Process for treating phosphate coating wastewater of steel pipes

A wastewater treatment and process technology, which is applied in metallurgical wastewater treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of water pollutants exceeding the standard, and achieve low production and operation costs and low one-time investment , The effect of easy operation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

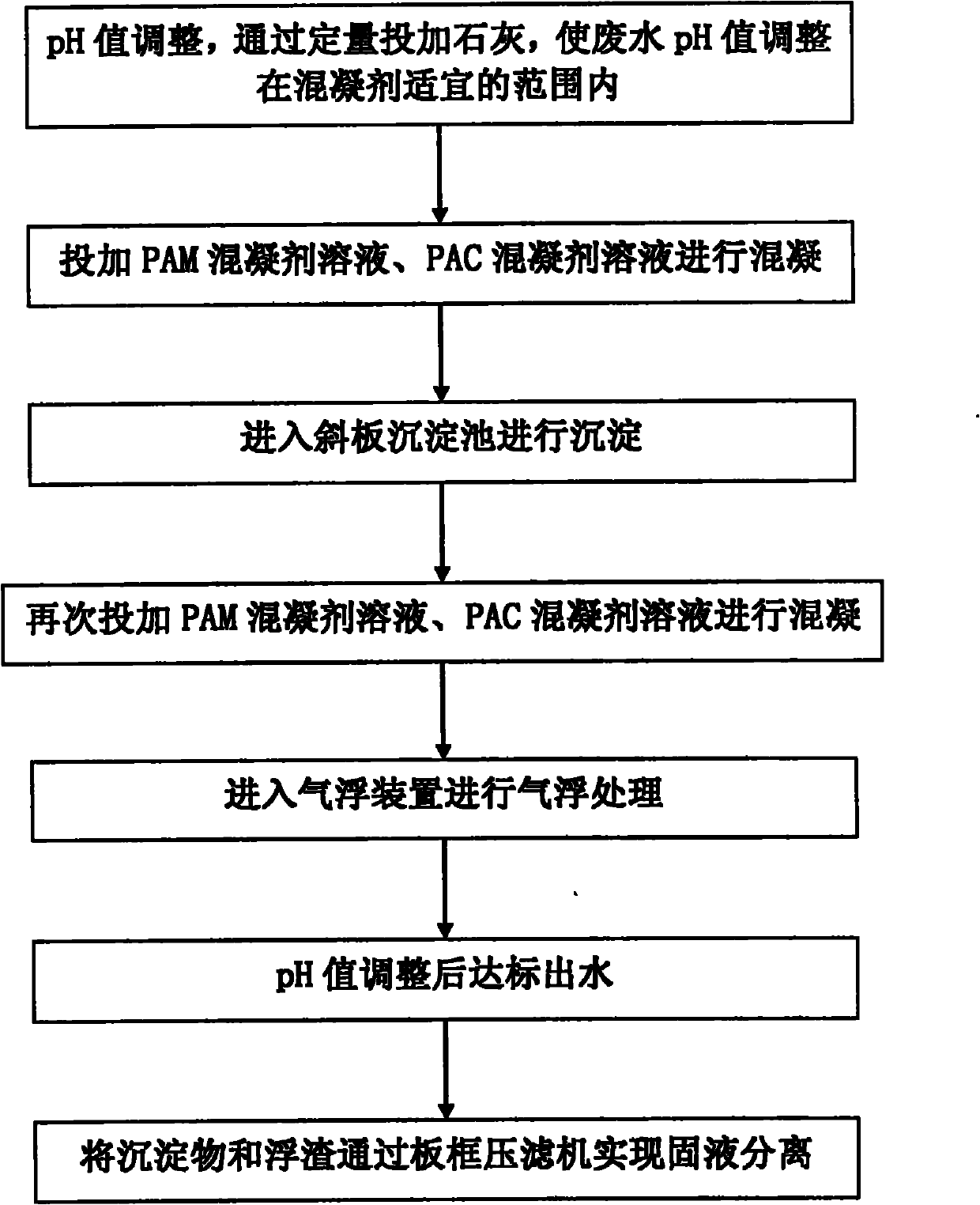

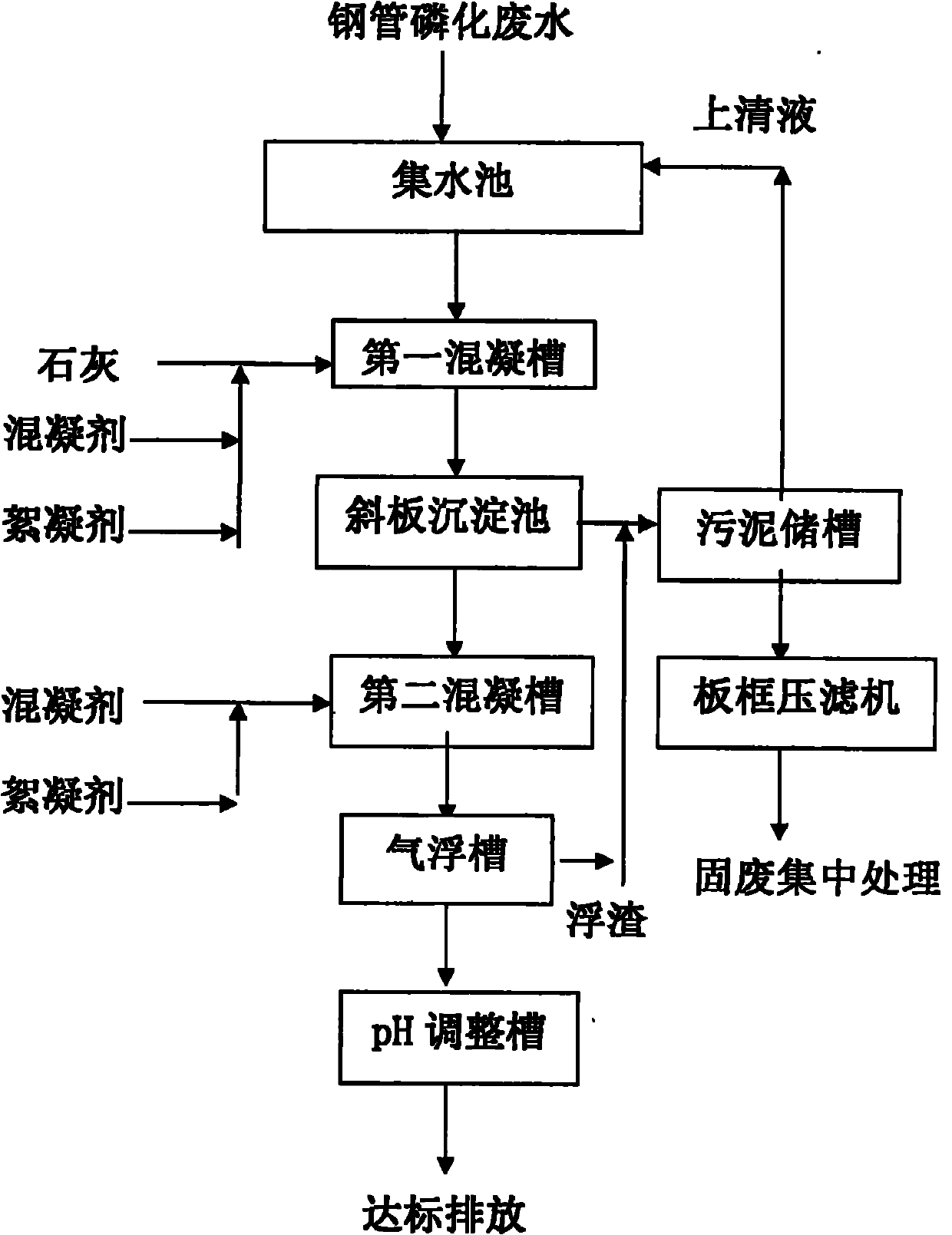

[0036] see figure 2 , by steel pipe phosphating wastewater treatment process of the present invention, its working process is as follows:

[0037] The phosphating wastewater is first collected into the sump or sump, and the phosphating wastewater is transported to the first coagulation tank through the water pump according to the liquid level, and the pH value adjustment and coagulation process are completed in this tank. During the pH value adjustment, the required The purity of the added lime is above 90%, and the process parameters for adjusting the pH value are: pH value 8-12; after that, add PAM coagulant solution with a concentration of 1‰. In the above two processes, a stirrer is required to stir, and the stirring speed range is 60-80rpm, so that the phosphating wastewater can be fully mixed and reacted.

[0038] The fully reacted wastewater enters the inclined plate sedimentation tank, so that the heavy metal pollutants in the phosphating wastewater are precipitated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com