Workpiece rapid locating and clamping device

A technology for positioning and clamping workpieces, which is applied to positioning devices, auxiliary devices, metal processing machinery parts, etc., and can solve the problems of poor positioning accuracy of the clamping device, adjusting the positioning position and clamping force, and inability to use positioning and clamping, etc. To achieve the effect of accurate processing size and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

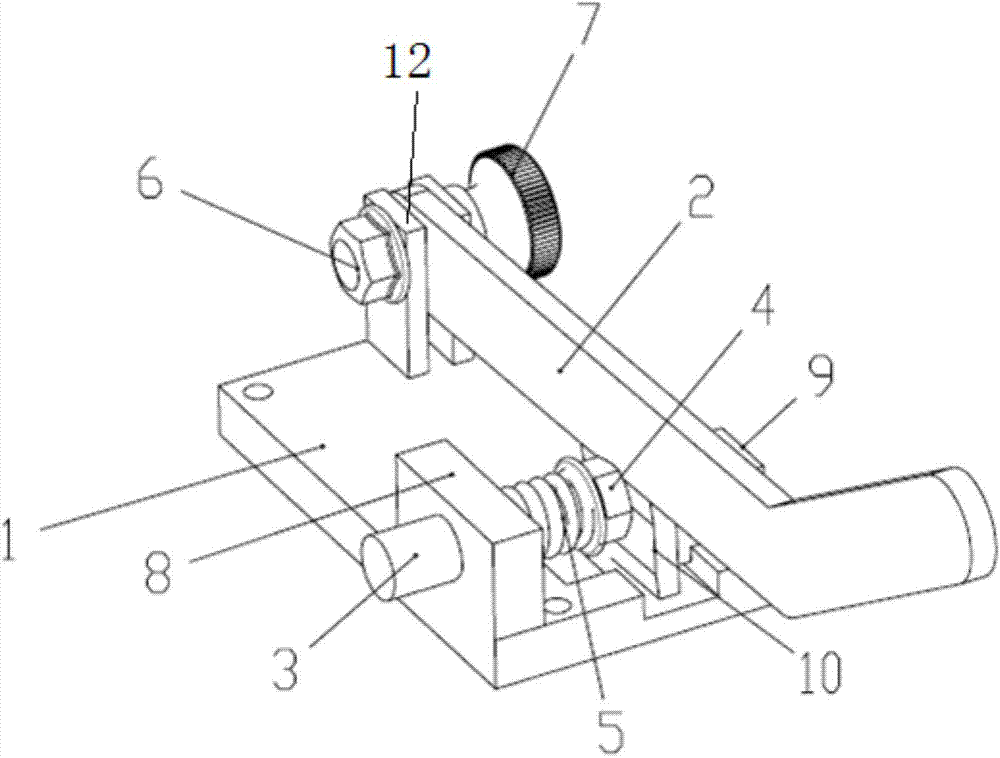

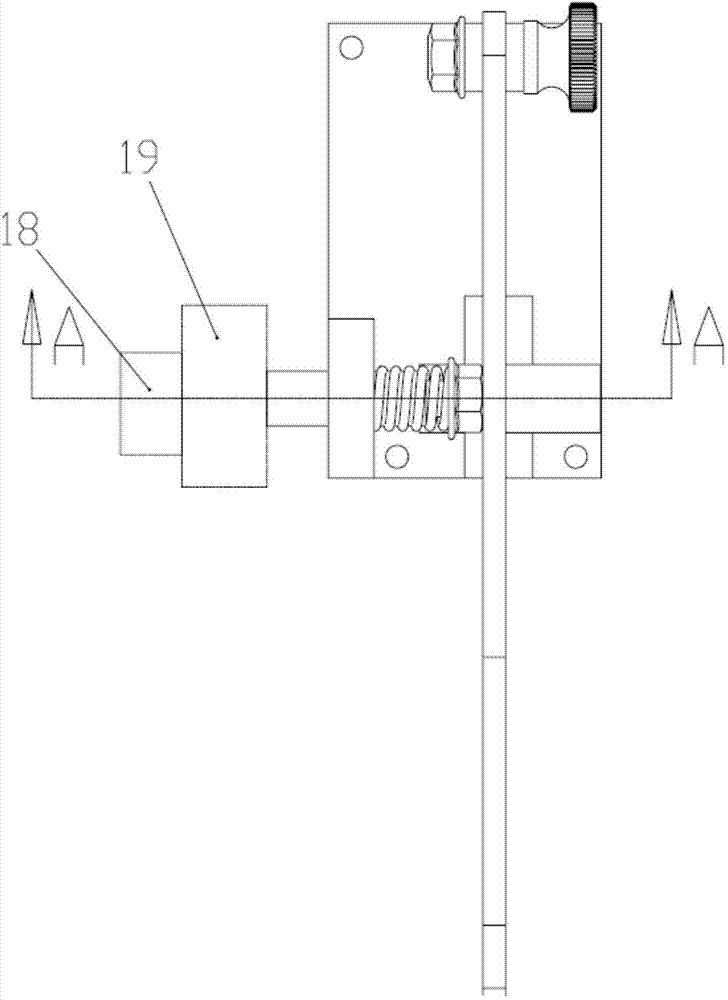

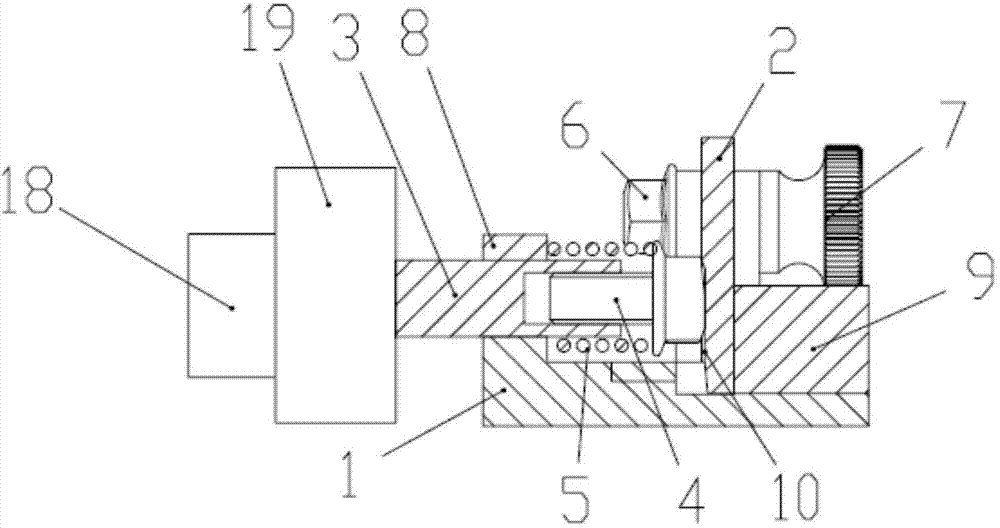

[0017] Such as Figure 1 to Figure 3 As shown, a fast positioning and clamping device for workpieces includes a base 1, a shaft seat 12, a guide seat 8, a clamping handle 2, a guide shaft 3, a distance adjusting bolt 4, a compression spring 5, a bolt 6, an adjusting nut 7, and a rear Fixed stop 9.

[0018] Base 1 upper rear end is provided with axle seat 12, front end one side is provided with guide seat 8, and the other side is provided with rear fixed block 9, and guide shaft 3 is movably connected in guide seat 8, and guide shaft 3 rear end internally rotates with adjustable The distance from the bolt 4, the rear end of the clamping handle 2 is connected with the shaft seat 12 through the bolt 6 and the adjusting nut 7, the lower end of the clamping handle 2 is provided with a clamping plate 10, and the contact surface between the clamping plate 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com