Mechanism capable of drilling radial holes in indexing manner and drilling method

A technology of radial holes and indexing holes, applied in boring/drilling, drilling/drilling equipment, parts of boring machines/drilling machines, etc., can solve problems such as design difficulties, affecting accuracy, and increasing manufacturing costs, and achieve The effect of reducing repeated design and assembly, precise and fast positioning and clamping, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

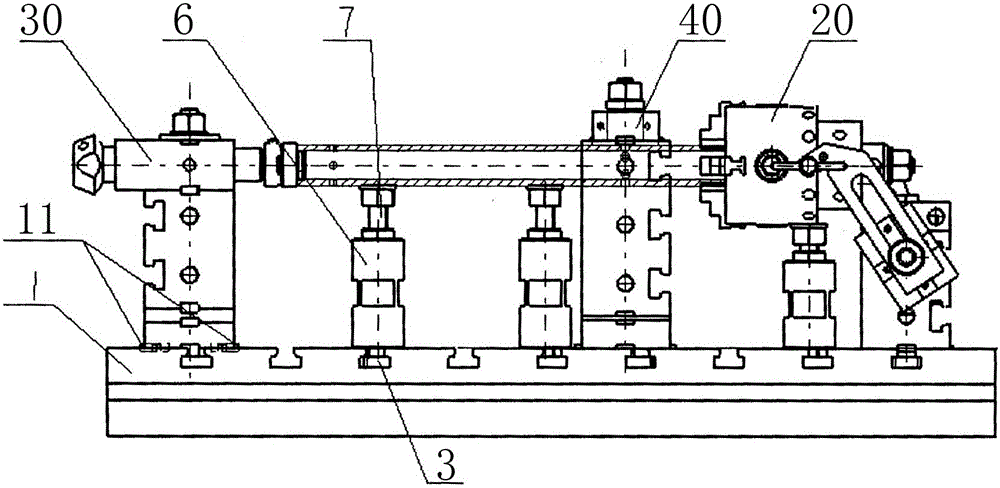

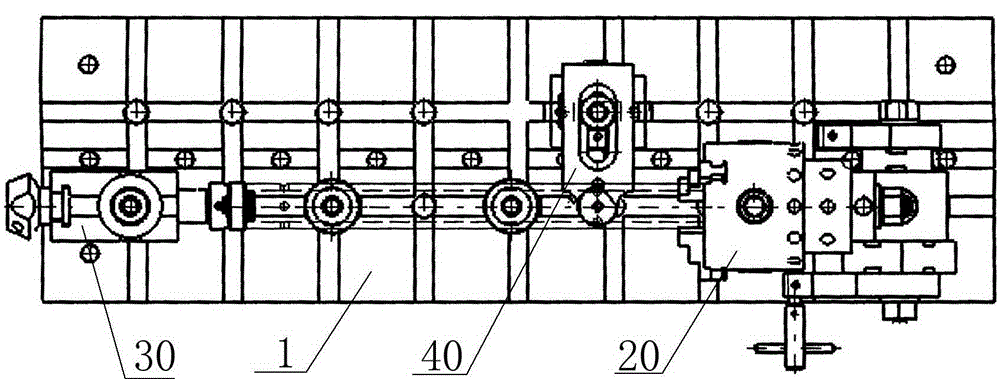

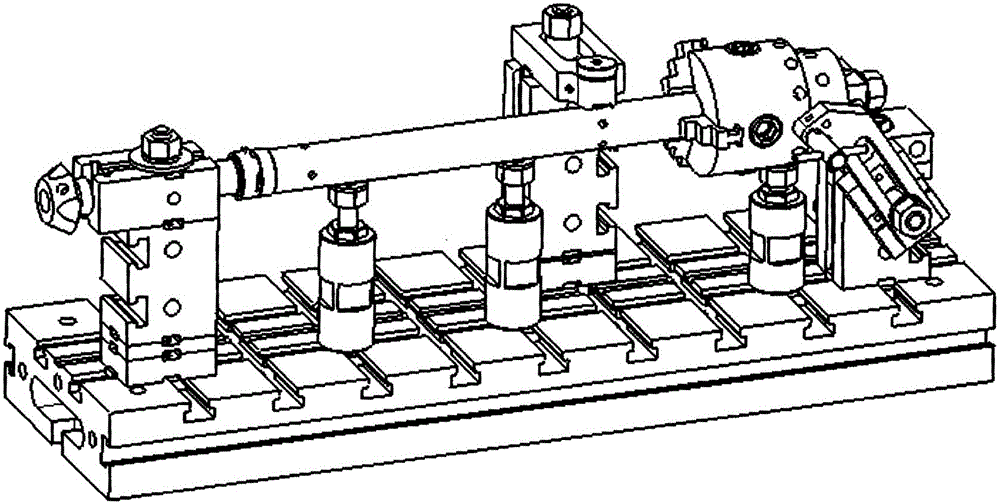

[0036] Such as Figure 1 to Figure 3 As shown in the figure, a mechanism capable of indexing radial holes is provided. On the upper surface of the rectangular base plate 1, T-shaped grooves of uniform specifications are arranged in a horizontal and vertical pattern, and a multi-index positioning and clamping mechanism is respectively provided on the rectangular base plate 1. 20. Auxiliary positioning clamping mechanism 30 and sliding drill formwork mechanism 40, the bottom of each mechanism is respectively provided with a cross-shaped groove, and a sliding key 2 is provided on the corresponding sliding direction in the cross-shaped groove, and the sliding key 2 is connected to the rectangular The narrow slot at the upper end of the T-shaped slot of the base plate 1 is slidingly connected; in the longitudinal direction of each mechanism, there are bolts 3 for the rectangular head slot, and the end of the bolt 3 for the rectangular head slot is connected to the T-shaped correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com