Automatic batch electroplating device for opening type steel cups

An electroplating device and batch technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of low processing efficiency, increase the difficulty of operation and labor intensity of workers, and the inability to realize mass production, so as to improve work efficiency and reduce labor intensity , the effect of perfect connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

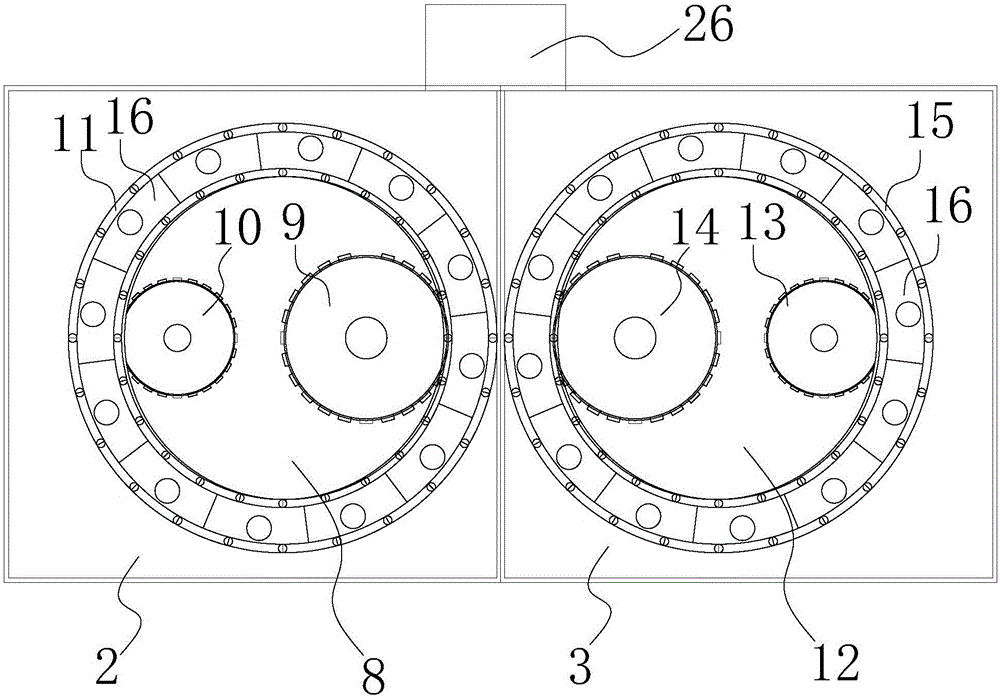

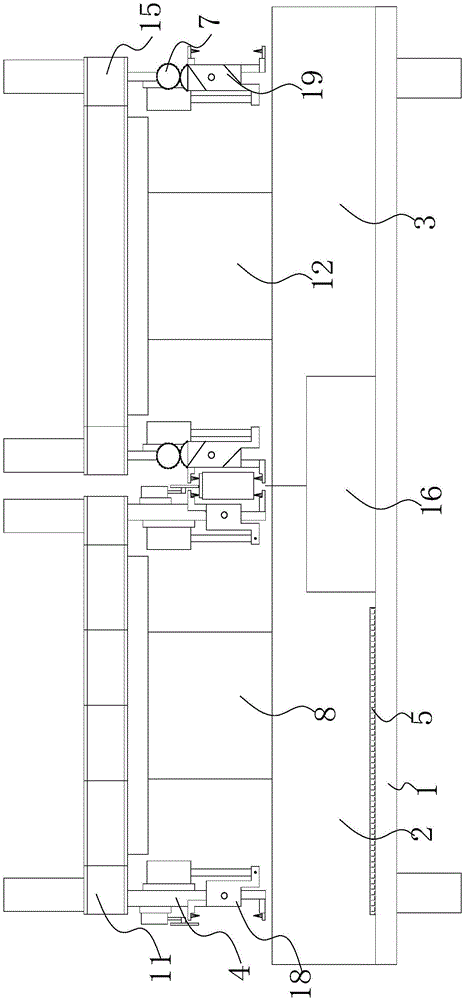

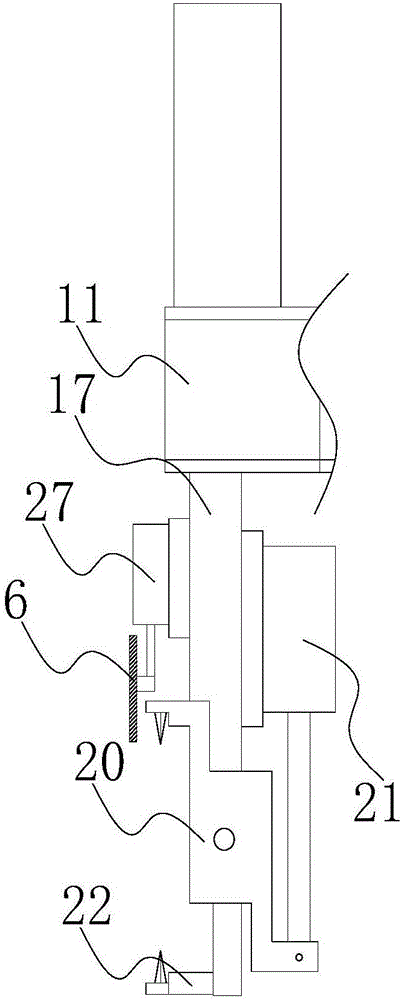

[0024] refer to Figure 1 to Figure 5 , the present invention includes a frame 1, an electroplating tank 2 fixed on the frame 1 and used to hold an electroplating solution, a cleaning tank 3 located on one side of the electroplating tank 2, and a cleaning tank 3 located at the electroplating tank 2 and the cleaning tank 3 respectively. The upper electroplating conveying mechanism and the cleaning conveying mechanism, one end of the electroplating conveying mechanism can be connected with the vibrating feeding tray (not shown) for feeding, and the electroplating conveying mechanism is equipped with several openings that can be opened up and down and used for clamping The electroplating mechanical arm 4 of the steel cup, the electroplating tank 2 is provided with an electroplating cathode 5, and the electroplating mechanical arm 4 is provided with an electroplating anode 6 corresponding to the electroplating cathode 5, and the electroplating mechanical arm 4 is vertically Liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com