Machining method for hard surface of screw drill and device for achieving method

A technology of screw drilling tools and processing methods, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as high cost, low efficiency, and unguaranteed accuracy, and achieve good compactness, reduce costs, and improve bonding accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

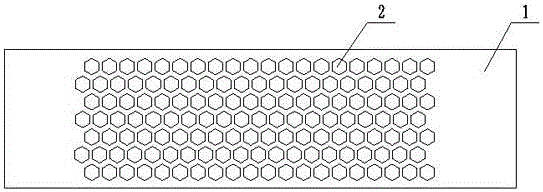

[0047] This embodiment provides a device for machining a cemented carbide layer on the hard surface of a screw drill. The device is a positioning groove plate, and its structural diagram is shown in the attached figure 1 shown. The positioning slot plate includes a base plate 1 and an alloy bar positioning slot arranged on the base plate 1. The alloy bar positioning slot is a slot grid composed of a number of hollowed out slot holes 2, and only one hard metal bar can be accommodated in the slot hole 2. Tungsten carbide strip 3; the size of the slot 2 is adapted to the size of the cemented carbide strip 3; the shape of the slot 2 is hexagonal.

[0048] The positioning groove plate base plate 1 and the positioning groove are an integrated structure, and the depth of the alloy strip positioning groove on the substrate 1 is not greater than the thickness of the hard alloy strip 3 . After placing an appropriate amount of cemented carbide strips 3 on the positioning slot plate, mos...

Embodiment 2

[0051] Based on the positioning groove plate described in Embodiment 1, this embodiment provides a hard surface processing method for screw drilling tools, and the schematic diagram of the process flow is shown in the attached Figure 5 shown. The method comprises the steps of:

[0052] S1. Prepare the positioning groove plate;

[0053] S2. Put the cemented carbide strip 3 on the positioning groove plate, place the cemented carbide strip 3 on the positioning groove plate as required, and drop the excess cemented carbide strip 3 from the positioning groove plate, so that the hard alloy strip 3 Quality alloy strips 3 are evenly arranged on the positioning groove plate;

[0054] S3. bonding the cemented carbide strip 3 with a perforated adhesive tape, so that the cemented carbide strip 3 and one side of the adhesive tape are firmly bonded to form a cemented carbide strip bonding plate including several cemented carbide strips 3;

[0055] This embodiment uses single-sided adhes...

Embodiment 3

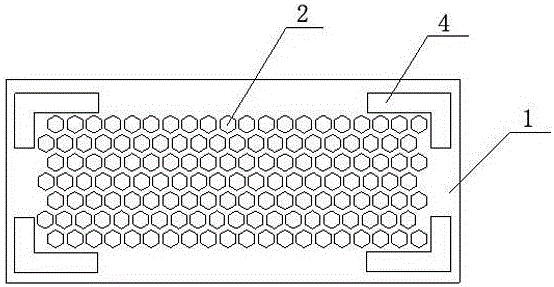

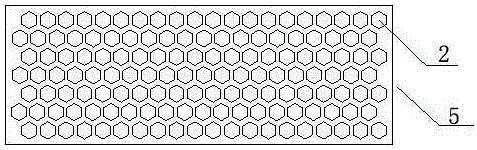

[0064] This embodiment provides another device for machining a cemented carbide layer on the hard surface of a screw drill, and its structural schematic diagram is shown in the attached image 3 and Figure 4 shown. The device is a positioning groove plate, and the positioning groove plate includes a base plate 1 and an alloy strip positioning groove 5 arranged on the base plate 1, such as Figure 4 As shown, the base plate 1 is composed of several liftable bosses 11, such as image 3 As shown, the alloy bar positioning groove 5 is a slot grid composed of several hollowed out slot holes 2, and only one hard alloy bar 3 can be accommodated in the slot hole 2; Rising or falling; the dimensions of the boss 11 and the slot 2 are matched and matched with the size of the hard alloy strip 3; the shape of the slot 2 is hexagonal. First, make the boss 11 in the initial state, and the plane formed by the boss 11 becomes the bottom surface of the groove. After placing an appropriate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com