Fixing method for honeycomb core-carbon pipe combination part

A honeycomb core and assembly technology, applied in the direction of clamping, metal processing mechanical parts, supports, etc., can solve the problems that the tape cannot provide sufficient holding strength, the deformation and tearing of the honeycomb core, and the difficulty in disassembling and cleaning parts. Achieve the effect of shortening preparation time, reducing local deformation and tearing, and avoiding tape detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present invention is a kind of holding method that is used for honeycomb core-carbon tube assembly, and the steps are:

[0035] Step 1. Check the blank 3 of the honeycomb core-carbon tube assembly, and clean the bottom surface of the part with absolute alcohol;

[0036] Step 2. Lay the dry peelable cloth 1 on the fixture of the flat plate, then bond the adhesive film 2 to the dry peelable cloth, and finally place the honeycomb core-carbon tube assembly blank 3 on the adhesive film to realize the Preliminary combination of peeling cloth-adhesive film-honeycomb core-carbon tube assembly;

[0037] Step 3. Place the laminated peelable cloth-adhesive film-honeycomb core-carbon tube assembly in a high-temperature-resistant vacuum bag. After vacuuming, send it to an autoclave for curing, so that the adhesive film is partially melted and bonded. Adhere to the side wall of the honeycomb core cell, and then fully cool to room temperature, so that the honeycomb core-carbon tu...

Embodiment 2

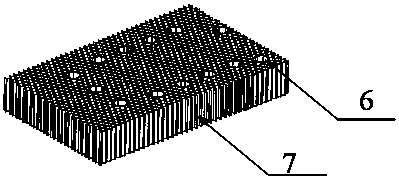

[0045] Such as figure 1 , is the blank of the carbon tube assembly, which is composed of a carbon tube 6 with a diameter D of Ф16, and a paper honeycomb core 7, and the two are connected by the MA562 (EF562) foam material through the two. Explanation:

[0046] Step 1. Check the blank of the honeycomb core-carbon tube assembly to confirm that there is no tear, indentation, scratch, deformation, or degumming, and use absolute alcohol to clean the holding surface of the part, that is, the bottom surface of the blank of the honeycomb core-carbon tube assembly

[0047] Step 2. Lay the dry peelable cloth 1 made of Diatex 1500 ev6 on the fixture of the flat plate, then bond the FM300K.05 adhesive film 2 on the dry peelable cloth, and finally combine the honeycomb core-carbon tube The piece blank is placed on the adhesive film to realize the preliminary combination of peelable cloth-adhesive film-honeycomb core-carbon tube assembly;

[0048] Step 3. Place the laminated peelable clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com