Pallet fork welding assembly system

A welding assembly and fork technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as waste, affect welding quality, damage forks, etc., achieve convenient and fast use, improve welding quality, Welding seam uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

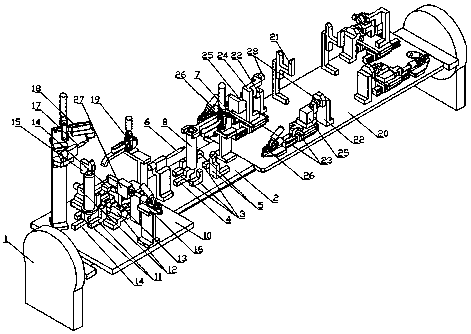

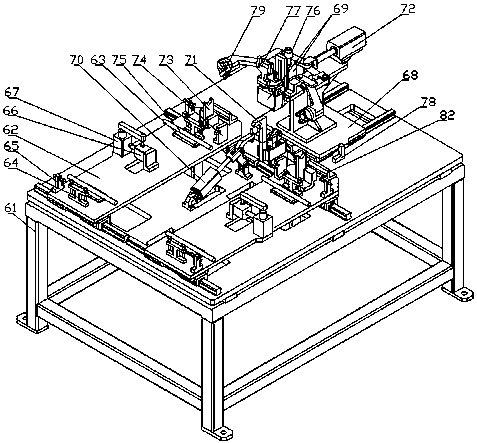

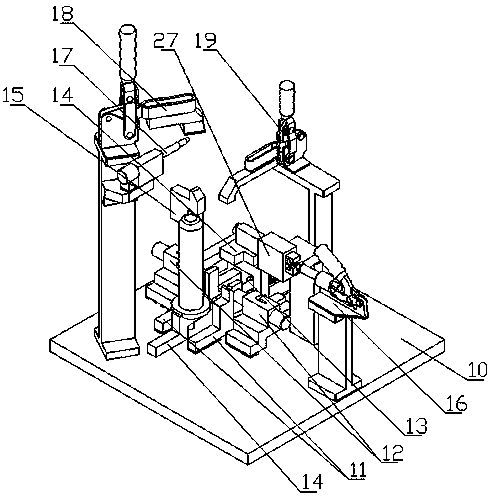

[0013] As shown in the drawings, the fork welding assembly system of the present invention includes lifting component group welding tooling 96 and fork body group welding tooling 97. Between the lifting component group welding tooling 96 and fork body group welding tooling 97 is provided a handling manipulator 98, lifting The component group welding tool 96 includes a rotary welding station 1, an oil tank welding section, a pump body welding section, and a lever frame welding section. The oil tank welding section includes an oil tank tooling table 2, three pump body support blocks 3, and a pump body. Mandrel positioning block 4, a pair of pump body side positioning blocks 5, pump body angle positioning pin 6 and oil storage cylinder compression fixture 7, three pump body support blocks 3 are fixed on the oil storage cylinder tooling table 2 in a triangle shape, The pump body core shaft positioning block 4 is provided with a positioning shaft 8. The pump body core shaft positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com