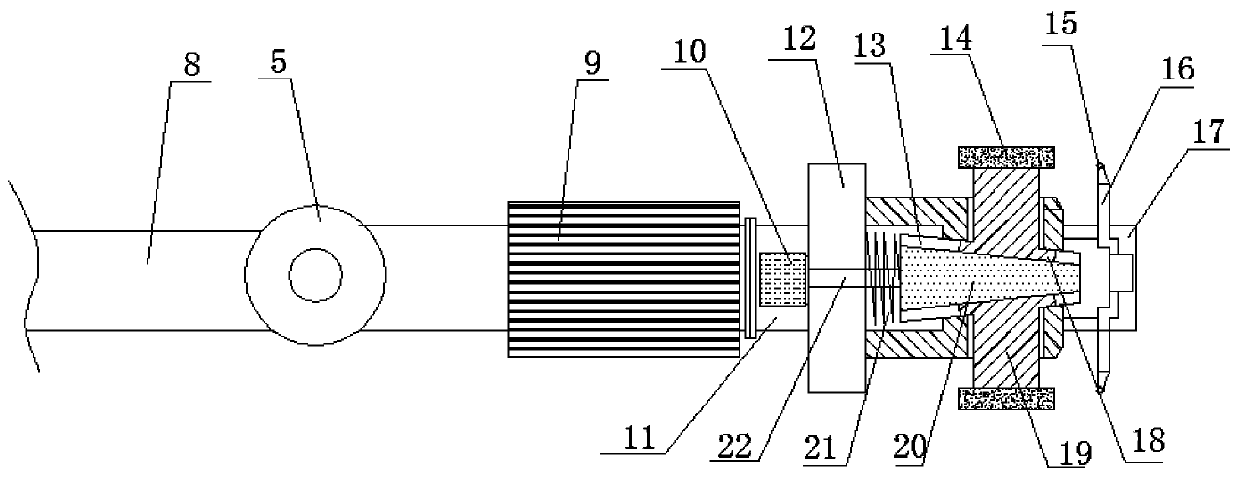

Resistor top-mounted type micro-thruster and manufacturing method thereof

InactiveCN103511125ATweak Burning BehaviorPromotes full combustionRocket engine plantsElectrical resistance and conductanceCombustion

The invention discloses a resistor top-mounted type micro-thruster and a manufacturing method of the resistor top-mounted type micro-thruster, and belongs to the field of micro-thrusting technologies and MEMSs. Ignition resistors 7 of the micro-thruster are respectively composed of multiple sets of resistance wires, the width of each resistance wire and the length of each resistance wire are design to form a certain proportion so that the combustion of fuel can be adjusted and full combustion of the fuel can be facilitated. A spray nozzle 4 is of a laval-like structure with the middle contracted and the two ends expanded, and therefore the flowing mode of the air flow can be improved, and the fuel energy utilization rate can be effectively improved. The ignition resistors 7 are placed on the periphery of the spray nozzle 4 and can not be easily damaged in the gunpowder filling process, the assembly process and other processes. According to a manufacturing method of the resistor top-mounted type micro-thruster, stability and consistency of device machining can be easily achieved, and the batch machining can be easily achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

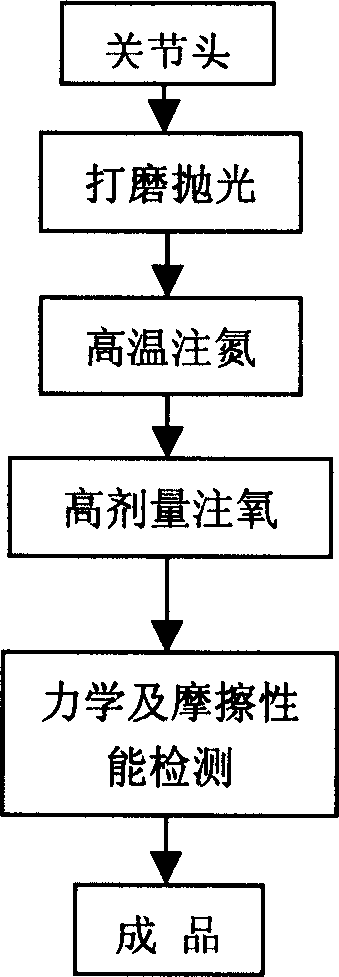

Method for producing gradient wear resistant layer from titanium oxide to titanium nitride on surface of titanium alloy artificial joint head

InactiveCN1715439AImprove wear resistanceImproved biocompatibility and corrosion resistanceSolid state diffusion coatingSurface oxidationCorrosion resistant

The present invention relates to the method of producing gradient wear resistant layer from titanium oxide to titanium nitride on surface of artificial joint head of titanium alloy. The present invention features the two-step omnibearing ion implantation process to form the gradient titanium oxide-titanium nitride film. After the artificial joint head of titanium alloy is polished to mirror surface, it is implanted first with nitrogen ion at high target temperature of 600-700 deg c in the implanted amount of 1017-1018 / sq cm inside the omnibearing ion implantation machine, and then with high dosage of oxygen ion at target temperature from room temperature to 300 deg c and in the implanted amount of 1018-1019 / sq cm, so as to obtain artificial joint head of titanium alloy with gradient titanium oxide-titanium nitride film. The artificial joint head has in the surface deep gradient film with high bearing capacity, high hardness, high combining strength, excellent lubricating performance and high smoothness.

Owner:NANJING UNIV OF SCI & TECH

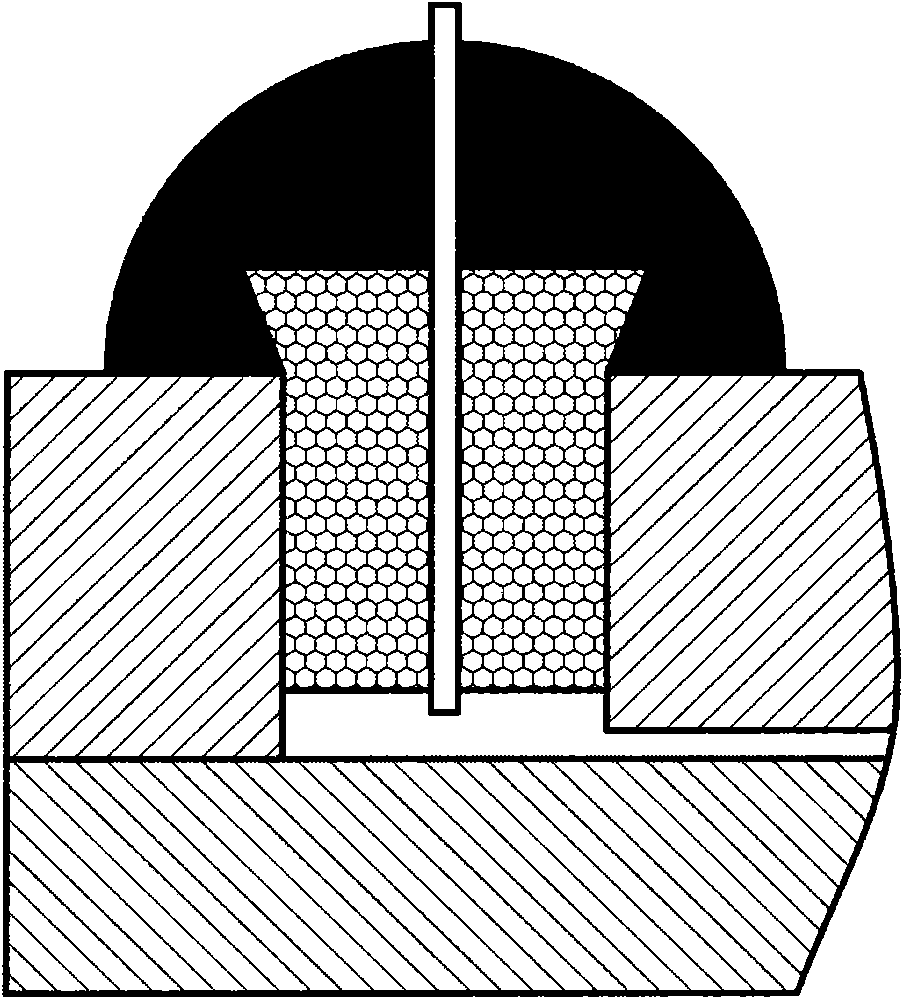

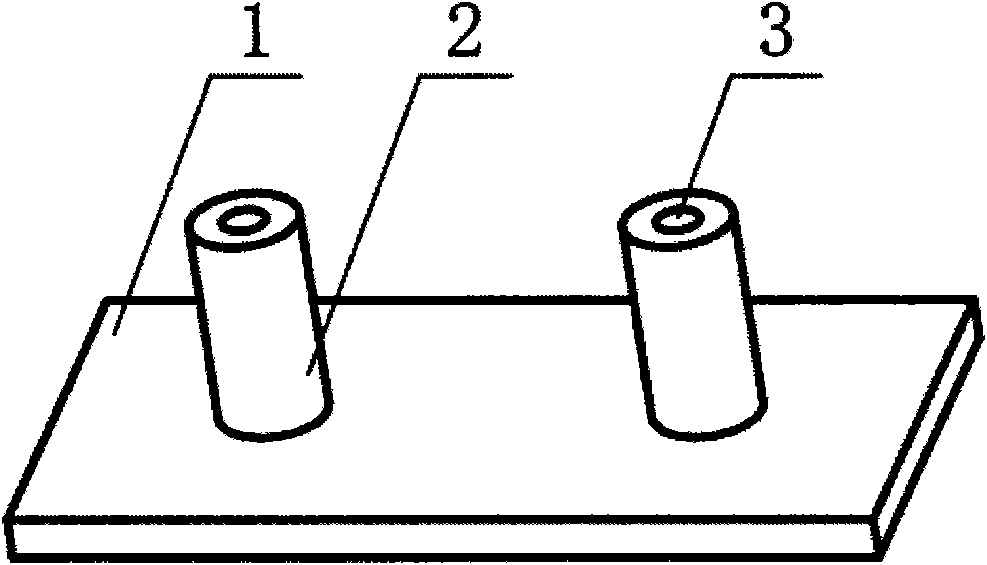

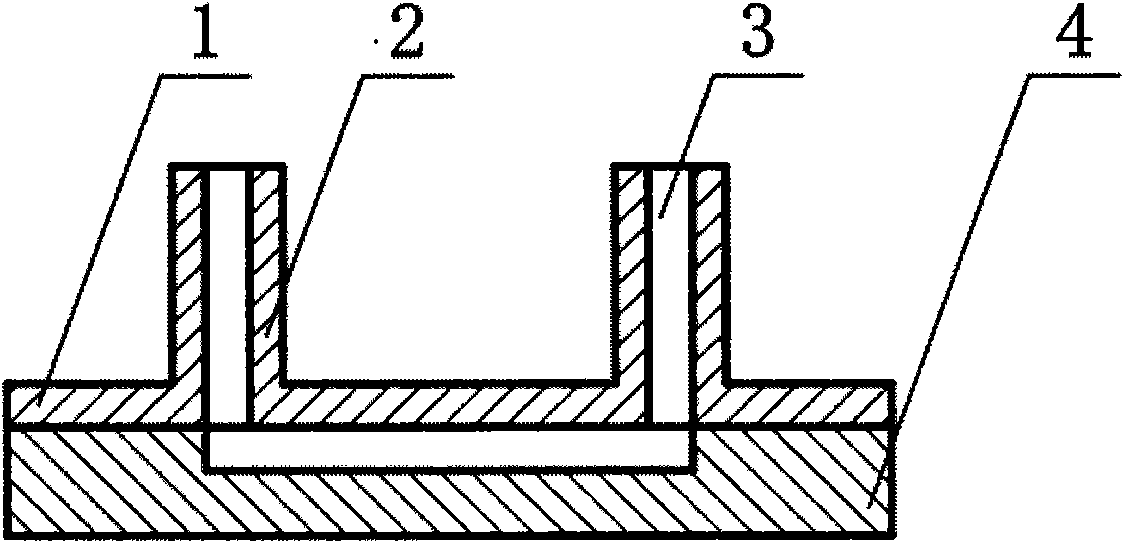

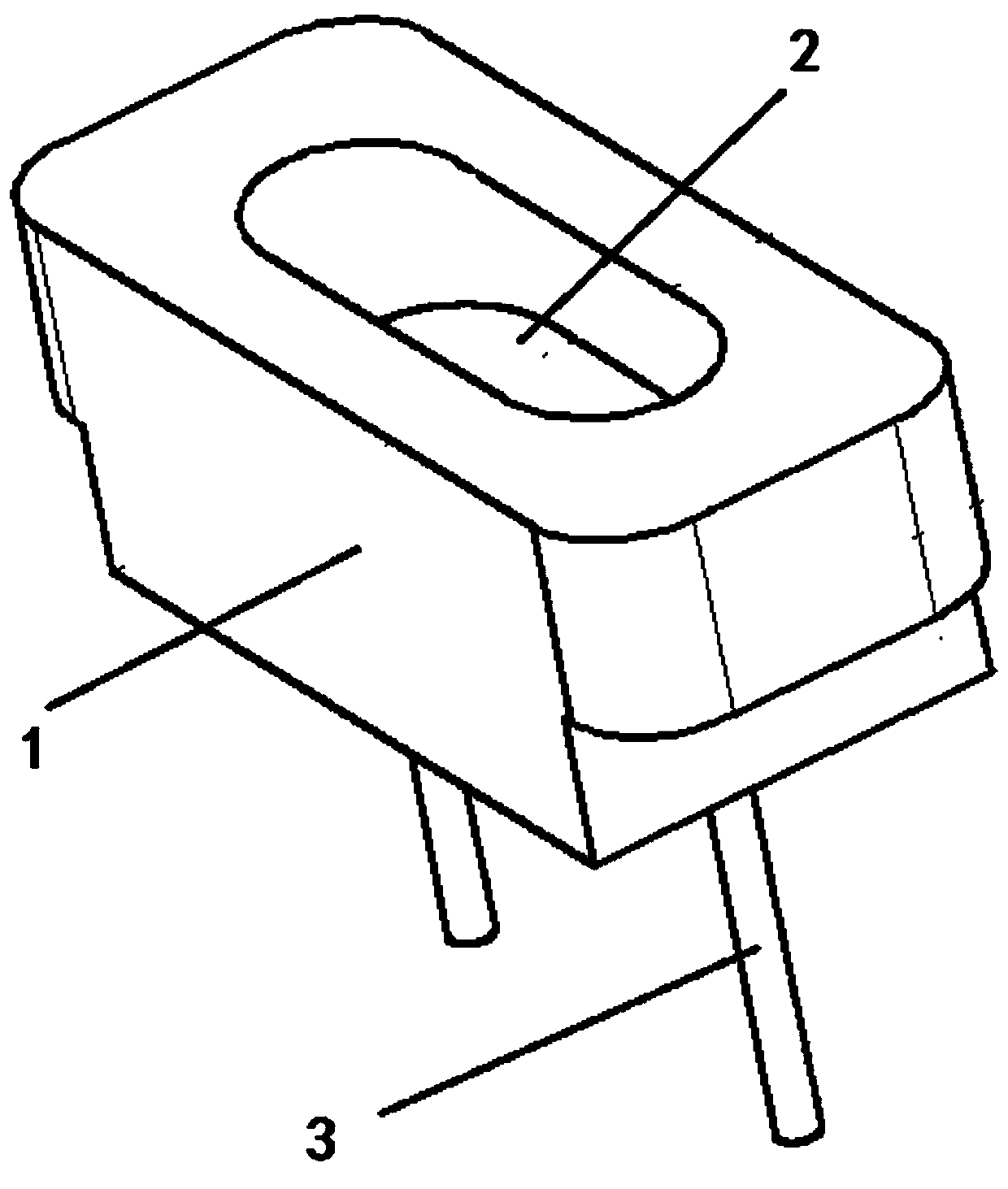

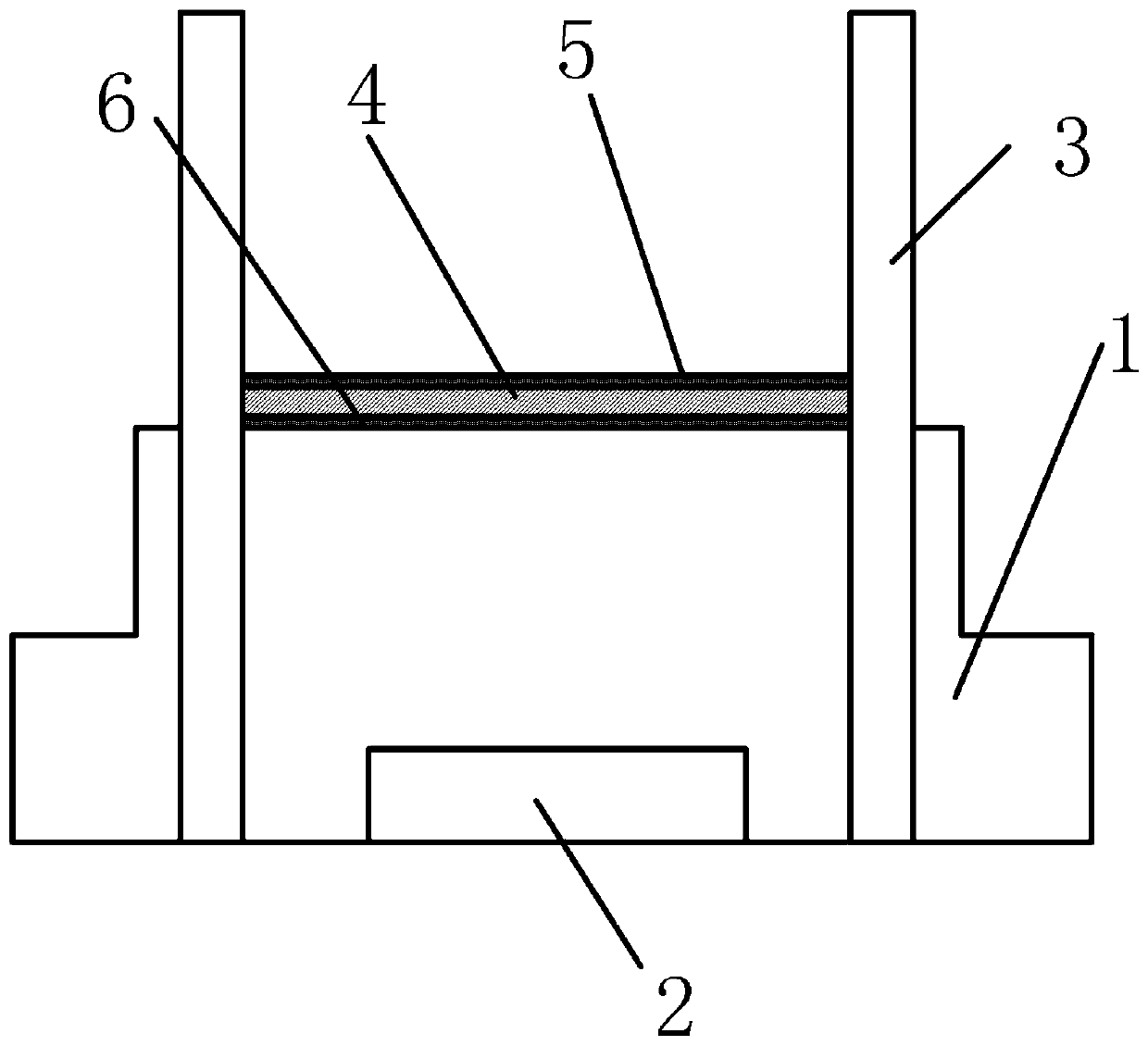

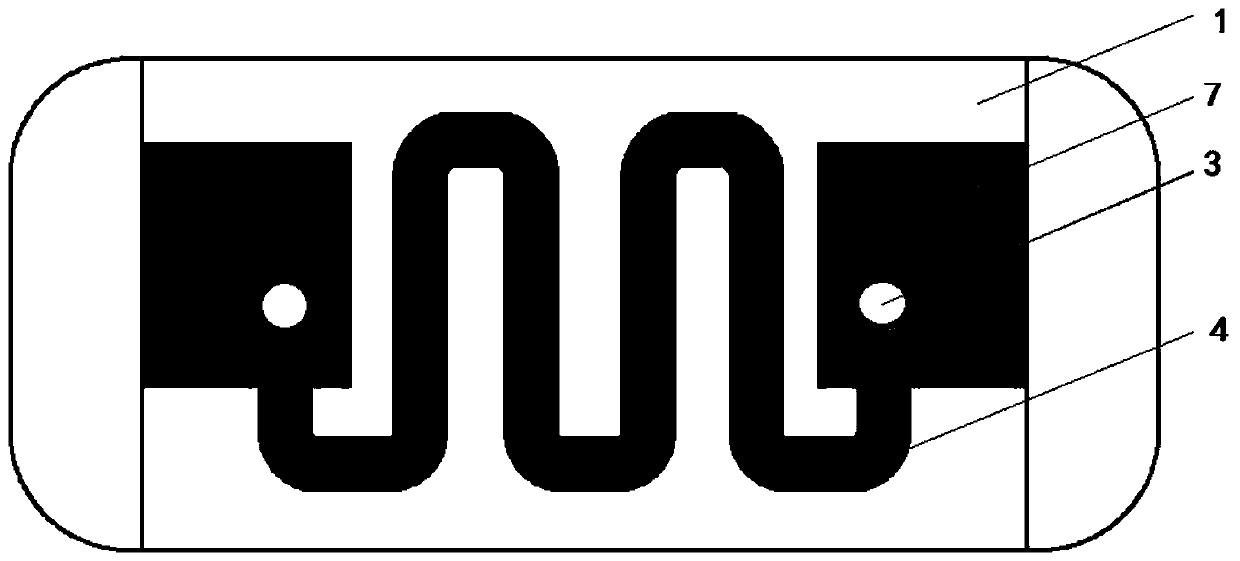

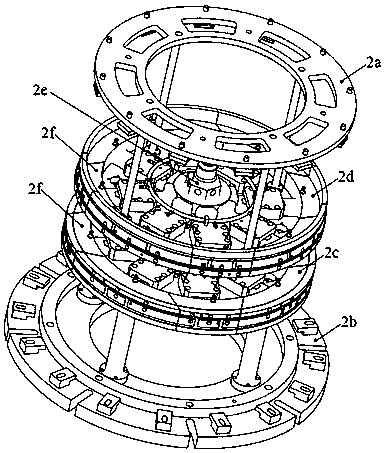

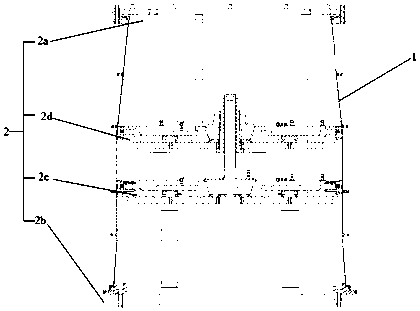

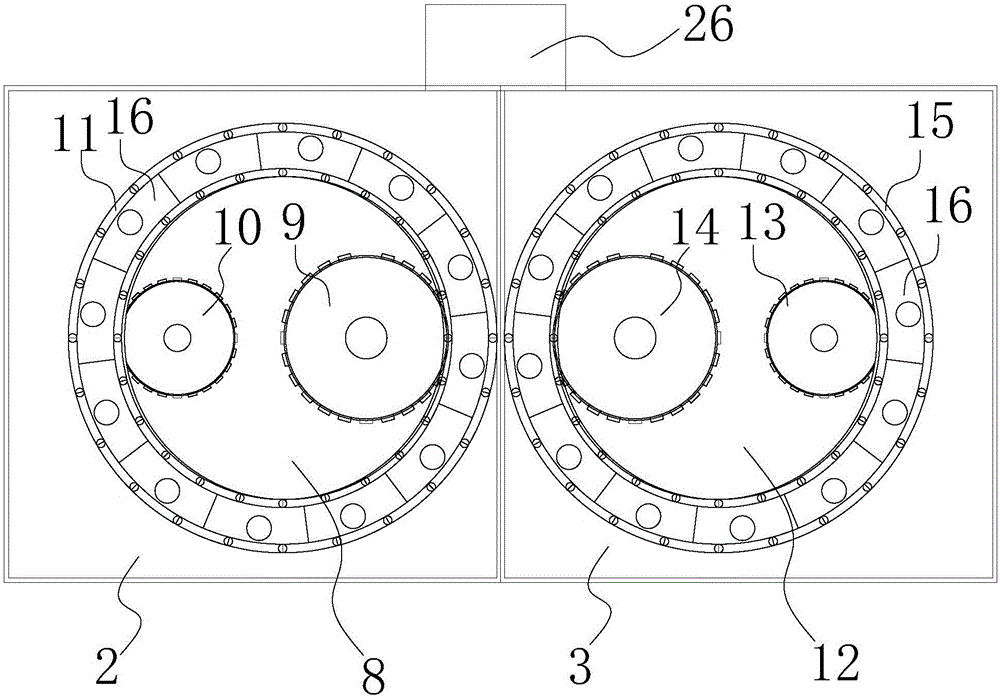

Integrated microfluidic chip interface, interface mould, and interface manufacturing and using methods

ActiveCN102033135ARealize batch processingAchieve connectionDecorative surface effectsChemical vapor deposition coatingAdhesiveEngineering

The invention discloses an integrated microfluidic chip interface, which belongs to the field of microfluidic chips. The interface comprises a horizontal substrate 1 and a plurality of lug bosses 2, wherein the horizontal substrate 1 is arranged above the microfluidic chip 4 in a sealing connection way; the plurality of lug bosses 2 are positioned on the horizontal substrate 1; and connecting pipelines 3 are arranged in the lug bosses 2, and communicate microchannels on the microfluidic chip 4 with the outside. In addition, the invention also discloses a method for manufacturing the interfacebased on a mould and an interface using method. The integrated microfluidic chip interface provided by the invention can realize connection between an external microscopic system and a microfluidic chip system without using an adhesive, achieves a good sealing effect and does not cause the blockage of the microchannels. In the method for manufacturing the interface, the batch machining of the integrated microfluidic chip interfaces can be realized by the interface mould.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Efficient automatic drilling machine

ActiveCN110369755ARealize batch processingImprove processing efficiencyWork clamping meansLarge fixed membersMachine toolMachining

The invention discloses an efficient automatic drilling machine, and relates to the technical field of machine tools. The efficient automatic drilling machine comprises a base, a drill bit and a workbench arranged on the base. The workbench comprises a wheel rotary table rotationally arranged on the base and a plurality of workpiece installation tables which are circumferentially and evenly distributed on the wheel rotary table. Each workpiece installation table is provided with a clamping assembly used for fixing workpieces. The base is provided with a first driving device used for driving the wheel rotary table to rotate; and when the wheel rotary table is rotated, the workpiece installation tables are alternately aligned with the drill bit. The efficient automatic drilling machine is stable in work, high in automation degree, convenient and fast to operate, wide in application range and capable of realizing batch and efficient machining of parts.

Owner:杭州临安华冠家具有限公司

Porous ceramic heating element and manufacturing method thereof

InactiveCN110074469AExtended service lifeDoes not affect heating atomizationTobacco devicesCorrosionHeating element

The invention discloses a porous ceramic heating element used for atomizing tobacco tar of an electronic cigarette. The porous ceramic heating element comprises a porous ceramic substrate, a resistivelayer jointed with the surface of the porous ceramic substrate, and a lead electrically connected with the resistive layer by means of an electrode, wherein the surface, jointed with the porous ceramic substrate, of the resistive layer is provided with a first protective layer for isolating tobacco tar. According to the heating element provided by the invention, the resistive layer is not directly contacted with the tobacco tar, so the the corrosion effect of the tobacco tar on the resistive layer is avoided, and the service life of the resistive layer is accordingly prolonged. The inventionalso provides a manufacturing method of the porous ceramic heating element; a first protective layer and the resistive layer are printed on the surface of a whole piece of porous ceramics, and the porous ceramics is then cut, so that a plurality of independent ceramic heating elements are obtained; therefore, the batch processing of heating parts of the porous ceramic heating element is realized,and the production efficiency of the porous ceramic heating element is increased to a certain extent.

Owner:珠海诗朗豪泰科技有限公司

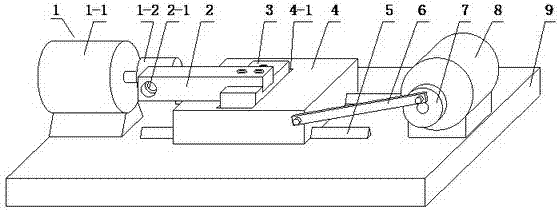

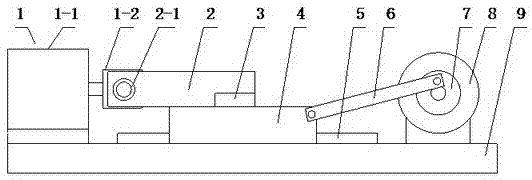

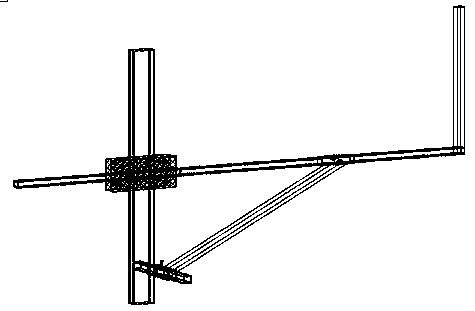

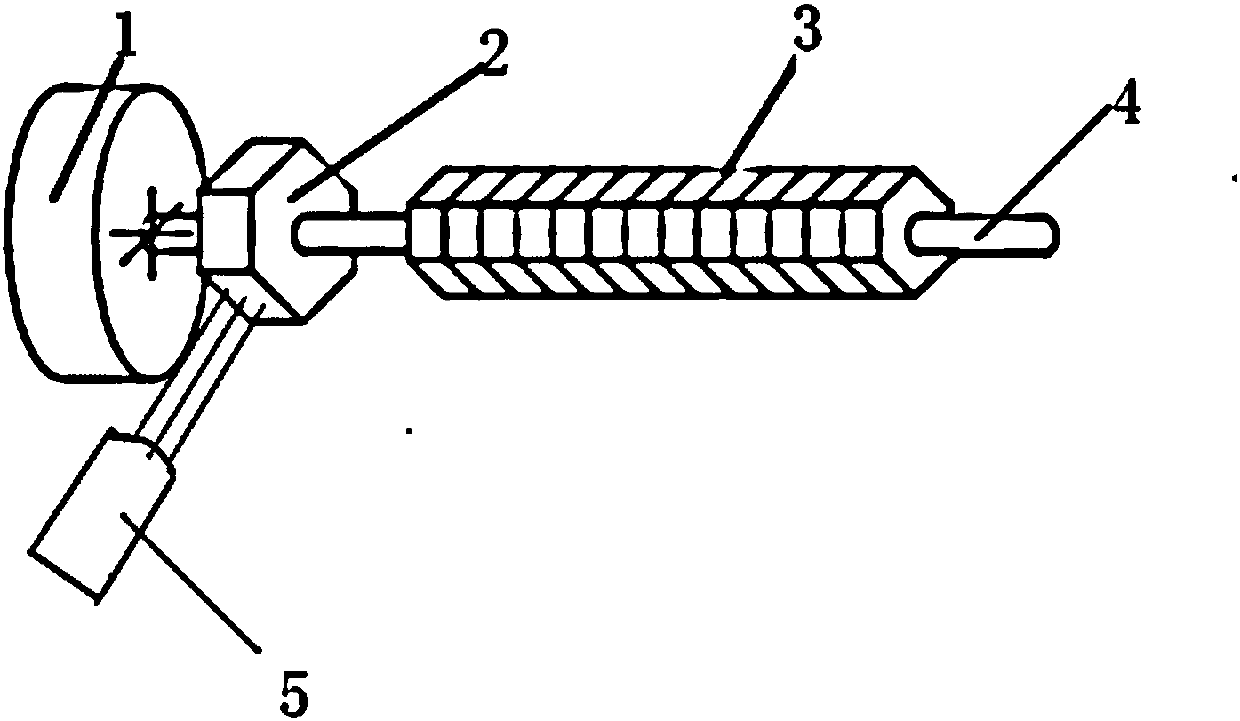

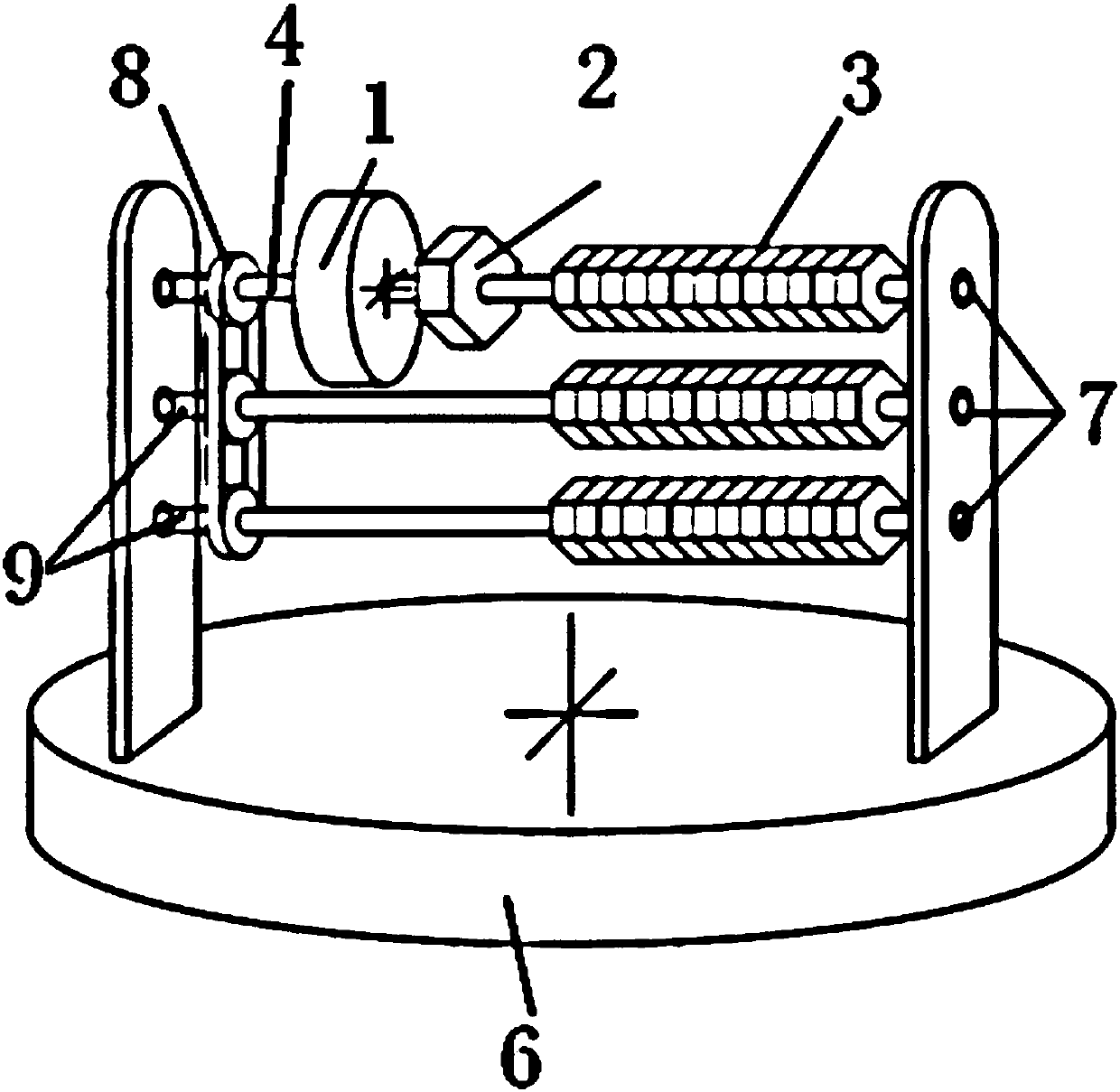

Probe grinding machine of wheel speed sensor

InactiveCN101817157AReasonable structureEasy to operateGrinding machinesElectric machineryProcessing accuracy

The invention relates to a grinding device, in particular to a probe grinding machine of a wheel speed sensor. The probe grinding machine comprises a grinding wheel machine, a stander, a transverse guide rail, a support plate, a probe rack, a connecting rod, an eccentric wheel and a motor, wherein the upper end of the stander is provided with the transverse guide rail; a guide groove is positioned under the support plate; the support plate is matched with the transverse guide rail by the guide rail and can slide at the left and the right along the transverse guide rail; the grinding wheel machine is positioned at the left side of the support plate, and thetor is arranged at the right side thereof; the power output direction of the motor is vertical to the transverse guide rail; the front end of a power output shaft of the motor is connected with the eccentric wheel; the two ends of the connecting rod are respectively articulated with the eccentric wheel and the support plate; and the right end of the probe rack is connected with the support plate, and the left end thereof is positioned at the outer side of a grinding wheel of the grinding wheel machine. The probe grinding machine has the advantages that the machine has reasonable structure, simple operation, safety and reliability as well as high working efficiency, can realize batch processing of products, is high in processing accuracy, and effectively reduces the rejection rate of the products.

Owner:杭州南科汽车传感器有限公司

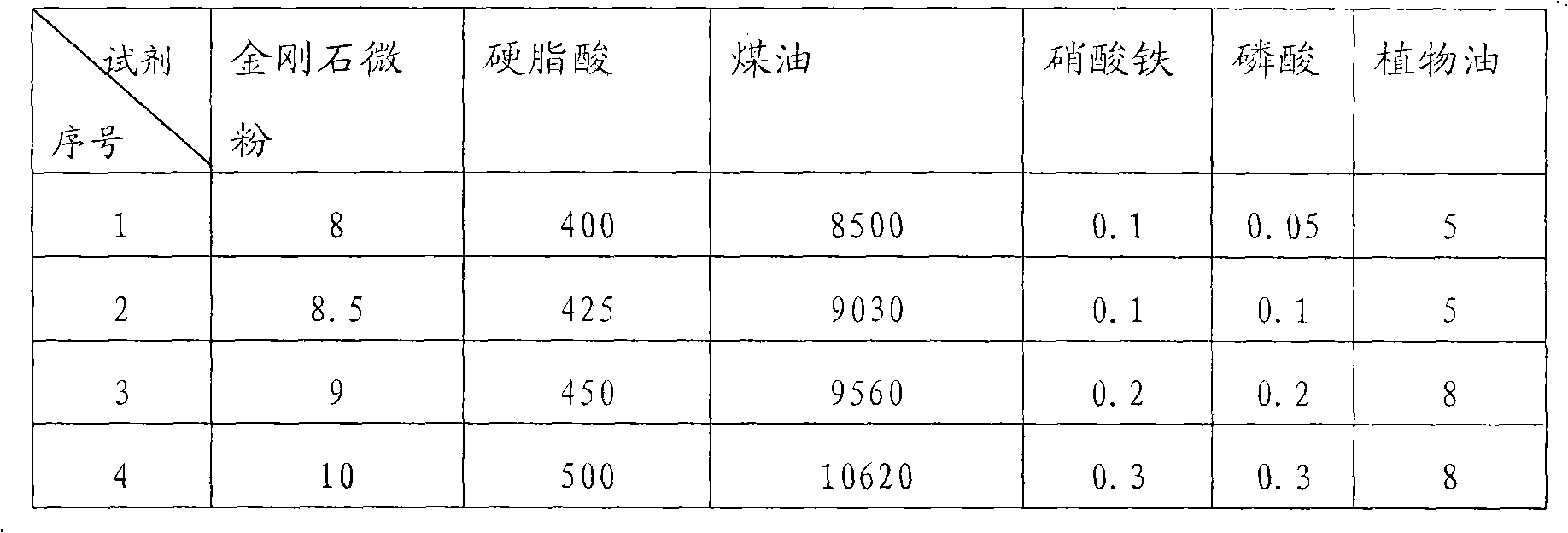

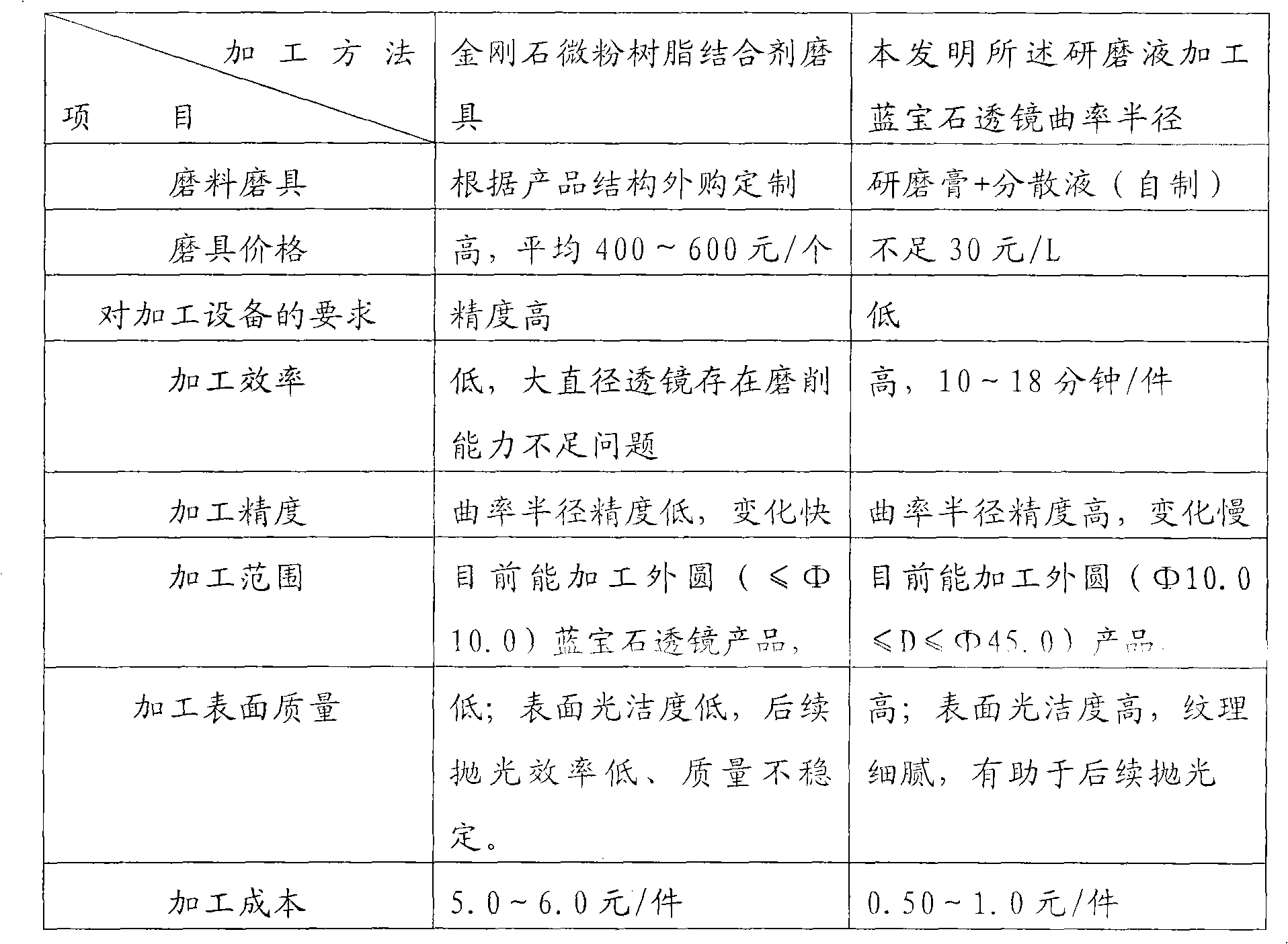

Grinding liquid for processing surface curvature radiuses of sapphires and preparation method

ActiveCN101993661AGood dispersionImprove liquidityPolishing compositions with abrasivesNitrateVegetable oil

The invention relates to a grinding liquid for processing surface curvature radiuses of sapphires and a preparation method. The grinding liquid is composed of grinding paste and a dispersion liquid with the weight proportion of 1:20, wherein the dispersion liquid comprises kerosene and vegetable oil with the weight proportion of 5:1, and the grinding paste comprises 80-100 parts of diamond micropowder, 4,000-5,000 parts of stearic acid, 200-500 parts of kerosene, 1-3 parts of ferric nitrate and 0.5-3 parts of phosphoric acid by weight. By adopting the grinding liquid in the invention for the fine surface curvature of a major-diameter sapphire lens, an obtained product has high surface quality, the processing state is stable, and requirements on subsequent polishing can be met; and moreover, the grinding liquid has the advantages of high processing efficiency, low cost and wide processing range.

Owner:CHONGQING CHUANYI AUTOMATION

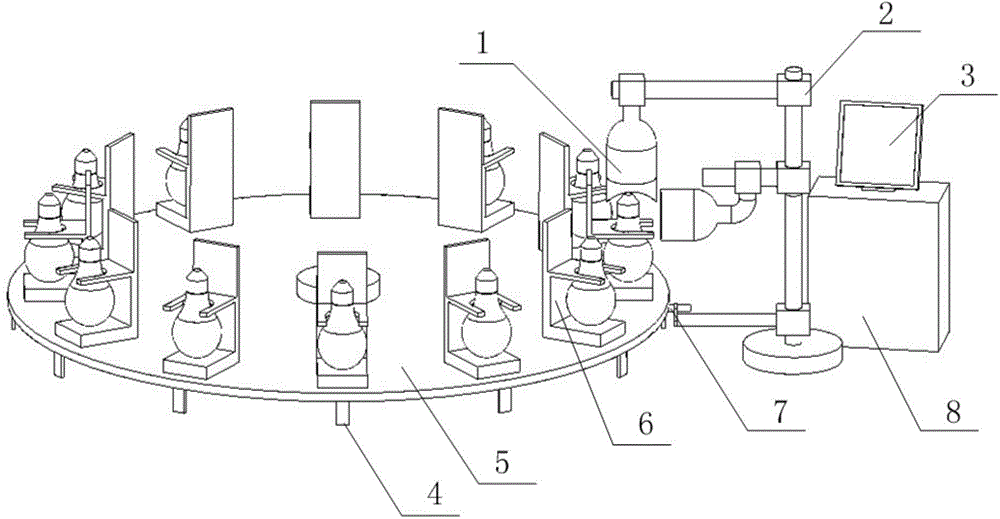

Lamp head tin scolding contact qualified rate detecting device and method

InactiveCN103913459ARealize batch processingReduce manufacturing costMaterial analysis by optical meansUsing optical meansImaging processingLiquid-crystal display

The invention discloses a lamp head tin scolding contact qualified rate detecting device and a method. The lamp head tin scolding contact qualified rate detecting device comprises a rotating disk, a rotating disk stopping baffle plate position detector, lamp position fixing clamps, a pedestal support, a video image acquisition device, an image processing subsystem, and a liquid crystal display screen; the rotating disk is used for delivering lamps to be detected at certain time intervals with certain distance; the rotating disk stopping baffle plate position detector is used for determining settled rotating distance of the rotating disk; the lamp position fixing clamps are used for settling orientation and distance of the lamps; the video image acquisition device is used for completing acquisition and sending of image data of a top view and a right lateral view; the image processing subsystem is used for processing and determining of real-time imagines via certain detecting algorithm; and the liquid crystal display screen is used for displaying finished results. The lamp head tin scolding contact qualified rate detecting device is capable of solving problems of artificial naked eye discrimination that labor cost is high, fatigue is caused easily, and detection accuracy rate is low; detection can be carried out for 24 hours; labor cost is reduced; and detection efficiency and accuracy rate are increased at the same time.

Owner:SOUTH CHINA UNIV OF TECH

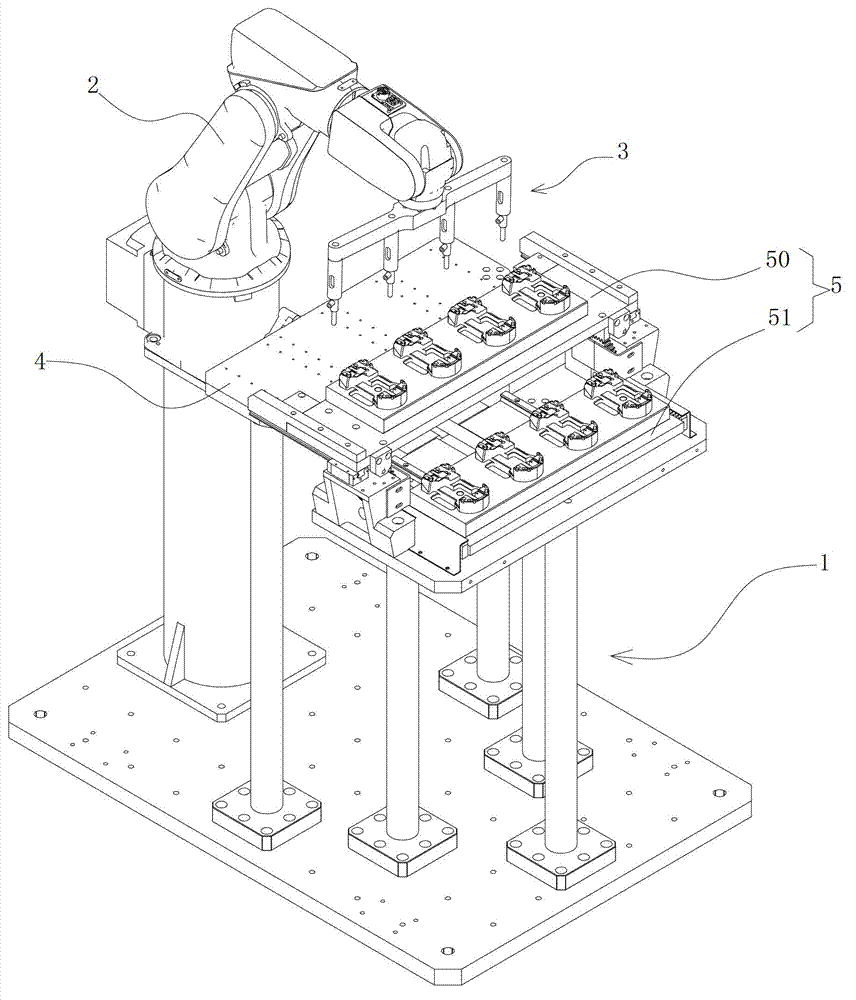

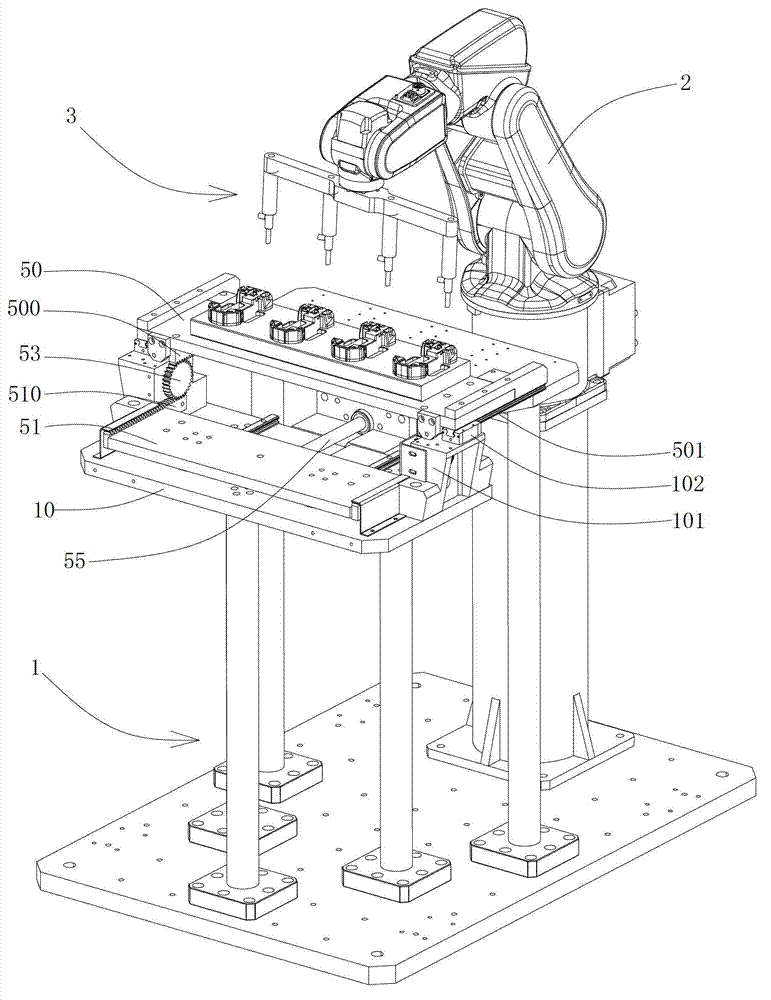

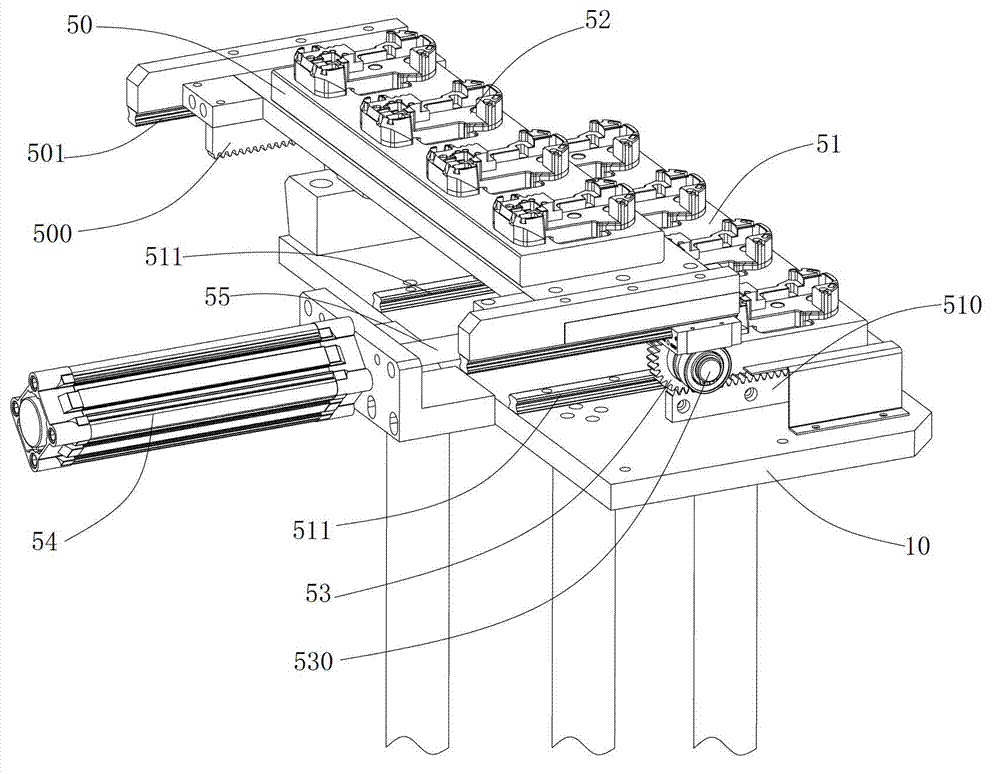

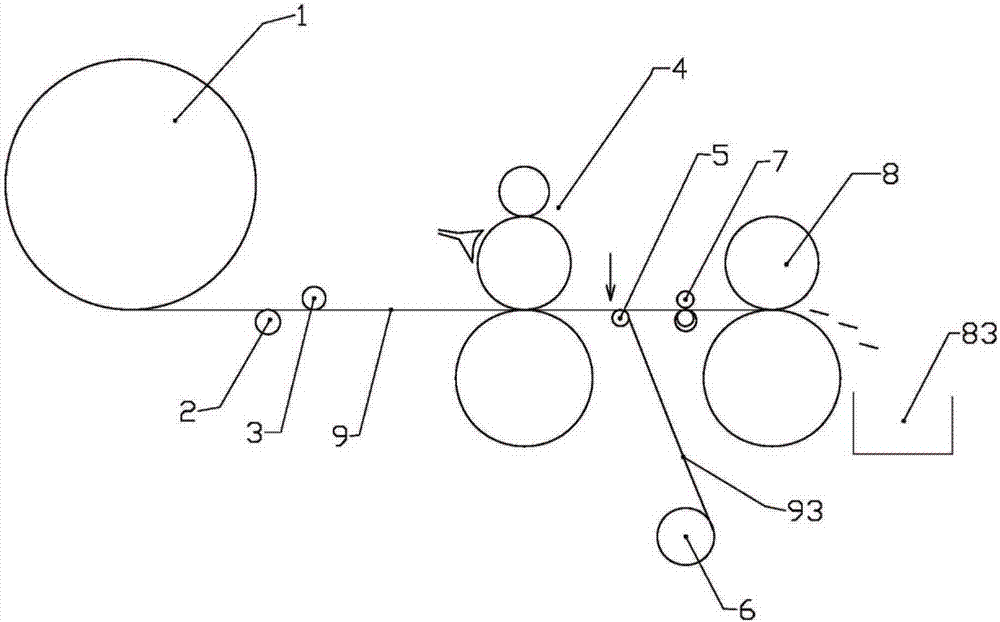

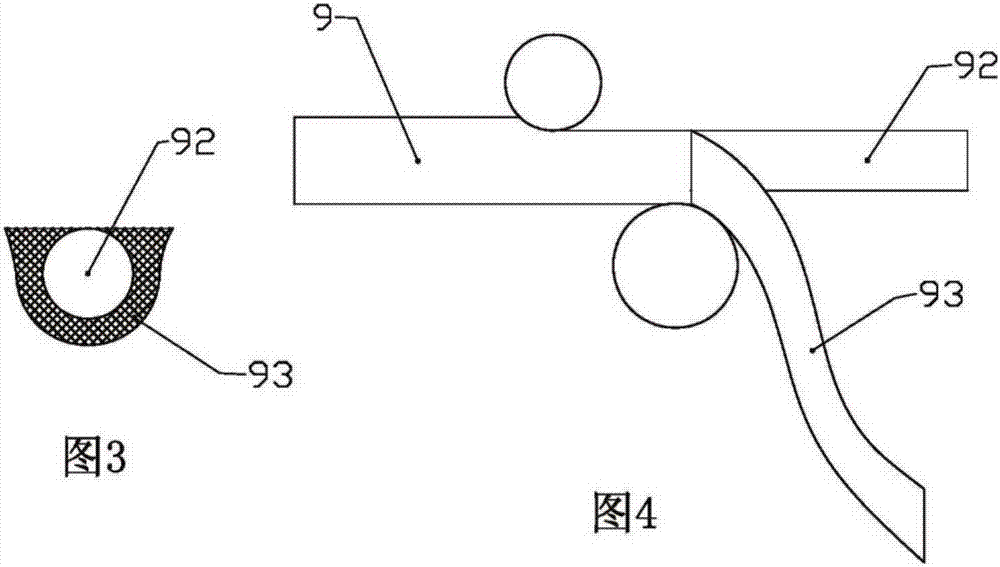

Conveying device and mouse pad laminating machine provided with the same

InactiveCN103086010ARealize batch processingFully automatedPackagingEngineeringMechanical engineering

The invention discloses a conveying device which comprises a conveying bottom board, an upper work platform, a lower work platform and two gears, wherein the two ends of the upper work platform are respectively provided with an upper work platform rack, and two ends of the lower work platform are respectively provided with a lower work platform rack. The tooth shape of the upper work platform rack and the tooth shape of the lower work platform rack are arranged in an opposite mode, the gears are arranged between the upper work platform rack and the lower work platform rack and are meshed with the upper work platform rack and the lower work platform rack, each gear is sleeved on a gear seat, and each gear seat is fixed on the conveying bottom board through a supporting part. A mouse pad laminating machine provided with the conveying device comprises a main frame provided with a robot arm, a platform plate and the conveying device, wherein the robot arm is provided with a suction device comprising a plurality of suction pipes used for sucking mouse pads, and the suction ports of the suction pipes are arranged downwards. The conveying device and the mouse pad laminating machine provided with the same can achieve lot sizing processing in processes of mouse pad adhesion, thereby saving working hours and reducing cost.

Owner:SHENZHEN RAPOO TECH

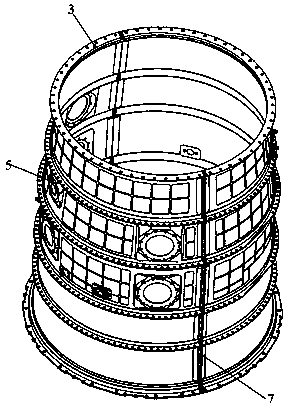

Mass production process suitable for plate welding receivers

ActiveCN110405426AGuaranteed deformationReduce distortionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

The invention relates to the field of machinery, in particular to a mass production process suitable for plate welding receivers. During welding, a tool I is adopted to expand a receiver main body, sothat the outer surface of the receiver main body is bonded with the inner surface of a flange edge, the welding line quality is guaranteed, and the deformation of the receiver main body is the smallest; the end with the smaller diameter of the receiver main body is downwards; then, a tool II is lifted into the receiver main body from the top; the receiver main body and the tool II are totally heated according to a heat treatment process; the tool II drops to the bottom under the effect of gravity to achieve a shape correcting effect; when the receiver main body is machined, the receiver mainbody is clamped by adopting a tool III; the receiver main body and the flange edge are machined according to a manufacturing process, and a longitudinal mounting edge window is formed in the receivermain body; and the tool III is totally bonded with the inner wall of the receiver main body to prevent vibration of the receiver main body and cutter avoidance, so that the deformation of the receivermain body is reduced, the cutting parameters in the machining process can be doubled or higher, the machining period is shortened, and the mass production is realized.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

Manufacturing method of tempered thin glass film

InactiveCN104086076AReasonable production process designShort processing cycleEdge grinding machinesRevolution surface grinding machinesNumerical controlBatch processing

The invention relates to a manufacturing method of a tempered thin glass film. The method comprises the following steps: raw material glass is selected; a glass cutting machine is used for carrying out high-precision cutting upon the raw material glass according to corresponding length and width outline dimensions, such that rectangular glass sheets with various specifications are obtained; a laser cutting machine is used for carrying out button hole and earphone hole preliminary processing upon the obtained rectangular glass sheets; a numerical control machine tool is used for carrying out outline, button hole and earphone hole fine trimming upon the obtained glass sheets; the glass blank sheets obtained after fine trimming are subjected to tempering processing in a tempering furnace; an anti-bursting adhesive layer is adhered to the surfaces of the tempered glass sheets; and packaging is carried out. The manufacturing method provided by the invention has the advantages of reasonable design and short processing period. With the method, batch processing can be realized. The method and the product are safe and healthy, and the product has high quality.

Owner:ZHEJIANG LANTE OPTICS

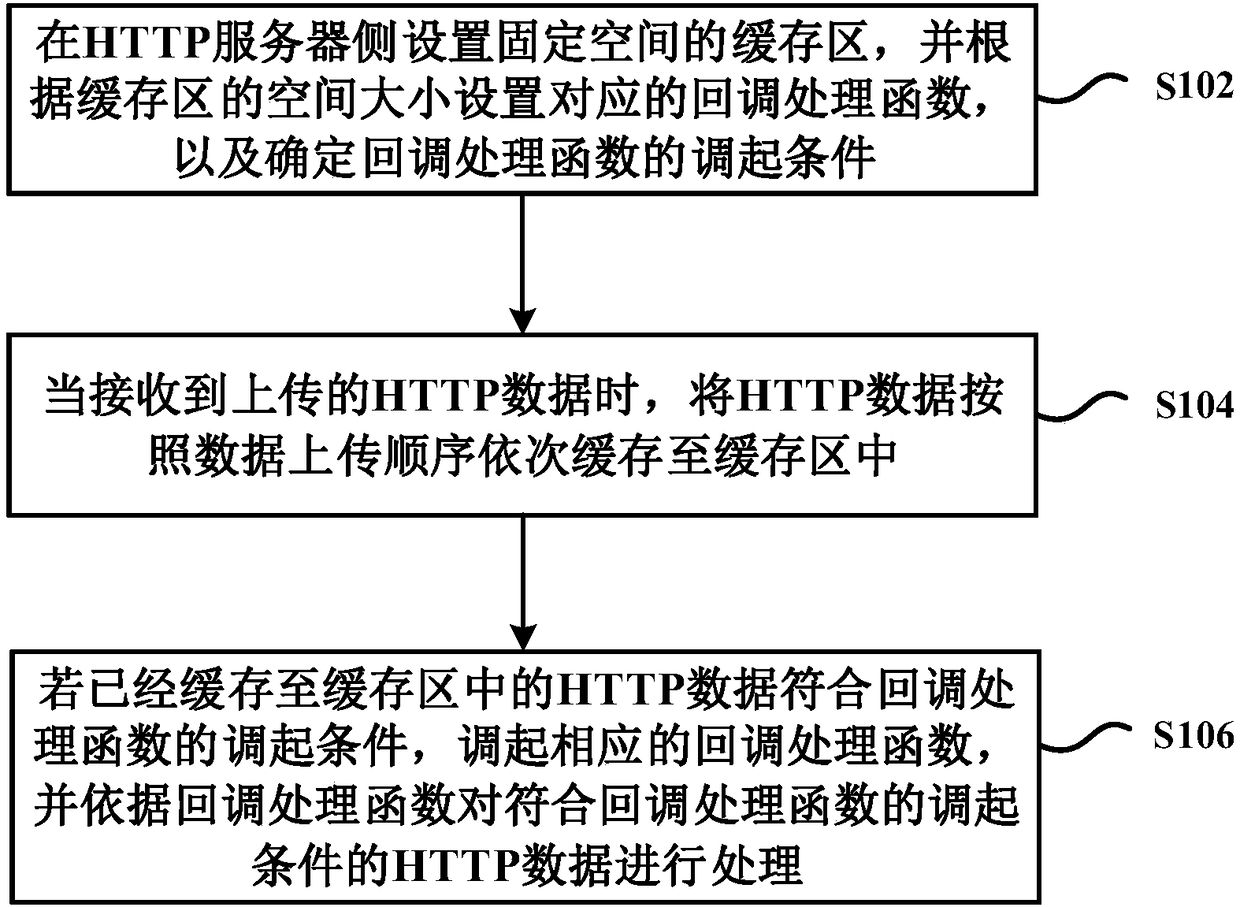

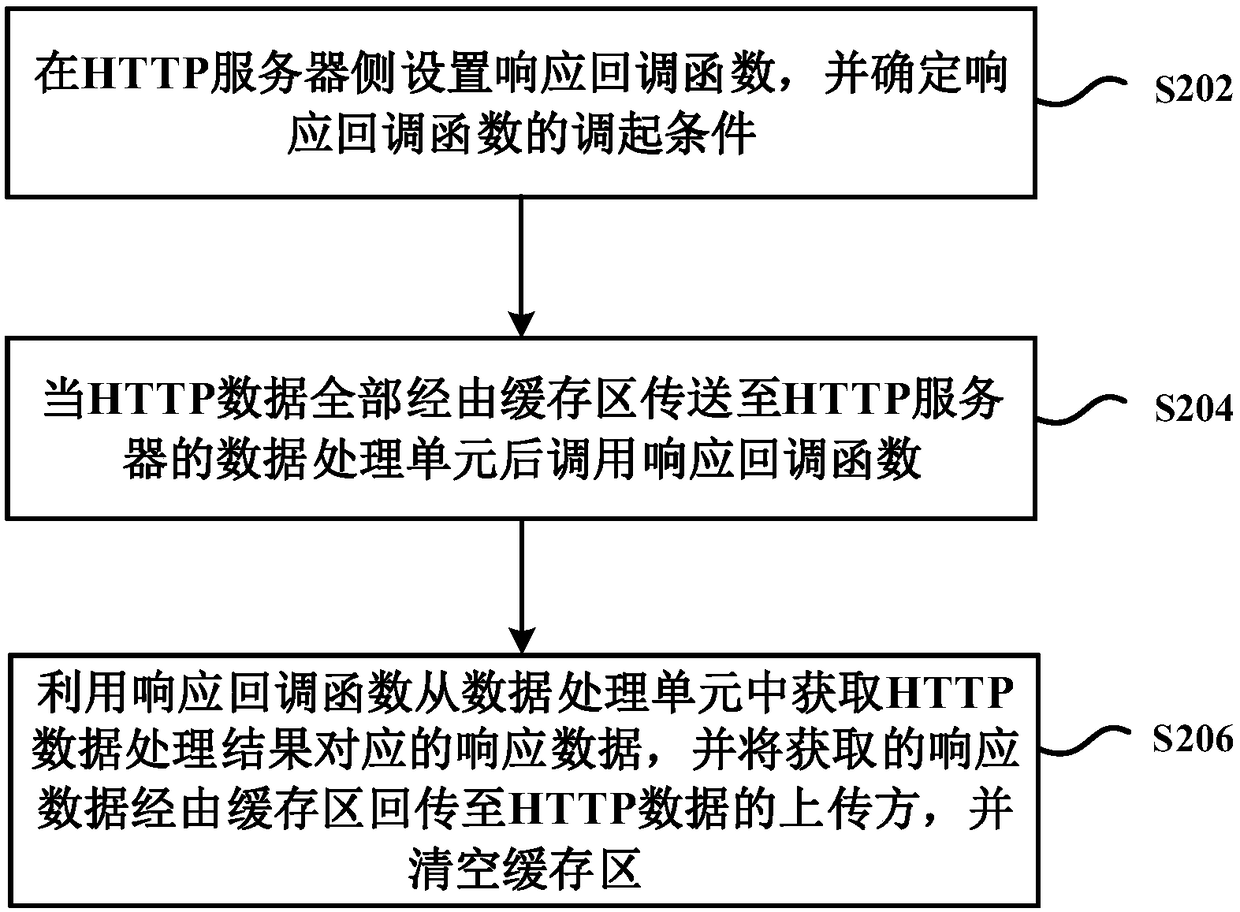

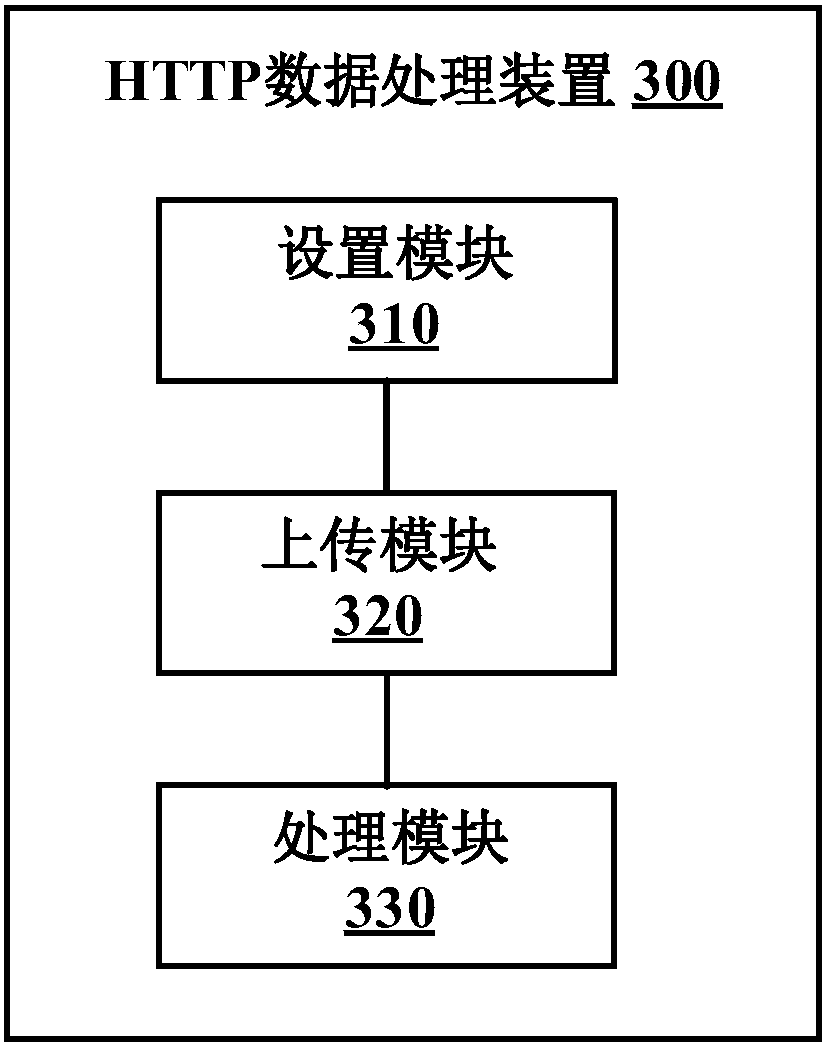

HTTP data processing method and device

The invention provides an HTTP data processing method and a device. The method comprises the following steps of arranging the cache region of a fixed space on an HTTP server side; according to the space size of the cache region, arranging a corresponding callback processing function and determining the calling condition of the callback processing function; when HTTP data uploaded by a client is received, successively caching the HTTP data to the cache region according to a data uploading sequence; and if the HTTP data which is cached to the cache region accords with the calling condition of the callback processing function, calling the corresponding callback processing function, and according to the callback processing function, processing the HTTP data according with the calling conditionof the callback processing function. In the invention, the data can be received, and at the same time, the data can be processed so that the batch processing process of the HTTP data is realized, andthe processing efficiency of the HTTP data is greatly increased.

Owner:BEIJING QIHOO TECH CO LTD

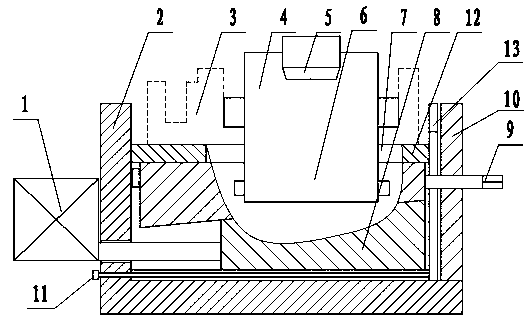

Turning tool capable of achieving rapid clamping and rapid clamping method using same

PendingCN109483283AImprove clamping strengthStable cutting processPositioning apparatusMetal-working holdersEngineeringMachining process

The invention relates to the technical field of machining of thin-walled parts, in particular to a turning tool capable of achieving rapid clamping. The turning tool comprises a base, a lower positioning device and an upper positioning device, wherein the lower positioning device and the upper positioning device are sequentially installed on the base from bottom to top, the turning tool further comprises a driving device, each of the upper positioning device and the lower positioning device is composed of a plurality of supporting blocks, moreover, the plurality of supporting blocks of each ofthe upper positioning device and the lower positioning device are arranged at intervals to form a circular support for the part correspondingly, a fitting surface matched with the inner wall of the part is arranged on the outer wall of each supporting block, the driving device can drive the supporting blocks in the upper positioning device to move synchronously, and can drive the supporting blocks in the lower positioning device to move synchronously. The turning tool achieves positioning through an upper section and a lower section, the circular supports are formed to the part from the innerwall of the part, then the problem that the quality of the part is influenced in the machining process due to insufficient strength of the thin-wall part is solved, the thin-walled part can be quickly clamped, the inner parts are tightly attached, then the cutting parameters can be improved, the production efficiency can be improved, batch machining can be realized, and the mass production chokepoint can be broken through.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

Waste cable recovery device

ActiveCN107195399ADoes not damage the surfaceQuality improvementBasic electric elementsApparatus for removing/armouring cablesPulp and paper industryCopper

The invention discloses a waste cable recovery device. The device comprises a unreeling machine, a steering shaft, a barking roller component, a flame heating device, a steering roller, a traction device and a chopper from front to the back in order, wherein the barking roller component comprises a hot roller and a carrier roller in pairwise, wherein the hot roller is located at the upper side of the barking roller component, the carrier roller is located at the lower side of the barking roller component, and a compression roller for preventing the hot roller from bending is arranged above the hot roller, the compression roller is directly pressed on the upper side of the hot roller, and the space between the hot roller and the carrier roller is adjustable, and the hot roller and the carrier roller are in synchronized reversing rotation; the power is from a first driving motor; the flame heating device is arranged at the front side position of the hot roller. The sheath of the cable is barked through a no-damage barking process, and the surface of the copper core cannot be damaged, so that the copper granules with high quality can be produced.

Owner:丁武轩

Stainless steel heat-preservation cup electroplating production line

The invention discloses a stainless steel heat-preservation cup electroplating production line comprising a feeding device, a discharging device and a processing electroplating tank. To-be-electroplated stainless steel heat-preservation cup liners are continuously clamped through the feeding device. The feeding device vertically rises and falls and moves in the left-right and front-back directionsto enable the stainless steel heat-preservation cup liners to be immersed into the processing electroplating tank. In the processing electroplating tank, after an electroplating cathode and an electroplating anode are connected, electroplating electric ions moving in electroplating liquid are generated to electroplate the stainless steel heat-preservation cup liners. After electroplating is finished, through the discharging device, the stainless steel heat-preservation cup liners are conveyed to a next work station (comprising a cleaning conveying station) one by one. Through the cleaning conveying station, the stainless steel heat-preservation cup liners are cleaned and transferred. In this way, feeding, electroplating and discharging are perfectly connected, mechanical connecting of electroplating and cleaning work is effectively achieved, batch processing is achieved, the work efficiency is improved, and meanwhile the labor intensity is reduced.

Owner:SONGYANG HENGLIANG STAINLESS STEEL PROD

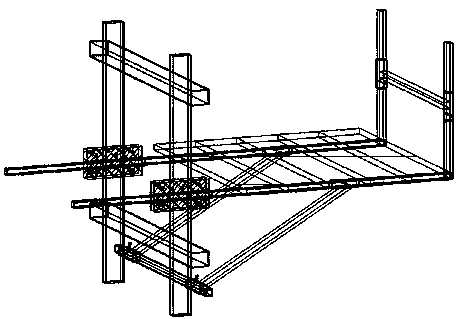

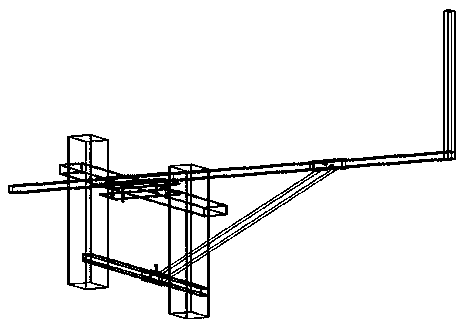

Overhanging support system attached to rectangular beams and columns

ActiveCN111173249ASimple structureEasy to assemble and disassembleScaffold accessoriesBuilding support scaffoldsSupporting systemArchitectural engineering

The invention specifically discloses an overhanging support system attached to rectangular beams and columns, and particularly relates to a support structure suitable for lateral installation and decorative construction of frame structure beams and columns. The overhanging support system is characterized by comprising a clamp, a supporting module and a safety fence which are in a full assembly mode; the overhanging system is fixedly connected to the beams or the columns or other firm rectangular structure bodies of a main structure through the clamp and the supporting module, the safety fenceis arranged on the supporting module, and therefore, the overhanging system attached to the rectangular beams and columns is formed. The overhanging support system can meet construction requirements simply by at least two supports, can meet local construction requirements, and can also meet large-range construction requirements, the flexibility and mobility are high, the circulation utilization rate is high, the wastage rate is low, and the measurement cost can be effectively controlled and reduced. The overhanging support system is particularly suitable for the construction of specially shaped structures, the technology is high in adaption, and the direction can be adjusted at random along with buildings.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

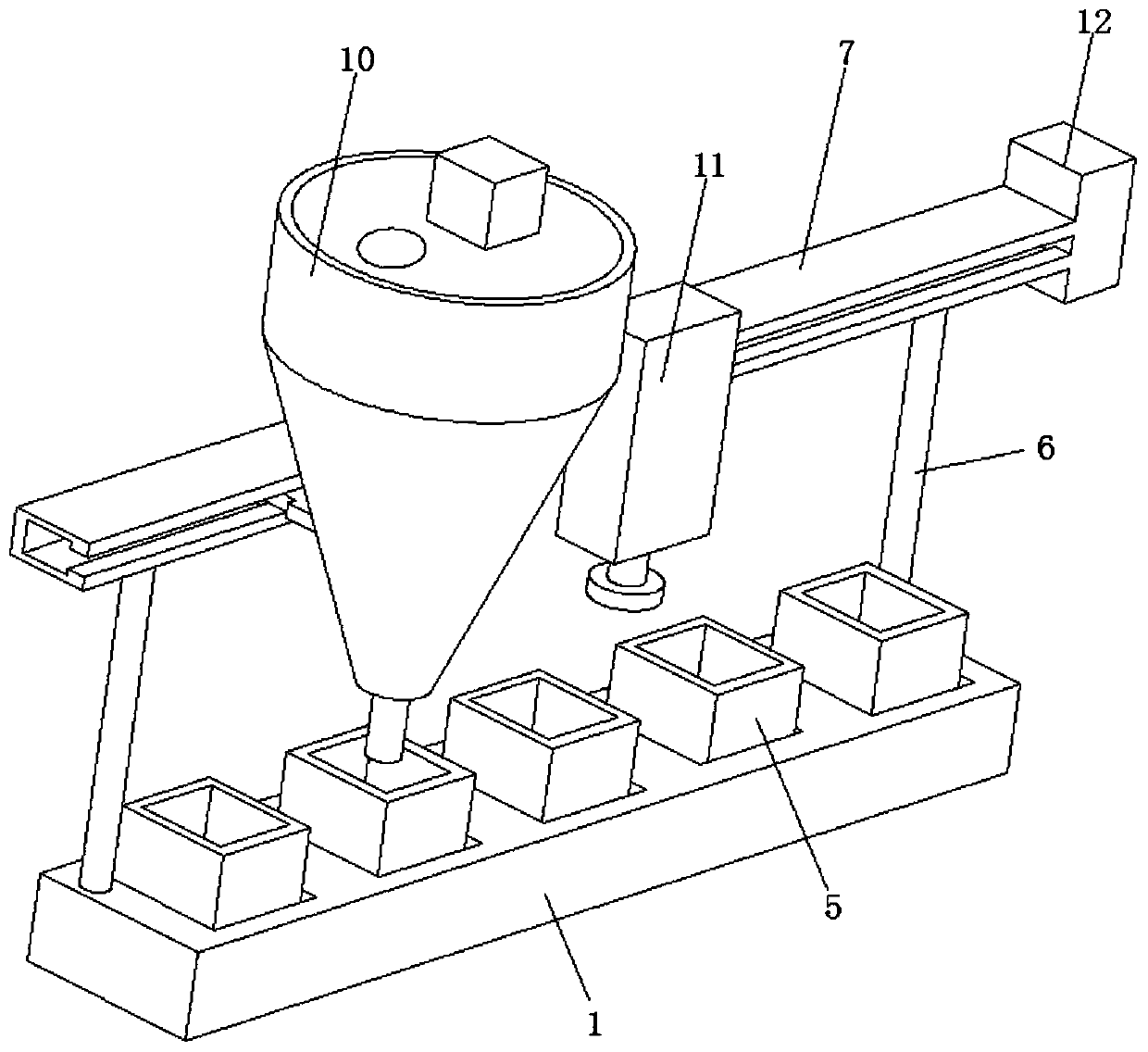

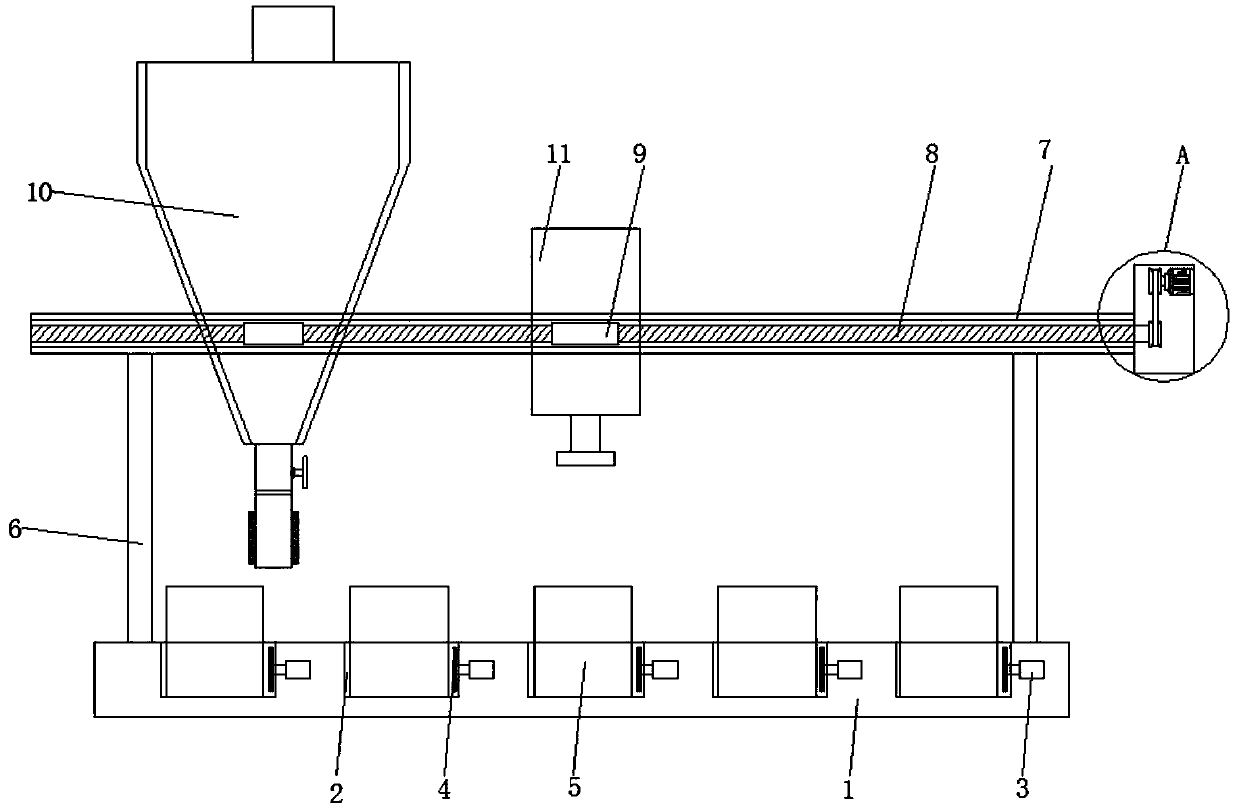

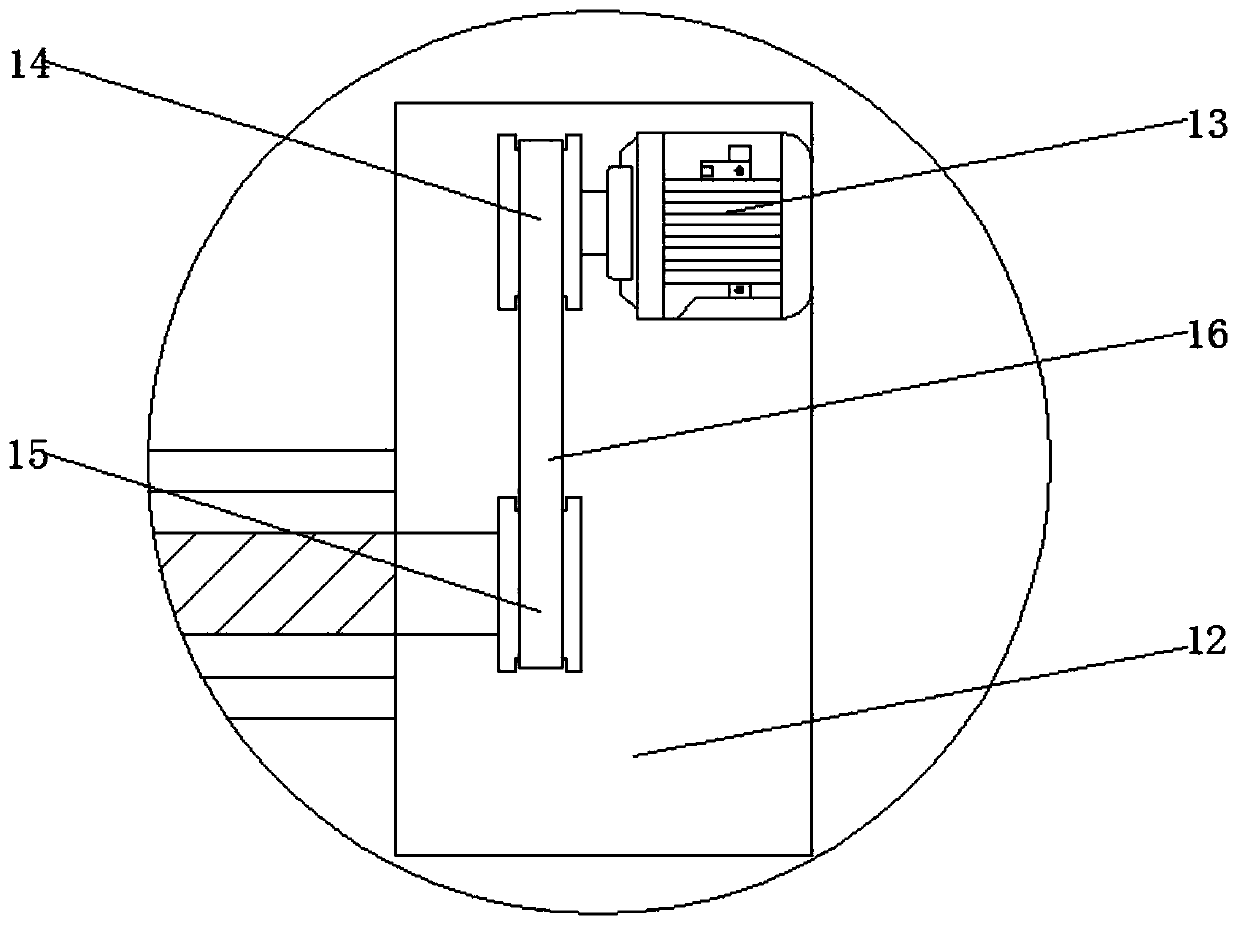

Production equipment of imitation ceramic composite plate and production process thereof

ActiveCN110666926AGuaranteed uniformityReduce stepsCeramic shaping apparatusCement mixing apparatusComposite materialManufacturing engineering

The invention discloses production equipment of a imitation ceramic composite plate, and relates to the technical field of manufacturing of imitation ceramic composite plates. The production equipmentcomprises a production bottom plate, the transverse position of the interior of the production bottom plate is uniformly provided with installation grooves at equal intervals, electric stretchable rods are fixedly connected to the interior of the production bottom plate and located on the right sides of the installation grooves, output ends of the electric stretchable rods are fixedly connected with side clamping plates, forming molds are arranged inside the installation grooves and located on the left sides of the side clamping plates, supporting side frames are fixedly connected to the twosides of the top of the production bottom plate, a supporting carrying plate is fixedly connected to the tops of the supporting side frames, a transmission threaded rod is rotationally connected to the transverse position inside the supporting carrying plate, transmission sliding blocks are arranged on the outer surfaces of the left side and the right side of the transmission threaded rod in a sleeving mode, and the outer sides of the transmission sliding blocks are fixedly connected with a material batching mechanism and a grinder correspondingly. The production equipment of the imitation ceramic composite plate achieves the purpose of reducing the operation steps, improving the production efficiency of the imitation ceramic composite plate and reducing the labor of workers.

Owner:湖南怀化永久轻建屋面科技开发有限公司

Method for processing wireless gold-plating printed plate

ActiveCN102143657AWill not polluteColor controllablePrinted circuit secondary treatmentEngineeringPotassium iodine

The invention discloses a method for processing a wireless gold-plating printed plate, which comprises the following steps of: removing goldclad wires from the printed plate through gold-plating and pertinency gold-removing manners, putting the printed board in a gold-removing solution at the temperature of 25+ / -5 DEG C and removing gold from the wire of the printed board to expose coppers, wherein gold-removing solution contains 90+ / - 10g / L iodine and 200+ / -20 g / L potassium iodide. According to the method, the gold on the goldclad wires is removed by using gold-removing liquid medicines so that the copper is exposed; the goldclad wire is etched and removed, so that advantages of no pollution to a gold cylinder and realization of mass processing are combined, and the color of the gold face is easy to control. That the method has the advantages of no pollution to the gold cylinder and realization of easy control of the colour of the gold face because the copper-naked printed board is plated with gold and no wet film is dissolved to cause pollution.

Owner:GCI SCI & TECH

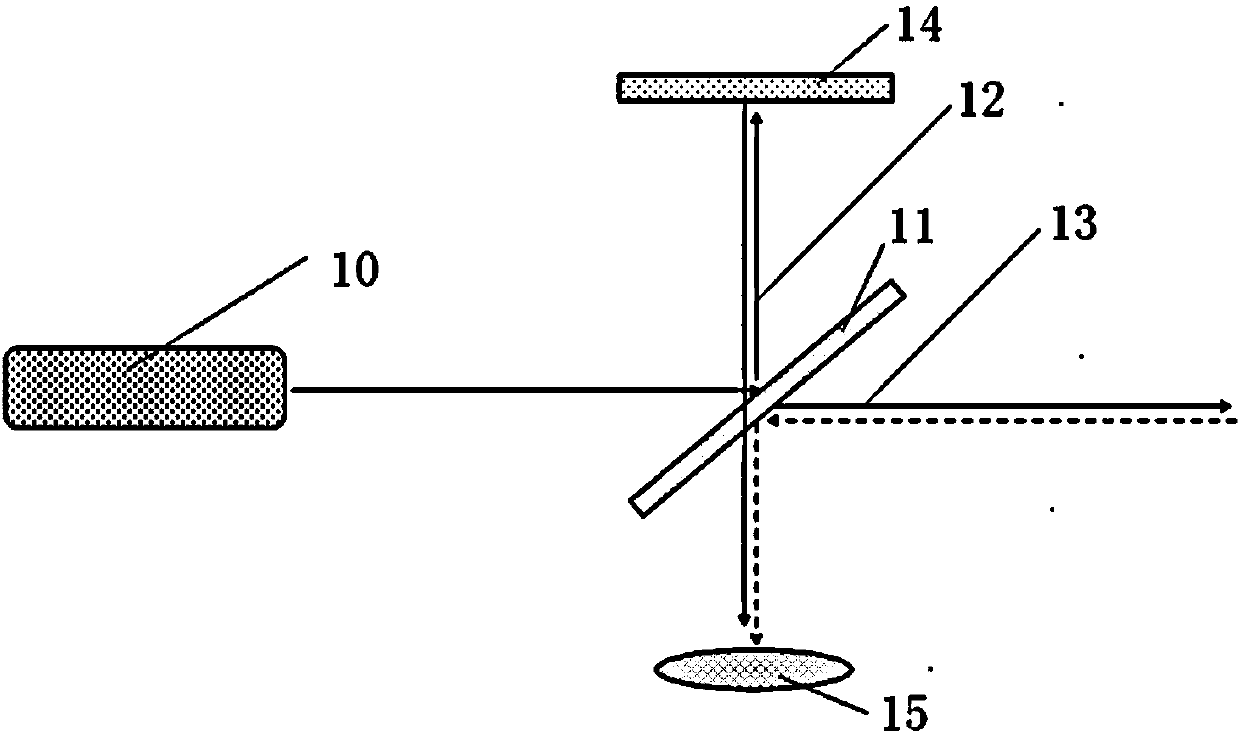

Processing method of metal multi-surface scanning prism

ActiveCN108051880AImprove stabilityRealize batch processingPrismsGlass severing apparatusNumerical controlOptical processing

The invention discloses a processing method of a metal multi-surface scanning prism, belongs to the technical field of optical processing, and specifically relates to a processing method of a multi-surface scanning prism. The processing method of a metal multi-surface scanning prism aims at solving the problem that the prior art is not high in the accuracy of the angel between each surface duringthe process of processing a multi-surface prism. The principle of the technical scheme of the processing method of a metal multi-surface scanning prism is characterized by accurately controlling the rotating angle of a rotating shaft through an auto-collimation optical path and a standard block, and being able to accurately copy the angle accuracy of each side surface of the standard block as theprism embryo of the metal multi-surface scanning prism to be processed and the standard block are arranged on the same rotating shaft. Application of the technical scheme of the processing method of ametal multi-surface scanning prism does not depend on a high accuracy numerical control rotating shaft, and processing of the metal multi-surface scanning prism can be completed on a two-shaft machine tool, so that the processing efficiency, the processing accuracy and the processing consistency can be greatly improved.

Owner:SUZHOU UNIV +1

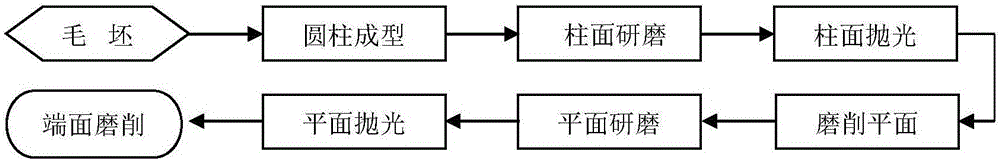

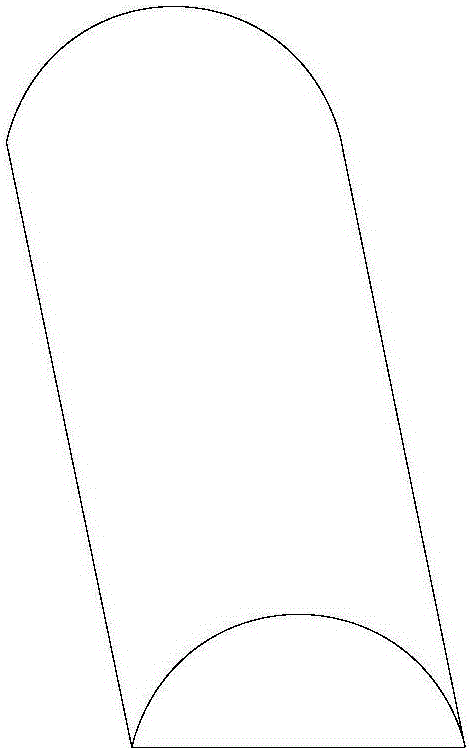

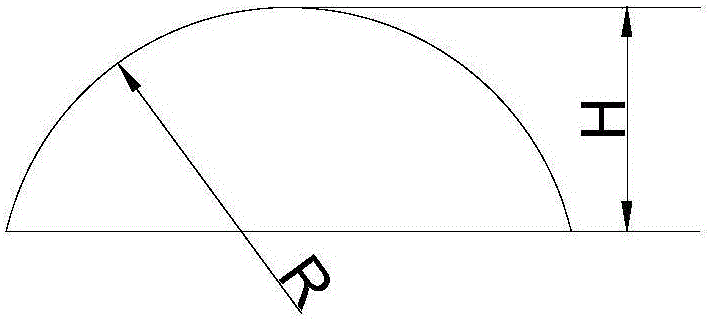

Processing method of plane convex cylindrical mirror

ActiveCN105751031ARealize batch processingImprove general performanceOptical surface grinding machinesLensEngineeringSurface grinding

The invention discloses a processing method of a plane convex cylindrical mirror. The processing method comprises the following steps that a glass blank material is coarsely ground into a cylinder; then, fine grinding and polishing are sequentially performed on the cylinder surface, so that the radius of the polished cylinder is in the radius requirement range of the plane convex cylindrical mirror; the polished cylinder and a plane mold are cast into a dish; the excessive cylinder surface of the cylinder is ground and cut into a plane along the axial direction of the cylinder to form a primary sample of the plane convex cylindrical mirror; the primary sample of the plane convex cylindrical mirror is demoulded; then, the plane of the primary sample of the plane convex cylindrical mirror is ground and polished, so that the arc height of the polished primary sample of the polished plane convex cylindrical mirror is in the arc height requirement range of the plane convex cylindrical mirror; the two ends of the polished primary sample of the polished plane convex cylindrical mirror is subjected to end surface grinding to obtain a finished product of the plane convex cylindrical mirror; the length is in the length requirement range of the plane convex cylindrical mirror. The processing method provided by the invention solves the problems of low precision and low efficiency of the existing processing method of the plane convex cylindrical mirror, and has the advantages that the universality is high; the dimension control precision is high; the mass processing of the plane convex cylindrical mirror can be realized.

Owner:CHINA BUILDING MATERIALS ACAD

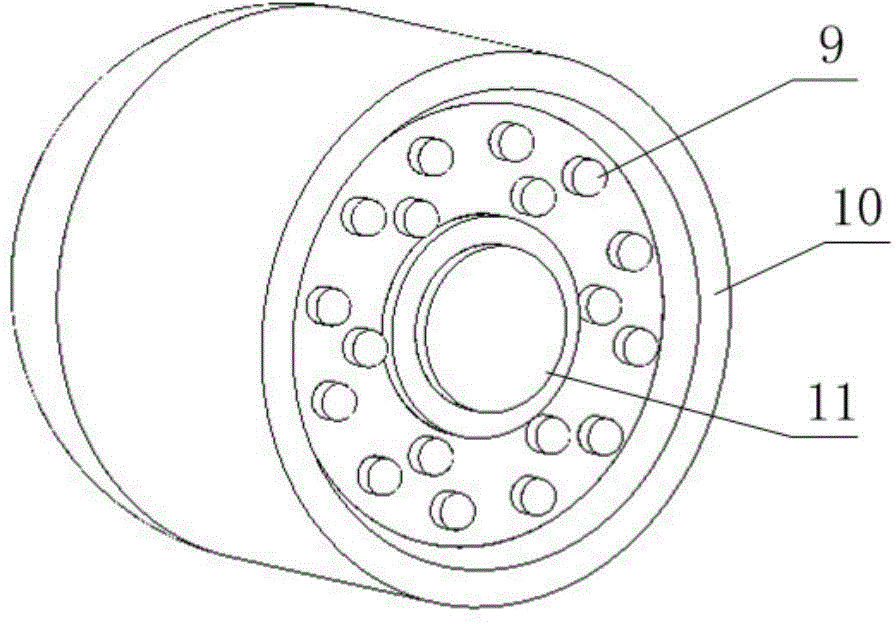

Quick polishing grinder

InactiveCN102441831AFast processingIncrease productivityBelt grinding machinesEngineeringBatch production

The invention discloses a quick polishing grinder which comprises a rack, a magnetic worktop, a clamping mechanism, an entire lifting mechanism and a walking mechanism. The quick polishing grinder is characterized in that: the clamping mechanism comprises multiple fixtures; a grinding roller is arranged in at least one of the fixtures; the grinding roller comprises a main shaft sleeve and a roller body; the roller body is a cylinder structure with a base, and the upper part of the roller body is covered by an upper cover; multiple through holes are arranged on the cylinder; an ejector pin is arranged in each through hole; each ejector pin comprises a pin head and a limiting platform at the bottom; the limiting platforms are located on the inner side of the cylinder; a check ring for preventing the ejector pin from falling off from the through hole is arranged on the inner side of each ejector pin; and an elastic washer and an annular abrasive belt are further sequentially arranged outside the cylinder. The quick polishing grinder disclosed by the invention has high processing speed and very high production efficiency. Moreover, the quick polishing grinder disclosed by the invention can be used for batch production and has great production capacity.

Owner:沈炳红

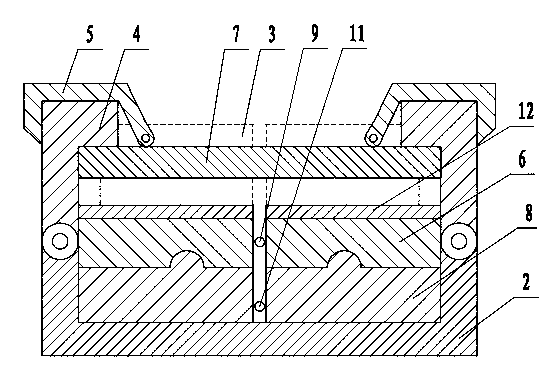

Special tool for milling and processing K2 side bearing axial trough

ActiveCN103056685AAvoid frettingEasy to fixPositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention discloses a special tool for milling and processing a K2 side bearing axial trough and belongs to the technical field of a mechanical processing tool. The tool comprises a recessed base of which the upper surface is provided with an opening, an upper tapered wedge and a lower tapered wedge are arranged in the base, two slopes of the upper tapered wedge and the lower tapered wedge are matched, left sides and right sides of the upper tapered wedge and the lower tapered wedge are matched with the inner surface of the vertical end plate of the base, a pressing plate and an upper limiting mechanism which limits the motion of the pressing plate are arranged on the upper portion of the upper tapered wedge, and the side of the lower tapered wedge is connected to a piston rod of a cylinder, which is arranged on the outer wall of the base. During the process of the K2 side bearing, the detection and classification process of the trough vertical face is omitted, the processing efficiency is improved, the assisting time is saved, the labor intensity is reduced, the efficacy is improved, and the processing quality is guaranteed.

Owner:CRRC SHIJIAZHUANG CO LTD

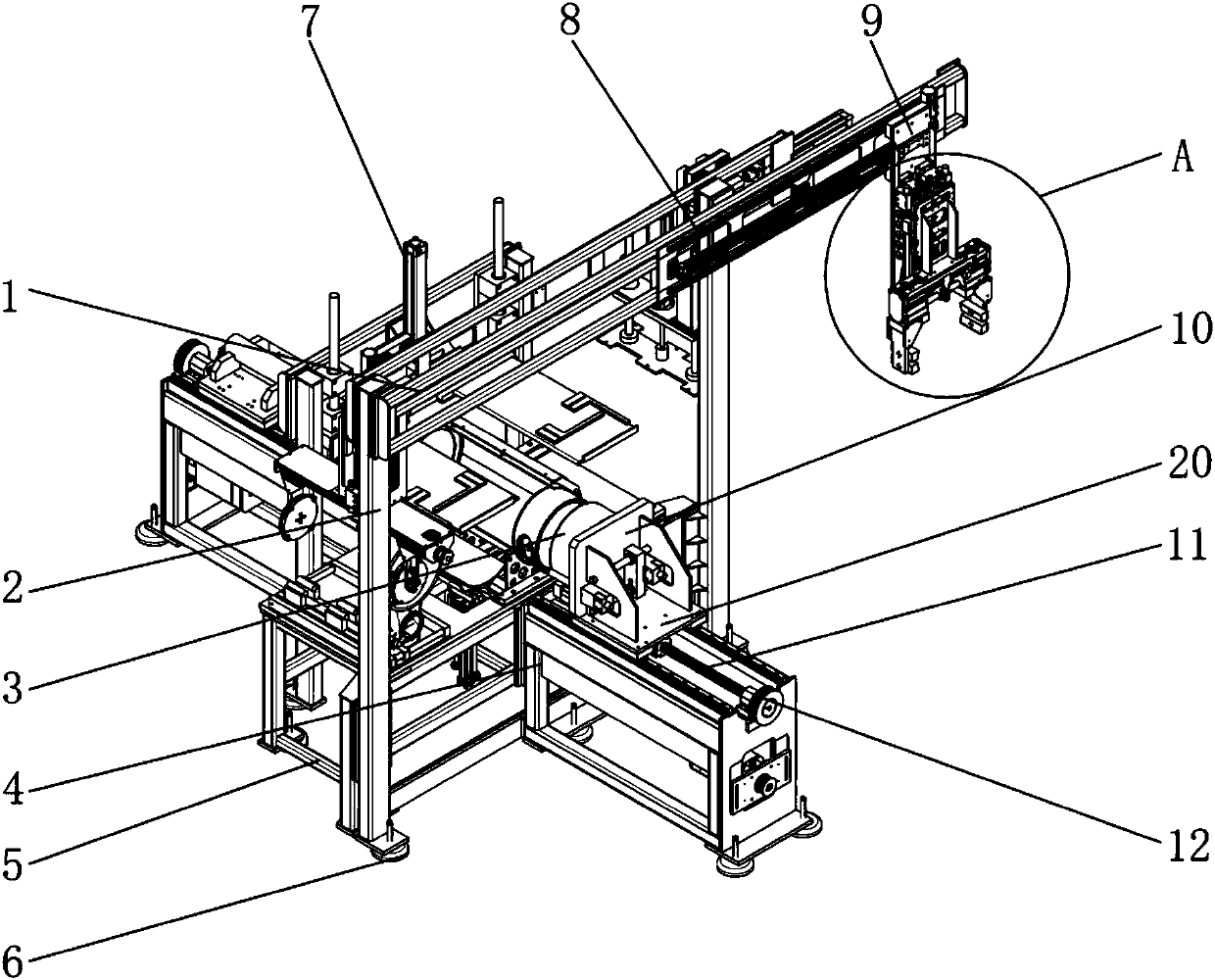

Automatic batch electroplating device for opening type steel cups

ActiveCN106086972AAchieving a perfect connectionRealize batch processingCellsEngineeringUltimate tensile strength

The invention discloses an automatic batch electroplating device for opening type steel cups. The automatic batch electroplating device for the opening type steel cups comprises a machine frame, an electroplating tank, a cleaning tank, an electroplating conveying mechanism and a cleaning conveying mechanism, wherein the electroplating conveying mechanism and the cleaning conveying mechanism are located above the electroplating tank and the cleaning tank correspondingly; the electroplating conveying mechanism is provided with a plurality of electroplating mechanical arms capable of being opened and closed in an up-down manner and used for clamping the steel cups; an electroplating cathode is arranged in the electroplating tank; the electroplating mechanical arms are provided with an electroplating anode; the electroplating mechanical arms can ascend and descend to soak the steep cups in the electroplating tank; the electroplating conveying mechanism can drive the electroplating mechanical arms to move towards the cleaning conveying mechanism; the cleaning conveying mechanism is provided with a plurality of cleaning mechanical arms capable of being opened and closed in an up-down manner and used for clamping the steel cups; and by moving the electroplating mechanical arms, the steel cups can be conveyed to the cleaning mechanical arms. Compared with the prior art, according to the automatic batch electroplating device for the opening type steel cups, the manner that the steel cups are manually clamped and subjected to electroplating and cleaning treatment is changed, automatic clamping is achieved, mechanical connection of the electroplating work and the cleaning work is achieved, batch machining is achieved, the work efficiency is improved, and meanwhile the labor intensity is reduced.

Owner:SONGYANG HENGLIANG STAINLESS STEEL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com