Shell leakage testing clamp

A leak test and fixture technology, which is applied in the direction of measuring the acceleration and deceleration rate of the fluid and using the liquid/vacuum degree for liquid tightness measurement, etc. Achieve the effect of ensuring sealing performance, high degree of automation, and accurate positioning and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

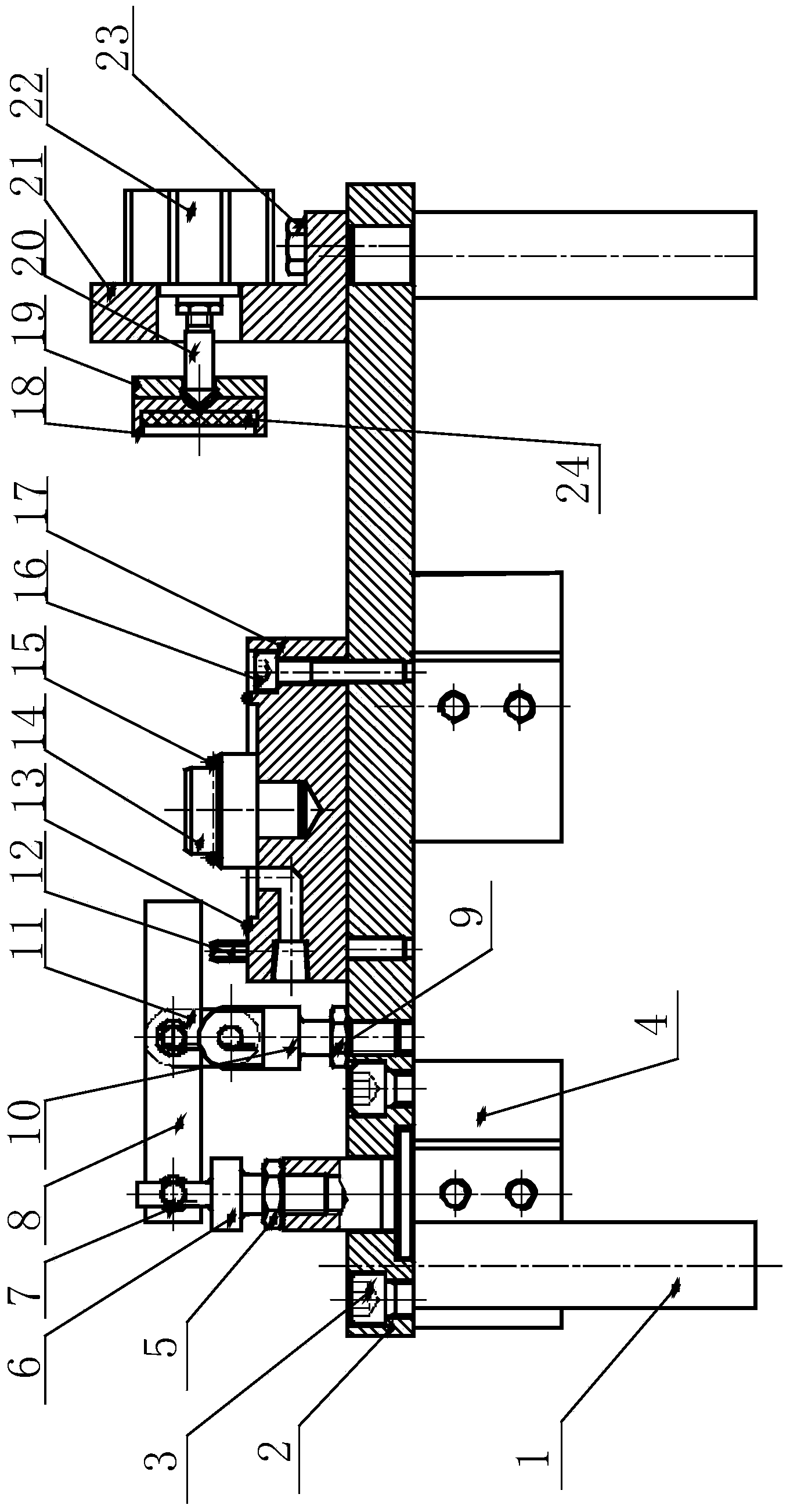

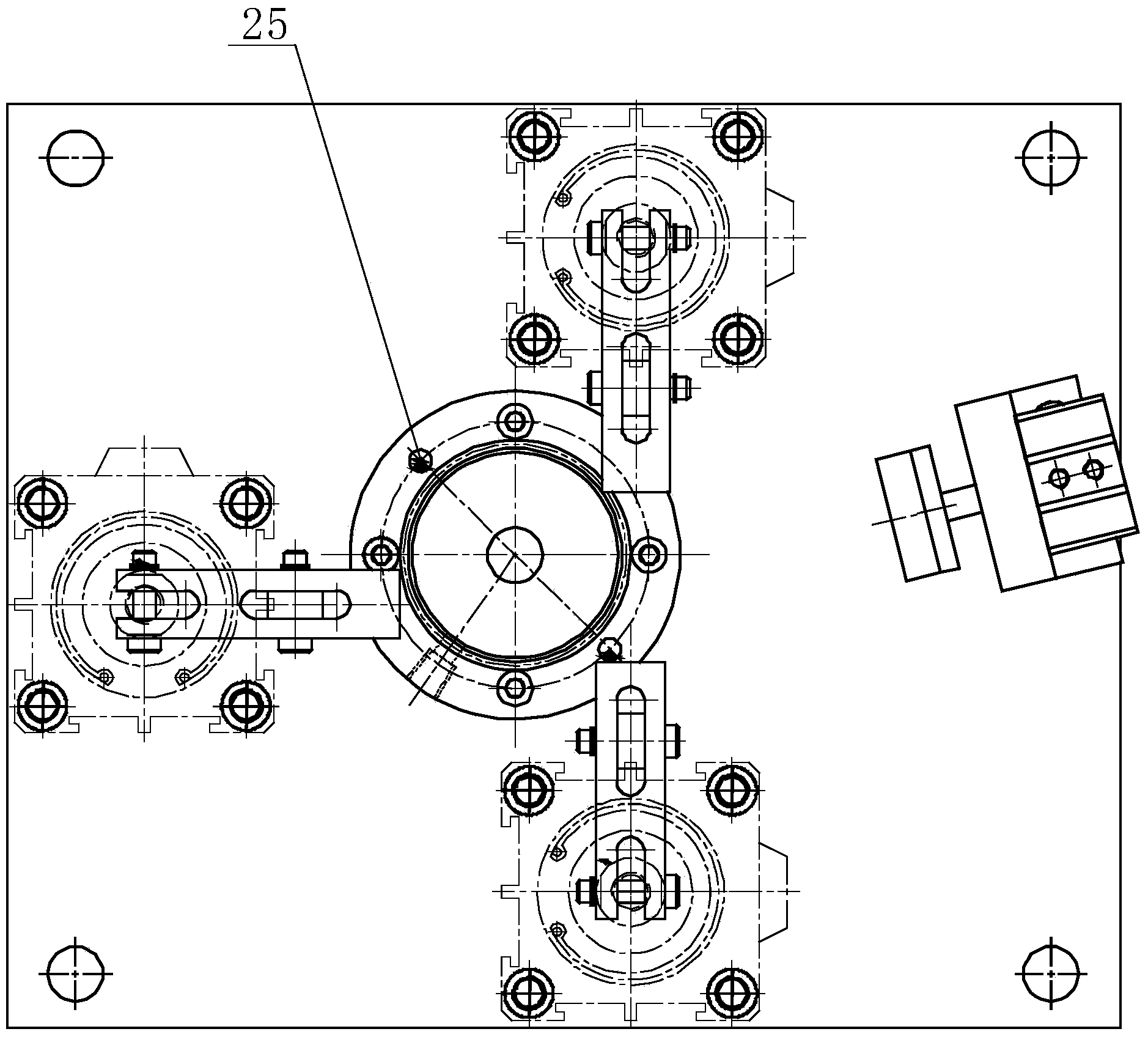

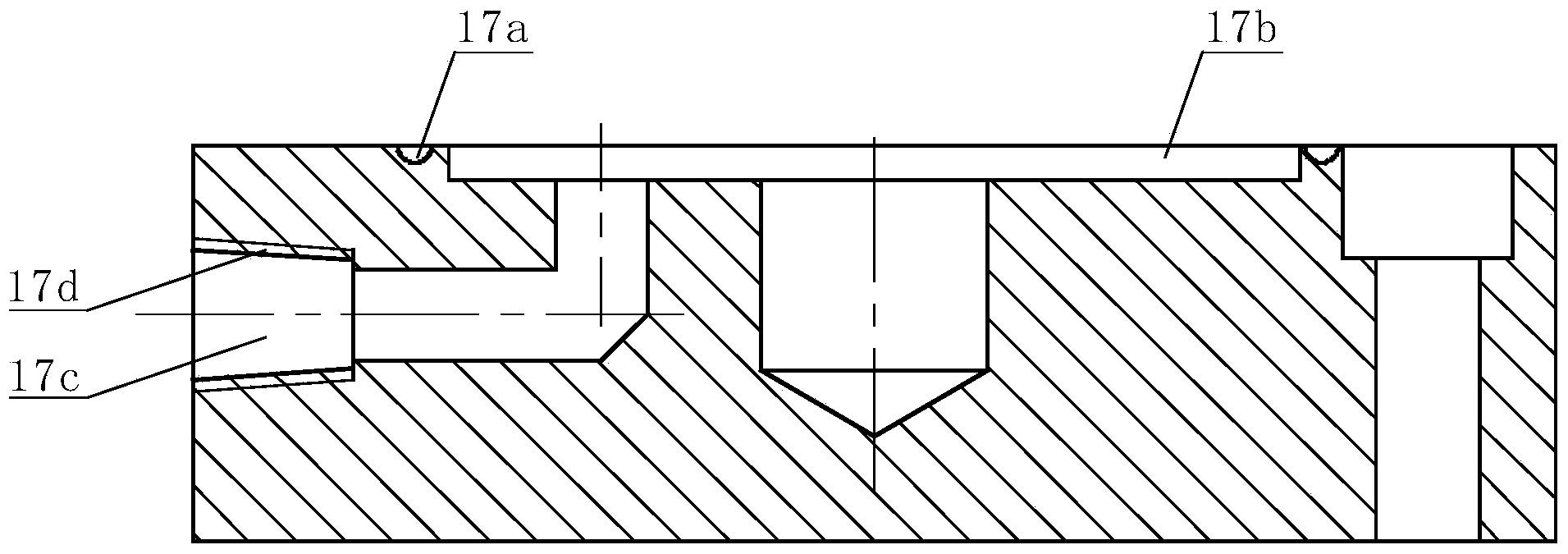

[0015] Such as Figure 1 to Figure 3 As shown, a shell leak test fixture includes a column 1 and a clamp body 2 installed on the upper end of the column 1. The front, rear and left parts of the clamp body 2 are equipped with pneumatic compression devices. The middle part of the concrete body 2 is equipped with a supporting positioning device, and the right part of the clamp body 2 is equipped with a mouth sealing device. Place the shell to be tested on the support and positioning device, then start the pneumatic clamping device to clamp, then start the sealing device to block the water inlet of the shell, and finally use the external equipment to fill the gap between the shell and the support and positioning device. Gas is injected into the sealed cavity to realize the purpose of testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com