Technique for clamping and positioning angle head by utilizing adjusting cushion block

A technology for adjusting pads and positioning angles, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of high dimensional accuracy and difficult processing of positioning blocks, and achieve short processing cycle, short design cycle and convenient storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

[0031] A process method of clamping and positioning the angle head by using the adjustment block:

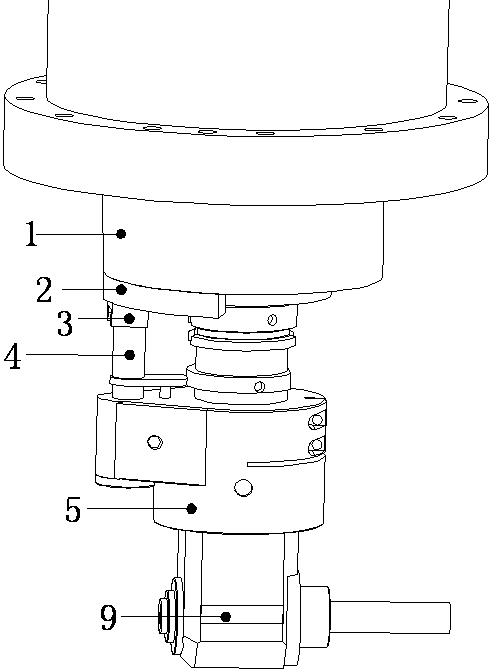

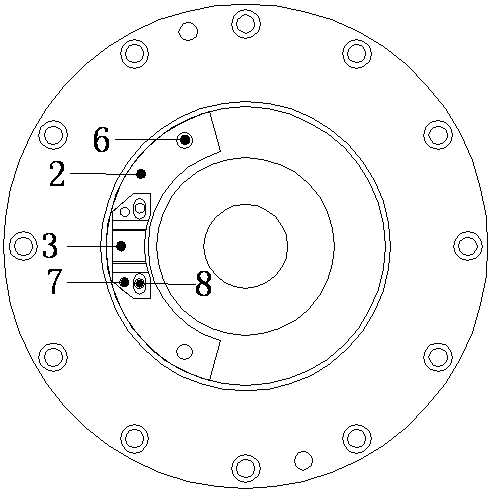

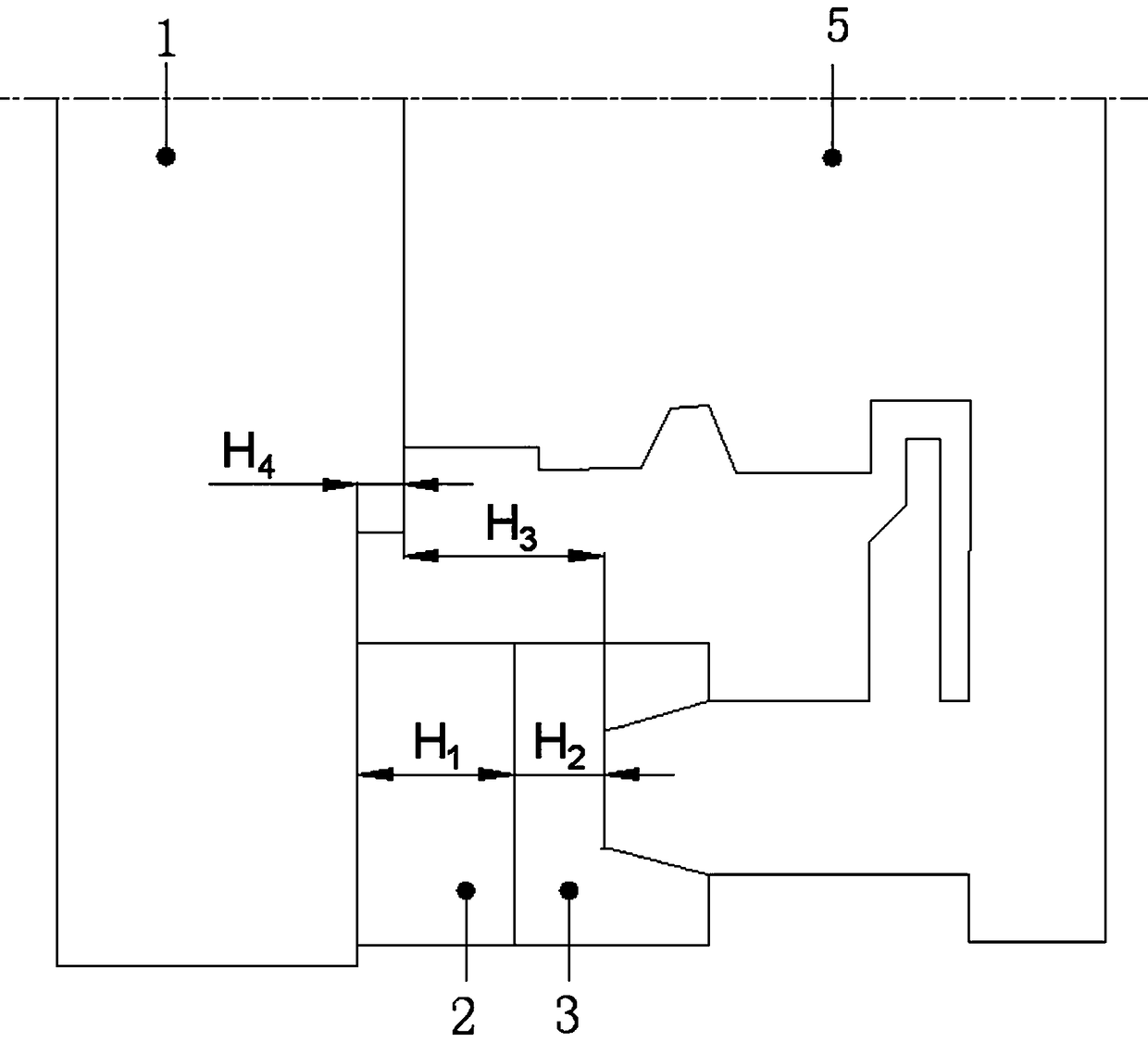

[0032] The angle head is clamped to the machine tool through the adjustment block, mainly including the following parts for cooperative control: machine tool spindle 1, adjustment block 2, standard positioning block 3, positioning bolt 4, angle head 5, adjustment block screw 6, standard Positioning block positioning pin 7, standard positioning block screw 8, calibration strip 9;

[0033] The design principle of adjusting the pad clamping positioning angle head to the processing machine tool is as follows:

[0034] a. According to the size requirements from the positioning bolt 4 in the angle head 5 to the end face of the machine tool and the thickness and size requirements of the standard positioning block 3, design the thickness of the corresponding adjustment block 2;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com