Patents

Literature

248results about How to "Quick positioning clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

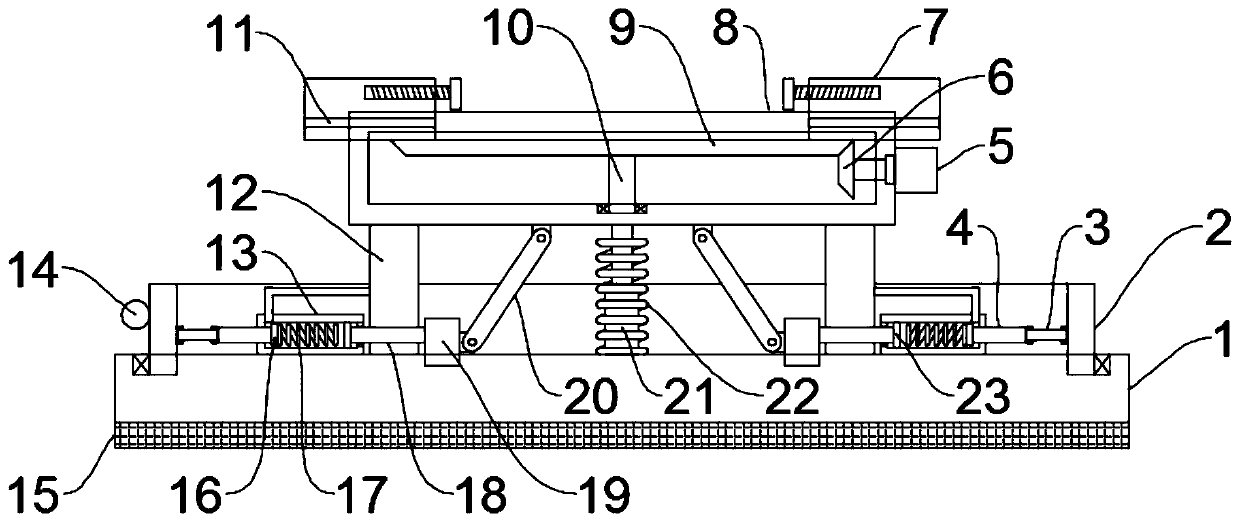

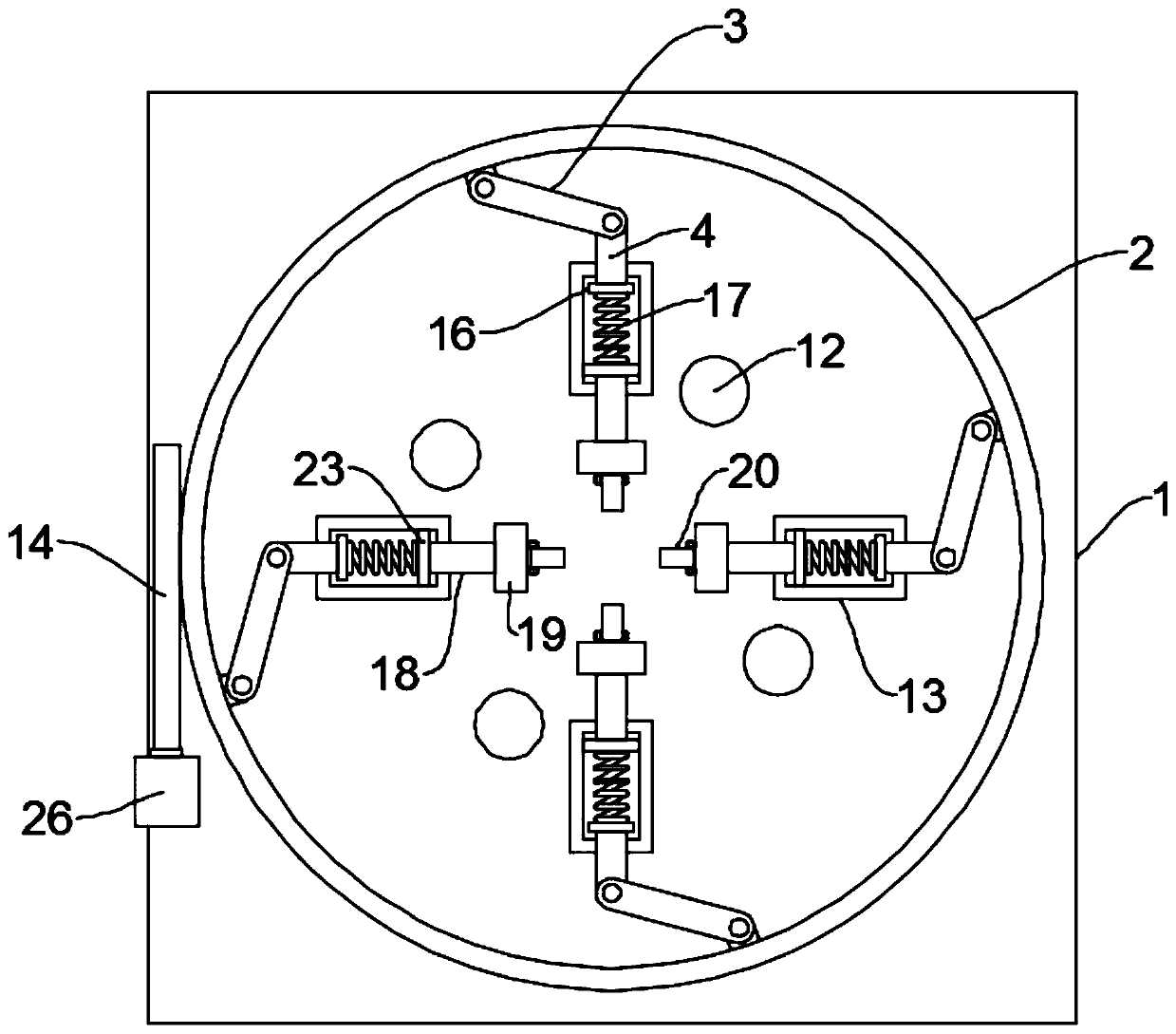

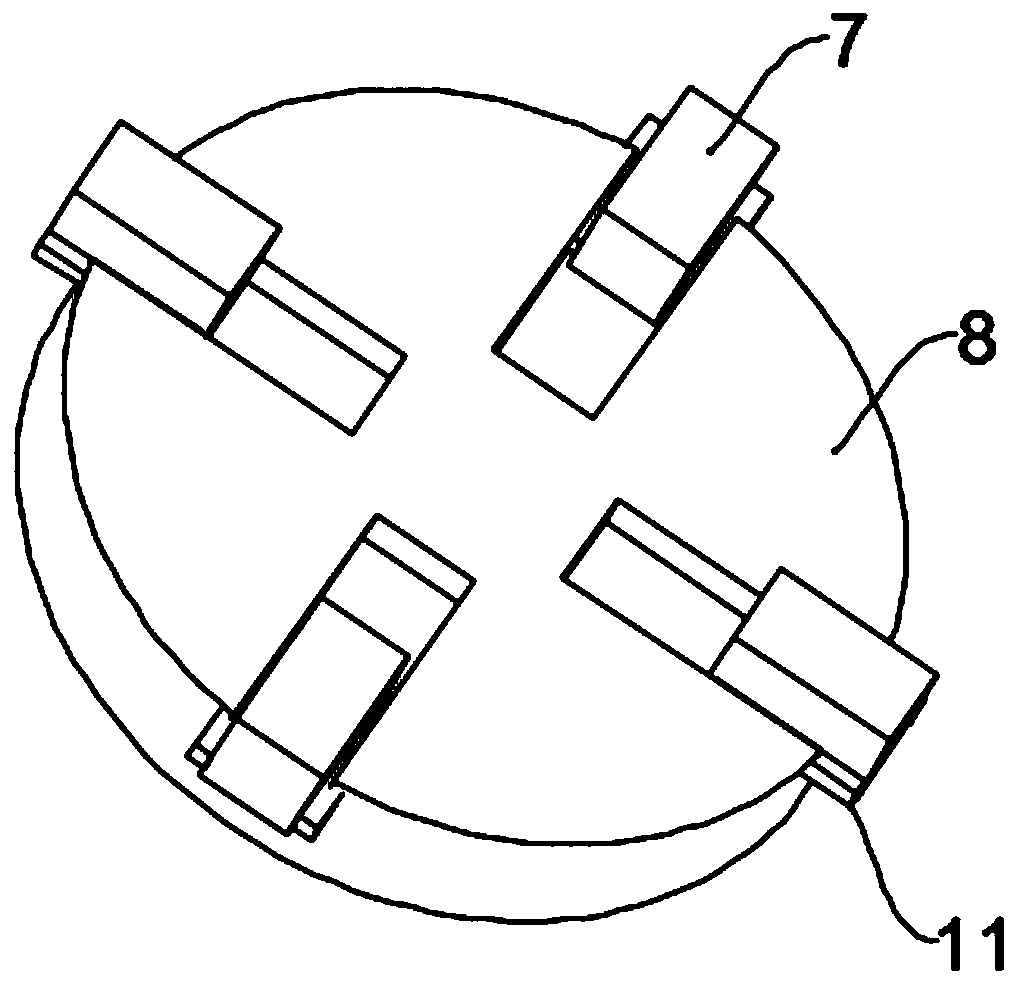

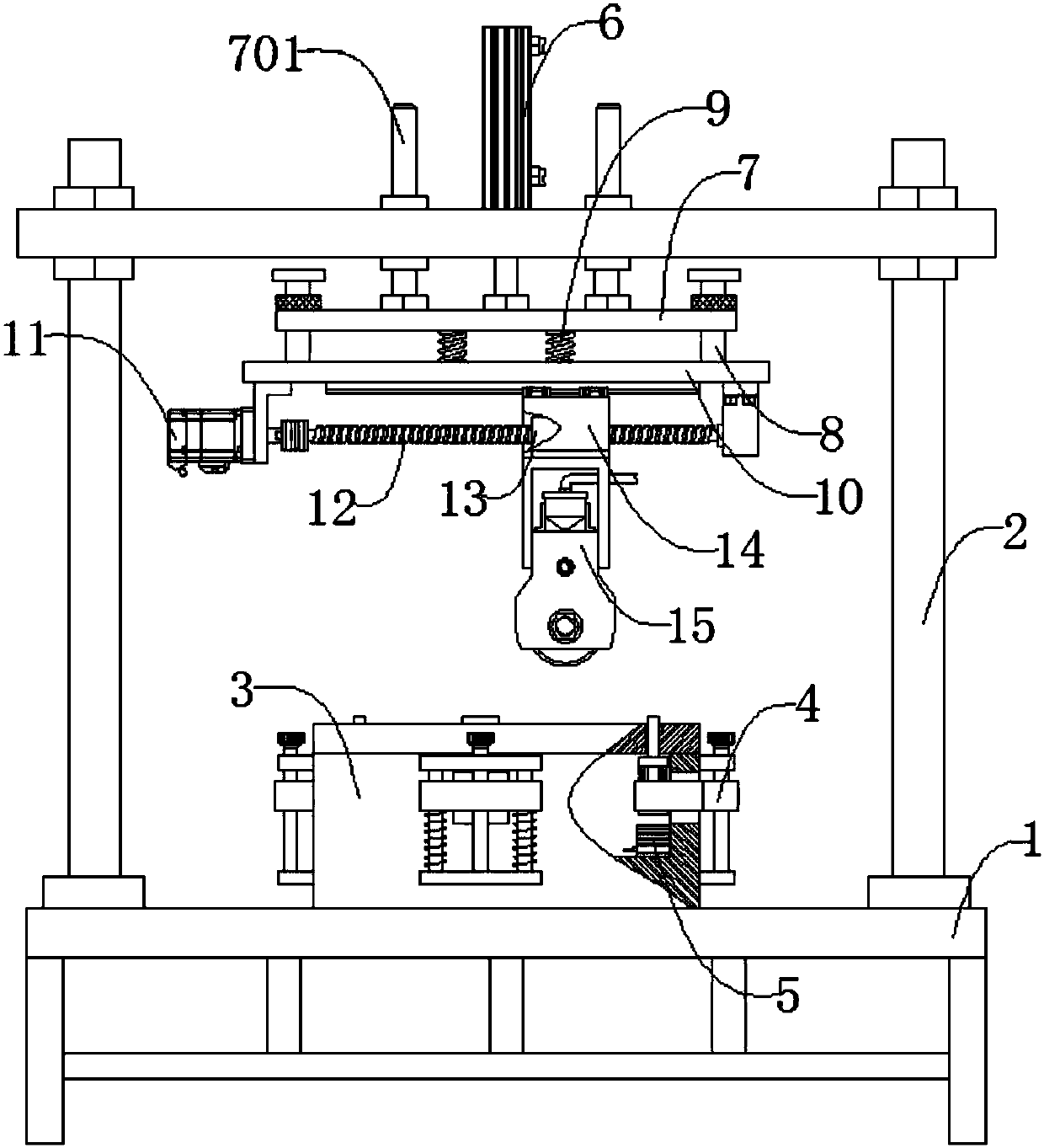

Efficient damping device for mechanical equipment

ActiveCN110486416AAdjust the amount of initial compressionAdjust the cushion strengthSpringsNon-rotating vibration suppressionMechanical equipmentEngineering

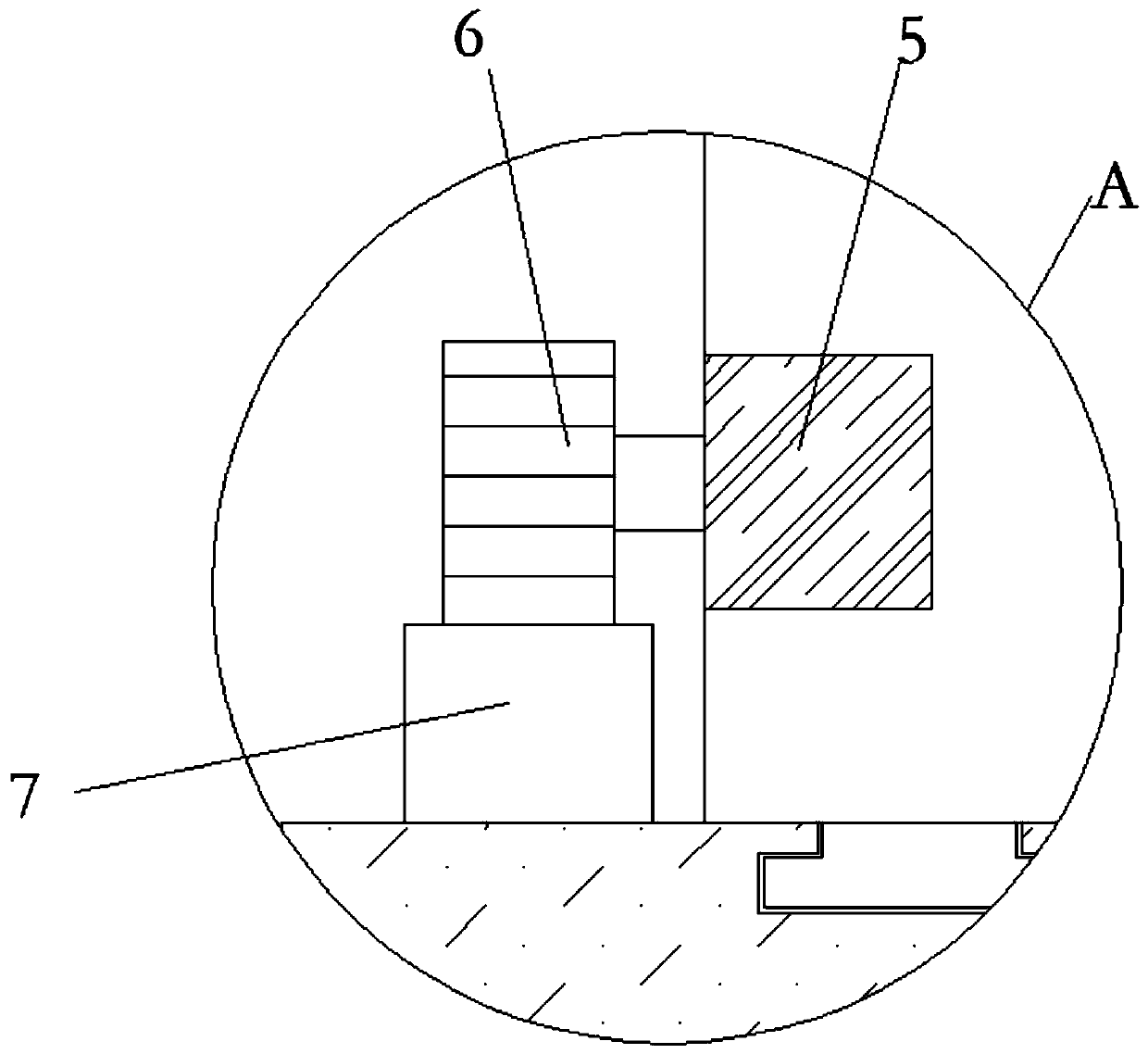

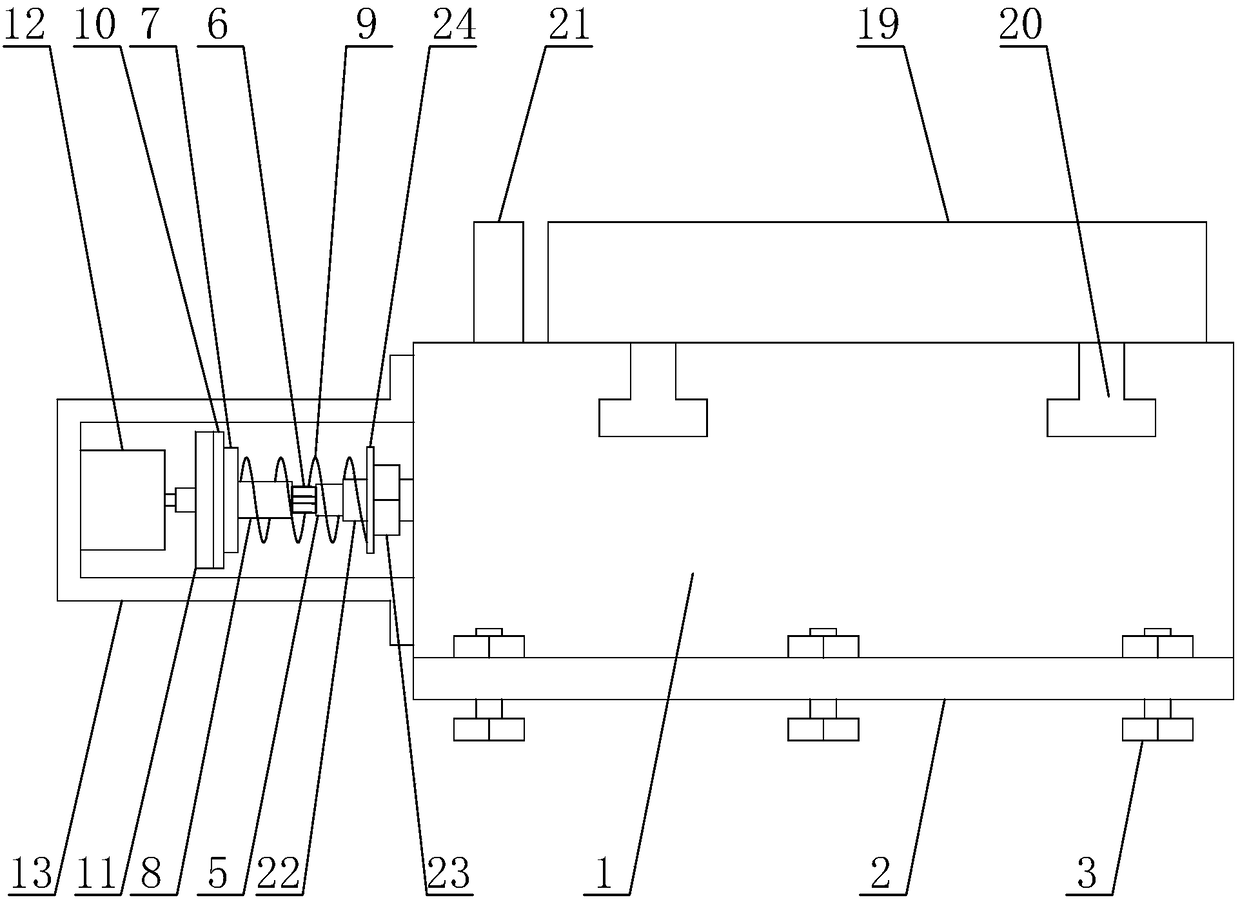

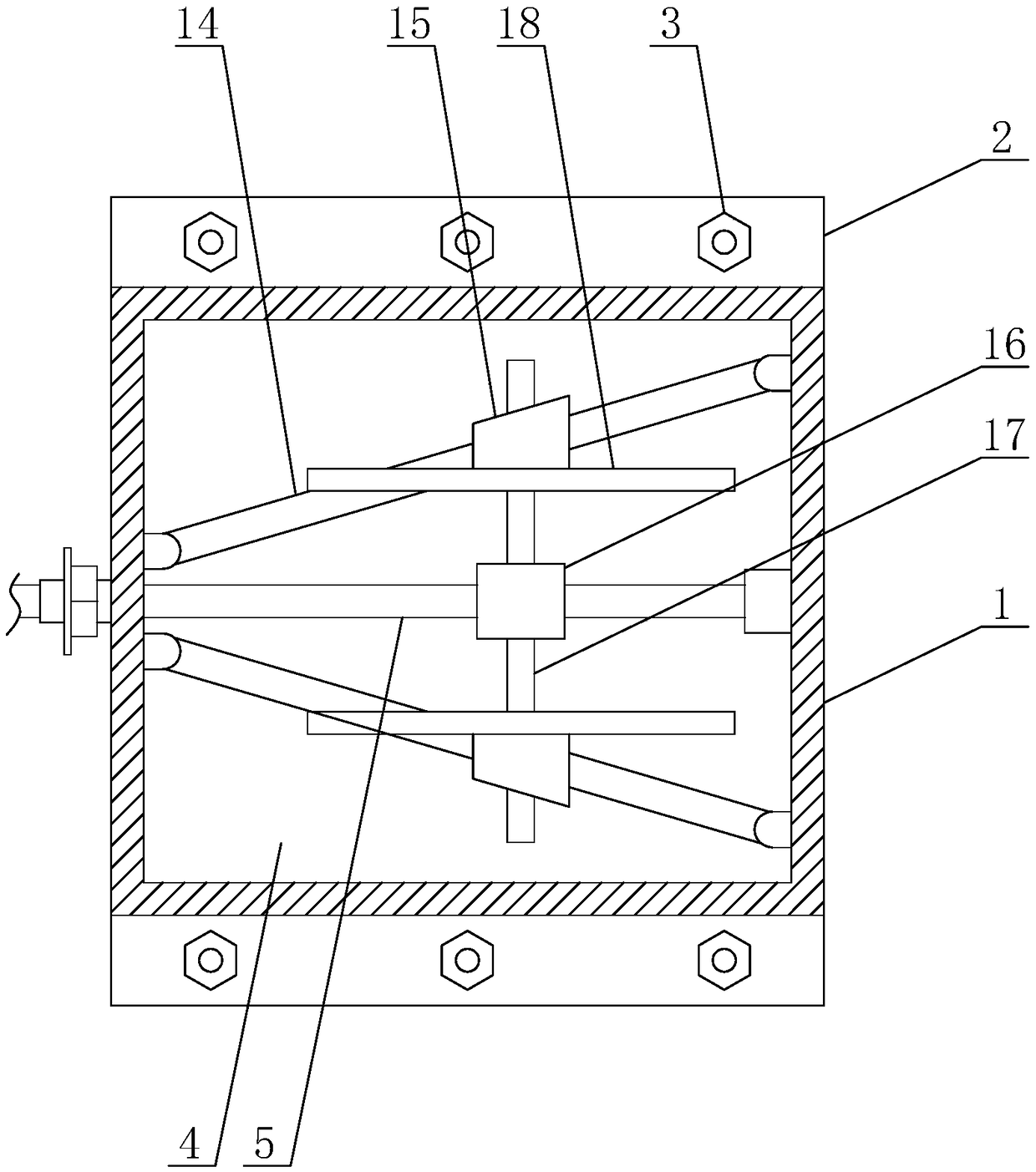

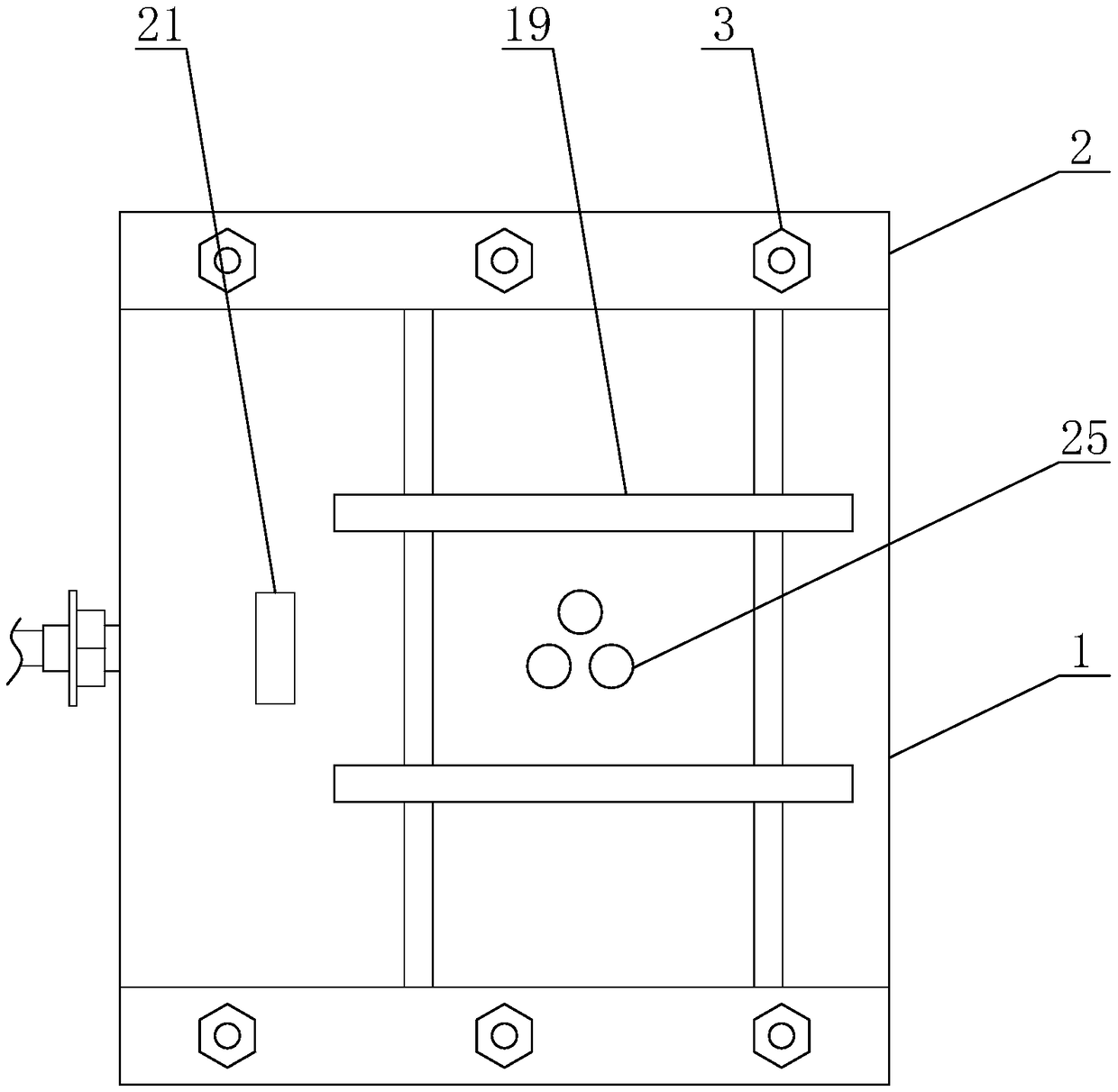

The invention discloses an efficient damping device for mechanical equipment. The efficient damping device comprises a base, a mounting seat for mounting the mechanical equipment and a damping mechanism, wherein the mounting seat is arranged above the base; the damping mechanism is connected between the mounting seat and the base and comprises a telescopic rod, a first spring, a worm, a worm wheelring, a first connecting rod, an adjusting rod, a plurality of cylinder blocks, an adjusting plate, a second spring, a piston, a piston rod, a movable block and a second connecting rod; air sacs aremounted on the upper surface, on one side of each of the cylinder blocks, of the base; and a mounting mechanism is arranged on the mounting seat and comprises a first stepping motor, a first bevel gear, a second bevel gear and a clamping positioning block. The efficient damping device is provided with the damping mechanism to realize efficient damping and adjust the initial compression amount andthe buffering strength of the second spring so as to be adapted to different buffering demands of mechanical equipment with different weight; the air sacs are arranged to improve the buffering effect;and the mounting mechanism is arranged to quickly clamp and position the mechanical equipment.

Owner:SUZHOU LAIJIN ELECTROMECHANICAL AUTOMATION CO LTD

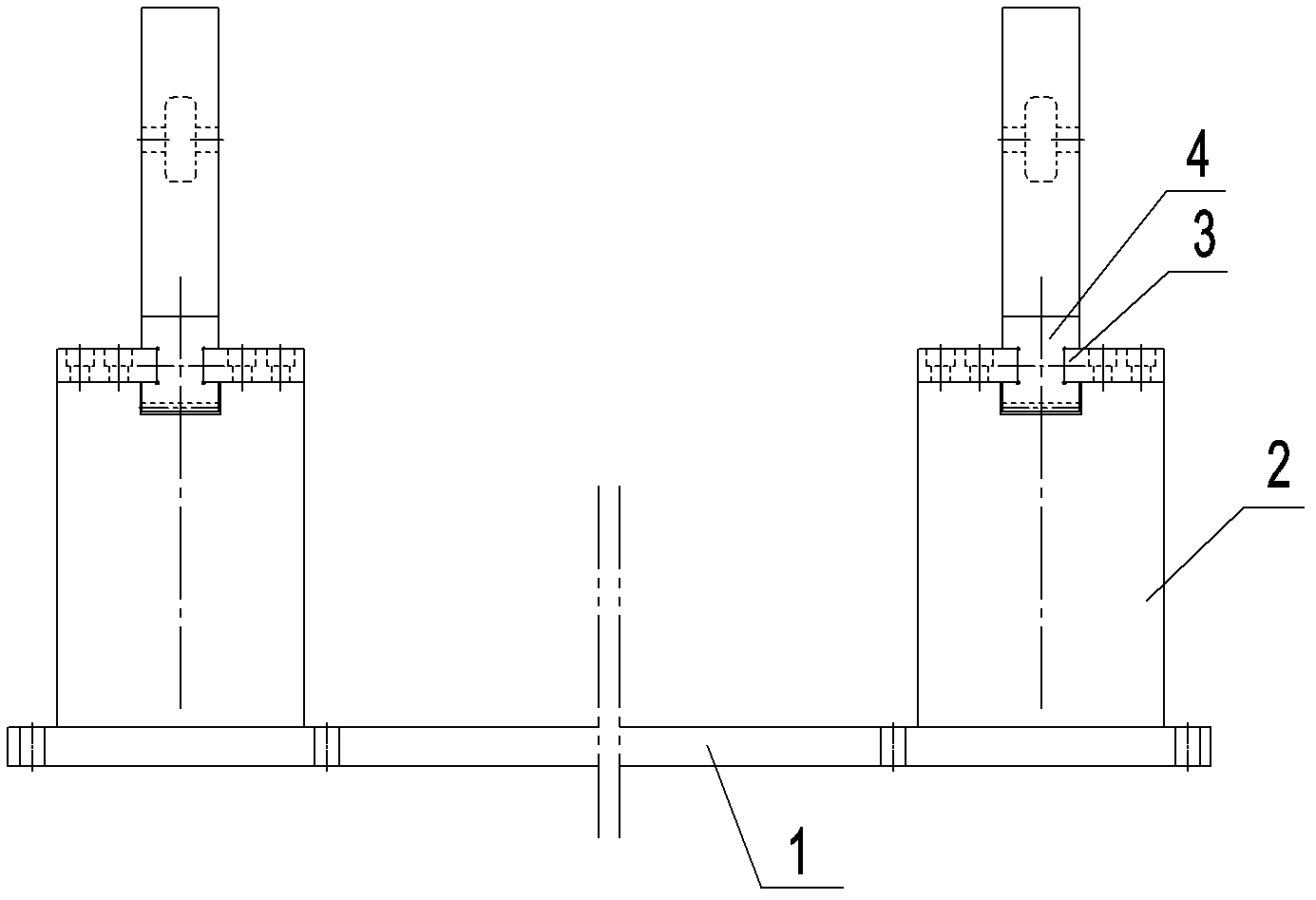

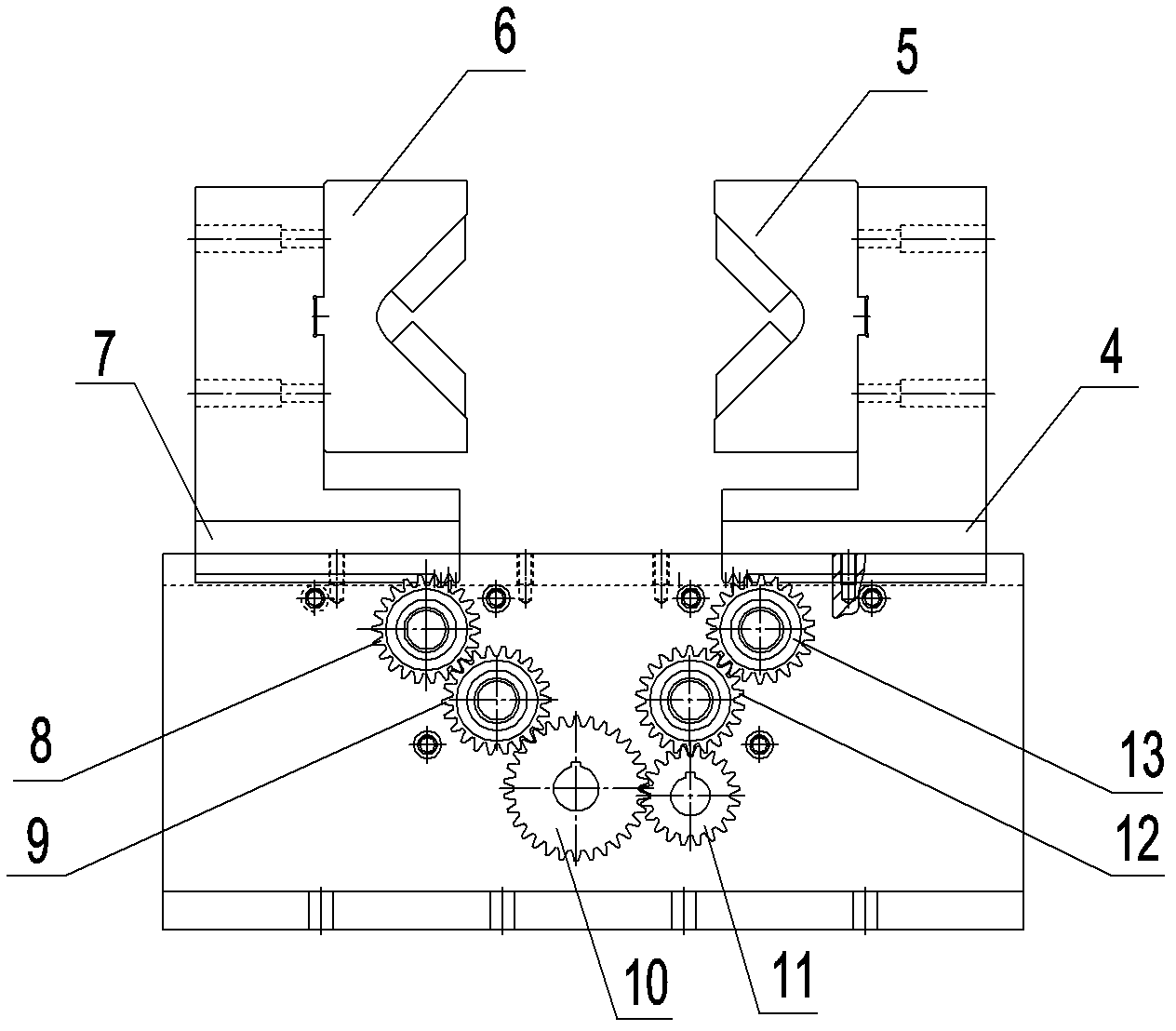

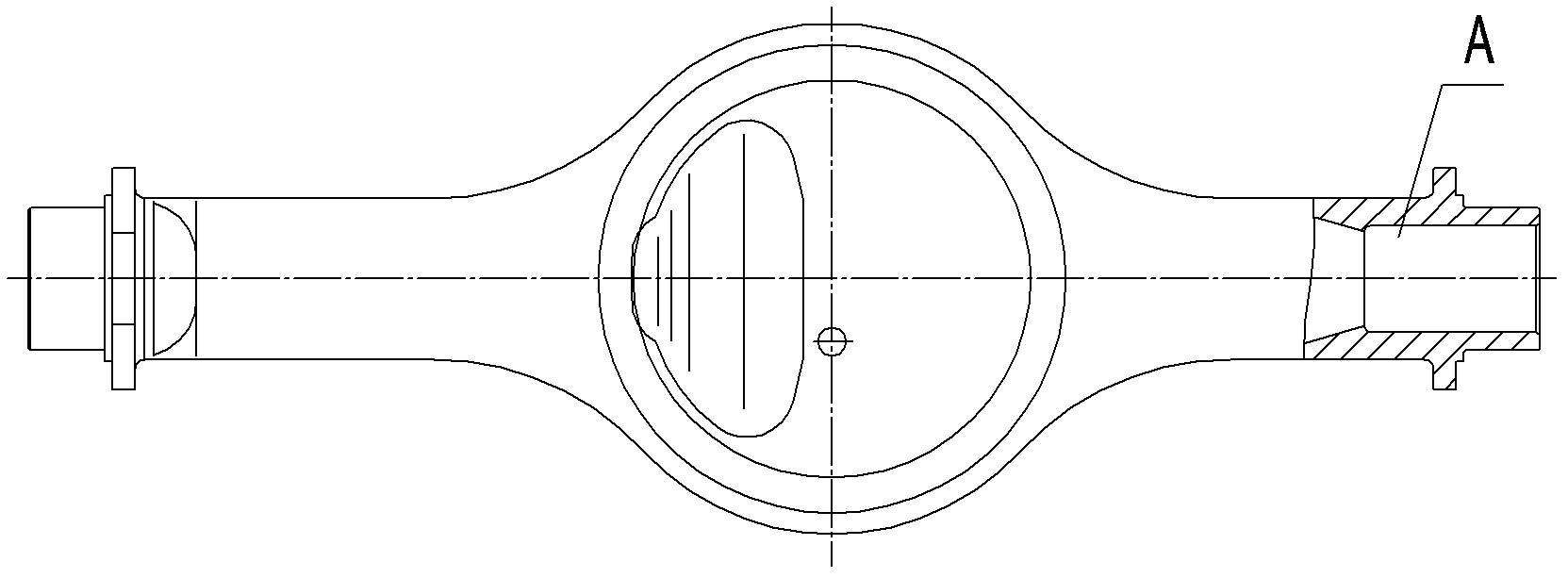

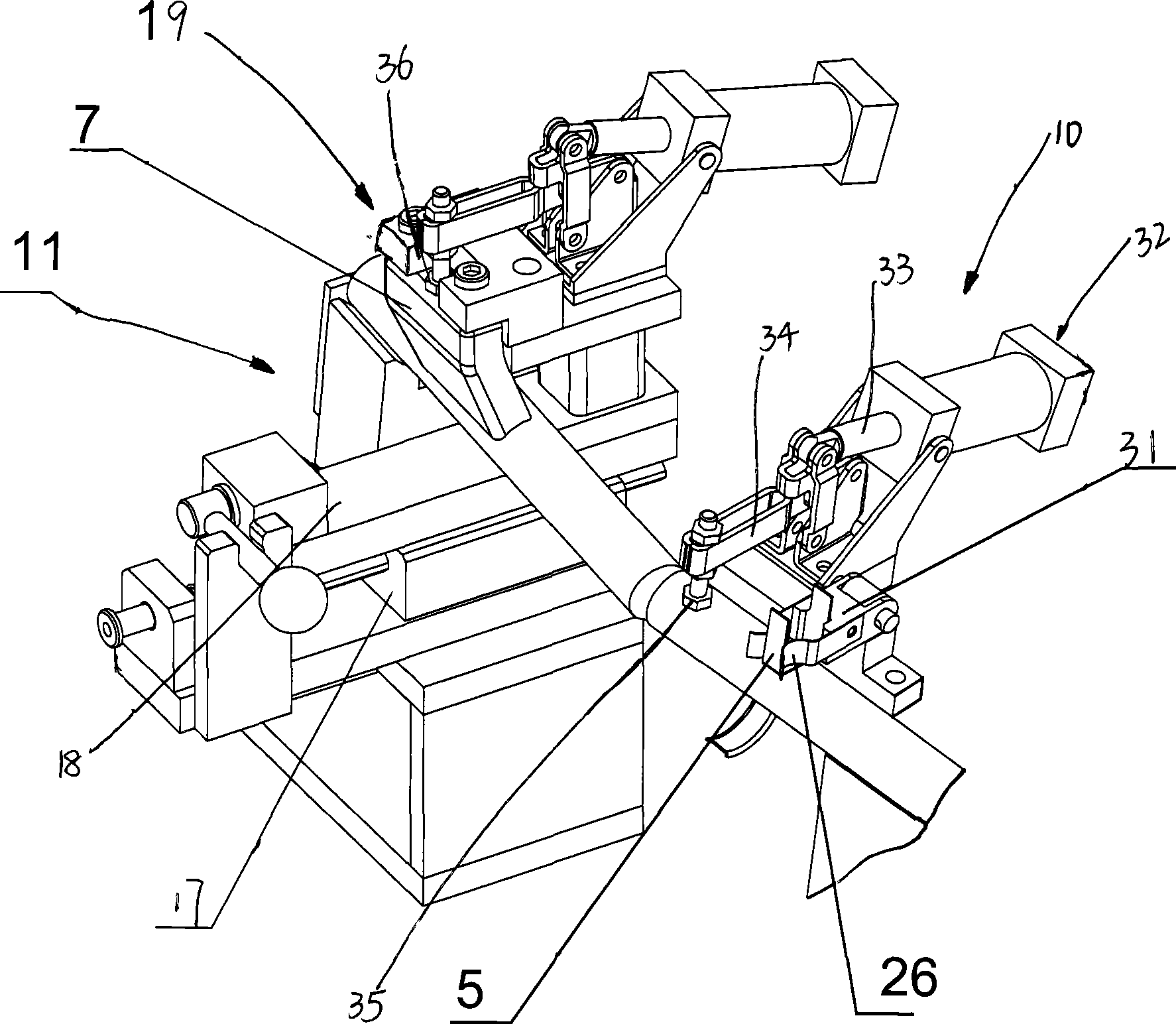

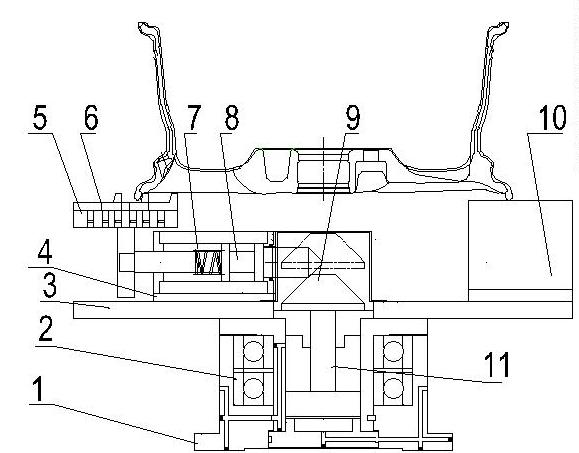

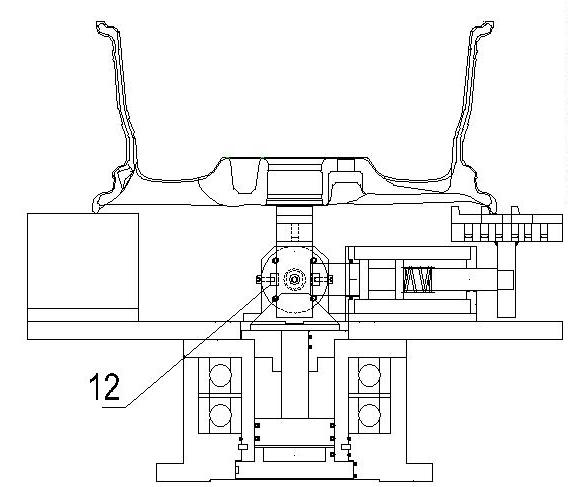

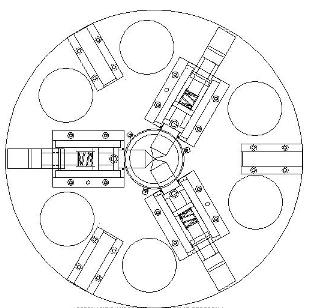

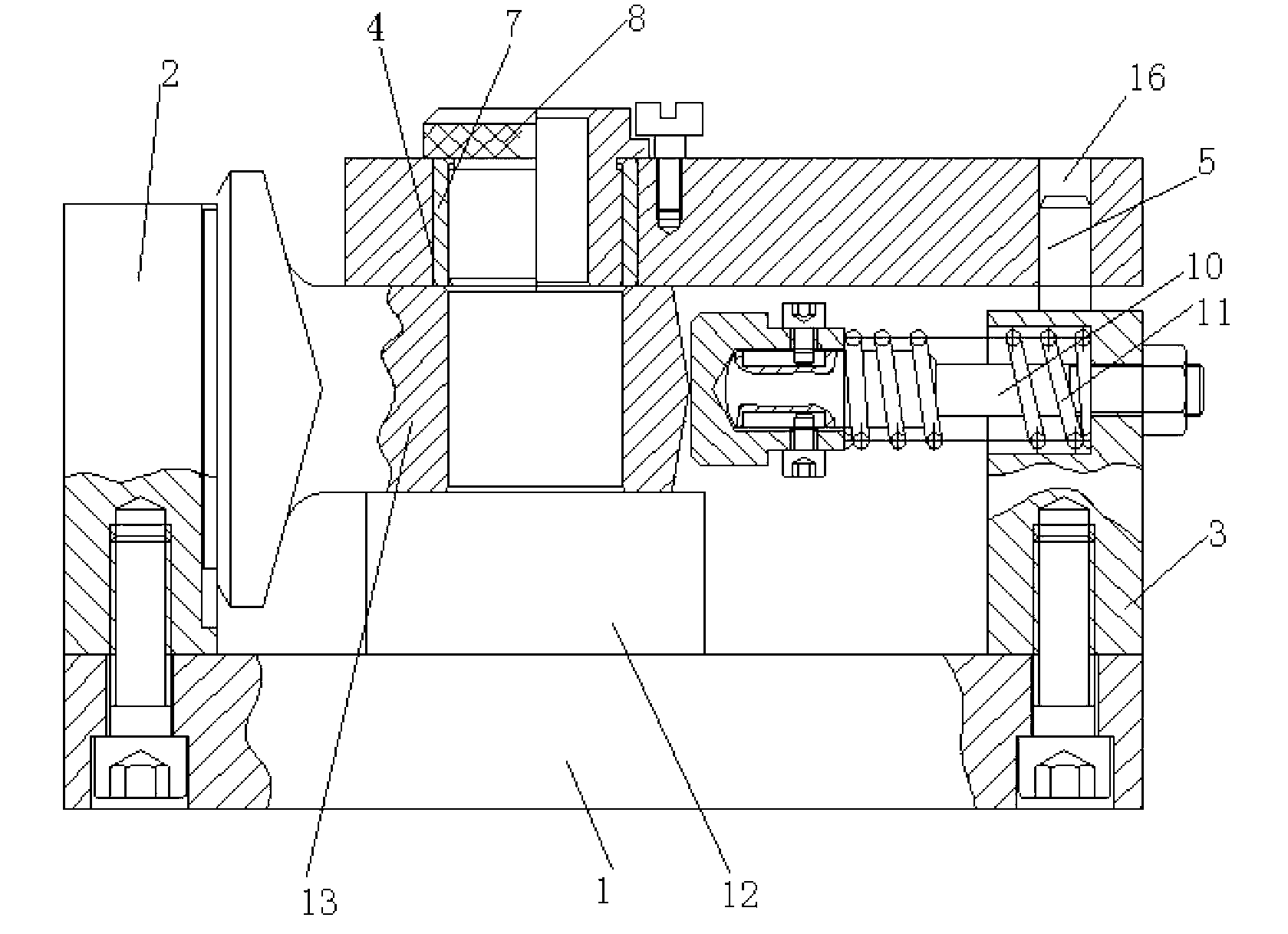

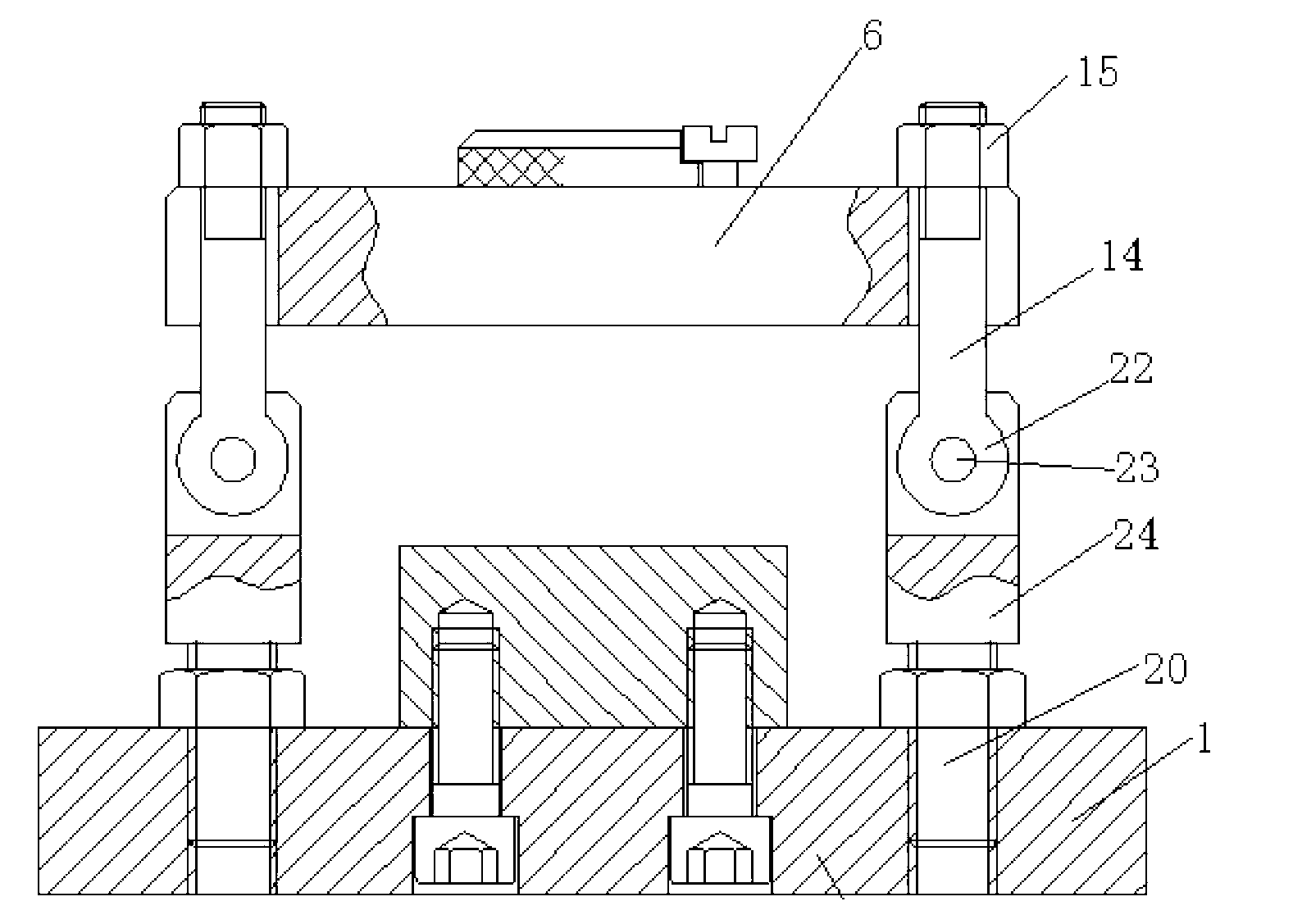

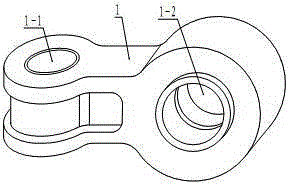

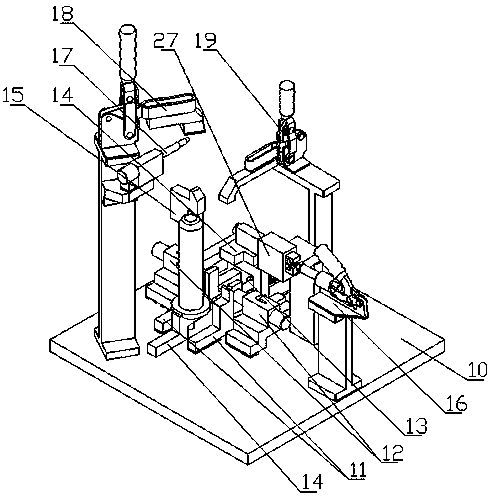

Boring automatic centering clamp of drive axle housing

InactiveCN102581641AGuaranteed machining accuracyImprove work efficiencyPositioning apparatusMetal-working holdersControl theoryMechanical engineering

The invention provides a boring automatic centering clamp of a drive axle housing, relating to a clamp for the mechanical processing field. The boring automatic centering clamp comprises a fixing base, and two sets of clamping positioning devices symmetrically connected to two ends of the fixing base, wherein each set of clamping positioning devices comprises a transmission case, a sliding block I, a sliding block II, a clamping block I and a clamping block II; a slide rail is mounted on the top wall of the transmission case; the sliding block I and the sliding block II are glidingly connected to the slide rail, and protruded on the upper surface of the top wall of the transmission case; the clamping block I is connected to the sliding block I, while the clamping block II is connected to the sliding block II; symmetrically mounted clamping parts having the same shape are concavely arranged in the clamping block I and the clamping block II, respectively; and the transmission case is internally provided with a transmission mechanism for sliding the sliding block I and the sliding block II to reversely move on the lead rail in order to control the clamping block I and the clamping block II to clamp or release the drive axle housing. The boring automatic centering clamp provided by the invention has the advantages of automatically aligning the axes of the sleeve holes at two ends of the drive axle housing, and quickly performing positioning and clamping.

Owner:LIUZHOU CITY LONGCHEN AXLE PARTS MFG

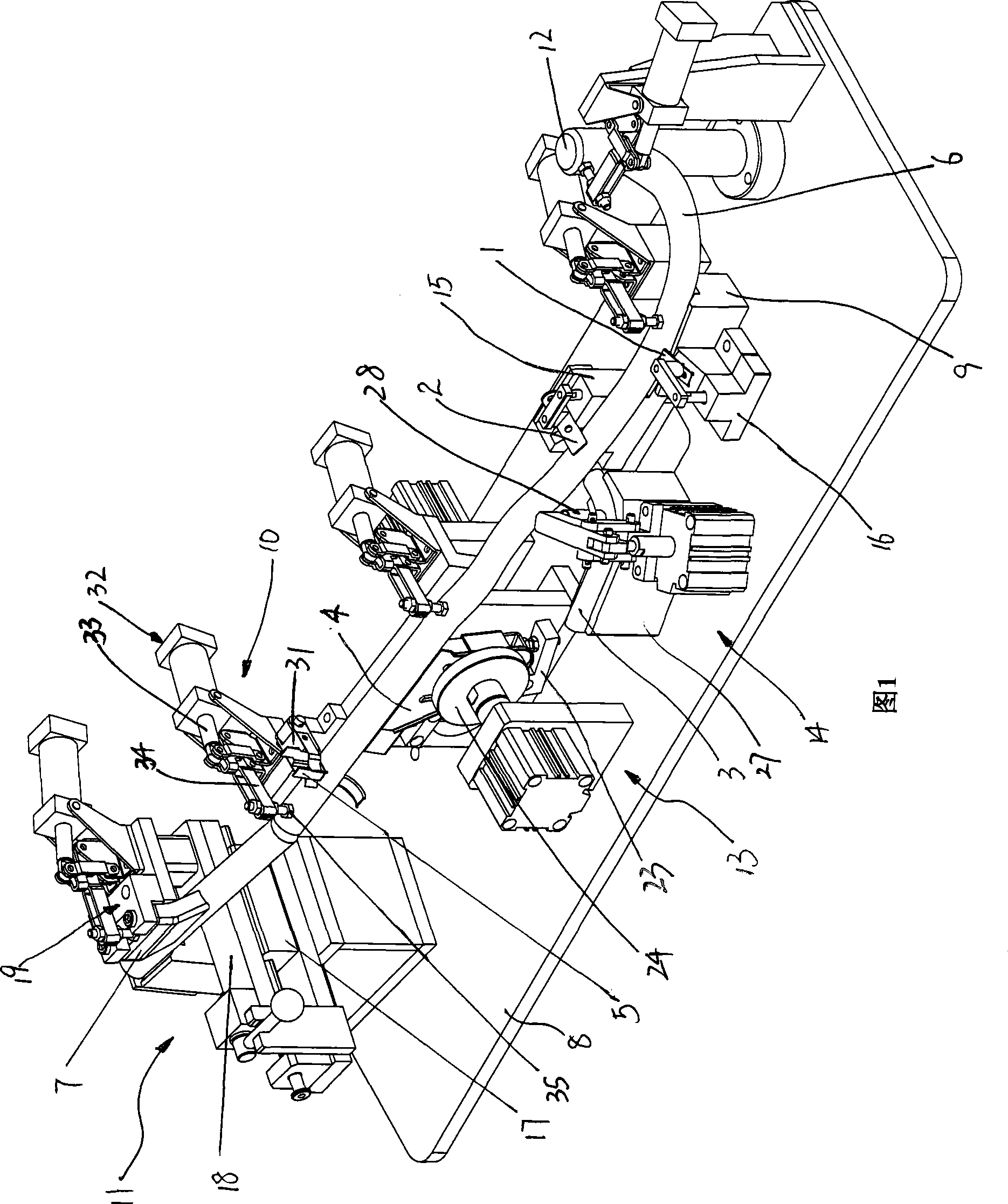

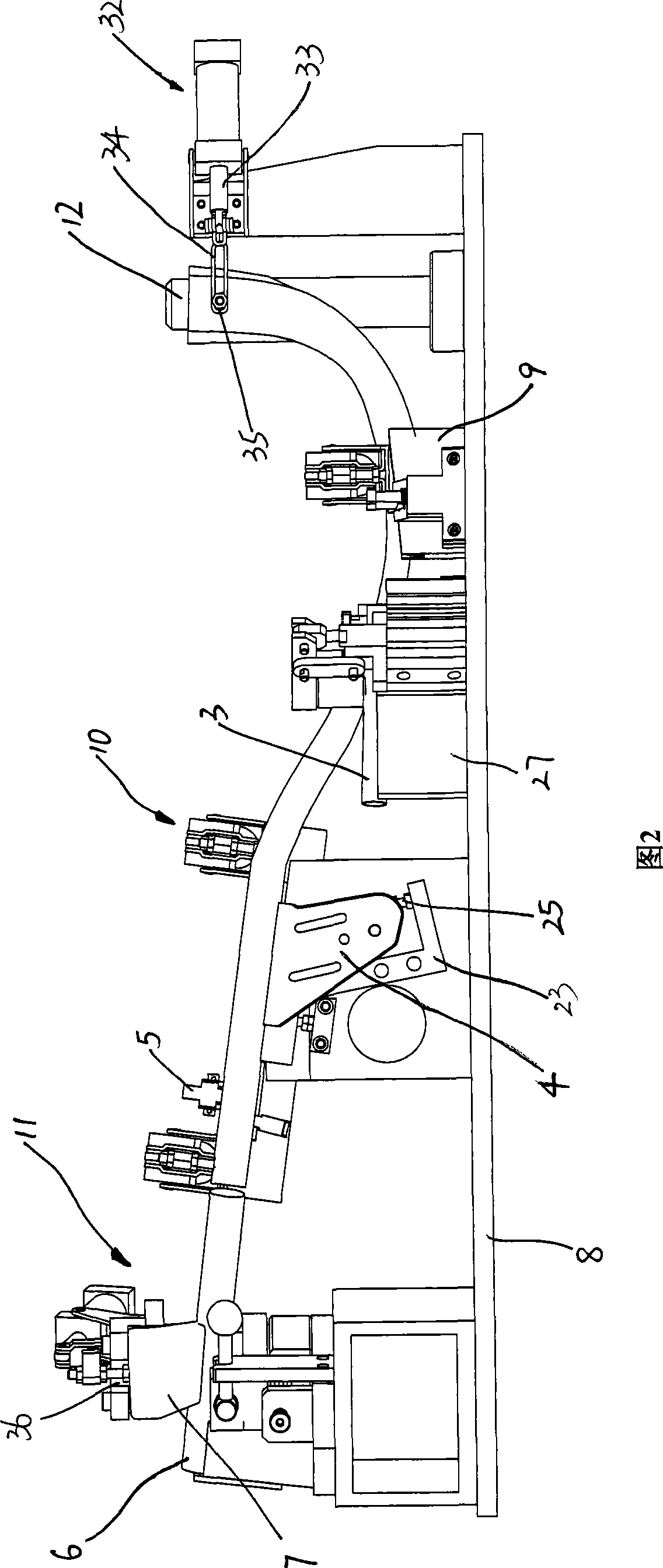

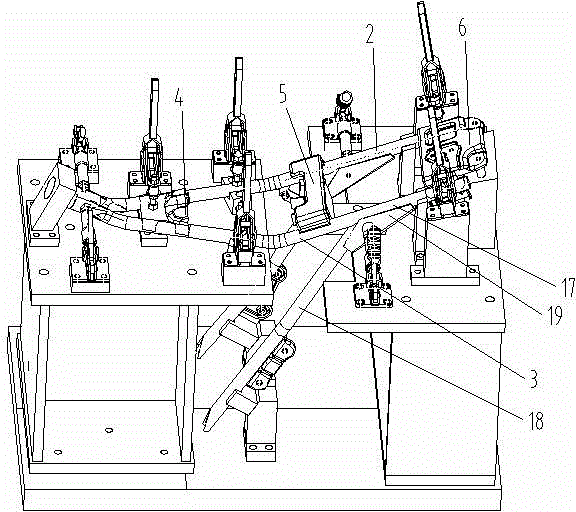

Welding clamp of winding pipe assembly

InactiveCN101376201AAccurate locationQuick positioning clampingWelding/cutting auxillary devicesAuxillary welding devicesFuel tankEngineering

The invention relates to a welding fixture of bent pipe components, which comprises a pedestal, a supporting module fixedly arranged on the pedestal and used for supporting workpieces to be welded, and a plurality of clamping devices with the parts clamped on the surfaces of the workpieces to be welded used for fixing the workpieces to be welded. A cylindrical positioning block is fixedly arranged at the front part of the pedestal, and an oil tank pressure plate fixing seat is arranged at the rear part of the pedestal; a power hanging frame fixing seat is also fixedly arranged between the oil tank pressure plate fixing seat and the positioning block; and a branch pipe fixing seat is also fixedly arranged on the pedestal in front of the power hanging frame fixing seat. The welding fixture can rapidly position and clamp components to be welded, thereby avoiding the complex preparatory work before welding, so as to allows the multi-step welding during the one-time process of clamping, and improve work efficiency; meanwhile, the invention can ensure accurate positions among the components when welding, and improve processing precision and qualified rate of the product.

Owner:庄添财

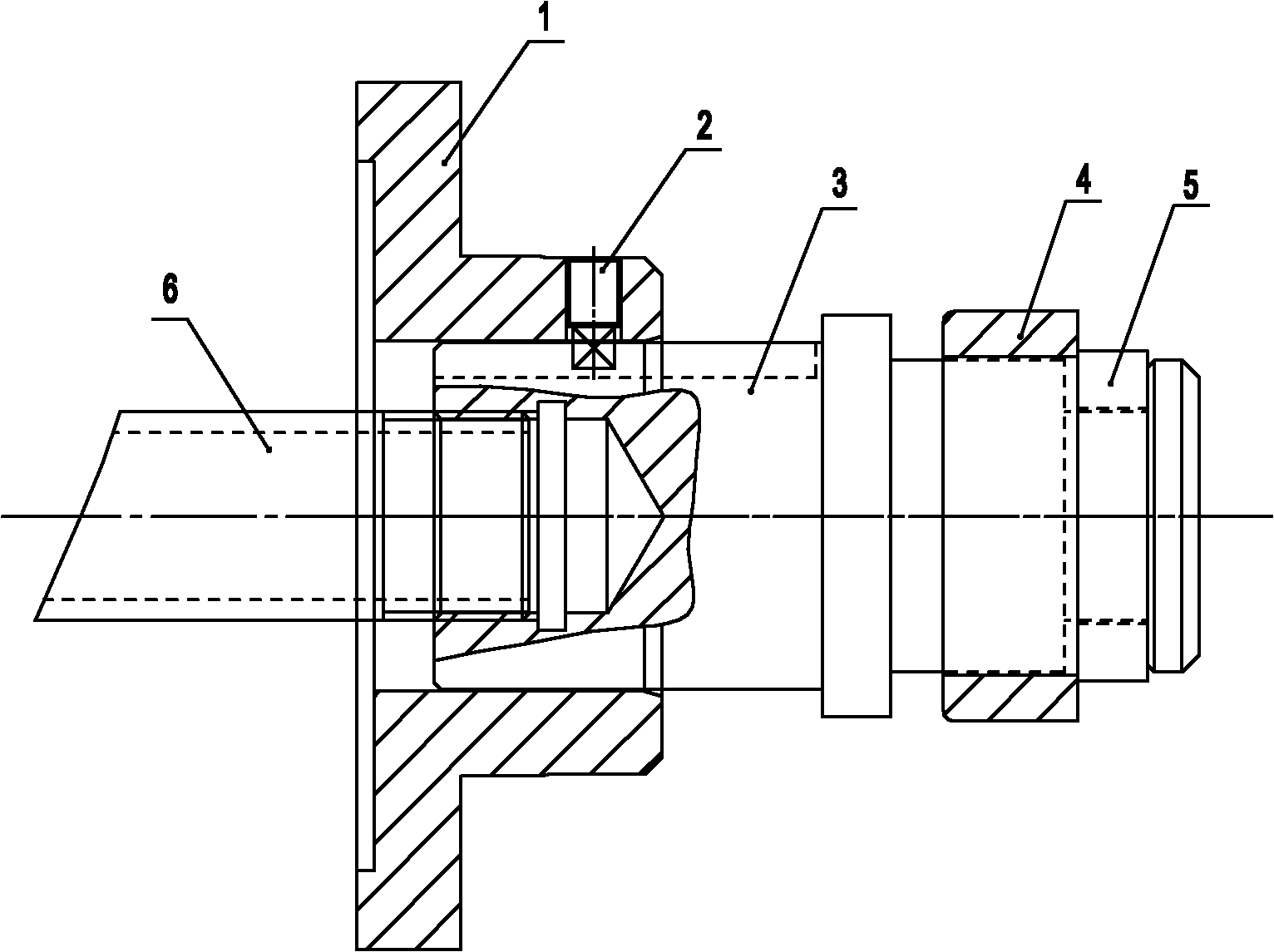

Hub lathe jig

InactiveCN102211209AQuick positioning clampingGuaranteed machining accuracyPositioning apparatusTurning machinesHydraulic cylinderEngineering

The invention provides a hub lathe jig, relating to a jig for the field of machining. The hub lathe jig comprises a positioning disc, a clamping pull head, a supporting sleeve, a tensioning spacer and a pull tube, wherein the positioning disc comprises a main body part and a positioning part, wherein the main body part is connected to a lathe principal shaft, and the positioning part protrudes out of one end of the main body part to position a hub bearing hole; the clamping pull head comprises a connecting shaft and a positioning shaft, wherein the connecting shaft is arranged in a through hole of the positioning disc, the positioning shaft is connected to one end of the connecting shaft, which is far away from the positioning disc, the end part of the connecting shaft is inwards concavely provided with a connecting hole, the positioning shaft is inwards concavely provided with an annular groove near the tail position of a free end, and a protruded clamping part is formed at the outer side of the groove; the supporting sleeve is sleeved on the surface of an excircle positioned at the inner side of the annular groove of the positioning shaft, the outer surface of the supporting sleeve is matched with the inner surface of one of inner holes of a hub, and the end surface of the inner side of the supporting sleeve is clamped on the end surface of the inner side of the inner hole of the hub; the tensioning spacer is arranged in the annular groove and clamped with the end surface of the outer side of the supporting sleeve; one end of the pull tube is connected with the connecting hole of the connecting shaft of the clamping pull head, and the other end of the pull tube is connected with a hydraulic cylinder.

Owner:LIUZHOU CITY LONGCHEN AXLE PARTS MFG

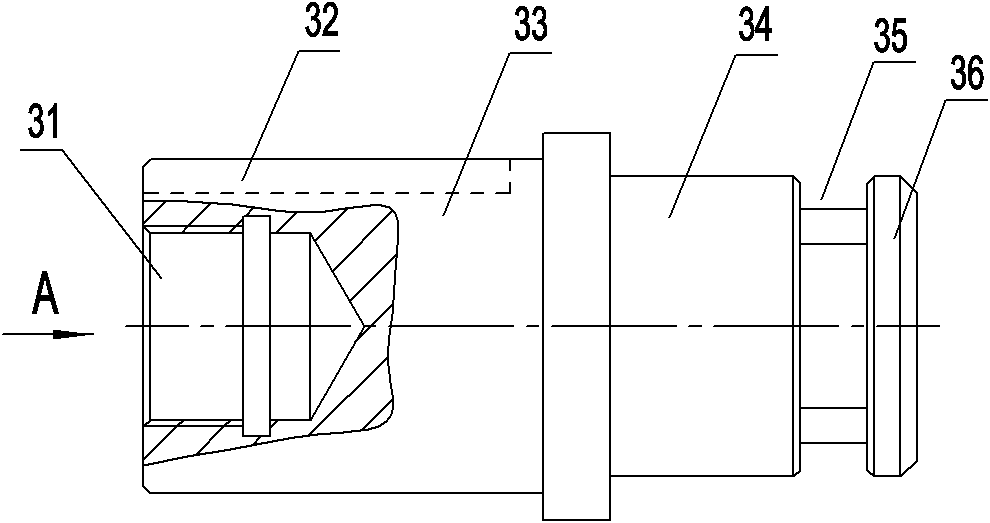

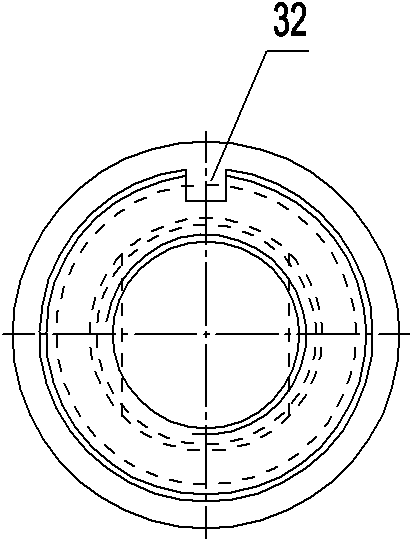

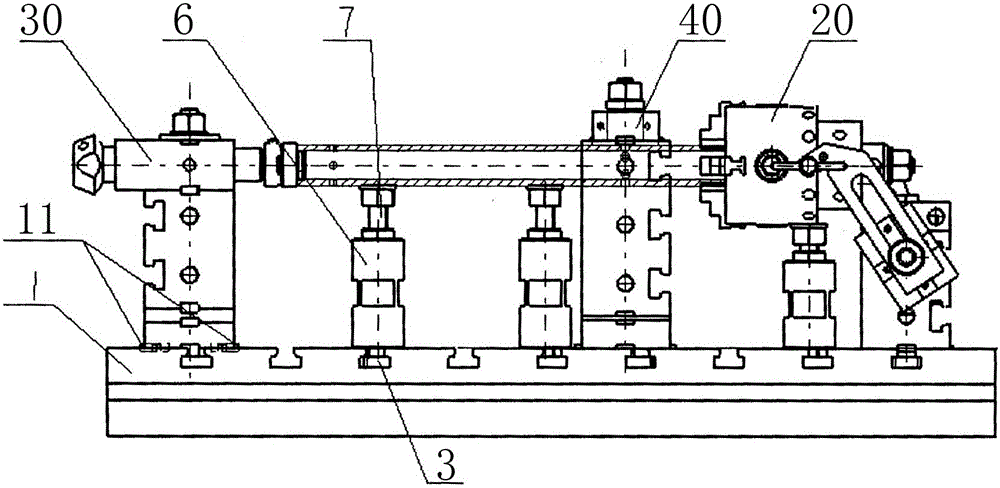

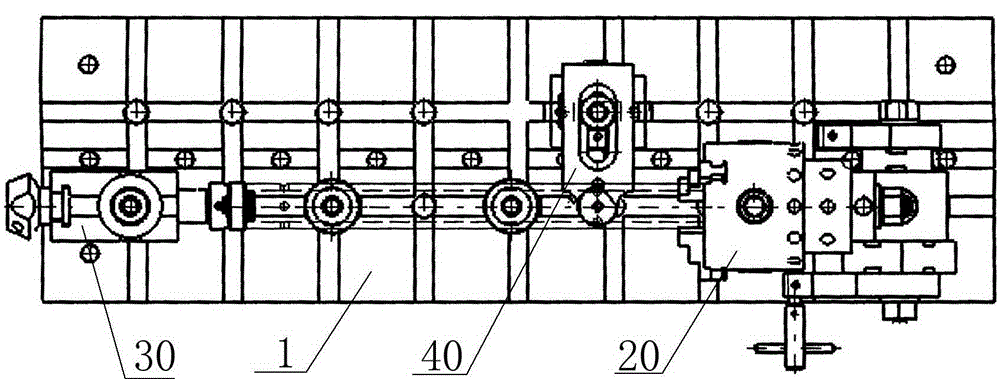

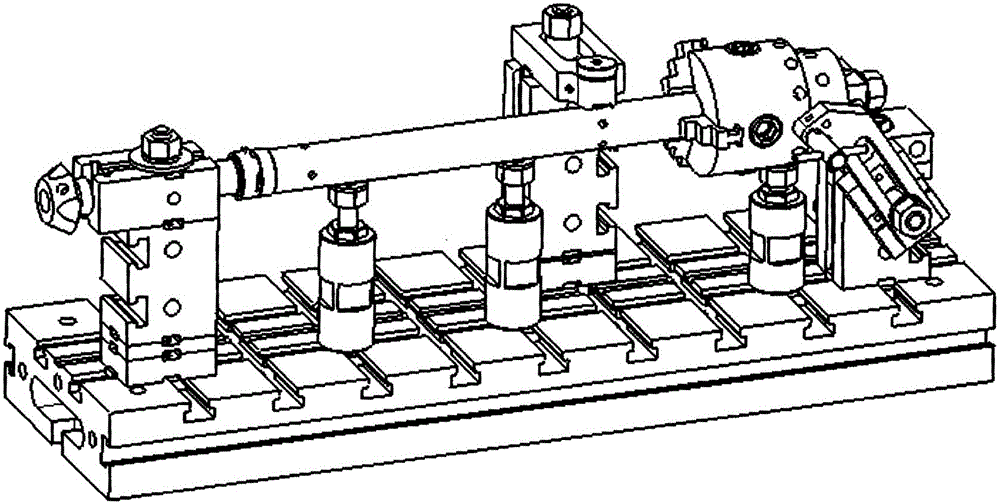

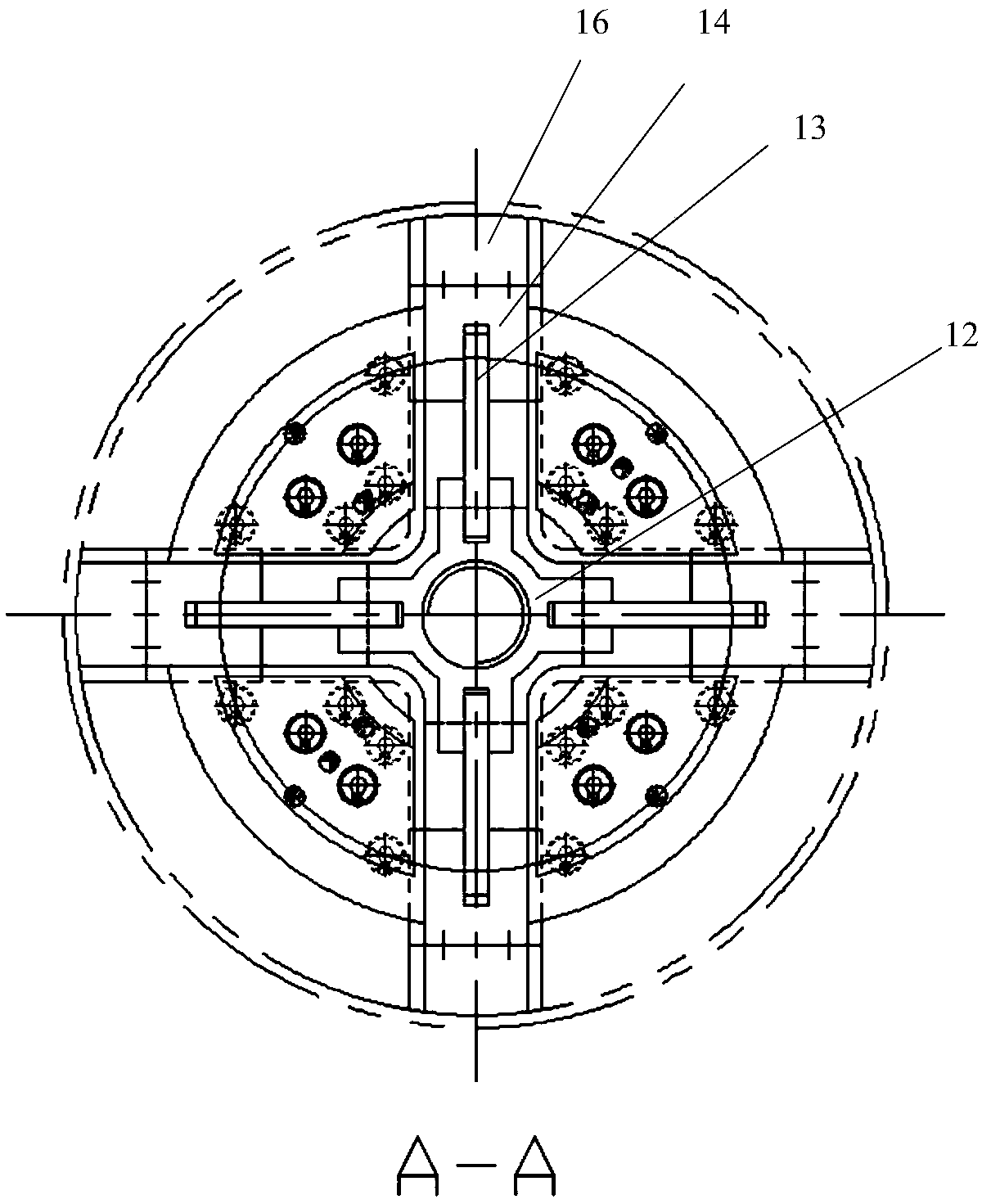

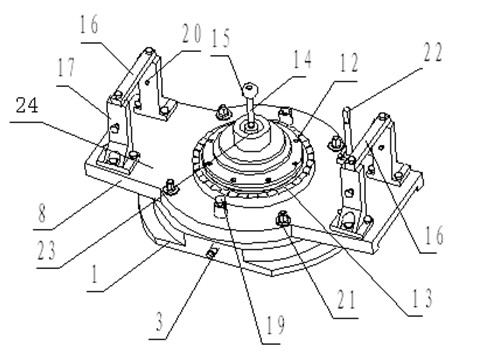

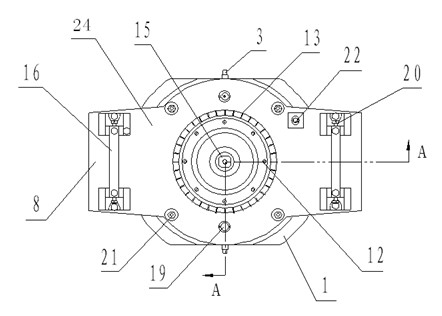

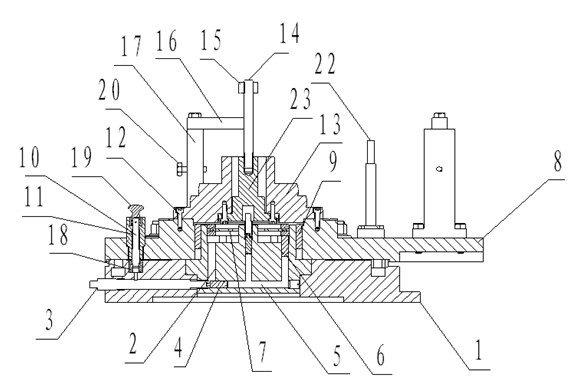

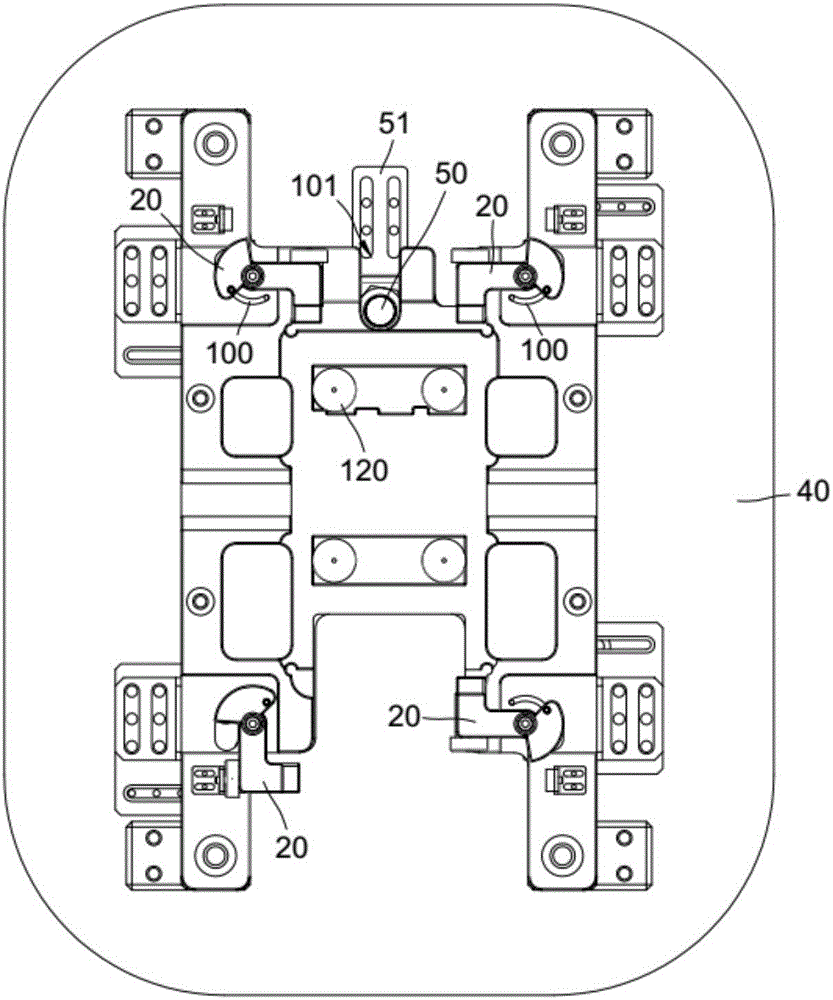

Mechanism capable of drilling radial holes in indexing manner and drilling method

ActiveCN105081406AReduce duplicationReduce assemblyPrecision positioning equipmentDrill jigsEngineeringMechanical engineering

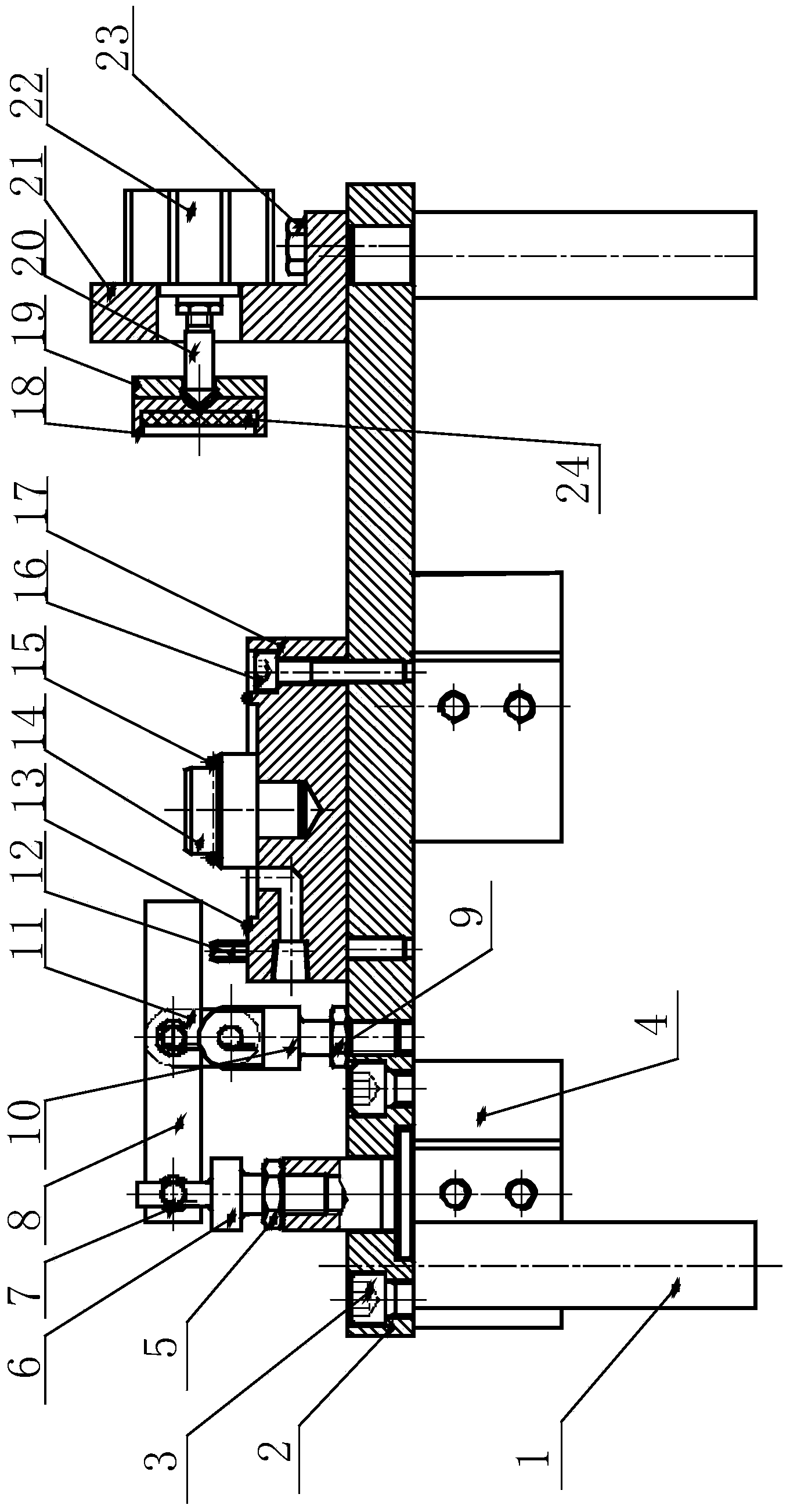

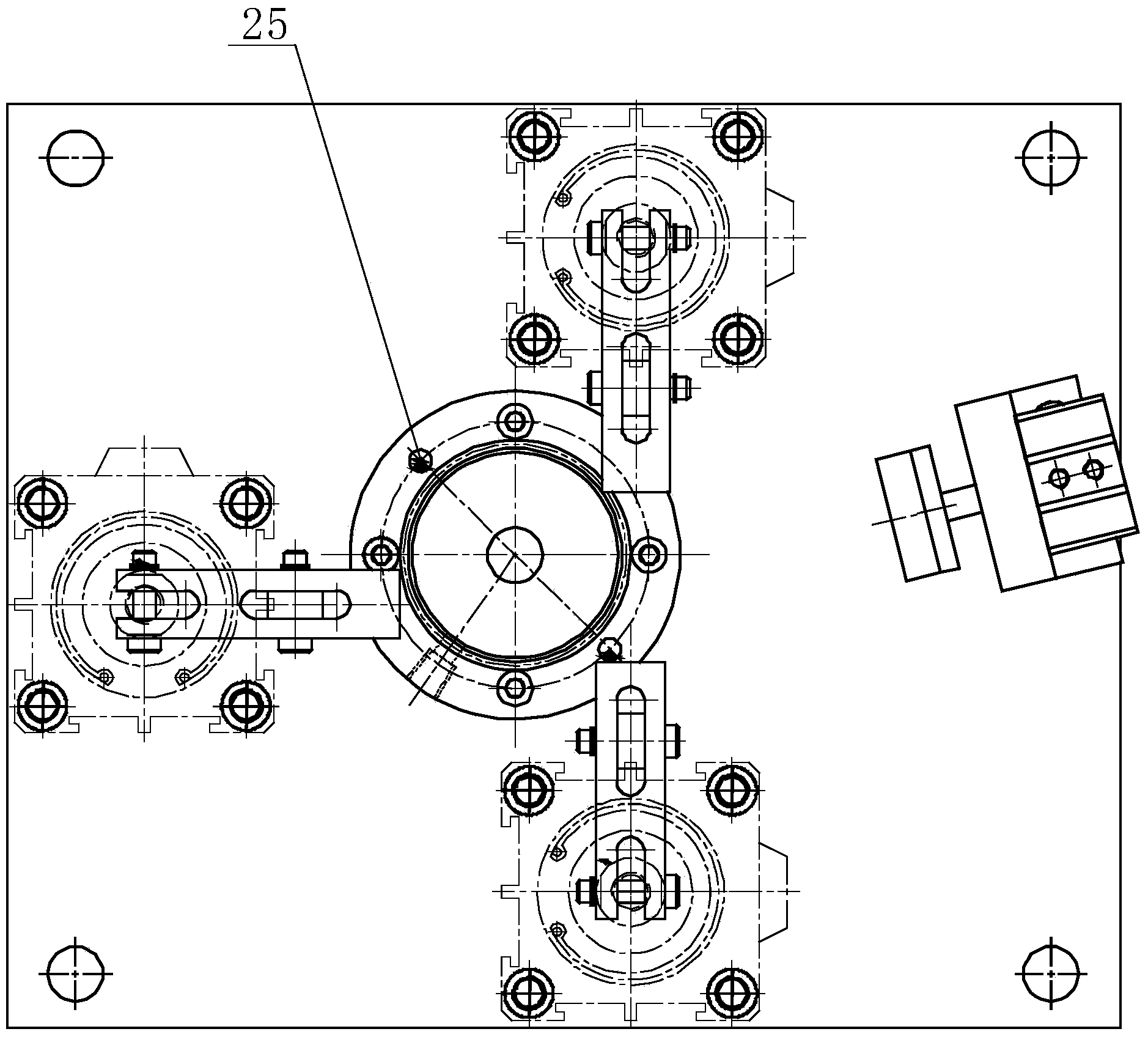

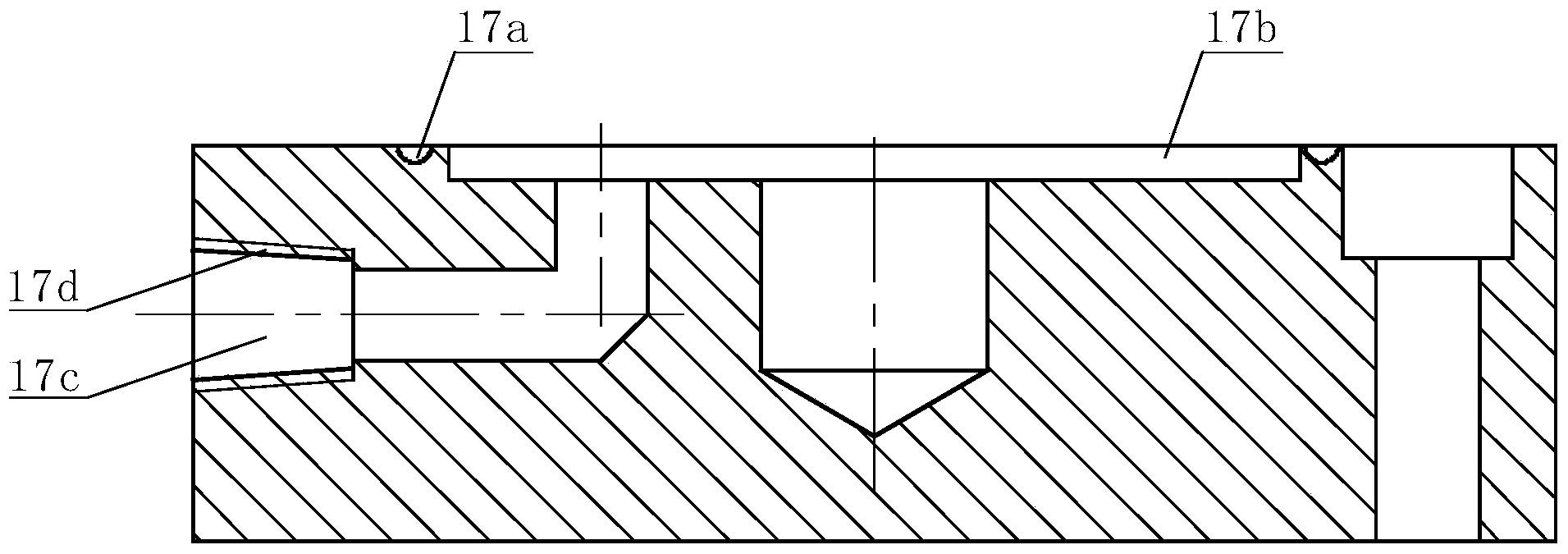

The invention relates to a mechanism capable of drilling radial holes in an indexing manner. According to the mechanism, T-shaped grooves which are transversally and longitudinally staggered, and provided with uniform specifications are formed in the upper surface of a rectangular foundation plate, a multi-index locating and clamping mechanism, an auxiliary locating and clamping mechanism and a slide drilling template mechanism are arranged on the rectangular foundation plate respectively, a cross-shaped groove is formed in the bottom of each mechanism, a slide-fit key is arranged in a corresponding side direction in each cross-shaped groove, and each slide-fit key is in slide connection with a narrow groove in the upper end of the corresponding T-shaped groove of the rectangular foundation plate; and a bolt for a rectangular head groove is arranged in the longitudinal direction of each mechanism, and an end head of each bolt for a rectangular head groove is in slide connection with a wide groove in the bottom of the T-shaped groove at a corresponding position on the rectangular foundation plate. According to the mechanism capable of drilling radial holes in the indexing manner and the drilling method, parts are located by a universal interchangeable structure, thus reducing repeated design and assembly for a fixture, reducing losses of raw materials, and improving product quality and production efficiency.

Owner:SHENYANG AIRCRAFT CORP

Device for full-automatic machining of graphene self-lubricating guide plates and machining method thereof

InactiveCN109866087AAvoid damageQuick sandingGrinding carriagesGrinding drivesBall bearingEngineering

The invention relates to the technical field of vehicle molds, and discloses a device for full-automatic machining of graphene self-lubricating guide plates. The device comprises a base; the same console is fixedly connected to four corners of the upper end of the base through support rods; the upper end of the console is slidingly connected with an U-shaped support plate; first motors are fixedlyembedded in the outer walls of the bottom ends of two vertical walls of the U-shaped support plate; output shafts of the first motors are fixedly connected with gears; the upper end of the console isfixedly connected with racks engaged with the gears; two opposite side walls of the U-shaped support plate near the upper end are rotationally connected with the same first screw rod through ball bearings; a second motor is fixedly connected to the outer wall of the U-shaped support plate; and an output shaft of the second motor penetrates through the side wall of the U-shaped support plate, andis fixedly connected with one end of the first screw rod. The device for full-automatic machining of the graphene self-lubricating guide plates and a machining method thereof have the advantages of capability of automatically polishing the guide plates and improvement of the polishing production efficiency.

Owner:浙江双展精密机械股份有限公司

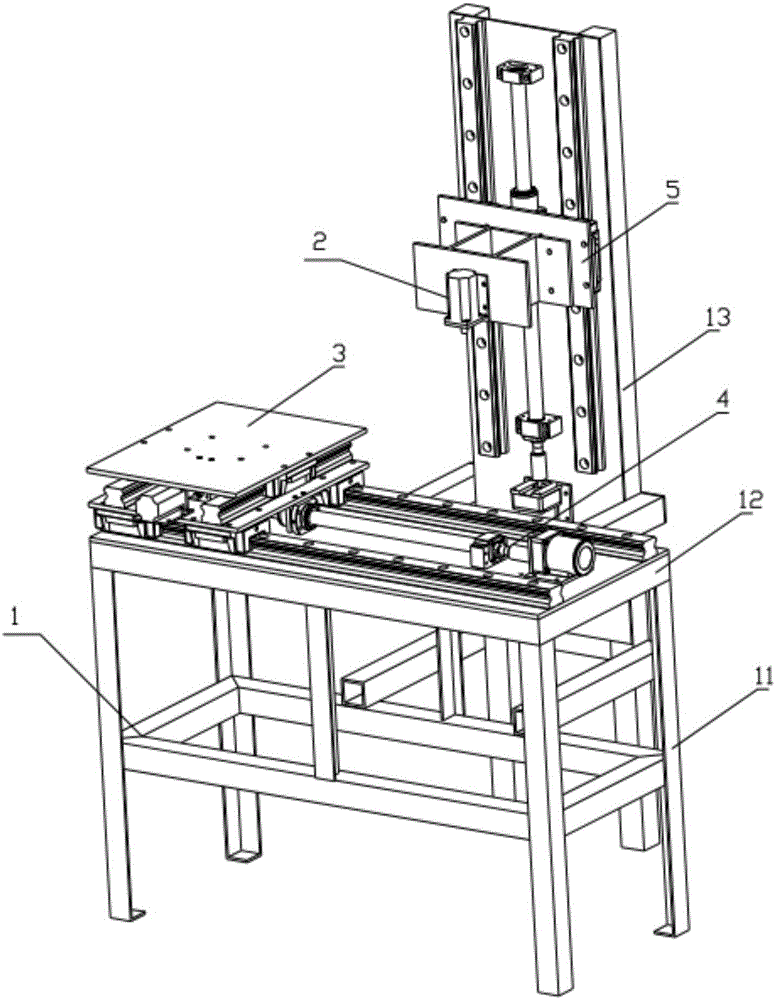

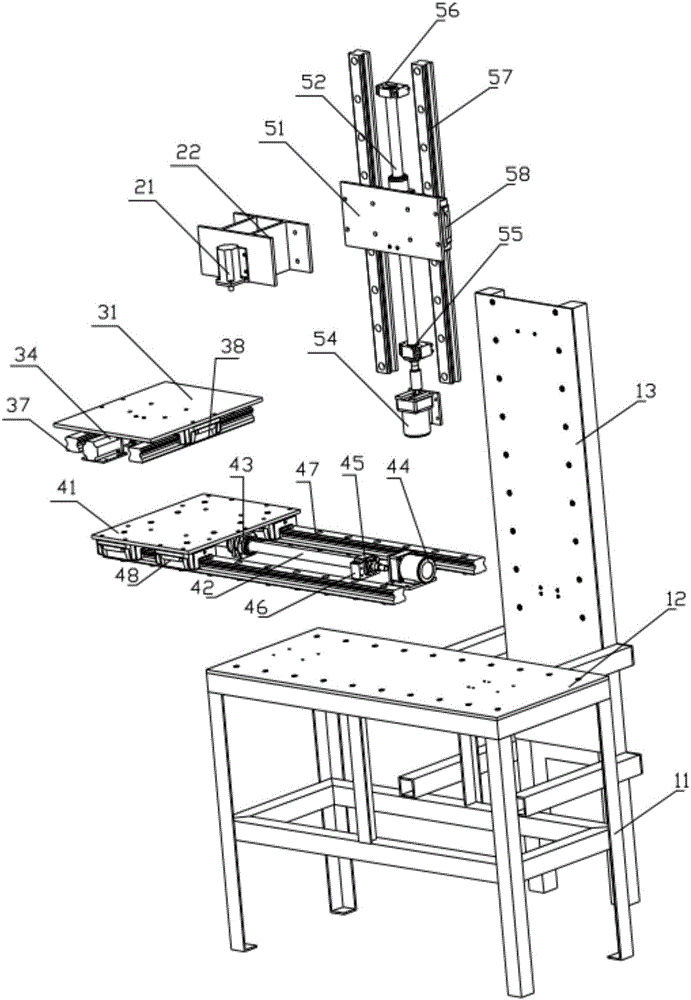

Printing structure for 3D printer

InactiveCN104028760AQuick positioning clampingSimple structureCeramic shaping apparatus3d printEngineering

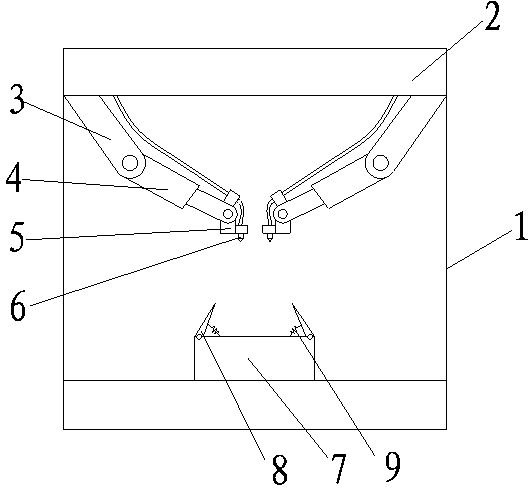

The invention discloses a printing structure for a 3D printer. The printing structure comprises a printer, wherein a mechanical assembly is arranged at the upper end of the inner part of the printer, and a model worktable is arranged at the lower end; the lower ends of both sides of the mechanical assembly are connected with one end of a driving arm, the other end of the driving arm is connected with one end of a driven arm, a clamping head is arranged at the other end of the driven arm, and a printing head is arranged on the clamping head; a plurality of triangular clamping claws are arranged at the outer edge of the model worktable, and clamping springs are arranged between the clamping claws and the model worktable. The printing structure has the advantages of simple structure and rationality in design. For the printing structure, the printing with multi angles and multi heights can be realized in the inner space of the printer, a molded product can be printed twice, and at the same time, the model worktable can be used for fast clamping and positioning a model.

Owner:SUZHOU XUANDONG THREE DIMENSIONAL SPACE TECH

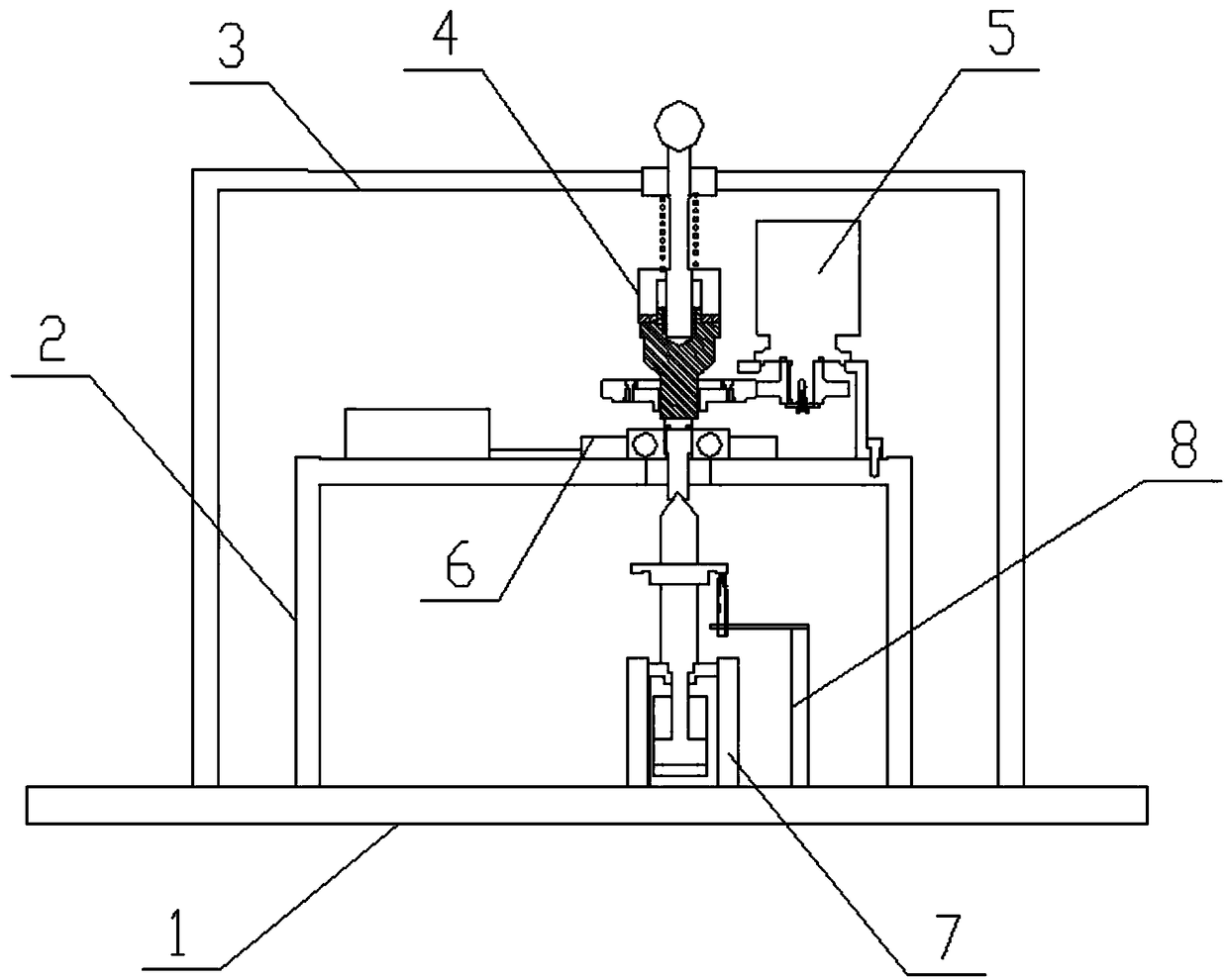

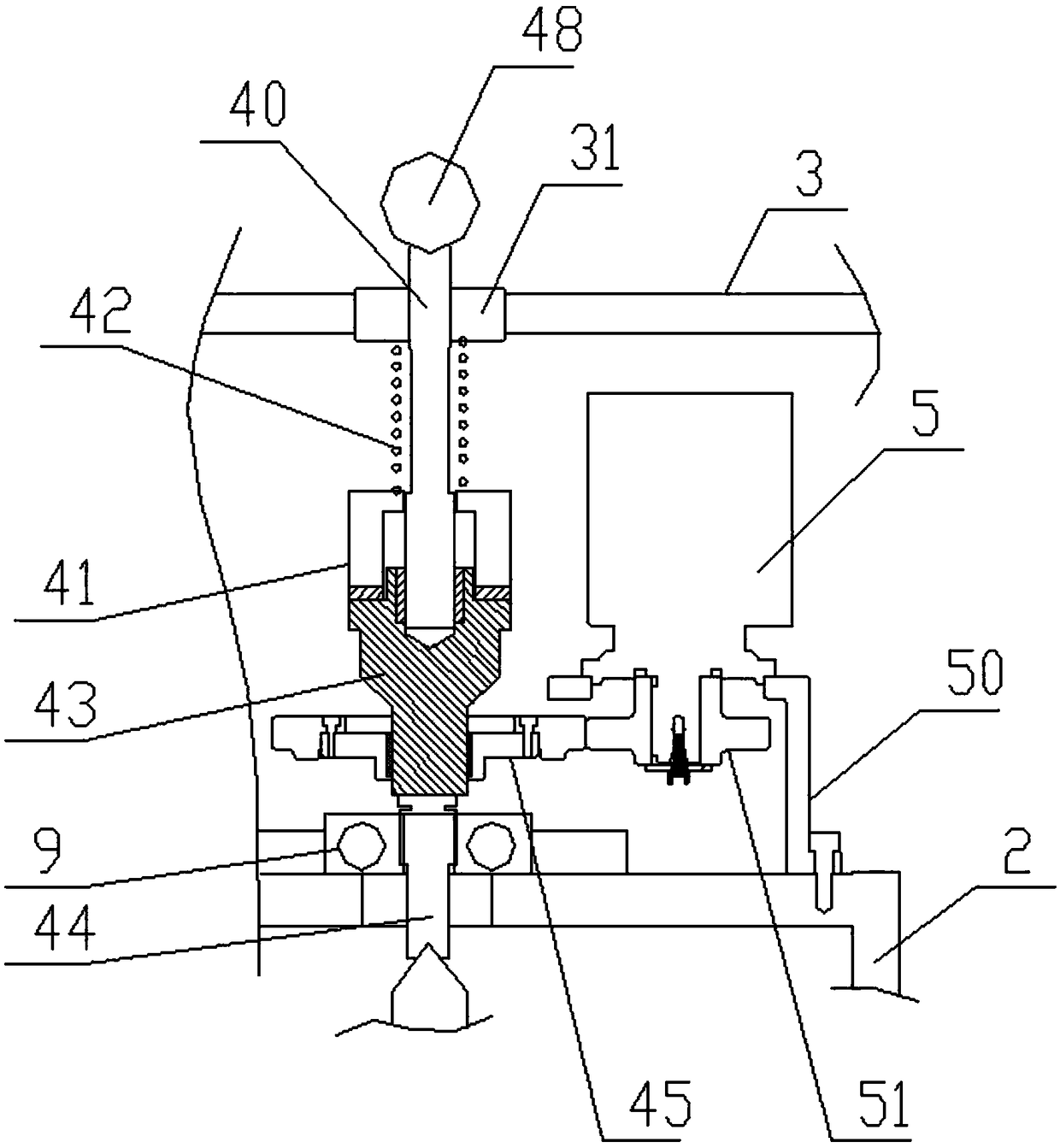

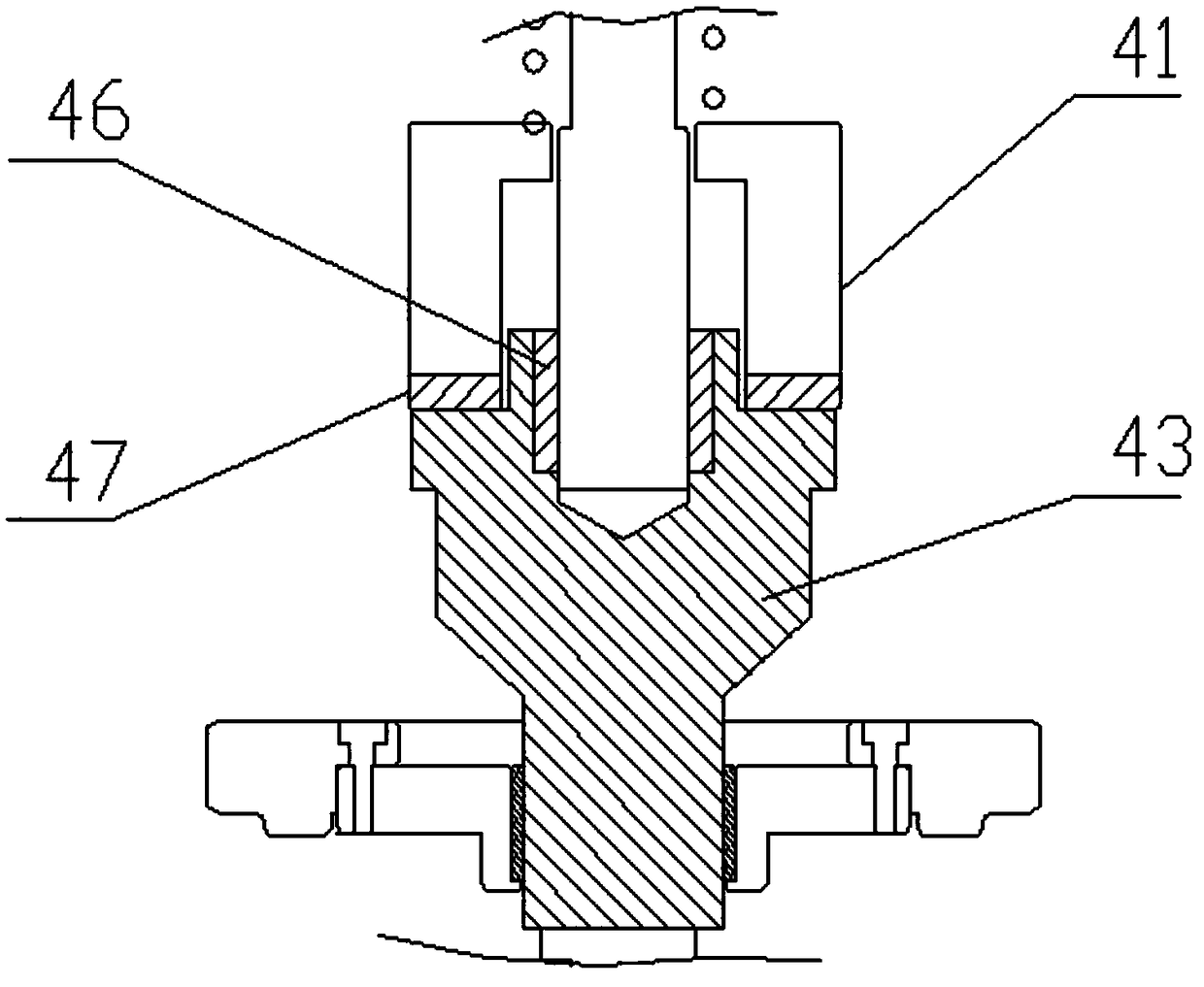

Portable efficient drilling machine

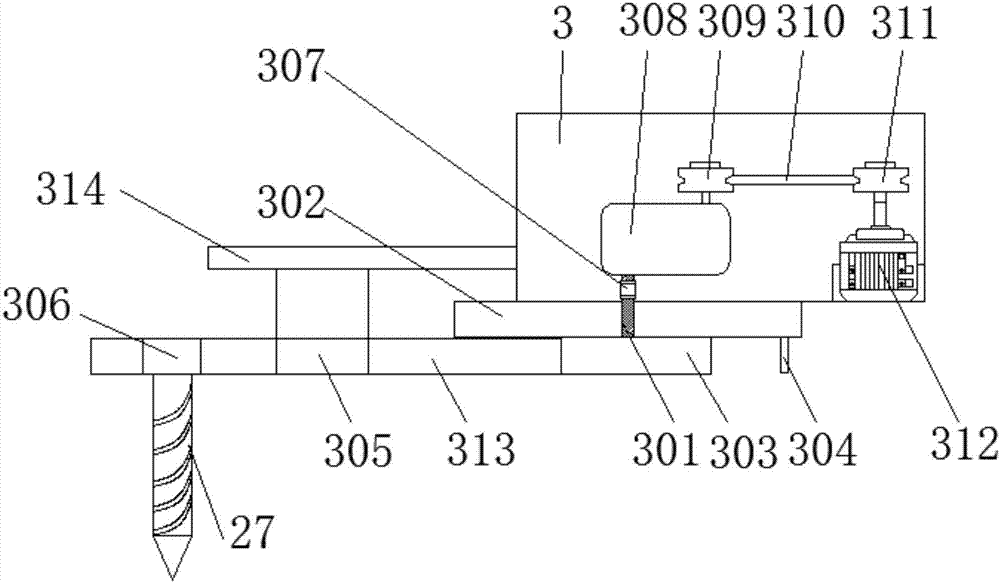

InactiveCN107322055ARealize moving up and downAchieve positioningBoring/drilling componentsBoring/drilling machinesEngineeringDrilling machines

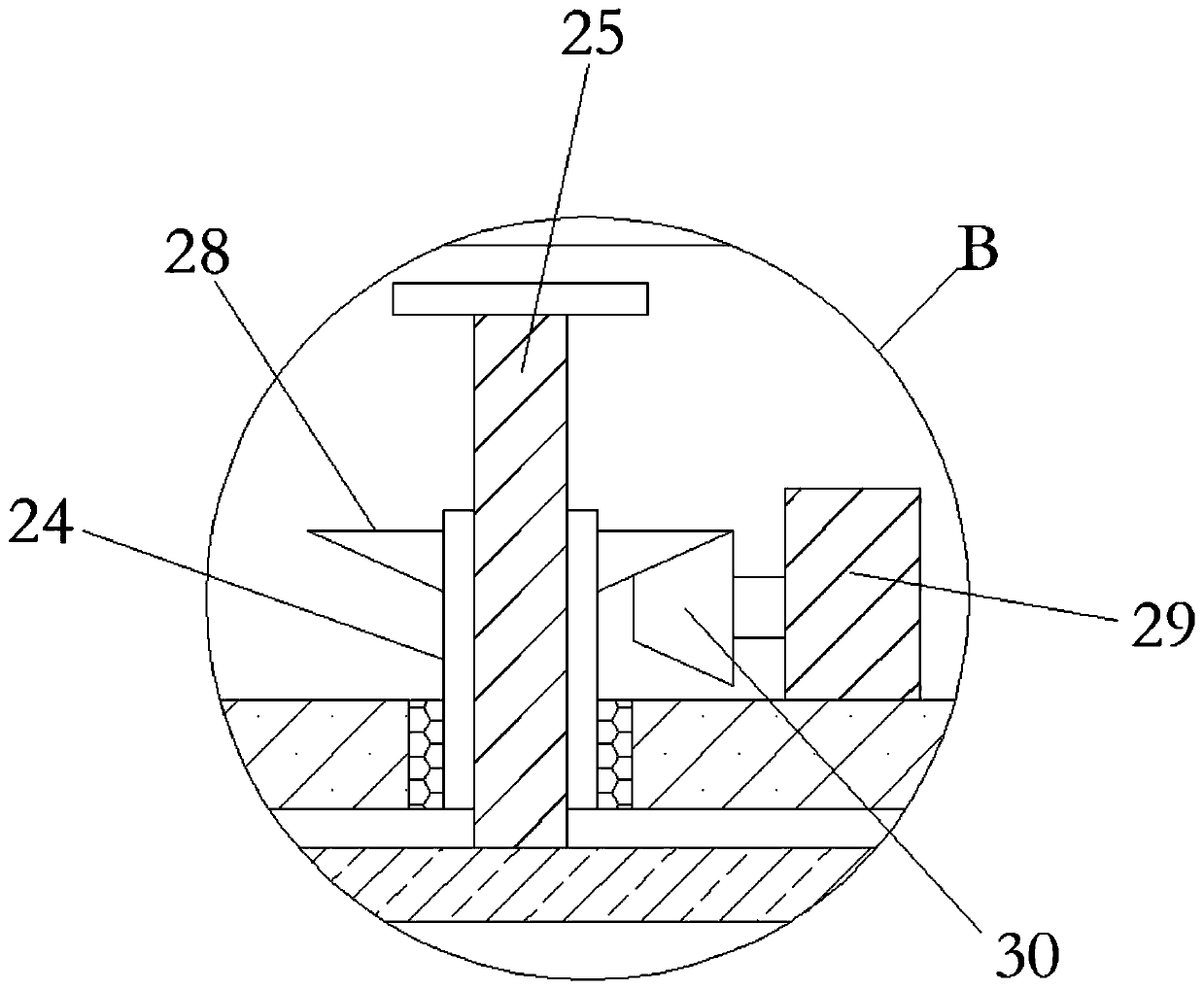

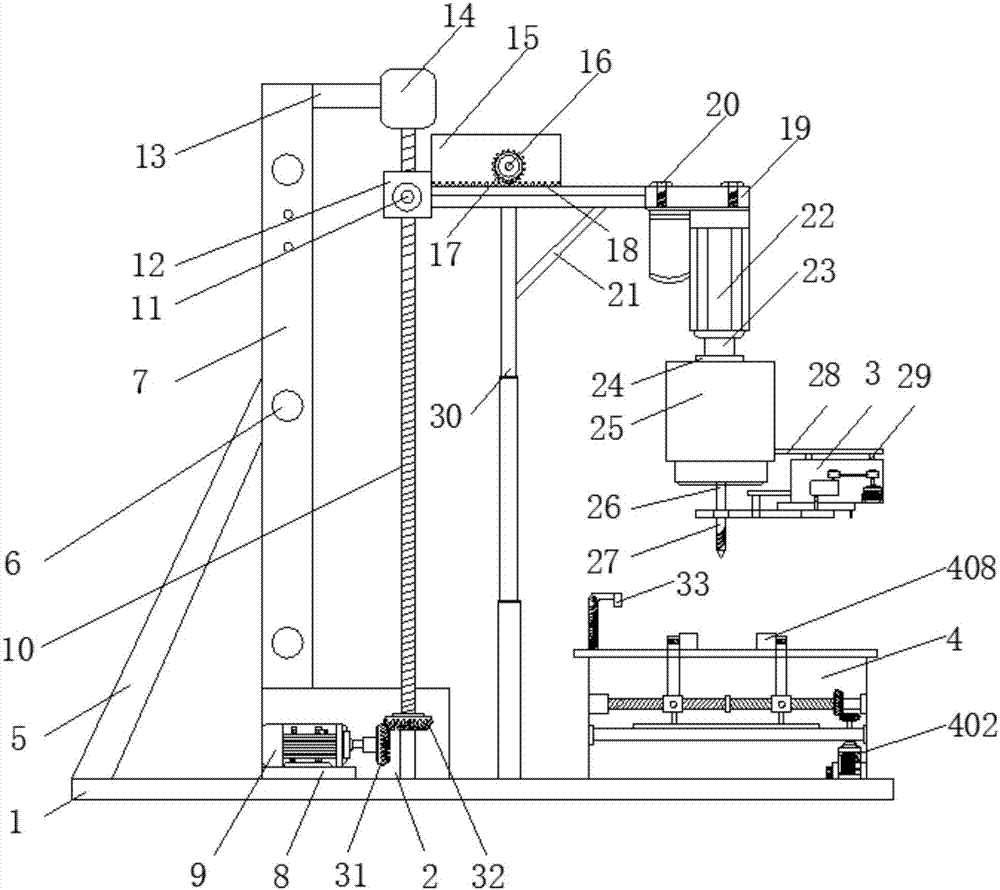

The invention discloses a portable efficient drilling machine. The drilling machine comprises a bottom plate; a motor box is fixedly connected in the middle of the top of the bottom plate; a motor mounting platform is fixedly connected at the bottom of the inner wall of the motor box; a first motor is fixedly connected at the top of the motor mounting platform; an output shaft of the first motor is fixedly connected with a first conical wheel; the first conical wheel is connected with a second conical wheel in a meshing manner; the second conical wheel is fixedly connected with a threaded shaft through a flat key; the outer wall of the threaded shaft is sleeved with a sliding block; and a fastening screw is arranged in the middle of one side of the sliding block. The invention relates to the technical field of engineering machinery. With the portable efficient drilling machine, the purpose that the drilling machine is adjustable vertically and horizontally, drill bits are replaceable, workpieces at different heights on a workbench can be perforated, and workpieces with relatively large horizontal sizes can be machined are achieved, the purpose of changing the bits quickly is achieved, the high working efficiency is guaranteed, light rays required during working can be supplemented, and the working quality can be guaranteed.

Owner:HUZHOU WUXING HUALONG MACHINERY CO LTD

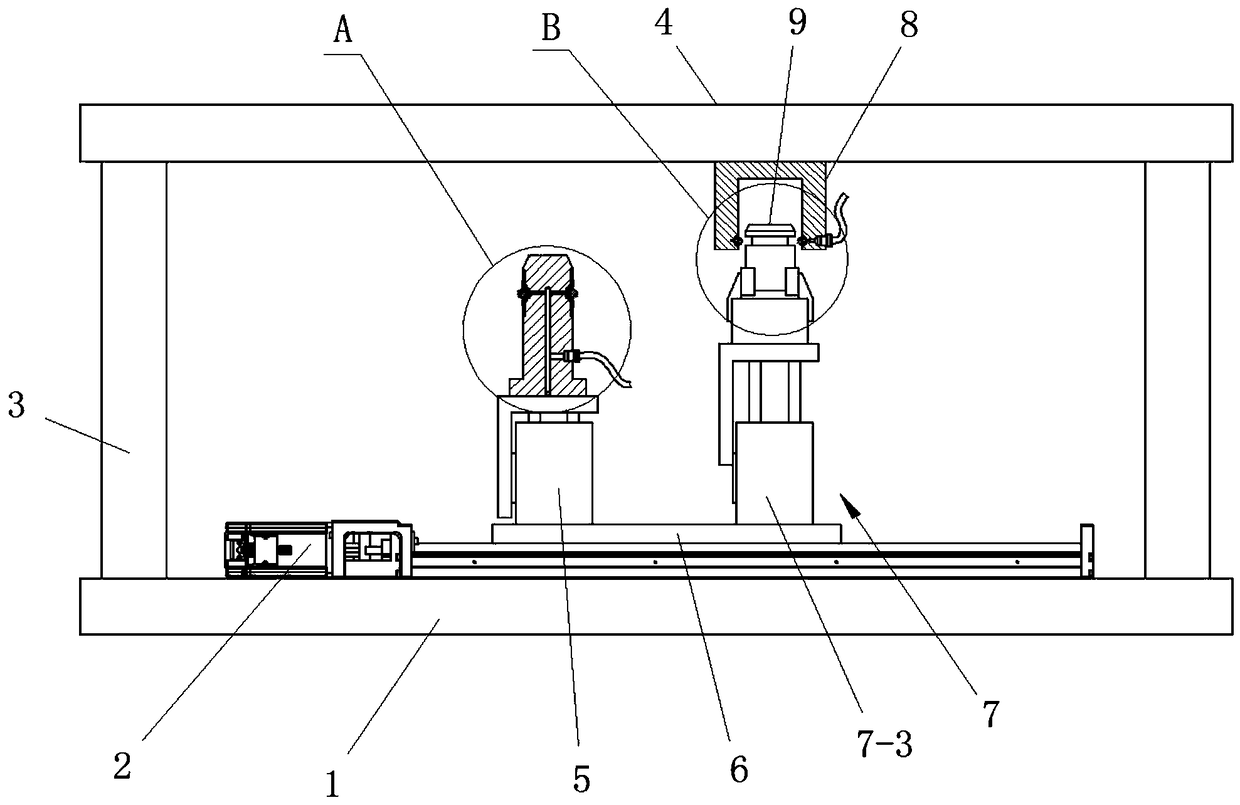

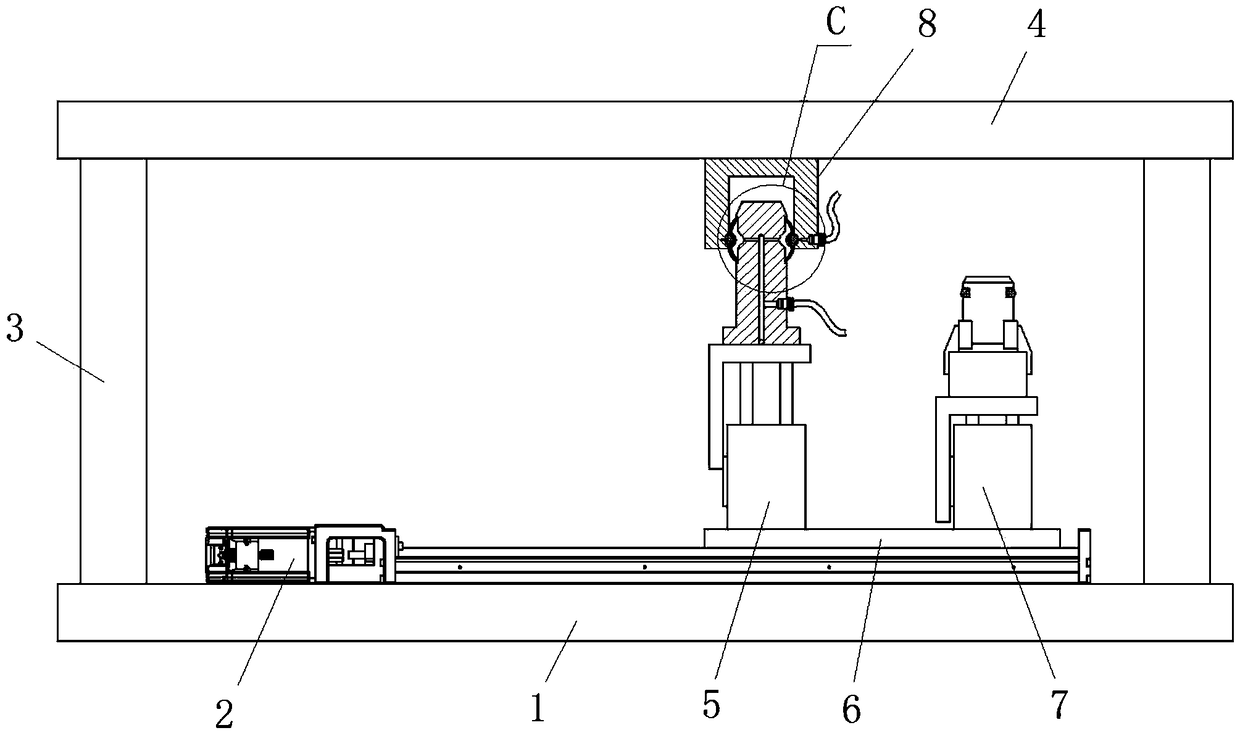

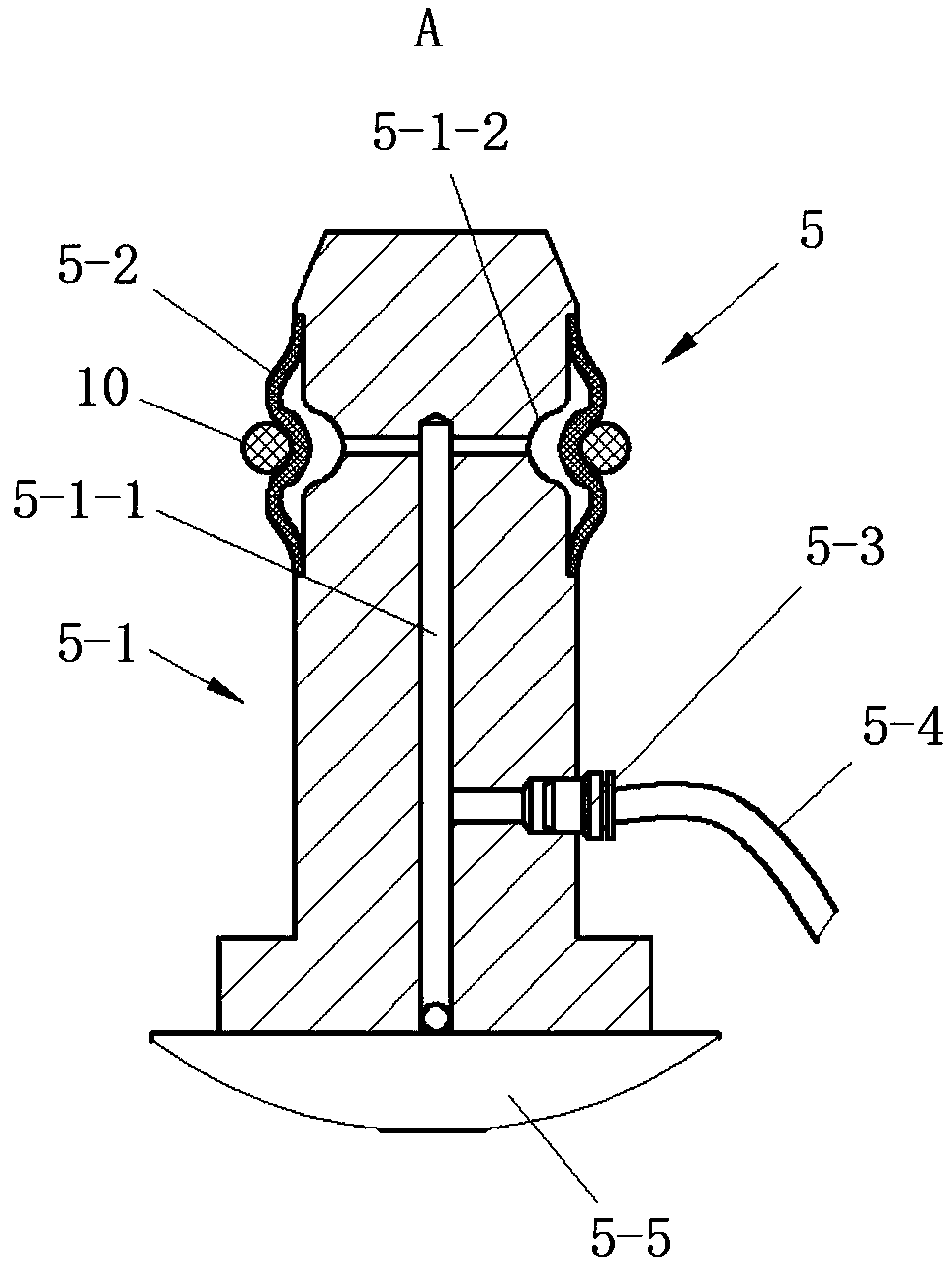

Multi-hole drilling machine

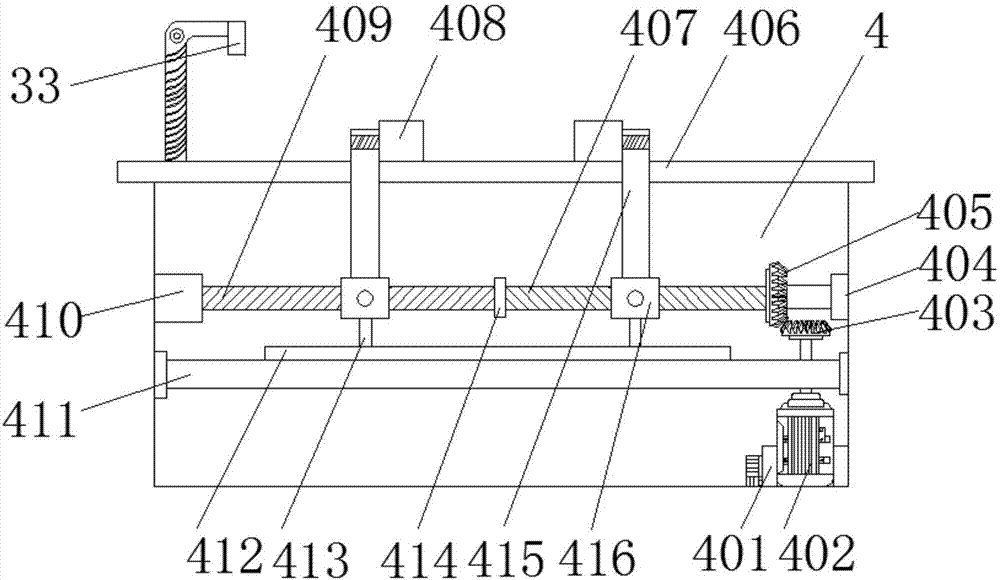

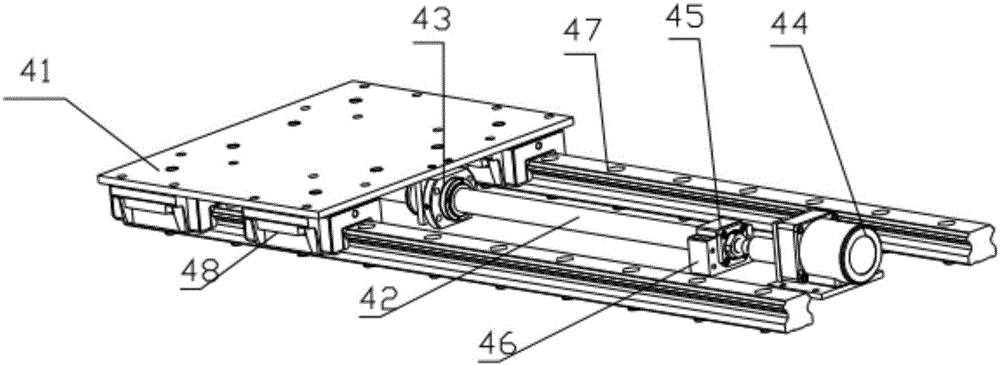

InactiveCN105665778AFast and effective multi-directional movementPrecise control over movementLarge fixed membersPositioning apparatusEngineeringMachining

The invention discloses a multi-hole drilling machine.The multi-hole drilling machine comprises a machine frame, a sliding mechanism and a drilling mechanism.The machine frame comprises a base, a working table arranged above the base and a support which is vertically arranged on one side of the base.The drilling mechanism comprises a drill bit and a drill bit motor.The multi-hole drilling machine is characterized in that the sliding mechanism comprises an X-axis sliding mechanism, a Y-axis sliding mechanism and a Z-axis sliding mechanism, wherein the X-axis sliding mechanism and the Y-axis sliding mechanism move horizontally, and the Z-axis sliding mechanism moves vertically; one sliding mechanism moving horizontally is arranged on the working table, the Z-axis sliding mechanism is arranged on the support, the other sliding mechanism moving horizontally is arranged on the working table or the support, and the drilling mechanism is arranged on the Z-axis sliding mechanism and can be driven by the Z-axis sliding mechanism to move along the Z axis.In this way, a workpiece can be moved more rapidly and effectively in multiple directions, and multi-hole machining is performed on the workpiece.

Owner:XIAMEN UNIV OF TECH

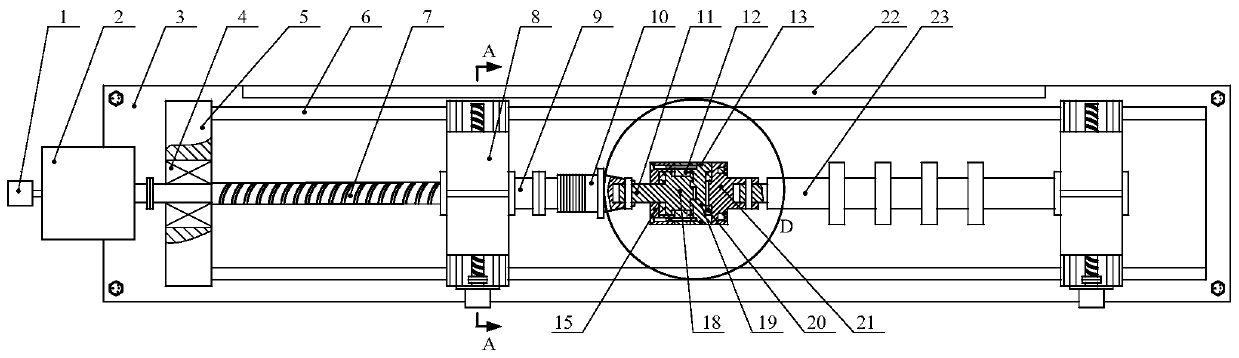

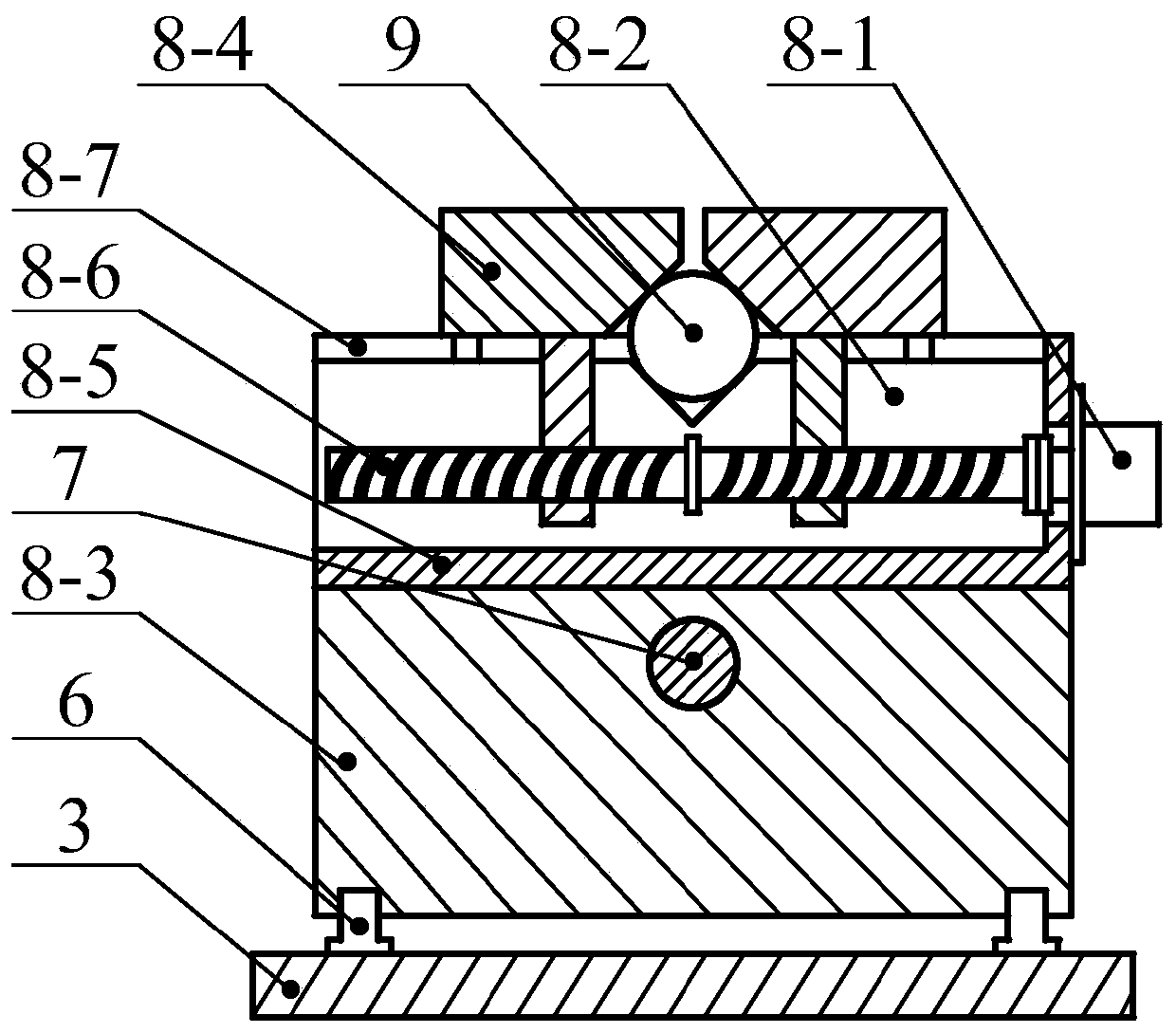

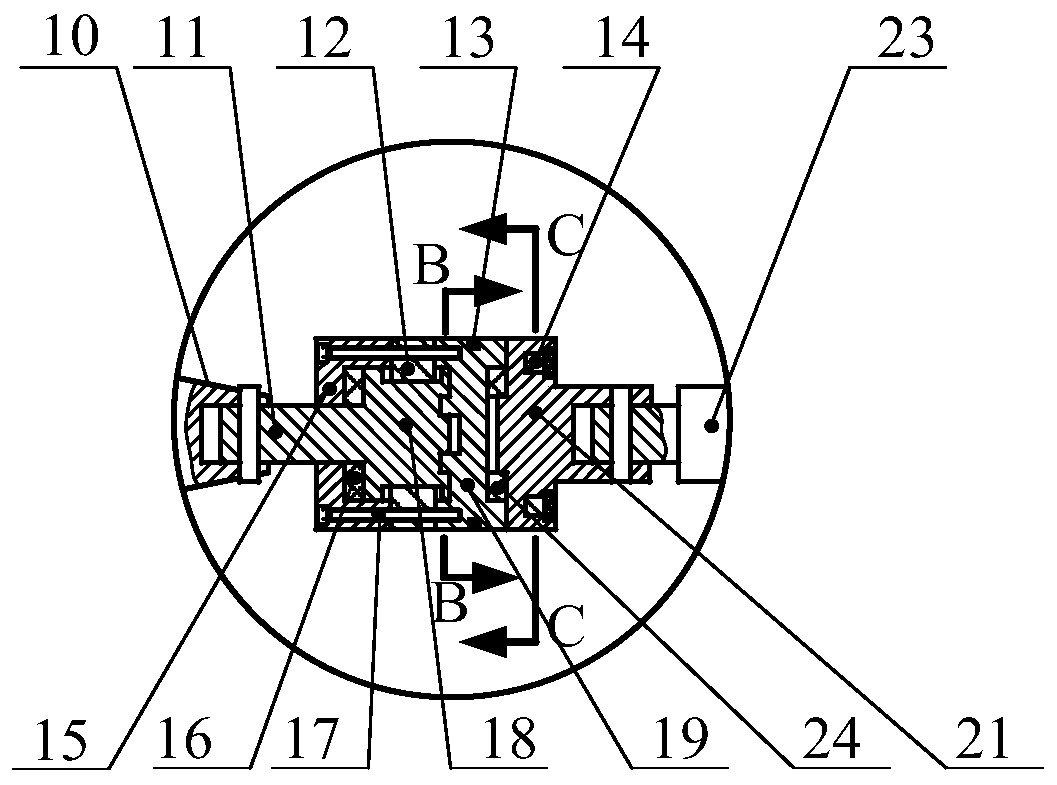

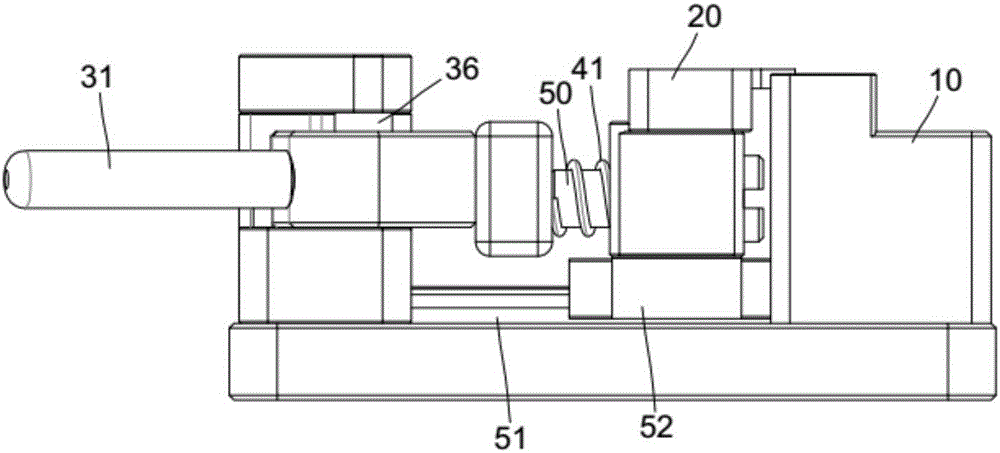

Ultrasonic broaching tool, high-efficiency precise ultrasonic broaching device and broaching process thereof

ActiveCN109967789AExtended service lifeImprove broaching efficiencyBroaching accessoriesBroaching toolsGratingUltrasonic sensor

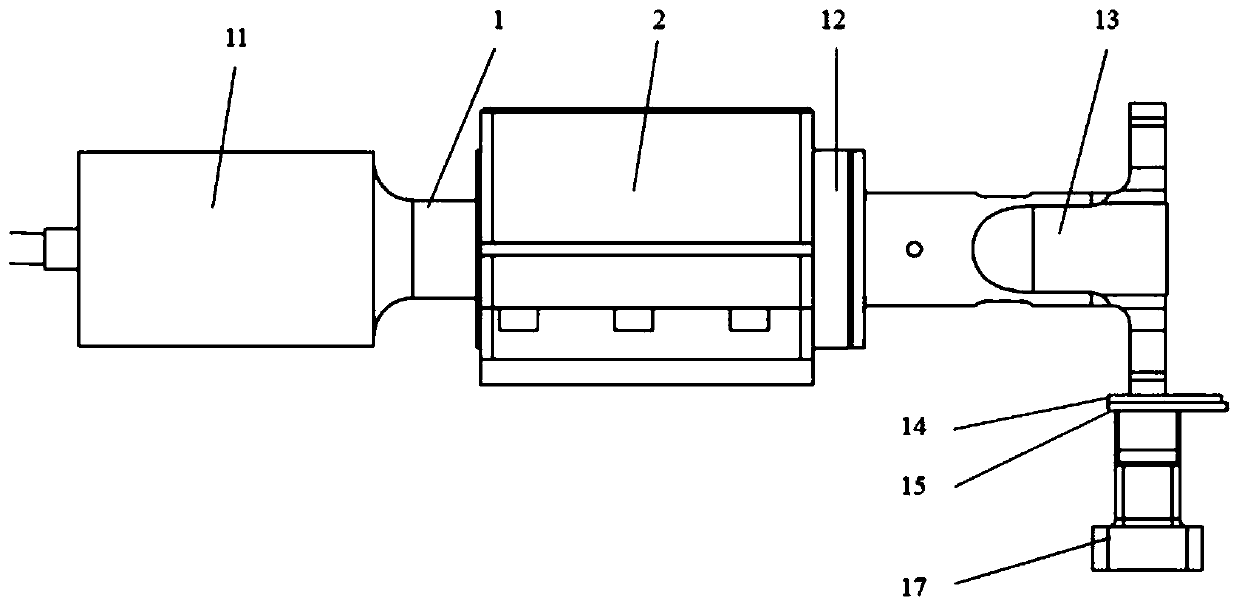

The invention discloses an ultrasonic broaching tool, a high-efficiency precise ultrasonic broaching device and a broaching process thereof. An existing broaching tool and an existing broaching machine are not provided with integrated information acquisition devices and are short in service life. The ultrasonic broaching tool comprises an ultrasonic transducer, a detection assembly and a broachingtool body. The detection assembly comprises a detection substrate, a laser transceiving belt, an image sensor, an axial pressure sensor, a first radial pressure sensor and a second radial pressure sensor. The high-efficiency precise ultrasonic broaching device comprises a broaching machine body, an optical grating and the ultrasonic broaching tool. The broaching machine body comprises a broachingmachine drive assembly, a broaching machine body, a broaching machine guide rail and a fast positioning and clamping device. A broaching tool three-directional vibration value, a broaching tool axialtensile force, a broaching tool displacement value, and a workpiece dimension based on an image are measured. Real-time detection data is provided for a working condition feedback loop and a stop control loop of a control system. The service life of the broaching tool can be effectively prolonged.

Owner:HANGZHOU DIANZI UNIV

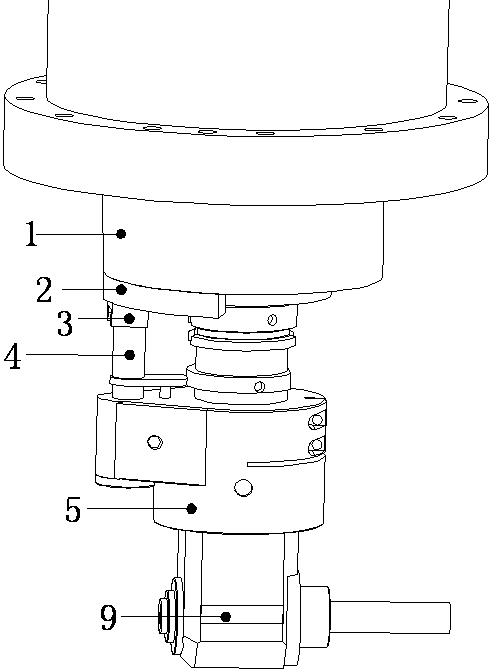

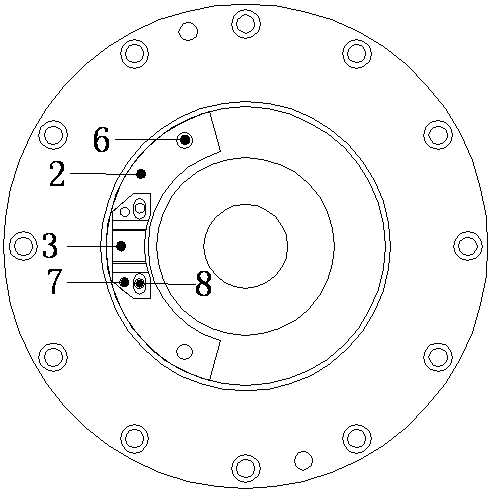

Wheel radial positioning device

InactiveCN102581653AQuick positioning clampingShort tripPositioning apparatusMetal-working holdersCircular disc

Owner:CITIC DICASTAL

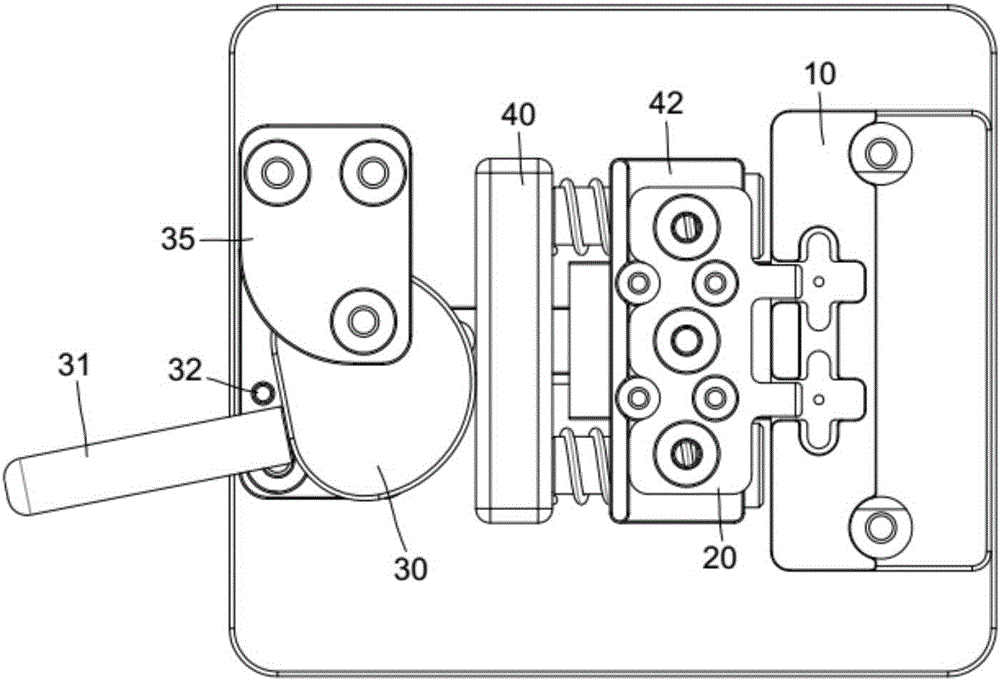

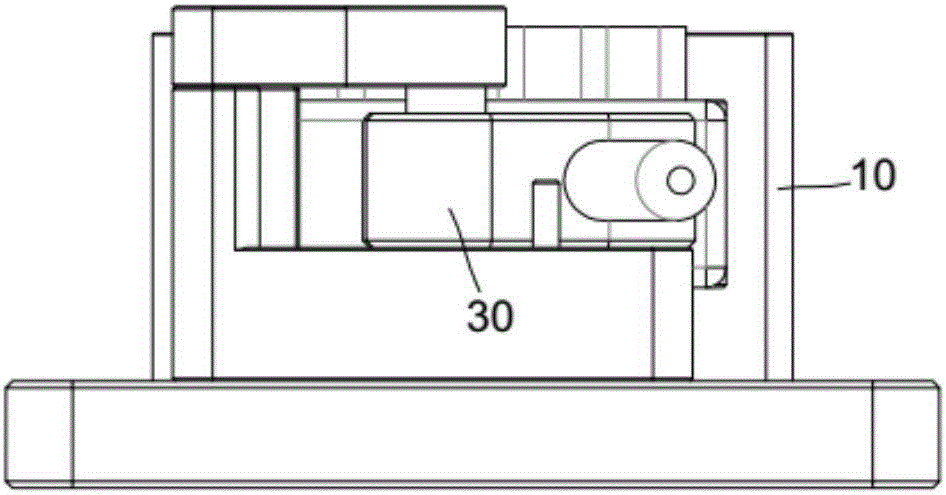

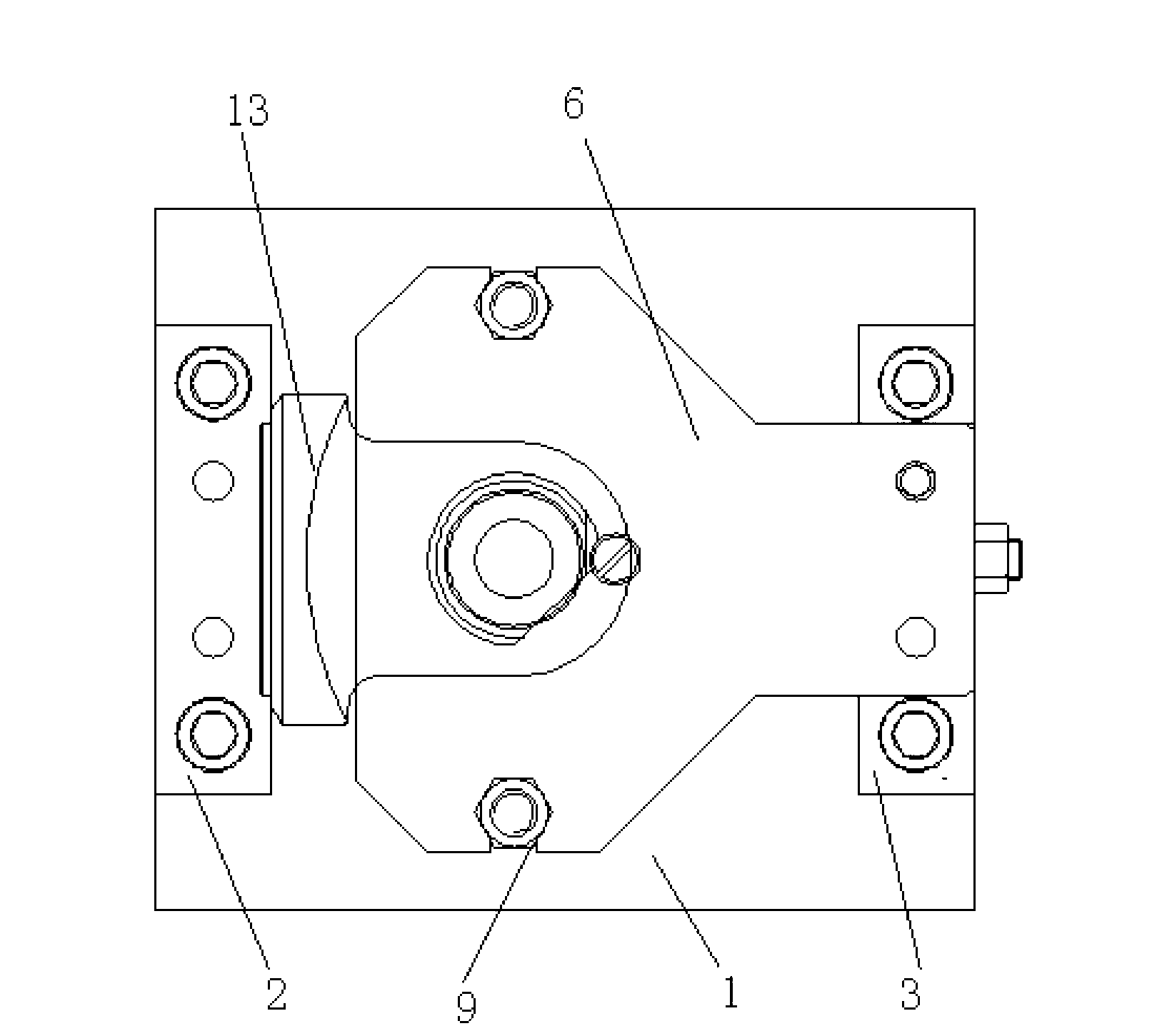

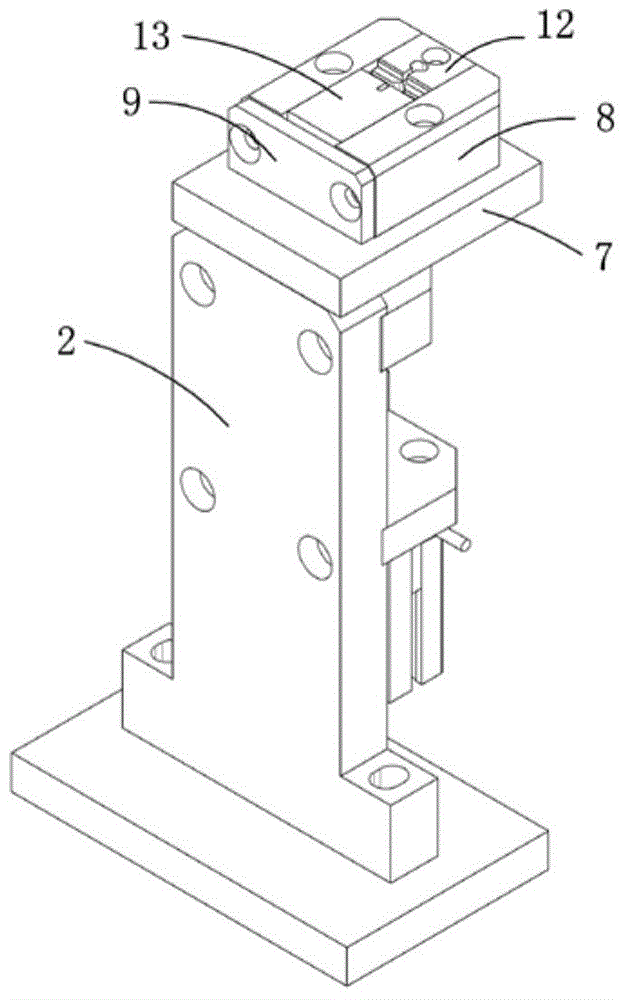

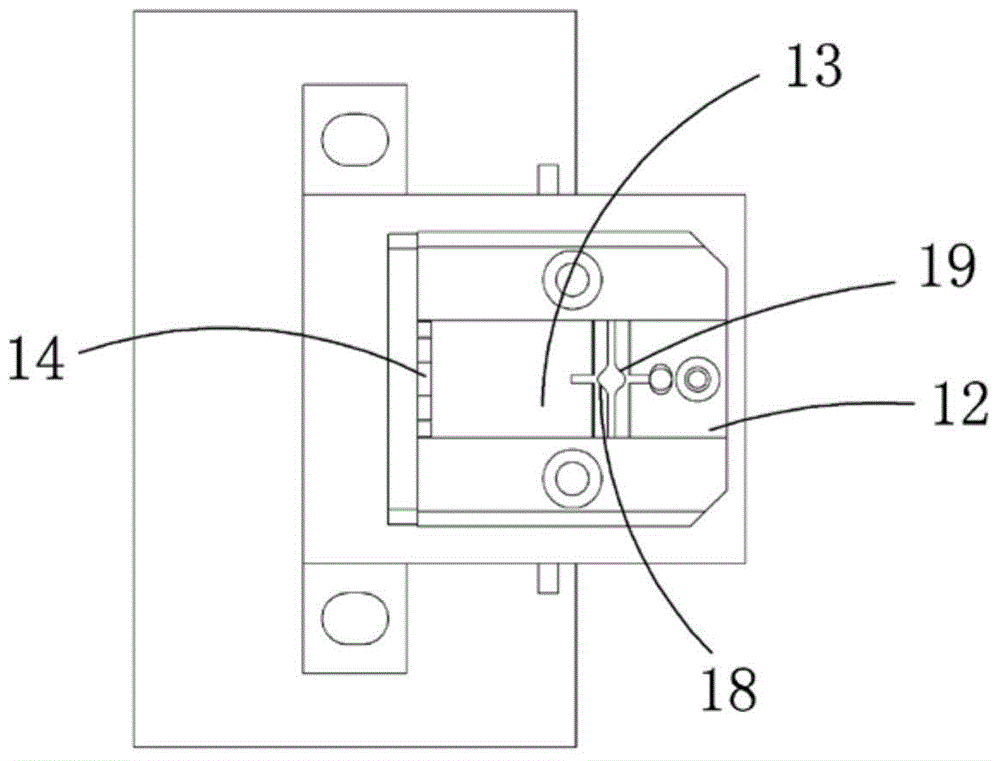

Cam clamping mechanism

ActiveCN106102326ASimple structureLow costCircuit board tools positioningWork holdersLinear motionEngineering

The invention relates to a cam clamping mechanism. The cam clamping mechanism includes a clamping block arranged beside a carrier, and a guide mechanism for guiding the linear motion of the clamping block; the clamping block is driven by a cam; and elastic pieces are arranged between the cam and the clamping block. In operation, the cam rotates and drives the clamping block to move linearly along the guide mechanism, so that the clamping block pushes a product in the carrier so as to clamp and position the product. The cam clamping mechanism of the invention has the advantages of simple structure and low cost. With the elastic pieces adopted, damage to the product during a clamping process can be effectively avoided. Clamping and positioning are quick, so that the improvement of production efficiency can be benefitted.

Owner:BOZHON PRECISION IND TECH CO LTD

Jig tool for inclined oil cylinder bottom bush hole

InactiveCN103286349AQuick clampingEasy to installPositioning apparatusMetal-working holdersEngineeringDrill

The invention discloses a jig tool for an inclined oil cylinder bottom bush hole, which comprises a jig bottom plate, wherein a left baffle and a right baffle are arranged on the two sides of the jig bottom plate; a jig plate is mounted on the right baffle in a matching manner by inserting a locating pin in a locating hole; a guide hole is formed in the jig plate; a fixed drill sleeve is mounted in the guide hole in a matching manner; a quick-change drill sleeve is mounted in the fixed drill sleeve in a matching manner; U-shaped grooves are formed on the two sides of the other end of the jig plate; a pushing rod is screwed in the middle of the right baffle; a spring is mounted on the pushing rod in a sleeving manner; a pushing block is mounted at the end part of the pushing rod; a cushion block is arranged in the middle of the jig bottom plate; hinge screw seats are mounted on the jig bottom plate on the two sides of the cushion block respectively; articulated screws are mounted on the hinge screw seats; and the upper end parts of the articulated screws are matched with the U-shaped grooves of the jig plate, and locked and fixed by nuts. The special jig tool for the inclined oil cylinder bottom bush hole is convenient and quick in clamping, time-saving and labor-saving, improves the working efficiency, and meets a requirement of batch processing production.

Owner:ANHUI ZHENYE MACHINERY

Quick-clamped PCB gluing device

InactiveCN107744917APrevent fallingImprove manufacturing yieldLiquid surface applicatorsCoatingsSlide plateControl theory

The invention discloses a quick-clamped PCB gluing device. The quick-clamped PCB gluing device comprises a frame, a portal, a fixture base, a positioning mechanism, an electromagnet, a cylinder, an upper push plate, a connecting rod, a first spring, a lower push plate, a servo motor, a lead screw, a feeding nut, a slide base and a gluing mechanism; the positioning mechanism further comprises an adjusting mechanism, a slide plate, a limiting rod, an upper limiting plate, a second spring and a lower limiting plate; the electromagnet is powered off; the second spring is returned to push the limiting rod to upwards move to extend outside the fixture base; a PCB to be machined is put in an area consisting of four limiting rods for positioning; the cylinder pushes the upper push plate to downwards move in place, so that the gluing mechanism is contacted with the PCB to be machined; the servo motor drives the gluing mechanism to move; the gluing mechanism glues the surface of the PCB; and after the gluing is finished, the electromagnet is electrified to suck with the lower limiting plate, so that the limiting rods are driven to downwards move to return, and operators can take away the glued PCB.

Owner:SUZHOU YILIHUA ELECTRONICS CO LTD

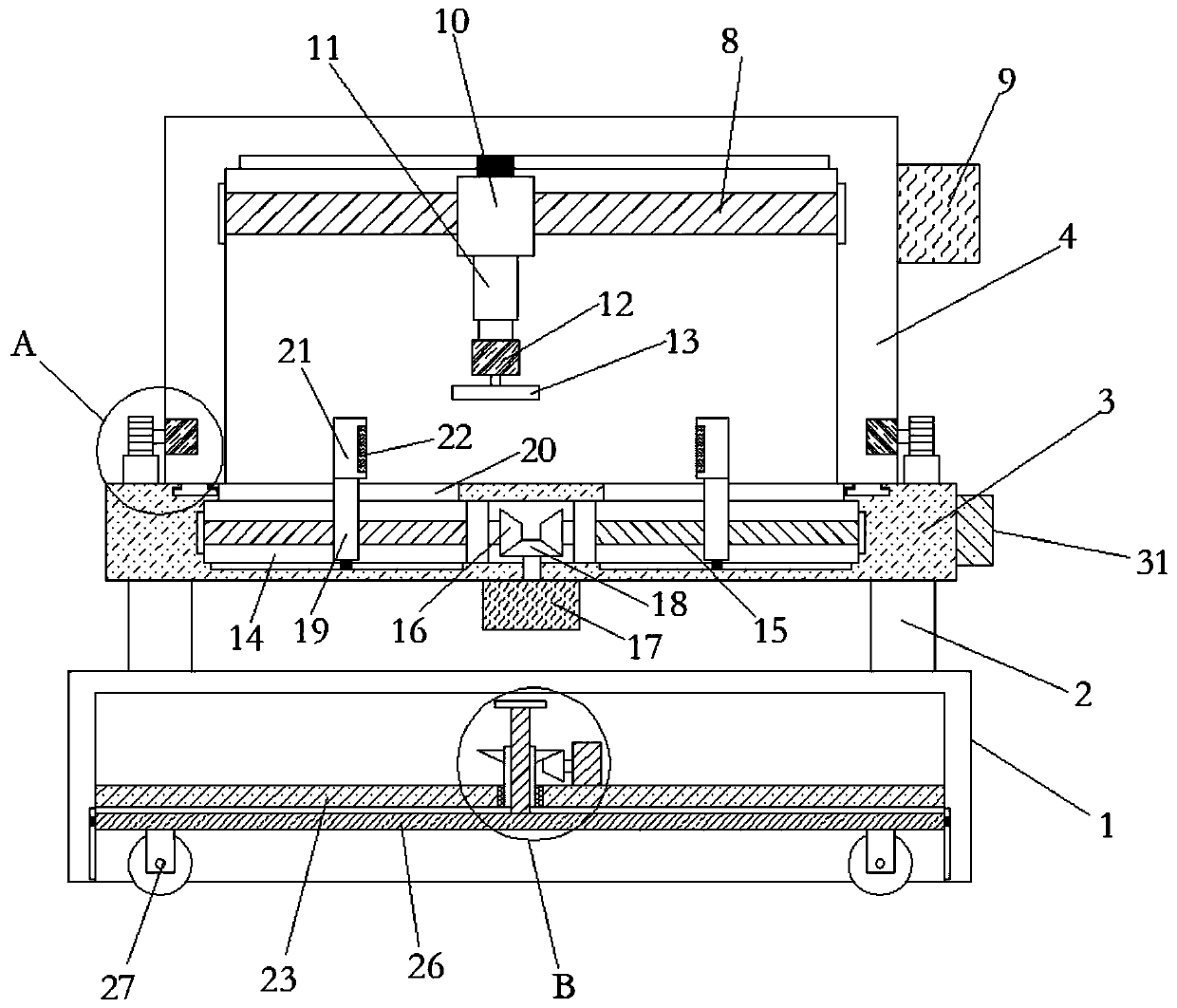

Engine bearing play detection apparatus and measuring method

ActiveCN108759758AQuick positioning clampingEasy clampingMeasurement devicesElectric machineryElectric machine

Owner:陈滨

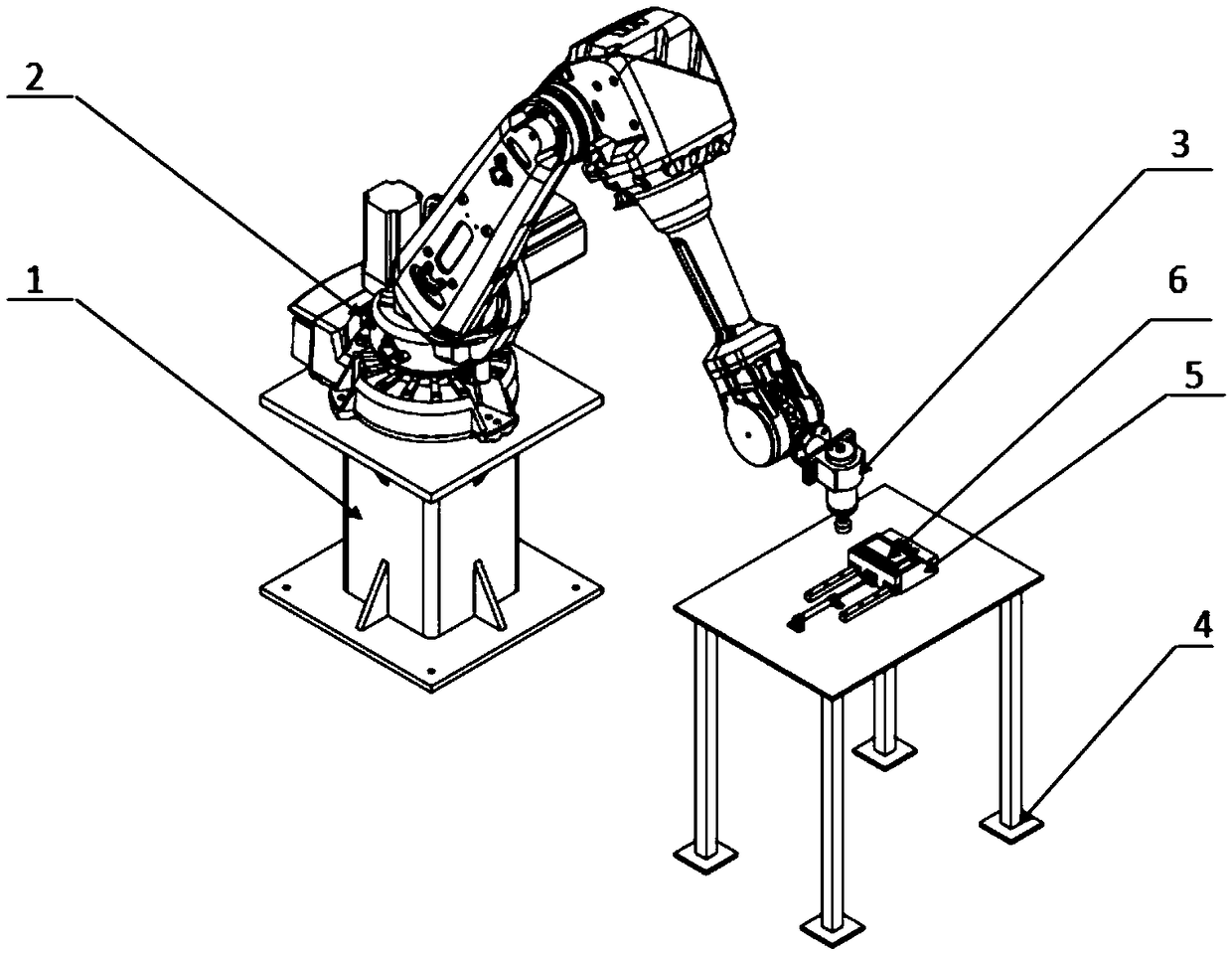

Hand-imitating silicon carbide dissociating abrasive polishing equipment and method

InactiveCN109397041AFast clamping and positioningImprove polishing efficiency and precisionGrinding carriagesPolishing machinesTelescopic cylinderFlange

The invention provides hand-imitating silicon carbide dissociating abrasive polishing equipment and method. The equipment comprises a robot base, a robot, an end-of-arm tool, a workpiece placing tableand a clamping mechanism, wherein the end-of-arm tool is composed of a connecting flange, a spindle holding seat, a high-speed spindle and a wool wheel and is used for polishing a silicon carbide part, the required optimal speed can be obtained by changing the rotating speed of the high-speed spindle, and the wool wheel can be replaced with a diamond grinding wheel so as to grind the part. The clamping mechanism is fixed on the workpiece placing table and used for positioning and clamping the silicon carbide part, and the clamping mechanism comprises a fixed part, a movable part, a telescopiccylinder used for enabling the movable part to act, a guide rail and a sliding block, wherein the telescopic cylinder is fixed to the workpiece placing table through a mounting support, the part canbe quickly clamped and positioned, the fixed part and the movable part are provided with rubber, and thus the silicon carbide part can be prevented from being damaged during clamping.

Owner:WUHAN UNIV OF TECH

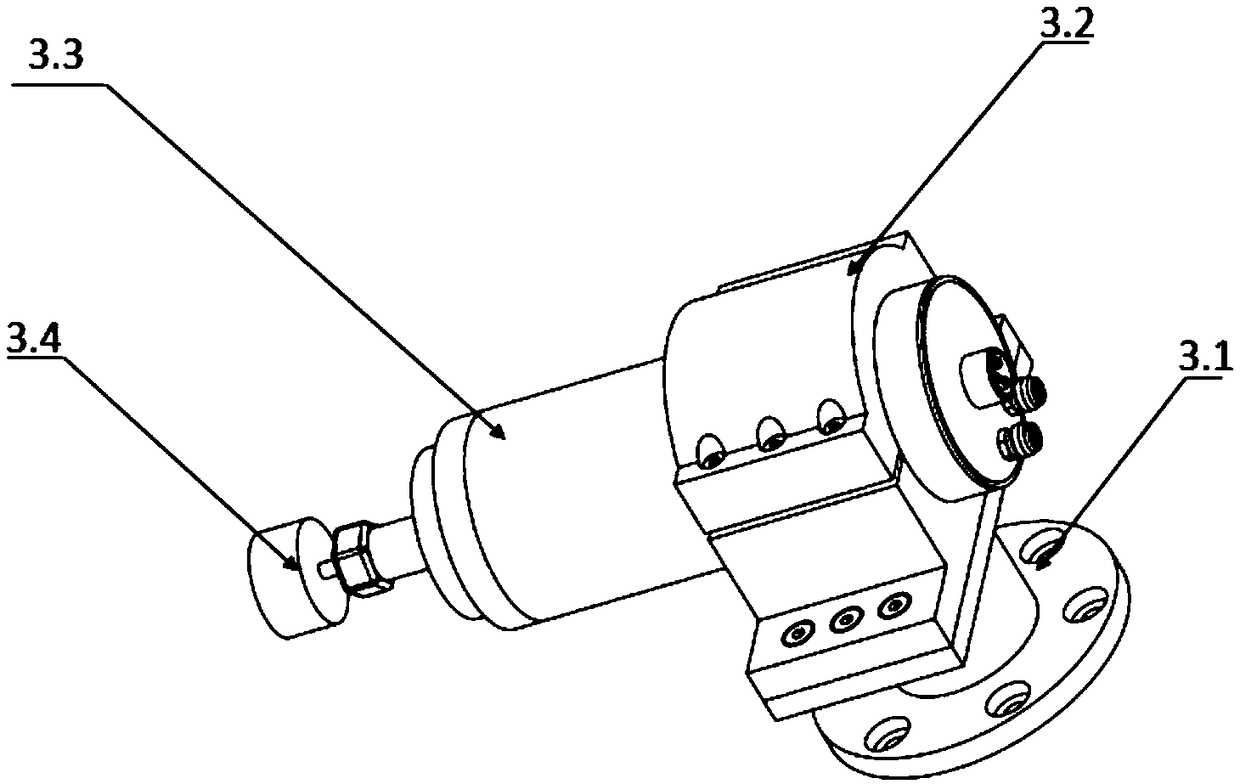

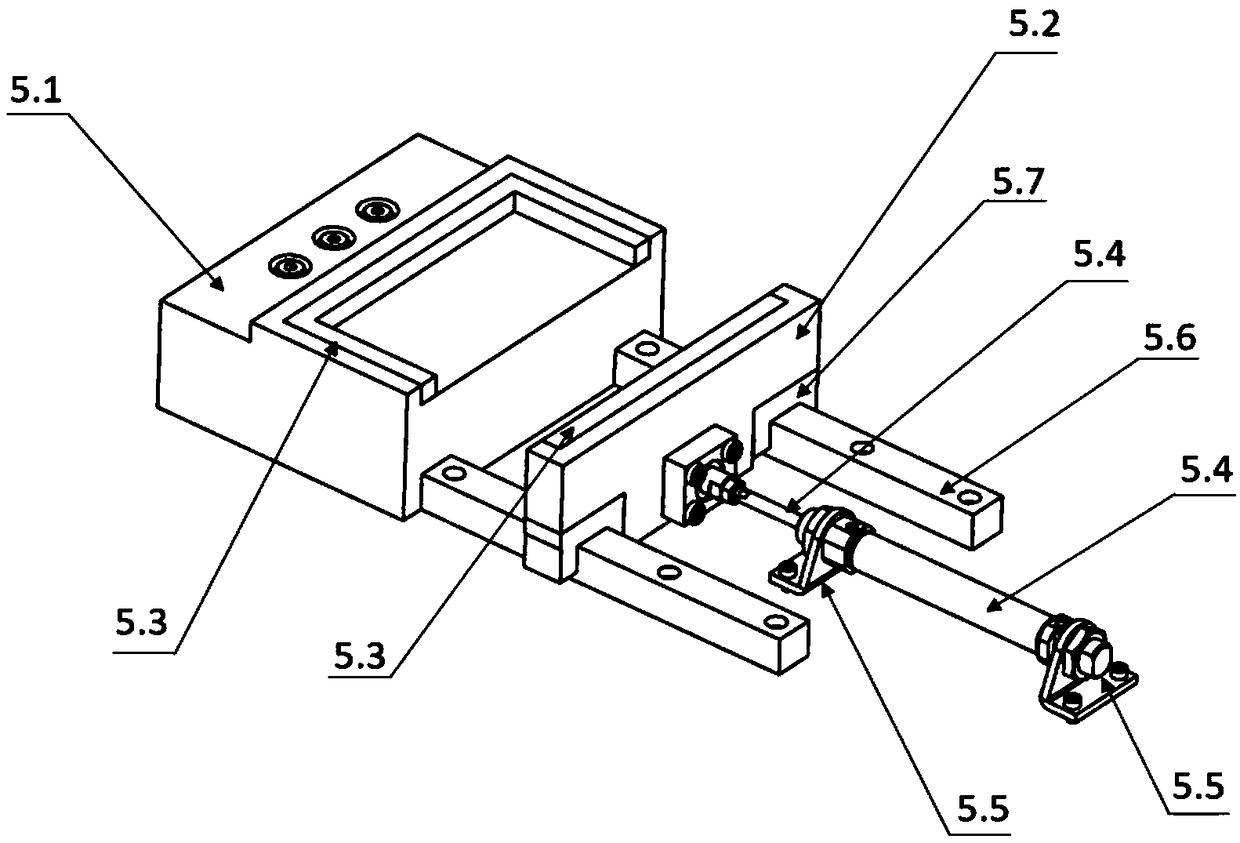

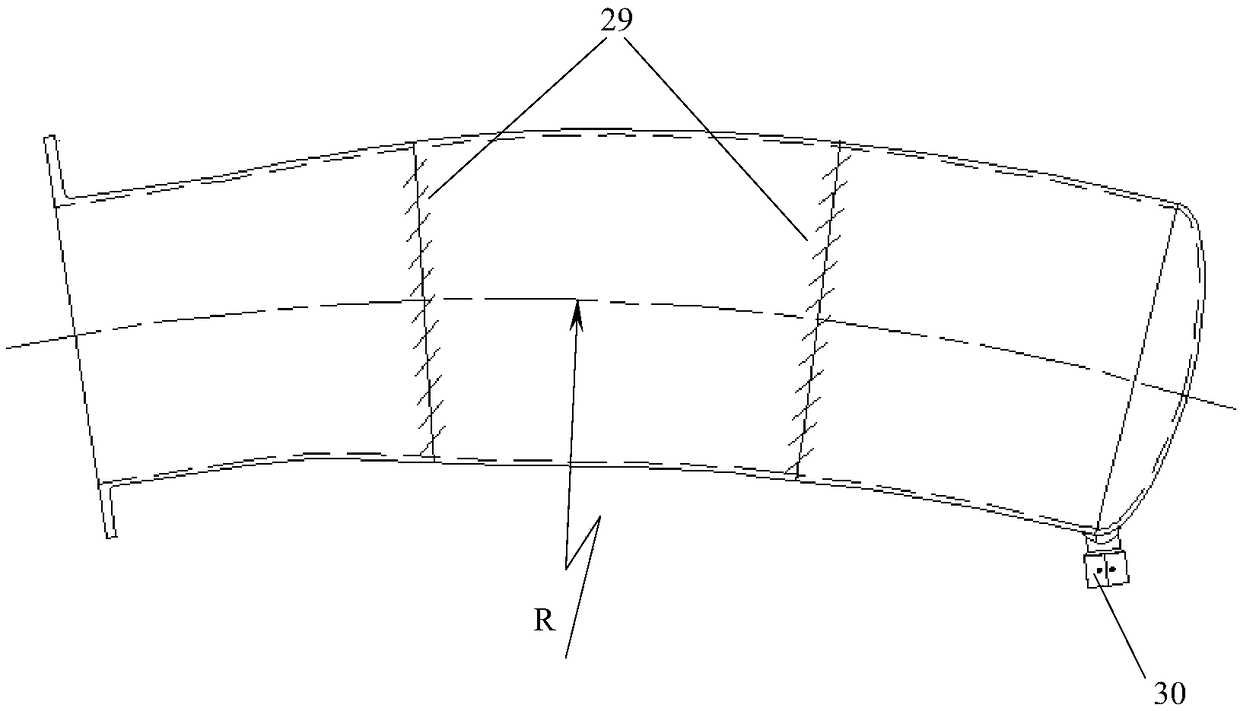

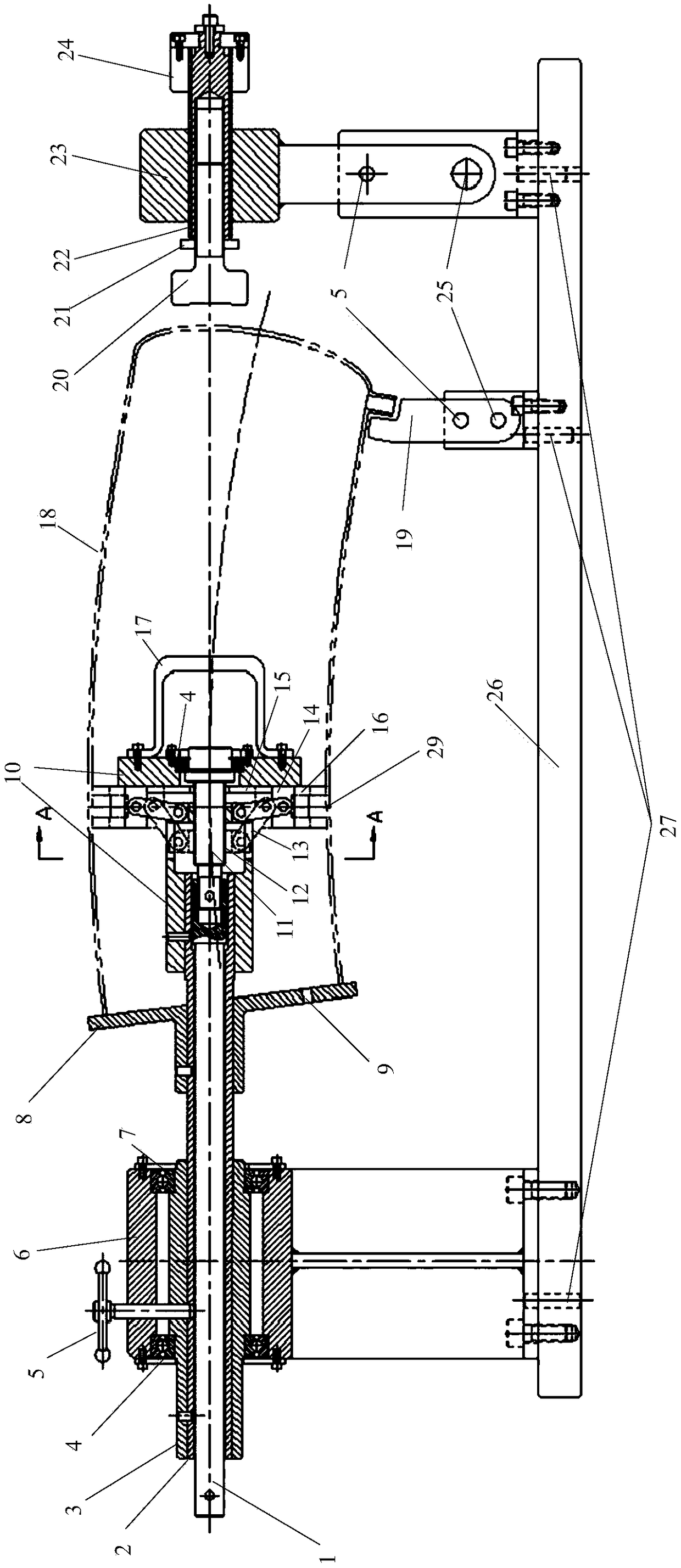

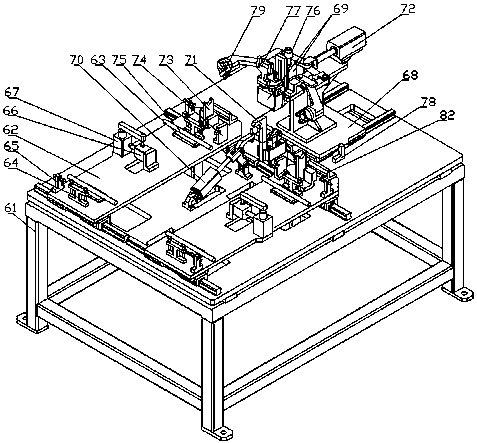

Laser welding clamping positioning device and method for curved cylinder type structure

ActiveCN109128645AGuaranteed welding deformationReduce frictional resistanceWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

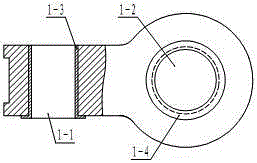

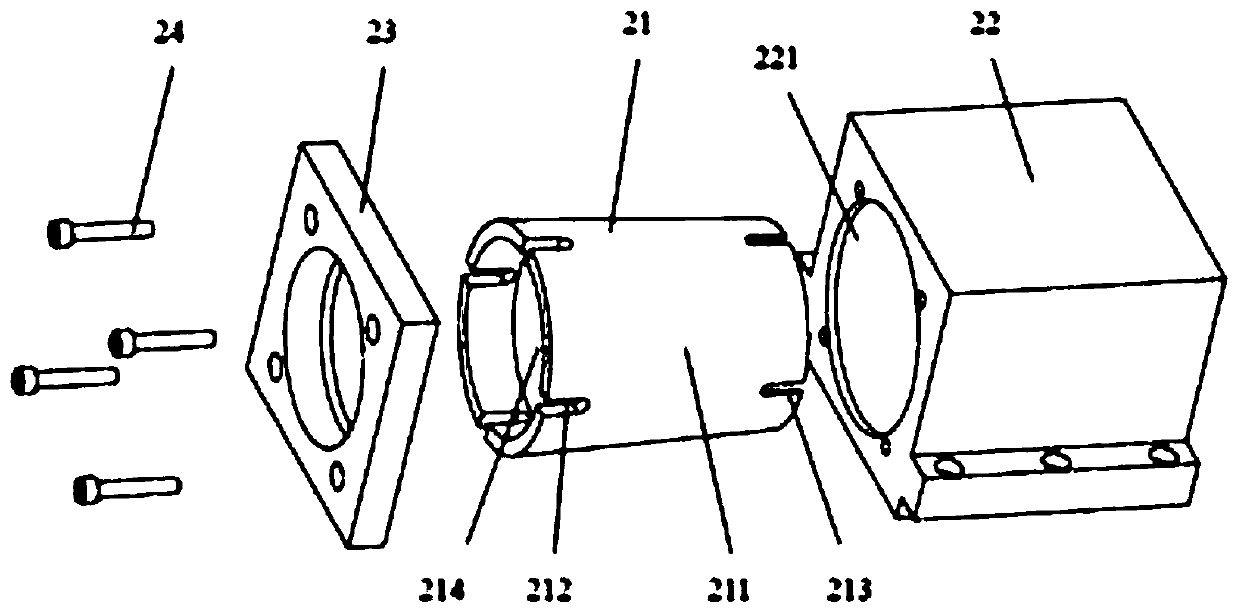

The invention discloses a laser welding clamping positioning device and method for a curved cylinder type structure. The laser welding clamping positioning device comprises a clamping rotating assembly at the front end, a positioning clamping assembly in the middle and a part jacking assembly at the tail end, wherein the clamping rotating assembly comprises load bearing columns, rolling bearings,rotating shaft sleeves, connecting shaft sleeves, a limiting pin and a center rotating shaft; the positioning clamping assembly comprises a positioning shaft sleeve, a nozzle positioning combination device, welding seam positioning combination devices and a threaded connecting shaft; and the part jacking assembly comprises a joint bearing, bearing sleeves and tail portion positioning columns. According to the laser welding clamping positioning method, by using the laser welding clamping positioning device, clamping positioning is realized, rapid and accurate positioning of a particular weldingplane annular welding seam is realized, friction resistance is significantly reduced, welding deformation of the cylinder structure is guaranteed, the assembly efficiency can be significantly improved, rapid clamping and positioning of curved cylinders are realized, the assembly stress is relieved, stress deformation in the welding process is controlled, and the welding quality is further improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Processing method and boring clamp of front axle shell for excavator

ActiveCN102642037AGuaranteed parallelSimple structurePositioning apparatusMetal-working holdersEngineeringExcavator

The invention discloses a processing method of a front axle shell for an excavator. When the front axle shell of the excavator is processed on an ordinary boring machine, a base provided with a horizontal datum plane is fixedly arranged on a working platform of the boring machine first; afterwards, by utilizing the end surface of a big hole in the front axle shell of the excavator as a positioning datum plane in a processing process, the end surface of the big hole in the front axle shell of the excavator as the positioning datum plane is mounted on the horizontal datum plane on the base in an abutting way; afterwards, after the front axle shell of the excavator is clamped and fixed through a clamping device mounted on the base, axle holes at two ends of the front axle shell of the excavator can be processed through the ordinary boring machine; in such a way, the axial axes of the processed axle holes at the two ends of the front axle shell of the excavator can be enabled to be on the same axial axis parallel to the positioning datum planes of the axle holes; and compared with the prior art, the processing method not only has the advantages of simple structure and convenience in mounting, but also has the advantages of being ingenious in design and high in precision, being safe and reliable, being quick to clamp and position, being capable of guaranteeing the processing precision of the front axle shell, improving work efficiency, and the like.

Owner:GUIZHOU JONYANG KINETICS

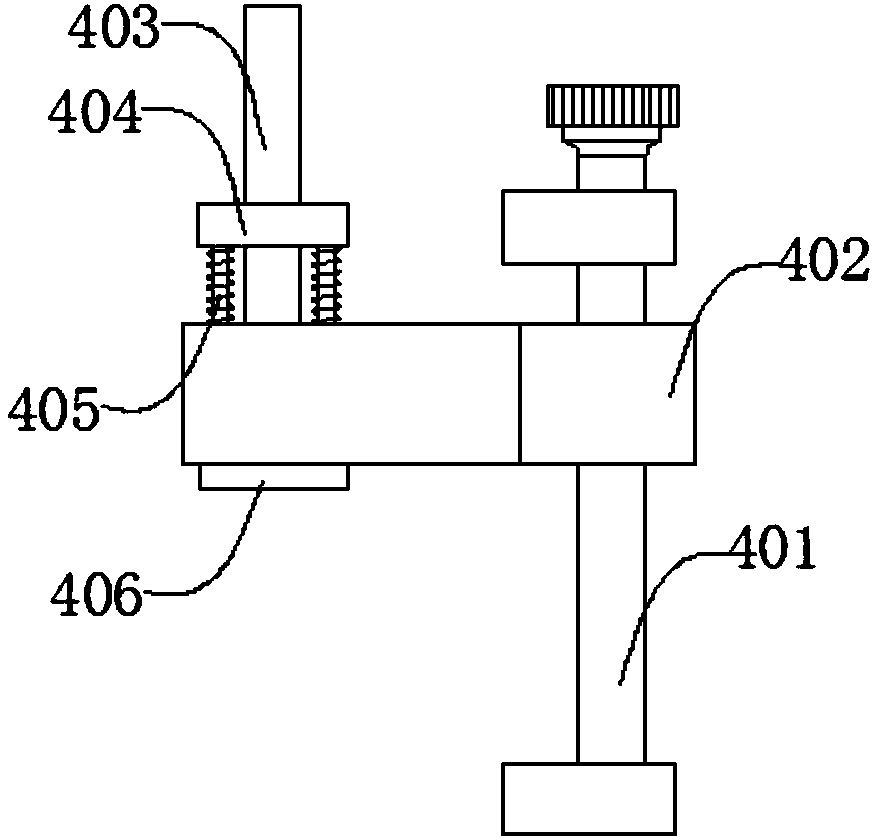

Motorcycle frame rear body assembly welding jig

InactiveCN104690472AMeets targeting requirementsSimple structureWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameLeft half

The invention discloses a motorcycle frame rear body assembly welding jig. The motorcycle frame rear body assembly welding jig is characterized in that a lower bottom plate is provided with a left half body assembly positioning mechanism, a right half body assembly positioning mechanism, a fuel tank rear mounting bracket component positioning mechanism, a left and right connecting plate positioning mechanism, and a seat lock mounting bracket component positioning mechanism; the left half body assembly positioning mechanism and the right half body assembly positioning mechanism are symmetrically arranged; an upper front bottom plate and an upper rear bottom plate are respectively arranged on the two sides of the lower bottom plate through support structures; a certain space is reserved between the upper front bottom plate and the upper rear bottom plate, so that a left half body assembly support pipe and a right half body assembly support pipe can pass in a downwardly inclined manner. The motorcycle frame rear body assembly welding jig provided by the invention has the advantages that clamp positioning of all parts of a motorcycle frame rear body assembly is integrated, so that the jig structure is simplified, fewer clamp positioning points and rapid clamping are achieved, accordingly, the product loading / unloading time for the jig is shortened, and the welding efficiency is improved; meanwhile, the positioning of all the parts is more accurate and precise, and the assembly positioning requirements are better met, so that the forming quality of the welded frame rear body assembly is higher.

Owner:力帆科技(集团)股份有限公司

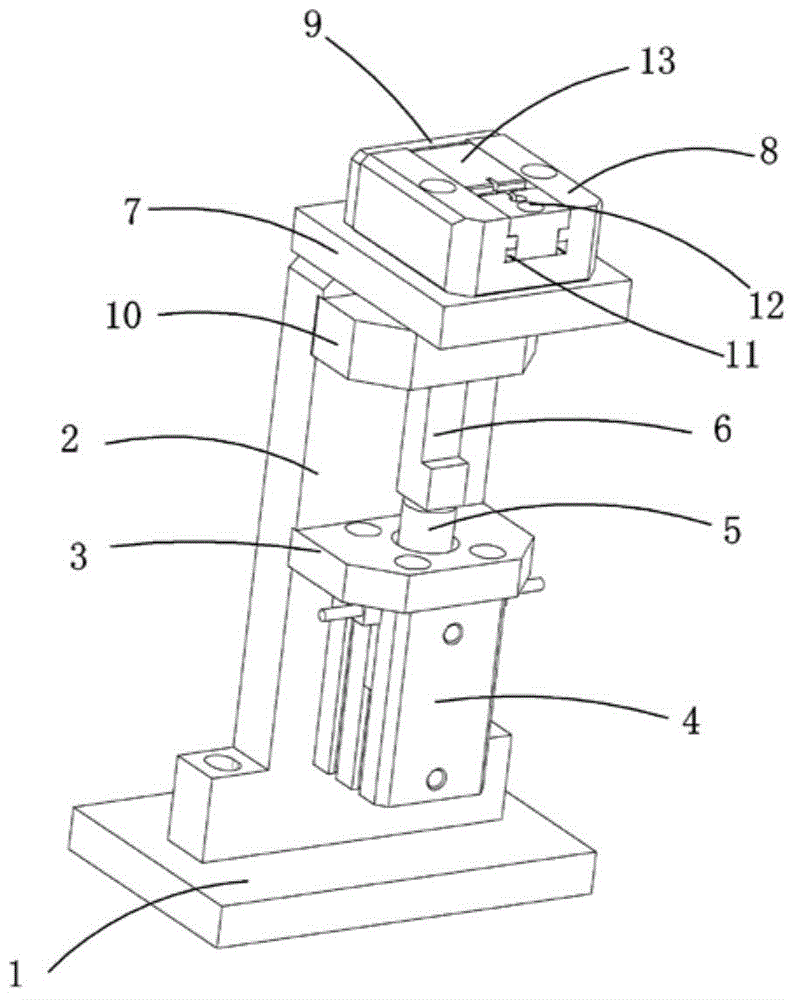

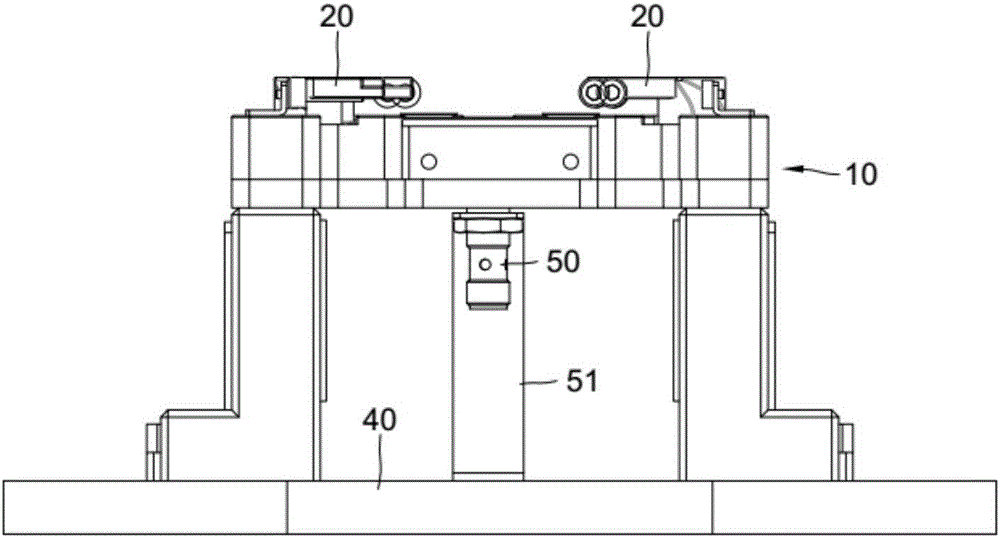

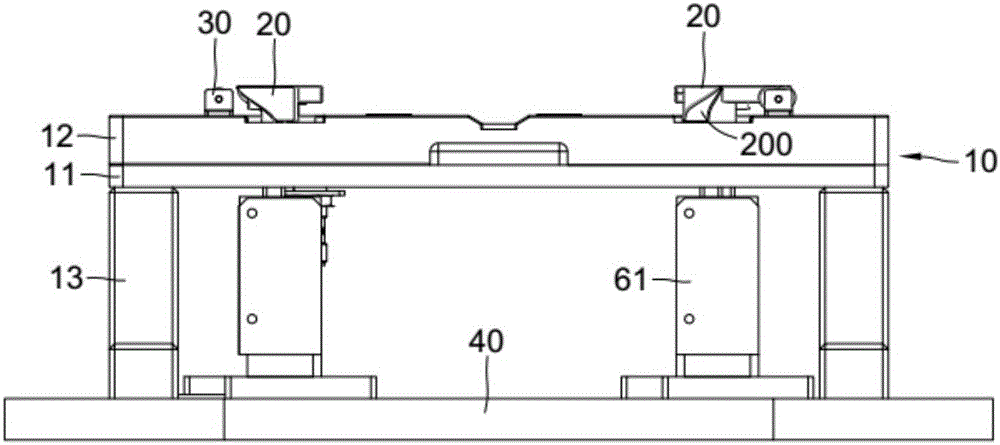

Product clamping mechanism

InactiveCN104690666AQuick positioning clampingIncrease productivityWork holdersPerpendicular directionPiston rod

The invention relates to a product clamping mechanism. A supporting plate is arranged on a base of the product clamping mechanism. A lifting cylinder fixing plate is fixedly arranged in the middle of the supporting plate. A lifting cylinder is arranged below the lifting cylinder fixing plate. A piston rod of the lifting cylinder penetrates through the lifting cylinder fixing plate. The upper end of the piston rod is connected with a lifting slide block. A fixing block is arranged at the upper end of the supporting plate. A fixing base is fixedly arranged on the upper portion of the fixing block. The left end of the fixing base is connected with a stop piece. An H-shaped groove is formed in the fixing base. A clamping block is fixed to the right side in the H-shaped groove. A movable block is arranged on the left side in the H-shaped groove in a matched mode. The movable block and the rear stop piece are connected through a spring. An inclined face a is arranged on the lifting slide block. The lower left portion of the movable block is connected with a connection block. An inclined plane b matched with the inclined face a is arranged on the connection block. The lifting cylinder drives the lifting slide block to make the inclined face a on the lifting slide block make contact with the inclined face b, the force, in the vertical and perpendicular direction, of the lifting slide block is converted into force in the horizontal direction, and the movable block moves leftwards and rightwards in the horizontal direction so that a product can be released or clamped.

Owner:BOZHON PRECISION IND TECH CO LTD

Mobile phone carrier mechanism

The invention discloses a mobile phone carrier mechanism. The mobile phone carrier mechanism comprises rotary clamping blocks pivoted to a carrier; twisting surfaces are arranged at the bottoms of the rotary clamping blocks; a lifting rod is arranged at the bottom of the carrier; the top end of the lifting rod upwards penetrates through the carrier to butt against the twisting surfaces; the carrier is provided with a return device of the rotary clamping blocks; and four rotary clamping blocks are provided, and are positioned at four corners of the carrier. A front screen of a mobile phone is placed on the carrier; the lifting rod upwards extends out of the carrier to butt against the twisting surfaces of the rotary clamping blocks so as to drive the rotary clamping blocks to rotate; and the four rotary clamping blocks at four corners of the carrier are positioned and clamped at four corners of the front screen of the mobile phone to position and clamp the front screen of the mobile phone. The mobile phone carrier mechanism is delicate in design, can quickly position and clamp products in the bionic carrier to reach standard operation positions, and is convenient for assembly operation of the front screen and a back cover of the mobile phone.

Owner:江苏戎汇智能科技有限公司

Anti-scratch assembly device for O-ring

InactiveCN109079487ASmall footprintHigh positioning accuracyMetal working apparatusEngineeringAir compressor

The invention relates to the technical field of automation equipment and particularly relates to an anti-scratch assembly device for an O-ring. Currently, the artificial assembly of the O-ring is implemented by sleeving the O-ring at one end of a part and then shifting the O-ring into a sealing groove of the part by a hand, the automation equipment mainly uses a tool to open the O-ring and sleevethe O-ring at one end of the part, and then other tools are used to shift the O-ring into the sealing groove of the part. But the O-ring is easily scratched or worn out in the above process, and causes sealing failure. An expansion ring component and a feed component are respectively arranged on the two sides of the upper end of a bottom plate, a module drives the expansion ring component and thefeed component to move to convert two stations, a groove and an elastic ring on an expansion ring shaft form an air cavity, the air cavity is communicated with an air compressor through a first air pipe, a sinking part is arranged on the elastic ring, then the occupied area is effectively reduced, the locating accuracy is improved, and the scratch is effectively prevented. The anti-scratch assembly device is mainly used for the assembly device for the O-ring.

Owner:常州思骁自动化科技有限公司

Positioning clamp and method for machining inner circle face of orthogonal shaft sleeve

ActiveCN105171447APrecise positioningGuarantee processing qualityPositioning apparatusMetal-working holdersJackscrewEngineering

The invention discloses a positioning clamp and method for machining an inner circle face of an orthogonal shaft sleeve, and belongs to the technical field of workpiece positioning clamping devices. The positioning clamp for machining the inner circle face of the orthogonal shaft sleeve comprises a fixing base, a positioning shaft, an adjusting sleeve, a clamping base, a pressing plate and jackscrews. The fixing base is provided with a base plate, a first front side wall, a first back side wall, a second front side wall and a second back side wall. The base plate is installed on a lathe chuck, positioning shafts of through structures are installed on the second front side wall and the second back side wall, and the pressing plate is assembled and hinged between the first front side wall and the first back side wall through a pressing plate pin shaft. The clamping base is installed on the base plate of the fixing base, and the adjusting sleeve is assembled on the clamping base. Each jackscrew comprises two symmetrical parts, wherein the two parts are installed on the second front side wall and the second back side wall of the fixing base respectively. By means of the positioning clamp and method, the aim that the inner circle face of the inner shaft sleeve with a vertical hole and a workpiece hole is finished on a lathe is achieved, rapid and accurate positioning of a workpiece is achieved, the product quality is guaranteed, and the work efficiency is improved.

Owner:FACTORY 5721 OF PLA

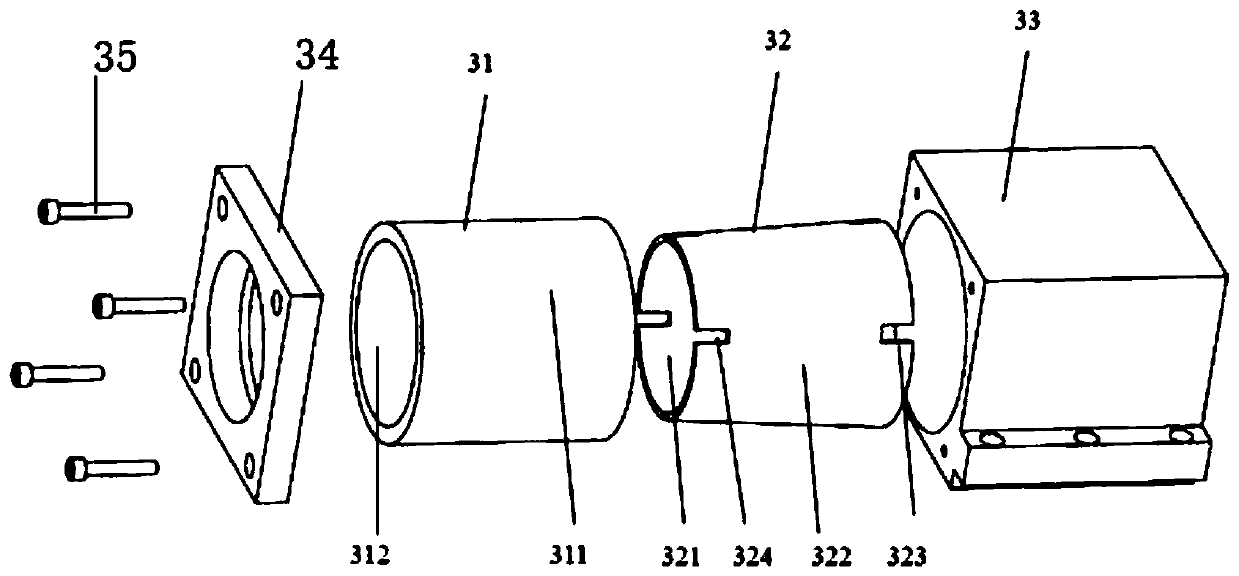

Clamp for ultrasonic welding machine

InactiveCN109909598AQuick positioning clampingFirm positioning and clampingWelding/cutting auxillary devicesAuxillary welding devicesUltrasonic weldingEngineering

The invention discloses a clamp for an ultrasonic welding machine. The clamp is reasonable and simple in structure, low in production cost, convenient to install and complete in function, and can realize rapid positioning and clamping of a welding triplicate assembly, and effectively improve the welding quality and the working efficiency. The clamp comprises a machine base, a bush and an end cover, wherein the machine base is fixed to a workbench of the welding machine, the bush is arranged at an inner ring of the machine base and provided with a groove, and the end cover is provided with a fixing screw hole and exerts clamping force. The bush is embedded into the machine base, the ultrasonic welding triplicate assembly is placed inwards, and ultrasonic triplicate leveling is completed. When the end cover is fixed to the machine base, the bush deforms in the machine base, so that the triplicate assembly can be stably clamped, the leveling state of the triplicate assembly is kept, and the purposes of fast positioning and clamping of the triplicate assembly are realized.

Owner:SBT ULTRASONIC TECH CO LTD

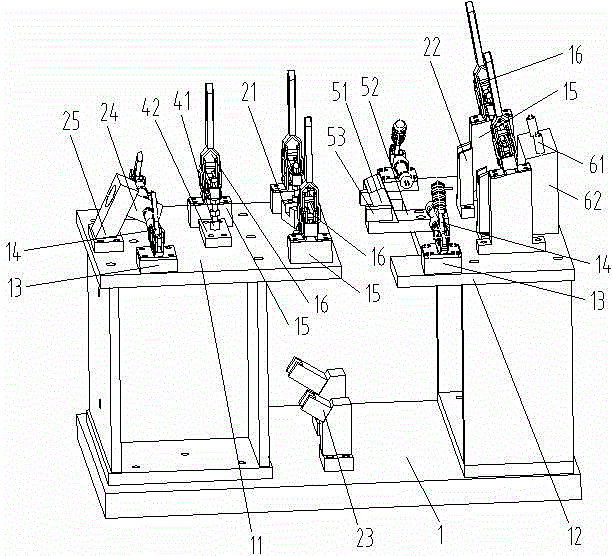

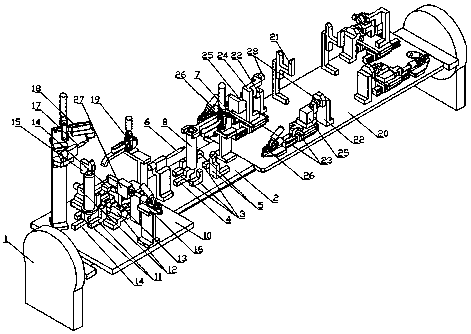

Pallet fork welding assembly system

InactiveCN107553040AQuick positioning clampingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismWeld seam

The invention discloses a pallet fork welding assembly system. The pallet fork welding assembly system comprises a lifting part assembly and welding tool (96) and a fork body assembly and welding tool(97), wherein a carrying manipulator (98) is arranged between the lifting part assembly and welding tool (96) and the fork body assembly and welding tool (97); the lifting part assembly and welding tool (96) comprises a rotary welding table (1), an oil storage barrel welding section, a pump body welding section and a lever rack welding section; and the fork body assembly and welding tool (97) comprises a rack (61), a pair of fork rod limiting locking mechanisms, a fork rod connecting box pneumatic clamp (70), a bearing top plate limiting locking mechanism and a triangular support limiting locking mechanism. The pallet fork welding assembly system has the advantages that: each part of a pallet fork is quickly positioned and clamped through a plurality of limiting locking air cylinders, thestructure is simple, use is convenient and quick, each welding seam is uniform, and welding quality is improved.

Owner:荆门市双创专利技术服务有限公司

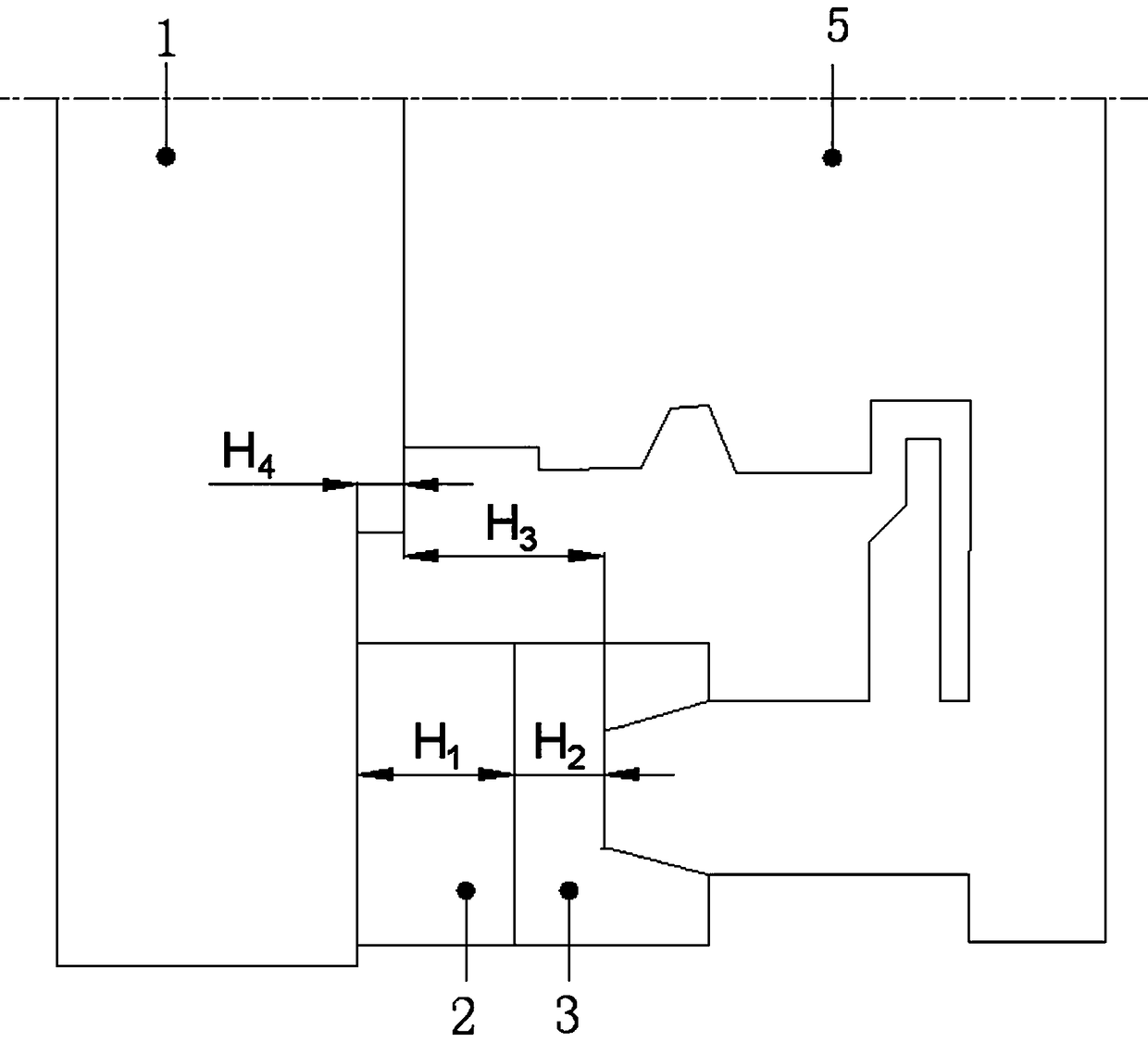

Technique for clamping and positioning angle head by utilizing adjusting cushion block

ActiveCN108098417ASimple structureShort processing cyclePositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to a technique for clamping and positioning an angle head by utilizing an adjusting cushion block, belongs to the technical field of numerical control machining, and particularlyrelates to the technical field of machining and application of the angle head on a numerical control machine tool. The technique mainly comprises the following parts which cooperate with one anotherfor control: a machine tool spindle, the adjusting cushion block, a standard positioning block, a positioning bolt, the angle head, an adjusting cushion block screw, a standard positioning block positioning pin, a standard positioning block screw and a check strip; and the technique realizes rapid positioning and clamping of the angle head and the machine tool, simplifies the structure of the adjusting cushion block and is beneficial for centralized management of the angle head and the standard positioning block.

Owner:JIANGXI HONGDU AVIATION IND GRP

Common positioning fixture for CNC milling machine

ActiveCN108637726APrevent crushingQuick positioning clampingPositioning apparatusMetal-working holdersEngineeringSetting time

The invention discloses a common positioning fixture for a CNC milling machine, and mainly relates to the field of mechanical manufacturing. The common positioning fixture comprises a base, a cavity is arranged at the bottom of the base, a lead screw is arranged at the middle portion of the interior of the cavity, a spline shaft is arranged at the end, extending out of the base, of the lead screw,the two sides of the lead screw are provided with inclined supporting rods, sliding blocks are arranged on the inclined supporting rods, a nut is arranged on the lead screw, guide rods are arranged on the two sides of the nut, the sliding blocks are provided with penetration holes matched with the guide rods, a vertical plate is vertically arranged on the tops of the sliding blocks, a clamping block is arranged on the side, close to the lead screw, of the vertical plate, T-shaped sliding blocks are symmetrically arranged at the bottom of the clamping block, the bottom faces of the T-shaped sliding blocks and the top faces of the sliding blocks are located on one horizontal face, and a positioning block is arranged at the end between the two clamping blocks. The common positioning fixturehas the beneficial effects that workpiece clamping and positioning can be quickly completed, the tool setting time number can be reduced, workpiece extrusion is avoided, the machining quality is guaranteed, and the working efficiency is improved.

Owner:重庆拓菱汽车配件有限责任公司

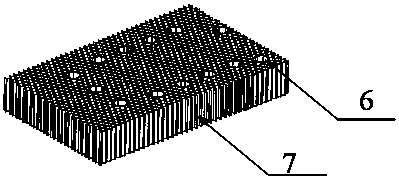

Fixing method for honeycomb core-carbon pipe combination part

InactiveCN110640510AQuick positioning clampingAvoid quality problemsPositioning apparatusMetal-working holdersHoneycombEngineering

The invention discloses a fixing method for a honeycomb core-carbon pipe combination part. The fixing method is used for fixing the honeycomb core-carbon pipe combination part. In the process of processing the honeycomb core-carbon pipe combination part, firstly, the fixing end face of a honeycomb core-carbon pipe combination part workblank is cleaned, a dry strippable cloth and adhesive film areused for gumming curing on the fixing face of a honeycomb core, then the bottom faces of a carbon pipe and a part which are located on the honeycomb core-carbon pipe combination part are quickly clamped and positioned on a vacuum milling clamp with a positioning pin, finally, the part is fixed to a tool through vacuum suction, and the honeycomb core-carbon pipe combination part is reliably and quickly fixed. By means of the the fixing method, the part is conveniently clamped and detached and reliably fixed, and accordingly the quality and efficiency of processing the honeycomb core-carbon pipecombination part are improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Shell leakage testing clamp

ActiveCN104236825AQuick positioning clampingAccurate clamping and positioningMeasurement of fluid loss/gain rateBiomedical engineeringAutomation

The invention relates to a shell leakage testing clamp. The shell leakage testing clamp comprises stand columns and a clamp body arranged at the upper ends of the stand columns. Pneumatic pressing devices are arranged on the front portion, the rear portion and the left portion of the clamp body respectively. A supporting and positioning device is arranged in the middle of the clamp body. A nozzle sealing device is arranged on the right portion of the clamp body. The shell leakage testing clamp has the advantages of being reasonable in structural design, high in automation degree, convenient to operate and regulate and the like, can rapidly clamp and position an automobile water pump shell, and is high in operation efficiency and accurate in positioning and clamping accuracy; the sealing performance of the sealing position is ensured, and therefore detection quality can be improved, and the possibility of wrong detection can be lowered.

Owner:HENAN FEILONG WUHU AUTOMOBILE PARTS

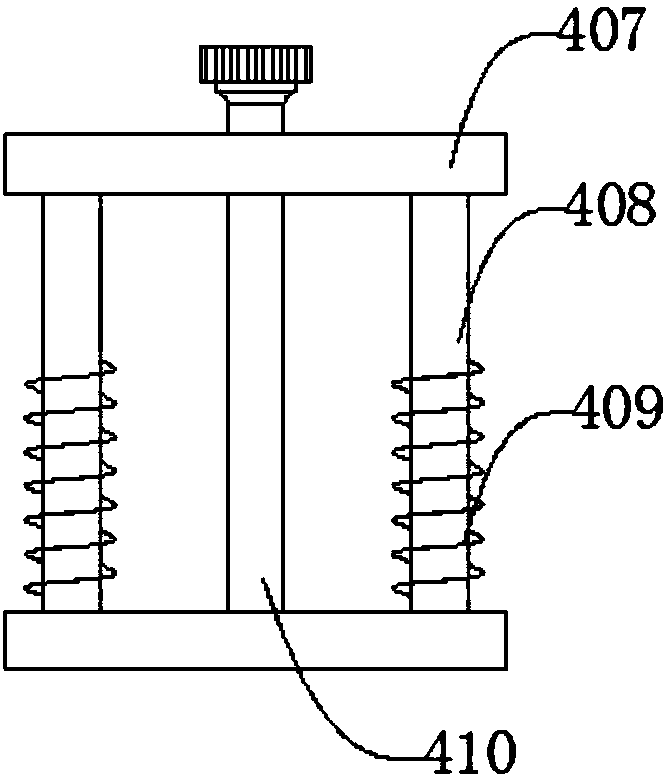

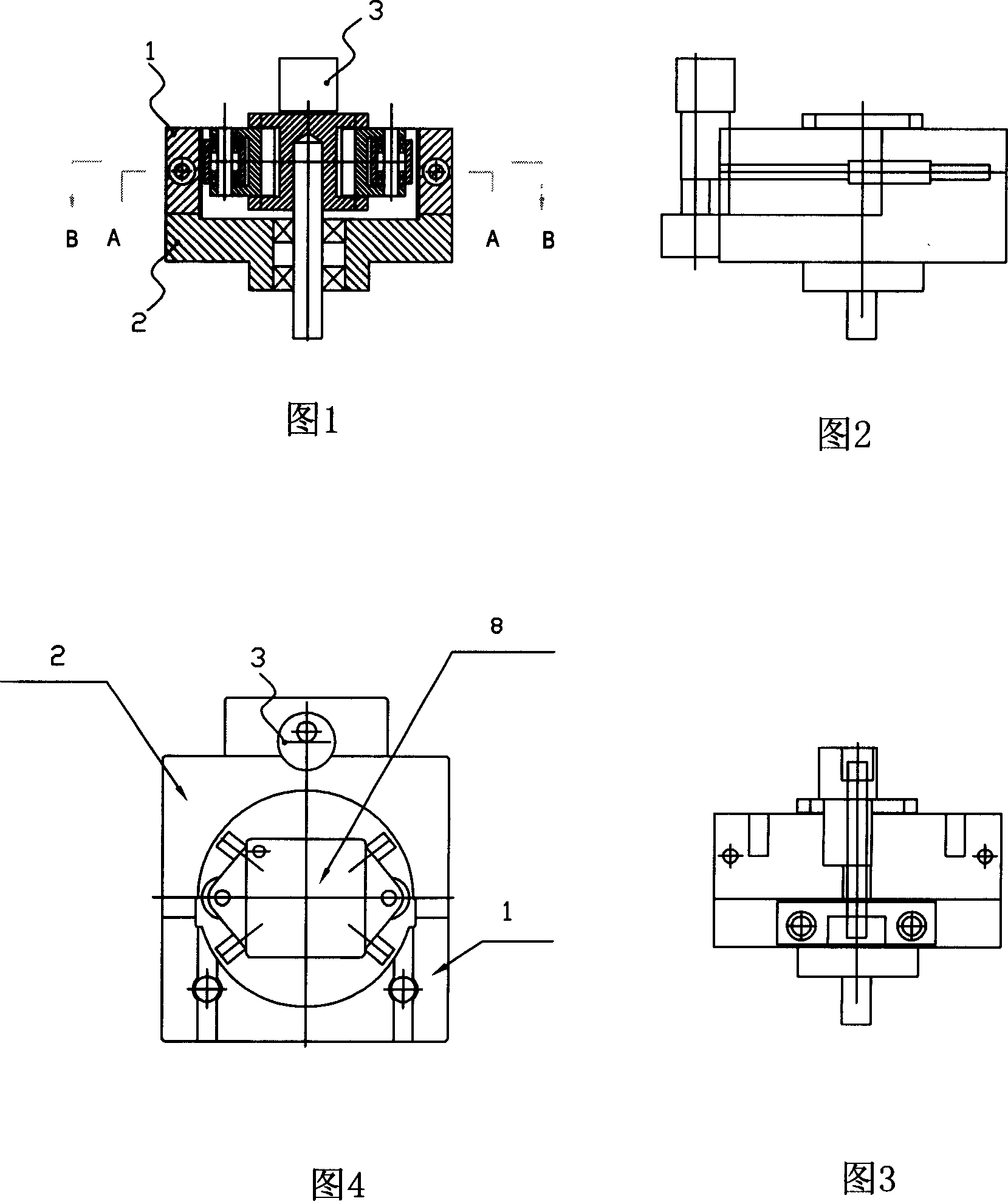

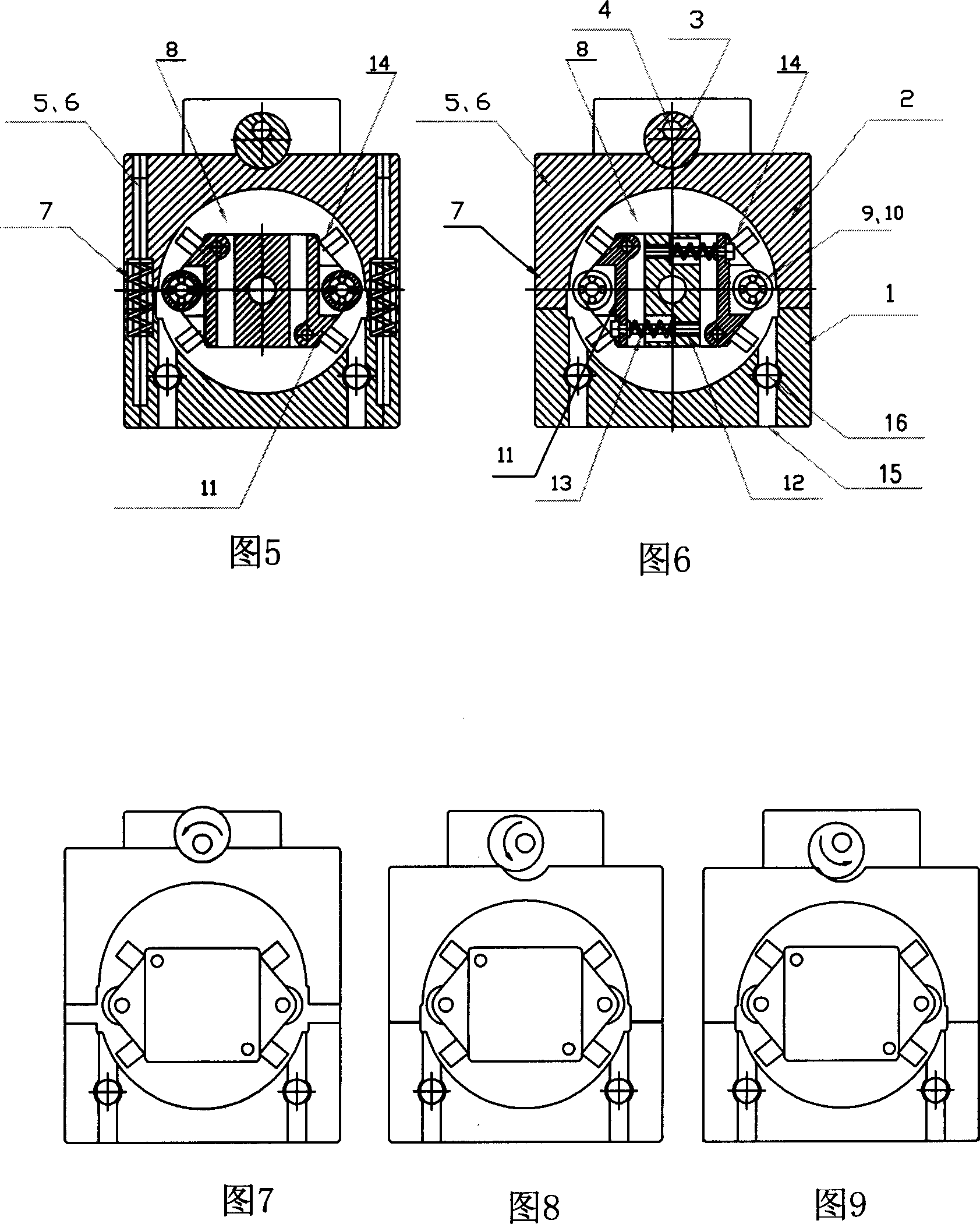

Roller rolling press pump

InactiveCN101016895ASimple structureEasy to manufactureFlexible member pumpsPositive-displacement liquid enginesEngineeringMechanical engineering

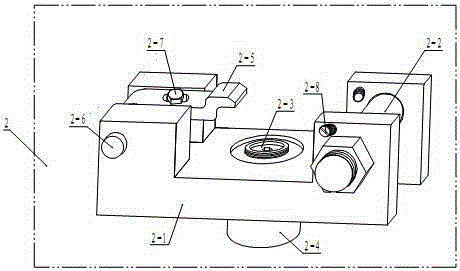

The invention relates to a small roller pump comprising a pump body 1, a block 2, and a pump element 8. The body and the block are locked and opened by a positioning eccentric wheel 3, arranged on a positioning base relative to the back of the block. The distance between the body and the block is smaller than two timed eccentric distance of the eccentric wheel, the back of the block is disposed with an arc cut relative to the positioning eccentric wheel, the body combine face combined with the block is arranged with a block guiding rod (5) protruded, and the combine face of the block is disposed with relative block guiding rod hole (6), engaged with the rod (5), the block guiding rod is sheathed with a block spring (7), the roller swing support (11), swing stop rod (12) and swing spring (13) form a self-elastic space adjuster of roller to automatically adjust the space between the roller and the inner wall of the pump, and limit the minimum space. The invention has simple structure, easy production and simple operation or the like.

Owner:张浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com