Product clamping mechanism

A clamping mechanism and product technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problem of not being able to hard contact clamping, and achieve the effect of improving production efficiency, saving manufacturing costs and management costs, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

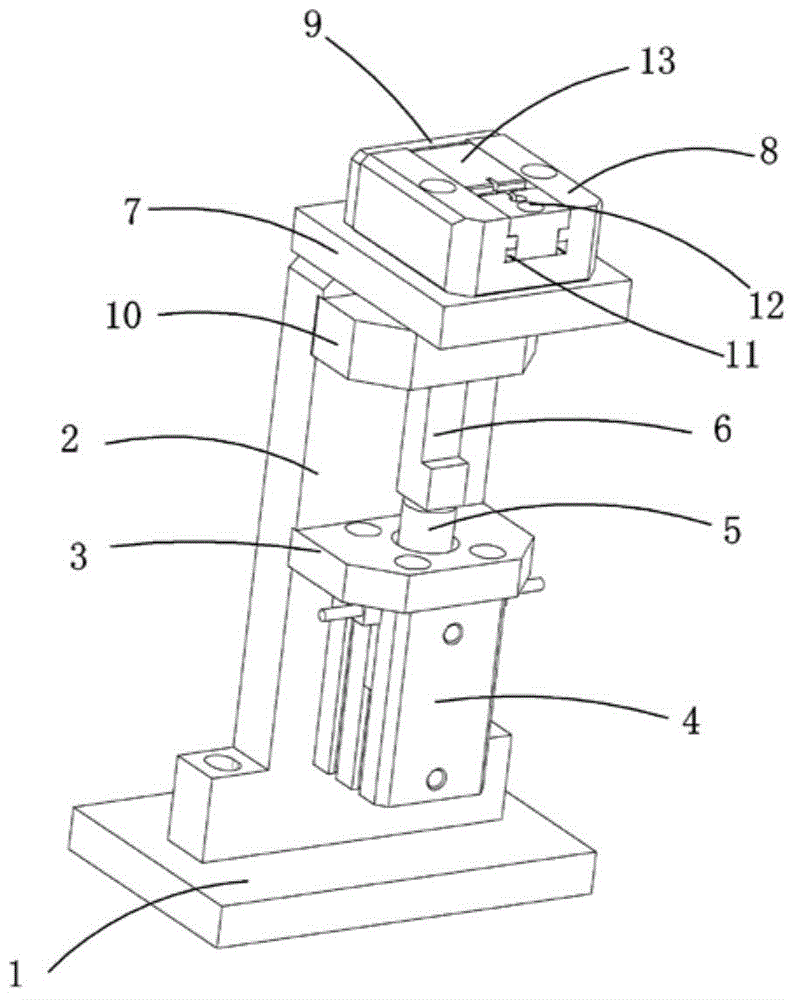

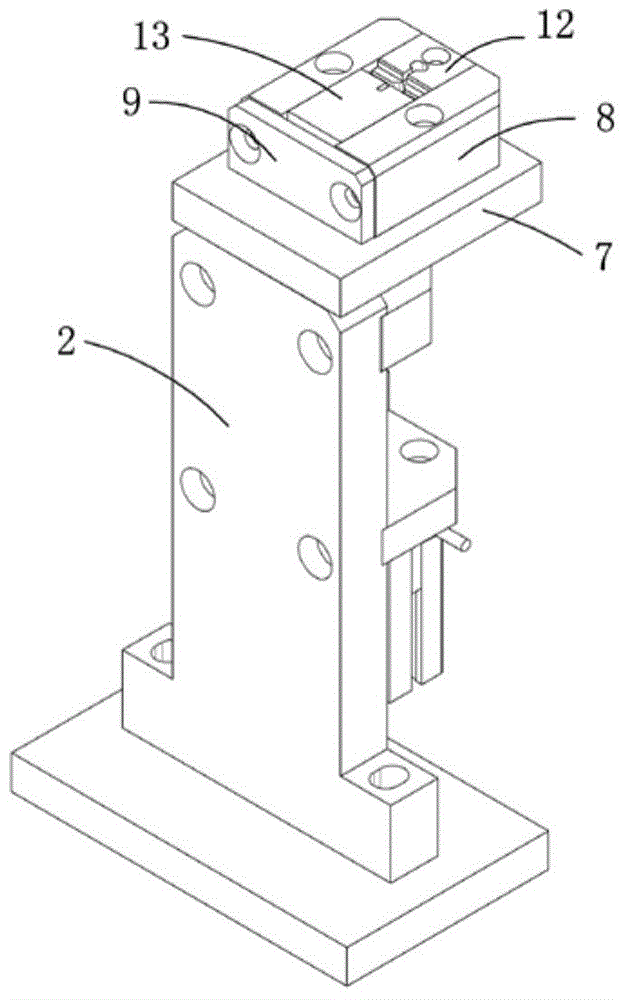

[0018] Examples, see attached Figure 1~4 , a product clamping mechanism, which includes a base 1, a plate 2 is vertically installed on the base, a lifting cylinder fixing plate 3 is fixedly installed in the middle of the supporting plate, and a lifting cylinder fixing plate 3 is installed below the lifting cylinder fixing plate. Cylinder 4, the piston rod 5 of the lifting cylinder passes through the lifting cylinder fixed plate, and the upper end of the piston rod is connected with a lifting slider 6; the driving of the lifting cylinder can drive the lifting slider to move up and down in the vertical direction.

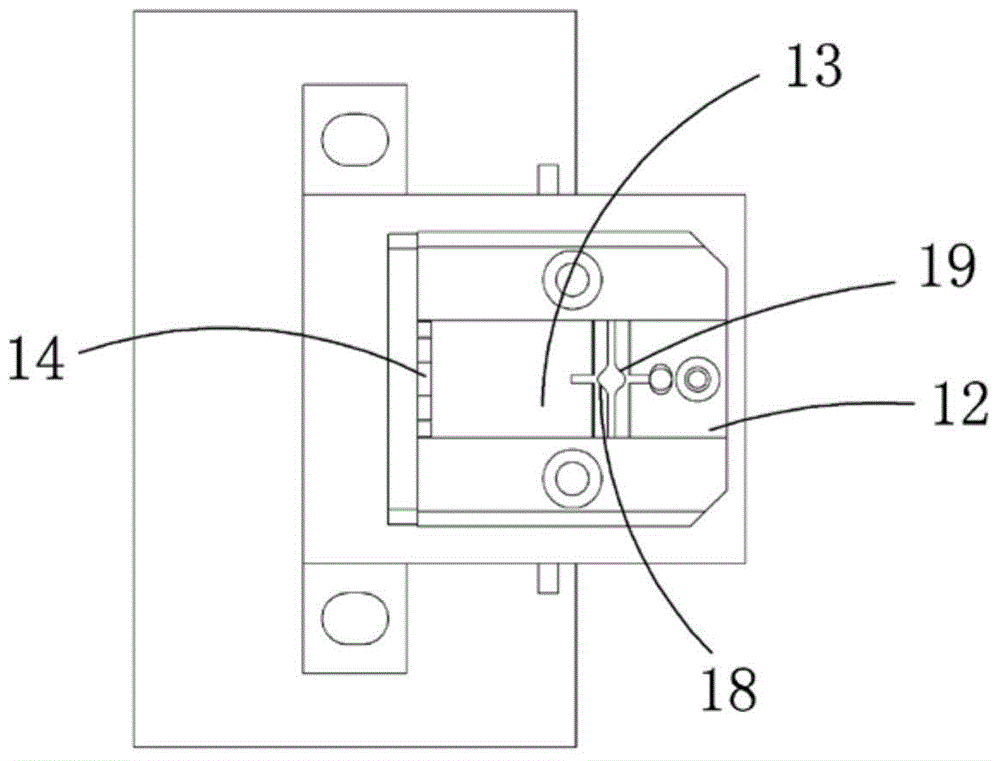

[0019] The upper end of the support plate is equipped with a fixed block 7, the top of the fixed block is screwed and fixedly installed with a fixed seat 8, and the left end of the fixed seat is screwed with a stopper 9, which has a blocking effect; the upper part of the support plate is installed There is a guide plate 10, the guide plate is positioned at the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com