Adjustable bearing machining fixing device

A bearing processing and fixing device technology, which is applied in the field of bearing processing, can solve the problems that the fixing device cannot be adjusted, the scope of application is narrow, and the processing cost is increased, and the effect of increasing the scope of use, reducing the processing cost and accurate processing size can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

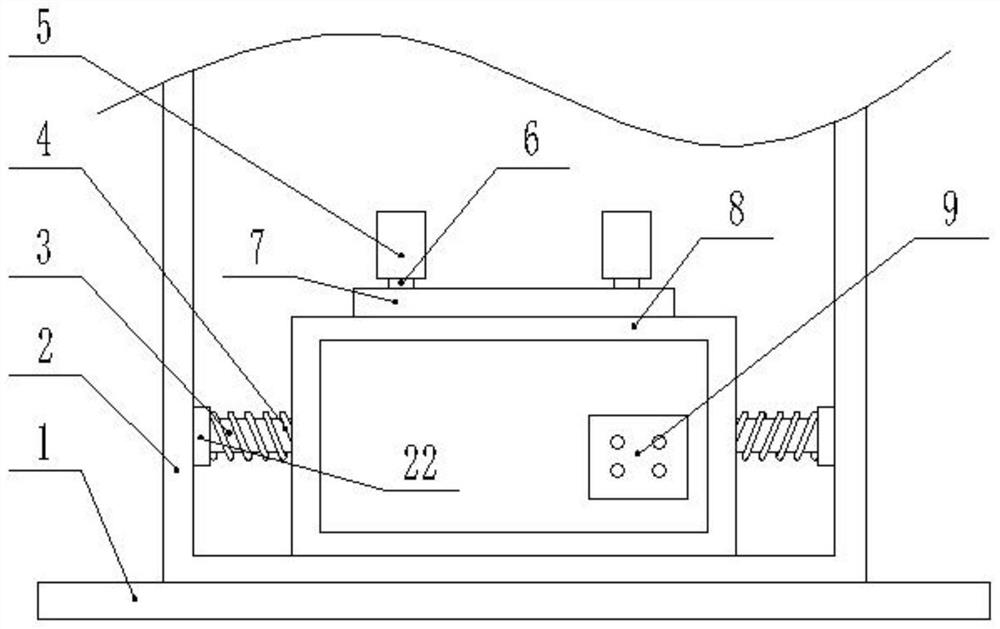

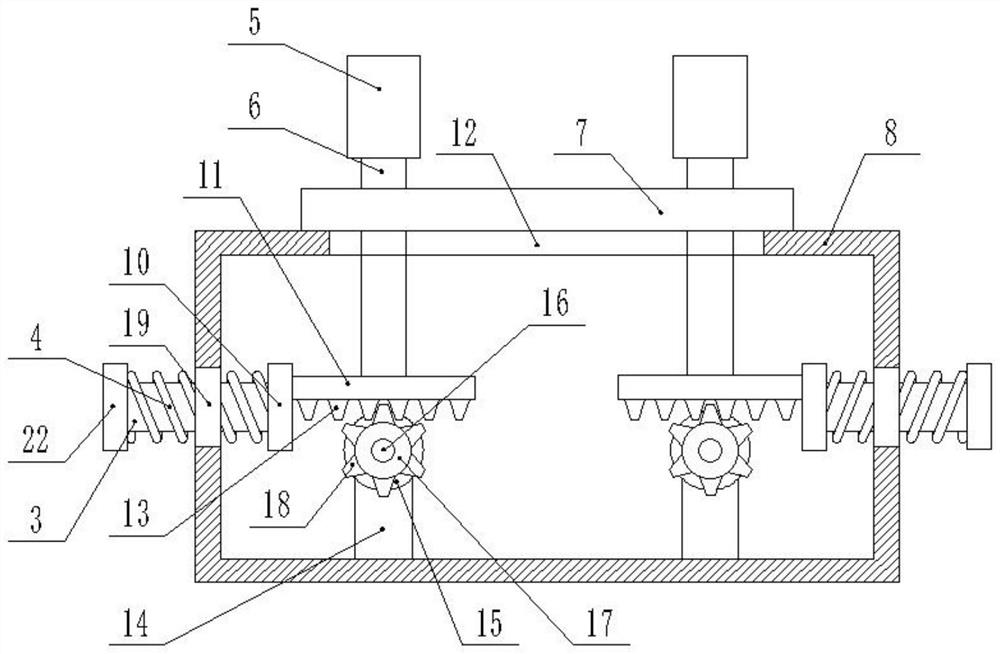

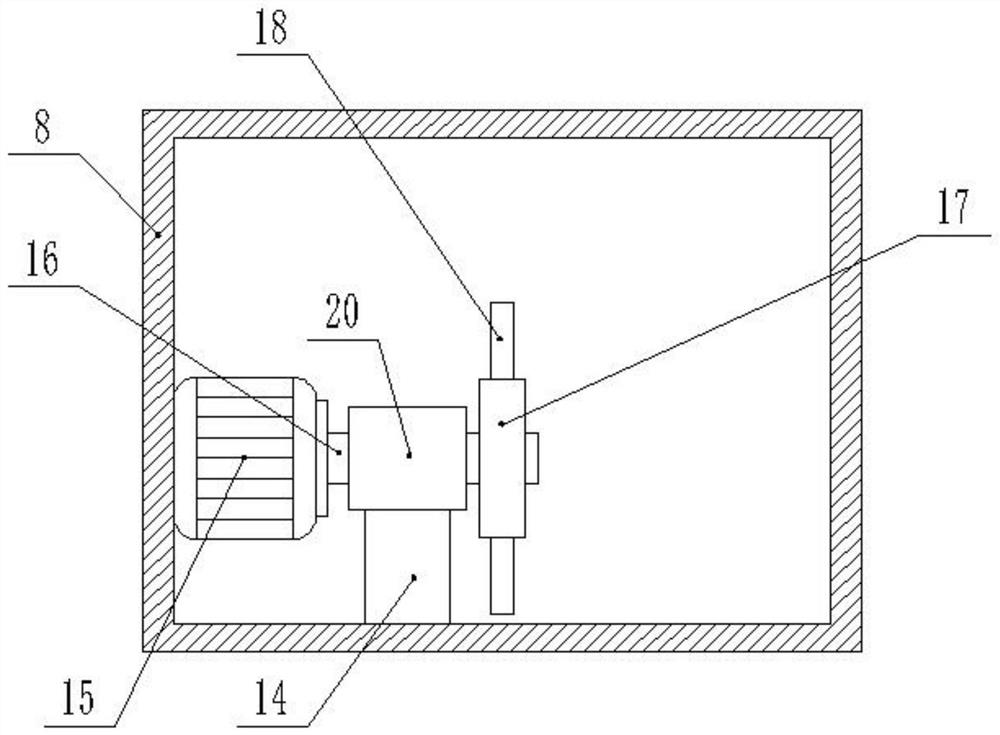

[0022] Such as Figure 1-4 As shown, in the embodiment of the present invention, an adjustable bearing processing and fixing device includes a box body 2, fixed plates 22 are symmetrically installed on the left and right inner walls of the box body 2, and telescopic rods 3 are connected to the fixed plate 22, so that A work box 8 is provided inside the box body 2, a chute 12 is provided in the middle of the upper end surface of the work box 8, a workbench 7 is provided at the upper end of the work box 8, and a rectangular groove 21 is provided in the middle of the workbench 7, The front portion of the working box 8 is provided with a control switch 9, the output end of the control switch 9 is electrically connected to the input end of the motor 15, by opening the control switch 9, the motor 15 is started to work, which improves the degree of mechanization of the device , the left and right inner walls of the working box 8 are provided with holes 19, the telescopic rod 3 passes...

Embodiment 2

[0025] The present invention also provides another embodiment. The difference between this embodiment and the above-mentioned embodiment is that: the bottom of the box body 2 is provided with a base 1, and the base 1 is welded to the box body 2, so that the device can The work is more stable when performing machining operations.

[0026] The working principle of the present invention is:

[0027] In this embodiment, the bearings to be processed are placed on the workbench 7, the control switch 9 is turned on, and the motor 15 is controlled to rotate through the control switch 9. The motor 15 drives the rotating shaft 16 to rotate, and the rotating shaft 16 drives the rotating disk 17. Rotate the rotating tooth 18 on the rotating disk 17 to follow the rotation of the rotating disk 17, because the rotating tooth 18 and the moving tooth 13 mesh with each other, the rotating tooth 18 can then drive the moving tooth 13 to move left and right, and then drive the moving plate 11 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com