Special tool for milling and processing K2 side bearing axial trough

A technology of milling processing and side bearings, which is applied in the direction of metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of lack of special fixtures, difficulty in dimensional accuracy, and many processing procedures, so as to change the manpower pressing process and save The effect of eliminating the classification and inspection process and shortening the auxiliary time of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

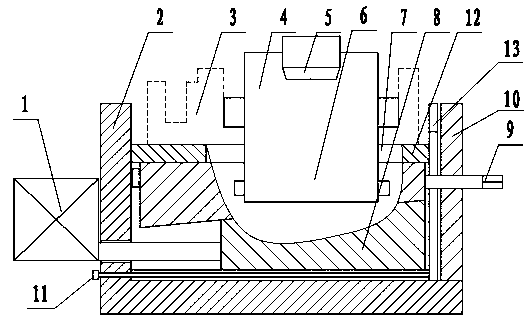

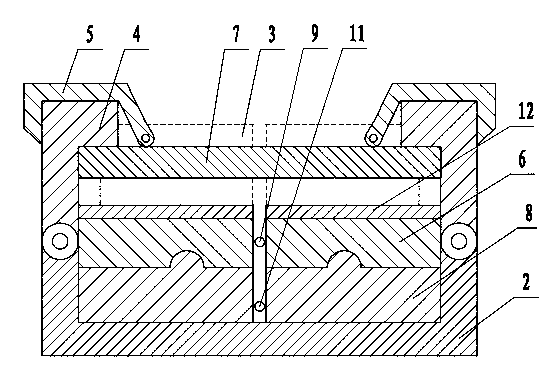

[0019] According to attached Figure 1-2 As shown, the present invention specifically relates to a special tool for milling shaft grooves of K2 side bearings, which is used for processing or repairing the shaft groove structure of K2 side bearings, and can realize batch operation. The structure includes a concave base 2 with an opening on the upper surface, and the base 2 is provided with an upper wedge 6 and a lower wedge 8, and the two slopes of the upper wedge 6 and the lower wedge 8 cooperate with each other. , the left and right sides of the upper slanting wedge 6 and the lower slanting wedge 8 cooperate with the vertical end plate inner surface of the base 2, and the upper slanting wedge 6 is provided with a pressing plate 7 and an upper limit mechanism that restricts the movement of the pressing plate 7. The side surface of the lower inclined wedge 8 is connected with the piston rod of the cylinder 1 which is located on the outer wall of the base 2 .

[0020] In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com