Jig tool for inclined oil cylinder bottom bush hole

A technology of tilting oil cylinders and bushing holes, which is applied to drilling dies, positioning devices, manufacturing tools, etc. for workpieces, can solve the problems of inability to meet batch processing production, troublesome clamping and positioning, and low work efficiency, and achieve convenient installation. , The effect of convenient clamping and positioning and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

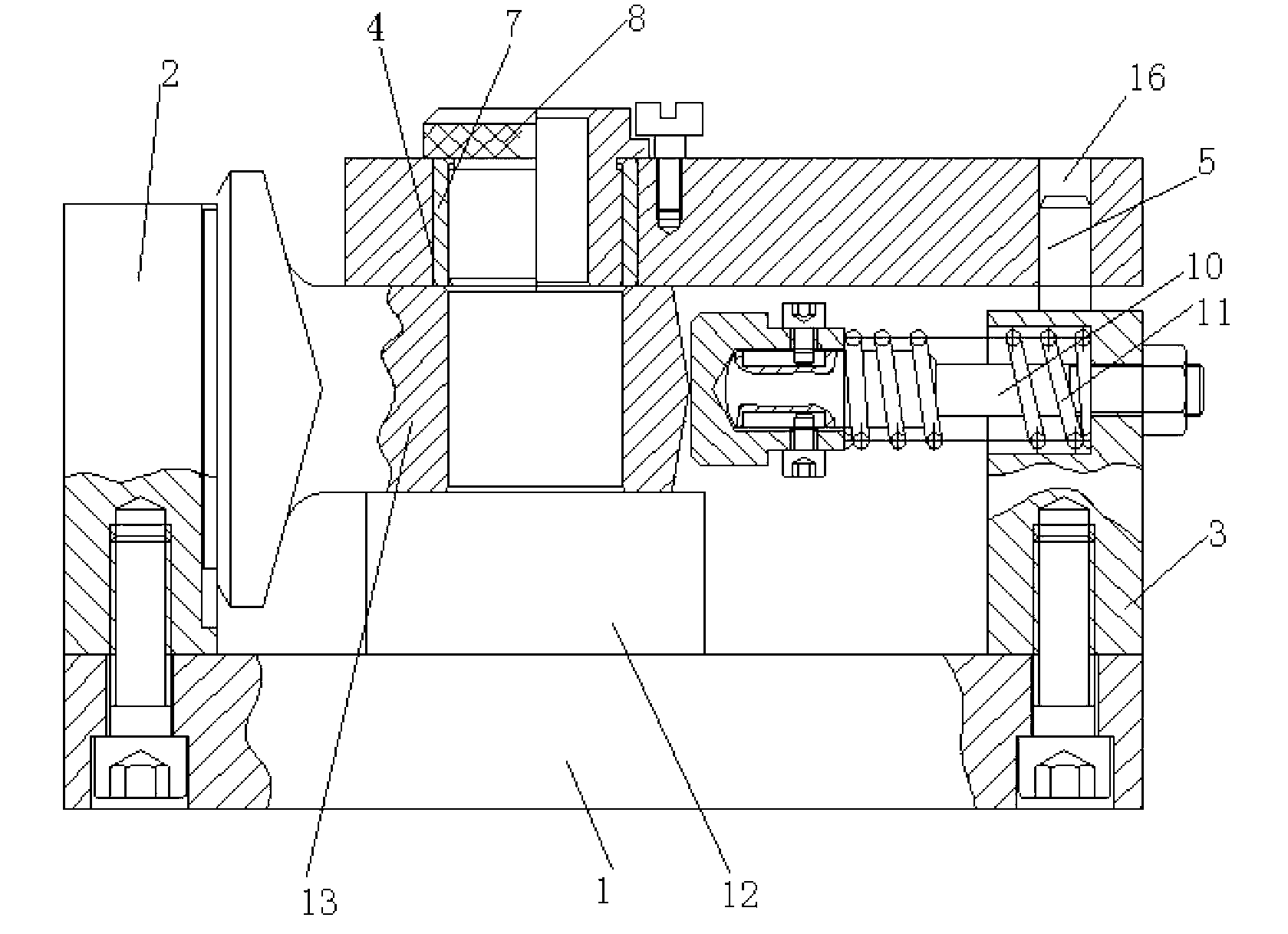

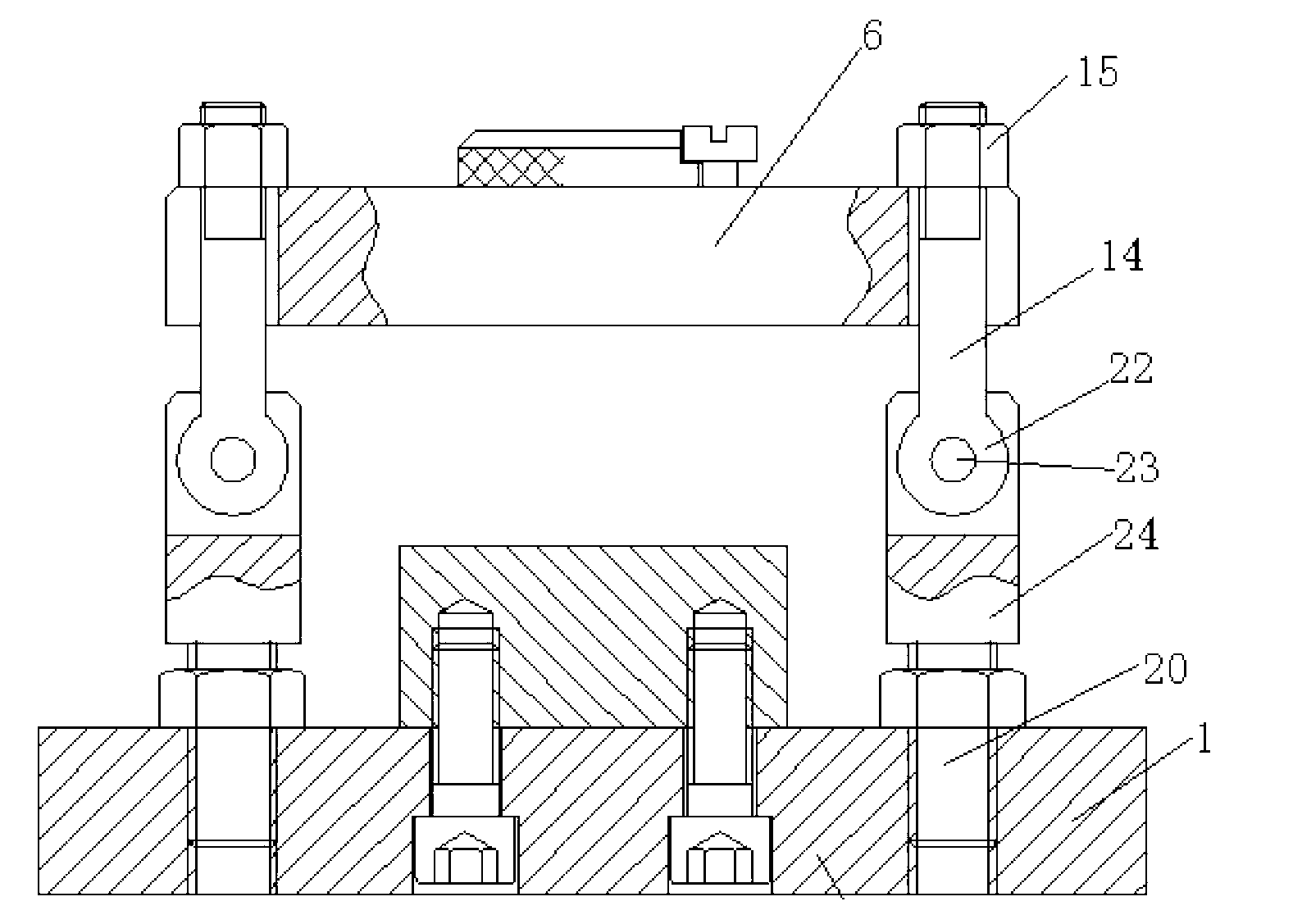

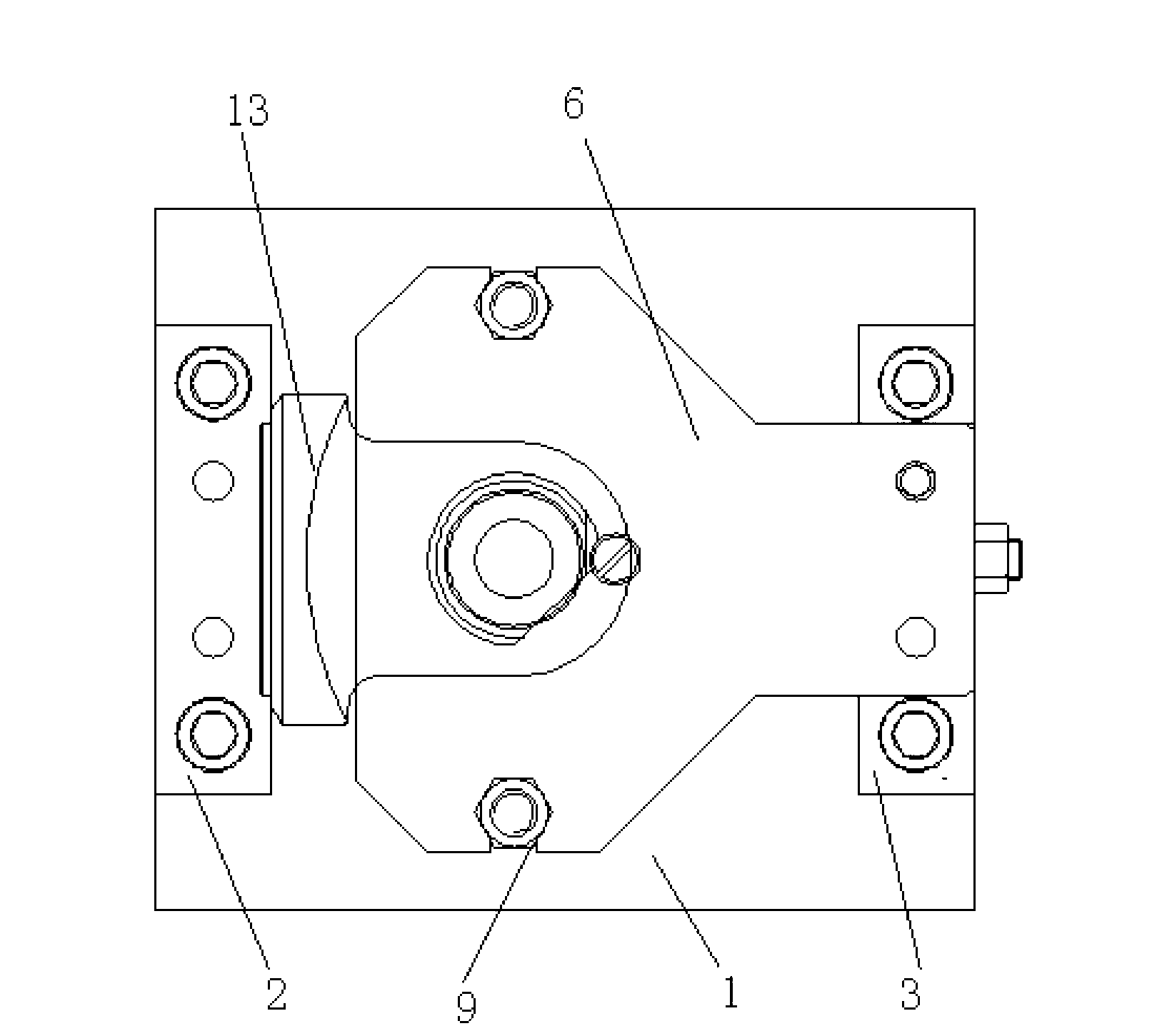

[0020] Referring to the accompanying drawings, a jig drilling tool for a liner hole at the bottom of an inclined oil cylinder includes a jig base plate 1, left and right baffles 2 and 3 are arranged on both sides of the jig jig base plate 1, and vertical The positioning hole in the vertical direction, and the positioning pin 5 is inserted into the positioning hole to cooperate with the installation of the drilling template 6. The drilling template 6 is provided with a guide hole 4, and a fixed drill sleeve 7 is installed in the guide hole 4, and the fixed drill sleeve 7 is matched. Quick-change drill bushing 8 is installed, and the both sides of drill template 6 other ends are provided with U-shaped groove 9, and the middle part of right template 3 is provided with the threaded hole of horizontal direction, and is screwed with push-up rod 10 in the threaded hole, push-up rod 10 There is a spring 11 on the upper sleeve, a push block 11 is installed at the end of the push rod 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com