Processing method of metal multi-surface scanning prism

A processing method and technology for multi-faceted prisms, which are applied in prisms, manufacturing tools, glass manufacturing equipment, etc., and can solve the problems of difficulty in controlling the angle accuracy of multi-faceted scanning prisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

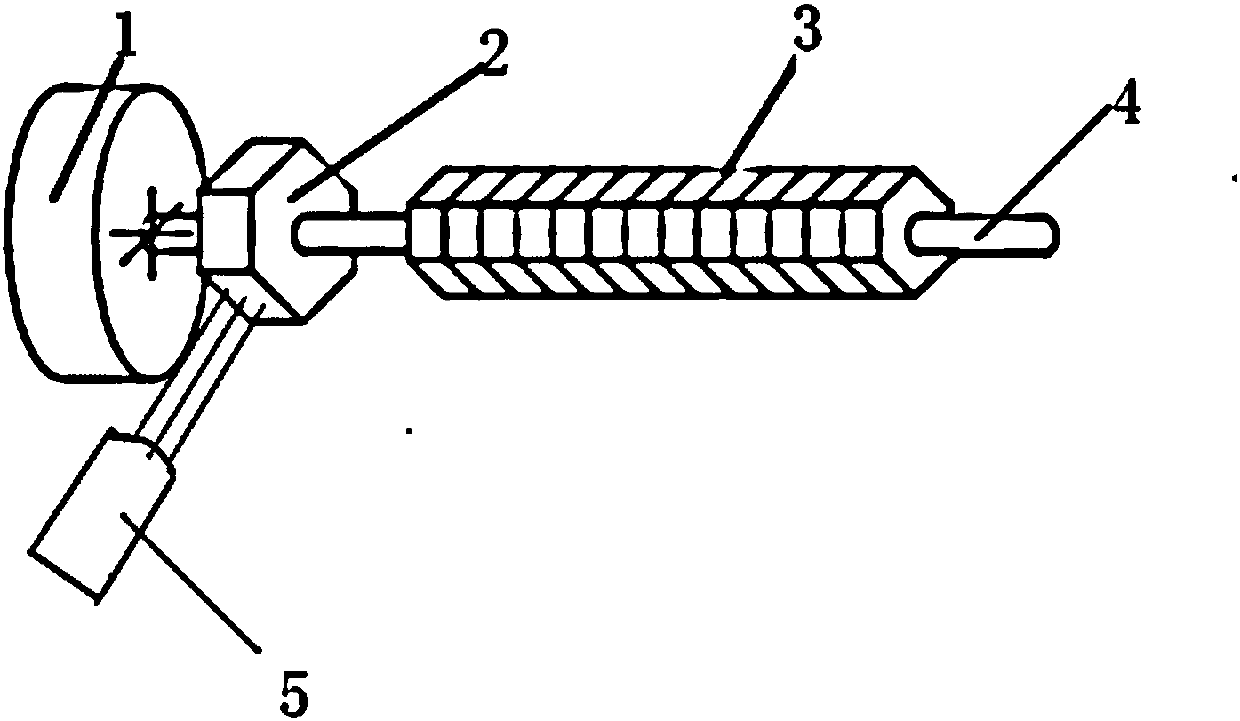

[0028] attached figure 1 The processing method of a metal multi-faceted scanning prism shown, the specific technical scheme is as follows:

[0029] 1) Process standard block step: process a polygonal prism whose precision is better than the design parameters of the metal polygonal scanning prism as standard block 2;

[0030] 2) Install and fix the standard block on the rotating shaft 4 of the electric control turntable 1, wherein the normal direction of the cross section of the standard block is parallel to the rotating shaft of the electric control turntable;

[0031] 3) The metal multi-faceted scanning prism blank 3 to be processed is also clamped on the rotating shaft of the electric control turntable, wherein the normal direction of the cross-section of the metal multi-face scanning prism blank is parallel to the rotating shaft of the electric control turntable;

[0032] 4) Build the self-collimating optical path 5 on the machine tool, and install the electric control tur...

Embodiment 2

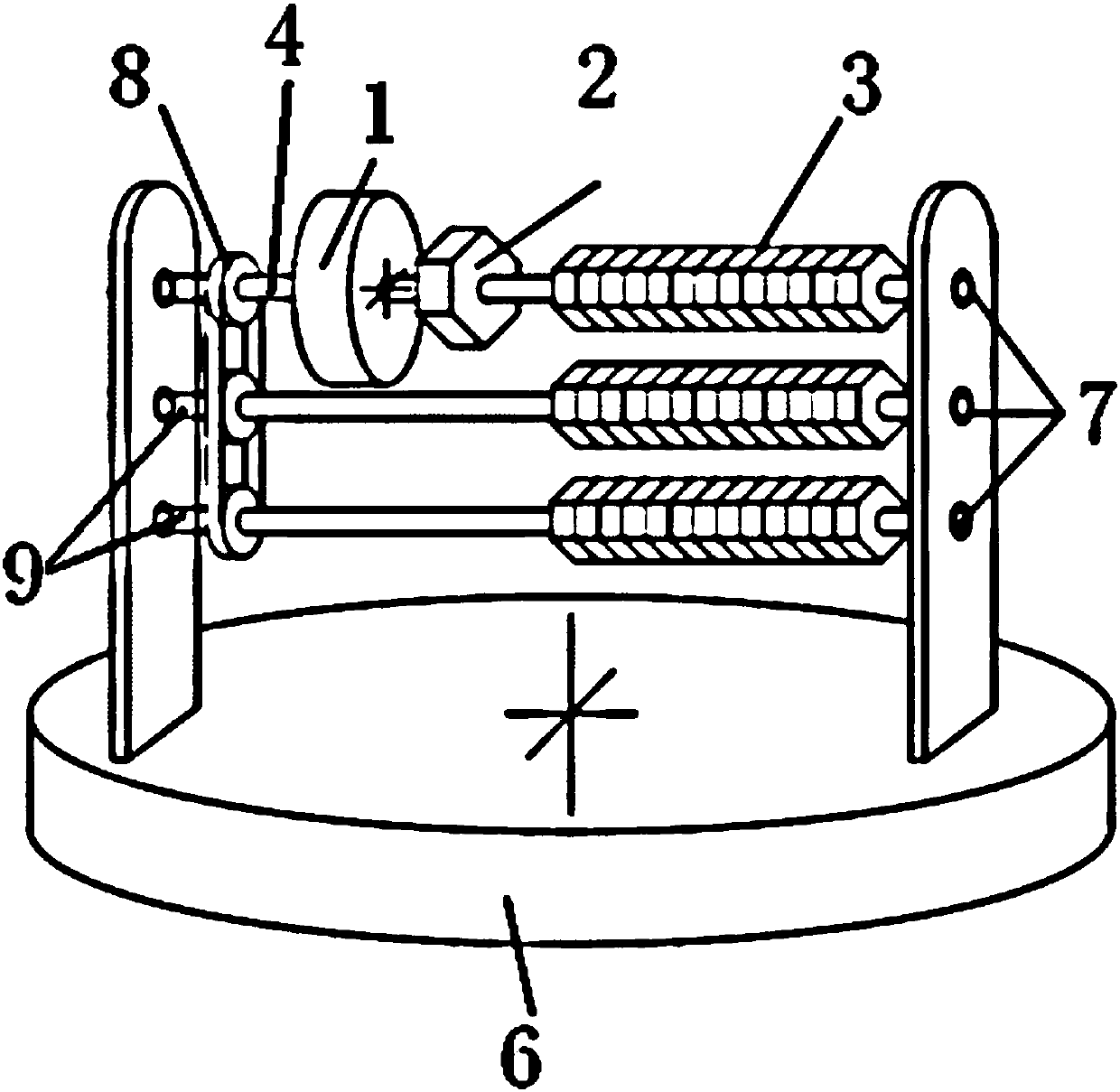

[0035] attached figure 2 The processing method of a metal multi-faceted scanning prism shown, the specific technical scheme is as follows:

[0036] 1) Process standard block step: process a polygonal prism whose precision is better than the design parameters of the metal polygonal scanning prism as standard block 2;

[0037] 2) Install and fix the standard block on the rotating shaft 4 of the electric control turntable 1, wherein the normal direction of the cross section of the standard block is parallel to the rotating shaft of the electric control turntable; the rotating shaft 2 of the electric control turntable 1 communicates with several driven The rotating shaft 9 is connected, and at least one metal multi-faceted scanning prism mirror blank 3 can be clamped on each driven rotating shaft. When the rotating shaft of the electric control turntable rotates, the driven rotating shaft also rotates at the same angle;

[0038] 3) Clamping a plurality of metal multi-faceted sca...

Embodiment 3

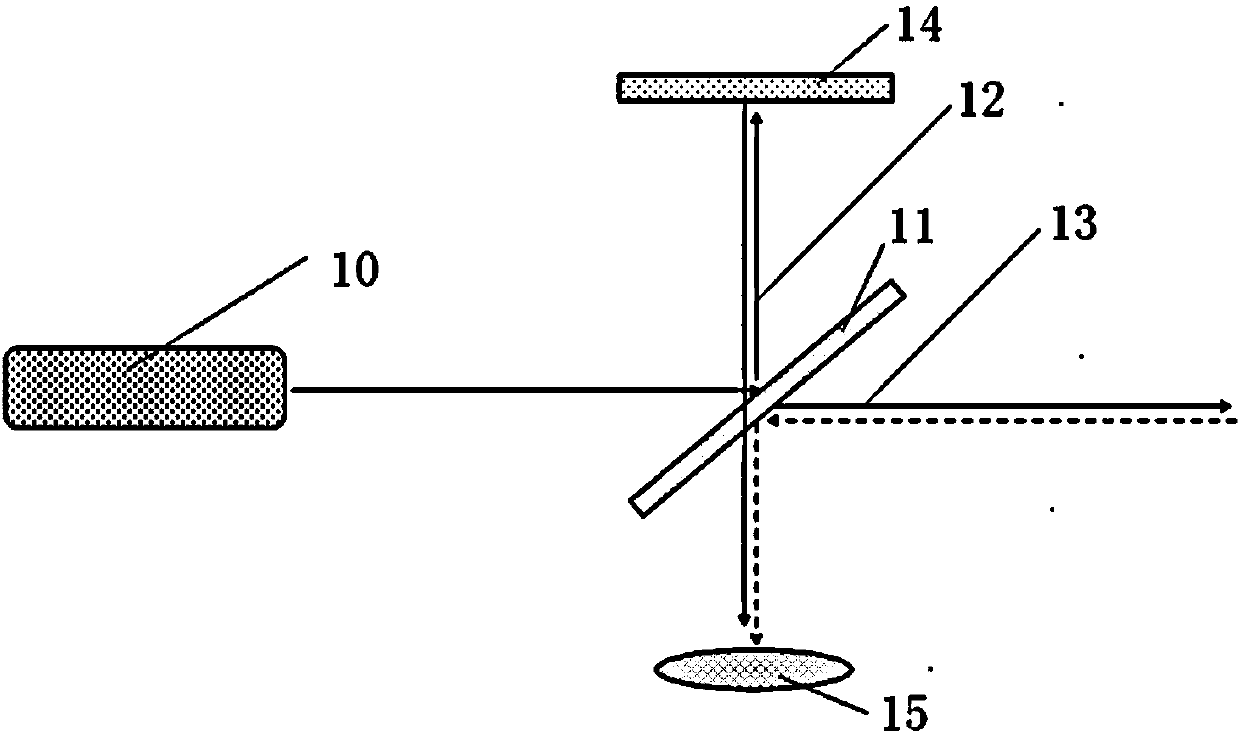

[0042] On the basis of the technical solution of Embodiment 1, the self-collimating optical path 5 is as follows image 3 As shown, it is composed of a parallel light laser 10, a beam splitter 11, a plane mirror 14, and an image screen 15, wherein the parallel light emitted by the parallel light laser is incident on the beam splitter, and the light reflected by the beam splitter is placed vertically on the optical path as a reference light 12 After being reflected by the plane mirror in the middle, it is incident to the image screen, and the light transmitted by the beam splitter is incident to any side of the standard block as the detection light 13; the electric control turntable is rotated, and the detection light is reflected to the image screen 15 by the side, Interference fringes are formed on the image screen. The optical path is actually a Michelson interference optical path, and the rotation angle of the electric control turntable can be controlled more precisely thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com