Patents

Literature

54results about How to "Precise processing size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

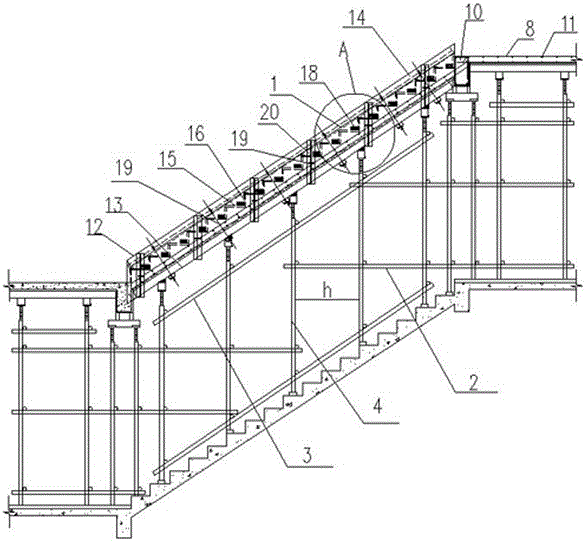

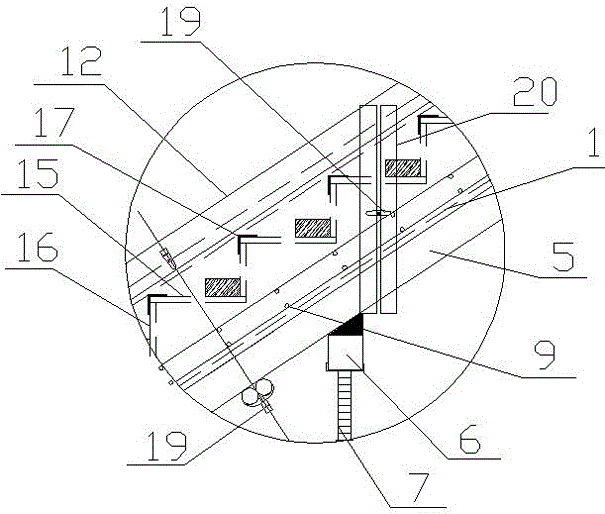

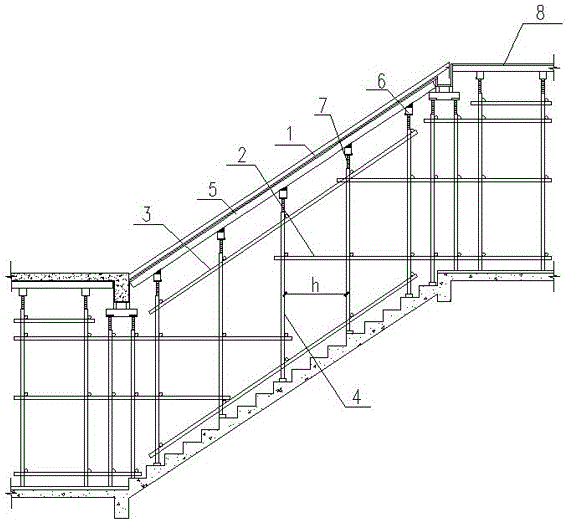

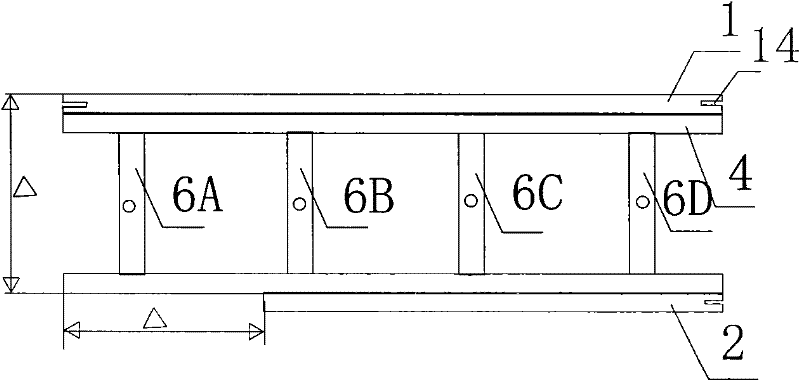

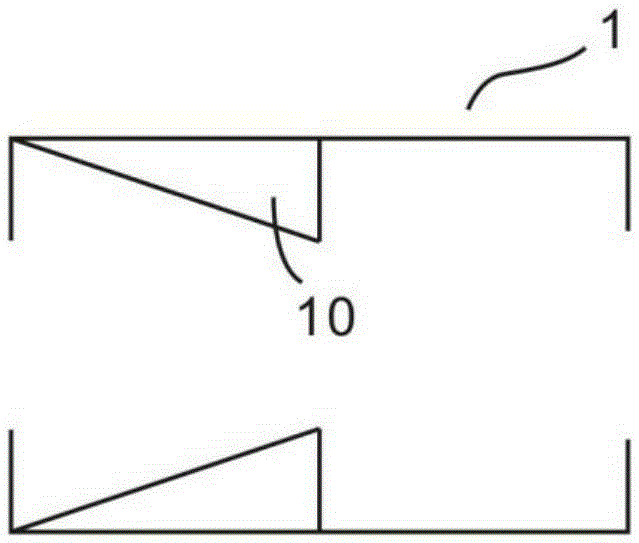

Formwork structure for sealing of cast-in-situ stairs and reversed concrete pouring construction method of formwork structure

The invention provides a formwork structure for sealing of cast-in-situ stairs and a reversed concrete pouring construction method of the formwork structure. The construction method comprises steps as follows: laying of a stair plate bottom formwork, mounting of ladder beams and platform plate formworks, erection of supporting frames, binding of steel bars for the stairs, layout of split heads, mounting of outer holding plates, mounting of horizontal and longitudinal step formworks, mounting of angle steel, reinforcement through upper and lower formworks of the stairs, reinforcement through side formworks of the stairs, concrete pouring and curing and detachment and circulating use of the bottom formwork and the outer holding plates. The formwork structure and the construction method have the benefits as follows: the upper surfaces of the stair steps are sealed through the formworks, concrete can be effectively prevented from overflowing, and materials are saved; concrete pouring is performed from the bottoms to the tops of the stairs, and vibration for compaction is performed during pouring.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

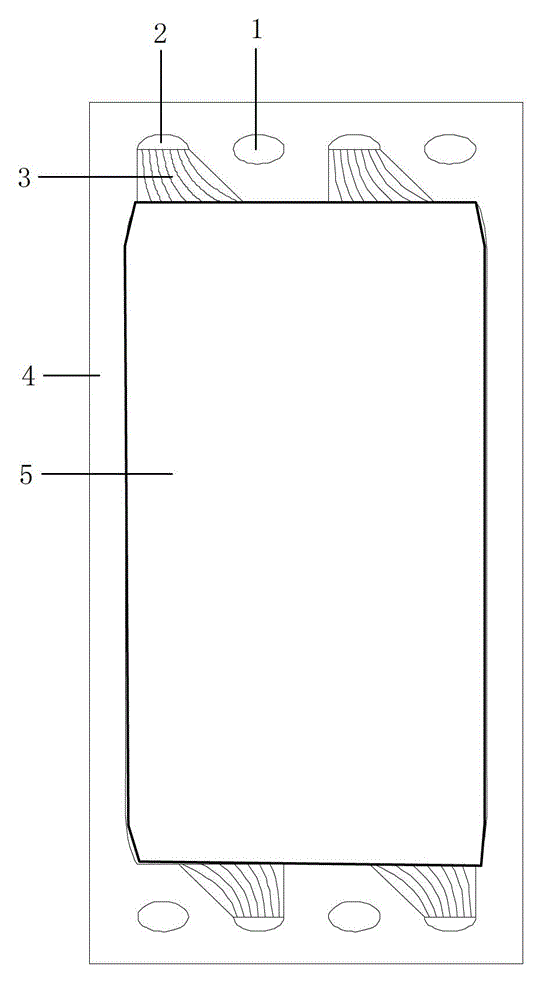

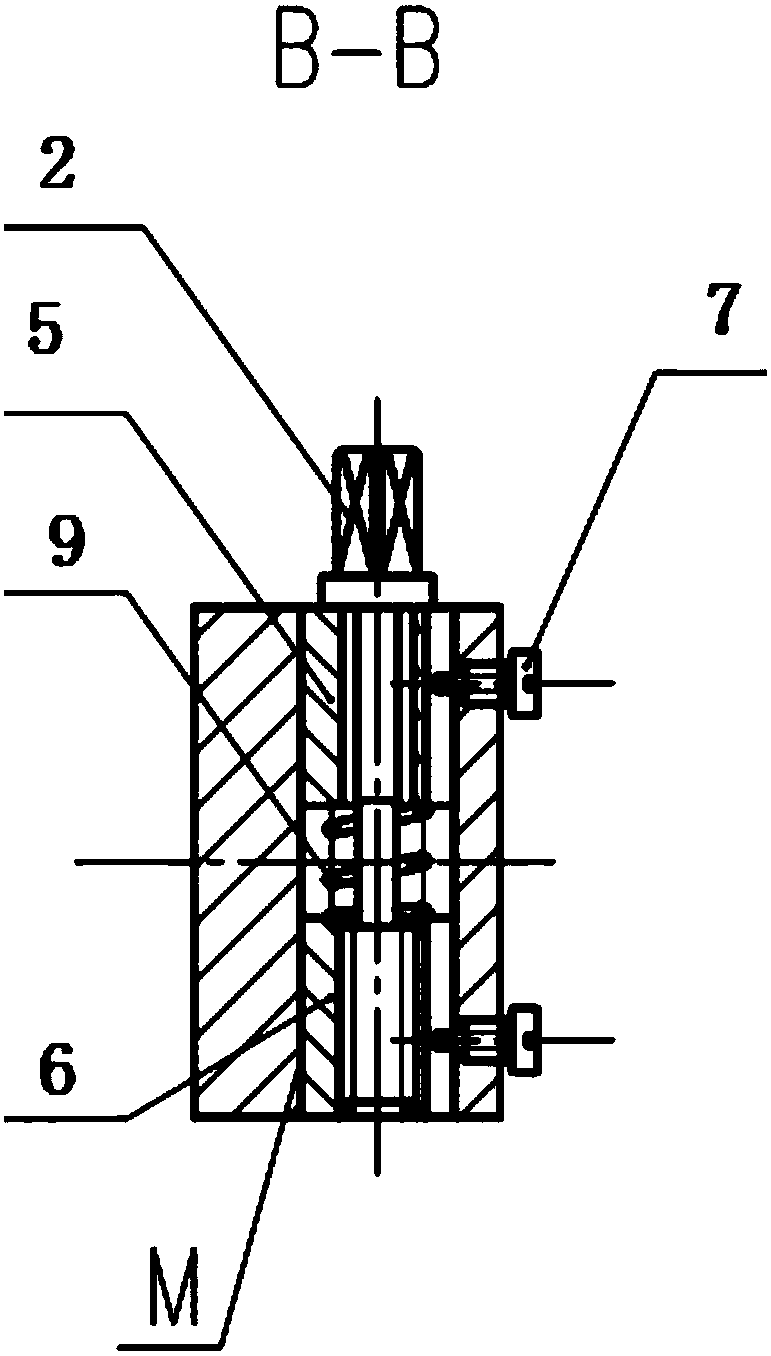

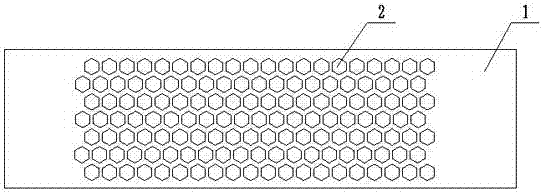

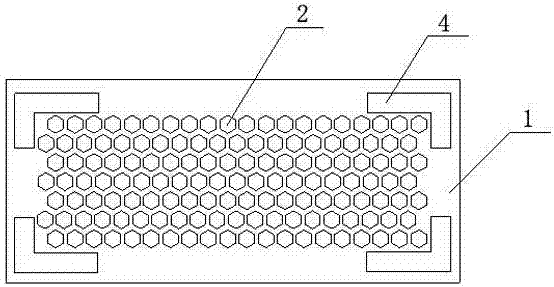

Electrodialysis spacer

InactiveCN102910713APrecise processing sizeFlat processing sizeDispersed particle separationElectricityOrganic solvent

The invention discloses the technical field of water treatment, and particularly relates to a spacer member in an electrodialysis device. An electrodialysis spacer comprises a board frame, a water distribution flow passage, liquid guide holes and a board-core grid, wherein half of the liquid guide holes are elliptical, and half of the liquid guide holes are semi-elliptical, connected with the water distribution flow passage and communicated with the inner cavity of the board frame; the elliptical liquid guide holes are arranged at one end of the board frame; and the board-core grid is distributed in the inner cavity of the board frame. The electrodialysis spacer has the advantages that the flow capacity can be improved and the resistance is reduced in the water flow process; and the electrodialysis spacer has the characteristics of being good in elasticity, resistant to strong acid, strong base and organic solvent, easy to seal and good in leak tightness.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

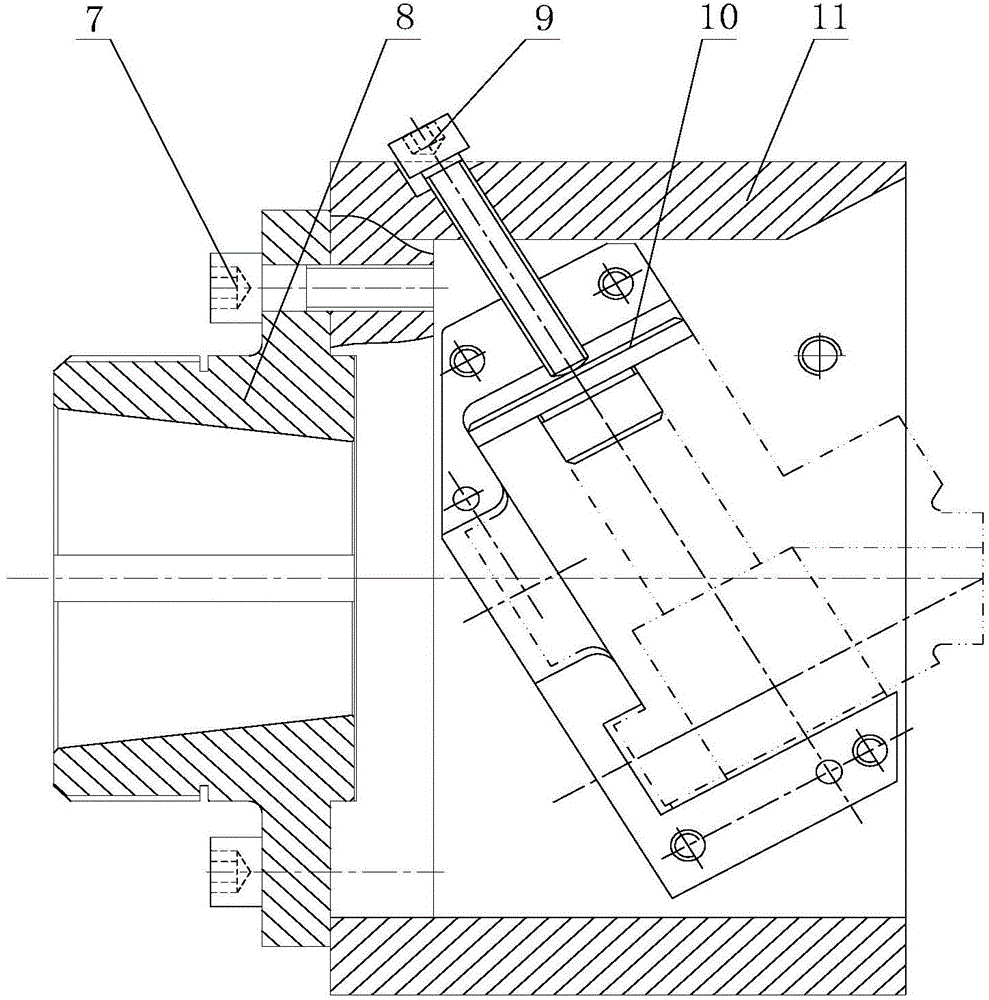

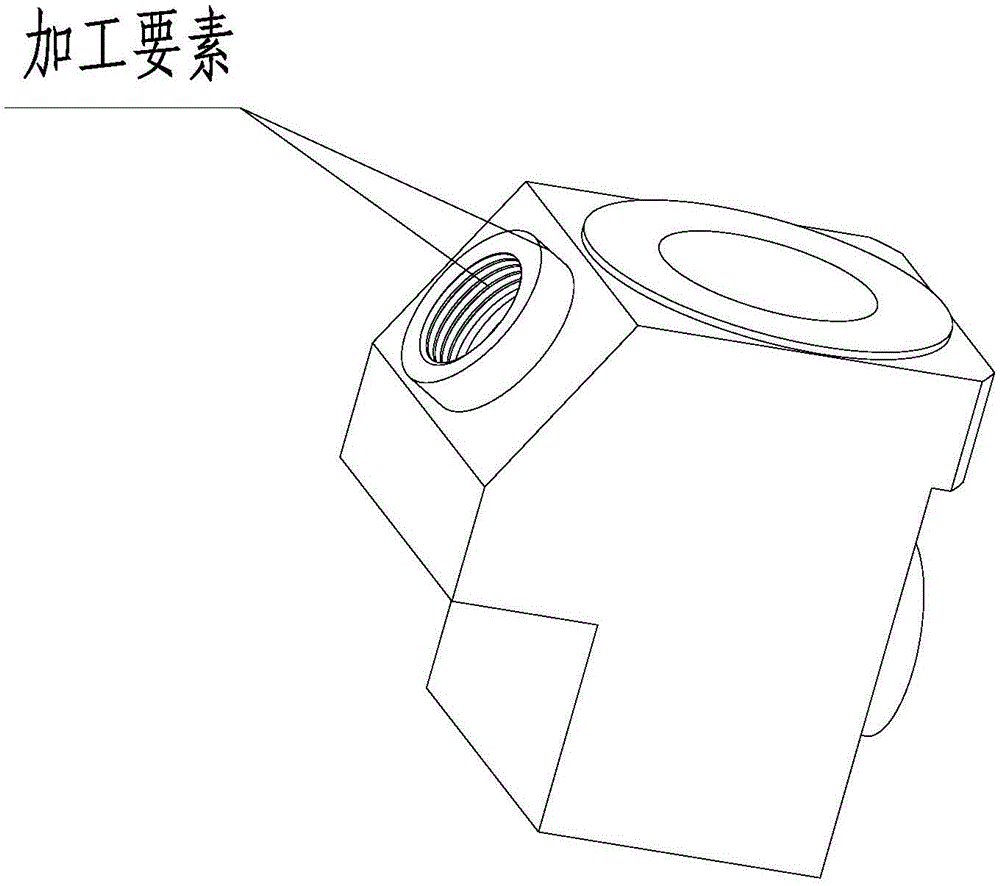

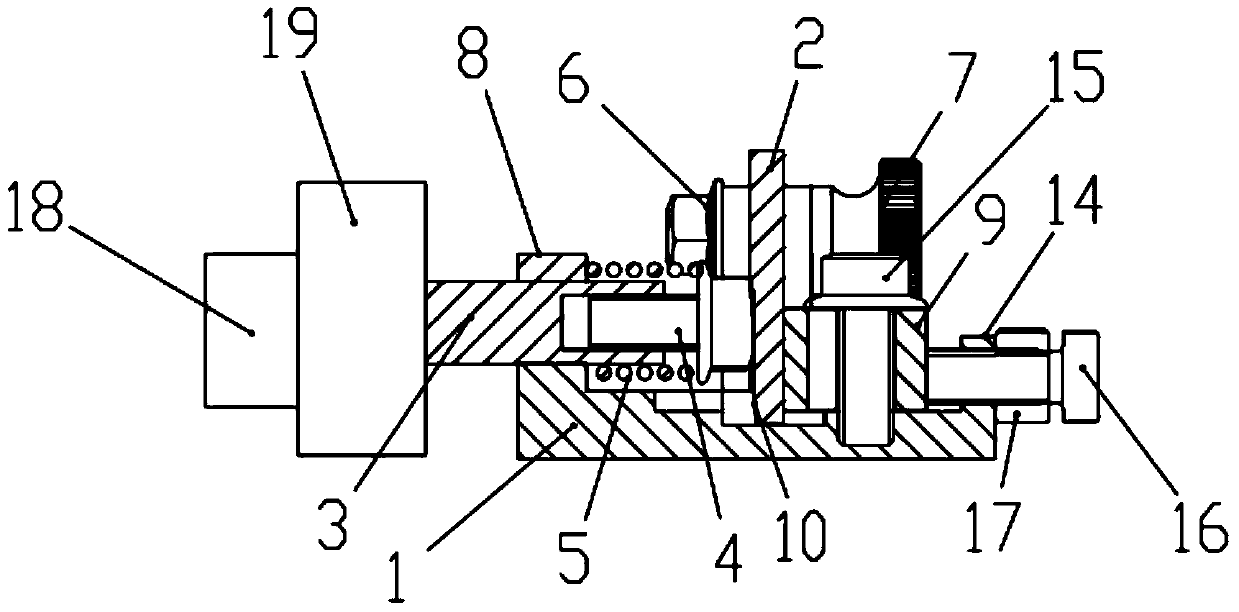

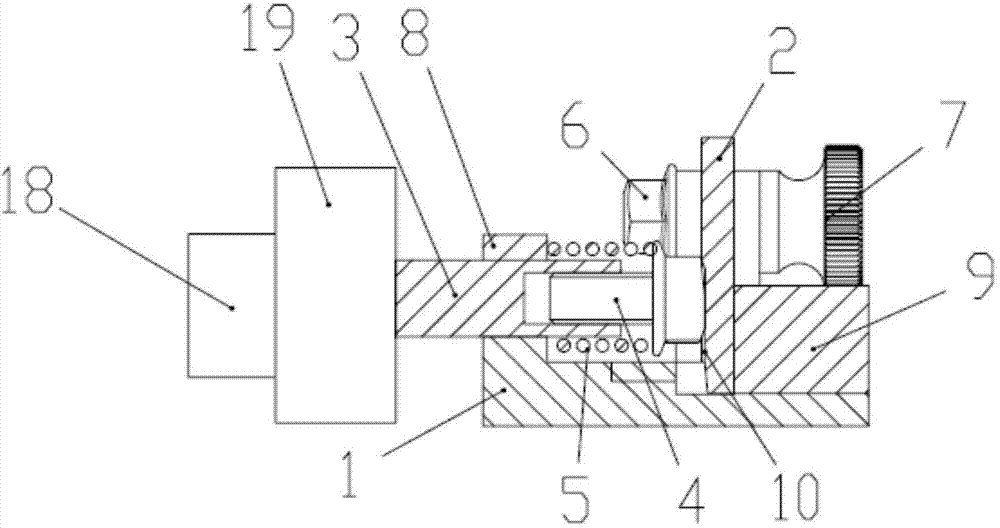

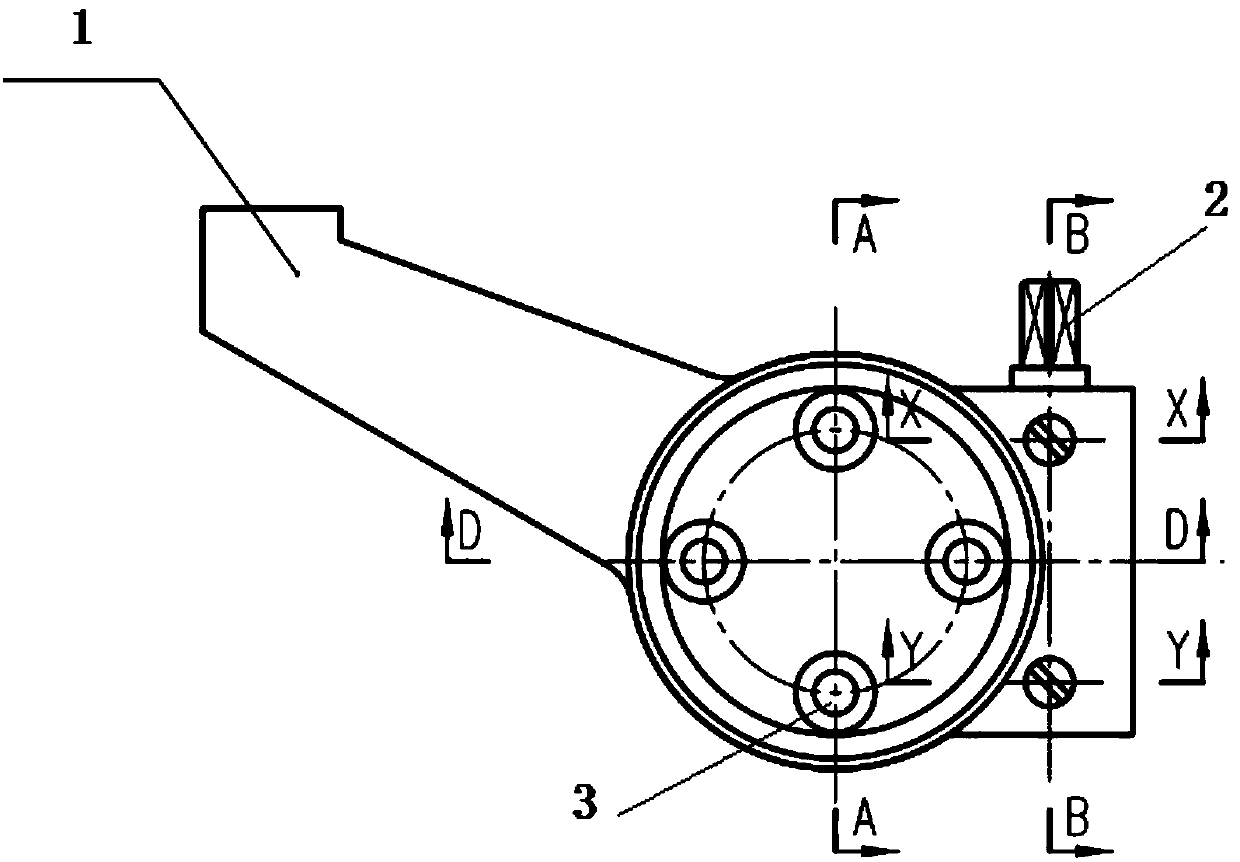

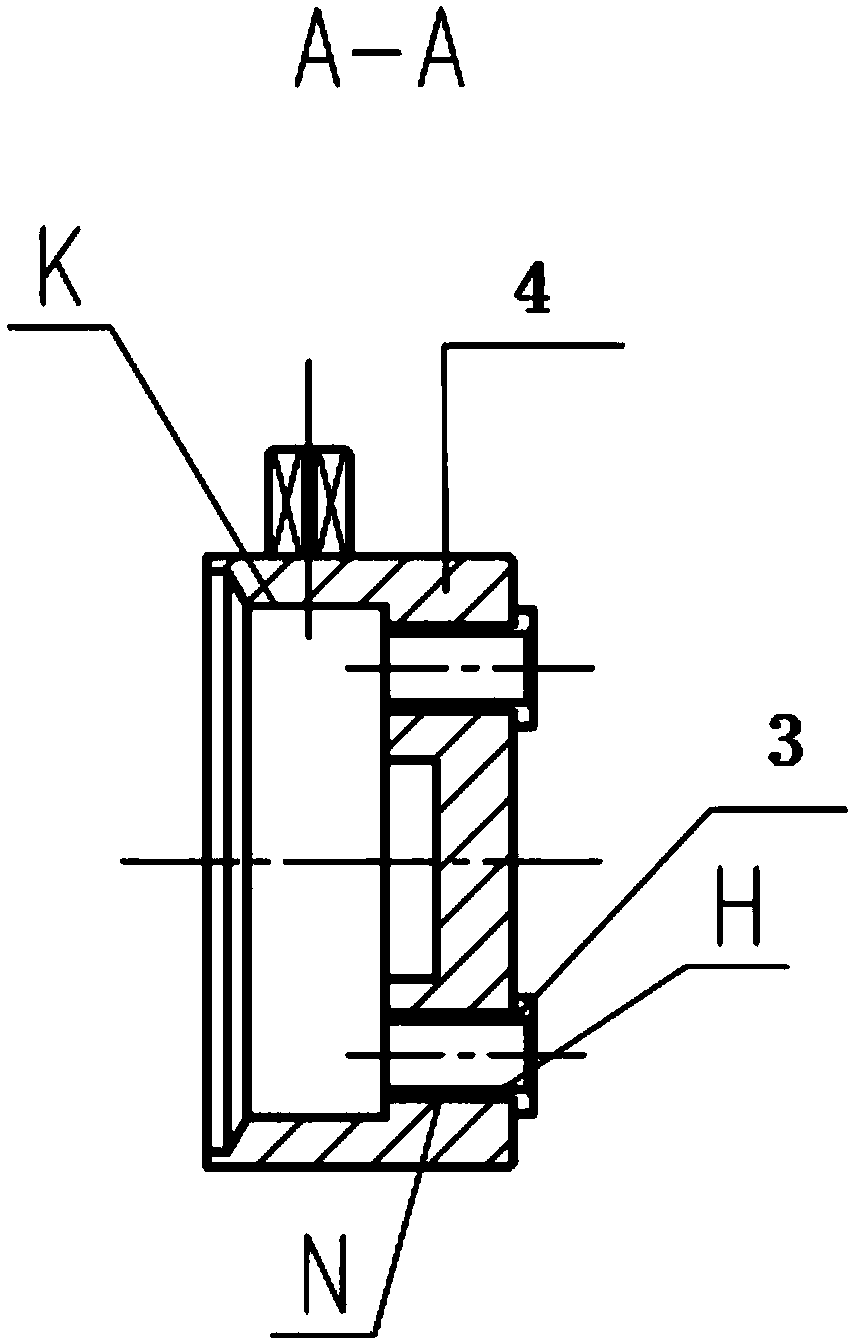

Turning clamp and application thereof

ActiveCN104440329ATurning is possibleGuaranteed accuracyWork clamping meansPositioning apparatusMachine toolSupport surface

The invention discloses a turning clamp. The turning clamp comprises a clamp body, a locating block, a pressing mechanism and a safety screw, wherein the clamp body is provided with a hollow cavity, one end of the clamp body is fixedly connected with a flange plate, and the flange plate is used for being fixedly connected with a machine tool; the locating block is fixed into the cavity of the clamp body through a pin, a certain angle is formed between the locating block and the central axis of the clamp body, the locating block is provided with a locating and supporting surface which is matched with the outline of a workpiece to be machined, and after the workpiece is fixed into the locating and supporting surface, the central axis of a round-ring-shaped machined factor on the workpiece and a spindle of the machine tool coincide; the pressing mechanism comprises a first-direction pressing mechanism body and a second-direction pressing mechanism body, and the first-direction pressing mechanism body and the second-direction pressing mechanism body are used for locking the workpiece in the first direction and the second direction; the safety screw penetrates through the cavity of the clamp body and is fixed to the two opposite side faces, and the safety screw is used for preventing the workpiece in the cavity from disengaging and flying out. The invention further discloses a method of the turning clamp. By the adoption of the turning clamp and the method of the turning clamp, turning of the round-ring-shaped machined factor with the inclined central axis can be achieved, and the problems that at present, the structures of machined workpieces are limited, the clamping stability is poor, and potential safety hazards exist are solved.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

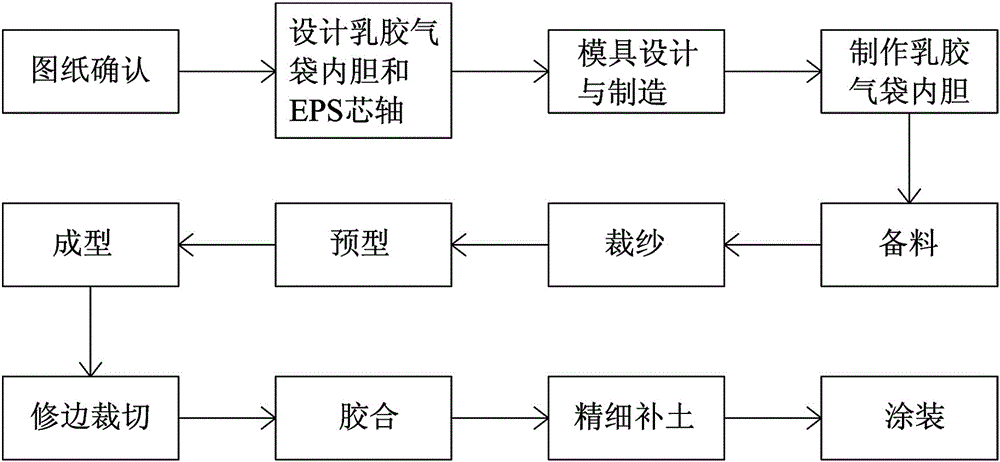

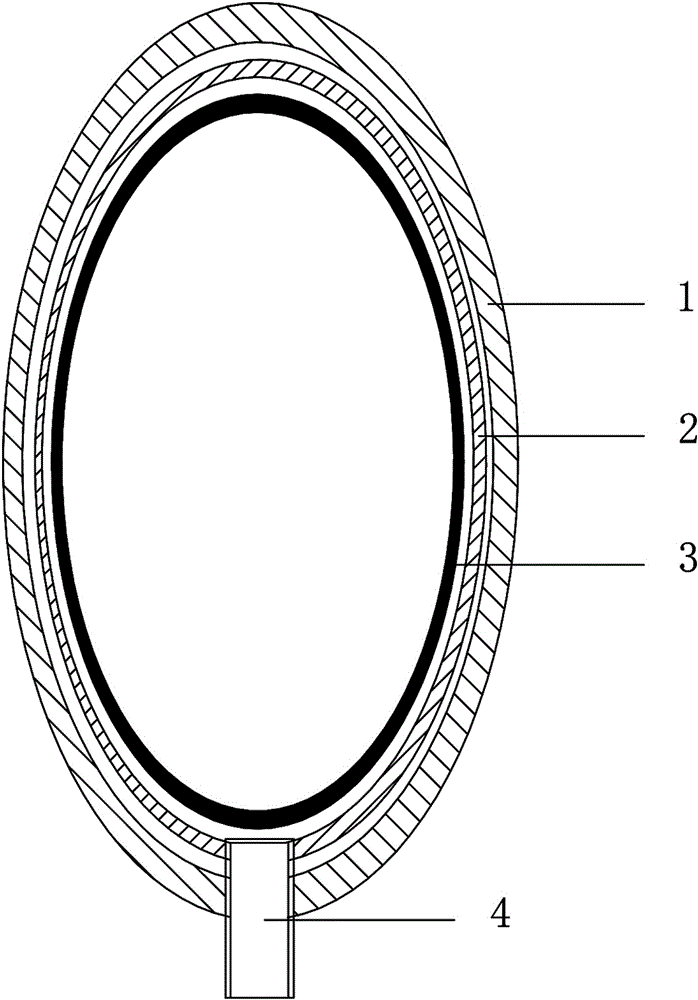

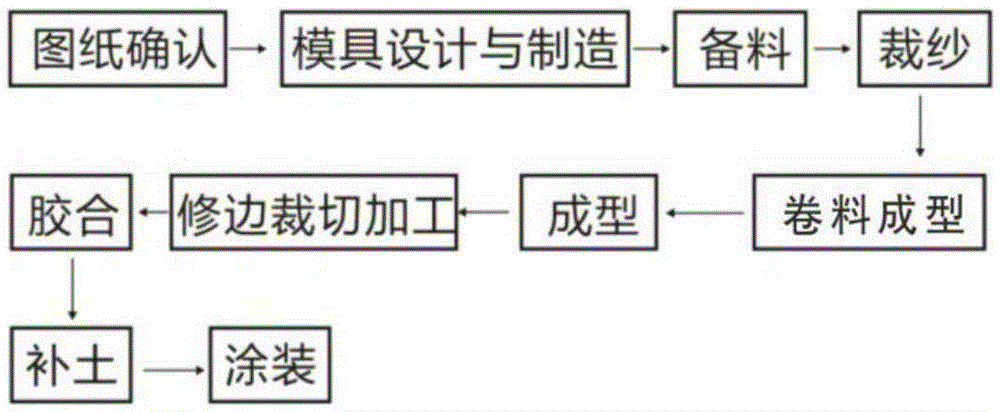

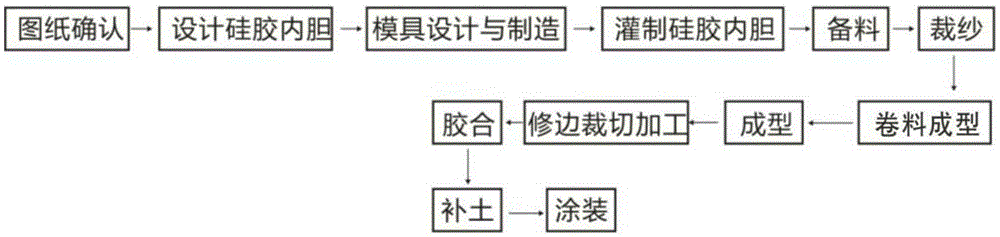

Production technology of carbon fiber composite aircraft

The invention discloses a production technology of a carbon fiber composite aircraft. The production technology comprises the steps that a product drawing is determined; a latex airbag inner container and an EPS central spindle are designed according to the drawing; an aircraft manufacturing mold and an EPS central spindle manufacturing mold are designed and manufactured; the EPS central spindle and the latex airbag inner container are manufactured; forming materials are prepared; carbon yarn fabric is cut according to an arranging and stacking sheet; the shape of the aircraft is rolled on the surface of the latex airbag inner container in advance; the latex airbag inner container is placed in an aircraft forming mold, the mold is closed and fed to a furnace stage to be heated, meanwhile, air pressure is provided for the interior of the latex airbag inner container through a charging port, a product is fed to be cooed after being formed, finally, the mold is opened, and the formed aircraft is taken out; trimming and cutting are carried out; other components which cannot be integrally formed are bonded and fixed to the aircraft; and polishing and puttying are carried out on the surface of the aircraft. The latex airbag inner container is inflated with high-pressure air for pressurization, extrusion forming is achieved, and the finished carbon fiber composite aircraft with steps on the inner wall of a shell can be obtained.

Owner:HARWAR INT AVIATION TECH SHENZHEN

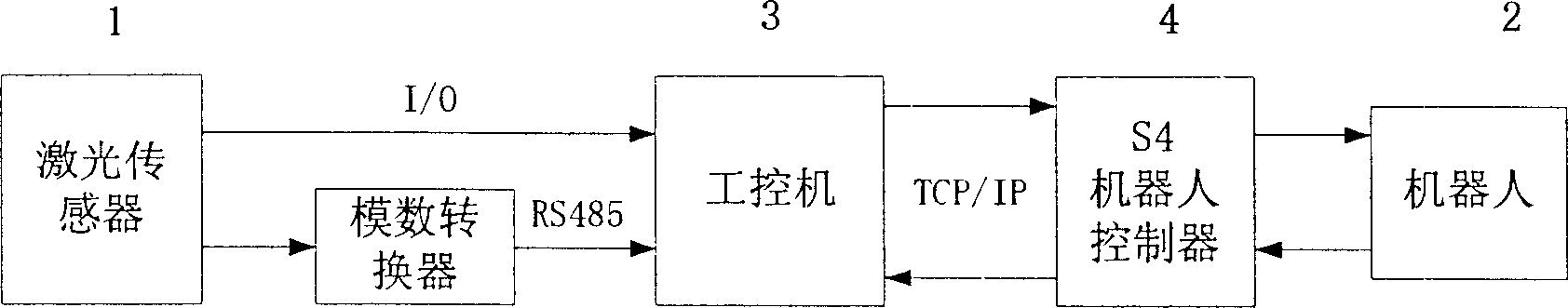

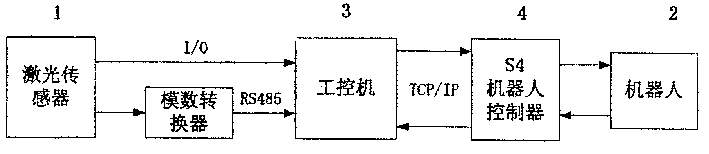

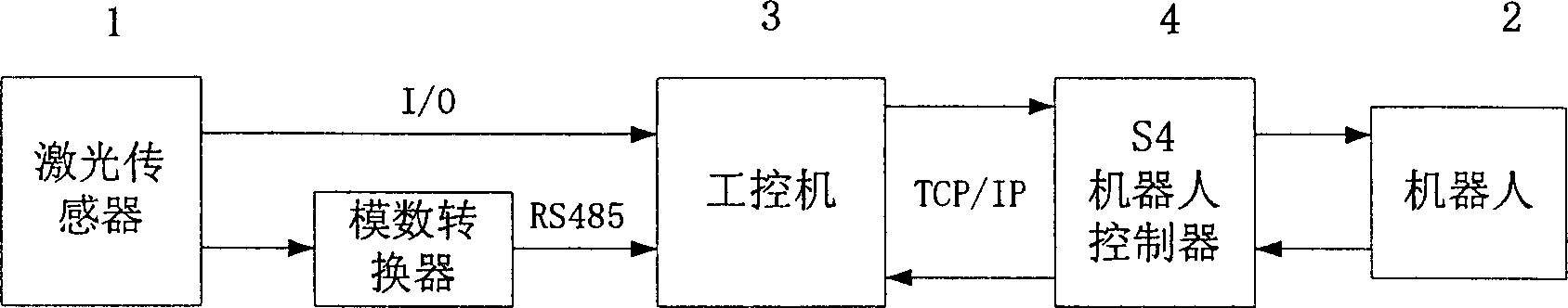

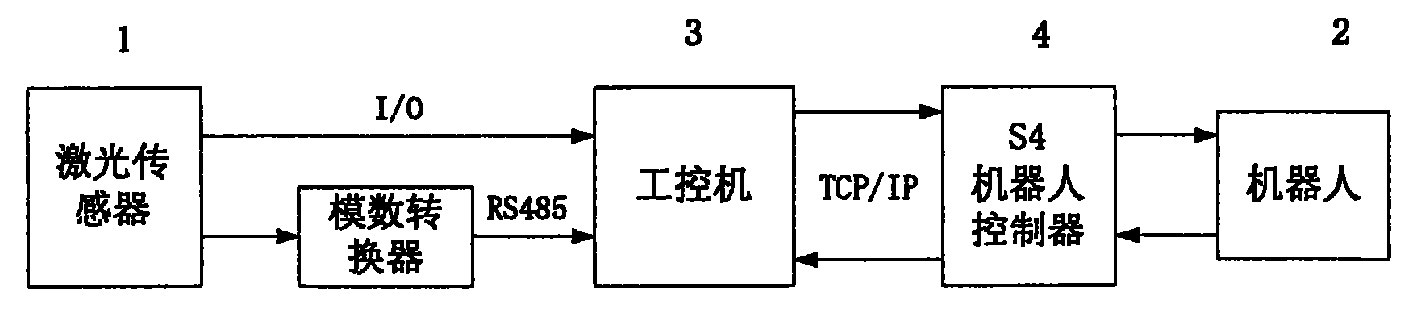

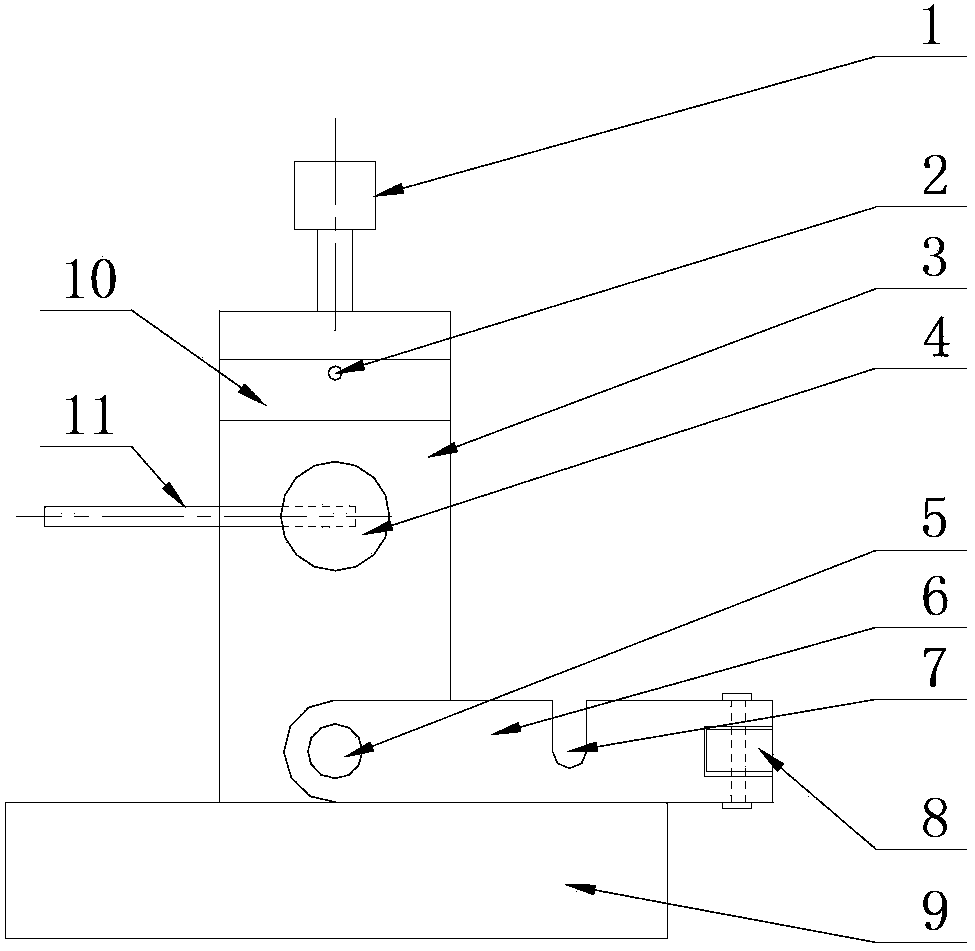

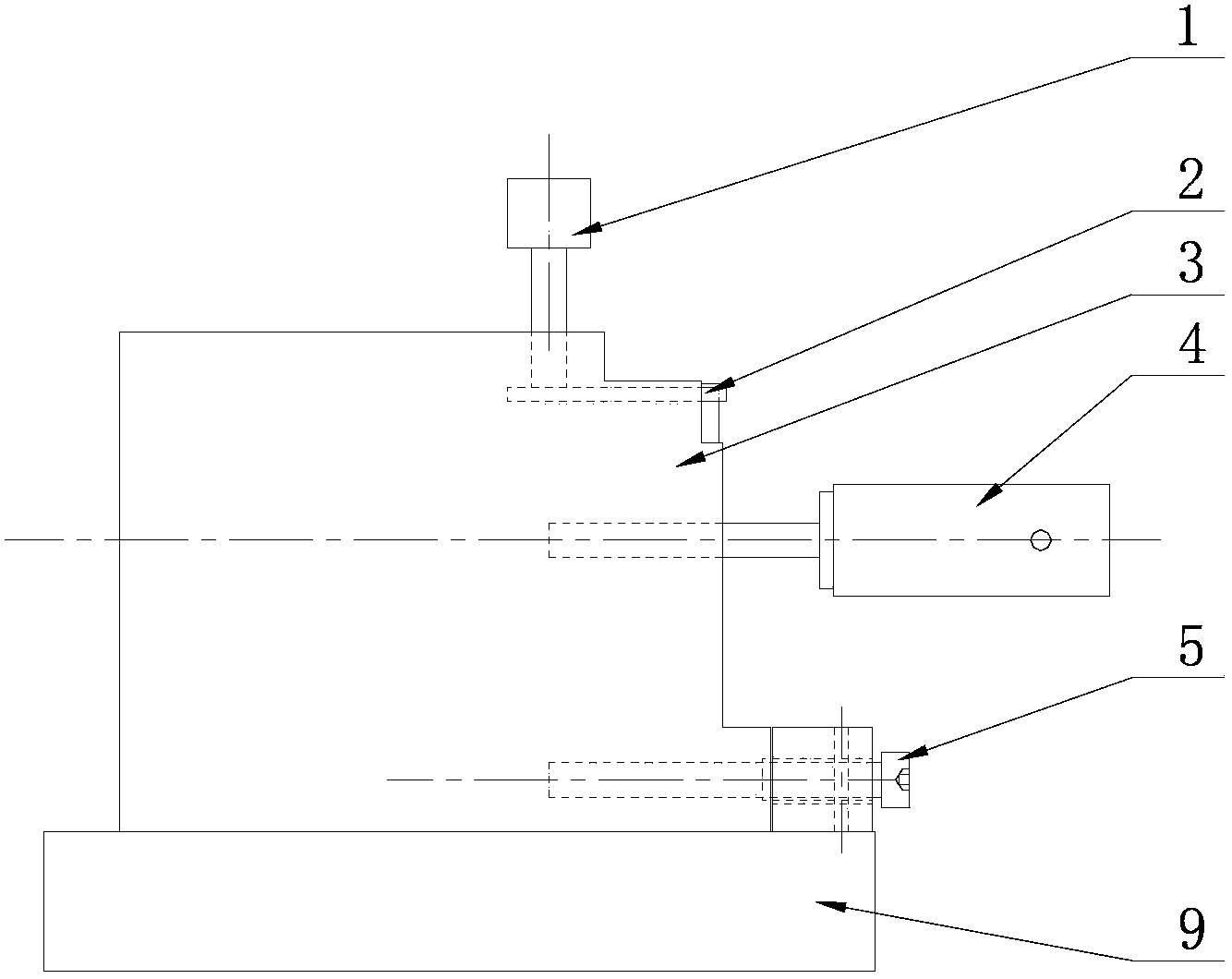

On-line compensating method for locus coordinates of moving robot

InactiveCN1415460ALarge amount of deformationPrecise processing sizeProgramme-controlled manipulatorGraphicsSimulation

An in-line compensating method for the running coordinate of robot features that the data about the profile and position of workpiece is read to computer by a sensor at the terminal of robot's arm, and then processed for compensaing the coordinate of the executing tracing for robot. Its advantages are freely putting sectional steel on bench, and high precision.

Owner:SHANGHAI JIAO TONG UNIV +1

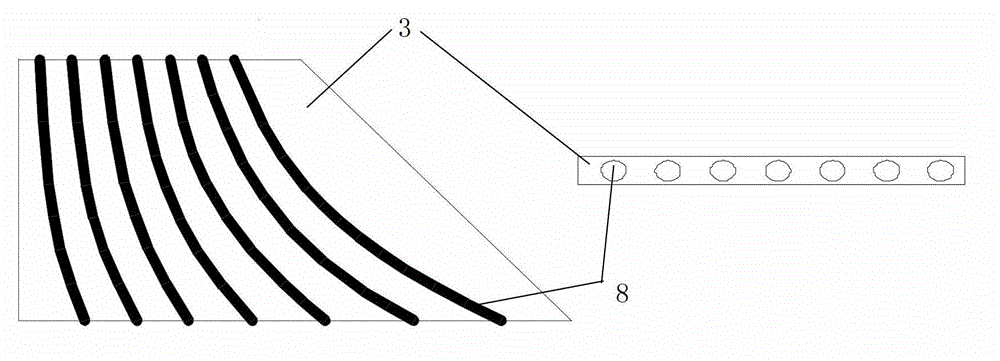

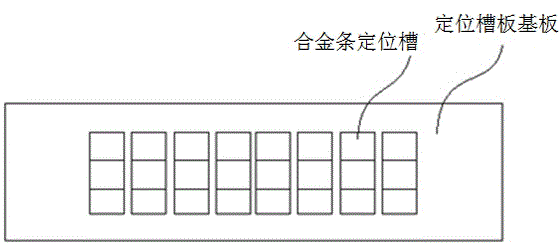

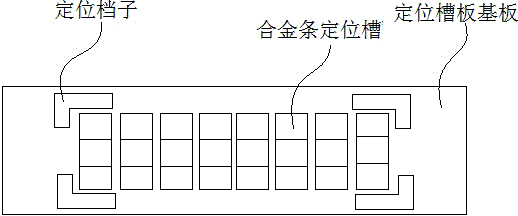

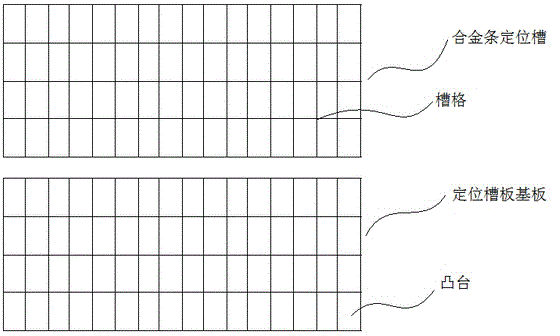

Single-face bonding method suitable for hard alloy strips in hard alloy hard-face machining process and application

ActiveCN104976201APrecise processing sizeHigh speedFastening meansWelding apparatusAdhesive beltAlloy

The invention provides a single-face bonding method suitable for hard alloy strips in a hard alloy hard-face machining process and application. A locating groove plate for bonding is scientifically designed, the hard alloy strips are placed on the locating groove plate, the hard alloy strips are bonded through punched single-face adhesive tape, and the hard alloy strips or blocks are fixed through spot welding; and then the adhesive tape is placed on a steel surface of a to-be-machined component, and through spray welding, bead weld and grinding, the steel surface is machined into a hard surface. According to the method, the aim that a large number of hard alloy strips are bonded at a time is simply and easily achieved, the bonding efficiency is greatly improved, and the conditions that due to manual operation, the bonding angles are different, and the bonding intervals are uneven are avoided; the bonding precision is improved, and wear resistance of the product hard surface can be effectively ensured and improved; and the method can be well applied to the aspect of hard-face machining of centering guides or TC bearings of drilling tools or screw drilling tools.

Owner:株洲金韦硬质合金有限公司

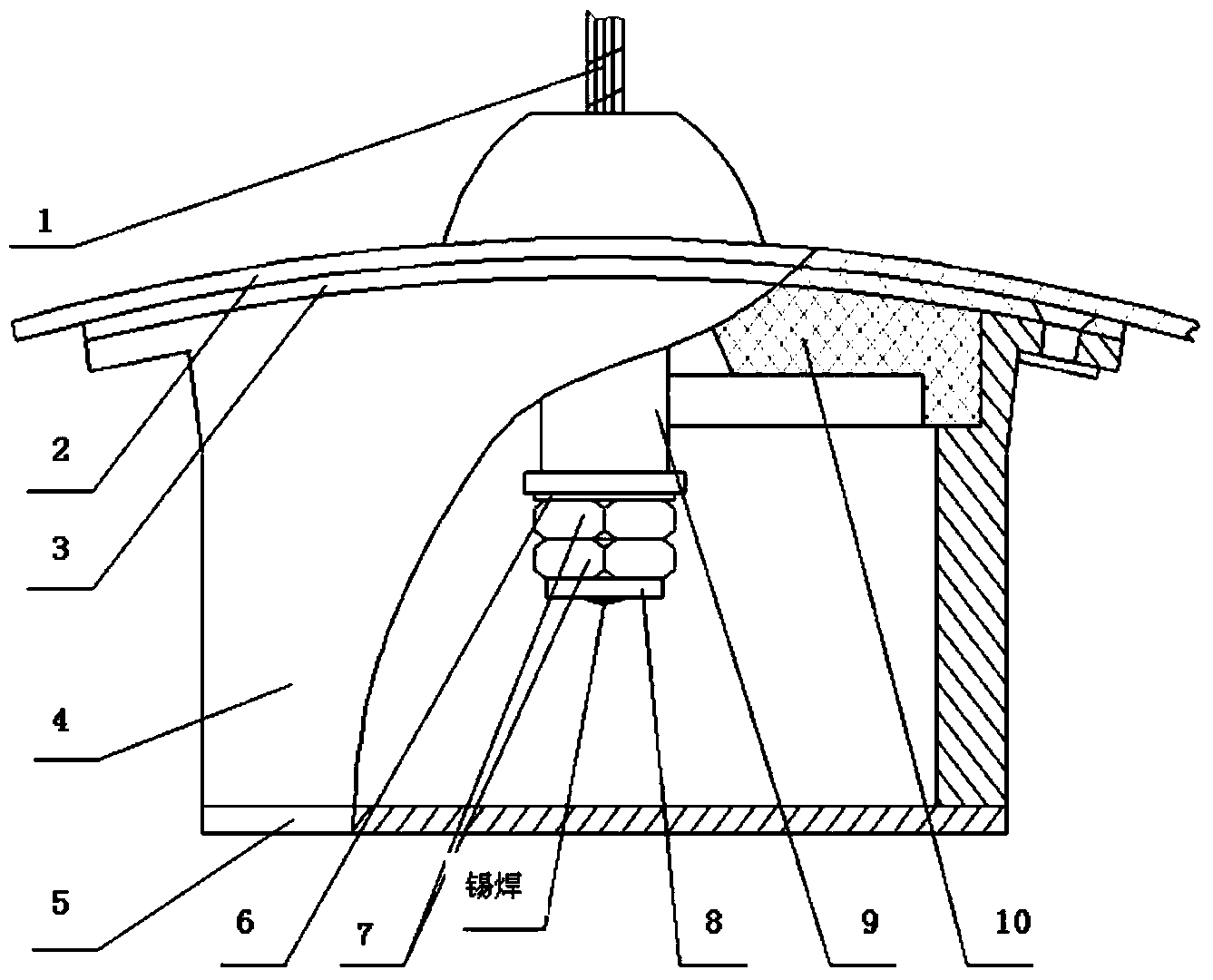

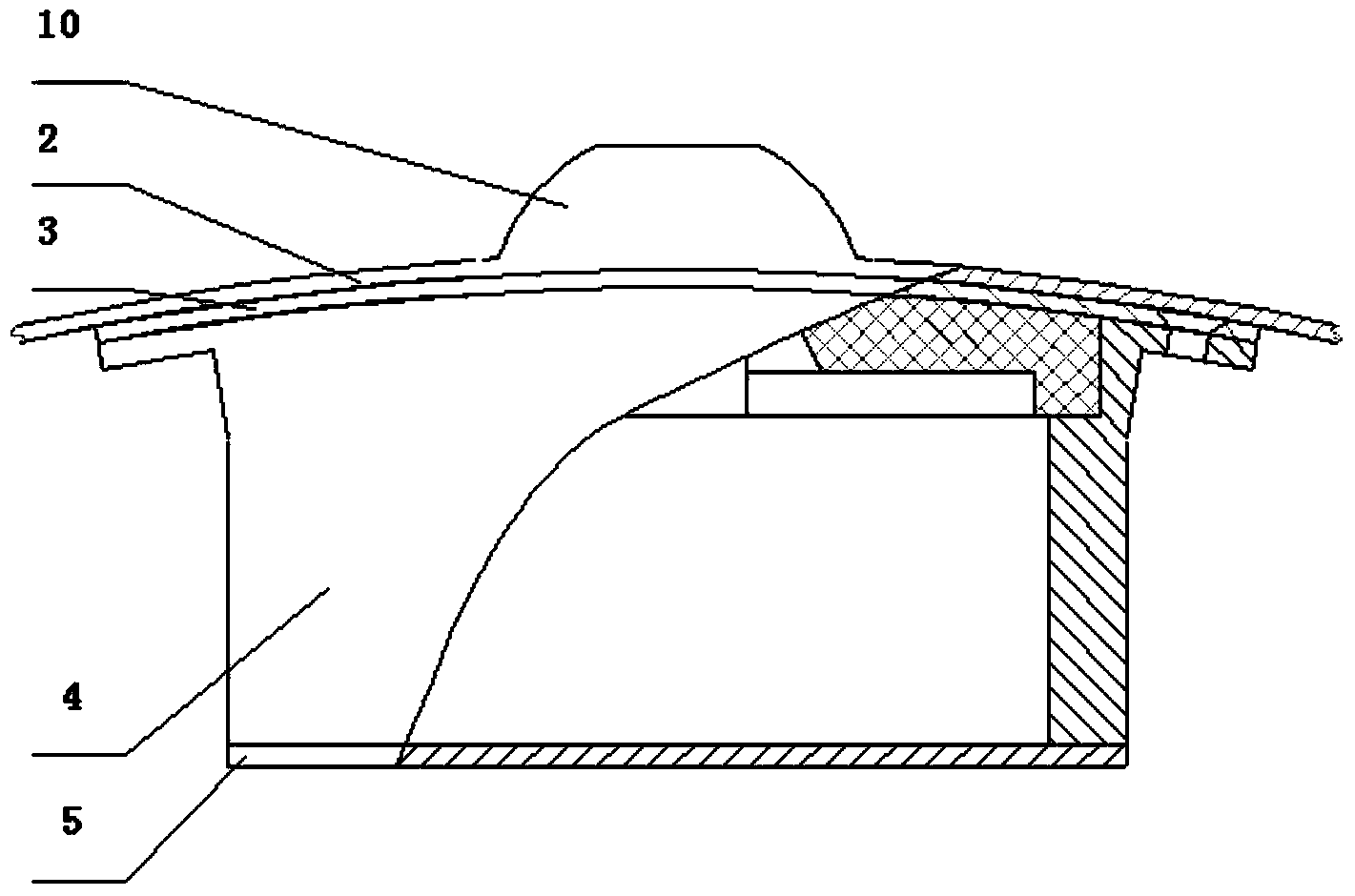

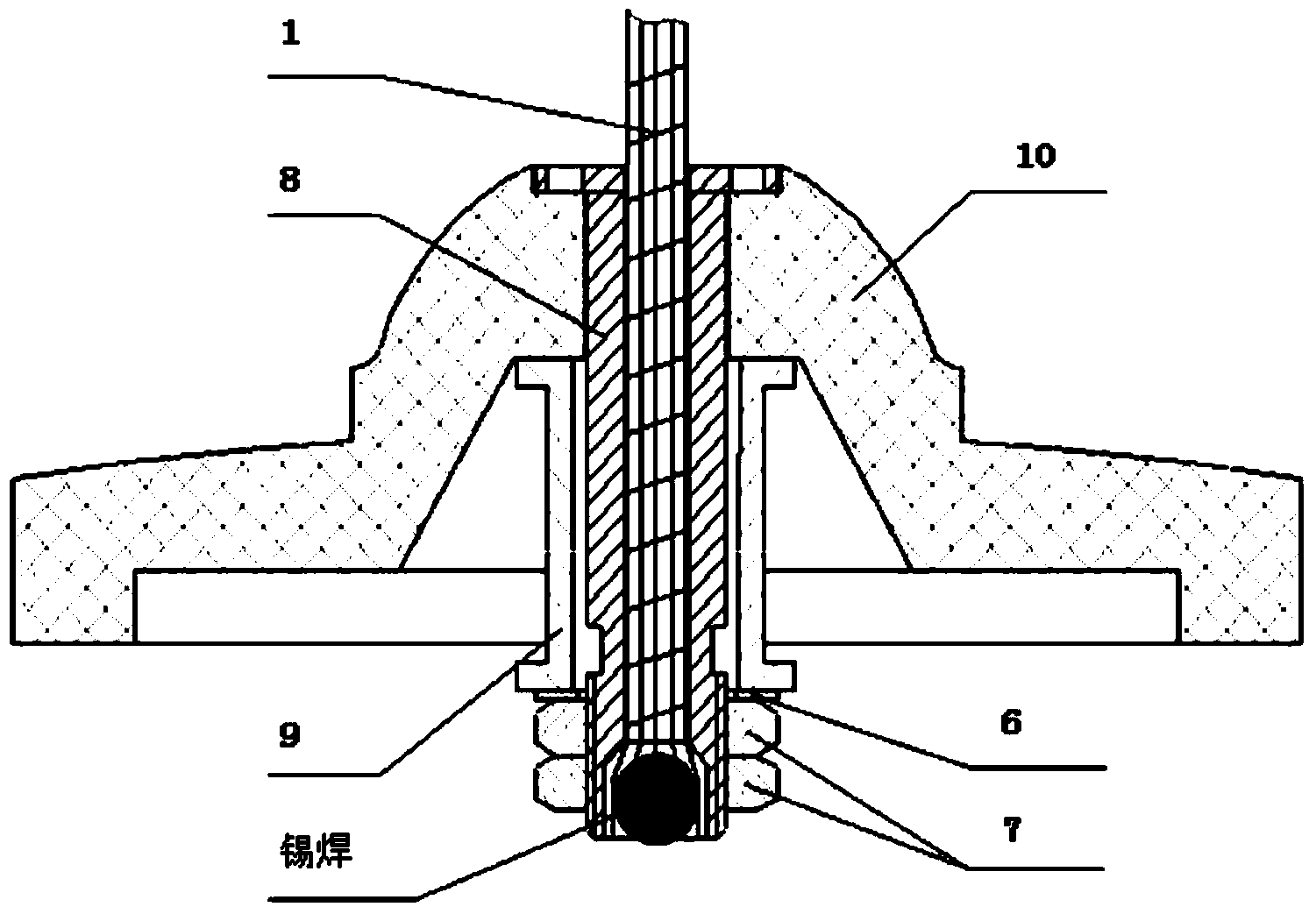

Airborne remote antenna mounting device

ActiveCN103682556AIt is not easy to disengage the extraction screw, etc.Small space requirementAntenna supports/mountingsPull forceEngineering

The invention provides an airborne remote antenna mounting device which includes an antenna fixing device, an antenna mounting matching box and a special spanner. The antenna fixing device includes an antenna steel rope, a hollow screw, a bush, a connecting piece, a double nut and an insulating base; the antenna steel rope is inserted into a screw through hole and a tail end of the antenna steel rope is welded inside a tail end opening of the hollow screw; the connecting piece is tightly fixed on an insulating seat through the bush and the double nut; the antenna mounting matching box comprises an antenna matching box cover plate, an antenna matching box shell, an antenna matching box bottom plate and the insulating base; the antenna matching box cover plate is arranged above the antenna matching box shell; the antenna matching box bottom plate is arranged below the antenna matching box shell with use of a blind hole; and the special spanner comprises a handle, a groove, a convex column, and is used to prevent the hollow screw from rotating in tightening the double nut. The airborne remote antenna mounting device of the invention is capable of overcoming such defects in the airborne remote antenna mounting process that the space position is small and the antenna steel rope is easily disengaged under the external force.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

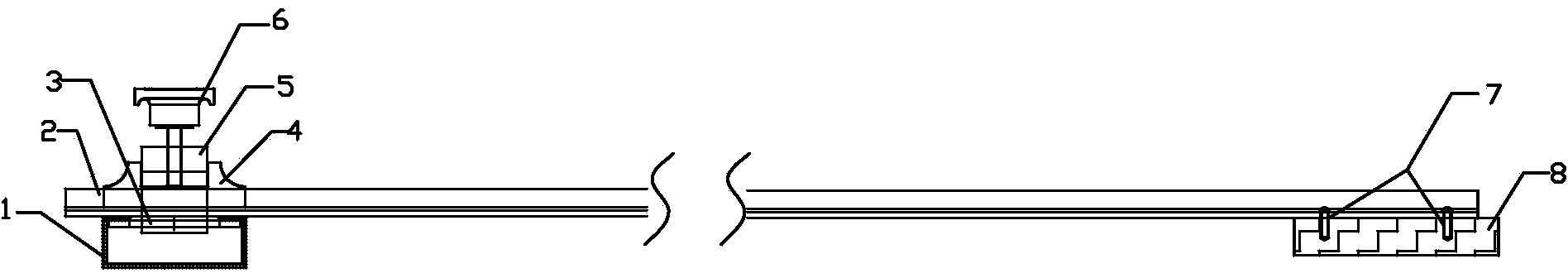

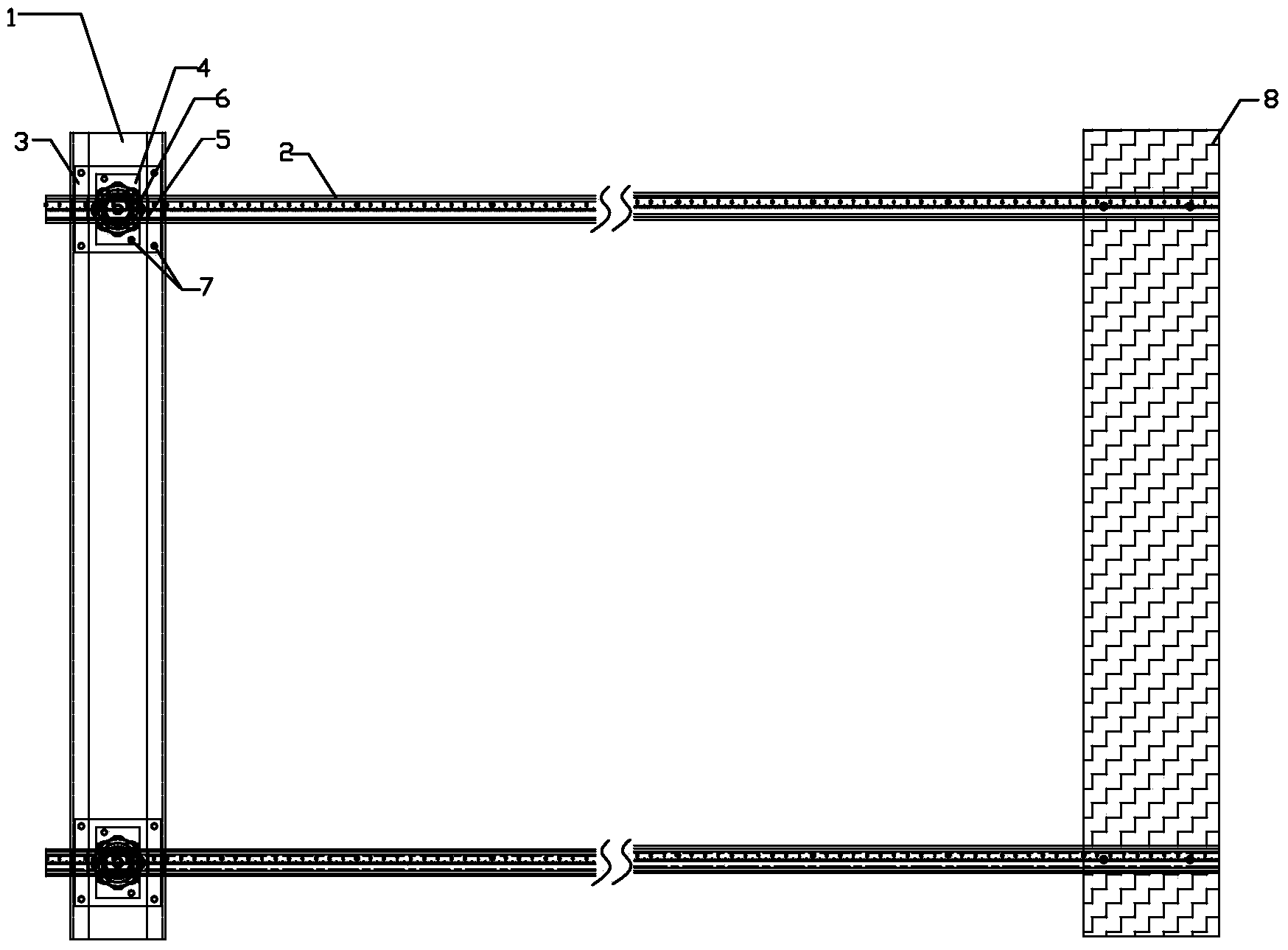

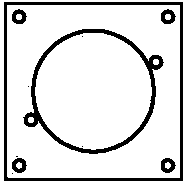

Movable boring device for tail wheel bracket of large towing winch

InactiveCN102151873AGuaranteed coaxialityGuaranteed parallelBoring/drilling componentsBoring/drilling machinesEconomic benefitsWinch

The invention relates to a movable boring device for a tail wheel bracket of a large towing winch, which is used for processing the tail wheel bracket of the large towing winch which requires higher coaxiality and is inconvenient to move. The movable boring device has the characteristics of simple and movable structure. According to the movable boring device, the coaxial holes of the tail wheel bracket of the towing winch can be processed conveniently and quickly, the cost for purchasing large machine tools and the cost during processing can be saved, the production cost is lowered, and further larger economic benefits can be created.

Owner:TIANJIN RUICHI SHIPPING MACHINERY

Corner building block for building three-dimensional structure

Owner:四川善晟建筑智能化工程有限公司

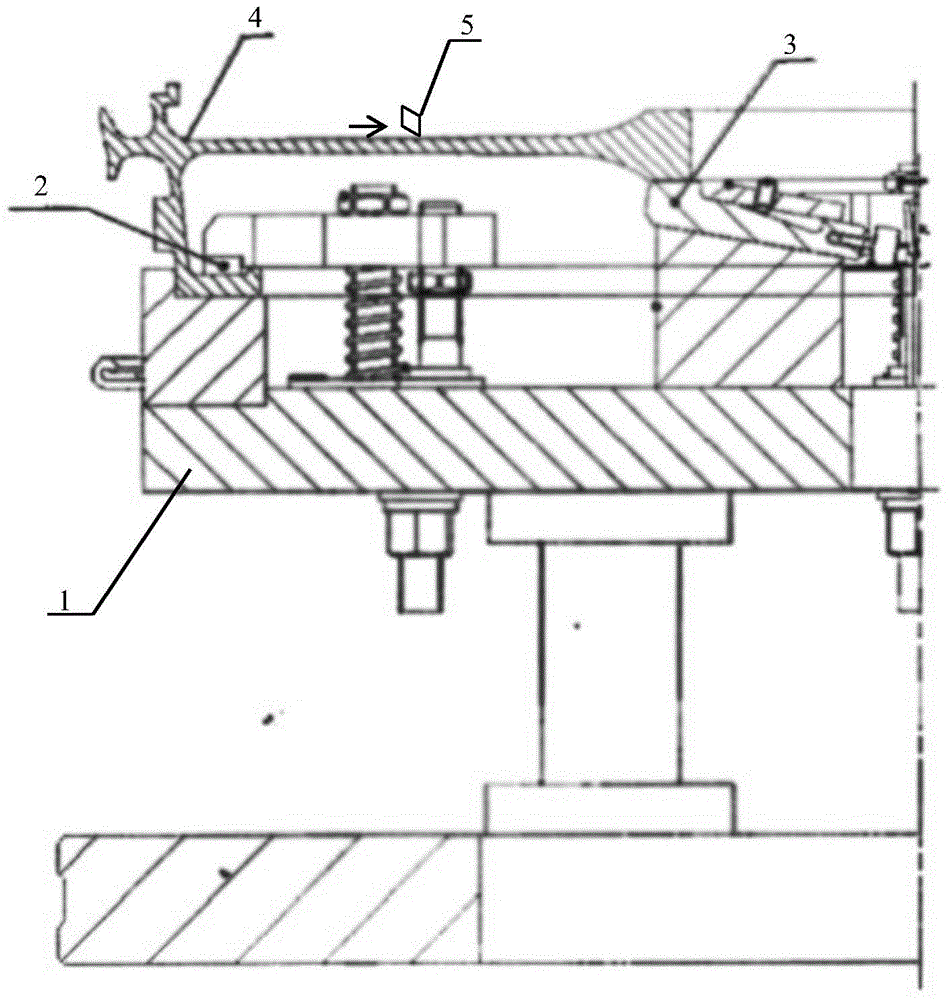

Special tool for milling and processing K2 side bearing axial trough

ActiveCN103056685AAvoid frettingEasy to fixPositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

The invention discloses a special tool for milling and processing a K2 side bearing axial trough and belongs to the technical field of a mechanical processing tool. The tool comprises a recessed base of which the upper surface is provided with an opening, an upper tapered wedge and a lower tapered wedge are arranged in the base, two slopes of the upper tapered wedge and the lower tapered wedge are matched, left sides and right sides of the upper tapered wedge and the lower tapered wedge are matched with the inner surface of the vertical end plate of the base, a pressing plate and an upper limiting mechanism which limits the motion of the pressing plate are arranged on the upper portion of the upper tapered wedge, and the side of the lower tapered wedge is connected to a piston rod of a cylinder, which is arranged on the outer wall of the base. During the process of the K2 side bearing, the detection and classification process of the trough vertical face is omitted, the processing efficiency is improved, the assisting time is saved, the labor intensity is reduced, the efficacy is improved, and the processing quality is guaranteed.

Owner:CRRC SHIJIAZHUANG CO LTD

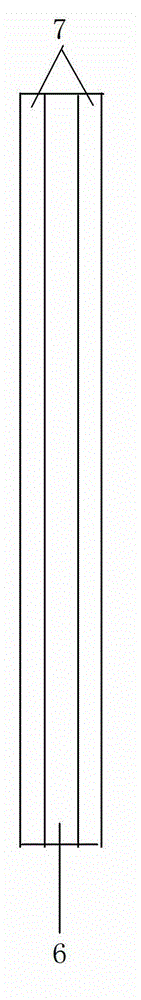

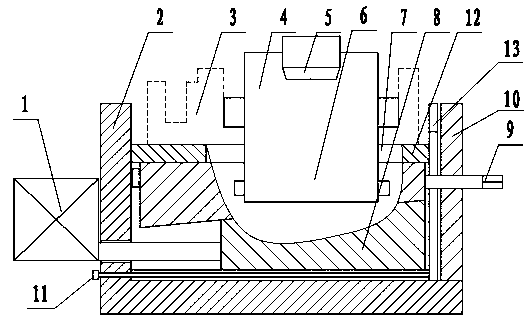

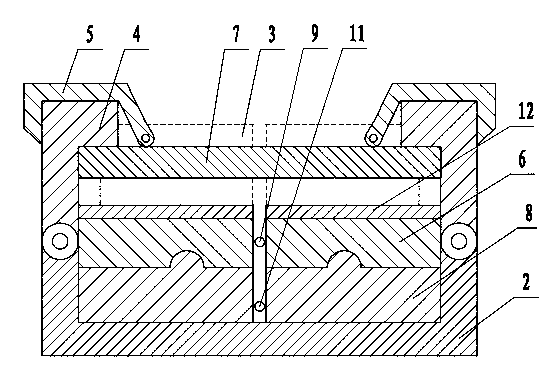

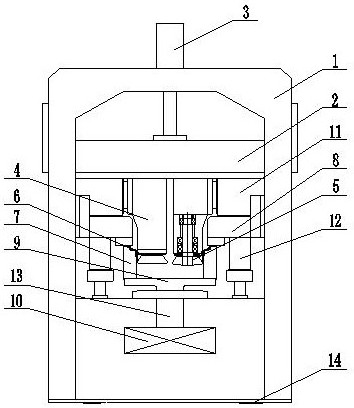

Die for machining powder metallurgy multi-step part

InactiveCN104368810APrecise processing sizeReduce manufacturing costPowder metallurgyBiomedical engineering

The invention discloses a die for machining a powder metallurgy multi-step part. The die comprises a female die and a puncher pin die assembly. The female die comprises a female die body and a die sleeve for fixing the part. A first through hole is formed in the die sleeve. The puncher pin die assembly comprises a first puncher pin die, a second puncher pin die, a third puncher pin die, a fourth puncher pin die and a fifth puncher pin die, wherein the second puncher pin die is located above the first through hole and provided with a second through hole which the first puncher pin die is allowed to enter, the third puncher pin die is located below the first through hole and provided with a third through hole which the fourth puncher pin die is allowed to enter, and the fourth puncher pin die is provided with a fourth through hole which the fifth puncher pin die is allowed to enter. According to the die, the powder metallurgy multi-step part can be simultaneously machined and formed at a time, the machining size is precise, and the cost is reduced.

Owner:TAICANG JINLIDE POWDER METALLURGY

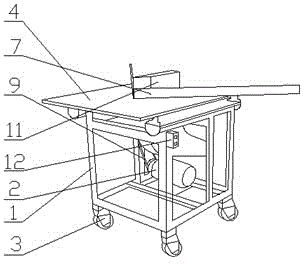

45-degree corner cutting device for New Year picture mounting frame

The invention discloses a 45-degree corner cutting device for a New Year picture mounting frame, and relates to the field of woodworking equipment. The 45-degree corner cutting device comprises a rack, a motor, lockable universal wheels, a workbench, a sliding guide rail, sliding blocks, limiting blocks, longitudinal ribbed plates, a belt, a saw web, a protection cover and a switch. The 45-degree corner cutting device is characterized in that blue paint is sprayed to the rack, the lockable universal wheels are arranged at the bottom of the rack, the sliding guide rail is arranged at the upper portion of the rack and connected with the rack through screws, and the sliding guide rail is provided with the sliding blocks; the workbench is located above the sliding blocks and connected with the limiting blocks, and the limiting blocks are provided with scales; and the motor is fixed in the rack through bolts. The 45-degree corner cutting device is novel in structure, convenient to operate and suitable for conducting inclined cutting on the New Year picture mounting frame, a cross-stitch frame, a photo frame, a wood strip, furniture, a plastic strip and a door frame.

Owner:TIANJIN XIANGYUAN SCI & TECH

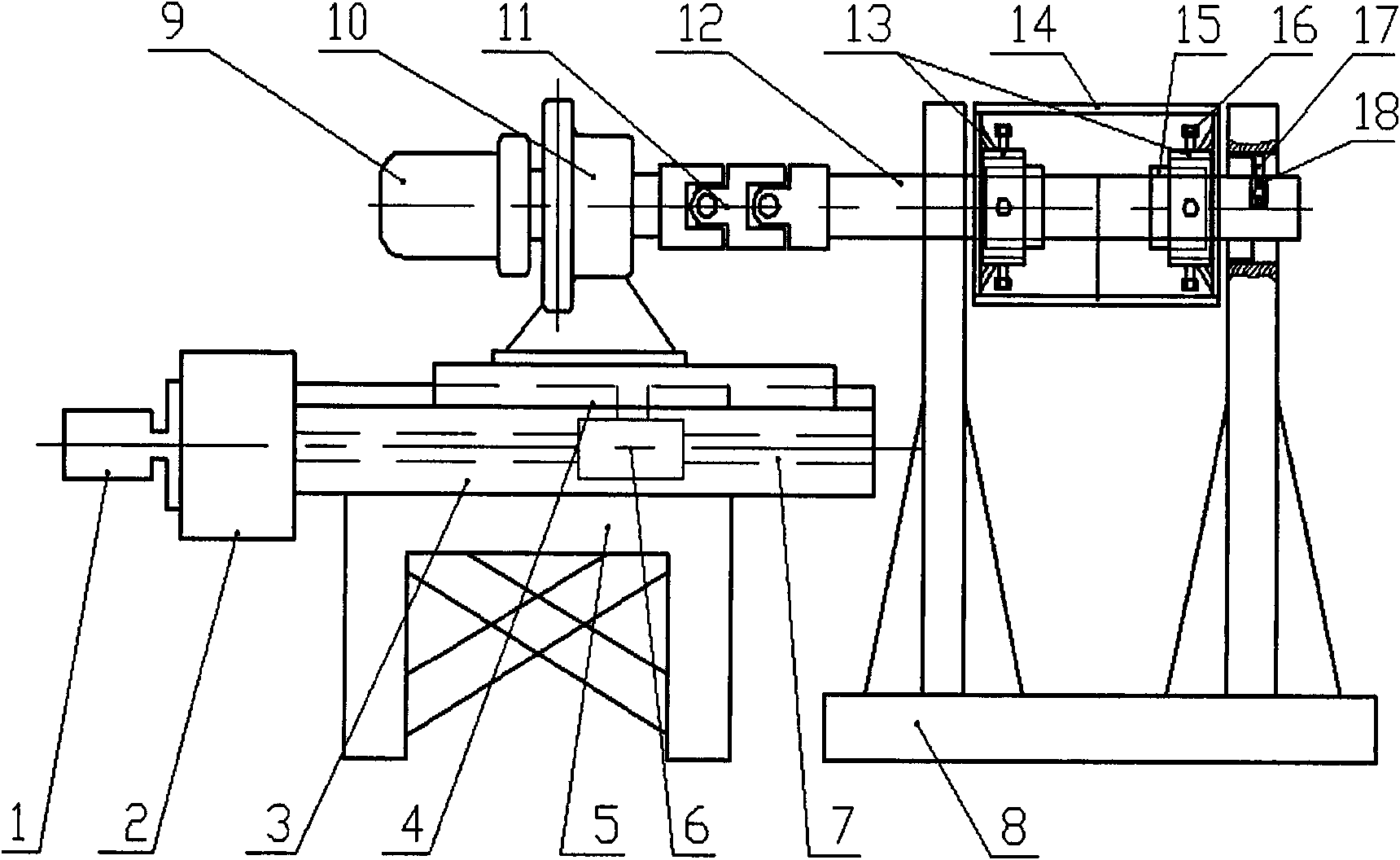

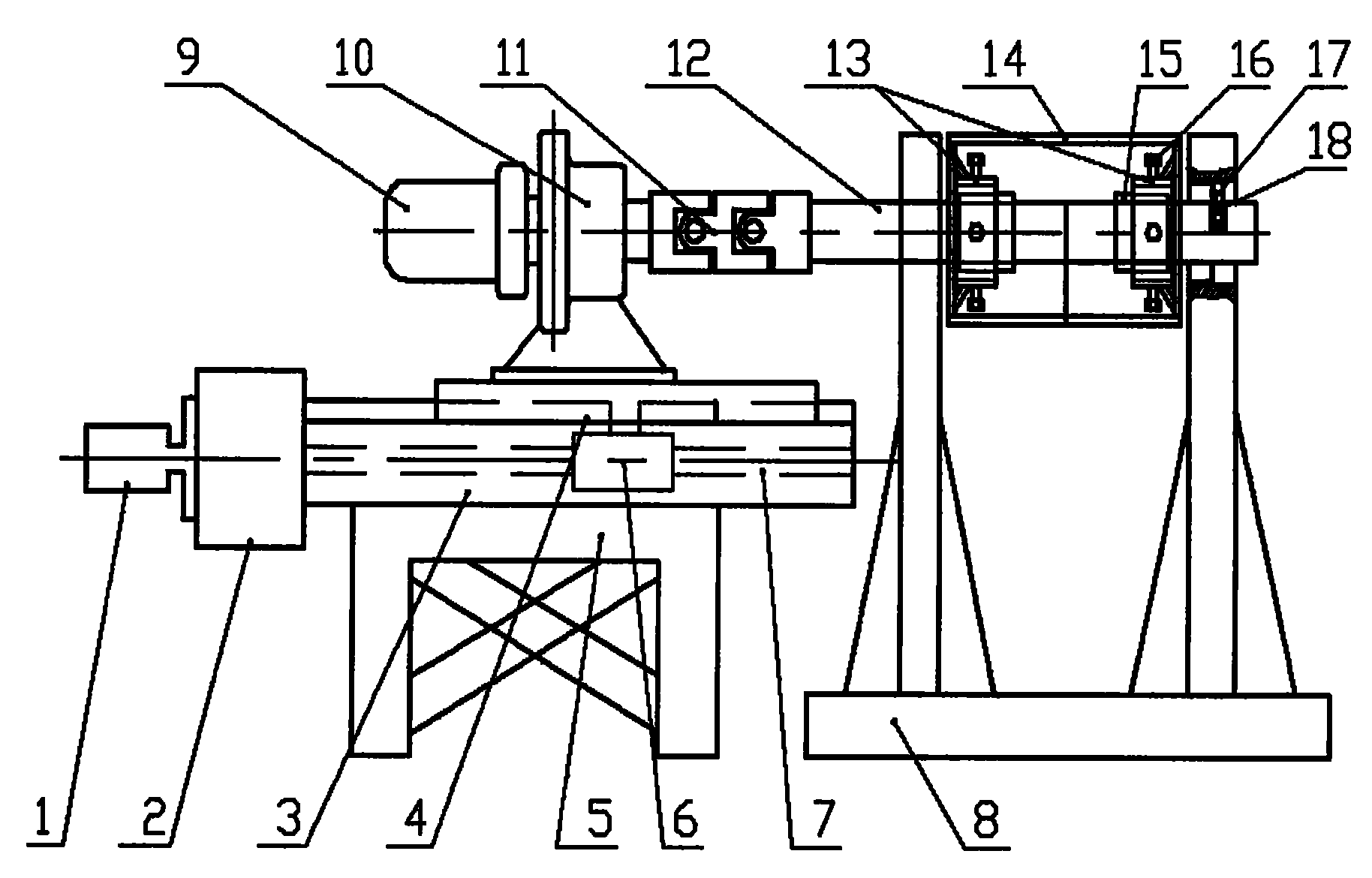

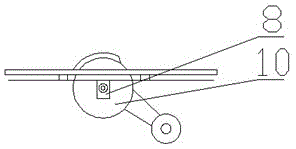

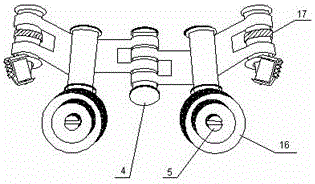

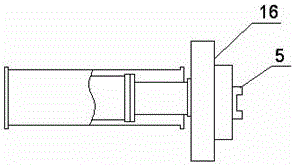

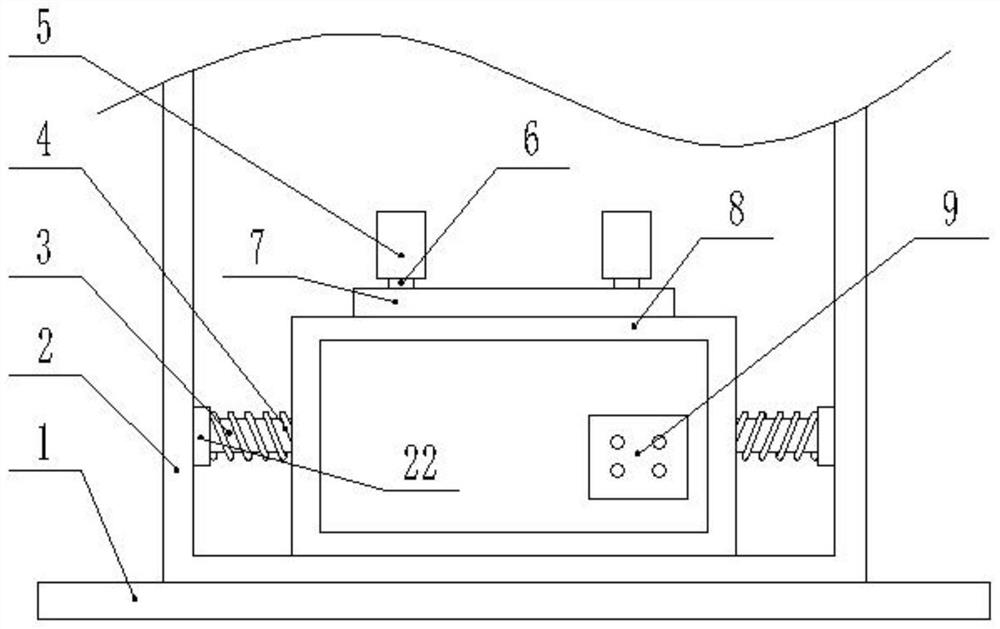

Profile bending machine

The invention relates a profile bending machine. The profile bending machine comprises a machine body, a working roll device, carrier roll devices and a transmission system, wherein the transmission system is connected with the working roll device and the carrier roll devices to provide power; three working rolls of the working roll device are driving rolls; and telescopic cylinders installed in working roll shaft sleeves drive molds at the front ends of the working rolls to make telescopic movement. According to the profile bending machine, through matched movement of the carrier roll device and the working roll device, a plurality of types of profiles can share one machine, the machining accuracy is high, the equipment size is small, and operation is convenient.

Owner:ANHUI SANXIN HEAVY IND MACHINERY MFG

Corner building block for building three-dimensional structure

Owner:四川善晟建筑智能化工程有限公司

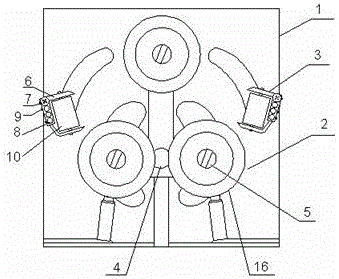

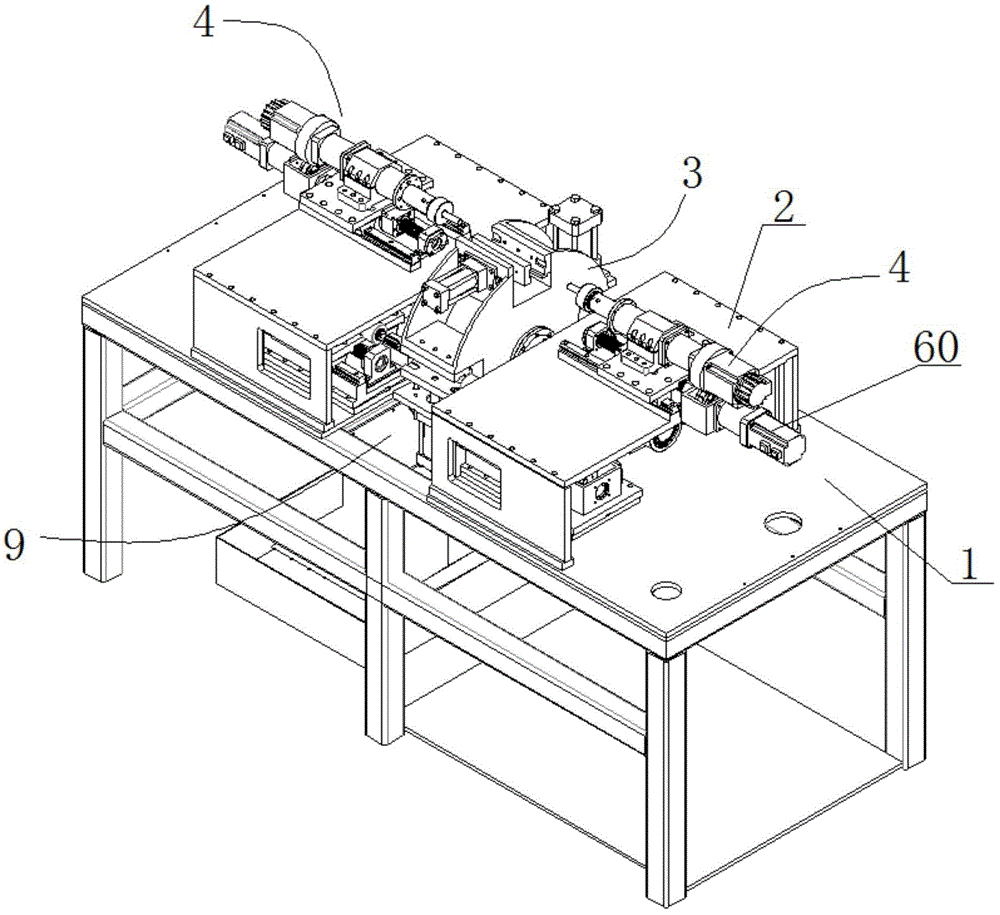

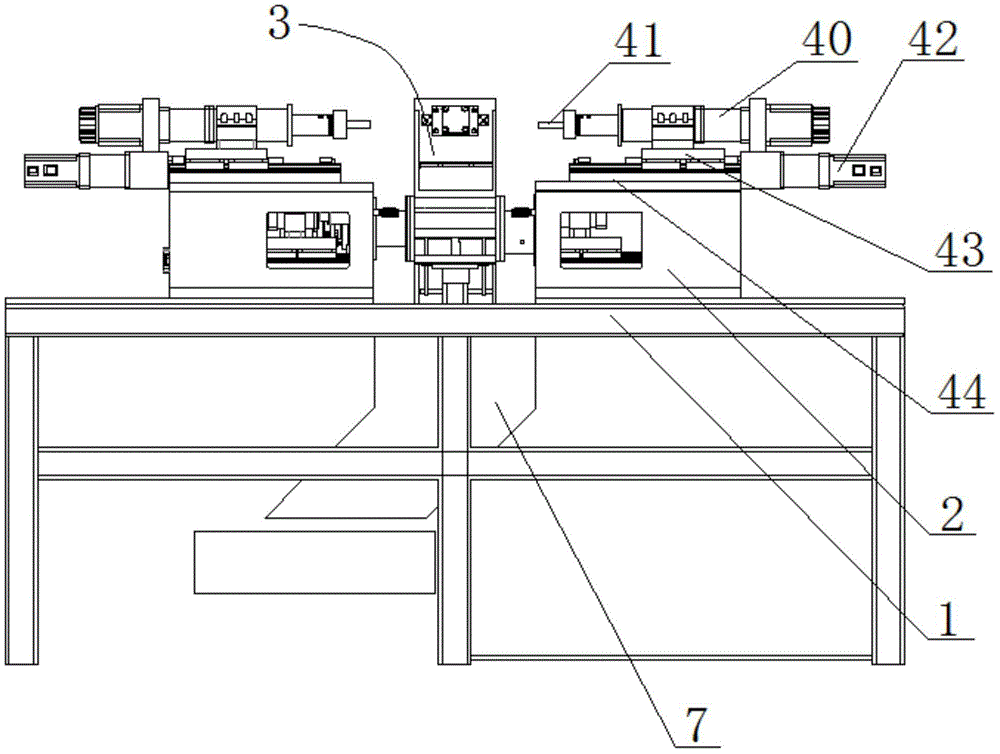

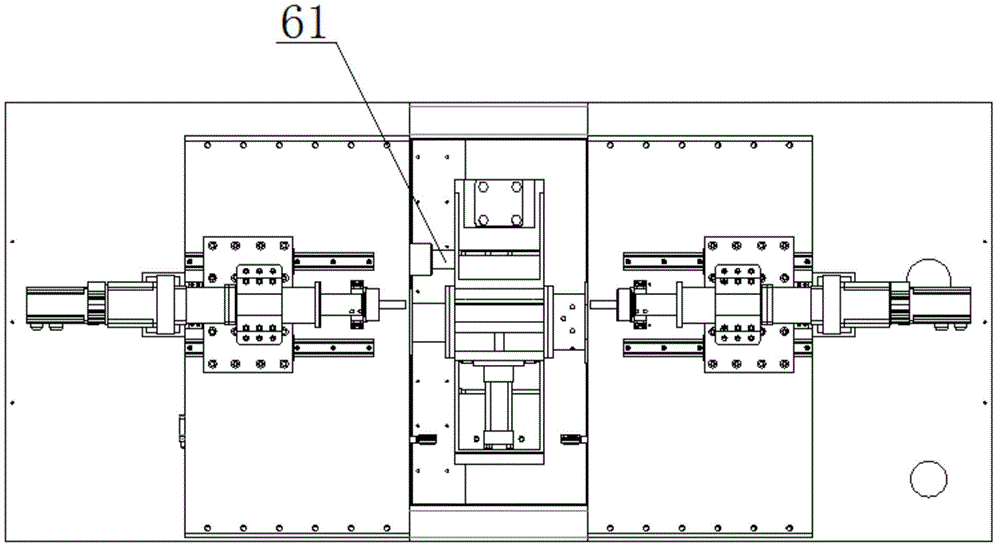

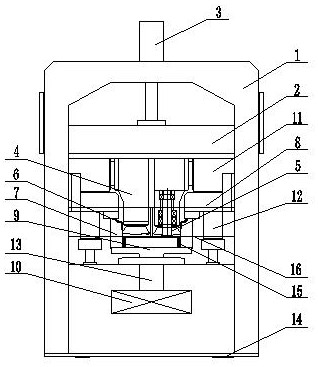

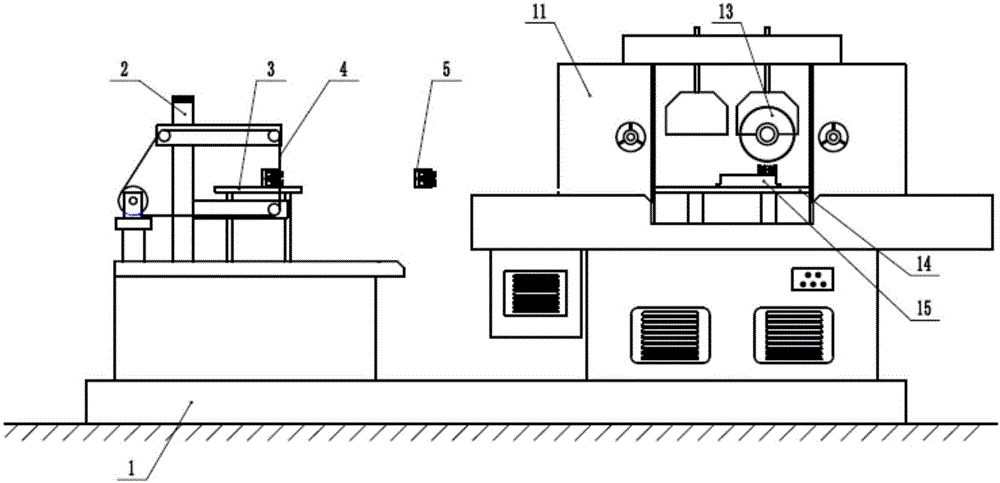

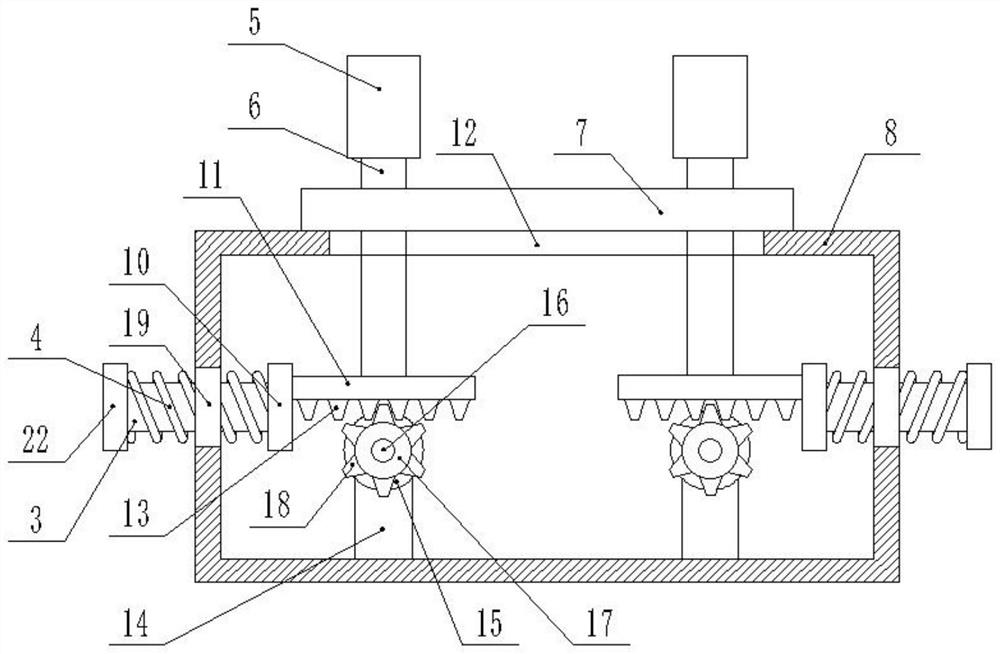

A kind of flower basket nut processing equipment

ActiveCN104308541BLower requirementImprove efficiencyOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention relates to a flower basket nut processing device comprising a rack, two bearing station, a position switching portion used for fixing and switching a workpiece, two drilling portions used for opening an through hole on an end portion of a flower basket nut, two tapping portions used for tapping the through hole on the end portion of the flower basket nut, and an output channel; an open slot is arranged in the middle of the rack; the two bearing stations fixedly connected on the rack are respectively disposed on the left and right side of the open slot; the position switching portion is arranged between the two bearing stations; the two drilling portions mounted on the bearing stations are radially located on the left and right side of the open slot; the two tapping portions arranged on the rack are radially positioned on the left and right side of the open slot; the output channel is fixedly connected to the bottom of a working surface of the rack; a top opening of the output channel is located on the open slot. The flower basket nut processing device has the advantages that the device is not necessary to stop for the clamping and removing of the workpiece; efficiency is high; processing size is accurate; low requirements are needed for operators; labor intensity is low.

Owner:青岛金年华机电制造有限公司

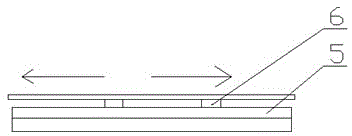

Positioning device for woodworker sawing machine to fast cut batten

The invention discloses a positioning device for a woodworker sawing machine to fast cut a batten. The positioning device comprises a fixing trough plate; connection plates are respectively arranged at two ends of the fixing trough plate; a movable positioning ruler is arranged on each connection plate; each positioning ruler is provided with a connection seat I for tightly compressing the positioning ruler onto the corresponding connection plate; each connection seat I is provided with a connection seat II; each connection seat II is provided with a trough end surface with a downward opening and clamps two side end surfaces of the corresponding connection seat I by the trough end surface; the bottom of the trough end surface of each connection seat II is provided with an edge connected with the corresponding connection plate; the initial ends of the two positioning rulers are fixed on one playwood. By the positioning device, a cutting operator can be helped to fast position and cut the batten, the machining size is accurate, the cutting quality is favorably improved, and the positioning device is particularly suitable for the cutting machining in batch, and an enterprise is helped to save production cost and improve the competitiveness.

Owner:JIANGMEN NANYANG SHIP ENG

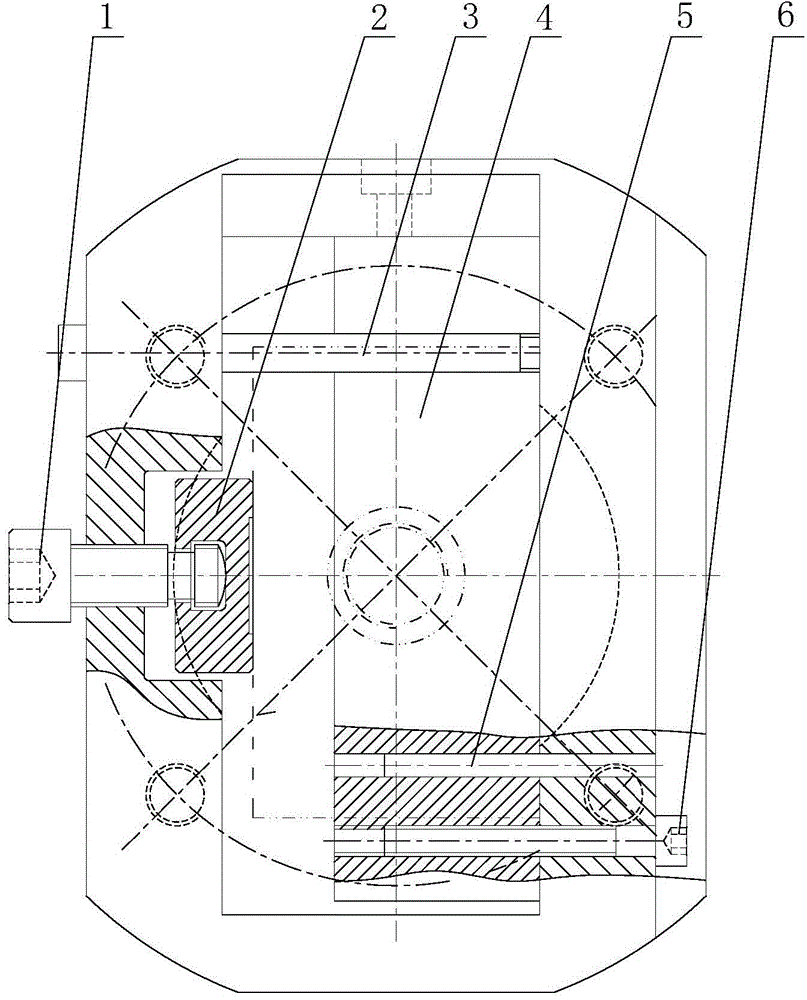

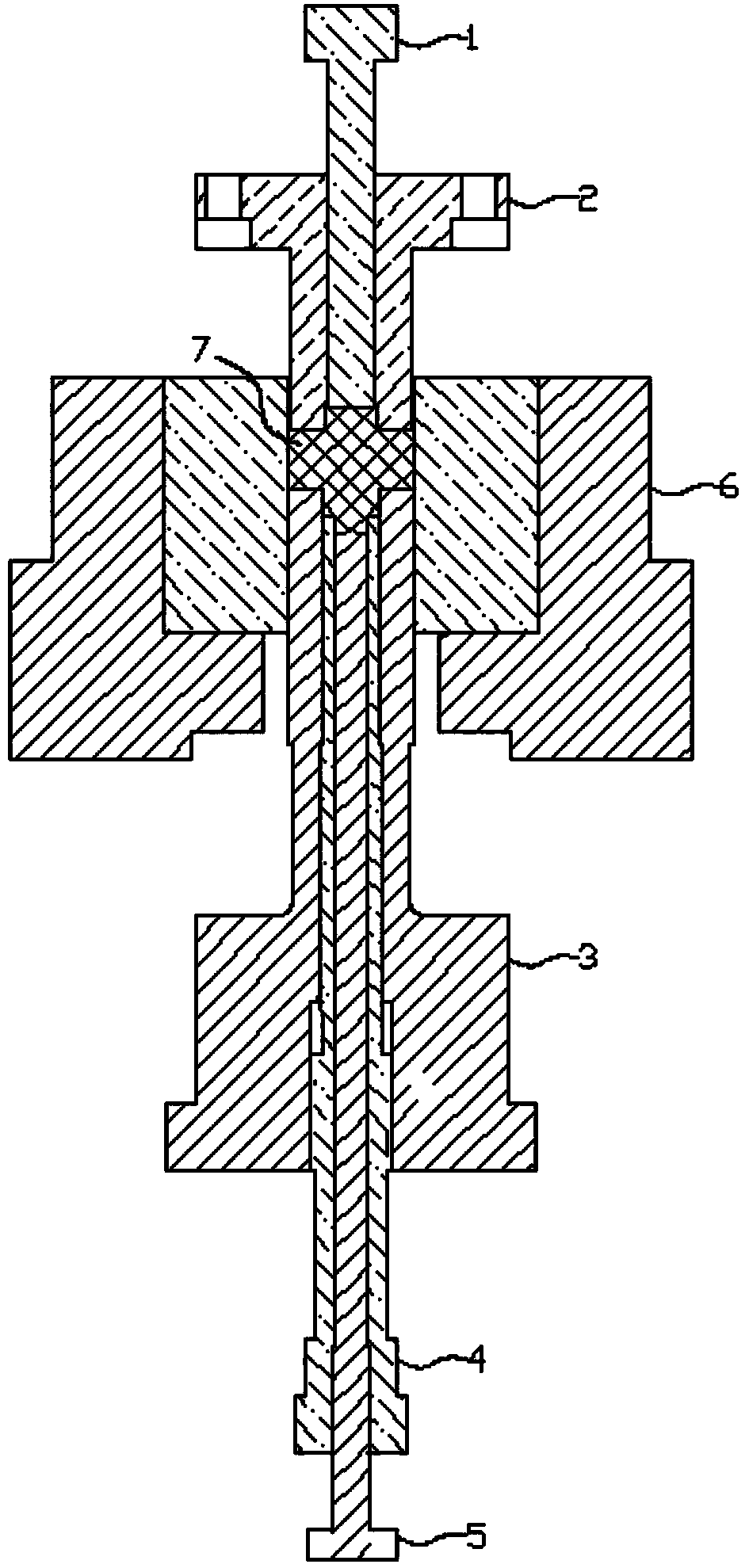

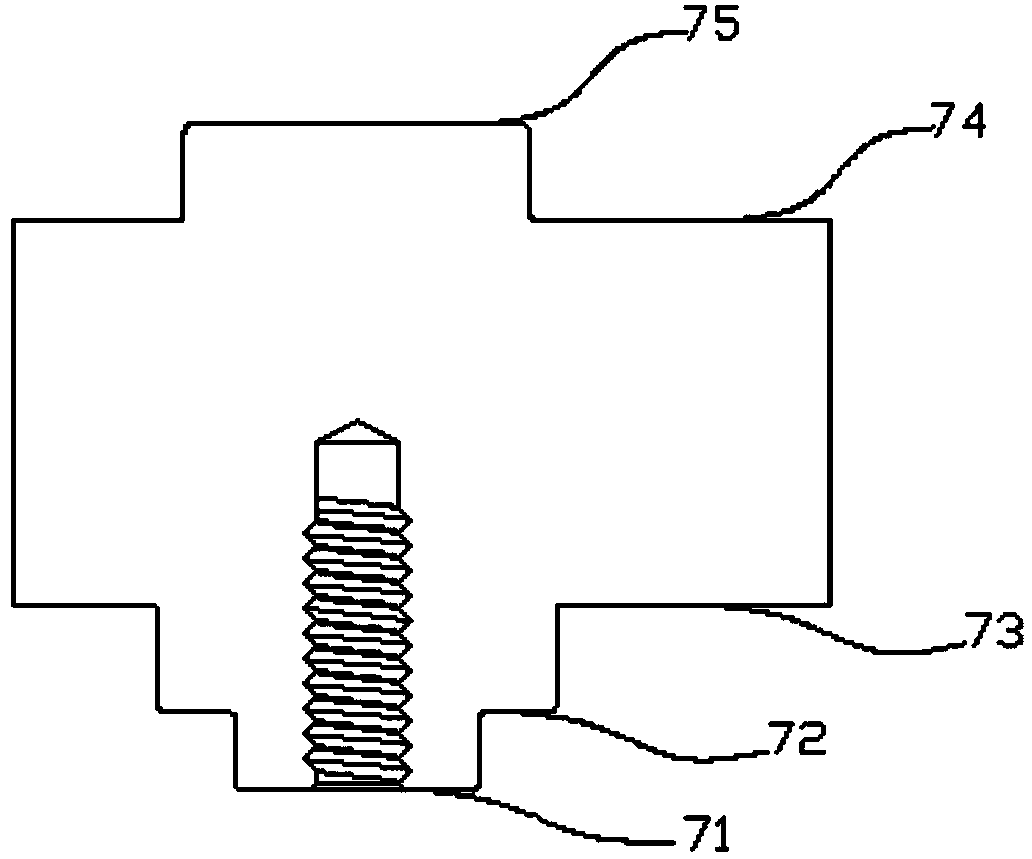

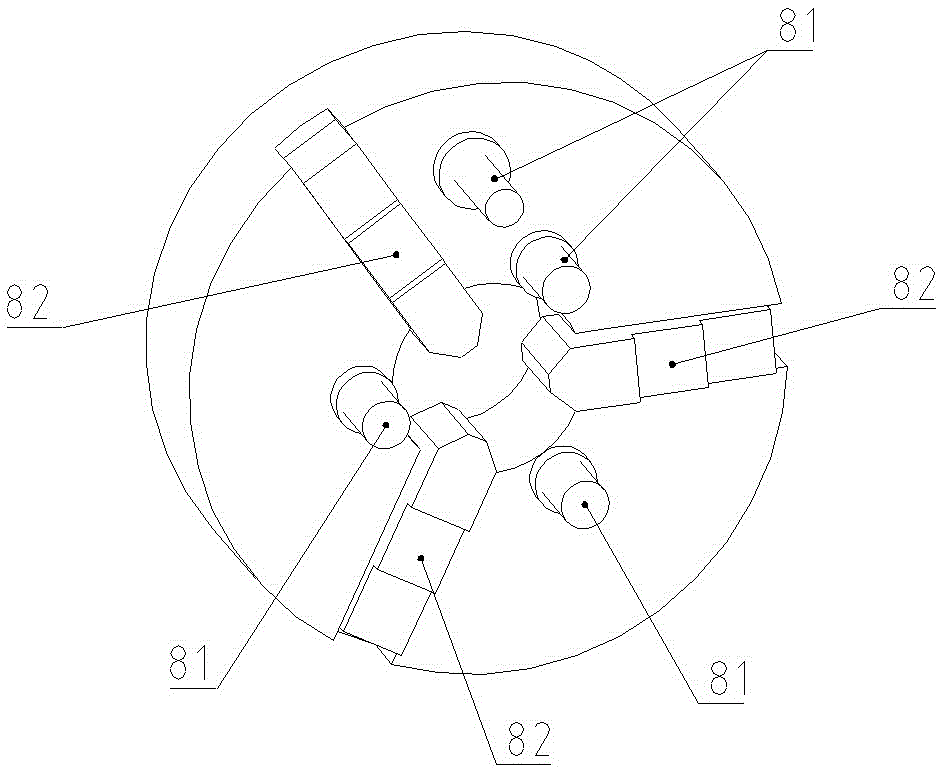

Clamp for rotation milling machining of gas compressor blade profile

ActiveCN106513801APrevent relative rotationGuaranteed processing sizeMilling equipment detailsBlade handleLocknut

The invention provides for a clamp for rotation milling machining of a gas compressor blade profile. The clamp for rotation milling machining of the gas compressor blade profile can solve the problems that when a common three-jaw chuck is adopted, blade clamping is not stable, and the machining size is out of tolerance. The clamp for rotation milling machining of the gas compressor blade profile comprises a rotation disk which is fixedly provided with a clamp body; a blade handle portion positioning and clamping assembly is installed on the clamp body and comprises a pressing plate and a positioning base fastened and installed on the clamp body; the positioning base is provided with a V-shaped positioning groove; one outer side end, located on the V-shaped positioning groove, of the positioning base is provided with a supporting block;, and the other outer side end is provided with a locking threaded rod; one end of the pressing plate is movably connected with the supporting block, and the other end of the pressing plate is fastened on the locking threaded rod through a locking nut; an inverted-V-shaped pressing block is arranged at the bottom of the pressing plate; and the inverted-V-shaped pressing block and the V-shaped positioning groove are right opposite to each other in an up-down manner.

Owner:WUXI TURBINE BLADE

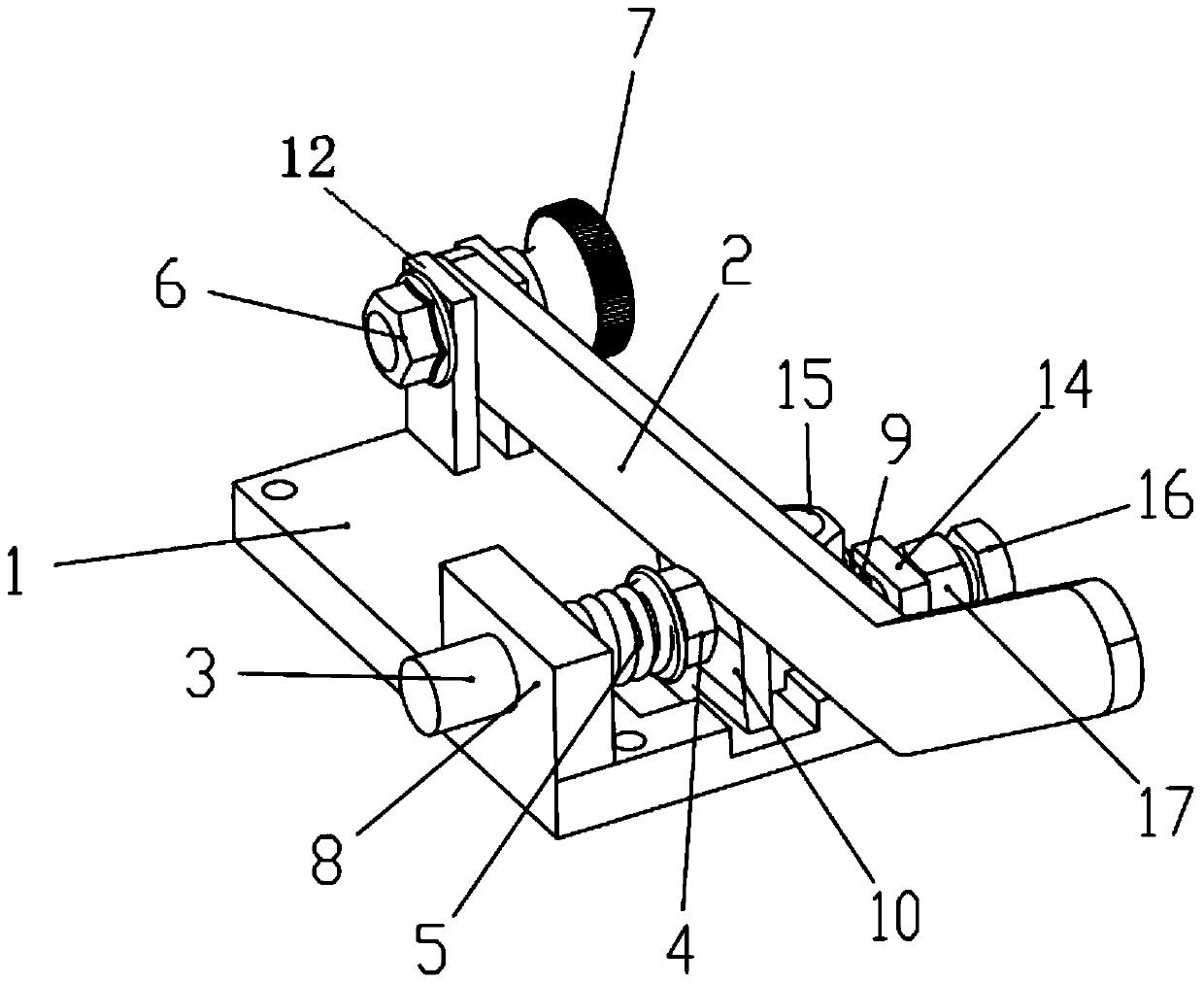

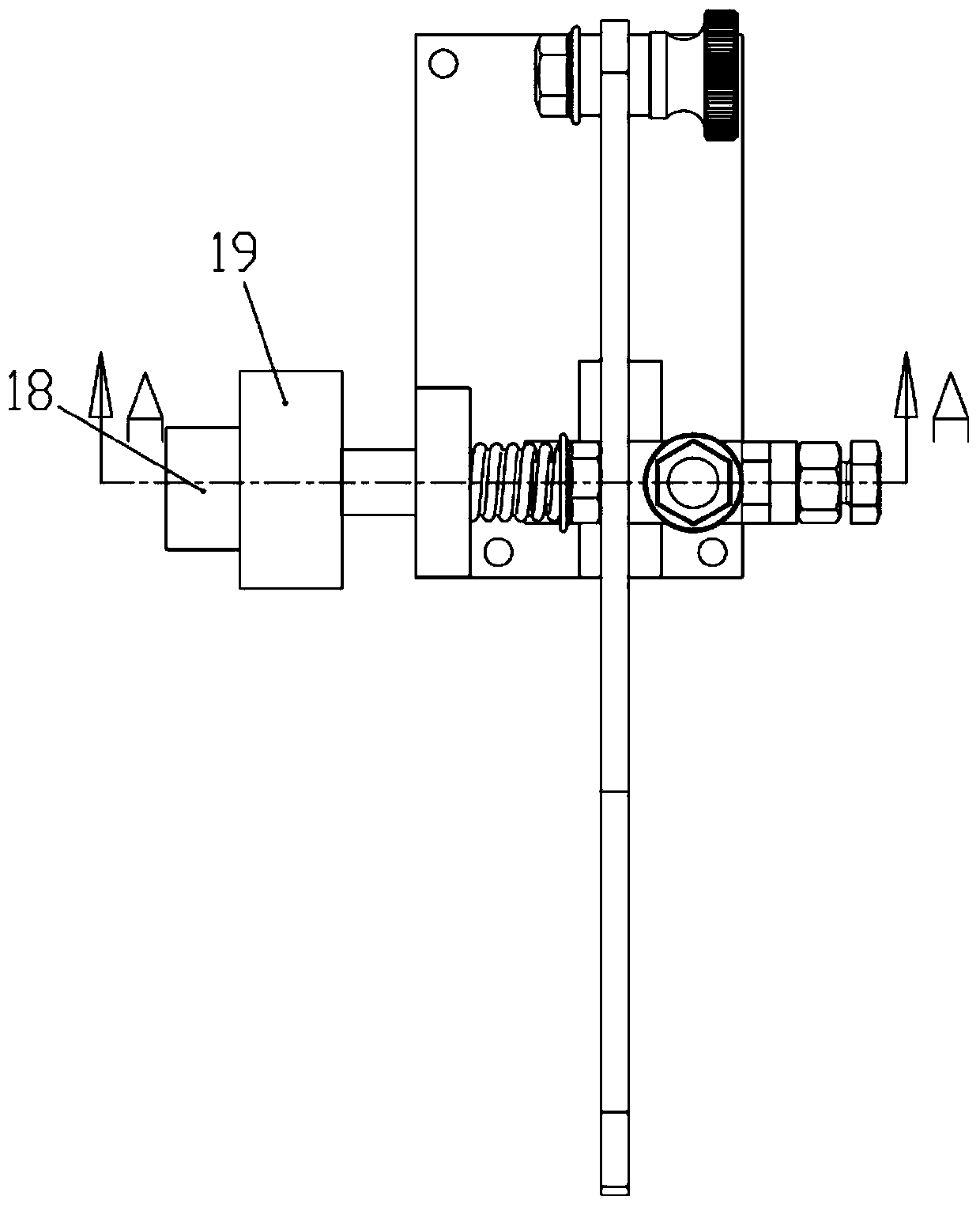

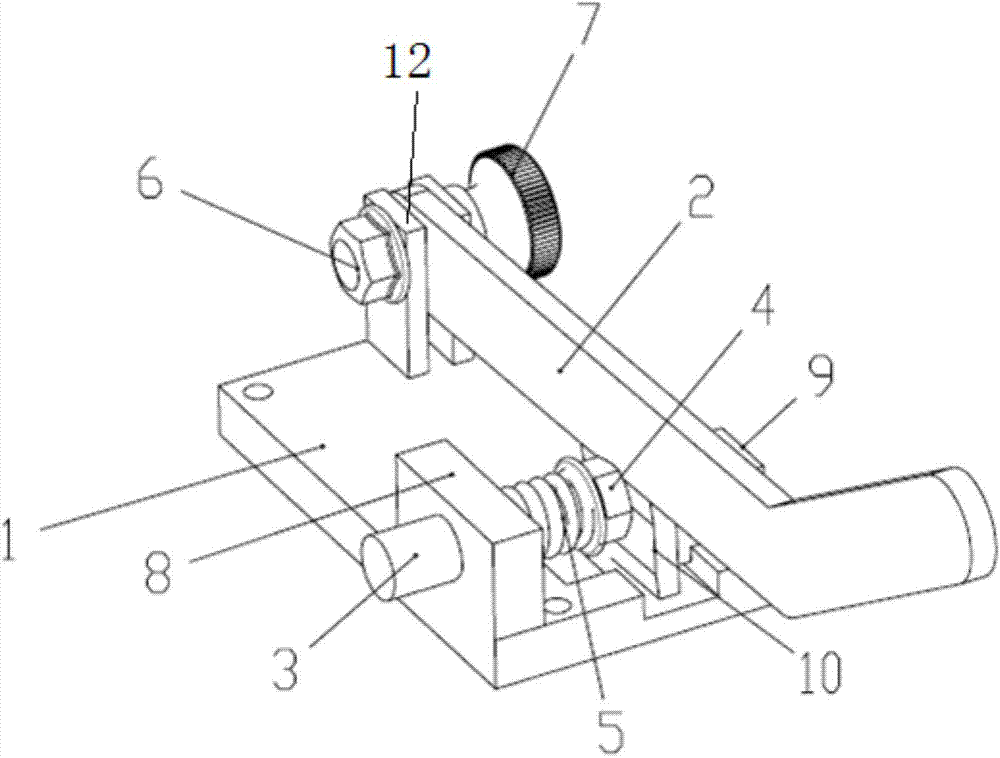

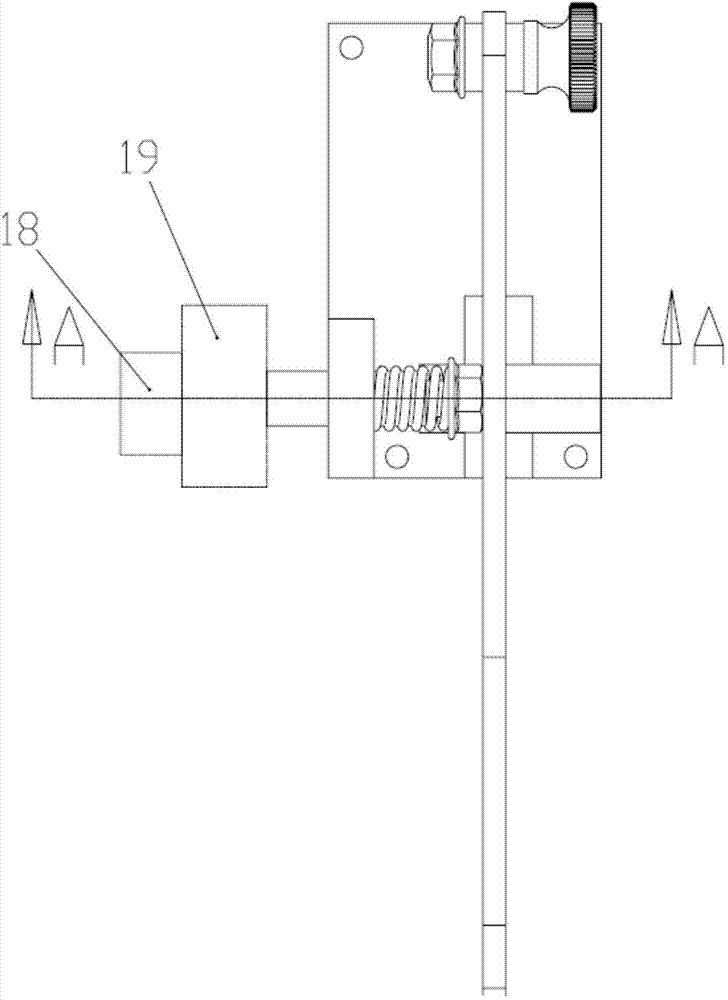

Quick workpiece positioning and clamping device capable of adjusting clamping force

InactiveCN103769788AQuick positioning clampingPrecise processing sizeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a quick workpiece positioning and clamping device capable of adjusting the clamping force. A shaft seat is arranged at the rear end on the upper surface of a base; a guide seat is arranged on one side of the front end, and the upper surface of the other side of the front end is connected with a rear fixed baffle in an adjustable manner through a locking screw; an adjustment boss is arranged on the rear end face of the base; an adjustment screw is arranged between the adjustment boss and the rear fixed baffle; the interior of the guide seat is movably connected with a guide shaft; a distance adjustment bolt is screwed into the rear end of the guide shaft; the rear end of a clamping handle is connected with the shaft seat through a bolt and an adjustment nut; a clamping plate is arranged at the lower end of the clamping handle; an upper wedged surface and a lower wedged surface are arranged on the head contact area of the clamping plate and the distance adjustment bolt; a compression spring is arranged between the distance adjustment bolt and the guide seat. The quick workpiece positioning and clamping device can quickly position and clamp a workpiece through the clamping handle; due to the upper wedged surface and the lower wedged surface on the clamping plate of the clamping handle, fine adjustment on the positioning position and the clamping force is realized; the clamping force on the clamped workpiece can be adjusted by adjusting the position of the rear fixed baffle; the compression spring is used for eliminating an adjustment clearance and resetting the guide shaft.

Owner:陈敏蓉

Turning technique for long spoke portion of integral impeller

The invention provides a turning technique for a long spoke portion of an integral impeller and belongs to the technical field of machine manufacturing. The turning technique comprises the following steps that firstly, a novel clamp is used for clamping a part; secondly, a rhombus cutter is used for conducting turning from inside to outside, and turning is conducted according to the processes of rough turning, primary semi-fine turning, secondary semi-fine turning and fine turning. The novel clamp used in the first step comprises a machine frame. A reversely hooking compressing block and an auxiliary supporting block are arranged on the machine frame, wherein the reversely hooking compressing block can be matched with the outer edge of the long spoke portion of the integral impeller, and the auxiliary supporting block can be matched with the spoke navel portion of the long spoke portion of the integral impeller. By the adoption of the turning technique for the long spoke portion of the integral impeller, the machined long spoke portion of the integral impeller is high in machining quality and accurate in machining size.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

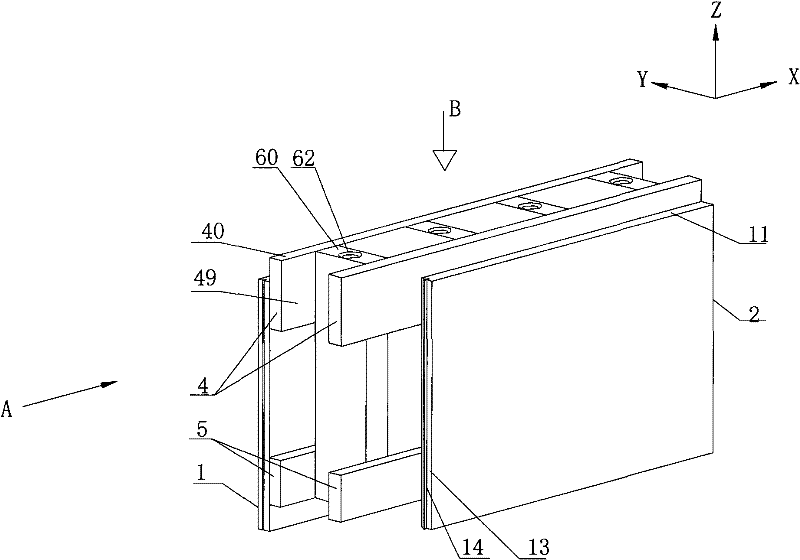

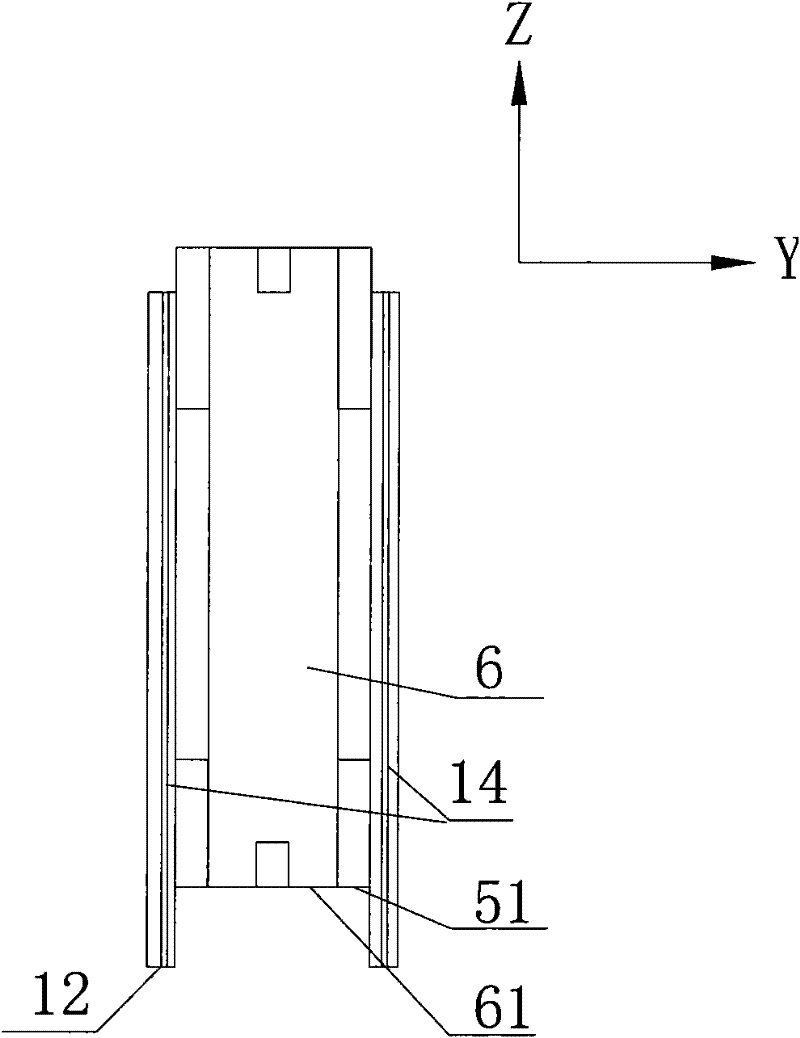

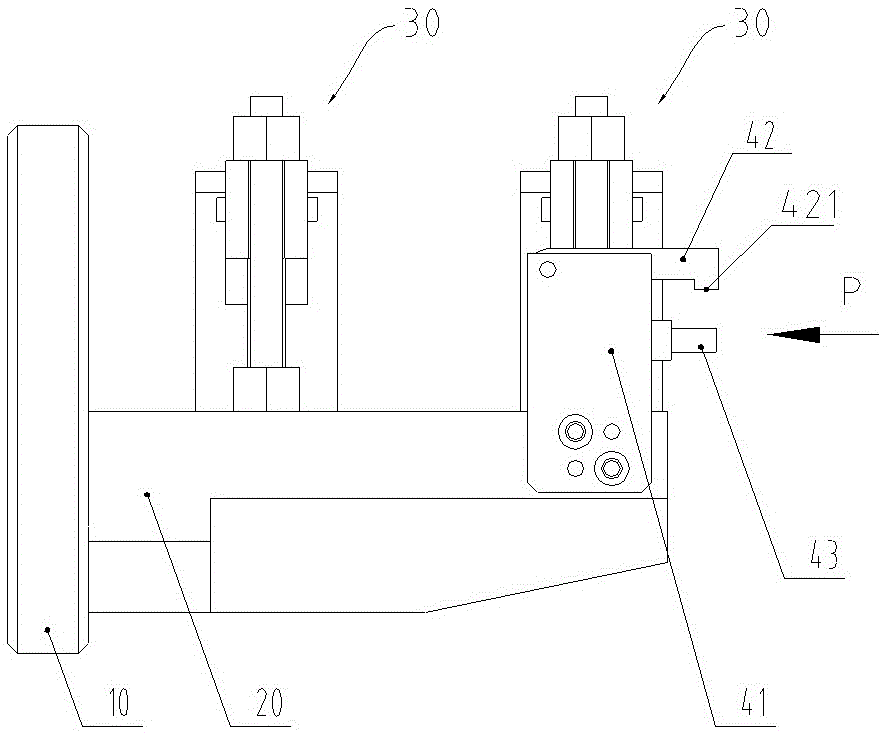

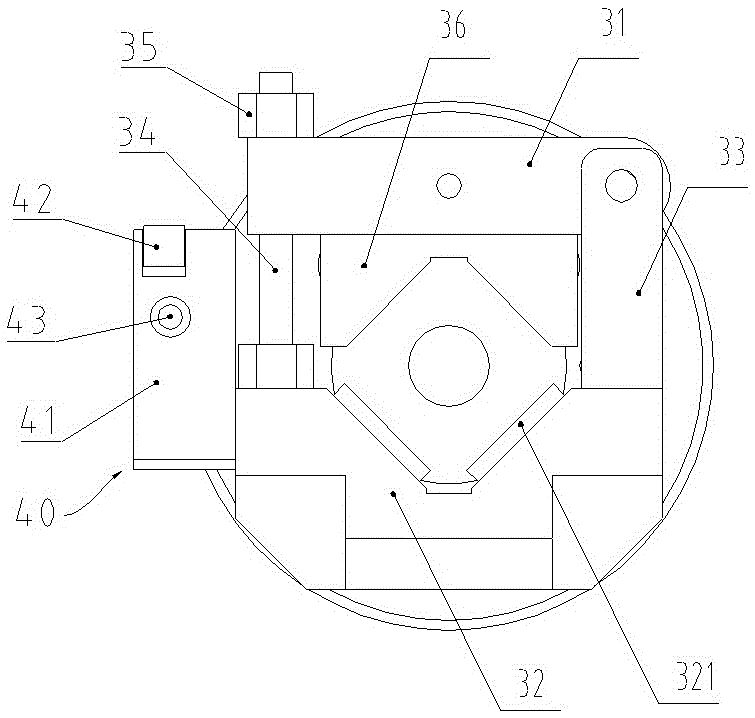

Universal internal rotation machine device for engineering wheels and machining method thereof

PendingCN112845784ACompact structurePrecise processing sizeMetal-working feeding devicesRimsPhysicsAutomatic control

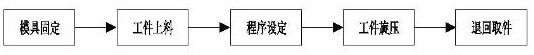

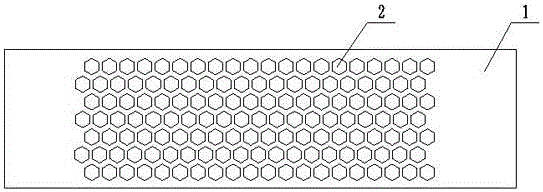

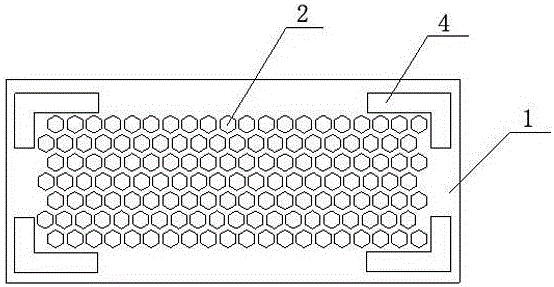

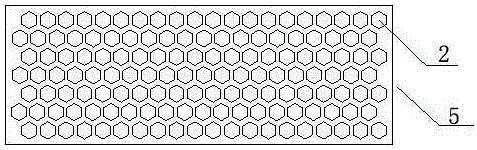

The invention provides a universal internal rotation machine device for engineering wheels. The universal internal rotation machine device for engineering wheels comprises a frame, a sliding block, a spinning roller mechanism, a pressing mechanism and a rotating platform are arranged in the frame, and the upper end of the sliding block is connected with an axial feeding mechanism. The lower end of the sliding block is connected with the spinning roller mechanism, and a spinning roller is arranged at the bottom of the spinning roller mechanism. A mold is fixed on the rotating platform, and the rotating platform is connected with a transmission mechanism through a main shaft. The pressing mechanism is connected with a pressing cylinder, and a workpiece is fixed in the mold through the pressing mechanism. The spinning roller mechanism is further connected with a radial feeding mechanism, and the axial feeding mechanism and the radial feeding mechanism are matched with an automatic control numerical control system to achieve feeding machining according to a product curve. The invention further provides a method for machining wheels through the universal internal rotation machine device for engineering wheels. The method specifically comprises the steps of mold fixing, feeding, spinning roller internal spinning, returning and workpiece taking and the like, unequal-thickness extension machining on engineering wheels can be completed, and the universal internal rotation machine device can be widely applied to the field of machining of rims of engineering wheels.

Owner:杭州润德车轮制造有限公司

Machining method for hard surface of screw drill and device for achieving method

ActiveCN105089518AImprove compactnessImprove wear resistanceDrilling rodsDrilling casingsAdhesive beltCurve shape

The invention provides a machining method for the hard surface of a screw drill and a device for achieving the method. Firstly, it is creatively designed that the shape of hard alloy bars is not square, gaps between the hard alloy bars are in a curve shape, in other words, welding lines are in a curve shape, so that most action force is decomposed to the hard alloy bars when erosion of slurry and drilling fluid occurs, and the abrasion resistance of a centering device and a TC bearing is improved. A device positioning trough plate adaptive to fast forming of the hard surface of the screw drill through the hard alloy bars is further provided, trough holes are formed in the positioning trough plate, and the shape of the trough holes is not square and is matched with that of the hard alloy bars. The positioning trough plate is used for orderly and evenly arranging the hard alloy bars as required, bonding of the mass hard alloy bars at a time is simply and easily achieved with the combination use of adhesive tape, the bonding efficiency is greatly improved, the situations that in manual operation, bonding angles are not uniform, the bonding intervals are not even are relieved, the bonding accuracy is improved, and the abrasion resistance of the hard surface of the product is effectively guaranteed and improved.

Owner:株洲金韦硬质合金有限公司

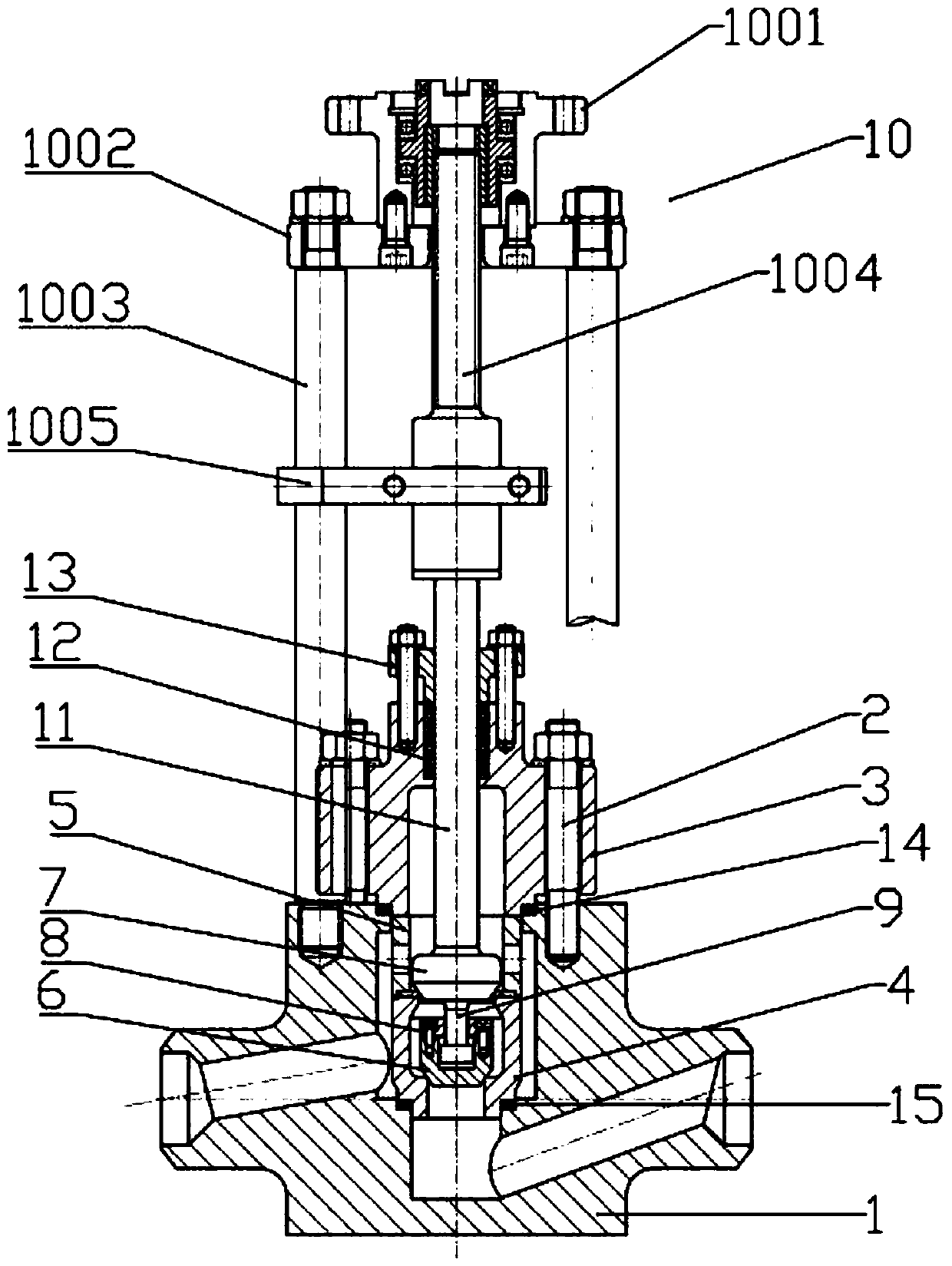

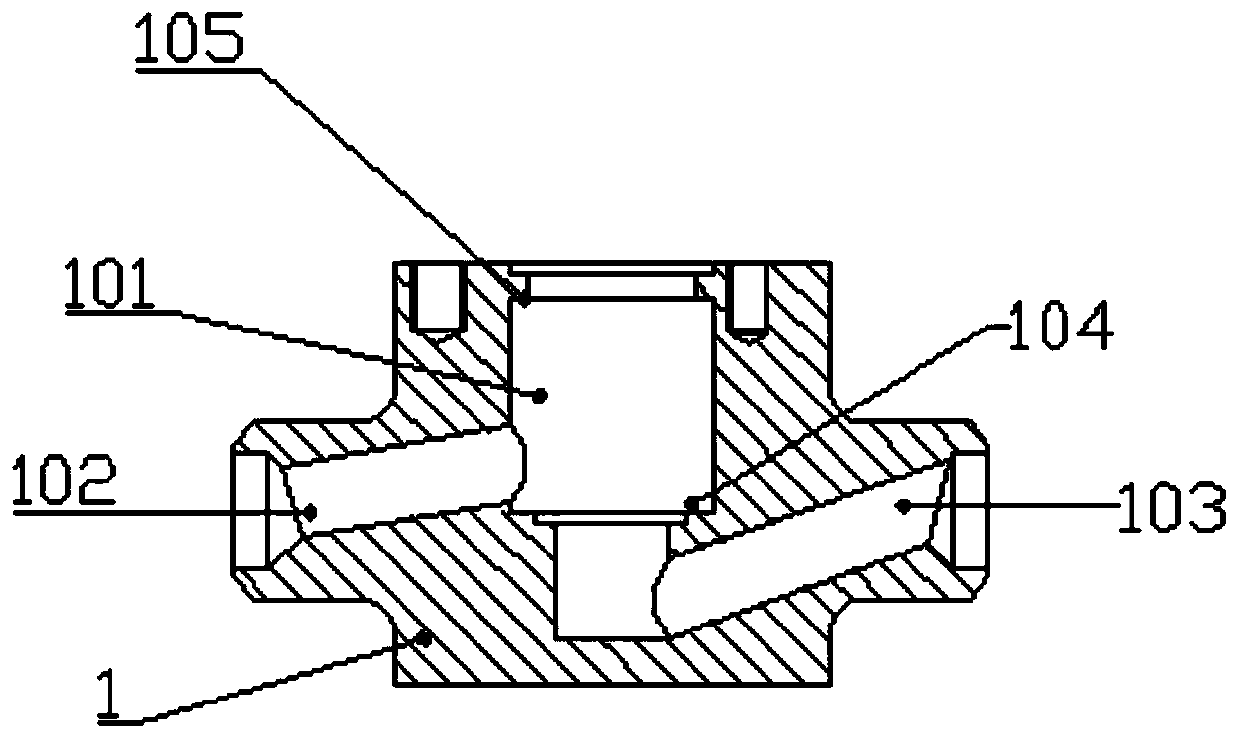

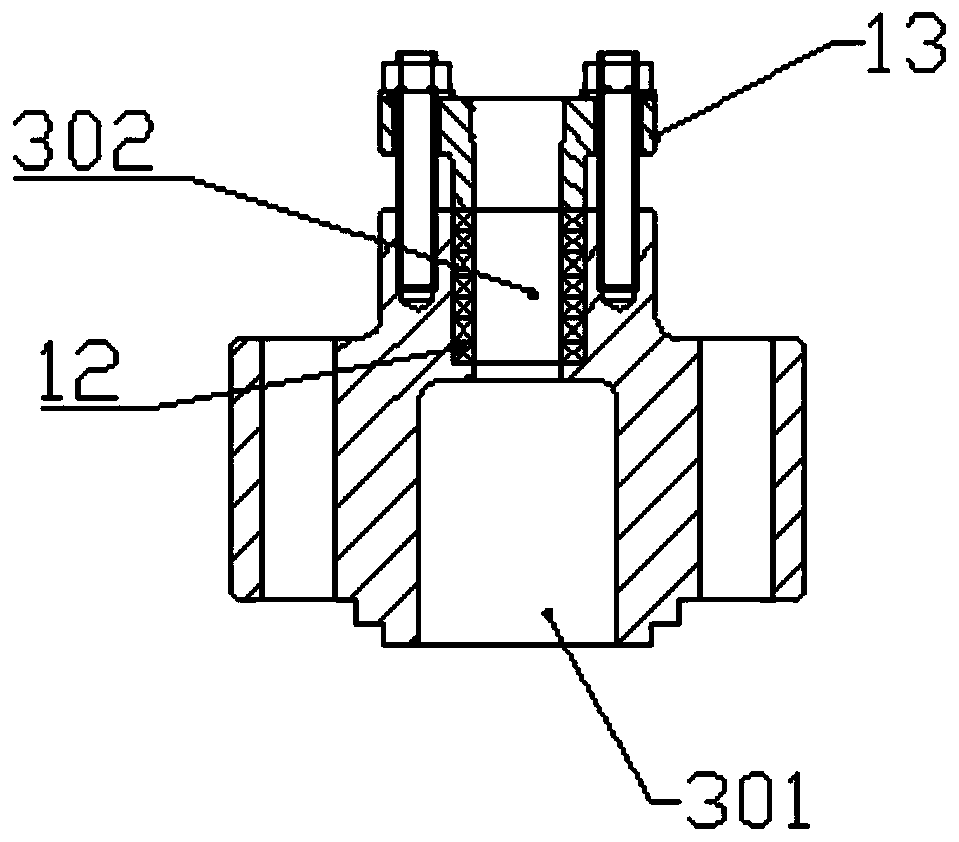

Quick-repair wash-free dual-valve-element shut-off valve convenient to replace

InactiveCN111188911AAvoid damageSolve the problem of internal leakageSpindle sealingsValve members for absorbing fluid energyPhysicsVertical motion

The invention relates to the technical field of valves, and more particularly relates to a quick-repair wash-free dual-valve-element shut-off valve convenient to replace. The quick-repair wash-free dual-valve-element shut-off valve convenient to replace comprises a valve body, a valve base, a primary valve element, a limit disc, a secondary valve element, a valve base sleeve, a valve cover, a packing gland, a valve rod and a valve drive mechanism, wherein when the shut-off valve is in the opening and closing states, an assembling unit formed by the primary valve element, the limit disc and thesecondary valve element vertically move, free stroke set in the primary valve element enables the position of the primary valve element to be automatically corrected under the action of the fluid pressure, the secondary valve element does not apply pushing force on the primary valve element downward after the valve elements are all closed in place, the condition that one valve element influencesthe sealing performance of the other valve element is completely avoided, and the distance between a secondary valve sealing surface and a secondary sealing surface of the valve base is larger when the shut-off valve is in a micro-open state, so that the secondary valve sealing surface and the secondary sealing surface of the valve base are not damaged by the impact of water flow, and the integrity of the secondary valve element sealing surface is guaranteed to the greatest extent. According to the quick-repair wash-free dual-valve-element shut-off valve convenient to replace, the service lifeis long, the sealing effect is good, and maintenance and replacement are convenient.

Owner:苗蕴博

Workpiece rapid locating and clamping device

InactiveCN104842105AQuick positioning clampingPrecise processing sizeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a workpiece rapid locating and clamping device. The device comprises a base, a shaft seat, a guide seat, a clamping handle, a guide shaft, a distance adjusting bolt and a rear fixed check block. The shaft seat is arranged at the rear end of the upper surface of the base; and the guide seat is arranged on one side of the front end of the base, and the rear fixed check block is arranged on the other side of the front end of the base. The guide shaft is movably connected with the guide seat internally, and the distance adjusting bolt is arranged in the rear end of the guide shaft in a screwed manner; the rear end of the clamping handle is connected with the shaft seat through a bolt and an adjusting bolt, and a clamping plate is arranged at the lower end of the clamping handle; and an upper wedge-shaped surface and a lower wedge-shaped surface are arranged on the contact surfaces of the clamping plate and the head of the distance adjusting bolt, and a compression spring is arranged between the distance adjusting bolt and the guide seat. According to the workpiece rapid locating and clamping device, a workpiece can be rapidly located and clamped through the clamping handle, it is ensured that the machined size is accurate, and deformation is not prone to occur; fine adjustment of the locating position and fine adjustment of clamping force can be achieved through the upper wedge-shaped surface and the lower wedge-shaped surface on the clamping plate of the clamping handle; and through the compression spring, the adjusting clearance is removed, and the guide shaft is reset.

Owner:陈敏蓉

Production process of carbon fiber composite aircraft with steps on the inner wall of the shell

Owner:佛山市铭特铝业科技有限公司

Machining device for high-temperature blade

InactiveCN105773150ANo wearNice appearanceOther manufacturing equipments/toolsEngineeringGrinding wheel

The invention belongs to the technical field of mechanical devices, and particularly relates to a machining device for a high-temperature blade. The machining device mainly solves the problems that an existing machining device is low in grinding efficiency, too quick in grinding wheel loss and high in machining cost. The machining device for the high-temperature blade is composed of a linear cutting device set, a creep grinding device set, a blade tool and a working platform. A linear cutting machine tool is arranged on the upper left portion of the working platform. A blade tool fixing frame is arranged on a working table of the linear cutting machine tool. A wire electrode is arranged in a wire winding mechanism of the linear cutting machine tool to conduct electrical discharge machining. The creep grinding device set is composed of a creep grinding machine, a working grinding wheel, a blade tool base fixing frame and a blade tool base.

Owner:SHANXI KAMEITE IND MACHINERY CO LTD

Crankshaft end connection screw hole drilling aids

ActiveCN106181476BHigh positioning accuracyReduce distortionDrilling/boring measurement devicesPositioning apparatusEngineeringMechanical engineering

The invention discloses a drilling auxiliary tool for a crankshaft end face connecting screw hole. The tool comprises a drilling template, a circumferential positioning plate is fixed to one side of the drilling template which is a cylindrical disc part, a crankshaft fixing hole is machined in the middle portion of the drilling template, the crankshaft fixing hole and the shaft neck of the end of a crankshaft are matched in size, a drilling sleeve mounting hole is machined in the position concentric with the crankshaft fixing hole, a drilling sleeve is mounted in the drilling sleeve mounting hole, and a drilling sleeve inner hole is matched with a drill bit; a clamping mechanism mounting hole is formed in the other side of the drilling template, and in the clamping process of a clamping screw, the positioning face of a positioning sleeve and the positioning face of a clamping sleeve are in contact with the shaft neck at the end of the crankshaft. The tool is simple in structure, easy and convenient to manufacture, convenient to use and operate, long in service life and high in machining precision.

Owner:LIAONING 518 INTERNAL COMBUSTION ENGINE FITTINGS

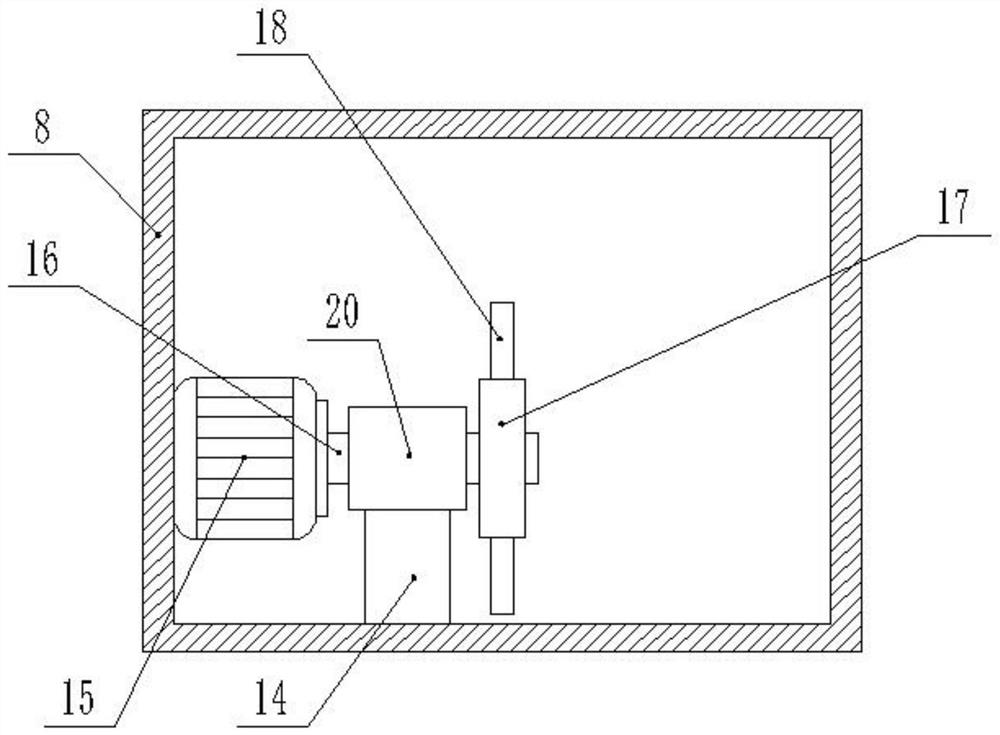

Adjustable bearing machining fixing device

InactiveCN112497056AEliminate the limitations of clampingPrevent slidingGrinding carriagesPositioning apparatusElectric machineryEngineering

The invention relates to the technical field of bearing machining, in particular to an adjustable bearing machining fixing device. The adjustable bearing machining fixing device comprises a box body,wherein fixing discs are symmetrically arranged on the left inner wall and the right inner wall of the box body; telescopic rods are connected to the fixing discs; a working box is arranged in the boxbody; hole grooves are formed in the left inner wall and the right inner wall of the working box; the telescopic rods penetrate through the hole grooves to be connected to connecting plates; a movable plate is connected to each connecting plate; the upper end of the movable plate penetrates through the upper end face of the working box to be provided with a connecting rod; a fixing clamp is connected to the connecting rod; movable teeth are arranged at the lower end of the movable plate; fixing bases are arranged in the working box; a lantern ring is arranged at the upper end of each fixing base; motors are arranged on the rear portion of the inner side of the working box; transmission shafts are rotatably connected to the motors; rotating discs are rotatably connected to the transmissionshafts; rotating teeth are uniformly distributed on the rotating discs; the problem that the device is single in machining is solved; the application range is enlarged; the sliding phenomenon of a bearing can be prevented in the machining process; and the machining size is more accurate.

Owner:东台立一工业技术有限公司

On-line compensating method for locus coordinates of moving robot

InactiveCN1255249CLarge amount of deformationPrecise processing sizeProgramme-controlled manipulatorGraphicsRobotics

The invention relates to an online compensation method for the coordinates of the running track of a robot, which belongs to the field of robots. Before the robot performs an operation, the shape and position data of the workpiece are read into the computer, and the computer transmits the coordinate data of the processed graphic elements of the section steel after compensation, and at the same time provides the basic processing graphic subroutine The coordinate variables of the graphic elements at the entrance are assigned values, and the computer performs data processing and calculation to compensate the previously set trajectory coordinates executed by the robot, so that the robot obtains the coordinates of the new processing operation trajectory. When the robot obtains the compensated After the data and the element coordinate data of the corresponding trajectory subroutine module, the robot main program detects the Boolean variable at the input port of each execution trajectory coordinate data subroutine module, and decides whether to execute the running trajectory coordinate data subroutine according to the value of the Boolean variable. The invention can obtain the running track coordinates online. The processed profile is allowed to have a large amount of deformation, and accurate processing dimensions can be obtained without rolling mill correction.

Owner:SHANGHAI JIAOTONG UNIV +1

Special fixing device for grinding toothed handle of feed dog

InactiveCN103506949ANo loosenessScientific and reasonable structure designGrinding work supportsEngineeringMechanical engineering

The invention relates to a special fixing device for grinding a toothed handle of a feed dog. The special fixing device is characterized by comprising a base, a fixed frame, a locating column, a pressing plate frame, a pressing plate and a pressing plate set screw. The fixed frame is vertically and fixedly installed on the upper surface of the base, a clamping table is installed on the front face of the upper portion of the fixed frame, the locating column with the front end extending out of the vertical face of the clamping table is installed on the fixed frame in a penetrating mode, the set screw is arranged on the front face in the middle of the fixed frame, the rotatable pressing plate frame is installed at the bottom of the fixed frame through a pin shaft, the pressing plate is installed at the upper end of the pressing plate frame, the pressing plate corresponds to the clamping table on the fixed frame after the pressing plate frame rotates to be erected, and a clamping groove clamped with the set screw is formed in the middle of the pressing plate frame. The special fixing device for grinding the toothed handle of the feed dog is scientific and reasonable in structural design, and has the advantages that clamping is convenient, looseness of a workpiece in the grinding process is avoided, machining size is accurate, and work efficiency is high.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com